Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

Commercial

Combination/

R

MENUMASTER

C O M M E R C I A L M I C R O W A V E O V E N

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Convection

Microwave

Oven

60 HZ Models

AMH20 P1330801M

AMH202 P1331101M

AMH20D P1332501M

JBH202 P1331102M

SZH20 P1331104M

50 HZ Models

AMH20A2 P1331103M

AMH20AD2 P1332504M

P1332506M

MMH20AD2 P1332505M

P1332507M

16023463

November 2006

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however, that during

its lifetime a product may require service. Products should be serviced only by a qualified service technician who is

familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO REVIEW ALL

APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

WARNING

Service Support Center

Contact your local product distributor or vist the Web site at www.amanacommercial.com.

Recognize Safety Symbols, Words, and Labels

DANGER!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16023463 ©2006 Maytag Services

Table of Contents

Important Information .................................................... 2

Important Safety Information ......................................... 4

Grounding Instructions ............................................... 7

Servicing of Grounded Products ................................. 8

Wiring ........................................................................ 8

Proper Grounding and Polarization of

208/230 Volts Wall Outlets ..................................... 8

Explanation ............................................................... 8

Test Procedures (2 Methods) ..................................... 8

General Test Information ............................................ 8

General Information

Unpacking Equipment ................................................ 9

Equipment Placement ............................................... 9

Radio Interference ...................................................... 9

Model Identification .................................................... 9

Service ....................................................................... 9

Parts and Accessories ............................................... 9

Troubleshooting Procedures .................................. 10-15

Component Testing Procedures ............................. 16-19

Power Test .................................................................. 20

Convection Temperature Test and Calibration ............. 21

Display Diagnostic ...................................................... 22

Service Test ................................................................ 23

Service Functions .................................................. 24-25

Disassembly Procedures

Door Handle ............................................................ 26

Magnetic Door Stop ................................................. 26

Outer Door .............................................................. 26

Inner Door Assembly ............................................... 26

Hinge ....................................................................... 26

Outer Case .............................................................. 27

Back Panel .............................................................. 27

Interlock Switch Module ........................................... 27

Stirrer Motor and Antenna Gears ............................. 27

RTD (Resistance Thermal Device) .......................... 28

Top Touch Panel Assembly ...................................... 28

Side Touch Panel Assembly .................................... 28

Display Module ........................................................ 28

Heating Elements (oven top) .................................... 28

Inlet Duct Assembly ................................................. 28

Halfwave Board ....................................................... 28

Control Board Assembly Bracket ............................. 29

High Voltage Circuit Board ...................................... 29

Auto Transformer..................................................... 29

Triacs ...................................................................... 29

Power Relay ............................................................ 29

Convection Motor Capacitor .................................... 29

Magnetron ............................................................... 29

Magnetron, Control, and Fan

Thermal Cutouts (TCO) ........................................ 30

Blower Bracket Assembly ........................................ 30

Microwave Blower Wheel and Motor ....................... 30

Fan Blade ................................................................ 30

Transformer ............................................................. 30

Capacitor / Diode .................................................... 31

Convection Box ....................................................... 31

Convection Element ................................................. 31

Thermal Limiter ........................................................ 31

Plenum Box ............................................................. 31

Fuse ........................................................................ 31

Power Cord ............................................................. 31

Component Location ........................................... 32-34

Appendix A

Owner’s Manual............................................. A-2-A-16

Appendix B

Quick Reference Guide .................................... B-2-B3

©2006 Maytag Services 16023463 3

Important Safety Information

WARNING

!

Read the following information to avoid possible exposure to microwave radiation:

The basic design of the Amana Microwave Oven makes it an inherently safe device to both use and service.

However, there are some precautions which should be followed when servicing the Radarange to maintain this

safety. These are as follows:

1. Always operate the unit from an adequately

grounded outlet. Do not operate on a two-wire

extension cord.

2. Before servicing the unit (if unit is operable) perform

the microwave leakage test.

3. The oven should never be operated if the door does

not fit properly against the seal, the hinges or hinge

bearings are damaged or broken; the choke is

damaged, (pieces missing, etc.); or any other

visible damage can be noted. Check the choke

area to ensure that this area is clean and free of all

foreign matter.

4. If the oven operates with the door open and

produces microwave energy, take the following

steps:

A. Tell the user not to operate the oven.

B. Contact Maytag Amana Manufacturing

immediately.

5. Always have the oven disconnected when the outer

case is removed except when making the "live"

tests called for in the Service Manual. Do not

reach into the equipment area while the unit is

energized. Make all connections for the test and

check them for tightness before plugging the cord

into the outlet.

6. Always ground the capacitors on the magnetron

filter box with an insulated-handle screwdriver

before working in the high voltage area of the

equipment compartment. Some types of failures

will leave a charge in these capacitors and the

discharge could cause a reflex action which could

make you injure yourself.

7. Always remember that in the area of the

transformer there is HIGH VOLTAGE. When the

unit is operating keep this area clear and free of

anything which could possibly cause an arc or

ground, etc.

8. Do not for any reason defeat the interlock

switches there is not valid reason for this action

at any time; nor will it be condoned by Amana.

9. IMPORTANT: Before returning a unit to a

customer, be sure to check for proper switch

interlock action.

10. Before returning a unit to a customer, be sure that

the door spacing is reasonably uniform along the

top, bottom, and sides, and that it measure

1/8" (3 mm) or less.

11. The Amana Microwave Oven should never be

operated with any components removed and/or

bypassed or when any of the safety interlocks are

found to be defective, or when any of the seal

surfaces are defective, missing, or damaged.

12. All Amana Microwave Ovens meet all

requirements of the radiation control for Health

and Safety Act of 1968. Due to measurement

uncertainties, the maximum leakage for the field

will be 4mw/cm

13. To ensure that the unit does not emit excessive

microwave leakage and to meet the Department

of Health and Human Services guidelines, check

the oven for microwave leakage using the

Holaday HI1510, HI1501, or HI1710 leakage

monitor as outlined in the instruction. The

maximum leakage level allowed when following

those instructions is 4mw/cm2.

14. If servicer encounters an emission reading over

4mw/cm2, the servicer is to cease repair and

contact the Amana Service Department

immediately for further direction. Amana

Manufacturing will contact the proper Government

Agency upon verification of the test results.

2.

4 16023463 ©2006 Maytag Services

Important Safety Information

Recognize this symbol as a SAFETY message

WARNING

!

When using electrical equipment, basic safety precautions should be followed to reduce the risk of burns,

electrical shock, fire, or injury to persons.

1. READ all instructions before using equipment.

2. READ AND FOLLOW the specific

“PRECAUTIONS TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE

ENERGY”.

3. This equipment MUST BE GROUNDED. Connect

only to properly GROUNDED outlet. See

“GROUNDING INSTRUCTIONS”.

4. Install or locate this equipment ONLY in

accordance with the installation instructions in this

manual.

5. Some products such as whole eggs and sealed

containers, for example, closed glass jars may

explode and SHOULD NOT be HEATED in this

oven.

6. Use this equipment ONLY for its intended use as

described in this manual. Do not use corrosive

chemicals or vapors in this equipment. This type

of oven is specifically designed to heat or cook. It

is not designed for industrial or laboratory use.

7. As with any equipment, CLOSE SUPERVISION

is necessary when used by CHILDREN.

8. DO NOT operate this equipment if it has a

damaged cord or plug, if it is not working

properly, or if it has been damaged or dropped.

9. This equipment, including power cord, must be

serviced ONLY by qualified service personnel.

Special tools are required to service equipment.

Contact nearest authorized service facility for

examination, repair, or adjustment.

10. DO NOT cover or block filter or other openings

on equipment.

11. DO NOT store this equipment outdoors. DO

NOT use this product near water, for example,

near a kitchen sink, in a wet basement, or near

a swimming pool, and the like.

12. DO NOT immerse cord or plug in water.

13. Keep cord AWAY from HEATED surfaces.

14. DO NOT let cord hang over edge of table or

counter.

15. See door cleaning instructions in “Care and

Cleaning” section.

16. For commercial use only.

CAUTION

!

To reduce risk of fire in the oven cavity:

a. DO NOT overcook food. Carefully attend

equipment if paper, plastic, or other combustible

materials are placed inside the oven to facilitate

cooking.

b. Remove wire twist-ties from paper or plastic

bags before placing bag in oven.

c. KEEP oven DOOR CLOSED, turn oven off, and

disconnect the power cord, or shut off power at

the fuse or circuit breaker panel, if materials

inside the oven should ignite. Fire may spread

if door is opened.

d. DO NOT use the cavity for storage. DO NOT

leave paper products, cooking utensils, or food

in oven.

SAVE THESE INSTRUCTIONS

©2006 Maytag Services 16023463 5

Important Safety Information

CAUTION

!

To avoid risk of personal injury or property damage, observe the following:

1. Briskly stir or pour liquids before heating with

microwave energy to prevent spontaneous boiling

or eruption. Do not overheat. If air is not mixed

into a liquid, liquid can erupt in oven or after

removal from oven.

2. Do not deep fat fry in oven. Fat could overheat

and be hazardous to handle.

3. Do not cook or reheat eggs in shell or with an

unbroken yolk using microwave energy. Pressure

may build up and erupt. Pierce yolk with fork or

knife before cooking.

4. Pierce skin of potatoes, tomatoes, and similar

foods before cooking with microwave energy.

When skin is pierced, steam escapes evenly.

5. Do not operate equipment without load or food in

oven cavity.

6. Use only popcorn in packages designed and

labeled for microwave use. Popping time varies

depending on oven wattage. Do not continue to

heat after popping has stopped. Popcorn will

scorch or burn. Do not leave oven unattended.

7. Do not use regular cooking thermometers in oven.

Most cooking thermometers contain mercury and

may cause an electrical arc, malfunction, or

damage to oven.

8. Do not heat baby bottles in oven.

9. Do not use metal utensils in oven.

10. Never use paper, plastic, or other combustible

materials that are not intended for cooking.

11. When cooking with paper, plastic, or other

combustible materials, follow manufacturer's

recommendations on product use.

12. Do not use paper towels which contain nylon

or other synthetic fibers. Heated synthetics could

melt and cause paper to ignite.

