a

Low Voltage Temperature Sensors

TMP35/TMP36/TMP37

FEATURES

Low Voltage Operation (2.7 V to 5.5 V)

Calibrated Directly in C

10 mV/C Scale Factor (20 mV/C on TMP37)

2C Accuracy Over Temperature (Typ)

0.5C Linearity (Typ)

Stable with Large Capacitive Loads

Specified –40C to +125C, Operation to +150C

Less than 50 A Quiescent Current

Shutdown Current 0.5 A Max

Low Self-Heating

APPLICATIONS

Environmental Control Systems

Thermal Protection

Industrial Process Control

Fire Alarms

Power System Monitors

CPU Thermal Management

PRODUCT DESCRIPTION

The TMP35, TMP36, and TMP37 are low voltage, precision

centigrade temperature sensors. They provide a voltage output that

is linearly proportional to the Celsius (Centigrade) temperature.

The TMP35/TMP36/TMP37 do not require any external

calibration to provide typical accuracies of ±1°C at +25°C and

±2°C over the –40°C to +125°C temperature range.

The low output impedance of the TMP35/TMP36/TMP37, and

its linear output and precise calibration simplify interfacing to

temperature control circuitry and A/D converters. All three devices

are intended for single-supply operation from 2.7 V to 5.5 V

maximum. Supply current runs well below 50 µA providing very

low self-heating—less than 0.1°C in still air. In addition, a

shutdown function is provided to cut supply current to less than

0.5 µA.

The TMP35 is functionally compatible with the LM35/LM45 and

provides a 250 mV output at 25°C. The TMP35 reads temperatures from 10°C to 125°C. The TMP36 is specified from –40°C to

+125°C, provides a 750 mV output at 25°C and operates to 125°C

from a single 2.7 V supply. The TMP36 is functionally compatible

with the LM50. Both the TMP35 and TMP36 have an output

scale factor of 10 mV/°C. The TMP37 is intended for applications

over the range 5°C to 100°C, and provides an output scale factor

of 20 mV/°C. The TMP37 provides a 500 mV output at 25°C.

Operation extends to 150°C with reduced accuracy for all devices

when operating from a 5 V supply.

The TMP35/TMP36/TMP37 are all available in low cost 3-pin

TO-92, and SO-8 and 5-pin SOT-23 surface mount packages.

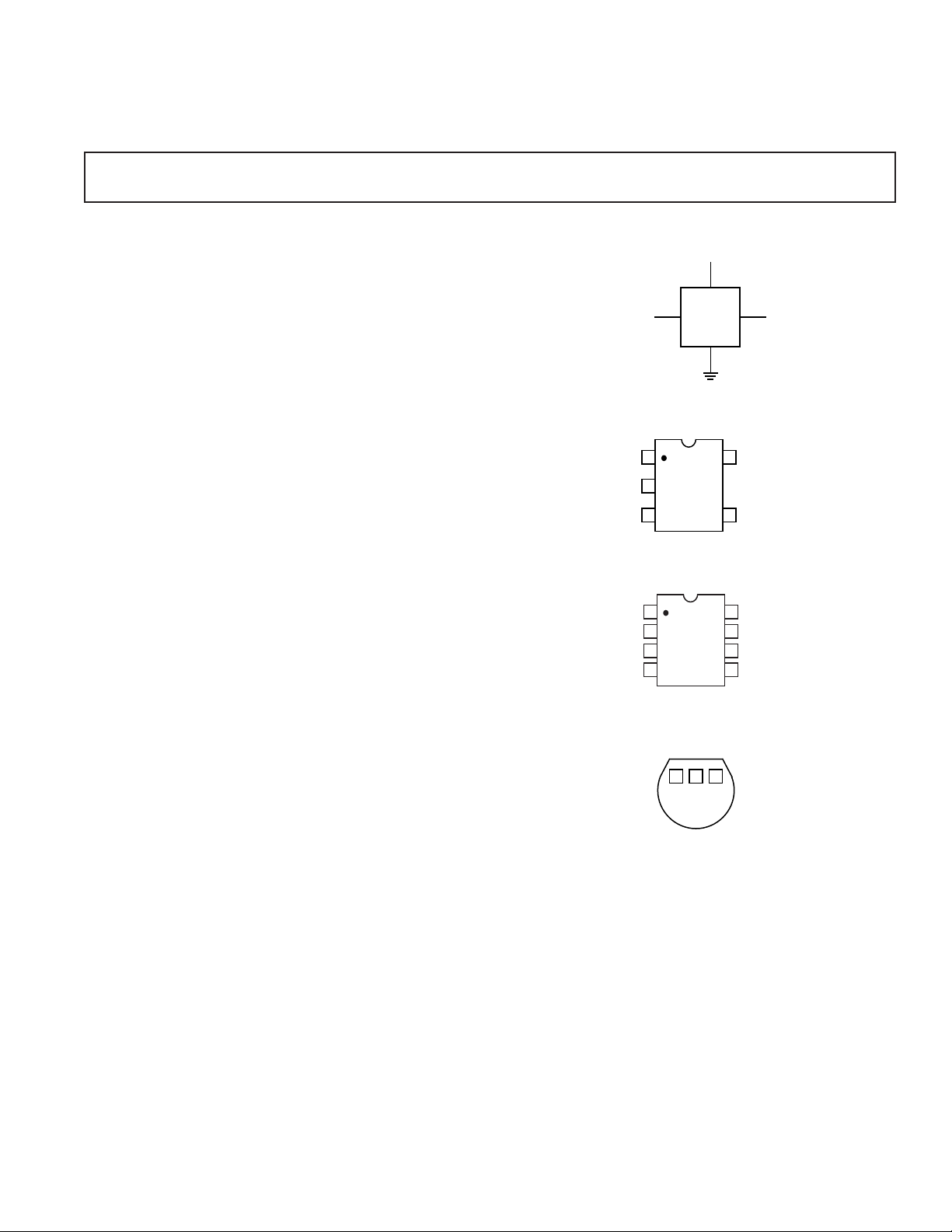

FUNCTIONAL BLOCK DIAGRAM

+Vs (2.7V to 5.5V)

TMP35/

SHUTDOWN

TMP36/

TMP37

V

OUT

PACKAGE TYPES AVAILABLE

RT-5 (SOT-23)

V

1

OUT

+V

2

S

3

NC

NC = NO CONNECT

TOP VIEW

(Not to Scale)

GND

5

4

SHUTDOWN

SO-8

1

V

OUT

2

NC

3

NC

4

GND

NC = NO CONNECT

TOP VIEW

(Not to Scale)

8

+V

S

7

NC

6

NC

5

SHUTDOWN

TO-92

2

1 3

BOTTOM VIEW

(Not to Scale)

