Alto Shaam KYSYS-48 Service Manual

#879 •7/2001

PRINTED IN U.S .A .

OPERATION and CARE MANUAL

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

®

COOK/HOLD/SERVE SYSTEMS

HOT FOOD DISPLAY CASE

MODELS: KYSYS-48

KYSYS-72

KYSYS-96

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558.8744

U.S.A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

KYSYS-48

KYSYS-96

HEATED DISPLAY CASES

The Alto-Shaam Hot Display Case has

been thoroughly tested, checked for

calibration, and inspected to insure only the

highest quality cabinet is provided. When

you receive your display case, check for any possible shipping

damage and report it at once to the delivering carrier.

See

Transportation Damage and Claims section located in this manual.

In order to maintain established National Sanitation

Foundation standards, all stationary floor models must be

sealed to the floor with a R.T.V. or silastic meeting N.S.F.

requirements or have 6"(153mm) unobstructed clearance

beneath the unit. Warranty will become null and void if these

directions are not followed.

Save all the information and instructions packed inside

the display case. Complete and return the warranty card to

the factory as soon as possible to assure prompt service in the

event of a warranty parts and labor claim.

NOTE: Any and all claims for warranty must include the full model and

serial number of the display case.

1. An identification tag is permanently mounted on case.

2. Position the unit so that the cord is easily accessible in case

of an emergency.

3. Plug the case into a properly grounded receptacle ONLY.

Arcing will occur when connecting or disconnecting the

display case unless all controls are in the OFF position.

Before operating the unit, clean both the interior and

exterior of the unit with a damp cloth and mild soap

solution. Rinse carefully. Make sure all accessories

supplied with the case are installed correctly. Become

familiar with the operation of the controls. Read this

manual carefully and keep it in a secure location.

1. DO NOT ADD WATER TO THE CASE

Halo Heat display cases maintain a constant but gentle

temperature and eliminate much of the moisture loss

associated with conventional display cases. Because of

this gentle heat, it is not necessary to add water to the case.

As a matter of fact, adding water is not recommended

since water will accelerate deterioration of the product,

and may damage the case and void the warranty.

2. PLACE DIVIDERS and SERVING PANS IN CASE

Refer to the pan layout diagrams for different types of pan

accommodations. A complete pan configuration layout is

located in this manual. It is VERY

important to note that

with any chosen pan configuration, pan separator bars or

divider bars must be used to close all gaps between pans,

and all gaps between the pans and the edges of the display

case. If these gaps are not closed, heat can be pulled out

of the bottom of the case, into the display area. As a

consequence, heat distribution will be uneven and

uniform temperature will be difficult to hold. If needed,

additional pan divider bars are available.

3. TURN BREAKER SWITCH and POWER ON

They are located on the control panel.

4. SET THE THERMOSTAT(s) TO “9” TO PREHEAT

An indicator light will illuminate when the thermostat(s)

is (are) turned “ON.” The indicator(s) will remain lit as

long as the unit is preheating or calling for heat. The unit

should be preheated, at the number 9 setting, for a

minimum of

60 minutes before loading the case with food.

When preheating is completed, or whenever the unit

reaches any temperature set by the operator between 1

and 10, the indicator light(s) will go “OUT”. Preheat the

unit along with any empty serving pans or containers

which will be used to transfer hot food for display. To

prolong the life of the bulbs, preheat the bulbs on high for

15-20 minutes before turning down to low.

5. LOAD HOT FOOD INTO THE CASE

Be certain only hot food is transferred into the unit. Before

loading food into the case, use a pocket-type meat

thermometer to make certain all products have reached an

internal temperature of 140° to 160° F (60° to 71°C). If any

food product is not at proper serving temperature, use a

Combitherm oven, or a Halo Heat cooking and holding

oven set at 250° to 275°F (121° to 135°C) to bring the

product within the correct temperature range.

✔ Use hand protection when handling hot items.

✔ Do not stack food containers.

