Page 1

101 Innovation Drive

San Jose, CA 95134

www.altera.com

QDRII SRAM Controller

MegaCore Function User Guide

MegaCore Version: 9.1

Document Date: November 2009

Page 2

Copyright © 2009 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific device designations, and all other words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the trademarks and

service marks of Altera Corporation in the U.S. and other countries. All other product or service names are the property of their respective holders. Altera products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights, and copyrights. Altera warrants

performance of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make

changes to any products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information, product, or service described herein except as expressly agreed to in writing by Altera

Corporation. Altera customers are advised to obtain the latest version of device specifications before relying on any published information and before placing orders for products or services.

UG-IPQDRII-8.1

ii MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide

Page 3

Contents

Chapter 1. About This MegaCore Function

Release Information ............................................................................................................................... 1–1

Device Family Support ......................................................................................................................... 1–1

Features ................................................................................................................................................... 1–2

General Description ............................................................................................................................... 1–2

OpenCore Plus Evaluation .............................................................................................................. 1–3

Performance and Resource Utilization ............................................................................................... 1–4

Chapter 2. Getting Started

Design Flow ............................................................................................................................................ 2–1

QDRII SRAM Controller Walkthrough .............................................................................................. 2–2

Create a New Quartus II Project .................................................................................................... 2–3

Launch IP Toolbench ....................................................................................................................... 2–4

Step 1: Parameterize ......................................................................................................................... 2–5

Step 2: Constraints ............................................................................................................................ 2–7

Step 3: Set Up Simulation ................................................................................................................ 2–7

Step 4: Generate ................................................................................................................................ 2–8

Simulate the Example Design ............................................................................................................ 2–11

Simulate with IP Functional Simulation Models ....................................................................... 2–11

Simulating With the ModelSim Simulator ................................................................................. 2–11

Simulating With Other Simulators .............................................................................................. 2–12

Simulating in Third-Party Simulation Tools Using NativeLink ............................................. 2–17

Edit the PLL .......................................................................................................................................... 2–18

Compile the Example Design ............................................................................................................ 2–19

Program a Device ................................................................................................................................ 2–21

Implement Your Design ..................................................................................................................... 2–21

Set Up Licensing .................................................................................................................................. 2–21

Chapter 3. Functional Description

Block Description ................................................................................................................................... 3–1

Control Logic .................................................................................................................................... 3–2

Resynchronization & Pipeline Logic ............................................................................................. 3–3

Datapath ............................................................................................................................................ 3–5

OpenCore Plus Time-Out Behavior .................................................................................................. 3–10

Interfaces & Signals ............................................................................................................................. 3–10

Interface Description ...................................................................................................................... 3–10

Signals .............................................................................................................................................. 3–22

Device-Level Configuration ............................................................................................................... 3–26

PLL Configuration ......................................................................................................................... 3–26

Example Design .............................................................................................................................. 3–27

Constraints ...................................................................................................................................... 3–29

Altera Corporation MegaCore Version 9.1 iii

Page 4

Contents

Parameters ............................................................................................................................................ 3–29

Memory ............................................................................................................................................ 3–30

Board & Controller ......................................................................................................................... 3–31

Project Settings ................................................................................................................................ 3–33

MegaCore Verification ........................................................................................................................ 3–34

Simulation Environment ............................................................................................................... 3–34

Hardware Testing ........................................................................................................................... 3–34

Additional Information

Revision History ............................................................................................................................... Info–i

How to Contact Altera ..................................................................................................................... Info–i

Typographic Conventions .............................................................................................................. Info–ii

iv MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide

Page 5

1. About This MegaCore Function

Release Information

f For more information about this release, refer to the MegaCore IP Library

Device Family Support

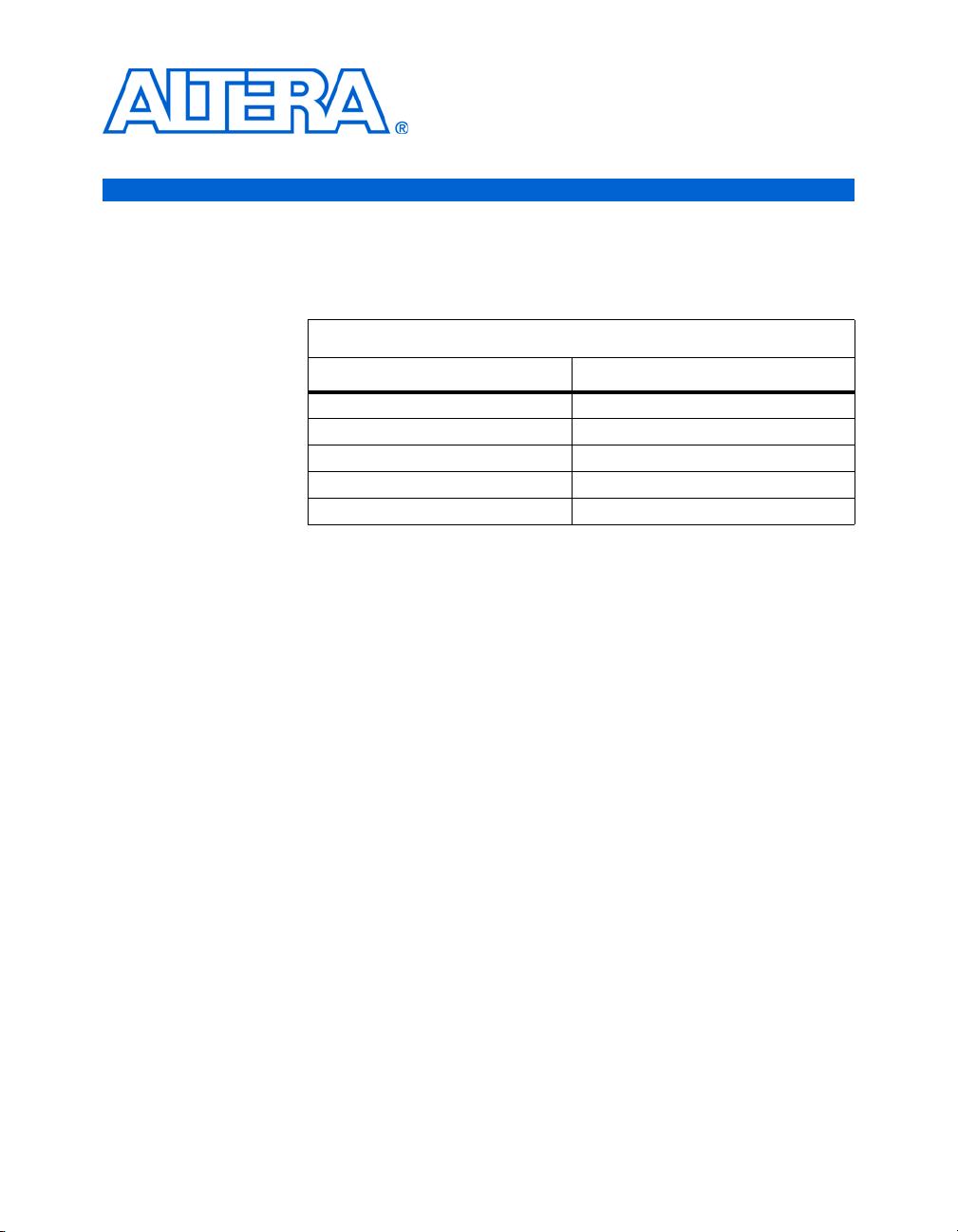

Table 1–1 provides information about this release of the Altera® QDRII

SRAM Controller MegaCore® function.

Table 1–1. Release Information

Item Description

Ver si on 9. 1

Release Date November 2009

Ordering Code IP-SRAM/QDRII

Product ID 00A4

Vendor ID 6AF7

Release Notes and Errata.

Altera verifies that the current version of the Quartus® II software

compiles the previous version of each MegaCore function. The MegaCore

IP Library Release Notes and Errata report any exceptions to this

verification. Altera does not verify compilation with MegaCore function

versions older than one release.

MegaCore functions provide either full or preliminary support for target

Altera device families:

■ Full support means the MegaCore function meets all functional and

timing requirements for the device family and may be used in

production designs

■ Preliminary support means the MegaCore function meets all

functional requirements, but may still be undergoing timing analysis

for the device family; it may be used in production designs with

caution.

Altera Corporation MegaCore Version 9.1 1–1

November 2009

Page 6

Features

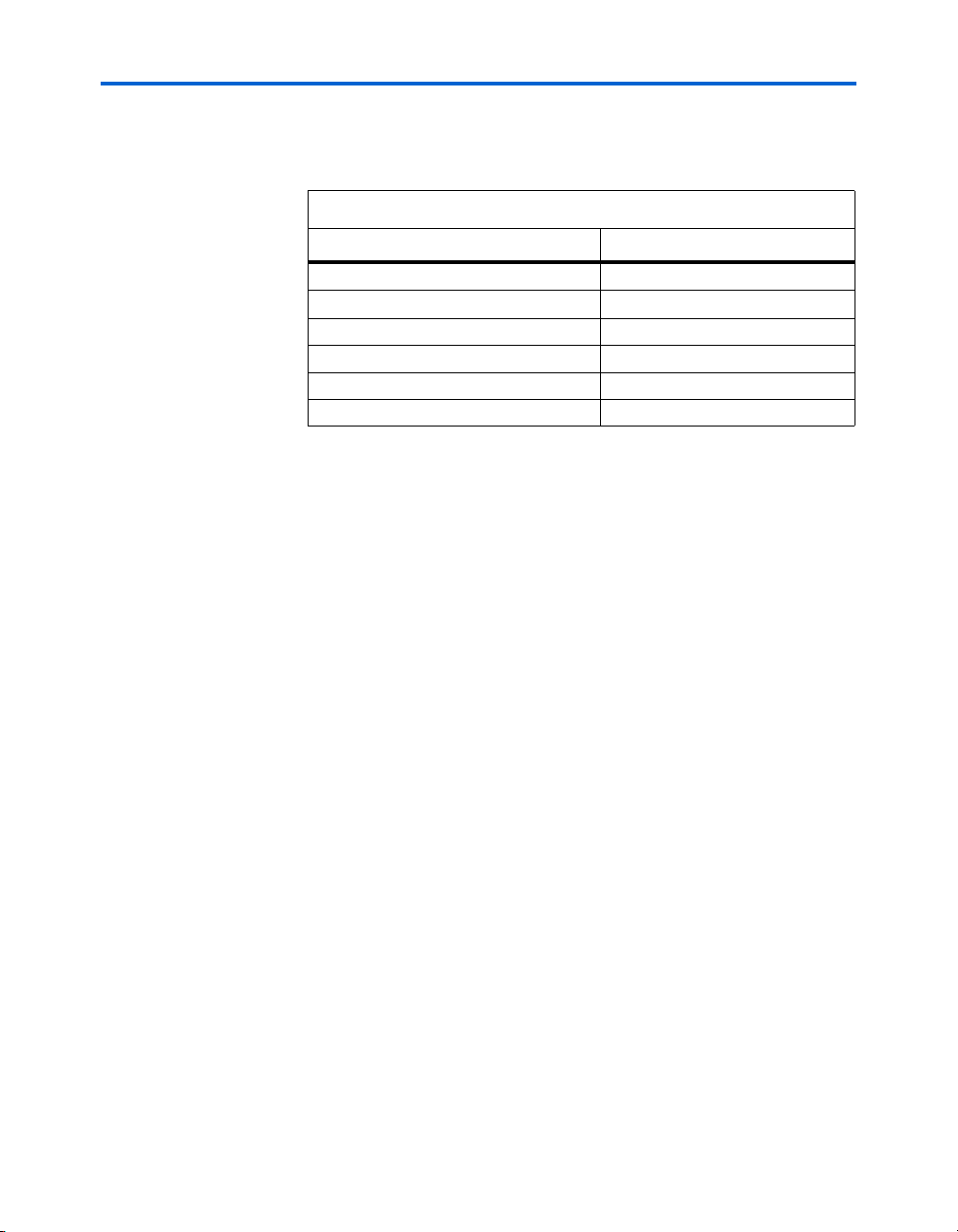

Table 1–2 shows the level of support offered by the QDRII SRAM

Controller MegaCore function to each Altera device family.

