High Speed ADC USB FIFO Evaluation Kit

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

FEATURES

Buffer memory board for capturing digital data

used with high speed ADC evaluation boards

to simplify evaluation

32 kB FIFO depth at 133 MSPS (upgradable)

Measures performance with ADC Analyzer™

Real-time FFT and time domain analysis

Analyzes SNR, SINAD, SFDR, and harmonics

Simple USB port interface (2.0)

Supporting ADCs with serial port interfaces (SPI®)

On-board regulator circuit, no power supply required

6 V, 2 A switching power supply included

Compatible with Windows® 98 (2nd ed.), Windows 2000,

Windows Me, and Windows XP

EQUIPMENT NEEDED

Analog signal source and antialiasing filter

Low jitter clock source

High speed ADC evaluation board and ADC data sheet

PC running Windows 98 (2nd ed.), Windows 2000,

Windows Me, or Windows XP

Latest version of ADC Analyzer

USB 2.0 port recommended (USB 1.1-compatible)

PRODUCT DESCRIPTION

The high speed ADC FIFO evaluation kit includes the latest

version of ADC Analyzer and a buffer memory board to capture

blocks of digital data from the Analog Devices high speed

analog-to-digital converter (ADC) evaluation boards. The FIFO

board is connected to the PC through a USB port and is used

with ADC Analyzer to quickly evaluate the performance of high

speed ADCs. Users can view an FFT for a specific analog input

and encode rate to analyze SNR, SINAD, SFDR, and harmonic

information.

The evaluation kit is easy to set up. Additional equipment needed

includes an Analog Devices high speed ADC evaluation board,

a signal source, and a clock source. Once the kit is connected

and powered, the evaluation is enabled instantly on the PC.

Two versions of the FIFO are available. The HSC-ADC-EVALBDC is used with multichannel ADCs and converters with demultiplexed digital outputs. The HSC-ADC-EVALB-SC evaluation

board is used with single-channel ADCs. See

the FIFO appropriate for your high speed ADC evaluation

board.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

Table 1 to choose

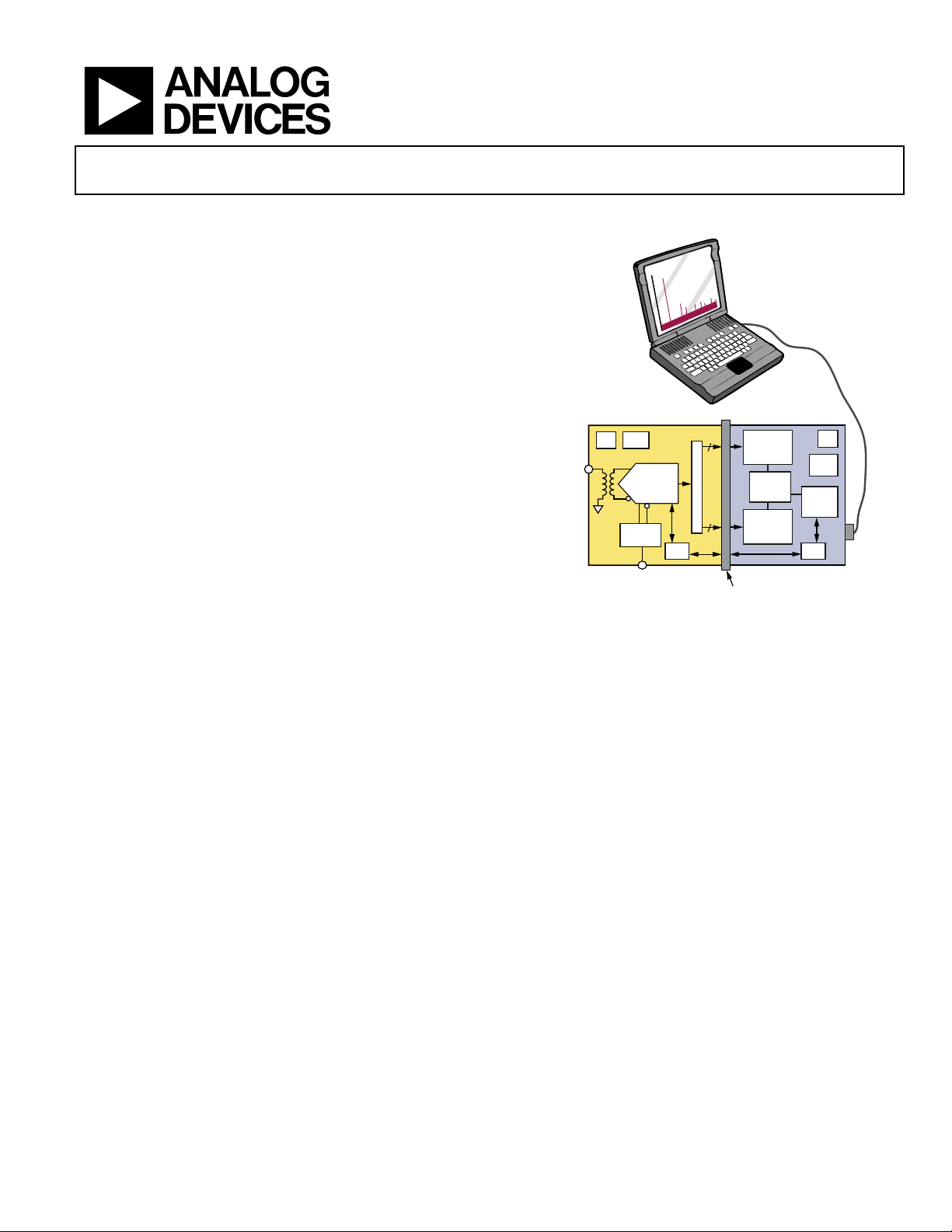

FUNCTIONAL BLOCK DIAGRAM

STANDARD

USB 2.0

HSC-ADC-EVALB-SC

HSC-ADC-EVAL B-DC

CHB FIFO,

32K,

133MHz

TIMING

CIRCUIT

CHA FIFO,

32K,

133MHz

120-PIN CO NNECTOR

OR

+3.0V

REG

USB

CTLR

SPI

FILTERED

ANALOG

INPUT

SINGLE OR DUAL

HIGH-SPEED ADC

EVALUATION BOARD

PS REG

ADC

CLOCK

CIRCUIT

CLOCK INP UT

n

LOGIC

n

SPI

Figure 1.

PRODUCT HIGHLIGHTS

1. Easy to Set Up. Connect the included power supply and

signal sources to the two evaluation boards. Then connect

to the PC and evaluate the performance instantly.

2. ADIsimADC™. ADC Analyzer supports virtual ADC

evaluation using ADI proprietary behavioral modeling

technology. This allows rapid comparison between multiple

ADCs, with or without hardware evaluation boards. For more

information, see AN-737 at

3. USB Port Connection to PC. PC interface is a USB 2.0

connection (1.1-compatible) to the PC. A USB cable is

provided in the kit.

4. 32 kB FIFO. The FIFO stores data from the ADC for processing.

A pin-compatible FIFO family is used for easy upgrading.

5. Up to 133 MSPS Encode Rate on Each Channel. Single-

channel ADCs with encode rates up to 133 MSPS can be used

with the FIFO board. Multichannel and demultiplexed output

ADCs can also be used with the FIFO board with clock rates

up to 266 MSPS.

6. Supports ADC with Serial Port Interface or SPI. Some ADCs

include a feature set that can be changed via the SPI. The FIFO

supports these SPI-driven features through the existing USB

connection to the computer without additional cabling needed.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

www.analog.com/ADIsimADC.

PS

05870-001

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

TABLE OF CONTENTS

Features .............................................................................................. 1

Equipment Needed........................................................................... 1

Product Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Product Highlights........................................................................... 1

Revision History ............................................................................... 2

FIFO Evaluation Board Easy Start.................................................. 3

Requirements ................................................................................ 3

Easy Start Steps ............................................................................. 3

Virtual Evaluation Board Easy Start With ADIsimADC ............ 4

Requirements ................................................................................ 4

Easy Start Steps ............................................................................. 4

FIFO 4.1 Data Capture Board Features ......................................... 5

FIFO 4.1 Supported ADC Evaluation Boards .......................... 6

Theory of Operation ........................................................................ 9

Clocking with Interleaved Data................................................ 10

Connecting to the HSC-ADC-FPGA-4/-8 ............................. 10

Connecting to the DEMUX BRD ............................................ 10

Upgrading FIFO Memory ......................................................... 10

Jumpers ............................................................................................ 11

Default Settings........................................................................... 11

Evaluation Board ............................................................................ 13

Power Supplies ............................................................................ 13

Connection and Setup ............................................................... 13

FIFO Schematics and PCB Layout............................................... 14

Schematics................................................................................... 14

PCB Layout ................................................................................. 21

Bill of Materials ............................................................................... 23

Ordering Information.................................................................... 25

Ordering Guide .......................................................................... 25

Clocking Description................................................................... 9

SPI Description ............................................................................. 9

REVISION HISTORY

2/06—Revision 0: Initial Version

ESD Caution................................................................................ 25

Rev. 0 | Page 2 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

FIFO EVALUATION BOARD EASY START

REQUIREMENTS

• FIFO evaluation board, ADC Analyzer, and USB cable

• High speed ADC evaluation board and ADC data sheet

• Power supply for ADC evaluation board

• Analog signal source and appropriate filtering

• Low jitter clock source applicable for specific ADC

evaluation, typically <1 ps rms

• PC running Windows 98 (2nd ed.), Windows 2000,

Windows Me, or Windows XP

• PC with a USB 2.0 port recommended (USB 1.1-

compatible)

EASY START STEPS

Note: You need administrative rights for the Windows

operating systems during the entire easy start procedure.

It is recommended to complete every step before reverting

to a normal user mode.

1. Install ADC Analyzer from the CD provided in the FIFO

evaluation kit or download the latest version on the Web.

For the latest updates to the software, check the Analog

Devices website at

2. Connect the FIFO evaluation board to the ADC evaluation

board. If an adapter is required, insert the adapter between

the ADC evaluation board and the FIFO board. If using

the HSC-ADC-EVALB-SC model, connect the evaluation

board to the bottom two rows of the 120-pin connector,

closest to the installed IDT FIFO chip. If using an ADC

with a SPI interface, remove the two 4-pin corner keys so

that the third row can be connected.

3. Connect the provided USB cable to the FIFO evaluation

board and to an available USB port on the computer.

4. Refer to

boards can be used with the default settings.

Table 5 for any jumper changes. Most evaluation

www.analog.com/hsc-FIFO.

6. Once the cable is connected to both the computer and the

FIFO board, and power is supplied, the USB drivers start

to install. To complete the total installation of the FIFO

drivers, you need to complete the new hardware sequence

two times. The first Found New Hardware Wizard opens

with the text message This wizard helps you install

software for…Pre-FIFO 4.1. Click the recommended

install, and go to the next screen. A hardware installation

warning window should then be displayed. Click Continue

Anyway. The next window that opens should finish the PreFIFO 4.1 installation. Click Finish. Your computer should

go through a second Found New Hardware Wizard, and

the text message, This wizard helps you install software

for…Analog Devices FIFO 4.1, should be displayed.