PIN 1, +Vs; PIN 2, V

; PIN 3, GND

OUT

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

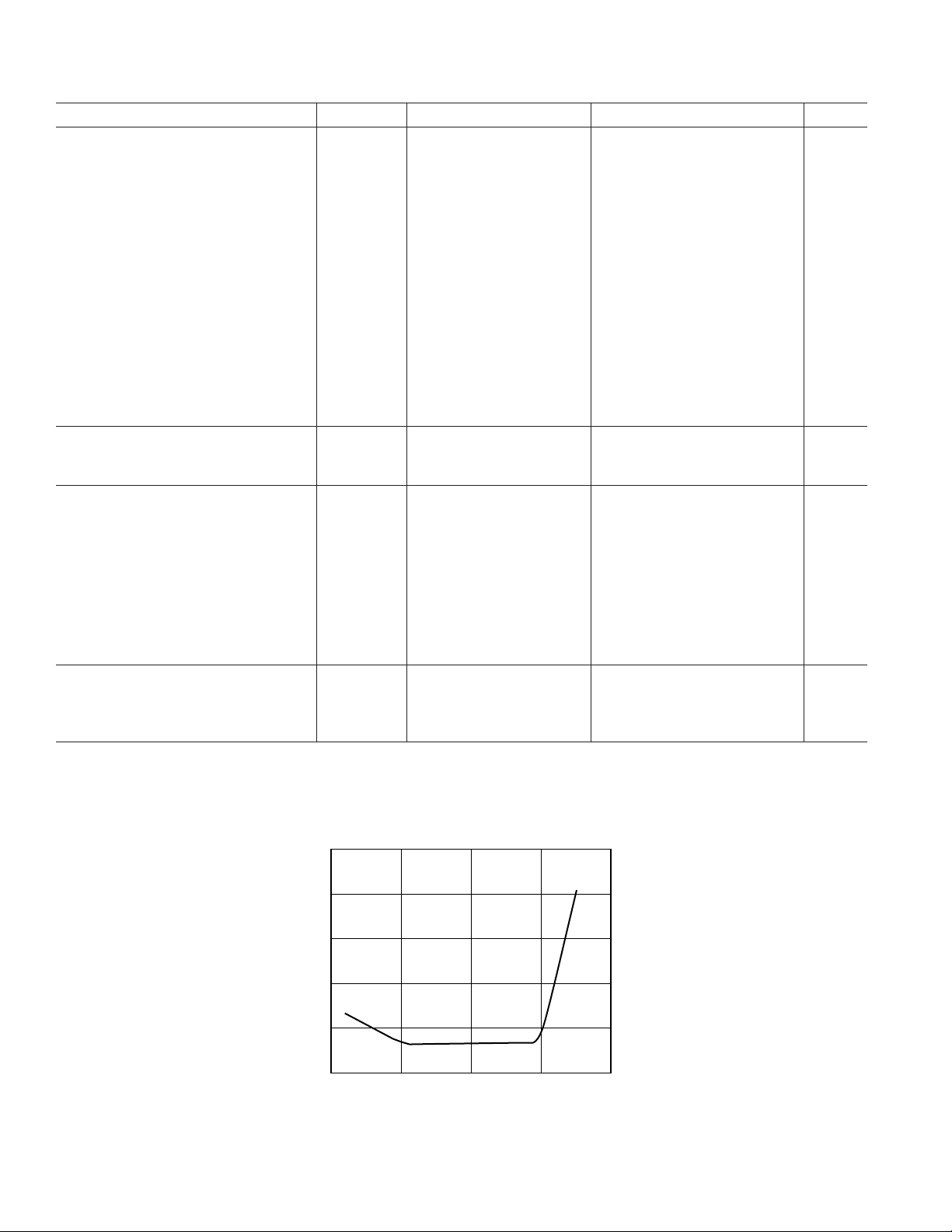

(VS = 2.7 V to 5.5 V, –40C ≤ TA ≤ +125C unless

1

TMP35/TMP36/TMP37–SPECIFICATIONS

otherwise noted)

Parameter Symbol Conditions Min Typ Max Unit

ACCURACY

TMP35/TMP36/TMP37F TA = 25°C ±1 ±2 °C

TMP35/TMP36/TMP37G T

= 25°C ±1 ±3 °C

A

TMP35/TMP36/TMP37F Over Rated Temperature ±2 ±3 °C

TMP35/TMP36/TMP37G Over Rated Temperature ±2 ±4 °C

Scale Factor, TMP35 10°C ≤ T

Scale Factor, TMP36 –40°C ≤ T

Scale Factor, TMP37 5°C ≤ T

5°C ≤ T

3.0 V ≤ +V

Load Regulation 0 µA ≤ I

–40°C ≤ T

–105°C ≤ T

Power Supply Rejection Ratio PSRR T

= 25°C 30 100 m°C/V

A

3.0 V ≤ +V

≤ 125°C 10 9.8/10.2 mV/°C

A

≤ +125°C 10 9.8/10.2 mV/°C

A

≤ 85°C 20 19.6/20.4 mV/°C

A

≤ 100°C 20 19.6/20.4 mV/°C

A

≤ 5.5 V

S

≤ 50 µA

L

≤ +105°C620m°C/µA

A

≤ +125°C2560m°C/µA

A

≤ 5.5 V 50 m°C/V

S

Linearity 0.5 °C

Long-Term Stability TA = +150°C for 1 kHrs 0.4 °C

SHUTDOWN

Logic High Input Voltage V

Logic Low Input Voltage V

IH

IL

VS = 2.7 V 1.8 V

VS = 5.5 V 400 mV

OUTPUT

TMP35 Output Voltage TA = 25°C 250 mV

TMP36 Output Voltage T

TMP37 Output Voltage T

= 25°C 750 mV

A

= 25°C 500 mV

A

Output Voltage Range 100 2000 mV

Output Load Current I

Short-Circuit Current I

Capacitive Load Driving C

Device Turn-On Time Output within ±1°C 0.5 1 ms

L

SC

Note 2 250 µA

L

No Oscillations

100 kΩ100 pF Load

2

2

050µA

1000 10000 pF

POWER SUPPLY

Supply Range +V

Supply Current I

Supply Current (Shutdown) I

NOTES

1

Does not consider errors caused by self-heating.

2

Guaranteed but not tested.

3

See Figure 1.

Specifications subject to change without notice.

S

SY (ON)

SY (OFF)

Unloaded 50 µA

Unloaded 0.01 0.5 µA

2.7 5.5 V

50

40

30

20

LOAD REG – mC/A

10

0

–50

0 50 100 150

TEMPERATURE – C

Figure 1. Load Reg vs. Temperature (m°C/µA)

–2–

REV. B

TMP35/TMP36/TMP37

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 V

Shutdown Pin . . . . . . . . . . . . . . GND

Output Pin . . . . . . . . . . . . . . . . . . . . . . GND ⱕ V

≤

SHUTDOWN ≤ +V

ⱕ +V

OUT

S

S

Operating Temperature Range . . . . . . . . . . –55°C to +150°C

Dice Junction Temperature . . . . . . . . . . . . . . . . . . . . . . 175°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +160°C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . 300°C

*CAUTION

1. Stresses above those listed under Absolute Maximum Ratings may cause

permanent damage to the device. This is a stress rating only; functional operation

at or above this specification is not implied. Exposure to the above maximum

rating conditions for extended periods may affect device reliability.

2. Digital inputs are protected; however, permanent damage may occur on

unprotected units from high-energy electrostatic fields. Keep units in conductive

foam or packaging at all times until ready to use. Use proper antistatic

handling procedures.

