American Baking S300 Parts List

MASTER

THE ATWOOD

SCALE - O - MATIC DOUGH DIVIDER

MODEL: S300

OPERATIONS AND SAFETY

MANUAL

INCLUDING PARTS CATALOG

AND MAINTENANCE INSTRUCTIONS

MODEL No.

SERIAL No.

CAUTION:

DO NOT OPERATE, CLEAN OR SERVICE THIS MACHINE BEFORE YOU READ THIS MANUAL, AND ARE FAMILIAR WITH THE SAFETY INSTRUCTIONS IN THIS MANUAL AND THOSE ON THE LABELS ON THE MACHINE. KEEP THIS MANUAL AND OTHER MATERIALS DELIVERED WITH THE MACHINE, ACCESSIBLE TO THE OPERATORS FOR EASY REFERENCE DURING USE.

IF YOU SHOULD HAVE ANY (?) QUESTIONS ABOUT GUARDS OR PLACEMENT CALL (708) 841-0959 or visit our web site.

THE ENTIRE CONTENTS OF THIS PUBLICATION ARE COPYWRITTEN AND ALL RIGHTS ARE RESERVED. REPRODUCTION IN WHOLE OR IN PART IS PROHIBITED WITHOUT WRITTEN PERMISSION OF A.M. MFG. INC.

THIS CATALOG BECOMES OBSOLETE ON 12/30/06. UPDATED CATALOGS ARE AVAILABLE DIRECTLY FROM A.M. MFG. INC.

MANUFACTURING COMPANY |

DIVISION OF THE ATWOOD CORPORATION |

14151 IRVING AVENUE DOLTON, ILLINOIS 60419 |

(708) 841-0959 (800) 342-6744 FAX: (708) 841-0975 www.ammfg.com |

© COPYRIGHT 2006 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

OWNERS RESPONSIBILITY

NOTE:

THE PARTS AND EQUIPMENT DESCRIBED IN THIS MANUAL MAY BE COVERED BY ONE OR MORE U.S.

AND FOREIGN PENDING PATENTS.

!

TO MAINTAIN MACHINE AND USER SAFETY, THE RESPONSIBILITY OF THE OWNER IS TO READ AND FOLLOW THESE INSTRUCTIONS AND TO ENSURE THAT ALL OPERATORS UNDERSTAND AND FOLLOW THESE AND OTHER SAFETY INSTRUCTIONS IN THIS MANUAL.

!FOLLOW ALL INSTALLATION INSTRUCTIONS.

!MAKE SURE INSTALLATION CONFORMS TO ALL APPLICABLE LOCAL, STATE, AND FEDERAL CODES, RULES AND REGULATIONS SUCH AS STATE AND FEDERAL OSHA REGULATIONS AND ELECTRICAL CODES.

!CAREFULLY CHECK THE UNIT FOR CORRECT INITIAL FUNCTION.

!READ AND FOLLOW THE SAFETY INSTRUCTIONS. KEEP THEM READILY AVAILABLE FOR MACHINE OPERATORS.

!MAKE CERTAIN ALL OPERATORS ARE PROPERLY TRAINED, KNOW HOW TO SAFELY AND CORRECTLY OPERATE THE UNIT AND ARE PROPERLY SUPERVISED.

!ALLOW UNIT OPERATION ONLY WITH ALL PARTS INCLUDING SAFETY EQUIPMENT, IN PLACE AND OPERATING SAFELY.

!CAREFULLY INSPECT THE UNIT ON A REGULAR BASIS AND PERFORM ALL MAINTENANCE AS REQUIRED.

!SERVICE AND MAINTAIN THE UNIT ONLY WITH AUTHORIZED OR APPROVED REPLACEMENT PARTS.

!KEEP ALL INSTRUCTIONS PERMANENTLY WITH THE UNIT ALONG WITH ALL DECALS AND WARNING LABELS ON THE UNIT CLEAN AND VISIBLE.

