Page 1

ReFlex Power™

Programming Manual

M380056-03 Rev M www.programmablepower.com

Page 2

Page 3

Page 4

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design and

manufacture of precision, programmable power supplies for R&D, test and measurement, process control, power

bus simulation and power conditioning applications across diverse industrial segments. From bench top supplies

to rack-mounted industrial power subsystems, AMETEK Programmable Power is the proud manufacturer of Elgar,

Sorensen, California Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical devices with

annualized sales of $2.5 billion. The Company has over 11,000 colleagues working at more than 80

manufacturing facilities and more than 80 sales and service centers in the United States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are

used herein for identification purposes only.

Notice of Copyright

ReFlex Power™ Programming Manual

© 2007-2014 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER

SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF

SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS

HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE

GUARANTEED. APPROVED AMETEK CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION,

WHICH IS POSTED AT WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

May 2014 revision L

Part Number

M380056-03

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales.ppd@ametek.com

service.ppd@ametek.com

Web: www.programmablepower.com

M380056-03 Rev M i

Page 6

This page intentionally left blank.

ii M380056-03 Rev M

Page 7

Elgar ReFlex Power™ Contents

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your particular application.

WARNING

WARNING

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform installation and

servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or chassis.

Similarly, other power ground lines including those to application and maintenance equipment must be grounded

properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis. However,

depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO HUMAN SAFETY may be

normally generated on the output terminals. The customer/user must ensure that the output power lines are labeled

properly as to the safety hazards and that any inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the electrical

circuits. Even when power is off, capacitors may retain an electrical charge. Use safety glasses during open cover

checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary sales

organizations can accept any responsibility for personnel, material or inconsequential injury, loss or damage that

results from improper use of the equipment and accessories.

Hazardous voltages may be present when covers are removed. Qualified personnel

must use extreme caution when servicing this equipment. Circuit boards, test points,

and output voltages also may be floating above (below) chassis ground.

The equipment used contains ESD sensitive parts. When installing equipment, follow

ESD Safety Procedures. Electrostatic discharges might cause damage to the

equipment.

SAFETY SYMBOLS

M380056-03 Rev L iii

Page 8

This page intentionally left blank.

iv M380056-03 Rev M

Page 9

Elgar ReFlex Power™ Contents

Product Family: ReFlex Power™

Warranty Period: One Year

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the Product stated

above, and if the Buyer discovers and notifies AMETEK in writing of any defect in material or workmanship within

the applicable warranty period stated above, then AMETEK may, at its option: repair or replace the Product; or

issue a credit note for the defective Product; or provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in accordance with the

return procedure specified below. AMETEK will, at its expense, deliver the repaired or replaced Product or parts

to the Buyer. Any warranty of AMETEK will not apply if the Buyer is in default under the Purchase Order

Agreement or where the Product or any part thereof:

•

is damaged by misuse, accident, negligence or failure to maintain the same as specified or

required by AMETEK;

•

is damaged by modifications, alterations or attachments thereto which are not authorized

by AMETEK;

•

is installed or operated contrary to the instructions of AMETEK;

•

is opened, modified or disassembled in any way without AMETEK’s consent; or

•

is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty until the Buyer has

made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be done in the

country in which it was purchased):

•

In the USA, contact the AMETEK Repair Department prior to the return of the product to

AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

•

Outside the United States, contact the nearest Authorized Service Center (ASC). A full

listing can be found either through your local distributor or our website,

www.programmablepower.com, by clicking Support and going to the Service Centers tab.

2. When requesting an RMA, have the following information ready:

•

Model number

•

Serial number

•

Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to an evaluation

fee and applicable freight charges.

M380056-03 Rev L v

Page 10

This page intentionally left blank.

vi M380056-03 Rev M

Page 11

Elgar ReFlex Power™ Contents

CONTENTS

1.

1.1

1.2

1.3

REMOTE PROGRAMMING OVERVIEW ................................. 15

System Level Introduction ............................................................................. 15

Features and Functions ................................................................................ 15

ReFlex Power™ IVI-COM drivers ................................................................. 15

1.4

2.

2.1

2.2

2.3

2.4

2.5

1.3.1 IVI-COM Drivers Installation ........................................................................... 16

1.3.2 IVI-COM Drivers Help .................................................................................... 16

ReFlex Power™ FIRMWARE COMPATIBILITY ........................................... 17

1.4.1 Firmware V3 Differences ................................................................................ 17

CONTROLLER MODULE REMOTE PROGRAMMING ............ 19

Introduction ................................................................................................... 19

Features and Functions ................................................................................ 19

Power-On Conditions and Address Configuration ......................................... 20

Ethernet Configuration and Remote Programming ....................................... 20

2.4.1 Ethernet Connection Requirements................................................................ 20

2.4.2 Ethernet Setup Procedure .............................................................................. 21

2.4.3 Launching Ethernet Communication ............................................................... 22

ReFlex Power™ Ethernet Interface ............................................................... 24

2.5.1 Home Page ................................................................................................... 24

2.5.2 LOGIN Screen ............................................................................................... 25

2.5.3 IP Configuration ............................................................................................. 26

2.5.4 Security Page ................................................................................................ 29

2.5.5 Modules Page ................................................................................................ 32

M380056-03 Rev L vii

Page 12

2.6

Launching Control Communication ............................................................... 33

2.6.1 Module Location Identification (Address) ........................................................ 35

2.6.2 Communication with the System .................................................................... 36

2.7

SCPI Command Operation ........................................................................... 36

2.7.1 Error/Event Queue ......................................................................................... 36

2.8

LXI™ and SCPI Conformance Information.................................................... 37

2.8.1 Parameter Definitions .................................................................................... 38

2.8.2 Numeric Data Dimensional Units .................................................................... 38

2.8.3 Conventions .................................................................................................. 38

2.8.4 Query Syntax ................................................................................................. 39

2.9

Common SCPI Commands ........................................................................... 40

2.10 EIB SCPI Commands.................................................................................... 41

2.10.1 EIB SCPI Command Summary ...................................................................... 41

2.10.2 EIB SCPI Command Reference ..................................................................... 41

2.11 SYSTEM:NETWORK SCPI Commands........................................................ 42

2.11.1 SYSTEM:NETWORK SCPI Command Summary ........................................... 42

2.11.2 SYSTEM:NETWORK SCPI Command Reference .......................................... 43

2.13 RFP Service Request.................................................................................... 44

2.13.1 Background ................................................................................................... 44

2.13.2 Theory of Operation ....................................................................................... 45

2.13.3 Event Status Register .................................................................................... 45

2.13.4 Protection Event Register .............................................................................. 45

2.13.5 Register Allocation ......................................................................................... 45

2.13.6 Execution time Operation ............................................................................... 46

2.13.7 SRQ related SCPI Commands ....................................................................... 47

2.13.8 Setting the SRQ bit in the STB, an example ................................................... 49

2.14 Trigger SCPI Commands .............................................................................. 50

2.14.1 TRIGGER SCPI Command Summary ............................................................ 50

2.14.2 TRIGGER SCPI Command Reference ........................................................... 50

2.15 MEMORY SCPI Commands ......................................................................... 51

2.15.1 MEMORY SCPI Command Summary ............................................................ 51

2.15.2 MEMORY SCPI Command Reference ........................................................... 51

viii M380056-03 Rev M

Page 13

3.

3.1

3.2

3.3

3.4

DC MODULE REMOTE PROGRAMMING ............................... 53

Introduction ................................................................................................... 53

Features and Functions ................................................................................ 53

Power-On Conditions .................................................................................... 54

Error Codes .................................................................................................. 54

3.4.1 Error/Event Queue ......................................................................................... 54

3.5

Common SCPI Commands ........................................................................... 56

3.6

CALIBRATION SCPI Commands .................................................................. 57

3.6.1 CALIBRATION SCPI Command Summary ..................................................... 57

3.6.2 CALIBRATION SCPI Command Reference .................................................... 58

3.7

MEASURE SCPI Commands ........................................................................ 59

3.7.1 MEASURE SCPI Command Summary ........................................................... 59

3.7.2 MEASURE SCPI Command Reference .......................................................... 59

3.8

OUTPUT SCPI Commands ........................................................................... 60

3.8.1 OUTPUT SCPI Command Summary .............................................................. 60

3.8.2 OUTPUT SCPI Command Reference ............................................................ 60

3.9

SOURCE SCPI Commands .......................................................................... 62

3.9.1 SOURCE SCPI Command Summary ............................................................. 62

3.9.2 SOURCE SCPI Command Reference ............................................................ 63

3.10 INPUT SCPI Commands ............................................................................... 64

3.10.1 INPUT SCPI Command Summary ................................................................. 64

3.10.2 INPUT SCPI Command Reference ................................................................ 64

3.11 STATUS SCPI Commands ........................................................................... 65

3.11.1 STATUS SCPI Command Summary .............................................................. 65

3.11.2 STATUS SCPI Command Reference ............................................................. 65

3.12 Trigger SCPI Commands and Lists ............................................................... 66

3.12.1 LIST and Trigger Command Operation........................................................... 66

3.13 Software Triggered Setpoints and Ramps .................................................... 78

3.13.1 Volt and Current Software Setpoints Command summary .............................. 78

3.13.2 Voltage and Current Software Ramps Command Summary ........................... 79

3.14 TRIGGER SCPI Commands ......................................................................... 81

3.14.1 TRIGGER SCPI Command Summary ............................................................ 81

3.14.2 Trigger SCPI Command Reference ................................................................ 81

M380056-03 Rev L ix

Page 14

3.15 LIST SCPI Commands .................................................................................. 82

3.15.1 LIST SCPI Command Summary ..................................................................... 82

3.15.2 LIST SCPI Command Reference ................................................................... 82

3.16 DC SYSTEM SCPI Commands..................................................................... 85

3.16.1 DC SYSTEM SCPI Command Summary ........................................................ 85

3.16.2 SYSTEM SCPI Command Reference ............................................................ 85

3.17 Examples of Using the SCPI Commands ...................................................... 86

4.

