Page 1

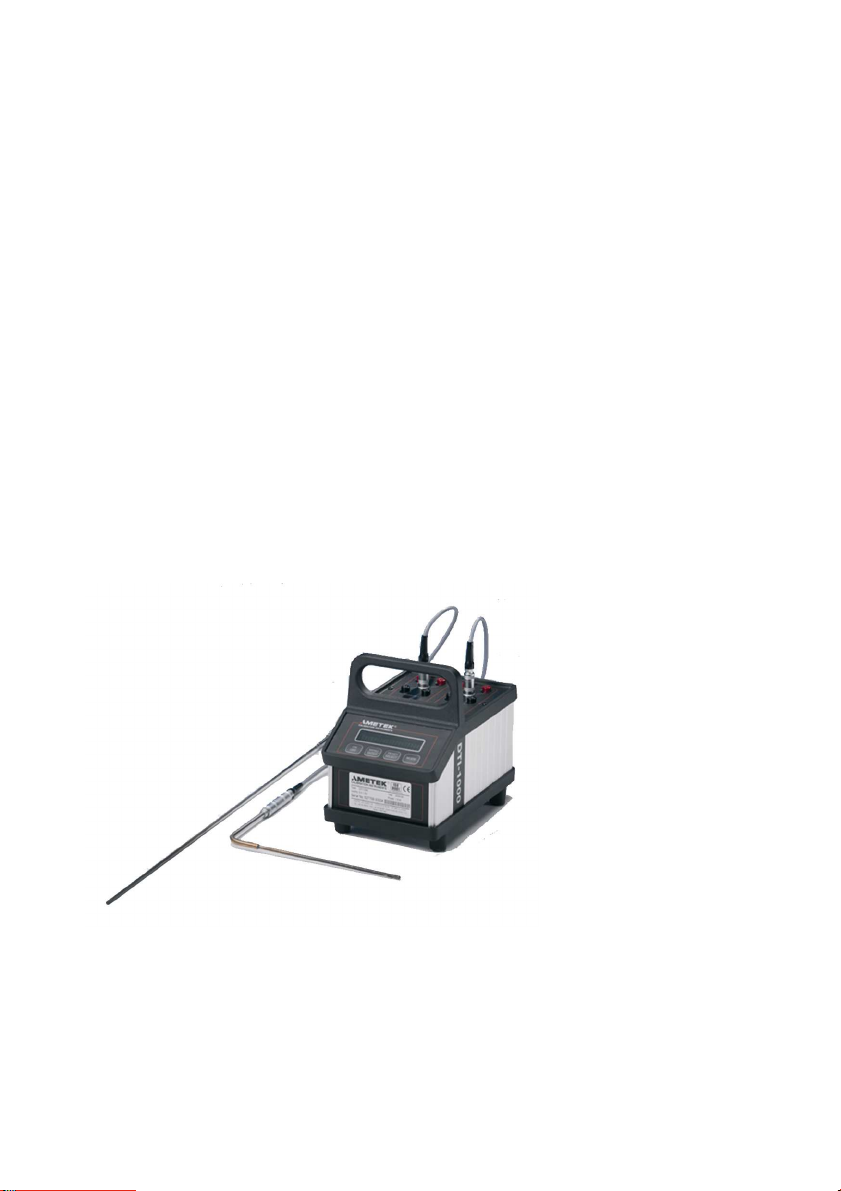

Reference manual

Digital Temperatur Indicator

Jofra DTI-1000 A/B

Page 2

Reference Manual

Digital Temperature Indicator

JOFRA DTI-1000 A/B

Copyright 2005 AMETEK Denmark A/S

Page 3

About this manual….

• The structure of the manual

This reference manual is aimed at users who are familiar with

AMETEK calibrators, as well as those who are not. The manual

is divided into 8 chapters, which describe how to set up,

operate, service and maintain the indicator. The technical

specifications are described as well.

• Safety symbols

This manual contains a number of safety symbols designed to

draw your attention to instructions which must be followed when

using the instrument, as well as any risks involved.

Warning

Conditions and actions which may compromise

the safe use of the instrument and result in

considerable personal injury or material damage.

Caution…

Conditions and actions which may compromise

the safe use of the instrument and result in slight

personal or material damage.

Note…

2 2017-08-10 124745 04

Special situations which demand the user’s

attention.

Page 4

List of contents

1.0 General information ................................................... 4

1.1 Warranty ..................................................................... 5

2.0 Safety instructions ..................................................... 6

3.0 Introduction ................................................................ 8

4.0 Functionality ............................................................... 9

4.1 Functional description ............................................... 11

4.2 Indicators .................................................................. 12

4.3 Touch pad ................................................................ 12

4.4 Connections.............................................................. 13

5.0 Operation .................................................................. 15

5.1 Operating area ......................................................... 15

5.2 Connection of sensors .............................................. 16

5.2.1 Power supply .............................................. 17

5.2.2 On / Off ....................................................... 18

5.2.3 Reset .......................................................... 19

5.2.4 Units ........................................................... 19

5.2.5 Resolution ................................................... 21

5.2.6 Checking sensor coefficients ...................... 23

5.2.7 Mode ........................................................... 27

6.0 Technical specifications .......................................... 28

7.0 Maintenance and display error messages ............ 30

7.1 Maintenance ............................................................. 30

7.2 Changing batteries ................................................... 30

7.3 Display and error messages ..................................... 31

8.0 Adjusting and calibrating the instrument .............. 32

8.1 Introduction to AmeTrim-ATC/DTI Software ............. 32

8.2 Installing the AmeTrim-ATC/DTI Software ................ 33

8.2.1 Connecting the PC and the ATC/DTI .......... 33

8.2.2 Starting the AmeTrim-ATC/DTI

software ...................................................... 34

8.2.3 Reference sensor ........................................ 36

8.2.4 Default values ............................................. 38

8.2.5 RTD input adjustment ................................. 39

8.2.6 Calibration date ........................................... 40

8.2.7 Analog output adjustment ........................... 41

8.3 Setup Printer ............................................................ 44

124745 04 2017-08-10 3

Page 5

1.0 General information

Congratulations on your new JOFRA DTI-1000!

