Amica EHEG 934 111 E operation manual

MENUMENU

2022GH3.33EZpHTbDpScVpAQaX / EHEG 934 111 E

2022GH2.33EZpHTbDpScVpAQaX / EHEG 933 100 E

(EN) INSTRUCTION MANUAL..........................................2

(NL) GEBRUIKERSHANDLEIDING...............................39

IO-CBI-0478 / 8070236

(07.2017 / v1)

DEAR CUSTOMER,

The cooker is exceptionally easy to use and extremely ecient. After reading the instruction

manual, operating the cooker will be easy.

Before being packaged and leaving the manufacturer, the cooker was thoroughly checked

with regard to safety and functionality.

Before using the appliance, please read the instruction manual carefully.

By following these instructions carefully you will be able to avoid any problems in using the

appliance.

It is important to keep the instruction manual and store it in a safe place so that it can be

consulted at any time.

It is necessary to follow the instructions in the manual carefully in order to avoid possible

accidents.

Caution!

Do not use the cooker until you have read this instruction manual.

The cooker is intended for household use only.

The manufacturer reserves the right to introduce changes which do not aect the

operation of the appliance.

2

TABLE OF CONTENTS

Safety instructions ............................................................................................................. 4

Description of the appliance ........................................................................................... 10

Installation ......................................................................................................................... 12

Operation ........................................................................................................................... 18

Baking in the oven – practical hints ............................................................................... 29

Cleaning and maintenance .............................................................................................. 32

Technical data ................................................................................................................... 38

3

SAFETY INSTRUCTIONS

Warning: The appliance and its accessible parts become hot

during use. Care should be taken to avoid touching heating

elements. Children less than 8 years of age shall be kept

away unless continuously supervised.

This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning

use of the appliance in a safe way and understand the hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

Warning: Unattended cooking on a hob with fat or oil can

be dangerous and may result in re.

NEVER try to extinguish a re with water, but switch o

the appliance and then cover ame e.g. with a lid or a re

blanket.

Warning: Danger of re: do not store items on the cooking

surfaces.

During use the appliance becomes hot. Care should be taken

to avoid touching heating elements inside the oven.

Accessible parts may become hot during use. Young children

should be kept away.

4

SAFETY INSTRUCTIONS

Warning: Do not use harsh abrasive cleaners or sharp metal

scrapers to clean the oven door glass since they can scratch

the surface, which may result in shattering of the glass.

Warning: Ensure that the appliance is switched o before re-

placing the lamp to avoid the possibillity of electric shock.

You should not use steam cleaning devices to clean the

appliance.

Danger of burns! Hot steam may escape when you open the

oven door. Be careful when you open the oven door during

or after cooking. Do NOT lean over the door when you open

it. Please note that depending on the temperature the steam

can be invisible.

5

SAFETY INSTRUCTIONS

Please pay attention to children whilst the cooker is in operation, as children do

not know the rules of cooker use. In particular, hot surface burners, the oven

chamber, grates, the door pane, and pans containing hot liquids standing on the

hob may cause burns to children.

Mind that electrical connection leads from other home appliances (e.g. of a food

mixer) do not touch hot parts of the cooker.

Do not place ammable material into the drawer whilst using the oven, as it may

catch a re.

Do not leave the cooker unattended when frying. Oils and fats may catch re due

to overheating.

At the point of boiling, mind to avoid spills on the burner.

If the cooker is damaged, it may be used again only after the fault has been xed

by a specialist.

Do not open the tap on the gas connection or cylinder valve before checking that

all burner knobs are closed.

Do not allow the burners to be soiled or liquids to spill on the burners. If soiled,

clean and dry burners immediately after they have cooled down.

Do not put pans directly onto burners.

Do not place pans with a weight greater than 10 kg onto the grate over one burner,

or pans with a total weight of over 40 kg on the whole grate.

Do not hit the knobs and burners.

Do not put objects with a weight greater than 15 kg onto the open oven door.

Alterations and repairs carried out by an unqualied person are not allowed.

Do not open the cooker knobs before already having a lighted match or a gas

lighter in your hand.

Do not put out a burner ame by blowing.

Before opening the cover, cleaning it of any dirt is recommended. The cooker

hob surface should be cooled down before closing the cover.

A glass cover may crack when heated. Switch o all the burners before lowering

the cover. (Cookers with a glass cover).

Do not make your own alterations to the cooker in order to adapt it to a dierent

type of gas, move the cooker to another place or make changes to the power

supply. These operations may only be carried out by an authorised electrician or

tter.

6

SAFETY INSTRUCTIONS

Do not use harsh cleaning agents or sharp metal objects to clean the door as

they can scratch the surface, which could then result in the glass cracking.

Keep young children and people not acquainted with the instruction manual away

from the cooker.

IN CASE OF ANY SUSPICION OF GAS LEAKAGE YOU MUST NOT:

light matches, smoke cigarettes, switch electrical receivers (door bell or light

switch) on and o, or use other electric and mechanical devices that create electrical or percussive sparks. In such a case, immediately close the cylinder valve

or tap cutting o gas supply, air the room, and then call a person authorised to

repair the source of the leakage.

In the event of any incident caused by a technical fault, disconnect the power (ap-

plying the above rule) and report the fault to the service centre to be repaired.

Do not attach any antenna cords (e.g. radio) to the gas supply.

In a case of gas escaping from leaky piping and catching re, close gas supply

immediately using a cutting-o valve.

In a case of gas escaping from a leaky cylinder and catching re: throw a wet

blanket over the cylinder to cool it down and turn o the cylinder valve. After it has

cooled down, take the cylinder out to an open space. Do not use the damaged

cylinder.

When the cooker is not to be used for several days, close the main valve on the

gas piping; when using a gas cylinder, close it after each use.

Using the appliance for cooking and baking results in the emission of heat and

moisture in the room in which it is installed. Make sure that kitchen is well ventilated. Natural ventilation openings or forced mechanical ventilation (exhaust

hood) should be available.

Prolonged intensive use of the appliance may require additional ventilation, for

example, opening a window or a more eective ventilation, such as increasing

eciency of mechanical ventilation, if applicable.

The appliance has been designed only for cooking. Any other use (for example

for heating) does not comply with its operating prole and may cause danger.

