High Precision

a

FEATURES

Laser Trimmed to High Accuracy:

10.000 V ⴞ5 mV (L and U Grades)

Trimmed Temperature Coefficient:

5 ppm/ⴗC max, (L and U Grades)

Noise Reduction Capability

Low Quiescent Current: 4 mA max

Output Trim Capability

MIL-STD-883 Compliant Versions Available

PRODUCT DESCRIPTION

The AD587 represents a major advance in the state-of-the-art in

monolithic voltage references. Using a proprietary ion-implanted

buried Zener diode and laser wafer trimming of high stability

thin-film resistors, the AD587 provides outstanding performance at low cost.

The AD587 offers much higher performance than most other

10 V references. Because the AD587 uses an industry standard

pinout, many systems can be upgraded instantly with the

AD587. The buried Zener approach to reference design provides lower noise and drift than bandgap voltage references. The

AD587 offers a noise reduction pin which can be used to further

reduce the noise level generated by the buried Zener.

The AD587 is recommended for use as a reference for 8-, 10-,

12-, 14- or 16-bit D/A converters which require an external

precision reference. The device is also ideal for successive

approximation or integrating A/D converters with up to 14 bits

of accuracy and, in general, can offer better performance than

the standard on-chip references.

The AD587J, K and L are specified for operation from 0°C to

+70°C, and the AD587S, T and U are specified for –55°C to

+125°C operation. All grades are available in 8-pin cerdip. The

J and K versions are also available in an 8-pin Small Outline IC

(SOIC) package for surface mount applications, while the J, K,

and L grades also come in an 8-pin plastic package.

