Page 1

Multiaxis Motor Control Board

MNL-1073 Reference Manual

This reference manual describes the Altera® Multiaxis Motor Control Board.

Efficient control of torque and speed of AC motors requires corresponding control of

voltage and frequency that you supply to the motor. Typically, you filter the AC input

voltage for electromagnetic interference (EMI), correct it to achieve unity power

factor, then rectify it to yield a DC voltage. You then invert the rectifier output again

through switching of power electronics, such as insulated-gate bipolar transistors

(IGBTs) to create the appropriate variable AC voltages and frequency for the motor.

Control algorithms such as Field Oriented Control (FOC) of PMSMs require you to

measure and analog to digitally A/D convert motor current and voltages, to provide

the required feedback to the controller. In addition, you use analog-to-digital

converters (ADCs ) to monitor the DC link voltage and current. Multiaxis drives

achieve either a high degree of coordination of control across motors or, in some

applications, integrate control of multiple independent motors to reduce overall

system cost. In closed-loop control systems, modern drive requirements continue to

evolve the need for higher precision position and velocity encoder feedback devices.

Standard encoder interfaces, 7such as EnDat, BiSS, and HiperFace, are based on

traditional sin and cosine encoder techniques. These encoder interfaces incorporate

communication controllers that can transmit information back to the drive digitally,

which enhances their performance in noisy environments. Encoder interfaces support

features, such as online inspection of motor parameters and line delay measurement,

which you can incorporate into the motor control algorithm.

Features

101 Innovation Drive

San Jose, CA 95134

www.altera.com

The Multiaxis Motor Control Board contains all the power electronics, current and

voltage sensing, and connections for motor position feedback. You can use the motor

Control Board to develop a motor control system that supports permanent magnet

synchronous motors (PMSMs) or brushless DC (BLDC) motors. The Multiaxis Motor

Control Board is suitable for single-axis and multiaxis motor control applications and

supports multiple position feedback interfaces..

The Multiaxis Motor Control Board has the following features:

■ Power factor correction (PFC) and EMI filter

■ DC link power supply of 400 V

■ Switch mode power supplies for logic

■ IGBT power stages

■ Sigma-delta ADCs for sensing voltages and currents

■ Brake (chopper) switch

© 2014 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, HARDCOPY, MAX, MEGACORE, NIOS,

QUARTUS and STRATIX words and logos are trademarks of Altera Corporation and registered in the U.S. Patent and Trademark

Office and in other countries. All other words and logos identified as trademarks or service marks are the property of their

respective holders as described at www.altera.com/common/legal.html. Altera warrants performance of its semiconductor

products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any

products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use

of any information, product, or service described herein except as expressly agreed to in writing by Altera. Altera customers are

advised to obtain the latest version of device specifications before relying on any published information and before placing orders

for products or services.

ISO

9001:2008

Registered

February 2014 Altera Corporation

Feedback Subscribe

Page 2

Page 2 Setting Up the Multiaxis Motor Control Board

■ Position feedback interfaces for:

■ EnDat

■ Bidirectional synchronous serial (BiSS)

■ HIPERFACE

■ Resolver

■ Quadrature

■ Hall effect

Setting Up the Multiaxis Motor Control Board

w The Multiaxis Motor Control Board operates at high voltages and currents that can

result in hazardous electrical shock. Ensure you understand and follow all necessary

safety precautions before you operate the board.

Altera supplies the Multiaxis Motor Control Board configured for EnDat interfaces, to

change these settings, perform the following steps:

1. Use the jumpers to select the encoder power supply.

2. Use the jumpers to configure the encoder RS485.

3. Configure the Multiaxis Motor Control Board to match the interface type that the

host board implements, otherwise unexpected damage may occur.

Connecting Encoders

To connect the EnDat encoder and motor, perform the following steps:

1. Consult the data sheet for your encoder and set the encoder power supply

jumpers to generate the required supply voltage (Ta bl e 1 0).

2. Set the DRV_x_SER_DATA jumpers for bidirectional signalling on the RX pair for

the channel you intend to use (Tab le 1 2)

3. Use the 20-way terminal block to connect each encoder. Ta ble 1 lists the four

terminal blocks.

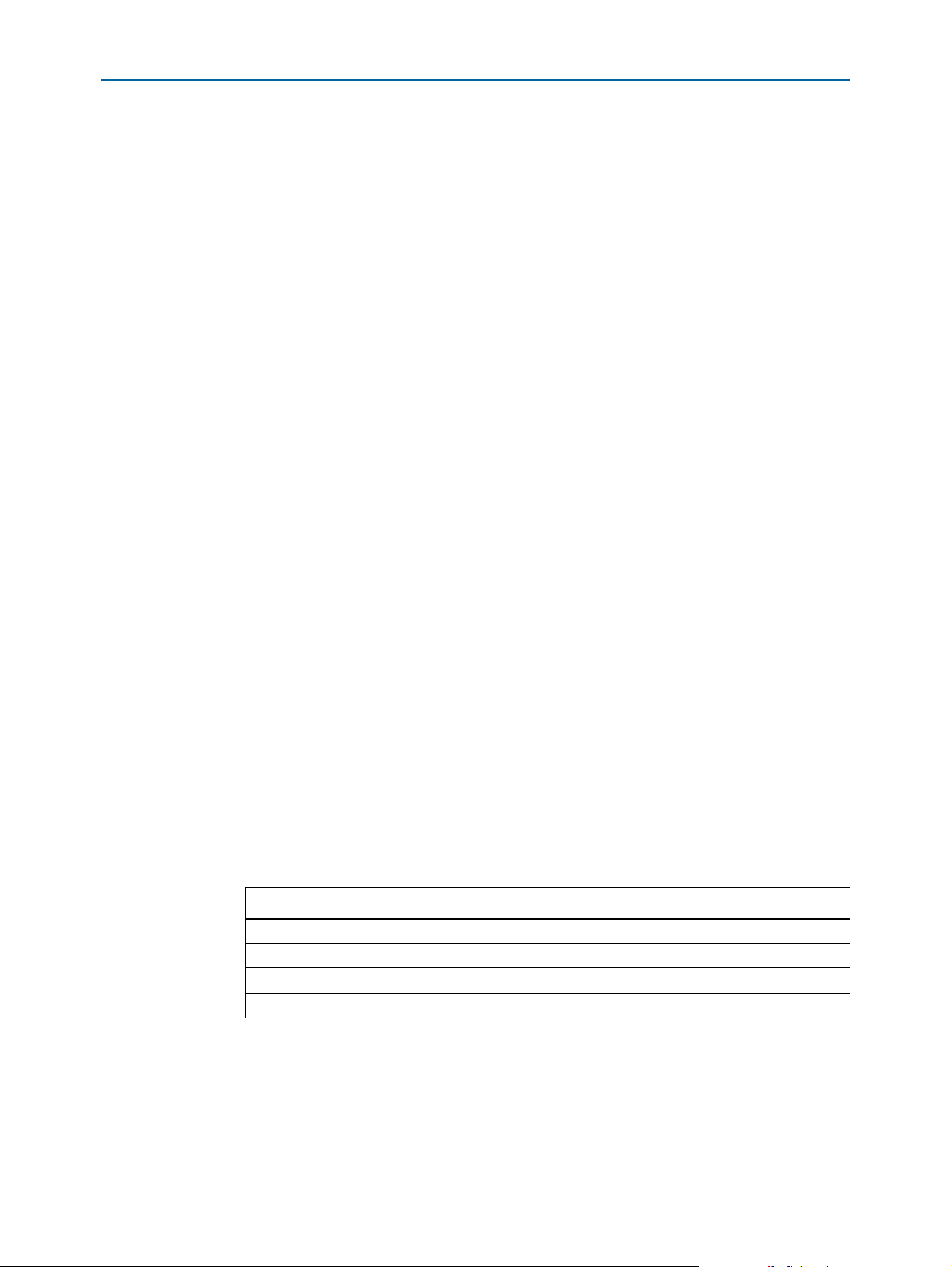

Table 1. Encoder terminal Blocks

Channel Encoder Terminal Block

0J9

1J23

2J37

3J51

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 3

Setting Up the Multiaxis Motor Control Board Page 3

4. Connect the encoder cable to the screw terminal on the relevant terminal block for

channel you intend to use (Tab le 2 ).