7

HOW TO SAVE ENERGY

Using energy in a responsible way not only saves

money but also helps the

environment. So let’s save

energy! And this is how you

can do it:

Use proper pans for cooking.

A saucepan should never be smaller than a

burner crown.

Always remember to cover and pans.

Ensure burners, the grate the hob are

clean.

Soils can prevent heat transfer – and repeatedly burnt-on spillages can often only be

removed by products which cause damage

to the environment.

In particular, ensure that ame openings in

the rings under caps, and openings of burner

nozzles are clean.

Do not uncover the pan too often (a

watched pot never boils!).

Do not open the oven door unnecessarily

often.

Make sure the oven door is properly

closed.

Heat can leak through spillages on the door

seals. Clean up any spillages immediately.

Do not install the cooker in the direct

vicinity of refrigerators/freezers.

Otherwise energy consumption increases

unnecessarily.

Only use the oven when cooking larger

dishes.

Meat of up to 1 kg can be prepared more

economically in a pan on the cooker burner.

Make use of residual heat from the

oven.

If the cooking time is greater than 40 minutes

it is recommended to switch o the oven 10

minutes before the end time.

8

UNPACKING

DISPOSAL OF THE APPLIANCE

During transportation, protective packaging was used to

protect the appliance against

any damage. After unpacking, please dispose of all

elements of packaging in a

way that will not cause damage to the environment.

All materials used for packaging the appliance are environmentally friendly; they are

100% recyclable and are marked with the

appropriate symbol.

Caution! During unpacking, the packaging materials (polythene bags, polystyrene

pieces, etc.) should be kept out of reach of

children.

Old appliances should not simply be disposed of with normal

household waste, but should

be delivered to a collection and

recycling centre for electric and

electronic equipment. A symbol

shown on the product, the

instruction manual or the packaging shows

that it is suitable for recycling.

Materials used inside the appliance are

recyclable and are labelled with information

concerning this. By recycling materials or

other parts from used devices you are making

a signicant contribution to the protection of

our environment.

Information on appropriate disposal centres

for used devices can be provided by your

local authority.