13. Do not heat sealed containers or plastic bags

in oven. Food or liquid could expand quickly and

cause container or bag to break. Pierce or open

container or bag before heating.

14. To avoid pacemaker malfunction, consult

physician or pacemaker manufacturer about

effects of microwave energy on pacemaker.

PRECAUTIONS TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

a. DO NOT attempt to operate this oven with the

door open since open-door operation can result in

harmful exposure to microwave energy. It is

important not to defeat or tamper with the safety

interlocks.

b. DO NOT place any object between the oven front

face and the door or allow soil or cleaner

residue to accumulate on sealing surfaces.

c. DO NOT operate the oven if it is damaged. It

is particularly important that the oven door close

properly and that there is no damage to the: (1)

door (bent), (2) hinges and latches (broken or

loosened), (3) door seals and sealing surfaces.

d. The oven should NOT be adjusted or repaired

by anyone except properly qualified service

personnel.

SAVE THESE INSTRUCTIONS

6 16023463 ©2006 Maytag Services

Important Safety Information

!

WARNING

Precautions to be observed before and during

servicing to avoid possible exposure to excessive

microwave energy, or electrical shock disconnect

power to oven.

• Do not operate or allow oven to be operated with door

open.

• Make the following safety checks on all ovens to be

serviced before activating the magnetron or other

microwave source, and make repairs as necessary:

• Interlock operation

• Proper door closing

• Seal and sealing surfaces (arcing, wear, and

other damage)

• Damage to or loosening of hinges and latches

• Evidence of dropping or abuse

• Before turning on microwave power for any service

test or inspection within the microwave generating

compartments, check the magnetron, waveguide or

transmission line, and cavity for proper alignment,

integrity, and connections.

• Any failed or misadjusted components in the

interlock, monitor, door seal, and microwave

generation and transmission systems shall be

repaired, replaced or adjusted by procedures

described in this manual before oven is released to

the consumer.

• Check microwave leakage to verify compliance with

the federal performance standard should be

performed on each oven prior to release to the

consumer.

!

WARNING

To avoid risk of electrical shock, injury or death; make

sure these grounding instructions are followed.

Grounding Instructions

!

WARNING

Do not remove grounding prong when installing

grounded appliance in a home or business that does

not have three wire grounding receptacle, under no

condition is grounding prong to be cut off or removed.

It is the personal responsibility of the consumer to

contact a qualified electrician and have properly

grounded three prong wall receptacle installed in

accordance with appropriate electrical codes.

WARNING

!

To avoid the risk of electrical shock or death, do not

alter the plug.

WARNING

!

To avoid the risk of electrical shock or death, this

equipment must be grounded.

This equipment MUST be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the

electric current. This oven is equipped with a cord

having a grounding wire with a grounding plug. The plug

must be plugged into an outlet that is properly installed

and grounded.

Consult a qualified electrician or servicer if grounding

instructions are not completely understood, or if doubt

exists as to whether the equipment is properly

grounded.

Do not use an extension cord. If the product power cord

is too short, have a qualified electrician install a threeslot receptacle. This oven should be plugged into a

separate 50 or 60 hertz circuit with the electrical rating

as shown in the appropriate drawing. Models operate

with a 208 or 230 supply voltage. When an oven is on a

circuit with other equipment, an increase in cooking

times may be required and fuses can be blown.

©2006 Maytag Services 16023463 7

Important Safety Information

Servicing of Grounded Products

The standard accepted color coding for grounding wires

is GREEN or GREEN WITH YELLOW STRIPE. These

ground leads are NOT to be used as current carrying

conductors. It is extremely important that the technician

replace any and all grounds prior to completion of the

service call. Under no condition should ground wire be

left off causing a potential hazard to technicians and

consumer.

Wiring

A good service practice is never route wiring over

terminals and/ or sharp edges. This applies to any wiring

without regard to the circuit voltage. Wire installation

material and thickness is designed and regulated for

electrical spacing purpose only, but cannot always be

relied upon because of possible cuts and/or abrasions,

which can occur during servicing.

WARNING

!

To avoid risk of electrical shock, personal injury or

death; verify the oven is properly grounded and

polarized.

Explanation

Polarization–This means that the larger slot must be

neutral and the small slot must be hot (live).

Mispolarized–The outlet is miswired so that the larger slot

is hot (live) and the smaller slot is neutral.

Grounded–This means the round hole connection is

connected to earth ground through a connection to the main

power panel.

Ungrounded–The round hole connection is not complete

to earth ground and/or the main power panel.

CAUTION

!

To avoid risk of electrical shock, personal injury or

property damage; wiring changes or grounding of wall

outlet are to be made only by a qualified electrician.

General Test Information

Most testing in the manual is conducted with an

ohmmeter using a multiplier scale of X 10k (k–thousand

ohms). When using this scale, it is important that your

fingers do not touch the metal parts of the test probes.

To do so will give a false indication of the ohm reading.

Proper Grounding and Polarization of

208/230 Volts Wall Outlets

For the safety of our customers and the service

technician ALL appliances have a three–prong power

cord and MUST be connected to a properly polarized and

grounded wall outlet.

This information was written for those who do not

understand grounding and polarization of a wall outlet.

A 208/230 volt wall outlet must always be wired as shown

below.

Neutral (N) - This slot is

the larger of the two and

should be neutral (dead)

with respect to ground.

N

G

Ground (G) - The round hole connection

is for the grounding circuit. Behind the

cover plate a green wire should be

connected to this terminal.

Hot (H) - This slot is

the smaller size and

should always be hot

(live) with respect to

neutral (N) and ground(G).

H

8 16023463 ©2006 Maytag Services

General Information

A

A

Unpacking Equipment

• Inspect oven for damage such as dents in door or

inside oven cavity.

• Report any dents or breakage to source of purchase

immediately. Do not attempt to use oven if

damaged.

• Remove all packing materials from oven interior.

• If oven has been stored in extremely cold area, wait a

few hours before connecting power.

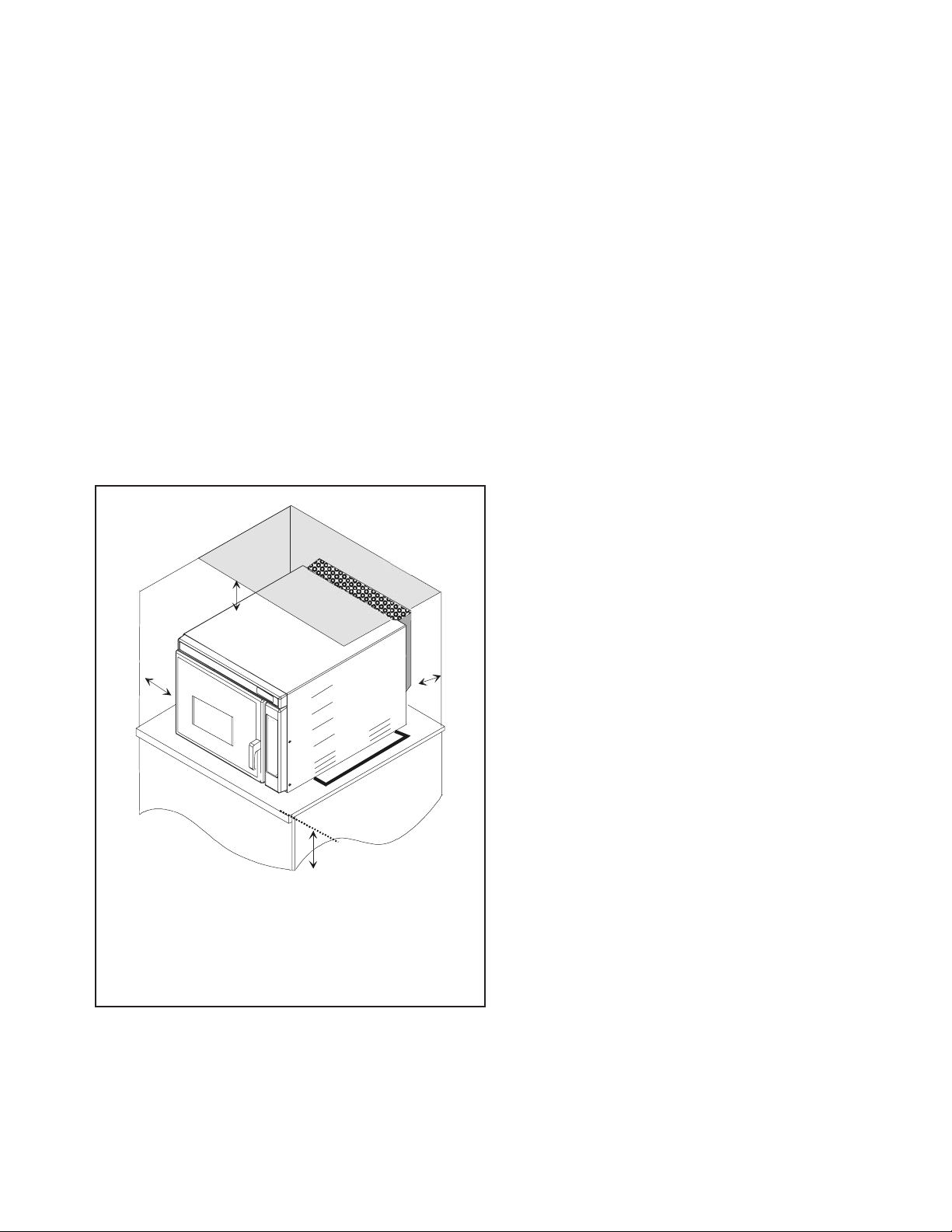

Equipment Placement

• Recommended countertop surface depth is 26” (66

cm).

• Do not install oven next to or above source of heat,

such as pizza oven or deep fat fryer. This could

cause microwave oven to operate improperly and

could shorten life of electrical parts.

• Do not block or obstruct oven filter. Allow access for

cleaning.

• Install oven on level countertop surface.

• Outlet should be located so that plug is accessible

when oven is in place.

A

Radio Interference

Microwave operation may cause interference to radio,

television, or similar equipment. Reduce or eliminate

interference by doing the following:

• Clean door and sealing surfaces of oven according to

instructions in “Care and Cleaning” section.

• Place radio, television, etc. as far as possible

from oven.