S300_i |

i |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

TABLE OF CONTENTS |

|

|

|

|

PAGE |

|

|

INSIDE |

OWNERS RESPONSIBILITIES |

|

COVER |

INTRODUCTION & SPECIFICATIONS & INSTALLATION |

2 |

|

SAFETY SIGNAL WORDS |

|

3 |

LOCATION OF WARNING LABELS & LOCATIONS |

4 |

|

REPRODUCTION OF WARNING LABELS |

|

5 |

GENERAL SAFETY INFORMATION |

|

6 |

OPERATING INSTRUCTIONS |

|

7 |

CLEANING INSTRUCTIONS |

|

8-12 |

GUIDE TO MAINTENANCE |

|

13-14 |

PARTS CATALOG |

|

|

DIVIDER SLIDE GUARD |

|

15 |

CABINET ASSEMBLY |

|

16-17 |

CYLINDER AND DRIVE ASSEMBLY |

|

18-19 |

PISTON AND CONNECTING ROD ASSEMBLY |

20-21 |

|

MEASURING CUP AND DIVIDER SLIDE ASSEMBLY |

22-23 |

|

SMALL TAKE-OFF CONVEYOR |

|

24-25 |

ROUNDER ASSEMBLY |

|

26-27 |

CONVEYOR ASSEMBLY |

|

28-29 |

ELECTRICAL / SENSOR SYSTEM |

|

30-31 |

OILING SYSTEM |

|

32 |

TROUBLE SHOOTING |

|

33 |

ELECTRICAL SCHEMATIC (SINGLE PHASE 208 – 230 VOLT) |

34 |

|

ELECTRICAL SCHEMATIC (3-PHASE 208 – 230 VOLT) |

35 |

|

ELECTRICAL SCHEMATIC (3-PHASE 380 – 480 VOLT) |

36 |

|

ELECTRICAL SCHEMATIC (3-PHASE 208 – 230 VOLT VARIABLE SPEED) |

37 |

|

ELECTRICAL SCHEMATIC (3-PHASE 380 – 480 VOLT VARIABLE SPEED) |

38 |

|

PARTS ORDERING INSTRUCTIONS |

|

39 |

NOTES |

|

40 |

IMPORTANT:

A.M. MANUFACTURING Co. RESERVES THE RIGHT TO MAKE CHANGES IN DESIGN, SPECIFICATIONS OR MANUFACTURING TO IMPROVE THEIR PRODUCTS WITHOUT NOTICE AND WITHOUT OBLIGATION TO CHANGE OR IMPROVE PREVIOUSLY BUILT PRODUCTS INCLUDING MANUALS AND CATALOGS.

ONLY USE FACTORY SUPPLIED REPLACEMENT PARTS TO MAINTAIN MACHINE SAFETY, PERFORMANCE AND SANITARY CONDITIONS. USE OF NON-APPROVED PARTS MAY VOID MANUFACTURERS WARRANTY.

KNOW YOUR UNIT. COMPARE DIAGRAMS IN THIS MANUAL WITH THE UNIT BEFORE STARTING SERVICE, TO OBTAIN MAXIMUM SAFETY AND PERFORMANCE.

TO ORDER REPLACEMENT PARTS:

TURN TO PAGE 39 OF THIS MANUAL.

WARNING:

WARNING:

THIS MANUAL CONTAINS CRITICAL SAFETY INSTRUCTIONS. READ AND FOLLOW THEM CAREFULLY. FAILURE TO FOLLOW WARNING AND INSTRUCTIONS MAY LEAD TO SERIOUS PERSONAL INJURY. THE OWNER IS RESPONSIBLE FOR MAINTAINING THE UNIT, ITS INSTRUCTIONS AND DECALS FOR OPERATION REFERENCE. FOR ADDITIONAL COPIES CONTACT A.M. MANUFACTURING: (800)342-6744.

S300_toc |

TOC |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

OPERATIONS AND SAFETY MANUAL

INCLUDING PARTS CATALOG

READ AND FAMILIARIZE YOURSELF WITH THIS MANUAL BEFORE OPERATING THIS MACHINE

FOLLOW INSTRUCTIONS DURING USE

INTRODUCTION

THE SCALE-O-MATIC MODEL – S300 DOUGH DIVIDER IS DESIGNED TO GIVE YOU OPTIMUM TIME AND LABOR SAVING SERVICE WITH A SPEED OF APPROXIMATELY 2000 PIECES PER HOUR. THE S300 CAN ACCURATELY SCALE FROM 1 oz. TO 32 ± ¼ oz. WITH THE PROPER ATTACHMENTS. NEW AND CURRENT EMPLOYEES CAN BE TAUGHT TO OPERATE THIS MACHINE EFFICIENTLY AND SAFELY IN A SHORT PERIOD OF TIME. WE URGE YOU TO STUDY THIS OPERATION AND SAFETY MANUAL FOR FULL BENEFITS….

CAUTION:

ALL OPERATORS MUST BE FULLY TRAINED AND INSTRUCTED IN SAFETY PROCEDURES BEFORE BEGINNING PRODUCTION.

|

SPECIFICATIONS |

HOPPER CAPACITY |

100 lbs. |

|

EXTENDED HOPPER (140 lbs. CAPACITY) |

PRODUCTION RATE |

2000 PIECES PER HOUR |

HEIGHT |

58” |

LENGTH |

64” |

WIDTH |

24” |

SHIPPING WEIGHT |

1000 lbs. |

DIVIDER |

3 PHASE, 2 H.P. MOTOR (STANDARD) |

|

SINGLE PHASE, 1½ H.P. MOTOR |

|

DOUBLE SHEAVE BELT DRIVE |

SMALL CONVEYOR |

1 PHASE, 1/4 H.P. MOTOR |

ROUNDER SCREW |

3 PHASE, 1 H.P. MOTOR (STANDARD) |

|

SINGLE PHASE, ¾ H.P. MOTOR |

RECIPROCAL MOTION

MECHANICAL DIVIDER

AUTOMATIC SPRING PRESSURE, SELF ADJUSTABLE EXTRA DIVIDER CUPS AVAILABLE AS OPTIONAL EQUIPMENT.

