Alto Shaam QC-100 Service Manual

TROUBLESHOOTING THE QUICKCHILLER

The QuickChiller is a stand alone, high capacity refrigeration system used to rapidly and uniformly lower

the temperature of a hot food product through the “chill danger zone.” There are five Quickchiller models

consisting of the QC3, QC20, QC40, QC50, and QC100. All models share the same basic electrical and

electronic components.

ELECTRICAL INSTALLATION

Basic installation must be made on a level, load-bearing surface and must have a drain available for

condensate. The electrical requirements are either 208VAC or 240VAC single-phase. All units are shipped in

the 240 VAC default setting. THE SUPPLY VOLTAGE MUST BE VERIFIED BEFORE HOOKUP.

If the supply voltage is 218 to 245 VAC, no changes are needed. If the supply voltage is less than 218 VAC

the leads of the transformer must be changed. Locate and remove the transformer orange lead from the

transformer to the terminal block. Remove the wire nut from the transformer red lead and install it on the

terminal block in the same location from which the

orange wire was removed. Install the wire nut on the

orange wire and secure it. Once again verify the power

supply matches the transformer setup. Once the power

supply is connected, the unit circuit breaker, which is

mounted on the relay board enclosure, must be

switched

ON.

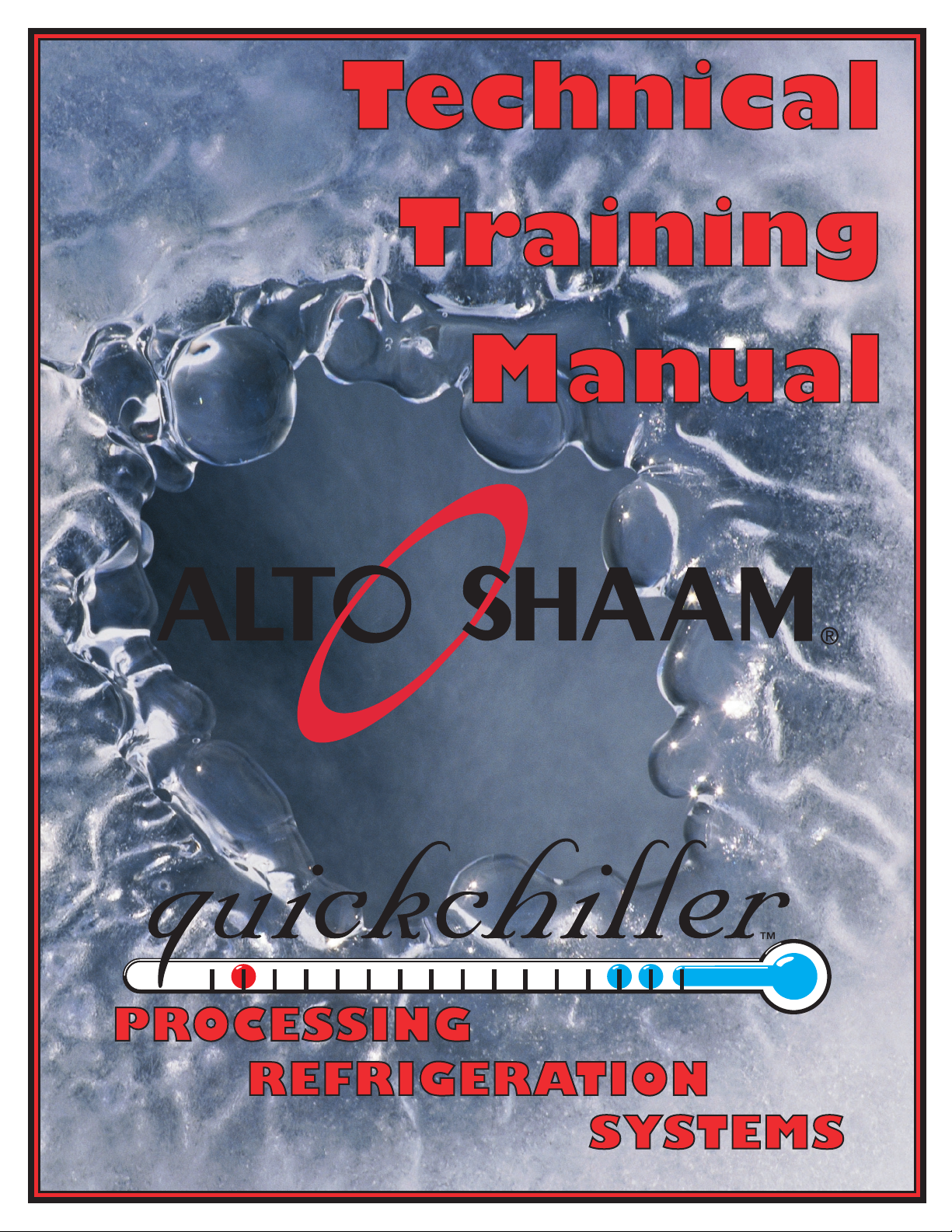

MICROPROCESSOR CONTROL

The Alto-Shaam Quickchiller has a microprocessor

control panel, which utilizes a menu screen to guide

the operator through all operation mode sequences.

The main menu screen should appear in the control

display (Figure 1). If the Main Menu screen does not

appear, the control display will show “SYSTEM

INITIALIZED” and an audible alarm will sound for 30

to 60 seconds. THE QUICKCHILLER SHOULD BE

LEFT IN THIS CONDITION FOR A PERIOD OF

TWO (2) MINUTES.

After waiting 2 minutes, turn the Quickchiller

circuit breaker

OFF for 30 seconds. Turn the

Quickchiller circuit breaker back ON and the Main

Menu screen will appear on the display.

QUICKCHILLER SET-UP SCREEN

From the Main Menu screen, press and hold the “1” key

