Page 1

Qí

Ш

Z

AWM093HX

AWM123HX

о

ь

Û

Z

о

U

—

<

Q_

CO

AOM183HX

(match AWM093HX+AWM093HX)

U

_ AOM243HX

Installation manual (match AWM123HX+AWM123HX or AWM093HX+AWM123HX)

www.amcorgroupusa.com

Page 2

Page 3

Foreword

This instruction Manual is the universal-purpose version for the models of separate wall-mounted

air conditioners manufactured by our Co.The appearance of the units that you purchase might be

slightly different from the ones described in the Manual, but it does not affect your proper

operations and usage.

Please read carefully the sections corresponding to the specific model you choose,and keep the

Manual properly so as to facilitate your reference at later time.

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards.

As the installer or service person , it is an important part of your job to install or service the system

so it operates safely and efficiently.

For safe installation and trouble-free operation.you must:

• Carefully read this instruction booklet before beginning.

• Follow each installation or repair step exactly as shown.

• Observe all local,state,and national electrical codes.

• Pay close attention to all danger,warning,and caution notices given in this manual.

WARNINGiThis symbol refers to a hazard or unsafe practice which can result in severe personal

injury or death.

CAUTION:This symbol refers to a hazard or unsafe practice which can result in personal injury

and the potential for product or property damage.

CONTENTS

SELECTING THE MOUNTING POSITION 1

INSTALLATION DIAGRAM OF INDOOR UNITS 2

FINISHING 6

FRONT PANEL REMOVALAND INSTALLATION 8

LOCATION OF OUTDOOR UNIT 9

ELECTRICAL CONNECTION BETWEEN OUTDOORAND INDOORUNIT 10

INSTALLATION/SERVICE TOOLS (ONLY FOR R41OA PRODUCT 12

REFRIGERANTTUBING 14

THE INTRODUCTION OF THE ROTATIONAL ADAPTER: 15

AIRPURGING 16

SELF DIAGNOSIS FUNTIONS 18

WIRE DIAGRAM 19-21

Page 4

This Split Air Conditioner is designed for versatile

application :

Cooling & Heating

Dehumidifying

Ventilation

Filtration

IMPORTANT NOTICE :

• This air œnditioner must be grounded to protect against electrical

shock.

• Installation of the air conditioner must be performed by an

experienced air conditioning installer, observing good

refrigeration practice.

• Failure to comply with the manufacturer's installation and

operation installation and operation instructions could affect

the performance of the air conditioner and the validity of the

warranty.

Page 5

SELECTING THE MOUNTING POSITION

Decide the mounting position with the customer as

foilows:

INDOOR UNIT

(1 ) Install the indoor unit level on a strong wall which is not subject

to vibration.

(2) The inlet and outlet ports should not be obstructed : the air

should be able to blow all over the room.

(3) Do not install the unit where it will be exposed to direct sunlight.

(4) Install the unit where connection to the outdoor unit is easy.

(5) Install the unit where the drain pipe can be easily installed.

(6) Take servicing,etc.into consideration and leave the spaces

shown in figure. Also install the unit where the filter can be

removed.

!\ WARNING

Install at a place that can withstand the weight of the indoor

and outdoor units and install positively so that the units will

not topple or fall.

CAUTION

(1) Do not install where there is the danger of combustible gas

leakage.

(2) Do not install near heat sources.

(3) If children under 10years old may approach the unit, take

preventive measures so that they cannot reach the unit.

