Page 1

MAX II Device Handbook

101 Innovation Drive

San Jose, CA 95134

www.alter a.com

MII5V1-3.3

Page 2

Copyright © 2009 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific device designations, and all other

words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the trademarks and service marks of Altera Corporation in the U.S. and other

countries. All other product or service names are the property of their respective holders. Altera products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights, and copyrights. Altera warrants performance of its semiconductor products to current specifications in accordance with Altera's standard warranty,

but reserves the right to make changes to any products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of

any information, product, or service described herein except as expressly agreed to in writing by Altera Corporation. Altera customers are advised to obtain the latest version of

device specifications before relying on any published information and before placing orders for products or services

.

Page 3

Contents

Chapter Revision Dates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

About this Handbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .About–xiii

How to Contact Altera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–xiii

Typographic Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–xiii

Section I. MAX II Device Family Data Sheet

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–1

Chapter 1. Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Chapter 2. MAX II Architecture

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Logic Array Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

LAB Interconnects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

LAB Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Logic Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

LUT Chain and Register Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

addnsub Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

LE Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Dynamic Arithmetic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Carry-Select Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

Clear and Preset Logic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

MultiTrack Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Global Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–16

User Flash Memory Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–18

UFM Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–19

Internal Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

Program, Erase, and Busy Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

Auto-Increment Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

UFM Block to Logic Array Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

MultiVolt Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–22

© August 2009 Altera Corporation MAX II Device Handbook

Page 4

iv

I/O Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–23

Fast I/O Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–23

I/O Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–24

I/O Standards and Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–26

PCI Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–28

Schmitt Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

Output Enable Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

Programmable Drive Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–29

Slew-Rate Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–30

Open-Drain Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–30

Programmable Ground Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–30

Bus Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

Programmable Pull-Up Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

Programmable Input Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

MultiVolt I/O Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–31

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–32

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–33

Chapter 3. JTAG and In-System Programmability

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

IEEE Std. 1149.1 (JTAG) Boundary-Scan Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

JTAG Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Parallel Flash Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

In System Programmability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

IEEE 1532 Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Jam Standard Test and Programming Language (STAPL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Programming Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

UFM Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

In-System Programming Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Real-Time ISP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Design Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Programming with External Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Chapter 4. Hot Socketing and Power-On Reset in MAX II Devices

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

MAX II Hot-Socketing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Devices Can Be Driven before Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

I/O Pins Remain Tri-Stated during Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Signal Pins Do Not Drive the V

CCIO

or V

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

CCINT

AC and DC Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Hot Socketing Feature Implementation in MAX II Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Power-On Reset Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Power-Up Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

Chapter 5. DC and Switching Characteristics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

MAX II Device Handbook © August 2009 Altera Corporation

Page 5

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Programming/Erasure Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

DC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Output Drive Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

I/O Standard Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

Bus Hold Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–7

Power-Up Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–8

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–8

Timing Model and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–8

Preliminary and Final Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–9

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–10

Internal Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–11

External Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–18

External Timing I/O Delay Adders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–21

Maximum Input and Output Clock Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–24

JTAG Timing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–25

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–26

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–27

v

Chapter 6. Reference and Ordering Information

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Device Pin-Outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Section II. PCB Layout Guidelines

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II–1

Chapter 7. Package Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Board Decoupling Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Device and Package Cross Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Thermal Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Package Outlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

68-Pin Micro FineLine Ball-Grid Array (MBGA) – Wire Bond . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

100-Pin Plastic Thin Quad Flat Pack (TQFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–5

100-Pin Micro FineLine Ball-Grid Array (MBGA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–7

100-Pin FineLine Ball-Grid Array (FBGA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

144-Pin Plastic Thin Quad Flat Pack (TQFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–10

144-Pin Micro FineLine Ball-Grid Array (MBGA) – Wire Bond . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–12

256-Pin Micro FineLine Ball-Grid Array (MBGA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

256-Pin FineLine Ball-Grid Array (FBGA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–15

324-Pin FineLine Ball-Grid Array (FBGA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–16