for 5 seconds. The Software Version screen (Figure 2)

will appear. NOTE: YOU MUST VERIFY THAT THE

QUICKCHILLER IS PROGRAMMED TO THE

SPECIFIC UNIT MODEL NUMBER. After verifying

the programmed model number is correct, press the

“D” key to return to the Main Menu screen.

1.

Figure 1

Figure 2

CONTROL

SERIAL PRINTER PORT

MENU SCREEN

QUICKCHILLER . QC-50

SOFTWARE VER. . 3.20

Vers: 01/17/01 08:43

1/17/01 08:43:01AM

KEYBOARD

QUICK

REFERENCE

OPERATION

GUIDE

®

™

QUICKCHILLER SET-UP

Since all Quickchillers use the same microprocessor, they

must be configured for each specific model. The set-up is

completed at the factory, however, if the unit is unplugged for

more than 14 days, the microprocessor will lose the factory set

memory and revert back to a default setup. The default is

always specific to the model QC 50.

The Main Menu screen must appear on the control

display. To access the Password screen, press and hold the

“0” key on the key board for 5 seconds. When the Password

screen is in view, enter the password 5588744 using the

control keyboard (Figure 3).

After entering the password on the Password screen, press

the “D” key on the keyboard to access the User Setting screen.

Press and hold the "1" button on the keyboard for a period of five (5)

seconds. The Software Version screen will appear. The Quickchiller

model number must appear.

Press and hold the "1" button on the keyboard for a period of five (5) seconds. The Software Version screen will

appear. The Quickchiller model number must appear.

If the model number does not appear, press and hold zero (0) button again until Password Entry screen appears.

Enter password 16021892 and press "D" button to access Set-up Menu Screen. Select option "C" and set correct chiller

model number using the "C" button. Following entry, press "D", and press "D" again to return to Main Menu screen.

NOTE: If the wrong password number is entered in error, “ACCESS DENIED” (Figure 4) will appear in the

display, an alarm will sound for 10 seconds, and the Main Menu screen will reappear. If this

situation occurs, press and hold the “0” key for 5 seconds and reenter the correct password.

