Alto Shaam TY-96 Operation Manual

#856-7 • 9/00

PRINTED IN U.S .A .

OPERATION and CARE MANUAL

®

COOK/HOLD/SERVE SYSTEMS

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558.8744 U.S.A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

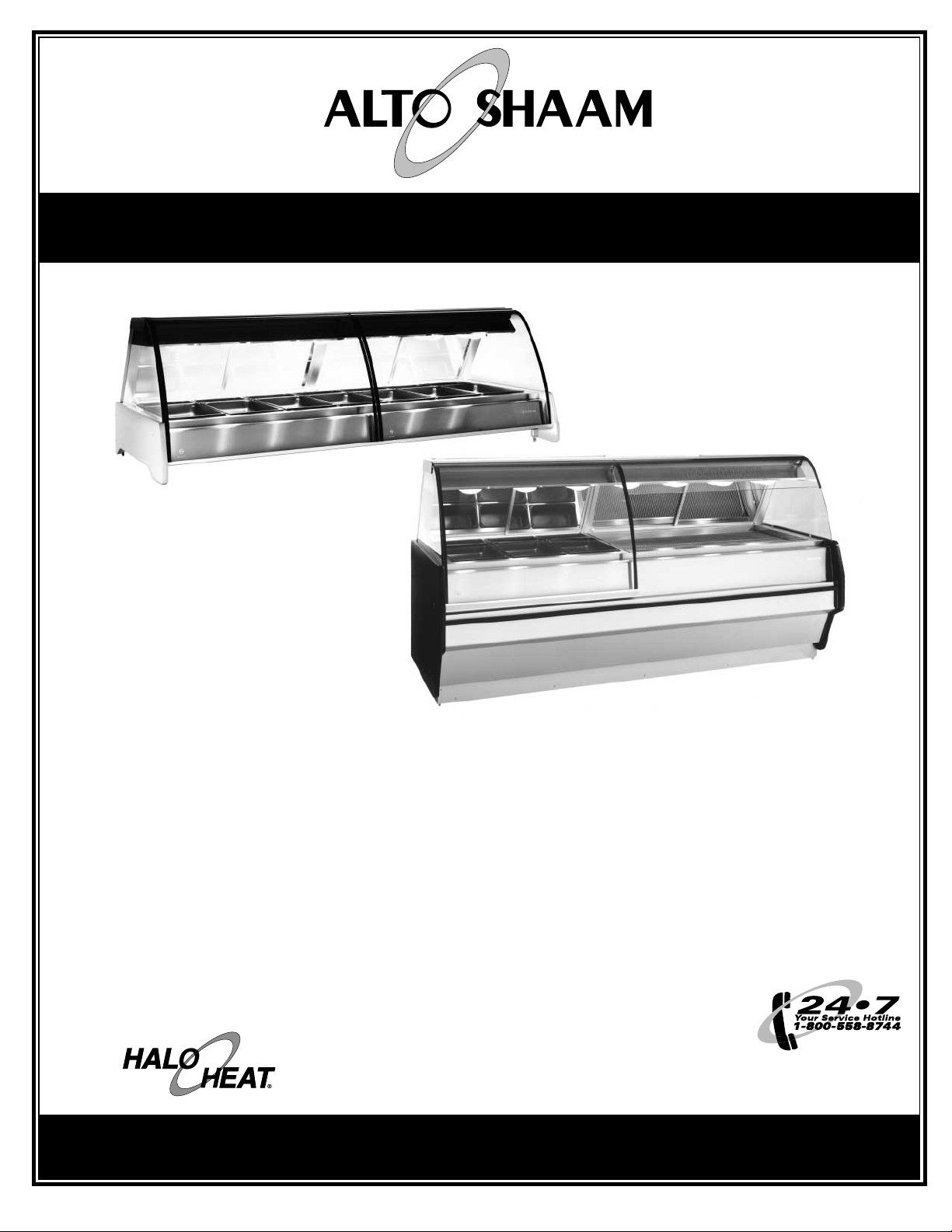

HOT DISPLAY CASE

MODELS: TY-96 TYSYS-96

TY-96/PR TYSYS-96/PR

TY-96/PL TYSYS-96/PL

TYSYS-96/4L TYSYS-96/4R

TYSYS-96/41L TYSYS-96/41R

UNPACKING

and SET-UP

The Alto-Shaam Hot Display

Case has been thoroughly tested,

checked for calibration, and

inspected to insure only the

highest quality cabinet is

provided. When you receive your display case, check for

any possible shipping damage and report it at once to the

delivering carrier.

In order to maintain established National Sanitation

Foundation standards, all floor models must be sealed to the

floor with a R.T.V. or silastic meeting N.S.F. requirements or

have 6" (152mm) unobstructed clearance beneath the unit.

Counter and table units must be mounted on legs of a

sufficient 4" (102mm) height to provide minimum

unobstructed space beneath the unit. These legs are

supplied with the unit. Warranty will become null and void

if these directions are not followed.

Save all the information and instructions packed inside

the display case. Complete and return the warranty card to

the factory as soon as possible to assure prompt service in

the event of a warranty parts and labor claim.

NOTE: Any and all claims for warranty must include the full

model and serial number of the display case.

ELECTRICAL INSTALLATION

The unit must be installed by an authorized service agent in

accordance with national codes.

1. An identification tag is permanently mounted on case.

2. Plug the case into a properly grounded receptacle ONLY.

Arcing will occur when connecting or disconnecting the

display case unless all controls are in the OFF position.

3. REGARDING INTERNATIONAL STANDARD UNITS:

If the unit is not equipped with flexible cord with plug,

an all-pole country approved disconnection device

which has a contact separation of at least 3mm in all

poles must be incorporated in the fixed wiring for

disconnection. When using a cord without a plug, the

green/yellow conductor shall be connected to the

terminal which is marked with the ground symbol. If a

plug is used, the socket outlet must be easily accessible.

If power cord needs replacement, use a similar one

obtained from the distributor.

1. DO NOT ADD WATER TO THE DISPLAY CASE

Halo Heat display cases maintain a constant but gentle

temperature and eliminate much of the moisture loss

associated with conventional display cases. Because of

this gentle heat, it is not necessary to add water to the

unit. As a matter of fact,

adding water is not

recommended

since water will accelerate the

deterioration of the product and may damage the unit.

2. PLACE DIVIDERS and SERVING PANS IN CASE

Refer to the pan layout diagrams for different types of

pan accommodations. A complete pan configuration

layout is located in this manual.

It is VERY important to

note,

no matter what type of pan configuration you

choose,

pan divider bars with the desired pans must be

in place prior to preheating the unit.

If air gaps are not

closed, heat distribution will be uneven, and uniform

temperature will be difficult to maintain. Additional pan

divider bars are available if needed.

3. TURN DISPLAY LIGHTS “ON” AND SET THE

THERMOSTAT(s) AT NUMBER “10” TO PREHEAT

An indicator light will illuminate when the thermostat(s)

is (are) turned “

ON.” The indicator(s) will remain lit as

long as the unit is preheating or calling for heat. The

unit should be preheated, at the number

10 setting, for a

minimum of twenty minutes before loading the case

with food. When preheating is completed, or whenever

the unit reaches any temperature set by the operator

between

1 and 10, the indicator light(s) will go “OUT”.

4. LOAD HOT FOODS INTO THE CASE

Be certain only hot food is transferred into the case.

Before loading food into the case, use a pocket-type meat

thermometer to make certain all products have reached

an internal temperature of 140° to 160° F (60° to 71°C). If

any food product is not at proper serving temperature,

use a Halo Heat cooking and holding oven, set at 250° to

275°F (121° to 135°C), or use an Alto-Shaam Combitherm

oven to bring the product within the correct temperature

range.

Be certain only hot PREPACKAGED foods

are used in the self-service section of the deli case.

5.

RESET THERMOSTAT AS NEEDED

After all products are loaded into the display case and

the doors are closed, reset the thermostat(s) to the

number “8” setting. THIS WILL NOT NECESSARILY

BE THE FINAL SETTING. Since proper temperature

range depends on the type of products and the quantities

being held, it is necessary to periodically use a pocket

thermometer to check each item to make certain the

correct temperatures are being maintained. Proper

temperature range is between 140° and 160°F (60° and

71°C). Normally, this will require a thermostat setting of

between number “6” and “8,” although a higher or lower

setting may sometimes be required.

