Page 1

Nios II Custom Instruction User Guide

Nios II Custom Instruction

User Guide

101 Innovation Drive

San Jose, CA 95134

www.altera.com

UG-N2CSTNST-2.0

Subscribe

Page 2

© 2011 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, HARDCOPY, MAX, MEGACORE, NIOS, QUARTUS and STRATIX are Reg. U.S. Pat.

& Tm. Off. and/or trademarks of Altera Corporation in the U.S. and other countries. All other trademarks and service marks are the property of their respective

holders as described at www.altera.com/common/legal.html. Altera warrants performance of its semiconductor products to current specifications in accordance

with Altera’s standard warranty, but reserves the right to make changes to any products and services at any time without notice. Altera assumes no responsibility or

liability arising out of the application or use of any information, product, or service described herein except as expressly agreed to in writing by Altera. Altera

customers are advised to obtain the latest version of device specifications before relying on any published information and before placing orders for products or

services.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 3

Contents

Chapter 1. Nios II Custom Instruction Overview

Custom Instruction Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Implementing Custom Instruction Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Implementing Custom Instruction Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Custom Instruction Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Combinational Custom Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Multicycle Custom Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Extended Custom Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Internal Register File Custom Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

External Interface Custom Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

Chapter 2. Software Interface

Custom Instruction Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Built-in Functions and User-defined Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Custom Instruction Assembly Software Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Chapter 3. Implementing a Nios II Custom Instruction in SOPC Builder

Design Example: Cyclic Redundancy Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Implementing Custom Instruction Hardware in SOPC Builder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Setting up the Design Environment for the Design Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Opening the Component Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Adding the HDL Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Configuring the Custom Instruction Signal Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Setting Up the Custom Instruction Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Setting the Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

Saving and Adding the Custom Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Generating the System and Compiling in the Quartus II Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Accessing the Custom Instruction from Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Using the User-defined Custom Instruction Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Chapter 4. Implementing a Nios II Custom Instruction in Qsys

Design Example: Cyclic Redundancy Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Implementing Custom Instruction Hardware in Qsys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Setting up the Design Environment for the Design Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Opening the Component Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Adding the HDL Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Configuring the Custom Instruction Signal Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Setting Up the Custom Instruction Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Setting the Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Saving and Adding the Custom Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Generating the System and Compiling in the Quartus II Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Accessing the Custom Instruction from Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Using the User-defined Custom Instruction Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

Appendix A. Custom Instruction Templates

VHDL Custom Instruction Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Verilog HDL Custom Instruction Template Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 4

iv Contents

Appendix B. Custom Instruction Built-in Functions

Built-in Functions that Return a Void Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

Built-in Functions that Return a Value of Type Int . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

Built-in Functions that Return a Value of Type Float . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–2

Built-in Functions that Return a Pointer Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–2

Appendix C. Floating Point Custom Instructions

Additional Information

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Info–1

How to Contact Altera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Info–1

Typographic Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Info–2

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 5

1. Nios II Custom Instruction Overview

Nios II Embedded Processor

+

-

&

<<

>>

Result

A

Nios II

ALU

B

Custom

Logic

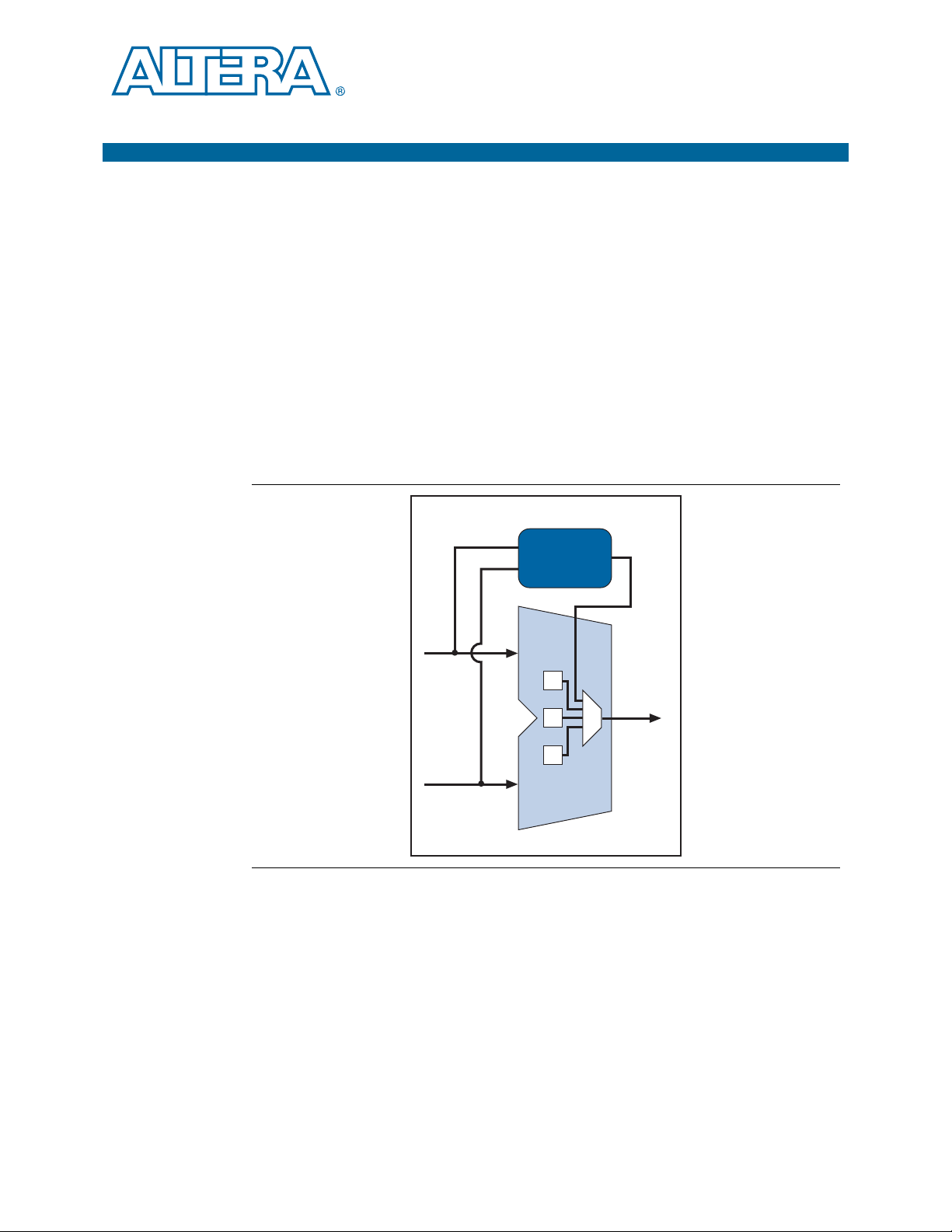

When you design a system that includes an Altera Nios II embedded processor, you

can accelerate time-critical software algorithms by adding custom instructions to the

Nios II processor instruction set. Custom instructions allow you to reduce a complex

sequence of standard instructions to a single instruction implemented in hardware.

You can use this feature for a variety of applications, for example, to optimize

software inner loops for digital signal processing (DSP), packet header processing,

and computation-intensive applications. In SOPC Builder, the Nios II parameter

editor provides a GUI to add custom instructions to the Nios II processor. In Qsys,

each custom instruction is a separate component in the Qsys system. You can add as

many as 256 custom instructions to your system.