SETTING TIME, DATE & OPTIONS

When the User Setting screen (Figure 5) appears on the

control display, push the “B” key on the keyboard to access

the time and date screen (Figure 6). The time and date are

very important particularly if a printer is used since

incorrect time and date settings will impact the printout.

NOTE: TIME MUST BE ENTERED AS 24 HOUR,

MILITARY TIME (HH:MM:SS).

After the time and date have been set, press the “C” key

to return to the User Setting screen. After the User Setting

screen appears, press the “C” (Miscellaneous) key to change

the following options. Press “A” to scroll to the next screen.

TEMPERATURE UNITS: Allows the user to choose

between Celsius and Fahrenheit.

KEYBOARD BUZZER: Allows the user to turn tone sound ON or OFF.

AUTOMATIC DEFROST: Allows the user to turn the Auto-Defrost ON or OFF.

DEFROST TIME: Allows the user to set the maximum minutes for the defrost cycle.

NOTE: DEFAULT IS SET FOR 20 MINUTES

AFTER ALL OPTIONS HAVE BEEN SELECTED, PRESS “D” TO EXIT AND RETURN TO THE USER SETTING SCREEN.

SETTING SET POINTS

From the user screen, press the”A” (Set Point) key to access the Numeric Setting screen (Figure 7). All

set points are shown in Celsius and can only be changed within an allowable range. Any value entered

outside of this range will result in a warning buzzer and the value must be reentered. To reset any set point

to the factory default, push the “CE” key to show the default values for each set point and then key in the

Q-CHILLER CONFIGURE

PASSWORD: 5588744

Figure 3

PASSWORD ENTRY SCREEN

Figure 4

PASSWORD DENIED SCREEN

Figure 5

USER SETTING MENU SCREEN

Figure 6

TIME AND DATE SCREEN

ACCESS DENIED

Set Points . . . . . . . . . . . . A

Time and Date . . . . . . . . . B

Miscellaneous . . . . . . . . . C

Exit . . . . . . . . . . . . . . . . D

Enter Time and Date

01/17/01 08:33:48

A=Left C=Accept

B=Right D=Cancel

2.

correct setting. Temperatures that require a negative number can

be entered by using the minus key ”-“ on the keyboard. To exit,

press the “D” key and return to the User Setting screen. To

return to the Main Menu screen press the “D” key again.

NOTE: THE SET POINT CONFIGURATIONS HAVE BEEN

ESTABLISHED AFTER EXTENSIVE TESTING.

CHANGING THE SET POINTS MAY SERIOUSLY

AFFECT THE OPERATION OF THE QUICKCHILLER.

The factory default set points for all the Quickchillers are

listed in the appendix at the end of the Trouble Shooting Guide.