3. Remove power before inserting or removing units from their sockets.

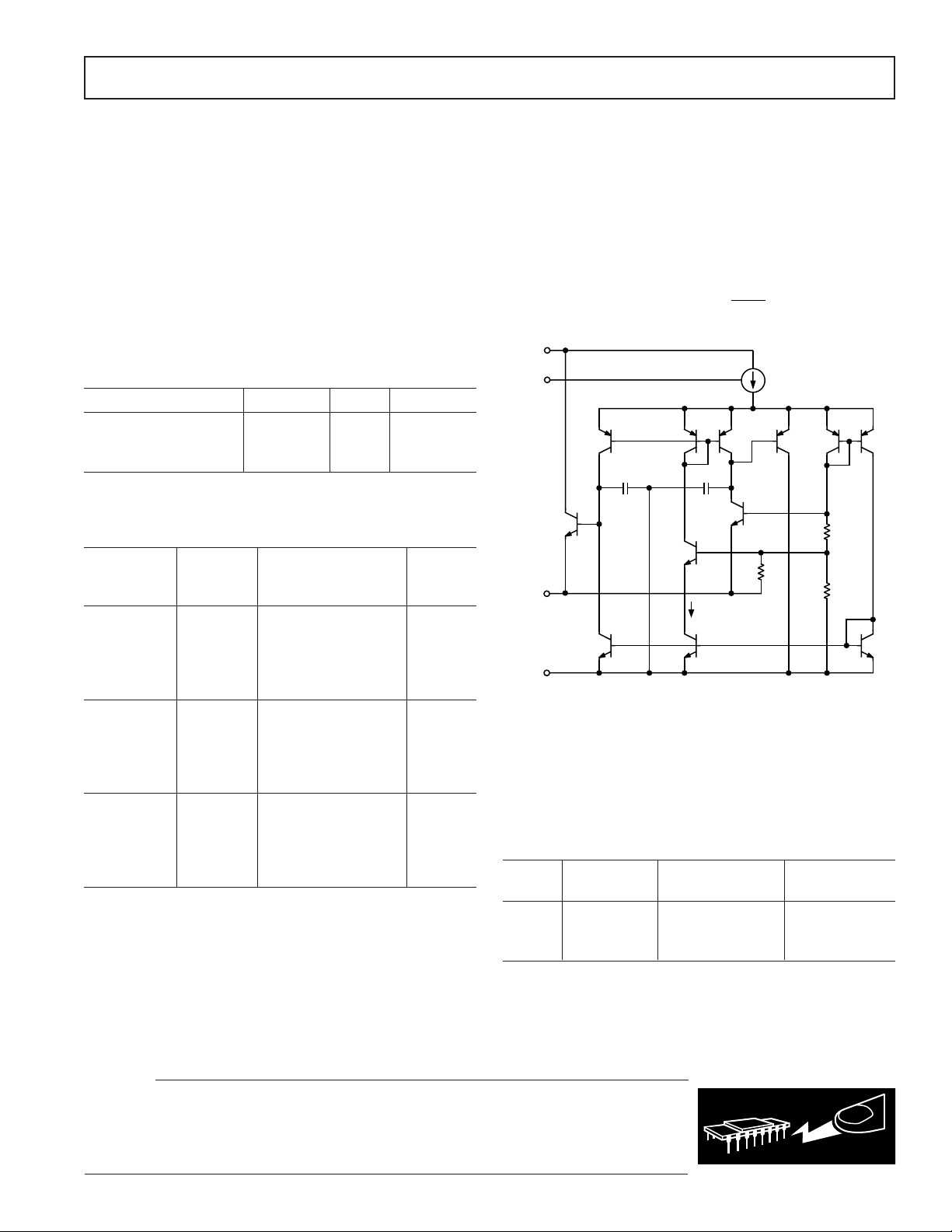

Package Type

JA

JC

Units

TO-92 (T9 Suffix) 162 120 °C/W

SO-8 (S Suffix) 158 43 °C/W

SOT-23 (RT Suffix) 300 180 °C/W

θJA is specified for device in socket (worst-case conditions).

ORDERING GUIDE

Accuracy Linear

at 25C Operating Package

Model (C max) Temperature Range Options

1

TMP35FT9 ±2.0 10°C to 125°C TO-92

TMP35GT9 ±3.0 10°C to 125°C TO-92

TMP35FS ±2.0 10°C to 125°C SO-8

TMP35GS ± 3.0 10°C to 125°C SO-8

TMP35GRT2±3.0 10°C to 125°C RT-5

TMP36FT9 ±2.0 –40°C to +125°C TO-92

TMP36GT9 ±3.0 –40°C to +125°C TO-92

TMP36FS ±2.0 –40°C to +125°C SO-8

TMP36GS ± 3.0 –40°C to +125°C SO-8

TMP36GRT2±3.0 –40°C to +125°C RT-5

TMP37FT9 ±2.0 5°C to 100°C TO-92

TMP37GT9 ±3.0 5°C to 100°C TO-92

TMP37FS ±2.0 5°C to 100°C SO-8

TMP37GS ± 3.0 5°C to 100°C SO-8

TMP37GRT2±3.0 5°C to 100°C RT-5

NOTES

1

SO = Small Outline; RT = Plastic Surface Mount; TO = Plastic.

2

Consult factory for availability.

FUNCTIONAL DESCRIPTION

An equivalent circuit for the TMP3x family of micropower,

centigrade temperature sensors is shown in Figure 2. At the

heart of the temperature sensor is a bandgap core, which is

comprised of transistors Q1 and Q2, biased by Q3 to approximately 8 µA. The bandgap core operates both Q1 and Q2 at the

same collector current level; however, since the emitter area of

Q1 is 10 times that of Q2, Q1’s V

and Q2’s VBE are not equal

BE

by the following relationship:

A

7.5A

Q2

1X

E,Q1

A

E,Q2

25A

3X

2X

R1

R3

R2

2X

+V

SHDN

+V

OUT

GND

∆VBE=VT× ln

S

Q4

Q1

10X

Q3

6X

Figure 2. Temperature Sensor Simplified

Equivalent Circuit

Resistors R1 and R2 are used to scale this result to produce the

output voltage transfer characteristic of each temperature sensor

and, simultaneously, R2 and R3 are used to scale Q1’s V

an offset term in V

. Table I summarizes the differences

OUT

BE

as

between the three temperature sensors’ output characteristics:

Table I. TMP3x Output Characteristics

Offset Output Voltage Output Voltage

Sensor Voltage (V) Scaling (mV/C) @ 25C

TMP35 0 10 250 mV

TMP36 0.5 10 750 mV

TMP37 0 20 500 mV

The output voltage of the temperature sensor is available at the

emitter of Q4, which buffers the bandgap core and provides load

current drive. Q4’s current gain, working with the available base

current drive from the previous stage, sets the short-circuit

current limit of these devices to 250 µA.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the TMP35/TMP36/TMP37 features proprietary ESD protection circuitry, permanent damage

may occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. B

–3–

TMP35/TMP36/TMP37

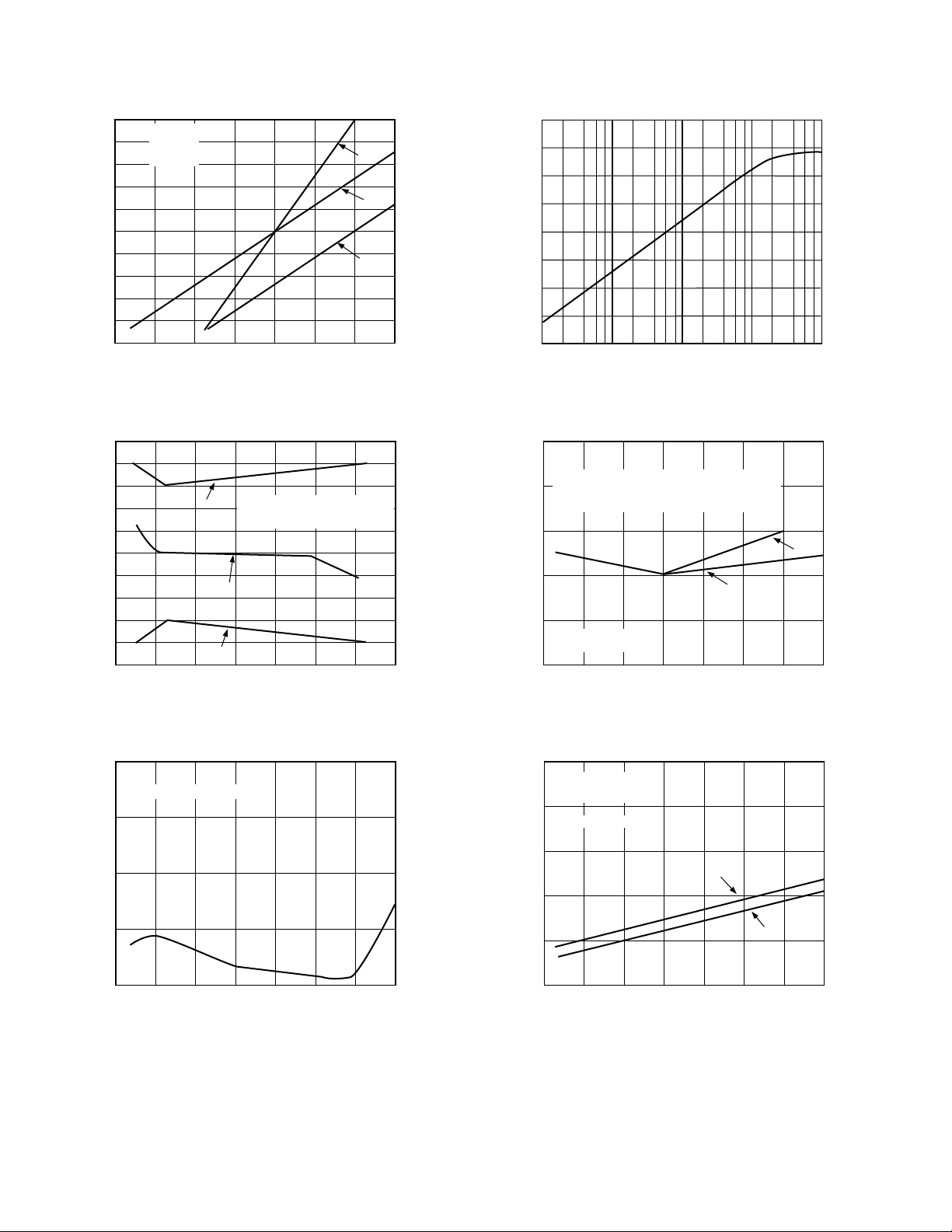

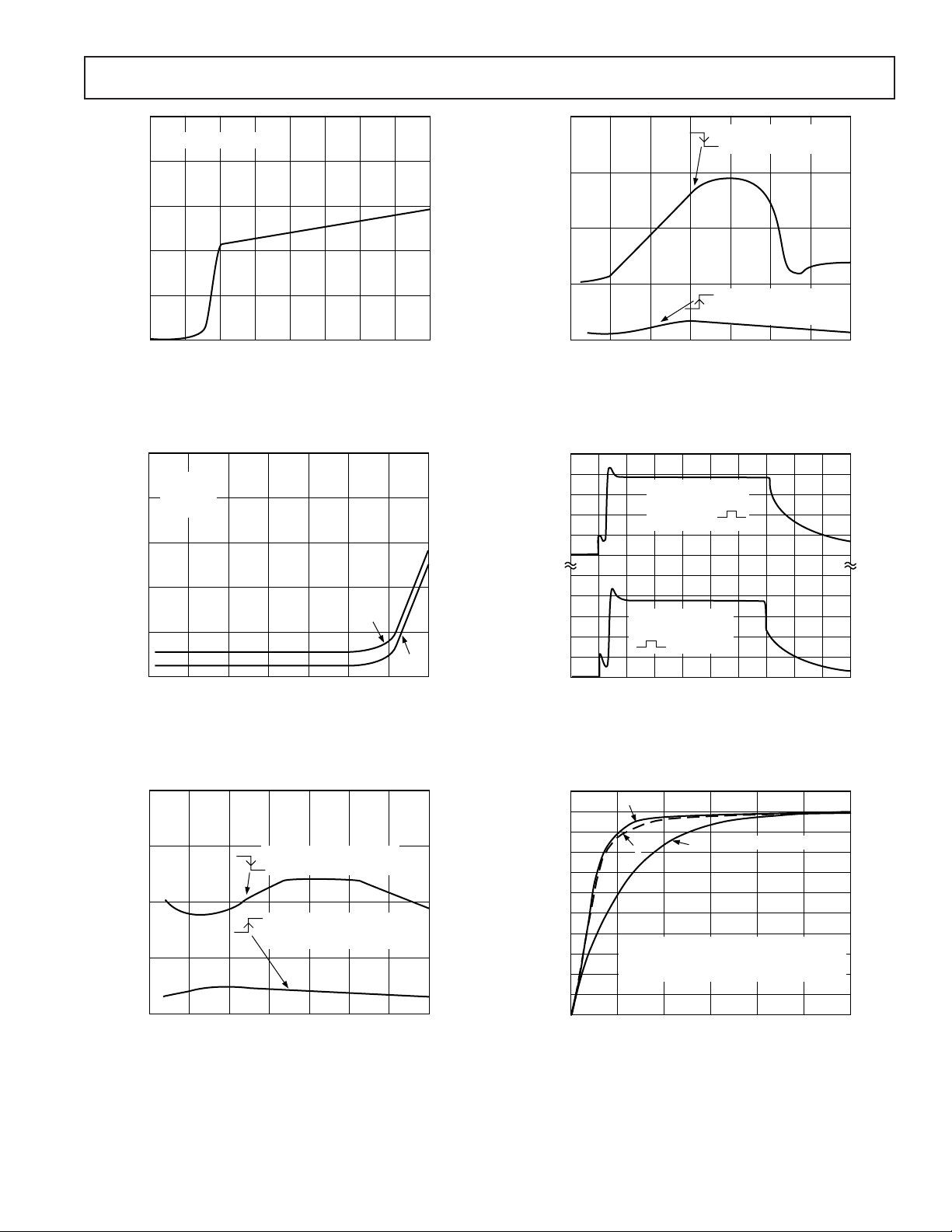

– Typical Performance Characteristics

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

OUTPUT VOLTAGE – V

0.4

0.2

50 25 0 25 50 75 100 125

a. TMP35

b. TMP36

c. TMP37

= 3V

V

S

0

TEMPERATURE – C

c

a

TPC 1. Output Voltage vs. Temperature

5

4

3

a. MAXIMUM LIMIT ( G GRADE )

2

1

0

1

2

ACCURACY ERROR – C

3

4

5

0 20 40 60 80 100 120 140

a

b. TYPICAL ACCURACY ERROR

c. MINIMUM LIMIT ( G GRADE )

b

c

TEMPERATURE – C

TPC 2. Accuracy Error vs. Temperature

100

31.6

10

b

3.16

1

0.32

0.1

POWER SUPPLY REJECTION – C/V

0.032

0.01

20 100k100 1k 10k

FREQUENCY – Hz

TPC 4. Power Supply Rejection vs. Frequency

5

MINIMUM SUPPLY VOLTAGE REQUIRED TO MEET

4

DATA SHEET SPECIFICATION

NO LOAD

3

b

2

1

MINIMUM SUPPLY VOLTAGE – V

a. TMP35/ TMP36

b. TMP37

0

50 12525 0 25 50 75 100

TEMPERATURE – C

a

TPC 5. Minimum Supply Voltage vs. Temperature

0.4

V+ = 3V to 5.5V, NO LOAD

0.3

0.2

0.1

POWER SUPPLY REJECTION – C/V

0

50 12525 0 25 50 75 100

TEMPERATURE – C

TPC 3. Power Supply Rejection vs. Temperature

–4–

60

a. V+ = 5V

50

40

30

SUPPLY CURRENT – A

20

10

b. V+ = 3V

NO LOAD

a

50 12525 0 25 50 75 100

TEMPERATURE – C

TPC 6. Supply Current vs. Temperature

b

REV. B

TMP35/TMP36/TMP37

50

TA = 25°C, NO LOAD

40

30

20

SUPPLY CURRENT – A

10

0

07123456

SUPPLY VOLTAGE – V

8

TPC 7. Supply Current vs. Supply Voltage

50

a. V+ = 5V

b. V+ = 3V

40

NO LOAD

30

20

SUPPLY CURRENT – nA

10

0

50 12525 0 25 50 75

TEMPERATURE – C

a

b

100

TPC 8. Supply Current vs. Temperature (Shutdown = 0 V)

400

= SHUTDOWN PIN

HIGH TO LOW (3V TO 0V)

300

200

RESPONSE TIME – s

100

0

50 12525 0 25 50 75

TPC 10. V

Response Time for Shutdown Pin vs.