NO. 1 DIVIDING CUP 1 TO 2 oz. NO. 2 DIVIDING CUP 2 TO 4 oz. NO. 3 DIVIDING CUP 4 TO 10 oz NO. 5 DIVIDING CUP 10 TO 32 oz

VOLTAGES: 3 PHASE, 208 - 230 VOLTS (STANDARD)

3 PHASE, 380 – 480 VOLTS

SINGLE PHASE, 208/220 VOLT (OPTIONAL) VARIABLE SPEED DIVIDER (OPTIONAL)

INSTALLATION INSTRUCTIONS

LOCATION:

SELECT LOCATION CAREFULLY. THE AREA SHOULD PROVIDE THE OPERATOR WITH ENOUGH SPACE TO USE THE EQUIPMENT IN A SAFE MANNER. THE FLOOR AREA SELECTED SHOULD BE EASY TO CLEAN AND SHOULD BE FREE OF OIL, GREASE, ETC. AVOID AREAS WHERE BYSTANDERS AND CUSTOMERS MAY BE PRESENT.

CAUTION

PROPER UNIT INSTALLATION IS NECESSARY FOR SAFE AND EFFICIENT OPERATION. PROPER INSTALLATION ALSO HELPS PROTECT THE UNIT FROM DAMAGE AND MAKES SERVICE EASIER.

S300_2 |

2 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

SAFETY

THIS MACHINE IS DESIGNED TO PROVIDE FOR SAFE OPERATION IF NORMAL OPERATING PROCEDURES AND SAFETY MESSAGES LOCATED ON THE MACHINE AND IN THIS MANUAL ARE FOLLOWED.

THIS IS A SAFETY ALERT SYMBOL. YOU WILL

FIND IT ON VARIOUS SAFETY LABELS ON THE

MACHINE AND IT WILL ALSO APPEAR IN THIS

MANUAL WHEREVER SAFETY MESSAGES ARE

GIVEN.

GET FAMILIAR WITH SIGNAL WORDS:

CAUTION, WARNING & DANGER

CAUTION:

INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY ALSO BE USED TO ALERT AGAINST UNSAFE PRACTICES.

WARNING:

INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

DANGER:

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS INJURY. THIS SIGNAL WORD IS TO BE LIMITED TO THE MOST EXTREME SITUATIONS.

NOTE:

A NOTE PROVIDES KEY INFORMATION TO MAKE PROCEDURES EASIER AND CLEARER.

S300_3 |

3 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

TYPICAL WARNING LOCATIONS

!

!

!

S300_4 |

4 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006

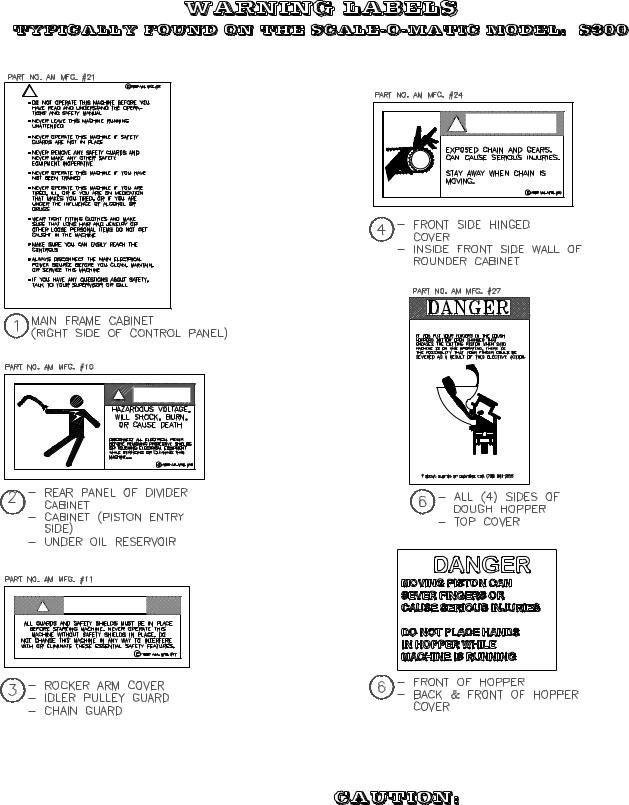

WARNING LABELS

TYPICALLY FOUND ON THE SCALE-O-MATIC MODEL: S300

? |

!"#$%&'(& |

)'*+&,-!(*$%"'&!$( |

|

|

'9"9-"'(:*';&:%!(< |

|

&$..-*%++-/0112-34567844 |

? |

='%(!(< |

? |

>'(<+% |

? |

='%(!(< |

NOTE:

MACHINE DESIGN AND SPECIFICATIONS MAY VARY. ACTUAL LABEL DESIGN AND PLACEMENT SUBJECT TO CHANGE WITHOUT NOTICE AND MAY VARY FROM THIS ILLUSTRATION.

