Page 1

Hydraulic Brake

Hydraulic Brake Systems

• Hydraulically Applied, Spring Released

• 6”-18” Diameters

• 150-1800 lbs./ft. Torque

• Parking Feature

• Remote Bleeding

• Air Assisted AC or DC Operation

• Conversion System

• Asbestos Free Linings

Type S Brake

Spring Set - Air Released

The Type S Brake provides parking for extended periods of

time as well as emergency braking in the event of system

pressure loss. It is designed in 10”, 14” and 18” sizes. This

brake will stop and hold the load in the static position when

air pressure is exhausted from the actuator. Application of

60psi or more of air pressure compresses the actuation

spring and releases the brake.

Type H and HM Brake

Manual Hydraulic Brake

Type H manually operated hydraulic brakes are actuated

by foot pedal. This system provides dynamic stopping

capability. Type HM brakes provide dynamic stopping

and are also equipped with a spring applied, hydraulically

released, electrically controlled parking actuator to provide

parking and holding capability. Both types deliver innitely

variable stopping torque in direct proportion to the force

applied to the foot pedal, for smooth, controlled service

stops.

Type A/H-ARC Brake

Air/Hydraulic - Air Remote Control

This brake provides smooth, dependable service stopping

and emergency stopping for large cranes or fast, high duty

cycle cranes. The brakes are controlled by a foot operated

air valve. Emergency braking is provided in the event of

low air pressure in the air supply system. If pressure in

the emergency tank falls below a preset level, the system

automatically applies the brakes. Within two hours, the

emergency tank bleeds down, releasing the emergency

brake application. This system is capable of operating

multiple brakes, as is the case with all air/hydraulic systems.

Type A/H-ERC Brake

Air/Hydraulic - Electrical Remote Control

This brake provides bridge braking on radio, pulpit,

or pendant controlled indoor overhead traveling

cranes. A two-step low/high pressure system, the

A/H-ERC automatically applies the low pressure, low

torque step when the bridge drive control is switched

to neutral. The high pressure, high torque step is

applied by operator signal, or in case of power failure.

When the crane is shut down, the high pressure

step is automatically applied. The pressure bleeds

down within two hours, releasing the automatic brake

application. The system is capable of operating

multiple brakes. An existing Type H manual brake

system may be converted to Type A/H-ERC systems

with the addition of a conversion package.

Type A/HM Brake

Air/Hydraulic with Parking

Type A/HM brake assemblies provide parking

capabilities. The A/HM-ARC, A/HM-ERC, and A/HMHRC systems all offer features of the Air Hydraulic

powered remote control and also provide long-term

parking capabilities.

Key Feature Summar y

H

HM

AH

AHM

CB

TM

ET

S

Hydraulically

Applied

Yes Yes

Yes Yes Yes

Yes Yes

Yes Yes Yes

Spring

Applied

Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes

Controlled

Stopping

Parking AISE

Rated

Industrial Brakes

Hydraulic, Magnetic & Electro-Thrust Brake Systems

Gemco Industrial Brakes stop

virtually any type of industrial

machine. Applications such as steel mills,

indoor and outdoor bridge cranes, gantries,

heavy-duty cranes, high-duty cycle cranes,

lock and dam projects, stacker reclaimers, and

commercial laundry equipment are just some of the

uses for Gemco Industrial Brakes.

These field proven, high performance brake systems

were originally designed and built by Westinghouse

and Wagner Industrial Brakes. They are tough,

reliable and provide extended, trouble free service.

That’s because they are designed and built to

exacting specifications. For more than 40

years, Gemco has been an acknowledged

leader in brake system technology for

heavy-duty industrial applications.