9

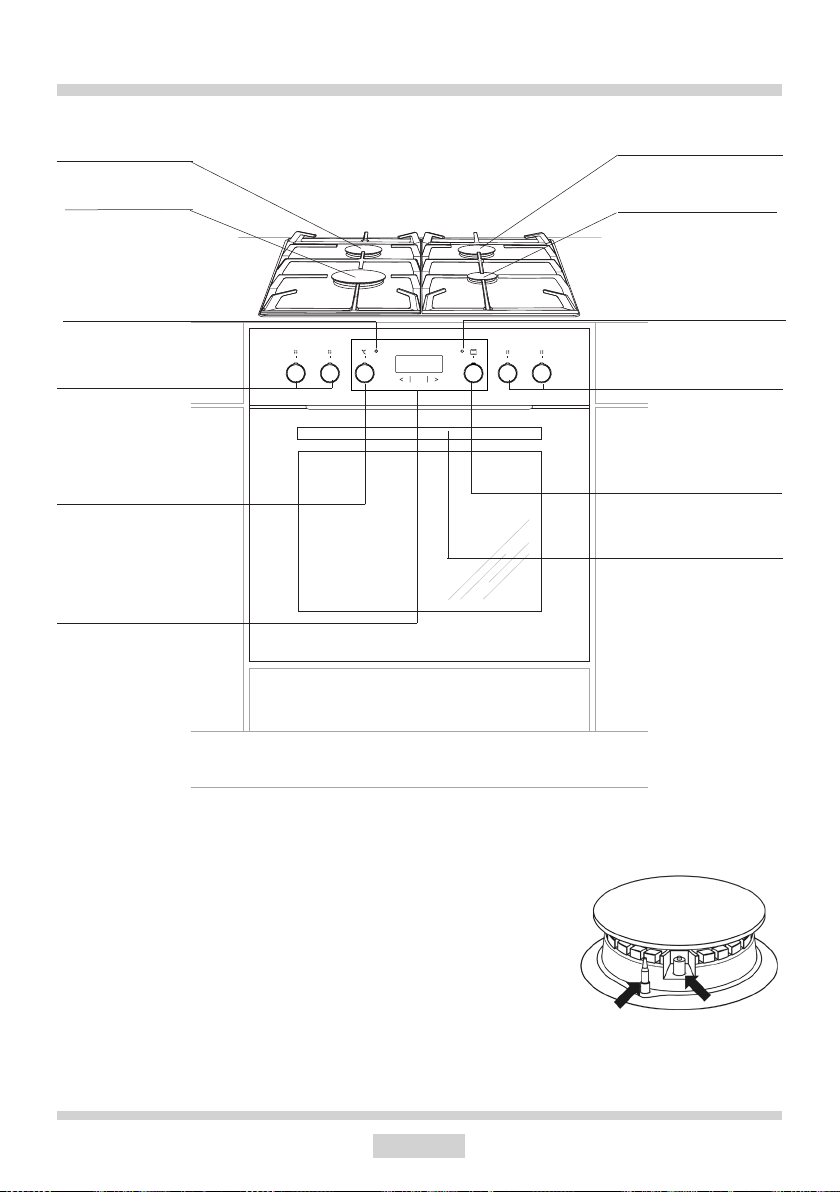

DESCRIPTION OF THE APPLIANCE

[10] Medium burner

[9] Large burner

[7] Temperaturere-

gulatorsignal light

[3,4] Gas burner

control knobs

[1] Temperature

control knob

[14] Electronic

programmer

[11] Medium burner

[12] Auxiliary burner

[8] Cooker opera-

tion signal light

[5,6] Gas burner

MENU

MENU

control knobs

[2] Oven function

selection knob

[13] Oven door

handle

10

Burner safety valve

Spark

ignitor

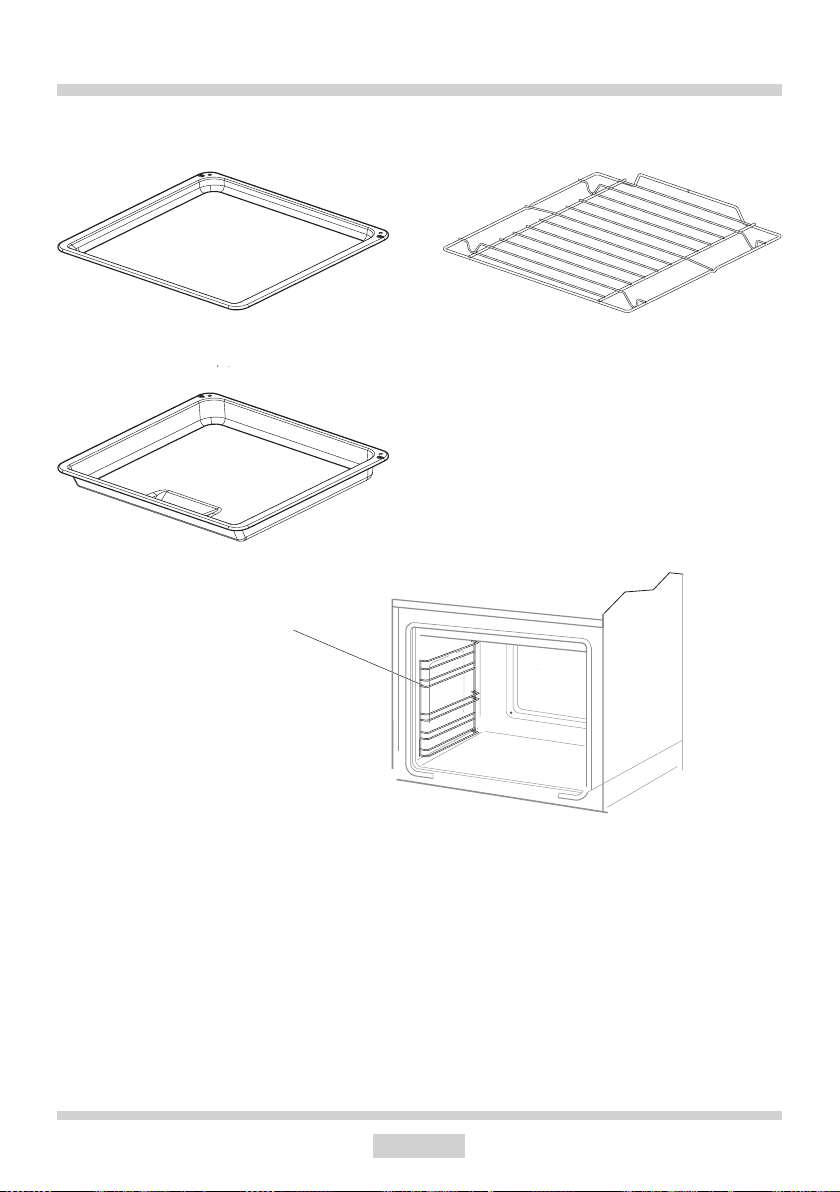

SPECIFICATIONS OF THE APPLIANCE

Cooker ttings:

Baking tray*

Roasting tray*

Grill grate

(drying rack)

Siderack

*optional

11

INSTALLATION

Cooker positioning and installation

● Kitchen should be dry, airy and have

efficient ventilation. Positioning of

the cooker in the kitchen should

guarantee unrestricted access to all

controls.

● Worktop must be made of materials, including veneer and adhesives, resistant to a

temperature of 100°C. Otherwise, veneer

could come o or surface of the worktop

become deformed.

● Furniture unit, which houses the oven

should be securely fastened.

● Furniture adjacent to the cooker, which

protrudes above its cooking surface should be placed at least 110 mm from the

edge of the burner plate.

● Hoods should be installed in accordance

with the instructions in the accompanying

instruction manual.

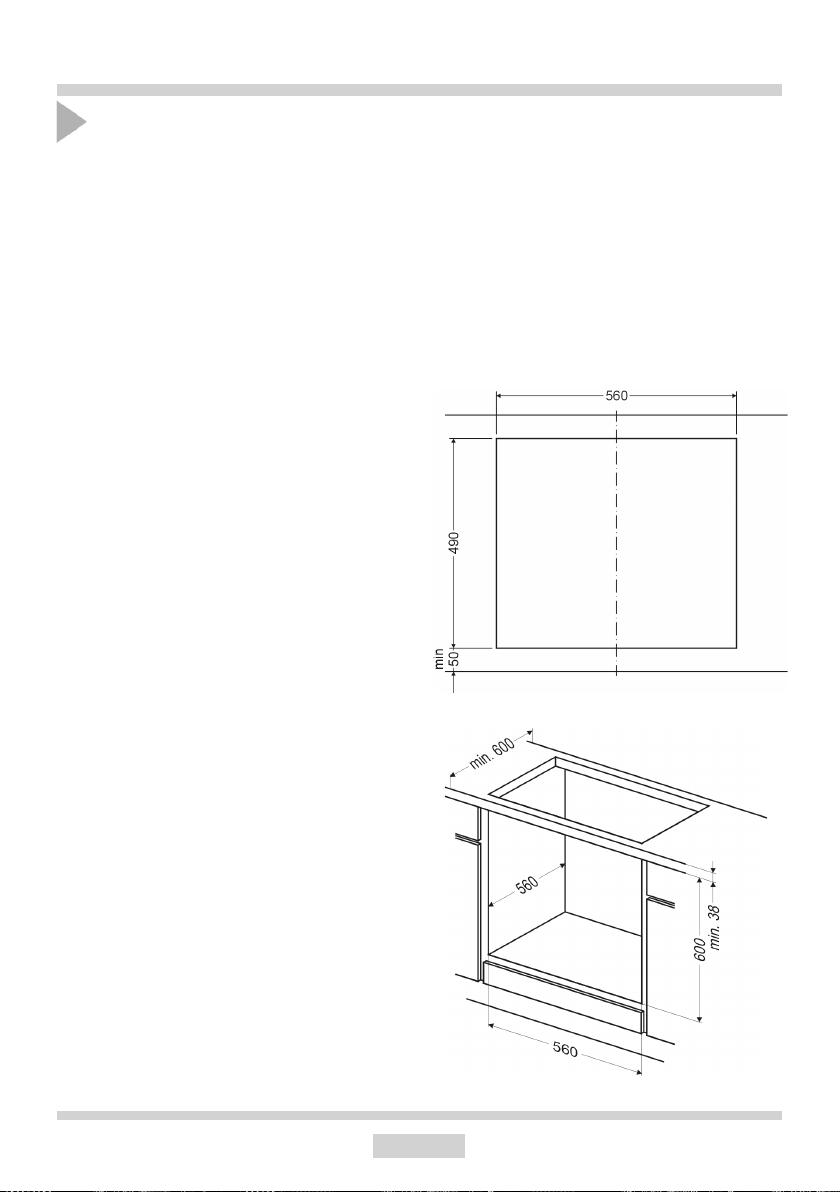

1.1 Installation.

Procedure:

1. Prepare an opening to install the cooking

surface according to Figure 1.

