Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

IN STALLATION & R EPAIR GUIDE

Split Wall-M ounted Air C onditioner

*

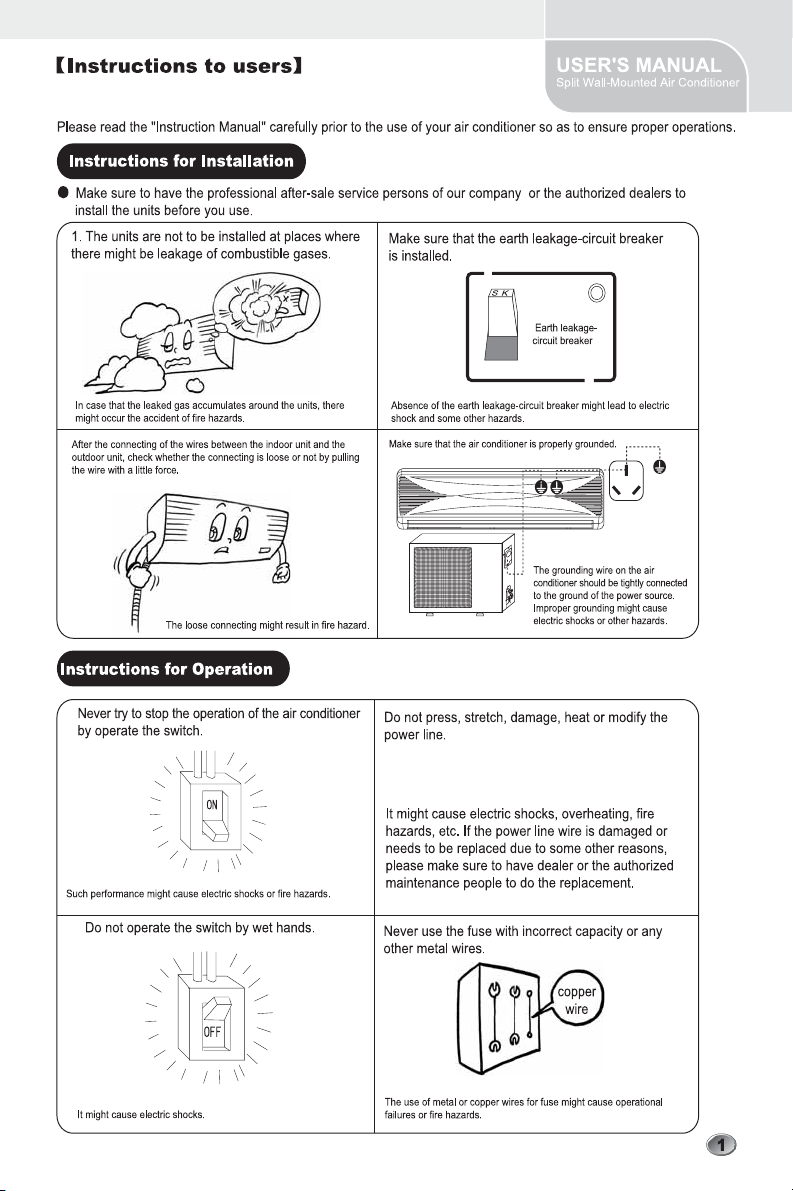

Selection of installation positions fo r indoor unit

*

*To be installed at the position w here the air deliver ed from the unit c an reac h ev ery cor ner of

the room ;

*To avoid being affected by the outdoor air;

*To avoid blockage to the air inlet or outlet of the unit;

*To avoid too

much oil sm oke or steam ;

*To avoid possible generation, inflow, lingering or leak age of flam m able gases ;

*To avoid high-frequency facilities (such as high frequency arc welders, etc.);

*To avoid the places where acid solutions are frequently us ed;

*To avoid t

he plac es w here som e special spr ay ers (sulfides) are frequently us ed.