Table 1–2. Device Family Support

Device Family Support

HardCopy® II

®

Stratix

Stratix

II Full

Stratix

II GX

Stratix GX Full

Other device families (1) No support

Note to Ta b l e 1– 2 :

(1) For more information on support for Stratix III or Stratix IV devices, contact

Altera.

Preliminary

Full

Full

Features

General Description

■ Support for burst of two and four memory type

■ Support for 8-, 18-, and 36-bit QDRII interfaces

■ Support for two-times and four-times data width on the local side

(four-times for burst of four only)

■ Operates at 300 MHz for QDRII and QDRII+ SRAM

■ Automatic concatenation of consecutive reads and writes (narrow

local bus width mode only)

■ Easy-to-use IP Toolbench interface

■ IP functional simulation models for use in Altera-supported VHDL

and Verilog HDL simulators

■ Support for OpenCore Plus evaluation

The QDRII SRAM Controller MegaCore function provides an easy-to-use

interface to QDRII SRAM modules. The QDRII SRAM Controller ensures

that the placement and timing are in line with QDRII specifications.

The QDRII SRAM Controller is optimized for Altera Stratix series. The

advanced features available in these devices allow you to interface

directly to QDRII SRAM devices.

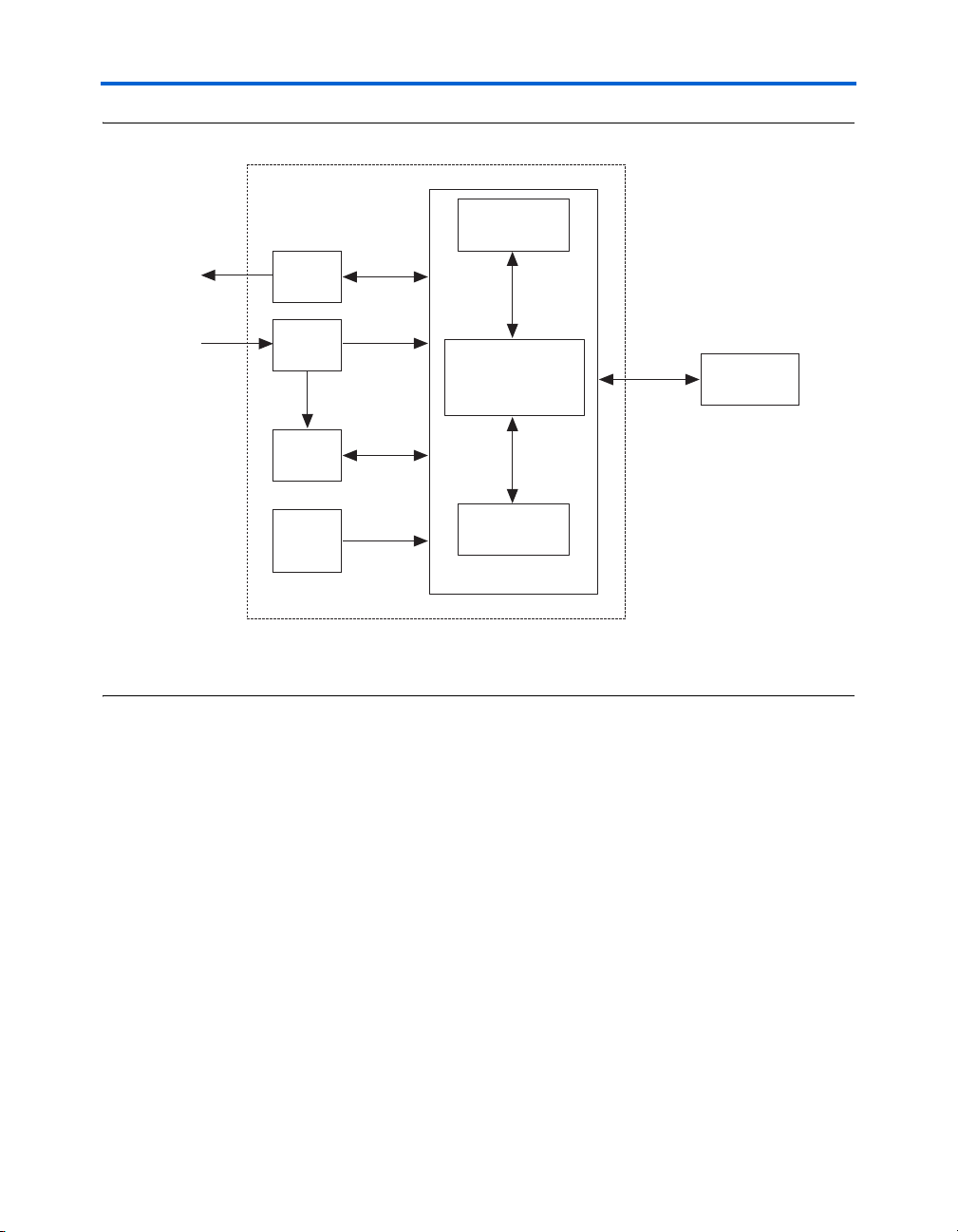

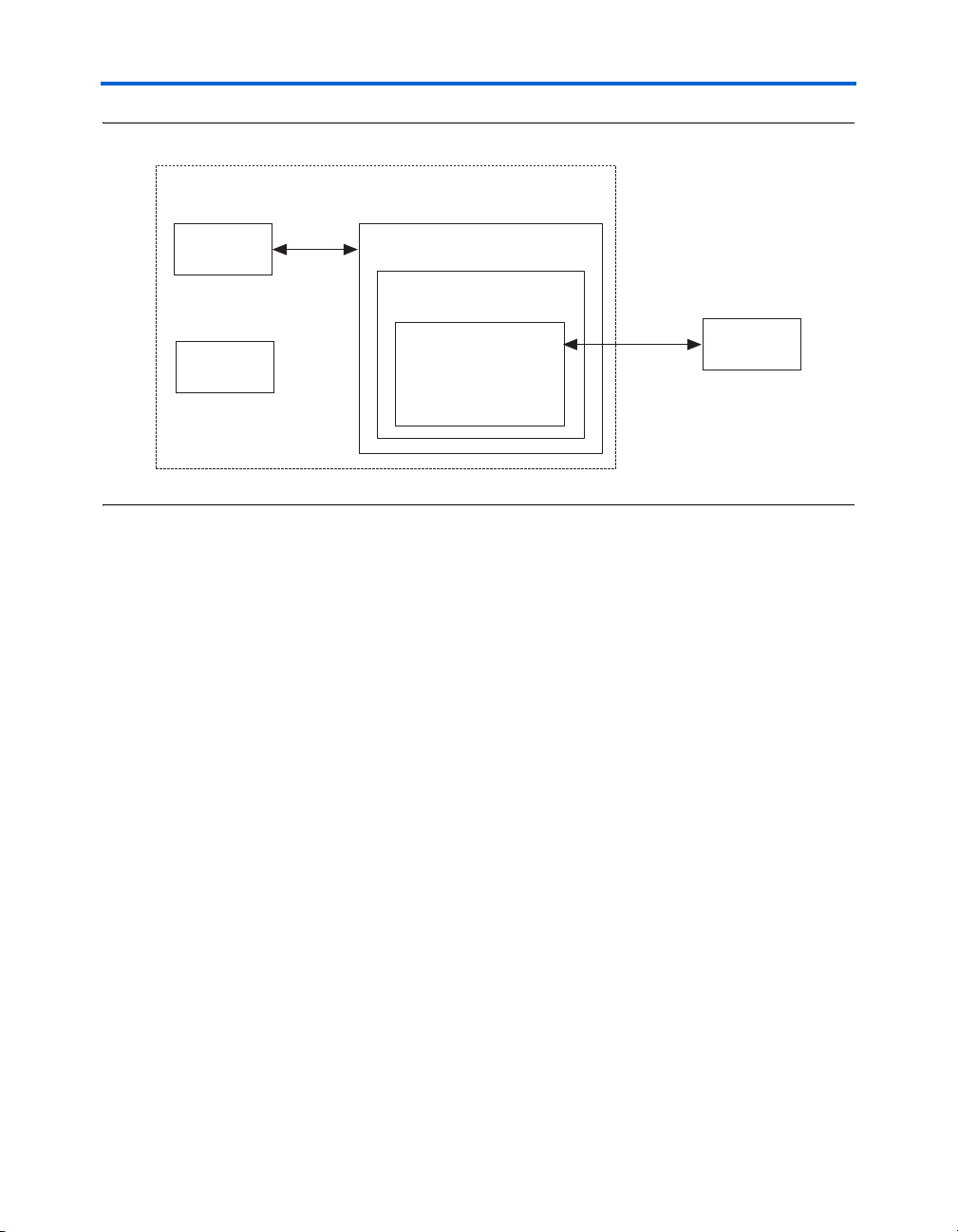

Figure 1–1 shows a system-level diagram including the example design

that the QDRII SRAM Controller MegaCore function creates for you.

1–2 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 7

Figure 1–1. QDRII SRAM Controller System-Level Diagram

Example Design

Control Logic

(Encrypted)

Pass

or Fail

Example

Driver

Local

Interface

About This MegaCore Function

Clock

Notes to Figure 1–1:

(1) Optional, for Stratix II devices only.

(2) Non-DQS mode only.

System

PLL

DLL (1)

Fedback

Clock

PLL (

2

)

The IP Toolbench-generated example design instantiates a phase-locked

loop (PLL), an optional DLL (for Stratix II devices only), an example

driver, and your QDRII SRAM Controller custom variation. The example

design is a fully-functional example design that can be simulated,

synthesized, and used in hardware. The example driver is a self-test

module that issues read and write commands to the controller and checks

the read data to produce the pass/fail and test complete signals.

Resynchronization

& Pipeline Logic

(Clear Text)

Datapath

(Clear Text)

QDRII SRAM Controller

QDRII

SRAM

Interface

QDRII SRAM

You can replace the QDRII SRAM controller encrypted control logic in

the example design with your own custom logic, which allows you to use

the Altera clear-text resynchronization and pipeline logic and datapath

with your own control logic.

OpenCore Plus Evaluation

With Altera’s free OpenCore Plus evaluation feature, you can perform

the following actions:

Altera Corporation MegaCore Version 9.1 1–3

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 8

Performance and Resource Utilization

■ Simulate the behavior of a megafunction (Altera MegaCore function

or AMPPSM megafunction) within your system

■ Verify the functionality of your design, as well as evaluate its size

and speed quickly and easily

■ Generate time-limited device programming files for designs that

include megafunctions

■ Program a device and verify your design in hardware

You only need to purchase a license for the megafunction when you are

completely satisfied with its functionality and performance, and want to

take your design to production.

f For more information on OpenCore Plus hardware evaluation using the

QDRII SRAM Controller, refer to “OpenCore Plus Time-Out Behavior”

on page 3–10 and AN 320: OpenCore Plus Evaluation of Megafunctions.

