Alto-Shaam QC-100 REMOTE User Manual

IT E M NO. _______________________

W164 N92 21 Wate r Street • P.O. B ox 450 • Me nomonee F al ls, Wi sc onsin 530 52 -0450 • U .S.A.

PH ON E: 262.251. 3800 800.5 58.8744 U .S.A ./C AN AD A FAX : 262.25 1.7067 800.329. 8744 U.S.A. ON LY

www.alto -s haam.com

D UE T O O N GO IN G P R OD U CT I M PR O VE M EN T, S PE C IF I CA TI ON S A R E S U BJ E CT T O C H AN GE W IT H OU T N OT I CE .P RI NT E D I N U .S .A .

ROCESSING FREEZER\CHILLER\REFRIGERATION SYSTEM

P

Q C - 1 0 0 R E M O T E

WI TH ROLL -I N CART

●

Enhanced food safety and production efficiency in a flexible

processing system designed to improve work flow and reduce

labor requirements.

●

eatures include a Quick-Freeze mode, Soft-Chill mode for less

F

dense items such as individual portions, Hard-Chill mode for

products with more density, a Holding mode for both chilled or

frozen items, and an automatic defrost.

●

Programmable preset capability for up to 20 menu items.

●

Safely and rapidly chills or freezes hot foods to proper holding

temperatures well within the HACCP/FDA food code guidelines.

●

The Quickchiller process allows chilled foods to be stored for

5 days, including the day of preparation and the day of service.

●

Reduces food preparation from a daily schedule to once or twice

a week to provide easier, more cost effective labor scheduling.

●

The roll-in pan cart mobilizes chilled product production and is

interchangeable with specified Combitherm

Combimate®holding cabinets to add to the efficiency of product

movement with effective rack management.

ovens and Halo Heat

®

®

Heavy duty stainless steel construction, fully insulated with high density polyurethane foam. The insulated stainless

steel door is hinged left as standard and includes one (1) self-adjusting, rotary door latch. An enclosed mullion heater is

located around the full perimeter of the door to eliminate condensation. The unit includes three (3) internal product

temperature probes and one (1) fan generating air circulation of 2,200 c.f.m. (62,3m

3

).

The Quickchiller features an electronic micro processor control with a vacuum florescent display. The control function

includes twenty (20) programmable presets; a display in English, Spanish, or French; and communication capability.

MODEL QC-100 Remote

■■

ADDITIONAL FEATURES & OPTIONS

●

The Quickchiller can be connected to a remote refrigeration system utilizing R-404A

refrigerant; a single, 3-1/2 hp compressor developing a total of 20,940 BTU's per hour at

-5°F (-21°C) in the freeze mode and 34,290 BTU's per hour at +20°F (-7°C) in the chill mode.

●

Rack management capabilities with roll-in pan cart [UN-27970] completely interchangeable

with 20•20 Combitherm and 20•20W Combimate® companion holding cabinet with:

Twenty (20) non-tilt pan supp ort rails

21-1/8" (537mm) horizontal width between rails

2-5/8" (67mm) vertical spacing between rails

Ten (10) stainless steel wire shelves

Removable drip tray and cart handle

●

Coved inside corners.

●

Optional HACCP Documentation software provides the ability to monitor, store,

and print all relevant time and temperature data through a Windows

●

Optional HACCP with Kitchen Management web-based software provides the ability to

based PC.

®

program, control, monitor, and store all relevant data.