*Not to install a fire alarming device near the air outlet of the unit (during operation, the fire alarm

device might be erroneously triggered by the war

*

M ake sure of enough space for installation and maintenance.

m air from the unit);

*To tak e into cons ideration the operational convenience and saf ety in installation, it is recom m ended

to ens ure enough spac e betw een the unit and the walls.

Ceiling

Above 100m m (4")

Left side: 150m m (6")

and above

Wall hanging plate

2300m m (7'6" )

and above

ground

*

Height limits of indoor and outdoor units.

*Either the indoor unit or the outdoor unit can be higher, but the height differenc e must com ply the stated

requirem ents.

*Try to reduce the bending of the piping line as much as possi ble so as to avoid possible negative im pacts upon the

orm ances of the units.

perf

Indoor unit

5m (16'5" )max.

outdoor

unit

Right side: 150m m (6")

and above

1

Page 15

INSTALLATION & REPAIR GUIDE

Split Wall-Mounted air c onditioner

*

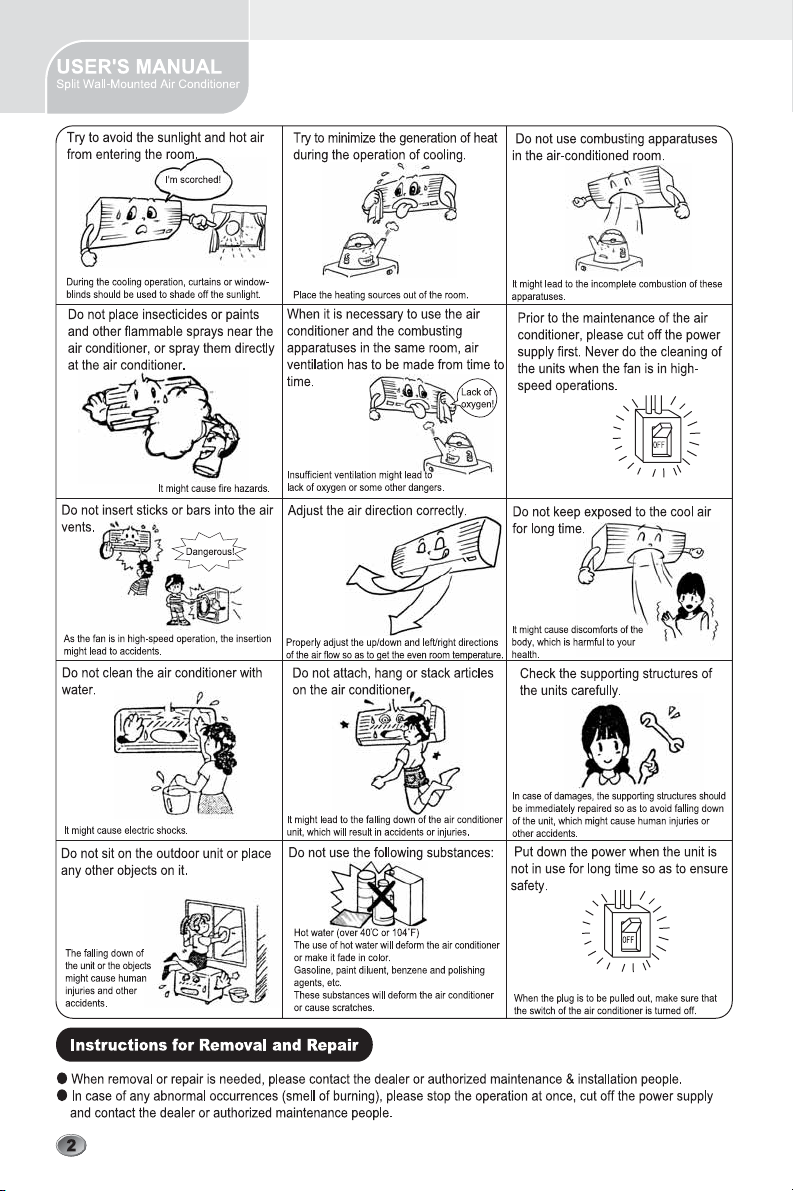

Selection of installation positions fo r outdoor unit

*

*To install the outdoor unit at the places which c an st and the load of the machine weight and will

not cause big vibrations and noises;