With the AMETEK indicator, you have chosen an extremely effective

instrument which we hope will live up to all your expectations. Over

the past many years, we have acquired extensive knowledge of

industrial temperature calibration. This expertise is reflected in our

products which are all designed for daily use in an industrial

environment. Please note that we would be very interested in hearing

from you if you have any ideas or suggestions for changes to our

products.

This reference manual applies to the following products:

• DTI-1000 A

• DTI-1000 B

ISO-9001 certified

AMETEK Denmark A/S was ISO-9001 certified in September

1994 by Bureau Veritas Certification Denmark.

CE-label

* DTI-1000 A / DTI-1000 B from serial no. xxxxxx-00541

4 2017-08-10 124745 04

Your new temperature calibrator bears the CE label

and conforms to the Electromagnetic Compatibility

(EMC) Directive 2014/30/EU and the Low Voltage

Directive 2014/35/EU and RoHS Recast (RoHS II)

Directive 2011/65/EU*.

Page 6

Technical assistance

Please contact the dealer from whom you acquired the instrument if

you require technical assistance.

1.1 Warranty

This instrument is warranted against defects in workmanship,

material and design for two (2) years from date of delivery to the

extent that AMETEK will, at its sole option, repair or replace the

instrument or any part thereof which is defective, provided, however,

that this warranty shall not apply to instruments subjected to

tampering or, abuse, or exposed to highly corrosive conditions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES

WHETHER EXPRESS OR IMPLIED AND AMETEK HEREBY

DISCLAIMS ALL OTHER WARRANTIES, INCLUDING, WITHOUT

LIMITATION, ANY WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE OR MERCHANTABILITY. AMETEK SHALL NOT BE

LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES,

INCLUDING, BUT NOT LIMITED TO, ANY ANTICIPATED OR LOST

PROFITS.

This warranty is voidable if the purchaser fails to follow any and all

instructions, warnings or cautions in the instrument’s User Manual.

If a manufacturing defect is found, AMETEK will replace or repair the

instrument or replace any defective part thereof without charge;

however, AMETEK’s obligation hereunder does not include the cost

of transportation, which must be borne by the customer. AMETEK

assumes no responsibility for damage in transit, and any claims for

such damage should be presented to the carrier by the purchaser.

124745 04 2017-08-10 5

Page 7

2.0 Safety instructions

Read this manual carefully before using

the instrument!

Please follow the instructions and procedures

described in this manual. They are designed to allow

you to get the most out of your DTI system and avoid

any personal injuries and/or damage to the instrument.

Disposal – WEEE Directive

These calibrators contain Electrical and Electronic

circuits and must be recycled or disposed of properly

(in accordance with the WEEE Directive 2012/19/EU).

Warning

• The indicator must not be used for any purposes

other than those described in this manual, as it

might cause a hazard.

• The indicator has been designed for indoor use

only and is not to be used in wet locations.

• The indicator is not to be used in hazardous

areas, where vapour or gas leaks, etc. may

constitute a danger of explosion.

• The indicator is not designed for operation in

altitudes above 2000 meters.

• Only use the specified mains adaptor approved for

the voltage and plug configuration in your area.

• Do not connect rated voltages to earth with a

maximum above 30V to the input terminals.

• Always position the indicator to enable easy and

quick disconnection of the power source (mains

adaptor).

6 2017-08-10 124745 04

Page 8

Caution…

When connecting the PC and the indicator please

ensure that both the PC and the indicator are switched

off at the mains. Failure to do so may result in your

equipment being damaged.

124745 04 2017-08-10 7

Page 9

3.0 Introduction

The DTI (Digital Temperature Indicator) system is designed for fast

and traceable calibration. The system is portable.

The DTI is prepared for re-calibration by your local calibration

laboratories, and all necessary instructions for the re-calibration is

stated in this manual.

The DTI is a precision instrument and to achieve the precision, a set

of sensor coefficients relating to the specific sensor must be present

in the DTI. Before use of the DTI, ensure that the correct coefficients

for each channel in the DTI are equal to those from the sensors

calibration certificate – see section 5.2.6.

How to install new sensor coefficients can be found in section 8.2.3.

Definitions and terminology used in this manual:

a. Text inside <> refer to soft-keys on the DTI panel or keys on

Text with big letters indicate the activated function if there

b. Display text on the DTI is shown inside rounded frames.

c. Screen menus in the DTI software are shown inside edged

Note…

The DTI is not designed for continuously data-logging

recording, since there is no guarantee for missed log

values during the data-logging

the PC keyboard.

are more than one function (example <ON/Off>).

frames.

