Page 1

Page 2

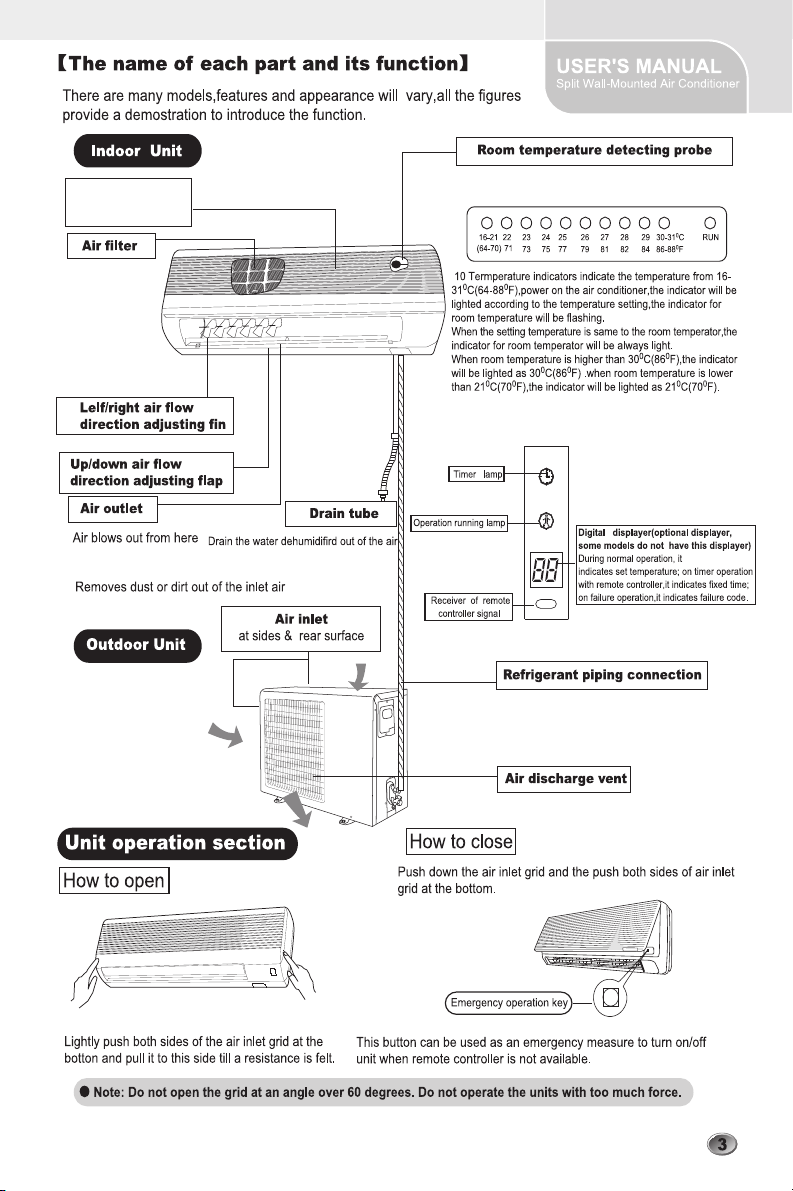

Page 3

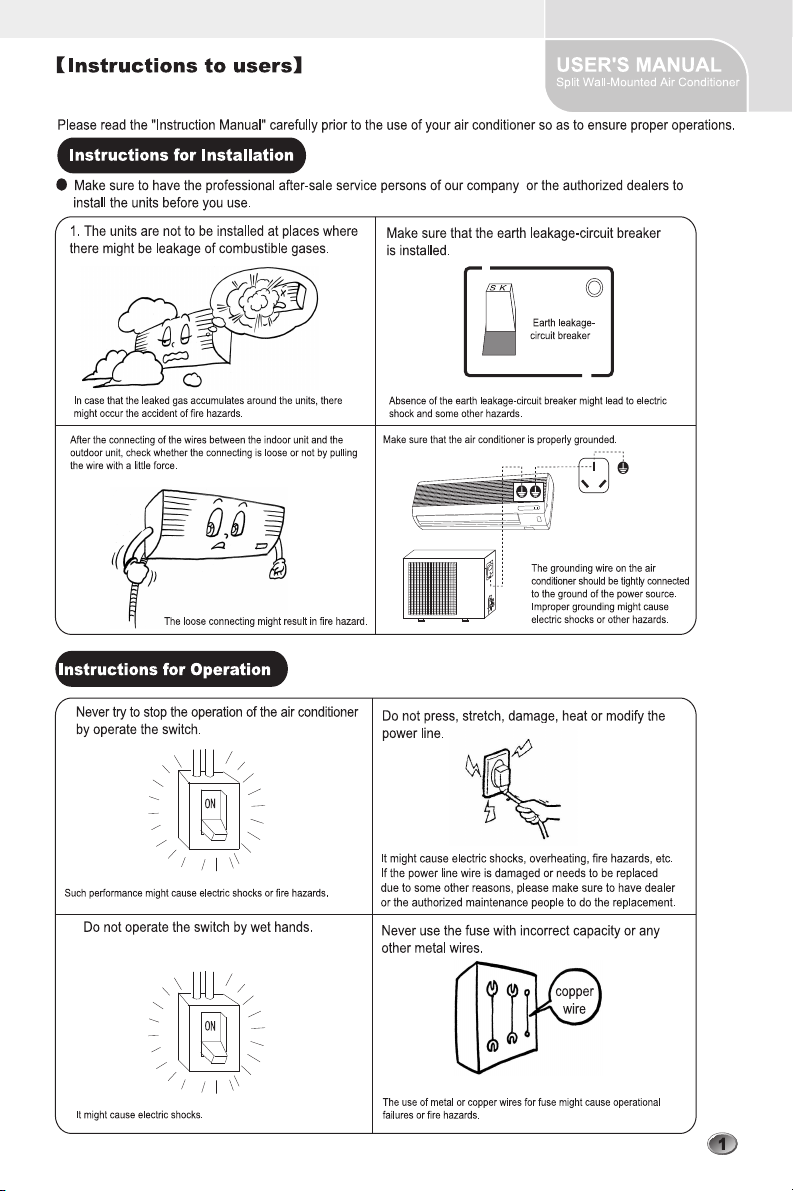

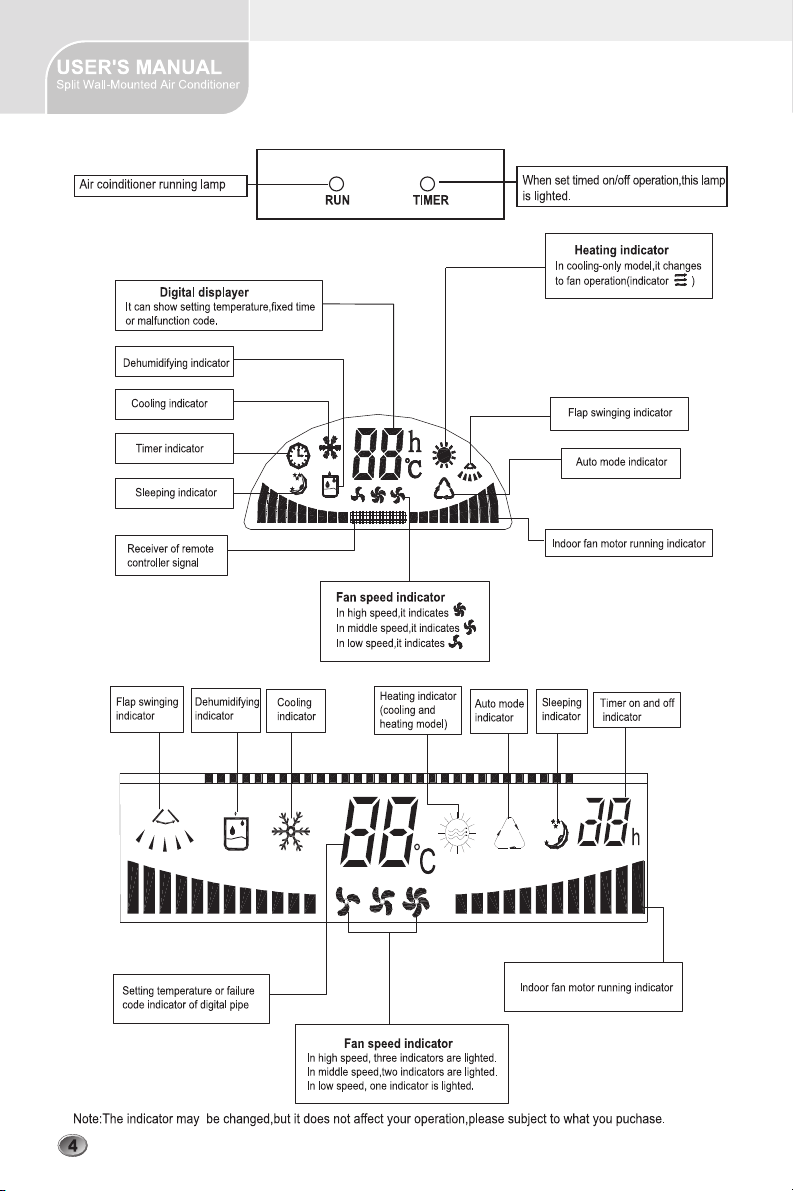

Page 4

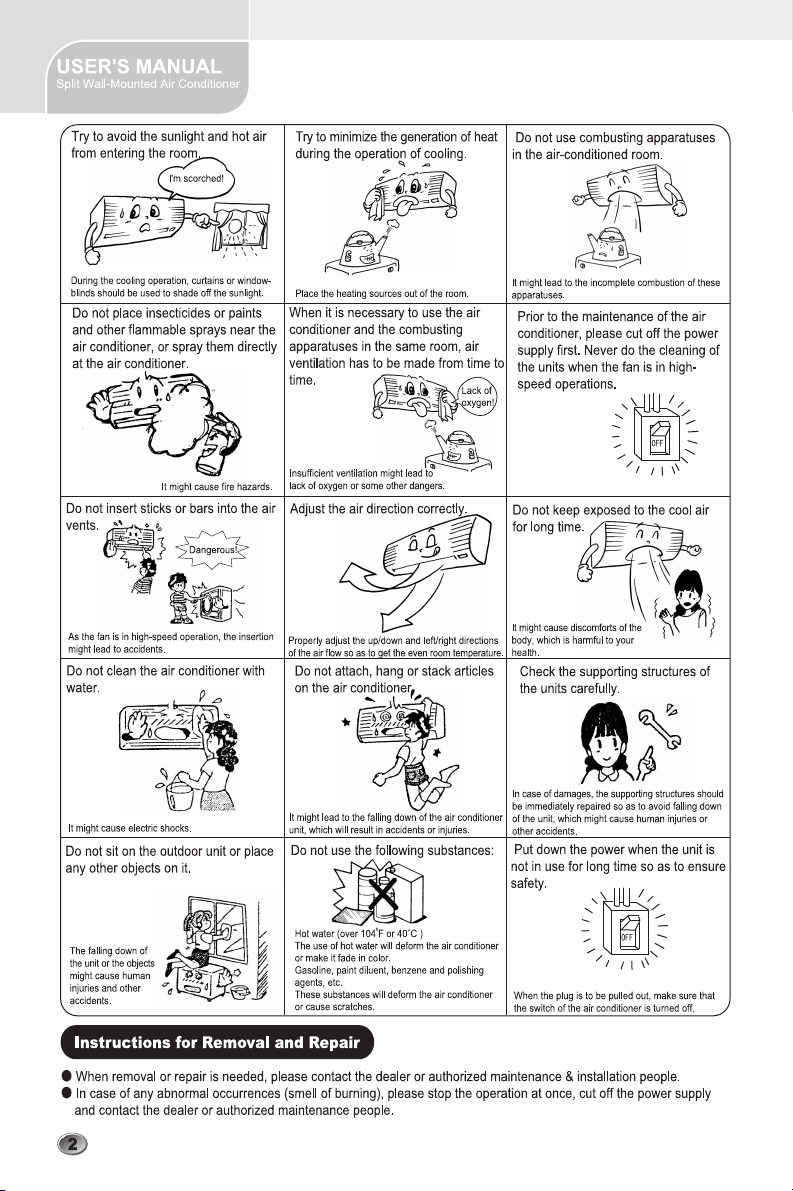

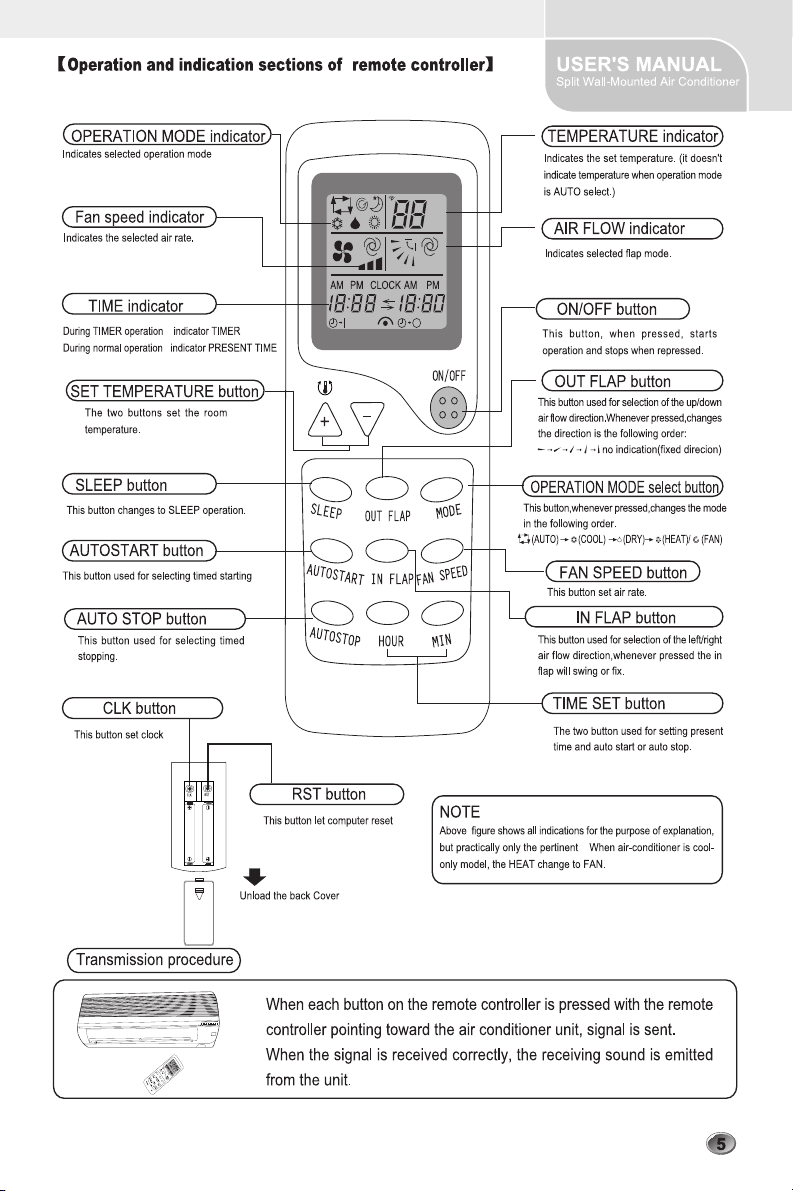

Page 5

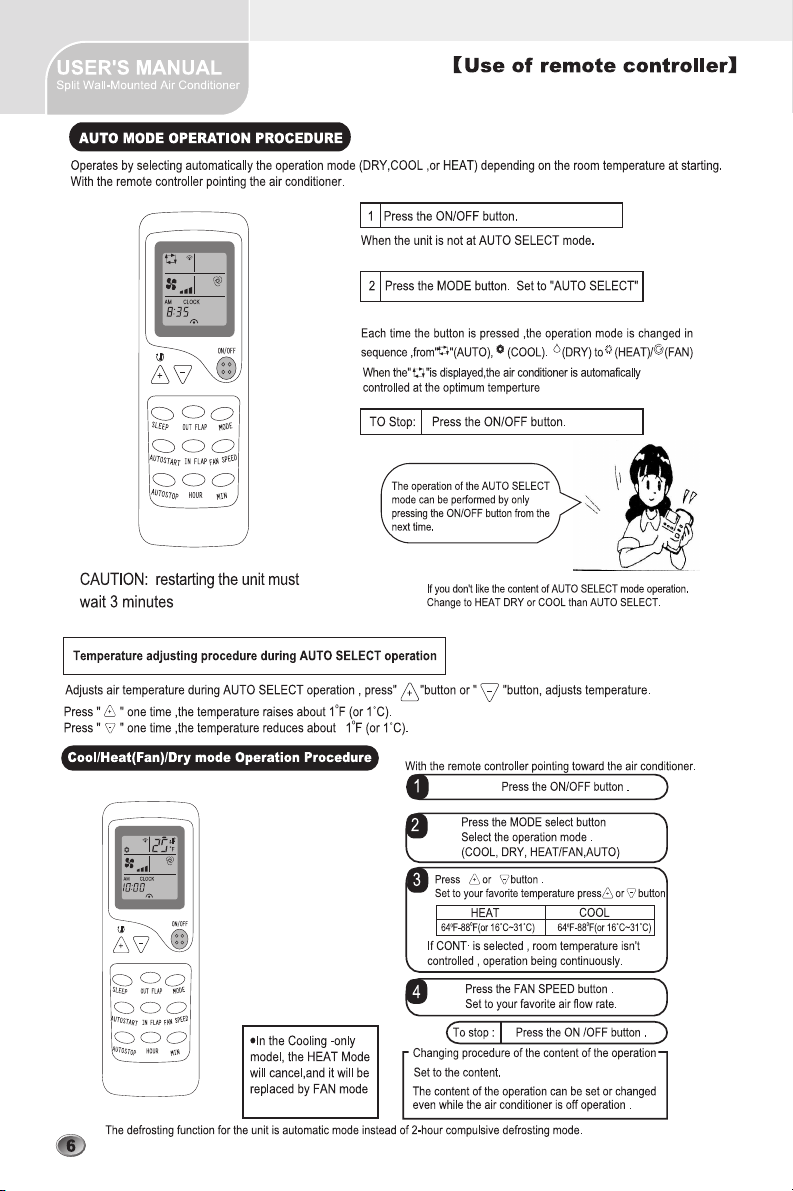

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted Air Conditioner

*

Selection of installation positions for indoor unit

*

* To be installed at the position where the air delivered from the unit can reach every corner of

the room;

* To avoid being affected by the outdoor air;

* To avoid blockage to the air inlet or outlet of the unit;