*To install the unit at the places not to be expos ed to rain or direc t sunshine, and the places with

good v entilation;

* The noises generated from the unit will not affect the neighboring plac es ;

*Do not install the unit on non-metal fram e;

*Not to install the unit at the places w here there might occur the generation, inflow, stay or

leakage of inflam m able gas es ;

*Pay attention to the drainage of the condensed water from the base plate during operations ;

*To avoid the air outlet being directly against the wind.

Detailed spac e requirem ents around the outdoor unit

1. W hen there are obstacles above

the unit

100mm(4") min

500mm(1'8") min

4. W hen there are obstacles at the front and rear sides.

2. W hen the front (air outlet) is open 3. W hen there are obstacles only in

200mm(8") min

200mm(8") min

300mm(1') min

100mm(4") min

1000mm(3'4") min

the front (air outlet)

500mm(1'8") min

Space for maintenance

Shown as in the follow ing figure. K eep

the maintenance

unit.

200mm

(8")min

5. W hen there are obstacles all ar ound

the unit on four sides.

Although the top side is open, the

installation is not to be done if there

are obstacles all ar ound.

spac e in front of the

500mm

Space for maintenance

(1'8")min

500mm(1'8") min

*At least two sides should

be kept open.

2

Page 16

*

In s ta llation fixture of indoor unit

IN STALLATION & R EPAIR GUIDE

Split Wall-M ounted air conditioner

*

Pipelines c an be connected in the directions of****

****and

*as indicated in Fig.1. W hen the pipelines

are connected to the direc tions of***and

*, a groov e

for the pipes has to be opened at the proper place on

the bas e stand.

1.Installation of wall-m ounting plate

Fix the wall-m ounting plate firmly on the wall with scr ews.

Make sur e of the leveling of the plate. Slanted wall-m ounting

plate might jeopardize the s m ooth disc harge of the c ondens ed

water.

2.Drill holes on the wall

Drill holes at places slightly below the wall-m ounting plate,

with hole diam eter of 65mm(2-3/5") and the outer edge of

the hole 5-10mm(1/5-2/5") low er (Fig.2) so that the condensed

water can sm oothly flow out. Cut the wall penetrating pipe

to proper length accor ding to the thickness of the wall (35mm(1/10-1/5") longer than the wall thickness) and insert

the pipe as indicated in Fig.2.

3.Installation of drain pipe

Ins tall the pipelines of the indoor unit in accor danc e with

the direction of the wall holes. Wrap tightly the drain pipe

and the pipelines with tape. Make sur e that the drain pipe

is underneath the pipelines. (Fig.3) (W hen the drain pipe

passes the room interior, som e c ondens ed water might

occur to its sur faces if the hum idity is ver y high).

Fig.1

*Right outlet

Fig.2

Wall cap

Fig.3

*Bottom outlet

Fix with a tape

Wall pipe

Drain pipe

*Rear outlet

Int erior

*Left out let

*Left rear outlet

5-10mm low er

(1/5-2/5" )

Wall

Exterior

Pipelines of indoor unit

Rear pipe

4.Installation of indoor unit

Pass the connec tion wires, c onnec ting pipelines and drain

pipe through the wall hole. Hang the indoor unit on the

hooks at the top of the wall-m ounting plate so that the

hooks at the bottom of the indoor unit match the hooks of

the wall-m ounting plate. (Fig.4)

3

Fig.4

Bottom hooks

Top hooks

Hook s upports

Page 17

IN STALLATION & R EPAIR GUIDE

Split Wall-Mounted air c onditioner

Inspections:

a. C heck if the hooks at the top and bottom

are firmly fixed.

b. C heck if the position of the master unit is

properly leveled.

c. The drain pipe should not cur ve upward

(Fig.5).

d. The drain pipe

of the wall pipes (Fig. 5).