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–18

Chapter 8. Using MAX II Devices in Multi-Voltage Systems

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

I/O Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

MultiVolt Core and I/O Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–3

5.0-V Device Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–3

© August 2009 Altera Corporation MAX II Device Handbook

Page 6

vi

Recommended Operating Condition for 5.0-V Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–7

Hot Socketing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–8

Power-Up Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–8

Power-On Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–8

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–8

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

Section III. User Flash Memory

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III–1

Chapter 9. Using User Flash Memory in MAX II Devices

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

UFM Array Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

Memory Organization Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

Using and Accessing UFM Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–2

UFM Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–3

UFM Address Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–5

UFM Data Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–5

UFM Program/Erase Control Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–6

Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–6

Instantiating the Oscillator without the UFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–7

UFM Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–9

Read/Stream Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–9

Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–10

Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–11

Programming and Reading the UFM with JTAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–12

Jam Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–12

Jam Players . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–12

Software Support for UFM Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–13

Inter-Integrated Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–14

I2C Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–14

Device Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–16

Byte Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–16

Page Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–17

Write Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–17

Erase Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–18

Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–20

ALTUFM I2C Interface Timing Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–22

Instantiating the I2C Interface Using the Quartus II altufm Megafunction . . . . . . . . . . . . . . . . . 9–22

Serial Peripheral Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–24

Opcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–25

ALTUFM SPI Timing Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–34

Instantiating SPI Using Quartus II altufm Megafunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–35

Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–36

ALTUFM Parallel Interface Timing Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–37

Instantiating Parallel Interface Using Quartus II altufm Megafunction . . . . . . . . . . . . . . . . . . . . 9–38

None (Altera Serial Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–39

Instantiating None Using Quartus II altufm Megafunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–39

Creating Memory Content File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–40

Memory Initialization for the altufm_parallel Megafunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–43

Memory Initialization for the altufm_spi Megafunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–43

Memory Initialization for the altufm_i2c Megafunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–44

MAX II Device Handbook © August 2009 Altera Corporation

Page 7

Simulation Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–46

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–46

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–47

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–47

Chapter 10. Replacing Serial EEPROMs with MAX II User Flash Memory

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–1

Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–1

List of Vendors and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–2

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–11

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–11

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–12

Section IV. In-System Programmability

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IV–1

Chapter 11. In-System Programmability Guidelines for MAX II Devices

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

General ISP Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

ISP Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

Input Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–2

UFM Operations During In-System Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–2

Interrupting In-System Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–3

MultiVolt Devices and Power-Up Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–3

V

Powered before V

CCIO

I/O Pins Tri-Stated during In-System Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–3

Pull-Up and Pull-Down of JTAG Pins During In-System Programming . . . . . . . . . . . . . . . . . . . . . 11–4

IEEE Std. 1149.1 Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–4

TCK Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–4

Programming via a Download Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–5

Disabling IEEE Std. 1149.1 Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–5

Working with Different Voltage Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–6

Sequential versus Concurrent Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–6

Sequential Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–6

Concurrent Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–6

ISP Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–7

Invalid ID and Unrecognized Device Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–7

Download Cable Connected Incorrectly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–7

TDO Is Not Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–8

Incomplete JTAG Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–8

Noisy TCK Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–8

Jam Player Ported Incorrectly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–8

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–8

Verify the JTAG Chain Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–8

Check the VCC Level of the Board During In-System Programming . . . . . . . . . . . . . . . . . . . . . . . 11–9

Power-Up Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–9

Random Signals on JTAG Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–9

Software Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–9

ISP via Embedded Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–9

Processor and Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–9

Porting the Jam Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–10

ISP via In-Circuit Testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–3

CCINT

vii

© August 2009 Altera Corporation MAX II Device Handbook

Page 8

viii

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–10

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–10

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–11

Chapter 12. Real-Time ISP and ISP Clamp for MAX II Devices

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–1

Real-Time ISP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–1

How Real-Time ISP Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–1

Real-Time ISP with the Quartus II Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–2

Real-Time ISP with Jam and JBC Players . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–4

ISP Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–4

How ISP Clamp Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–5

Using ISP Clamp in the Quartus II Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–5

Using the IPS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–6

Defining the Pin States in Assignment Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–9