CAUTION:

CAUTION:

IF ANY SAFETY LABELS ARE MISSING,. THEY

MUST BE REPLACED! CONTACT YOUR DEALER OR A.M. MFG. FOR REPLACEMENT.

S300_5 |

5 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

SAFETY RULES

IMPORTANT:

READ AND FOLLOW THESE SAFETY RULES. THEY ARE FOR YOUR PROTECTION AND THE PROTECTION OF THOSE WORKING WITH YOU.

!DO NOT OPERATE THIS MACHINE BEFORE YOU READ AND UNDERSTAND THE OPERATIONS AND SAFETY MANUAL.

!FOLLOW ALL INSTRUCTIONS DURING USE OF THIS MACHINE.

!LEAVE ALL GUARDS IN PLACE. INSTALL ALL GUARDS IF THEY WERE REMOVED FOR CLEANING, MAINTENANCE, REPAIR OR OTHER REASONS.

!NEVER OPERATE THE MACHINE IF YOU HAVE NOT BEEN TRAINED TO OPERATE THE MACHINE PROPERLY.

!NEVER OPERATE THE MACHINE IF YOU ARE TIRED, ILL, ON MEDICATION, OR UNDER THE INFLUENCE OF ALCOHOL OR DRUGS.

!WEAR TIGHT FITTING CLOTHES. MAKE SURE THAT LONG HAIR, JEWELRY, OR LOOSE PERSONAL ITEMS ARE SECURED SO THEY CANNOT GET CAUGHT IN THE MACHINE. THIS CAN LEAD TO SERIOUS INJURIES.

!MAKE SURE YOU CAN EASILY REACH ALL CONTROLS. IF NOT, A STABLE AND SAFE ELEVATED PLATFORM OR OTHER WORK-AID MUST BE PROVIDED.

!ALWAYS DISCONNECT THE MAIN ELECTRICAL POWER SOURCE BEFORE CLEANING, IF MAINTENANCE OR SERVICE IS PERFORMED, OR IF THE MACHINE IS OUT OF SERVICE.

!NEVER CLEAN CONVEYOR BELTS ON MACHINE, ALWAYS REMOVE BELT FROM MACHINE TO CLEAN OR SERVICE.

!NEVER LEAVE THIS MACHINE RUNNING UNATTENDED.

!GUARDS ARE INTERLOCKED; MACHINE WILL NOT OPERATE WITHOUT GUARDS IN PLACE.

IMPORTANT:

IF YOU HAVE ANY QUESTIONS ABOUT THESE SAFETY RULES, SEE YOUR SUPERVISOR OR CALL A.M. MANUFACTURING Co. TOLL FREE: (800)342-6744

S300_6 |

6 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

OPERATING INSTRUCTIONS

WARNING:

WARNING:

UNIT MUST BE PROPERLY OPERATED AND MAINTAINED TO PREVENT MACHINE DAMAGE OR PERSONAL INJURY. REVIEW INSTRUCTIONS WITH ALL EMPLOYEES BEFORE USE.

CAUTION:

CAUTION:

BEFORE BEGINNING START - UP, READ ALL INSTRUCTIONS AND FAMILIARIZE YOURSELF WITH THE LOCATIONS OF ALL CONTROLS. KNOW HOW TO SHUT DOWN THE UNIT IMMEDIATELY IN CASE OF TROUBLE. MAKE CERTAIN ALL PERSONNEL NOT INVOLVED IN THE START - UP ARE SAFELY AWAY FROM THE MACHINE BEFORE ANY SYSTEMS ARE STARTED...

I.PRELIMINARY START-UP PROCEDURE

A.REMOVE PACKING, PACKING SLIPS, DOCUMENTS AND OTHER OBSTRUCTIONS FROM HOPPER.

B.MAKE SURE MACHINE IS ON A FLAT SURFACE

C.MOVE MACHINE INTO POSITION & LOCK CASTERS.

D.PLUG POWER CORD INTO PROPER RECEPTACLE. / PROPER GROUNDING IS NECESSARY TO PREVENT ANYTYPE OF

ELECTROSTATIC PHENOMENA.

E.REMOVE SMALL INSPECTION DOOR.

F.PUSH DIVIDER START BUTTON AND TEST BUTTON SIMULTANEOUSLY AND HOLD.

G.CHECK ROTATION OF DIVIDER BY LOOKING THROUGH SMALL INSPECTION DOOR. LARGE GEAR SHOULD BE TURNING (C.W.) CLOCK-WISE.

H.IF THE GEAR IS TURNING IN THE (C.C.W.) COUNTERCLOCK WISE DIRECTION, CONSULT A PROPERLY TRAINED ELECTRICIAN.

I.IF ROTATION IS CORRECT, YOU ARE READY TO CONTINUE ON WITH THESE PROCEDURES.