AC MODULE REMOTE PROGRAMMING ............................... 89

4.1

Introduction ................................................................................................... 89

4.2

Features and Functions ................................................................................ 89

4.3

Power-On Conditions .................................................................................... 90

4.4

Error Codes .................................................................................................. 91

4.4.1 SCPI Error Codes .......................................................................................... 91

4.4.2 Error/Event Queue ......................................................................................... 92

4.5

Common SCPI Commands ........................................................................... 93

4.6

CALIBRATION SCPI Commands .................................................................. 94

4.6.1 CALIBRATION SCPI Command Summary ..................................................... 94

4.6.2 CALIBRATION SCPI Command Reference .................................................... 96

4.7

MEASURE SCPI Commands ........................................................................ 99

4.7.1 MEASURE SCPI Command Summary ........................................................... 99

4.7.2 MEASURE SCPI Command Reference .......................................................... 99

4.8

OUTPUT SCPI Commands ......................................................................... 100

4.8.1 OUTPUT SCPI Command Summary ............................................................ 100

4.8.2 OUTPUT SCPI Command Reference .......................................................... 100

4.9

SOURCE SCPI Commands ........................................................................ 101

4.9.1 SOURCE SCPI Command Summary ........................................................... 101

4.9.2 SOURCE SCPI Command Reference .......................................................... 102

4.10 STATUS SCPI Commands ......................................................................... 106

4.10.1 STATUS SCPI Command Summary ............................................................ 106

4.10.2 STATUS SCPI Command Reference ........................................................... 106

4.11 SYSTEM SCPI Commands ......................................................................... 108

4.11.1 SYSTEM SCPI Command Summary ............................................................ 108

4.11.2 SYSTEM SCPI Command Reference .......................................................... 108

x M380056-03 Rev M

Page 15

4.12 EXAMPLE SCPI COMMANDs to set phase and parallel groups ................. 108

4.12.1 Examples Creating a Phase Group .............................................................. 108

4.12.2 Example creating a Parallel Group ............................................................... 109

5.

LOAD MODULE REMOTE PROGRAMMING ........................ 111

5.1

Introduction ................................................................................................. 111

5.2

Features and Functions .............................................................................. 111

5.3

Power-On Conditions .................................................................................. 112

5.4

Error Codes ................................................................................................ 113

5.4.1 SCPI Error Codes ........................................................................................ 113

5.4.2 Error/Event Queue ....................................................................................... 113

5.5

Common SCPI Commands ......................................................................... 114

5.6

Calibration SCPI Commands ...................................................................... 115

5.6.1 CALIBRATION SCPI Command Summary ................................................... 115

5.6.2 CALIBRATION SCPI Command Reference .................................................. 116

5.7

MEASURE SCPI Commands ...................................................................... 117

5.7.1 MEASURE SCPI Commands Summary ....................................................... 117

5.7.2 MEASURE Commands Reference ............................................................... 117

5.8

INPUT SCPI Commands ............................................................................. 118

5.8.1 INPUT SCPI Command Summary ............................................................... 118

5.8.2 INPUT SCPI Command Reference .............................................................. 118

5.9

SOURCE SCPI Commands ........................................................................ 119

5.9.1 SOURCE SCPI Command Summary ........................................................... 119

5.9.2 SOURCE SCPI Command Reference .......................................................... 119

5.10 STATUS SCPI Commands ......................................................................... 120

5.10.1 STATUS SCPI Command Summary ............................................................ 120

5.10.2 STATUS SCPI Command Reference ........................................................... 120

5.11 SYSTEM SCPI Commands ......................................................................... 121

5.11.1 SYSTEM SCPI Command Summary ............................................................ 121

5.11.2 SYSTEM SCPI Command Reference .......................................................... 122

6.

FIXED POWER DC REMOTE PROGRAMMING .................... 123

6.1

Introduction ................................................................................................. 123

6.2

Features and Functions .............................................................................. 123

M380056-03 Rev L xi

Page 16

6.3

6.4

6.5

6.6

6.7

6.8

6.2.2 Power-On Conditions ................................................................................... 124

Error Codes ................................................................................................ 124

6.3.1 SCPI Error Codes ........................................................................................ 124

6.3.2 Error/Event Queue ....................................................................................... 125

Common SCPI Commands ......................................................................... 125

CALIBRATION SCPI Commands ................................................................ 126

6.5.1 CALIBRATION SCPI Command Summary ................................................... 126

6.5.2 CALIBRATION SCPI Command Reference .................................................. 127

OUTPUT SCPI Commands ......................................................................... 128

6.6.1 OUTPUT SCPI Command Summary ............................................................ 128

6.6.2 OUTPUT SCPI Command Reference .......................................................... 128

STATUS Commands .................................................................................. 129

6.7.1 STATUS SCPI Command Summary ............................................................ 129

6.7.2 STATUS SCPI Command Reference ........................................................... 129

SYSTEM Commands .................................................................................. 129

6.8.1 SYSTEM SCPI Command Summary ............................................................ 129

6.8.2 SYSTEM SCPI Command Reference .......................................................... 129

xii M380056-03 Rev M

Page 17

LIST OF TABLES

Table 2-1. Remote Power-On Conditions ....................................................................................... 20

Table 2-2. SCPI Error Codes ......................................................................................................... 37

Table 2-3. Parameter Definitions .................................................................................................... 38

Table 2-4. Numeric Data Units ....................................................................................................... 38

Table 2-5. Common SCPI Commands ........................................................................................... 40

Table 2-6. Module *TST? Error Response Bits .............................................................................. 40

Table 3-1. Remote Power-on Conditions........................................................................................ 54

Table 3-2. Common SCPI Commands ........................................................................................... 56

Table 3-3. Fault and Enable Register ............................................................................................. 65

Table 3-4. SCPI for Module Trigger Routing .................................................................................. 70

Table 3-5. Input Trigger Signal Specifications ............................................................................... 71

Table 3-6. Output Trigger Specifications ....................................................................................... 72

Table 3-7. Group Pulse Function ................................................................................................... 77

Table 3-8. Software Triggered Setpoints ....................................................................................... 79

Table 3-9. Software Ramps ............................................................................................................ 80

Table 4-1. Remote Power-On Conditions ....................................................................................... 90

Table 4-2. AC Enable Register 0 .................................................................................................. 107

Table 4-3. AC Enable Register 1 .................................................................................................. 107

Table 5-1. Load Power-on Conditions .......................................................................................... 112

Table 5-2. Enable Register ........................................................................................................... 121

Table 6-1. Remote Power-on Conditions...................................................................................... 124

Table 6-2. Faults / Enable Register .............................................................................................. 129

M380056-03 Rev L xiii

Page 18

LIST OF FIGURES

Figure 2-1. Ethernet Network Connection ..................................................................................... 21

Figure 2-2. Ethernet Direct Connection ......................................................................................... 22

Figure 2-3. LXI Discovery Browser Window .................................................................................. 23

Figure 2-4. ReFlex Power™ Ethernet Interface Home Page ......................................................... 24

Figure 2-5. LOGIN Page with Authorization warning ..................................................................... 25

Figure 2-6. IP CONFIGURATION Page, Default ........................................................................... 26

Figure 2-7. IP CONFIGURATION Static IP selected, but not yet applied. ..................................... 27

Figure 2-8. IP CONFIGURATION Page with Error Message for invalid IP Address ...................... 28

Figure 2-9. Security Page .............................................................................................................. 29

Figure 2-10. Security: Add New User ............................................................................................ 30

Figure 2-11. Security: Edit Existing User ....................................................................................... 31

Figure 2-12. MODULES Page Showing Installed Power Modules ................................................. 32

Figure 2-13. Net Test Window ........................................................................................................ 33

Figure 2-14. Query IP Address Example ........................................................................................ 34

Figure 2-15. Address Location and Chassis Configuration ............................................................. 35

Figure 2-16. Photo of Multi-Chassis ReFlex Power™ System ....................................................... 35

Figure 3-1. RFP Trigger Logic ........................................................................................................ 67

Figure 3-2. Fixed Mode Trigger Input ............................................................................................. 68

Figure 3-3. Module/Buss Trigger Input ........................................................................................... 69

Figure 3-4. Module/Buss Trigger Out ............................................................................................. 69

Figure 3-5. Trigger Signal Types ................................................................................................... 71

Figure 3-6. Output Trigger Timing ................................................................................................. 72

Figure 3-7. Trigger Input Responses ............................................................................................. 73

Figure 3-8. List Mode Logic ........................................................................................................... 74

Figure 3-9. Group Pulse Sequence ............................................................................................... 76

xiv M380056-03 Rev M

Page 19

WARNING

1.

1.1

REMOTE PROGRAMMING OVERVIEW

SYSTEM LEVEL INTRODUCTION

This manual covers remote programming of the ReFlex Power™ system and

should be used in conjunction with the ReFlex Power™ Operation Manual,

M380056-01.This remote programming interface enables system operation

from a computer via Ethernet, allowing full remote programming control and

monitoring of all system modules, which include five basic types: the ReFlex

Power™ Controller (RFPC), AC, DC, Active Load (AL) and Fixed Power

modules. This programming manual is divided among sections addressing

each module type, beginning with the RFPC and its set up and connection

instructions for Ethernet control via SCPI commands. Set up includes

installing IVI-COM driver files, connecting the control computer with the

RFPC, and launching Ethernet and control communications. The remaining

module types are addressed in subsequent sections, each with their

applicable SCPI commands.