• Use a properly installed antenna on radio, television,

etc. to obtain stronger signal reception.

Model Identification

• For Amana product call 1-866-426-2621 or visit the

Web Site at www.amanacommercial.com

When contacting for service support, provide product

information located on rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an authorized

servicer:

• For Amana product call 1-866-426-2621 or visit the

Web Site at www.amanacommercial.com

Warranty service must be performed by an authorized

servicer. We also recommend contacting an authorized

servicer, if service is required after warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product contact

your local product distributor or vist the Web site at

www.amanacommercial.com.

B

A—Allow at least 2" (5 cm) of clearance around top, back and

sides of oven. Proper air flow around oven cools electrical

components. With restricted air flow, oven may not operate

properly and life of electrical parts is reduced.

B—Install combination oven so oven bottom is at least 3 feet

(91 cm) above floor.

©2006 Maytag Services 16023463 9

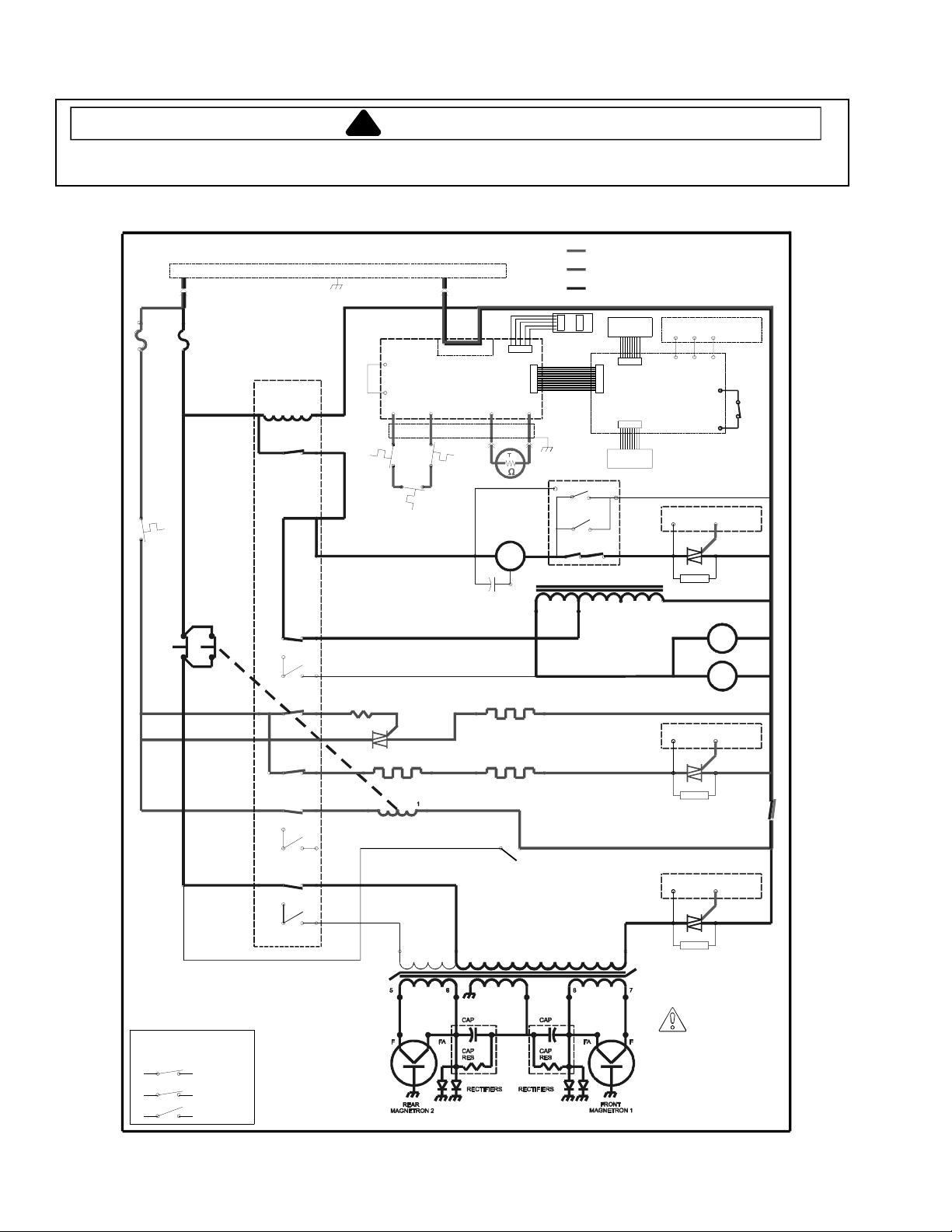

60 Hz Troubleshooting Procedures

A

)

)

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Stand By Condition

(230)

(208)

(230)

K1

K5

K3

K2

K7

K6

K9

K8

(208 )

NO

K4

NO

NO

NO

NO

NO

NO

NO

NO

208/ 230V 60H Z

J1-2

J2-5

E4

E5

J3-3

J3-1

J2-3

J2-3NOJ2-3

J2-4

J4-6

J4-7

J4-1

J4-2

J4-3

J4-4

MAG 2

TCO

360 ½ W

RESIS TOR

POW ER BOAR D

J8-1

J8-2

J8-3

RAD IANT HEATE R

(LH)

0

POWER R

ELAY COIL

E1 E2 /E3

CURR ENT

SENS E

J8-4 J 8-6

CONT ROL

TCO

MAG 1

TCO

230

L2L2

L2GNDL1

CONV ECTION FAN

M2

CAPACI TOR

CONV ECTION HEATER

(REAR )

RADIA NT HEATE R

(RH)

7 8

INTE RLOCK

(MO NITOR)

POWE R TRAN SFORM ER

208

J5

J8-7

RTD

P

2

DATA KEY

BOAR D

SHIEL DED

CAB LE

HAL FWAVE

PROT ECTION

BOAR D

NC

E5

NC

NO

RLY1 R LY2

UTO TR ANSFO RMER

208 120

CONTROL/TEMPERATURE

CONVECTION (FUSE 2

MICROWAVE (FUSE 1

P

1

UPPE R

SWITC H

J4

J

6

DISP LAY

BOAR D

J5

LOW ER

SWITC H

RLY1

RLY2

E2

TRIAC (TR1)

BLOW ER

NO

(RIGH T)

COM230

TRIA C (TR2)

HEATER

(MIDD LE)

TRIA C (TR3)

MAGN ETRON

(LEFT )

COM

J1-4 J1- 2 J1-1

J2-1J2-2J2-4

J1-3

J1-1

J7-5

J7-6 J7-5

G

G

SNU BBER

COO LING FAN

STIR RER

J7-4 J7-3

J7-3

G

G

T2

SNU BBER

J7-2 J7-1

J7-1

G

G

T2

SNU BBER

SNU BBER

DOO R

INTE RLOCK

(PRI MARY)

POWE R

BOA RD

T1T2

M1

M3

POWE R

BOA RD

T1

(SEC ONDAR Y)

POWE R

BOA RD

T1

SPEA KER

BOA RD

4

5

INTE RLOCK

2

3

SCHEM ATIC CO NDITIO N: DOO R CLOSE D

25A

TEM P

LIMITE R

25A

MAG

FUSE 1

J1-1

POWER

RELAY

6

8

J2-1

J2-2

J4-5

E6

E7

2

4

HEATER

FUS E 2

POWE R BOAR D

NC

NC

NC

CAUTION:

DO NOT REMOVE WIRE FROM TRIAC TERMINAL

T2 DURING TESTING. THIS WILL CAUSE

HV BOARD TO SHORT OUT.

INTER LOCK S WITCH SCHEMATI C

DOOR CLOSE D

2

4

7

10

16023463 ©2006 Maytag Services

3 SEC ONDAR Y

5 PRI MARY

8 M ONITOR

REAR

MAG NETRON 2

REC TIFIERS

REC TIFIERS

FRON T

MAGN ETRON 1

DANGER

HIGH VOLTAGE

60 Hz Troubleshooting Procedures

A

)

)

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Pre-Heat Condition

(230)

K5

(208)

(230)

K1

K3

K2

K7

K6

K9

K8

(208)

NO

K4

NO

NO

NO

NO

NO

NO

NO

NO

208/ 230V 60H Z

J1-2

J2-5

E4

E5

J3-3

J3-1

J2-3

J2-3

J2-4

J4-6

J4-7

J4-1

J4-2

J4-3

J4-4

MAG 2

TCO

360 ½ W

RESI STOR

RADIA NT HEATE R

0

POW

POWE R BOAR D

J8-1

J8-2

J8-3

(LH)

R RELAY COI

E

230

E1 E2 /E3

CURR ENT

SENS E

J8-4 J 8-6

CONT ROL

TCO

MAG 1

TCO

L

208

L2

L2GNDL1

J

6

J5

J8-7

CONV ECTIO N FAN

M2

CAPACI TOR

CONV ECTION HEATER

(REAR)

RAD IANT HEAT ER

(RH)

7 8

INTER LOCK

(MO NITOR)

POWE R TRAN SFORM ER

RTD

DATA KEY

SHIE LDED

CAB LE

E5

208 120

CONTROL/TEMPERATURE

CONVECTION (FUSE 2

MICROWAVE (FUSE 1

P1P

2

BOA RD

HALF WAVE

PROT ECTION

BOA RD

NC

NC

NO

RLY1 R LY2

UTO TR ANSFO RMER

RLY1

RLY2

UPPE R

SWITC H

J4

J

6

DISPL AY

J5

LOW ER

SWITC H

E2

TRIAC (TR1)

BLOW ER

NO

(RIGH T)

TRIA C (TR2 )

HEATER

(MIDD LE)

TRIA C (TR3 )

MAGN ETRON

(LEFT )

COM

BOA RD

COM230

J1-4 J 1-2 J1-1

J2-1J2-2J2-4

J1-3

J1-1

J7-6 J7-5

J7-5

G

G

SNU BBER

COO LING FAN

J7-4 J7-3

J7-3

G

G

T2

SNUB BER

J7-2 J7-1

J7-1

G

G

T2

SNU BBER

SNU BBER

DOOR

INTE RLOCK

(PRIM ARY)

T1T2

M1

M3

STIR RER

T1

(SECO NDARY )

T1

SPEA KER

BOAR D

POW ER

BOAR D

POW ER

BOAR D

INTER LOCK

POW ER

BOAR D

4

5

2

3

SCH EMATIC CO NDITIO N: DOO R CLOSE D

25A

TEM P

LIMITE R

25A

MAG

FUSE 1

J1-1

POWER

RELAY

6

8

J2-1

J2-2

J4-5

E6

E7

2

4

HEATER

FUS E 2

POWE R BOAR D

NC

NC

NC

CAUTION:

DO NOT REMOVE WIRE FROM TRIAC TERMINAL

T2 DURING TESTING. THIS WILL CAUSE

HV BOARD TO SHORT OUT.