J.RE-INSTALL SMALL INSPECTION DOOR.

K.CHECK POWER SUPPLY TO ROUNDER AND DISCHARGE CONVEYOR BY FLIPPING THE SWITCH LABELED “ROUNDER” ON THE CONTROL PANEL. THE ROUNDING DRUM SHOULD BE TURNING IN A (C.C.W.) ROTATION, AND THE DISCHARGE CONVEYOR SHOULD BE RUNNING FORWARD, OUT FROM MACHINE.

II.OPERATION OF DIVIDER

A.FILL THE OIL RESERVOIR WITH LIGHTWEIGHT MINERAL OIL. BE SURE TO CLEAN ANY OIL SPILL AROUND MACHINE. THESE SURFACES BECOME SLIPPERY.

B.WITH THE SQUIRT BOTTLE SUPPLIED, APPLY A SMALL AMOUNT OF MINERAL OIL TO THE INSIDE SIDES OF THE DOUGH HOPPER.

C.OPEN THE VALVE LOCATED ON THE TOP GIB BAR APPROXIMATELY 1/8 OF A TURN.

D.REMOVE BACK CABINET DOOR.

E.OPEN THE CYLINDER VALVE APPROXIMATELY 1/8 OF A TURN. THIS VALVE IS LOCATED ON THE OIL PUMP OF THE REAR DOOR.

F.REINSTALL THE BACK CABINET DOOR.

G.FILL THE HOPPER WITH DOUGH. BY LOADING DOUGH @ 20 lbs. PIECES. DO NOT LIFT MORE THAN 20 lbs. PIECES. THIS COULD CAUSE SERIOUS LOWER BACK INJURY.

H.SET HOPPER COVER ON TOP OF DOUGH

I.SWITCH CONVEYOR TO THE ON POSITION.

J.SWITCH ROUNDER TO THE ON POSITION.

K.PRESS DIVIDER BUTTON.

L.HOPPER SHOULD BE OILED EVERY TIME YOU PLACE NEW DOUGH IN IT.

|

CAUTION |

|

PISTON WILL MOVE AFTER POWER IS TURNED |

III. DIVIDING THE DOUGH |

OFF OR DISCONNECTED. |

|

A.DOUGH IS PORTIONED IN THE CUP LOCATED ON THE DIVIDER SLIDE.

B.TO ADJUST THE WEIGHT, STOP MACHINE.

C.BY TURNING THE HANDLE IN A COUNTER CLOCKWISE MOTION, THE DOUGH WEIGHT WILL INCREASE. THE DOWN (CLOCKWISE) MOTION DECREASES THE DOUGH WEIGHT.

D.FIND YOUR DESIRED DOUGH WEIGHT BY WEIGHING THE DOUGH PIECE.

E.ONCE YOU HAVE ACHIEVED THIS, ADJUST THE LOCKING STAR KNOB (529MS-2D) TO THE TOP OF THE MEASURING CUP TO KEEP SCALING ACCURATE.

S300_7 |

7 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

DIVIDER CLEANING PROCEDURES

THESE PROCEDURES ARE VERY IMPORTANT TO MAINTAIN

PRODUCT QUALITY AND MACHINE PERFORMANCE.

ALL A.M. MANUFACTURING MACHINES ARE TESTED WITH DOUGH DURING THE IN-HOUSE RUN-IN AND QUALITY AUDIT PROCEDURE. ALTHOUGH THE MACHINE HAS BEEN CLEANED, SOME EVIDENCE OF DOUGH ON AND IN THE MACHINE MAY BE DETECTED. THIS IS NORMAL. ALL PARTS IN CONTACT WITH DOUGH SHOULD BE WASHED THOROUGHLY AFTER USE, USING A MILD SOAP AND WATER SOLUTION. DISASSEMBLY OF THIS MACHINE FOR CLEANING IS OUTLINED BELOW AND ILLUSTRATED FOR YOUR CONVENIENCE. INSTRUCTIONS IN MANUAL INDICATE THE NEED FOR REGULAR INSPECTIONS & CLEANING TO PREVENT INFESTATION.

I.DIVIDER

A.DANGER: SHUT OFF ALL ELECTRICAL POWER

B.REMOVE COVER OVER DRIVE END OF SLIDE

C.LOOSEN FOUR (4) SOCKET SCREWS AT TOP OF CUP; TWIST AND REMOVE CUP.

D.REMOVE INSERT. (IF APPLICABLE)

E.REMOVE TWO (2) END BOLTS AT DRIVE END OF SLIDE.

F.LOOSEN EIGHT (8) HEX HEAD NUTS AT TOP OF GIB BARS AND REMOVE SLIDE.

G.REMOVE GIB BARS.

H.REMOVE PISTON BY – INSERTING CRANK IN PINION GEAR ON SIDE OF CABINET THEN:

1.LOOSEN TWO (2) SCREWS ON THE SIDE OF SPRING ASSEMBLY AND SLIDE TO RIGHT.