✔ Be certain hot foods in appropriate heat tested

containers are used in this hot display case.

6. RESET THERMOSTAT AS NEEDED

After all products are loaded into the display case and

the doors are closed, reset the thermostat(s) to the

number “8” setting. THIS WILL NOT NECESSARILY

BE THE FINAL SETTING. Since proper temperature

range depends on the type of products and the quantities

being held, it is necessary to periodically use a thermometer to check each item to make certain the correct

temperatures are being maintained. Proper temperature

range is between 140° and 160°F (60° and 71°C). Normally, this will require a thermostat setting of between

number “6” and “8,” although a higher or lower setting

may sometimes be required.

7. SERVE FRESH HOT FOOD

Keep hot foods looking fresh. Occasionally stir or rotate

foods as needed. Serve products in the proper package or

container. Keep case doors closed after serving. Wipe

spills immediately to assure maximum eye appeal and to

ease end of the day cleanup.

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON NAMEPLATE OF UNIT

Operation & Care Manual #878 • Pg. 1

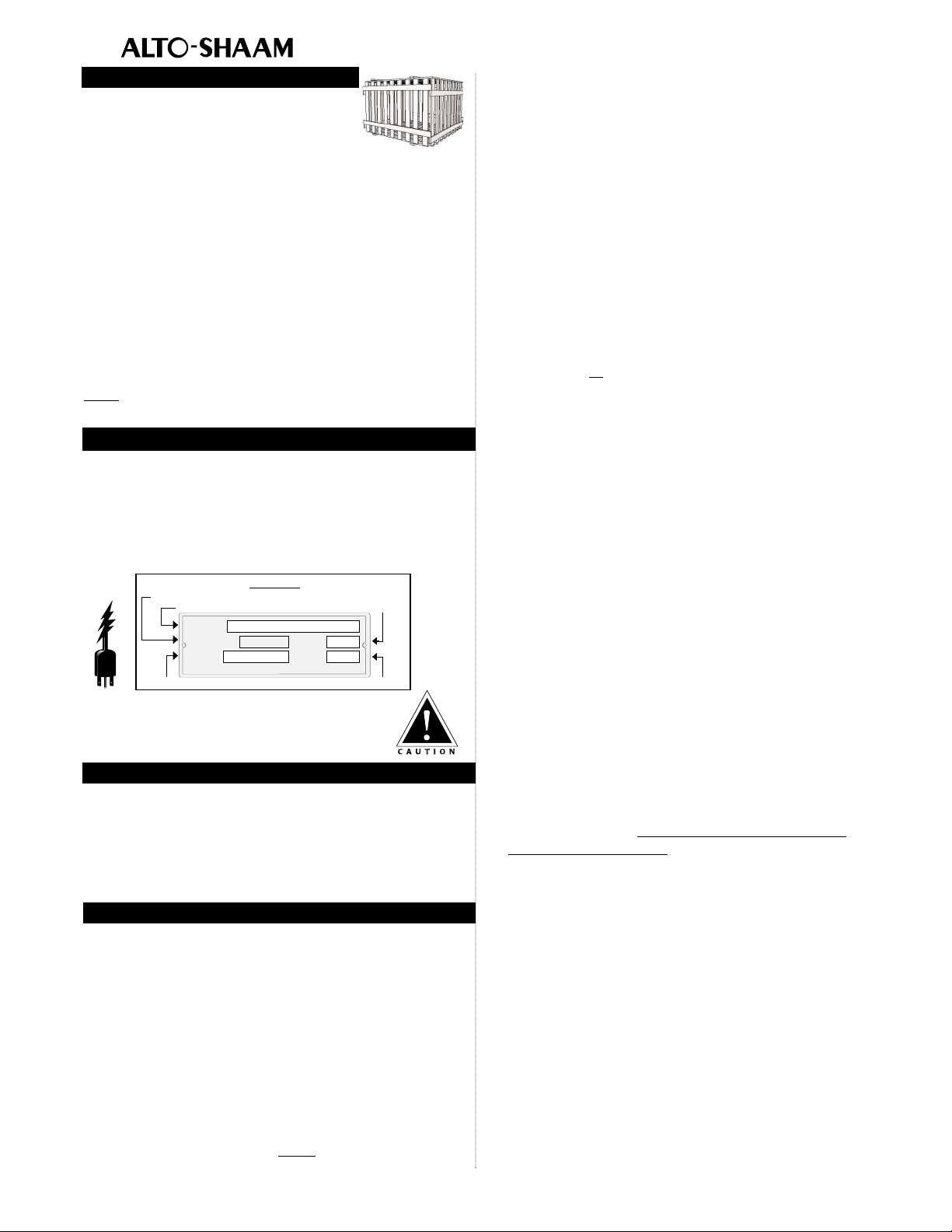

ELECTRICAL INSTALLATION

START UP

PROCEDURES

UNPACKING & SET-UP

®

SERIAL NUMBER AND WARRANTY CODE

IDENTIFICATION MODEL NUMBER

MODEL

SERIAL NO. WATTS

VOLTS

MAXIMUM RATED VOLTAGE MAXIMUM RATED FREQUENCY

EXAMPLE

xxx-xx

xxxx-xx xxxx

ALTO-SHAAM INC. MILW. WI. PAT. NO. 3521030

AC

1 PH

MAXIMUM RATED

WATTAGE

xx

HZxxx

The cleanliness and appearance of this unit

will contribute considerably to operating

efficiency and savory, appetizing food.

Good equipment kept clean works better and

lasts longer.

1. Turn lights and adjustable thermostat(s) to the “OFF”

position, and disconnect unit from power source.

2. Remove, cover or wrap, and store unused products under

refrigeration. Let unit cool.

3. Clean the interior metal surfaces of the unit with a

damp cloth and any good alkaline or alkaline