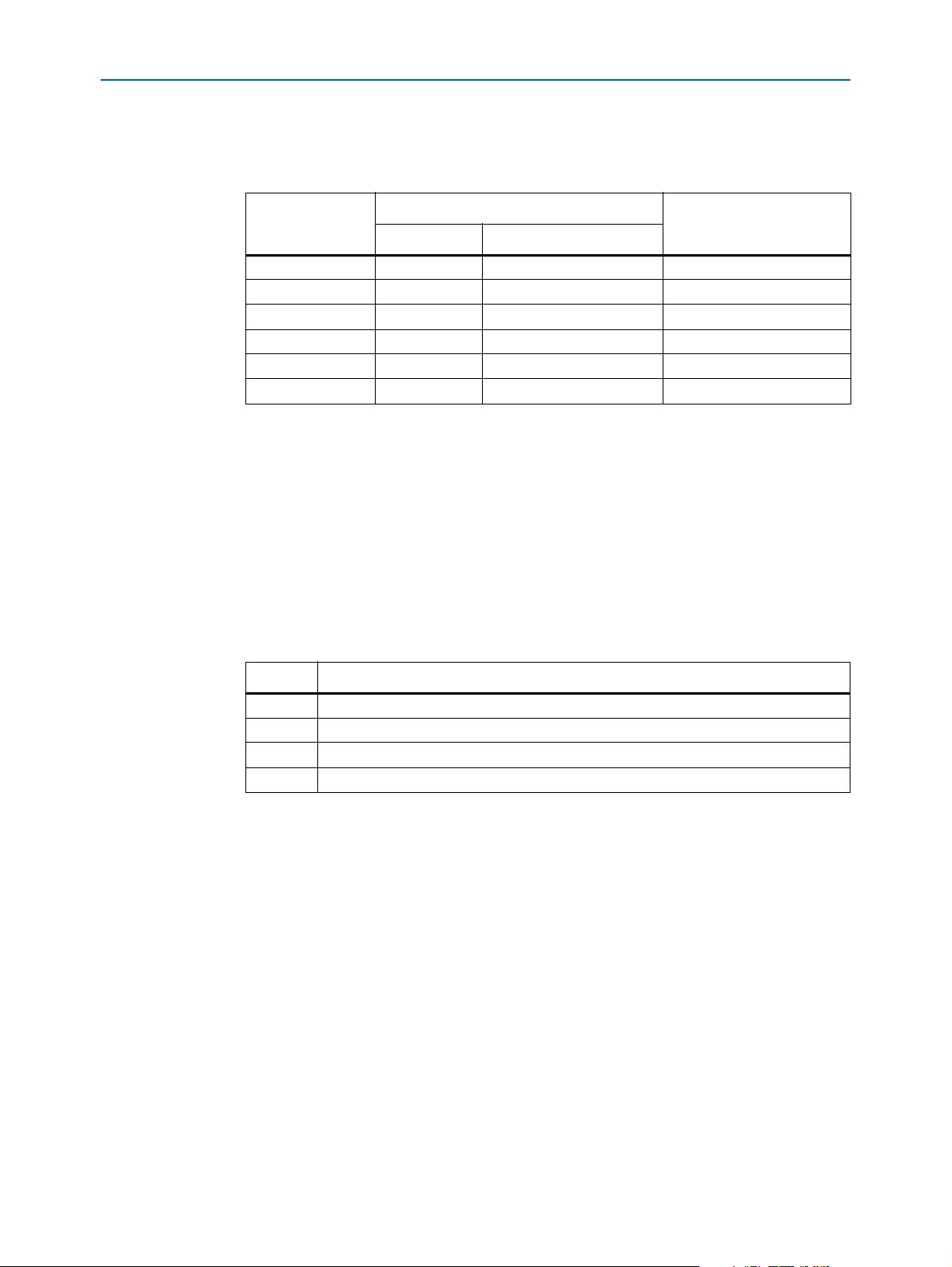

Table 2. Screw Terminal Connections for BiSS and EnDat Encoders

Signal Name

Data+

Data-

Clock+

Clock-

Power

Ground

Connecting the Motors

To prevent electrical shocks before connecting or disconnecting the motor:

1. Always shut down the motor control application on the host board.

2. Disconnect the Multiaxis Motor Control Board from the mains supply.

3. Ensure the DC link capacitors are discharged.

4. Use the four-way screw terminal block to connect each motor. Ta bl e 3 lists motor

connectors.

Table 3. Motor Connectors

Cable Color

BiSS EnDat

PInk Grey 18

Grey Pink 19

Yellow Violet 14

Green Yellow 15

White Blue and brown/green 1

Brown White and white/green 20

Screw Terminal

(J9, J23, J37, J51)

Channel Motor Connector

0J2

1J16

2J30

3J44

5. Connect the motor to the screw terminal connector for the channel you intend to

use (Tab le 6 ).