Continue as you did in the previous installation and click

Continue Anyway. Then click Finish on the next two

windows. This completes the installation.

7. (Optional) Verify in the device manager that Analog

Devices, FIFO4.1 is listed under the USB hardware.

8. Apply power to the evaluation board and check the voltage

levels at the board level.

9. Connect the appropriate analog input (which should be

filtered with a band-pass filter) and low jitter clock signal.

Make sure the evaluation boards are powered on before

connecting the analog input and clock.

10. Start ADC Analyzer.

11. Choose an existing configuration file for the ADC

evaluation board or create one.

12. Click Time Data in ADC Analyzer (left-most button under

the menus). A reconstruction of the analog input is

displayed. If the expected signal does not appear, or if there

is only a flat red line, refer to the ADC Analyzer data sheet

at

www.analog.com/hsc-FIFO for more information.

5. After verification, connect the appropriate power supplies

to the ADC evaluation boards. The FIFO evaluation board

is supplied with a wall mount switching power supply that

provides a 6 V, 2 A maximum output. Connect the supply

end to the rated 100 ac to 240 ac wall outlet at 47 Hz to

63 Hz. The other end is a 2.1 mm inner diameter jack that

connects to the PCB at J301. Refer to the instructions

included in the

about the ADC evaluation board’s power supply and other

requirements.

ADC data sheet for more information

Rev. 0 | Page 3 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

VIRTUAL EVALUATION BOARD EASY START WITH ADIsimADC

REQUIREMENTS

Requirements include

• Completed installation of ADC Analyzer, Version 4.5.17 or

later.

• ADIsimADC product model files for the desired converter.

Models are not installed with the software, but they can be

downloaded from the

Board website

at no charge.

ADIsimADC Virtual Evaluation

5. In the ADC Modeling dialog box, click the Device tab and

then click the

box. This opens a file browser and displays all of the

models found in the default directory: c:\program

files\adc_analyzer\models. If no model files are found,

follow the on-screen directions or see Step 1 to install

available models. If you have saved the models somewhere

other than the default location, use the browser to navigate

to that location and select the file of interest.

… (Browse) button, adjacent to the dialog

No hardware is required. However, if you wish to compare

results of a real evaluation board and the model, you can switch

easily between the two, as outlined in the following

Steps

section.

Easy Start

EASY START STEPS

1. To get ADC model files, go to www.analog.com/ADIsimADC

for the product of interest. Download the product of

interest to a local drive. The default location is

files\adc_analyzer\models

2. Start ADC Analyzer (see the

3. From the menu, click Config > Buffer > Model as the

buffer memory. In effect, the model functions in place of

the ADC and data capture hardware.

4. After selecting the model, click the Model button (located

next to the Stop button) to select and configure which

converter is to be modeled. A dialog box appears in the

workspace, where you can select and configure the

behavior of the model.

.

ADC Analyzer User Manual).

c:\program

6. From the menu, click Config > FFT. In the FFT

Configuration dialog box, ensure that the Encode

Frequency is set for a valid rate for the simulated device

under test. If set too low or too high, the model does not run.

7. Once a model has been selected, information about the

model displays on the Device tab of the ADC Modeling

dialog box. After ensuring that you have selected the right

model, click the Input tab. This lets you configure the

input to the model. Click either Sine Wave or Two Tone

for the input signal.

8. Click Time Data (left-most button under the pull-down

menus). A reconstruction of the analog input is displayed.

The model can now be used just as a standard evaluation

board would be.

9. The model supports additional features not found when

testing a standard evaluation board. When using the

modeling capabilities, it is possible to sweep either the

analog amplitude or the analog frequency. For more

information consult the

www.analog.com/hsc-FIFO.

ADC Analyzer User Manual at

Rev. 0 | Page 4 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

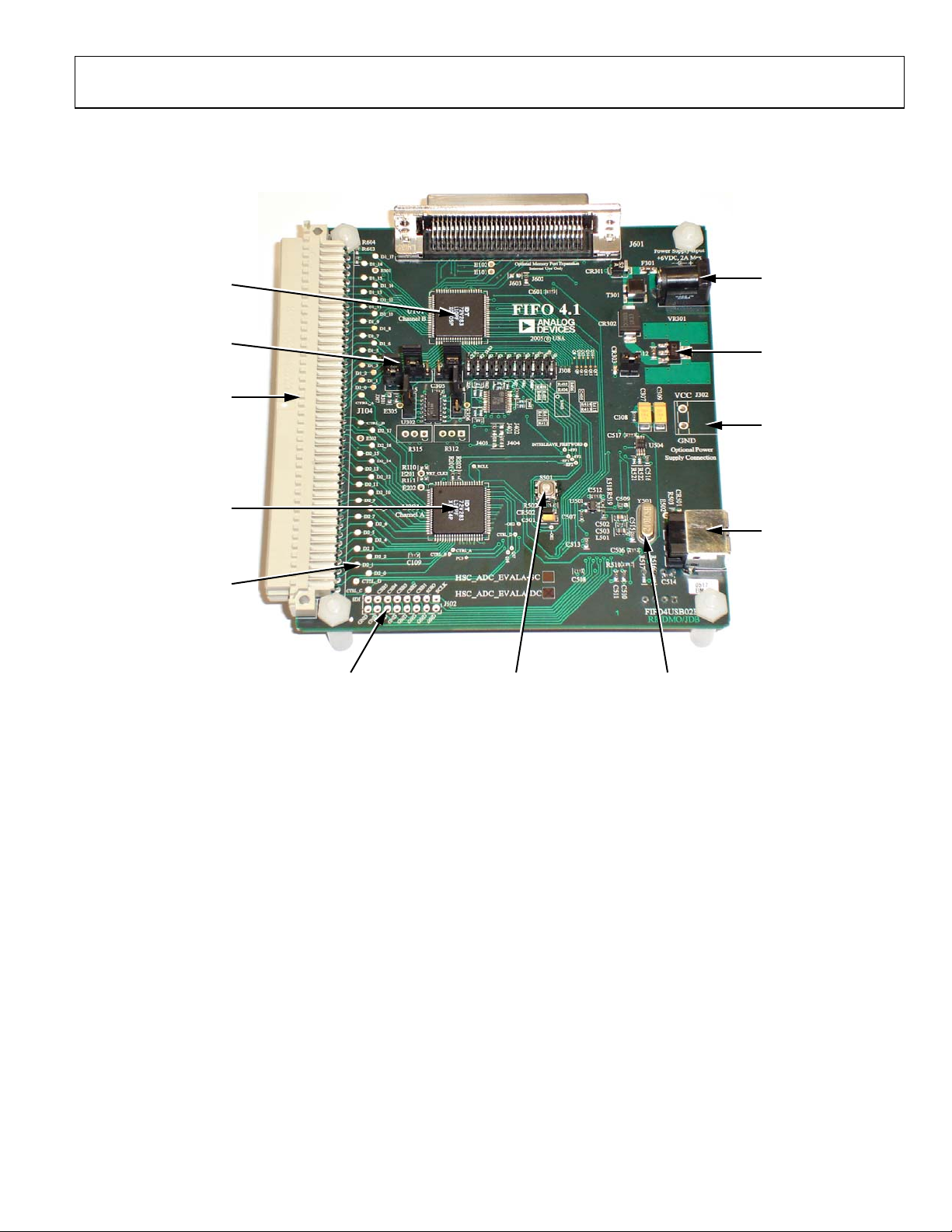

FIFO 4.1 DATA CAPTURE BOARD FEATURES

IDT72V283 32k ⋅

16-BIT 133MHz FIFO

TIMING ADJUSTMENT

16-BIT 133MHz FIFO

OPEN SOLDER MASK

CLOCK LINES FOR

JUMPERS

120-CONNECTOR

(PARALLEL CMOS

ON ALL DATA AND

INPUTS)

IDT72V283 32k ⋅

EASY PROBING

OPTIONAL SERIAL

PORT INTERFACE

CONNECTOR

RESET SWITCH

WHEN ENCODE RATE

IS INTERRUPTED

Figure 2. FIFO Components (Top View)

µCONTROLLER CRYSTAL

CLOCK = 24MHz,

OFF DURING

DATA CAPTURE

6V SWITCHING

POWER SUPPLY

CONNECTION

ON BOARD +3.3V

REGULATOR

OPTIONAL POWER

CONNECTION

USB CONNECTION

TO COMPUTER

05870-002

Rev. 0 | Page 5 of 28

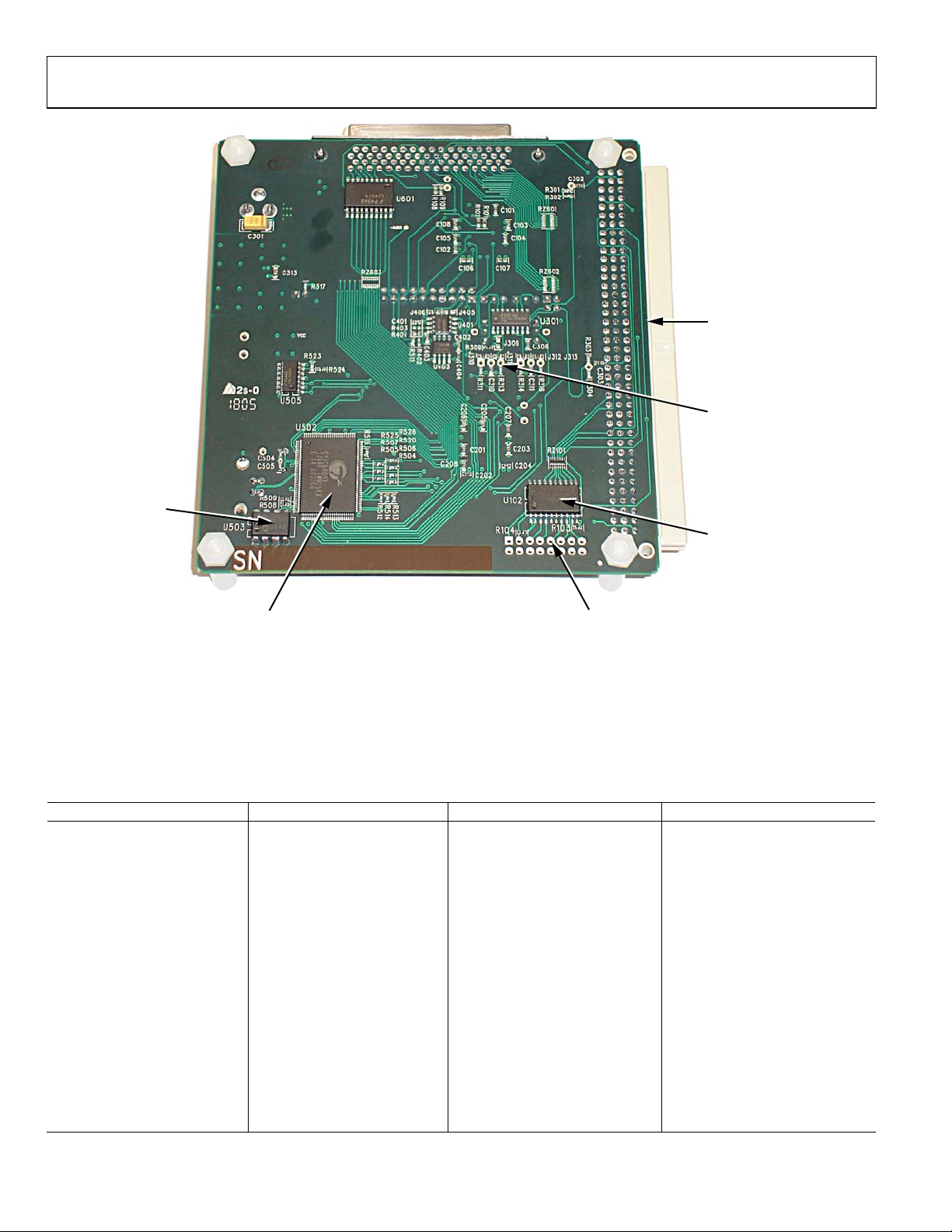

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

120-CONNECTOR

(PARALLEL CMOS

INPUTS)