* To avoid too much oil smoke or steam;

* To avoid possible generation, inflow, lingering or leakage of flammable gases;

* To avoid high-frequency facilities (such as high frequency arc welders, etc.);

* To avoid the places where acid solutions are frequently used;

* To avoid the places where some special sprayers (sulfides) are frequently used.

* Not to install a fire alarming device near the air outlet of the unit (during operation, the fire alarm

device might be erroneously triggered by the warm air from the unit);

*

Make sure of enough space for installation and maintenance.

* To take into consideration the operational convenience and safety in installation, it is recommended

to ensure enough space between the unit and the walls.

Ceiling

Above 100mm(4")

Left side: 150mm(6")

and above

Wall hanging plate

2300mm(7'6")

and above

ground

*

Height limits of indoor and outdoor units.

* Either the indoor unit or the outdoor unit can be higher, but the height difference must comply the stated

requirements.

* Try to reduce the bending of the piping line as much as possible so as to avoid possible negative impacts upon the

performances of the units.

Indoor unit

5m(16'5")max.

outdoor

unit

Right side: 150mm (6")

and above

1

Page 18

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted air conditioner

*

Selection of installation positions for outdoor unit

*

* To install the outdoor unit at the places which can stand the load of the machine weight and will

not cause big vibrations and noises;

* To install the unit at the places not to be exposed to rain or direct sunshine, and the places with

good ventilation;

* The noises generated from the unit will not affect the neighboring places;

* Do not install the unit on non-metal frame;

* Not to install the unit at the places where there might occur the generation, inflow, stay or

leakage of inflammable gases;

* Pay attention to the drainage of the condensed water from the base plate during operations;

* To avoid the air outlet being directly against the wind.

Detailed space requirements around the outdoor unit

1. When there are obstacles above

the unit

100mm(4") min

500mm(1'8") min

4. When there are obstacles at the front and rear sides.

2. When the front (air outlet) is open 3. When there are obstacles only in

200mm(8") min

200mm(8") min

300mm(1') min

100mm(4") min

1000mm(3'4") min

the front (air outlet)

500mm(1'8") min

Space for maintenance

Shown as in the following figure. Keep

the maintenance space in front of the

unit.