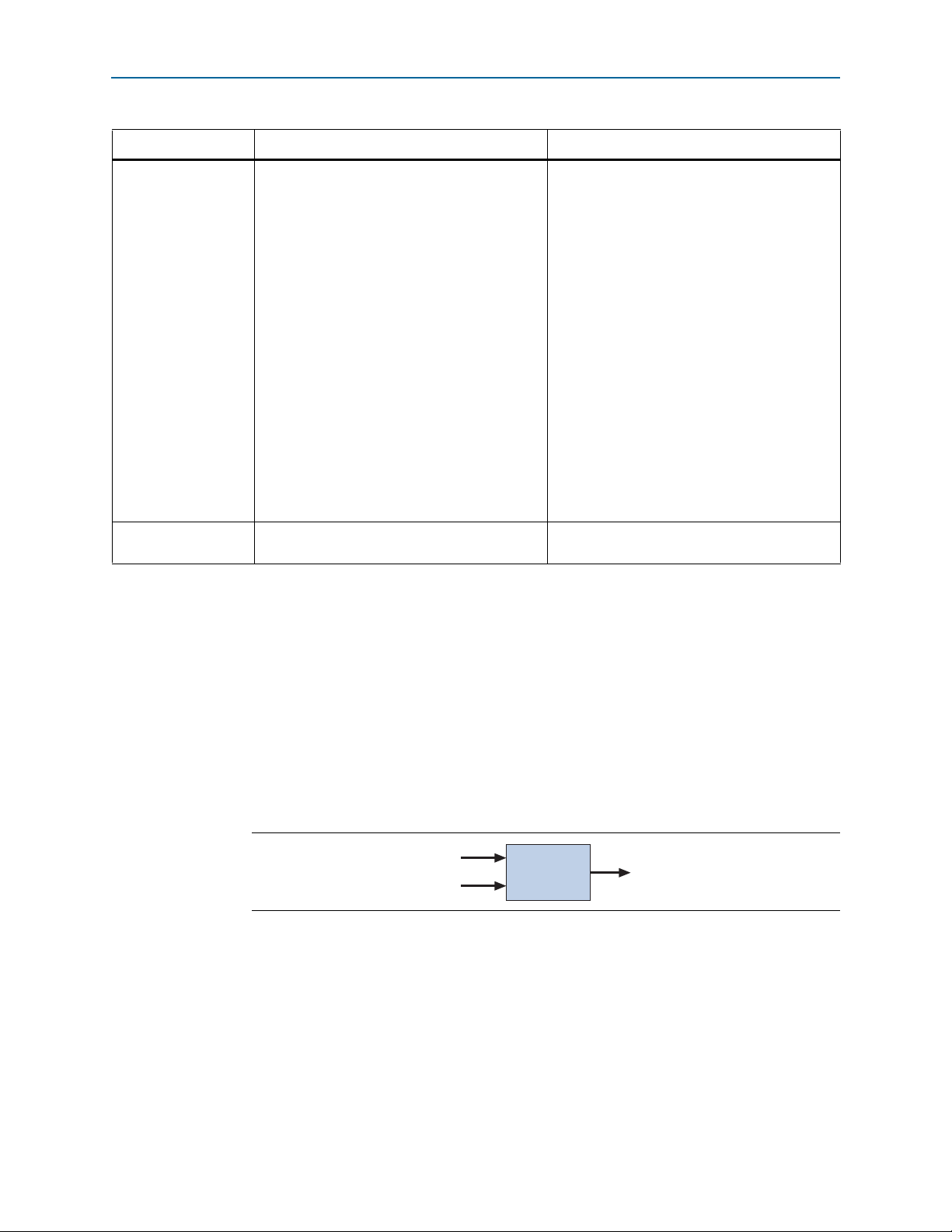

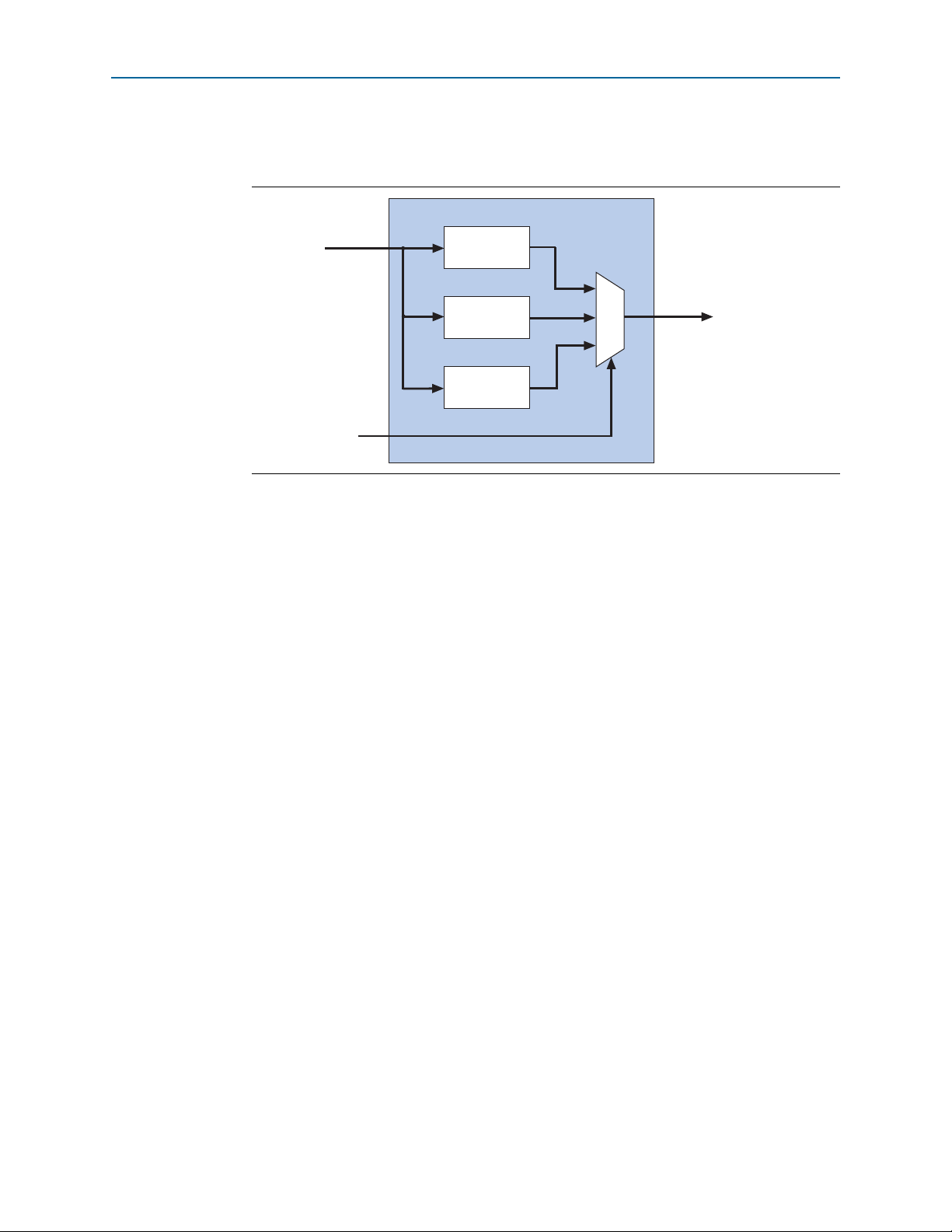

In SOPC Builder, the custom instruction logic connects directly to the Nios II

arithmetic logic unit (ALU) as shown in Figure 1–1.

Figure 1–1. Custom Instruction Logic Connects to the Nios II ALU in SOPC Builder Systems

This chapter contains the following sections:

■ “Custom Instruction Overview”

■ “Custom Instruction Types” on page 1–3

For information about the custom instruction software interface, refer to Chapter 2,

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Software Interface. For step-by-step instructions for implementing a custom

instruction, refer to Chapter 3, Implementing a Nios II Custom Instruction in SOPC

Builder or Chapter 4, Implementing a Nios II Custom Instruction in Qsys.

Page 6

1–2 Chapter 1: Nios II Custom Instruction Overview

Combinatorial

Conduit interface to external

memory, FIFO, or other logic

Multi-cycle

result

Extended

Internal

Register File

[31..0]

done

dataa[31..0]

datab[31..0]

clk

clk_en

reset

start

n[7..0]

a[4..0]

readra

b[4..0]

readrb

c[4..0]

writerc

Combinational

Custom

Logic

Custom Instruction Overview

Custom Instruction Overview

Nios II custom instructions are custom logic blocks adjacent to the ALU in the

processor’s datapath. Custom instructions give you the ability to tailor the Nios II

processor core to meet the needs of a particular application. You can accelerate time

critical software algorithms by converting them to custom hardware logic blocks.

Because it is easy to alter the design of the FPGA-based Nios II processor, custom

instructions provide an easy way to experiment with hardware-software tradeoffs at

any point in the design process.