6. MULTIPLE TIMER/PROBE OPTION

A multiple timer/probe system is available for this case.

This system is a timer-based food management system,

utilized with HACCP programs, that ensures proper

rotation, food integrity, safety and quality. The multipletimer station keys correspond to various pan locations

Operation & Care Manual #856-7 • 1

HOT DISPLAY CASES

ENSURE POWER SOURCE MATCHES

VOLTAGE STAMPED

ON NAMEPLATE OF UNIT

PROCEDURES

®

SERIAL NUMBER AND WARRANTY CODE

IDENTIFICATION MODEL NUMBER

MODEL

SERIAL NO. WATTS

VOLTS

MAXIMUM RATED VOLTAGE MAXIMUM RATED FREQUENCY

EXAMPLE

MAXIMUM RATED

WATTAGE

xxx-xx

xxxx-xx xxxx

ALTO-SHAAM INC. MILW. WI. PAT. NO. 3521030

AC

1 PH

xx

HZxxx

in the display case. Please contact the factory for further

information.

7. PLACEMENT OF FOOD PROBE (OPTIONAL)

If the unit is equipped with the probe accessory, wipe

each probe and probe tip with a disposable alcohol pad to

clean and sanitize before using. If the probe is left in its

bracket, the LED temperature display will indicate the

ambient air temperature inside the case. To place a probe

into food kept in the case, remove the probe from the

bracket and push the probe tip halfway into the product,

positioning the tip at the center of the food mass. If

placing into solid foods such as meat roast or poultry

breasts, push the probe in from a straight downward

position or in from the side to the center position.

If placing into a semi-liquid or liquid product, the probe

cable will probably need to be secured to keep the probe

positioned properly. Do not let the probe tip touch the

edges or side of the container. Tape the probe cable to the

lip or edge of the container. Wipe each probe tip with a

clean paper towel to remove food debris after each use.

Follow by wiping probes with a disposable alcohol pad.

Return each probe to the proper bracket position.

8. SERVE FRESH HOT FOOD

Keep hot foods looking fresh. Occasionally stir or rotate

foods as needed. Serve products in the proper package or

container. Keep doors closed after serving. Wipe spills

immediately – assuring maximum eye appeal.

THOROUGHLY CLEAN THE

DISPLAY CASE DAILY

1. Turn lights and adjustable

thermostat(s) to the “

OFF” position.

Remove, cover or wrap, and store

unused products under refrigeration.

2. Clean the interior metal surfaces of the cabinet with a

damp cloth and any good alkaline or alkaline chlorinated

based commercial detergent or grease solvent at the

recommended strength. Use a plastic scouring pad or

oven cleaner for difficult areas. Avoid the use of abrasive

cleaning compounds, chloride based cleaners, or cleaners

containing quatenary salts. Rinse well to remove all

residue and wipe dry.

NOTE: Never use hydrochloric acid (muriatic acid) on

stainless steel.

3. Clean the glass with glass cleaner.

4. Maintain the protective film coating on polished stainless

steel by cleaning the exterior with a cleaner recommended

for stainless steel. Spray the cleaning agent on a clean

cloth and wipe with the grain of the stainless steel.

Remember to follow appropriate state or local health

(hygiene) regulations regarding all applicable cleaning

and sanitation requirements for equipment.

DISCONNECT UNIT FROM POWER SOURCE

BEFORE CLEANING OR SERVICING.

AT NO TIME SHOULD THE CASE BE STEAM

CLEANED, FLOODED WITH WATER OR LIQUID

SOLUTION. NEVER STEAM CLEAN. SEVERE

DAMAGE OR ELECTRICAL HAZARD COULD

RESULT.

CLEAN THE PROBES DAILY

Remove all food soil from probes. Wipe entire probe and

cable assembly with warm detergent solution and a clean

cloth. Remove detergent by wiping each probe and cable

with clean rinse water and a cloth. Wipe probes with

disposable alcohol pad or sanitizing solution

recommended for food contact surfaces. Allow probe and

cable to air dry in probe holding bracket.

Operation & Care Manual #856-7 • 2

CARE and CLEANING

SAFETY ALERT

This units performance has been

optimized using the factory provided

lamps. These lamps should be

replaced with an exact

replacement or with a factory

recommended replacement. These lamps have

been treated to resist breakage and

must be replaced with similarly

treated lamps in order to maintain

compliance with NSF standards.

Hood glass extended to the full upright

position is stabilized through the use

of gas struts designed for the full

!

CAUTION

environmental conditions or aging.

Operators should be aware of any decrease in effort to lift

the hood and initiate an immediate gas strut safety check.

DO NOT LIFT THE HOOD IN THIS CONDITION.

load bearing weight. These struts

could weaken or fail due to wear,

Operation & Care Manual #856-7 • 3

SANITATION GUIDELINE

Food flavor and aroma are usually so closely related

that it is difficult, if not impossible, to separate them.

There is also an important, inseparable relationship

between cleanliness and food flavor. Cleanliness, top

operating efficiency, and appearance of equipment

contribute considerably to savory, appetizing foods. Good

equipment that is kept clean, works better and lasts longer.

Most food imparts its own particular aroma and many

foods also absorb existing odors. Unfortunately, during

this absorption, there is no distinction between

GOOD

and BAD odors. The majority of objectionable flavors and

odors troubling food service operations are caused by

bacteria growth. Sourness, rancidity, mustiness, stale or

other

OFF flavors are usually the result of germ activity.

The easiest way to insure full, natural food flavor is

through comprehensive cleanliness. This means good

control of both visible soil (dirt) and invisible soil (germs).

A thorough approach to sanitation will provide essential

cleanliness. It will assure an attractive appearance of

equipment, along with maximum efficiency and utility.

More importantly, a good sanitation program provides one

of the key elements in the prevention of food-borne

illnesses. A controlled holding environment for prepared

foods is just one of the important factors involved in the

prevention of food-borne illnesses. Temperature

monitoring and control during receiving, storage,

preparation, and the service of foods are of equal

importance.

The most accurate method of measuring safe temper-

atures of both

hot and cold

foods is by

internal

product

temperature.

A quality

thermometer

is an effective

tool for this

purpose, and

should be

routinely

used on all products that require holding at a specific

temperature.

A comprehensive sanitation program should focus on

the training of staff in basic sanitation procedures. This

includes personal hygiene, proper handling of raw foods,

cooking to a safe internal product temperature, and the

routine monitoring of internal temperatures from receiving

through service.

Most food-borne illnesses can be prevented through

proper temperature control and a comprehensive program

of sanitation. Both these factors are important to build

quality service as the foundation of customer satisfaction.

Safe food handling practices to prevent food-borne illness

is of critical importance to the health and safety of your

customers. HACCP, an acronym for Hazard Analysis (at)

Critical Control Points, is a quality control program of

operating procedures to assure food integrity, quality, and

safety. Taking steps necessary to augment food safety

practices are both cost effective and relatively simple.

While HACCP guidelines go far beyond the scope of this

manual, additional information is available by contacting

the USDA/FDA Food-borne Illness Education Information

Center at (301)504-6803.

GENERAL HOLDING GUIDELINE

Chefs, cooks and other specialized food service

personnel employ varied methods of cooking. Proper

holding temperatures for a specific food product must be

based on the moisture content of the product, product

density, volume, and proper serving temperatures. Safe

holding temperatures must also be correlated with

palatability in determining the length of holding time for a

specific product.

Halo Heat maintains the maximum amount of product

moisture content without the addition of water, water vapor,

or steam. Maintaining maximum natural product moisture

preserves the natural flavor of the product and provides a

more genuine taste. In addition to product moisture

retention, the gentle properties of Halo Heat maintain a

consistent temperature throughout the cabinet without the

necessity of a heat distribution fan, thereby preventing

further moisture loss due to evaporation or dehydration.