INTER LOCK S WITCH S CHEMAT IC

DOO R CLOSE D

2

4

7

3 SEC ONDAR Y

5 PRI MARY

8 MO NITOR

REAR

MAGN ETRON 2

REC TIFIERS

REC TIFIERS

FRON T

MAG NETRON 1

©2006 Maytag Services 16023463 11

DANGER

HIGH VOLTAGE

60 Hz Troubleshooting Procedures

A

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Cook Condition

SCHE MATIC CO NDITIO N: DOO R CLOSE D

25A

FUSE 2

TEMP

LIMITE R

25A

MAG

FUSE 1

J1-1

6

2

8

4

POWER

RELAY

J2-1

J2-2

J4-5

E6

E7

HEATER

POWE R BOAR D

NC

NC

NC

(230)

(230)

(208 )

208/2 30V 60H Z

L2GNDL1

CONTROL/TEMPERATURE

CONVECTION (FUSE 2)

MICROWAVE (FUSE 1)

RLY1

RLY2

UPP ER

P

1

SWITC H

J

6

LOW ER

SWITC H

NO

TRIA C (TR2)

(MIDD LE)

TRIA C (TR3)

MAGN ETRON

COM

J4

DISPL AY

BOAR D

J5

E2

TRIAC (TR1)

BLOW ER

(RIGH T)

COM230

HEATER

(LEF T)

J1-4 J1- 2 J1-1

J7-6 J 7-5

SNU BBER

J7-4 J 7-3

T2

SNU BBER

J7-2 J 7-1

T2

SNU BBER

SNU BBER

J2-1J 2-2J2-4

J1-3

J1-1

INTE RLOCK

(PRI MARY)

J7-5

G

G

COO LING FAN

STIR RER

J7-3

G

G

T1

J7-1

G

G

T1

SPEA KER

BOA RD

DOO R

POW ER

BOAR D

T1T2

M1

M3

POW ER

BOAR D

INTE RLOCK

(SECO NDARY )

POW ER

BOAR D

4

5

2

3

P

2

DATA KEY

POWE R BOAR D

J8-1

J8-2

MAG 2

TCO

360 ½ W

RESIS TOR

0

J8-3

RADIA NT HEATE R

POWER REL

J1-2

K1

J2-5

NO

E4

E5

K4

(208 )

J3-3

NO

J3-1

NO

K5

J2-3

NO

NO

K3

J2-4

NO

K2

K7

J4-6

NO

J4-7

NO

K6

K9

J4-1

J4-2

NO

J4-3

J4-4

NO

K8

J8-4 J8-6

MAG 1

TCO

(LH)

Y COI

A

230

E1 E2/E3

CONT ROL

TCO

L

CURR ENT

SENS E

208

CONV ECTION FAN

M2

CAPACI TOR

CONV ECTION HEATER

(REAR )

RADIA NT HEATE R

(RH)

7 8

INTE RLOCK

(MON ITOR)

POWE R TRANS FORM ER

J

6

J5

J8-7

RTD

SHIEL DED

CAB LE

E5

BOAR D

HALF WAVE

PROT ECTION

BOAR D

NC

NC

NO

RLY1 RLY2

UTO TR ANSFO RMER

208 120

CAUTION:

DO NOT REMOVE WIRE FROM TRIAC TERMINAL

T2 DURING TESTING. THIS WILL CAUSE

HV BOARD TO SHORT OUT.

