Alto Shaam PDSYS-48-P Service Manual

#899 • 4/2005

PRINTED IN U. S .A .

INSTALLATION

OPERATION

AND

MAINTENANCE

MANUAL

HEATED

DISPLAY CASES

FULL SERVICE OR

SELF SERVICE

PEDESTAL BASE

SERIES:

PDSYS-48

PDSYS-48/P

PDSYS-72

PDSYS-72/P

PDSYS-96

PDSYS-96/PL

PDSYS-96/PR

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558-8744 USA/CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

PDSYS-48

PDSYS-96

#899 • PDSYS Series Operation & Care Manual • 1

HOT DISPLAY CASES

®

Unpacking & Setup

The Alto-Shaam Heated Display

Case has been thoroughly tested,

checked for calibration, and inspected

to insure only the highest quality unit is

provided. When you receive your case,

check for any possible shipping

damage and report it at once to the

delivering carrier. See Transportation

Damage and Claims section located in this manual.

In order to maintain established National

Sanitation Foundation standards, all stationary floor

models must be sealed to the floor with a R.T.V. or

silastic meeting N.S.F. requirements or have 6"

(153mm) unobstructed clearance beneath the unit.

Counter and table units must be mounted on

legs of a sufficient 4" (102mm) height to provide

minimum unobstructed space beneath the unit.

These legs are supplied with the unit. Warranty

will become null and void if these directions are

not followed.

Save all the information and instructions packed

inside the display case. Complete and return the

warranty card to the factory as soon as possible to

assure prompt service in the event of a warranty

parts and labor claim.

Alto-Shaam heated display cases are designed for

the purpose of maintaining hot food at a temperature

for safe consumption. The unit must be installed on a

level surface in a location that will permit the equipment

to function for its intended purpose and allow adequate

access for proper cleaning and maintenance.

The unit must not be installed in any area where it

will be affected by steam, grease, dripping water, high

temperatures, or any other severely adverse conditions.

NOTE:Any and all claims for warranty must include

the full model and serial number of the

display case.

Electrical Installation

If necessary, permanent wiring or electrical

outlets for this display case must be installed by an

licensed electrician in accordance with local, country

or national codes.

SAMPLE

An identification tag is permanently mounted on

case. Plug the case into a properly grounded

receptacle ONLY. Arcing will occur when connecting

or disconnecting the display case unless all controls

are in the OFF position. Always position the

appliance so the power supply cord is easily

accessible in case of emergency.

REGARDING INTERNATIONAL STANDARD UNITS:

If the unit is not equipped with flexible cord with

plug, an all-pole country approved disconnection

device which has a contact separation of at least

3mm in all poles must be incorporated in the fixed

wiring for disconnection. When using a cord without

a plug, the green/yellow conductor shall be

connected to the terminal which is marked with

the ground symbol. If a plug is used, the socket

outlet must be easily accessible. If the power cord

needs replacement, use a similar one obtained from

the distributor.

For 230V units:

To prevent an electrical shock

hazard between the appliance and other appliances

or metal parts in close vicinity, an equalizationbonding stud is provided. An equalization bonding

lead must be connected to this stud and the other

appliances / metal parts to provide sufficient

protection against potential difference. The terminal

is marked with the following symbol.

®

®

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED ON

NAMEPLATE OF UNIT

PATENT NOS.

3521030

4595247

®

PH

DO NOT INSTALL A HEATED DISPLAY

CASE NEAR A COLD AIR SOURCE SUCH

AS A FREEZER, AIR CONDITIONING

VENTS, OR IN ANY AREA WHERE

OUTSIDE AIR FLUCTUATION CAN

AFFECT PERFORMANCE.