200mm

(8")min

500mm

(1'8")min

5. When there are obstacles all around

the unit on four sides.

Although the top side is open, the

installation is not to be done if there

are obstacles all around.

500mm(1'8") min

Space for maintenance

* At least two sides should

be kept open.

2

Page 19

*

Installation fixture of indoor unit

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted air conditioner

*

Pipelines can be connected in the directions of****

****and* as indicated in Fig.1. When the pipelines

are connected to the directions of***and*, a groove

for the pipes has to be opened at the proper place on

the base stand.

1.Installation of wall-mounting plate

Fix the wall-mounting plate firmly on the wall with screws.

Make sure of the leveling of the plate. Slanted wall-mounting

plate might jeopardize the smooth discharge of the condensed

water.

2.Drill holes on the wall

Drill holes at places slightly below the wall-mounting plate,

with hole diameter of 65mm(2-3/5") and the outer edge of

the hole 5-10mm(1/5-2/5") lower (Fig.2) so that the condensed

water can smoothly flow out. Cut the wall penetrating pipe

to proper length according to the thickness of the wall (35mm(1/10-1/5") longer than the wall thickness) and insert

the pipe as indicated in Fig.2.

3.Installation of drain pipe

Install the pipelines of the indoor unit in accordance with

the direction of the wall holes. Wrap tightly the drain pipe

and the pipelines with tape. Make sure that the drain pipe

is underneath the pipelines. (Fig.3) (When the drain pipe

passes the room interior, some condensed water might

occur to its surfaces if the humidity is very high).

Fig.1

*Right outlet

Fig.2

Wall cap

Fig.3

*Bottom outlet

Fix with a tape

Wall pipe

Drain pipe

*Rear outlet

Interior

*Left outlet

*Left rear outlet

5-10mm lower

(1/5-2/5")

Wall

Exterior

Pipelines of indoor unit

Rear pipe

4.Installation of indoor unit

Pass the connection wires, connecting pipelines and drain

pipe through the wall hole. Hang the indoor unit on the

hooks at the top of the wall-mounting plate so that the

hooks at the bottom of the indoor unit match the hooks of

the wall-mounting plate. (Fig.4)

3

Fig.4

Bottom hooks

Top hooks

Hook supports

Page 20

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted air conditioner

Inspections:

a. Check if the hooks at the top and bottom

are firmly fixed.

b. Check if the position of the master unit is

properly leveled.

c. The drain pipe should not curve upward

(Fig.5).

d. The drain pipe should be at the lower part

of the wall pipes (Fig. 5).

*

Installation fixture of outdoor unit

* Try to ship the product to the installation location in its original package;

* As the gravity center of the unit is not at the installation center, special caution should be taken

when using hoisting cables to lift it up;

* During shipping, the outdoor unit must not be slanted to over 45 degrees (Do not store the unit

in a horizontal way).

* Use expansion bolts to fix the mounting supports on the wall;

* Use bolts and nuts to fix the outdoor unit firmly on the supports and keep on the same level;

* If the unit is installed on the wall or at the rooftop, the supports have to be firmly fixed so as to

resist earthquake or strong wind.

*

Drain pipe

Connecting wires

Fig.5

Connecting pipe

Wall pipe

Drain pipe

Dimensions for parallel units installations

300mm(1')min

*

Pipelines connection

*

Ordinary pipelines connection (it is suitable for non-quick coupler)

No dust ,foreign articles,air or moisture should be allowed to enter the air conditioning system.Careful

attention should be paid when pipeline connection for outdoor unit is made.Try to avoid repeated

curves as much as possible,otherwise hardening or cracks might be caused to the copper pipes.Suitable

wrenches should be used when the pipeline connection is done so as to ensure appropriate torque(refer

to following torque Table 1).Excessive torque might damage the joints while too little torque might

lead to leakage.