In an enclosed holding environment, too much moisture

content is a condition which can be relieved. A product

achieving extremely high temperatures in preparation must

be allowed to decrease in temperature before being placed in

a controlled holding atmosphere. If the product is not

allowed to decrease in temperature, excessive condensation

will form increasing the moisture content on the outside of

the product.

Most Halo Heat Holding Equipment is provided with a

thermostat control between 60° and 200°F (16° to 93°C). If

the unit is equipped with vents, close the vents for moist

holding and open the vents for crisp holding.

If the unit is equipped with a thermostat indicating a

range of between 1 and 10, use a metal-stemmed indicating

thermometer to measure the internal temperature of the

product(s) being held. Adjust the thermostat setting to

achieve the best overall setting based on internal product

temperature.

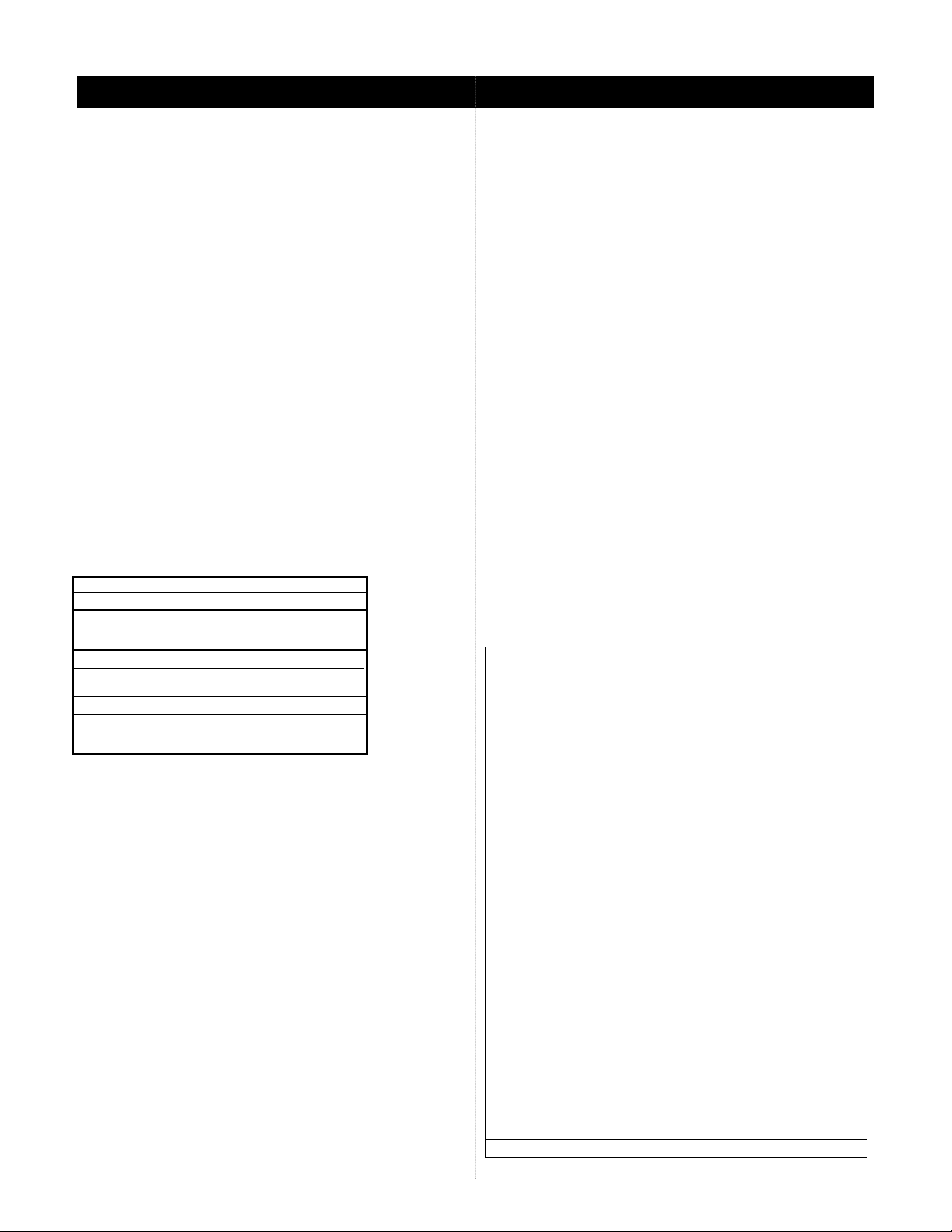

HOLDING TEMPERATURE RANGE

MEAT FAHRENHEIT CELSIUS

BEEF ROAST — Rare 140°F60°C

BEEF ROAST — Med/Well Done 160°F71°C

BEEF BRISKET 160°— 175° F71°— 79°C

CORN BEEF 160°— 175° F71°— 79°C

PASTRAMI 160°— 175° F71°— 79°C

PRIME RIB — Rare 140°F60° C

STEAKS — Broiled/Fried 140°— 160° F60°— 71°C

RIBS — Beef or Pork 160°F71°C

VEAL 160°— 175° F71°— 79°C

HAM 160°— 175° F71°— 79°C

PORK 160°— 175°F71°— 79°C

LAMB 160°— 175° F71°— 79°C

POULTRY

CHICKEN — Fried/Baked 160°— 175° F71°— 79°C

DUCK 160°— 175°F71°— 79° C

TURKEY 160°— 175° F71°— 79°C

GENERAL 160°— 175° F71°— 79°C

FISH/SEAFOOD

FISH — Baked/Fried 160°— 175° F71°— 79°C

LOBSTER 160°— 175° F71°— 79°C

SHRIMP — Fried 160°— 175° F71°— 79°C

BAKED GOODS

BREADS/ROLLS 120°— 140°F49°— 60°C

MISCELLANEOUS

CASSEROLES 160°— 175° F71°— 79°C

DOUGH — Proofing 80°— 100°F27°— 38°C

EGGS —Fried 150°— 160°F66°— 71°C

FROZEN ENTREES 160°— 175°F71°— 79°C

HORS D'OEUVRES 160°— 180°F71°— 82°C

PASTA 160°— 180° F71°— 82° C

PIZZA 160°— 180° F71°— 82° C

POTATOES 180° F82°C

PLATED MEALS 180°F82° C

SAUCES 140°— 200° F60°— 93° C

SOUP 140°— 200°F60°— 93°C

VEGETABLES 160°— 175°F71°— 79°C

THE HOLDING TEMPERATURES LISTED ARE SUGGESTED GUIDELINES.

INTERNAL FOOD PRODUCT TEMPERATURES

HOT FOODS

DANGER ZONE 40° TO 140° F(4° TO 60°C)

CRITICAL ZONE 70° TO 120° F (21° TO 49° C)

SAFE ZONE 140° TO 165° F (60° TO 74°C)

COLD FOODS

DANGER ZONE ABOVE 40°F (ABOVE 4°C)

SAFE ZONE 36° F TO 40°F(2°C TO 4° C)

FROZEN FOODS

DANGER ZONE ABOVE 32°F (ABOVE 0°C)

CRITICAL ZONE 0° TO 32° F (-18° TO 0° C)

SAFE ZONE 0°F OR BELOW (-18°C OR BELOW)

Operation & Care Manual #856-7 • 4

(35mm x 706mm)

(83mm x 178mm)

(25mm x 708mm)

(25mm x 324mm)

(83mm x 706mm)

(45mm x 451mm)

(150mm x 706mm)

(95mm x 706mm)

(22mm x 708mm)

SHEET PAN DIVIDER BAR

ONE-THIRD SIZE PAN

FULL, HALF & THIRD SIZE - LONG

FULL, HALF & THIRD SIZE - SHORT

SHEET PAN DIVIDER BAR

SHEET PAN DIVIDER BAR

SHEET PAN DIVIDER BAR

SHEET PAN FILLER

GASTRONORM DIVIDER (220V)

1-3/8" x 27-13/16"

3-1/4" x 7"

1" x 27-7/8"

1" x 12-3/4"

3-1/4" x 27-3/16"

1-3/4" x 17-3/4"

5-29/32" x 27-13/16"

3-3/4" x 27-13/16"

7/8" x 27-7/8"

STANDARD PAN DIVIDER & SEPARATOR BARS

ITEM NO.