#899 • PDSYS Series Operation & Care Manual • 2

INSTALLATION

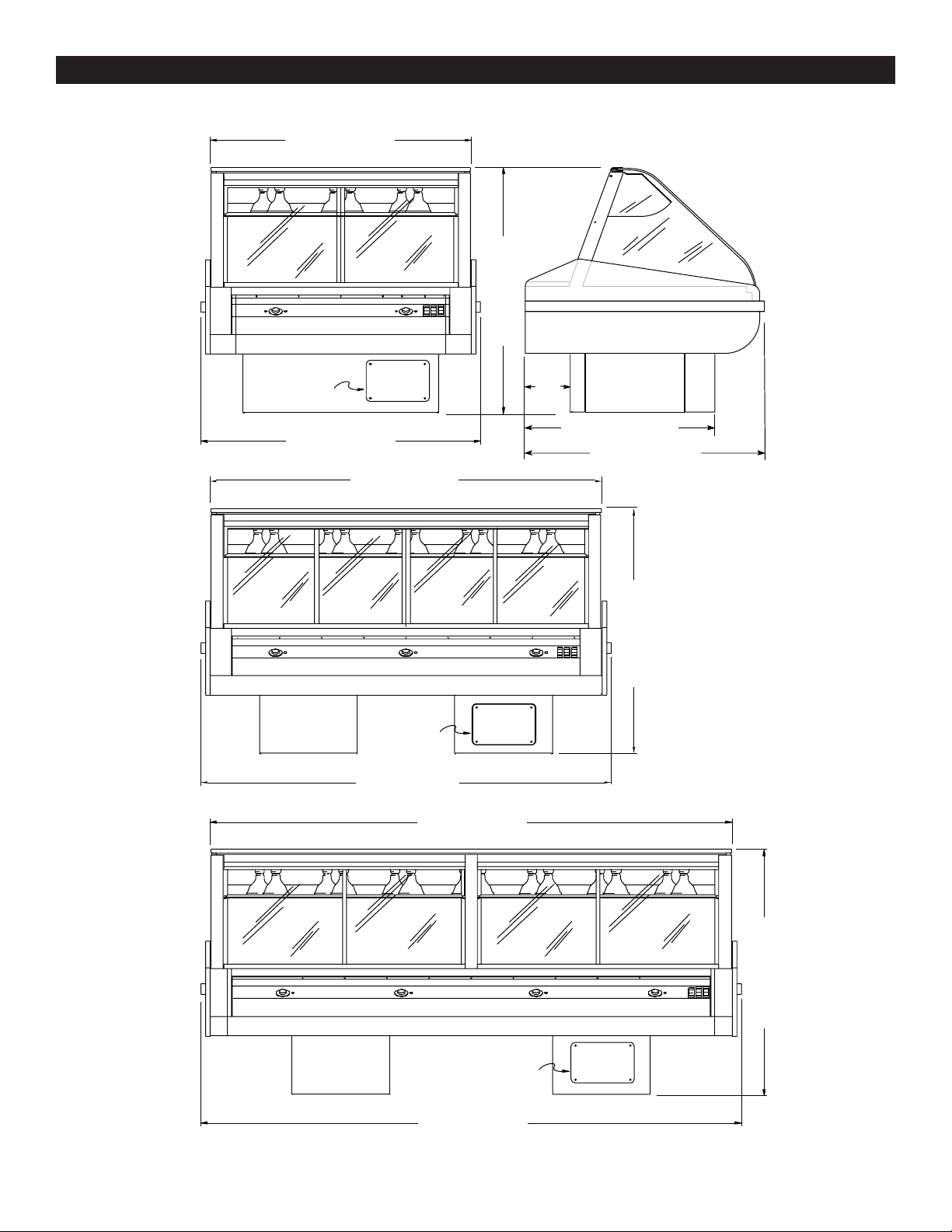

OUTSIDE DIMENSIONS - PDSYS

48-1/8" (1222mm)

45-3/8" (1153mm)

51-1/2" (1308mm)

72-1/8" (1832mm)

75-1/2 (1918mm)

45-3/8" (1153mm)

96-1/8" (2442mm)

99-1/2" (2527mm)

45-3/8" (1153mm)

OPERATOR VIEW

8-5/16"

(212mm)

34-13/16" (884mm)

43-7/8" (1114mm)