2.REMOVE UPPER PIN AND CRANK ASSEMBLY THROUGHT ONE (1) ROTATION, THUS SEPARATING THE SHAFT.

3.PUT LOWER PIN IN UPPER HOLE AND ROTATE UNIT UNTIL PISTON COMES OUT OF THE CYLINDER.

4.REMOVE PISTON AND CLEAN.

5.REMOVE SEAL SCRAPER RING AND “O” RING ON FACING OF CYLINDER AND CLEAN.

6.CLEAN ALL DOUGH RESIDUE OFF OF FACING AND INNER CYLINDER. MAKE SURE YOU CLEAN OUT THE OIL HOLE. (CHECK VALVE)

I.REPLACE PISTON BY:

1.MAKING SURE PISTON IS IN EXTENDED POSITION w/ PIN IN UPPER HOLE.

2.PUT PISTON IN CYLINDER – GUIDING SHAFT INTO THE SPRING ASSEMBLY.

3.TAKE OTHER PIN AND PUT IT THROUGH SPRING ASSEMBLY AND LOWER SHAFT HOLE.

4.ROTATE CRANK UNTIL UPPER PIN IS VISIBLE AND REMOVE.

5.TURN CRANK UNTIL SHAFT COLLAPSES AND TWO (2) UPPER HOLES MEET, INSERT PIN AND PUSH SLIDE OVER AND TIGHTEN ALLEN SCREWS.

6.BE SURE PISTON IS COLLAPSED BY MAKING ONE FULL ROTATION NOTING THAT PISTON DOES NOT COME ABOVE UPPER CYLINDER.

J.REPLACE GIB BARS & SLIDE AND ATTACH TWO (2) END BOLTS TIGHTLY.

K.TIGHTEN THE EIGHT (8) HEX HEAD NUTS ON THE GIB BARS.

L.REPLACE INSERT AND MEASURING CUP, RE-TIGHTEN FOUR (4) SOCKET HEAD SCREWS.

M.PUT SAFETY COVER BACK OVER DRIVE END OF SLIDE.

N.REMOVE HAND CRANK FATER ASSEMBLY.

PRACTICE SAFETY FIRST:

ALWAYS DISCONNECT ELECTRICAL SERVICE WHEN CLEANING OR MAINTAINING THIS MACHINE, THUS AVOIDING CHANCE OF SERIOUS INJURIES. MACHINES ARE NOT DANGEROUS IF COMMON SENSE IS APPLIED AND THE INSTRUCTIONS ARE CAREFULLY FOLLOWED. THINK AND PRACTICE SAFETY FIRST.

S300_8 |

8 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

ROUNDER CLEANING PROCEDURES

THESE PROCEDURES ARE VERY IMPORTANT TO MAINTAIN

PRODUCT QUALITY AND MACHINE PERFORMANCE.

II.ROUNDER

A.DANGER: SHUT OFF ALL ELECTRICAL POWER.

B.OPEN AND TILT FRONT OF ROUNDER

C.LIFT HANDLE ON SMALL INSPECTION DOOR SIDE.

D.TILT ROUNDER ASSEMBLY FORWARD.

E.REMOVE FUNNEL (PART NO. R116RA).

F.REMOVE ROUNDER SCREW (PART NO. R122RA)

1.DO NOT DROP OR SET DOWN ON SCREW STEM (THIS CAN MUSHROOM THE STEM SO THAT THE SCREW WILL NOT RE-ENTER BASE). IT IS RECOMMENDED THAT THE SCREW BE LAID ON ITS SIDE. BEWARE NOT TO BUMP THE OUTER EDGE (WHICH IS NICKEL COATED) AS THIS CAN CAUSE FLAKING OF THE NICKEL.

2.THE SCREW SHOULD BE CLEANED WITH WARM WATER AND A NON-ABRASIVE PAD. REMOVE ALL DRIED DOUGH FROM THE EDGE AND ROUNDING SURFACE WITH A PLASTIC SCRAPER IF NEEDED. DRY COMPLETELY.

3.DO NOT PLACE IN AN AUTOMATIC DISHWASHER

A.REMOVE DRUM (PART NO. R117RA)

1.TAKE THE DRUM OUT OF THE MACHINE: DO NOT LAY DRUM ON ITS SIDE (THIS CAN CAUSE WARPING OF THE DRUM, WHICH WILL NOT ALLOW THE DRUM AND SCREW TO FIT TOGETHER). IT IS RECOMMENDED THAT THE DRUM BE STOOD ON END.

2.THE DRUM SHOULD BE CLEANED WITH WARM WATER (WATER TEMP. SHOULD NOT EXCEED 190°F) AND A NONABRASIVE PAD (PLASTIC BRISTLE BRUSH RECOMMENDED). REMOVE ALL DRIED DOUGH FROM THE GROOVED AND INNER SURFACE OF THE DRUM. DRY COMPLETELY.