Avoid personal injury or damage to any part of the system, observe all

electrical safety precautions described in the ReFlex Power™ operation

manuals when operating a ReFlex Power™ system. When developing a

program to control a ReFlex Power™ system, strictly adhere to connections

instructions and avoid contact with the power module outputs.

1.2

FEATURES AND FUNCTIONS

Features and functions are as follows:

• SCPI compliant command set

• Field-upgradeable firmware for all modules via Ethernet

• System extensible up to eight Mainframes and ninety-six modules

• Configuration flexibility

1.3

REFLEX POWER™ IVI-COM DRIVERS

This programming manual was not written for users who will develop

applications using the ReFlex Power™ IVI-COM (Interchangeable Virtual

Instrument Component Object Model) drivers. However, it is a good

supplement to help the developer understand the exact behavior of the

M380056-03 Rev M 15

Page 20

ReFlex Power™ Programming Manual Remote Programming Overview

hardware in response to the individual SCPI commands produced by the

drivers.

The ReFlex Power™ IVI-COM drivers allow users to develop applications in

Windows to control a ReFlex Power™ system in several programming

languages and environments, including C++, VB 6.0, VB.Net, C# or Lab

VIEW. The drivers also include an IVI-C wrapper for use with LabWindows or

the C programming language.

1.3.1 IVI-COM

There are three ReFlex Power™ IVI-COM drivers for the ReFlex Power™

system, one each for DC, AC and Loads. They are available as three

separate Windows .msi installation files on the CD-ROM (M380399-01)

supplied with the unit, and must be installed in the following sequence:

1. Install the IVI Foundations shared components (must be accomplished

first in order to successfully install the ReFlex Power™ IVI-COM

drivers). You may either click the IVI Shared Components link at the

bottom of the Downloads page at

http://www.programmablepower.com/go/rfp_downloads, or go directly

to http://www.ivifoundation.org/shared_components/Default.aspx, and

choose between the .msi file or.exe file.

2. Install a VISA (Virtual Instrument Software Architecture) layer such as

NI-VISA. Again, either click the VISA RTE link also at the bottom of the

Downloads page, or go directly to http://www.ni.com/support/visa/.

3. Install the applicable driver files (AC, DC, Loads) located in the

RFP_IVI-COM Drivers folder on the CD-ROM.

1.3.2 IVI-COM

The three IVI-COM drivers include extensive help files and sample

applications. Once installation is complete, the help files and readme.txt will

be available on your Start menu.

DRIVERS INSTALLATION

DRIVERS HELP

If you are not already familiar with IVI-COM drivers, it is strongly

recommended that you read the entire “Getting Started with the IVI-COM

Driver” section of the help files. This should answer all questions about

installation, compliance, configuration, and development with IVI-COM. It

also references several other good sources for information on IVI-COM

development such as the IVI Foundation, National Instruments, and Pacific

MindWorks Web sites.

16 M380056-03 Rev M

Page 21

Remote Programming Overview ReFlex Power™ Programming Manual

1.4

REFLEX POWER™ FIRMWARE COMPATIBILITY

With the release of firmware version 3.000.000 and higher, the controller

firmware revision and the firmware in the power and load modules must be at

the same major revision level. Thus, it is not possible to mix revision

2.000.000 and revision 3.000.000 assets. When powering up a system with

mixed revision assets installed, the red Fault LED will blink on a version 3

controller, if a version 2 module is detected. If a version 3 Module detects a

version 2 controller, the Module’s red Fault LED will blink indicating the

firmware miss-match. The *TST? response will also have an error bit set

indicating miss-matched firmware.

RFP version 2 Modules can be upgraded to version 3, and version 3 modules

can be downgraded to version 2.

The Order numbers for version 2 and version 3 Modules are different, contact

Sales for further information.

1.4.1 F

Programmatically firmware version 3 is a superset of the functionality in V2.

There are some differences because of new features that have been added,

and some because of enhancements.

In general; non-setting related query commands now execute much faster, by

as much as a second in some cases. As an example meas:volt? the

response time is in the order of 10-15msec. The number of digits after the

decimal point in a measure query response is now proportional to the module

ratings, i.e. more digits on a 16 volt module and less on a 450 volt module.

AC Group operation can now be paced by the execution speed of the group

rather than using fixed delays. See AC Module Group operation examples for

details on command usage. An AC power measurement subsystem, and a

transient upset event generator has been added. Control of CC Mode (as

RMS current) has been added.

IRMWARE V3 DIFFERENCES

M380056-03 Rev L 17

Page 22

ReFlex Power™ Programming Manual Remote Programming Overview

This page intentionally left blank.

18 M380056-03 Rev M

Page 23

2.

2.1

CONTROLLER MODULE REMOTE

PROGRAMMING

INTRODUCTION

This section covers the set up and remote programming of the ReFlex

Power™ system Controller (RFPC). All SCPI commands for the ReFlex

Power™ system will pass through the RFPC, which validates the command

syntax and confirms that the target module(s) exist, before sending the

command through. While most commands are intended for specific modules

or module groups, some commands will affect the entire system, and others

will return information from the RFPC.

The syntax of all SCPI commands implemented by the ReFlex Power™

system and documented in this manual, are either SCPI confirmed in the

SCPI 1999.0 Specification, Volume 2: Command Reference, or they are

customized commands not part of the SCPI definition but conform to SCPI

syntax.

The design of the RFP System is based on a loosely coupled, multi-user,

multi-processor, pre-emptive multitasking, and multi-threaded control system,

composed of semi-autonomous modules. This allows multiple users to control

various parts of the RFP system independently from each other. User

coordination is required.

2.2

FEATURES AND FUNCTIONS

F

EATURES

R

EADBACK FUNCTIONS

M380056-03 Rev M 19

• SCPI compliant command set

• Field-upgradeable firmware via Ethernet

• Support for 96 modules

• Status and Accumulated Status registers

• Programming error codes

• Fault codes

• Manufacturer, power supply model, serial number, and firmware

version identification

Page 24

ReFlex Power™ Programming Manual Controller Module Remote Programming

configuration.

2.3

POWER-ON CONDITIONS AND ADDRESS

CONFIGURATION

Table 2-1 presents remote power-on conditions for the ReFlex Power™

Controller (RFPC).

Table 2-1. Remote Power-On Conditions

Condition Default

Off, can be enabled by command and IVI Driver

2.4

Service Request Capability

ETHERNET CONFIGURATION AND REMOTE

PROGRAMMING

Operating the ReFlex Power™ system via the Controller module requires

a computer with an Ethernet LAN connection. The Controller

communication interface conforms to IEEE 802.3, commonly known as

Ethernet 10 Base-T and 100 Base-T, and is

Instrumentation) class C compliant.

™ (LAN eXtensions for

After installing the IVI-COM drivers (Section 1.3.1), begin the Ethernet

connection and setup for communication.

2.4.1 E

For Ethernet connection between the ReFlex Power™ Controller module

and the control computer, you will need:

•

•

•

•

THERNET CONNECTION REQUIREMENTS

EnetTest.exe file located in the RFP Download folder on the ReFlex

Power™ CD-ROM (P/N M380399-01) supplied with your product

LXI_Browser_setup.exe file (if you don’t know the IP address of the

Controller module), which is also located in the RFP Download folder

RJ45-type connectors with Category 5 or 5e (Cat 5) cables:

o For a network connection, via local router, switch or hub, to

isolate the local nodes and segments from the rest of the

network, use two straight-through cables.

o For a direct connection, if the control computer’s Ethernet

interface does not support Auto-MDIX, use a crossover cable

to connect the control computer directly to the Controller

module via their respective Net/LAN connectors.

Jumper plug to enable voltage output of each module as follows:

o For the ReFlex Power™ Controller module, you will need

either Loop-back Connector Assembly 5380509-01 or Cable

Assembly 5380441-01 or –03.

20 M380056-03 Rev M

Page 25

Controller Module Remote Programming ReFlex Power™ Programming Manual

o For all other modules (power supplies and loads), you will

need either Loop-back Connector Assembly 5380508-01 or

Cable Assembly 5380443-01 or-03.

2.4.2 E

The ReFlex Power™ Quick Reference Guide (M380056-04) is a

condensed version of this procedure for Ethernet setup.

1.