10 V Reference

AD587

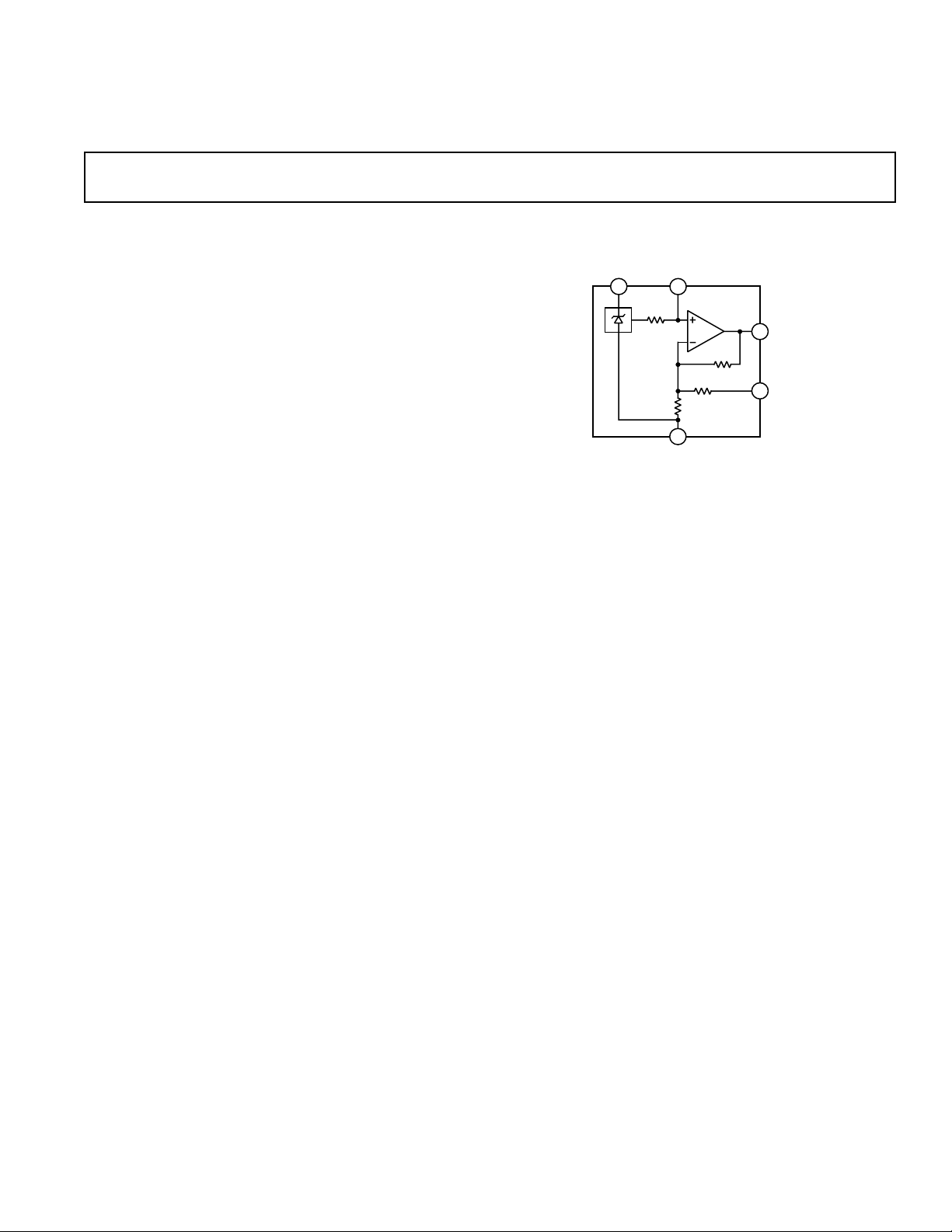

FUNCTIONAL BLOCK DIAGRAM

IN

2

NOISE

REDUCTION

8

R

S

R

I

4

GND

A1

R

R

T

AD587

V

6

OUT

F

5

TRIM

+V

NOTE:

PINS 1,3, AND 7 ARE INTERNAL TEST POINTS.

NO CONNECTIONS TO THESE POINTS.

PRODUCT HIGHLIGHTS

1. Laser trimming of both initial accuracy and temperature

coefficients results in very low errors over temperature without the use of external components. The AD587L has a

maximum deviation from 10.000 V of ±8.5 mV between 0°C

and +70°C, and the AD587U guarantees ±14 mV maximum

total error between –55°C and +125°C.

2. For applications requiring higher precision, an optional fine

trim connection is provided.

3. Any system using an industry standard pinout 10 volt reference can be upgraded instantly with the AD587.

4. Output noise of the AD587 is very low, typically 4 µV p-p. A

noise reduction pin is provided for additional noise filtering

using an external capacitor.

5. The AD587 is available in versions compliant with MILSTD-883. Refer to the Analog Devices Military Products

Databook or current AD587/883B data sheet for detailed

specifications.