Performance

and Resource

Utilization

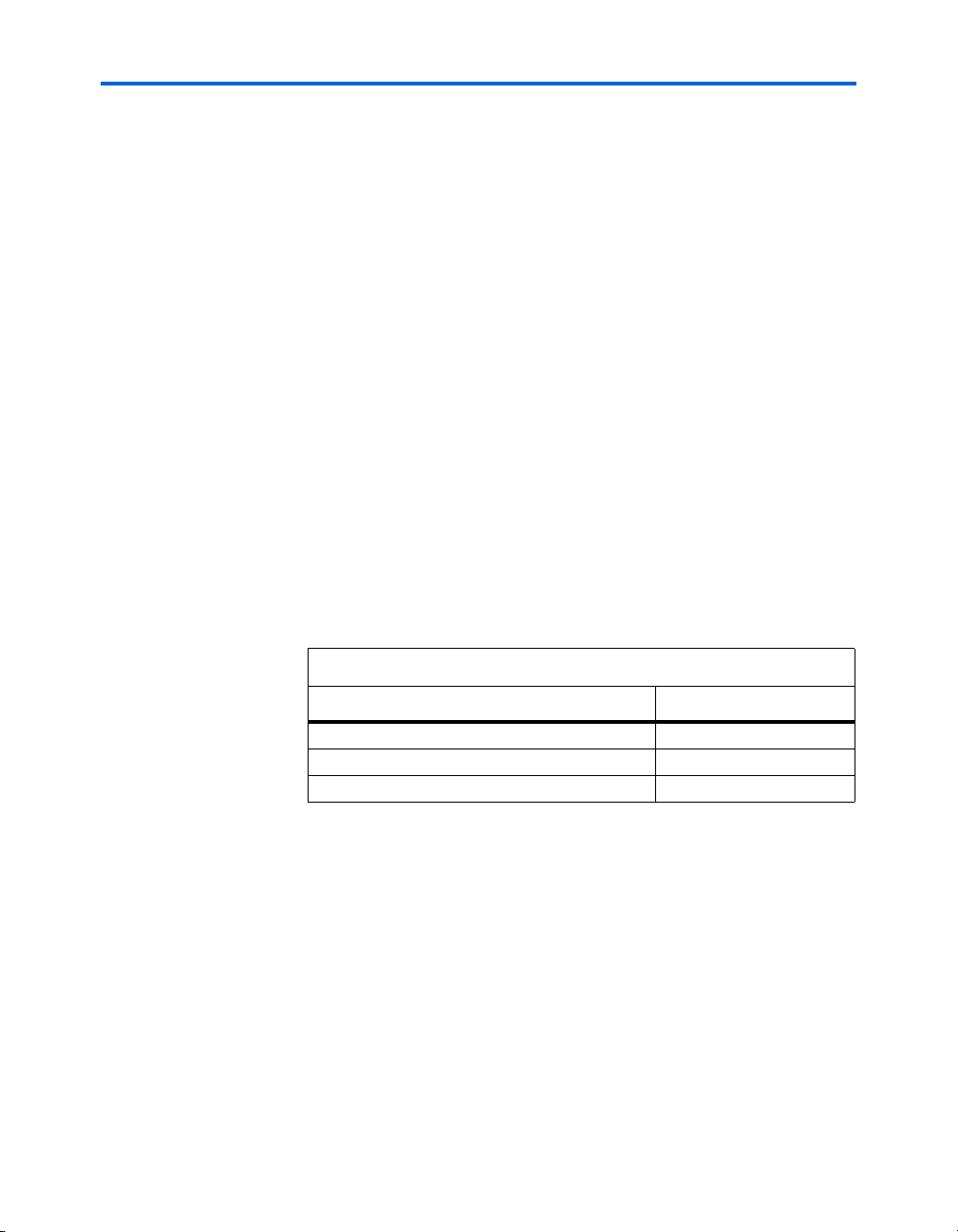

Table 1–3 shows typical expected performance for the QDRII SRAM

Controller MegaCore function, with the Quartus II software version 9.1.

1 The example driver, which only demonstrates basic read and

write operation, can limit the performance, particularly in wide

interfaces. To improve performance, replace the example driver

or remove it and use the virtual pins on the controller.

Table 1–3. Performance

(MHz)

Device

Stratix II (EP2S60F1020C3) 300

Stratix II GX (EP2SGX30CF780C3) 300

Stratix (EP1S25F780C5) 200

Stratix II and Stratix II GX devices support QDRII SRAM at up to

300 MHz/1,200 Megabits per second (Mbps). Stratix and Stratix GX

devices support QDRII SRAM at up to 200 MHz/800 Mbps. Tables 1–4

through 1–6 show the clock frequency support for each device family,

with the Quartus II software version 9.1.

f

MAX

1–4 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 9

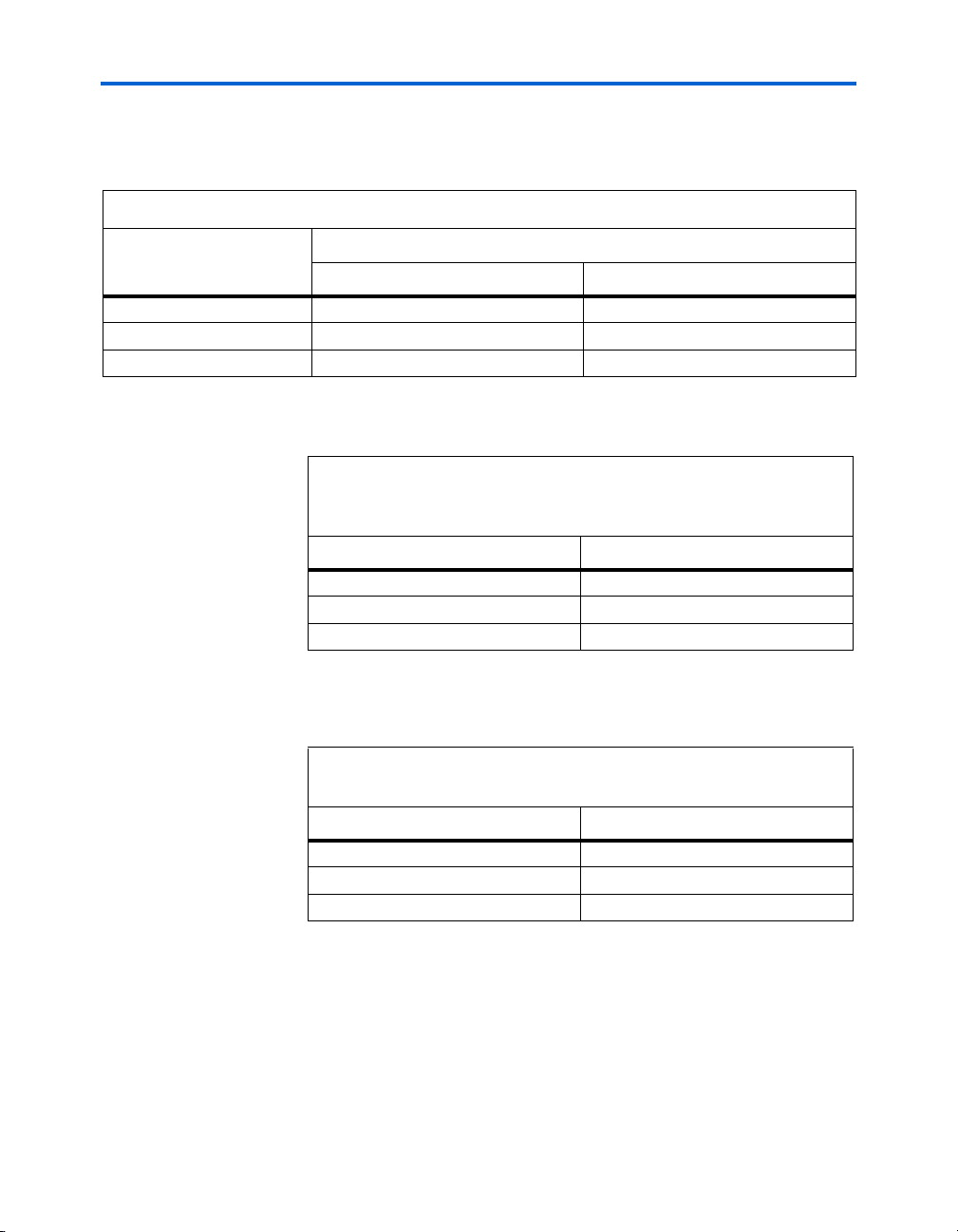

About This MegaCore Function

1 These numbers apply to both commercial and industrial

devices.

Table 1–4. QDRII SDRAM Maximum Clock Frequency Support in Stratix II & Stratix II GX Devices (1)

Speed Grade

Frequency (MHz)

DLL-Based Implementation PLL-Based Implementation

–3 300 200

–4 200 167

–5 200 167

Notes to Ta b l e 1– 4 :

(1) This analysis is based on the EP2S90F1020 device. Ensure you perform a timing analysis for your chosen FPGA.

Table 1–5. QDRII SRAM Maximum Clock Frequency Supported in Stratix &

Stratix GX Devices (EP1S10 to EP1S40 & EP1SGX10 to EP1SGX40 Devices)

(1)

Speed Grade Frequency (MHz)

–5 200

–6 167

–7 133

Notes to Ta b l e 1– 5 :

(1) This analysis is based on the EP1S25F1020 device. Ensure you perform a timing

analysis for your chosen FPGA.

Table 1–6. QDRII SRAM Maximum Clock Frequency Supported in Stratix

Devices (EP1S60 to EP1S80 Devices) (1)

Speed Grade Frequency (MHz)

–5 167

–6 167

–7 133

Notes to Ta b l e 1– 6 :

(1) This analysis is based on the EP1S60F1020 device. Ensure you perform a timing

analysis for your chosen FPGA.

Altera Corporation MegaCore Version 9.1 1–5

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 10

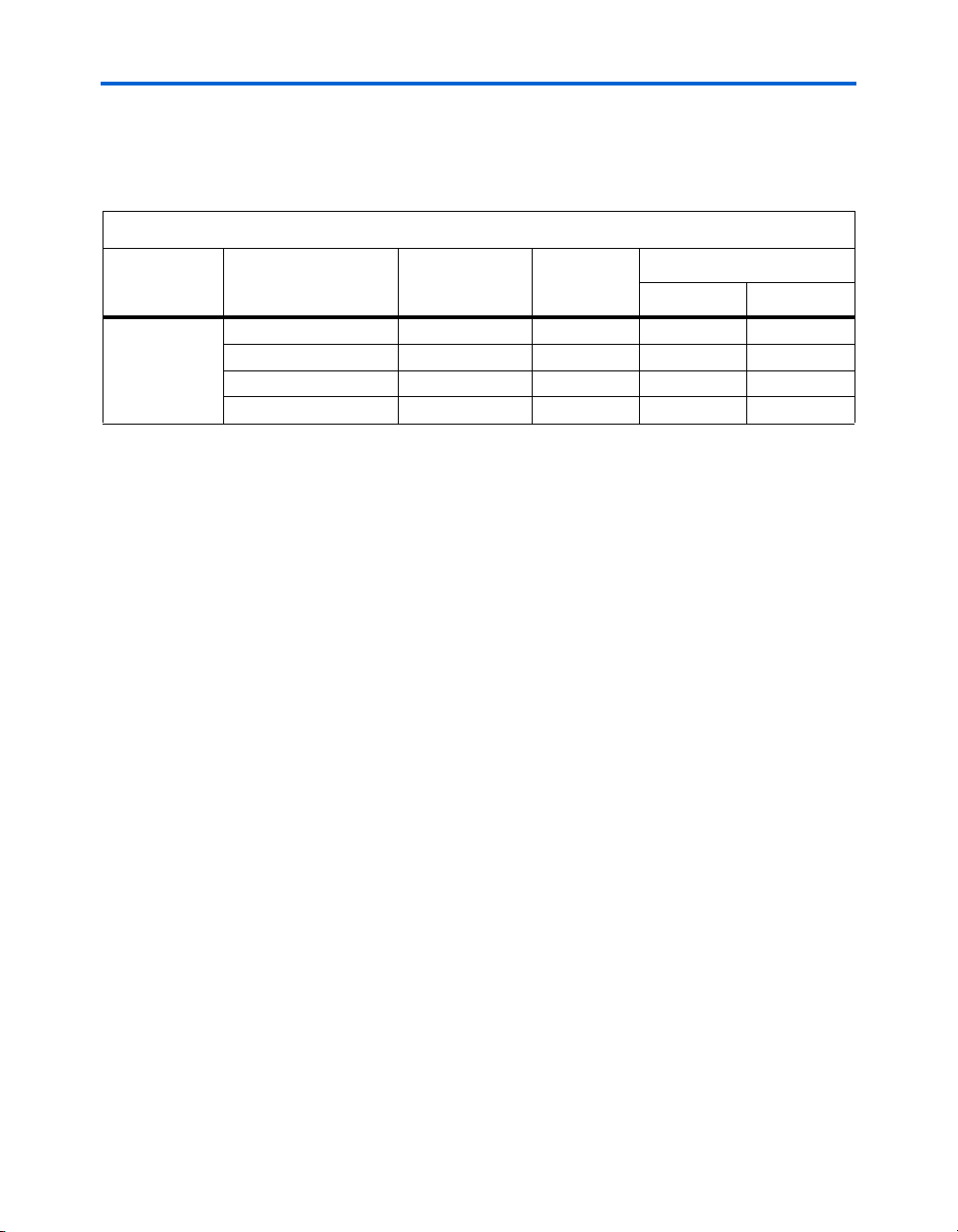

Performance and Resource Utilization

Table 1–7 shows typical sizes in combinational adaptive look-up tables

(ALUTs) and logic registers for a QDRII SRAM controller with a burst

length of 4 in narrow mode.