8 2017-08-10 124745 04

Page 10

4.0 Functionality

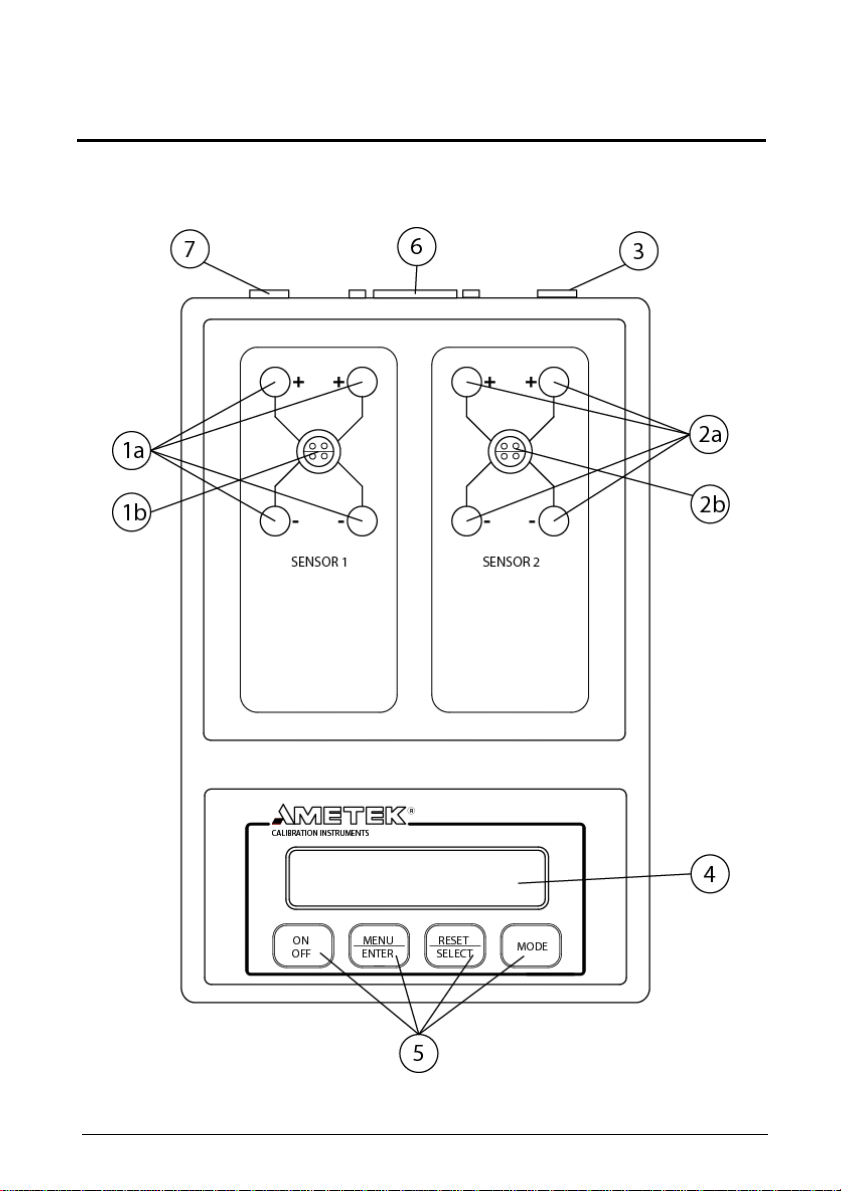

Overview:

124745 04 2017-08-10 9

Page 11

POS Description

1a Sensor 1 connections

1b Sensor 1 connections

2a Sensor 2 connections

2b Sensor 2 connections

3 Ground terminal for cable shields

4 Display with 2 * 20 characters

5 Soft keys

6 RS232 connector

7 Power inlet for mains adapter

10 2017-08-10 124745 04

Page 12

4.1 Functional description

The DTI is used for measuring inputs from two RTD sensors. The two

sensors are connected to the connectors in the top plate. The input

signal is compared to the two internal resistor references from which

the input signal can be determined.

The DTI operates with a 2*20 character display, which continuously

read out the two inputs.

The input value can be shown as the actual read value for both

sensors, the peak values for sensor 1 or 2, the differential value for

the two sensors or as the differential peak value for the two sensors.

The input value can be shown in Ω, °C, °F or K selected by the user.

The resolution in temperature can be 0.1, 0.01 or 0.001.

The sensor coefficients can be inspected by the user and changed in

the software program.

The power supply is made by eight 1.5 Volt batteries or a mains

adapter. Use only mains adapter supplied by AMETEK in order to

comply with the requirements in EN50081-1 (1992) and EN50082-1

(1992).

It is possible to connect the shields from the cables to the cabinet, in

order to reduce the influence of noise.

The DTI-1000 is supplied with RS232 and software, in order to have

the possibility of saving the measured data and to recalibrate the DTI

or the sensors.