INTER LOCK S WITCH SCHEMAT IC

DOO R CLOSE D

2

4

7

12

16023463 ©2006 Maytag Services

3 SE CONDAR Y

5 PRI MARY

8 MO NITOR

DANGER

HIGH VOLTAGE

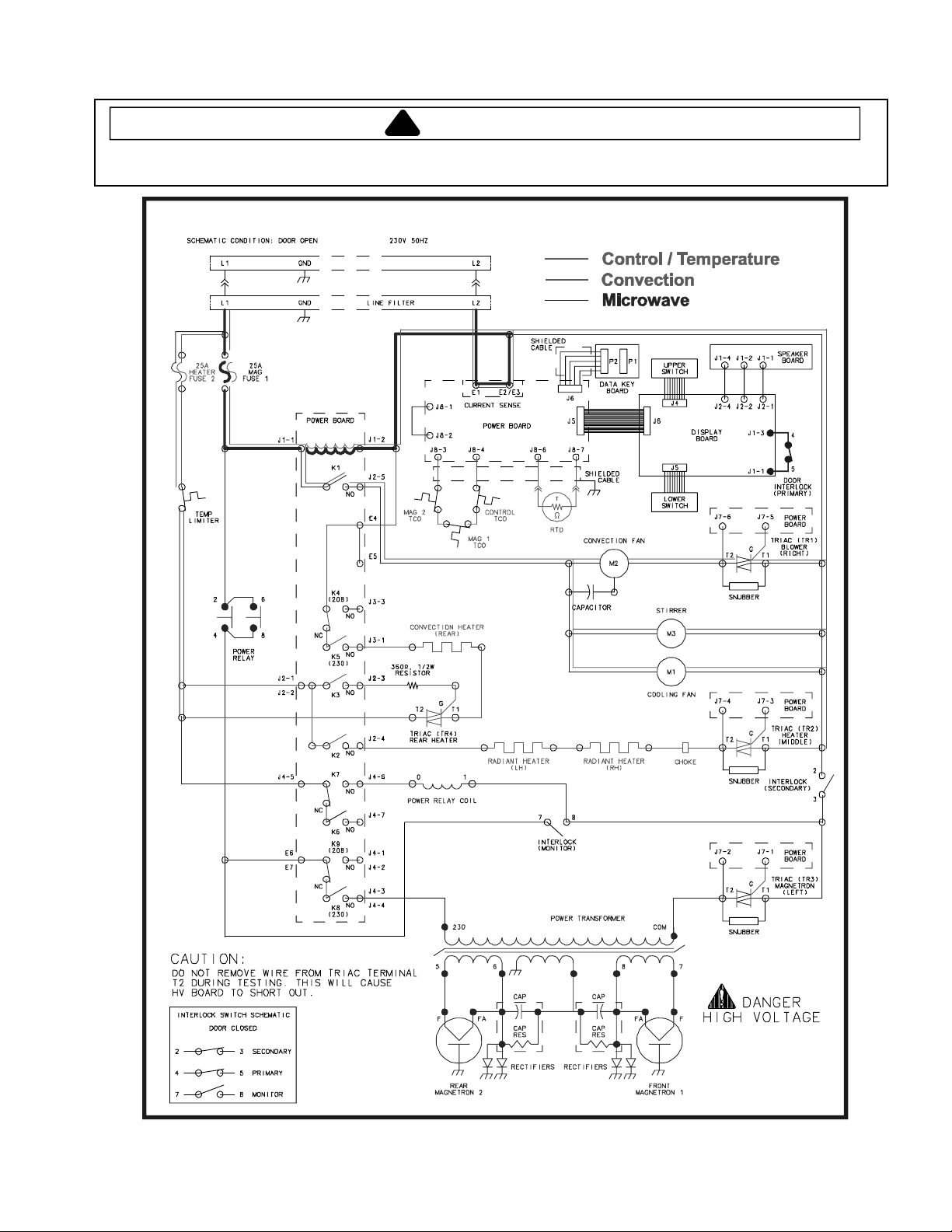

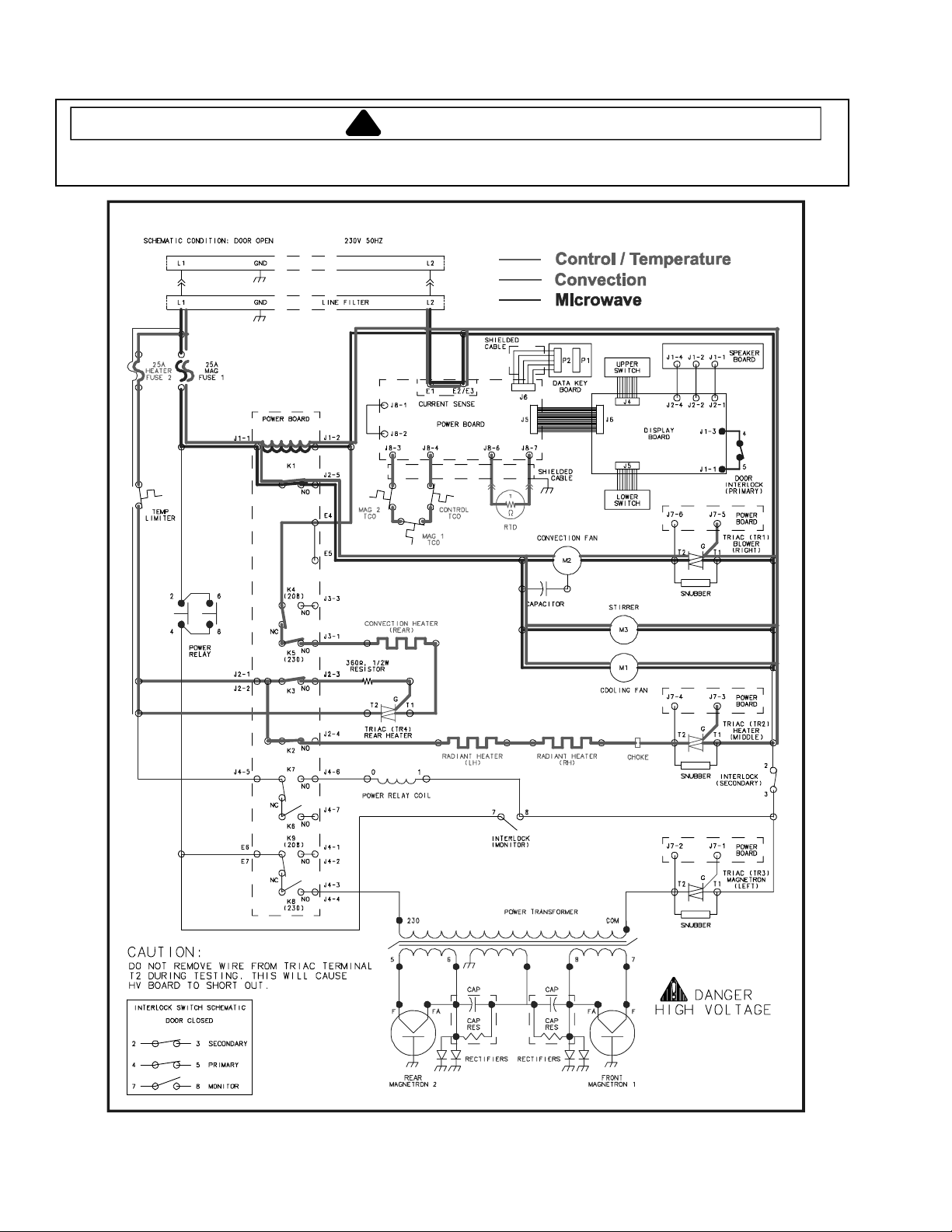

50 Hz Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

Stand-By Condition

©2006 Maytag Services 16023463 13

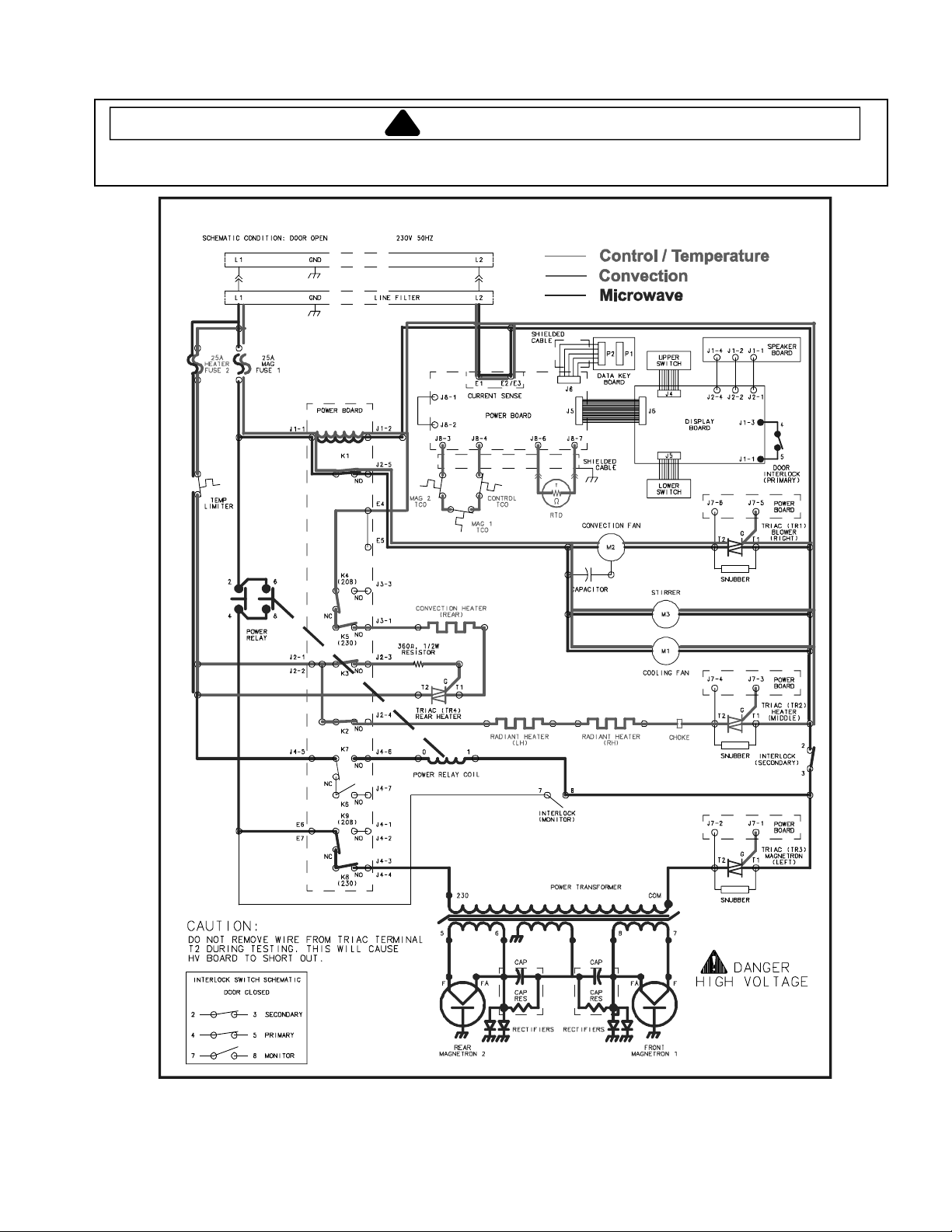

50 Hz Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

Pre Heat Condition

14

16023463 ©2006 Maytag Services

50 Hz Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

Cook Condition

©2006 Maytag Services 16023463 15

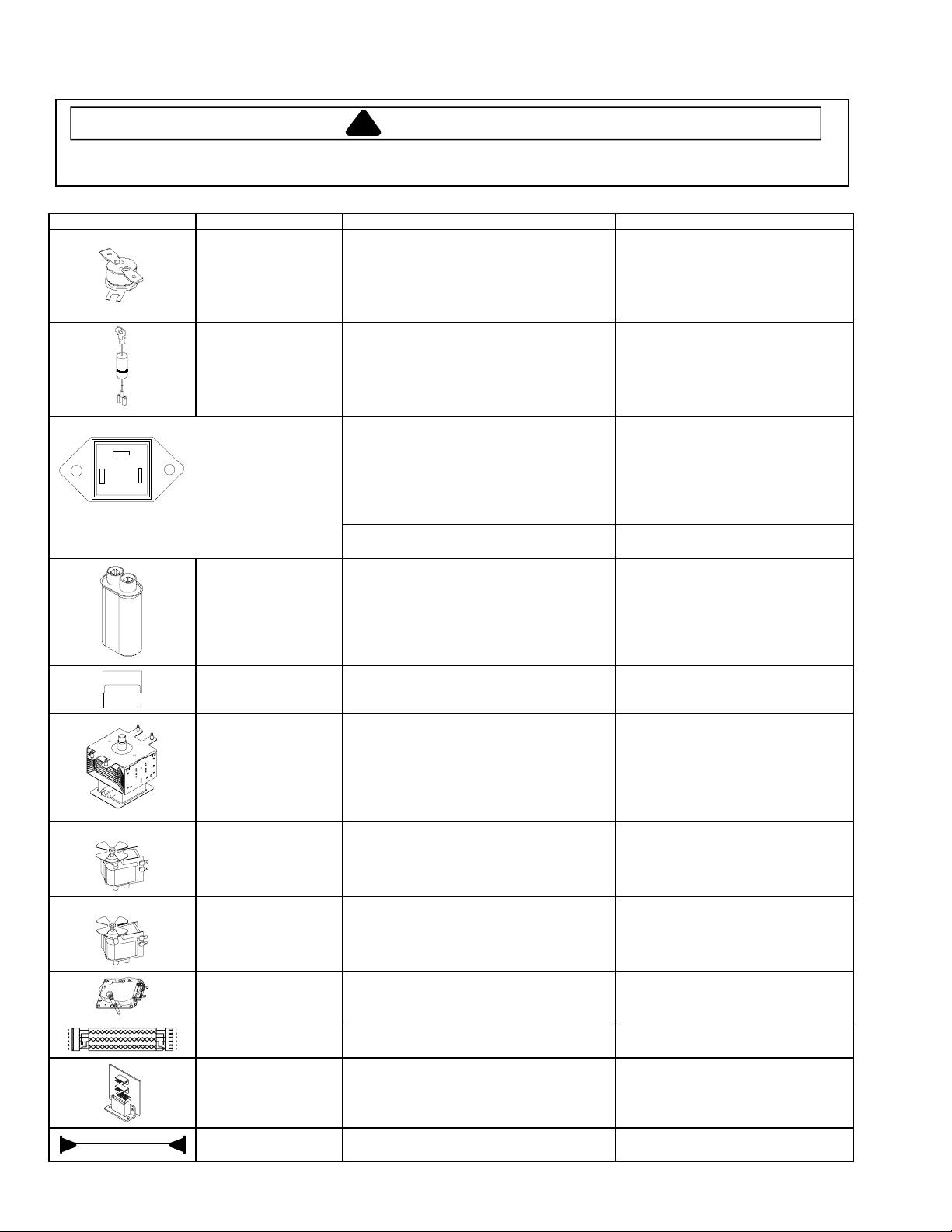

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Illustration Component Test Results

Thermal cutout Disconnect all wires from TCO.

Diode Discharge Capacitor

Triac Disconnect wires to triac.

MT2

MT1 GATE

Triac 1 (top) is for front element.

Triac 2 (middle) is for rear element.

60 HZ Models only

Capacitor Discharge Capacitor

Snubber assembly Disconnect wires to snubber.

Magnetron Discharge Capacitor

Microwave blower

motor

Measure resistance across terminals.

Control TCO ...............................................

Magnetron TCO..........................................

Remove diode lead from capacitor and

connect ohmmeter.

Reverse leads for second test.

Measure resistance from:

MT1 to MT2................................................

MT1 to Gate ...............................................

MT2 to Gate ...............................................

All terminals to ground................................

Measure voltage from MT1 to Gate ...............

Remove wires from capacitor terminals and

connect ohmmeter, set on highest

resistance scale to terminals.

Also check between each terminal and

capacitor case................................................

Measure resistance across terminals.............

Remove wires from magnetron and

connect ohmmeter to terminals. Also check

between each terminal and ground.

Remove all wires from motor.

Measure resistance across coil......................

Closed at 113° C (235° F) and open

at 66° C (150° F).