Table 1–7. Typical Size (1)

Device Memory Width (Bits)

Stratix II 9 360 598 – 1

18 369 633 1 –

36 390 708 2 –

72 (2 × 36) 459 880 4 –

Notes to Ta b l e 1– 7 :

(1) These sizes are a guide only and vary with different choices of parameters.

Combinational

ALUTs

Logic

Registers

Memory Blocks

M4K M512

1–6 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 11

2. Getting Started

Design Flow

To evaluate the QDRII SRAM Controller using the OpenCore Plus

feature, include these steps in your design flow:

1. Obtain and install the QDRII SRAM Controller.

The QDRII SRAM Controller is part of the MegaCore IP Library, which is

distributed with the Quartus II software and downloadable from the

Altera website, www.altera.com.

f For system requirements and installation instructions, refer to Altera

Software Installation and Licensing.

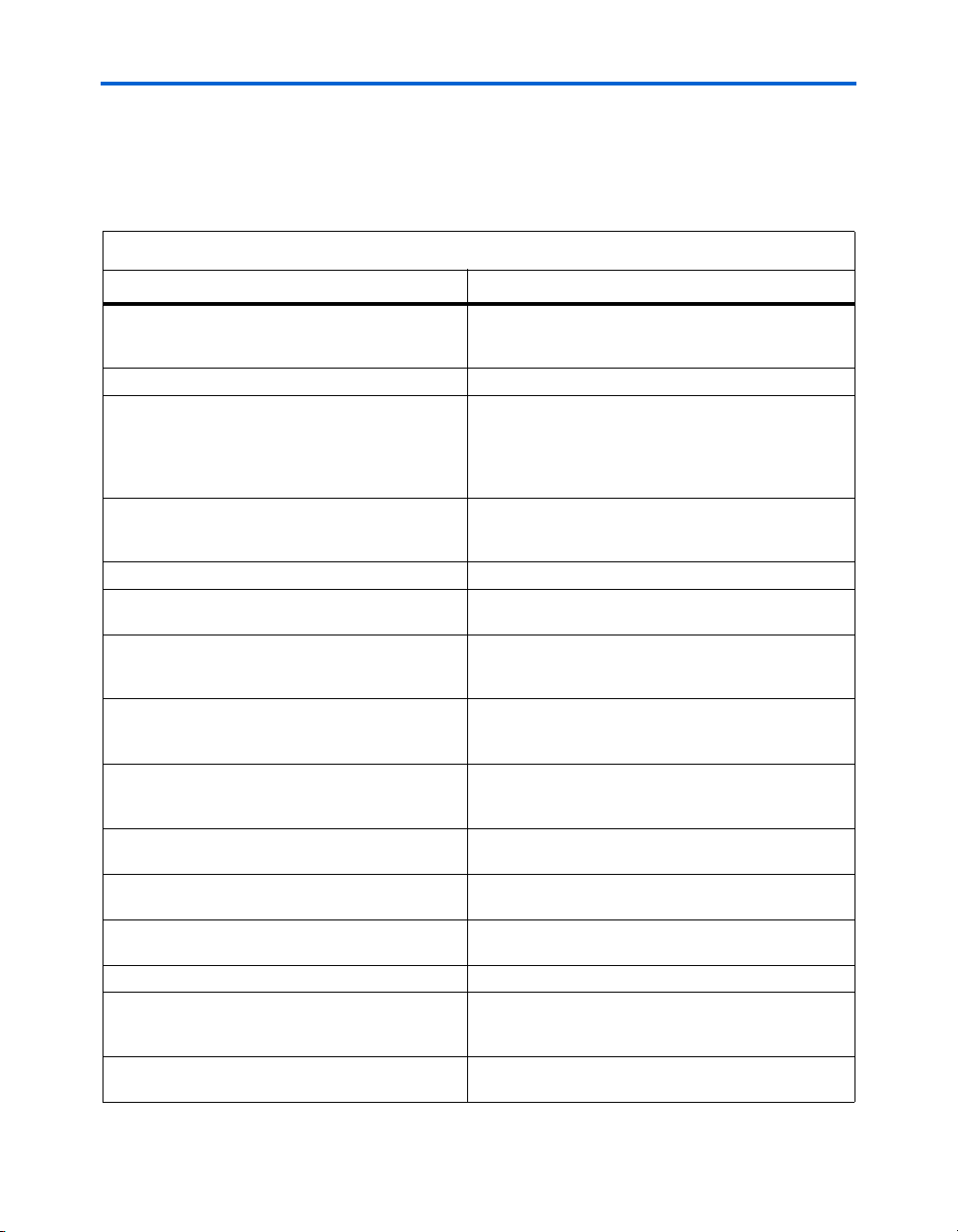

Figure 2–1 shows the directory structure after you install the QDRII

SRAM Controller, where <path> is the installation directory. The default

installation directory on Windows is c:\altera\<version>; on Linux it is

/opt/altera<version>.

Figure 2–1. Directory Structure

<path>

Installation directory.

ip

Contains the Altera MegaCore IP Library and third-party IP cores.

altera

Contains the Altera MegaCore IP Library.

common

Contains shared components.

qdrii_sram_controller

Contains the QDRII SRAM Controller MegaCore function files and documentation.

constraints

Contains scripts that generate an instance-specific Tcl script for each instance of

the QDRII SRAM Controller in various Altera devices.

dat

Contains a data file for each Altera device combination that is used by the

Tcl script to generate the instance-specific Tcl script.

doc

Contains the documentation for the QDRII SRAM Controller MegaCore function.

lib

Contains encrypted lower-level design files and other support files.

2. Create a custom variation of the QDRII SRAM Controller MegaCore

function using IP Toolbench.

Altera Corporation MegaCore Version 9.1 2–1

November 2009

Page 12

QDRII SRAM Controller Walkthrough

1 IP Toolbench is a toolbar from which you quickly and easily

3. Implement the rest of your design using the design entry method of

your choice.

4. Use the IP Toolbench-generated IP functional simulation model to

verify the operation of your design.

f For more information on IP functional simulation models, refer to the

Simulating Altera IP in Third-Party Simulation Tools chapter in volume 3 of

the Quartus II Handbook.

5. Edit the PLL(s).

6. Use the Quartus II software to add constraints to the example

design and compile the example design.

7. Perform gate-level timing simulation, or if you have a suitable

development board, you can generate an OpenCore Plus

time-limited programming file, which you can use to verify the

operation of the example design in hardware.

view documentation, specify parameters, and generate all

of the files necessary for integrating the parameterized

MegaCore function into your design.

8. Either obtain a license for the QDRII SRAM controller MegaCore

function or replace the encrypted QDRII SRAM controller control

logic with your own logic and use the clear-text data path.

1 If you obtain a license for the QDRII SRAM controller, you

must set up licensing.

9. Generate a programming file for the Altera device(s) on your board.

10. Program the Altera device(s) with the completed design.

QDRII SRAM

Controller

Walkthrough

2–2 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

This walkthrough explains how to create a QDRII SRAM controller using

the Altera QDRII SRAM controller IP Toolbench and the Quartus II

software. When you are finished generating a custom variation of the

QDRII SRAM Controller MegaCore function, you can incorporate it into

your overall project.

1 IP Toolbench only allows you to select legal combinations of

parameters, and warns you of any invalid configurations.

This walkthrough requires the following steps:

Page 13

Getting Started

■ “Create a New Quartus II Project” on page 2–3

■ “Launch IP Toolbench” on page 2–4

■ “Step 1: Parameterize” on page 2–5

■ “Step 2: Constraints” on page 2–7

■ “Step 3: Set Up Simulation” on page 2–7

■ “Step 4: Generate” on page 2–8

Create a New Quartus II Project

Before you begin, you must create a new Quartus II project. With the New

Project wizard, you specify the working directory for the project, assign

the project name, and designate the name of the top-level design entity.

You will also specify the QDRII SRAM Controller user library. To create a

new project, follow these steps:

You need to create a new Quartus II project with the New Project Wizard,

which specifies the working directory for the project, assigns the project

name, and designates the name of the top-level design entity. To create a

new project follow these steps:

1. Choose Programs > Altera > Quartus II <version> (Windows Start

menu) to run the Quartus II software. Alternatively, you can use the

Quartus II Web Edition software.

2. Choose New Project Wizard (File menu).

3. Click Next in the New Project Wizard Introduction page (the

introduction page does not display if you turned it off previously).

4. In the New Project Wizard: Directory, Name, Top-Level Entity

page, enter the following information:

a. Specify the working directory for your project. For example,

this walkthrough uses the c:\altera\temp\qdr_project

directory.

b. Specify the name of the project. This walkthrough uses project

for the project name.

1 The Quartus II software automatically specifies a top-level

design entity that has the same name as the project. Do not

change it.

5. Click Next to close this page and display the New Project Wizard:

Add Files page.

Altera Corporation MegaCore Version 9.1 2–3

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 14

QDRII SRAM Controller Walkthrough

1 When you specify a directory that does not already exist, a

6. If you installed the MegaCore IP Library in a different directory

from where you installed the Quartus II software, you must add the

user libraries:

a. Click User Libraries.

b. Type <path>\ip into the Library name box, where <path> is the

c. Click Add to add the path to the Quartus II project.

d. Click OK to save the library path in the project.

7. Click Next to close this page and display the New Project Wizard:

Family & Device Settings page.

8. On the New Project Wizard: Family & Device Settings page,

choose the target device family in the Family list.

9. The remaining pages in the New Project Wizard are optional. Click

Finish to complete the Quartus II project.

message asks if the specified directory should be created.

Click Yes to create the directory.

directory in which you installed the QDRII SRAM Controller.

You have finished creating your new Quartus II project.

Launch IP Toolbench

To launch IP Toolbench in the Quartus II software, follow these steps:

1. Start the MegaWizard® Plug-In Manager by choosing MegaWizard

Plug-In Manager (Tools menu). The MegaWizard Plug-In Manager

dialog box displays.

1 Refer to Quartus II Help for more information on how to

use the MegaWizard Plug-In Manager.

2. Specify that you want to create a new custom megafunction

variation and click Next.

3. Expand the Interfaces > Memory Controllers directory then click

QDRII SRAM Controller-v8.1.

4. Select the output file type for your design; the wizard supports

VHDL and Verilog HDL.

2–4 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 15

Getting Started

5. The MegaWizard Plug-In Manager shows the project path that you

specified in the New Project Wizard. Append a variation name for

the MegaCore function output files <project path>\<variation name>.

1 The <variation name> must be a different name from the

project name and the top-level design entity name.

6. Click Next to launch IP Toolbench.

Step 1: Parameterize

To parameterize your MegaCore function, follow these steps:

1. Click Step 1: Parameterize in IP Toolbench.

f For more information on the parameters, refer to “Parameters” on

page 3–29).

2. Set the memory type:

a. Choose the Memory device.

b. Select either QDRII or QDRII+.

c. Set the Clock speed.

d. Choose the Voltage.

e. Choose the Burst length.

f. Choose the Data bus width.

g. Choose the Address bus width.

h. Choose the Memory Latency.

i. Select the Narrow mode or Wide mode to set the local bus

width.

3. Set the memory interface.

a. Set Device width.

b. Set Device depth.

c. Turn off Use ALTDDIO pin, if you are targeting HardCopy II

devices.

Altera Corporation MegaCore Version 9.1 2–5

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 16

QDRII SRAM Controller Walkthrough

4. Click Board & Controller tab or Next.

f For more information on board and controller parameters, refer to

“Board & Controller” on page 3–31.

5. Choose the number of pipeline registers.

6. To set the read latency, turn on Manual read latency setting and

specify the latency at Set latency to clock cycle.

7. Turn on the appropriate capture mode—DQS or non-DQS capture

mode. If you turn off Enable DQS mode (non-DQS capture mode),

you can turn on Use migratable bytegroups.

8. Enter the pin loading for the FPGA pins.

9. Click Project Settings tab or Next.

f For more information on the project settings, refer to “Project Settings”

on page 3–33.