2. Disable the Remote Inhibit of the Controller module, by connecting their

3. Enable the voltage output of all other power supply and/or load

4. Create either a Network or direct connection between the control

THERNET SETUP PROCEDURE

With all power disabled, assemble your ReFlex Power™ system and

main power connections according to the ReFlex Power™ Operation

Manual, M380056-01.

discrete signals with a jumper plug that connects Pins 1 and 9 on the

front panel interface connector, using either Loop-back Connector

Assembly 5380509-01 or Cable Assembly 5380441-01 or –03.

modules by connecting their discrete signals with a jumper plug that

connects Pins 1 and 6 on the front panel interface connector of each

module, using either Loop-back Connector Assembly 5380508-01 or

Cable Assembly 5380443-01 or-03.

computer and the ReFlex Power™ system, using Category 5 or 5e (Cat

5) cables with RJ45-type connectors, as follows:

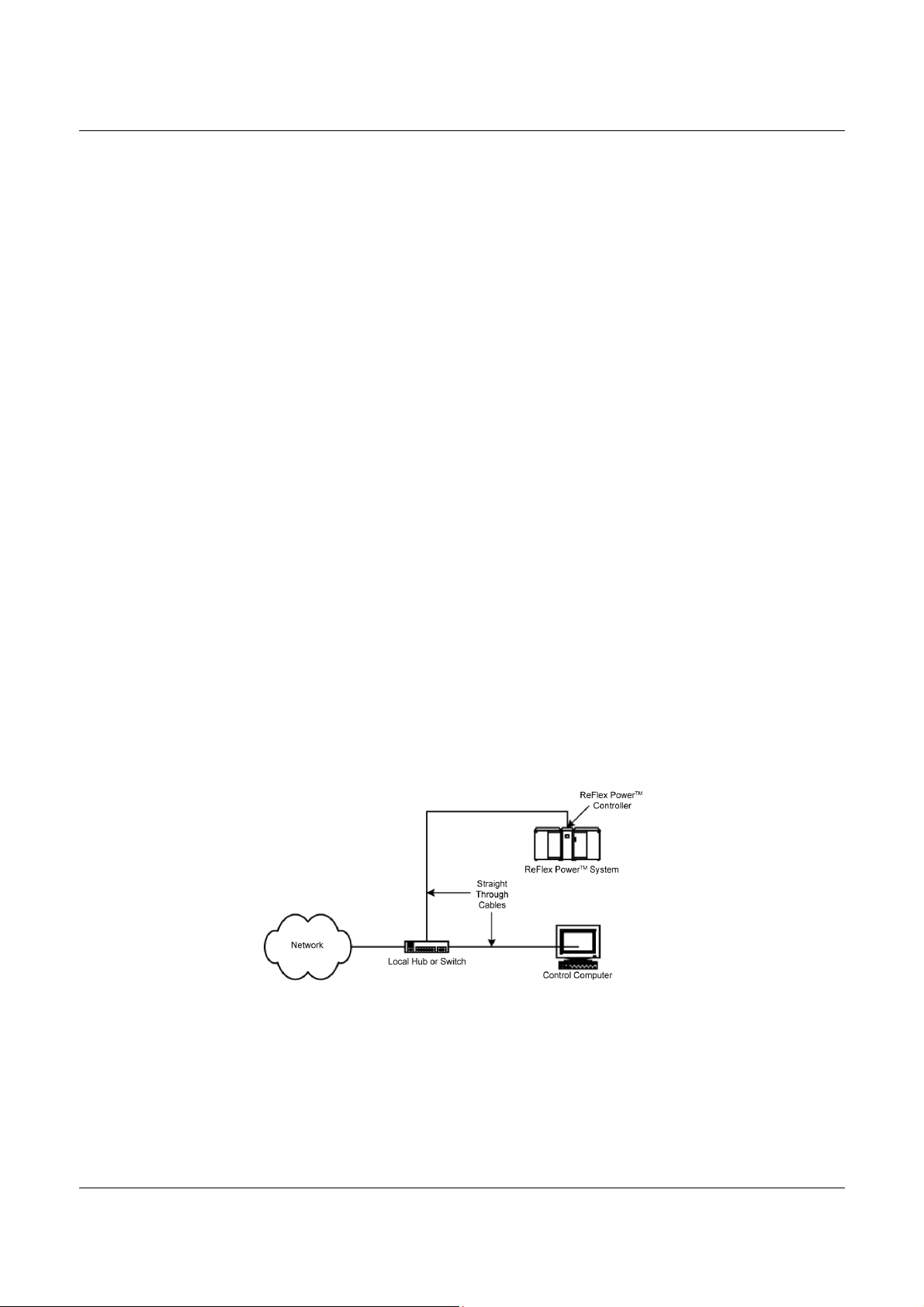

Ethernet Network Connection

A Network connection via local router, or switch isolates the local

nodes and segments from the rest of the Network, a hub does not. Use

two straight through cables to connect the control computer and the

ReFlex Power™ Controller from their respective Net/LAN connectors,

to a local router, switch or hub (Figure 2-1). ReFlex Power™ Controller

will DHCP if available from the network.

Figure 2-1. Ethernet Network Connection

M380056-03 Rev L 21

Page 26

ReFlex Power™ Programming Manual Controller Module Remote Programming

Direct Connection

If the control computer’s Ethernet interface does not support AutoMDIX, use a crossover cable to connect the control computer directly to

the Controller module between their respective Net/LAN connectors

(Figure 2-2). The factory default ReFlex Power™ Controller settings will

select an AutoIP address, it will be in the 169.254.1-254.NNN range, if

DHCP is not available, check the Control computer for proper settings.

Figure 2-2. Ethernet Direct Connection

5. Press the POWER switch on the Controller’s front panel to power on

the system. Allow time for the system to boot.

6. Launch the Ethernet connection (Section 2.4.3), or go straight to the

Net Test window to begin control communication (Section 2.6).

2.4.3 L

AUNCHING ETHERNET COMMUNICATION

Once the Ethernet connection is made and the system is powered on, the

Controller module’s LEDs, LAN and Con, are lit, and Net is lit during

network traffic.

When there is no Network traffic, the Net LED is not lit.

If the Con LED is not lit, the RFPC is not connected to a functioning

network.

If the LAN LED is not lit, the RFPC does not have an active TCP/IP

address, it has detected that it cannot retrieve an IP address via DHCP, or

if configured for a fixed IP address, the requested IP address is already in

use, or the RFPC can’t initialize the Ethernet system for some reason.

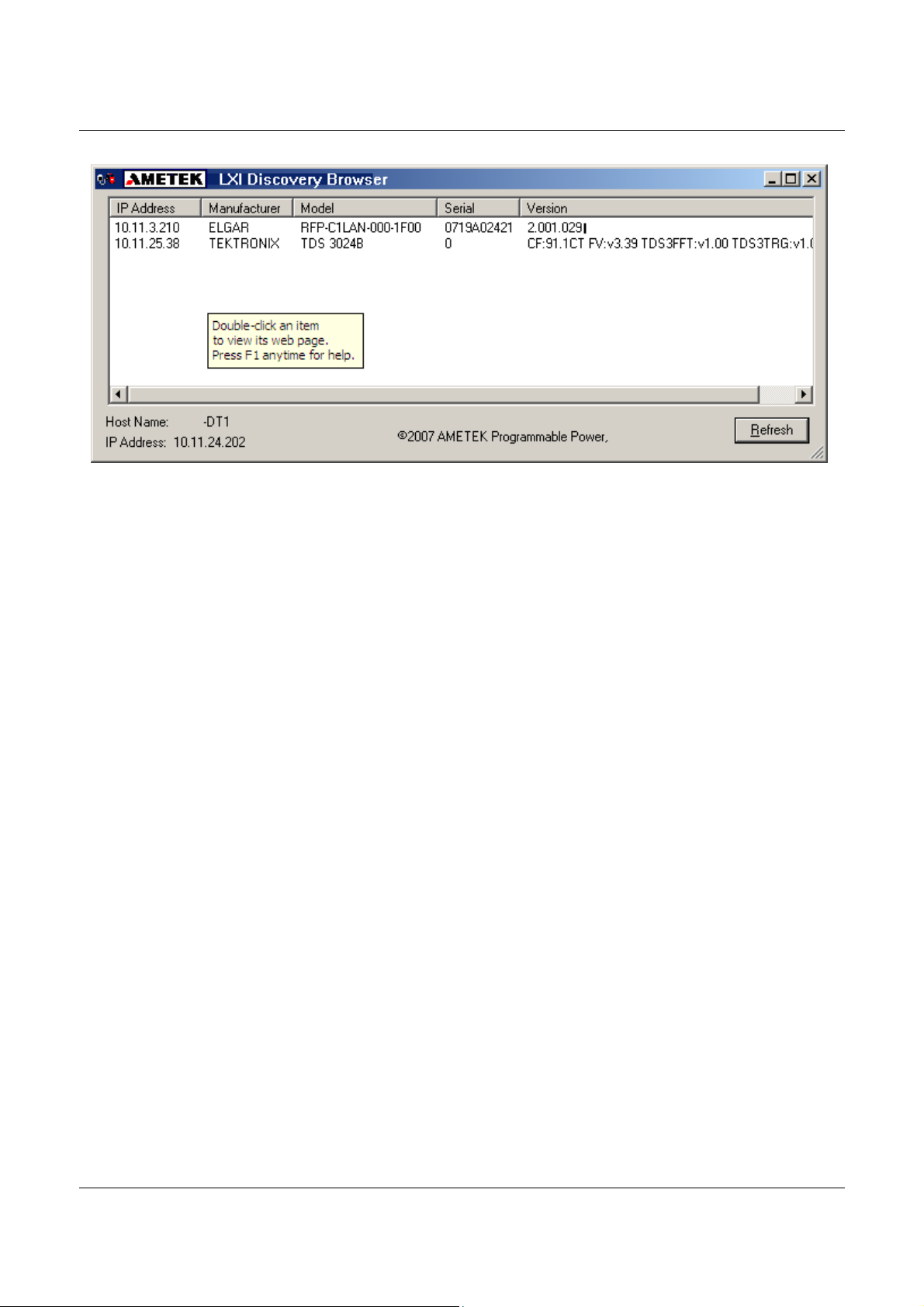

Execute the LXI™_Browser_setup file located in the ReFlex Power

executables folder on the ReFlex Power™ CD-ROM, M380399-01. This

will bring up the LXI™ Discovery Browser interface (Figure 2-3), which will

find and display the IP address of the ReFlex Power™ Controller module.