Page 6

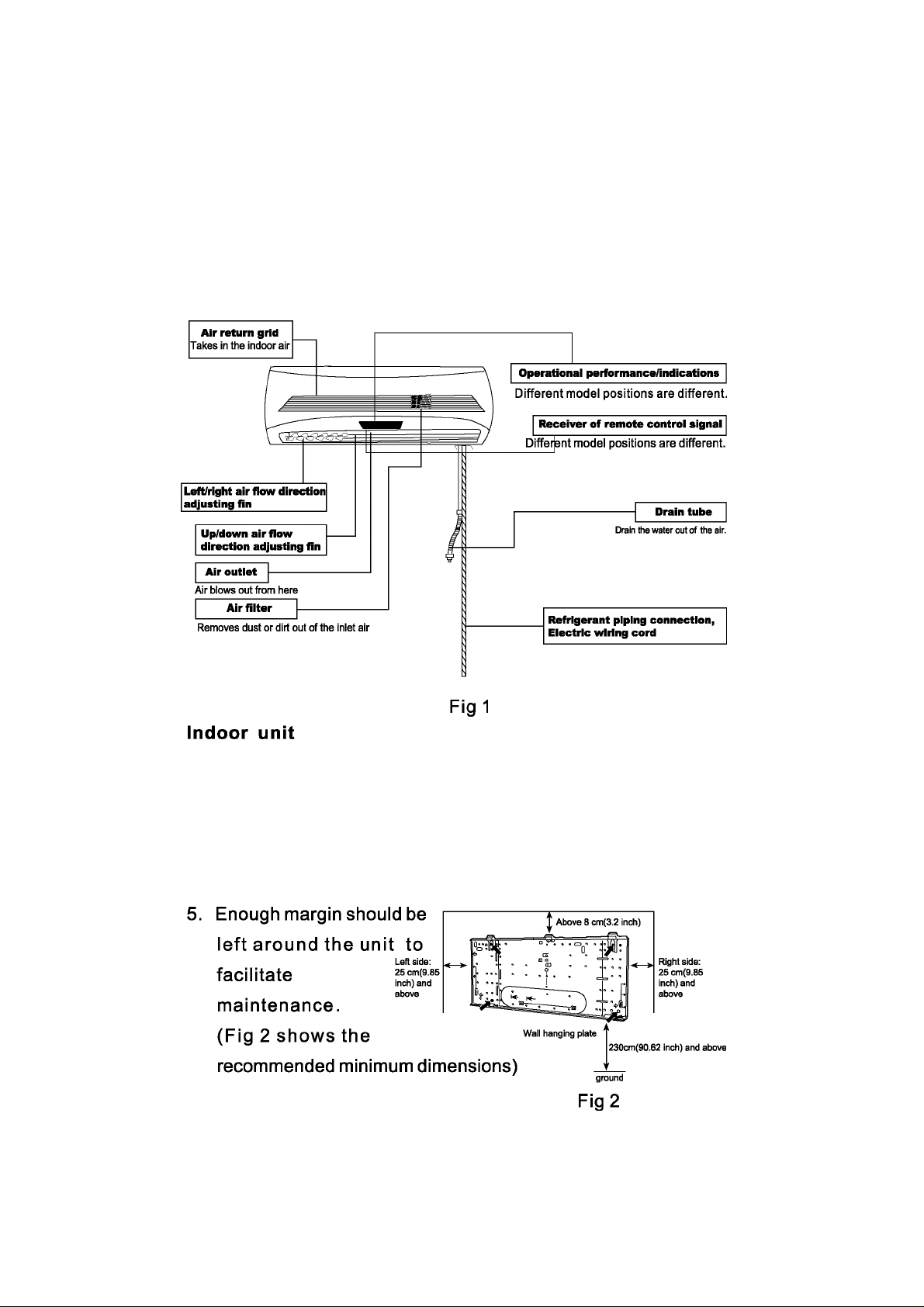

INSTALLATION DIAGRAM OF INDOOR UNITS

Wall-mounted Type

1. Firmly install it on the rigid wall.

2. The air intake and outlet vents should be unblocked, and the

cold air can be blown to the whole room.

3. Away from thermal sources or sources of combustible gases.

4. Not exposed to direct sunlight.

Ceiling

Page 7

Installation of wall-mounting plate

Fix the wall-mounting plate firmly on the wall with screws.Make

sure of the leveling of the place. Slanted wall-mounting plate

might jeopardize the smooth discharge of condensed water.

1. Drill holes on the wall

Drill holes places slightly below the wall-mounting plate,with

hole diameter of 65mm and the outer

Fix with a tapi

edge of the hole 5-10mm lower (

Fig3) so that the condensed water

can smoothly flow out. Cut the waiicap-

wall penetrating pipe to proper

length according to the thickness

Fig3

/1 Exterior

of the wall(3-5mm longer than

the wall thickness)and insert the pipe as indicated in Fig 4.