124745 04 2017-08-10 11

Page 13

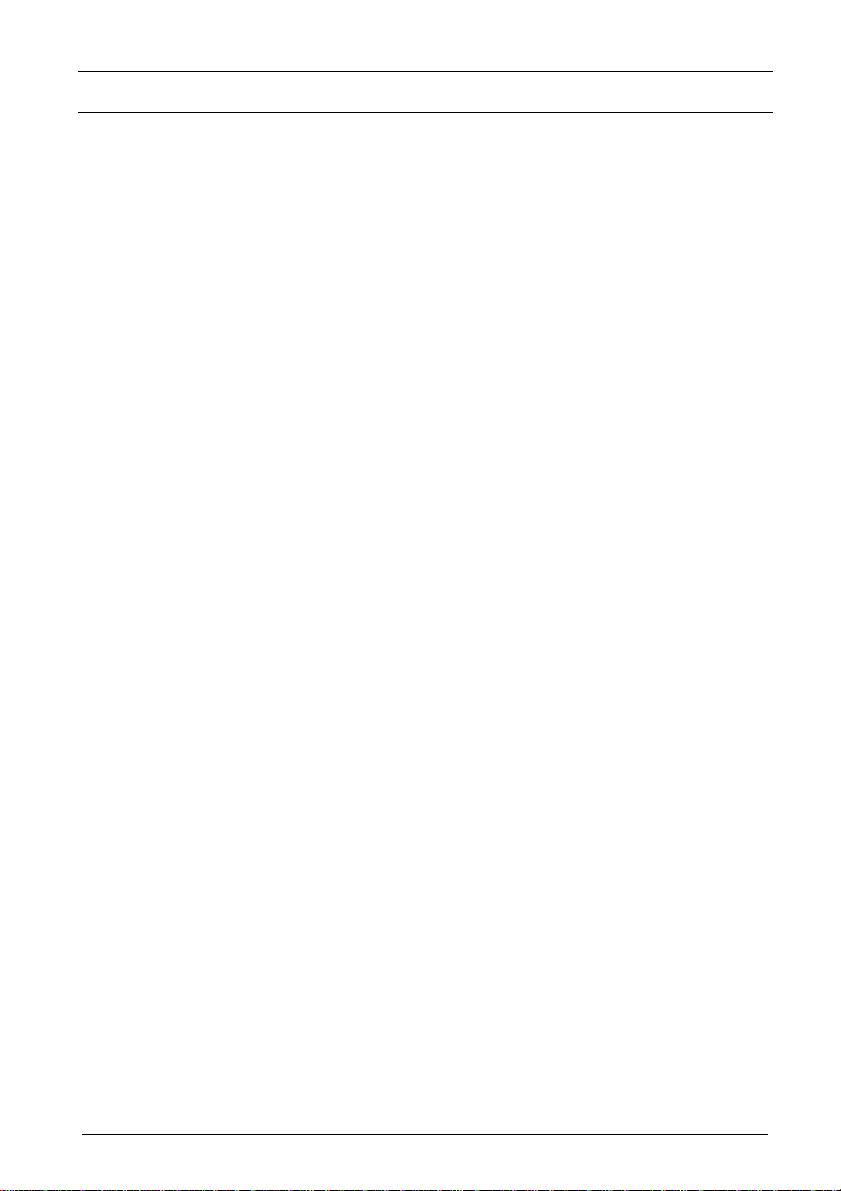

4.2 Indicators

The DTI only uses the display for all indications. The display has 2*20

characters which will swap between read-out values or menu

selection when requested. Please see section 5.2.1 to 5.2.7 for

possible display read-outs. Please note that the error messages will

also be showed in the display, see section 7.3.

CALIBRATION INSTRUMENTS

T1

T2

ON MENU RESET

R

23.65

23.60

ENTEROFF

SELECT

MODE

4.3 Touch pad

There are 4 soft-keys on the touch pad panel, where 2 of the softkeys have a double function.

ON

OFF

Switch ON or switch OFF the DTI. Please press

down the key at least 0.2 seconds in order to switch

on the unit.

MENU toggles between the menus:

MENU

ENTER

Mode/Unit/Resolution/Sensor

ENTER enters the menu function selected with the

RESET/SELECT key.

RESET

SELECT

RESET resets peak values for both channels.

SELECT toggles between the selected menu

functions.

Toggles between the following display modes: T1/T2,

MODE

Diff(T1-T2), T1MAX./T1MIN., T2 MAX./T2 MIN., DIFF

MAX./DIFF MIN.

12 2017-08-10 124745 04

Page 14

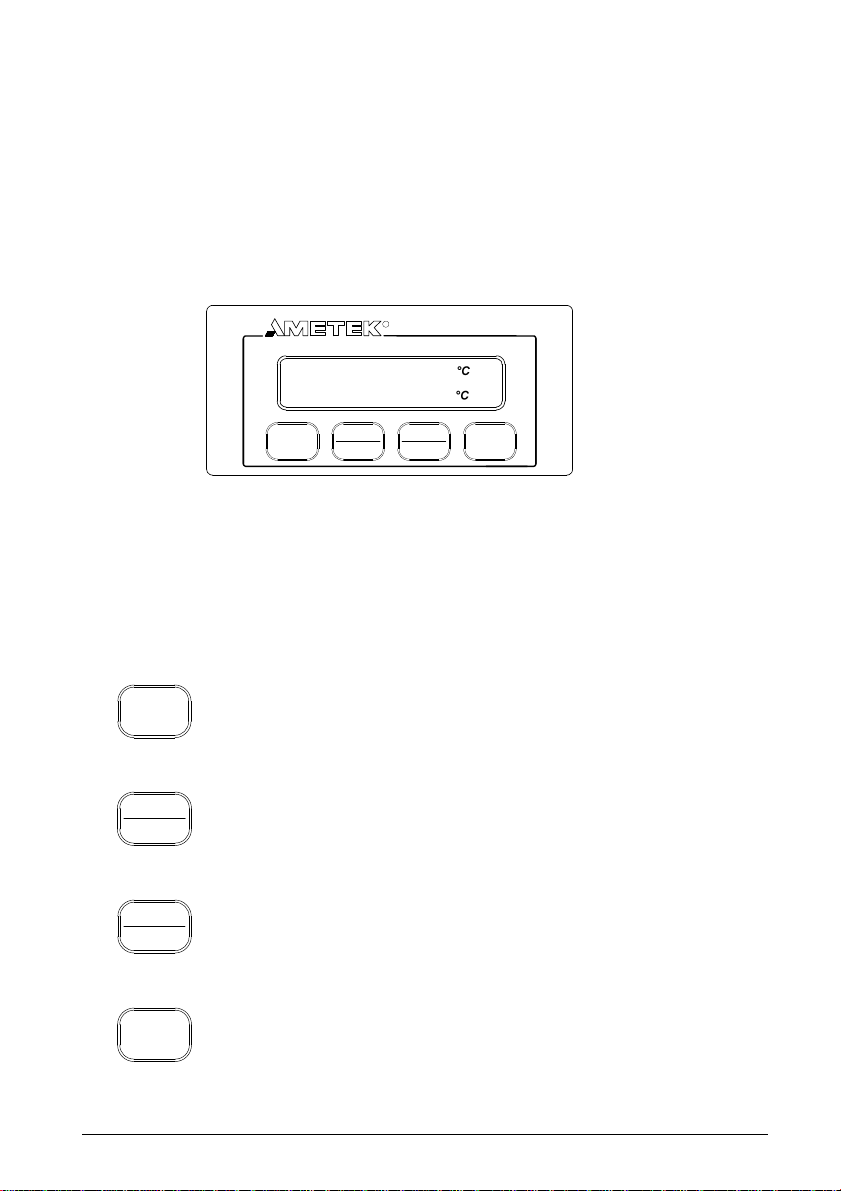

4.4 Connections

All signal cables have to be connected to the top plate (grounding on

the back plate).

Power and communication cables have to be connected on the back

plate.

Top plate connections

+

+ +

+

-

-

SENSOR 1 SENSOR 2

-

-

Back plate connections

2 x 4 PCS BATTERIES TYPE AA

Connections for sensors, where channel 1 is

RS 232

9VDC

200 mA

-

shown.

Please note that the LEMO-connector is only

available on the DTI-1000 model.

SENSOR 1

124745 04 2017-08-10 13

Page 15

RS 232

9VDC

200 mA

Ground terminal for shield on the signal cables.

-

Power input for mains adapter 9VDC 200mA.

Connector for RS232C interface.