SIDE VIEW

TERMINAL

BLOCK

TERMINAL

BLOCK

TERMINAL

BLOCK

PDSYS-48

PDSYS-72

PDSYS-96

#899 • PDSYS Series Operation & Care Manual • 3

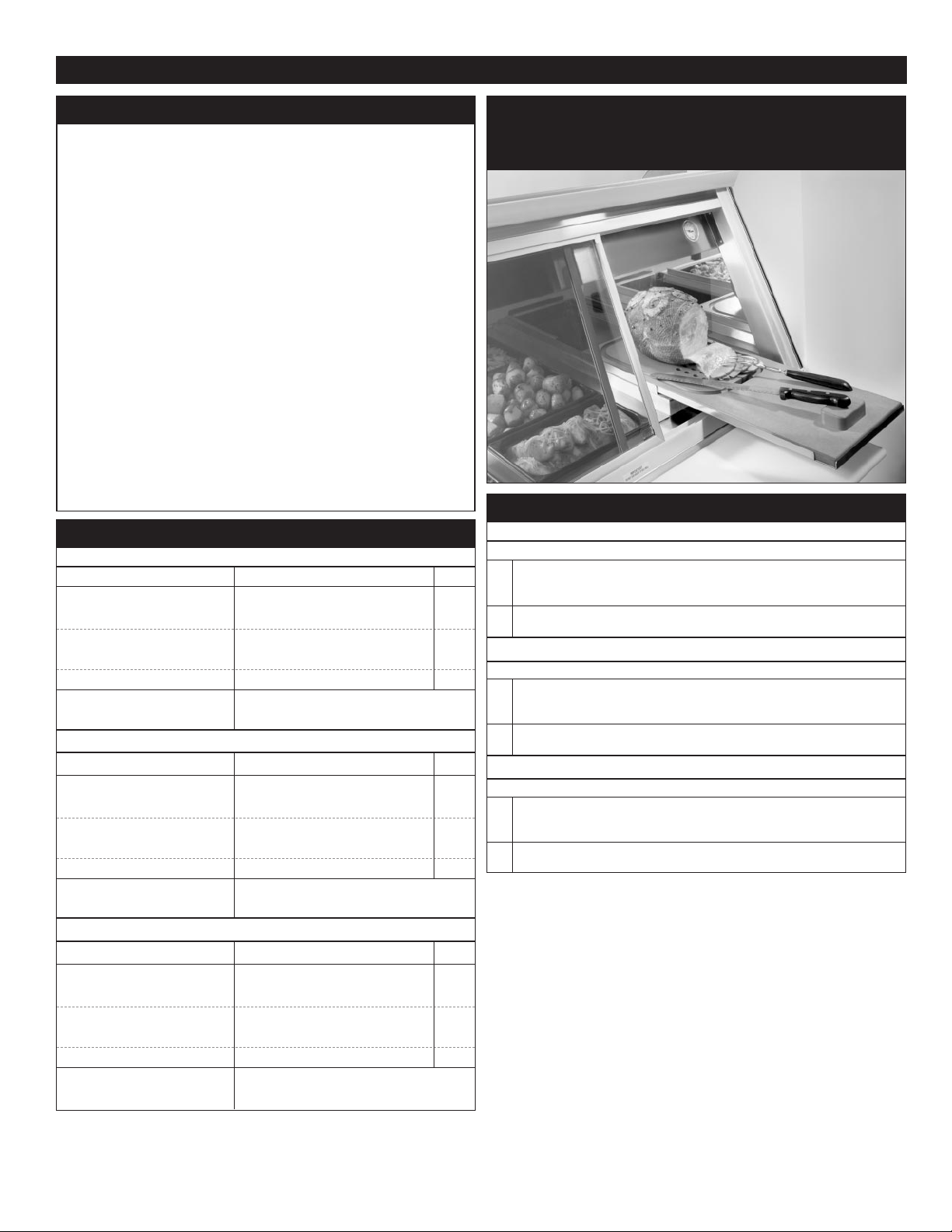

Carving Station . . . . . . . . . . . . . . . . . . . . . . .5001874

Gauge, Ambient Air Temperature . . . . . . . . . .GU-33384

Glass Divider

(TO BUTT MULTIPLE CASES) . . . . . . . .GL-23512

Glass Tempered End Pane - Bronze Reflective

Left-Hand . . . . . . . . . . . . . . . . . . . . . . . . .GL-23488

Right-Hand . . . . . . . . . . . . . . . . . . . . . . . .GL-23489

Panel, Front Custom Color

PDSYS-48

SERIES . . . . . . . . . . . . . . . . . . . . . . .P125

PDSYS-72

SERIES . . . . . . . . . . . . . . . . . . . . . . .P126

PDSYS-96

SERIES . . . . . . . . . . . . . . . . . . . . . . .P127

Panel, Stainless Steel, End . . . . . . . . . . . . . . . . .44280

Pedestal Surround

(PDSYS-72 & -96 ONLY) . . . . . .Available

STAINLESS STEEL SKIRT ENCLOSURE AROUND BASE PEDESTALS

Platform Scale (120/208-240 VAC ONLY)

CUSTOMER VIEW LEFT-HAND . . . . . . . . . . . . . . . . .14602

CUSTOMER VIEW RIGHT-HAND . . . . . . . . . . . . . . . .14601

INSTALLATION

OPTIONS AND ACCESSORIES

PDSYS Heated Display Case

with optional carving station and

interior temperature gauge

SPECIFICATIONS

ELECTRICAL

PDSYS-48

VOLTAGE PHASE CYCLE/HZ AMPS kW

at 208 1 60 13.37 2.9 NO CORD - NO PLUG

at 240 14.58 3.5

at 230 1 50 14.3 3.3

NO CORD - NO PLUG

PDSYS-72

VOLTAGE PHASE CYCLE/HZ AMPS kW

at 208 1 60 21.0 4.5 NO CORD - NO PLUG

at 240 22.5 5.4

at 230 1 50 22.2 5.1

NO CORD - NO PLUG

PDSYS-96

VOLTAGE PHASE CYCLE/HZ AMPS kW

at 208 1 60 27.98 6.1 NO CORD - NO PLUG

at 240 30.42 7.3

at 230 1 50 31.1 6.85

NO CORD - NO PLUG

230 208-240

230 208-240230 208-240

PAN CONFIGURATION

PDSYS-48

PAN SIZE DIMENSIONS QTY.