1080 North Crooks Road, Clawson, MI 48017

Phone: 248-435-0700 Toll Free: 800-635-0289

Fax: 248-435-8120 www.ametekapt.com

BRK.F1R

10/12.Z329

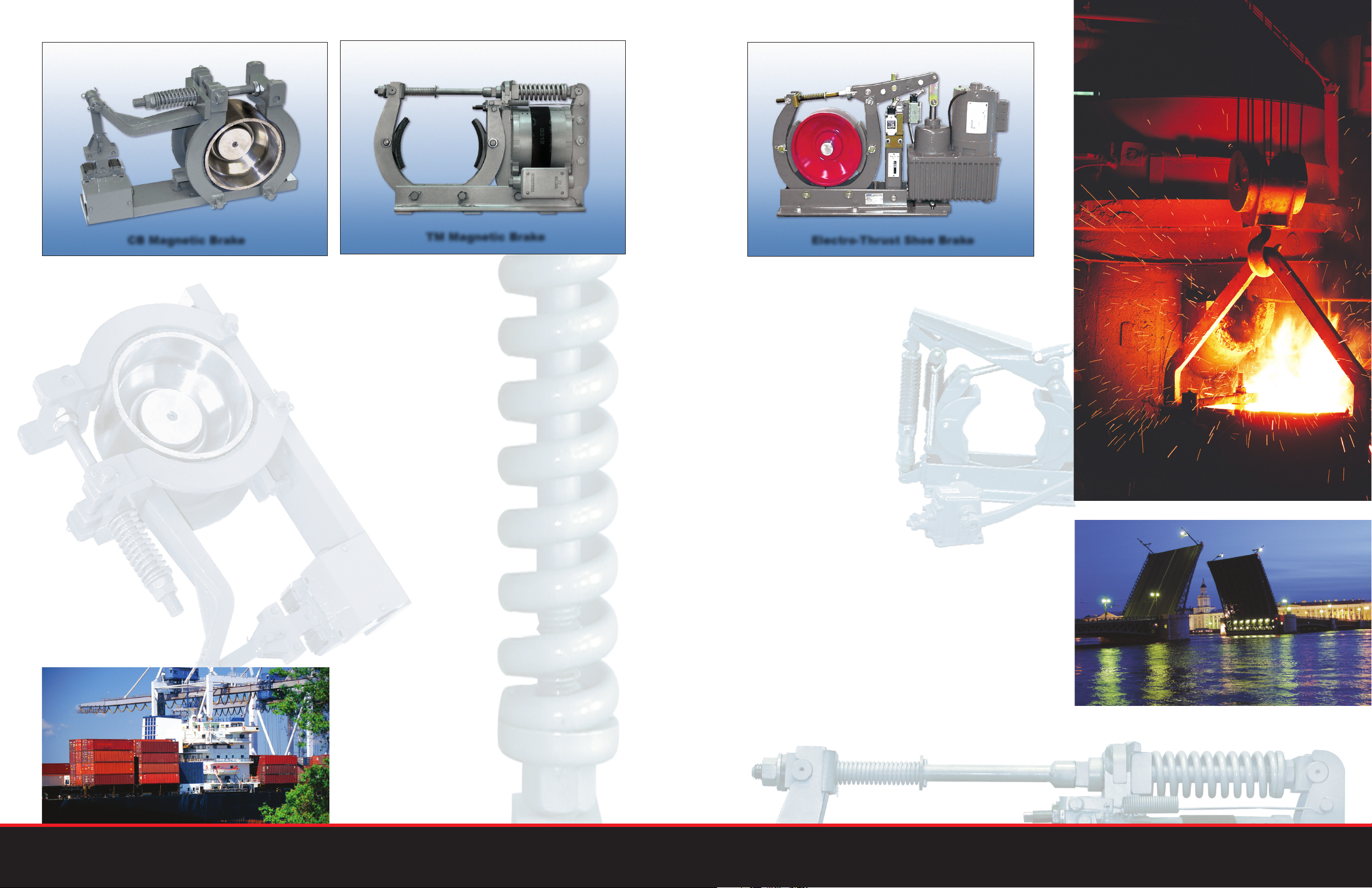

Page 2

CB Magnetic Brake

TM Magnetic Brake

Electro-Thrust Shoe Brake

CB Magnetic Brakes

• Spring Applied, Electrically Released

• 4 1/2”-10” Diameter

• 10-160 lbs./ft. Torque

• AC Solenoid Operation

• Single Phase, 60 Hertz Coils

• Asbestos Free Linings

Options

• Enclosures

• Epoxy coatings

CB AC Brakes

• Clean, simple, reliable design with the fewest parts of

any AC brake available today.

• Rugged, long life solenoid - tested in more than two

million operational cycles without electrical failure.

• Simple one-point torque adjustment.

• No separate hand release is required. The brake can be

released by light hand pressure on the solenoid arm.

• Solenoid plunger travel indicator - a mark on the

plunger indicates when the brake should be adjusted for

lining wear.

• Simple two point adjustment for lining wear.

TM Magnetic Brakes

• Spring Applied, Electrically Released

• AISE Rated

• 4 1/2”-30” Diameter

• 15-9000 lbs./ft. Torque

• DC Operation

• Series or Shunt Coils

• Asbestos Free Linings

Options

• Rectiers for AC Operation

• Hand Release

• Self-Centering (TMSC Style)

• Hydraulic Over-Ride

• Limit Switches

• Enclosures

• Epoxy coatings

TM DC Brakes

Shunt or Series Wound

• Mechanically independent coils can be removed without

releasing the brake shoes. In an emergency, short-time

operation on a single coil is possible.

• Twin-magnet coils are epoxy-encapsulated for

permanent protection against dust, water, grease, oil,

chemicals, and mechanical impact (TM43 and TM63

have single coils).

• Self-aligning cast iron brake shoes are lined with long

wearing molded linings.

• Shoe travel indicator provides a positive visual check of

lining wear for quick maintenance/inspection.

• Over-the-wheel tie rod is a simple, rugged, easily

accessible linkage, permitting all adjustments from

the top. Standard TM style brakes have two easy

adjustments for lining wear and spring tension. TMSC

style brakes have a single point adjustment for lining

wear and spring tension.

• Utilized tie rod-and-spring assembly facilitates shoe

replacement. The brake can be released manually if

required.

Electro-Thrust Shoe Brakes

• Spring Applied, Electrically Released

• AISE Rated

• 6”-30” Diameters

• 60-9000 lbs./ft. Torque

• AC or DC Actuators

• Self-Centering

• Multiple Voltage Inputs

• External Torque Springs

• Asbestos Free Linings

• Set Delay Valve

• Adjustable Setting Time

• Stainless Steel Pivot Pins

Options

• Hand Release

• Low Temperature Fluid

• Limit Switches

• Hydraulic Over-Ride

• Enclosures

• Epoxy Paint Coatings

• Self-Adjusting

ET Electro-Thrust Brakes

• Electro-thrust actuator

• Self aligning cast iron shoes

• Over-the-wheel tie rod-and-spring assembly

• Asbestos free bonded linings

• External torque spring

• Floor mounting

• Torque indicator

• Hand release

• Corrosion-resistant ttings

Hydraulic, Magnetic & Electro-Thrust Brake Systems Hydraulic, Magnetic & Electro-Thrust Brake Systems

Loading...

Loading...