Implementing Custom Instruction Hardware

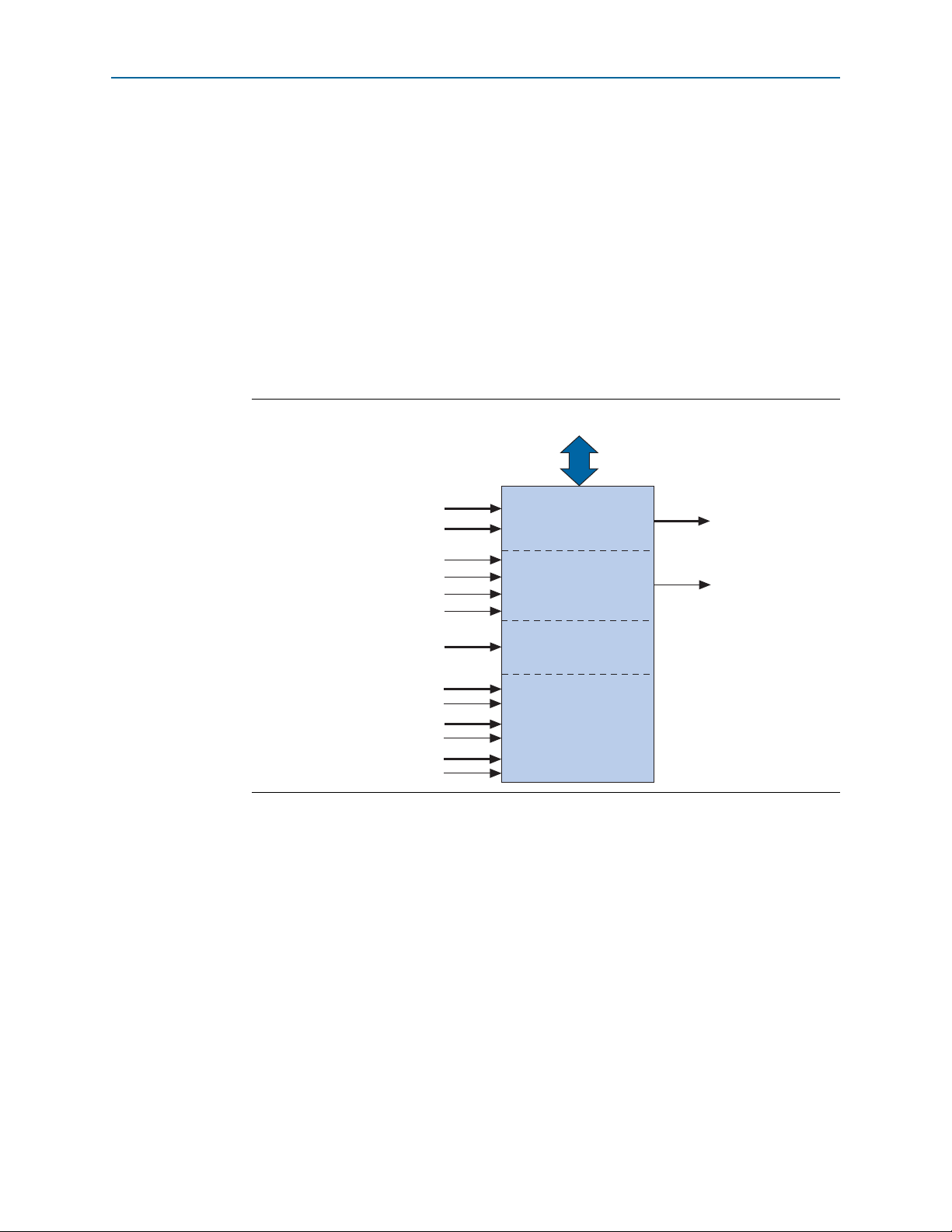

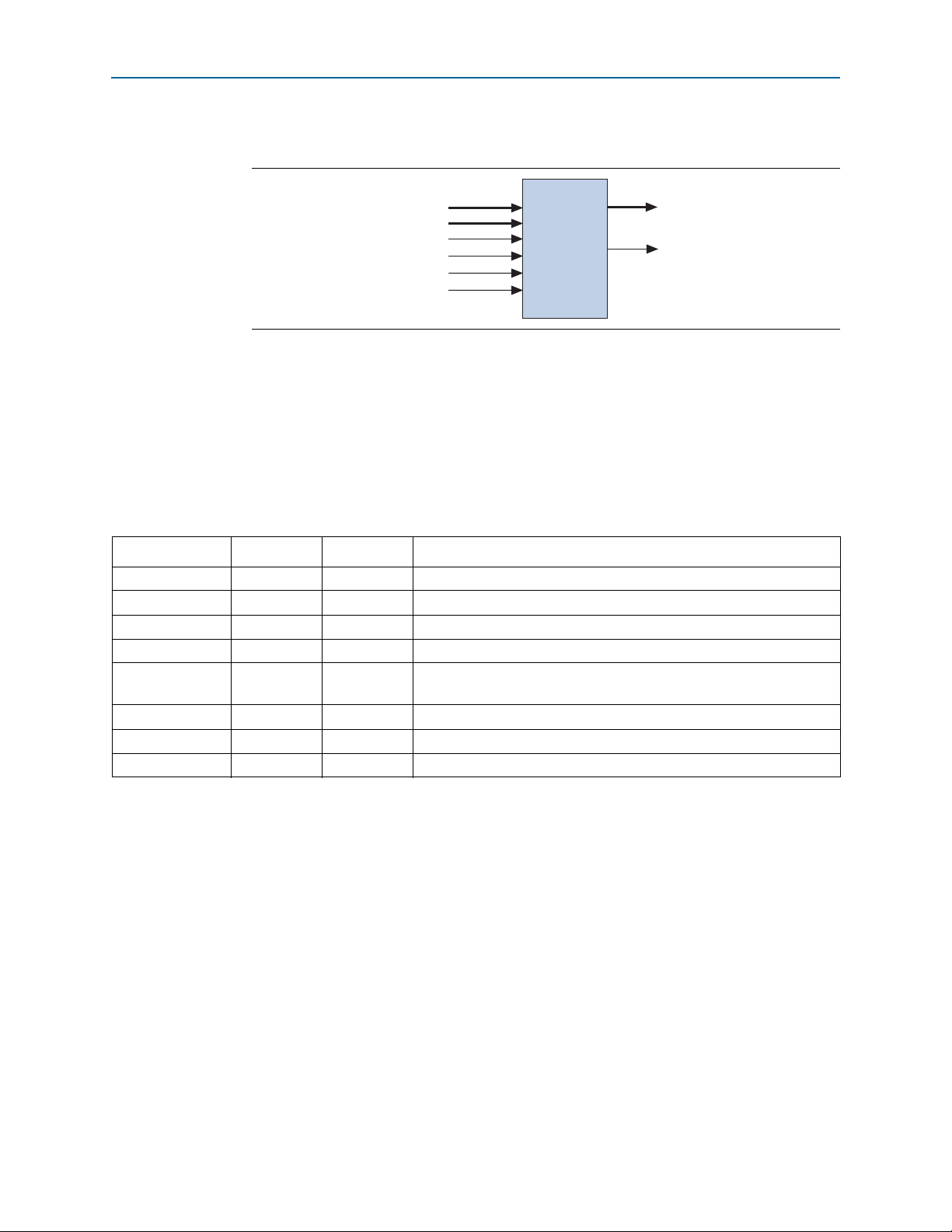

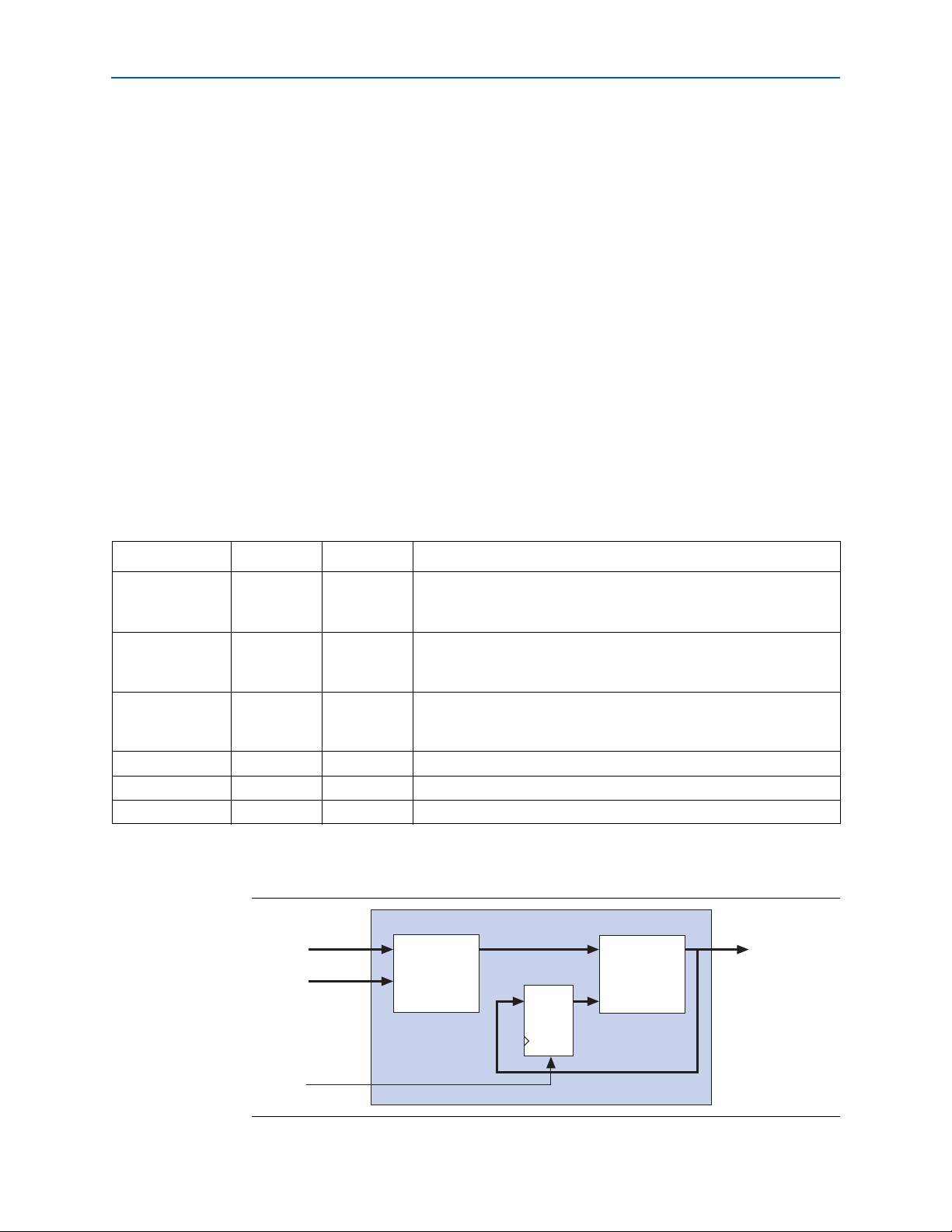

Figure 1–2 is a hardware block diagram of a Nios II custom instruction.

Figure 1–2. Hardware Block Diagram of a Nios II Custom Instruction

Nios II Custom Instruction User Guide January 2011 Altera Corporation

A Nios II custom instruction logic receives input on its

datab

ports, and drives out the result on its

provides a result based on the inputs provided by the Nios II processor.

The Nios II processor supports different types of custom instructions. Figure 1–2 lists

the additional ports that accommodate different custom instruction types. Only the

ports used for the specific custom instruction implementation are required.

Figure 1–2 also shows a conduit interface to external logic. The interface to external

logic allows you to include a custom interface to system resources outside of the

Nios II processor datapath.

result

dataa

port, or on its

dataa

and

port. The custom instruction logic

Page 7

Chapter 1: Nios II Custom Instruction Overview 1–3

Custom Instruction Types

Implementing Custom Instruction Software

The Nios II custom instruction software interface is simple and abstracts the details of

the custom instruction from the software developer. For each custom instruction, the

Nios II Embedded Design Suite (EDS) generates a macro in the system header file,

system.h. You can use the macro directly in your C or C++ application code, and you

do not need to program assembly code to access custom instructions. Software can

also invoke custom instructions in Nios II processor assembly language.

For more information about the custom instruction software interface, refer to

Chapter 2, Software Interface.

Custom Instruction Types

Different types of custom instructions are available to meet the requirements of your

application. The type you choose determines the hardware interface for your custom

instruction.

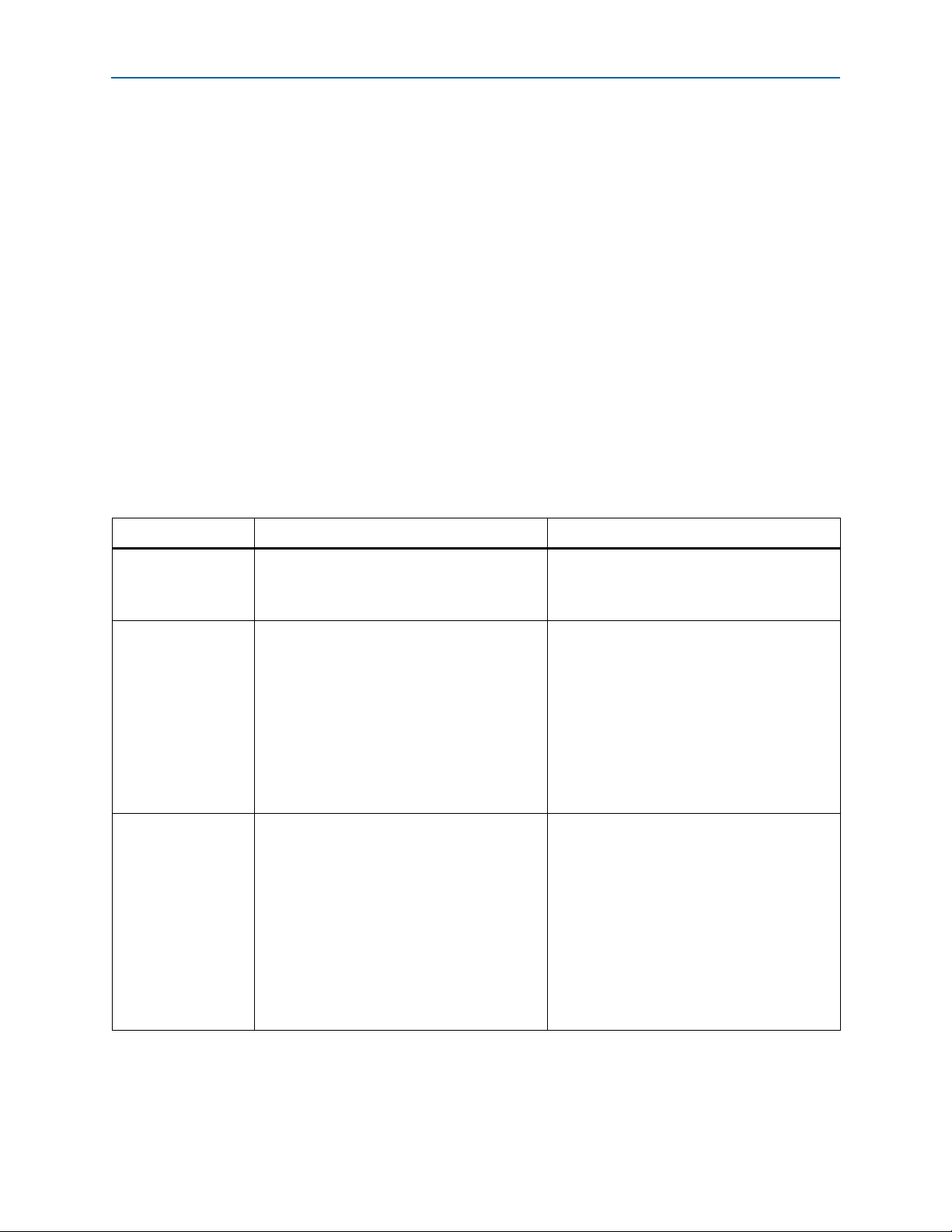

Tab le 1– 1 shows the available custom instruction types, applications, and associated

hardware ports.

Table 1–1. Custom Instruction Types, Applications, and Hardware Ports (Part 1 of 2)

Type Application Hardware Ports

■

dataa[31:0]

Combinational Single clock cycle custom logic blocks.

Multicycle

Extended

Multi-clock cycle custom logic blocks of fixed or

variable durations.

Custom logic blocks that are capable of

performing multiple operations

■

datab[31:0]

■

result[31:0]

■

dataa[31:0]

■

datab[31:0]

■

result[31:0]

■

clk

■

clk_en (1)

■

start

■

reset

■

done

■

dataa[31:0]

■

datab[31:0]

■

result[31:0]

■

clk

■

clk_en (1)

■

start

■

reset

■

done

■

n[7:0]

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 8

1–4 Chapter 1: Nios II Custom Instruction Overview

Custom Instruction Types

Table 1–1. Custom Instruction Types, Applications, and Hardware Ports (Part 2 of 2)

Type Application Hardware Ports

■

dataa[31:0]

■

datab[31:0]

■

result[31:0]

■

clk

■

clk_en

■

start

■

Internal register file

External interface

Note to Table 1–1:

(1) The

clk_en

needs to stall the custom instruction during execution.

input signal must be connected to the

Custom logic blocks that access internal register

files for input or output or both.

Custom logic blocks that interface to logic

outside of the Nios II processor’s datapath

clk_en

signals of all the registers in the custom instruction, in case the Nios II processor

reset

■

done

■

n[7:0]

■

a[4:0]

■

readra

■

b[4:0]

■

readrb

■

c[4:0]

■

writerc

Standard custom instruction ports, plus

user-defined interface to external logic.

The following sections discuss the basic functionality and hardware interface of each

of the custom instruction types listed in Table 1–1.