chlorinated based commercial detergent or grease

solvent at the recommended strength. Use a

plastic scouring pad or oven cleaner for difficult

areas. Avoid the use of abrasive cleaning

compounds, chloride based cleaners, or cleaners

containing quaternary salts. Rinse well to remove all

residue and wipe dry.

NOTE: Never use hydrochloric acid (muriatic acid) on

stainless steel.

4. Clean the glass with a window cleaner.

5. To help maintain the protective film coating on polished

stainless steel, clean the exterior of the unit with a cleaner

recommended for stainless steel surfaces. Spray the

cleaning agent on a clean cloth and wipe with the grain of

the stainless steel.

6. Clean other exterior surfaces with a clean cloth and hot

soapy water. Rinse carefully and dry.

Always follow appropriate state or local health (hygiene)

regulations regarding all applicable cleaning and sanitation

requirements for equipment.

Remember to turn power and breaker switches ON before use.

Operation & Care Manual #879 • Pg. 2

Always disconnect unit from power

source before cleaning or servicing.

THOROUGHLY CLEAN UNIT DAILY

Bulbs, 150W, 230V . . . . . . . . . . . . . . . . . . . . . . . . . .LP-33513

Custom Panels & Bumper Colors . . . . . . . . .

FACTORY QUOTE

Glass Divider (FOR BUTTING MULTIPLE CASES) . . . . . .GL-24562

Interior Ambient Temperature Gauge . . . . . . . . . .GU-33384

Menu Board System

— KYSYS-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MB-23092

— KYSYS-72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MB-23093

— KYSYS-96 (2 required) . . . . . . . . . . . . . . . . . . . .MB-23092

Platform, Scale, LH . . . . . . . . . . . . . . . . . . . . . . . . . . . .14975

Platform, Scale, RH . . . . . . . . . . . . . . . . . . . . . . . . . . . .14976

Pocket Thermometer °F . . . . . . . . . . . . . . . . . . . . . . .TH-3300

Pocket Thermometer °C . . . . . . . . . . . . . . . . . . . . . .TH-3412

Stainless Steel Exterior Front Skirt Panels . . .