10. Altera recommends that you turn on Automatically apply QDRII

SRAM controller-specific constraints to the Quartus II project so

that the Quartus II software automatically applies the constraints

script when you compile the example design.

11. En sure Update the example design that instantiates the QDRII

SRAM controller variation is turned on, for IP Toolbench to

automatically update the example design file.

12. Turn off Update example design system PLL, if you have edited the

PLL and you do not want the wizard to regenerate the PLL when

you regenerate the variation.

1 The first time you create a custom variation, you must turn

on Update example design system PLL.

13. The constraints script automatically detects the hierarchy of your

design. The constraints script analyzes and elaborates your design

to automatically extract the hierarchy to your variation. To prevent

the constraints script analyzing and elaborating your design, turn

on Enable hierarchy control, and enter the correct hierarchy path to

your variation. The hierarchy path is the path to your QDRII SRAM

controller, without the top-level name. Figure 2–2 shows the

following example hierarchy:

my_system:my_system_inst|sub_system:sub_system_inst|

2–6 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 17

Figure 2–2. System Naming

QDRII SRAM

Other Logic

PLL

QDRII SRAM

Interface

example_top

Example Design

QDRII SRAM Controller

my_system_inst

System

sub_system_inst

Subsystem

Getting Started

14. IP Toolbench uses a prefix (e.g., qdrii_) for the names of all memory

interface pins. Enter a prefix for all memory interface pins

associated with this custom variation.

15. Click Finish.

Step 2: Constraints

To choose the constraints for your device, follow these steps:

1. Click Step 2: Constraints in IP Toolbench.

2. Choose the positions on the device for each of the QDRII SRAM

byte groups. To place a byte group, select the byte group in the

drop-down box at your chosen position.

1 The floorplan matches the orientation of the Quartus II

floorplanner. The layout represents the die as viewed from

Step 3: Set Up Simulation

An IP functional simulation model is a cycle-accurate VHDL or Verilog

HDL model produced by the Quartus II software. The model allows for

fast functional simulation of IP using industry-standard VHDL and

Verilog HDL simulators.

Altera Corporation MegaCore Version 9.1 2–7

November 2009 QDRII SRAM Controller MegaCore Function User Guide

above. A byte group consists of a cq pin and a number of q

pins (the same number as the data width).

Page 18

QDRII SRAM Controller Walkthrough

c You may only use these simulation model output files for

To generate an IP functional simulation model for your MegaCore

function, follow these steps:

1. Click Step 3: Set Up Simulation in IP Toolbench.

2. Turn on Generate Simulation Model.

3. Choose the language in the Language list.

4. Some third-party synthesis tools can use a netlist that contains only

the structure of the MegaCore function, but not detailed logic, to

optimize performance of the design that contains the MegaCore

function. If your synthesis tool supports this feature, turn on

Generate netlist.

5. Click OK.

Step 4: Generate

simulation purposes and expressly not for synthesis or any

other purposes. Using these models for synthesis will create a

nonfunctional design.

1. To generate your MegaCore function, click Step 4: Generate in IP

To ol be n ch .

1 The Quartus II IP File (.qip) is a file generated by the

MegaWizard interface, and contains information about a

generated IP core. You are prompted to add this .qip file to the

current Quartus II project at the time of file generation. In most

cases, the .qip file contains all of the necessary assignments and

information required to process the core or system in the

Quartus II compiler. Generally, a single .qip file is generated for

each MegaCore function or system in the Quartus II compiler.

2–8 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 19

Getting Started

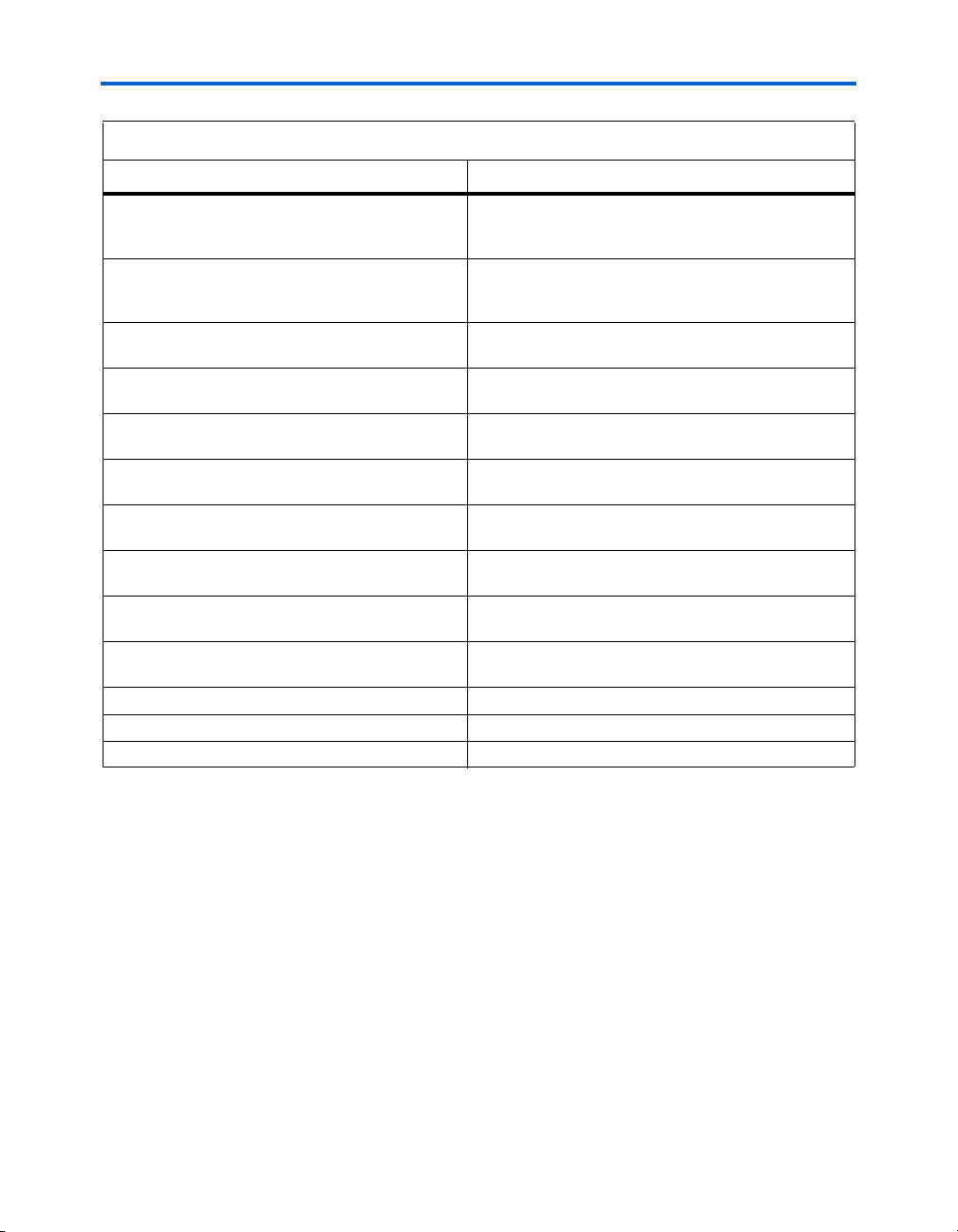

Table 2–1 describes the generated files and other files that may be in your

project directory. The names and types of files specified in the IP

Toolbench report vary based on whether you created your design with

VHDL or Verilog HDL

Table 2–1. Generated Files (Part 1 of 2) (1), (2) & (3)

Filename Description

<variation name>.bsf Quartus II symbol file for the MegaCore function

variation. You can use this file in the Quartus II block

diagram editor.

<variation name>.html MegaCore function report file.

<variation name>.vhd, or .v A MegaCore function variation file, which defines a

VHDL or Verilog HDL top-level description of the custom

MegaCore function. Instantiate the entity defined by this

file inside of your design. Include this file when compiling

your design in the Quartus II software.

<variation name>_bb.v Verilog HDL black-box file for the MegaCore function

variation. Use this file when using a third-party EDA tool

to synthesize your design.

<variation name>_auk_qdrii_sram.vhd or .v File that instantiates the control logic and the datapath.

<variation

name>_auk_qdrii_sram_addr_cmd_reg.vhd or .v

<variation

name>_auk_qdrii_sram_avalon_controller_ipfs_

wrap.vhd or .v

<variation

name>_auk_qdrii_sram_avalon_controller_ipfs_

wrap.vho or .vo

<variation

name>_auk_qdrii_sram_capture_group_wrapper.

vhd or .v

<variation name>_auk_qdrii_sram_clk_gen.vhd or .vThe clock output generators.

The address and command output registers.

File that instantiates the controller.

VHDL or Verilog HDL IP functional simulation model.

File that contains all the capture group modules (CQ and

CQN group modules and read capture registers).

<variation

name>_auk_qdrii_sram_cq_cqn_group.vhd or .v

<variation name>_auk_qdrii_sram_datapath.vhd

or .v

<variation name>_auk_qdrii_sram_dll.vhd or .v DLL.

<variation

name>_auk_qdrii_sram_example_driver

.vhd or .v

<variation

name>_auk_qdrii_sram_read_group.vhd or .v

Altera Corporation MegaCore Version 9.1 2–9

November 2009 QDRII SRAM Controller MegaCore Function User Guide

The CQ and CQN module.

Datapath.

The example driver.

The read capture registers.

Page 20

QDRII SRAM Controller Walkthrough

Table 2–1. Generated Files (Part 2 of 2) (1), (2) & (3)

Filename Description

<variation

name>_auk_qdrii_sram_pipe_resynch_wrapper.v

hd or .v

<variation

name>_auk_qdrii_sram_pipeline_addr_cmd.vhd

or .v

<variation

name>_auk_qdrii_sram_pipeline_rdata.vhd or .v

<variation

name>_auk_qdrii_sram_pipeline_wdata.vhd or .v

<variation

name>_auk_qdrii_sram_read_group.vhd or .v

<variation

name>_auk_qdrii_sram_resynch_reg.vhd or .v

<variation

name>_auk_qdrii_sram_train_wrapper.vhd or .v

<variation

name>_auk_qdrii_sram_test_group.vhd or .v

<variation

name>_auk_qdrii_sram_write_group.vhd or .v

<variation name>.qip Contains Quartus II project information for your

<top-level name>.vhd or .v (1) Example design file.

add_constraints_for_

qdrii_pll_stratixii.vhd or .v Stratix II PLL.

<variation name>.tcl The add constraints script.

File that includes the write data pipeline and includes the

address and command, read command, write data, and

write command pipeline.

Address and command pipeline.

Read data pipeline.

Write data pipeline.

The read registers.

The resynchronization FIFO buffers.

File that contains all the training group modules.

Training module, which realigns latency.

The write registers.

MegaCore function variations.

Notes to Ta b l e 2– 1 :

(1) <top-level name> is the name of the Quartus II project top-level entity.

(2) <variation name> is the name you give to the controller you create with the Megawizard.

(3) IP Tooblench replaces the string qdrii_sram with qdriiplus_sram for QDRII+ SRAM controllers.

2. After you review the generation report, click Exit to close IP

To ol be n ch .

You have finished the walkthrough. Now, simulate the example design

(refer to “Simulate the Example Design” on page 2–11), edit the PLL(s)

(refer to “Edit the PLL” on page 2–18), and compile (refer to “Compile the

Example Design” on page 2–19).

2–10 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 21

Getting Started

Simulate the Example Design

f For more information on the testbench, refer to “Example Design” on

This section describes the following simulation techniques:

■ Simulate with IP Functional Simulation Models

■ Simulating With the ModelSim Simulator

■ Simulating With Other Simulators

■ Simulating in Third-Party Simulation Tools Using NativeLink

Simulate with IP Functional Simulation Models

You can simulate the example design using the IP Toolbench-generated IP

functional simulation models. IP Toolbench generates a VHDL or Verilog

HDL testbench for your example design, which is in the testbench

directory in your project directory.

page 3–27.

You can use the IP functional simulation model with any

Altera-supported VHDL or Verilog HDL simulator. The instructions for

the ModelSim simulator are different to other simulators.

Simulating With the ModelSim Simulator

Altera supplies a generic memory model, lib\qdrii_model.v, which

allows you to simulate the example design with the ModelSim simulator.