2. Prepare an opening in furniture unit

(cabinet) with dimensions shown in Figure

2, to t oven.

3. Loosen the screws No. 2, Figure 3

4. Carefully insert in the oven into previously

prepared opening in furniture unit

(cabinet), protect against sliding out

using four screws in the locations shown

in Figure 4.

5. Lift the burner plate to the furniture

worktop, expand the plate mounting

brackets to a maximum size of the

opening in the worktop and tighten the

screws No. 2 maintaining equal distance

on all sides of the opening.

6. Position the burner plate to achieve 90

mm distance (Fig. 5) and using screws

No. 1 (Fig. 3) fix the burner plate in

worktop opening.

7. CONNECT THE APPLIANCE TO THE

GAS LINE AND ELECTRICITY MAINS

according to the following chapter.

8. Place cooking surface on the burner

plate and fasten it to the burners using

8 screws with M-3 washer (Fig. 5).

9. Place burner caps and pan supports.

Fig.1

Fig.2

12

INSTALLATION

Screw 1

Furniture worktop

Blat meblowy

Screw 2 Burner plate

Wkrêt 2Wkrêt 1

Ramazpalnikami

Mounting bracket

Uchwyt mocuj¹cy

ramê

Fig.3

Fig.4

1.2 Installation of a cooker with pre-stres-

sed glass cooking surface.

Procedure:

follow steps 1-5 as in paragraph 1.1, then,

6. Position the burner plate to achieve 90

mm distance (Fig. 6) and using 4 screws

No. 1 (Fig. 3) x the burner plate in worktop opening.

7. CONNECT THE APPLIANCE TO THE

GAS LINE AND ELECTRICITY MAINS

according to the following chapter.

8. Place pre-stressed glass plate on the

burner plate, then place decorative rings

on the pre-stressed glass plate and the

burners. Fasten pre-stressed glass plate

and decorative rings with 8 screws and

M3 washers, starting with rear middle

burners followed by large and small

burners.

9. Place burner caps and pan supports.

Screw

Wkrêt

Aluminium washer

Podk³adka aluminiowa

Decorative ring

Nak³adka ozdobna

Screw

Wkrêt

Aluminium washer

Podk³adka aluminiowa

90

90

Fig.6

Fig.5

13

INSTALLATION

Gas connection

Caution!

The cooker should be connected to a

gas supply of the particular type of gas

that the appliance is manufactured to

function with. Information about the

type of gas that the cooker has been

adapted to by the factory is shown on

the data plate. The cooker should be

connected exclusively by an appropri-

ately authorised tter and only he or

she has the right to adapt the cooker

to a dierent type of gas.

Fitting guidelines

A tter should:

have a gas tter’s authorisation,

be acquainted with the information in-

cluded on the data plate of the cooker

about the type of gas to which the cooker

is adapted; the information should be

compared with gas supply conditions at

the place of installation,

check:

- airing eciency, that is eciency of air

exchange in the rooms,

- tightness of gas tting connections,

- eectiveness of all functional elements of

the cooker,

- if the electricity supply is adapted to func-

tion with a safety ground lead (zero).

Connection with a exible steel hose.

If the cooker is connected according to the

class 2 specications, sub-class I, only exible metal hose can be used which meet the

valid national regulations. Gas feeding connector must be G ½” threaded coupling.

Use only pipes and ttings that meet the

requirements of the valid standards. Maxi-

mum admissible length of the exible hose

is 2000 mm.

Make sure the connection is not touching

any mobile elements which could damage

the hose.

Connection with a stable pipework.

The cooker comes with a G ½” threaded

coupling.

The connection to gas supply must be done in

a manner that excludes stresses in any point

of the pipework or parts of the appliance.

Make sure you do not exceed the torque

when making the connection (maximum

torque is 20 Nm). Otherwise, the connection

may be faulty or leaks may occur.

The gas hose should not touch metal elements of the cooker back shield.

Important!

Each time you replace a reducer

carry out technical inspection of the

cooker that covers gas valves and

proper operation of the ame failure

cut-o device.

provide the user with a connection cer-

ticate and give him or her instructions

in cooker use.

Caution!

The cooker may only be connected

to a liquid gas cylinder or the existing

gas supply by an authorised tter,

observing all safety rules.

Caution!

On completion of the cooker installation, the tightness of all connections

should be checked, e.g. applying

water with soap.

Do not use re to check tightness.

14

INSTALLATION

Electrical connection

The oven is manufactured to work with

a one-phase alternating current (230V

1N~50 Hz) and is equipped with a 3

x 1,5 mm2 connection lead of 1.5 mm

length with a plug including a protection

contact.

A connection socket for electricity supply

should be equipped with a protection

pin and may not be located above the

cooker. After the cooker is positioned, it is

necessary to make the connection socket

accessible to the user.

Before connecting the oven to the socket,

check if:

- the fuse and electricity supply are able to

withstand the cooker load,

- the electricity supply is equipped with an

ecacious ground system which meets

the requirements of current standards

and provisions,

- the plug is within easy reach.

Adapting the cooker to another

type of gas.

This operation may only be carried out by an

appropriately authorised tter.

If the gas the cooker is to be supplied with

diers from the gas provided for the cooker

by the manufacturer, that is G20 20 mbar,

burner nozzles must be exchanged and the

ame needs to be adjusted.

15

INSTALLATION

In order to adapt the cooker to burn a dierent

type of gas, you should:

exchange nozzles (see tables below),

adjust the “economical” ame.

Caution!

The cookers provided by the manufacturer

have burners which are factory-adapted to

use the gas specied on their data plates and

guarantee cards.