*

In s ta llation fixture of outdoor unit

*Try to ship the product to the installation location in its original pack age;

*As the gravity center of the unit is not at the installation center, s pec ial caution should be taken

when using hoist ing c ables to lift i

*During shipping, the outdoor unit must not be slanted to over 45 degrees (Do not store the unit

in a horizontal way).

*Use expans ion bolts to fix the m ounting supports on the wall;

*Use bolts and nuts to fix the outdoor unit

*If the unit is ins talled on the wall or at the rooftop, the supports hav e to be firmly fixed so as to

resist earthquake or strong wind.

should be at the lower part

*

t up;

firmly on the s upports and keep on the sam e lev el;

Drai n pi pe

Connecting wires

Fig.5

Connecting pipe

Wall pipe

Drai n pi pe

Dim ensions for parallel units installations

300m m (1')min

*

Pipelines connection

*

Ordinary pipelines connection (it is suitable for non-quick coupler)

No dust ,foreign articles,air or moisture s hould be allow ed to enter the air conditioning system .Careful

attention should be paid when pipeline connection for outdoor unit is m ade.Try t

cur ves as much as possi ble,otherwise hardening or cr acks might be caused to the copper pipes.Suitable

wrenches should be used w hen the pipeline connection is done so as to ensure appr opriate torque(refer

to follow ing torque Table 1).Excessive torque might

lead to leakage.

*

o avoid repeated

dam age the joints while too little torque might

4

Page 18

Table 1 Torque bas ed upon the wrenc h to be used

Outer diam eter of

copper pipe

6.35(1/4")

9.52(3/8")

12.7(1/2")

15.88(5/8")

19.05(3/4")

*

Special pipelines connection(it is suitable for quick c oupler)

Tightening torque

160kgf.cm ( 63kgf.inch)

300kgf.cm ( 118kgf.inch)

500kgf.cm ( 197kgf.inch)

750kgf.cm ( 295kgf.inch)

1200kgf.cm ( 472kgf.inch)

Strengthened tightening torque

200kgf.cm ( 79kgf.inch)

350kgf.cm ( 138kgf.inch)

550kgf.cm ( 216kgf.inch)

800kgf.cm ( 315kgf.inch)

1400kgf.cm ( 551kgf.inch)

In case of the users purc has ing the machine for quick

coupler,there is no need to do the air purging proc edures

and the follow ing pipeline connec tion procedures should

be adopted:

IN STALLATION & R EPAIR GUIDE

Split Wall-M ounted air conditioner

Fig.6

1.Remove the dus t caps from the indoor and out

door units,

and the c onnec ting pipe.

2.Align the joint counter of c onnec ting pipe with the proper

indoor and outdoor joint c onic sur faces,tighten the connecting

nut m anually.Then,make it secur e with a wrench as shown

Fig. 6 ,applying to above torque Table

1.

3.Remove the two valve cor e c aps from the outdoor unit.

4.Turn on the high and low pressur e valve cor es with an

socket wrench,then tighten the two valve cor e caps of the

outdoor unit (Fig.7).

5.Finally ,wrap the hot insulating cot ton around the joints

of indoor and outdoor units.

*

Notes on installation of quick coupler:

1.Connecting pipe bending minimum radius param eters

(Table 2)

2.Quick c oupler assem bly and disassem bly limit:

the assem bly and disassem bly times are inadv isably

more than 7.