To simulate the example design with the ModelSim® simulator, follow

these steps:

1. Copy the generic memory model to the <directory name>\testbench

directory.

2. Open the memory model and the testbench (<top-level

name>_vsim.v or .vhd) in a text editor and ensure the signal names

have the same capitalization in both files.

3. Start the ModelSim-Altera simulator.

4. Change your working directory to your IP Toolbench-generated file

directory <directory name>\testbench\modelsim.

5. To simulate with an IP functional simulation model simulation, type

the following command:

source <variation name>_vsim.tcl

Altera Corporation MegaCore Version 9.1 2–11

November 2009 QDRII SRAM Controller MegaCore Function User Guide

r

Page 22

Simulate the Example Design

6. For a gate-level timing simulation (VHDL or Verilog HDL

ModelSim output from the Quartus II software), type the following

commands:

set use_gate_model 1

r

source <variation name>_vsim.tclr

Simulating With Other Simulators

The IP Toollbench-generated Tcl script is for the ModelSim simulator

only. If you prefer to use a different simulation tool, follow these

instructions. You can also use the generated script as a guide. You also

need to download and compile an appropriate memory model.

1 The following variables apply in this section:

● <QUARTUS ROOTDIR> is the Quartus II installation directory

● <simulator name> is the name of your simulation tool

● <device name> is the Altera device family name

● <project name> is the name of your Quartus II top-level entity or

module.

● <MegaCore install directory> is the QDRII SRAM Controller

installation directory

VHDL IP Functional Simulations

For VHDL simulations with IP functional simulation models, follow

these steps:

1. Create a directory in the <project directory>\testbench directory.

2. Launch your simulation tool inside this directory and create the

following libraries:

● altera_mf

● lpm

● sgate

● <device name>

● auk_qdrii_lib

2–12 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 23

3. Compile the files in Table 2–2 into the appropriate library. The files

are in VHDL93 format.

Table 2–2. Files to Compile—VHDL IP Functional Simulation Models

Library Filename

altera_mf <QUARTUS ROOTDIR>/eda/sim_lib/altera_mf_components.vhd

<QUARTUS ROOTDIR>/eda/sim_lib/altera_mf.vhd

lpm <QUARTUS ROOTDIR>/eda/sim_lib/220pack.vhd

<QUARTUS ROOTDIR>/eda/sim_lib/220model.vhd

sgate <QUARTUS ROOTDIR>/eda/sim_lib/sgate_pack.vhd

<QUARTUS ROOTDIR>/eda/sim_lib/sgate.vhd

<device name><QUARTUS ROOTDIR>/eda/sim_lib/<device name>_atoms.vhd

<QUARTUS ROOTDIR>/eda/sim_lib/<device name>_components.vhd

auk_qdrii_lib <project directory>/<variation name>_auk_qdrii_sram_clk_gen.vhd

<project directory>/<variation name>_auk_qdrii_sram_addr_cmd_reg.vhd

<project directory>/<variation name>_auk_qdrii_sram_cq_cqn_group.vhd

<project directory>/<variation name>_auk_qdrii_sram_read_group.vhd

<project directory>/<variation name>_auk_qdrii_sram_capture_group_wrapper.vhd

<project directory>/<variation name>_auk_qdrii_sram_resynch_reg.vhd

<project directory>/<variation name>_auk_qdrii_sram_write_group.vhd

project directory>/<variation name>_auk_qdrii_sram_datapath.vhd

<

<project directory>/<variation name>_auk_qdrii_sram_test_group.vhd

<project directory>/<variation name>_auk_qdrii_sram_train_wrapper.vhd

<project directory>/<variation name>_auk_qdrii_sram_pipeline_wdata.vhd

<project directory>/<variation name>_auk_qdrii_sram_pipeline_rdata.vhd

<project directory>/<variation name>_auk_qdrii_sram_pipeline_addr_cmd.vhd

<project directory>/<variation name>_auk_qdrii_sram_pipe_resynch_wrapper.vhd

<project directory>/<variation

name>_auk_qdrii_sram_avalon_controller_ipfs_wrap.vho

<project directory>/<variation name>_auk_qdrii_sram.vhd

<project directory>/<variation name>.vhd

<project directory>/qdrii_pll_stratixii.vhd

<project directory>/<variation name>_auk_qdrii_sram_dll.vhd

<project directory>/<variation name>_auk_qdrii_sram_example_driver.vhd

<project directory>/<project name>.vhd

<project directory>/testbench/<project name>_tb.vhd

Getting Started

Altera Corporation MegaCore Version 9.1 2–13

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 24

Simulate the Example Design

4. Set the Tcl variable gRTL_DELAYS to 1, which tells the testbench to

model the extra delays in the system necessary for RTL simulation

5. Load the testbench in your simulator with the timestep set to

picoseconds.

VHDL Gate-Level Simulations

For VHDL simulations with gate-level models, follow these steps:

1. Create a directory in the <project directory>\testbench directory.

2. Launch your simulation tool inside this directory and create the

following libraries.

● <device name>

● auk_qdrii_lib

3. Compile the files in Table 2–3 into the appropriate library. The files

are in VHDL93 format.

Table 2–3. Files to Compile—VHDL Gate-Level Simulations

Library Filename

<device name><QUARTUS ROOTDIR>/eda/sim_lib/<device name>_atoms.vhd

<QUARTUS ROOTDIR>/eda/sim_lib/<device name>_components.vhd

auk_qdrii_lib <project directory>/simulation/<simulator name>/<project name>.vho

<project directory>/testbench/<project name>_tb.vhd

4. Set the Tcl variable gRTL_DELAYS to 0, which tells the testbench not

to use the insert extra delays in the system, because these are

applied inside the gate-level model.

5. Load the testbench in your simulator with the timestep set to

picoseconds.

Verilog HDL IP Functional Simulations

For Verilog HDL simulations with IP functional simulation models,

follow these steps:

1. Create a directory in the <project directory>\testbench directory.

2. Launch your simulation tool inside this directory and create the

following libraries.:

2–14 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 25

● altera_mf_ver

● lpm_ver

● sgate_ver

● <device name>_ver

● auk_qdrii_lib

3. Compile the files in Table 2–4 into the appropriate library.

Table 2–4. Files to Compile—Verilog HDL IP Functional Simulation Models (Part 1 of 2)

Library Filename

altera_mf_ver <QUARTUS ROOTDIR>/eda/sim_lib/altera_mf.v

lpm_ver <QUARTUS ROOTDIR>/eda/sim_lib/220model.v

sgate_ver <QUARTUS ROOTDIR>/eda/sim_lib/sgate.v

<device name>_ver <QUARTUS ROOTDIR>/eda/sim_lib/<device name>_atoms.v

Getting Started

Altera Corporation MegaCore Version 9.1 2–15

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 26

Simulate the Example Design

Table 2–4. Files to Compile—Verilog HDL IP Functional Simulation Models (Part 2 of 2)

Library Filename

auk_qdrii_lib <project directory>/<variation name>_auk_qdrii_sram_clk_gen.v

<project directory>/<variation name>_auk_qdrii_sram_addr_cmd_reg.v

<project directory>/<variation name>_auk_qdrii_sram_cq_cqn_group.v

<project directory>/<variation name>_auk_qdrii_sram_read_group.v

<project directory>/<variation

name>_auk_qdrii_sram_capture_group_wrapper.v

<project directory>/<variation name>_auk_qdrii_sram_resynch_reg.v

<project directory>/<variation name>_auk_qdrii_sram_write_group.v

<project directory>/<variation name>_auk_qdrii_sram_datapath.v

<project directory>/<variation name>_auk_qdrii_sram_test_group.v

<project directory>/<variation name>_auk_qdrii_sram_train_wrapper.v

<project directory>/<variation name>_auk_qdrii_sram_pipeline_wdata.v

<project directory>/<variation name>_auk_qdrii_sram_pipeline_rdata.v

<project directory>/<variation

name>_auk_qdrii_sram_pipeline_addr_cmd.v

<project directory>/<variation

name>_auk_qdrii_sram_pipe_resynch_wrapper.v

<project directory>/<variation

name>_auk_qdrii_sram_avalon_controller_ipfs_wrap.vo

<project directory>/<variation name>_auk_qdrii_sram.v

<project directory>/<variation name>.v

<project directory>/qdrii_pll_stratixii.v

<project directory>/<variation name>_auk_qdrii_sram_dll.v

<project directory>/<variation name>_auk_qdrii_sram_example_driver.v

<project directory>/<project name>.v

<project directory>/testbench/<project name>_tb.vhd

4. Set the Tcl variable gRTL_DELAYS to 1, which tells the testbench to

model the extra delays in the system necessary for RTL simulation.

5. Configure your simulator to use transport delays, a timestep of

picoseconds and to include the auk_qdrii_lib, sgate_ver, lpm_ver,

altera_mf_ver, and <device name>_ver libraries.

Verilog HDL Gate-Level Simulations

For Verilog HDL simulations with gate-level models, follow these steps:

2–16 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 27

Getting Started

1. Create a directory in the <project directory>\testbench directory.

2. Launch your simulation tool inside this directory and create the

following libraries:

● <device name>_ver

● auk_qdrii_lib

3. Copy the <project directory>/simulation/<simulator name>_v.sdo file

into the compilation directory.

4. Compile the files in Table 2–5 into the appropriate library.

Table 2–5. Files to Compile—Verilog HDL Gate-Level Simulations

Library Filename

<device name>_ver <QUARTUS ROOTDIR>/eda/sim_lib/<device name>_atoms.v

auk_qdrii_lib <project directory>/simulation/<simulator name>/<toplevel_name>.vo

<project directory>/testbench/<project name>_tb.v

5. Set the Tcl variable gRTL_DELAYS to 0, which tells the testbench not

to use the insert extra delays in the system, because these are

applied inside the gate level model. Configure your simulator to use

transport delays, a timestep of picoseconds, and to include the

auk_qdrii_lib and <device name>_ver library.

Simulating in Third-Party Simulation Tools Using NativeLink

You can perform a simulation in a third-party simulation tool from within

the Quartus II software, using NativeLink.

f For more information on NativeLink, refer to the Simulating Altera IP

Using NativeLink chapter in volume 3 of the Quartus II Handbook.

To set up simulation in the Quartus II software using NativeLink, follow

these steps:

1. Create a custom variation with an IP functional simulation model.

2. Obtain and copy a memory model to a suitable location, for

example, the testbench directory.

1 Before running the simulation you may also need to edit the

testbench to match the chosen memory model.

Altera Corporation MegaCore Version 9.1 2–17

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 28

Edit the PLL

3. Check that the absolute path to your third-party simulator

executable is set. On the Tools menu click Options and select EDA

Tools Options.

4. On the Processing menu, point to Start and click Start Analysis &

Elaboration.

5. On the Assignments menu click Settings, expand EDA Tool

Settings and select Simulation. Select a simulator under Too l N ame

and in NativeLink Settings, select Compile Test Bench and click

Test Benches.

6. Click New.

7. Enter a name for the Test bench name.

8. Enter the name of the automatically generated testbench, <project

name>_tb, in Test bench entity.

9. Enter the name of the top-level instance in Instance.

10. Change Run for to 500 s.

11. Add the testbench files. In the File name field browse to the location

of the memory model and the testbench, <project name>_tb, click OK

and click Add.

12. Click OK.

13. Click OK.

14. On the Tools menu point to EDA Simulation Tool and click Run

EDA RTL Simulation.

Edit the PLL

The IP Toolbench-generated example design includes up to two PLLs

(system PLL and fedback clock PLL), which have an input to output clock

ratio of 1:1 and a clock frequency that you entered in IP Toolbench. In

addition, IP Toolbench correctly sets all the phase offsets of all the

relevant clock outputs for your design. You can edit either PLLs’ input

clock to make it conform to your system requirements. If you re-run IP

Toolbench, it does not overwrite the system PLL, if you turn off Reset the

PLL to the default setting, so your edits are not lost.

f For more information on the PLL, refer to “PLL Configuration” on

page 3–26.

2–18 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 29

Getting Started

To edit the example PLL, follow these steps:

1. Choose MegaWizard Plug-In Manager (Tools menu).

2. Select Edit an existing custom megafunction variation and click

Next.