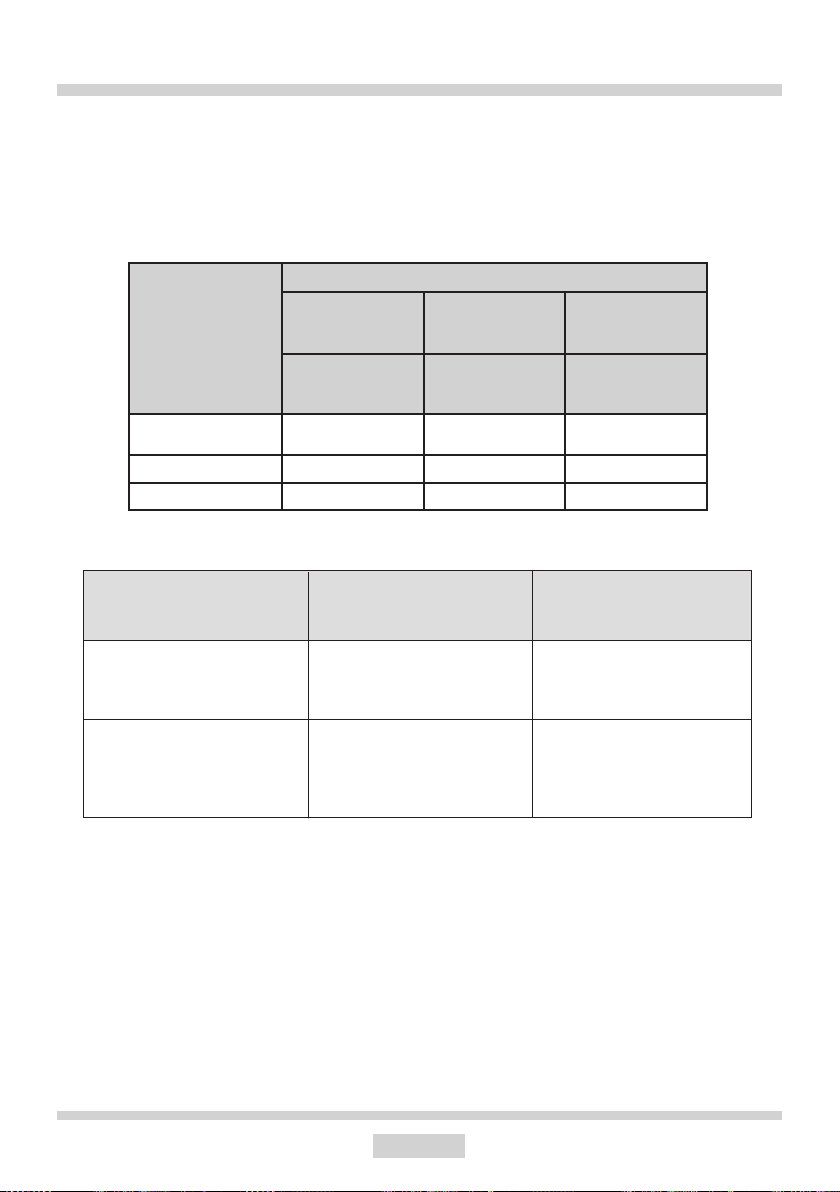

Burner of DEFENDI type (according to the “Defendi” symbol on burner components)

Burner

auxiliary

Type of gas

G20 2E - 20mbar

G25 2L - 25mbar

G30 3B/P - 50mbar 0,46 0,60 0,79

G30 3B/P - 30mbar 0,50 0,65 0,87

Burner ame

gas injector

diameter [mm]

nominal

thermal power

1,00 kW

0,77 0,97 1,29

Re-arming from liquid

to natural gas

1. Exchange a burner noz-

Full

zle for the appropriate type

according to the nozzle

table.

2. Unscrew an adjusting

Economical

bolt slightly and adjust the

ame size.

medium

gas injector

diameter [mm]

thermal power

gas

nominal

1,75 kW

large

gas injector

diameter [mm]

nominal

thermal power

3,00 kW

Re-arming from natural

gas

to liquid gas

1. Exchange a burner

nozzle for the appropriate

type according to the nozzle table.

2. Screw in an adjusting

bolt slightly and check the

ame size.

In order to perform adjusting operations, take o the knobs.

16

INSTALLATION

Surface burners applied do not require adjustment of primary air. A correct ame has distinct internal cones of blue and green colour.

A short, humming ame or long, yellow and

smoking one, without clearly outlined cones,

shows improper quality of gas in the household piping or a damaged or soiled burner.

In order to check a ame, heat a burner for

around 10 minutes with a full ame, and next

turn the valve knob to the economical ame

position. The ame should not go out or jump

onto the nozzles.

Exchange of a burner nozzle – unscrew the nozzle

with special socket spanner No 7 and replace with

a new one according to a

type of gas (see tables).

Caution!

Adapting the appliance to a dierent

type of gas than that indicated by the

manufacturer of the cooker on the

data plate, or purchasing a cooker for

a dierent type of gas than supplied to

the house, is exclusively the responsi-

bility of the user and the tter.