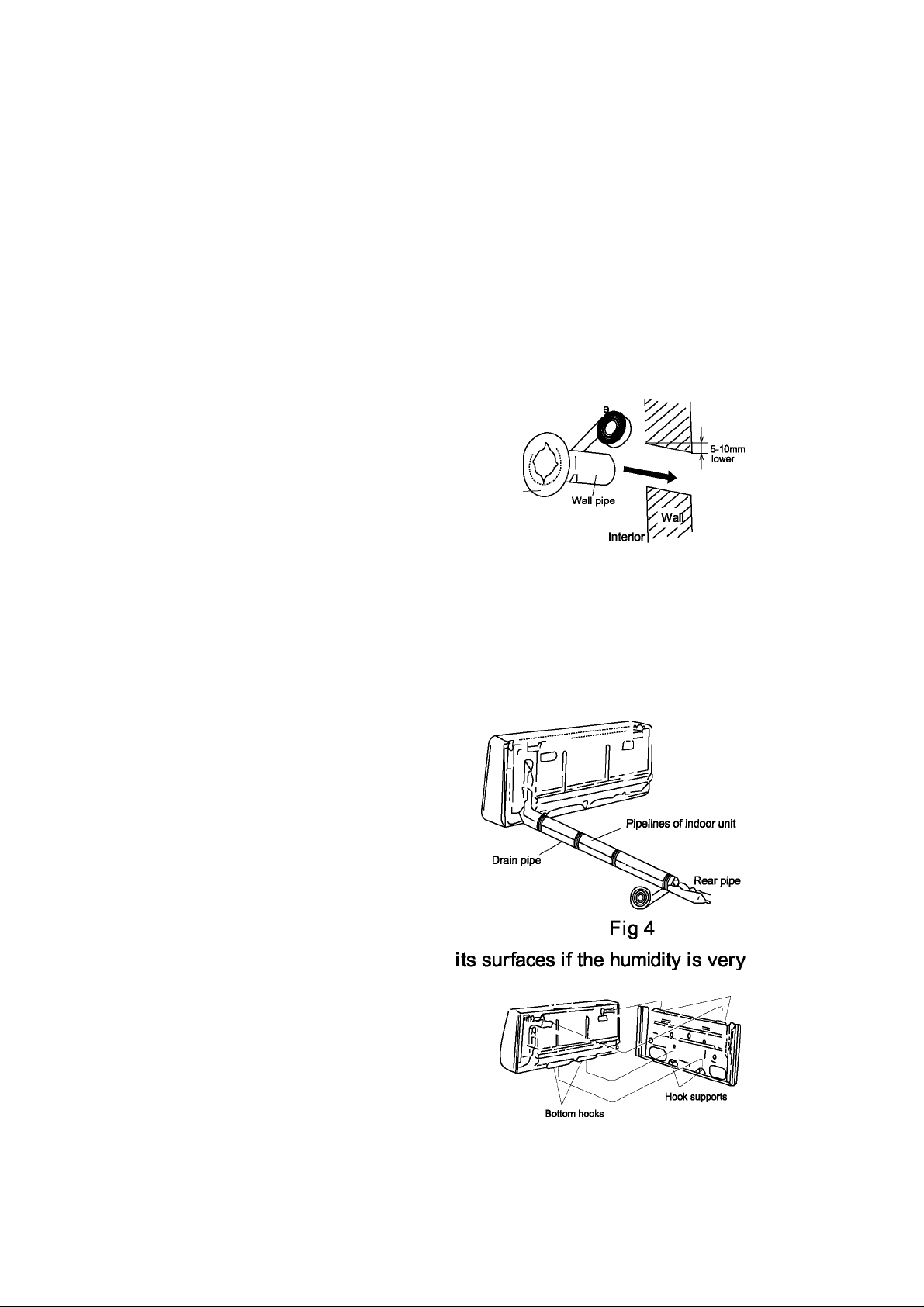

2. Installation of drain pipe

Install the pipelines of the indoor unit in accordance with the

direction of the wall holes.

Wrap tightly the drain pipe

and the pipelines with tape.

Make sure that the drain pipe

is underneath the pipelines ,

(Fig 4)(When the drain pipe

passes the room interior, so me

condensed water might occur to

high).

3. Installation of indoor unit pass

the connection wires,connecting

pipelines and drain pipe through

the wall hole.Hang the indoor unit pjg 5

Top hooks

Page 8

on the hooks at the top of the wall-mounting plate so that the

hooks at the bottom of the indoor unit match the hooks of the

wall-mounting plate. (Fig 5)

Inspections:

a. See if the hooks at the top and bottom are firmly fixed.

b. See if the position of the master unit is

properly leveled.