11046

11047

11317

11318

11319

11320

11357

11732

1865

SIZE (W x L)DESCRIPTION

48 72 96

1

1

2

9

1

2

—

—

2

—

—

4

15

—

3

2

—

4

—

—

6

21

—

4

3

1

6

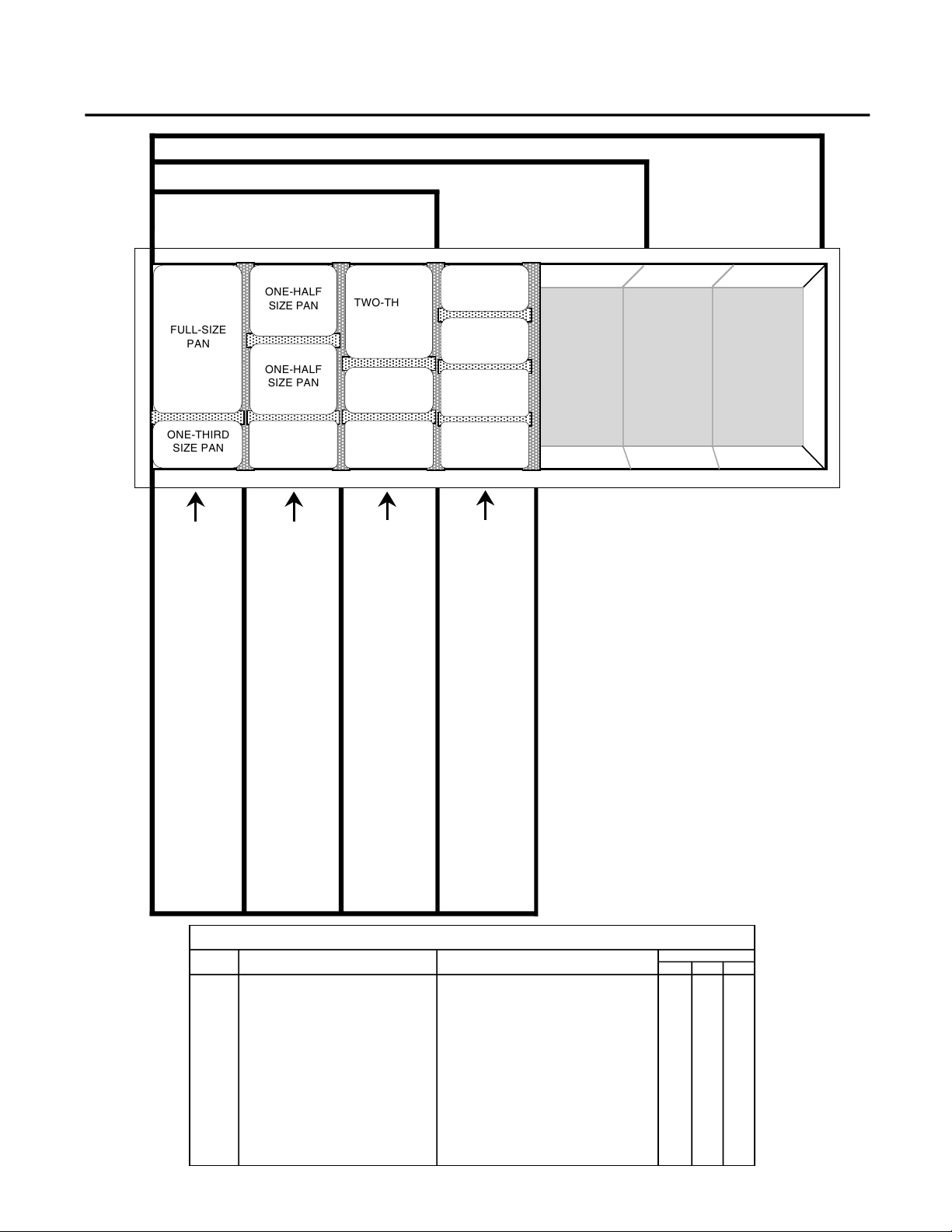

PAN CONFIGURATIONS • HOT DELI DISPLAY CASES

NOTE: ADDITIONAL PAN

SEPARATOR BARS MAY

BE REQUIRED TO

ACCOMMODATE MAXIMUM

CAPACITIES.

FULL-SIZE

PAN

ONE-THIRD

SIZE PAN

ONE-HALF

SIZE PAN

ONE-HALF

SIZE PAN

TWO-THIRDS

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

48 Models

72 Models

96 Models

3 PAN ZONES 5 PAN ZONES

7 PAN ZONES

One (1) FULL-SIZE PAN and

One (1) ONE-THIRD SIZE PAN per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 3 Full-Size Pans with 3 One-Third Size Pans

Up to 5 Full-Size Pans with 5 One-Third Size Pans

Up to 7 Full-Size Pans with 7 One-Third Size Pans

Two (2) ONE-HALF SIZE PANS and

One (1) ONE-THIRD SIZE PAN per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 6 One-Half Size Pans with 3 One-Third Size Pans

Up to 10 One-Half Size Pans with 5 One-Third Size Pans

Up to 14 One-Half Size Pans with 7 One-Third Size Pans

One (1) TWO-THIRDS SIZE PAN and

Two (2) ONE-THIRD SIZE PANS per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 3 Two-Thirds Size Pans with 6 One-Third Size Pans

Up to 5 Two-Thirds Size Pans with 10 One-Third Size Pans

Up to 7 Two-Thirds Size Pans with 14 One-Third Size Pans

Four (4) ONE-THIRD SIZE PANS per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 12 One-Third Size Pans per display case