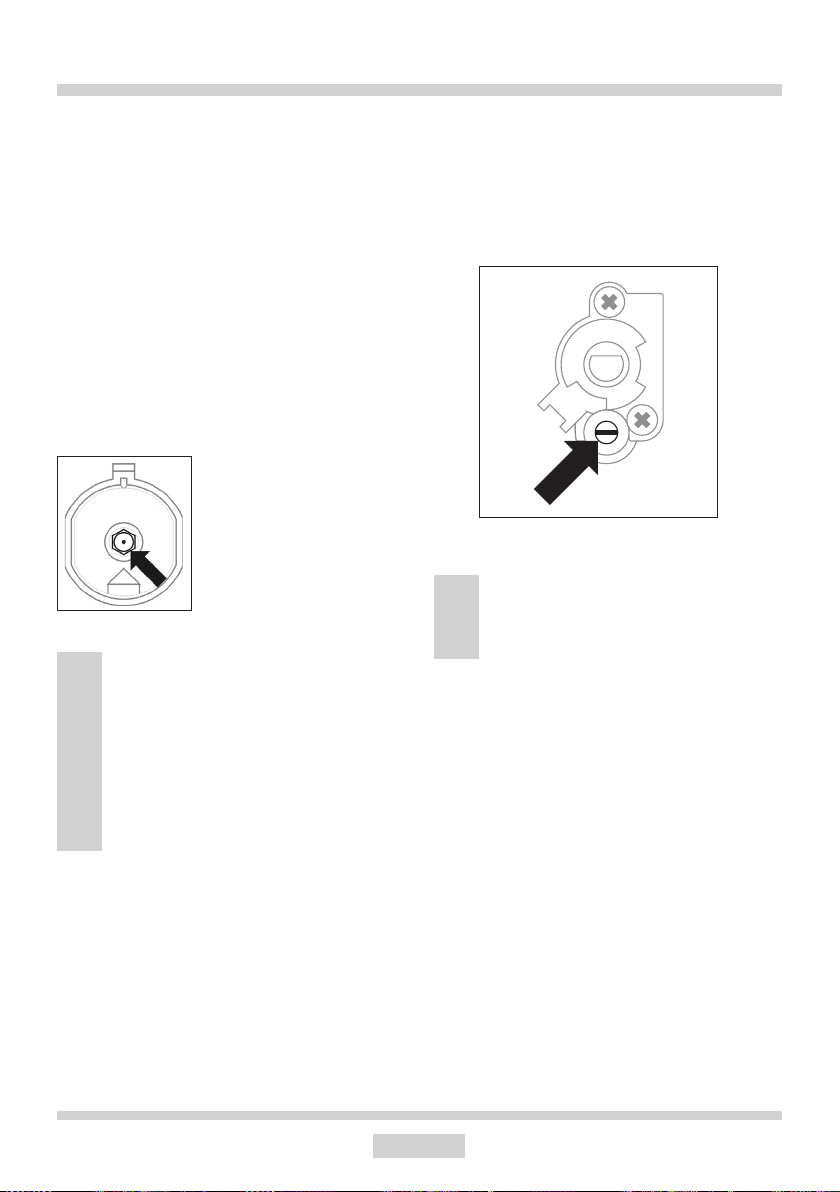

In cookers with a safety device, a knob with

a surface burner safety valve is used, g.

Knobs should be adjusted with the burner

switched on and set to the economical ame

position, using an adjustment screwdriver of

the 2.5 mm size.

Caution!

After adjustment is completed, place

a label indicating the type of gas to

which the cooker is now adapted.

17

OPERATION

Before using the oven for the rst time

Remove packaging, clean the interior of

the oven,

Take out and wash the oven ttings with

warm water and a little washing-up liquid,

Switch on the ventilation in the room or

open a window,

Gently press the knob and turn it right to

position or (see section: electronic programmer operation and oven

control),

Heat up the oven (to a temperature of

250°C for approximately 30 minutes),

remove any stains and wash the interior

carefully.

Important!

In ovens equipped with the electronic

programmer Tb, the time “0.00” will

start ashing in the display eld upon

connection to the power supply.

The programmer should be set with

the current time. (See Electronic

programmer ). If the current time

is not set operation of the oven is

impossible.

The electronic prgrammer Tb is

equipped with electronic sensors which

are switched on by touching or pressing the sensor surface for at least one

second.

Each sensor reaction is conrmed by

the beep.Keep the sensor surface clean

at all times.

Important!

To clean the oven, only use a cloth

well rang out with warm water to

which a little washing-up liquid has

been added.

18

OPERATION

How to use surface burners

Choice of cookware

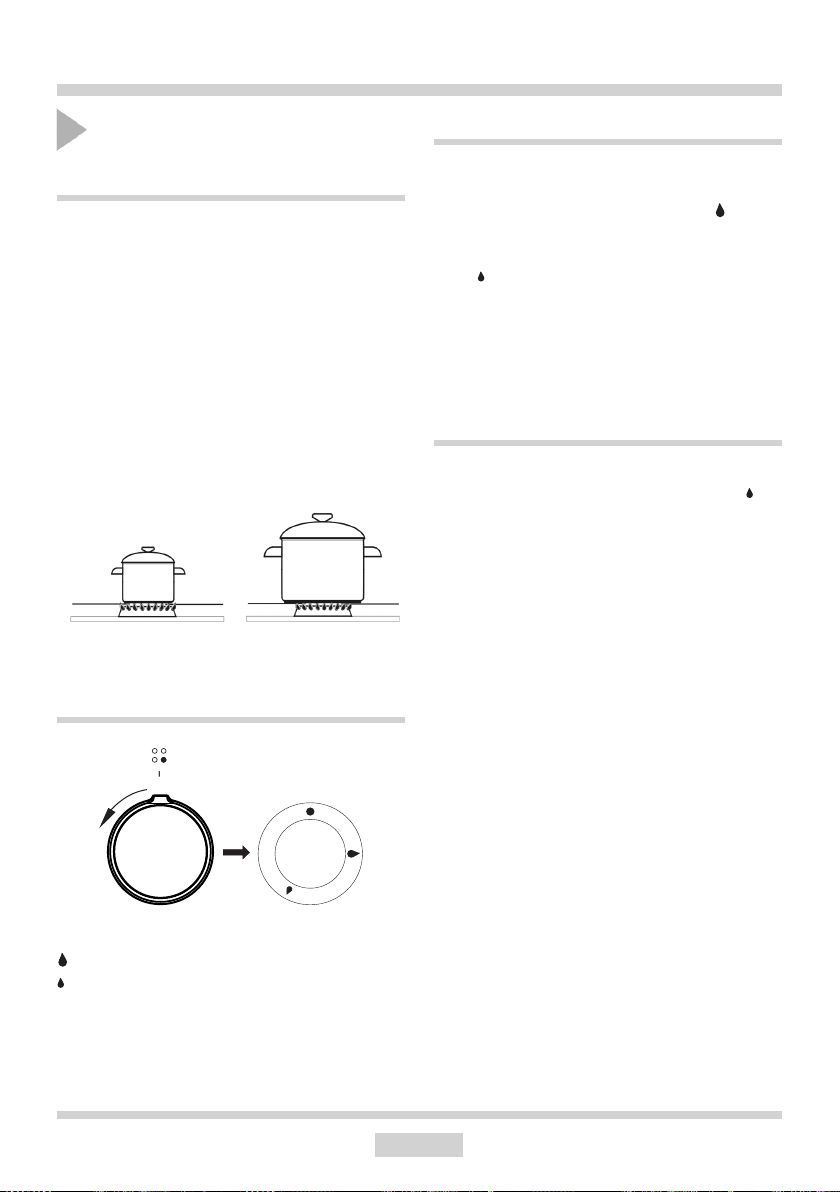

Mind that the diameter of a pan base is always

larger than the burner ame crown, and that

the pan itself is covered. The recommended

pan diameter is around 2.5 to 3 times larger

than the burner diameter, that is, for:

an auxiliary burner – a pan with a diameter

of 90 to 150 mm,

a medium burner – a pan with a diameter

of 160 to 220 mm,

a large burner – a pan with a diameter of

200 to 240 mm, and the pan height should

not be greater than its diameter.

