Alto-Shaam QC-100 User Manual

IT EM NO . _______________________

W164 N9221 Wat er Street • P.O . Box 450 • Menomo nee Falls, Wisconsin 53052-0450 • U.S.A.

PH ONE: 262.251.3800 800.55 8.8744 U.S .A./CAN ADA FAX : 262.251.7067 80 0.329.8744 U.S.A . ON LY

www.alto- shaam.com

D UE T O O N GO IN G P R OD U CT I M PR O VE M EN T, S PE C IF I CA TI ON S A R E SU B JE C T TO CH A NG E W IT H OU T N OT I CE .P RI NT E D I N U .S .A .

PROCESSING FREEZER\ CHILLER\R EFRIGERATION SYSTEM

Q C - 1 0 0

WI TH ROL L-IN CAR T

●

Enhanced food safety and production efficiency in a flexible

processing system designed to improve work flow and reduce

labor requirements.

●

Features include a Quick-Freeze mode, Soft-Chill mode for less

dense items such as individual portions, Hard-Chill mode for

products with more density, a Holding mode for both chilled or

frozen items, and an automatic defrost.

●

Programmable preset capability for up to 20 menu items.

●

Safely and rapidly chills or freezes hot foods to proper holding

temperatures well within the HACCP/FDA food code guidelines.

●

The Quickchiller process allows chilled foods to be stored for

5 days, including the day of preparation and the day of service.

●

Reduces food preparation from a daily schedule to once or twice

a week to provide easier, more cost effective labor scheduling.

●

The roll-in pan cart mobilizes chilled product production and is

interchangeable with specified Combitherm

Combimate®holding cabinets to add to the efficiency of product

movement with effective rack management.

ovens and Halo Heat

®

®

Heavy duty stainless steel construction, fully insulated with high density polyurethane foam. The insulated stainless

steel door is hinged left as standard and includes one (1) self-adjusting, rotary door latch. The Quickchiller is furnished

with a self-contained, refrigeration system utilizing R-404A refrigerant; a single, 3-1/2 hp compressor developing a total

of 20,940 BTU's per hour at -5°F (-21°C) in the freeze mode and 35,800 BTU's per hour at +20°F (-7°C) in the chill mode;

and two (2) fans generating air circulation of 5700 c.f.m. (161m

3

). An enclosed mullion heater is located around the full

perimeter of the door to eliminate condensation. The unit includes three (3) internal product temperature probes.

The Quickchiller features an electronic micro processor control with a vacuum florescent display. The control function

includes twenty (20) programmable presets; a display in English, Spanish, or French; and communication capability.

MODEL QC-100

■■

5- Year L imite d

Warra nty on

se lf-co ntained

co mpres sor

Effecti ve from date o f

shipment. (

EX CLUD ES LAB OR)

STANDARD FEATURES AND ACCESSORIES

●

Rack management capabilities with roll-in pan cart [UN-27970] completely

interchangeable with 20•20 Combitherm and 20•20W Combimate® companion

holding cabinet with:

Twenty (20) non-tilt pan supp ort rails

21-1/8" (537mm) horizontal width between rails

2-5/8" (67mm) vertical spacing between rails

Ten (10) stainless steel wire shelves

Removable drip tray and cart handle

●

Coved inside corners.

● Optional HACCP Documentation web-based software provides the ability to monitor,

store, and print all relevant data.

● Optional HACCP with Kitchen Management web-based software provides the ability

to program, control, monitor, and store all relevant data.