FULL-SIZE & ONE-THIRD: 20" x 12" x 2-1/2" (GN 1/1) 3

12" x 6" (

GN 1/3) 3

HALF-SIZE & ONE-THIRD: 12" x 10" x 2-1/2" (GN 1/2) 6

12" x 6" (

GN 1/3) 3

FULL-SIZE SHEET PANS: 18" x 26" x 1" 2

MAX. CAPACITY/VOLUME: 48 lbs (22 kg)

30

QUARTS (36 LITERS)

PDSYS-72

PAN SIZE DIMENSIONS QTY.

FULL-SIZE & ONE-THIRD: 20" x 12" x 2-1/2" (GN 1/1) 5

12" x 6" (

GN 1/3) 5

HALF-SIZE & ONE-THIRD: 12" x 10" x 2-1/2" (GN 1/2) 10

12" x 6" (

GN 1/3) 5

FULL-SIZE SHEET PANS: 18" x 26" x 1" 3

MAX. CAPACITY/VOLUME: 80 lbs (36 kg)

50.5

QUARTS (60 LITERS)

PDSYS-96

PAN SIZE DIMENSIONS QTY.

FULL-SIZE & ONE-THIRD: 20" X 12" X 2-1/2" (GN 1/1) 7

12"

X 6" (GN 1/3) 7

HALF-SIZE & ONE-THIRD: 12" X 10" X 2-1/2" (GN 1/2) 14

12"

X 6" (GN 1/3) 7

FULL-SIZE SHEET PANS: 18" X 26" X 1" 4

MAX. CAPACITY/VOLUME: 112 lbs (51 kg)

70.7

QUARTS (84 LITERS)

* Pans are not included with display case.