Up to 20 One-Third Size Pans per display case

Up to 28 One-Third Size Pans per display case

ONE-THIRD

SIZE PAN

MODELS

Operation & Care Manual #856-7 • 5

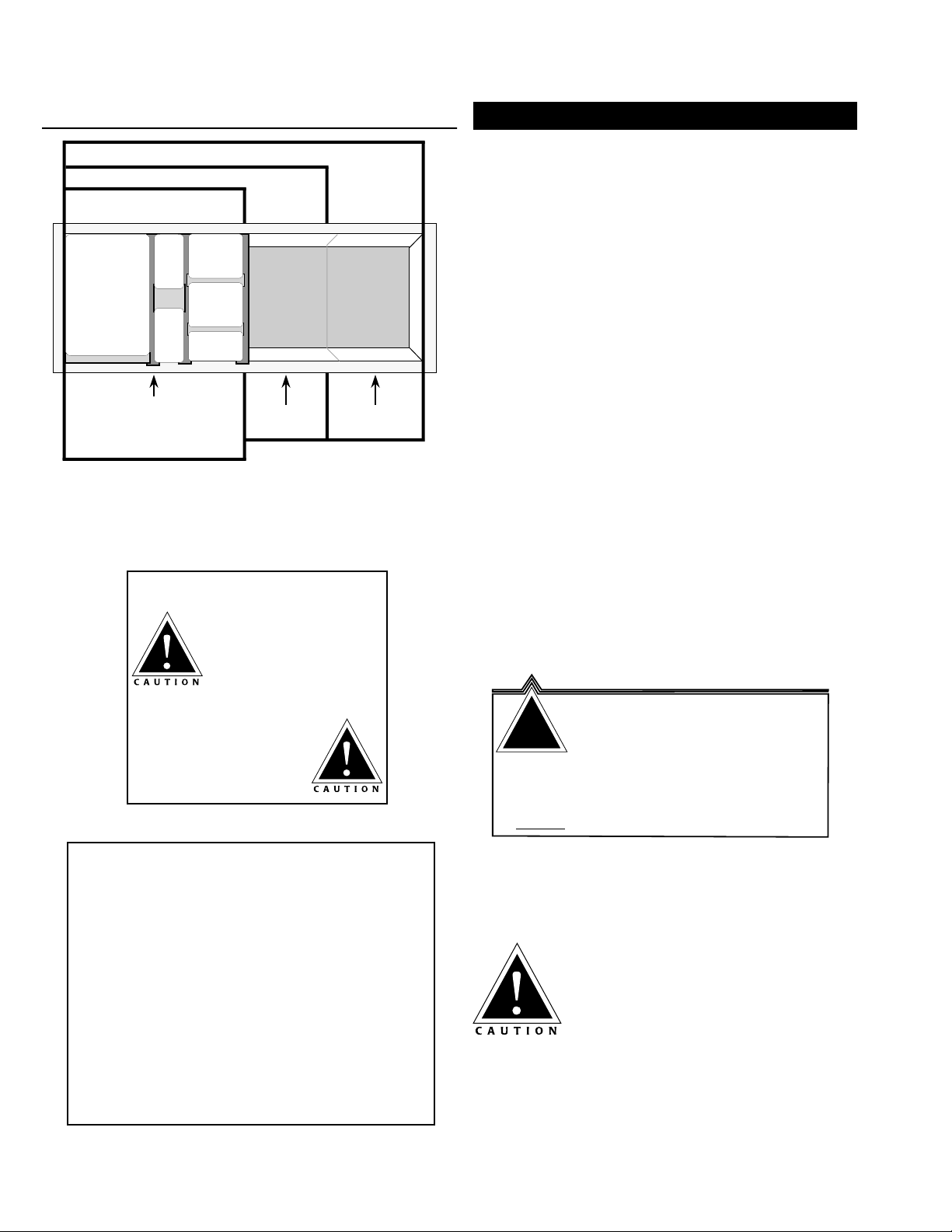

SHEET PAN CONFIGURATIONS • HOT DELI DISPLAY CASES

Custom Panel, End Panel & Bumper Colors . . . . . FACTORY QUOTE

End Panels

— Black Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PE-22708

— Solid Black Patch, Right Hand . . . . . . . . . . . . . . . . . . PE-23674

— Solid Black Patch, Left Hand. . . . . . . . . . . . . . . . . . . . PE-23675

End Patch/Kiosk Assembly Kit, s/s, TY ONLY . . . . . . . . . . . . 14600

Bulbs

— 100 Watt, 120V STANDARD . . . . . . . . . . . . . . . . . . . . . . . LP-3333

— 100 Watt, 130V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LP-33253

— 100 Watt, 230V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LP-3384

Independent Circuit Cordset Pkg. TY 120V ONLY . . . . . . . . . . . 14221

Independent Load Center Pkg. TYSYS 120V ONLY . . . . . . . . . . . . 14220

NOT CSA APPROVED

Interior Ambient Temperature Gauge . . . . . . . . . . . . . . GU-33384

Menu Board System (two required). . . . . . . . . . . . . . . . MB-23092

Pocket Thermometer °F . . . . . . . . . . . . . . . . . . . . . . . . . . . TH-3300

Pocket Thermometer °C . . . . . . . . . . . . . . . . . . . . . . . . . . TH-3412

Product Probe Package: 120V ONLY

— TY-96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5297

— TY-96/PL, /PR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5296

— TY-96/4L, /4R, /41L, /41R. . . . . . . . . . . . . . . . . . . . . . . . . . 5295

Reflective Tempered Glass Case End Panes

— RIGHT-HAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GL-22539

— LEFT-HAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GL-22538

Scale Platform Package 120V ONLY . . . . . . . . . . . . . . . . . . . . . 14102

Stainless Steel Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 12646

Tempered Glass End Spacer . . . . . . . . . . . . . . . . . . . . . . GL-22719

Display Case Multiple Timer/Probe . . . . . . . . . . . FACTORY QUOTE

ACCESSORIES

Cable Heating Service Kits

for TY-96/PL & TY-96/PR

and TYSYS-96/PL or PR

Nos. 4881 & 4878

include:

CB-3045 Cable Heating Element 210' 72'

CR-3226 Ring Connector 12 4

IN-3488 Insulation Corner 1' 1'

BU-3105 Shoulder Bushing 12 4

BU-3106 Cup Bushing 12 4

SL-3063 Insulating Sleeve 12 4

TA-3540 Electrical Tape 1 roll 1 roll

NU-2215 10x32 Hex Nut 24 8

ST-2439 Stud 12 4

Hood glass extended to the full upright

position is stabilized through the use

of gas struts designed for the full

load bearing weight. These struts

could weaken or fail due to wear,

environmental conditions or aging.

Operators should be aware of any decrease in effort to lift

the hood and initiate an immediate gas strut safety check.

DO NOT LIFT THE HOOD IN THIS CONDITION.

SAFETY ALERT

This units performance has been

optimized using the factory provided

lamps. These lamps should be

replaced with an exact

replacement or with a factory

recommended replacement. These lamps have

been treated to resist breakage and

must be replaced with similarly

treated lamps in order to maintain

compliance with NSF standards.

At no time should the inside or outside of

the cabinet be washed down, flooded with

water or liquid solution. NEVER STEAM

CLEAN.

Severe damage or electrical

hazard could result.

48 Models

2 SHEET PAN ZONES

SIZE PAN

FULL-SIZE

SHEET PAN

2 Full-size Sheet Pans per display case

ONE-THIRD

SIZE PAN

ONE-THIRD

48 MODELS

OR

1 Full-size Sheet Pan

2 One-half Size Pans

3 One-third Size Pans

72 Models

3 SHEET PAN

ZONES

ONE-HALF

SIZE PAN

ONE-HALF

SIZE PAN

ONE-THIRD

SIZE PAN

72 MODELS

3 Full-size Sheet Pans

per display case

4 Full-size Sheet Pans

96 Models

4 SHEET PAN

ZONES

96 MODELS

per display case

!