5

Fig.7

Low pressure val ve

High pressure val ve

Table 2 Minimum bending radius

Normial

diam eter(mm)

DN8(5/16")

DN 10- 12

(1/2" )

DN 14- 16

(5/8" )

Minimum bending

radius(mm)

80(3")

100(4")

150(6")

Quick c oupler

(wrapping with insulating cot ton)

Valve cor e cap

cooling capacity

2100~2300W

(7000~8000BTU )

2500~5100W

(9000~18000BTU )

6100~7000W

(22000~24000BTU )

Page 19

IN STALLATION & R EPAIR GUIDE

Lo Hi

Split Wall-M ounted air conditioner

*

Air purging

*

Air purging with vacuum pum p

*

1.C heck that pipelines connec tion have been properly

connec ted,rem ove the charging port cap,and connect

the m anifold gauge and the vacuum pum p to the

charging valve by ser vice hoses as s hown Fig.8.

2.O pen the valve of the low pressur e side of m anifold

gauge,then,run the vacuum pum p.Vacuum the i

ndoor

unit and the c onnec ting pipes until the pressur e in

them low ers to below 1.5mmHG(The operation time

for vacuum ing is about 10 minutes ).W hen the desired

vacuum is reached,close the valve of the low pressur e

of the m anifold and stop the vacuum pum p.

3.Disconnec t the ser vice hos es and fit the cap to

the c harging valve.

4.Remove the blank caps ,and fully open the spindles

of the 2-way and 3-w ays valves with a service valve

wrench.

5.Tighten the blank caps of the 2-way and 3-w ays

valves,applying the above torque Table 1.

Indoor unit

Outdoor unit

Pressur e gauge

M anifold gauge

Charging

port

3-way valve

2-way valve

Union nut

Blank cap

Valve stem

Service hose

*

Adding re frigerant

Vacuum pum p

Refrigerant must be added if the piping m easures more

than 5 metres(16'5") in length.This operation can only

be perform ed by a professional technician,for the

additional am ount,see the table 3 below .

Table 3

Liquid pipe diam eter 6.35(1/4")

(p i ping length-5)m x30g

or (p iping length-16)ftx0.3oz

*

G as leakage inspection

Additional refrigerant am ount

Liquid pipe diam eter:

(p i ping length-5)m x65g

or (p iping length-16)ftx0.7oz

9.52(3/8")

Fig. 8

After the pipieline c onnec tion is done,use a leakage inspection device or soap s uds to car efully check

if there is any leakage at the joints.This is an im porant step to ensure the quality of ins tallation.Once

a leakage is detected,proper t

reatm ent should be taken im m ediately.

6

Page 20

IN STALLATION & R EPAIR GUIDE

Split Wall-M ounted air conditioner

*

C onnection of pow er cable

1.Remove the draw er of the outdoor unit.

2.Non-quick coupler:connec t the indoor pow er and control

wires with the matched outdoor wires in accor danc e

with the electric schem atic diagram and make sur e

that the connec tion is firmly done

Quick coupler :directl

indoor and outdoor quick cable couplers after disassem bly

of the outdoor unit connec ting box cover

3.Use a press plate to fix the wires firmly,and re-install

the draw er.

Note:Do not c onnec t the wires in a wrong way,otherwise electric malfunc tions will be caus ed and

even dam ages to the units will occur .The appliance s hall be inst

wiring regulation.If the supply cor d is dam aged,it must be replaced by the m anufacturer or its ser vice

agent or a similarly qualified pers on in order to avoid a hazard.The plug shall be accessible af

installing the applianc e.If the m odel have not plug that a sw itch which hav e a contact separation

of at leas t 3 mm(1/10") in all poles s halled be added in fix ed wiring.

*

Finishing touches

*Use thermal tube to wrap the joints and wrap the tube tightly with ethy lene tapes.

*Fix the wrapped pipelines on the exterior wall with clam ps.

*Fill in the gaps left over by the pipeline hole and wall hole to prevent rain-water from entering.

*

Test running

* Connect to the pow er source, check if the function selection keys on the rem ote controller are

working properly.