Combinational Custom Instructions

A combinational custom instruction is a logic block that completes its logic function in

a single clock cycle. Figure 1–3 shows a block diagram of a combinational custom

instruction.

Figure 1–3. Combinational Custom Instruction Block Diagram

dataa[31..0]

datab[31..0]

dataa

and

In Figure 1–3 the

results on the

result

port. Because the logic function completes in a single clock cycle,

a combinational custom instruction does not require control ports.

datab

Combinational result[31..0]

ports are inputs to the logic block, which drives the

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 9

Chapter 1: Nios II Custom Instruction Overview 1–5

clk

T0 T1 T3T2 T4

dataa[ ]

datab[ ]

result[ ]

dataa[ ] valid

datab[ ] valid

result valid

Custom Instruction Types

Tab le 1– 2 describes the combination custom instruction ports.

Table 1–2. Combinational Custom Instruction Ports

Port Name Direction Required Description

dataa[31:0]

datab[31:0]

result[31:0]

Input No Input operand to custom instruction

Input No Input operand to custom instruction

Output Yes Result of custom instruction

The only required port for combinational custom instructions is the

dataa

and

datab

ports are optional. Include them only if the custom instruction

result

port. The

functionality requires input operands. If the custom instruction requires only a single

input port, use

dataa

.

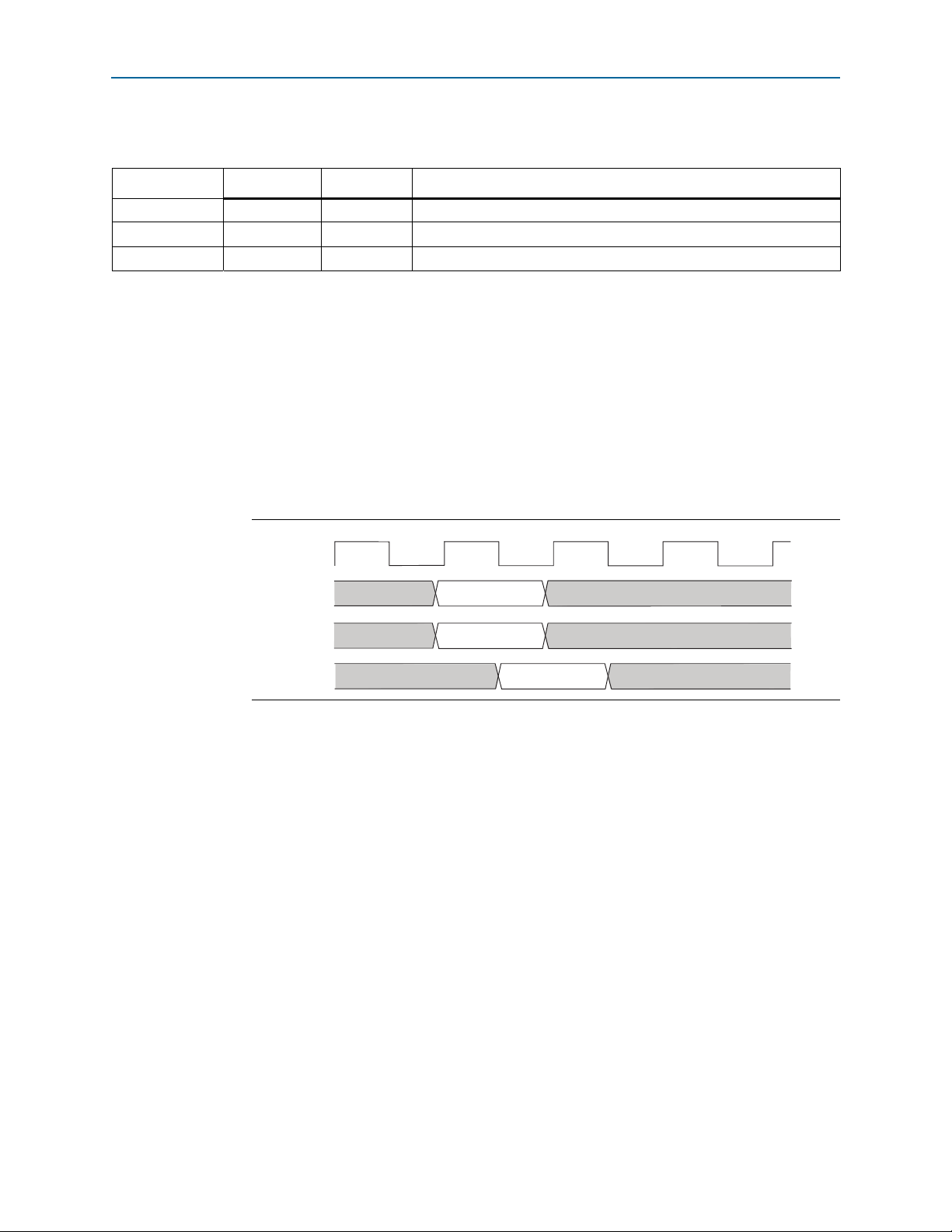

Figure 1–4 shows the combinational custom instruction hardware port timing

diagram.

In Figure 1–4, the processor presents the input data on the dataa and datab ports on

the rising edge of the processor clock. The processor reads the result port on the

rising edge of the following processor clock cycle.

Figure 1–4. Combinational Custom Instruction Timing Diagram

The Nios II processor issues a combinational custom instruction speculatively; that is,

it optimizes execution by issuing the instruction before knowing whether it is

necessary, and ignores the result if it is not required. Therefore, a combinational

custom instruction must not have side effects. In particular, a combinational custom

instruction cannot have an external interface.

You can further optimize combinational custom instructions by implementing the

extended custom instruction. Refer to “Extended Custom Instructions” on page 1–7.

Multicycle Custom Instructions

Multicycle or sequential, custom instructions consist of a logic block that requires two

or more clock cycles to complete an operation. Additional control ports are required

for multicycle custom instructions, as shown in Table 1–3.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 10

1–6 Chapter 1: Nios II Custom Instruction Overview

Custom Instruction Types

Figure 1–5 shows the multicycle custom instruction block diagram.

Figure 1–5. Multicycle Custom Instruction Block Diagram

dataa[31..0]

datab[31..0]

clk

clk_en

reset

start

Multi-cycle

Multicycle custom instructions complete in either a fixed or variable number of clock

cycles. For a custom instruction that completes in a fixed number of clock cycles, you

specify the required number of clock cycles at system generation. For a custom

instruction that requires a variable number of clock cycles, you instantiate the

and

done

ports. These ports participate in a handshaking scheme to determine when

the custom instruction execution is complete.

Tab le 1– 3 describes the multicycle custom instruction ports.

Table 1–3. Multicycle Custom Instruction Ports

Port Name Direction Required Description

clk

clk_en

reset

start

done

dataa[31:0]

datab[31:0]

result[31:0]

Input Yes System clock

Input Yes Clock enable

Input Yes Synchronous reset

Input No Commands custom instruction logic to start execution

Output No

Custom instruction logic indicates to the processor that execution is

complete

Input No Input operand to custom instruction

Input No Input operand to custom instruction

Output No Result of custom instruction

result[31..0]

done

start

As indicated in Tab le 1– 3, the

custom instructions. However, the

clk, clk_en

, and

reset

start, done, dataa, datab

ports are required for multicycle

, and

result

ports are

optional. Implement them only if the custom instruction functionality requires them.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 11

Chapter 1: Nios II Custom Instruction Overview 1–7

clk

dataa[]

datab[]

result[]

valid

valid

T0 T1 T3T2 T4 T5 T6

valid

done

clk_en

start

reset

Custom Instruction Types

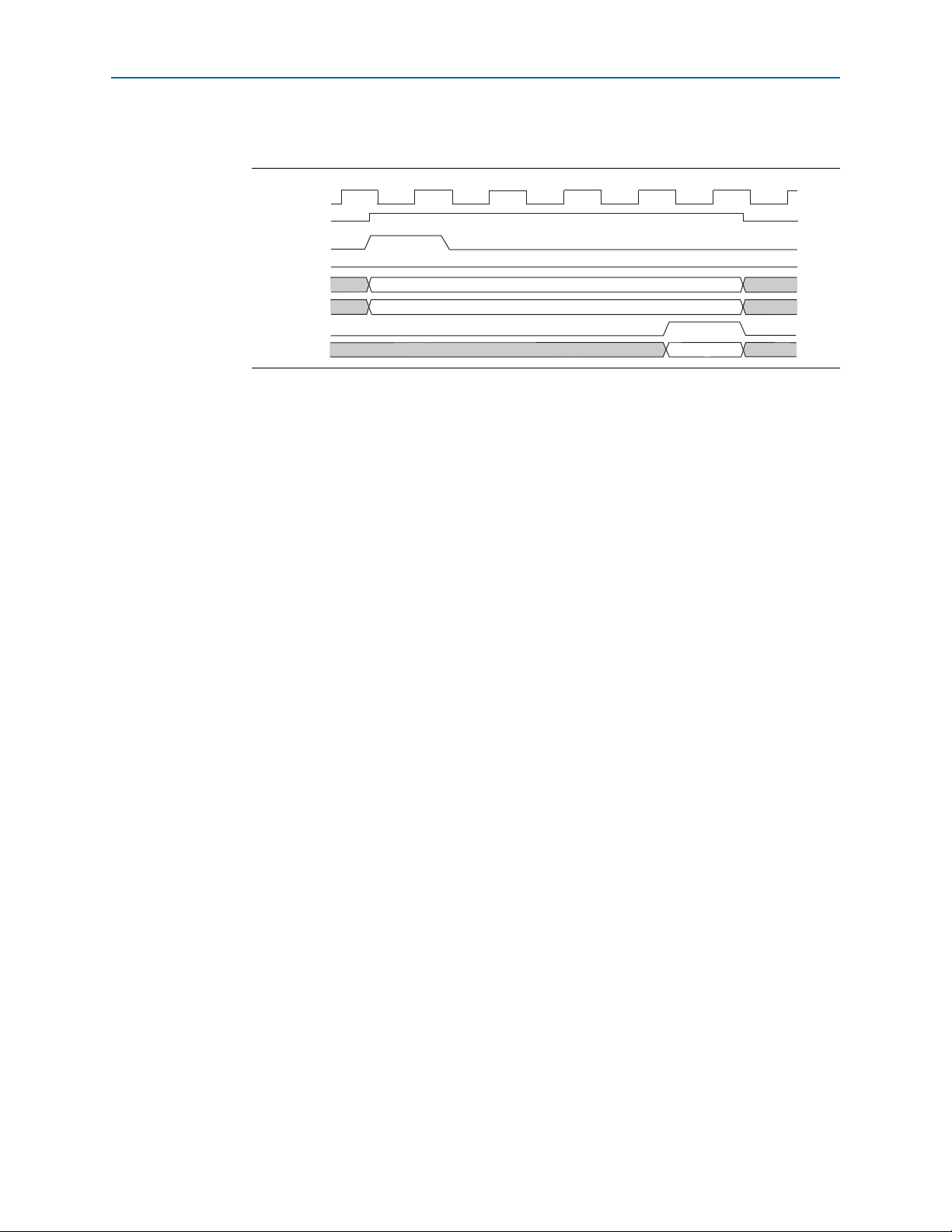

Figure 1–6 shows the multicycle custom instruction hardware port timing diagram.