OUT

TEMPERATURE – C

= SHUTDOWN PIN

LOW TO HIGH (0V TO 3V)

SETTLES WITHIN ±1°C

V

OUT

Temperature

1.0

0.8

0.6

0.4

0.2

0

1.0

0.8

0.6

OUTPUT VOLTAGE – Volts

0.4

0.2

0

50 2500 10050 150 200 300 350 400 450

TPC 11. V

Response Time to Shutdown and V+

OUT

= 25°C

T

A

V+ = 3V

SHUTDOWN =

SIGNAL

T

= 25°C

A

V+ AND SHUTDOWN =

SIGNAL

TIME – µs

Pins vs. Time

100

400

300

200

RESPONSE TIME – s

100

0

50 12525 0 25 50 75

TPC 9. V

Response Time for V+ Power-Up/Power-

OUT

Down vs. Temperature

REV. B

= V+ AND SHUTDOWN PINS

HIGH TO LOW (3V TO 0V)

= V+ AND SHUTDOWN PINS

LOW TO HIGH (0V TO 3V)

SETTLES WITHIN ±1°C

V

OUT

TEMPERATURE – C

100

–5–

110

100

90

80

70

60

50

40

30

PERCENT OF CHANGE – %

20

10

0

0

a

b

a. TMP35 SOIC SOLDERED TO 0.5" x 0.3" Cu PCB

b. TMP36 SOIC SOLDERED TO 0.6" x 0.4" Cu PCB

c. TMP35 TO-92 IN SOCKET SOLDERED TO

1" x 0.4" Cu PCB

100

c

200 300 400 500 600

TIME – sec

VIN = 3V, 5V

TPC 12. Thermal Response Time in Still Air

TMP35/TMP36/TMP37

140

a. TMP35 SOIC SOLDERED TO 0.5" x 0.3" Cu PCB

120

100

b. TMP36 SOIC SOLDERED TO 0.6" x 0.4" Cu PC

c. TMP35 TO-92 IN SOCKET SOLDERED TO

1" x 0.4" Cu PCB

10mV

100

90

1ms

80

60

40

TIME CONSTANT – sec

20

0

0 100 200 300 400 500 600

VIN = +3V, +5V

b

c

a

700

AIR VELOCITY – FPM

TPC 13. Thermal Response Time Constant in Forced Air

110

100

90

80

70

60

50

CHANGE – %

40

30

20

10

a

c

b

a. TMP35 SOIC SOLDERED TO 0.5" x 0.3" Cu PCB

b. TMP36 SOIC SOLDERED TO 0.6" x 0.4" Cu PCB

c. TMP35 TO-92 IN SOCKET SOLDERED TO

1" x 0.4" Cu PCB

0

10

0

VIN = +3V, +5V

20 30 40 50 60

TIME – sec

TPC 14. Thermal Response Time in Stirred Oil Bath

VOLT/DIVISION

10

0%

TIME/DIVISION

TPC 15. Temperature Sensor Wideband Output

Noise Voltage. Gain = 100, BW = 157 kHz

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

VOLTAGE NOISE DENSITY – nV/ Hz

a. TMP35/36

b. TMP37

200

0

10 10k100 1k

FREQUENCY – Hz

b

a

TPC 16. Voltage Noise Spectral Density vs. Frequency

–6–

REV. B

TMP35/TMP36/TMP37

TP T

D C CA AJJ

=× +

()

+

θθ

APPLICATIONS SECTION

Shutdown Operation

All TMP3x devices include a shutdown capability that reduces

the power supply drain to less than 0.5 µA, maximum. This

feature, available only in the SO-8 and the SOT-23 packages, is

TTL/CMOS level compatible, provided that the temperature

sensor supply voltage is equal in magnitude to the logic supply

voltage. Internal to the TMP3x at the SHUTDOWN pin, a

pull-up current source to V

is connected. This permits the

IN

SHUTDOWN pin to be driven from an open-collector/drain

driver. A logic LOW, or zero-volt condition on the SHUTDOWN

pin, is required to turn the output stage OFF. During shutdown, the output of the temperature sensors becomes a high

impedance state where the potential of the output pin would

then be determined by external circuitry. If the shutdown feature is not used, it is recommended that the SHUTDOWN pin

be connected to V

(Pin 8 on the SO-8, Pin 2 on the SOT-23).

IN

The shutdown response time of these temperature sensors is

illustrated in TPCs 9, 10, and 11.

Mounting Considerations

If the TMP3x temperature sensors are thermally attached and

protected, they can be used in any temperature measurement

application where the maximum temperature range of the

medium is between –40°C to +125°C. Properly cemented or

glued to the surface of the medium, these sensors will be within

0.01°C of the surface temperature. Caution should be exercised,

especially with TO-92 packages, because the leads and any

wiring to the device can act as heat pipes, introducing errors if

the surrounding air-surface interface is not isothermal. Avoiding

this condition is easily achieved by dabbing the leads of the

temperature sensor and the hookup wires with a bead of

thermally conductive epoxy. This will ensure that the TMP3x

die temperature is not affected by the surrounding air temperature.

Because plastic IC packaging technology is used, excessive

mechanical stress should be avoided when fastening the device

with a clamp or a screw-on heat tab. Thermally conductive epoxy

or glue, which must be electrically nonconductive, is recommended

under typical mounting conditions.

These temperature sensors, as well as any associated circuitry,

should be kept insulated and dry to avoid leakage and corrosion.

In wet or corrosive environments, any electrically isolated metal

or ceramic well can be used to shield the temperature sensors.

Condensation at very cold temperatures can cause errors and

should be avoided by sealing the device, using electrically nonconductive epoxy paints or dip or any one of many printed circuit

board coatings and varnishes.

Thermal Environment Effects

The thermal environment in which the TMP3x sensors are used

determines two important characteristics: self-heating effects

and thermal response time. Illustrated in Figure 3 is a thermal

model of the TMP3x temperature sensors that is useful in

understanding these characteristics.

T

J

T

JC

C

CA

In the TO-92 package, the thermal resistance junction-to-case,

θ

, is 120°C/W. The thermal resistance case-to-ambient, θCA, is

JC

the difference between θ

and θJC, and is determined by the

JA

characteristics of the thermal connection. The temperature

sensor’s power dissipation, represented by P

, is the product of

D

the total voltage across the device and its total supply current

(including any current delivered to the load). The rise in die

temperature above the medium’s ambient temperature is given by:

Thus, the die temperature rise of a TMP35 “RT” package

mounted into a socket in still air at 25°C and driven from a 5 V

supply is less than 0.04°C.

The transient response of the TMP3x sensors to a step change

in the temperature is determined by the thermal resistances and

the thermal capacities of the die, C

thermal capacity of the case, C

, and the case, CC. The

CH

, varies with the measurement

C

medium since it includes anything in direct contact with the

package. In all practical cases, the thermal capacity of the case is

the limiting factor in the thermal response time of the sensor

and can be represented by a single-pole RC time constant

response. TPC 12 and 14 illustrate the thermal response time of

the TMP3x sensors under various conditions. The thermal time

constant of a temperature sensor is defined as the time required

for the sensor to reach 63.2% of the final value for a step change

in the temperature. For example, the thermal time constant of a

TMP35 “S” package sensor mounted onto a 0.5" by 0.3" PCB

is less than 50 sec in air, whereas in a stirred oil bath the time

constant is less than 3 seconds.

Basic Temperature Sensor Connections

Figure 4 illustrates the basic circuit configuration for the

TMP3x family of temperature sensors. The table shown in the

figure illustrates the pin assignments of the temperature sensors

for the three package types. For the SOT-23, Pin 3 is labeled as

“NC” are as Pins 2, 3, 6, and 7 on the SO-8 package. It is recommended that no electrical connections be made to these

pins. If the shutdown feature is not needed on the SOT-23

or the SO-8 package, the SHUTDOWN pin should be connected to V

.

S

2.7V < Vs < 5.5V

0.1F

V

s

V

S

TMP3x

GND

GND

V

OUT

SHDN

PIN ASSIGNMENTS

PACKAGE

SO-8 8 4 1 5

SOT-23-5 2 5 1 4

TO-92 1 3 2 NA

V

OUT

SHDN

P

D

Figure 3. TMP3x Thermal Circuit Model

REV. B

C

CH

C

C

T

Figure 4. Basic Temperature Sensor Circuit Configuration

A

–7–

TMP35/TMP36/TMP37

Note the 0.1 µF bypass capacitor on the input. This capacitor

should be a ceramic type, have very short leads (surface mount

would be preferable), and be located as close a physical proximity to the temperature sensor supply pin as practical. Since these

temperature sensors operate on very little supply current and

could be exposed to very hostile electrical environments, it is

important to minimize the effects of RFI (Radio-Frequency

Interference) on these devices. The effect of RFI on these

temperature sensors in specific and analog ICs in general is

manifested as abnormal dc shifts in the output voltage due to

the rectification of the high frequency ambient noise by the IC.