3.DO NOT PLACE IN AN AUTOMATIC DISHWASHER (THIS, TOO, CAN CAUSE WARPING OF THE DRUM WHICH WOULD NOT ALLOW THE DRUM AND SCREW TO FIT TOGETHER).

A.REMOVE PLASTIC SEAL RING (PART NO. 141RA).

B.REMOVE EXCESS DOUGH FROM ROUNDER BASE.

C.REASSEMBLY IS REVERSE OF DISASSEMBLY.

D.MAKE SURE TO REPLACE PLASTIC SEAL RING.

E.SLIP THE DRUM OVER THE ROUNDER BASE SO THAT THE DRIVE SLOTS ARE LOCKED OVER THE DRIVE PINS IN THE ROUNDER BASE.

F.CARE SHOULD BE TAKEN TO SEE THAT THE EXIT RAMP ON THE SCREW IS FACING DISCHARGE END OF MACHINE.

G.TILT ROUNDER ASSEMBLY BACKWARD AND LOCK IN PLACE.

H.WIPE EXCESS DOUGH FROM CONVEYOR BELT AND AREA AROUND ROUNDER.

II. NOTES

ALL PARTS AND AREAS MENTIONED MUST BE CLEANED EVERY DAY.

IF UNABLE TO REMOVE ROUNDER SCREW:

A.PLUG MACHINE IN, TURN MACHINE ON.

B.ADD A SMALL AMOUNT OF WARM WATER TO CONTACT AREA BETWEEN SCREW AND DRUM.

C.AFTER DOUGH SOFTENS, TURN OFF ROUNDER.

D.UNPLUG MACHINE.

E.REMOVE ROUNDER SCREW.

PRACTICE SAFETY FIRST:

ALWAYS DISCONNECT ELECTRICAL SERVICE WHEN CLEANING OR MAINTAINING THIS MACHINE, THUS AVOIDING CHANCE OF SERIOUS INJURIES. MACHINES ARE NOT DANGEROUS IF COMMON SENSE IS APPLIED AND THE INSTRUCTIONS ARE CAREFULLY FOLLOWED. THINK AND PRACTICE SAFETY FIRST.

S300_9 |

9 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

|

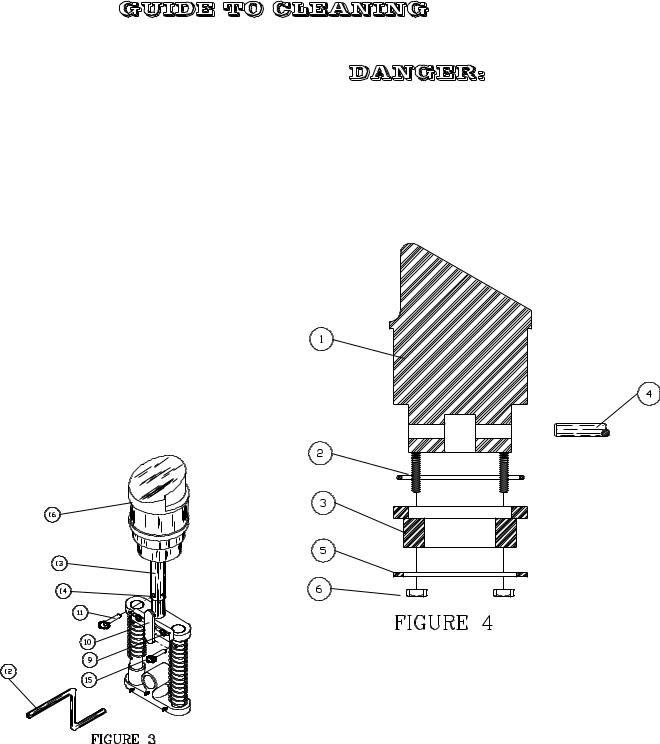

GUIDE TO CLEANING |

|

|

DANGER: |

|

|

ALWAYS DISCONNECT ELECTRICAL SERVICE WHEN |

|

|

CLEANING, MAINTAINING OR REPAIRING THIS MACHINE... |

|

STEP 1

USING A ALLEN WRENCH, LOOSEN SOCKET HEAD SCREWS (2) AND LIFT OFF DIVIDER PLUNGER (MEASURING CUP) (3). WHEN A #2 OR #3 MEASURING CUP IS IMPLOYED ON DIVIDER, THE DIVIDER CYLINDER MUST ALSO BE REMOVED FROM SLIDE FOR CLEANING.

STEP 5

WIPE EXCESS DOUGH FROM INSIDE OF DOUGH HOPPER.

NOTE:

NEVER USE METAL EDGED SCRAPER FOR CLEANING ANY PART. USE OF SUCH TOOLS CAN RESULT IN DAMAGE.

STEP 2

LOOSEN EIGHT HEX HEAD BOLTS AT TOP OF GIB BARS. USING WRENCH (1) REMOVE TWO HEX HEAD SCREWS (4) AND PUSH DIVIDER SLIDE (5) REARWARD TO EXPOSE CYLINDER OPENING.