TIMING ADJUSTMENT

JUMPERS

EPROM TO LOAD

USB FIRMWARE

DRIVER CIRCUIT FOR

SERIAL PORT INTERFACE

(SPI) LINES

CYPRESS Fx2 HIGH SPEED

USB 2.0 µCONTROLLER

Figure 3. FIFO Components (Bottom View)

OPTIONAL SERIAL

PORT INTERFACE

(SPI) CONNECTOR

05870-003

FIFO 4.1 SUPPORTED ADC EVALUATION BOARDS

The evaluation boards in Tab l e 1 can be used with the high speed ADC FIFO evaluation kit. Some evaluation boards require an adapter between

the ADC evaluation board connector and the FIFO connector. If an adapter is needed, send an email to

the part number of the adapter and a mailing address.

Table 1. HSC-ADC-EVALB-DC- and HSC-ADC-EVALB-SC-Compatible Evaluation Boards

Evaluation Board Model Description of ADC FIFO Board Version Comments

AD6644ST/PCB 14-bit, 65 MSPS ADC SC

AD6645-80/PCB

14-bit, 80 MSPS ADC SC

AD6645-105/PCB 14-bit, 105 MSPS ADC SC

AD9051/PCB 10-bit, 60 MSPS ADC SC Requires AD9051FFA

AD9200SSOP-EVAL 10-bit, 20 MSPS ADC SC Requires AD922xFFA

AD9200TQFP-EVAL 10-bit, 20 MSPS ADC SC Requires AD922xFFA

AD9201-EVAL Dual 10-bit, 20 MSPS ADC

1

SC Requires AD922xFFA

AD9203-EB 10-bit, 40 MSPS ADC SC Requires AD922xFFA

AD9212-65EB

1

Octal 10-bit, 65 MSPS ADC DC Requires HSC-ADC-FPGA-8

AD9215BCP-65EB 10-bit, 65 MSPS ADC SC

AD9215BCP-80EB 10-bit, 80 MSPS ADC SC

AD9215BCP-105EB 10-bit, 105 MSPS ADC SC

AD9215BRU-65EB 10-bit, 65 MSPS ADC SC

AD9215BRU-80EB 10-bit, 80 MSPS ADC SC

AD9215BRU-105EB 10-bit, 105 MSPS ADC SC

AD9216-80PCB Dual 10-bit, 80 MSPS ADC DC

AD9216-105PCB Dual 10-bit, 105 MSPS ADC DC

highspeed.converters@analog.com with

1

Rev. 0 | Page 6 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

Evaluation Board Model Description of ADC FIFO Board Version Comments

AD9218-105PCB 10-bit, 105 MSPS ADC DC

AD9218-65PCB 10-bit, 65 MSPS ADC DC

AD9219-65EB

AD9220-EB 12-bit, 10 MSPS ADC SC Requires AD922xFFA

AD9222-65EB

AD9226-EB 12-bit, 65 MSPS ADC SC Requires AD922xFFA

AD9226QFP-EB 12-bit, 65 MSPS ADC SC Requires AD922xFFA

AD9228-65EB

AD9229-65EB

AD9233-80EB 12-bit, 80MSPS ADC SC

AD9233-105EB 12-bit, 105MSPS ADC SC

AD9233-125EB 12-bit, 125MSPS ADC SC

AD9234-EB 12-bit, 150MSPS ADC SC

AD9235BCP-20EB 12-bit, 20 MSPS ADC SC

AD9235BCP-40EB 12-bit, 40 MSPS ADC SC

AD9235BCP-65EB 12-bit, 65 MSPS ADC SC

AD9235-20PCB 12-bit, 20 MSPS ADC SC

AD9235-40PCB 12-bit, 40 MSPS ADC SC

AD9235-65PCB 12-bit, 65 MSPS ADC SC

AD9236BRU-80EB 12-bit, 80 MSPS ADC SC

AD9236BCP-80EB 12-bit, 80 MSPS ADC SC

AD9237BCP-20EB 12-bit, 20 MSPS ADC SC

AD9237BCP-40EB 12-bit, 40 MSPS ADC SC

AD9237BCP-65EB 12-bit, 65 MSPS ADC

AD9238BST-20PCB Dual 12-bit, 20 MSPS ADC DC

AD9238BST-40PCB Dual 12-bit, 40 MSPS ADC DC

AD9238BST-65PCB Dual 12-bit, 65 MSPS ADC DC

AD9238BCP-20EB Dual 12-bit, 20 MSPS ADC DC

AD9238BCP-40EB Dual 12-bit, 40 MSPS ADC DC

AD9238BCP-65EB Dual 12-bit, 65 MSPS ADC DC

AD9240-EB 14-bit, 40 MSPS ADC SC Requires AD922xFFA

AD9241-EB 14-bit, 1.25 MSPS ADC SC Requires AD922xFFA

AD9243-EB 14-bit, 3 MSPS ADC SC Requires AD922xFFA

AD9244-40PCB 14-bit, 40 MSPS ADC SC

AD9244-65PCB 14-bit, 65 MSPS ADC SC

AD9245BCP-20EB 14-bit, 20 MSPS ADC

AD9245BCP-40EB 14-bit, 40 MSPS ADC

AD9245BCP-65EB 14-bit, 65 MSPS ADC

AD9245BCP-80EB 14-bit, 80 MSPS ADC

AD9246-80EB 14-bit, 80 MSPS ADC

AD9246-105EB 14-bit, 105 MSPS ADC

AD9246-125EB 14-bit, 125 MSPS ADC

AD9248BST-65EB Dual 14-bit, 65 MSPS ADC DC

AD9248BCP-20EB Dual 14-bit, 20 MSPS ADC DC

AD9248BCP-40EB Dual 14-bit, 40 MSPS ADC DC

AD9248BCP-65EB Dual 14-bit, 65 MSPS ADC DC

AD9259-50EB

AD9260-EB 16-bit, 2.5 MSPS ADC SC Requires AD922xFFA

AD9280-EB 8-bit, 32 MSPS ADC SC Requires AD922xFFA

AD9281-EB Dual 8-bit, 28 MSPS ADC SC Requires AD922xFFA

AD9283/PCB 8-bit, 100 MSPS ADC SC Requires AD9283FFA

AD9287-100EB

AD9289-65EB

AD9411/PCB 10-bit, 200 MSPS ADC DC Requires DEMUX BRD

1

1

1

1

Quad 10-bit, 65 MSPS ADC DC Requires HSC-ADC-FPGA-4/-8

Octal 12-bit, 65 MSPS ADC DC Requires HSC-ADC-FPGA-8

Quad 12-bit, 65 MSPS ADC DC Requires HSC-ADC-FPGA-4/-8

Quad 12-bit, 65 MSPS ADC DC Requires HSC-ADC-FPGA-4/-8

SC

SC

SC

SC

SC

SC

SC

SC

1

1

1

Quad 14-bit, 50 MSPS ADC DC Requires HSC-ADC-FPGA-4/-8

Quad 8-bit, 100 MSPS ADC DC Requires HSC-ADC-FPGA-4/-8

Quad 8-bit, 65 MSPS ADC DC Requires HSC-ADC-FPGA-9289

Rev. 0 | Page 7 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

Evaluation Board Model Description of ADC FIFO Board Version Comments

AD9430-CMOS/PCB 12-bit, 210 MSPS ADC DC

AD9430-LVDS/PCB

AD9432/PCB 12-bit, 105 MSPS ADC SC

AD9433/PCB 12-bit, 125 MSPS ADC SC

AD9444-CMOS/PCB 14 bit, 80 MSPS ADC SC

AD9444-LVDS/PCB 14 bit, 80 MSPS ADC SC

AD9445-IF-LVDS/PCB 14-bit, 125 MSPS ADC SC

AD9445-BB-LVDS/PCB 14-bit, 125 MSPS ADC SC

AD9446-80LVDS/PCB 16-bit, 80 MSPS ADC SC

AD9446-100LVDS/PCB 16-bit, 100 MSPS ADC SC

AD9460-80EB-IF 16-bit, 80 MSPS ADC SC

AD9460-80EB-BB 16-bit, 80 MSPS ADC SC

AD9460-105EB-IF 16-bit, 105 MSPS ADC SC

AD9460-105EB-BB 16-bit, 105 MSPS ADC SC

AD9461-130EB-IF 16-bit, 130 MSPS ADC SC

AD9461-130EB-BB 16-bit, 130 MSPS ADC SC

AD9480-LVDS/PCB

AD9481-PCB 8-bit, 250 MSPS ADC DC

AD10200/PCB Dual 12-bit, 105 MSPS ADC DC Requires GS09066

AD10201/PCB Dual 12-bit, 105 MSPS ADC DC Requires GS09066

AD10226/PCB Dual 12-bit, 125 MSPS ADC DC Requires GS09066

AD10265/PCB Dual 12-bit, 65 MSPS ADC DC Requires GS09066

AD10465/PCB Dual 14-bit, 65 MSPS ADC DC Requires GS09066

AD10677/PCB 16-bit, 65 MSPS ADC SC Requires GS09066

AD10678/PCB 16-bit, 80 MSPS ADC SC Requires GS09066

AD15252/PCB 12-bit, Dual 65 MSPS ADC DC

AD15452/PCB 12-bit, Quad 65 MSPS ADC DC Requires HSC-ADC-FPGA-4/-8

1

The high speed ADC FIFO evaluation kit can be used to evaluate two channels at a time.

2

If a DEMUX BRD is needed, send an email to highspeed.converters@analog.com.

2

2

12-bit, 210 MSPS ADC DC Requires DEMUX BRD

8-bit, 250 MSPS ADC DC Requires DEMUX BRD

Rev. 0 | Page 8 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

THEORY OF OPERATION

The FIFO evaluation board can be divided into several circuits,

each of which plays an important part in acquiring digital data

from the ADC and allows the PC to upload and process that

data. The evaluation kit is based around the IDT72V283 FIFO

chip from Integrated Device Technology, Inc (IDT). The system

can acquire digital data at speeds up to 133 MSPS and data

record lengths up to 32 kB using the HSC-ADC-EVALB-SC

FIFO evaluation kit. The HSC-ADC-EVALB-DC, which has

two FIFO chips, is available to evaluate multichannel ADCs or

demultiplexed data from ADCs sampling faster than 133 MSPS.