In those cases where the devices are operated in the presence of

high frequency radiated or conducted noise, a large value tantalum capacitor (⬎2.2 µF) placed across the 0.1 µF ceramic may

offer additional noise immunity.

Fahrenheit Thermometers

Although the TMP3x temperature sensors are centigrade temperature sensors, a few components can be used to convert the

output voltage and transfer characteristics to directly read Fahrenheit temperatures. Shown in Figure 5a is an example of a

simple Fahrenheit thermometer using either the TMP35 or the

TMP37. This circuit can be used to sense temperatures from

41°F to 257°F, with an output transfer characteristic of 1 mV/°F

using the TMP35, and from 41°F to 212°F using the TMP37

with an output characteristic of 2 mV/°F. This particular

approach does not lend itself well to the TMP36 because of its

inherent 0.5 V output offset. The circuit is constructed with an

AD589, a 1.23 V voltage reference, and four resistors whose values

for each sensor are shown in the figure table. The scaling of the

output resistance levels was to ensure minimum output loading

on the temperature sensors. A generalized expression for the

circuit’s transfer equation is given by:

V

OUT

=

R1

R1+ R2

TMP 35

()

+

R3 + R4

R3

AD589

()

where: TMP35 = Output voltage of the TMP35, or the TMP37,

at the measurement temperature, T

, and

M

AD589 = Output voltage of the reference = 1.23 V.

Note that the output voltage of this circuit is not referenced to

the circuit’s common. If this output voltage were to be applied

directly to the input of an ADC, the ADC’s common should be

adjusted accordingly.

V

TMP35/37

AD589

1.23V

S

V

GND

S

TCV

OUT

V

OUT

R1 (k)

R2 (k)R3 (k)R4 (k)

R1

R2

V

OUT

R3

R4

0.1F

PIN ASSIGNMENTS

SENSOR

TMP35 1mV/F 45.3 10 10 374

TMP37 2mV/F 45.3 10 10 182

The same circuit principles can be applied to the TMP36, but

because of the TMP36’s inherent offset, the circuit uses two less

resistors as shown in Figure 5b. In this circuit, the output

voltage transfer characteristic is 1 mV/°F, but is referenced to

the circuit’s common; however, there is a 58 mV (58°F) offset

in the output voltage. For example, the output voltage of the

circuit would read 18 mV, were the TMP36 placed in –40°F

ambient environment, and 315 mV at 257°F.

V

S

V

S

V

GND

OUT

R1

45.3k

R2

10k

V

@ –40F = 18mV

OUT

V

@ 257F = 315mV

OUT

@ 1mV/F – 58F

V

OUT

0.1F

TMP36

Figure 5b. TMP36 Fahrenheit Thermometer Version 1

At the expense of additional circuitry, the offset produced by the

circuit in Figure 5b can be avoided by using the circuit in Figure 5c. In

this circuit, the output of the TMP36 is conditioned by a singlesupply, micropower op amp, the OP193. Although the entire

circuit operates from a single 3 V supply, the output voltage of the

circuit reads the temperature directly, with a transfer characteristic of 1 mV/°F, without offset. This is accomplished through

the use of an ADM660, a supply voltage inverter. The 3 V

supply is inverted and applied to the P193’s V– terminal. Thus,

for a temperature range between –40°F and 257°F, the output

of the circuit reads –40 mV to 257 mV. A general expression for

the circuit’s transfer equation is given by:

OUT

=

R5+ R6

V

R6

R4

1+

TMP 36

()

R3

V

R4

R3

S

2

−

Average and Differential Temperature Measurement

In many commercial and industrial environments, temperature

sensors are often used to measure the average temperature in a

building, or the difference in temperature between two locations

on a factory floor or in an industrial process. The circuits in

Figures 6a and 6b demonstrate an inexpensive approach to

average and differential temperature measurement. In Figure

6a, an OP193 is used to sum the outputs of three temperature

sensors to produce an output voltage scaled by 10 mV/°C that

represents the average temperature at three locations. The circuit

can be extended to as many temperature sensors as required as

long as the circuit’s transfer equation is maintained. In this

application, it is recommended that one temperature sensor type

be used throughout the circuit; otherwise, the output voltage of

the circuit will not produce an accurate reading of the various

ambient conditions.

Figure 5a. TMP35/TMP37 Fahrenheit Thermometers

–8–

REV. B

10F/0.1F

TMP36

@ T1

0.1F

0.1F

2

3

4

6

7

OP193

1F

V

OUT

R3*

R4*

R2*R1*

2.7V < V

S

< 5.5V

TMP36

@ T2

R5

100k

R6

100k

V

OUT

= T2 – T1 @ 10mV/ C

V

S

2

*R1–R4, CADDOCK T914–100k–100, OR EQUIVALENT

0.1F

R7

100k

R8

25k

R9

25k

0 ⱕ TA ⱕ 125 C

CENTERED AT

CENTERED AT

V

TMP36

GND

S

V

ELEMENT

R2

R4

R5

R6

50k

50k

OUT

+3V

R1

R2

TMP36

258.6k

10k

47.7k

10k

10F

C1

NC

10F

R3 R4

R5

R6

8

1

2

ADM660

4

3

5

6

7

Figure 5c. TMP36 Fahrenheit Thermometer Version 2

TMP35/TMP36/TMP37

0.1F

8

2

V

@ 1mV/ F

OP193

3

4

6

–3V

10F

NC

OUT

–40F ⱕ TA ⱕ 257 F

The circuit in Figure 6b illustrates how a pair of TMP3x sensors

can be used with an OP193 configured as a difference amplifier

to read the difference in temperature between two locations. In

these applications, it is always possible that one temperature

sensor would be reading a temperature below that of the other

sensor. To accommodate this condition, the output of the OP193

is offset to a voltage at one-half the supply via R5 and R6. Thus,

the output voltage of the circuit is measured relative to this point,

< 5.5V

2.7V < +V

S

0.1F

V

7

2

OP193

3

4

TMP3x

TMP3x

TMP3x

Figure 6a. Configuring Multiple Sensors for Average

Temperature Measurements

R1

300k

R2

300k

R3

300k

R4

7.5k

FOR R1 = R2 = R3 = R;

V

R4 = R6

TEMP(AVG)

R1

R5 =

3

TEMP(AVG)

@ 10mV/ C FOR TMP35/36

@ 20mV/ C FOR TMP35/36

1

R5

100k

R6

7.5k

= 1 (TMP3x1 + TMP3x2+ TMP3x3)

3

as shown in the figure. Using the TMP36, the output voltage of

the circuit is scaled by 10 mV/°C. To minimize error in the difference between the two measured temperatures, a common, readily

available thin-film resistor network is used for R1–R4.

Figure 6b. Configuring Multiple Sensors for Differential

Temperature Measurements

REV. B

–9–

TMP35/TMP36/TMP37

Microprocessor Interrupt Generator

These inexpensive temperature sensors can be used with a

voltage reference and an analog comparator to configure an

interrupt generator useful in microprocessor applications. With

the popularity of fast 486 and Pentium laptop computers, the

need to indicate a microprocessor over-temperature condition

has grown tremendously. The circuit illustrated in Figure 7

demonstrates one way to generate an interrupt using a TMP35,

a CMP402 analog comparator, and a REF191, a 2 V precision

voltage reference.

The circuit has been designed to produce a logic HIGH interrupt

signal if the microprocessor temperature exceeds 80°C. This

80°C trip point was arbitrarily chosen (final value set by the

microprocessor thermal reference design) and is set using an

R3–R4 voltage divider of the REF191’s output voltage. Since

the output of the TMP35 is scaled by 10 mV/°C, the voltage at

the CMP402’s inverting terminal is set to 0.8 V.