FACTORY QUOTE

Stainless Steel End Panels . . . . . . . . . . . . . . .FACTORY QUOTE

Pan Separator Bars

— Third Size Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11047

— Full/Half/Third (Long Bar) . . . . . . . . . . .

FACTORY QUOTE

— Full/Half/Third (Short Bar) . . . . . . . . . . . . . . . . . . .11318

— Sheet Pan (Long) KYSYS-48 . . . . . . . . . . . . . . . . . . .11319

— Sheet Pan (Long) KYSYS-72 and -96 . . . . . . . . . . . . .11357

— Sheet Pan (Short) . . . . . . . . . . . . . . . . . . . . . . . . . . . .11320

— 3/4 Sheet Pan Filler . . . . . . . . . . . . . . . . . . . . . . . . . .11732

Options & Accessories

At no time should the inside or outside

of the unit be washed down, flooded

with water or liquid solution.

NEVER STEAM CLEAN. Do not use

water jet to clean. Severe damage or

electrical hazard could result, voiding

the warranty.

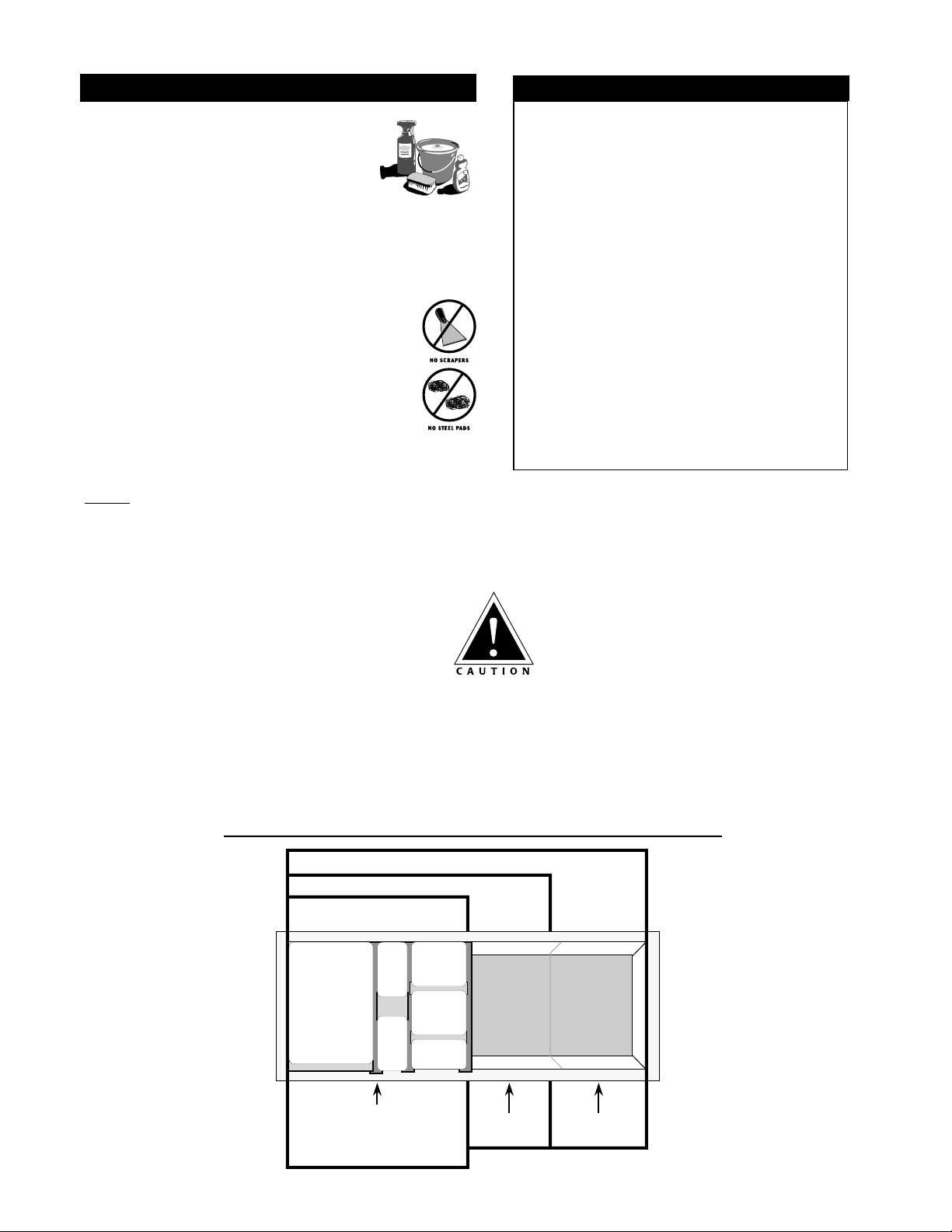

SHEET PAN CONFIGURATIONS • HOT DELI DISPLAY CASES

96 Models

72 Models

48 Models

2 SHEET PAN ZONES

SIZE PAN

FULL-SIZE

SHEET PAN

2 Full-size Sheet Pans per display case

ONE-THIRD

SIZE PAN

ONE-THIRD

48 MODELS

OR

1 Full-size Sheet Pan

2 One-half Size Pans

3 One-third Size Pans

ONE-HALF

SIZE PAN

ONE-HALF

SIZE PAN

ONE-THIRD

SIZE PAN

3 SHEET PAN

ZONES

72 MODELS

3 Full-size Sheet Pans

per display case

4 SHEET PAN

ZONES

96 MODELS

4 Full-size Sheet Pans

per display case

Operation & Care Manual #879 • 3.