14 2017-08-10 124745 04

Page 16

5.0 Operation

5.1 Operating area

Both of the DTI models are intended for use in areas which meet the

following:

Temperature range : 0°C to 50°C (32°F to 122°F)

Humidity : 0% to 90%

Protection class : IP20

Warning

• The indicator must not be used for any purposes other

than those described in this manual, as it might cause a

hazard.

• The indicator has been designed for indoor use only

and is not to be used in wet locations.

• The indicator is not to be used in hazardous areas,

where vapour or gas leaks, etc. may constitute a

danger of explosion.

124745 04 2017-08-10 15

Page 17

5.2 Connection of sensors

The sensor should be connected to the terminals as shown in the

figure below:

Use the ground terminal (see the figure "Overview" section 4, pos. 3)

for the cable shields in order to reduce noise.

The connector type to extra connector on DTI-1000 is: LEMO FFA 1S

304 CNAC.

16 2017-08-10 124745 04

Page 18

5.2.1 Power supply

The DTI is supplied with 8 1.5 Volt batteries as standard. When the

battery voltage is low following message will appear:

BATTERY LOW

PRESS ANY KEY

This message will only appear one time after the DTI has been

switched on, and is removed by pressing the key <Menu/Enter> or

<Reset/Select>. The DTI is still able perform accurate measurements

a little while longer.

The batteries are placed in the two battery holders shown in the

figure below:

It is also possible to supply the DTI from a mains adapter at the

connector shown in the figure above. The mains adapter can be

supplied by AMETEK.

2 x 4 PCS BATTERIES TYPE AA

RS 232

9VDC

200 mA

-

Mains adapter

124745 04 2017-08-10 17

Page 19

5.2.2 On / Off

Start the DTI by activating the softkey <ON/Off>. Following message

will be shown in the display:

SELF-CALIBRATION

AND TESTING 1

This information states that the internal references and the sensor

coefficients are checked. If the coefficients are incorrect an error

message will occur which is described in section 7.3.

The next message shown in the display will be:

SELF-CALIBRATION

AND TESTING 2

In this step the A/D converter is calibrated which approximately takes

1 second. When the calibration is over following message will be

shown:

SELF-CALIBRATION

AND TESTING 3

Test 3 is an internal voltage reference check, which approximately

takes 4 seconds.

When all tests have succeeded, the DTI will show the model type and

last calibration date in the display:

Ver. X.XX DTI-1000

CAL. DATE 031216

18 2017-08-10 124745 04

Page 20

After this the input values will be shown in the display in the same

format, as before the DTI was shut off last time:

T1 23.65 °C

T2 23.60 °C

If there is no input signal or it is outside the measuring range a

hyphen will be shown for that specific channel.

5.2.3 Reset

Use the softkey <RESET/Select> in order to reset the peak values in

the selected difference mode.

5.2.4 Units

In order to change the unit of the read-out, you must press the

softkey <MENU/Enter> 1 time. The following message will be shown

in the display:

UNIT: °C

124745 04 2017-08-10 19

Page 21

Use the softkey <Reset/SELECT> to scroll between following types

of units:

UNIT SELECTION MENU READ-OUT MODE

UNIT: °C T1 23.65 °C

T2 23.60 °C

│

UNIT: °F T1 74.57 °F

T2 74.48 °F

│

UNIT: Ω R1 109.210 Ω

R2 109.191 Ω

│

UNIT: K T1 296.80 K

T2 296.75 K

Use the softkey <Menu/ENTER> to select the specific read-out unit.

Please note that read-out in Ω has one more digit than specified in

the resolution set-up.

20 2017-08-10 124745 04

Page 22

5.2.5 Resolution

In order to change the resolution on the read-out, you must press the

softkey <MENU/Enter> 2 times. The following message will be shown

in the display:

RESOLUTION: 0.01

Use the softkey <Reset/SELECT> to scroll between following types

of resolution:

RESOLUTION SELECTION MENU READ-OUT MODE

RESOLUTION: 0.01 T1 23.65 °C

T2 23.60 °C

│

RESOLUTION: 0.001 T1 23.651°C

T2 23.599°C

│

RESOLUTION: 0.1 T1 23.7 °C

T2 23.6 °C

Use the softkey <Menu/ENTER> to select the specific read-out unit.

124745 04 2017-08-10 21

Page 23

The sample period is dependent on the selected resolution which can

be longer than sample rate to the display if a resolution above 0.1 is

selected. The sample rates for the different resolutions are shown

below:

Resolution 0.1 0.01 0.001

Sample period 2 s 3 s 12 s

Please note that read-out in Ω has one more digit than specified in

the resolution set-up.

22 2017-08-10 124745 04

Page 24

5.2.6 Checking sensor coefficients

In order to check the sensor ID and coefficients on the DTI, press the

softkey <MENU/Enter> 4 times.

If Callendar van Dusen coefficients is used for the sensor, the

following message will be shown in the display:

SENSOR 1: 9402244

R0 : 1.0000000E+02

Use the softkey <Reset/SELECT> to scroll through the coefficients:

(example with both sensors using default coefficients)

SENSOR 1: 9402244 SENSOR 2: 9402246

R0 : 1.0000000E+02 R0 : 1.0000000E+02

│ │

SENSOR 1: 9402244 SENSOR 2: 9402246

A : 3.9080200E-03 A : 3.9080200E-03

│ │

SENSOR 1: 9402244 SENSOR 2: 9402246

B : -5.8020000E-07 B : -5.8020000E-07

│ │

SENSOR 1: 9402244 SENSOR 2: 9402246

C : -4.2735000E-12 C : -4.2735000E-12

124745 04 2017-08-10 23

Page 25

Use the softkey <Menu/ENTER> to leave this menu.