#40 4 - 12 /0 8

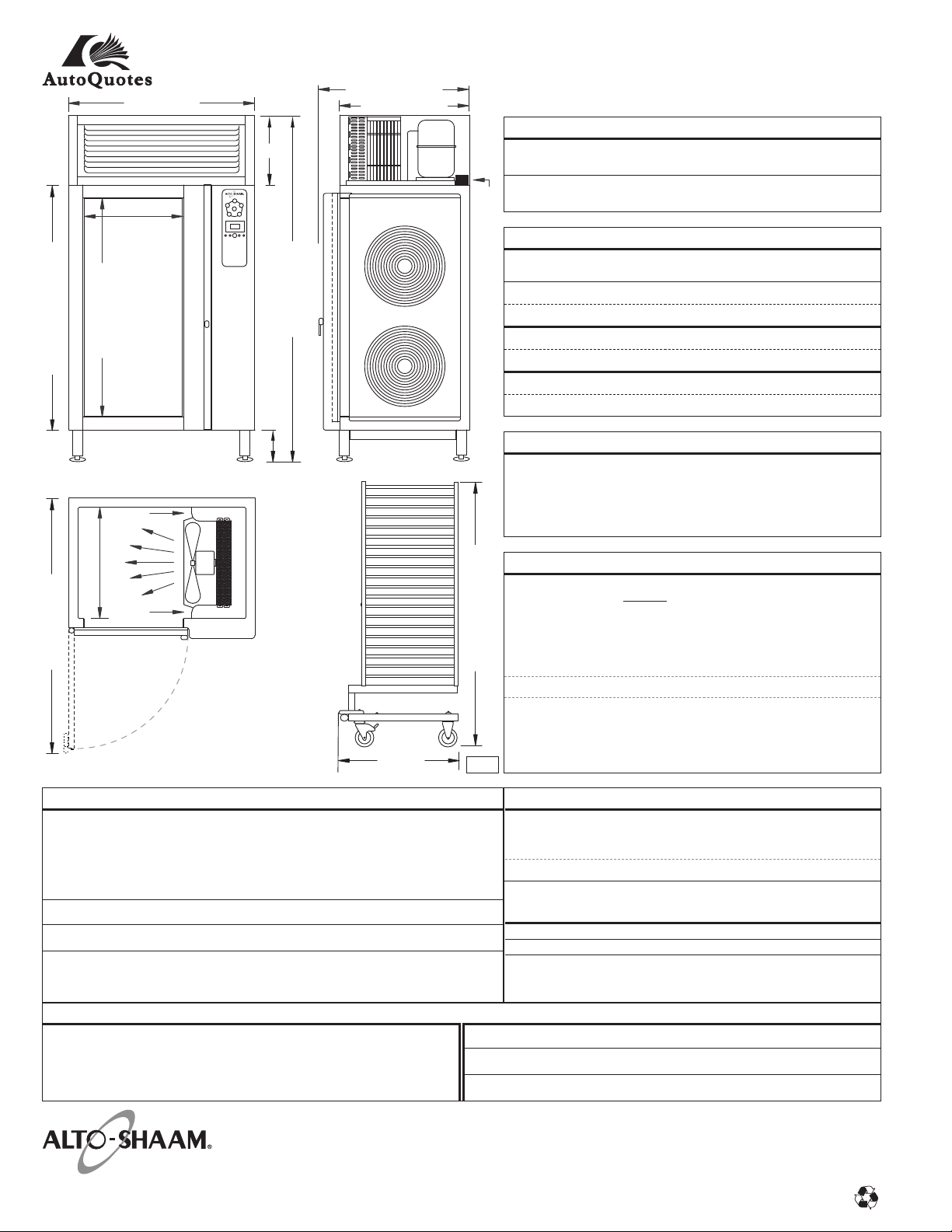

20-1/4"

(641mm)

93-1/2" (2375mm)

58-1/2" (1486mm)*

27-3/4"

(705mm)*

DOOR NOT SHOWN

FOR CLARITY

8" (203mm)

ADJUSTABLE

51" (1295mm)

35-1/2" (902mm)

41-1/8" (1045mm)

65-1/4" (1657mm) DOOR

30-1/2"

(775mm)

75" (1905mm)

ELECTRICAL CONNECTION

65-11/16" (1668mm)

* Door opening

33-1/4"

(714mm)

W164 N9221 Wat er Street • P.O . Box 450 • Menomo nee Falls, Wisconsin 53052-0450 • U.S.A.