22 M380056-03 Rev M

Page 27

Controller Module Remote Programming ReFlex Power™ Programming Manual

Figure 2-3. LXI Discovery Browser Window

M380056-03 Rev L 23

Page 28

ReFlex Power™ Programming Manual Controller Module Remote Programming

2.5

REFLEX POWER™ ETHERNET INTERFACE

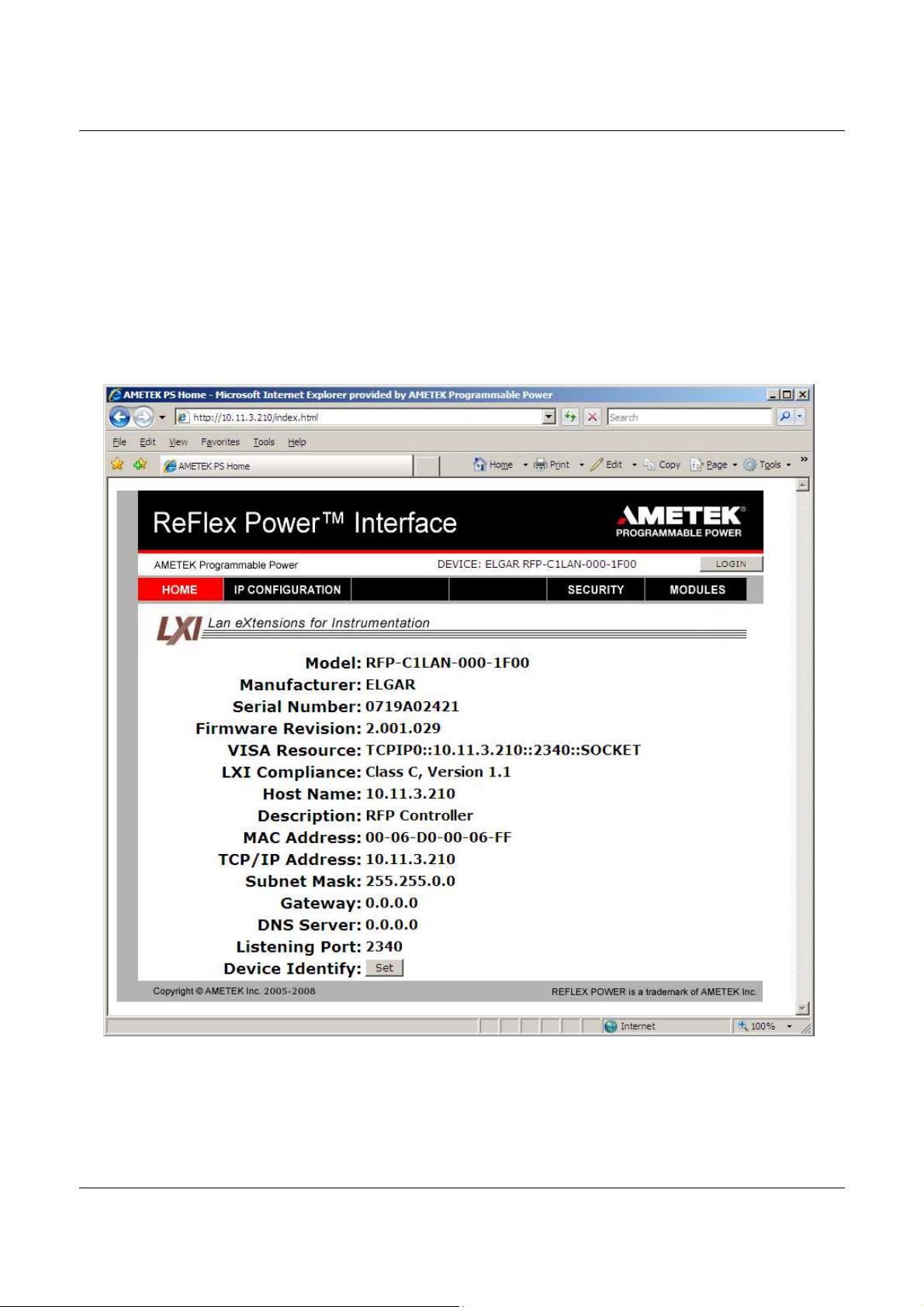

To bring up the ReFlex Power™ Ethernet Interface, in the LXI™

Discovery Browser, double click the IP address of the Controller module.

This brings up that Controller module’s HOME page (Figure 2-4).

2.5.1 H

The ReFlex Power™ Ethernet interface HOME page displays the current

information about the specific Controller module that you are connected to.

OME PAGE

Figure 2-4. ReFlex Power™ Ethernet Interface Home Page

24 M380056-03 Rev M

Page 29

Controller Module Remote Programming ReFlex Power™ Programming Manual

If you are not sure you are connected to the correct Controller module, e.g.,

multiple Controller modules were listed in the LXI™ Discovery Browser, click

the SET button at the bottom of the HOME page (when clicked, the SET

button becomes the CLEAR button). SET causes that Controller module’s

LAN LED to blink for identification purposes. Click the CLEAR button to stop

the blinking (CLEAR button changes back to SET).

The HOME page has links (tabs) to three other pages in the ReFlex Power™

Interface: IP CONFIGURATION, SECURITY and MODULES. Also, in the

upper right area of the interface is the LOGIN button.

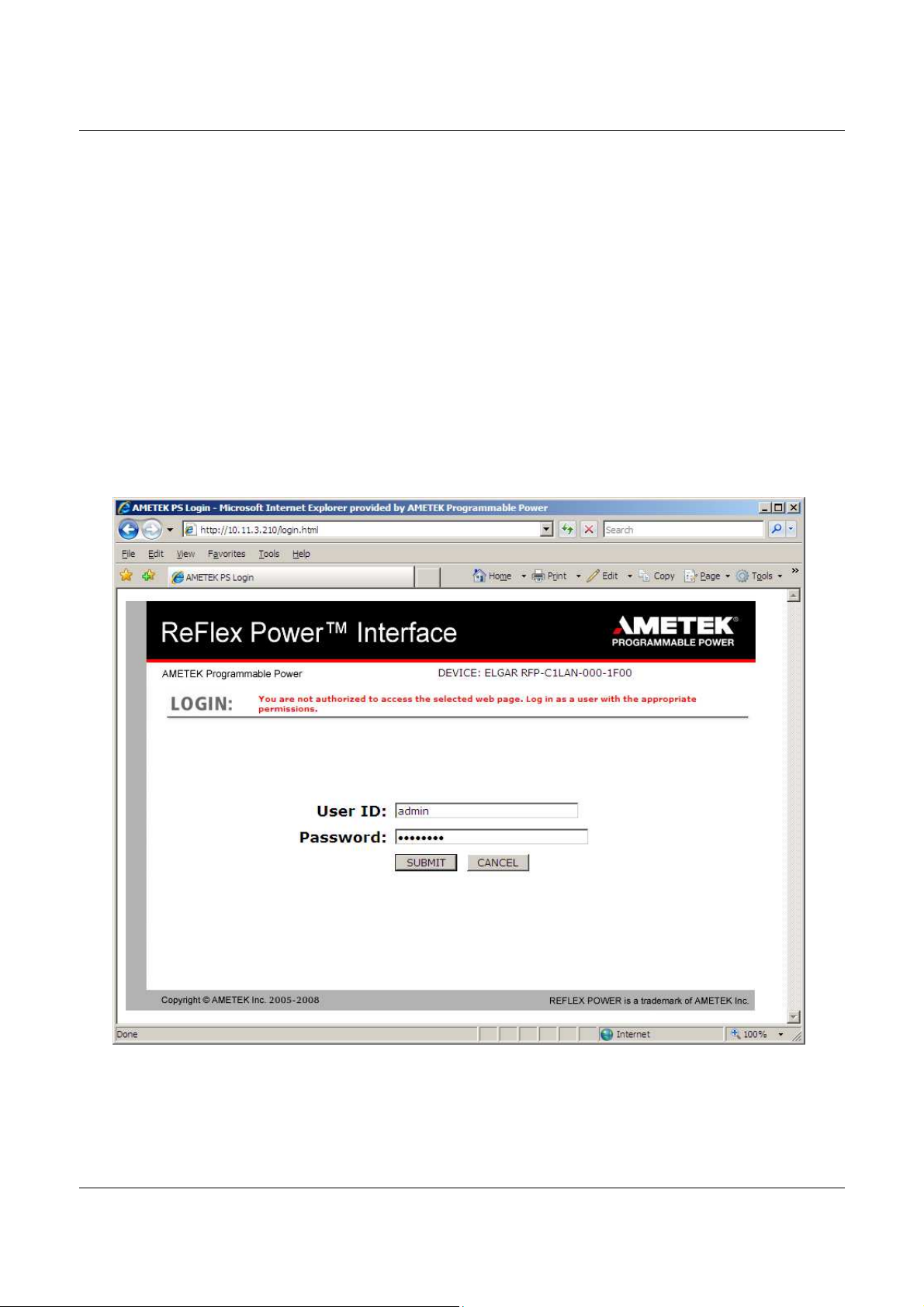

2.5.2 LOGIN

SCREEN

Click the LOGIN button to log in; clicking the IP CONFIGURATION tab also

brings up the LOGIN page, but with an error message prompting you to log in

(Figure 2-5).

Figure 2-5. LOGIN Page with Authorization warning

M380056-03 Rev L 25

Page 30

ReFlex Power™ Programming Manual Controller Module Remote Programming

With authorized log-in (default parameters: User ID = admin; Password =

password), click the IP CONFIGURATION tab (Figure 2-6) where you can

customize the Host Name and Description, and/or select Use a Static IP

Address (Figure 2-7) to change IP Address, Subnet Mask, Gateway, DNS

Server and Listening Port. Please ask your IT Administrator for support.