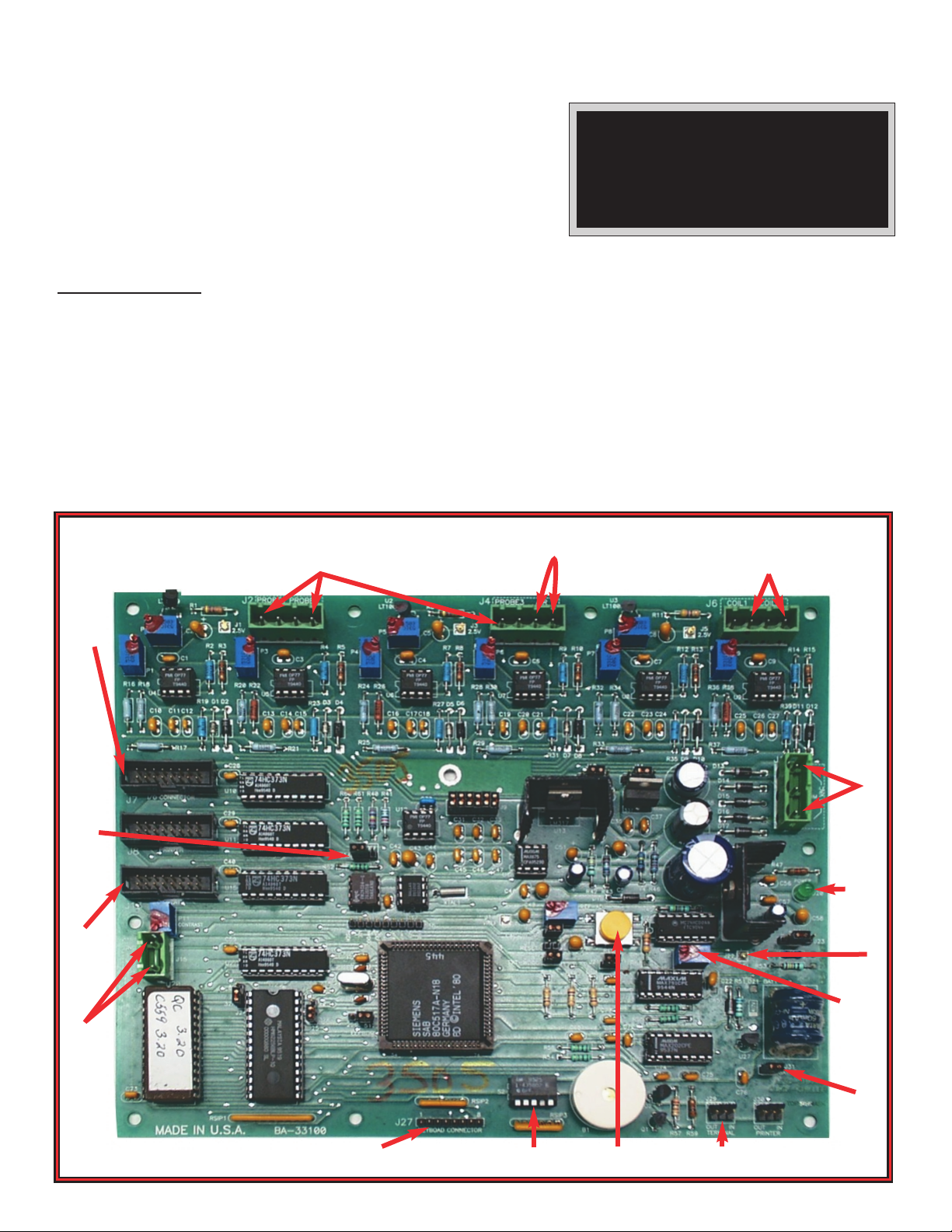

CPU BOARD

The CPU board is the microprocessor for the Quickchiller. It processes and controls all input from the

product probes, air temperature sensor, the coil 1 and coil 2 RTD sensors, the LCD driver board, the keyboard

touch pad, and the printer. The microprocessor has a battery that will allow the CPU board to hold a program

for up to 14 days in the event of a power failure. A ribbon cable allows the relay board to communicate with

the CPU board.

The CPU reset and power LED are located at the bottom part of the board (

Figure 8).

NOTE: THERE IS AN RTD SENSOR BUILT INTO A CHIP TO MONITOR TEMPERATURE IN THE CPU

ENCLOSURE. IF THE TEMPERATURE IN THE ENCLOSURE EXCEEDS 115 DEGREES F. (46°C), THE

CONTROL WILL FAIL. THERE ARE NO SERVICEABLE PARTS ON THE CPU BOARD.

Figure 8

PRODUCT PROBE

1, 2, 3

KEYBOARD

RIBBON

DIP

SWITCHES

CPU

RESET

PRINTER SERIAL

PORT CONNECTOR

AIR SENSOR COIL 1 & COIL 2

RTD SENSORS

RELAY/CPU

RIBBON CABLE

24VAC (J12)

POWER LED

PFI PIN

P12 TRIM-POT

BATTERY

SWITCH

WRITE

PROTECT SWITCH

DISPLAY RIBBON

CABLE

5VDC

Figure 7

USER SETTING MENU SCREEN

Set Points . . . . . . . . . . . . A

Time and Date . . . . . . . . . B

Miscellaneous . . . . . . . . . C

Exit . . . . . . . . . . . . . . . . D

3.