Open at 149° C (300° F) and closed

at 125° C (257° F).

Infinite resistance should be

measured in one direction and 50K

or more in the opposite direction.

NOTE: Ohmmeter must contain a

battery of 6 volts minimum.

Caution - Do not operate oven with

wire to terminal MT2 removed.

Infinite.

Approximately 15 , then reverse

meter leads 30 .

Infinite.

Infinite.

0.8 VAC when energized. If no

voltage, check H.V. board and wiring.

Between Terminals: Meter should

momentarily deflect towards zero

then return to over 5 M . If no

deflection occurs, or if continuous

deflection occurs, replace capacitor.

Terminal to Case: Infinite resistance.

Infinite.

Between Terminals: Less than 1 .

Each terminal to ground measures

Infinite resistance.

NOTE: This test is not conclusive. If

oven does not heat and all other

components test good, replace the

magnetron and retest.

Approximately 26 .

50 HZ Models only

16023463 ©2006 Maytag Services

16

Microwave blower

motor

Stirrer motor Remove all wires from terminals.

EZCard Harness Test continuity of wires .................................. Continuity.

EZCard Board Insert EZCard to determine if unit can be

HV board to display

module wiring harness

Remove all wires from motor.

Measure resistance across coil......................

Measure resistance from terminal to

terminal..........................................................

programmed .................................................. If unit can not be programmed, verify

Test resistance of wires ................................. Continuity.

Approximately 33.5 .

Approximately 29K .

EZCard harness is good. If harness

is good, replace EZCard Board.

Component Testing Procedures

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

.

.

.

.

.

.

.

.

.

.

.

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Illustration Component Test Results

Measure voltage across terminals:

With Convection on:

E5 to MTR ..........................................

T2 to E5..............................................

E2 to E5 .............................................

With Convection off:

E5 to MTR ..........................................

T2 to E5..............................................

E2 to E5 .............................................

Resistance of 2 amp fuse on circuit board.

Disconnect wire from terminals.

Measure resistance from:

Blue to Blue............................................

Brown to Brown......................................

Discharge Capacitor

Remove all wires from terminals.

Measure resistance from:

230 to COM............................................

230 to Ground ........................................

Terminal 5 to 6 .......................................

Terminal 7 to 8 .......................................

Terminal 4 to Ground .............................

Discharge Capacitor

Remove all wires from terminals.

Measure resistance from:

Primary...................................................

Filament .................................................

Secondary to Ground screw on

transformer stack ...................................

Discharge Capacitors

Remove all wires from terminals.

Measure resistance from:

230 V to 0 V ...........................................

208 V to 0 V ...........................................

120 V to 0 V ...........................................

Disconnect wires to switch.

With door open, measure resistance:

Terminal 2 to 3 .......................................

Terminal 4 to 5 .......................................

Terminal 7 to 8 .......................................

With door closed, measure resistance:

Terminal 2 to 3 .......................................

Terminal 4 to 5 .......................................

Terminal 7 to 8 .......................................

Measure resistance across terminals ........

Disconnect wires from terminals.

Measure resistance across element ..........

Remove all wires from terminals.

Measure resistance across terminals ........

Thermal limiter opens when oven temp.

reaches 279° C (535° F). It automatically

resets at approx. 204° C (400° F).

Remove all wires from terminals.

Measure resistance across terminals ........

Thermal limiter will open when oven

temperature reaches 279° C (535° F)........

Line voltage.

Line voltage.

Line voltage.

No voltage.

No voltage.

No voltage.

Continuity.

< 1 .

< 1 .

Less than 1 .

Infinite.

300 .

300 .

Approx. 28.2 .

Less than <1 .

Less than <1 .

Approx. 100 – 120 .

Approximately 38 .

Approximately 37 .

Approximately 25 .

Infinite.

Infinite.

Continuity.

Continuity.

Continuity.

Infinite.

Approx. 349 .

Approx. 27.4 .

Continuity.

If not, replace limiter.

Continuity.

If not, replace limiter.

Reset by pressing RESET.

60 HZ Models only

50 HZ Models only

50 HZ Models only

6

5

COM

230 V

60 HZ Models only

60 HZ Models only

7

8

2

3

5

Halfwave board

Line filter

H. V. Transformer

9

7

9

4

4

8

H. V. Transformer

Auto Transformer

Interlock switch

Door Closed

2

4

7

Secondary

3

Primary

5

Monitor

8

Convection blower motor Remove wires from motor.

Convection heating element

(2100 W)

Thermal limiter

(Auto Reset)

(See NOTE below.)

Thermal limiter

(Manual Reset)

(See NOTE below.)

NOTE: Early limiters required a manual reset. This is accomplished by pressing a red reset button. Limiters

produced recently reset automatically and do not have a reset button.

©2006 Maytag Services 16023463 17

Component Testing Procedures

.

.

.

.

.

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Illustration Component Test Results

0 1

2 4

6 8

HIDDEN

PAD

THEN

Cavity heating element Disconnect wires from terminals.

Measure resistance across heating

element (900 W) ..................................

Resistance thermal

device (RTD)

Relay (contains diode in

relay circuit)

0 1

2 4

TEMP

ENTRY

6

8

Temperature

0° C (32° F) .........................................

230° C or 250° C (450° F or 475° F)....

Measure resistance from:

Terminal 0 to terminal 1 (coil)...........

Measure voltage from:

Terminal 0 to Terminal 1 (coil)..........

TIME

HIDDEN

PAD

PREHEAT

ON / OFF

ENTRY

TEMP

ENTRY

POWER

LEVEL

STAGE

Side touch panel Continuity is 100 and

below.

Top touch panel Continuity is 100 and

below.

=

PROG RAM

SAVE

Pad

1

2

3

4

5

6

7

8

9

0

Start

Stop/Reset

Pad

Preheat

Time Entry

Power Level

Stage

Program

Quantity

Temperature

Menu

Hidden Pad

Approx. 12 .

Resistance

Approx. 1000 .

Approx. 1850 to 1900 .

Approx. 6 to 7 M .

230 VAC with oven in microwave

COOK mode.

NOTE: Analog meter is

recommended for measurement.

Trace

(measure both)

3 & 1, 5 & 1

3 & 1, 6 & 1

3 & 1, 7 & 1

3 & 1, 8 & 1

3 & 1, 9 & 1

4 & 1, 5 & 1

4 & 1, 6 & 1

4 & 1, 7 & 1

4 & 1, 8 & 1

4 & 1, 9 & 1

5 & 1, 6 & 1

6 & 1, 9 & 1

Trace

(measure both)

3 & 1, 4 & 1

5 & 1, 7 & 1

5 & 1, 8 & 1

5 & 1, 9 & 1

6 & 1, 7 & 1

6 & 1, 8 & 1

7 & 1, 8 & 1

7 & 1, 9 & 1

8 & 1, 9 & 1

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Display Board

Interlock

Connector

Side

Touch

Panel

Connector

H.V. Board

Connector

3.5 VAC when oven is connected to power supply.

Speaker Board

Connector

Top

Touch

Panel

Connector

If voltage is present but display does not work, replace display board.

If voltage is not present, check wire harness connections and H.V. board.

18 16023463

©2006 Maytag Services

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

H.V. Board

Pin 1

J5

E1

E2

E3

Pin 28

J1

Pin 50

Pin 1

Pin 1

J8

In straight convection mode, both elements operate simultaneously.

In combination mode, the rear element will operate simultaneously with either the microwave or front element.

Function Test Set-Up

Input to H.V. board At H.V. board Volts

Output to display board

Disconnect

J5 connector

J6

Pin 1

Meter

Setting

Volts

J7

Probe Placement Results

J1 pin 1 (Black wire)

& J1 pin 2 (Red wire)

J5 pin 28 &

J5 pin 50

Pin 1

Pin 1

J2

E4 E5

J3

E7 E6

Line voltage

- 24 VDC

Pin 1

Pin 1

J4

NOTE: For the following test, place oven in Service Test Mode (see page 23).

Relay Function

K1

K2

K3

K5

K7

K8

K4

K9

Cooling &

Conv fan

Heater Top

RH & LH

Convection

heater

Cooling &

Conv fan

Microwave Volts

Microwave

Cooling &

Conv fan

Microwave

Meter

Setting

Volts

Volts

Volts

Volts

Volts

Volts

Volts

Probe Placement Results

E2 (Red wire) &

E4 (Black wire)

E2 (Red wire) &

Back terminal on Heating Element (Hinge

Side) (Violet wire)

E2 (Red wire) & Convection Heating

Element (Gray wire)

E2 (Red wire) & Auto Transformer

(Orange wire 230 terminal)

E2 (Red wire) & Power Relay (Orange

wire terminal 0)

E2 (Red wire) & Transformer

(Red wire 230 terminal)

E2 (Red wire) & Auto Transformer (Yellow

wire 208 V terminal)

E2 (Red wire) & Transformer

(Black wire 208 terminal)

Test mode pad 1 off – No voltage

Test mode pad 1 on – Voltage

Test mode pad 2 off – No voltage

Test mode pad 2 on – Voltage

Test mode pad 4 off – No voltage

Test mode pad 4 on – Voltage

Test mode pad 1 off – No voltage

Test mode pad 1 on – Voltage

Test mode pad 3 off – No voltage

Test mode pad 3 on – Voltage

Test mode pad 3 off – No voltage

Test mode pad 3 on – Voltage

Test mode pad 1 off – No voltage

Test mode pad 1 on – Voltage

Test mode pad 3 off – No voltage

Test mode pad 3 on – Voltage

©2006 Maytag Services 16023463 19

Power Test Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

All Amana and Menumaster microwave oven power outputs are rated using the IEC705 standards. Using the

IEC705 test method requires precision measurements and equipment that is not practical to be performed in the

field. Using the test shown below will indicate if the oven performance is satisfactory.

Test equipment required:

• 1000 ml test container and thermometer (Amana power test kit R0157397 Fahrenheit / Menumaster power

test kit M95D5 Celsius).

Important Notes:

• Low line voltage will cause low temperature rise / power output.

• Ovens must be on a dedicated circuit, properly grounded, and polarized. Other equipment on the same

circuit may cause a low temperature rise / power output.