STEP 3

REMOVE CABINET DOOR (6).

STEP 4

WITH CYLINDER OPENING EXPOSED, REMOVE SEAL SCRAPER RING (7) AND RUBBER “O” RING (8). CLEAN ALL EXPOSED SURFACES INCLUDING “O” RING GROOVE AND DIVIDING SLIDE OF ACCUMULATED DOUGH, OIL, ETC. WIPE EXCESS DOUGH FROM TOP AND INTERIOR OF CYLINDER.

SCALE - O - MATIC NAME PLATE

THIS PLATE HAS A 2-CHANNEL GROOVE THAT CATCHES EXCESS OIL AND DRAINS INTO DRIP PAN AT THE BOTTOM OF THE MACHINE. THIS PLATE SHOULD BE REMOVED BY LOOSENING AND REMOVING A SMALL ALLEN SCREW IN THE CENTER OF THE PLATE. CLEAN PLATE, AND CHECK PLASTIC DRAIN LINE TO SEE THAT IT IS CLEAN AND FREE OF ANY SEDIMENT SO OIL CAN DRAIN PROPERLY. DRIP PAN AT BOTTOM OF MACHINE SHOULD BE EMPTIED EVERY DAY.

S300_10 |

10 |

4/06 |

AM MFG. CO. |

MASTER |

MODEL: |

DIV. OF ATWOOD CORP. |

|

S300 |

© 2006 |

|

|

|

GUIDE TO CLEANING |

|

STEP 5

LOOSEN SOCKET SCREWS (9) ENOUGH TO SLIDE PIN LOCK BRACKET (10) EXPOSING LOCK PIN (11). REMOVE PIN (11).

STEP 6

INSERT CRANK HANDLE (12) THROUGH HOLE IN CABINET AND ENGAGE WITH PINION SHAFT. CRANK ONE COMPLETE TURN COUNTER CLOCK-WISE THUS EXTENDING PISTON ROD UNTIL HOLE (14) IS IN LINE WITH UPPER HOLE IN ROD (13).

STEP 7

PLACE PIN (11) INTO HOLE (14) TEMPORARILY. NOW REMOVE PIN (15), CONTINUE TO CRANK UNTIL PISTON (16) EMERGES FROM THE TOP OF THE CYLINDER. LIFT OUT CAREFULLY BY HAND. THOROUGHLY CLEAN PISTON AND CYLINDER TO REMOVE ALL ACCUMULATED DOUGH WITH A MILD SOAP AND WASTER SOLUTION. DRY THOROUGHLY AND COAT ALL SURFACES WITH A LIGHT COATING OF DIVIDER OIL. TO REASSEMBLE, REVERSE STEPS 1 THROUGH 7.

WHEN CLEANING OR ADJUSTING PISTON, DO NOT OVER TIGHTEN ADJUSTING NUTS. THIS WILL OVER SPREAD YOUR PLASTIC PISTON RING AND WILL CAUSE EXCESSIVE WEAR, AND IT WILL ALSO BE HARD TO REPLACE PISTON BACK INTO THE CYLINDER. THIS COULD RESULT IN THE CUTTING OF YOUR PISTON RING WHICH WOULD DESTROY YOUR PISTON RING.

IMPORTANT: WHEN RE-ASSEMBLING, DO NOT OVER TIGHTEN ANY OF THE SCREWS, AS THIS TENDS TO STRIP THREADS CAUSING PROBLEMS IN THE FUTURE. BE SURE RING ON PIN (11) OF FIGURE 3 IS SECURELY FASTENED OVER LATCH (10). THIS WILL PREVENT LATCH FROM MOVING, SHOULD THE SOCKET HEAD SCREWS (9) LOOSEN DURING OPERATION.

DANGER:

DANGER:

ALWAYS DISCONNECT ELECTRICAL POWER SOURCE WHEN CLEANING, MAINTAINING OR REPAIRING THIS MACHINE....

REPLACEMENT OF PISTON RING

TO DISMANTLE PISTON IN FIGURE 4, REMOVE THE SIX HEX NUTS (6), SLIP RING (5) DOWN AND OFF, THEN WITH SLIGHT PRESSURE, PUSH PISTON RING (3) OFF PISTON, REMOVE WRIST PIN (4) AND RUBBER “O” RING (2). WHEN REASSEMBLING THE PISTON, A VERY IMPORTANT STEP IS TO MAKE SURE THE SIX NUTS (6) ARE NOT OVERLY TIGHTENED, MERELY SNUG. AS THE RING WEARS OVER A PERIOD OF TIME, CONTINUE TO SNUG UP THE SIX NUTS. THIS PROCEDURE WILL NOT ONLY PROVIDE LONG LIFE TO THE PISTON RING BUT WILL MAINTAIN FULL VACUUM.

S300_11 |

11 |

4/06 |

Loading...

Loading...