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 4

Page 4 Functional Description

Functional Description

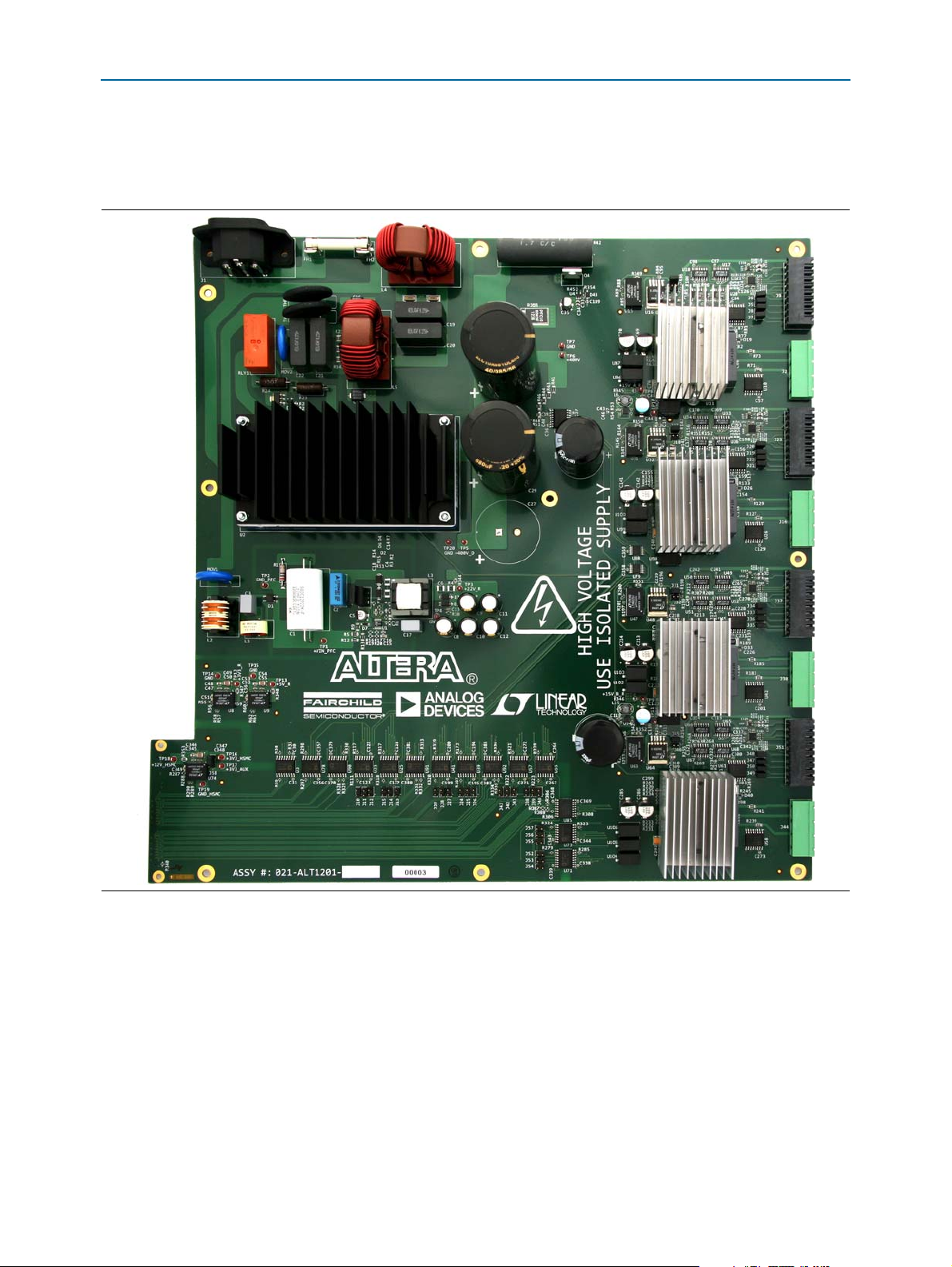

Figure 1 shows the Multiaxis Motor Control Board.

Figure 1. Multiaxis Motor Control Board

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 5

Functional Description Page 5

Isolated

22-V Supply

Low-Voltage

Logic Supplies

400-V

DC Link

Bootstrap

Circuit

IGBTs

x4 Channel

Encoder

Interface

Current and

Voltage

Sensing

Ballast/

Brake

Mains

Input

Digital I/O Isolators

HSMC

Motors

Encoders

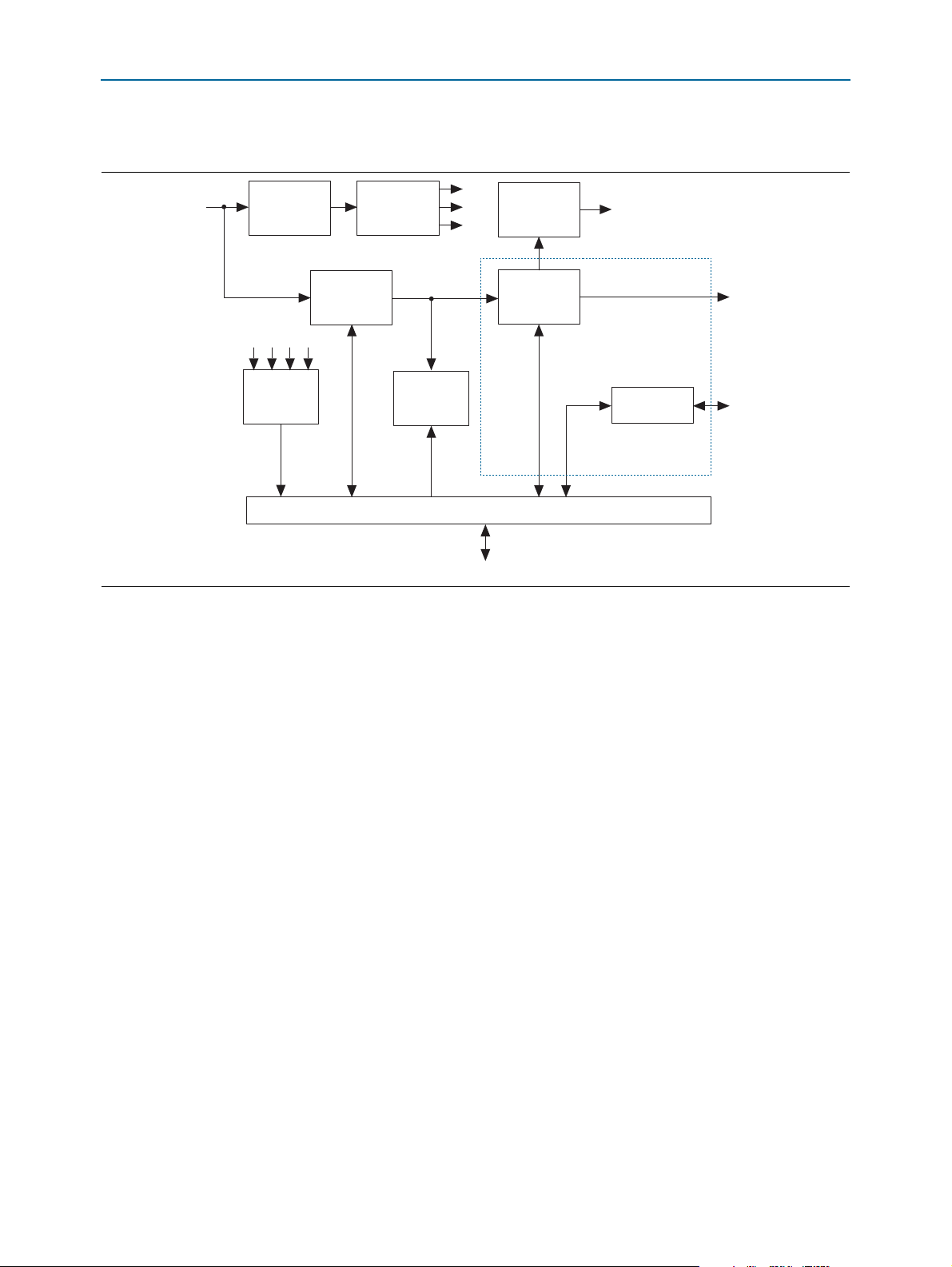

Figure 2 shows a high-level block diagram of the Multiaxis Motor Control Board.

Figure 2. Block Diagram

The following sections describe the functional blocks.

Digital I/O Isolators

Analog Devices ADuM1401 digital isolators isolate all digital I/O signals on the

Multiaxis Motor Control Board. They provide complete electrical isolation between

the host FPGA board and the power electronics on the Multiaxis Motor Control

Board. In some circuit locations, the board uses Silicon Labs Si8440 or Si8441 digital

isolators for their output behavior during power down, to prevent transient control

signals on the IGBT drivers.

One side of each isolator connects to the HSMC connector and takes power from the

HSMC connector. The other side of each isolator takes power from an isolated power

supply on the Multiaxis Motor Control Board.

Power Supplies

The Multiaxis Motor Control Board converts mains input to the DC link and a number

of lower voltages for logic and interfacing.