• This test and results are not a true IEC705 test procedures and are only intended to provide servicers with

an easy means of determining if the microwave oven cooking output is correct.

• Oven must be cold, before performing this test.

Procedure

1. Fill the test container to the 1000 ml line with cool tap water.

NOTE: Water temperature should be approximately 60° F / 16° C

2. Using the thermometer, stir water for five to ten seconds; measure, and record the temperature (T1).

3. Place test container of water in the center of oven cavity using the lowest rack position and close door.

4. Heat the water for a 33-second full power cycle by using the microwave service test procedure.

a. Oven must be in STANDBY mode.

b. Close the door.

c. Press Hidden Pad, 1, 3, 5, 7, 9.

d. Press 3 to activate microwave service mode.

e. Open the door after 33 seconds have elapsed.

5. At end of the cycle, remove test container. Using the thermometer, stir water for five to ten seconds and record

temperature (T2).

6. Subtract the starting water temperature (T1), from the ending water temperature (T2) to obtain the temperature

T).

rise (

7. If the temperature rise (

fails to meet the minimum temperature rise, test the line voltage to verify it is correct. Then repeat steps 1-6

making sure to change the water. If the temperature rise (

the oven will require service.

T) meets or exceeds the minimum, the test is complete. If the temperature rise ( T)

T) fails to meet the minimum temperature rise again,

Minimum Temperature Rise at Thirty -Three (33) Seconds Run Time

T Cooking T Cooking

(°F) Power Output (°C) Power Output

20..................2000 11 ..............2000

20 16023463

©2006 Maytag Services

Convection Temperature Test and Calibration

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Convection Temperature Test

NOTE: It is absolutely necessary to own and use a

thermocouple type oven tester to accurately

measure oven temperature. No other type of

thermometer can take its place.

NOTE: Before testing an oven to check calibration,

inspect the RTD for proper mounting.

1. Place one wire rack in center position. Remove

any other racks and utensils.

2. Clip thermocouple to the center rack and run lead

outside oven door, or wrap thermocouple around

rack and have the tip of thermocouple extend

upward towards top of cavity approximately 1

inch.

3. Press PREHEAT ON/OFF pad.

4. Press PROGRAM SAVE pad.

5. Press TEMP pad.

6. Enter 230° C (450° F).

7. Allow oven to cycle one time.

8. Record high and low peaks from next two cycles.

NOTE: Display does not

are on or off.

Fahrenheit Example:

LOW

Cycle 1 440° F 460° F

Cycle 2 439° F

879° F + 921° F = 1800° F

1800° F / 4 = 450° F average temperature

HIGH

indicate if heating elements

461° F

WARNING

Convection Temperature Calibration

NOTE: It is normal for the average oven temperature

to vary from the oven setting by as much as

14° C (25° F). Difference will not effect

cooking since recipes are written with this

difference in mind.

Calibration

NOTE: Door must be closed and unit must be in

STANDBY mode.

1. Press HIDDEN PAD.

2. Press pads 1,3,5,7, 9.

3. Press "0" pad.

NOTE: Display will show the current offset setting.

4. Press the "0" pad to change the offset.

Fahrenheit

NOTE: Offset temperature range is +40° F to -40° F

and advances in 2° and 3° increments.

Celsius

NOTE: Offset temperature range is +22° C to -22° C

and advances in 1° and 2° increments.

5. Press STOP/RESET pad to save offset changes.

NOTE: Retest the oven after any offset changes are

made.

Celsius Example:

LOW

Cycle 1 230° C 240° C

Cycle 2 230° C

460° C + 480° C = 940° C

940° C / 4 = 230° C average temperature

If the average temperature is too high or too low the

oven temperature offset needs to be calibrated.

©2006 Maytag Services 16023463 21

HIGH

240° C

• Oven temperature is set for 450° F.

• Average of temperature test is 475° F.

• Offset setting must be reduced by 25° F.

• If offset is shown as 10°F, press the "0" pad.

• Oven temperature is set for 230° C.

• Average of temperature test is 240° C.

• Offset setting must be reduced by 10° C.

• If offset is shown as 5°C, press the "0" pad

Fahrenheit Example:

until -15 is shown in the display (10 – 25 = –15).

Celsius Example:

until -5 is shown in the display (5 – 10 = –5).

Display Diagnostics

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

All repairs as described in this troubleshooting section are to be performed only after the caution procedures one through

eight listed below have been followed.

1. Check grounding before checking for possible causes.

2. Be careful of the high voltage circuit.

3. Discharge high voltage capacitor.

4. When checking the continuity of the switches or the high voltage transformer, disconnect one lead wire from these parts

and then check continuity with the AC plug removed. To do otherwise may result in a false reading or damage to your

meter.

5. Do not touch any parts of the circuitry on the P.C. Board circuit since static electric discharge may damage this control

panel. Always touch yourself to ground while working on this panel to discharge any static charge in your body.

6. 208/230 VAC is present in the high voltage circuit board, power relay and primary circuit of low voltage transformer.

7. When troubleshooting, be cautious of possible electrical hazard.

8. When testing convection operation, convection fan may start at any time or if oven is hot.

WARNING

CAUTION

!

Error Codes

During operation, the display may show the following service codes:

NOTE: Before scheduling service for any error codes, instruct customer to unplug oven for 1 minute, reconnect

power, and retest. If unit operates properly, no service call is required.

Display Description Corrective Action

Err1

Err2

Err3

Err4

Err5

Err6

Err7

Err70

Err71

Err72

Err8

Err9

HOT

HOT

Checksum failure Replace Power Board

Hardware problem

Hardware problem

Wrong jumper setting Check cable to Power Board

Shorted keypad

Options scrambled Replace Power Board

Problem with RTD Additional info displayed

0 – Uncalibrated

1 – Shorted

2 – Open

Over temperature

Over temperature

Current < 2 amps

Over temperature

(During Cook Time)

Remains in the display

Replace Power Board

Replace Keyboard

Replace Power Board

Replace Keyboard

NOTE: If Touch Panel is pressed for more than 30 seconds, error code

Err5 displays.

1. Disconnect oven from power supply.

2. Disconnect side touch panel connector from display board (J5).

3. Reconnect oven to power supply.

4. If Err5 reappears after 30 seconds, replace top touch panel.

5. If Err5 does not reappear after 30 seconds, replace side touch panel.

Replace Power Board

Check RTD, connections and J8 cable on HV Board

Check RTD and connections

Inform Customer to press STOP/RESET Twice

Check Triac (TR2)

Check that Relay (K3) is cycling (Convection HTR)

Check Thermal Limiter

Check Triac (TR2)

Check that Relay (K3) is cycling (Convection HTR)

See Important Notes Section

Check Magnetron TCO

Check harness from H.V. Board J8 to TCOs: Short together J8-3 to J8-4:

If HOT error clears, check or replace cable. If HOT error remains, replace

H.V. Board.

22 16023463

©2006 Maytag Services

Service Test

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

Service Test

Putting the oven into Service Test allows you to individually diagnose individual components of

the oven, as well as access the Tube Hours and Door Cycles the oven has experienced.

Entering Service Test

Step Action Display Description

Turn OFF

oven by

1

2

LEVEL

LEVEL

Pressing

PREHEAT

ON/OFF

Press

HIDDEN

PAD

STG indicates input power is 230 VAC.

QTY indicates input power is 50 Hz.

Press 1, 3,

3

LEVE L

5, 7, 9

PADS

©2006 Maytag Services 16023463 23

Service Functions

AMPS

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

Action Display Description

For Pads 1 – 3, Display shows amps being

drawn.

Counter

Appears if plugged into 230 V

1 = ON 0 = OFF

LEVE L

Pad #

Press pad once to turn on.

Press again to turn off.

On Pads 2 & 3, counter will

count up to 62 seconds, then

output will turn off.

Convection Fan

LEVE L

(Internal Cooling Fan runs

also to prevent unit from

overheating)

Radiant Heater

LEVE L

(Convection Fan runs also to

prevent unit from

overheating)

Magnetrons

LEVE L

(Internal Cooling Fan runs

also to prevent magnetrons

from overheating)

Convection Heater

LEVE L

(Convection Fan runs also to

prevent unit from

overheating)

Internal Cooling Fan

LEVE L

(Convection Fan runs also to

prevent unit from

overheating)

24 16023463

©2006 Maytag Services

Service Functions

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

Action Display Description

Mag Hours

(241 shown in this example)

LEVE L

Door Cycles

LEVE L

(13,895 shown in this

example)

0

LEVE L

Displays OFFSET

temperature

©2006 Maytag Services 16023463 25

Disassembly

!

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Door Handle

Remove door handle by removing plastic plugs to gain

access to set screws. Loosen set screws using a

(3/32 inch allen screws), one located to the left of the

door handle and one located on the bottom of the door

handle.

Tighten first

Plastic plugs

NOTE: When replacing door handle, tighten side set

screw first and apply LOCTITE.

NOTE: If set screws are removed, the set screw with

the flat end must be used in the bottom of the

door handle.

Magnetic Door Stop

1. Open the oven door.

2. Remove screws securing magnetic door stop to door

hinge.

3. Reverse procedure to reassemble.

Outer Door

1. Remove door handle, see “Door Handle” procedure.

2. Remove plastic plugs covering screws with a thin flat

blade screwdriver.

3. Remove thumb screws securing door heat shield to

outer door.

4. Remove crows foot screws, securing outer door to

inner door assembly.

5. Remove outer door from inner door assembly.

6. Reverse procedure to reassemble.

Pointed tip

Flat tip

WARNING

Inner Door

Assembly

Outer

Insulation

Inner

Insulation

Outer

Door

Inner Door Assembly

1. Remove outer door, see “Outer Door” procedure.

2. Remove insulation pads from inner door assembly.

3. Remove screws securing inner door assembly to

hinge.

4. Reverse procedure to reassemble.

Hinge

1. Remove outer case, see “Outer Case” procedure.

2. Open oven door and remove screws securing

magnetic door guard from door hinge.

3. Remove outer door, see “Outer Door” procedure.

4. Remove hinge mounting screws from hinge (five on

front, four on side).

NOTE: Discard foam gasket on side of hinge.

5. When reinstalling hinge mounting screws, keep the

side screws loose and tighten the front screws, close

door, press door against oven on the hinge side and

tighten side hinge mounting screws in the sequence

shown below.