c. The drain pipe should not curve

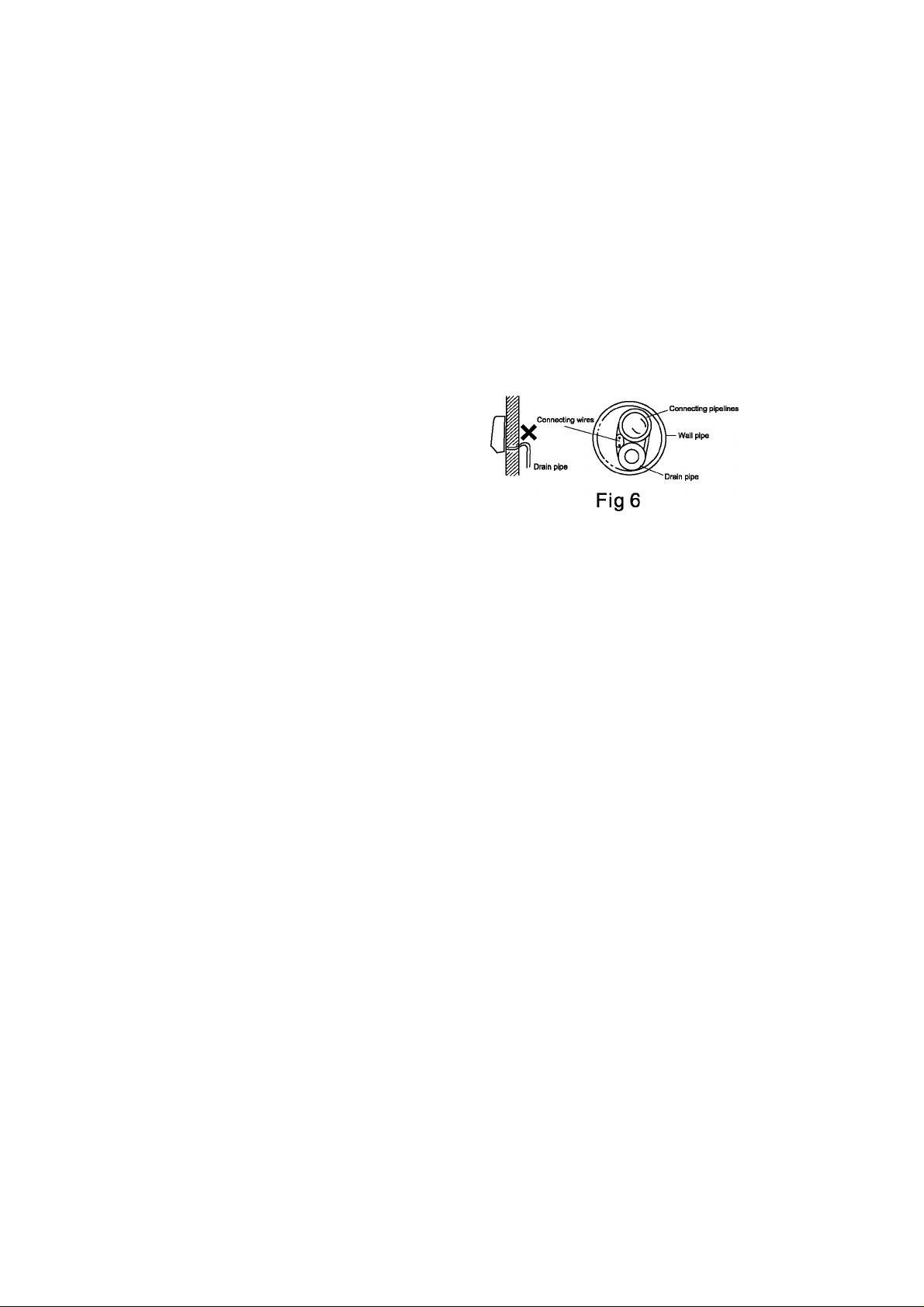

upward( Fig 6).

d. The drain pipe should be at the

lower part of the wall pipes(Fig 6).

4. Wire connections of indoor and outsoor units connect the wires

of the indoor and outdoor units properly according to the schematic

diagram.

Note: Do not connect the wires in a wrong way, otherwise electric

malfunctions will be caused and ever damages to the units will

occur.

The appliance is fitted with means for disconnection from the

supply mains having a contact separation in all poles that provide

full disconnection under over voltage category III conditions,

and these means must be incorporated in the fixed wiring in

accordance with the wiring rules.

Page 9

Installation of the connection pipe

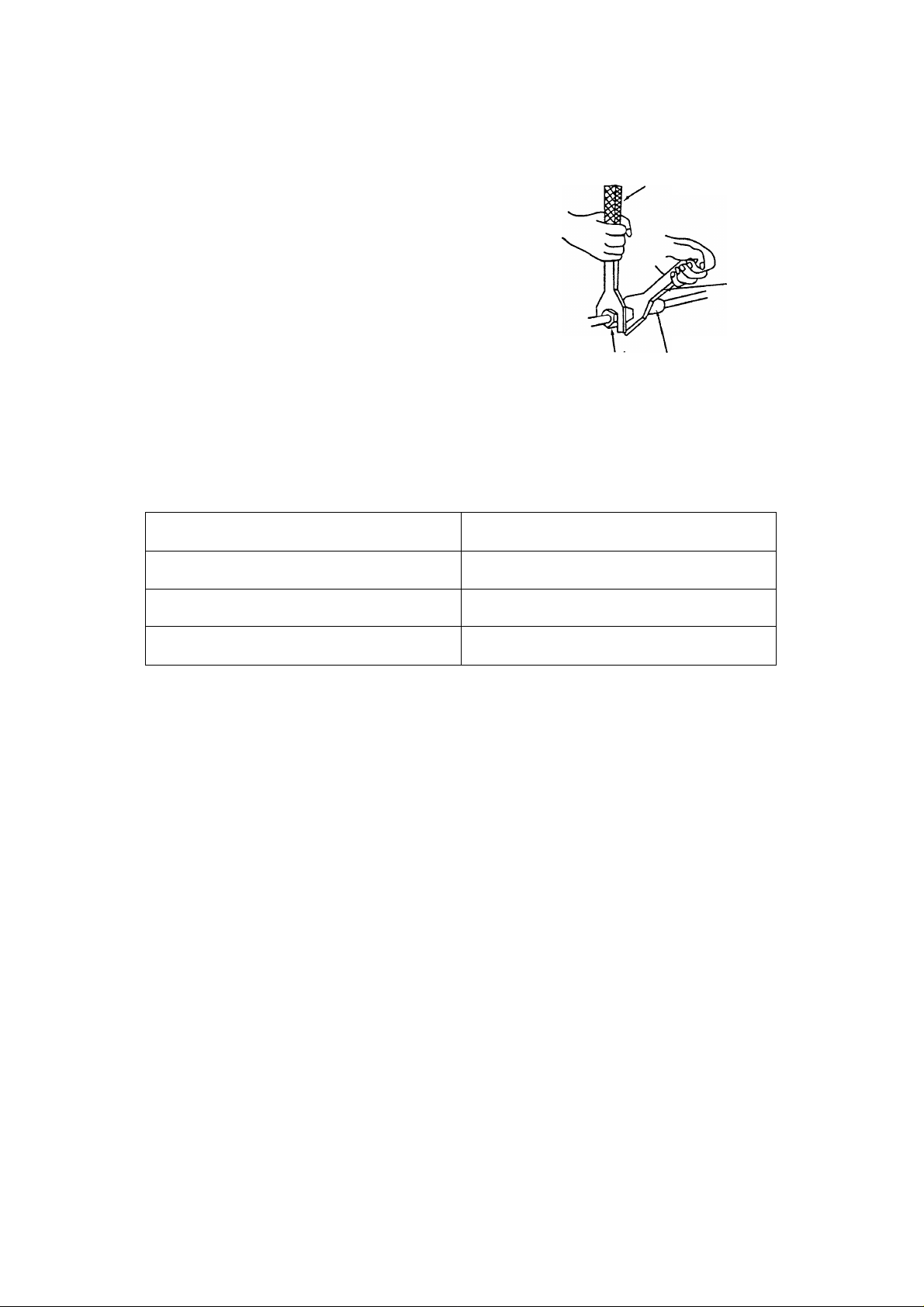

1. Align the center of the piping flare

with the relevant valve.