Figure 1–6. Multicycle Custom Instruction Timing Diagram

start

The processor asserts the active high

instruction execution. At this time, the

remain valid throughout the duration of the custom instruction execution. The

port on the first clock cycle of the custom

dataa

and

datab

ports have valid values and

start

signal is asserted for a single clock cycle.

For a fixed length multicycle custom instruction, after the instruction starts, the

processor waits the specified number of clock cycles, and then reads the value on the

result

data on the n

signal. For an n-cycle operation, the custom logic block must present valid

th

rising edge after the custom instruction begins execution.

For a variable length multicycle custom instruction, the processor waits until the

active high

clock edge on which

result

done

signal is asserted. The processor reads the

done

is asserted. The custom logic block must present data on the

port on the same clock cycle on which it asserts the

The Nios II system clock feeds the custom logic block’s

system’s master reset feeds the active high

when the whole Nios II system is reset.

The custom logic block must treat the active high

qualifier signal, ignoring

clk

You can further optimize multicycle custom instructions by implementing the

extended internal register file, or by creating external interface custom instructions.

Refer to “Extended Custom Instructions”, “Internal Register File Custom

Instructions” on page 1–9, or “External Interface Custom Instructions” on page 1–10.

Extended Custom Instructions

Extended custom instruction allows a single custom logic block to implement several

different operations. Extended custom instructions use an index to specify which

operation the logic block performs. The index can be as many as eight bits wide,

allowing a single custom logic block to implement as many as 256 different

operations.

while

clk_en

reset

port. The

clk_en

is deasserted.

result

done

clk

port, and the Nios II

reset

port on the same

signal.

port is asserted only

port as a conventional clock

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 12

1–8 Chapter 1: Nios II Custom Instruction Overview

Custom Instruction Types

Figure 1–7 is a block diagram of an extended custom instruction with bit-swap,

byte-swap, and half-word swap operations.

Figure 1–7. Extended Custom Instruction with Swap Operations

Custom

dataa[31..0]

n[1..0]

bit-swap

operation

byte-swap

operation

half-word-swap

operation

Instruction

0

1

2

result[31..0]

The custom instruction in Figure 1–7 performs swap operations on data received at

the

dataa

port. It uses the two-bit-wide n port to select the output from a multiplexer,

determining which result is presented to the

result

port.

1 This logic is just a simple example, using a multiplexer on the output. You can

implement function selection based on an index in any way that is appropriate for

your application.

Extended custom instructions can be combinational or multicycle custom

instructions. To implement an extended custom instruction, simply add an n port to

your custom instruction logic. The bit width of the

n

port is a function of the number

of operations the custom logic block can perform.

Extended custom instructions occupy multiple custom instruction indices. For

example, the custom instruction illustrated in Figure 1–7 occupies 4 indices, because

is two bits wide. Therefore, when this instruction is implemented in a Nios II system,

256 - 4 = 252 available indices remain.

For information about the custom instruction index, refer to “Custom Instruction

Assembly Software Interface” on page 2–3.

All extended custom instruction port operations are identical to those for the

combinational and multicycle custom instructions, with the exception of the

n

which is not present in combinational and multicycle custom instructions. The

timing is the same as that of the

multicycle custom instruction, the processor presents the index value to the

the same rising edge of the clock at which

dataa

port. For example, for an extended variable

start

is asserted, and the n port remains

n

stable during execution of the custom instruction.

port,

n

port

port on

n

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 13

Chapter 1: Nios II Custom Instruction Overview 1–9

dataa[31..0]

datab[31..0]

writerc

result[31..0]

Multiplier

Adder

DQ

CLR

Custom Instruction Types

Internal Register File Custom Instructions

The Nios II processor allows custom instruction logic to access its own internal

register file. This provides you the flexibility to specify if the custom instruction reads

its operands from the Nios II processor’s register file or from the custom instruction’s

own internal register file. In addition, a custom instruction can write its results to the

local register file rather than to the Nios II processor’s register file.

Custom instructions containing internal register files use

signals to determine if the custom instruction should use the internal register file or

the

dataa, datab

, and

result

signals. Ports a, b, and c specify the internal registers

from which to read or to which to write. For example, if

(specifying a read operation from the internal register), the

index to the internal register file. Ports

a, b

, and c are five bits each, allowing you to

address as many as 32 registers.

f For further details of Nios II custom instruction implementation, refer to the

Instruction Set Reference chapter of the Nios II Processor Reference Handbook.

Tab le 1– 4 lists the internal register file custom instruction-specific optional ports. Use

the optional ports only if the custom instruction functionality requires them.

Table 1–4. Internal Register File Custom Instruction Ports

Port Name Direction Required Description

If

readra

is high, the Nios II processor supplies

readra

readrb

writerc

a[4:0]

b[4:0]

c[4:0]

Input No

Input No

Input No

readra

if

indexed by

If

if

indexed by

If

if

is low, custom instruction logic reads the internal register file

a

.

readrb

is high, the Nios II processor supplies

readrb

is low, custom instruction logic reads the internal register file

b

.

writerc

writerc

is high, the Nios II processor writes to the

is low, custom instruction logic writes to the internal

register file indexed by

c

.

Input No Custom instruction internal register file index

Input No Custom instruction internal register file index

Input No Custom instruction internal register file index

readra, readrb

readra

is deasserted

a

signal value provides an

dataa

datab

, and

;

;

result

writerc

port;

Figure 1–8 shows a simple multiply-accumulate custom logic block.

Figure 1–8. Multiply-accumulate Custom Logic Block

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 14

1–10 Chapter 1: Nios II Custom Instruction Overview

When

writerc

result

port. The accumulated value is stored in an internal register. Alternatively, the

processor can read the value on the

is deasserted, the Nios II processor ignores the value driven on the

result

port by asserting

Custom Instruction Types

writerc

. At the same

time, the internal register is cleared so that it is ready for a new round of multiply and

accumulate operations.

The

readra, readrb, writerc, a, b

custom instruction begins, the processor presents the new values of the

readrb, writerc, a, b

, and c ports on the rising edge of the processor clock. All six of

, and c ports behave similarly to

dataa

. When the

readra

,

these ports remain stable during execution of the custom instructions.

To determine how to handle the register file, custom instruction logic reads the active

high

readra, readrb

file indexes. When

the corresponding

writerc

result

is asserted, the custom instruction logic ignores the c port and writes to the

port.

, and

writerc

readra

a

or

or b port, and receives data from the

ports. The logic uses the a, b, and c ports as register

readrb

is asserted, the custom instruction logic ignores

dataa

or

datab

port. When

All other custom instruction port operations behave the same as for combinational

and multicycle custom instructions.

External Interface Custom Instructions

Nios II custom instructions allow you to add an interface to communicate with logic

outside of the processor’s datapath. At system generation, conduits propagate out to

the top level of the SOPC Builder or Qsys system, where external logic can access the

signals.

By enabling custom instruction logic to access memory external to the processor,

external interface custom instructions extend the capabilities of the custom instruction

logic.

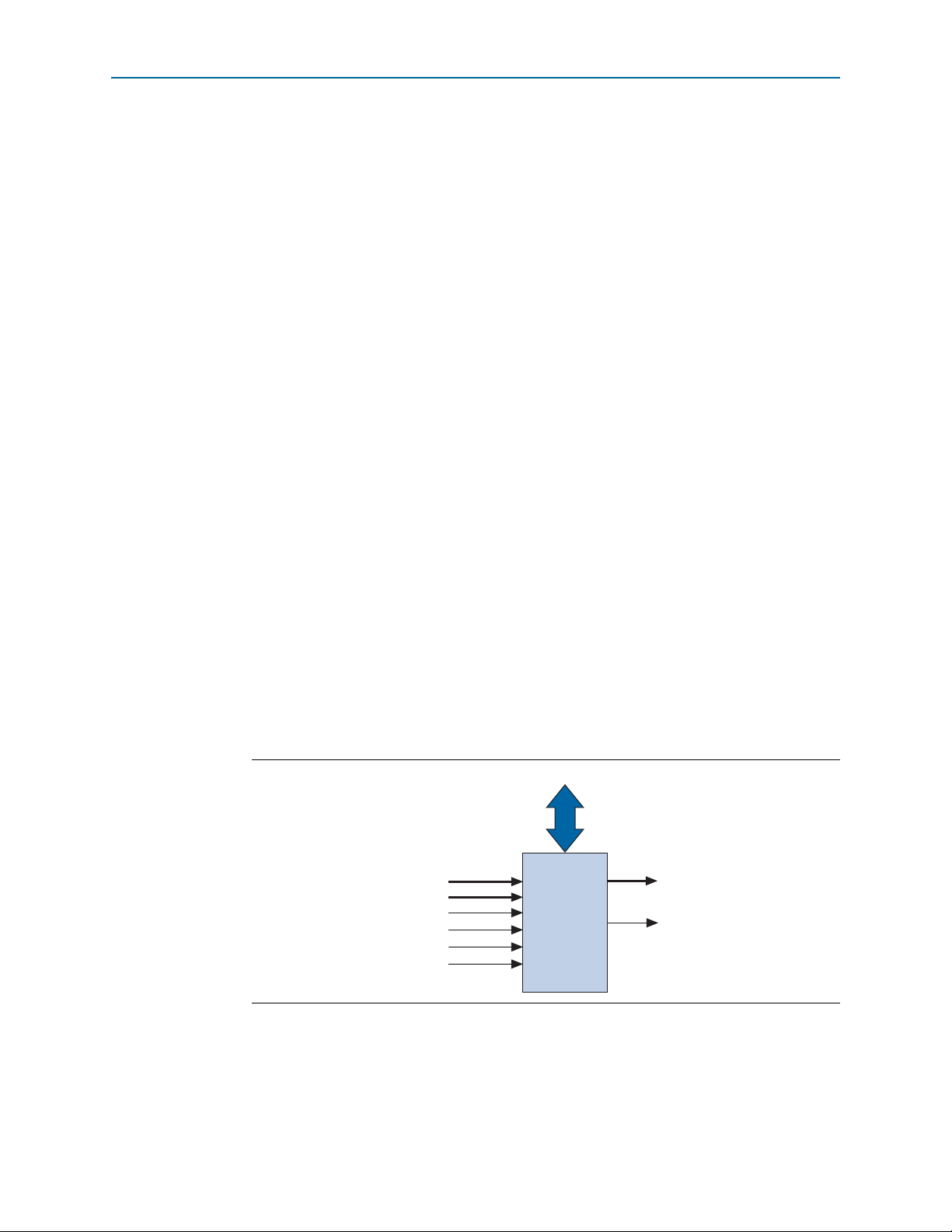

Figure 1–9 shows a multicycle custom instruction that has an external memory

interface.

Figure 1–9. Custom Instructions Allow the Addition of an External Interface

dataa[31..0]

datab[31..0]

clk

clk_en

reset

start

Conduit Interface

result[31..0]

done

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 15

Chapter 1: Nios II Custom Instruction Overview 1–11

Custom Instruction Types

Custom instruction logic can perform various tasks such as storing intermediate

results or reading memory to control the custom instruction operation. The conduit

interface also provides a dedicated path for data to flow into or out of the processor.

For example, custom instruction logic with an external interface can feed data directly

from the processor’s register file to an external first-in first-out (FIFO) memory buffer.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 16

1–12 Chapter 1: Nios II Custom Instruction Overview

Custom Instruction Types

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 17

The Nios II custom instruction software interface abstracts logic implementation

details from the application code. During the build process the Nios II software build

tools generate macros that allow easy access from application code to custom

instructions.