3. In your Quartus II project directory, for VHDL choose

qdrii_pll_<device name>.vhd; for Verilog HDL choose

qdrii_pll_<device name>.v.

4. Click Next.

5. Edit the PLL parameters in the altpll MegaWizard Plug-In.

f For more information on the altpll megafunction, refer to the

Quartus II Help or click Documentation in the altpll MegaWizard

Plug-In.

Compile the Example Design

Before the Quartus II software compiles the example design it runs the IP

Toolbench-generated Tcl constraints script, auto_add_constraints.tcl.

The auto_add_qdrii_constraints.tcl script calls the

add_constraints_for_<variation name>.tcl script for each variation in your

design. The add_constraints_for_<variation name>.tcl script checks for

any previously added constraints, removes them, and then adds

constraints for that variation.

The constraints script analyzes and elaborates your design, to

automatically extract the hierarchy to your variation. To prevent the

constraints script analyzing and elaborating your design, turn on Enable

hierarchy control in the wizard, and enter the correct hierarchy path to

your data path (refer to step 13 on page 2–6).

When the constraints script runs, it creates another script,

remove_constraints_for_<variation name>.tcl, which you can use to

remove the constraints from your design.

To compile the example instance, follow these steps:

1. Optional. Enable TimeQuest Timing Analyzer.

a. On the Assignments menu click Settings, expand Timin g

Analysis Settings, and select Use TimeQuest Timing

Analyzer.

Altera Corporation MegaCore Version 9.1 2–19

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 30

Compile the Example Design

b. Use the DDR timing wizard (DTW) to generate the required

QDRII SRAM Synopsys design constraint (SDC) TimeQuest

constraints for the design.

f For more information on the DTW, refer to the DTW User Guide.

2. Choose Start Compilation (Processing menu), which runs the add

constraints scripts, compiles the example design, and performs

timing analysis.

3. View the Classic or TimeQuest Timing Analyzer to verify your

design meets timing.

If your design does not meet timing requirements, add the following lines

to you .qsf file:

set_instance_assignment -name GLOBAL_SIGNAL OFF -to soft_reset_n

set_global_assignment -name OPTIMIZE_FAST_CORNER_TIMING ON

If the compilation does not reach the frequency requirements, follow

these steps:

1. Choose Settings (Assignments menu).

2. Choose Analysis and Synthesis Settings in the category list.

3. Select Speed in Optimization Technique.

4. Click OK.

5. Re-compile the example design by choosing Start Compilation

(Processing menu).

To view the constraints in the Quartus II Assignment Editor, choose

Assignment Editor (Assignments menu).

1 If you have “?” characters in the Quartus II Assignment Editor,

the Quartus II software cannot find the entity to which it is

applying the constraints, probably because of a hierarchy

mismatch. Either edit the constraints script, or enter the correct

hierarchy path in the Hierarchy tab (refer to step 13 on

page 2–6).

f For more information on constraints, refer to “Constraints” on

page 3–29.

2–20 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 31

Getting Started

Program a Device

f For more information on OpenCore Plus hardware evaluation using the

Implement Your Design

Set Up Licensing

After you have compiled the example design, you can perform gate-level

simulation (refer to “Simulate the Example Design” on page 2–11) or

program your targeted Altera device to verify the example design in

hardware.

With Altera's free OpenCore Plus evaluation feature, you can evaluate the

QDRII SRAM Controller MegaCore function before you obtain a license.

OpenCore Plus evaluation allows you to generate an IP functional

simulation model, and produce a time-limited programming file.

QDRII SRAM Controller MegaCore function, refer to “OpenCore Plus

Evaluation” on page 1–3, “OpenCore Plus Time-Out Behavior” on

page 3–10, and AN 320: OpenCore Plus Evaluation of Megafunctions.

To implement your design based on the example design, replace the

example driver in the example design with your own logic.

You need to obtain a license for the MegaCore function only when you are

completely satisfied with its functionality and performance, and want to

take your design to production.

After you obtain a license for QDRII SRAM Controller, you can request a

license file from the Altera web site at www.altera.com/licensing and

install it on your computer. When you request a license file, Altera emails

you a license.dat file. If you do not have Internet access, contact your

local Altera representative.

Altera Corporation MegaCore Version 9.1 2–21

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 32

Set Up Licensing

2–22 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 33

3. Functional Description

avl_clk

avl_clk_wr

avl_resetn

dll_delay_ctrl

resynch_clk

avl_addr_wr

avl_byteen_wr

avl_chipselect_wr

avl_data_wr

avl_write

avl_wait_request_wr

avl_addr_rd

avl_byteen_rd

avl_chipselect_rd

avl_read

avl_data_rd

avl_datavalid_rd

avl_wait_request_rd

Control

Logic

(Encrypted)

QDRII SRAM Controller

Datapath

(Clear Text)

Resynchronization

& Pipeline Logic

(Clear Text)

qdrii_a

qdrii_bwsn

qdrii_cq

qdrii_cqn

qdrii_d

qdrii_k

qdrii_kn

qdrii_q

qdrii_rpsn

qdrii_wpns

Block

Figure 3–1 shows a block diagram of the QDR SRAM controller

MegaCore function.

Description

Figure 3–1. QDRII SRAM Controller Block Diagram (1)

Notes to Figure 3–1:

(1) You can edit the qdrii_ prefix.

Altera Corporation MegaCore Version 9.1 3–1

November 2009

The QDRII SRAM Controller comprises the following three parts:

■ The control logic gets read and write requests from the Avalon

interface and turn them into QDRII SRAM read and write requests,

with the correct timing and concatenating consecutive addresses

where applicable.

■ The resynchronization and pipeline logic provides the

resynchronization system, the training block, and the optional

pipeline logic.

■ The datapath contains all the I/O and the clock generation.

®

Page 34

Block Description

Avalon

Slave

Interface

Write

FSM

Avalon

Slave

Interface

Read

FSM

Pause

Control Logic

(Encrypted)

1 You can use the datapath on its own if you want to create you

own resynchronization scheme or want to have an interface

similar to the QDRII SRAM v1.0.0 interface.

Control Logic

Figure 3–2 shows the control logic block diagram.

Figure 3–2. Control Logic Block Diagram

The basic architecture comprises two separate almost independent

channels. The write channel sends data to the memory. The read channel

receives the data. The address port on the QDRII SRAM interface is

shared— a write takes precedence when simultaneous reads and writes

occur. On the Avalon interface, all the signals are independent.

The write channel comprises an Avalon interface and a small pipeline to

perform two-cycle bursts. A finite state machine (FSM) controls the

signaling to the Avalon interface and deals with the data from Avalon

interface. The data and address are then passed to the I/O and sent to the

memory.

Similarly for the read channel, a FSM controls the signaling to the Avalon

interface and deals with the data going to Avalon interface. The read

command is passed to the QDRII SRAM interface and the data is

3–2 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

captured when arriving back. Simultaneous read and write operations

may lead to pauses on the Avalon read interface.

Page 35

Resynchronization & Pipeline Logic

Optional

Address &

Command

Pipeline

Optional

Read Data

Pipeline

Optional

Write Data

Pipeline

From Datapath

Capture

Registers

To Control

Block

Read FSM

From

Control

Logic

From

Control

Logic

Resynchronization

Resynchronization

Training

Group

Module

Training Group

Modules

Training

Group

Module

Resynchronization

& Pipeline Logic

Figure 3–3 shows the resynchronization and pipeline logic block

diagram.

Figure 3–3. Resynchronization & Pipeline Logic Block Diagram

Functional Description

Address & Command Pipeline

The optional address and command pipeline pipelines all commands and

addresses by a predefined number of cycles.

Altera Corporation MegaCore Version 9.1 3–3

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 36

Block Description

Write Data Pipeline

The write data pipeline pipelines the write data by a specified number of

clock cycles.The number of pipelines is equal to the address and

command pipelines, because the controller already aligns the data,

address and command correctly, therefore the amount of delay going to

the I/O is identical.

Training Group Module

The training group module sends all the control, data, and address

during training; it reverts to the controller-issued signals after training. It

also pauses the controllers for the duration of the training and sends some

feedback to the resynchronization logic to realign the pointers to get to

the desired latency. To ensure stability the read pointer is aligned only

after the DLL is stable. The write pointer is synchronously reset after the

read pointer. You can view the training signals from outside the example

design.

Read Data Pipeline

The optional read data pipeline pipelines the data after it is

resynchronized by a predefined number of cycles.

Resynchronization Logic

The resynchronization logic transfers the data from the QDRII SRAM

clock domain onto the system clock domain.

A small dual-port RAM block resynchronizes the data onto the system

clock. It writes and reads data every cycle. The frequency is the same on

either side.

The amount of buffering in the dual-port RAM automatically

compensates for any phase effects. However, there is no way of knowing

in which cycle the data is valid. Also the latency may vary from board to

board, even device to device depending on the timing relationship of the

clocks. Thus the training group module guarantees that each QDRII

device has the same read latency and that the latency is fixed and known

at startup.

Data is sent to a specific address. The same address is read at the same

time. It takes a certain amount of time to propagate the first data to the

memory and read it back. This first set of clock cycles is deemed invalid

and is not taken into account.

3–4 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 37

Functional Description

When this initialization time has elapsed, the training group module

monitors the data coming back and checks for its validity.

When the training group module detects a pattern, it checks to see if it is

too early, too late, or on time. If the pattern is too early, the pointer moves

by one; too late, the pointer moves by one in the other direction. The

training group module retrains until the pointer is correct.

The RAM size ensures there is minimal latency, but there is enough slack

to compensate for the training pattern realignment.

Datapath

Figure 3–4 on page 3–6 shows the datapath block diagram.

Altera Corporation MegaCore Version 9.1 3–5

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 38

Block Description

Clock

Generator

Address & Command

Output Registers

Capture Group

Modules

To Resynchronization

Write

Registers

From Write FSM

Write

Registers

From Control Logic

Address &

Command

Output

Registers

Address &

Command

Output

Registers

Read

Capture

Registers

CQ/CQN

Group

Read

Capture

Registers

CQ/CQN

Group

Datapath

Figure 3–4. Datapath Block Diagram

3–6 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 39

Functional Description

Clock Generator

The clock generator generates the memory signals k and kn. The clocks

are derived from the PLL-generated clock and are shifted by 90 to the

system clock.

Address & Command Output Registers

The address and command output registers generate the following

outputs:

■ Address

■ Read

■ Wri te

■ Wri t e b y te enable

There is one set of signals per device on a board.

With more than one device on a board, a suffix indicates the width

position and depth position. The width can be anything up to what the

device supports (for example, you can make a 72-bit interface out of four

18-bit interfaces). The depth is limited to 2.

For a device depth of two, you must connect the reads and writes to each

device. The top address bit going into the address command top-level file

is a device select, which selects device 0 or 1 by setting the read and write

of the unused device to 1.

Write Registers

The write registers comprise write I/O blocks going to the memory. For

each memory in width, the controller creates a data bus. For a device

depth of two, the controller shares the data bus between the two devices.

The Capture Group Module

The capture group module comprises the following elements:

■ CQ/CQN group module

■ Read capture registers

The controller uses the 90shifted cq and cqn clocks for the capture

registers of the q bus.

When captured, the controller synchronizes the two words on a double

width bus.

Altera Corporation MegaCore Version 9.1 3–7

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 40

Block Description

With more than one device, one cq/cqn pair and q bus are connected per

device in the width direction. For a device depth of two, it shares the q

and cq/cqn signals.

All the signals go out of the block with their associated internal cq clock,

so you can use Altera's resynchronization scheme or implement your

own.

Altera recommends the following read capture implementation for data

captures from QDRII SRAM devices when using complementary echo

clocks (cq and cqn signals).

The Stratix II IOE contains two input registers and a latch. The cq and

cqn echo clock signals clock the positive and negative half-cycle registers

during reads. The latch holds the negative half-cycle data until the next

rising edge on cq. However, the latch in the IOE is not recommended

when the complementary clocks do not have 50% duty cycle or skew,

because the latch, controlled by the cq clock, is still transparent until just

after the register clocked on the cqn signal captures the data.