ISP Clamp with Jam/JBC Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–10

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–10

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–10

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–11

Chapter 13. IEEE 1149.1 (JTAG) Boundary-Scan Testing for MAX II Devices

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–1

IEEE Std. 1149.1 BST Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–2

IEEE Std. 1149.1 Boundary-Scan Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–3

Boundary-Scan Cells of a MAX II Device I/O Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–4

JTAG Pins and Power Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–5

IEEE Std. 1149.1 BST Operation Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–6

SAMPLE/PRELOAD Instruction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–9

EXTEST Instruction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–11

BYPASS Instruction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–13

IDCODE Instruction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–14

USERCODE Instruction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–14

CLAMP Instruction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–14

HIGHZ Instruction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–14

I/O Voltage Support in JTAG Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–15

BST for Programmed Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–15

Disabling IEEE Std. 1149.1 BST Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–16

Guidelines for IEEE Std. 1149.1 Boundary-Scan Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–16

Boundary-Scan Description Language (BSDL) Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–17

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–17

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–17

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–18

Chapter 14. Using Jam STAPL for ISP via an Embedded Processor

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–1

Embedded Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–1

Connecting the JTAG Chain to the Embedded Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–1

Example Interface PLD Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–2

Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–3

TCK Signal Trace Protection and Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–4

Pull-Down Resistors on TCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–4

JTAG Signal Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–4

External Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–4

MAX II Device Handbook © August 2009 Altera Corporation

Page 9

Software Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–4

Jam Files (.jam and .jbc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–5

ASCII Text Files (.jam) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–5

Jam Byte-Code Files (.jbc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–5

Generating Jam Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–5

Using Jam Files with the MAX II User Flash Memory Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–7

Jam Players . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–7

Jam Player Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–7

The Jam STAPL Byte-Code Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–7

Porting the Jam STAPL Byte-Code Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–8

Jam STAPL Byte-Code Player Memory Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–11

Updating Devices Using Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–14

MAX II Jam/JBC Actions and Procedure Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–15

Running the Jam STAPL Byte-Code Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–17

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–18

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–18

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–19

Chapter 15. Using the Agilent 3070 Tester for In-System Programming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–1

New PLD Product for Agilent 3070 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–1

Device Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–1

Agilent 3070 Development Flow without the PLD ISP Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–2

Step 1: Create a PCB and Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–3

Creating the PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–3

Creating the Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–3

Step 2: Create a Serial Vector Format File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–4

Step 3: Convert SVF Files to PCF Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–5

Step 4: Create Executable Tests from Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–5

Create the Library for the Target Device or Scan Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–5

Run the Test Consultant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–6

Create Digital Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–6

Create the Wirelist Information for the Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–6

Modify the Test Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–6

Step 5: Compile the Executable Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–7

Step 6: Debug the Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–7

Development Flow for Agilent 3070 with PLD ISP Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–8

Programming Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–10

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–10

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–11

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–11

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15–11

ix

Section V. Design Considerations

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V–1

Chapter 16. Understanding Timing in MAX II Devices

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–1

External Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–1

Internal Timing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–2

Internal Timing Parameters for MAX II UFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–3

Timing Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–4

© August 2009 Altera Corporation MAX II Device Handbook

Page 10

x

Calculating Timing Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–5

Setup and Hold Time from an I/O Data and Clock Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–6

Programmable Input Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–7

Timing Model versus Quartus II Timing Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–7

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–8

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–8

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16–8

Chapter 17. Understanding and Evaluating Power in MAX II Devices

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–1

Power in MAX II Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–1

MAX II Power Estimation Using the PowerPlay Early Power Estimator . . . . . . . . . . . . . . . . . . . . . . . . 17–3

PowerPlay Early Power Estimator Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–3

Input Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–4

Clock Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–5

Logic Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–6

UFM Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–8

I/O Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–8

Other Input Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–11

Set Toggle % . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–11

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–12

Importing the Quartus II Early Power Estimator File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–12

Power Estimation Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–13

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–13

Thermal Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–14

Power Supply Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–15

Power Saving Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–15

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–16

Referenced Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–16

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17–17

MAX II Device Handbook © August 2009 Altera Corporation

Page 11

Chapter Revision Dates

The chapters in this book, MAX II Device Handbook, were revised on the following

dates. Where chapters or groups of chapters are available separately, part numbers are

listed.