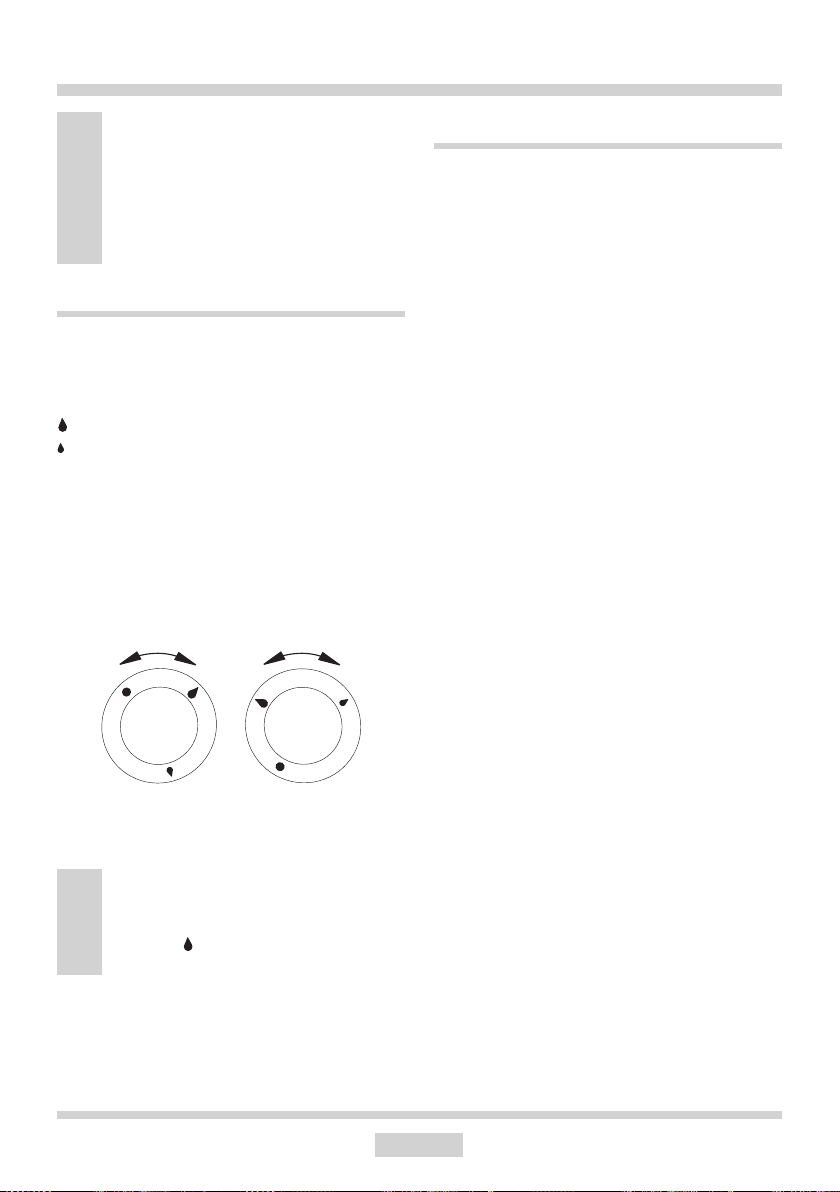

WRONG

Gas burner control knobs

RIGHT

Ignition without an ignitor*

light a match,

press in the knob to the end and turn it

left to the “large ame” position

ignite gas with a match,

set required ame size (e.g. “economical”

),

switch off the burner after finishing

cooking, turning the knob right (to the o

position).

Knob ignition

press in the knob to the end and turn it left

to the “economical ame” position ,

hold until gas is lit,

after the ame is lighted release the pres-

sure on the knob and set a required ame

size.

● Position burner “switched o”

Position “large ame”

Position “economical ame”

*optional

19

OPERATION

Caution!

In cooker models equipped with a

surface burner safety valve, hold the

knob pressed down to the end when

igniting for 10 seconds at the “large

ame” position to activate the safety

device.

Selection of the appropriate ame

A correctly adjusted burner has a light blue

ame with a clearly visible internal cone. Selection of ame size depends on the position

of the burner knob which has been set:

large ame

small ame (“economical ame”)

burner switched o (gas supply is cut o)

Depending on requirements, ame size can

be set in a continuous manner.

Operation of the burner protection valve

Some models are equipped with an automatic

system that cuts o gas supply to a burner

when the ame has disappeared.

This system protects the cooker against gas

leakage when the ame on a burner goes out

e.g. in case of spillage.

The user’s intervention is needed to re-ignite

the burner.

WRONG

Caution!

Do not adjust the ame between the

o position and the large ame

position .

RIGHT

20

OPERATION

Electronic programmer

functions

MENU – function selection button 1

< – sensor “–” 2

> – sensor “+” 3

The electronic prgrammer is equipped with

electronic sensors which are switched on by

touching or pressing the sensor surface for at

least one second.

Each sensor reaction is conrmed by the beep.

Keep the sensor surface clean at all times.