PH ONE: 262.251.3800 800.55 8.8744 U.S .A./CAN ADA FAX : 262.251.7067 80 0.329.8744 U.S.A . ON LY

www.alto- shaam.com

D UE T O O N GO IN G P R OD U CT I M PR O VE M EN T, S PE C IF I CA TI ON S A R E SU B JE C T TO CH A NG E W IT H OU T N OT I CE .

P RI NT E D I N U .S .A .

Q C - 1 0 0

WI TH R OLL-IN C ART

D I MENSI O N S (H x W x D)

EX TERIOR: 95" x 51" x 41-1/8"

(2413mm x 1295mm x 1045mm)

INTE RIOR: 60" x 33-1/4" x 30-1/2"

(1524mm x 845mm x 775mm)

E L ECTRI C A L

REC OMMENDE D

VOLTAGE PH ASE CYCLE/ HZ CIRC UIT AMP ERAGE

208-240 1 50/60 60

REC OMMENDED WIRE SIZE #6/2 w.g.

208-240 3 50/60 40

REC OMMENDED WIRE SIZE #8/3 w.g.

380-415 3 50/60 30

REC OMMENDED WIRE SIZE #10/2 w.g.

R E FRIGE R ATIO N

R404a Refrigerant

One (1) 3-1/2 hp Condensing Unit:

FR EEZ E MODE: 20,940 BTU's per hour at -5°F (-21°C)

CH ILL MOD E: 35,800 BTU's per hour at +20°F (-7°C)

I N STA L L AT I O N R E QUIR E M E N T S

P R ODUC T \ PAN CA PACIT Y

Approximately 480 lb (218 kg), 300 quarts (380 liters)

MAXIM UM PRO DUC T CAPACI TY —

MAXIM UM CHI LLI NG CAPACITY —

Approximately 240 lb (109kg), 150 quarts (190 liters)

FULL-SIZE PANS: 20" x 12" x 2-1/2" (GN1/1) 40

FULL-SIZE SHEET PANS: 18" x 26" x 1" 20*

*ON WIRE SHELVE S ONLY. E XTRA OPTION AL W IRE SHE LVES REQUIRED FOR

MAX IMUM C APACITY SHOWN A BOVE.

O P TION S & A C C E S S O RIES

HACCP Network Software Options

HACCP Documentation

■■

■■

HACCP with Kitchen Management

REFE R TO HA CCP SPECIFICATION #9015 FOR APPL ICABLE PART NU MBERS.

N.T.S.

Prechill Sealing Strip 5008856

■■

Roll-In Pan Cart (Trolley) UN-27970

■■

Wire Shelves, Stainless Steel SH-22473

■■

Unit must NOT be tipped on its side

at any time.

Tipping will cause damage to the unit

and void the warranty.

One (1) Floor Drain: 1/2" (12,7mm) diameter

Unit must be installed level. Unit must not be

installed in any area where it may be affected by

steam, grease, dripping water, high temperatures,

or any other severely adverse conditions.

C L EARAN C E R E Q U IREME N T S

BACK: 6" (152mm) TOP: 6" (152mm)

SIDES: 4" (102mm) minimum at both sides.

18" (457mm)

W E IGHT (A PPR OXI M AT E )

NE T 1152 lb (523 kg) 120 lb (54 kg)

SHIPPING 1450 lb (658 kg) 161 lb (73 kg)

CRATED 55" X 48" X 98"

DIMENSIONS: (1397mm x 1219mm x 2489mm)

MIN. FROM H EAT PRO DUC ING EQ UIP MEN T.

CABINET ROLL-IN PAN CART

#40 4A - 1 2/ 08

Loading...

Loading...