This chapter contains the following sections:

■ “Custom Instruction Examples” on page 2–1

■ “Built-in Functions and User-defined Macros” on page 2–2

■ “Custom Instruction Assembly Software Interface” on page 2–3

Custom Instruction Examples

Example 2–1 shows a portion of the system.h header file that defines a macro for a

bit-swap custom instruction. This bit-swap example accepts one 32-bit input and

performs only one function.

2. Software Interface

Example 2–1. Bit Swap Macro Definition

#define ALT_CI_BITSWAP_N 0x00

#define ALT_CI_BITSWAP(A) __builtin_custom_ini(ALT_CI_BITSWAP_N,(A))

In Example 2–1,

ALT_CI_BITWSWAP_N

instruction’s index. The

ALT_CI_BITSWAP(A)

is defined to be 0x0, which is the custom

macro is mapped to a

gcc

built-in

function that takes a single argument.

For more information about the

gcc

built-in functions, refer to Appendix B, Custom

Instruction Built-in Functions.

Example 2–2 illustrates application code that uses the bit-swap custom instruction.

Example 2–2. Bit Swap Instruction Usage

#include "system.h"

int main (void)

{

int a = 0x12345678;

int a_swap = 0;

a_swap = ALT_CI_BITSWAP(a);

return 0;

}

The code in Example 2–2 includes the system.h file to enable the application software

to use the custom instruction macro definition. The example code declares two

integers,

and the results are loaded in

January 2011 Altera Corporation Nios II Custom Instruction User Guide

a

and

a_swap

. Integer a is passed as input to the bit swap custom instruction

a_swap

.

Page 18

2–2 Chapter 2: Software Interface

Built-in Functions and User-defined Macros

Example 2–2 illustrates how most applications use custom instructions. The macros

defined by the Nios II software build tools use C integer types only. Occasionally,

applications require input types other than integers. In those cases, you can use a

custom instruction macro to process non-integer return values.

1 You can define custom macros for Nios II custom instructions that allow other 32-bit

input types to interface with custom instructions.

Built-in Functions and User-defined Macros

The Nios II processor uses gcc built-in functions to map to custom instructions. By

default, the integer type custom instruction is defined in a system.h file. However, by

using built-in functions, software can use non-integer types with custom instructions.

Fifty-two built-in functions are available to accommodate the different combinations

of supported types.

Built-in function names have the following format:

__builtin_custom_

<return type>n<parameter types>

Tab le 2– 1 lists the 32-bit types supported by custom instructions as parameters and

return types, as well as the abbreviations used in the built-in function names.

Table 2–1. 32-bit Types Supported by Custom Instructions

32-bit Type Built-in Function Abbreviation

int i

float f

void * p

Example 2–3 shows the prototype definitions for two built-in functions.

Example 2–3. Two Example Built-in Function Prototypes

void __builtin_custom_nf (int n, float dataa);

float __builtin_custom_fnp (int n, void * dataa);

The built-in function

return a value. In contrast, the built-in function

as input, and returns a

__builtin_custom_nf

float

.

takes a

float

as an input, and does not

__builtin_custom_fnp

takes a pointer

To support non-integer input types, define macros with mnemonic names that map to

the specific built-in function required for the application.

f Refer to Appendix B, Custom Instruction Built-in Functions for detailed information

and a list of built-in functions.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 19

Chapter 2: Software Interface 2–3

Custom Instruction Assembly Software Interface

Example 2–4 shows user-defined custom instruction macros used in an application.

Example 2–4. Custom Instruction Macro Usage Example

1. /* define void udef_macro1(float data); */

2. #define UDEF_MACRO1_N 0x00

3. #define UDEF_MACRO1(A) __builtin_custom_nf(UDEF_MACRO1_N, (A));

4. /* define float udef_macro2(void *data); */

5. #define UDEF_MACRO2_N 0x01

6. #define UDEF_MACRO2(B) __builtin_custom_fnp(UDEF_MACRO2_N, (B));

7.

8. int main (void)

9. {

10. float a = 1.789;

11. float b = 0.0;

12. float *pt_a = &a;

13.

14. UDEF_MACRO1(a);

15. b = UDEF_MACRO2((void *)pt_a);

16. return 0;

17. }

On lines 2 through 6, the user-defined macros are declared and mapped to the

appropriate built-in functions. The macro UDEF_MACRO1 takes a float as an input

parameter and does not return anything. The macro UDEF_MACRO2 takes a pointer as

an input parameter and returns a float. Lines 14 and 15 show code that uses the two

user-defined macros.

Custom Instruction Assembly Software Interface

The Nios II custom instructions are also accessible in assembly code. This section

describes the assembly interface.

Custom instructions are R-type instructions, containing:

■ A 6-bit opcode

■ Three 5-bit register index fields

■ Three 1-bit fields for the

■ An 8-bit

N

field, used for the custom instruction index (opcode extension), and

optionally including a function select subfield

readra, readrb

, and

writerc

signals

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 20

2–4 Chapter 2: Software Interface

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

NC

BA

uP OPCode = Custom

writerc

readrb

readra

A = Register index of operand A

B = Register index of operand B

C = Register index of operand C

N = 8-bit number that selects instruction

readra = 1 i f instruction uses processor’s register rA, 0 otherwise

readrb = 1 if instruction uses processor’s register rB, 0 otherwise

writerc = 1 i f instruction provides result for processor’s register rC, 0 otherwise

Instruction Fields:

Custom Instruction Assembly Software Interface

Figure 2–1 shows a diagram of the custom instruction word.

Figure 2–1. Custom Instruction Format

Bits 5–0 are the Nios II custom instruction opcode. The opcode for a custom

instruction is 0x32.

f A list of opcodes appears in the “Instruction Opcodes” section in the Instruction Set

Reference chapter of the Nios II Processor Reference Handbook.

The

N

field, bits 13:6, is the custom instruction index. The custom instruction index

distinguishes between different custom instructions, allowing the Nios II processor to

support as many as 256 distinct custom instructions. Depending on the type of

custom instruction, the

■ A unique custom instruction index, for logic that implements a single custom

N

field has one of the following functions:

function

■ An extended custom instruction index, for logic that implements several custom

functions

Example 2–5 shows the assembly language syntax for the custom instruction.

Example 2–5. Custom Instruction Assembly Syntax

custom N, xC, xA, xB

In the assembly code instruction in Example 2–5,

is the destination for the

result[31:0]

port, xA is the

port. To access the Nios II processor’s register file, replace

register file, replace

instruction has the

x

with c. The use of r or c determines whether the custom

readra, readrb

, and

writerc

N

is the custom instruction index, xC

dataa

port, and xB is the

x

with r. To access a custom

bits held high or low. Refer to

Figure 2–1 for the location of these three bits in the custom instruction low-level

format.

Example 2–6, Example 2–7, and Example 2–8 demonstrate the syntax for custom

instruction assembler calls.

Example 2–6. Assembly Language Call to Customer Instruction I

Nios II Custom Instruction User Guide January 2011 Altera Corporation

custom 0, r6, r7, r8

datab

Page 21

Chapter 2: Software Interface 2–5

Custom Instruction Assembly Software Interface

Example 2–6 shows a call to a custom instruction with index 0. The input to the

instruction is the current contents of the Nios II processor registers

results are stored in the Nios II processor register

Example 2–7. Assembly Language Call to Customer Instruction II

custom 3, c1, r2, c4

r6

.

r7

and r8, and the

Example 2–7 shows a call to a custom instruction with index 3. The input to the

instruction is the current contents of the Nios II processor register

register

Example 2–8. Assembly Language Call to Customer Instruction III

custom 4, r6, c9, r2

c4

, and the results are stored in custom register c1.

r2

and the custom

Example 2–8 shows a call to a custom instruction with index 4. The input to the

instruction is the current contents of the custom register

register

r2

, and the results are stored in Nios II processor register r6.

c9

and the Nios II processor

f For more information about the binary format of custom instructions, refer to the

Instruction Set Reference chapter of the Nios II Processor Reference Handbook.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 22

2–6 Chapter 2: Software Interface

Custom Instruction Assembly Software Interface

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 23

3. Implementing a Nios II Custom

This chapter describes the process of implementing a Nios II custom instruction with

the SOPC Builder component editor. The component editor enables you to create new

SOPC Builder components, including Nios II custom instructions. This chapter also

describes the process of accessing Nios II custom instructions from software.

f For detailed information about the SOPC Builder component editor, refer to the

“Component Editor” chapter of the SOPC Builder User Guide.

Design Example: Cyclic Redundancy Check

The cyclic redundancy check (CRC) algorithm detects the corruption of data during

transmission. It detects a higher percentage of errors than a simple checksum. The

CRC calculation consists of an iterative algorithm involving XOR and shift operations.

These operations are carried out concurrently in hardware and iteratively in software.

Because the operations are carried out concurrently, the execution is much faster in

hardware.

Instruction in SOPC Builder

The CRC design files demonstrate the steps to implement an extended multicycle

Nios II custom instruction. These design files are available for you to download from

the Nios II Custom Instruction Design Example web page.

Implementing Custom Instruction Hardware in SOPC Builder

This section describes the custom instruction tool-flow, and walks you through the

process of implementing a Nios II custom instruction. Implementing a Nios II custom

instruction hardware entails the following tasks:

■ “Opening the Component Editor”

■ “Adding the HDL Files”

■ “Configuring the Custom Instruction Signal Type” on page 3–3

■ “Setting Up the Custom Instruction Interfaces” on page 3–3

■ “Setting the Details” on page 3–4

■ “Saving and Adding the Custom Instruction” on page 3–5

■ “Generating the System and Compiling in the Quartus II Software” on page 3–5

The following sections detail the steps required to set up the design example

environment and to perform the list of tasks.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 24

3–2 Chapter 3: Implementing a Nios II Custom Instruction in SOPC Builder

Implementing Custom Instruction Hardware in SOPC Builder

Setting up the Design Environment for the Design Example

Before you start the design example, you must set up the design environment to

accommodate the processes described in the following sections. To set up the design

example environment, follow these steps:

1. Open the ug_custom_instruction_files.zip file from the Nios II Custom

Instruction Design Example web page and extract all the files to a new directory.

2. Follow the instructions in the Quartus II Project Setup section in the

readme_sopcb.txt file in the extracted design files. The instructions direct you to

determine a <project_dir> working directory for the project, to download an

appropriate Quartus II project for your development board, and to open the

design example project in the Quartus II software.

Opening the Component Editor

After you follow the steps in the Quartus II Project Setup section of the

readme_sopcb.txt file, you have an Quartus II project located in the <project_dir>

directory and open in the Quartus II software.

To open the component editor, follow these steps:

1. To open the SOPC Builder system, on the Tools menu, click SOPC Builder.

2. On the SOPC Builder System Contents tab, double-click cpu. The Nios II

Processor parameter editor appears.

3. On the Parameter Settings page, on the Custom Instructions tab, click Import.

The component editor appears, displaying the Introduction tab.

Adding the HDL Files

To specify the synthesis HDL files for your custom instruction, follow these steps:

1. Click Next to display the HDL Files tab.

2. Click Add.

3. Browse to <project_dir>/crc_hw, the location of the HDL files for this design

example.

4. Select the CRC_Custom_Instruction.v and CRC_Component.v files and click

Open.

1 The Quartus II Analysis and Synthesis program checks the design for errors

when you add the files. Confirm that no error message appears.