PAN CONFIGURATION

#899 • PDSYS Series Operation & Care Manual • 4

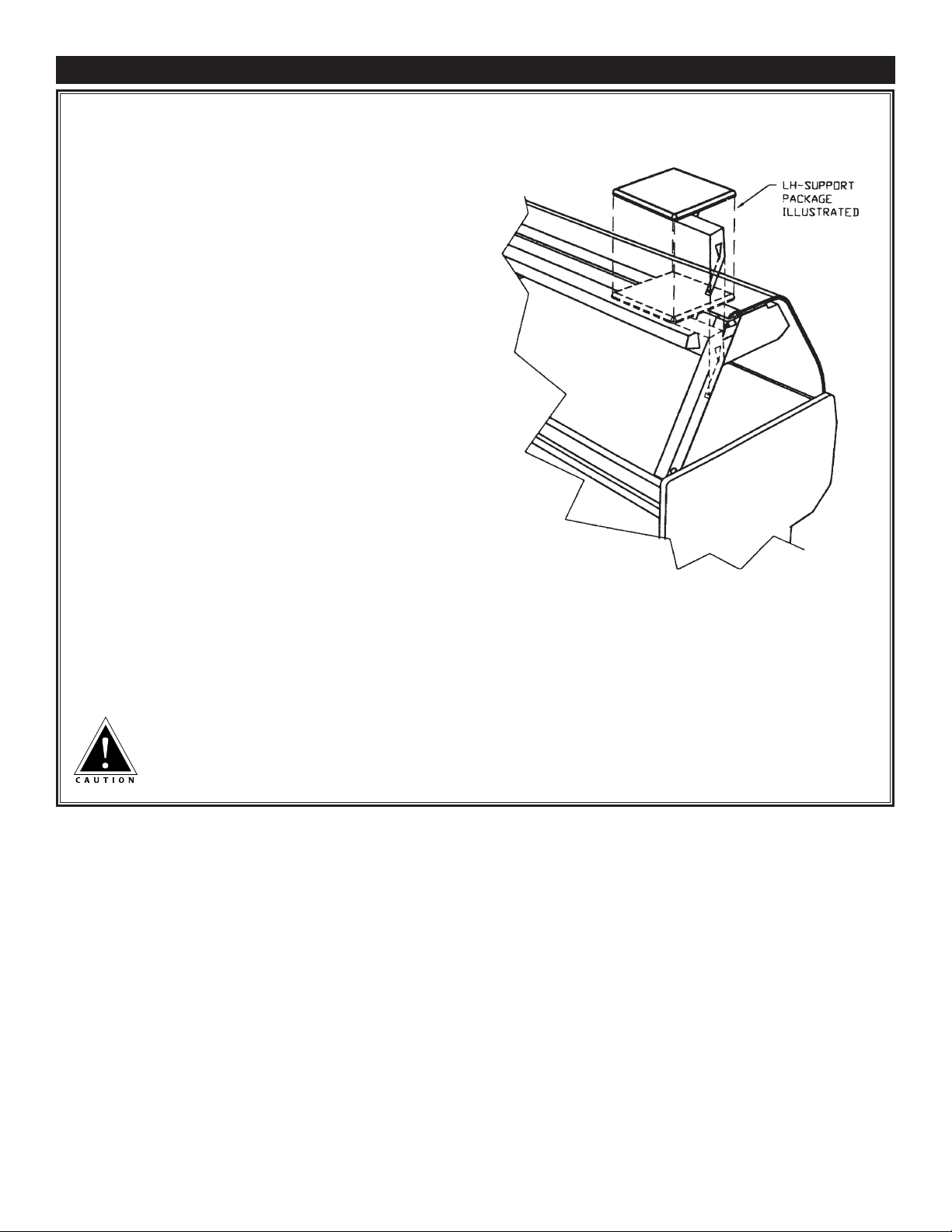

INSTALLATION INSTRUCTIONS — OPTIONAL SCALE PLATFORM

1. Disconnect the unit from the power source.

2. Lift hood glass up to access the outer top.

3. Position the platform mounting bracket in the desired

location along the upper rear edge on the outer top,

making sure that the bracket is tight against the bend in

the top. Using the bracket as a template, mark and

punch six mounting holes in the outer top. Drill these six

holes with a No. 21 drill, and tap with a 10-32 UNF

thread.

4. Attach the scale shelf assembly to the outer top using the

six 10-32x1/2" slotted truss-head screws provided (AltoShaam part number SC-2661).

5. Remove the four nuts from the bottom of the platform.

Mount support (bracket provided) to platform using

screws as a guide. While pushing up on support, mark

two mounting holes on the support.

6. Remove the support. Drill these mounting holes with a

No. 21 drill and tap with a 10-32" UNF thread. Replace

support and mount to unit with the two 10-32x1/2"

screws provided (Alto-Shaam part number SC-2661).

Replace nuts on platform bottom and tighten support to

platform.

7. Apply a silicone bead to all perimeter meeting surfaces

between the mounting bracket and the outer top.

NOTE: These platforms are intended for use in the

CLOSED position ONLY. They slide away from the unit for

cleaning.

Using scales with platforms in the OUT position

may result in incorrect data on scales.

The scale shelf platform can be removed from the mounting bracket assembly by removing

the 10-32 screw/stop located on the bottom of the scale shelf. Removing the screw allows

the shelf to be slid past, and lifted off the shelf guide pins. Failure to replace this

screw prior to use could result in serious bodily injury, and/or damage to equipment.