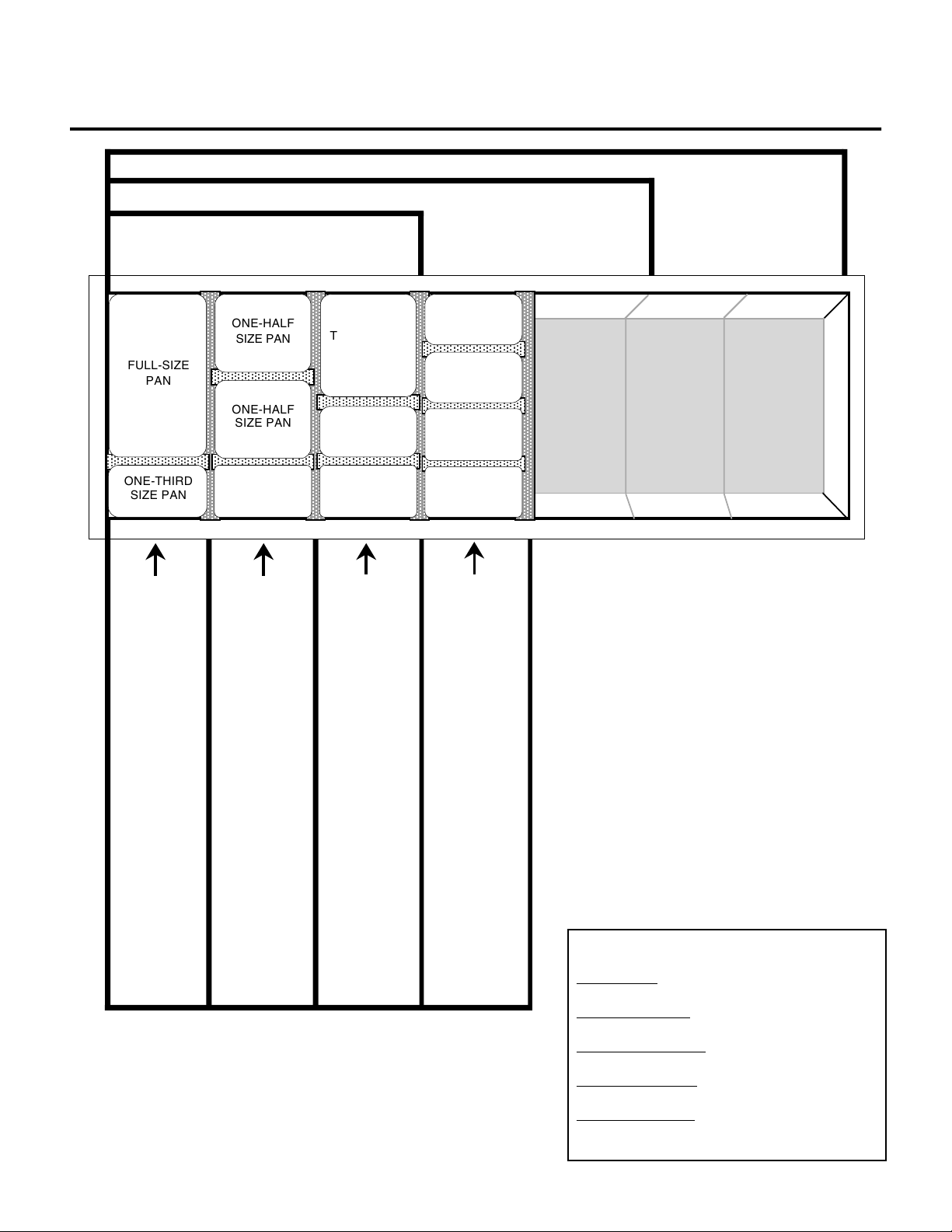

PAN CONFIGURATIONS • HOT DELI DISPLAY CASES

NOTE: ADDITIONAL PAN

SEPARATOR BARS MAY

BE REQUIRED TO

ACCOMMODATE MAXIMUM

CAPACITIES.

FULL-SIZE

PAN

ONE-THIRD

SIZE PAN

ONE-HALF

SIZE PAN

ONE-HALF

SIZE PAN

TWO-THIRDS

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

ONE-THIRD

SIZE PAN

48 Models

72 Models

96 Models

3 PAN ZONES 5 PAN ZONES

7 PAN ZONES

One (1) FULL-SIZE PAN and

One (1) ONE-THIRD SIZE PAN per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 3 Full-Size Pans with 3 One-Third Size Pans

Up to 5 Full-Size Pans with 5 One-Third Size Pans

Up to 7 Full-Size Pans with 7 One-Third Size Pans

Two (2) ONE-HALF SIZE PANS and

One (1) ONE-THIRD SIZE PAN per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 6 One-Half Size Pans with 3 One-Third Size Pans

Up to 10 One-Half Size Pans with 5 One-Third Size Pans

Up to 14 One-Half Size Pans with 7 One-Third Size Pans