Torque wrench

2. Screw in the flare nut by hand and

Spanner

then tighter the nut with spanner and

torque wrench refer to the diagram

at right.

Nut of

connection pipe

Fig?

Joint

Note: Exceeding tightening torque will damage the flare surface.

Tightening torque table

Hex nut diameter

4>6mm(1/4")

4)9.5mm(3/8")

4)12mm(1/2 ")

Tightening torque(N.m)

15-20

31-35

50-55

Page 10

FINISHING

1. Insulate between pipes.

• For rear,right,and beween piping,overlap

the connection pipe heat insulation and

indoor unit pipe heat insulation and bind

them with vinyl tape so that there is no gap.

• Forleftand left rear piping,butthe connection

pipe heat insulation and indoor unit pipe

heat insulation together and bind them

with vinyl tape so that there is no gap .

• For left and left rear piping , bundle the

(Saddle)

P i pe

piping and drain hose together by wrapping

them with cloth tape over the range within

which they fit into the rear piping hosing

section.

2. Temporarily fasten the connection cord

along the connection pipe with vinyl tape.(

Wrap to about 1/3 the width of the tape

the bottom of the pipe so that water does not

enter.)

3. Fasten the connection pipe to the outside

wall with a saddle etc.

4. Fill the gap between the outside wall pipe

hole and the pipe with sealer so that rain

water and wind cannot blow in.

Connection^^e

So that there is no gap.

P i pe

(Outdoors)

Over lapthe insulation

vinyl tape

with

0 I oth tape

Cloth tape

5. Fasten the drain hose to the outside wall,

etc.

©

Page 11

For connection from the left rear Check the following: View from indoors

BAD BAD

©

Page 12

FRONT PANEL REMOVAL AND INSTALLATION

AIR CLEANING UNIT REMOVAL

1. Open the intake grille ,and then remove the right air filter.

2. Pull the air cleaning unit grip in the direction of the arrow and

remove the unit.

AIR CLEANING UNIT INSTALLATION

1. Open the intake grille, and then insert the dust collection unit

into the indoor unit.

2. Install the right air filter, and then close the intake grille.

THE INTAKE GRILLE REMOVAL

1. Open the intake grille.

2. Pull down the knob.

3. Lift the intake grille upward, until the axle at the top of the intake

grille is removed .

THE INTAKE GRILLE INSTALLATION

1. The fixing axle of the intake grille is installed on the Panel.

2. Lay down the intake grille.

THE FRONT PANEL REMOVAL

1. Remove intake grille (Reference the intake grille removal.)

2. Remove four screws.

3. The thumb is hung on the lower part as shown in the figure ,

and it pulls to the front, pushing [ V ] mark,and bottom hooks (

two position)is removed from wall hook bracket.

4. The front panel bottom is pulled to the front, and bottom hooks

is removed indoor unit.

5. The front panel is pulled to the front, raising the upper surface,

and a front panel is removed.

THE FRONT PANEL INSTALLATION

1. Firstly, fit the lower part of the front panel,and insert top and

bottom hooks.(Three top sides, six bottom sides)

2. Four screws is attached.

3. The intake grille is attached.

Page 13

LOCATION OF OUTDOOR UNIT

Select the location considering the foiiowing:

OUTDOOR UNIT

1 .The location must allow easy servicing and provide good air circulation as shown in f i g 8.

2.The unit may be suspended from a wall by a bracked(Optional)or located in a free standing

position on the flooripreferably slightly elevated).

3.lf the unit is suspended , ensure that the bracket is firmly connected and the wall is strong

enough to withstand vibrations.

4. Unit location should not disturb neighbours with noise or exhaust air stream.

5. Place the mounting pads under the unit legs.

6. Refer to figuregfor allowed installation distances.

25mm(82FT)

L,+L2^30m(100FT)

H„H2^10m(33FT)

Fig 8

L„L„L3^25m(82FT)

L,+L2+L3^50m(164FT)

H,,H2,H3^10m(33FT)

Page 14

ELECTRICAL CONNECTION BETWEEN

OUTDOOR AND INDOOR UNIT

ELECTRICAL REQUIREMENTS

Electrical wiring and connections should be made by qualified electricians and in accordance

with local electrical codes and regulation.The air conditioner units must be grounded.

The air conditioner units must be connected to an adequate power outlet from a separate

branch circuit protected by atimedelay circuit breaker, as specified on unit's nameplate.

Voltage should not vary beyond ± 10% of the rated voltage.

1 .Remove the power supply cable that is connected to the indoor unit!

2. To connect the indoor units to the outdoor units,use the foiiowing eiectrical cabies.

Electrical connections:

Power input cable: 1 group 3wiresX14AWG

cable between indoor and

outdoor units: 2 group 4 wiresX14AWG(some modeis are 2 group 2 wiresX14AWG)

3. Prepare the cable ends for the power input and for the cables between outdoor and indoor

units as shown in figure 3a and 3b respectively.

4. Connect the cable ends to the terminals of the indoor and outdoor units , as show in fig4, figS.

Please select corresponding connection according to the different indoor units.

5.Secure the multiple wire power cable with the cable clamps.

•Power input cable

8mm

(0.315inch).