4.

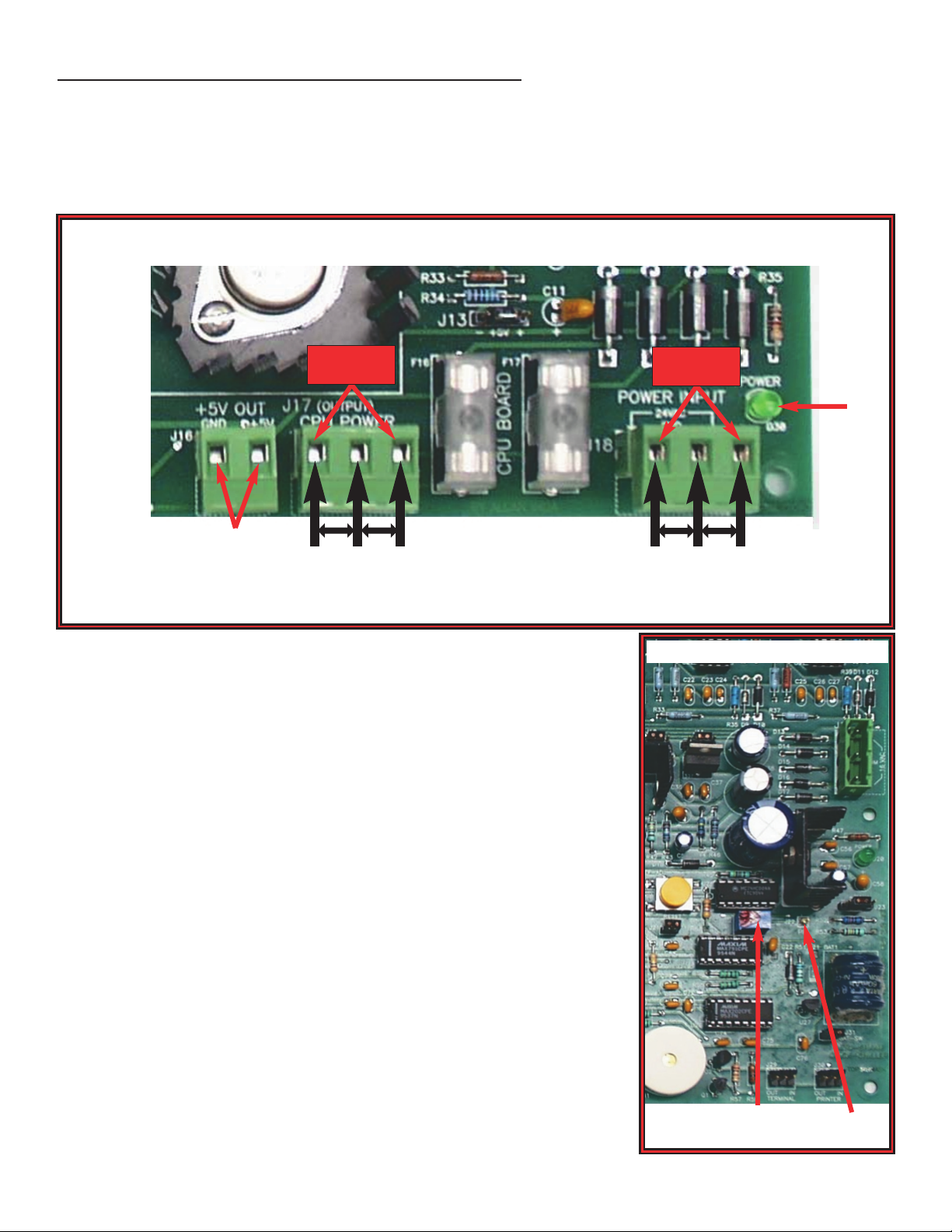

TROUBLE SHOOTING THE CPU BOARD

If the CPU board is suspected as the problem, open the locked CPU access door and verify the green