REV. D

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

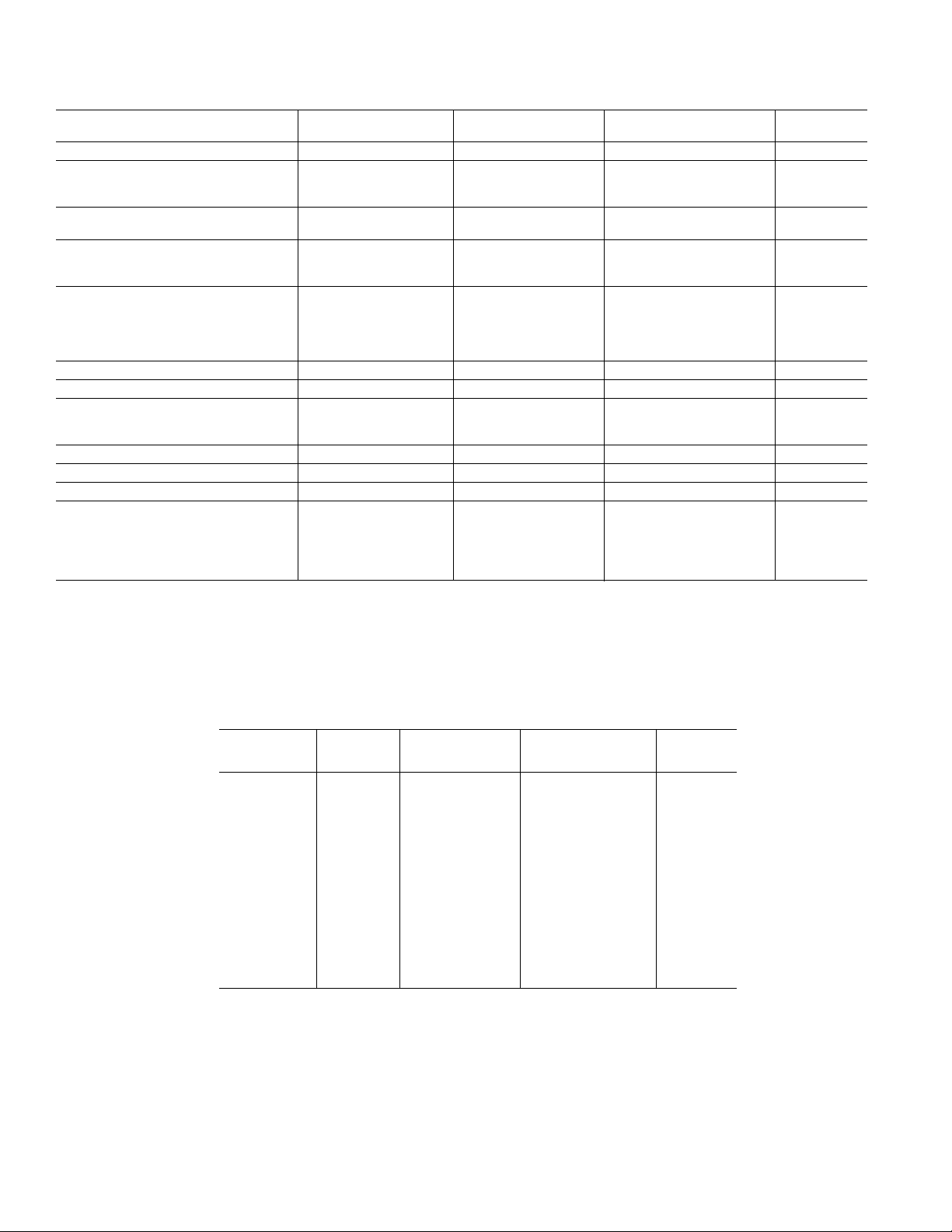

AD587–SPECIFICATIONS

(TA = +25ⴗC, VIN = +15 V unless otherwise noted)

Model AD587J/S AD587K/T AD587L/U

OUTPUT VOLTAGE 9.990 10.010 9.995 10.005 9.995 10.005 V

OUTPUT VOLTAGE DRIFT

0°C to +70°C 20 10 5 ppm/°C

–55°C to +125°C 20105

GAIN ADJUSTMENT +3 +3 +3 %

LINE REGULATION

13.5 V ≤ + VIN ≤ 36 V

T

to T

MIN

MAX

LOAD REGULATION

Sourcing 0 < I

T

to T

MIN

Sourcing –10 < I

T

to T

MIN

QUIESCENT CURRENT 2 4 2 4 2 4 mA

POWER DISSIPATION 30 30 30 mW

OUTPUT NOISE

0.1 Hz to 10 Hz 4 4 4 µV p-p

Spectral Density, 100 Hz 100 100 100 nV/√Hz

LONG-TERM STABILITY 15 15 15 ±ppm/1000 Hr.

SHORT-CIRCUIT CURRENT-TO-GROUND 30 70 30 70 30 70 mA

SHORT-CIRCUIT CURRENT-TO-V

TEMPERATURE RANGE

Specified Performance (J, K, L) 0 +70 0 +70 0 +70 °C

Operating Performance (J, K, L)

Specified Performance (S, T, U) –55 +125 –55 +125 –55 +125

Operating Performance (S, T, U)

NOTES

1

Spec is guaranteed for all packages and grades. Cerdip packaged parts are 100% production test.

2

Load Regulation (Sinking) specification for SOIC (R) package is ±200 µV/mA.

3

The operating temperature ranged is defined as the temperatures extremes at which the device will still function. Parts may deviate from their specified performance

outside their specified temperature range.

Specifications subject to change without notice.