INSTALLATION

#899 • PDSYS Series Operation & Care Manual • 5

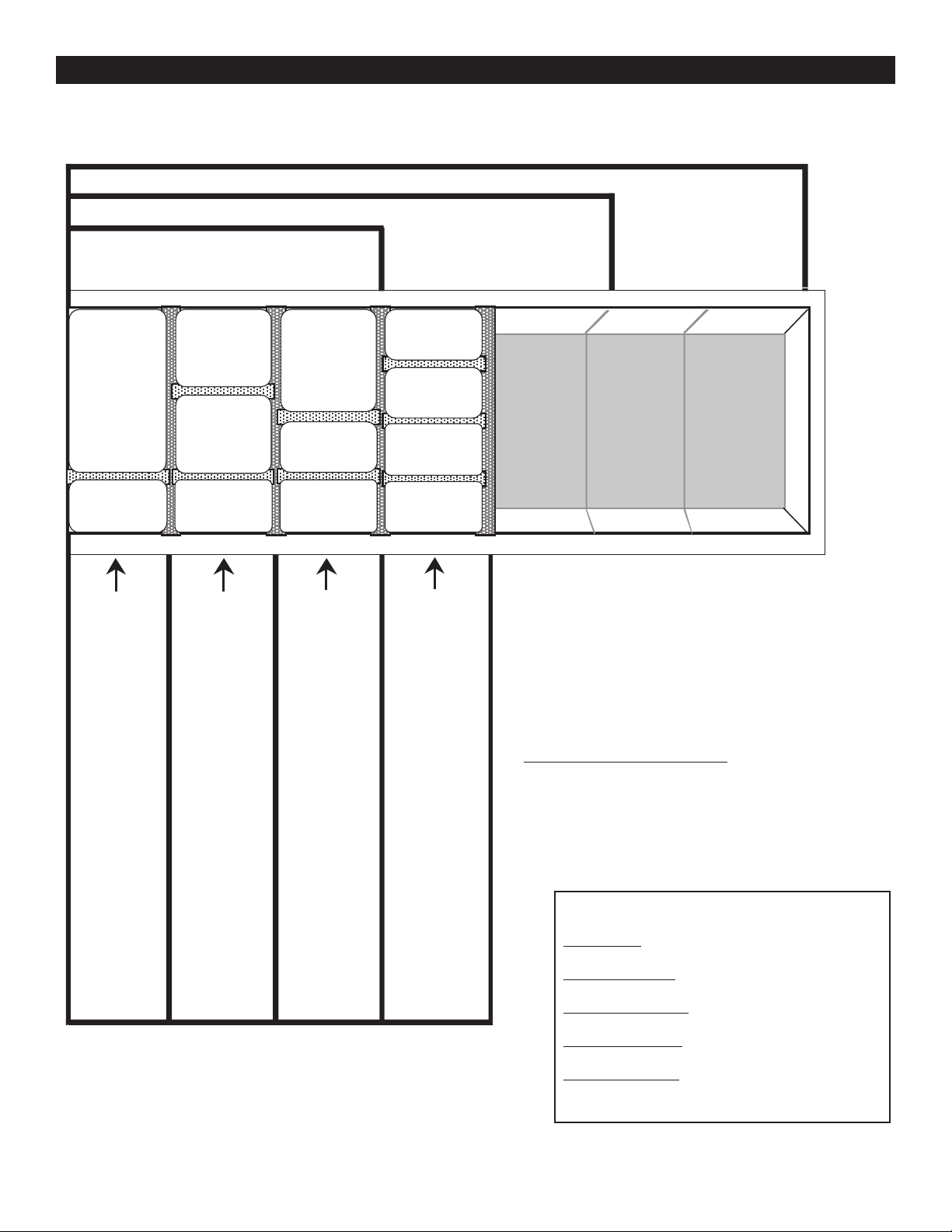

OPERATION

FULL-S IZE

PAN

ONE-THIRD

SIZE PAN

ONE-HALF

SIZE PAN

ONE-HALF

SIZE PAN

TWO-THIRDS

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

48 Models

72 Models

96 Models

3 PAN ZONES 5 PAN ZONES

7 PAN ZONES

One (1) F ULL-S IZ E PAN and

One (1) ONE -THIRD SIZ E PAN per p an zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 3 Full-Siz e Pans with 3 One-Third Siz e Pans

Up to 5 Full-Siz e Pans with 5 One-Third Siz e Pans

Up to 7 Full-Siz e Pans with 7 One-Third Siz e Pans

Two (2) ONE -HALF SIZE PANS a nd

One (1) ONE -THIRD SIZ E PAN per p an zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 6 One-Half S ize Pans with 3 One -Third S ize Pans

Up to 10 One -Half Siz e P ans with 5 One-Third Siz e P ans

Up to 14 One -Half Siz e P ans with 7 One-Third Siz e P ans

One (1) TWO-THIRDS SIZ E PAN and

Two (2) ONE -THIRD SIZ E PANS pe r pan zo ne .

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 3 Two-Thirds Size Pa ns with 6 One-Third Size Pa ns

Up to 5 Two-Thirds Size Pa ns with 10 One-Third Siz e Pans

Up to 7 Two-Thirds Size Pa ns with 14 One-Third Siz e Pans

F

ou

r (4

) O

NE

-T

HIR

D

SIZ

E

PA

NS

p

er p

an

z

one

.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 12 One -Third Siz e P ans per dis play ca se

Up to 20 One -Third Siz e P ans per dis play ca se

Up to 28 One -Third Siz e P ans per dis play ca se

ONE-THIRD

SIZE PAN

PAN CONFIGURATIONS • HEATED DISPLAY CASES

Note:

Additional Pan Separator Bars may

be required to accommodate maxium

capacities.

STANDARD PAN SIZES

Full-Size Pan

12” x 20” x 2-1/2” (325mm x 530mm x 65 mm) GN1/1

One-Half Size Pan

12” x 10” x 2-1/2” (325mm x 265mm x 65mm) GN 1/2

Two-Thirds Size Pan

12” x 14” x 2-/12” (325mm x 352mm x 65mm) GN 2/3

One-Third Size Pan

12” x 6” x 2-1/2” (325mm x 176mm x 65mm) GN 1/3

Full-Size Sheet Pan

18” x 26” x 1 (457mm x 660mm x 25mm) N/A

Note: For PDSYS-72 Series

End divider bars (#13738) are to

be placed at each end of well.