*

4

Page 21

Table 1 Torque based upon the wrench to be used

Outer diameter of

copper pipe

6.35(1/4")

9.52(3/8")

12.7(1/2")

15.88(5/8")

19.05(3/4")

*

Special pipelines connection(it is suitable for quick coupler)

Tightening torque

160kgf.cm(63kgf.inch)

300kgf.cm(118kgf.inch)

500kgf.cm(197kgf.inch)

750kgf.cm(295kgf.inch)

1200kgf.cm(472kgf.inch)

Strengthened tightening torque

200kgf.cm(79kgf.inch)

350kgf.cm(138kgf.inch)

550kgf.cm(216kgf.inch)

800kgf.cm(315kgf.inch)

1400kgf.cm(551kgf.inch)

In case of the users purchasing the machine for quick

coupler,there is no need to do the air purging procedures

and the following pipeline connection procedures should

be adopted:

1.Remove the dust caps from the indoor and outdoor units,

and the connecting pipe.

2.Align the joint counter of connecting pipe with the proper

indoor and outdoor joint conic surfaces,tighten the connecting

nut manually.Then,make it secure with a wrench as shown

Fig. 6 ,applying to above torque Table 1.

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted air conditioner

Fig.6

Fig.7

3.Remove the two valve core caps from the outdoor unit.

4.Turn on the high and low pressure valve cores with an

socket wrench,then tighten the two valve core caps of the

outdoor unit (Fig.7).

5.Finally ,wrap the hot insulating cotton around the joints

of indoor and outdoor units.

*

Notes on installation of quick coupler:

1.Connecting pipe bending minimum radius parameters

(Table 2)

2.Quick coupler assembly and disassembly limit:

the assembly and disassembly times are inadvisably

more than 7.

5

Low pressure valve

High pressure valve

Table 2 Minimum bending radius

Normial

diameter(mm)

DN8(5/16")

DN10-12

(1/2")

DN14-16

(5/8")

Minimum bending

radius(mm)

80(3")

100(4")

150(6")

Quick coupler

(wrapping with insulating cotton)

Valve core cap

cooling capacity

2100~2300W

(7000~8000BTU)

2500~5100W

(9000~18000BTU)

6100~7000W

(22000~24000BTU)

Page 22

INSTALLATION & REPAIR GUIDE

Lo Hi

Split Wall-Mounted air conditioner

*

Air purging

*

Air purging with vacuum pump

*

1.Check that pipelines connection have been properly

connected,remove the charging port cap,and connect

the manifold gauge and the vacuum pump to the

charging valve by service hoses as shown Fig.8.

2.Open the valve of the low pressure side of manifold

gauge,then,run the vacuum pump.Vacuum the indoor

unit and the connecting pipes until the pressure in

them lowers to below 1.5mmHG(The operation time

for vacuuming is about 10 minutes).When the desired

vacuum is reached,close the valve of the low pressure

of the manifold and stop the vacuum pump.

3.Disconnect the service hoses and fit the cap to

the charging valve.

4.Remove the blank caps,and fully open the spindles

of the 2-way and 3-ways valves with a service valve

wrench.

5.Tighten the blank caps of the 2-way and 3-ways

valves,applying the above torque Table 1.

Indoor unit

Outdoor unit

Pressure gauge

Manifold gauge

Charging

port

3-way valve

2-way valve

Union nut

Blank cap

Valve stem

Service hose

*

Adding refrigerant

Vacuum pump

Refrigerant must be added if the piping measures more

than 5 metres(16'5") in length.This operation can only

be performed by a professional technician,for the

additional amount,see the table 3 below.

Table 3

Liquid pipe diameter 6.35(1/4")

(piping length-5)mx30g

or (piping length-16)ftx0.3oz

*

Gas leakage inspection

Additional refrigerant amount

Liquid pipe diameter: 9.52(3/8")

(piping length-5)mx65g

or (piping length-16)ftx0.7oz

Fig. 8

After the pipieline connection is done,use a leakage inspection device or soap suds to carefully check

if there is any leakage at the joints.This is an imporant step to ensure the quality of installation.Once

a leakage is detected,proper treatment should be taken immediately.

6

Page 23

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted air conditioner

*

Connection of power cable

1.Remove the drawer of the outdoor unit.

2.Non-quick coupler:connect the indoor power and control

wires with the matched outdoor wires in accordance

with the electric schematic diagram and make sure

that the connection is firmly done

Quick coupler:directly connect quick cable couplers with

indoor and outdoor quick cable couplers after disassembly

of the outdoor unit connecting box cover

3.Use a press plate to fix the wires firmly,and re-install

the drawer.