Chapter 1 Introduction

Revised: August 2009

Part Number: MII51001-1.9

Chapter 2 MAX II Architecture

Revised: October 2008

Part Number: MII51002-2.2

Chapter 3 JTAG and In-System Programmability

Revised: October 2008

Part Number: MII51003-1.6

Chapter 4 Hot Socketing and Power-On Reset in MAX II Devices

Revised: October 2008

Part Number: MII51004-2.1

Chapter 5 DC and Switching Characteristics

Revised: August 2009

Part Number: MII51005-2.5

Chapter 6 Reference and Ordering Information

Revised: August 2009

Part Number: MII51006-1.6

Chapter 7 Package Information

Revised: October 2008

Part Number: MII51007-2.1

Chapter 8 Using MAX II Devices in Multi-Voltage Systems

Revised: October 2008

Part Number: MII51009-1.7

Chapter 9 Using User Flash Memory in MAX II Devices

Revised: October 2008

Part Number: MII51010-1.8

Chapter 10 Replacing Serial EEPROMs with MAX II User Flash Memory

Revised: October 2008

Part Number: MII51012-1.5

Chapter 11 In-System Programmability Guidelines for MAX II Devices

Revised: October 2008

Part Number: MII51013-1.7

Chapter 12 Real-Time ISP and ISP Clamp for MAX II Devices

© August 2009 Altera Corporation MAX II Device Handbook

Page 12

xii

Revised: October 2008

Part Number: MII51019-1.6

Chapter 13 IEEE 1149.1 (JTAG) Boundary-Scan Testing for MAX II Devices

Revised: October 2008

Part Number: MII51014-1.7

Chapter 14 Using Jam STAPL for ISP via an Embedded Processor

Revised: October 2008

Part Number: MII51015-1.8

Chapter 15 Using the Agilent 3070 Tester for In-System Programming

Revised: October 2008

Part Number: MII51016-1.5

Chapter 16 Understanding Timing in MAX II Devices

Revised: October 2008

Part Number: MII51017-2.1

Chapter 17 Understanding and Evaluating Power in MAX II Devices

Revised: October 2008

Part Number: MII51018-2.1

MAX II Device Handbook © August 2009 Altera Corporation

Page 13

This handbook provides comprehensive information about the Altera® MAX® II

family of devices.