1

3

4

2

Magnetic

Hinge Cover

26 16023463 ©2006 Maytag Services

Disassembly

4

!

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Outer Case

1. Remove screws securing outer flue, located on the

back of the unit.

2. Remove screws securing outer case to chassis, see

illustration below.

3. Slide outer case back and lift off.

4. Reverse procedure to reassemble.

WARNING

Interlock Switch Module

1. See “Component Location” Figure 2, for location.

2. Remove outer case, see “Outer Case” procedure.

3. Disconnect wiring from interlock switch assembly.

4. Remove mounting screws securing interlock switch.

5. When replacing assembly, all wires must be

connected before operating oven.

NOTE: When the line fuse is blown, interlock switch

module must be replaced.

7

8

2

Back Panel

1. Remove outer case, see “Outer Case” procedure.

2. Remove screws securing inner flue, located on the

back of the unit.

3. Remove screws securing back panel.

4. Reverse procedure to reassemble.

3

5

Adjustment

1. To adjust interlock switch assembly, close door.

2. Loosen bottom and top screw on the interlock switch

assembly, allowing switch assembly to move in or out.

3. With door closed, push forward on interlock assembly

to engage door latch. Then pull back on interlock

assembly until door is "snug" against front oven cavity

and tighten bottom screw first, then top screw.

4. Door will remain latched when proper adjustment is

made.

NOTE: If door is not properly adjusted display will

indicate DOOR when the door is closed.

Stirrer Motor and Antenna Gears

1. Unplug oven and place unit on its side.

2. Removing screw securing bottom access panel.

3. Remove screws securing stirrer motor to chassis.

4. Remove retainer clip securing antenna gear to

antenna shaft.

5. Reverse procedure to reassemble.

©2006 Maytag Services 16023463 27

Disassembly

!

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

WARNING

RTD (Resistance Thermal Device)

1. See “Component Location” Figure 3, page 53.

2. Remove outer case, see “Outer Case” procedure.

3. Disconnect RTD harness connector.

4. Remove mounting screws securing RTD to plenum

box, located inside oven.

5. Remove RTD by lifting from top of the oven.

6. Reverse procedure to reassemble.

Top Touch Panel Assembly

1. See “Component Location” Figure 1, page 32.

2. Remove outer case, see “Outer Case” procedure.

3. Disconnect all wire connectors and ribbon cables from

display board.

4. Remove screws securing top touch panel to unit.

5. Remove screws securing display board to top touch

panel assembly.

6. Reverse procedure to reassemble.

Access

Panel

Insulation

Pad

Side Touch Panel Assembly

1. See “Component Location” Figure 1, page 32.

2. Remove outer case, see “Outer Case” procedure.

3. Remove ribbon cable from display board.

4. Remove mounting screws securing side touch panel

to unit.

5. Reverse procedure to reassemble.

Display Module

1. See “Component Location” Figure 1.

2. Remove top touch panel, see “Top Touch Panel

Assembly” procedure.

3. Remove screws securing display module to top touch

panel.

4. Reverse procedure to reassemble.

Heating Elements (oven top)

1. Remove outer case, see “Outer Case” procedure.

2. Remove Plenum Plate. See “Component Location”

Figure 2, page 32.

3. Remove screws securing top of heating element

clamp, located inside the oven cavity.

4. Remove screw securing access plate (see figure 6) to

insulation retainer.

5. Remove access plate (figure 2, page 32) and

insulation from unit to gain access to calrod block.

6. Disconnect wire terminals from calrod at terminals.

7. Loosen set screw enough to separate calrod block

from around heating element.

8. Slowly maneuver heating element from inside the oven

cavity to remove.

9. Reverse procedure to reassemble.

Figure 6

NOTE: When reassembling unit verify insulation is

properly placed around the element(s), before

securing access panel.

Inlet Duct Assembly

1. Remove back panel, figure 3, page 33, and see “Back

Panel” procedure.

2. Disconnect and label wire terminals from convection

fan motor.

3. Disconnect connector plug, remove from inlet duct.

4. Slide inlet duct assembly away from unit to remove.

5. Reverse procedure to reassemble.

Halfwave Board (60 Hz Models Only)

1. See figure 3, page 33 for location.

2. Disconnect wire terminals from halfwave board.

3. Release mounting clips securing board and remove

board.

4. Reverse procedure to reassemble.

28 16023463 ©2006 Maytag Services

Disassembly

!

WARNING

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Control Board Assembly Bracket

1. Remove back panel, see “Back Panel” procedure

(page 33).

2. Remove inlet duct assembly, see “Inlet Duct Assembly”

procedure.

3. Disconnect wire harness from plastic clips.

4. Slide bracket towards the center of the unit.

5. Raise bracket up and pull outward towards the rear of

Auto Transformer (60 Hz Models Only)

1. Remove back panel, see “Back Panel” procedure

(page 33).

2. Disconnect and label wire terminals from auto

transformer.

3. Remove screws securing auto transformer to power

assembly bracket.

4. Reverse procedures to reassemble.

unit to remove.

6. Reverse procedures to reassemble.

Convection

Capacitor

H.V.

Board

Triacs (Figure 3, Page 33)

1. Remove back panel, see “Back Panel” procedure

(page 33).

2. Disconnect and label wire terminals from selected

triac.

3. Remove screws securing triac to power assembly

bracket.

Power

4. Reverse procedures to reassemble.

Relay

Power Relay (Figure 3, Page 33)

Auto

Transformer

1. Remove back panel, see “Back Panel” procedure.

2. Disconnect and label wire terminals from power relay.

3. Remove screws securing power relay to power

assembly bracket.

4. Reverse procedures to reassemble.

Triac(s)

High Voltage Circuit Board

1. See “Component Location“ Figure 2, page 33.

2. Remove outer case, see “Outer Case” procedure.

3. Disconnect and label connectors and wire terminals

from H.V. Board.

4. Release mounting clips securing board and remove

board.

5. Reverse procedure to reassemble.

Pin 1

Pin 1

J3

Clip

Clip

J4

E6

E7

E4

E5

Pin 1

J2

Pin 1

Clip

J7

Pin 1

Clip

J1

Pin 50

Pin 1

J5

Pin 28

E3

E2

Clip

NOTE: When reassembling, verify cable connection with

illustration of cable locations.

©2006 Maytag Services 16023463 29

Clip

Pin 1

J8

J6

Pin 1

E1

Clip

1. Remove outer case, see “Outer Case” procedure

2. Disconnect and label wire terminals from capacitor.

3. Remove screws securing capacitor bracket to power

assembly bracket.

4. Reverse procedures to reassemble.

Magnetron

1. See “Component Location” Figure 3, page 33.

2. Remove outer case, see “Outer Case” procedure.

3. Remove screws securing magnetron inlet cover and

remove cover.

4. Remove screws securing waveguide duct.

5. Remove wire terminals from magnetron.

6. Remove allen screws securing magnetron thermal

cutout bracket to magnetron.

7. Remove magnetron mounting nuts and remove front

magnetron cover bracket.

8. Remove magnetron.

9. When replacing magnetron, verify wire mesh gasket

is reinstalled properly.

NOTE: When reinstalling magnetron, slide air baffle

inside magnetron before mounting magnetron in

place.

NOTE: Place front magnetron cover bracket in place

before securing magnetron.

Convection Motor Capacitor (Fig 3, Page 33)

Disassembly

!

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Magnetron, Control, and Fan Thermal

Cutouts (TCO)

1. See figures 4 and 5, page 34, for location.

2. Remove outer case, see “Outer Case” procedure.

3. Disconnect and label wire terminals from selected

thermal cutout.

4. Remove screws securing thermal cutout.

5. Reverse procedure to reassemble thermal cutout.

WARNING

Fan

Blade

Fan

Motor

Scroll

Blower Bracket Assembly

1. Remove back panel, see “Back Panel” procedure.

2. Disconnect and label wire terminals from blower

motor.

3. Disconnect and label wire terminals from fuse block.

4. Disconnect L2 connector plug.

5. Remove screws securing blower bracket to exterior of

oven cavity.

• one located at the rear on the bottom of bracket

• one located above the rear magnetron

6. Reverse procedure to reassemble.

Blower

Wheel

Microwave Blower Wheel and Motor

1. Remove blower bracket assembly, see “Blower

Bracket Assembly” procedure, also see figure 7.

2. Remove screws securing blower assembly to bracket.

3. Loosen allen set screw securing blower wheel to

motor shaft.

4. Remove blower wheel.

5. Remove screws securing motor to scroll.

6. Reverse procedure to reassemble.

NOTE: When reinstalling blower wheel, push blower

wheel on shaft, tighten, and rotate to insure

clearance between blower wheel, and blower

housing.

Figure 7

Fan Blade

1. Pull blade off shaft.

2. When reinstalling blade, push blade on shaft and

rotate to insure clearance between fan blade and

motor mounting bolt.

Transformer

1. See “Component Location” Figure 3, page 33.

2. Remove back panel, see “Back Panel” procedure.

3. Remove screws securing transformer to chassis.

4. Pry upward and pull back to release transformer from

chassis.

5. Disconnect and label wire terminals from transformer.

NOTE: When placing transformer back into chassis.

Front portion of transformer must slide into

base pan tab.

6. Reverse procedure to reassemble

30 16023463 ©2006 Maytag Services

Disassembly

!

To avoid the risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitors

before following any disassembly procedure.

Capacitor / Diode

1. See figure 3, page 33 for location.

2. Remove outer case, see “Outer Case” procedure.

3. Discharge capacitor and remove wire terminals from

capacitor.

4. Remove screws securing capacitor mounting bracket

to oven chassis.

5. Loosen screws securing capacitor strap to capacitor.

6. Reverse procedure to reassemble.

Convection Box

1. See “Component Location” Figure 5, page 34.

2. Remove back panel, see “Back Panel” procedure.

3. Remove inlet duct assembly, See “Inlet Duct

Assembly” procedure.

4. Remove control board bracket assembly, see “Control

Board Bracket Assembly” procedure.

5. Disconnect and label wire terminals from Heating

Element, TCO, and Temperature Sensor.

6. Remove screws securing thermal limiter to convection

box.

7. Remove screws securing convection box to plenum

box.