#404A - 0 6/ 08

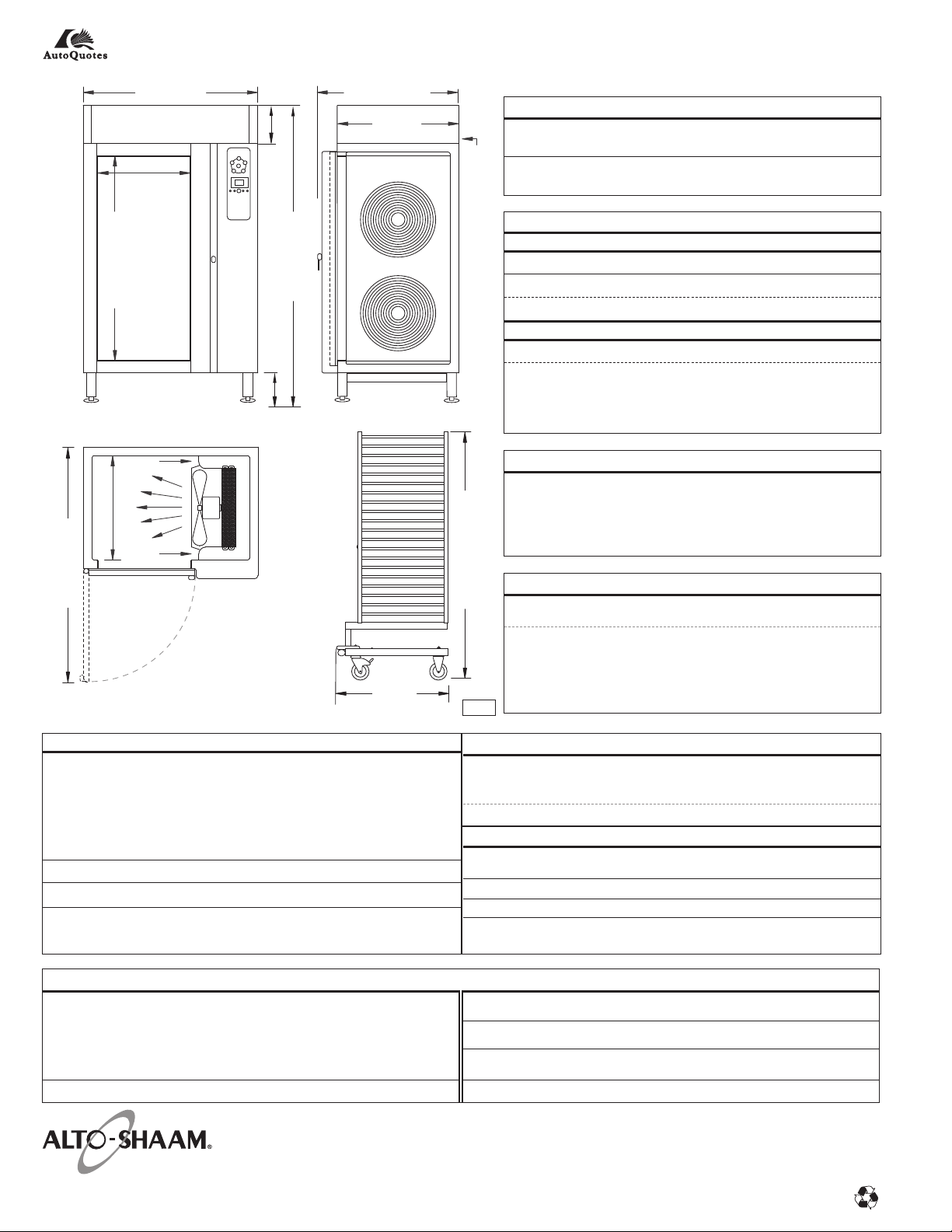

9"

(229mm)

82-1/4" (2089mm)

58-1/2" (1486mm)*

27-3/4"

(705mm)*

DOOR NOT SHOWN

FOR CLARITY

8" (229mm)

ADJUSTABLE

51" (1295mm)

41-1/8" (1045mm)

30-1/2"

(775mm)

75" (1905mm)

ELECTRICAL CONNECTION

3

5-1/2

"

(902mm)

65-11/16" (1668mm)

33-1/4"

(714mm)

*

Door opening

Q C - 1 0 0 R E M O T E

W164 N92 21 Wate r Street • P.O. B ox 450 • Me nomonee F al ls, Wi sc onsin 530 52 -0450 • U .S.A.