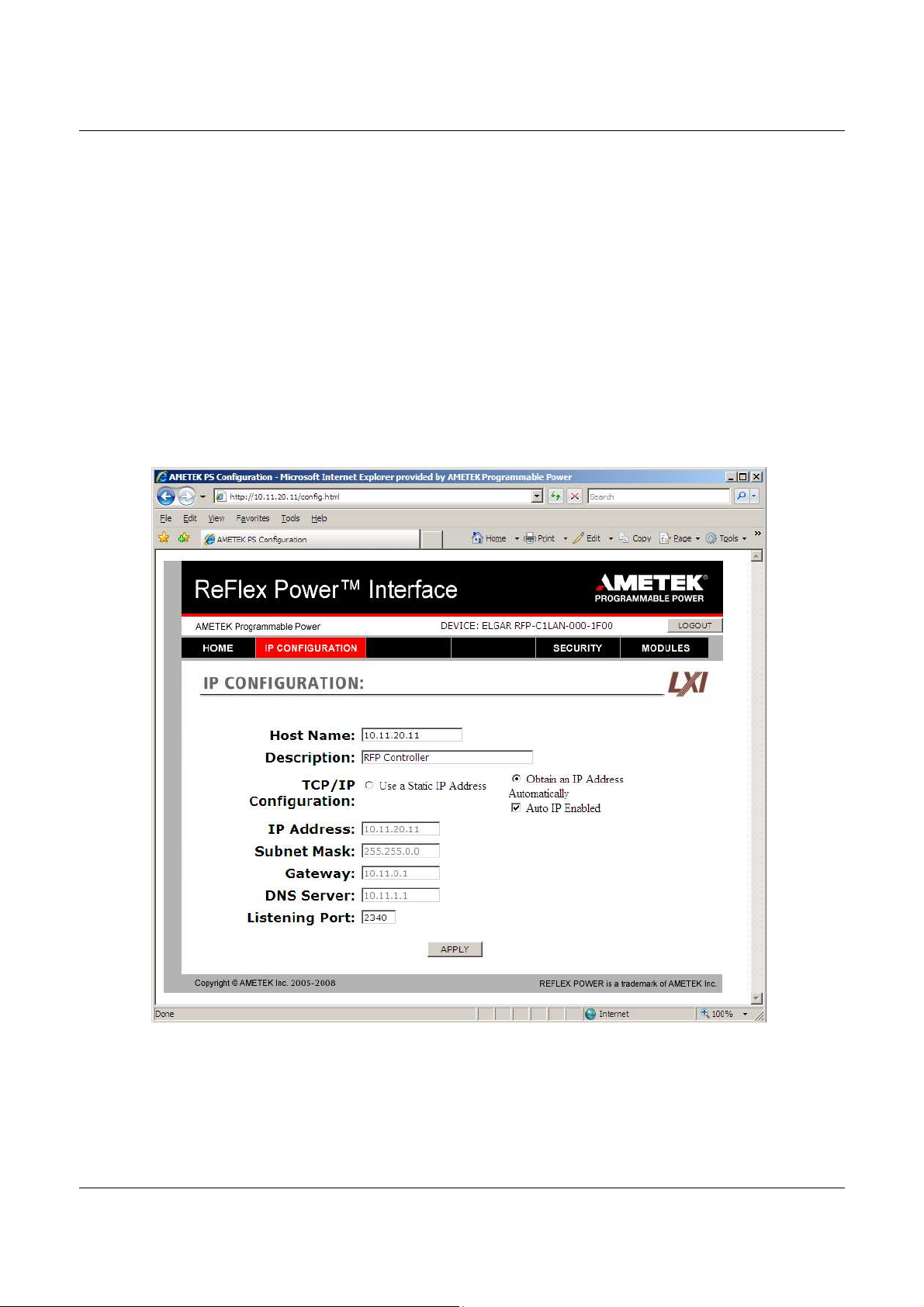

2.5.3 IP

CONFIGURATION

The default IP Address configuration is DHCP-enabled and Auto IP-enabled. If

a DHCP server is not found, an address in the range of 169.254.[1 thru 254].[0

thru 255] will be selected. If there is no DHCP server on your local network,

your PC must also be configured for Auto-IP for the RFP system to be

discovered. For only DHCP, select “Obtain an IP Address Automatically” and

deselect “Auto IP Enabled”). Click the APPLY button to set your inputs.

Figure 2-6. IP CONFIGURATION Page, Default

26 M380056-03 Rev M

Page 31

Controller Module Remote Programming ReFlex Power™ Programming Manual

Figure 2-7. IP CONFIGURATION Static IP selected, but not yet applied.

When an IP Address is in error, it needs to be “checked”, an error message is

displayed, and the page refreshes back to the previous settings. (Figure 2-8)

An invalid IP address can be the result of invalid values entered in the address

fields, or the requested IP address is already in use. The chosen IP address

should be ‘PINGED’ to check that it is free and available for use before trying

to set the RFPC to that address.

M380056-03 Rev L 27

Page 32

ReFlex Power™ Programming Manual Controller Module Remote Programming

Figure 2-8. IP CONFIGURATION Page with Error Message for invalid IP Address

28 M380056-03 Rev M

Page 33

Controller Module Remote Programming ReFlex Power™ Programming Manual

2.5.4 S

ECURITY PAGE

Click the SECURITY tab to open the Security page, which displays the user

names and their permissions (Figure 2-9).

Figure 2-9. Security Page

Click the ADD button to add a new user and assign Password and Permissions

(Figure 2-10). To remove an existing user, select that user’s name and click the

REMOVE button. That row is deleted from the main Security page. To change

anything for an existing user, select that user’s name and click the EDIT button,

which takes you to the EDIT EXISTING USER page (Figure 2-11).

M380056-03 Rev L 29

Page 34

ReFlex Power™ Programming Manual Controller Module Remote Programming

Figure 2-10. Security: Add New User

In the ADD NEW USER page, click the cursor in each field and type the inputs,

select the Permission level from the drop-down menu and click the SUBMIT

button to set the new user settings. To clear the fields and start over, click the

RESET button. Clicking the CANCEL button reverts back to the previous

Security page without changes taking effect.

30 M380056-03 Rev M

Page 35

Controller Module Remote Programming ReFlex Power™ Programming Manual

Figure 2-11. Security: Edit Existing User

Make the desired changes to the applicable fields and click the SUBMIT button

to set the new user settings. To clear the fields and start over, click the RESET

button. Clicking the CANCEL button reverts back to the previous Security page

without changes taking effect.

M380056-03 Rev L 31

Page 36

ReFlex Power™ Programming Manual Controller Module Remote Programming

2.5.5 M

ODULES PAGE

Click the MODULES tab to reveal the “address” or Slot Location (SL), the

model number, the serial number and the firmware revision of the modules that

are installed in the system. (Figure 2-12 shows a system with the ReFlex

Power™ Controller module in Mainframe slot 1, and three AC power modules,

in slots 5, 8, and 12).

Figure 2-12. MODULES Page Showing Installed Power Modules

32 M380056-03 Rev M

Page 37

Controller Module Remote Programming ReFlex Power™ Programming Manual

2.6

LAUNCHING CONTROL COMMUNICATION

When the Ethernet interface is up and running, then start the communication

program as follows:

1. Copy the EnetTest.exe file supplied on the ReFlex Power™ CD-ROM into

any convenient directory on the control computer.

2. In its new location double-click the EnetTest.exe file.

This brings up the Elgar Net Test window (Figure 2-13) where the Host IP

and Port addresses must be set before control communication can begin.

Figure 2-13. Net Test Window

In the Host and Port fields of the Net Test window:

3. Enter the Host IP address acquired by the LXI™ Discovery Browser (Section

2.4.3), or the static IP address that you entered in the Ethernet Configuration

page (AutoIP will be in the range of 169.254.[1 thru 254].[0 thru 255].

4. Set the Port address to: 2340 (required)

5.

Click the Connect button.

M380056-03 Rev L 33

Page 38

ReFlex Power™ Programming Manual Controller Module Remote Programming

The field to the left of the Clear button, now appears white (not grayed out), to

allow SCPI command input.

It may be necessary to change the IP address, due to address conflicts and

other system requirements. (SYSTem:NETwork:IP <ipaddress>

).

Figure 2-14. Query IP Address Example

Figure 2-14 displays an example of querying and changing the IP address to

static. Note that the response to the IP address query after the address is

changed, includes the current IP address followed by the new IP address. The

following are commands associated with setting and querying the IP address:

SYSTem:NETwork:IP? Query to get the IP address from the

ReFlex Power™ system.

SYSTem:NETwork:IP <ipaddress> Sets the ReFlex Power™ system IP

address following the format:

NNN.NNN.NNN.NNN

The ReFlex Power™ System will reconfigure its TCP/IP address to the

requested address, after validating that the requested address is valid and

available for use. When the IP address is set, the IP address configuration is

automatically set to static.

The new IP address is reconfigured a few seconds after being validated, all

current TCP/IP connections will be closed, and new connections at the new

address will have to be created to communicate with the ReFlex Power™

System.

34 M380056-03 Rev M

Page 39

Controller Module Remote Programming ReFlex Power™ Programming Manual

Test the communication interface by issuing the *IDN? and/or *IDN<n>?

commands, which will return, respectively, the Controller’s or specific module’s

model and firmware versions without affecting output.