OUT

MAX

MAX

< 10 mA

OUT

1

1

< 0 mA

1

2

IN

3

3

Min Typ Max Min Typ Max Min Typ Max Units

–1 –1 –1

100 100 100 ±µV/V

100 100 100 ±µV/mA

100 100 100

30 70 30 70 30 70 mA

–40 +85 –40 +85 –40 +85

–55 +125 –55 +125 –55 +125

ORDERING GUIDE

Initial Temperature Temperature Package

Error Coefficient Range Options

Model

1

AD587JQ 10 mV 20 ppm/°C0°C to +70°C Q-8

AD587JR 10 mV 20 ppm/°C0°C to +70°C SO-8

AD587JN 10 mV 20 ppm/°C0°C to +70°C N-8

AD587KQ 5 mV 10 ppm/°C0°C to +70°C Q-8

AD587KR 5 mV 10 ppm/°C0°C to +70°C SO-8

AD587KN 5 mV 10 ppm/°C0°C to +70°C N-8

AD587LQ 5 mV 5 ppm/°C0°C to +70°C Q-8

AD587LN 5 mV 5 ppm/°C0°C to +70°C N-8

AD587SQ 10 mV 20 ppm/°C –55°C to +125°C Q-8

AD587TQ 10 mV 10 ppm/°C –55°C to +125°C Q-8

AD587UQ 5 mV 5 ppm/°C –55°C to +125°C Q-8

AD587JCHIPS 10 mV 20 ppm/°C0°C to +70°C

NOTES

1

For details on grade and package offerings screened in accordance with MIL-STD-883, refer to the

Analog Devices Military Products Databook or current AD587/883B data sheet.

2

N = Plastic DIP; Q = Cerdip; SO = SOIC.

2

REV. D–2–

AD587

ABSOLUTE MAXIMUM RATINGS*

VIN to Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 V

Power Dissipation (+25°C) . . . . . . . . . . . . . . . . . . . . . 500 mW

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . +300°C

Package Thermal Resistance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22°C/W

θ

JC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110°C/W

θ

JA

Output Protection: Output safe for indefinite short to ground and

momentary short to V

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

.

IN

The following specifications are tested at the die level for AD587JCHIPS. These die are probed at +25°C only.

(T

DIE SPECIFICATIONS

= +25°C, V

A

AD587JCHIPS

Parameter Min Typ Max Units

Output Voltage 9.990 10.010 V

Gain Adjustment –1 3 %

Line Regulation

13.5 V < + VIN < 36 V 100 ±µV/V

= +15 V unless otherwise noted)

IN

PIN CONFIGURATION

NOISE

1

TP*

+V

TP*

GND

*TP DENOTES FACTORY TEST POINT.

NO CONNECTIONS SHOULD BE MADE

TO THESE PINS.

IN

AD587

2

TOP VIEW

3

(Not to Scale)

4

8

REDUCTION

7

TP*

6

V

OUT

TRIM

5

DIE LAYOUT

Load Regulation

Sourcing 0 < I

Sinking –10 < I

< 10 mA 100 µV/mA

OUT

< 0 mA 100 µV/mA

OUT

Quiescent Current 2 4 mA

Short-Circuit Current-to-Ground 70 mA

Short-Circuit Currrent-to-V

OUT

NOTES

1

Both V

2

Sense and force grounds must be tied together.

Die Thickness: The standard thickness of Analog Devices Bipolar dice is 24 mils ± 2 mils.

Die Dimensions: The dimensions given have a tolerance of ± 2 mils.

Backing: The standard backside surface is silicon (not plated). Analog Devices does not recommend

gold-backed dice for most applications.

Edges: A diamond saw is used to separate wafers into dice thus providing perpendicular edges halfway through the die.

In contrast to scribed dice, this technique provides a more uniform die shape and size . The perpendicular edges facilitate handling (such as tweezer pick-up) while the uniform shape and size simplifies

substrate design and die attach.

Top Surface: The standard top surface of the die is covered by a layer of glassivation . All areas are

covered except bonding pads and scribe lines.

Surface Metalization: The metalization to Analog Devices bipolar dice is aluminum. Minimum

thickness is 10,000Å.

Bonding Pads: All bonding pads have a minimum size of 4 mils by 4 mils. The passivation windows

have 3.5 mils by 3.5 mils minimum.

pads should be connected to the output.

OUT

70 mA

Die Size: 0.081 × 0.060 Inches

REV. D –3–

Loading...

Loading...