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 6

Page 6 Functional Description

PFC

Bus

Converter

EMI

Filter

~~+

_

400 V at 4 A

22 V at 1A

90 - 240 VAC

50/60 Hz

Emerson

400-V PFC

Module

Isolated

SD-ADC

20 MSPS

3.3 V

3.3 V

400 V at 4 A

Emerson

400-V PFC

Module

Isolated

SD-ADC

20 MSPS

Mains Input

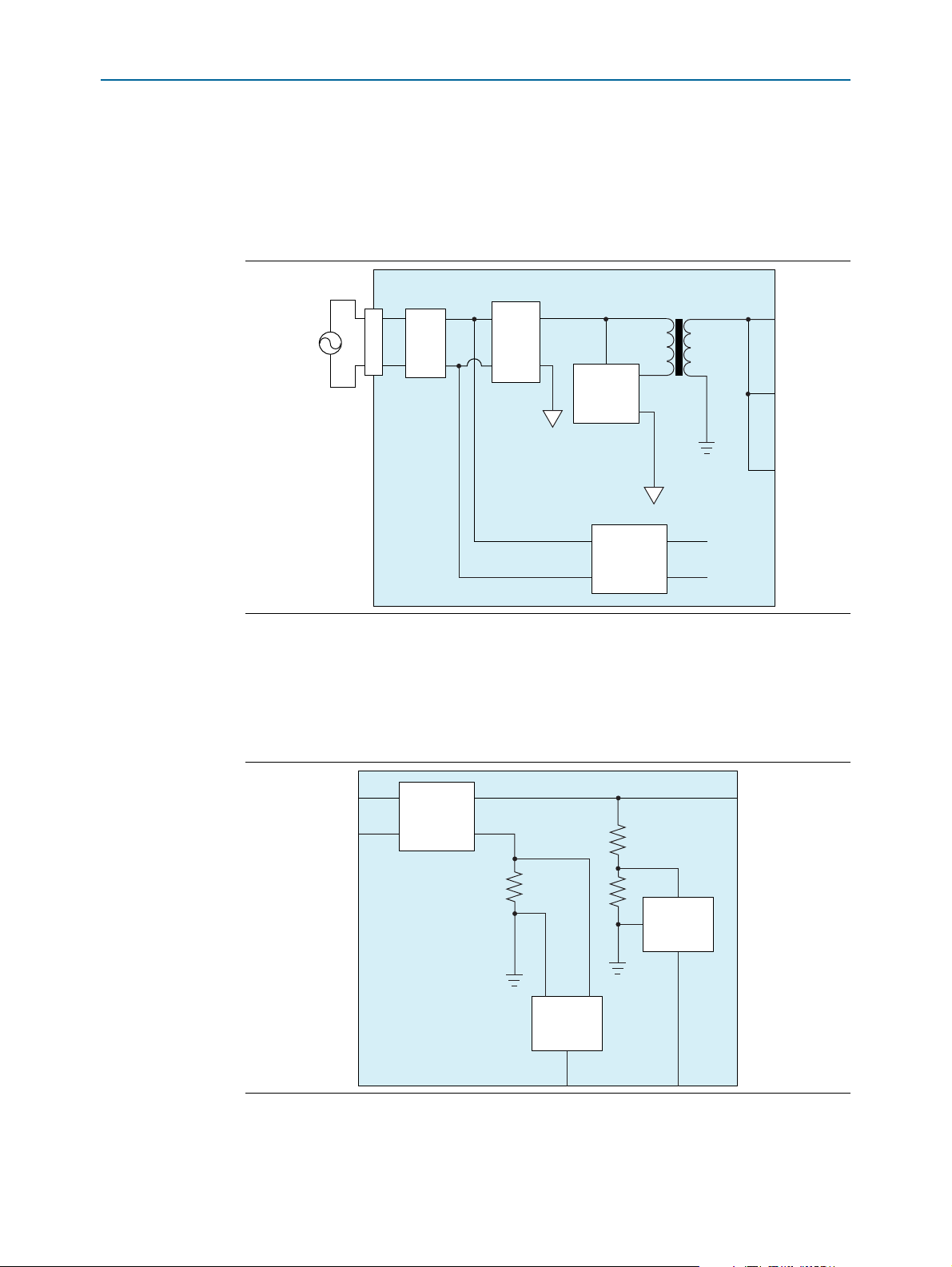

The Multiaxis Motor Control Board filters the mains input (Figure 3) and then splits to

the DC link and the 22-V power supply. Both power supplies incorporate PFC. The

Multiaxis Motor Control Board works with mains input voltages of 85 to 264 VAC, 50

or 60 Hz. The mains input includes an EMI filter.

Figure 3. Mains Input Filtering

DC Link and PFC

To provide unity power factor with very low-level harmonic distortion in line current,

an Emerson AIF04ZPFC-01L module produces the 400-V DC link voltage (Figure 4).

The PFC works over all typical line voltages used worldwide.

Figure 4. DC Link Voltage PFC Supply

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 7

Functional Description Page 7

The DC link can supply up to 1.5 kW in total, across all four motor channels with a

mains input of 240 V. At lower mains voltages, the Multiaxis Motor Control Board

reduces the maximum power. For example, 1 kW at 110 V input. Isolated sigma-delta

ADCs allow you to monitor the DC link voltage and current.

Isolated 22 V Supply

A Linear Technology LT3798 provides an isolated 22-V supply that feeds further

switch mode regulators to generate all of the required voltages on the Multiaxis Motor

Control Board.

15 V IGBT Gate Drive Supply

Two Linear Technology LTC3631EDD#PBF generate the 15-V supplies that the IGBT

modules require. One LTC361 supplies motor channels 0 and 1; the other one supplies

motor channels 2 and 3.

3.3 V and 5 V Logic Supplies

The 3.3-V and 5-V supplies for logic devices both use Linear Technology LTM8022

DC/DC micromodules.

Brake

3.3 V Isolator Supply

The isolators connected to the HSMC connector can receive power directly from the

HSMC 3.3-V pins or from the HSMC 12-V pin via a Linear Technology LTM8022

micromodule switch mode power supply.

Encoder Power Supplies

Each motor channel includes a power supply (LTM8025 micromodule) for the

encoder interface that you can configure for 3.3 V, 5 V, or 12 V as required by the

encoder.

The Multiaxis Motor Control Board includes incorporates a brake circuit with a

Fairchild FAN3111E gate driver, Fairchild FGP15N60 IGBT, and 100-Ohm brake

resistor.

During braking, the kinetic energy of the motor feeds back into the DC link circuit as

extra stored energy in the DC link capacitor. You can turn on the brake resistor to

dissipate excess energy and prevent the DC link voltage from rising too high.

The peak power dissipation in the brake resistor is:

2

V

/R = V

As the brake resistor is rated for only 20 W continuous power dissipation, only use it

for only a few milliseconds. The gate drive to the brake circuit is AC coupled.The

FPGA must drive a square wave on the

A steady signal, either high or low, results in the Power Supply turning off the brake.

Furthermore, the FPGA should implement some form of time out to prevent you from

activating the brake for too long.

DCLINK

2

/100 = 1.6 kW

HSMC_MOTOR_BRAKE

signal to activate the brake.

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 8

Page 8 Functional Description

The time constant of the AC coupling allows the brake resistor to be active for no

more than 1 ms if the

HSMC_MOTOR_BRAKE

signal remains asserted.

IGBTs

The Multiaxis Motor Control Board uses Fairchild FNB41560/B2 600V/15A smart

power modules for each of the four motor channels (Figure 5). These modules are

three-phase IGBT inverter bridges including control ICs for gate driving and

protection.

Murata MEE1S2415SC isolated DC/DC converters generate floating bootstrap

supplies for the gate drivers from the 15V supply. The bootstrap voltages also power

the ADCs that sample the motor current, via simple zener diode regulators.

The Multiaxis Motor Control Board uses software to ensure that the low side IGBT

activates long enough to produce the correct bootstrap voltage (refer to the Fairchild

AN-9070 Smart Power Module Motion-SPM Products Application Note). The bootstrap

capacitor for each channel on the Multiaxis Motor Control Board is 22 F.

Figure 5. IGBTs

Sigma-Delta Modulator ADCs

The Multiaxis Motor Control Board includes multiple Analog Devices AD7401

differential input sigma-delta modulators, each clocked at 20 MHz to monitor and

measure key voltage, current, and resolver output quantities. The Multiaxis Motor

Control Board uses isolated ADCs except the resolver encoder feedback conversion.

The Multiaxis Motor Control Board demodulates the bit streams from the ADCs in the

FPGA on the host board. The Multiaxis Motor Control Board isolates the digital

encoded data at the HSMC connector.

3-Phase

IGBT Inverter

500 W

Isolated

SD-ADC

20 MSPS

Isolated

SD-ADC

20 MSPS

Isolated

SD-ADC

20 MSPS

3.3 V

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 9

Functional Description Page 9

DC Link Monitor

The Multiaxis Motor Control Board measures the DC Link voltage, V

sensing the voltage across a resistor divider chain representing:

DCLINK,

by

82/199682 * V

DCLINK

For example, a voltage of 41 mV corresponds to a DC link voltage of 100 V. The

sigma-delta modulated reading is available on the HSMC connector

HSMC_ADC_400V_PFC_V_DATA

signal.