2.6.1 M

ODULE LOCATION IDENTIFICATION (ADDRESS

)

To control a specific module, use its address identified by its location in the

ReFlex Power™ Mainframe. Each Mainframe houses 12 address locations, one

for each single-width slot; the first slot on the left is numbered 1; the last on the

right is numbered 12. Additional mainframes continue the count; i.e., the

second Mainframe addresses are 13 through 24 from left to right (Figure 2-15).

The address for a double or triple-width module is always the rightmost slot

position that it occupies. Hence, a triple-width module covering slots 17, 18, and

19 is identified by address 19.

A ReFlex Power™ system is extendable up to eight (8) chassis, with the first

mainframe chassis (primary) configured as output only; any intervening chassis

would have both input and output inter-chassis connections, and the last would

be configured as input only. Refer to the ReFlex Power™ Operation Manual

(M380056-01) for additional information on multiple chassis interconnection

requirements.

Figure 2-15. Address Location and Chassis Configuration

Figure 2-16. Photo of Multi-Chassis ReFlex Power™ System

M380056-03 Rev L 35

Page 40

ReFlex Power™ Programming Manual Controller Module Remote Programming

2.7

2.6.2 C

Click within the Net Test window (Figure 2-14) to begin control

communications by inputting SCPI commands per the proper syntax and

conventions described herein.

SCPI COMMAND OPERATION

The SCPI command sets provide programming, query, and status commands

that facilitate remote control of the ReFlex Power™ system.

The system supports the SCPI 1999.0 status reporting data structures. These

structures are comprised of status registers and status register enable mask

pairs. The following sections describe these pairs.

2.7.1 E

The Error/Event Queue, defined by SCPI holds up to ten error events. Issue

the SYSTem:ERRor? query to read the queue in a First In/First Out (FIFO)

manner. The read operation removes the entry from the queue. Issue the

*CLS command to clear all entries from the queue.

The following SCPI-defined error codes are in the range of [-32768, 32767].

SCPI reserves the negative error codes and 0, while error codes greater than

0 are device-specific errors.

OMMUNICATION WITH THE SYSTEM

RROR/EVENT QUEUE

36 M380056-03 Rev M

Page 41

Controller Module Remote Programming ReFlex Power™ Programming Manual

Error Code

Description

No Error

Invalid

Index

When a command is issued to an empty slot

Wrong Module Type

Feature not supported

Feature Not Implemented

System too Busy

TrigChannel not available

Requested trigger channel is already used in the system

Wrong Group

Config/Oper

Module inhibited asserted

List Seq Buffer Full

Syntax error

Execution error

A command could not be executed due to the current condition of the module.

Data out of range

"Name not found/invalid

Name already exists

System Error

Queue overflow

Table 2-2. SCPI Error Codes

0

2

11

12

14

15

206

251

252

253

-102

-200

-222

The error queue is empty.

Command is not correct for the specific module type.

Specific command may not get implemented for the module type

Command will be implemented in the future

System is busy executing a previous command, the command causing this error will

not be executed.

Group creation failed for stated reason.

Module Inhibit is asserted in the RFPC for the ReFlex Power™ system.

The LIST being created, is too long.

An unrecognized command or data type was encountered.

Parameter exceeded range of valid values.

2.8

-292

-293

-331

-350

LXI™ AND SCPI CONFORMANCE INFORMATION

Requested File name either not found or the name was not valid.

Requested name already exists.

A valid command could not be executed due to some internal/earlier error.

The error queue can contain up to ten entries. If more than ten error/event conditions

are logged before a SYSTem:ERRor? Query, an overflow will occur; the last queue

entry will be overwritten with error -350. When the queue overflows, the least recent

error/events remain in the queue and the most recent error/events are discarded.

The ReFlex Power™ Controller Ethernet is IEEE 802.3 and LXI™ (LAN eXtensions

for Instrumentation) class C compliant.

The syntax of all SCPI commands implemented by the ReFlex Power™ system

and documented in this manual, are either SCPI commands confirmed in the SCPI

1999.0 Specification, Volume 2: Command Reference, or they are customized

commands, not part of the SCPI definition, but do conform to SCPI syntax.

M380056-03 Rev L 37

Page 42

ReFlex Power™ Programming Manual Controller Module Remote Programming

2.8.1 P

Table 2-3. Parameter Definitions

Type Valid Arguments

<bool> 1 or “ON”; 0 or “OFF”

<NRi>

<0+NRi> Zero and positive integer numeric values.

<-NRi> Negative integer numeric values.

<NRf>

<+NRf> Positive non-zero floating point numeric values.

<0+NRf> Zero and positive floating point numeric values.

<-NRf> Negative floating point numeric values.

<string> Text characters enclosed by double quotes.

<Arg> Text characters with no quotes.

<n> The address number of the module in the RFP chassis system.

The data format <NRi> is defined in IEEE-488.2 for integers.

Zero, positive and negative integer numeric values are valid data.

The data format <NRf> is defined in IEEE-488.2 for flexible Numeric Representation.

Zero, positive and negative floating point numeric values are some examples of valid data.

ARAMETER DEFINITIONS

Note: Channel number 0 is invalid for any auxiliary device, because the

ReFlex Power™ implementations of the SCPI language reserves channel 0

for the “global” address to address all channels.

2.8.2 N

UMERIC DATA DIMENSIONAL UNITS

The Ethernet interface accepts these dimensional units for numeric values of

parameters as listed below. For example, the command SOUR:VOLT 115

programs 115.0 volts when setting the output voltage of the supply.

Table 2-4. Numeric Data Units

Parameter Dimensional Unit

Voltage Volt

Current Ampere

Time Seconds

Frequency Hertz

Phase Angle Degrees

2.8.3 C

ONVENTIONS

Optional keywords and parameters are enclosed by left and right square

brackets: [ ]. The parameter <n>, in a command, indicates the address

number of the module being commanded.

• Discrete module numbers are separated by commas: <n,n,n>.

38 M380056-03 Rev M

Page 43

Controller Module Remote Programming ReFlex Power™ Programming Manual

• If nothing is entered, the default global command is automatically selected, if

the global context can be logically correct.

Required input parameters are enclosed by left and right less-than /

greater-than brackets: < > in the format indicated. For example:

• <bool> 0 or 1, for Off or On, respectively.

• <string> alphanumeric string enclosed by double quotes.

• <NRf> defined in IEEE 488.2 for flexible Numeric

Representation, e.g., zero, positive and negative floating

point numeric values.

• <NRi> defined in IEEE 488.2 for integers, e.g., zero, positive

and negative integer numeric values.

• <t> indicates Trigger channel input/output connections

(applies only to Controller and programmable DC

modules; see the Trigger command section of this

manual for further details on the <t> parameter).

The shorthand version of a command is indicated by capital letters

(minimum required components of a command). For example, SOURce

<n>:VOLTage <NRf>, can be written as:

• SOURCE<n>:VOLTAGE 120 //set output voltage to 120.0V

• SOUR<n>;VOLTAGE 120.0 //set output voltage to 120.0V

• SOUR<n>:VOLT 120 //set output voltage to 120.0V

2.8.4 Q

The query syntax is identical to the command syntax, but with a question mark

(?) replacing the command’s argument. For example, to query the

programmed output voltage on a Module at address 1, send the command,

SOUR1:VOLT?. A Module number is required. A value such as 65.00 will be

returned when read.

The ReFlex Power™ Controller requires all commands received to be

terminated with any combination of CR (0x0D), and or LF (0x0A). All

responses are terminated by default with CR/LF (0x0D 0x0A). Response

termination can be changed by using SYST:NET:TERM <NRi>. Each new

user connection is always initializes to CR/LF.

UERY SYNTAX

M380056-03 Rev L 39

Page 44

ReFlex Power™ Programming Manual Controller Module Remote Programming

Command

Description

Response

Definition for all Modules

2.9

COMMON SCPI COMMANDS

Table 2-5 shows commands that are common to all SCPI instruments.

Table 2-5. Common SCPI Commands

Clears all status reporting data structures including the Status Byte, the Standard

*CLS

*IDN<n>?

*OPC<n>?

*STB?

*SRE?

*SRE <NRi>

*ESR?

*ESE?

*ESE <NRi>

*RST<n>

*TST<n>

*TST<n>?

*TST?

Table 2-6. Module *TST? Error Response Bits Note: The *TST command can’t be interrupted.

Event Status Register, the Protection Event Status Register, and the Error Queue.

Enable registers are not cleared by this command.

Returns the device identification as an ASCII string.

Response: <Manufacturer>,<model>,<serial number>,<firmware version>

Example: ELGAR,RFP-C1LAN-000-0000,1234A56789,3.000.001

Operation Complete Query: Returns value of 1, when all pending operations are

complete. Returns value of 0, when long, or multipart commands are not complete.

Query User’s STatus Byte

Query the user’s enable bits in the Service Request Enable register

Set the enable bits in the Service Request Enable register

Query the user’s standard Event Status Register, if bit 0 is set, a *RST is required.

Query the user’s Enable Standard Event status register

Set the user’s enable bits in the Enable Standard Event status register.

Resets the specific slot module to its Power ON state. Clears status reporting data

structures, including the Protection Condition Status Registers. Enable registers are

not cleared by this command. *RST will reset all modules.

Initiate self test NOTE: Module must be OUTP:STATE 0 and not a group member.

Returns the results from the last self test the module performed. Returns a decimal

value, convert to Hex because more than one bit can be set. See Table 2-6.

Returns the results from all the modules in the system or’ed together. See *TST<n>?

0x00 No Selftest Errors

0x01 The Firmware Version of the Controller and Module are not compatible

0x02 Flash image, tag mismatch

0x04 Flash image, version mismatch

0x08 Isolation relay closed

0x10 Sense relay closed

0x20 Current measurement error. For DC, measured current not zero.