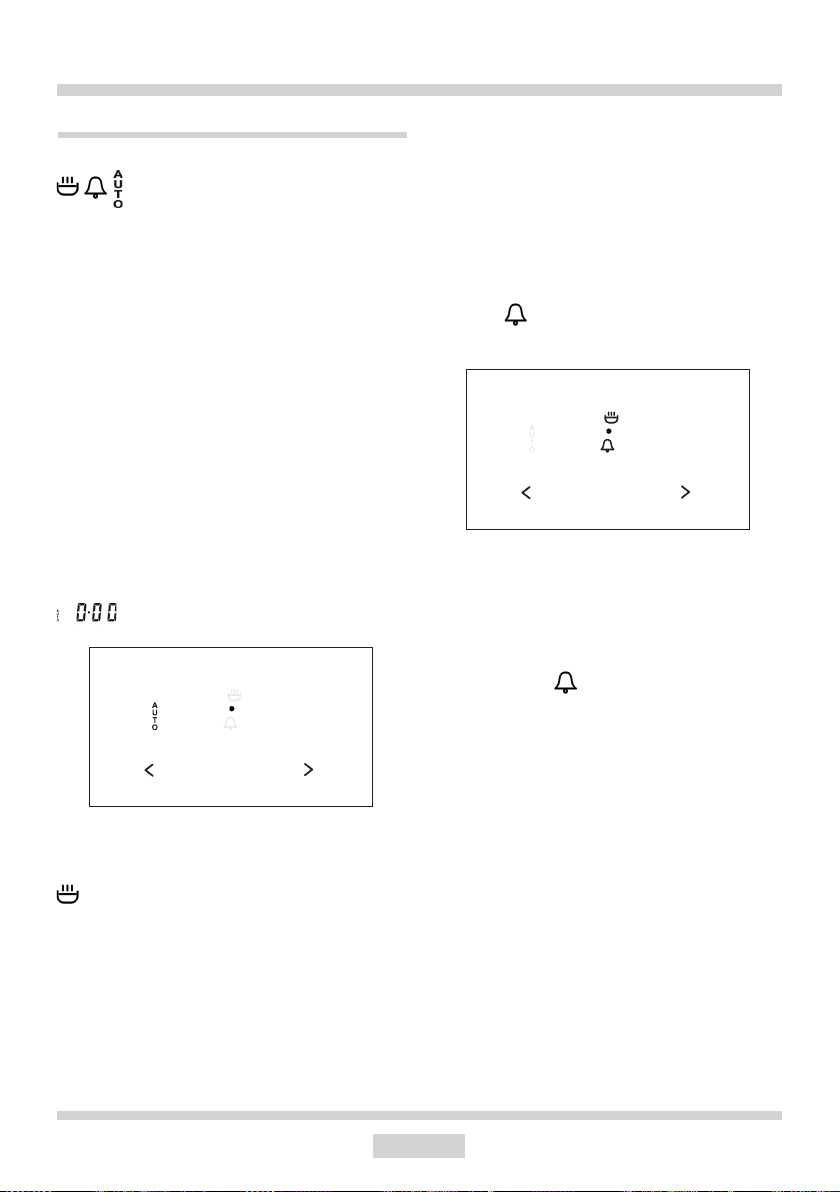

Setting the time

After connection to the mains or reconnec-

tion after a power cut the display shows ash

Timer

The timer can be activated at any time, regardless of the status of other functions. The

timer can be set for from 1 minute to up to 23

hours and 59 minutes.

To set the timer you should:

Press sensor 1, then the display will show

ashing ,

0000

MENU

set the timer using sensors 3 and 2.

The time set is shown on the display and the

signal function is on.

0000

MENU

2 31

Press sensor 1, then the display will show

,

set the time using sensors 3 and 2.

7 seconds after the time has been set the

new data will be saved.

Caution!

If the correct time is not set then proper operation of the oven is not possible.

21

Press sensor 1, 2 or 3 in order to switch o

the signal, the signal function will go out and

the display will show the current time.

Caution!

If the alarm signal is not turned o manually,

it will be turned o automatically after approx.

7 minutes.

OPERATION

Semi–automatic operation

If the oven is to be switched o at a given

time, then you should:

Set the oven function knob and the temperature regulator knob to the setting at which

you want the oven to operate.

Press sensor 1 until the display will show:

80 80

MENU

Set the required time using sensors 3 and

2, within a range from 1 minute to 10 hours.

The set time will be introduced to the memory

after approx. 7 seconds and the display will

show AUTO function.

When the set time has passed the oven is

switched o automatically, the alarm signal

is activated and the signal function AUTO

ashing again;

Automatic operation

If the oven is to be switched on for a specied

period of time and switched o at a xed hour

then you should set the operation time and

the operation end time:

Press sensor1 until the display will show:

80 80

MENU

Set the required time using the sensors

3 and 2 within a range from 1 minute to 10

hours.

Press sensor 1 until the display will show:

88 80

MENUMENU

Set the oven function knob and the tem-

perature regulator knob to the switched–o

position.

Press sensor 1, 2 or 3 in order to switch o

the signal; the signal function will go out and

the display will show the current time.

Caution!

In ovens equipped with one control knob,

the oven function knob is integrated with the

temperature regulator knob.

Set the switch–o time (operation end time)

using sensors 3 and 2, which is limited to a

period of 23 hours and 59 minutes from the

current time.

Set the oven function knob and the temperature regulator knob to the setting at which

you want the oven to operate.

The signal lights by and are now on;

the oven will start operating from the point

when the dierence between the set op

22

OPERATION

eration end time and the operation duration

time occurs (e.g. the operation time is set to

1 hour, the operation end time is set to 14.00,

so the oven will start working automatically

at 13.00).

The function AUTO is now on; the oven will

start operating from the point when the dierence between the set operation end time and

the operation duration time occurs (e.g. the

operation time is set to 1 hour, the operation

end time is set to 14.00, so the oven will start

working automatically at 13.00).

When the oven reaches the operation end

time it will switch o automatically, the alarm

will be activated and the function AUTO will

start ashing again.

Set the oven function knob and the tem-

perature regulator knob to the switched–o

position.

Press sensor 1, 2 or 3 in order to switch o

the alarm; the function AUTO will go out and

the display will show the current time.

Cancel settings

Timer and automatic function settings may

be cancelled at any time.

Cancel automatic function settings:

press sensors 2 and 3 simultaneously,

Cancel timer settings:

press sensor 1 to select timer settings,

press sensors 2 and 3 again,

Change the timer beeps

The tone of the timer beeps may be

changed as follows:

press sensors 2 and 3 simultaneously,

select “tone” function with the 1 sensor,

the display panel will start to blink:

88 81

MENU

12 35

MENU

● with the 2 sensor press the appropriate

sensors from 1 to 3 to select the option you

wish.

23

Loading...

Loading...