L«25m(81.9673FT)

U25m(81.9673FT)

L«25m(81.9673FT)

8mm

J

(0.315inch)

100mm

(3.937inch)

Fig 12

40mm _wR

(1.575inch)

Page 15

For North America Model: Fig 13.14

Electrical connections:

Power input cable: 1 group 3 wiresX14AWG

cable between indoor an outdoor units: 2group4wiresX14AWG

This figure adapt to AOM183HX(AWM093HX+AWM093HX)

Electrical connections:

Power input cable: 1 group 3 wiresX 14AWG

cable between indoor and outdoor units: 2 group 2 wiresXI4AWG

This figure adapt to AOM243HX(AWM123HX+AWM123HX or AWM093HX+AWM123HX)

Page 16

INSTALLATION/SERVICE TOOLS(QNLY FOR R410A PRODUCT)

CAUTION

New Refrigerant Air Conditioner Installation

This air conditioner adopts the new MFC refrigerant (R41OA) which does not destroy ozone layer.

R41 OA refrigerant is approx . 1.6 times of refigerant R22. Accompanied with the adoption of the

new refrigerant, the refrigeration machine oil has also been changed.

Therefore,during installation work, be sure that water, dust, former refrigerant, or refrigeration

machine oil does not enter into the new type refrigerant R41 OA air conditioner circuit.The system

must not be left open to the atmosphere for any reason for any period of time as the systems oil

quickly absorbs moisture and will contaminate and damage the system.

A refrigerant liquid line drier is recommended.

To prevent mixing of refrigerant or refrigerating machine oil ,the sizes of connoting sections of

charging port on main unit and installation tools are different from those used for the conventional

refrigerant units. Accordingly,special tools are required forthe new refrigerant (R410A) units.

For connecting pipes use new and clean piping materials with high pressure fitting made for

R41 OA only, so that water and/or dust does not enter. Moreover, do not use the existing piping

becausetherearesomeproblemswithpresure fittings and possible impurities in existing

piping .

Changes in the product and components

In air conditioners using R41 OA ,in order to prevent any other refrigerant from being accedentally

charged .the service port diameter size of the outdoor unit control valve (3 way valve ) has been

changed. (1/2 UFN 20 threads per inch)

• In order to increase the pressure resisting strength of the refrigerant piping ,flare processing

diameter and opposing flare nuts sizes have been changed.! fot copper pipes with nomensions

1/2 and 5/8)

Page 17

New tools for R410A

Nes tools for R410A

Chages

As the working pressure is high , it is impossible to measure the

Gauge manifold

working pressure using conventional gauges. In order to prevent

any other refrigerant from being charged,any other refrigerant

from being charged, the port diameters have been changed.

In order to increase pessure resisting strength, hose materials

Charge hose

and port sizes have been changed(to 1/2 UNF 20 threads

per inch).When puchasing a charge hose,be sure to confirm

the port size.

Electronic balance for refrigerant

charging

As working pressure is high and gasification speed is faft,

it is difficuit to read the indicated value by means of

charging cylinder ,as air bubbles occur.

The size of opposing flare nuts have been increased ,

Torque wrench (nominal dia.1/4,3/8)

incidentally,a common wrench is used for nominal

diameters 1/4 and 3/8.

Flare tooKclutch type)

By increasing the clamp bar'receiving hole size , strength

of spring in the tool has been improved.

Gauge for projection adjustment Used when flare is made by using conventional flare tool.

Connected to conventional vacuum pump,it is necessary to use an adapter

to prevent vacuum pump oil from flowing back into the charge hose , The

Vacuum pump adapter

charge hose connecting part has two ports-one for conventional refrigerant

(7/16 UNF 20 theads per inch )and one for R410A,if the vacuum pump oil (

mineraDmixes with R41OA a sludge may occur and damage the equipment.

Gas leakage detector Exclusive for MFC refrigerant

• lncidentally,the "refrigerant cylinder"comes with the refrigerant des i gnat ion (R410A)and

protector coating in the U.S's ARI specified rose color (Ari color code; PMS 507).

•Also the "charge port and packing for refrigerant cylinder"requires 1/2 UNF 20 theads per inch

corresponding to the charge pOse's port size.

Page 18

REFRIGERANT TUBING

CONNECT THE INDOORTOTHE OUTDOOR UNIT

The indoor unit contains a small quantity of nitrogen.Do not unscrew the nuts from the unit until

you are ready to

connect the tubing.The outdoor unit is supplied with suffcient refrigerant charge(R410A).Refer

to outdoor unit nameplate.

To prevent crushing,bend tubes using a bending tool.

NOTE:U se refrigeration R41OA type copper tubing only.

1 .Open the valve cover.

2. Use tubing diameter that corresponds to the tubing diameter of the indoor and outdoor units.

Note that the liquid and suction tubes have different diameters.(See tube size,torque tightening

table.)

3. Place flares nuts on tube ends before preparing them with a flaring tool.Use the flare nuts that

are mounted on the supplied outdoor and indoor units.

4. Connecttheallendsofthetubingtotheindoorandoutdoorunits.Noticethesign.AII ends

should correspond one by one.

5.Insulate each tube separately,and their unions,with at least 6mm thick of insulation .Wrap the

refrigerant tubing,drain hose and electric cables together with a vinyl tape (UV protected).

Caution!

When unscrewing the

valve caps, do not stand

in front ofthemorthe

spindles at any time,as

the system is under

pressure.