Since temperature is a slowly moving quantity, the possibility

for comparator chatter exists. To avoid this condition, hysteresis

is used around the comparator. In this application, a hysteresis

of 5°C about the trip point was arbitrarily chosen; the ultimate

value for hysteresis should be determined by the end application.

The output logic voltage swing of the comparator with R1 and

R2 determine the amount of comparator hysteresis. Using a 3.3 V

supply, the output logic voltage swing of the CMP402 is 2.6 V;

thus, for a hysteresis of 5°C (50 mV @ 10 mV/°C), R1 is set to

20 kΩ and R2 is set to 1 MΩ. An expression for this circuit’s

hysteresis is given by:

R1

V

=

HYS

V

()

LOGIC SWING, CMP402

R2

Since the likelihood that this circuit would be used in close

proximity to high-speed digital circuits, R1 is split into equal

values and a 1000 pF is used to form a low-pass filter on the

output of the TMP35. Furthermore, to prevent high frequency

noise from contaminating the comparator trip point, a 0.1 µF

capacitor is used across R4.

3.3V

Thermocouple Signal Conditioning with Cold-Junction

Compensation

The circuit in Figure 8 conditions the output of a Type K

thermocouple, while providing cold-junction compensation, for

temperatures between 0°C and 250°C. The circuit operates

from single 3.3 V to 5.5 V supplies and has been designed to

produce an output voltage transfer characteristic of 10 mV/°C.

A Type K thermocouple exhibits a Seebeck coefficient of

approximately 41 µV/°C; therefore, at the cold junction, the

TMP35, with a temperature coefficient of 10 mV/°C, is

used with R1 and R2 to introduce an opposing cold-junction

temperature coefficient of –41 µV/°C. This prevents the

isothermal, cold-junction connection between the circuit’s PCB

tracks and the thermocouple’s wires from introducing an error

in the measured temperature. This compensation works extremely

well for circuit ambient temperatures in the range of 20°C to

50°C. Over a 250°C measurement temperature range, the

thermocouple produces an output voltage change of 10.151 mV.

Since the required circuit’s output full-scale voltage is 2.5 V, the

gain of the circuit is set to 246.3. Choosing R4 equal to 4.99 kΩ

sets R5 equal to 1.22 MΩ. Since the closest 1% value for R5 is

1.21 MΩ, a 50 kΩ potentiometer is used with R5 for fine trim of

the full-scale output voltage. Although the OP193 is a superior

single-supply, micropower operational amplifier, its output stage

is not rail-to-rail; as such, the 0°C output voltage level is 0.1 V.

If this circuit were to be digitized by a single-supply ADC, the

ADC’s common should be adjusted to 0.1 V accordingly.

Using TMP3x Sensors in Remote Locations

In many industrial environments, sensors are required to operate in the presence of high ambient noise. These noise sources

take on many forms; for example, SCR transients, relays, radio

transmitters, arc welders, ac motors, et cetera. They may also be

used at considerable distance from the signal conditioning circuitry.

These high noise environments are very typically in the form of

electric fields, so the voltage output of the temperature sensor

can be susceptible to contamination from these noise sources.

V

S

V

GND

OUT

3

R5

100k

REF191

2

4

0.1F

TMP35

Figure 7. Pentium Over-Temperature Interrupt Generator

Pentium is a registered trademark of Intel Corporation.

10k

0.1F

6

R1A

1F

1

C1 = CMP402

4

C

1000p

F

R3

16k

L

–10–

R1B

10k

R4

10k

R2

1M

0.1F

3

6

5

V

REF

0.1F

4

C1

13

2

14

<80C

INTERRUPT

>80C

REV. B

3.3V < V

< 5.5V

S

TMP35/TMP36/TMP37

TYPE K

THERMOCOUPLE

0.1F

CHROMEL

ALUMEL

0C ⱕ T ⱕ 250C

V

S

TMP35

GND

COLD

JUNCTION

ISOTHERMAL

BLOCK

V

OUT

R1*

24.9k

CU

CU

R2*

102

R3

R4

10M

4.99k

5%

NOTE: ALL RESISTORS 1%

UNLESS OTHERWISE NOTED

2

3

7

OP193

R5*

1.21M

0.1F

6

4

50k

R6

100k

5%

P1

0 – 2.5V

Figure 8. A Single-Supply, Type K Thermocouple Signal Conditioning Circuit with Cold-Junction Compensation

Illustrated in Figure 9 is a way to convert the output voltage of a

TMP3x sensor into a current to be transmitted down a long

twisted-pair shielded cable to a ground referenced receiver. The

temperature sensors do not possess the capability of high output

current operation; thus, a garden variety PNP transistor is used

to boost the output current drive of the circuit. As shown in the

table, the values of R2 and R3 were chosen to produce an arbitrary full-scale output current of 2 mA. Lower values for the

full-scale current are not recommended. The minimum-scale

output current produced by the circuit could be contaminated

by nearby ambient magnetic fields operating in vicinity of the

circuit/cable pair. Because of the use of an external transistor,

the minimum recommended operating voltage for this circuit is

5 V. Note, to minimize the effects of EMI (or RFI) both the

circuit’s and the temperature sensor’s supply pins are bypassed

with good quality, ceramic capacitors.

A Temperature to 4–20 mA Loop Transmitter

In many process control applications, two-wire transmitters are

used to convey analog signals through noisy ambient environments. These current transmitters use a “zero-scale” signal

current of 4 mA that can be used to power the transmitter’s

signal conditioning circuitry. The “full-scale” output signal in

these transmitters is 20 mA.

A circuit that transmits temperature information in this fashion

is illustrated in Figure 10. Using a TMP3x as the temperature

sensor, the output current is linearly proportional to the temperature of the medium. The entire circuit operates from the

3 V output of the REF193. The REF193 requires no external

trimming for two reasons: (1) the REF193’s tight initial output

voltage tolerance and (2) the low supply current of TMP3x, the

OP193 and the REF193. The entire circuit consumes less than

3 mA from a total budget of 4 mA. The OP193 regulates the

output current to satisfy the current summation at the noninverting

node of the OP193. A generalized expression for the KCL

equation at the OP193’s Pin 3 is given by:

TMP 3x × R3

I

OUT

1

R 7

×

R1

=

V

× R3

REF

+

R2

For each of the three temperature sensors, the table below illustrates the values for each of the components, P1, P2 and R1–R4:

0.1F

0.01F

R1

4.7k

TMP3x

5V

2N2907

V

S

V

OUT

V

OUT

R3

V

OUT

GND

SENSOR R2 R3

TMP35 634 634

TMP36 887 887

TMP37 1k 1k

R2

TWISTED PAIR

BELDEN TYPE 9502

OR EQUIVALENT

Figure 9. A Remote, Two-Wire Boosted Output Current

Temperature Sensor

REV. B

Table II. Circuit Element Values for Loop Transmitter

Sensor R1() P1() R2() P2() R3() R4()

TMP35 97.6 k 5 k 1.58 M 100 k 140 k 56.2 k

TMP36 97.6 k 5 k 931 k 50 k 97.6 k 47 k

TMP37 97.6 k 5 k 10.5 k 500 84.5 k 8.45 k

–11–

TMP35/TMP36/TMP37

TMP3x

V

S

GND

6

4

2

3

7

8

5

1

AD654

V

OUT

10F/0.1F

5V

P2

100k

R

OFF1

470

f

OUT

OFFSET

R

OFF2

10

R1

P1

R

T

*

0.1F

C

T

*

5V

R

PU

5k

f

OUT

NB: ATTA (min),

f

OUT

= 0Hz

*

RT AND CT – SEE TABLE

SENSOR R

T

(R1 + P1) C

T

TMP35

TMP36

TMP37

11.8k + 500

16.2k + 500

18.2k + 1k

1.7nF

1.8nF

2.1nF

The 4 mA offset trim is provided by P2, and P1 provides the

circuit’s full-scale gain trim at 20 mA. These two trims do not

interact because the noninverting input of the OP193 is held at

a virtual ground. The zero-scale and full-scale output currents of

the circuit are adjusted according to the operating temperature

range of each temperature sensor. The Schottky diode, D1, is

required in this circuit to prevent loop supply power-on transients from pulling the noninverting input of the OP193 more

than 300 mV below its inverting input. Without this diode, such

transients could cause phase reversal of the operational amplifier

and possible latchup of the transmitter. The loop supply voltage

compliance of the circuit is limited by the maximum applied

input voltage to the REF193 and is from 9 V to 18 V.