5. Ensure the Synth setting is turned on for both files. This setting directs the

component editor to generate models for synthesis.

6. Turn on the To p parameter for the CRC_Custom_Instruction.v file, to indicate it is

the top-level HDL file for this custom instruction.

1 The Quartus II Analysis and Synthesis program checks the design for errors

when you change the To p setting. Confirm that no error message appears.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 25

Chapter 3: Implementing a Nios II Custom Instruction in SOPC Builder 3–3

Implementing Custom Instruction Hardware in SOPC Builder

7. Click Top Level Module and select the name of the top-level module of your

custom instruction logic. The top-level module for this design example is

CRC_Custom_Instruction.

8. To enable simulating the system in the ModelSim simulator, you can turn on Sim

for both files. In cases other than the design example, you may need to add

additional simulation files in the component editor HDL Files tab, turn on Sim

and turn off Synth for these simulation-only files, and turn off Sim for the

synthesis-only files.

Configuring the Custom Instruction Signal Type

To configure the custom instruction signal type, follow these steps:

1. Click Next to display the Signals tab.

2. For each port listed in the tab, follow these steps:

a. Select the port.

b. In the Interface column, select the name of the interface to which you want to

assign the port. For the design example, select

nios_custom_instruction_slave_0.

c. In the Signal Type column, select the appropriate signal type for the port. The

available types are described in “Custom Instruction Types” on page 1–3.

Setting Up the Custom Instruction Interfaces

To set up the custom instruction interfaces, follow these steps:

1. Click Next to display the Interfaces tab.

2. For Typ e, select Custom Instruction Slave.

3. For the design example, maintain the interface name

nios_custom_instruction_slave_0.

1 If you rename an interface by changing the value in the Name field, the

Signals tab Interface column value changes automatically. The value

shown in the block diagram updates when you change tabs and return to

the Interfaces tab.

4. For Clock Cycles, type 0 for a variable multicycle type custom instruction, and

otherwise type the number of clock cycles your custom instruction logic requires.

The design example builds a variable multicycle type custom instruction.

1 If the interface includes a

editor automatically infers that the interface is a variable multicycle type

custom instruction interface, and sets the value to

done

signal and a

clk

signal, the component

0

.

5. For Clock Cycle Type, type

instruction,

Combinatorial

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Multicycle

for a combinational type custom instruction.

Variable

for a fixed multicycle type custom instruction, or

for a variable multicycle type custom

Page 26

3–4 Chapter 3: Implementing a Nios II Custom Instruction in SOPC Builder

Implementing Custom Instruction Hardware in SOPC Builder

1 If the interface does not include a

clk

signal, the component editor

automatically infers that the interface is a combinational type interface. If

the interface includes a

clk

signal, the component editor automatically

infers that the interface is a multicycle interface. If the interface does not

include a

fixed multicycle type interface. If the interface includes a

done

signal, the component editor infers that the interface is a

done

signal, the

component editor infers that the interface is a variable multicycle type

interface.

6. For Operands, type the number of operands for your custom instruction. For the

design example, type

1

.

7. If the warning message Interface has no signals appears, click Remove Interfaces

With No Signals.

If your custom instruction logic requires additional interfaces, either to the

Avalon-MM fabric or outside the SOPC Builder system, you can specify the additional

interfaces in the Interfaces tab. The design example does not require additional

interfaces.

1 Most custom instructions use some combination of standard custom instruction ports,

such as

dataa, datab

, and

result

, and do not require additional interfaces.

The following instructions provide the information you need if a custom instruction

in your own design requires additional interfaces. If you are walking through the

design example, proceed to “Setting the Details”.

To specify additional interfaces on the Interfaces tab, follow these steps:

1. Click Add Interface. The new interface has Custom Instruction Slave interface

type by default.

2. For Typ e, select the desired interface type.

3. Set the parameters for the newly created interface according to your system

requirements.

Setting the Details

To specify the final details in the custom instruction parameter editor, follow these

steps:

1. Click Next to display the HDL Parameters tab.

2. Click Next to display the Library Info tab.

3. For Name and for Display Name, type

4. For Ver s io n , type

5. Leave the Group field blank.

6. Optionally, set the Description, Created by, and Icon fields as you prefer.

7. If the bottom pane of the dialog box displays something other than the message

Info: No errors or warnings, review the other tabs to ensure you followed the

instructions correctly.

1.0

CRC

.

.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 27

Chapter 3: Implementing a Nios II Custom Instruction in SOPC Builder 3–5

Implementing Custom Instruction Hardware in SOPC Builder

Saving and Adding the Custom Instruction

To save the custom instruction and add it to your Nios II processor, follow these steps:

1. Click Finish. A dialog box prompts you to save your changes before exiting.

2. Click Yes, Save. In the Nios II processor parameter editor, on the Custom

Instructions tab, the new custom instruction appears in the left panel.

3. If the new custom instruction does not appear on the Custom Instructions tab in

the left panel, follow these steps:

a. Click Finish to exit the Nios II processor parameter editor.

b. On the SOPC Builder System Contents tab, double-click cpu to reopen the

Nios II parameter editor.

4. In the left panel of the Custom Instructions tab, select CRC, the new custom

instruction you created in the design example.

5. Click Add to add the new instruction to the Nios II processor. Information about

the new instruction appears in the right panel, listing the name, Clock Cycles

value, N Port information, and Opcode Extension.

If the custom instruction is an extended type instruction, the N Port field specifies

the function select bits in the

N

port. Otherwise, the N Port field contains a dash.

The Opcode Extension field displays the custom instruction index (

instruction word in both binary and decimal formats. For more information about

the

N

field, refer to “Custom Instruction Assembly Software Interface” on

page 2–3.

6. Click Finish to complete the addition of the custom instruction to the SOPC

Builder system and return to SOPC Builder.

N

field) of the

Generating the System and Compiling in the Quartus II Software

After you add the custom instruction logic to the system, you can generate the system

and compile it in the Quartus II software. During system generation, SOPC Builder

connects the custom logic to the Nios II processor.

To generate the system and compile, follow these steps:

1. In SOPC Builder, on the System Generation tab, turn on Simulation. Create

project simulator files if you want to simulate your system.

2. Click Generate. System generation may take several seconds to complete.

3. After system generation completes, click Exit.

4. In the Quartus II software, on the Processing menu, click Start Compilation.

f For detailed information about SOPC Builder systems and their generation, refer to

the SOPC Builder User Guide or the SOPC Builder Help system.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 28

3–6 Chapter 3: Implementing a Nios II Custom Instruction in SOPC Builder

Accessing the Custom Instruction from Software

Accessing the Custom Instruction from Software

Adding a custom instruction to a Nios II processor results in a significant change to

the SOPC Builder system. In this section, you create and build a new software project

using the Nios II software build flow, and run the software that accesses the custom

instruction. The software source files are included in the downloadable design files.

Tab le 3– 1 lists the CRC application software source files and their corresponding

descriptions.

Table 3–1. CRC Application Software Source Files

File Name Description

Main program that populates random test data, executes the CRC both in

crc_main.c

crc.c Software CRC algorithm run by the Nios II processor.

crc.h Header file for crc.c.

ci_crc.c Program that accesses CRC custom instruction.

ci_crc.h Header file for ci_crc.c.

software and with the custom instruction, validates the output, and reports

the processing time.

To run the application software, you must create an Executable and Linking Format

File (.elf) first. To create the .elf file, follow the instructions in the Nios II Software

Build Flow section in the readme_sopcb.txt file in the extracted design files.

The application program runs three implementations of the CRC algorithm on the

same pseudo-random input data: an unoptimized software implementation, an

optimized software implementation, and the custom instruction CRC. The program

calculates the processing time and throughput for each of the versions, to demonstrate

the improved efficiency of a custom instruction compared to a software

implementation.

Example 3–1 shows the output from the application program run on a Nios II

Embedded Evaluation Kit, Cyclone III Edition (NEEK) using the Quartus II software

v10.1 and Nios II Embedded Design Suite (EDS) v10.1.

The output shows that the custom instruction CRC is 75 times faster than the

unoptimized CRC calculated purely in software and is almost 50 times faster than the

optimized version of the software CRC. The results you see using different target

device and board may vary depending on the memory characteristics of the board

and the clock speed of the device, but these ratios are representative.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 29

Chapter 3: Implementing a Nios II Custom Instruction in SOPC Builder 3–7

Accessing the Custom Instruction from Software

Example 3–1. Output of the CRC Design Example Software Run on a NEEK Using the Quartus II Software v10.1

******************************************************************************

Comparison between software and custom instruction CRC32

******************************************************************************

System specification

-------------------System clock speed = 62.5 MHz

Number of buffer locations = 16

Size of each buffer = 65535 bytes

Initializing all of the buffers with pseudo-random data

------------------------------------------------------Initialization completed

Running the software CRC

-----------------------Completed

Running the optimized software CRC

---------------------------------Completed

Running the custom instruction CRC

---------------------------------Completed

Validating the CRC results from all implementations

--------------------------------------------------All CRC implementations produced the same results

Processing time for each implementation

--------------------------------------Software CRC = 9938.35 ms

Optimized software CRC = 6472.89 ms

Custom instruction CRC = 132.29 ms

Processing throughput for each implementation

--------------------------------------------Software CRC = 0.84 Mbps

Optimized software CRC = 1.30 Mbps

Custom instruction CRC = 63.41 Mbps

Speedup ratio

------------Custom instruction CRC vs software CRC = 75.1

Custom instruction CRC vs optimized software CRC = 48.9

Optimized software CRC vs software CRC = 1.5

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 30

3–8 Chapter 3: Implementing a Nios II Custom Instruction in SOPC Builder

Using the User-defined Custom Instruction Macro

Using the User-defined Custom Instruction Macro

The design example software uses a user-defined macro to access the CRC custom

instruction. Example 3–2 shows the macro that is defined in the ci_crc.c file.

Example 3–2. CRC Custom Instruction Macro Usage

#define CRC_CI_MACRO(n, A) __builtin_custom_ini(ALT_CI_CRC_INST_N + (n & 0x7), (A))

This macro takes a single

CRC custom instruction has extended type; the

int

type input operand and returns an

n

value in the macro

int

type value. The

CRC_CI_MACRO()

indicates the operation to be performed by the custom instruction. The custom

instruction index is added to the value of

n

. The n value is masked because the n port

of a custom instruction has only three bits.

To initialize the custom instruction, for example, you can add the initialization code in

Example 3–3 to your application software.

Example 3–3. Using the User-defined Macro to Initialize the Custom Instruction Logic

/* Initialize the custom instruction CRC to the initial remainder value: */

CRC_CI_MACRO (0,0);

For details of each operation of the CRC custom instruction and the corresponding

index value

n

, refer to the comments in the ci_crc.c file.

Example 3–2 and Example 3–3 demonstrate that you can define the macro in your

application to accommodate your requirements. For example, you can determine the

number and type of input operands, decide whether to assign a return value, and

vary the custom instruction index. However, the macro definition and usage must be

consistent with the port declarations of the custom instruction. For example, if you

define the macro to return an

int

value, the custom instruction must have a

port.

result

f For details about writing software for Nios II custom instructions, refer to Chapter 2,

Software Interface.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 31

4. Implementing a Nios II Custom

This chapter describes the process of implementing a Nios II custom instruction with

the Qsys component editor. The component editor enables you to create new Qsys

components, including Nios II custom instructions. This chapter also describes the

process of accessing Nios II custom instructions from software.

f For detailed information about the Qsys component editor, refer to Creating Qsys

Components in volume 1 of the Quartus II Handbook.