0x40 Voltage measurement error

0x80 Output turn on error

0x100 RAM Configuration error

0x200 Module Enable is false, selftest can’t be executed

0x400 Module On, Active selftest can’t be executed

0x800 OVP test failed

0x1000 UVP test failed

0x2000 Housekeeping supply fault

0x4000 Overtemp fault

0x8000 Ground fault

0x10000 Tried to run selftest on a Group Member

0x20000 OCP test failed

0x40000 Configuration or Calibration file error

0x1000000 Failed at 0% Volt setting, only with other bits set

40 M380056-03 Rev M

Page 45

Controller Module Remote Programming ReFlex Power™ Programming Manual

Response

Definition for all Modules

Command

Description

0x2000000 Failed at 10% Volt setting, only with other bits set

0x4000000 Failed at 90% Volt setting, only with other bits set

0x20000000

0x40000000 Selftest in progress. Only valid via *TST?, non applicable at module level.

0x80000000 Module Clear in progress. Only valid via *TST?, non applicable at module level.

The Controller is unable to detect with any other Modules (Chassis faults / Slot

Power?)

2.10

EIB SCPI COMMANDS

The EIB (Elgar Interface Bus) subsystem is a proprietary set of customized

commands, conforming to SCPI syntax but not defined by the SCPI

Standard.

2.10.1 EIB

EIB

:CONFigure

:DNUMber?

:INFormation

:ALL?

:VERBose?

:LADDress?

2.10.2 EIB

EIB

:CONFigure

:DNUMber?

:INFormation

:ALL?

:VERBose?

:LADDress?

SCPI C

SCPI C

OMMAND SUMMARY

OMMAND REFERENCE

EIB subsystem.

CONFigure sub-commands

Returns the number of devices in the system including the

controller.

Returns the model information string of the devices in the

system.

Returns the model information string of the devices in the

system with the corresponding logical Address.

Returns the logical Address of the devices in the system; the

first address is that of the controller.

M380056-03 Rev L 41

Page 46

ReFlex Power™ Programming Manual Controller Module Remote Programming

2.11

SYSTEM:NETWORK SCPI COMMANDS

2.11.1 SYSTEM:NETWORK

SYSTem

:ERRor?

:VERsion?

:FAULt?

:MODSRQ?

:NETwork

:AUTOIP <bool>

:AUTOIP?

:DESC <string>

:DESC?

:DHCPMODE <bool>

:DHCPMODE?

:DNS <IP Address>

:DNS?

:GATE <IP Address>

:GATE?

:HOST <string>

:HOST?

:IP <IP Address>

:IP?

:LANLED BLINKON

:LANLED BLINKOFF

:LANLED?

:MAC?

:MASK <IP Address>

:MASK?

:PING <IP address>?

:PORT <NRi>

:PORT?

:TERM <NRi>

:TERM?

SCPI C

OMMAND SUMMARY

42 M380056-03 Rev M

Page 47

Controller Module Remote Programming ReFlex Power™ Programming Manual

Command

Description

rack is being addressed). BLINKOFF stops LAN LED blinking.

2.11.2 SYSTEM:NETWORK

SYSTem

:ERRor?

:VERsion?

:FAULt? 3

:MODSRQ?

:NETwork

:AUTOIP <bool>1

:AUTOIP?

:DESC <string>

:DESC?

:DHCPMODE <bool>

:DHCPMODE?

:DNS <IP address>

:DNS?

:GATE <IP address>

:GATE?

:HOST <string>

:HOST?

:IP <IP address>

:IP?

:LANLED <BLINKON |

BLINKOFF>

:LANLED?

2,3

SCPI C

System subsystem.

Queries Error Queue for next error/event entry (first in, first

out). Entries contain an error number and descriptive text. A 0

return value indicates no error occurred; negative numbers

are reserved by SCPI. The maximum string length returned is

255 characters. The queue holds up to 10 error/entries. All

entries are cleared (per user) by the

Returns the SCPI version number for the instrument. The

response is in the format YYYY.V where the Y’s represent the

year and V represents the approved version number for that

year (e.g., 1999.0)

Returns a Hex number. If a module has an active Hardware

fault condition, the corresponding bit will be a ‘1’, else ‘0’.

Returns a Hex number. If a module has an active SRQ event,

the corresponding bit will be a ‘1’, else ‘0’.

Network Subsystem

Sets the network Auto IP mode.

0 = disable AutoIP; 1 = enable AutoIP

0 = AutoIP disabled; 1 = AutoIP enabled.

Set the network Description, a 64 character alphanumeric

string surrounded by quotes

Returns the network Description.

1 = enable, 0 = disable DHCP mode. Reboot to take effect.

Returns Y if DHCP Mode is enabled.

Returns N if DHCP mode is disabled.

Set the IP address of the Domain Name System for the device

(IP address is in the format NNN.NNN.NNN.NNN where

“NNN” = 0 through 255, inclusive.

Returns the network DNS address for the device.

Sets the network gateway IP address for the device. The IP

address format is NNN.NNN.NNN.NNN where “NNN” = 0

through 255, inclusive.

Returns the network gateway IP address for the device.

Set the network Host Name, a 15-character (maximum)

alphanumeric quoted “string”.

Returns the network Host Name

Configures the RFPC to STATIC IP mode, delays several

seconds, closes all network connections, then uses the new

IP address. The IP address format is NNN.NNN.NNN.NNN,

where “NNN” = 0 through 255, inclusive.

Returns two IP addresses: the first is the IP address presently

in use by the power supply; the second is the IP address to be

used when the system re-configures.

BLINKON blinks LAN LED. (Used to identify which RFPC in a

Returns state of the LAN LED:

0 – Off; 1 – On, 2 - blinking.

OMMAND REFERENCE

*CLS

command.

M380056-03 Rev L 43

Page 48

ReFlex Power™ Programming Manual Controller Module Remote Programming

Command

Description

:MAC?

:MASK <IP address>

:MASK?

:PING <IP address>?

:PORT <NRi>

:PORT?

:TERM <NRi>

:TERM?

1

When an AutoIP address is acquired, it’s range will be 169.254.1-254.NNN

2

To receive SRQ events at a host computer, a “TCPIP0::10.11.3.210::inst0::INSTR”

Returns the network MAC address.

xx-xx-xx-xx-xx-xx (Hexadecimal digit pairs)

Set the network Subnet Mask for the device. The mask is in

the format NNN.NNN.NNN.NNN

where “NNN” = 0 through 255, inclusive.

Returns the network Subnet Mask for the device.

Pings the IP address and returns the statistics

Set the network TCP/IP socket listening port. The Port

address is not changeable.

Returns the network TCP/IP socket listening port address,

which is 2340.

Set the return string terminator to be sent by the device. The

valid range is 1-4. The TERM value is user specific, for each

individual connection lifetime. Connection Default is 3.

Values indicate the following terminator(s):

1 = 0x0D only (CR), 2 = 0x0A only (LF), 3 = 0x0D 0x0A (CR

LF), 4 = 0x0A 0x0D (LF CR)

Returns the string terminator value used by the device.

connection must be instantiated by the IVI Driver, and the user application must call the

proper initialization and setup routines.

3

The Hex formatted number is 96 bits in length, which has a one-to-one correspondence for

each possible module in the system. The bits are numbered 96 down to 1.

2.13

RFP SERVICE REQUEST

2.13.1

BACKGROUND

The idea of Service ReQuest (SRQ) generation over Ethernet in RFP is to

allow the system to selectively and asynchronously alert each user to specific

events that have occurred in the system depending on which modules are

SRQ enabled. Because SRQ’s are asynchronous, the instrument does not

require to be polled, which lowers overhead and bandwidth requirements.

The RFP system provides a command and control interface via Ethernet.

Because the client side implementation of SRQ for Ethernet is implemented

using SUN RPC™ and VXI-11™ protocol, the RFPC implements a VXI-11

Server. A socket-based connection can set an SRQ event into the STatus

Byte register, (STB), but since there is no driver notification in this mode, it

would only be detected in a polling mode.

Note: One Ethernet connection, whether socket or instrument, will never ‘see’

another connection’s SRQ information or status. See below for details.

44 M380056-03 Rev M

Page 49

Controller Module Remote Programming ReFlex Power™ Programming Manual

2.13.2

The RFPC implements the RPC port 111-portmapper function for both TCP

and UDP. This allows the client to acquire the port # for the VXI-11 Server.

The VXI-11 Server connects to the client and translates the VXI-11 requests

into a form that can be sent to RFP modules, and receives the responses

from the RFP modules and formats them back into VXI-11 responses. The

VXI-11 server can support 16 concurrent client connections.

The VXI-11 server receives SRQ events from the RFPC (if enabled) and

sends (if SRQ enabled) a device interrupt request to the client.

The RFPC implements a multi-client SRQ mechanism based on the software

model of the SCPI Status Register structure. The RFPC maintains a SCPI

status and SRQ structure that is separate and unique per connection/user.

The association of a module level SRQ and the user occurs when the user

has programmed a module’s Protection EVent enable register (PEV) to a

non-zero value, and disconnected when the module’s PEV is set to zero, or

the user closes the Ethernet session.

There are two classes of SRQ’s, the first class is events generated from the

standard Event Status Register, (ESR) and the second class is events

generated from the module Protection Event register. (PE) The summary of

all these events is located in the STB.

THEORY OF OPERATION

2.13.3

The standard Event Status Register (ESR) handles events that are generally

caused by user commands. These include errors generated by command or

execution errors. There is a corresponding Enable Standard Event register