____________

Fig 15

1.INDOOR UNIT

2.Liquid tube(small dia.)

3.Suction tubedarge dia.)

4. Plugs

5. Flare nuts

6. Tubing between units

7.Suction tube

8.Liquid tube

9.OUTDOOR UNIT

10.Flare nuts

11 .Suction valve(larger)

12.Liquid valve(smal)

NOTE:1. ForunituseconnectionsA,B

and D

2. For large indoor unit of 5.0KW

Use the lower connection(unit D)

and use the 3/8"-1/2"transition(

supplied)

3. The electric control channel must

match the tube channel.

Page 19

Tightening

torques of unions

and valve caops:

TUBE SIZE TORQUE

Liquid line 1/4"

Suction line 3/8"

Suction line 1/2"

Suction line 5/8"

\

15-20 N.M.

30-35 N.M.

50-54 N.M.

75-78 N.M.

Gx.

-----

Fig 9

1. Wrench

2. Torque wrench

3. Union

i J

Fig 10

To prevent refrigerant

leakage,coat the fiared

surface with

refrigeration oil

Gr

Figli

1 .Suction valve

2.Service port

3.Liquid valve

The introduction of the rotationai adapter:

The size of two calibers of the rotational adapter isdifferent:

one is 1/2" and the other is 3/8". The rotational adapter is

applicable for aom 243HXunit, the detail can be referred to the

following figure.

Indoor unit

Page 20

Air Purging

Air andmoistureremaining in theref rigerant system have undesrable efTects asindicatedbelow.

•Pressur e inth esyste m rises.

•Ope ratingcurren t rises.

•Cooling(o rheating )efficienc ydrop s.

•Moisture inth eref rigerantcircui t mayfree zean d biockcapiiia rytubing.

•Water mayiea d tocorrosio n ofpa rts inth eref rigerationsystem.

Therefore,th eindoo runi t andtubin gbet weenth eindoo ran doutdoo r unit must beiea ideste dan d evacuated

torem ove anynoncondensa biesan dmoistur efro mth esystem.

AirpurgingWith N^cuumPump

Preparation

•Che ck that each tubing(both iiquid and gas side

tubes)bet weenth eindoo ran doutdoo runit s have

beenprope riyconnecte d andai iwi ring forth etest

run has been compieted. Remove the service

vaivecap sfro mbot hth ega san dth eiiqui dside

onth eoutdoo runit .Not etha tbot hth eiiqui dand

thega ssid ese rvice vaives onth eoutdoo runi tare

keptciose d atthi sstag e.

Leakiest

•Connect the manifoid vaive(wilh pressure

gauges) and dry nitrogen gas cyiinder to this

servicepo rtwit hcharg ehose s.

Besur e tous e amani foid vaive forair

purging, if it isno t avaiiabie,us e astop

vaive forthi spu rpose.Th e"Hi "kno bof

themani foid vaive mustai ways be kept

ciose.

•Pressurizeth esystem to nomore than150 P.S.i.G

with dry nitrogen gas and ciose the cyiinder vaive

whenth e gaugereadingreached 150 P.S.i.G. Next;

test fiorieakswithiiquidsoa p.

• Do aiea k test ofai ijoints ofth etubing(bothindoor

andoutdoor)an dbothgasan diiquidsid e service

vaives.

Bubbies indicate aieak. Besure towipeoffth esoap

with aciea ncioth.

•Afte rth esyste m is found to be free of ieate,reii eve

the nitrogenpressure byiooseningth echarg ehose

connecter atth enitrogen cyiinder.Whenth esystem

pressure isreduced tono rmai,disconnectth ehose

fromth ecyiinder.

Indoor unit

Toavodnitrogeen teingtherefigerartsysten in

ai iqud staè,thetop ofthecylindemust beh ighe

th aii ts bo ttoiw h 31 youp ressdzet he sy ste m

Usu^thecyiindeis us si in averticástandig

position

Page 21

Installation

— Soapwate rmethod

(1) Rem oveth ecap sfro mth e gassid eand

liquidsid e valves.

(2) Rem oveth ese rvice-portca pfro mth egas

side valve.

(3) Toope nth ega ssid e valvetu rnth e valve

stemcounterclo ckwiseappr oximately90 °,

wait forabou t2~ 3second s,an dclos eit.

(4) Appl y asoa p water or allqui dneut ral

detergent onth eindoo runi tconnectio nor

outdooruni tconnection s by asof t brushto

check forleakag e ofth econnectin gpoints

ofth epiping.

(5) If bubblescom eout ,th epipe s have

leakage.

-------------------------

Evacuation

•Connec tth echarg ehos een ddesc ribed inthe

precedingstep s toth e vacuumpum pto

evacuateth etubin gan dindoo runit.

Confirmth e"Lo "kno b ofth emani fold valveis

open.Then, runth e vacuumpum p.

Theope ratlontim e for evacuation varleswith

tubinglengt han dcapacit y ofth epum p.The

followingta blesh owsth etim erequire d for

evacuation.

Required time for evacuatlonwhe n 30gal/h

Iflubln glengt h Isless

thanlO m(3 3ft)

vacuumpum p isused

Iftubln glengt h Islonger

thanlO m(3 3fl)

lOmin .ormore 15min . ormore

Indoor unit

Outdoor unit

•Whe nth edesire d vacuum Isreached ,clos ethe

"Lo"kno b ofth emani fold valvean dsto pthe

vacuumpum p.