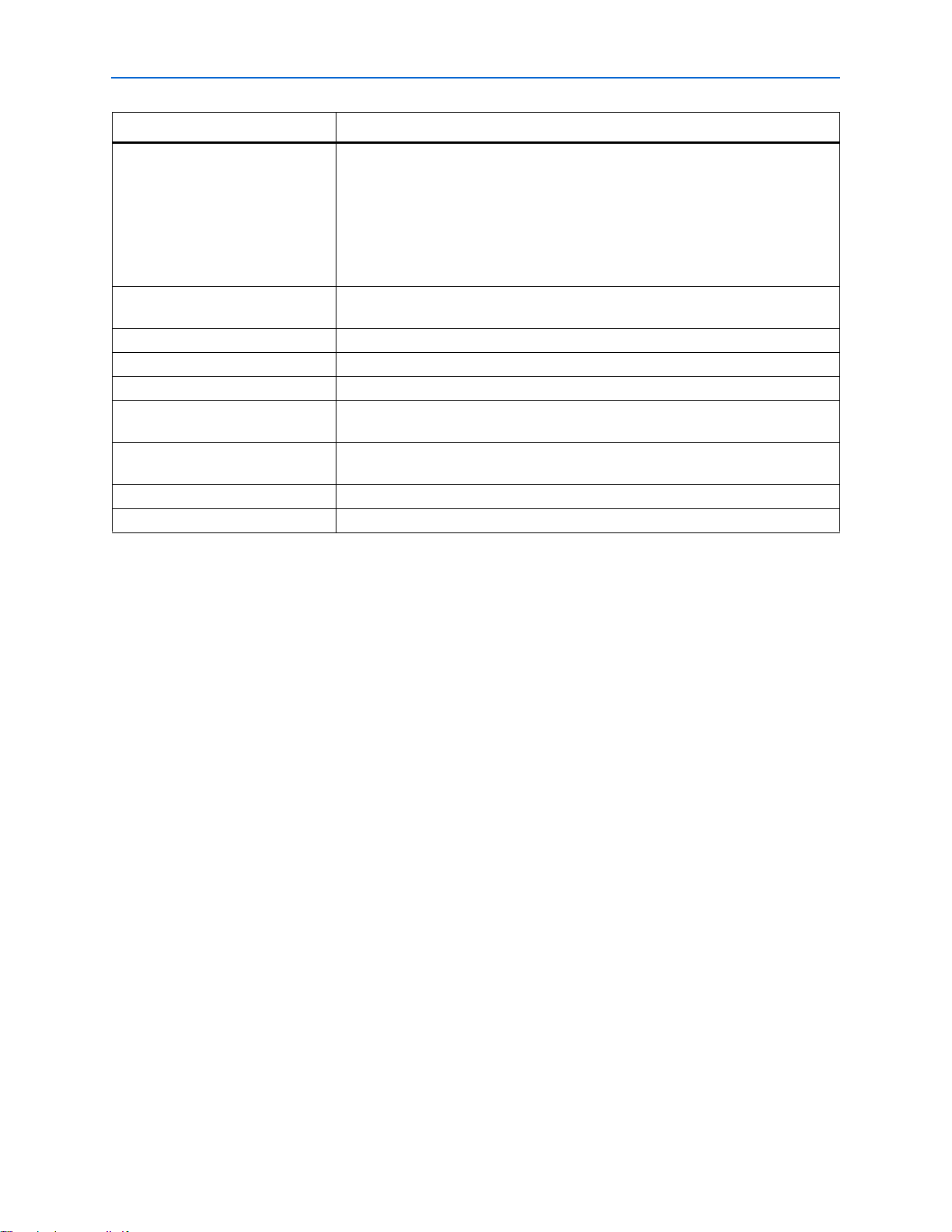

How to Contact Altera

For the most up-to-date information about Altera products, refer to the following

table.

Contact (Note 1)

Technical support Website www.altera.com/support

Technica l training Website www.altera.com/training

Altera literature services Email literature@altera.com

Non-technical support (General) Email nacomp@altera.com

(Soft ware Licensing) Email authorization@altera.com

Note:

(1) You can also contact your local Altera sales office or sales representative.

About this Handbook

Contact

Method Address

Email custrain@altera.com

Typographic Conventions

This document uses the typographic conventions shown in the following table.

Visual Cue Meaning

Bold Type with Initial Capital

Letters

bold t ype Exter nal timing parameters, dir ectory names, project names, disk drive names, file

Italic Type with Initial Capital Letters Document titles are shown in italic type with initial capital letters. Example: AN 75:

Italic type Internal timing paramet ers and variables are shown in italic type.

Initial Capital Letters Keyboard keys and menu names are shown with initial capital letters. Examples:

“Subheading Title” References to sections within a document and titles of on-line help topics are shown

Command names, dialog box titles, checkbox options, and di alog box options ar e

shown in bol d, initial capita l let ters. Example: Save As dialog box.

names, file name extensions, and software utility names are shown in bold type.

Examples: f

High-Speed Board Design.

Examples: t

Variable names are enclosed in angle brackets (< >) and shown in italic type.

Example: <file name>, <project name>.pof file.

Delete key, the Op tions menu.

in quotation marks. Example: “Typographic Conventions.”

, \qdesigns director y, d: drive, chiptrip.gdf file.

MAX

, n + 1.

PIA

© August 2009 Altera Corporation MAX II Device Handbook

Page 14

xiv

Typographic Conventions

Visual Cue Meaning

Courier type Signal and port names are shown in lowercase Courier type. Exampl es: data1, tdi,

input. Active-low signals are denoted by suffix n, e.g., resetn.