power LED is illuminated. If the LED is not illuminated and there is 24VAC on the J12 connector across L1

and L2, the CPU board is defective and must be replaced (

Figure 8). Also check for 12VAC from L1 to COM

and from L2 to COM. If there is no voltage or 1/2 voltage present, check for 24VAC across the 2 outside

terminals at the J17 connector on the relay board (Figure 9). If there is 24VAC on the J17 connector, the

wiring from the relay board to the CPU board is defective and needs to be replaced.

If there is no 24VAC across L1 and L2 on the J17 plug, check the F16

and F17 1 AMP fuses. If the fuses are good and there is no 24VAC present

at J18 connector or if the green power LED on the relay board is not

illuminated, the circuit breaker switch is tripped or defective. If the circuit

breaker switch is turned

ON and appears good, check for line voltage

through the filter at the terminal block mounted at the top of the relay

board enclosure. If there is line voltage at the terminal block, the

transformer is defective and needs to be replaced.

If the LCD display is blank and the circuit breaker switch is turned ON,

check that the LCD display ribbon cable is not cut or damaged. If it is

connected properly to the LCD driver board and the pins on the board are

clean, check to make certain it is plugged into the J13 connector and seated

properly. If the above checks out good, power down the control by turning

the circuit breaker switch

OFF. Inspect chip-set U15, U11 and U10 to make

certain they are seated properly. Turn the circuit breaker switch ON and

check the display. If there is still no display, check to make certain the

power failure threshold is set to between 1.70 and 1.85VDC.

To set the power failure threshold, locate the P12 trim-pot at the lower

left-hand portion of the CPU board (

Figure 10). Using a multi-meter set to

the DC volts scale, place the red lead onto pin connector PFI and the black

lead onto the metal board retaining nut. Adjust the trim-pot P12 until the

voltage reading is between 1.70 and 1.85VDC.

Figure 9

24VAC

24VAC

12VAC FROM

L1TO GROUND

AND

L2TO GROUND

5VDC

POWER LED

12VAC FROM

L1TO GROUND

AND

L2TO GROUND

ADJUST TRIM-POT TO

RAISE THRESHOLD

TO 1.70 - 1.85 VDC (P12)