After filtering in the FPGA, the Multiaxis Motor Control Board calculates the DC link

voltage, according to the equation:

DC link voltage (V) = ADC value × 0.048

The reference design software uses an equivalent formula based on integer arithmetic.

The Multiaxis Motor Control Board measures the ground return current of the PFC by

sensing the voltage across a 0.01 Ohm resistor in the ground return path. The sigmadelta modulated reading is available on the HSMC connector

HSMC_ADC_400V_PFC_I_DATA

signal.

After filtering in the FPGA, the Multiaxis Motor Control Board calculates the the DC

link return current, according to the equation:

DC Link return current (mA) = ADC value × 1.95

The reference design software uses an equivalent formula based on integer arithmetic.

IGBT Return Current

The Multiaxis Motor Control Board measures the ground return currents of the IGBT

modules by sensing the voltage across 0.05 Ohm resistors in the ground return paths.

The sigma-delta modulated readings are available on the HSMC connector

DRV_x_HSMC_MOTOR_RTN_DATA_OUT

signals.

After filtering in the FPGA, the Multiaxis Motor Control Board calculates the IGBT

return current according to the equation:

I (mA) = ADC value × 0.195

The drive on chip reference design software uses an equivalent formula based on

integer arithmetic.

Motor Phase Currents

Currents are measured in two of the three phases, U and W, by sensing the voltages

across 0.05 Ohm shunt resistors in series with the motor connections. The Vin+

terminals of the ADCs are connected nearest the motor. The Vin– terminals of the

ADCs are connected nearest the IGBT module.

After filtering in the FPGA, the Multiaxis Motor Control Board calculates motor phase

current according to the equation:

I (mA) = ADC value × 0.195

The reference design software uses an equivalent formula based on integer arithmetic.

The sigma-delta modulated readings are available on the HSMC connector

DRV_x_HSMC_U_DATA_OUT

and

DRV_x_HSMC_W_DATA_OUT

signals.

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 10

Page 10 Functional Description

TI CDCLVC116

1:6 Buffers

Motor

Channel 0

ADCs

Total Current

& DC Link

ADCs

ADC

ADC Data

Feedback Clock

Isolator

HSMC

Connector

Motor

Channel 1

ADCs

Motor

Channel 2

ADCs

Motor

Channel 3

ADCs

The following equation calculates the current in the third, V, phase:

= –Iu –I

I

v

w

ADC Clock Tree

The 20-MHz ADC sample clock from the HSMC connector,

by a tree of CDCLVC1106 low-skew clock buffers (Figure 6).

To compensate for the isolator device propagation delays, the HSMC connector

provides a feedback clock,

CLK_HSMC_FEEDBACK

, to the FPGA. The Multiaxis Motor

Control Board compensates for the isolator propagation delays, but you must still

account for the part-to-part skew when creating I/O timing constraints for the FPGA

design.

Alternatively, you can use a PLL in the FPGA to create a phase shifted version of the

ADC clock for sampling the inputs.

Figure 6. Clock Tree

CLK_HSMC_ADC

, is buffered

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 11

Functional Description Page 11

5 V

3.3 V3.3 V3.3 V

3.3 V3.3 V

3.3 V

3.3 V

5 V5 V

3.3 V

3.3 V

x2

x2

6

6

6

SE to Diff

SD-ADC

10 MSPS

RS-485

Transceiver

RS-485

Transceiver

Isolator

RS-485

Transceiver

Isolator Isolator Isolator Isolator

2

2

2

2

2

2

6

Resolver

SinCos

Quadrature/

Hall Effect

M

EnDAT

BiSS

Hiperface

EnDat, BiSS, and

HiperFace DSL

Encoder Interfaces

Resolver Sine and Cosine

Encoder Interface

Quadrature and Hall Effect

Encoder Interface

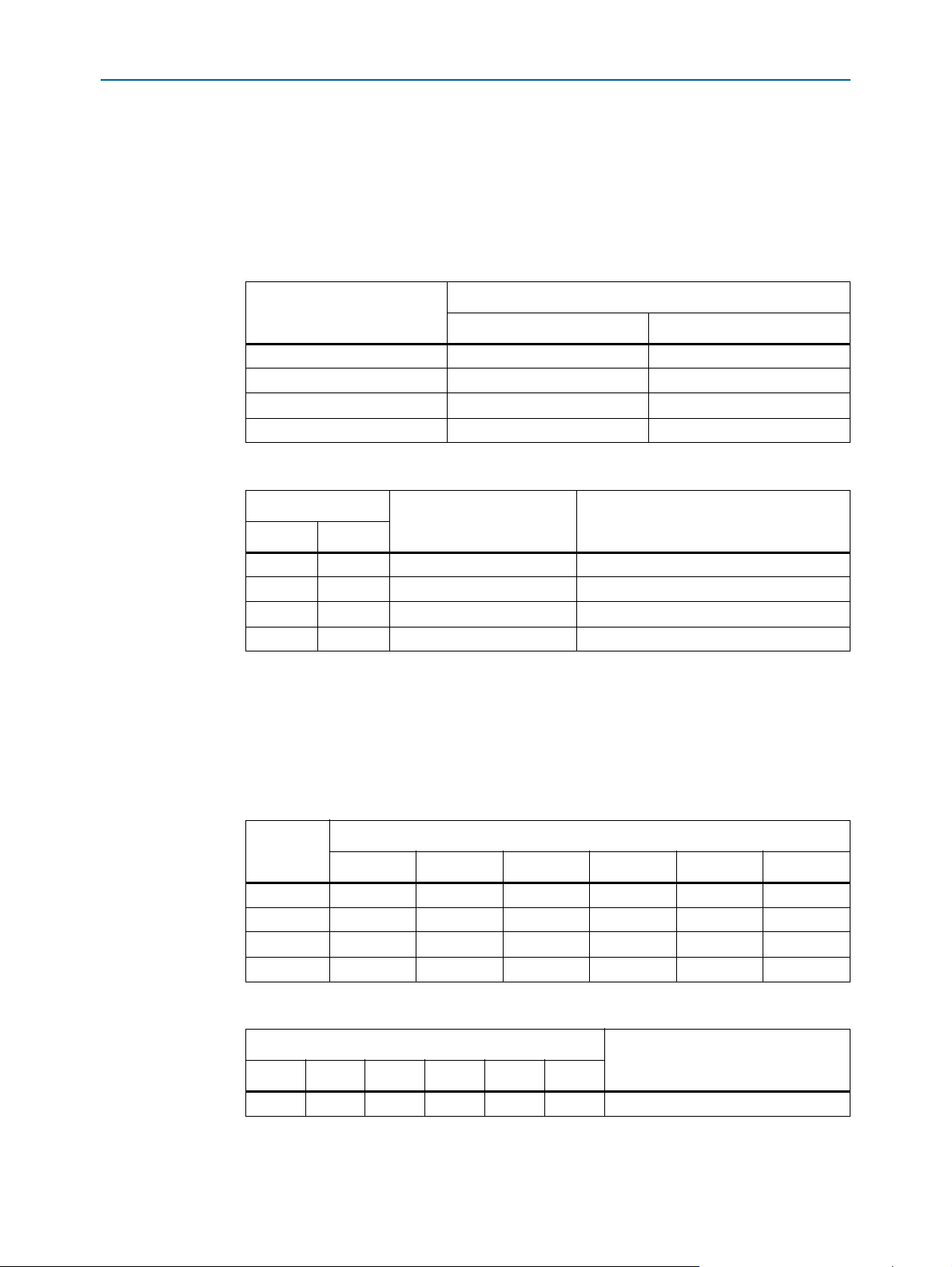

Tab le 4 lists the ADCs.