Instead, the captured read data is recaptured with the cq echo clock in the

FPGA fabric using a zero-cycle path. The cq echo clock is routed into the

FPGA fabric using dedicated clock routing (Altera recommends global

routing) to provide minimum clock skew across all recapture registers. If

you do not have enough global clock network resources, you have the

option of using the regional clock network. Routing the cq over a clock

network adds delay. The Quartus II software fitter places and routes the

recapture registers so that the data delay is sufficient to meet the setup

and hold requirements at the device registers.

1 You should only use regional routing if you run out of the global

clock networks.

Figure 3–5 shows a block diagram of the new read capture

implementation.

3–8 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 41

Figure 3–5. Block Diagram of the New Read Capture Implementation

I/O

AB

Fabric

To

FIFO

Buffer

EN

cqn

cq

Latch

Routing

Delay

Routing

Delay

Clock

Network

Delay

The data from the latch becomes valid following the rising edge of the cq

signal (when the latch becomes transparent) and, in a worst-case

condition, becomes invalid following the rising edge of cqn signal (when

roughly half a cycle = t

), which is done by creating a zero-cycle path

KHKH

between the latch and a device register. The data is re-captured in the

device using the same edge of the cq signal that makes the latch

transparent. Both the cq signal and the data cross the IOE-to-device

boundary where they are delayed. The cq signal is delayed by slightly

more than by the data needed to meet the setup time for this register.

However, the delay is not enough to violate its hold time,which is related

to the rising edge of cqn signal. Because the data is recaptured in the

FPGA while the latch is valid, the IOE capture register timing margins are

not impacted.

Functional Description

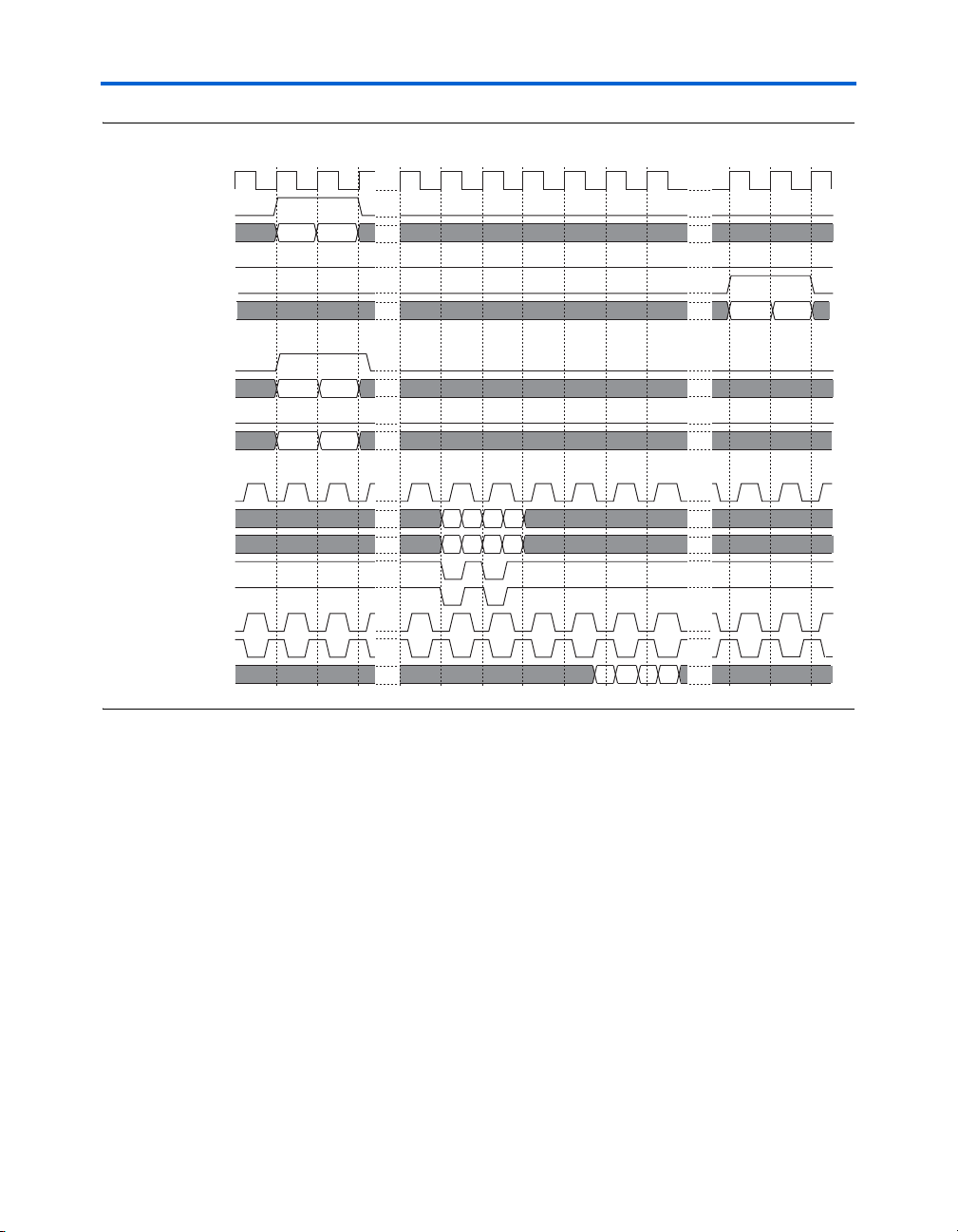

Figure 3–6 is a timing diagram of the IOE that assumes the latch is still

transparent when cqn rising edge occurs. The real B, expected B, and

delayed cq signals represent the data and clock to the re-capture

Altera Corporation MegaCore Version 9.1 3–9

November 2009 QDRII SRAM Controller MegaCore Function User Guide

registers. The output of latch B is either real B or expected B, depending

on the relationship between cq and cqn. To cover both cases, the usable

part of B signal should be captured before going to the resynchronization

FIFO buffers. Routing delay aligns the data with the clock.

Page 42

OpenCore Plus Time-Out Behavior

cqn

cq

I/O A[7:0]

Expected B[7:0]

Real B[7:0]

Usable

part of B[7:0]

Delayed cq

00 01 02 0303

00 01 02 0302

00

01 02 0303

00 01 02 0303

Figure 3–6. Timing Diagram of the IOE

OpenCore Plus

OpenCore Plus hardware evaluation can support the following two

modes of operation:

Time-Out

Behavior

f For more information on OpenCore Plus hardware evaluation, refer to

Interfaces & Signals

3–10 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

■ Untethered—the design runs for a limited time

■ Tethered—requires a connection between your board and the host

computer. If tethered mode is supported by all megafunctions in a

design, the device can operate for a longer time or indefinitely

All megafunctions in a device time out simultaneously when the most

restrictive evaluation time is reached. If there is more than refer to one

megafunction in a design, a specific megafunction’s time-out behavior

may be masked by the time-out behavior of the other megafunctions.

1 For MegaCore functions, the untethered time out is 1 hour; the

tethered time out value is indefinite.

Your design stops working after the hardware evaluation time expires,

the reads and writes go low, and the wait output goes high.

“OpenCore Plus Evaluation” on page 1–3 and AN 320: OpenCore Plus

Evaluation of Megafunctions.

This section describes the following topics:

■ “Interface Description” on page 3–10

■ “Signals” on page 3–22

Interface Description

This section describes the following Avalon interface requests:

Page 43

Functional Description

clk

avl_write

avl_data_wr[35:0]

avl_adr_wr[19:0]

avl_wait_request_wr

write_clk

system_clk

qdrii_d[17:0]

qdrii_a[19:0]

qdrii_bwsn[1:0]

qdrii_wpsn

0001000200010002

00010001

0001 00020002

00010001

00 1111

■ Wri te s

■ Reads

■ Simultaneous Read & Write Timing

f For more information on the Avalon interface, refer to the Avalon

Interface Specifications.

Writes

This section discusses the following topics:

■ “Isolated Write” on page 3–11

■ “Bursts” on page 3–13

■ “Bursts with Pauses” on page 3–14

If the address is the consecutive, you can have consecutive write cycles

(refer to “Bursts” on page 3–13). Non-consecutive addresses are split

into two transfers and you must pause a transfer (refer to “Bursts with

Pauses” on page 3–14).

Isolated Write

Figure 3–7 shows an isolated write transaction on a burst of four (narrow

mode). The Avalon interface receives a write request, which the

controller immediately accepts. It then transfers the write data (the exact

timing may vary) to the QDRII SRAM interface. As it receives only half

the required data for a burst of four, it masks the second part of the burst

on the QDRII SRAM interface as invalid.

Figure 3–7. Isolated Write—Burst of Four (Narrow Mode)

Altera Corporation MegaCore Version 9.1 3–11

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 44

Interfaces & Signals

Figure 3–8 shows a burst of two, the controller takes the data straight

away and puts it on the QDRII SRAM interface a few cycle later (the exact

timing may change). Because it takes as many Avalon clock cycles as

QDRII SRAM clock cycles to write the data, you can put write accesses

back-to-back. The write cycles have no influence on the read cycles as the

address is put on half a clock cycle.

Figure 3–8. Write—Burst of Two

avl_clk

avl_write

avl_data_wr[35:0]

avl_adr_wr[19:0]

avl_wait_request_wr

avl_clock_wr

system_cl k

qdrii_d[17:0]

qdrii_a[19:0]

qdrii_bwsn[1:0]

qdrii_wpsn

00010002 00010002

0001 0001

0001 0002 0002

00010001

00 00

Figure 3–9 on page 3–13 shows a burst of four (wide mode), all the data is

present in one clock cycle. After one Avalon write, you can transfer data

for two clock cycles on the QDRII SRAM interface. In this example, all the

data bits are valid and the byte mask is set to enable the whole transfer.

3–12 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 45

Figure 3–9. Write—Burst of Four (Wide Mode)

avl_clk

avl_write

avl_data_wr[35:0]

avl_adr_wr[19:0]

avl_wait_request_wr

avl_clock_wr

system_clk

qdrii_d[17:0]

qdrii_a[19:0]

qdrii_bwsn[1:0]

qdrii_wpsn

0102030401020304

00010001

Bursts

Bursts are only possible on the Avalon side in the burst of two mode,

where you can transfer data every clock cycle and in bursts of four

(narrow mode). It is not possible in the burst of four (wide mode), because

it takes two QDRII SRAM clock cycles to transfer one Avalon clock cycle

of data.

Functional Description

01 02 03 0404

00010001

0000

Figure 3–10 on page 3–14 shows the burst of four (narrow mode). When

two write requests are sent on the Avalon interface at consecutive

addresses, the controller automatically concatenates them and transfers

them to the QDRII SRAM, if the first one is an even address. If more data

is coming in the following cycle, it is also sent straight away, without any

pause.

Altera Corporation MegaCore Version 9.1 3–13

November 2009 QDRII SRAM Controller MegaCore Function User Guide

Page 46

Interfaces & Signals

Figure 3–10. Write—Burst of Four (Narrow Mode)

avl_clk

avl_write

avl_data_wr[35:0]

avl_adr_wr[19:0]

avl_wait_request_wr

avl_clock_wr

system_clk

qdrii_d[17:0]

qdrii_a[19:0]

qdrii_bwsn[1:0]

qdrii_wpsn

00010002 0003000400030004

0002 0003

This section does not illustrate the burst of two example, because you can

transfer any data at any address in every Avalon clock cycle. The timing

of the qdrii_a signal is different, refer to Figure 3–7 on page 3–11.

0001 0002 0003 00040004

0002

0000

Bursts with Pauses

There are no pauses when using a burst of two memories. For the burst of

four, there are some pauses (depending on the mode). In narrow mode, if

the transfers are to consecutive addresses all the time, no pause occurs. If

the transfers are to non-consecutive addresses, a pause may occur, refer

to Figure 3–11 on page 3–15. a pause occurs only in the following

conditions:

■ A one-cycle write to address <a> followed straight away by a two-

cycle transfer to addresses <b> and <b + 1>

■ The second half of the transfer to <b> is paused for a clock cycle

3–14 MegaCore Version 9.1 Altera Corporation

QDRII SRAM Controller MegaCore Function User Guide November 2009

Page 47

Figure 3–11. Write Burst with Pause—Burst of Four (Narrow Mode)

write

avl_data_wr

[35:0]

avl_addr_wr

[19:0]

avl_wait_

request_wr