A USB 2.0 microcontroller communicating with ADC Analyzer

allows for easy interfacing to newer computers using the USB 2.0

(USB 1.1-compatible) interface.

The process of filling the FIFO chip or chips and reading the

data back requires several steps. First, ADC Analyzer initiates

the FIFO chip fill process. The FIFO chips are reset, using a

master reset signal (MRS). The USB microcontroller is then

suspended, which turns off the USB oscillator and ensures that

it does not add noise to the ADC input. After the FIFO chips

completely fill, the full flags from the FIFO chips send a signal

to the USB microcontroller to wake up the microcontroller

from suspend. ADC Analyzer waits for approximately 30 ms

and then begins the readback process.

During the readback process, the acquisition of data from

FIFO 1 (U201) or FIFO 2 (U101) is controlled via Signal OEA

and Signal OEB. Because the data outputs of both FIFO chips

drive the same 16-bit data bus, the USB microcontroller

controls the OEA and OEB signals to read data from the correct

FIFO chip. From an application standpoint, ADC Analyzer

sends commands to the USB microcontroller to initiate a read

from the correct FIFO chip, or from both FIFO chips in dual or

demultiplexed mode.

CLOCKING DESCRIPTION

Each channel of the buffer memory requires a clock signal to

capture data. These clock signals are normally provided by the

ADC evaluation board and are passed along with the data

through Connector J104 (Pin 37 for both Channel A and

Channel B). If only a single clock is passed for both channels,

they can be connected together by Jumper J303.

Jumpers J304 and J305 at the output of the LVDS receiver allow

the output clock to be inverted by the LVDS receiver. By default,

the clock outputs are inverted by the LVDS receiver.

The single-ended clock signal from each data channel is

buffered and converted to a differential CMOS signal by two

gates of a low voltage differential signal (LVDS) receiver, U301.

This allows the clock source for each channel to be CMOS,

TTL, or ECL.

The clock signals are ac-coupled by 0.1 μF capacitors.

Potentiometer R312 and Potentiometer R315 allow for fine

tuning the threshold of the LVDS gates. In applications where

fine-tuning the threshold is critical, these potentiometers can be

replaced with a higher resistance value to increase the

adjustment range. Resistors R301, R302, R303, R304, R311,

R313, R314, and R316 set the static input to each of the

differential gates to a dc voltage of approximately 1.5 V.

At assembly, Solder Jumper J310 to Solder Jumper J313 are set

to bypass the potentiometer. For fine adjustment using the pot,

the solder jumpers must be removed, and R312 and R315 must

be populated.

U302, an XOR gate array, is included in the design to let users

add gate delays to the FIFO memory chip clock paths. They are

not required under normal conditions and are bypassed at

assembly by Jumper J314 and Jumper J315. Jumper J306 and

Jumper J307 allow the clock signals to be inverted through an

XOR gate. In the default setting, the clocks are not inverted by

the XOR gate.

The clock paths described above determine the WRT_CLK1 and

WRT_CLK2 signals at each FIFO memory chip (U101 and

U201). The timing options above should let you choose a clock

signal that meets the setup and hold time requirements to

capture valid data.

A clock generator can be applied directly to S1 and/or S3. This

clock generator should be the same unit that provides the clock

for the ADC. These clock paths are ac-coupled, so that a sine

wave generator can be used. DC bias can be adjusted by

R301/R302 and R303/R304.

The DS90LV048A differential line receiver is used to square the

clock signal levels applied externally to the FIFO evaluation

board. The output of this clock receiver can either directly drive

the write clock of the IDT72V283 FIFO(s), or first pass through

the XOR gate timing circuitry described above.

SPI DESCRIPTION

The Cypress IC (U502) supports the HSC SPI standard to allow

programming of ADCs that have SPI-accessible register maps.

U102 is a buffer that drives the 4-wire SPI (SCLK, SDI, SDO,

1

CSB

) through the 120-pin connector (J104) on the third or top

row. J502 is an auxiliary SPI connector to monitor the SPI

signals connected directly to the Cypress IC. For more

information on this and other functions, consult the user

manual titled Interfacing to High Speed ADCs via SPI at

www.analog.com/hsc-FIFO.

1

Note that CSB1 is the default CSB line used.

Rev. 0 | Page 9 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

The SPI interface designed on the Cypress IC can communicate

with up to five different SPI-enabled devices. The CLK and data

lines are common to all SPI devices. The correct device is

chosen to communicate by using one of the five active low chip

select pins. This functionality is controlled by selecting a SPI

channel in the software.

CLOCKING WITH INTERLEAVED DATA

ADCs with very high data rates can exceed the capability of a

single buffer memory channel (~133 MSPS). These converters

often demultiplex the data into two channels to reduce the rate

required to capture the data. In these applications, ADC Analyzer

must interleave the data from both channels to process it as a

single channel. The user can configure the software to process

the first sample from Channel A, the second from Channel B,

and so on, or vice versa. The synchronization circuit included in

the buffer memory forces a small delay between the write enable

signals (WENA and WENB) to the FIFO memory chips (Pin 1,

U101, and U201), ensuring that the data is captured in one

FIFO before the other. Jumper J401 and Jumper J402 determine

which FIFO receives WENA and which FIFO receives WENB.

CONNECTING TO THE HSC-ADC-FPGA-4/-8

ADCs that have serial LVDS outputs require another board that

is connected between the ADC evaluation board and the FIFO

data capture card. This board converts the serial data into

parallel CMOS so that the FIFO data capture card can accept

the data. For more detailed information on this board, refer to

the HSC-ADC-FPGA datasheet at

www.analog.com/hsc-FIFO.

CONNECTING TO THE DEMUX BRD

ADCs that have parallel LVDS outputs require another board

that is connected between the ADC evaluation board and the

FIFO data capture card. This board converts parallel LVDS to

parallel CMOS, using both channels of the FIFO data capture

card. For more detailed information on this board, send an

email to highspeed.converters@analog.com

UPGRADING FIFO MEMORY

The FIFO evaluation board includes one or two 32 kB FIFOs

that are capable of 133 MHz clock signals, depending on the

model number. Pin-compatible FIFO upgrades are available

from IDT. See

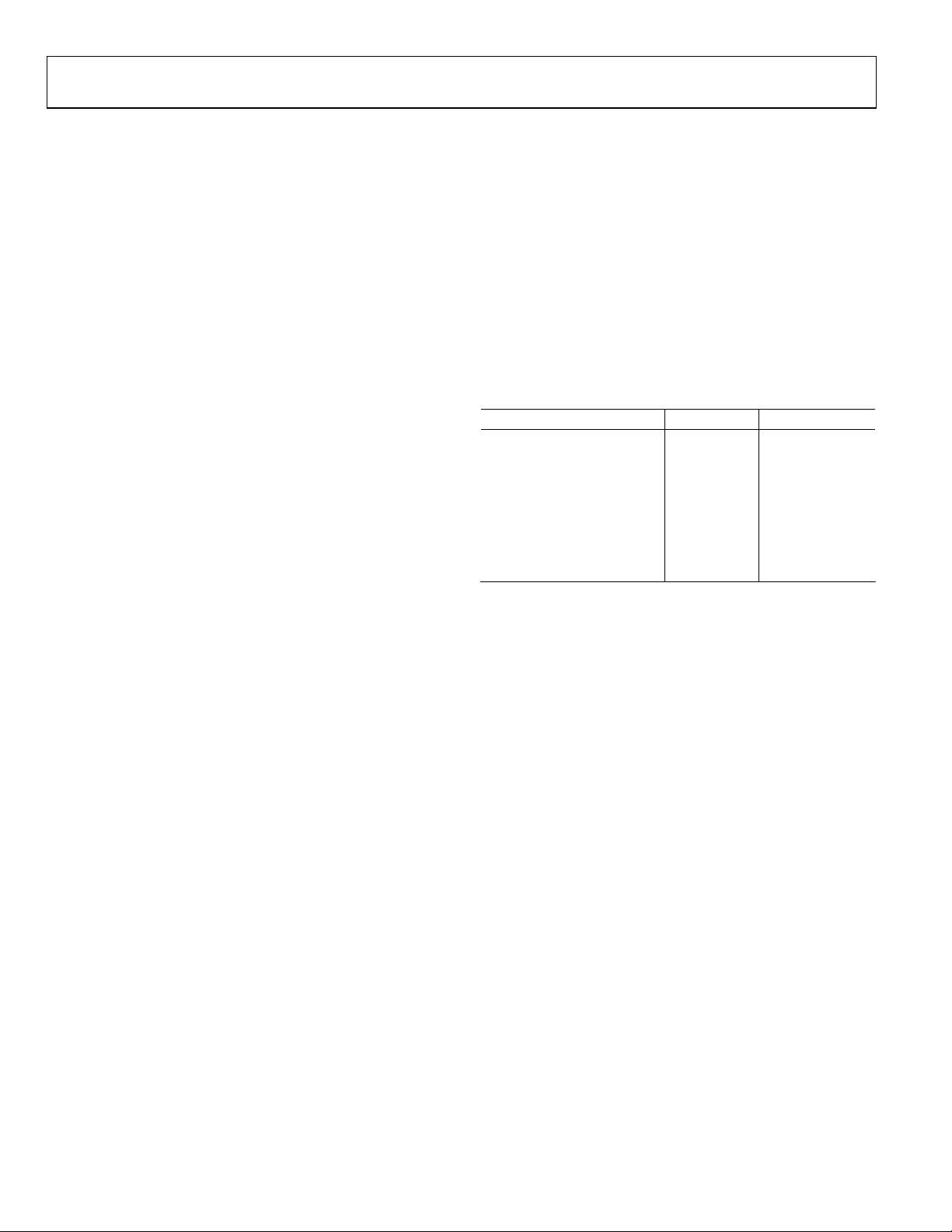

Table 2. IDT Part Number Matrix

Part Number FIFO Depth FIFO Speed

IDT72V283-L7-5PF (Default ) 32 kB 133 MHz

IDT72V293-L7-5PF 64 kB 133 MHz

IDT72V2103-L7-5PF 132 kB 133 MHz

IDT72V2113-L7-5PF 256 kB 133 MHz

IDT72V283-L6PF 32 kB 166 MHz

IDT72V293-L6PF 64 kB 166 MHz

IDT72V2103-L6PF 132 kB 166 MHz

IDT72V2113-L6PF 256 kB 166 MHz

For more information, visit www.idt.com.

Table 2 for the IDT part number matrix.

Rev. 0 | Page 10 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

JUMPERS

Use the legends in Tab le 3 and Table 4 to configure the jumpers. On the FIFO evaluation board, Channel A is associated with the bottom

IDT FIFO chip, and Channel B is associated with the top IDT FIFO chip (closest to the Analog Devices logo).

Table 3. Jumper Legend

Position Description

In Jumper in place (2-pin header).

Out Jumper removed (2-pin header).

Position 1 or Position 3 Denotes the position of a 3-pin header. Position 1 is marked on the board.

Table 4. Solder Jumper Legend

Position Description

In Solder pads should be connected with 0 Ω resistor.

Out Solder pads should not be connected with 0 Ω resistor.