* C heck if the room tem perature adjustm ents and timer settings are working properly.

* C heck if the drain is sm ooth.

* C heck if there is any abnormal noise or vibration during operation.

* C heck if there is leakage of refrigerant.

*

Is the unit installed correctly?

*

Suitable Installation Position

*

Isn't there anything which prev ents ventilation or obstructs operation in front of the indoor unit ?

Do not install the unit following plac e .

*

Inflam m able gases may leak .

*

Oil splashes a lot .

*

In case where the unit is used in such places as poisonous or sultry gases are generated or s easide

dist rict expos ed to sea breezes cor ros ion may cause malfunction . C onsult with y our dist ributor .

*

Air conditioner body and rem ote c ontroller must be I m(39-3/4") or more aw ay from a TV or a radio.

Drain the dehum idified water from the indoor unit to a place which drains well .

y connect quick cable couplers with

*

(Fig.9).

*

*

(Fig.10).

*

Fig.9

wire pressing plate

Drawer

screw

Fig.10

alled in accor dance with national

ter

*

Pay attention to operation noise

*

W hen ins talling the unit , choose a place which c an stand the weight of the unit well and does

not increase the operation noise or vibration . E s pec ially w here there is a possibility that vibration

be trans m itted to the house ,

unit and fittings .

fix the unit by inserting attac hed vibration -proof pads between the

7

Page 21

IN STALLATION & R EPAIR GUIDE

Split Wall-M ounted air conditioner

*

Choose the place w here hot air and operation noise from the outlet of the outdoor unit do not annoy

the neighborhood .

*

Things left near the outlet and inlet of the outdoor unit caus e malfunc tion or increased operation

noise . Do not leave obstacles near the outlet and inlet .

*

If irregular sound is heard during operation , consult with y our dist ributor .

*

Inspection and Maintenance

*

Accor ding to the ser vice conditions and operating environm ent , the inside of the air conditioner

will bec om e dirty after sever al seas ons (3 to 5years ) of ser vice , resulting in decreased operating

perform ance .Inspec tion and maintenance are recom m ended in addition to us ual cleaning (The

air conditioner can be used for a longer period and without anxiety .)

*

As to inspection and maintenance , consult your dealer or any one of business offices of dealing

com panies .(Service c harge is required in this case .)

*

We recom m end to perform inspection and maintenanc e during an off s eas ons .

*

Sel f Diagnosis Funct ions

*

Our com pany prov ides the thoughtful ser vices for custom er,air conditioners had been

installed self diagnosis system to display the information for the units.

Self-c heck

information

Hint to defrosting

Hint to defense

against cold wind

Failure of room

tem perature s ens or

Failure of coiled

pipe sensor

Abnormality of

outdoor unit

Without feedback of

internal fan motor

Zero cr ossing signal

without cur rent

External feedbac k

failure

Overheatprotection

Water pum p failure

Self-check c ode of lum inotron/

(Self-check c ode of running lam p)

Flicker 1 time/1s

Flicker 1 time/3s

Flicker 2 times/4s

(Flicker 2 times/8s)

Flicker 3 times/5s

(Flicker 1 time/8s)

Flicker 4 times/6s

(lum inating)

Flicker 5 times/7s

(Flicker 6 times/8s)

6 times/8s

Flicker

Flicker 7 times/9s

Flicker 8 times/10s

Flicker 9 times/11s

Digital self-check c ode/

(Polychr om e scr een self-check c ode)

Indicates "dF"or defro s ting

indicat or displays

Fan motor pict ure not running

E2/(L2)

E3/(L1)

E4/(E5)

E5/(L6)

E6

E7

E8

E9

Note:A bov e self check information is com m only applicable in our most air c onditioners,but som e

are special,you can refer to the User's M anual for information or contact the dealer or authorized

maintenanc e people for help.

8

Page 22

Page 23

Page 24

Loading...

Loading...