PH ON E: 262.251. 3800 800.5 58.8744 U .S.A ./C AN AD A FAX : 262.25 1.7067 800.329. 8744 U.S.A. ON LY

www.alto -s haam.com

D UE T O O N GO IN G P R OD U CT I M PR O VE M EN T, S PE C IF I CA TI ON S A R E S U BJ E CT T O C H AN GE W IT H OU T N OT I CE .

P RI NT E D I N U .S .A .

WI T H RO LL -I N CART

D I M E N S I ON S (H x W x D)

EX TERIOR: 83-3/4" x 51" x 41-1/8"

(2127mm x 1295mm x 1045mm)

INTE RIOR: 60" x 33-1/4" x 30-1/2"

(1524mm x 845mm x 775mm)

E L E C T R I CA L

C A BI NE T

VOLTAGE PHASE CYCLE/ HZ AMP S

208-240 1 60 30

REC OMME NDE D W IRE SIZE #10/2 w.g.

R E MO TE CO N DE NS E R P A C KA G E (OPTI ON AL)

208-240 1 60 60 A MP L INE

MAX F USE SIZE: 60 AMP

REC OMME NDED WIRE SIZE

REQU IRES TWO (2) #12 WIRES F ROM

QUIC KCH ILLE R TO CON DENSER

#8/2 w.g.

P R O D U C T \PA N C A PA C I T Y

MAXI MUM PR ODUCT CAPACI TY —

Approximately 480 lb (218 kg), 300 quarts (380 liters)

Approximately 240 lb (109kg), 150 quarts (190 liters)

MA XI MUM CH ILLING CA PAC IT Y —

FULL-SIZE PANS: 20" x 12" x 2-1/2" (GN1/1) 40

FULL-SIZE SHEET PANS: 18" x 26" x 1" 20*

ON WIRE SHELVE S ONLY. EX TRA OPTIONAL WIRE SHELVES

*

REQUIRE D F OR MA XIMUM CAPACITY SHOW N ABOVE

.

R E F R I G E RAT I ON (O

PT IO NAL REMOT E C ON DENS ER PK G

.)

R404a Refrigerant

One (1) 3-1/2 hp Condensing Unit:

FR EE ZE M ODE: 20,940 BTU's per hour at -5°F (-21°C)

CH IL L M ODE: 34,290 BTU's per hour at +20°F (-7°C)

I N S TA L L AT I O N R EQ U IR E M E NT S

One (1) Floor Drain: 1/2" (12,7mm) diameter

Unit must be installed level. Unit must not be

installed in any area where it may be affected by

steam, grease, dripping water, high temperatures,

N.T.S.

or any other severely adverse conditions.

C L E A R A N CE R E Q U IR E M E NT S

BACK: 6" (152mm) TOP: 6" (152mm)

SIDES: 4" (102mm) minimum at both sides.

18" (457mm)

MI N. FROM HE AT PR OD UCING EQU IP MENT.

W E I G H T

REMOTE ROLL -IN

CABINET CON DENSER PAN CA RT

NE T 902 lb (409 kg) 250 lb (113 kg) 120 lb (54 kg)

SHIPPIN G 1200 (544 kg) 380 lb (172 kg) 161 lb (73 kg)

CRATED 55" X 48" X 98"

DIMENSION S: (1397mm x 1219mm x 2489mm)

O P T I O N S & A CC E S S OR I E S

HACCP Network Software Options

■■

HACCP Documentation

HACCP with Kitchen Management

■■

REFER TO HACCP SPECIFICATION #9015, FOR A PPLICABLE PART NUMBERS.

■■

Prechill Sealing Strip 5008856

#404A - 0 6/ 08

Weather Protective Enclosure HS-27872

■■

Remote Condenser Package RE-34217

■■

Roll-In Pan Cart (Trolley) UN-27970

■■

■■

Wire Shelves, Stainless Steel SH-22473

Loading...

Loading...