CAUTION

Operation & Care Manual #856-7 • 6

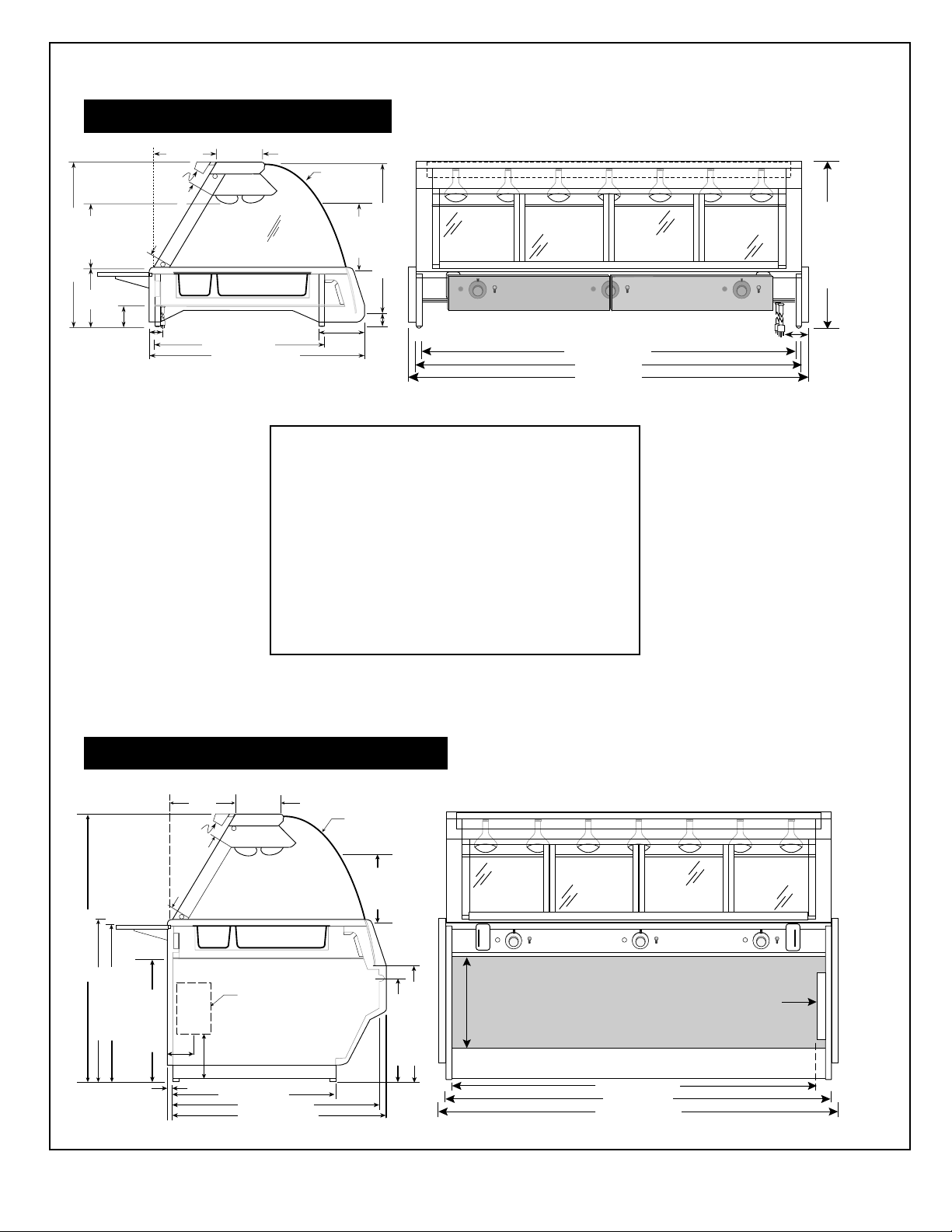

TY-96 HOT DISPLAY CASE

TYSYS-96 HOT DISPLAY CASE

Cable Heating Service Kit No. 14228

for TY-96 & TYSYS-96

includes:

CB-3045 Cable Heating Element . . . . . . . . . . . . . . . . . . . . . 265 feet

CR-3226 Ring Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IN-3488 Insulation Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 foot

BU-3105 Shoulder Bushing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BU-3106 Cup Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SL-3063 Insulating Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TA-3540 Electrical Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 roll

NU-2215 10x32 Hex Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ST-2439 Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

98" (2489mm)

96" (2438mm)

31-3/8" (797mm)

93-1/4" (2369mm)

CUTTING BOARDS IN “DOWN” POSITION

4"

(102mm

15-11/16" (398mm)

12-1/16"

(307mm)

PLATFORM

9-3/8" (238mm)

10" (254mm)

WORK SHELF

31-3/8" (797mm)

13" (330mm)

SELF-SERVE OPENING

FRONT GLASS

95 DEGREE LIFT-UP

GAS STRUT ASSIST

12-31/32"

(329mm)

ONE-THIRD — FULL-SIZE

PAN CONFIGURATION

TY CASES

7/25/94

12"

(305mm)

28-9/16" (725mm)

41-15/16" (1065mm)

34-3/8" (873mm)

1-5/8" (41mm) for 120/240V models

1-3/4" (44mm) for 220V models

8"

(203mm)

4-1/8"

(105mm)

2-13/16"

(72mm)

SCALE

OUTLETS

96" (2438mm)

98-1/4" (2496mm)

90-3/8" (2296mm)

17-1/2"

(445mm)

LOAD CENTER

CIRCUIT BREAKERS

31-3/16" (792mm)

30-7/16" (773mm)

23" (584mm)

31-5/8" (803mm)

40-1/4" (1022mm)

42-1/2" (1079mm)

20-3/16 (512mm)

15-11/16" (398mm)

PLATFORM

9-3/8" (238mm)

10" (254mm)

WORK SHELF

22-13/32 (569mm)

51-3/4" (1314mm)

0.67"

(17mm)

ONE-THIRD SIZE – FULL-SIZE

PAN CONFIGURATION

12-1/16"

(307mm)

FRONT GLASS

95 DEGREE LIFT-UP

GAS STRUT ASSIST

13" (330mm)

SELF-SERVE OPENING

SCALE

OUTLETS

6-1/2"

(165mm)

8-5/8"

(219mm)

CIRCUIT BREAKER

BOX

Operation & Care Manual #856-7 • 7

Cable Heating Service Kit No. 14228 for

TYSYS-96/4L & TYSYS-96/4R

TYSYS-96/41L & TYSYS-96/41R

includes:

CB-3045 Cable Heating Element . . . . . . . . . . . . . . . . . . . . . 265 feet

CR-3226 Ring Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IN-3488 Insulation Corner . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 foot

BU-3105 Shoulder Bushing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BU-3106 Cup Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SL-3063 Insulating Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TA-3540 Electrical Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 roll

NU-2215 10x32 Hex Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ST-2439 Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

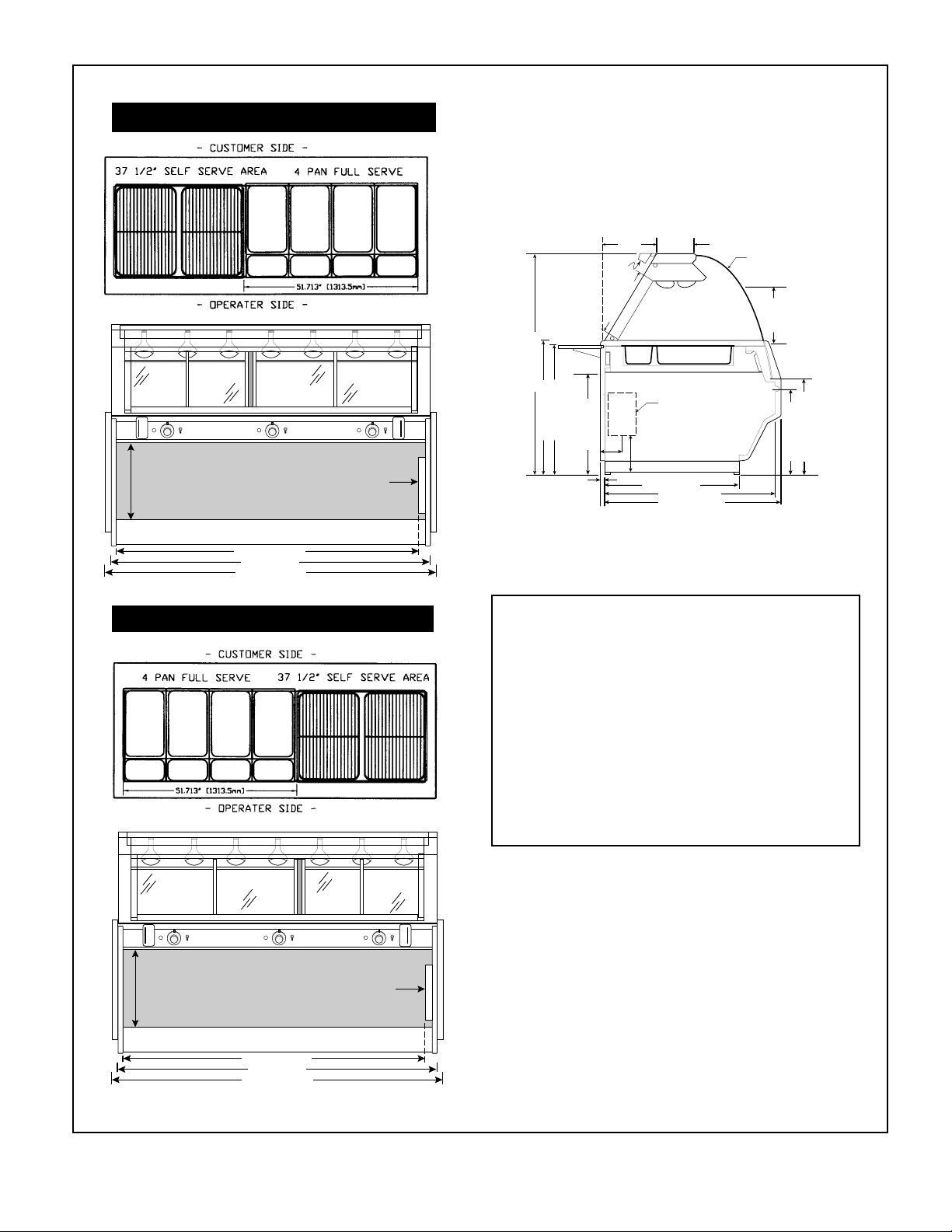

TYSYS-96/41R

TYSYS-96/41L

96" (2438mm)

98-1/4" (2496mm)

90-3/8" (2296mm)

17-1/2"

(445mm)

LOAD CENTER

CIRCUIT BREAKERS

96" (2438mm)

98-1/4" (2496mm)

90-3/8" (2296mm)

17-1/2"

(445mm)