DEFAULT SETTINGS

Tabl e 5 lists the default settings for each model of the FIFO evaluation kit. The single channel (SC) model is configured to work with a

single channel ADC using the bottom FIFO, U201. The dual channel (DC) model is configured to work with demultiplexed ADCs (such

as the AD9430). Dual channel ADC settings are shown in a separate column, as are settings for the opposite (top) FIFO, U101 for a single

channel ADC. To align the timing properly, some evaluation boards require modifications to these settings. Refer to the

Description

section in the Theory of Operation section for more information.

Clocking

Another useful way to configure the jumper settings easily for various configurations is to consult ADC Analyzer under Help > About

HSC_ADC_EVALB, and click Set Up Default Jumper Wizard. Then click the configuration setting that applies to the application of

interest. A picture of the FIFO board is displayed for that application with a visual of the correct jumper settings already in place.

Table 5. Jumper Configurations

Single Channel

Settings, Default

Jumper #

J303 In Out Out In Position 2 to Position 4, ties write clocks together

J304 In In In In

J305 In In In In

J306 Out Out Out Out

J307 Out Out Out Out

J310 to

J313

J314 In In In In

J315 In In In In

J316 In In In In Power connected using switching power supply

J401 In In In In

J402 Out Out Out Out

J403 Out Out Out Out

J404 In In In In

J405 Out In Out Out

(Bottom)

In In In In

Demultiplexed

Settings

Dual-Channel

Settings

Single-Channel

Settings (Top)

1

Description

Position 1 to Position 2, POS3: invert clock out of

DS90 (U301)

Position 2 to Position 3, POS3: invert clock out of

DS90 (U301)

No invert to encode clock from XOR (U302),

0 Ω resistor

No invert to encode clock from XOR (U302),

0 Ω resistor

All solder jumpers are shorted with 0 Ω resistors

(bypass level shifting to input of DS90)

Position 1 to Position 2, one XOR gate timing

delay for top FIFO (U101)

Position 1 to Position 2, one XOR gate timing

delay for bottom FIFO (U201)

Controls if top FIFO (U101) gets write enable

before or after bottom FIFO, 0 Ω resistor

Controls if top FIFO (U101) gets write enable

before or after bottom FIFO, 0 Ω resistor

Controls if bottom FIFO (U201) gets a write

enable before or after the top FIFO, 0 Ω resistor

Controls if bottom FIFO (U201) gets a write

enable before or after the top FIFO, 0 Ω resistor

When in, WRT_CLK1 is used to create write enable

signal for FIFOs, 0 Ω resistor (significant only for

interleave mode)

Rev. 0 | Page 11 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

Single Channel

Demultiplexed

Settings

Jumper #

Settings, Default

(Bottom)

J406 In In In In

J503 In In In In

J504 Out Out Out Out N/A

J505 In In In In

J506 Out Out Out Out N/A

J602 Out Out Out Out N/A

J603 In In In In N/A

1

Some jumpers can be a 0 Ω resistor instead of a physical jumper. This is shown in Table 5 in the jumper description column.

Dual-Channel

Settings

Single-Channel

Settings (Top)

1

Description

WRT_CLK2 is used to create write enable signal

for FIFOs, 0 Ω resistor (significant only for

interleave mode)

Connect enable empty flag of top FIFO (U101)

to USB MCU, 0 Ω resistor

Connect enable full flag of top FIFO (U101)

to USB MCU, 0 Ω resistor

Rev. 0 | Page 12 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

T

EVALUATION BOARD

The FIFO provides all of the support circuitry required to

accept two channels of an ADC’s digital parallel CMOS outputs.

Each of the various functions and configurations can be selected by

proper connection of various jumpers (see

Tabl e 5). When

using this in conjunction with an ADC evaluation board, it is

critical that the signal sources used for the analog input and

clock have very low phase noise (<1 ps rms jitter) to realize the

ultimate performance of the converter. Proper filtering of the

analog input signal to remove harmonics and lower the integrated

or broadband noise at the input is also necessary to achieve the

specified noise performance.

Figure 5 to Figure 15 for complete schematics and layout plots.

See

POWER SUPPLIES

The FIFO board is supplied with a wall mount switching power

supply that provides a 6 V, 2 A maximum output. Connect the

supply to the rated 100 ac to 240 ac wall outlet at 47 Hz to 63 Hz.

The other end is a 2.1 mm inner diameter jack that connects to

the PCB at J301. On the PC board, the 6 V supply is then fused

and conditioned before connecting to the low dropout 3.3 V

linear regulator that supplies the proper bias to the entire board.

WALL OUTLE

100V TO 240V AC

47Hz TO 63Hz

SWITCHING

POWER

SUPPLY

EVALUATION

XFMR

INPUT

CLK

BOARD

ROHDE & SCHWARZ,

SMHU,

2V p-p SIGNAL

SYNTHESIZER

ROHDE & SCHWARZ,

SMHU,

2V p-p SI GNAL

SYNTHESIZER

BAND-PASS

FILTER

Figure 4. Example Setup Using Quad ADC Evaluation Board and FIFO Data Capture Board

PAR ALL EL

OUTPUTS

PAR ALL EL

OUTPUTS

When operating the evaluation board in a non-default

condition, J316 can be removed to disconnect the switching

power supply. This enables the user to bias the board

independently. Use P302 to connect an independent supply to

the board. A 3.3 V supply is needed with at least a 1 A current

capability.

CONNECTION AND SETUP

The FIFO board has a 120-pin (40-pin, triple row) connector

that accepts two 16-bit channels of parallel CMOS inputs (see

Figure 6). For those ADC evaluation boards that have only an

80-pin (40-pin, double row) connector, it is pertinent for the

lower two rows of the FIFO’s triple row connector to be connected

in order for the data to pass to either FIFO channel correctly.

The top or third row is used to pass SPI signals across to the

adjacent ADC evaluation board that supports this feature.

3.3V

–+

VCC

GND

HSC-ADC-EVALB-DC

FIFO DATA

CAPTURE

BOARD

USB

CONNECT ION

SPI

PC

RUNNING

ADC

ANALYZER

SPISPI

05870-004

CHB

CMOS

CHB

CMOS

6V DC

2A MAX

Rev. 0 | Page 13 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

A

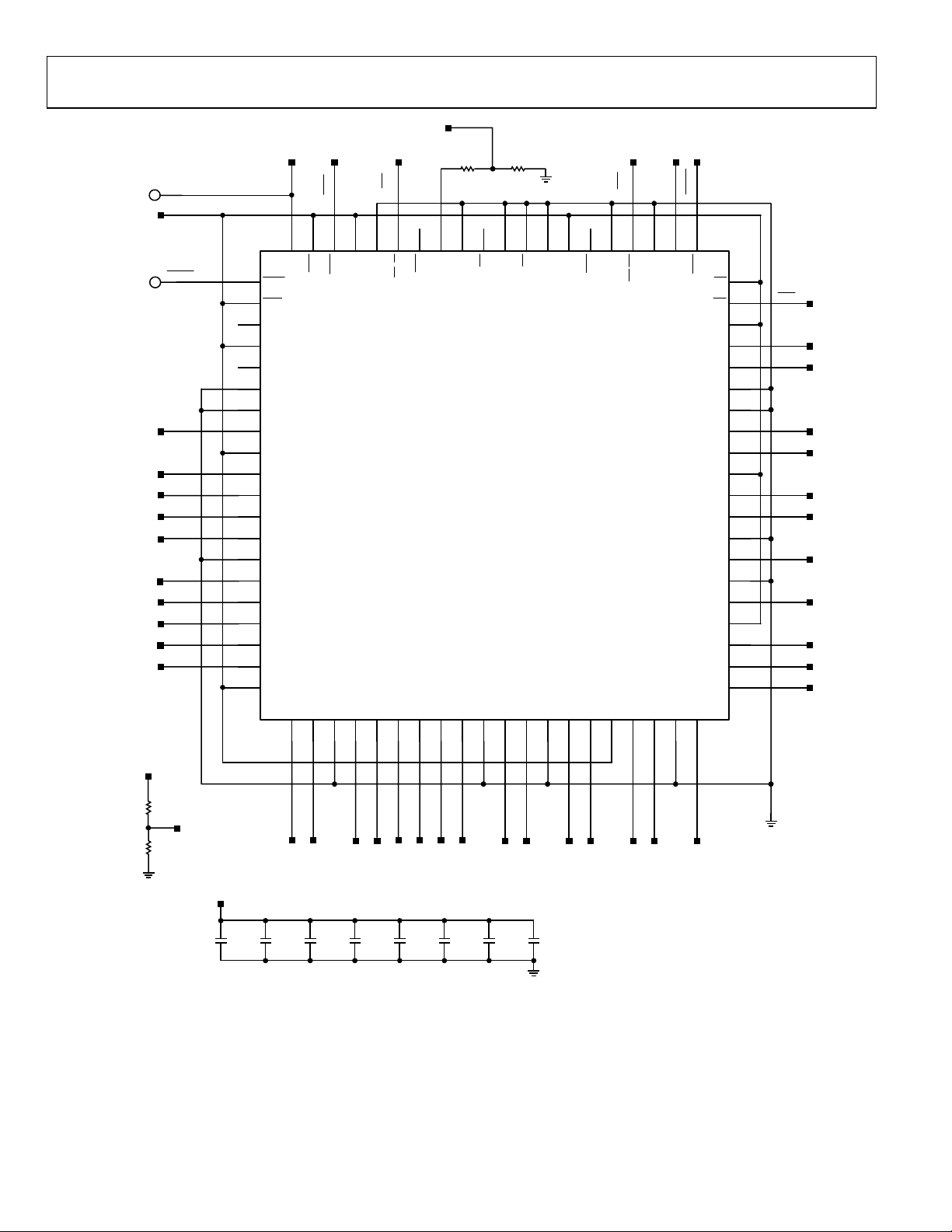

FIFO SCHEMATICS AND PCB LAYOUT

SCHEMATICS

LLOW Fx2 TO CONTROL FIFO’S OUTPUT WIDTH

PC2: TRISTATED, NORMAL 16-BIT DATA PATH

PC2: DRIVEN HIG H, 9-BIT OUTPUT ALLOWS

READING 18 BITS IN TWO READS.