A Temperature to Frequency Converter

Another common method of transmitting analog information

from a remote location is to convert a voltage to an equivalent in

the frequency domain. This is readily done with any of the

low cost, monolithic voltage-to-frequency converters (VFCs)

available. These VFCs feature a robust, open-collector output

transistor for easy interfacing to digital circuitry. The digital

signal produced by the VFC is less susceptible to contamination

from external noise sources and line voltage drops because the

only important information is the frequency of the digital signal.

As long as the conversions between temperature and frequency

are done accurately, the temperature data from the sensors can

be reliably transmitted.

The circuit in Figure 11 illustrates a method by which the

outputs of these temperature sensors can be converted to a

frequency using the AD654. The output signal of the AD654 is

a square wave that is proportional to the dc input voltage across

Pins 4 and 3. The transfer equation of the circuit is given by:

f

OUT

V

=

− V

TMP

10 × RT× C

OFFSET

()

T

Figure 11. A Temperature-to-Frequency Converter

An offset trim network (f

circuit to set f

at 0 Hz when the temperature sensor’s mini-

OUT

OFFSET ) is included with this

OUT

mum output voltage is reached. Potentiometer P1 is required to

calibrate the absolute accuracy of the AD654. The table in the

figure illustrates the circuit element values for each of the three

sensors. The nominal offset voltage required for 0 Hz output

from the TMP35 is 50 mV; for the TMP36 and TMP37, the

offset voltage required is 100 mV. In all cases for the circuit

values shown, the output frequency transfer characteristic of the

circuit was set at 50 Hz/°C. At the receiving end, a frequencyto-voltage converter (FVC) can be used to convert the frequency

back to a dc voltage for further processing. One such FVC is

the AD650.

For complete information on the AD650 and AD654, please

consult the individual data sheets for those devices.

TMP3x

V

S

R1*

V

OUT

GND

*SEE TEXT

FOR VALUES

P1*

20mA

ADJUST

R3*

R2*

P2*

4mA

ADJUST

7

3

2

D1

D1 : HP5082–2810

A1 : OP193

4

R4*

3V

6

REF193

1F

0.1F

R5

100k

4

R6

100k

2

100

R7

Figure 10. A Temperature to 4-to-20 mA Loop Transmitter

–12–

Q1

2N1711

I

L

V

LOOP

9V TO 18V

V

OUT

R

250

L

REV. B

TMP35/TMP36/TMP37

Driving Long Cables or Heavy Capacitive Loads

Although the TMP3x family of temperature sensors is capable

of driving capacitive loads up to 10,000 pF without oscillation,

output voltage transient response times can be improved with

the use of a small resistor in series with the output of the temperature

sensor, as shown in Figure 12. As an added benefit, this resistor

forms a low-pass filter with the cable’s capacitance, which helps

to reduce bandwidth noise. Since the temperature sensor is

likely to be used in environments where the ambient noise level

can be very high, this resistor helps to prevent rectification by the

devices of the high frequency noise. The combination of this

resistor and the supply bypass capacitor offers the best protection.

+V

S

750

V

0.1F

TMP3x

GND

OUT

LONG CABLE OR

HEAVY CAPACITIVE

LOADS

Figure 12. Driving Long Cables or Heavy Capacitive Loads

Commentary on Long-Term Stability

The concept of long-term stability has been used for many years

to describe by what amount an IC’s parameter would shift during its lifetime. This is a concept that has been typically applied

to both voltage references and monolithic temperature sensors.

Unfortunately, integrated circuits cannot be evaluated at room

temperature (25°C) for 10 years or so to determine this shift. As

a result, manufacturers very typically perform accelerated lifetime testing of integrated circuits by operating ICs at elevated

temperatures (between 125°C and 150°C) over a shorter period

of time (typically, between 500 and 1000 hours).

As a result of this operation, the lifetime of an integrated circuit

is significantly accelerated due to the increase in rates of reaction within the semiconductor material. A well-understood, and

universal, model used by the semiconductor industry, that

relates the change in rates of reaction to a change in elevated

temperatures, is the Arrhenius model. From the Arrhenius

model, an acceleration factor can be calculated and applied

to the parameter specified. For example, this acceleration

factor can be used to reduce a temperature sensor’s long-term

stability (e.g., 0.4°C after 1000 hours at T

= 150°C) to an

J

observed shift in that parameter at 25°C. For any semiconductor

device, the acceleration factor is expressed as:

F = exp

E

1

a

×

T1

k

1

−

T 2

where F = Calculated acceleration factor;

E

= Activation energy in eV = 0.7 eV;

a

k = Boltzmann’s constant = 8.63 × 10

T1 = Test temperature in Kelvin, T

–5

eV/K;

= 150°C = 423.15 K;

J

and

T2 = Desired operating temperature in Kelvin,

= 25°C = 298.15 K

T

J

For example, if the desired operating temperature of an IC is

25°C and has been subjected to test temperature of 150°C, the

acceleration factor is:

F = 3.23 ×10

−4

With this background information, the TMP3x family’s longterm stability can be mapped to what its equivalent observed

shift would be at T

= 25°C. As quoted in the data sheet, the

A

long-term stability of these temperature sensors after 1000 hours

at 150°C is 0.4°C. This shift is equivalent to 0.01°C/day at

= 150°C. To determine what the observed shift would be at

T

J

T

= 25°C is a matter of applying the acceleration factor calculated

A

above to this result:

4

0 01 3 23 10 0 003 25

./ . . /@°××= ° °

C day m C day C

−

Thus, if any of the TMP3x devices were to be used at 25°C, the

observed shift would be no more than 0.003 m°C per day, or

0.1 m°C per month. Calculating the observed shift for any other

operating temperature is simply a matter of calculating a new

acceleration factor.

REV. B

–13–

TMP35/TMP36/TMP37

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

3-Lead Plastic Package

(TO-92)

0.135

(3.43)

MIN

SEATING

PLANE

0.500

(12.70)

MIN

0.105 (2.66)

0.095 (2.42)

0.105 (2.66)

0.080 (2.42)

0.105 (2.66)

0.080 (2.42)

123

BOTTOM VIEW

0.205 (5.20)

0.175 (4.96)

0.210 (5.33)

0.170 (4.38)

0.050

(1.27)

MAX

0.019 (0.482)

0.016 (0.407)

SQUARE

0.055 (1.39)

0.045 (1.15)

0.165 (4.19)

0.125 (3.94)

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

0.0669 (1.70)

0.0590 (1.50)

0.0512 (1.30)

0.0354 (0.90)

0.0059 (0.15)

0.0019 (0.05)

SEATING

PLANE

PIN 1

8-Lead SOIC

0.1968 (5.00)

0.1890 (4.80)

8

5

0.2440 (6.20)

41

0.2284 (5.80)

PIN 1

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

5-Lead Surface Mount

RT-5 (SOT-23 Type)

0.1181 (3.00)

0.1102 (2.80)

4 5

1 3

2

0.0374 (0.95) BSC

0.0748 (1.90)

BSC

0.0197 (0.50)

0.0138 (0.35)

(R-8)

0.0098 (0.25)

0.0075 (0.19)

0.1181 (3.00)

0.1024 (2.60)

0.0571 (1.45)

0.0374 (0.95)

SEATING

PLANE

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

10°

0°

x 45°

0.0079 (0.20)

0.0031 (0.08)

0.0217 (0.55)

0.0138 (0.35)

Revision History

Location Page

Data Sheet changed from REV. A to REV. B.

Edits to SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Addition of new Figure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Deletion of WAFER TEST LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

–14–

REV. B

–15–

C00337a–0–9/01(B)

–16–

PRINTED IN U.S.A.

Loading...

Loading...