Design Example: Cyclic Redundancy Check

The cyclic redundancy check (CRC) algorithm detects the corruption of data during

transmission. It detects a higher percentage of errors than a simple checksum. The

CRC calculation consists of an iterative algorithm involving XOR and shift operations.

These operations are carried out concurrently in hardware and iteratively in software.

Because the operations are carried out concurrently, the execution is much faster in

hardware.

Instruction in Qsys

The CRC design files demonstrate the steps to implement an extended multicycle

Nios II custom instruction. These design files are available for you to download from

the Nios II Custom Instruction Design Example web page.

Implementing Custom Instruction Hardware in Qsys

This section describes the custom instruction tool-flow, and walks you through the

process of implementing a Nios II custom instruction. Implementing a Nios II custom

instruction hardware entails the following tasks:

■ “Opening the Component Editor”

■ “Adding the HDL Files”

■ “Configuring the Custom Instruction Signal Type” on page 4–3

■ “Setting Up the Custom Instruction Interfaces” on page 4–3

■ “Setting the Details” on page 4–4

■ “Saving and Adding the Custom Instruction” on page 4–5

■ “Generating the System and Compiling in the Quartus II Software” on page 4–5

The following sections detail the steps required to set up the design example

environment and to perform the list of tasks.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 32

4–2 Chapter 4: Implementing a Nios II Custom Instruction in Qsys

Implementing Custom Instruction Hardware in Qsys

Setting up the Design Environment for the Design Example

Before you start the design example, you must set up the design environment to

accommodate the processes described in the following sections. To set up the design

example environment, follow these steps:

1. Open the ug_custom_instruction_files.zip file from the Nios II Custom

Instruction Design Example web page and extract all the files to a new directory.

2. Follow the instructions in the Quartus II Project Setup section in the

readme_qsys.txt file in the extracted design files. The instructions direct you to

determine a <project_dir> working directory for the project and to open the design

example project in the Quartus II software.

Opening the Component Editor

After you follow the steps in the Quartus II Project Setup section of the

readme_qsys.txt file, you have an Quartus II project located in the <project_dir>

directory and open in the Quartus II software.

To open the component editor, follow these steps:

1. To open Qsys, on the Tools menu, click Qsys.

2. In Qsys, on the File menu, click Open.

3. Browse to the <project_dir> directory if necessary, select the .qsys file, and click

Open.

4. On the Qsys Component Library tab, click New. The component editor appears,

displaying the Introduction tab.

Adding the HDL Files

To specify the synthesis HDL files for your custom instruction, follow these steps:

1. Click Next to display the HDL Files tab.

2. Click Add.

3. Browse to <project_dir>/crc_hw, the location of the HDL files for this design

example.

4. Select the CRC_Custom_Instruction.v and CRC_Component.v files and click

Open.

1 The Quartus II Analysis and Synthesis program checks the design for errors

when you add the files. Confirm that no error message appears.

5. Ensure the Synth setting is turned on for both files. This setting directs the

component editor to generate models for synthesis..

6. Turn on the To p parameter for the CRC_Custom_Instruction.v file, to indicate it is

the top-level HDL file for this custom instruction.

1 The Quartus II Analysis and Synthesis program checks the design for errors

when you change the To p setting. Confirm that no error message appears.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 33

Chapter 4: Implementing a Nios II Custom Instruction in Qsys 4–3

Implementing Custom Instruction Hardware in Qsys

7. Click Top Level Module and select the name of the top-level module of your

custom instruction logic. The top-level module for this design example is

CRC_Custom_Instruction.

8. To enable simulating the system in the ModelSim simulator, you can turn on Sim

for both files. In cases other than the design example, you may need to add

additional simulation files in the component editor HDL Files tab, turn on Sim

and turn off Synth for these simulation-only files, and turn off Sim for the

synthesis-only files.

Configuring the Custom Instruction Signal Type

To configure the custom instruction signal type, follow these steps:

1. Click Next to display the Signals tab.

2. For each port listed in the tab, follow these steps:

a. Select the port.

b. In the Interface column, select the name of the interface to which you want to

assign the port.

For the design example, for the first port you configure, select New Custom

Instruction Slave. For the remaining ports, select the name created for the first

port, which is nios_custom_instruction_slave. These selections ensure that the

ports appear together on a single interface, using the name assumed by the

design example crc_hw files.

c. In the Signal Type column, select the appropriate signal type for the port. The

available signal types are described in “Custom Instruction Types” on

page 1–3. In the design example, the correct signal type for each signal has the

same name as the signal.

Setting Up the Custom Instruction Interfaces

To set up the custom instruction interfaces, follow these steps:

1. Click Next to display the Interfaces tab.

2. If the Remove Interfaces With No Signals button is active, click it.

3. Ensure that a single interface remains, with Name set to the name in the Signals

tab. For the design example, maintain the interface name

nios_custom_instruction_slave.

1 If you rename an interface by changing the value in the Name field, the

Signals tab Interface column value changes automatically. The value

shown in the block diagram updates when you change tabs and return to

the Interfaces tab.

4. Ensure the Typ e for this interface is Custom Instruction Slave.

5. For Clock Cycles, type 0 for a variable multicycle type custom instruction, and

otherwise type the number of clock cycles your custom instruction logic requires.

The design example builds a variable multicycle type custom instruction.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 34

4–4 Chapter 4: Implementing a Nios II Custom Instruction in Qsys

Implementing Custom Instruction Hardware in Qsys

1 If the interface includes a

done

signal and a

clk

signal, the component

editor automatically infers that the interface is a variable multicycle type

custom instruction interface, and sets the value to

6. For Clock Cycle Type, type

instruction,

Combinatorial

Multicycle

for a fixed multicycle type custom instruction, or

for a combinational type custom instruction. Because the design

Variable

for a variable multicycle type custom

0

.

example builds a variable multicycle type custom instruction, Clock Cycle Type is

set to Va ri a bl e .

1 If the interface does not include a

clk

signal, the component editor

automatically infers that the interface is a combinational type interface. If

the interface includes a

clk

signal, the component editor automatically

infers that the interface is a multicycle interface. If the interface does not

include a

fixed multicycle type interface. If the interface includes a

done

signal, the component editor infers that the interface is a

done

signal, the

component editor infers that the interface is a variable multicycle type

interface.

7. For Operands, type the number of operands for your custom instruction. For the

design example, type

1

.

If your custom instruction logic requires additional interfaces, either to the

Avalon-MM fabric or outside the Qsys system, you can specify the additional

interfaces in the Interfaces tab. The design example does not require additional

interfaces.

1 Most custom instructions use some combination of standard custom instruction ports,

such as

dataa, datab

, and

result

, and do not require additional interfaces.

The following instructions provide the information you need if a custom instruction

in your own design requires additional interfaces. If you are walking through the

design example, proceed to “Setting the Details”.

To specify additional interfaces on the Interfaces tab, follow these steps:

1. Click Add Interface. The new interface has Custom Instruction Slave interface

type by default.

2. For Typ e, select the desired interface type.

3. Set the parameters for the newly created interface according to your system

requirements.

Setting the Details

To specify the final details in the custom instruction parameter editor, follow these

steps:

1. Click Next to display the HDL Parameters tab.

2. Click Next to display the Library Info tab.

3. For Name and for Display Name, type

CRC

.

4. For Ver s io n , type

Nios II Custom Instruction User Guide January 2011 Altera Corporation

1.0

.

Page 35

Chapter 4: Implementing a Nios II Custom Instruction in Qsys 4–5

Accessing the Custom Instruction from Software

5. Leave the Group field blank.

6. Optionally, set the Description, Created by, and Icon fields as you prefer.

7. If the bottom pane of the dialog box displays something other than the message

Info: No errors or warnings, review the other tabs to ensure you followed the

instructions correctly.

Saving and Adding the Custom Instruction

To save the custom instruction and add it to your Nios II processor, follow these steps:

1. Click Finish. A dialog box prompts you to save your changes before exiting.

2. Click Yes, Save. The new custom instruction appears in the Qsys Component

Library.

3. In the Qsys Component Library, under Library, select CRC, the new custom

instruction you created in the design example.

4. Click Add to add the new instruction to the Qsys system.

5. In the Connections panel, connect the new CRC_0 component’s

nios_custom_instruction_slave interface to the cpu component’s

custom_instruction_master interface.

Generating the System and Compiling in the Quartus II Software

After you add the custom instruction logic to the system, you can generate the Qsys

system and compile it in the Quartus II software.

To generate the system and compile, follow these steps:

1. In Qsys, on the Generation tab, turn on Create HDL design files for synthesis.

2. Click Generate. System generation may take several seconds to complete.

3. After system generation completes, on the File menu, click Exit.

4. In the Quartus II software, on the Project menu, click Add/Remove Files in

Project.

5. Ensure that the .qip file in the synthesis subdirectory is added to the project.

6. On the Processing menu, click Start Compilation.

f For detailed information about Qsys systems and their generation, refer to the System

Design with Qsys section in volume 1 of the Quartus II Handbook.

Accessing the Custom Instruction from Software

Adding a custom instruction to a Nios II processor results in a significant change to

the Qsys system. In this section, you create and build a new software project using the

Nios II software build flow, and run the software that accesses the custom instruction.

The software source files are included in the downloadable design files.

January 2011 Altera Corporation Nios II Custom Instruction User Guide

Page 36

4–6 Chapter 4: Implementing a Nios II Custom Instruction in Qsys

Accessing the Custom Instruction from Software

Tab le 4– 1 lists the CRC application software source files and their corresponding

descriptions.

Table 4–1. CRC Application Software Source Files

File Name Description

Main program that populates random test data, executes the CRC both in

crc_main.c

crc.c Software CRC algorithm run by the Nios II processor.

crc.h Header file for crc.c.

ci_crc.c Program that accesses CRC custom instruction.

ci_crc.h Header file for ci_crc.c.

software and with the custom instruction, validates the output, and reports

the processing time.

To run the application software, you must create an Executable and Linking Format

File (.elf) first. To create the .elf file, follow the instructions in the Nios II Software

Build Flow section in the readme_qsys.txt file in the extracted design files.

The application program runs three implementations of the CRC algorithm on the

same pseudo-random input data: an unoptimized software implementation, an

optimized software implementation, and the custom instruction CRC. The program

calculates the processing time and throughput for each of the versions, to demonstrate

the improved efficiency of a custom instruction compared to a software

implementation.

Example 4–1 shows the output from the application program run on a Nios II

Embedded Evaluation Kit, Cyclone III Edition (NEEK) using the Quartus II software

v10.1 Service Pack 1 and Nios II Embedded Design Suite (EDS) v10.1 Service Pack 1.

The output shows that the custom instruction CRC is more than 70 times faster than

the unoptimized CRC calculated purely in software and is more than 45 times faster

than the optimized version of the software CRC. The results you see using different

target device and board may vary depending on the memory characteristics of the

board and the clock speed of the device, but these ratios are representative.

Nios II Custom Instruction User Guide January 2011 Altera Corporation

Page 37

Chapter 4: Implementing a Nios II Custom Instruction in Qsys 4–7

Accessing the Custom Instruction from Software

Example 4–1. Output of the CRC Design Example Software Run on a NEEK Using the Quartus II Software v10.1 SP1

******************************************************************************

Comparison between software and custom instruction CRC32