10kΩ

EF1_TF

REN1

RCLK

E101

VCC

PC2

R1010ΩR102

WRT_CLK1

MRS

FF1_TF

WRT_CLK1

R108

DNP

R109

DNP

VCC

75

76

80

WEN1

E102

POPULATE WITH PIN SOCKET

D1_17

D1_16

D1_15

D1_14

D1_13

D1_12

D1_11

D1_10

D1_9

D1_8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

U101

WEN

SEN

DNC

VCC

DNC

IW

GND

D17

VCC

D16

D15

D14

D13

GND

D12

D11

D10

D9

D8

VCC

WCLK

D7

21

77

78

79

LD

PRS

MRS

D6

GND

23

24

22

FF/IR

FWFT/SI

D5

D4D3D2D1D0

26

25

72

73

74

OW

PAF

70

71

HF

FSEL1

FSEL0

IDT72V283

TQFP80

TOP FIFO

CHANNEL B

Q0

GND

31

30

29

28

27

67

68

69

IP

BE

VCC

Q1

Q2

GND

32

33

34

64

65

66

PAE

PFM

Q3

VCC

36

35

62

63

61

RM

REN

RCLK

EF/OR

Q4

Q5

GND

39

37

38

60

RT

59

OE

VCC

Q17

Q16

GND

GND

Q15

Q14

VCC

Q13

Q12

GND

Q11

GND

Q10

VCC

Q9

Q8

Q7

Q6

40

OE1

58

57

Q17

56

Q16

55

54

53

Q15

52

Q14

51

50

Q13

49

Q12

48

47

Q11

46

45

Q10

44

43

Q9

42

Q8

41

Q7

D1_1

D1_0

D1_2

C106

0.1µF

Q0

C107

0.1µF

Q1

C108

0.1µF

Q2

Q3

C109

0.1µF

Q4

Q5

Q6

5870-005

VCC

C101

0.1µF

C102

0.1µF

D1_3

D1_5

C104

0.1µF

D1_4

C105

0.1µF

D1_7

D1_6

C103

0.1µF

Figure 5. PCB Schematic

Rev. 0 | Page 14 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

CMOS INPUTS

CHB

CHA

J104

CLKB

MSB

LSB

CLKA

MSB

LSB

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

A37

A38

A39

A40

TEST POINTS

D1_15

D1_14

D1_13

D1_12

D1_11

D1_10

D1_9

D1_8

D1_7

D1_6

D1_5

D1_4

D1_3

D1_2

D1_1

D1_0

CTRL_B

D2_15

D2_14

D2_13

D2_12

D2_11

D2_10

D2_9

D2_8

D2_7

D2_6

D2_5

D2_4

D2_3

D2_2

D2_1

D2_0

CTRL_D

DUT_CLK1

D1_15

D1_14

D1_13

D1_12

D1_11

D1_10

D1_9

D1_8

D1_7

D1_6

D1_5

D1_4

D1_3

D1_2

D1_1

D1_0

CTRL_B

DUT_CLK2

D2_15

D2_14

D2_13

D2_12

D2_11

D2_10

D2_9

D2_8

D2_7

D2_6

D2_5

D2_4

D2_3

D2_2

D2_1

D2_0

CTRL_D

J104

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

B37

B38

B39

B40

TEST POINTS

D1_17

D1_16

CTRL_A

D2_17

D2_16

CTRL_C

D1_17

D1_16

CTRL_A

D2_17

D2_16

CTRL_C

PLACEMENT OF HEADER KEY HERE

J104

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

C27

C28

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

C40

SDO

ALL SPI LABELS ARE WITH

RESPECT TO THE DUT.

19

18

16

15

14

13

12

11

10

1

2

17

3

16

15

4

14

5

6

13

7

22

9

RZ101

12

11

8

20

OE2

Y0

Y1

U102

Y2

74VHC541MTC

Y3

Y4

Y5

Y6

Y7

GND

10

VCC

VCC

1

OE

2

A0

3

A1

A2

A3

A4

A5

A6

A7

CSB1

4

CSB2

5

6

SCLK

7

CSB3

8

CSB4

9

R103

10kΩ

R104

10kΩ

SDI

PLACEMENT OF HEADER KEY HERE

Figure 6. Schematic (Continued)

Rev. 0 | Page 15 of 28

05870-006

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

A

E201

VCC

TE WITH PI N SOCKET

POPUL

E202

WEN2

D2_17

D2_16

D2_15

D2_14

D2_13

D2_12

D2_11

D2_10

D2_9

D2_8

WRT_CLK2

1

WEN

2

SEN

3

DNC

4

VCC

5

DNC

6

IW

7

GND

8

D17

9

VCC

10

D16

11

D15

12

D14

13

D13

14

GND

15

D12

16

D11

17

D10

18

D9

19

D8

20

VCC

U201

MRS

76

80

WCLK

D7

21

77

78

79

LD

PRS

MRS

D5

D6

GND

23

25

24

22

PC3

R2010ΩR202

FF2

75

FF/IR

FWFT/SI

72

73

74

OW

PAF

BOTTOM FIFO

D4D3D2D1D0

29

28

27

26

10kΩ

70

71

HF

FSEL1

FSEL0

IDT72V283

TQFP80

CHANNEL A

Q0

GND

31

30

EF2

67

68

69

IP

BE

VCC

Q1

Q2

GND

32

33

34

64

65

66

PAE

PFM

EF/OR

Q3

Q4

VCC

36

35

37

REN2

RCLK

62

63

61

RM

REN

RCLK

Q5

GND

39

38

60

RT

59

OE

VCC

Q17

Q16

GND

GND

Q15

Q14

VCC

Q13

Q12

GND

Q11

GND

Q10

VCC

Q9

Q8

Q7

Q6

40

OE2

58

57

Q17

56

Q16

55

54

53

Q15

52

Q14

51

50

Q13

49

Q12

48

47

Q11

46

45

Q10

44

43

Q9

42

Q8

41

Q7

R203

DNP

R204

DNP

VCC

WRT_CLK2

VCC

C201

0.1µF

C202

0.1µF

Q0

Q1

Q2

Q3

Q4

Q5

D2_1

D2_3

D2_5

D2_7

D2_6

C203

0.1µF

D2_4

C204

0.1µF

C205

0.1µF

D2_0

D2_2

C206

C207

0.1µF

C208

0.1µF

0.1µF

Q6

05870-007

Figure 7. Schematic (Continued)

Rev. 0 | Page 16 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

R

R

TOP FIFO

WRT_CLK1

CONTROLS

3

J314

6

U302

4

U302

1

C305

R303

0.1µF

BOTTOM FIFO

C303

13

6

9

DUT_CLK2

0.1µF

331Ω

R302

331Ω

INVERT CLOCK 1

VCC

EN

EN

R304

VCC

TOP FIFO

DUT_CLK1

C302

0.1µF

E301E302

PIN SOCKET

POPULATE WITH

VCC

VCC

R301

331Ω

GATE DELAYS

1

SET 0, 1, OR 2 XO

E306

74VCX86

5

3

74VCX86

1kΩ

R309

2

J306

3

J304

1

14

15

ROUT2

ROUT1

DS90LV048A

RIN1+

RIN1–1RIN2+3RIN2–4RIN3+6RIN3–5RIN4+7RIN4–

2

J303

331Ω

INVERT CLOCK 1

VCC

VCC

2

1

DNP

R310

1kΩ

J307

C306

0.1µF

INVERT CLOCK 2

ROUT311ROUT4

4

3

R314

331Ω

DNP

J312

12

12U301

J313

DNP

CHANNEL CONFIG URATION

74VCX86

INVERT CLOCK 2

ON TOP SIDE

GATE DELAYS

1

SET 0, 1, O R 2 XO

WRT_CLK2WRT_CLK1

RCLK

E305

2

74VCX86

C311

0.1µF

R316

331Ω

J308

1

34

56

VCC

AUX CLOCK SIGNAL MONITOR CONNECTOR

VR301

ADP3339AKC-3.3

CR302

SK33MSCT

T103

12

PLACE JUMPERS BETWEEN PADS

F301

EF2

FF2

10

11 12

78

9

FF1_F

EF1_F

TOP FIFO BOTTOM FIFO

2

VOVI

4

VO

3

43

CR301

S2A

2.2A

C301

10µF

+

OE2

13 14

OE1

C313

ADJ

C312

REN2

15 16

REN1

J316

12

1µF

1

1µF

WENS

20

DNP

17 18

19

MRS

OPTIONAL POWER

R317

C309

+

C308

C307

+

INPUT HEADER

CR303

499Ω

10µF

0.1µF

10µF

J302

VCC

12

DNP

CONTROL S

WRT_CLK2

BOTTOM FIFO

3

J315

11

U302

13

8

U302

9

10

1

J305

3

10

GND

8

REMOVE JUMPER FOR DUAL

R315

C310

0.1µF

SHORT C302 AND C303

REMOVE R301- R304 AND

FOR COHERENT SAMPL ING

J310

VCC

R311

331Ω

R312

J311

DNP

R313

331Ω

Figure 8. Schematic (Continued)

POWER SUPPLY INPUT 6V, 2A MAX

J301

PJ-102A

132

5870-008

Rev. 0 | Page 17 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

CONTROLS TOP FI FO

CONTROLS BOTTOM FIFO

WEN2

WEN1

DNP

J403

J404

J401

J402

DNP

6

U403

MC100EPT23

4

3

R414

49.9Ω

R415

40.2Ω

R413

49.9Ω

R412

R411

7

U403

MC100EPT23

1

2

40.2Ω

49.9Ω

R410

49.9Ω

S0 18

R0 19

Q0 17

Q0 16

S

R

3

VBB

Q

Q

D

CLK

MC100EP29

VCC

VCC

10

R406

40.2Ω

R405

49.9Ω

1

R404

49.9Ω

7

VCC

DNP

R402

R401

20KΩ

WENS

1D0

2

R403

DNP

C401

2D0

U401

DNP

4CLK0

5CLK0

6CLK

MC100EPT22

S1 13

S

8D1

6

DNP

R1 12

Q

Q

CLK

GND

11

U402

9D1

R409

R408

R407

4

J406

40.2Ω

49.9Ω

49.9Ω

WRT_CLK2

Q1 15

Q1 14

R

D

7CLK

3

U401

MC100EPT22

J405

WRT_CLK1

C405

0.1µF

C404

0.1µF

C403

0.1µF

C402

0.1µF

VCC

05870-009

Figure 9. Schematic (Continued)