LOAD CENTER

CIRCUIT BREAKERS

31-3/16" (792mm)

30-7/16" (773mm)

23" (584mm)

31-5/8" (803mm)

40-1/4" (1022mm)

42-1/2" (1079mm)

20-3/16 (512mm)

15-11/16" (398mm)

PLATFORM

9-3/8" (238mm)

10" (254mm)

WORK SHELF

22-13/32 (569mm)

51-3/4" (1314mm)

0.67"

(17mm)

ONE-THIRD SIZE – FULL-SIZE

PAN CONFIGURATION

12-1/16"

(307mm)

FRONT GLASS

95 DEGREE LIFT-UP

GAS STRUT ASSIST

13" (330mm)

SELF-SERVE OPENING

SCALE

OUTLETS

6-1/2"

(165mm)

8-5/8"

(219mm)

CIRCUIT BREAKER

BOX

Operation & Care Manual #856-7 • 8

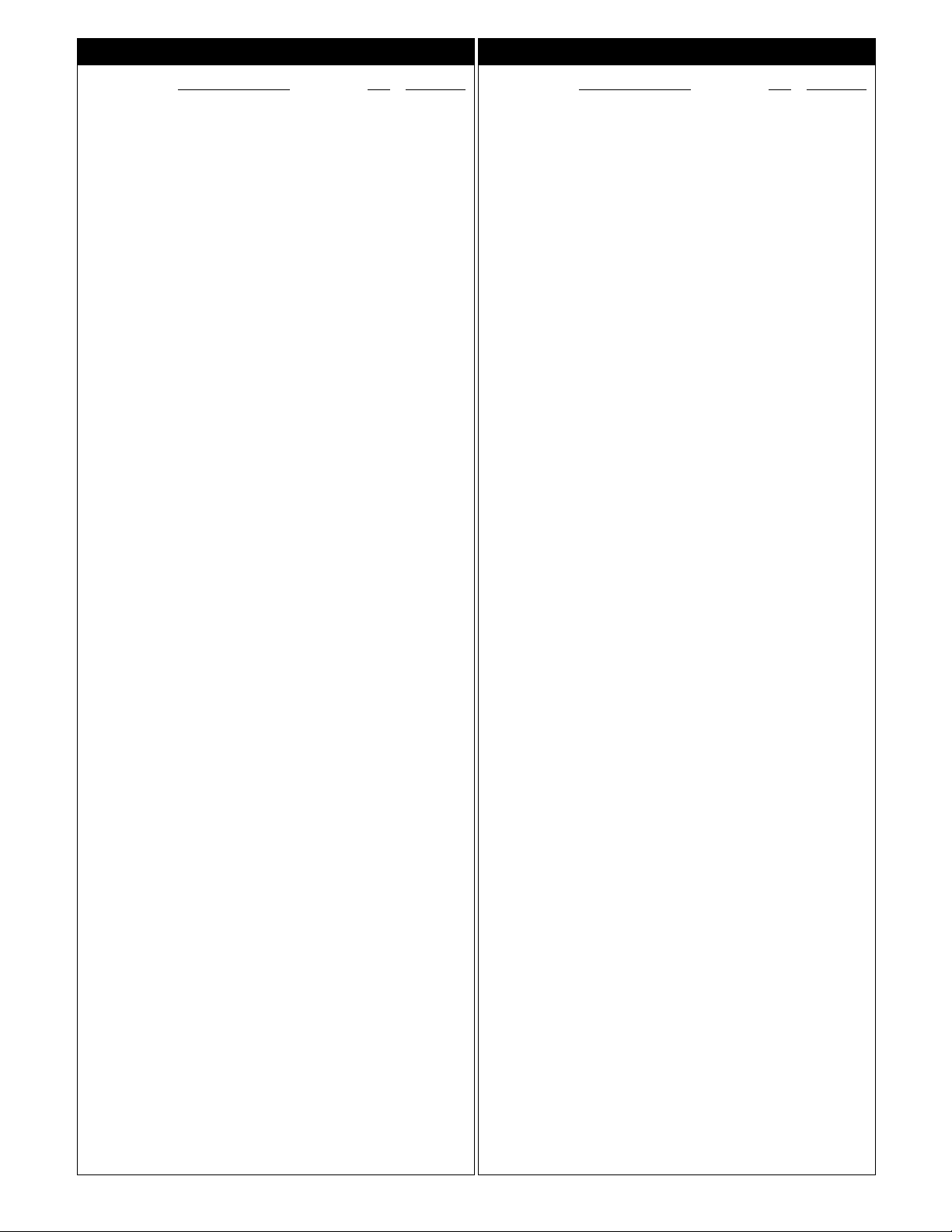

TY-96

9/16/99

PART DESCRIPTION QTY A/S PT NO.

1. END PANEL BOTTOM, 120V 1 13028

END PANEL BOTTOM, 230V 1 13986

4' (1219mm) RIGHT-HAND BOTTOM PANEL 1 13029

8' (2438mm) BOTTOM PANEL 1 13032

6' (1829mm) BOTTOM PANEL 1 13031

4' (1219mm) LEFT-HAND BOTTOM PANEL 1 13030

2. 8-32X1/2" S/S TRUSS HEAD SCREWS 29 SC-2425

8-32X1/4" S/S TRUSS HEAD SCREWS 2 SC-2459

3. CORD, 125V 1 CD-3987

CORD, 230V 1 CD-33489

4. PLUG 120/240V 1 PG-3988

5. CONTROL PANEL MOUNTING SCREWS 5 SC-2459

6. INSULATION: 34" x 95" (864mm x 2413mm) 2 IN-22364

7. CABLE CONNECTION HARDWARE

8. HEATING CABLE CB-3045

9. THERMOSTAT 3 TT-3498

THERMOSTAT KNOB 3 KN-3473

10. INDICATOR LIGHT, 125V 3 LI-3025

INDICATOR LIGHT, 230V 3 LI-3951

INDICATOR LIGHT MOUNTING NUT 3 NU-3335

11. LAMP SWITCH 3 SW-3616

12. FUSEHOLDER (120V UNITS) 2 FU-33041

INCLUDES:

FUSE, 15 AMP 2 FU-3775

FUSEHOLDER MOUNTING SCREWS 4 SC-2077

13. TOP 1 4449

TOP MOUNTING SCREWS 7 SC-2425

TOP MOUNTING SCREWS 7 SC-2459

14. BULB, 120V 14 LP-3333

BULB, 230V 14 LP-3384

15. BULB SOCKETS, 120V 14 RP-3952

BULB SOCKETS, 230V 14 RP-3955

16. DOOR ASSEMBLY 1 DR-22482

INCLUDES:

LEFT HAND GLASS DOOR - IN 2 DR-22482A

RIGHT HAND GLASS DOOR - OUT 2 DR-22482B

TOP TRACK 2 TK-23750

BOTTOM TRACK, 8' (2438mm) 2 TK-24267

GUIDES #44049 16 DR-22480F

DOOR BUMPER ASSEMBLY 2 DR-22480G

17. END PANEL 2 PE-22585

18. CUTTING BOARD ASSEMBLY 2 4016

19. CUTTING BOARD BRACKET (BASE) 4 12069

CUTTING BOARD BRACKET MTG. SCREWS 12 SC-24520

20. CUTTING BOARD BRACKET 4 BT-2342

23. END GLASS 2 GL-22479

END GLASS GASKET: 5' (1524mm) 1 GS-22547

24. FRONT GLASS 2 GL-22477

25. PAN DIVIDER BARS (not shown)

FULL/HALF/THIRD (LONG BAR) 6 11317

FULL/HALF/THIRD (SHORT BAR) 21 11318

SHEET PAN 4 11320

S-PAN DIVIDER (LONG) 3 11357

SHEET PAN FILLER BAR: 3-3/4" (95mm) 1 11732

26. ADJUSTABLE LEGS 4 LG-22686

27. TERMINAL BLOCK, 4 POS. 2 BK-3597

28. SNAP-IN RECEPTACLES 2 RP-3396

RECEPTACLE FUSE, 15A 1 FU-33351

RECEPTACLE FUSEHOLDER, 15A 1 FU-33352

29. OUTLET HOUSING COVER 1 4981

30. 8' PROBE PACKAGE OPTION (not shown)