The coefficients are used in the equations:

= R(t)

Below 0°C:

Above 0°C:

If ITS-90 coefficients is used for the sensor, the following message

will be shown in the display:

R

0

= R(t)

R

0

B+tA+(1

B+tA+(1

t

2

)

⋅⋅⋅

t

⋅⋅⋅⋅

32

100)-(tC+

)

t

CH1: 9402244

RTPW: 1.0000000E+02

Use the softkey <Reset/SELECT> to scroll through the coefficients:

(example with both sensors using default coefficients)

24 2017-08-10 124745 04

Page 26

CH1: 9402244 CH2: 9402245

RTPW: 1.0000000E+02 R0 : 1.0000000E+02

│ │

CH1: 9402244 CH2: 9402245

aLR: 0.000000E-00 aLR: 0.000000E-00

│ │

CH1: 9402244 CH2: 9402245

bLR: 0.000000E-00 bLR: 0.000000E-00

│ │

CH1: 9402244 CH2: 9402244

cLR: 0.000000E-00 cLR: 0.000000E-00

│ │

CH1: 9402244 CH2: 9402245

aHR: 0.000000E-00 aHR: 0.000000E-00

│ │

CH1: 9402244 CH2: 9402245

bHR: 0.000000E-00 bHR: 0.000000E-00

│ │

CH1: 9402244 CH2: 9402245

cHR: 0.000000E-00 cHR: 0.000000E-00

│ │

CH1: 9402244 CH2: 9402245

dHR: 0.000000E-00 dHR: 0.000000E-00

124745 04 2017-08-10 25

Page 27

Use the softkey <Menu/ENTER> to leave this menu.

Use the table below to convert ITS90 coefficient nomination to DTI-

1000 nomination.

ITS90 Subrange

3 4 5 6 7 8 9 10 11

aLR a3 a4 0

bLR b3 b4 0

cLR c3 0 0

aHR a5 a6 a7 a8 a9 a10 a11

bHR b5 b6 b7 b8 b9 0 0

cHR 0 c6 c7 0 0 0 0

DTI-1000

coefficient

dHR 0 d 0 0 0 0 0

26 2017-08-10 124745 04

Page 28

5.2.7 Mode

In order to change the reading, you must press the softkey <MODE>

to scroll between following types of read-out:

READ-OUT MODE

T1 23.65 °C

T2 23.60 °C

DIFF (T1-T2)

0.05 °C

T1MAX. 23.66 °C

T1MIN. 23.64 °C

T2MAX. 23.61 °C

T2MIN. 23.59 °C

DIFFMAX. 0.07 °C

DIFFMIN. 0.03 °C

124745 04 2017-08-10 27

Page 29

6.0 Technical specifications

Electrical specifications

Measuring input: : 2 channels for 4 wire RTD sensors

Measuring range DTI-1000 A : 0 to 360 Ω (-200 to 750°C / -328 to

1382°F)

Measuring range DTI-1000 B : 0 to 95 Ω (-200 to 750°C / -328 to

1382°F)

Accuracy DTI-1000 A : ±6 ppm rdg + 1,4 mΩ (12 months use)

Accuracy DTI-1000 B : ±6 ppm rdg + 0,7 mΩ (12 months use)

Measuring current : 1mA, 18% duty cycle

Temperature coefficient : ± 0.8 ppm/°C. outside 23±3°C (73.4±

5.4°F)

Temperature resolution : 0.1 / 0.01 / 0.001.

Units : °C / °F / Ω / K.

Supply : 8 pcs. 1.5 V type AA batteries or 9 V

mains adapter.

Battery life : 15 hours

Mechanical specifications

Weight : 2.2 kg. / 4.9 lb.

Dimensions (H/W/D) : 195 mm / 135 mm / 225 mm.

7.7 in. / 5.3 in. / 8.9 in.

Operating conditions :

Temperature range : 0 to 50 °C (32 to 122°F)

Humidity range : 0 to 90 %

Protection class : IP20

Storage temperature : -20 to 60°C (-4 to 140°F)

28 2017-08-10 124745 04

Page 30

Mechanical specifications

Electromagnetic : Designed for use in controlled

environment electromagnetic environment as defined

EN61326-1 2013.

Additional data - directives observed

The following standards are

observed according to the EMCDirective (2014/30/EU)

EN 61326-1: 2013: Electrical

equipment for measurement, control

and laboratory use – EMC

requirements.

124745 04 2017-08-10 29

Page 31

7.0 Maintenance and display error

messages

7.1 Maintenance

The DTI does not require specific maintenance before or after use.

The user may carry out the following procedures himself.

Cleaning surfaces Use alcohol or water and a soft cloth.

Re-calibrate or change Use the software in order to re-

coefficients for sensors calibrate/change the sensor

coefficients (see section 8.0).

Re-calibration of DTI Use the calibration routines in the

references or analog out software to re-calibrate the DTI (see

section 8.0).