Rev. 0 | Page 18 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

123456789101112131415

DNP

J502

CONTROL FIFO

Q16

72

DPLUS

18

Q17

PC0/GPIFADR0

PC2

PC1/GPIFADR1

DMINUS

PC3

757473

PC2/GPIFADR2

U502

A0

OUTPUT W IDTH

PC3/GPIFADR3

CY7C68013_128AXC

A1

76

PC4/GPIFADR4

A2

77

PC5/GPIFADR5

A3

9796959419

PC6/GPIFADR6

VCC;17,26, 43,48,64, 68,81,100,107

GND;20;27; 49;58;65;80; 93;116 ;12 5

A4

117

PC7/GPIFADR7

A5

118

SDI

CSB1

CSB2

SCLK

111

110

1087978

109

PE2/T2OUT

PE0/T0OUT

PE1/T1OUT

SDO

CSB5

CSB3

CSB4

15

115

114

113

112

PE5/INT6

PE6/T2EX

PE4/RXD1OUT

PE3/RXD0OUT

PE7/GPI FADR8

16

14

NC3

NC2

NC1

ALL SPI

TO THE DUT

LABELSARE

WITH RESPECT

A15

A14

A13

A12

A11

A10A9A8

A7

A6

119

120

21

128

127

126

25

242322

INTERLEAVE _ F I R S T W O R D

OE1

CTRL_A

CTRL_B

CTRL_C

R504 24.9Ω

R505 24.9Ω

R506 24.9Ω

82

28

106

OE2

CTRL_D

R507 24.9Ω

R520 24.9Ω

R525 24.9Ω

R526 24.9Ω

929190

89

858483

INT4

PA1/I NT1

PA0/I NT0

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Q9

Q10

Q11

C501

1µF

S501 = RESET USB CONTROLLER

+

3

4

Q12

Q13

Q14

Q15

S501

1

2

FF_USB

VCC

R502

100kΩ

CR502

VCC

C503

PB1/FD1

45

PB2/FD2

46

PB3/FD3

47

PB4/FD4

54

PB5/FD5

55

PB6/FD6

56

PB7/FD7

57

PD0/FD8

102

PD1/FD9

103

104

105

121

122

123

124

RXD1

53

TXD1

52

RXD0

51

TXD0

50

101

RESET

99

DVCC

2

AVCC

10

IFCLK

CLKOUT INT5

1

32

0.1µF

PB0/FD0

44

PA3/ *WU2

PA2/ *SLOE

PA6/ *PKTEND

PA5/FIFOADR1

PA4/FIFOADR0

PA7/*F LAG/SLC S

PD2/FD10

PD3/FD 11

PD4/FD12

PD5/FD13

PD6/FD14

PD7/FD15

*WAKEU P

RDY1/*SLWR

RDY0/*SLR D

4

RDY5

RDY4

RDY3

RDY2

XTALIN

XTALOUT

98765

11

12

D7

D6

D5

D4

D3

D2

D1

D0

T0

T1

T2

CTL5

CTL4

CTL3

CTL2/*FLAGC

CTL1/*FLAGB

CTL0*FLAG A

RESE RVED

BKPT

EA

SCL

SDA

OE

PSEN

RD

WR

CS

GND

AGND

16

CONNECTIO N

AUX SPI PORT

88

87

86

63

62

61

60

59

29

30

31

98

67

66

71

70

69

33

34

35

36

37

38

39

40

41

42

3

13

REN2M

R515 24.9Ω

REN2

R514 24.9Ω

R513 24.9Ω

R512 24.9Ω

R511 24.9Ω

R510 24.9Ω

R509 10kΩ

R508 10kΩ

VCC

RENEXT

REN1

WENS

MRS

2kΩ

2kΩ

R516

R517

VCC

5

6

7

8

WP

SCL

SDA

VCC

A0

A1

VSS

A2

U503

1

2

4

3

RCLK

C502

2.2µF

L501

12

VCC

FF_USB

4

3

5

+V

GND

VCC

1

2

U501

R518

10kΩ

R519

10kΩ

FF2

FROM TO P FIFO

FIFO

FROM

BOT TOM

J503

J504

DNP

J506 J505

EF1_BHB EF1_TF

FF1_BHB FF1_TF

FF2

EF2

1423

Y501

24MHz

1

2

12pF

C504

12pF

C505

J501

R503

E502

USB_VBUS

499Ω

CR501

C517

0.1µF

C516

0.1µF

C515

0.1µF

INTERLEAVE_FIRSTWORD

0Ω

C514

0.1µF

DNP

USB CONNECTIO N

E503

E504

E505

GROUND TEST POINTS

C513

0.1µF

C512

0.1µF

C511

0.1µF

C510

0.1µF

VCC

VCC

R522

C509

0.1µF

C508

0.1µF

C507

0.1µF

C506

0.1µF

VCC

R524

R523

2kΩ

VCC

6

U505

5

MRS

6

5

3

Q

Q

8

VCC

U504

7

4

332Ω

U505

3

FF1_TF

4

GND

CLK

D

PRE CLR

2

1

VCC

2

R521

332Ω

7

14

U505

VCC

1

TOP

FIFO

FROM

FIFO

FROM

FF2

BOT TOM

05870-010

Figure 10. Schematic (Continued)

Rev. 0 | Page 19 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

V

D1_8

D1_9

D1_10

D1_12

D1_13

D1_14

D1_15

D1_0

D1_1

D1_2

D1_3 DC3

D1_4

D1_5

D1_6

D1_7

1

2

3

4

5

6

7

RZ601

1

2

3

4

5

6

7

89

RZ602

R603

0Ω

R604

0Ω

EXTERNAL MEMORY OVERRIDES ON BOARD MEMORIES WHEN PLUGGED IN. ONLY A SIDE DATA.

16

DC8

15

DC9

14

DC10

13

DC11D1_11

12

DC12

11

DC13

10

DC14

98

DC15

16

DC0

15

DC1

14

DC2

13

12

DC4

11

DC5

10

DC6

DC7

DC16D1_16

DC17D1_17

CONNECTIONS FOR 2M WO RD EXTERNAL MEMORY

DNP

J601

35

1

DC0

DC3

DC2

DC6

DC8

DC7

DC11

DC10

DC13

DC4

DC5

DC9

DC17

EF1_BHB

FF1_BHB

WRT_CLK1

QL0

QL3

QL4

QL7

36

2

37

3

4

38

5

39

6

40

7

41

8

42

9

43

44

10

45

11

46

12

47

13

48

14

49

15

50

16

51

17

52

18

53

19

54

20

55

21

56

22

57

23

58

24

59

25

60

26

61

27

62

28

63

29

64

30

65

31

66

32

67

33

68

34

DC14

DC15

DC16

DC1

DC12

REN1

RCLK

MRS

WEN1

QL1

QL2

QL5

QL6

RENEXT

QL0

QL1

QL2

QL3

QL4

QL5

QL6

QL7

1

2

3

4

5

6

7

8

9

10

J603: ALLOW S 2 MEG BUF FER TO READ BACK DATA

ON EACH RCLK EDGE.

J602: ALLOW S 2 MEG BUF FER TO READ BACK 1 DATA

ON EVERY 3RD RCLK EDGE. J602 IS FOR

BACKWARD COMPATABILITY IF NEEDED.

Figure 11. Schematic (Continued)