Finishing thejob

•Wit h ase rvice valvewrench ,tu rnth e valve

stem ofllqui dsid e valvecounter-cio ckwiseto

fullyope nth e valve.

• Turnth e valveste m ofga ssid e valvecounterclockwise to fullyope n the valve.

•Loose nth echarg ehos e connected toth ega s

sidese rvicepo rtsllghtly toreleaseth epressure,

theorem oveth ehos e.

•Replaceth efiare nutan d itsbonnet onth e gas

sidese rvicepo rtan d fastenth e flare nut secure^

with anadjustablewrench.Thisprocess Is very

important topreveit leakacpfro mth esystem.

•Replaceth e valve caps atbothgasan dliquid side

service valvesan d fastenthemtight.

Thiscompletesal rpurging with a vacuumpum p.

Theal rconditloner Is nowready totes t run.

Pressure

gauge

Open

Manifold valve

Close

Vacuum pump

Page 22

Self DiagnosisFuntions

Our company has provided the thoughtful services for customers, and

the air conditioner had been installed self diagnosis system to display

the code for failure.

(1) Indoor unit fault shows as following:

Failure Failure code

Communication failure

Failure of room temperature sensor.

Failure oftube-exit temperature sensor

Failure oftube-entry temperature sensor

Failure oftube-midpointtemperature sensor

Failure of PG fan F4

(2) Outdoor unit fault shows as following:

Fault Fault code

Fault ofoutdoor unit transducer module

protecting.

Outdoor unit AC input too big.

Outdoor unit compressor exhaust temperature

too high, outdoor environment temperature

ultra warm, compressor outer cover temperature

switch disconnection .

The outdoor machine direct current bus bar

is unusual in voltage.

F1

F2

F3

F3

F3

P2

P3

P4

P7

Fault of lack refrigerant or fault of reversing

valve.

Faultoftheoutdoor temperature sensor.

Fault of outdoor unit drive, fault of compressor

start.

P8

F6

FC

Page 23

AWM093HX & AWM123HX indoor wire diagram

Page 24

REACTOR

AOM183HX outdoor wire diagram

To coopretsai tupeiituiel

protector

INSTRUCTION:

COMPRESSOR:

BROWN (U),BLACK(V),BLUE(W)

WIRE COLOUR;

BL (BLUE),BK(BLACK),

BR(BROWN), RD(RED),

GR(GREEN), YL(YELLOW),

WH(WHITE), OR(ORANGE)

simulant quantity input;

IA1 :exhaust temperature (3950)

IA2:outside temperature ( 3470)

I A3: condensator midpiont temperature ( 3470)

IA4: inspiration temperature(3470)

(li>^

GIXtlD

CHOP)

CID^

BL

R

RD

EARTH

f A

-----------------------

FILTER

GR

AC-N

AC-L

^BK

GR

-«3

(DX^

(0)9(ID

(11X3®

cnx3®

Page 25

AOM243HX outdoor wire diagram

Page 26

Page 27

Page 28

Tsim Sha Tsui, Kowloon,

Hong Kong

Tel: +852 2997 6865

Fax: +852 2997 6091

Email: amcorhk@amcorgroup.com

United Kingdom

Amcor Ltd

9 Ryan Drive, West Cross Centre,

Great West Road, Brentford,

Middlesex, TW8 9ER,

United Kingdom

Tel: +44 20 8560 4141

Fax: +44 20 8232 8814

Email: amcoruk@amcorgroup.com

USA

Amcor Inc.

685A Gotham Parkway, Carlstadt,

New Jersey 07072,

United States of America

Tel: +1 201 460 8100

Fax: +1 201 460 9481

Email: amcorusa@amcorgroup.com

The Netherlands

Amcor B.V.

Anton Philipsweg 9-11,

1422 AL Uithoorn,

The Netherlands

Tel: +31 297 560 079

Fax: +31 297 523 062

Email: amcorex@amcorgroup.com

Israel

Amcor International Ltd

3 Sapir Street, Herzelia Pituach,

46733, Israel

Tel: +972 9 951 5351

Fax: +972 9 958 5650

Email: amcoril@amcorgroup.com

Singapore

Amcor Investments (Singapore) Pte Ltd

545 Orchard Road,

#13-02, Far East Shopping Centre,

Singapore 238882

Tel: +65 6297 9881

Fax: H-6s 6297 8891

Email: amcorsg@amcorgroup.com

Amcor (Guangzhou) Ltd - China

Room 2903, 29/F Renfeng Tower,

490 Tianhe Road, Tianhe District,

Gianzhou, China 510630

Tel: -1-86 20 3888 6708

Fax: -1-86 20 3888 6619

amcorgz@amcorgroup.com

Amcor Ltd - Dong Cuan, China

8/F Changwang Bldg, Dongxing Road

ChangpingTown, Dongguan City,

Guangdong Province, China

Tel: -1-8676981175780

Fax: -1-86 769 8117 5785

amcorcn@amcorgroup.com

Amcor Industries Ltd - China Factory

Xialiao village, longxi Town,

Boluo County, Huizhou City

Guandong Province, China

Tel: -1-867526879015

Fax: -1-86 752 6383 170

amcorappl@amcorgroup.com

^^1 P^US

3058080

00

VO

00

www.amcorgroupusa.com

800-584-6484

Loading...

Loading...