Table 4. ADCs

ADC Measured Quantity

DC-link monitor DC-link voltage 0.048

DC-link monitor DC-link current 1.95

IGBT return IGBT return current 0.195

Motor phase U Motor phase U current 0.195

Motor phase W Motor phase W current 0.195

Encoder Interfaces

Figure 7 shows the encoder interface.

Figure 7. Encoder Interface

Scaling

Factor

HSMC Signals

HSMC_ADC_400V_PFC_V_DATA

HSMC_ADC_400V_PFC_I_DATA

DRV_x_HSMC_MOTOR_RTN_DATA_OUT

DRV_x_HSMC_U_DATA_OUT

DRV_x_HSMC_W_DATA_OUT

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 12

Page 12 Functional Description

VDD

DE

D

R

RE

NC1

NC2

Y

Z

A

B

NC3

GND1

GND2

+5 V

J5

J6

J7

J8

DRV_0_RS485_EN

DRV_0_RS485_TX

DRV_0_RS485_RX

+5 V

DRV_0_SER_DATA_TX_P

DRV_0_SER_DATA_TX_N

DRV_0_SER_DATA_RX_P

DRV_0_SER_DATA_RX_N

LTC1687CS

DNP

330 pF

200 V

DNP

330 pF

200 V

56 R

56 R

4K7

16 V

0.1 µF

16 V

2.2 µF

EnDat, BiSS, HIPERFACE DSL Encoder Interface

The Multiaxis Motor Control Board supports connection of encoders with RS485

interfaces. You may configure each motor channel independently for any of the

encoder interface types.

Each encoder interface type requires you to implement the appropriate interface IP

cores in the FPGA on the host board. Altera partners provide appropriate IP cores

with the reference design.

The Multiaxis Motor Control Board includes different electrical termination schemes

for the encoder interfaces. Figure 8 shows an example a channel (channel 0) interface

termination. Capacitors C107 and C111 are not fitted, Resistors R103, R106 and

capacitor C109 are fitted. The jumpers allow for independent pairs for TX and RX or

one common pair. Refer to Tab le 11 for other channel jumper settings.

Figure 8. Encoder Interface Termination

Multiaxis Motor Control Board February 2014 Altera Corporation

Resolver Sine and Cosine Encoder Interface

The FPGA on the host board implements IP cores to drive the single-ended resolver

stimulus signal with a sigma-delta encoded 8-kHz sine wave. The Multiaxis Motor

Control Board converts and filters this signal to a differential drive for the resolver.

ADS1205 dual channel 10-MHz sigma-delta ADCs, with a ±2.5-V input range, clocked

at 20 MHz, digitize resolver encoder sine and cosine feedback signals. The ADS1205

divides the applied clock internally to generate the 10-Mbps data rate. The Multiaxis

Motor Control Board passes the resulting bitstreams through isolators for isolation.

Page 13

Functional Description Page 13

Quadrature and Hall Effect Encoder Interface

The Multiaxis Motor Control Board allows you to connect two- and three-channel

quadrature encoders with RS485 interfaces.

IP cores in the FPGA on the host board decode the encoder signals.

HSMC Connector

The HSMC connector allows you to connect the Multiaxis Motor Control Board to an

FPGA host board.

f For more information on the HSMC connector, refer to the High Speed Mezzanine Card

(HSMC) Specification.

Tab le 5 lists the pin assignments for the HSMC connector. I/O direction is relative to

the Multiaxis Motor Control Board: input indicates input to the Multiaxis Motor

Control Board from the host board; output indicates an output signal from the

Multiaxis Motor Control Board to the host board.

Table 5. HSMC Connector Pin Assignments

Pin Signal Direction Function

1 to 38 — — Not used.

39

40

41

42

43

44

45 3.3 V — Power.

46 12 V — Power.

47

48

49

50

51 3.3 V — Power.

52 12 V — Power.

53

54

55

56

57 3.3 V — Power.

58 12 V — Power.

59

60

CLK_HSMC_ADC

CLK_HSMC_FEEDBACK

400V_PFC_PFW

DRV_0_HSMC_DRV_WH

400V_PFC_LD_EN

DRV_0_HSMC_DRV_VH

HSMC_MOTOR_BRAKE

DRV_0_HSMC_DRV_UH

400V_PFC_PF_EN

DRV_0_HSMC_W_DATA_OUT

HSMC_ADC_400V_PFC_I_DATA

DRV_0_HSMC_MOTOR_RTN_DATA_OUT

HSMC_ADC_400V_PFC_V_DATA

DRV_0_HSMC_U_DATA_OUT

DRV_0_HSMC_RS485_TX

DRV_0_HSMC_RSLVR_DRV_HALL_QUAD_A

Input Clock input for sigma-delta ADCs.

Output

Output PFC power fail warning.

Input Channel 0 phase W high side.

Output PFC load enable.

Input Channel 0 phase V high side.

Input Brake (chopper) enable.

Input Channel 0 phase U high side.

Input PFC enable.

Output Channel 0 phase W ADC data.

Output PFC return current ADC data.

Output Channel 0 IGBT return current ADC data.

Output PFC voltage ADC data.

Output Channel 0 phase U ADC data.

Input Channel 0 RS485 encoder TX data.

Input/Output Encoder dependent.

Feedback clock compensating for isolator

delays.

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 14

Page 14 Functional Description

Table 5. HSMC Connector Pin Assignments

Pin Signal Direction Function

61

62

DRV_0_HSMC_RS485_EN

DRV_0_HSMC_RSLVR_COS_HALL_QUAD_B

Input Channel 0 RS485 encoder TX enable.

Output Encoder dependent.

63 3.3 V — Power.

64 12 V — Power.

65

66

67

68

CLK_DRV_0_HSMC_SER

DRV_0_HSMC_RSLVR_SIN_HALL_QUAD_C

DRV_0_HSMC_RS485_RX

DRV_0_HSMC_MOTOR_DRV_FAULT

Input Channel 0 encoder clock.

Output Encoder dependent.

Output Channel 0 RS485 encoder RX data.

Output Channel 0 IGBT fault status.

69 3.3 V — Power.

70 12 V — Power.

71

72

73

74

DRV_1_HSMC_RS485_TX

DRV_0_HSMC_DRV_WL

DRV_1_HSMC_RS485_EN

DRV_0_HSMC_DRV_VL

Input Channel 1 RS485 encoder TX data.

Input Channel 0 phase W low side.

Input Channel 0 RS485 encoder TX enable.

Input Channel 0 phase V low side.

75 3.3 V — Power.

76 12 V — Power.

77

78

79

80

CLK_DRV_1_HSMC_SER

DRV_0_HSMC_DRV_UL

DRV_1_HSMC_RS485_RX

DRV_1_HSMC_W_DATA_OUT

Input Channel 1 encoder clock.

Input Channel 0 phase U low side.

Output Channel 1 RS485 encoder RX data.

Output Channel 1 phase W ADC data.

81 3.3 V — Power.

82 12 V — Power.

83

84

85

86

DRV_1_HSMC_RSLVR_COS_HALL_QUAD_B

DRV_1_HSMC_MOTOR_RTN_DATA_OUT

DRV_1_HSMC_RSLVR_DRV_HALL_QUAD_A

DRV_1_HSMC_U_DATA_OUT

Output Encoder dependent.

Output Channel 1 IGBT return current ADC data.

Input/Output Encoder dependent..

Output Channel 1 phase U ADC data.

87 3.3 V — Power.

88 12 V — Power.

89

90

91

92

DRV_2_HSMC_RS485_EN

DRV_1_HSMC_MOTOR_DRV_FAULT

DRV_1_HSMC_RSLVR_SIN_HALL_QUAD_C

DRV_1_HSMC_DRV_WL

Input Channel 1 RS485 encoder TX enable.