One (1) TWO-THIRDS SIZE PAN and

Two (2) ONE-THIRD SIZE PANS per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 3 Two-Thirds Size Pans with 6 One-Third Size Pans

Up to 5 Two-Thirds Size Pans with 10 One-Third Size Pans

Up to 7 Two-Thirds Size Pans with 14 One-Third Size Pans

Four (4) ONE-THIRD SIZE PANS per pan zone.

— 48 MODELS:

— 72 MODELS:

— 96 MODELS:

Up to 12 One-Third Size Pans per display case

Up to 20 One-Third Size Pans per display case

Up to 28 One-Third Size Pans per display case

ONE-THIRD

SIZE PAN

STANDARD PAN SIZES

Full-Size Pan

12” x 20” x 2-1/2” (325mm x 530mm x 65 mm) GN1/1

One-Half Size Pan

12” x 10” x 2-1/2” (325mm x 265mm x 65mm) GN 1/2

Two-Thirds Size Pan

12” x 14” x 2-/12” (325mm x 352mm x 65mm) GN 2/3

One-Third Size Pan

12” x 6” x 2-1/2” (325mm x 176mm x 65mm) GN 1/3

Full-Size Sheet Pan

18” x 26” x 1 (457mm x 660mm x 25mm) N/A

Loading...

Loading...