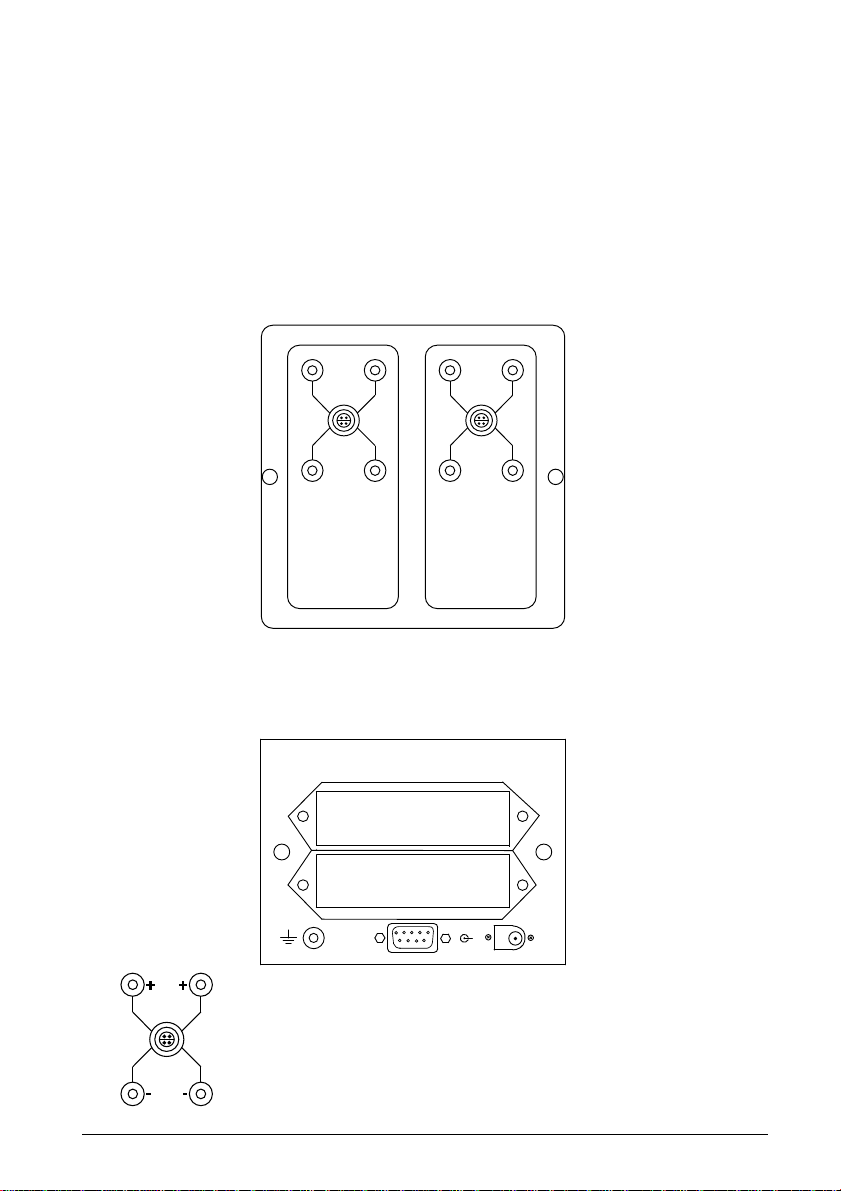

7.2 Changing batteries

The batteries are placed in the two battery holders shown in the

figure below. The battery holders can be pulled out by pressing the

locks on both sides simultaneously.

2 x 4 PCS BATTERIES TYPE AA

RS 232

30 2017-08-10 124745 04

9VDC

200 mA

-

Press

Page 32

7.3 Display and error messages

If the DTI detects an error while running, it will automatically appear

in the display. Following error messages can occur:

Display message: Meaning/Action:

BATTERY LOW Battery voltage low.

PRESS ANY KEY Change batteries

(section 7.2).

No sensor connected to input

T1 ////.///°C or measuring input outside

T2 ////.///°C range.

Downloaded coefficients

CONSTANT ERRORS rejected.

DEFAULT VALUES Check calibration.

Default sensor coefficients

used are:

R0: +100.000000

A:+3.90802E-3

B : -5.80200E-7

C : -4.27350E-12

Press any key to continue

124745 04 2017-08-10 31

Page 33

8.0 Adjusting and calibrating the

instrument

You are advised to return the DTI-1000 A/B to AMETEK Denmark

A/S or an accredited laboratory at least once a year for calibration.

Alternatively you can calibrate/adjust the DTI-1000 A/B yourself using

the AmeTrim-ATC/DTI Adjust and Calibration software. AmeTrimATC/DTI also supports DTI-100 and DTI-1000 manufactured in 1996

or later or with firmware version 1.60 or later. This software is divided

into 5 different processes:

• Reference sensor: Use this feature to manage the

coefficients of the sensors in the DTI.

• Set to default values: Use this feature to set internal

reference resistor values to default values if odd values have

been downloaded.

• RTD-input adjustment: Use this feature to calculate and

download new values for internal reference resistors.

• Calibration date: Use this feature to download a new

calibration date to the DTI.

• Analog output adjustment: Use this feature to adjust the

analog output (only DTI-1000 with firmware version 1.60 or

earlier).

8.1 Introduction to AmeTrim-ATC/DTI Software

This software is supplied on the JOFRACal CD-ROM. It can be run

directly from this CD-ROM and requires no special installation.

It is possible to make a disk containing the AmeTrim-ATC/DTI

software. From this disk AmeTrim-ATC/DTI can be installed on the

harddisk of the computer, but the disk has to be in the disk drive

when running the software.

To use the software, you need:

32 2017-08-10 124745 04

Page 34

PC hardware requirements

• IBM compatible PC with 486 or higher processor (PentiumTM 200

MHz recommended).

• 32 MB of RAM (64 MB recommended).

• 4 MB available hard-disk space.

• Standard VGA monitor (800 x 600, 256 colours), (1024 x 768

recommended).

• CD-ROM drive.

• One vacant RS 232 Serial Port.

PC software requirements

• Microsoft Windows®98, Microsoft Windows® NT 4.0, Microsoft

Windows® 2000, Microsoft Windows® ME, Microsoft Windows®

XP.

• System font: MS Sans Serif and Arial.

8.2 Installing the AmeTrim-ATC/DTI Software

The software comes on a CD-ROM and is ready to run – no

installation is required. Simply insert the CD-ROM and run the

ATC/DTI-adjustment program.

8.2.1 Connecting the PC and the ATC/DTI

Caution…

1. Ensure that both the PC and the ATC/DTI are switched

off at the mains. Failure to do so may result in your

equipment being damaged.

2. Connect the serial cable provided to the “RS 232” port on

the back of the DTI and to the COM port on the PC.

3. Switch on the PC and the DTI.

124745 04 2017-08-10 33

Page 35

8.2.2 Starting the AmeTrim-ATC/DTI Software

ATC/DTI software.

Note…

Before starting this software, the PC and the ATC/DTI must

be connected together and the indicator switched on (see

section 8.2.1).

The ATC must not be performing any tasks like switch test,

auto step or workorders. That means that the ATC must be

in the main menu before starting the software.

Use the normal Windows procedure to start the AmeTrim-

If you are unsure on how to start software programs, refer to

your Windows Help

34 2017-08-10 124745 04

Page 36

In the main menu select “Run Program” to start the calibration.

Select “DTI” and “Comport” in the “Device Quick Connect” dialog box

and press “Connect”. If the DTI is not switched on or is not connected

to the selected port, then the software returns to the AmeTrim

adjustment software main menu.