Bars have 1/8" holes in tabs to

indicate they are end bars.

#899 • PDSYS Series Operation & Care Manual • 6

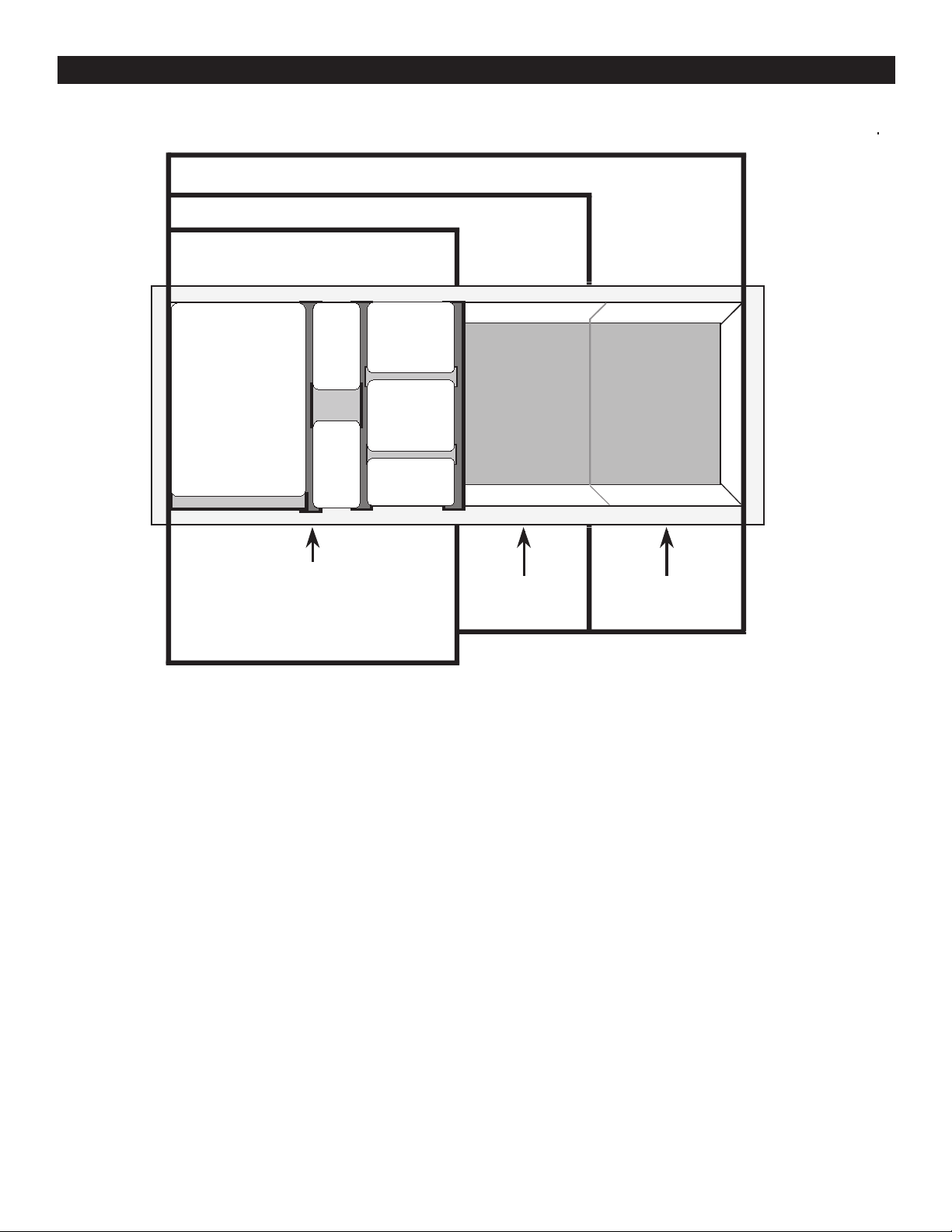

OPERATION

SHEET PAN CONFIGURATIONS • HOT DISPLAY CASES

48 Models

72 Models

96 Models

2 SHEET PAN ZONES

3 SHEET PAN

ZONES

4 SHEET PAN

ZONES

ONE-THIRD

SIZE PAN

ONE-HALF

SIZE PAN

ONE-HALF

SIZE PAN

72 MODELS

3 Full-size Sheet Pans

per display case

48 MODELS

2 Full-size Sheet Pans per display case

OR

1 Full-size Sheet Pan

2 One-half Size Pans

3 One-third Size Pans

96 MODELS

4 Full-size Sheet Pans

per display case

FULL-SIZE

SHEET PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

OPERATING PROCEDURES

1. DO NOT ADD WATER TO DISPLAY CASE

Halo Heat display cases maintain a constant but

gentle temperature and eliminate much of the

moisture loss associated with conventional display

cases. Because of this gentle heat, it is not necessary

to add water to the display case. As a matter of fact,

adding water is not recommended since water

will accelerate the deterioration of the product, and

may damage the unit voiding the warranty.

2. PLACE DIVIDERS AND SERVING PANS IN CASE

Refer to the pan layout diagrams for different types

of pan accommodations. A complete pan

configuration layout is located in this manual.

It is

VERY

important to note, no matter what type of

pan configuration chosen, pan separator bars or

divider bars must be used to close all gaps between

pans, and all gaps between the pans and the edges of

the display case. If these gaps are not closed, heat

will escape from the bottom of the case into the

display area. As a consequence, heat distribution will

be uneven and uniform temperature will be difficult to

hold. If needed, additional pan divider bars are

available. The supplied self-serve pan inserts with

wire grids are for use with pre-packaged foods in the

self-serve sections of the units.

3. TURN DISPLAY LIGHTS “ON” AND SET THE

THERMOSTAT(S) AT NUMBER “10” TO PREHEAT

A indicator light will illuminate when the

thermostat(s) is (are) turned “

ON.” The indicator(s)

will remain lit as long as the unit is preheating or

calling for heat. The unit should be preheated at the

10 setting for a minimum of 30-45 minutes before

loading the case with hot food. When preheating is

completed, or whenever the unit reaches any

temperature set by the operator between

1 and 10,

the indicator light(s) will go “

OUT”.

4. LOAD HOT FOODS INTO DISPLAY CASE

Be certain only hot food is transferred into the

display case. Before loading food into the case, use

a pocket-type meat thermometer to make certain all

products have reached an internal temperature of

140° to 160° F (60° to 71°C). If any food product is

not at proper serving temperature, use a Halo Heat