Output Channel 1 IGBT fault status.

Output Encoder dependent.

Input Channel 1 phase W low side.

93 3.3 V — Power.

94 12 V — Power.

95

96

97

98

DRV_2_HSMC_RS485_TX

CLK_DRV_0_HSMC_ADC_OUT

DRV_2_HSMC_RS485_RX

CLK_DRV_1_HSMC_ADC_OUT

Input Channel 2 RS485 encoder TX data.

Output Channel 0 Resolver ADC output clock.

Output Channel 2 RS485 encoder RX data.

Output Channel 1 resolver ADC output clock.

99 3.3 V — Power.

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 15

Functional Description Page 15

Table 5. HSMC Connector Pin Assignments

Pin Signal Direction Function

100 12 V — Power.

101

102

103

104

DRV_2_HSMC_U_DATA_OUT

DRV_1_HSMC_DRV_VL

DRV_2_HSMC_MOTOR_RTN_DATA_OUT

DRV_1_HSMC_DRV_UL

Output Channel 2 phase U ADC data.

Input Channel 1 phase V low side.

Output Channel 2 IGBT return current ADC data.

Input Channel 1 phase U low side.

105 3.3 V — Power.

106 12 V — Power.

107

108

109

110

CLK_DRV_2_HSMC_SER

DRV_1_HSMC_DRV_WH

DRV_2_HSMC_W_DATA_OUT

DRV_1_HSMC_DRV_VH

Input Channel 2 encoder clock.

Input Channel 1 phase W high side.

Output Channel 2 phase W ADC data.

Input Channel 1 phase V high side.

111 3.3 V — Power.

112 12 V — Power.

113

114

115

116

DRV_2_HSMC_RSLVR_COS_HALL_QUAD_B

DRV_1_HSMC_DRV_UH

DRV_2_HSMC_RSLVR_DRV_HALL_QUAD_A

DRV_3_HSMC_RS485_RX

Output Encoder dependent.

Input Channel 1 phase U high side.

Input/Output Encoder dependent.

Output Channel 3 RS485 encoder RX data.

117 3.3 V — Power.

118 12 V — Power.

119

120

121

122

DRV_2_HSMC_DRV_WH

DRV_3_HSMC_RS485_TX

DRV_2_HSMC_RSLVR_SIN_HALL_QUAD_C

DRV_3_HSMC_RS485_EN

Input Channel 2 phase W high side.

Input Channel 3 RS485 encoder TX data.

Output Encoder dependent.

Input Channel 3 RS485 encoder TX enable.

123 3.3 V — Power.

124 12 V — Power.

125

126

127

128

DRV_2_HSMC_DRV_UH

DRV_3_HSMC_RSLVR_SIN_HALL_QUAD_C

DRV_2_HSMC_DRV_VH

DRV_3_HSMC_RSLVR_COS_HALL_QUAD_B

Input Channel 2 phase U high side.

Output Encoder dependent.

Input Channel 2 phase V high side.

Output Encoder dependent.

129 3.3 V — Power.

130 12 V — Power.

131

132

133

134

DRV_2_HSMC_DRV_WL

DRV_3_HSMC_RSLVR_DRV_HALL_QUAD_A

DRV_2_HSMC_MOTOR_DRV_FAULT

DRV_3_HSMC_MOTOR_DRV_FAULT

Input Channel 2 phase W low side.

Input/Output Encoder dependent.

Output Channel 2 IGBT fault status.

Output Channel 3 IGBT fault status.

135 3.3 V — Power.

136 12 V — Power.

137

138

DRV_2_HSMC_DRV_UL

DRV_3_HSMC_DRV_WL

Input Channel 2 phase U low side.

Input Channel 3 phase W low side.

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 16

Page 16 Functional Description

Table 5. HSMC Connector Pin Assignments

Pin Signal Direction Function

139

140

141 3.3 V — Power.

142 12 V — Power.

143

144

145

146

147 3.3 V — Power.

148 12 V — Power.

149

150

151

152

153 3.3 V — Power.

154 12 V — Power.

155 — — Not used.

156

157 — — Not used.

158

159 3.3 V — Power.

160

161 to

172

DRV_2_HSMC_DRV_VL

DRV_3_HSMC_DRV_VL

DRV_3_HSMC_DRV_VH

DRV_3_HSMC_DRV_UL

DRV_3_HSMC_DRV_UH

DRV_3_HSMC_W_DATA_OUT

CLK_DRV_3_HSMC_SER

DRV_3_HSMC_MOTOR_RTN_DATA_OUT

DRV_3_HSMC_DRV_WH

DRV_3_HSMC_U_DATA_OUT

CLK_DRV_2_HSMC_ADC_OUT

CLK_DRV_3_HSMC_ADC_OUT

PSNTn

0 V — Ground.

Input Channel 2 phase V low side.

Input Channel 3 phase V low side.

Input Channel 3 phase V high side.

Input Channel 3 phase U low side.

Input Channel 3 phase U high side.

Output Channel 3 phase W ADC data.

Input Channel 3 encoder clock.

Output Channel 3 IGBT return current ADC data.

Input Channel 3 phase W high side.

Output Channel 3 phase U ADC data.

Output Channel 2 resolver ADC output clock.

Output Channel 3 Resolver ADC output clock.

Input Presence.

Mains Input Fuse

A fuse, replacement part number LittleFuse 0324015 250V AC 15A, or equivalent

protects the mains input.

Motor Connectors

Tab le 6 lists the pin assignments for each channel.

Table 6. Motor Connector Pin Assignments

Pin Signal

1 Earth ground.

2 Motor phase U.

3 Motor phase V.

4 Motor phase W.

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 17

Functional Description Page 17

Encoder Connectors

Tab le 7 lists the pin assignments for each channel. Not every encoder type requires all

connections to be made.

You may link the TX and RX pairs on pins 16, 17 and 18, 19 by jumpers on the

Multiaxis Motor Control Board to create a single bidirectional data pair.

Table 7. Encoder Connector Pin Assignments

Pin Signal I/O Encoder Type(s) SIgnal

1 Supply — — —

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20 Ground — — —

DRV_x_SIN_DRV_P

DRV_x_SIN_DRV_N

DRV_x_RESOLVER_COS_N

DRV_x_RESOLVER_COS_P

DRV_x_RESOLVER_SIN_N

DRV_x_RESOLVER_SIN_P

DRV_x_HALL_QUAD_A_P

DRV_x_HALL_QUAD_A_N

DRV_x_HALL_QUAD_B_P

DRV_x_HALL_QUAD_B_N

DRV_x_HALL_QUAD_C_P

DRV_x_HALL_QUAD_C_N

CLK_DRV_x_SER_P

CLK_DRV_x_SER_N

DRV_x_SER_DATA_TX_P

DRV_x_SER_DATA_TX_N

DRV_x_SER_DATA_RX_P

DRV_x_SER_DATA_RX_N

O Resolver Stimulus+

O Resolver Stimulus–

I Resolver Cosine- signal

I Resolver Cosine+ signal

I Resolver Sine- signal

I Resolver Sine+ signal

I Hall, Quadrature Channel A+

I Hall, Quadrature Channel A–

I Hall, Quadrature Channel B+

I Hall, Quadrature Channel B–

I Hall, Quadrature Channel C+

I Hall, Quadrature Channel C–

O EnDat/BiSS/HIPERFACE Clock+

O EnDat/BiSS/HIPERFACE Clock–

O EnDat/BiSS/HIPERFACE TX+ data

O EnDat/BiSS/HIPERFACE TX– data

I EnDat/BiSS/HIPERFACE RX+ data

I EnDat/BiSS/HIPERFACE RX– data

Jumper Settings

Tab le 8 lists the jumpers.

Table 8. Jumpers

Jumper Function

J3 Channel 0 encoder power supply.

J4 Channel 0 encoder power supply.