120-208V 1 5297

31. FRONT GLASS STRUTS 4 SU-22702

32. OPTION (not shown) *

NOT CSA APPROVED

INDEPENDENT CIRCUIT CORDSET 120V 1 14221

INDEPENDENT CIRCUIT CORDSET 220V 1 14222

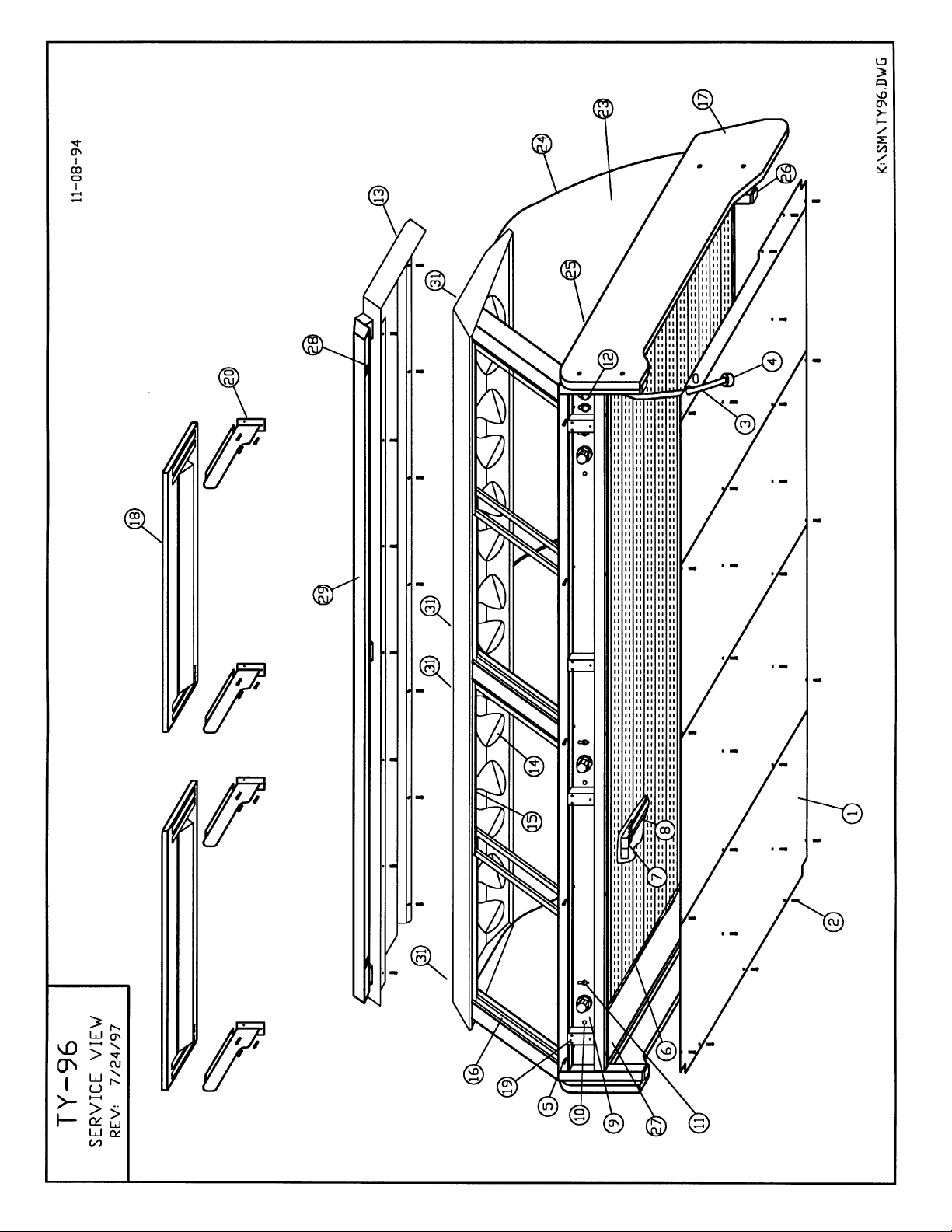

TYSYS-96

9/16/99

PART DESCRIPTION QTY A/S PT NO.

1. END PANEL BOTTOM, 120V 1 13028

END PANEL BOTTOM, 230V 1 13986

4' (1219mm) RIGHT-HAND BOTTOM PANEL 1 13029

8' (2438mm) BOTTOM PANEL 1 13032

6' (1829mm) BOTTOM PANEL 1 13031

4' (1219mm) LEFT-HAND BOTTOM PANEL 1 13030

2. 8-32X1/2" S/S TRUSS HEAD SCREWS 29 SC-2425

8-32X1/4" S/S TRUSS HEAD SCREWS 2 SC-2459

3. CONTROL PANEL MOUNTING SCREWS 5 SC-2459

4. CONDUIT TUBING: 6" (152,4mm) 2 TU-3874

5. INSULATION: 34" x 95" (864mm x 2413mm) 2 IN-22364

6. CABLE CONNECTION HARDWARE

7. HEATING CABLE CB-3045

8. THERMOSTAT 3 TT-3498

THERMOSTAT KNOB 3 KN-3473

9. INDICATOR LIGHT, 125V 3 LI-3025

INDICATOR LIGHT, 230V 3 LI-3951

INDICATOR LIGHT MOUNTING NUT 3 NU-3335

10. LAMP SWITCH 3 SW-3616

11. TOP 1 4449

TOP MOUNTING SCREWS 7 SC-2425

TOP MOUNTING SCREWS 7 SC-2459

12. BULB, 120V 14 LP-3333

BULB, 230V 14 LP-3384

13. BULB SOCKET, 120V 14 RP-3952

BULB SOCKET, 230V 14 RP-3955

14. CIRCUIT BOX (120V & 220V) 1 CI-3906

INCLUDES: BREAKER, 15 AMP 2 CI-33071

BREAKER, 30 AMP 2 CI-3908

GROUND BAR KIT 1 CI-3878

15. DOOR ASSEMBLY 1 DR-22482

INCLUDES: LEFT HAND GLASS DOOR - IN 2 DR-22482A

RIGHT HAND GLASS DOOR - OUT 2 DR-22482B

TOP TRACK 2 TK-23750

BOTTOM TRACK, 8' (2438mm) 2 TK-24267

GUIDES #44049 16 DR-22480F

DOOR BUMPER ASSEMBLY 2 DR-22480G

16. END PANEL 2 PE-22493

17. CUTTING BOARD ASSEMBLY 2 4016

18. CUTTING BOARD BRACKET (BASE) 4 12069

CUTTING BOARD BRACKET MTG. SCREWS 12 SC-24520

19. CUTTING BOARD BRACKET 4 BT-2342

22. END GLASS 2 GL-22479

END GLASS GASKET: 5' (1524mm) 1 GS-22547

23. FRONT GLASS 2 GL-22477

24. BASE BOTTOM 1 1420

25. PAN DIVIDER BARS (not shown)

FULL/HALF/THIRD (LONG BAR) 6 11317

FULL/HALF/THIRD (SHORT BAR) 21 11318

SHEET PAN 4 11320

S-PAN DIVIDER (LONG) 3 11357

SHEET PAN FILLER BAR: 3-3/4" (95mm) 1 11732

26. SNAP-IN RECEPTACLES 2 RP-3396

27. OUTLET HOUSING COVER 1 4981

28. RECEPTACLE FUSE, 15A 1 FU-33351

RECEPTACLE FUSEHOLDER, 15A 1 FU-33352

29. FRONT GLASS STRUTS 4 SU-22702

30. 8' PROBE PACKAGE OPTION (not shown)

120-208V 1 5297

31. OPTIONAL LOAD CENTER PACKAGE (not shown) 1 14220

INCLUDES: LOAD CENTER 1 CI-3877

GROUND BAR KIT 1 CI-3878

BREAKER, 15 AMP 1 CI-33071

CONNECTOR 1 CR-3953

NUT 1 NU-3954

Operation & Care Manual #856-7 • 9

Operation & Care Manual #856-7 • 10

Loading...

Loading...