As the software starts, it detects the type of calibrator connected to

the PC and reads its serial number. This information is displayed at

the bottom of the DTI main menu window

124745 04 2017-08-10 35

Page 37

A new dialogue with a table containing the coefficients

8.2.3 Reference sensor

This option enables you to view the calibration values currently

loaded in the DTI for the reference sensors as well as enter and

download values for new reference sensors. In addition to the

equipment already described in sections 8.1 and 8.2.1, you also

require the calibration certificate for the new reference sensor.

In DTI main menu, click “Sensor coefficients”.

stored in the DTI for sensor 1 and sensor 2. Current sensor

coefficients are automatically uploaded.

36 2017-08-10 124745 04

Page 38

124745 04 2017-08-10 37

Page 39

To enter values for a new reference sensor

Click a radio button to select sensor 1 or sensor 2. And

press “Upload” to read current coefficients.

8.2.4 Default values

This option downloads a set of default values, which are stored in the

AmeTrim-ATC/DTI software.

Type in a unique and descriptive name for the reference

sensor.

Use the mouse to position the pointer in the boxes in the

table.

Select “ITS-90” or “Callendar van Dusen coefficients” and

type in the coefficients from the Calibration Certificate

supplied with the reference sensor.

When all the values from the Calibration Certificate have

been entered, click “Download” values.

When the values are downloaded they overwrite the ones

stored in the indicator.

Note…

These coefficients are not saved. Therefore, they must be

typed in and downloaded when they need to be used.

Press “Yes” to download default values to the DTI.

38 2017-08-10 124745 04

Page 40

8.2.5 RTD input adjustment

This option allows you to adjust the DTI by calculating and

downloading new values for the internal reference resistors.

For adjusting the internal reference resistors, you need the following:

DTI-100 / DTI-1000 / DTI-1000 A :

50 ohm resistor

350 ohm resistor

DTI-1000 B :

12 ohm resistor

85 ohm resistor

It is recommended to use resistors with an accuracy of 6 ppm or

better.

124745 04 2017-08-10 39

Page 41

Connect the reference resistors to the input channels and enter the

resistor values. Press “Start measurement”, wait until the readings for

“New low reference value” and “New high reference value” have

stabilized (approx. 2 minutes) and press “Lock new values” to stop

the measurement. The locked values can now be downloaded to the

DTI or cancelled.

8.2.6 Calibration date

This option allows you to change the calibration date without

adjusting the DTI.

Select the date of calibration and press “Download”.

40 2017-08-10 124745 04

Page 42

8.2.7 Analog output adjustment

(only DTI-1000 with firmware ver. 1.60 or earlier).

This option allows you to adjust the analog output of the DTI-1000.

For adjusting the analog output you need a voltmeter 0V to 5V range

with 0.1mV resolution and an accuracy of 0.1 mV.

After entering the DTI analog output adjustment window, press “Start”

to begin the adjustment procedure.

124745 04 2017-08-10 41

Page 43

Measure the output voltages of the two analog outputs, enter the

values and press “Next”.

42 2017-08-10 124745 04

Page 44

Repeat the measurement of the output voltage for high output, enter

the values and press “Next”.

Press “Yes” to download calibration date and then “Exit” to return to

the main menu.

124745 04 2017-08-10 43

Page 45

8.3 Setup Printer

This option provides a standard Windows procedure which enables

you to edit the settings for the current printer or change to another

printer.

If you are unsure how to use these settings, refer to your Windows

Help.

44 2017-08-10 124745 04

Page 46

AMETEK Sensors, Test & Calibration

A busine ss unit of AME TEK Measure ment &

Calibration Technologies Division offering the

followi ng industry leading bran ds for test and

Portable dry-block calibrators, precision

therm ometers and li quid baths. Tempe rature

Conveni ent electro nic systems ra nging from

-25 mbar to 100 0 bar - fully temp erature-

compensated for problem-free and accurate

Process signal mea surement an d simulation fo r

easy control loop cal ibration and m easuremen t

Pneumatic floating-ball or hydraulic piston dead

weight te sters with ac curacies to 0.015% of

readin g. Pressure ge nerators de livering up to

Digital pressure g auges and cal ibrators tha t are

accurate, easy-to-u se and reliable. Designed for

use in the h arshest env ironments ; most products

Materials testing machines and software that

guara ntees exper t materials te sting soluti ons.

Also covering Texture Ana lysers to per form rapid,

gener al food testin g and detaile d texture analysis

on a diver se range of foods and cosmetics.

Allows measuremen t and characte rization of

moisture-sensitive PET polymers and polymer

The han d held force gau ges and motorized

tester s have earned th eir reputation for qualit y,

reliab ility and acc uracy and they r epresent th e de

facto standard for force measurement.

Hardness testers, durometers, optical systems

and sof tware for dat a acquisitio n and analysi s.

calibration instrumentation.

JOFRA Calibration Instruments

Temperature Calibrators

sensors for industrial and marine use.

M&G Deadweig ht Testers & Pu mps

carr y an IS, IP67 and DN V rating.

Davenport Polymer Test Equipment

Chatillon Force Measurement

Pressure Calibrators

field use.

Signal Instruments

tasks.

1,000 bar.

Crystal Pressure

Lloyd Materials Testing

densit y.

Newage Hardness Testing

www.ametekcalibration.com

United Kingdom

Tel +44 (0)1243 833 302

caluk.sales@ametek.com

France

Tel +33 (0)1 30 68 89 40

general.lloyd-instruments@ametek.fr

Germany

Tel +49 (0)2159 9136 510

info.mct-de@ametek.de

Denmark

Tel +45 4816 8000

jofra@ametek.com

Information in this document is subject to change without notice. ©2016, by AMETEK, Inc., www.ametek.com. All rights reserved.

USA

Florida

Tel +1 (800) 527 9999

cal.info@ametek.com

California

Tel +1 (800) 444 1850

crystal@ametek.com

India

Tel +91 22 2836 4750

jofra@ametek.com

Singapore

Tel +65 6484 2388

jofra@ametek.com

China

Shanghai

Tel +86 21 5868 5111

Beijing

Tel +86 10 8526 2111

jofra.sales@ametek.com.cn

Loading...

Loading...