J5 Channel 0 encoder RS485 data configuration.

J6 Channel 0 encoder RS485 data configuration.

J7 Channel 0 encoder RS485 data configuration.

J8 Channel 0 encoder RS485 data configuration.

J10 Channel 0 encoder interface selection.

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 18

Page 18 Functional Description

Table 8. Jumpers

Jumper Function

J11 Channel 0 encoder interface selection.

J12 Channel 0 encoder interface selection.

J13 Channel 0 encoder interface selection.

J14 Channel 0 encoder interface selection.

J15 Channel 0 encoder interface selection.

J17 Channel 1 encoder power supply.

J18 Channel 1 encoder power supply.

J19 Channel 1 encoder RS485 data configuration.

J20 Channel 1 encoder RS485 data configuration.

J21 Channel 1 encoder RS485 data configuration.

J22 Channel 1 encoder RS485 data configuration.

J24 Channel 1 encoder interface selection.

J25 Channel 1 encoder interface selection.

J26 Channel 1 encoder interface selection.

J27 Channel 1 encoder interface selection.

J28 Channel 1 encoder interface selection.

J29 Channel 1 encoder interface selection.

J31 Channel 2 encoder power supply.

J32 Channel 2 encoder power supply.

J33 Channel 2 encoder RS485 data configuration.

J34 Channel 2 encoder RS485 data configuration.

J35 Channel 2 encoder RS485 data configuration.

J36 Channel 2 encoder RS485 data configuration.

J38 Channel 2 encoder interface selection.

J39 Channel 2 encoder interface selection.

J40 Channel 2 encoder interface selection.

J41 Channel 2 encoder interface selection.

J42 Channel 2 encoder interface selection.

J43 Channel 2 encoder interface selection.

J45 Channel 3 encoder power supply.

J46 Channel 3 encoder power supply.

J47 Channel 3 encoder RS485 data configuration.

J48 Channel 3 encoder RS485 data configuration.

J49 Channel 3 encoder RS485 data configuration.

J50 Channel 3 encoder RS485 data configuration.

J52 Channel 3 encoder interface selection.

J53 Channel 3 encoder interface selection.

J54 Channel 3 encoder interface selection.

J55 Channel 3 encoder interface selection.

Multiaxis Motor Control Board February 2014 Altera Corporation

Page 19

Functional Description Page 19

Table 8. Jumpers

Jumper Function

J56 Channel 3 encoder interface selection.

J57 Channel 3 encoder interface selection.

J58 3.3V isolated power supply.

Encoder Power Supply

The Multiaxis Motor Control Board can supply 3.3V, 5V or 12V encoder power supply

voltages. You may configure each channel's encoder power supply independently.

Tab le 9 lists the jumpers to set for each channel. Ta b le 1 0 lists the jumper positions for

encoder power supplies. Out means fit no jumper; in means fit a jumper.

Table 9. Jumpers for Encoder Power Supply

Channel

0J3J4

1 J17 J18

2 J31 J32

3 J45 J46

Table 10. Encoder Power Supply Selection

Jumper Position

Voltage (V) Encoder

AB

Out Out 12 EnDat

Out In 3.3 —

In Out 5 EnDat, BiSS

In In Invalid —

Jumpers

AB

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 20

Page 20 Functional Description

Encoder RS485

For encoders that use an RS485 interface, configure the data pins for full-duplex

operation with combined TX and RX data or half-duplex operation with separate TX

and RX data. You may configure each channel independently. Ta ble 11 lists the

jumpers to set for each channel. Tabl e 12 lists the jumper positions for encoder RS485s.

Out means fit no jumper; in means fit a jumper.

Table 11. Jumpers for Each Channel for Encoder RS485 Data Configuration

Channel

AB

0 J5, J6 J7, J8

1 J19, J20 J21, J22

2 J33, J34 J35, J36

3 J47, J48 J49, J50

Table 12. Encoder RS485 Data Configuration

Jumper Position

Data Configuration Encoder

Ab

Out Out RX only. —

Out In Bidirectional on RX pair. EnDat

In Out Separate RX and TX. —

In In Bidirectional on TX pair. —

Jumpers

Encoder Interface

The Multiaxis Motor Control Board supports RS485, resolver, Hall effect and

quadrature encoders. You can configure each channel independently to support one

of these encoder standards at any one time. Tab le 1 3 lists the jumpers to set for each

channel. Ta bl e 1 4 lists the jumper positions for encoder interface selection.

Table 13. Jumpers for Each Channel for Encoder Selection

Channel

ABCDEF

0 J10 J11 J12 J13 J14 J15

1 J24 J25 J26 J27 J28 J29

2 J38 J39 J40 J41 J42 J43

3 J52 J53 J54 J55 J56 J57

Table 14. Encoder Interface Selection

Jumper Positions

ABCDEF

In In In Out Out Out Resolver.

Multiaxis Motor Control Board February 2014 Altera Corporation

Jumpers

Encoder Interface

Page 21

References Page 21

Table 14. Encoder Interface Selection

Jumper Positions

ABCDEF

Out Out Out In In In Hall effect, quadrature.

All other combinations Invalid.

The function of the three

DRV_x_HSMC_RSLVR_DRV_HALL_QUAD_y

Encoder Interface

signals on the HSMC

changes according to the jumper settings for resolver (Tab le 1 5) and Hall effect and

quadrature (Tab le 1 6).

Table 15. Resolver Interface Signals

Signal Direction Function

DRV_x_HSMC_RSLVR_DRV_HALL_QUAD_A

DRV_x_HSMC_RSLVR_COS_HALL_QUAD_B

DRV_x_HSMC_RSLVR_SIN_HALL_QUAD_C

Table 16. Hall Effect and Quadrature Signals

Signal Direction Function

DRV_x_HSMC_RSLVR_DRV_HALL_QUAD_A

DRV_x_HSMC_RSLVR_COS_HALL_QUAD_B

DRV_x_HSMC_RSLVR_SIN_HALL_QUAD_C

Input Resolver drive.

Output Resolver cosine ADC bitstream.

Output Resolver sine ADC bitstream.

Output Channel A.

Output Channel B.

Output Channel C.

HSMC Isolator Power Supply

References

You may source the power supply for the host FPGA board side of the isolators

directly from the HSMC 3.3-V supply or derive it from the HSMC 12-V supply by a

switching regulator module (Tab le 1 7). This feature allows for situations where

insufficient power is available from one or the other of the HSMC supplies.

Table 17. Isolator Isolated Power Supply

J58 Pins Linked Isolator 3.3V_ISO Power Supply

1 to 2 3.3-V auxiliary from HSMC 12 V via LTM8022 module.

2 to 3 Direct from HSMC 3/3 V.

■ Altera HSMC Specification

■ Altera Multiaxis Motor Control Board Schematics

■ Astec AIF – PFC 1600W AC-DC Converter Module Technical Reference Note

■ Fairchild FNB41560/B2 Smart Power Module Data Sheet

■ Fairchild AN-9070 Smart Power Module Motion-SPM Products Application Note

■ Analog Devices AD7401 Isolated Sigma-Delta Modulator Data Sheet

Multiaxis Motor Control BoardFebruary 2014 Altera Corporation

Page 22

Page 22 Document Revision History

■ Analog Devices ADS1205 Two 1-Bit, 10MHz, 2nd-Order, Delta-Sigma Modulator A-to-

D Converter Data Sheet

■ Analog Devices ADuM1401 Quad-Channel Digital Isola2014tors Data Sheet

■ Silicon Laboratories Si844x Digital Isolators Data Sheet

Document Revision History

Tab le 1 8 lists the revision history for this document.

Table 18. Document Revision History

Date Version Changes

February 2014 1.1 Replaced iCouplers with isolators.

August 2012 1.0 Initial release.

Multiaxis Motor Control Board February 2014 Altera Corporation

Loading...

Loading...