PFI

Figure 10

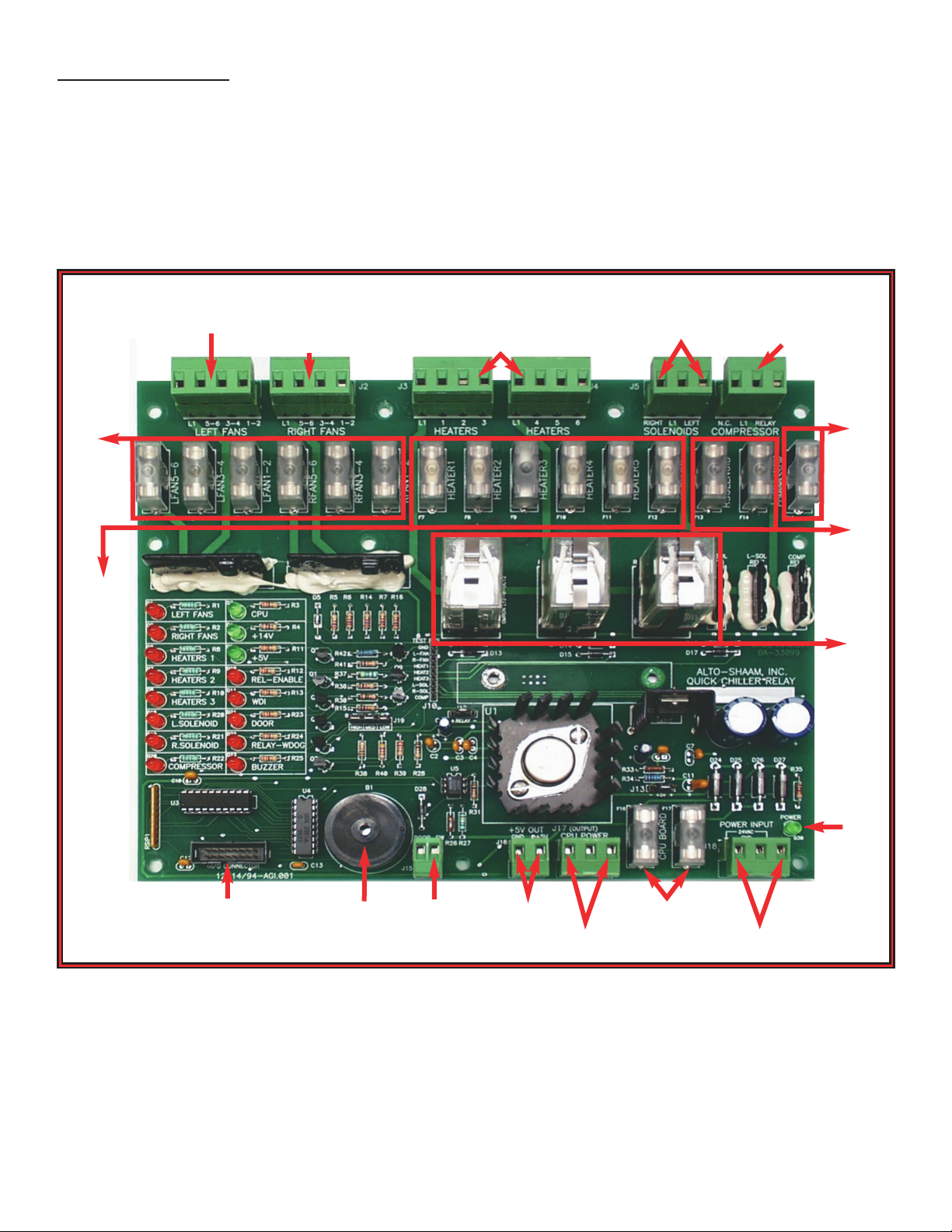

RELAY BOARD

The relay board (Figure 11) is mounted in a metal enclosure with a metal or lexan cover over it. For the

QC-3 it is located behind the front grille, mounted to the left of the compressor and can be slid out for

servicing. For the QC-20 it is located behind the CPU enclosure, laying flat and can be slid out for servicing.

For the QC-40 it is located behind the lower grille, mounted to the left of the compressors and can be slid

out for servicing. For the QC-50 it is located behind the upper grille, to the left of the compressors and can

be accessed by removing the metal cover. For the QC-100 it is located inside the locked CPU enclosure at the

top of the enclosure.

The relay board has 6 (F1-F6) 2A fuses to protect the fans. There are 6 (F7-F12) 4A fuses to protect the

defrost heaters in all Quickchillers except the QC-40 which uses 6.3 Amp fuses. All units use 2 (F13-F14)

300MA fuses to protect the refrigerant solenoids and 1 (F14) 250MA fuse to protect the compressor relays. The

2 (F16-F17) 1A fuses protect the 24 VAC power to the CPU board.

5.

Figure 11

FAN FUSES

DEFROST

HEATER

FUSES

COMPRESSOR

FUSE

SOLENOID

FUSES

HEATER DEFROST

RELAYS 14VDC

POWER LED

EVAPORATOR FANS

LEFT

RIBBON CABLE

CONNECTOR

DOOR

SWITCH

BEEPER 5DVC

TO CPU BOARD

24VAC

TO CPU BOARD

24VAC

FROM

TRANSFORMER

CPU

POWER FUSES

EVAPORATOR FANS

RIGHT

DEFROST

HEATERS

REFRIGERANT

SOLENOID

RIGHT LEFT

COMPRESSORS

Loading...

Loading...