cooking and holding oven, set at 250° to 275°F

(121° to 135°C), or a Combitherm oven to bring the

product within the correct temperature range.

Use hand protection when handling hot items.

Be certain only hot PREPACKAGED foods in

appropriate heat tested containers are used in the

self-service section of the display case.

Do not stack food containers.

5. RESET THERMOSTAT(S) AS NEEDED

After all products are loaded into the display case

and the doors are closed, it is necessary to reset the

thermostat(s). For fully enclosed sections, reset the

thermostat to the number “8” setting. Cases with a

self-service section should be maintained between

number “9” and number “10” for the self-service

section

only. THESE SETTINGS WILL NOT

NECESSARILY BE FINAL. Since proper

temperature range depends on the type of products

and the quantities being held, it is necessary to

periodically use a pocket thermometer to check each

item to make certain the correct temperatures are

being maintained. Proper temperature range is

between a minimum of 140° and 160° F (60° and

71° C). Normally, this will require a thermostat

setting of between number “6” and “8” in fully

enclosed cases. Self-service cases or sections will

always require a higher thermostat setting.

6. PLACEMENT OF FOOD PROBE

If the unit is equipped with the probe accessory, wipe

each probe and probe tip with a disposable alcohol

pad to clean and sanitize before using. If the probe

is left in its bracket, the LED temperature display will

indicate the ambient air temperature inside the case.

To place a probe into food kept in the case, remove

the probe from the bracket and push the probe tip

halfway into the product, positioning the tip at the

center of the food mass. If placing into solid foods

such as meat roast or poultry breasts, push the probe

in from a straight downward position or in from the

side to the center position. If placing into a semiliquid or liquid product, the probe cable will probably

need to be secured to keep the probe positioned

properly. Do not let the probe tip touch the edges or

sides. Tape the probe cable to the lip or edge of the

container. Wipe each probe tip with a clean paper

towel to remove food debris after each use. Follow

by wiping probes with a disposable alcohol pad, and

return each probe to the proper bracket position.

7. SERVE FRESH HOT FOOD

Keep hot foods looking fresh. Occasionally stir or

rotate food as needed. Serve food products in

appropriate heat tested packages or containers.

Keep display case doors closed after serving. Wipe

spills immediately to assure maximum eye appeal and

to ease end of the day cleanup.

#899 • PDSYS Series Operation & Care Manual • 7

OPERATION

Loading...

Loading...