CC

C601

0.1µF

U601

D0

D1

D2

D3

D4

D5

D6

D7

GND

74LCX574

REN2M RCLK

VCCOUT_EN

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

CLOCK

J602

DNP

20

VCC

19

18

17

16

15

14

13

12

11

1

2

3

4

5

6

7

J603

16

15

14

13

12

11

10

98

RZ605

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

05870-011

Rev. 0 | Page 20 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

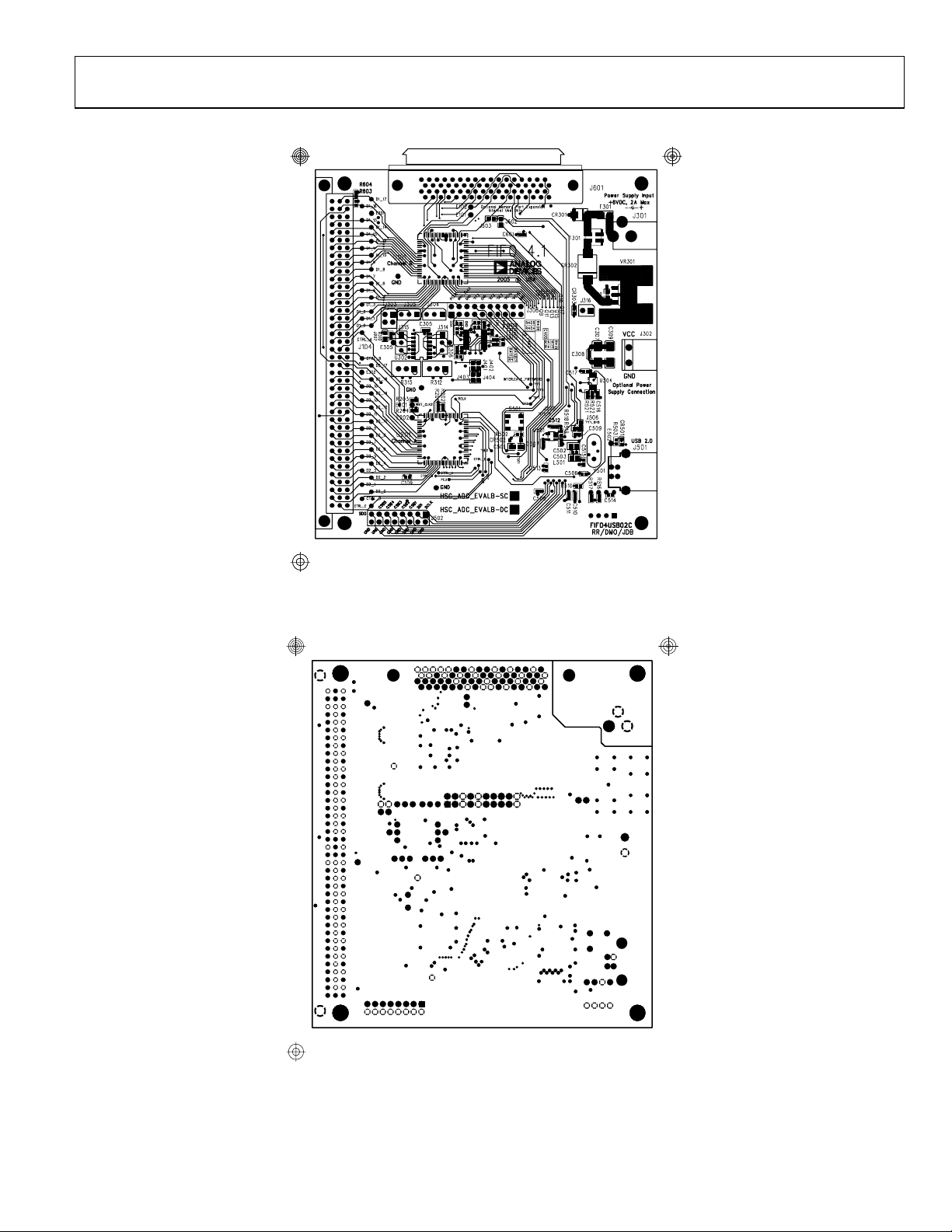

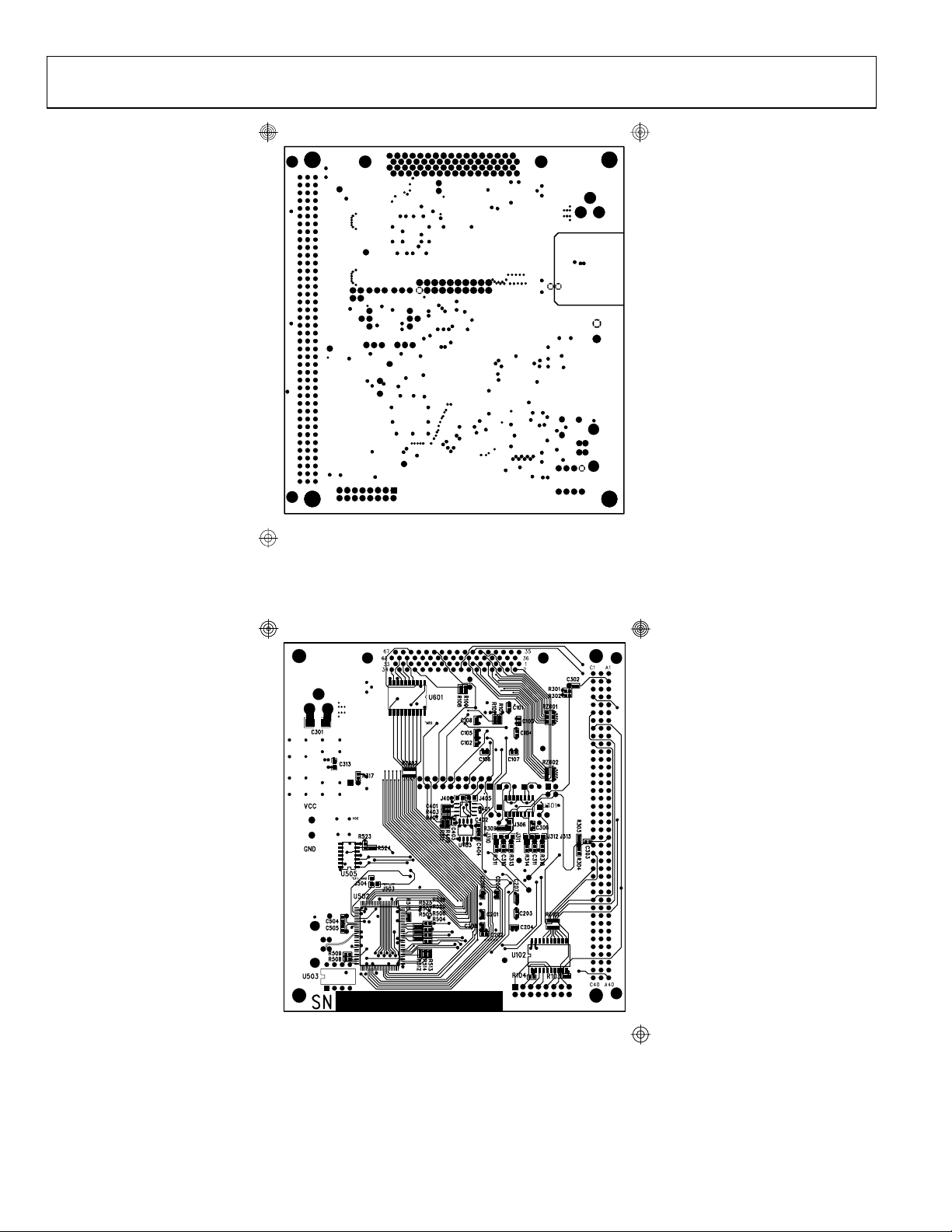

PCB LAYOUT

05870-012

Figure 12. Layer 1—Primary Side

Figure 13. Layer 2—Ground Plane

Rev. 0 | Page 21 of 28

05870-013

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

05870-014

Figure 14. Layer 3—Power Plane

05870-015

Figure 15. Layer 4—Secondary Side

Rev. 0 | Page 22 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

BILL OF MATERIALS

Table 6. HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC Bill of Materials

Item Qty Reference Designation Device Package Description Manufacturer Mfg Part Number

1 42 C101 to C109, C201 to C208,

C302, C303, C305, C306, C308,

C310, C311, C402 to C405,

C503, C506 to C517, C601

2 3 C301, C307, C309 Capacitor 6032-28 Tantalum, 10 μF, 16 V,

3 2 C312, C313 Capacitor 603 Ceramic, 1 μF, 10 V,

4 1 C501 Capacitor 3216-18 Tantalum, 1 μF, 16 V,

5 1 C502 Capacitor 805 Ceramic, 2.2 μF, 25 V,

6 2 C504, C505 Capacitor 402 Ceramic, 12 pF,

7 1 CR301 Diode DO-214AA Schottky diode,

8 1 CR302 Diode DO-214AB Schottky diode,

9 2 CR303, CR501 LED 603 Green, 4 V 5 m,

10 1 CR502 Diode SOD-123 Switching, 75 V,

11 1 F301 Fuse 1210 6.0 V, 2.2 A trip current

12 1 J104 Connector 120-pin, female,

13 1 J301 Connector 0.08”, PCMT RAPC722, power

14 1 J303 Connector 4-pin Male, straight,

15 4 J304, J305, J314, J315 Connector 3-pin Male, straight, 100 mil SAMTEC TWS-103-08-G-S

16 8 J310 to J313, J401, J404, J406,

J603

17 1 J316 Connector 2-pin Male, straight, 100 mil SAMTEC TSW-1002-08-G-S

18 1 J501 Connector 4-pin USB, PC mount, right

19 1 L501 Ferrite

20 5 R101, R201, R524, R603, R604 Resistor 402 0 Ω, 1/16 W, 5% Panasonic ERJ-2GE0R00X

21 8 R102 to R04, R202, R508, R509,

R518, R4519

22 10 R301 to R304, R311, R313,

R314, R316, R521, R522

23 2 R309, R310 Resistor 402 1 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF1002X

24 2 R317, R503 Resistor 402 499 Ω, 1/16 W, 1% Panasonic ERJ-2RKF1001X

25 1 R401 Resistor 402 20 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF4990X

26 8 R404, R405, R407, R408, R410,

R411, R413, R414

27 4 R406, R409, R412, R415 Resistor 402 40.2 Ω, 1/16 W, 1% Panasonic ERJ-2RKF40R2X

28 1 R502 Resistor 402 100 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF1003X

29 13 R504, R506, R507, R510 to R515,

R520, R525, R526

30 3 R516, R517, R523 Resistor 402 2 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF2001X

31 1 RZ101 Resistor Resistor array, 22 Ω,

32 1 S501 Switch Momentary (normally

Capacitor 402 Ceramic, 0.1 μF, 16 V,

Connector 603 2-pin solder jumper,

805 500 mA, 600 Ω @

Bead

Resistor 402 10 kΩ, 1/16 W, 1% Panasonic ERJ-2RKF1002X

Resistor 402 332 Ω, 1/16 W, 1% Panasonic ERJ-2RKF3320X

Resistor 402 49.9 Ω, 1/16 W, 1% Panasonic ERJ-2RKF2002X

Resistor 402 24.9 Ω, 1/16 W, 1% Panasonic ERJ-2RKF24R9X

Rev. 0 | Page 23 of 28

X5R, 10%

10%

X5R, 10%

20%

X5R 10%

NPO, 50 V, 5%

50 V, 2 A, SMC

30 V, 3 A, SMC

candela

150 mA

resettable fuse

PC mount, right angle

supply connector

100 mil

0 Ω, 1/10 W, 5%

angle, Type B, female

100 MHz

1/4 W, 5%

open), 100 GE, 5 mm,

SPST

Panasonic ECJ-0EB1C014K

Kemet T491C106K016AS

Panasonic ECJ-1VB1A105K

Panasonic ECS-T1CY105R

Panasonic ECJ-2FB1E225K

Panasonic ECJ-0EC1H120J

Micro Commercial

Group

Micro Commercial

Group

Panasonic LNJ314G8TRA

Diodes, Inc. 1N4148W-7

Tyco, Raychem NANOSMDC110F-2

AMP 650874

Switchcraft SC1153

SAMTEC TSW-1-10-08-GD

Panasonic ERJ-3GEY0R00V

AMP 787780-1

Steward HZ0805E601R-00

Panasonic EXB-2HV220JX

Panasonic EVQ-PLDA15

S2A

SK33MSCT

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

Item Qty Reference Designation Device Package Description Manufacturer Mfg Part Number

33 1 T301 Choke 2020 10 μH, 5 A, 50 V,

3412 U101, U201 IC TQFP80 3.3 V,

35 1 U102 IC SOIC20 74VHC541,

36 1 U301 IC SOIC16 DS90LV048A National

37 1 U302 IC SOIC14 74VCX86 Fairchild 74VCX86

38 1 U401 IC SO8M1 MC100EPT22D Motorola MC100EPT22D

39 1 U402 IC TSSOP20 MC100EP29DT ON Semiconductor MC100EP29DT

40 1 U403 IC SO8M1 MC100EPT23D Motorola MC100EPT23D

41 1 U501 IC SOT23L5 NC7SZ32M5,

42 1 U502 IC TQFP128 CY7C68013 Cypress CY7C68013-128AXC

43 1 U503 IC DIP8 24LC00P Microchip 24LC00P

44 1 U504 IC DCT_8PIN_06,

5 mm

45 1 U505 IC SOIC 14 74LVQ04SC, low

46 1 U601 IC DIP20/SOL 74LCX574WM-ND,

47 1 VR301 IC SOT-223HS High accuracy,

48 1 Y501 Crystal Crystal Oscillator, 24 MHz Ecliptek EC-12-24.000M

49 6 See schematic for placement Connector 100 mil

50 4 Insert from bottom side of

51 2 See schematic for placement Connector Third-row

1

Only U201 is populated for the single-channel version (HSC-ADC-EVALB-SC).

board

Standoff Plastic mount

jumper

standoffs

header key

190 Ω @ 100 MHz

IDT72V283L7-5PF

octal buffer/line

driver, three-state

NC7SZ32, tiny log

UHS 2-input or gate

SN74LVC2G74DCTR,

D-type flip-flop,

DCT_8PIN_0.65MM

voltage hex inverter

74LCX574 octal D-type

flip-flop

ADP3339AKC-3.3, 3.3 V

0.1” jumpers Samtec SNT-100-BK-G-H

7/8” height, standoffs Richco CBSB-14-01A-RT

These header inserts

for J104, Pin 81, and

Pin 120 are located

on the edges of the

top row

Murata DLW5BSN191SQ2L

IDT IDT72V283L7-5PF

Fairchild 74VHC541M

DS90LV048A

Semiconductor

Fairchild NC7SZ32M5

or

CY7C68014A-128AXC

Texas Instruments SN74LVC2G74DCTR

Fairchild 74LVQ04SC

Fairchild 74LCX574WM-ND

Analog Devices ADP3339AKC-3.3

Samtec TSW-104-07-T-S

Rev. 0 | Page 24 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

ORDERING INFORMATION

ORDERING GUIDE

Model Description

HSC-ADC-EVALB-SC Single FIFO Version of USB Evaluation Kit

HSC-ADC-EVALB-DC Dual FIFO Version of USB Evaluation Kit

HSC-ADC-FPGA-4/-8

HSC-ADC-FPGA-9289 Quad Serial LVDS to Dual Parallel CMOS Interface for the AD9289 Only (Not Included in Evaluation Kit)

AD922XFFA

AD9283FFA

AD9059FFA

AD9051FFA

LG-0204A

1

If an adapter is needed, send an email to highspeed.converters@analog.com.

1

1

1

1

1

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Quad/Octal Serial LVDS to Dual Parallel CMOS Interface; supports all Quad/Octal ADCs in this family except

the AD9289 (not Included in Evaluation Kit)

Adapter for AD922x Family (Not Included in Evaluation Kit)

Adapter for the AD9283 and AD9057 (Not Included in Evaluation Kit)

Adapter for the AD9059 (Not Included in Evaluation Kit)

Adapter for the AD9051 (Not Included in Evaluation Kit)

Adapter for the AD10xxx and AD13xxx Families (Not Included in Evaluation Kit)

Rev. 0 | Page 25 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

NOTES

Rev. 0 | Page 26 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

NOTES

Rev. 0 | Page 27 of 28

HSC-ADC-EVALB-SC/HSC-ADC-EVALB-DC

NOTES

©2006 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

EB05870-0-2/06(0)

Rev. 0 | Page 28 of 28

Loading...

Loading...