Note:Do not connect the wires in a wrong way,otherwise electric malfunctions will be caused and

even damages to the units will occur.The appliance shall be installed in accordance with national

wiring regulation.If the supply cord is damaged,it must be replaced by the manufacturer or its service

agent or a similarly qualified person in order to avoid a hazard.The plug shall be accessible after

installing the appliance.If the model have not plug that a switch which have a contact separation

of at least 3 mm(1/10") in all poles shalled be added in fixed wiring.

*

Finishing touches

* Use thermal tube to wrap the joints and wrap the tube tightly with ethylene tapes.

* Fix the wrapped pipelines on the exterior wall with clamps.

* Fill in the gaps left over by the pipeline hole and wall hole to prevent rain-water from entering.

*

Test running

* Connect to the power source,check if the function selection keys on the remote controller are

working properly.

* Check if the room temperature adjustments and timer settings are working properly.

* Check if the drain is smooth.

* Check if there is any abnormal noise or vibration during operation.

* Check if there is leakage of refrigerant.

*

Is the unit installed correctly?

*

Suitable Installation Position

*

Isn't there anything which prevents ventilation or obstructs operation in front of the indoor unit ?

Do not install the unit following place .

*

Inflammable gases may leak .

*

Oil splashes a lot .

*

In case where the unit is used in such places as poisonous or sultry gases are generated or seaside

district exposed to sea breezes corrosion may cause malfunction . Consult with your distributor .

*

Air conditioner body and remote controller must be I m(39-3/4") or more away from a TV or a radio.

Drain the dehumidified water from the indoor unit to a place which drains well .

*

(Fig.9).

*

*

(Fig.10).

*

Fig.9

Drawer

Fig.10

wire pressing plate

screw

*

Pay attention to operation noise

*

When installing the unit , choose a place which can stand the weight of the unit well and does

not increase the operation noise or vibration . Especially where there is a possibility that vibration

be transmitted to the house , fix the unit by inserting attached vibration -proof pads between the

unit and fittings .

7

Page 24

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted air conditioner

*

Choose the place where hot air and operation noise from the outlet of the outdoor unit do not annoy

the neighborhood .

*

Things left near the outlet and inlet of the outdoor unit cause malfunction or increased operation

noise . Do not leave obstacles near the outlet and inlet .

*

If irregular sound is heard during operation , consult with your distributor .

*

Inspection and Maintenance

*

According to the service conditions and operating environment , the inside of the air conditioner

will become dirty after several seasons (3 to 5years ) of service , resulting in decreased operating

performance .Inspection and maintenance are recommended in addition to usual cleaning (The

air conditioner can be used for a longer period and without anxiety .)

*

As to inspection and maintenance , consult your dealer or any one of business offices of dealing

companies .(Service charge is required in this case .)

*

We recommend to perform inspection and maintenance during an off seasons.

*Self Dia gnosis Functions*

Our company provides the thoughtful services for customer,air conditioners had been

installed self diagnosis system to display the information for the units.

Self-check

information

Hint to defrosting

Hint to defense

against cold wind

Failure of room

temperature sensor

Failure of coiled

pipe sensor

Abnormality of

outdoor unit

Without feedback of

internal fan motor

Zero crossing signal

without current

External feedback

failure

Overheat protection

Water pump failure

Self-check code of luminotron/

(Self-check code of running lamp)

Flicker 1 time/1s

Flicker 1 time/3s

Flicker 2 times/4s

(Flicker 2 times/8s)

Flicker 3 times/5s

(Flicker 1 time/8s)

Flicker 4 times/6s

(luminating)

Flicker 5 times/7s

(Flicker 6 times/8s)

Flicker 6 times/8s

Flicker 7 times/9s

Flicker 8 times/10s

Flicker 9 times/11s

Digital self-check code/

(Polychrome screen self-check code)

Indicates "dF"or defrosting

indicator displays

Fan motor picture not running

E2/(L2)

E3/(L1)

E4/(E5)

E5/(L6)

E6

E7

E8

E9

Note:Above self check information is commonly applicable in our most air conditioners,but some

are special,you can refer to the User's Manual for information or contact the dealer or authorized

maintenance people for help.

8

Page 25

Page 26

Page 27

Loading...

Loading...