Anything that must be typed exactly as it appears is shown in Couri er type. For

example:

c:\qdesigns\tutorial\chiptrip.gdf. Also, sections of an actual

file, such as a Report File, references to parts of files (e.g., the AHDL keyword

SUBDESIGN), as well as logic function names (e.g., TRI) are shown in Courier.

1., 2., 3., and

a., b., c., etc.

■ ■ Bullets are used in a list of items when the sequence of the items is not important.

Numbered steps are used in a list of items when the sequence of the items is

important, such as the steps listed in a procedure.

v The checkmark indicates a procedure that consist s of one step only.

1 The hand points to information that requires special attention.

c

w

A caution calls attention to a condition or possible situation that can damage or

destroy the product or the user’s work.

A warning calls attention to a condition or possible situation that can cause injury to

the user.

r The angled arrow indicates you should pr ess the Enter key.

f The feet direct you to more information on a particular topic.

MAX II Device Handbook © August 2009 Altera Corporation

Page 15

Section I. MAX II Device Family Data

Sheet

This section provides designers with the data sheet specifications for MAX® II devices.

The chapters contain feature definitions of the internal architecture, Joint Test Action

Group (JTAG) and in-system programmability (ISP) information, DC operating

conditions, AC timing parameters, and ordering information for MAX II devices.

This section includes the following chapters:

■ Chapter 1, Introduction

■ Chapter 2, MAX II Architecture

■ Chapter 3, JTAG and In-System Programmability

■ Chapter 4, Hot Socketing and Power-On Reset in MAX II Devices

■ Chapter 5, DC and Switching Characteristics

■ Chapter 6, Reference and Ordering Information

Revision History

Refer to each chapter for its own specific revision history. For information about when

each chapter was updated, refer to the Chapter Revision Dates section, which appears

in the complete handbook.

© August 2009 Altera Corporation MAX II Device Handbook

Page 16

I–2 Section I: MAX II Device Family Data Sheet

Revision History

MAX II Device Handbook © August 2009 Altera Corporation

Page 17

MII51001-1.9

Introduction

Features

1. Introduction

The MAX® II family of instant-on, non-volatile CPLDs is based on a 0.18-µm,

6-layer-metal-flash process, with densities from 240 to 2,210 logic elements (LEs) (128

to 2,210 equivalent macrocells) and non-volatile storage of 8 Kbits. MAX II devices

offer high I/O counts, fast performance, and reliable fitting versus other CPLD

architectures. Featuring MultiVolt core, a user flash memory (UFM) block, and

enhanced in-system programmability (ISP), MAX II devices are designed to reduce

cost and power while providing programmable solutions for applications such as bus

bridging, I/O expansion, power-on reset (POR) and sequencing control, and device

configuration control.

The MAX II CPLD has the following features:

■ Low-cost, low-power CPLD

■ Instant-on, non-volatile architecture

■ Standby current as low as 25 µA

■ Provides fast propagation delay and clock-to-output times

■ Provides four global clocks with two clocks available per logic array block (LAB)

■ UFM block up to 8 Kbits for non-volatile storage

■ MultiVolt core enabling external supply voltages to the device of either

3.3 V/2.5 V or 1.8 V

■ MultiVolt I/O interface supporting 3.3-V, 2.5-V, 1.8-V, and 1.5-V logic levels

■ Bus-friendly architecture including programmable slew rate, drive strength,

bus-hold, and programmable pull-up resistors

■ Schmitt triggers enabling noise tolerant inputs (programmable per pin)

■ I/Os are fully compliant with the Peripheral Component Interconnect Special

Interest Group (PCI SIG) PCI Local Bus Specification, Revision 2.2 for 3.3-V

operation at 66 MHz

■ Supports hot-socketing

■ Built-in Joint Test Action Group (JTAG) boundary-scan test (BST) circuitry

compliant with IEEE Std. 1149.1-1990

■ ISP circuitry compliant with IEEE Std. 1532

© August 2009 Altera Corporation MAX II Device Handbook

Page 18

1–2 Chapter 1: Introduction

Features

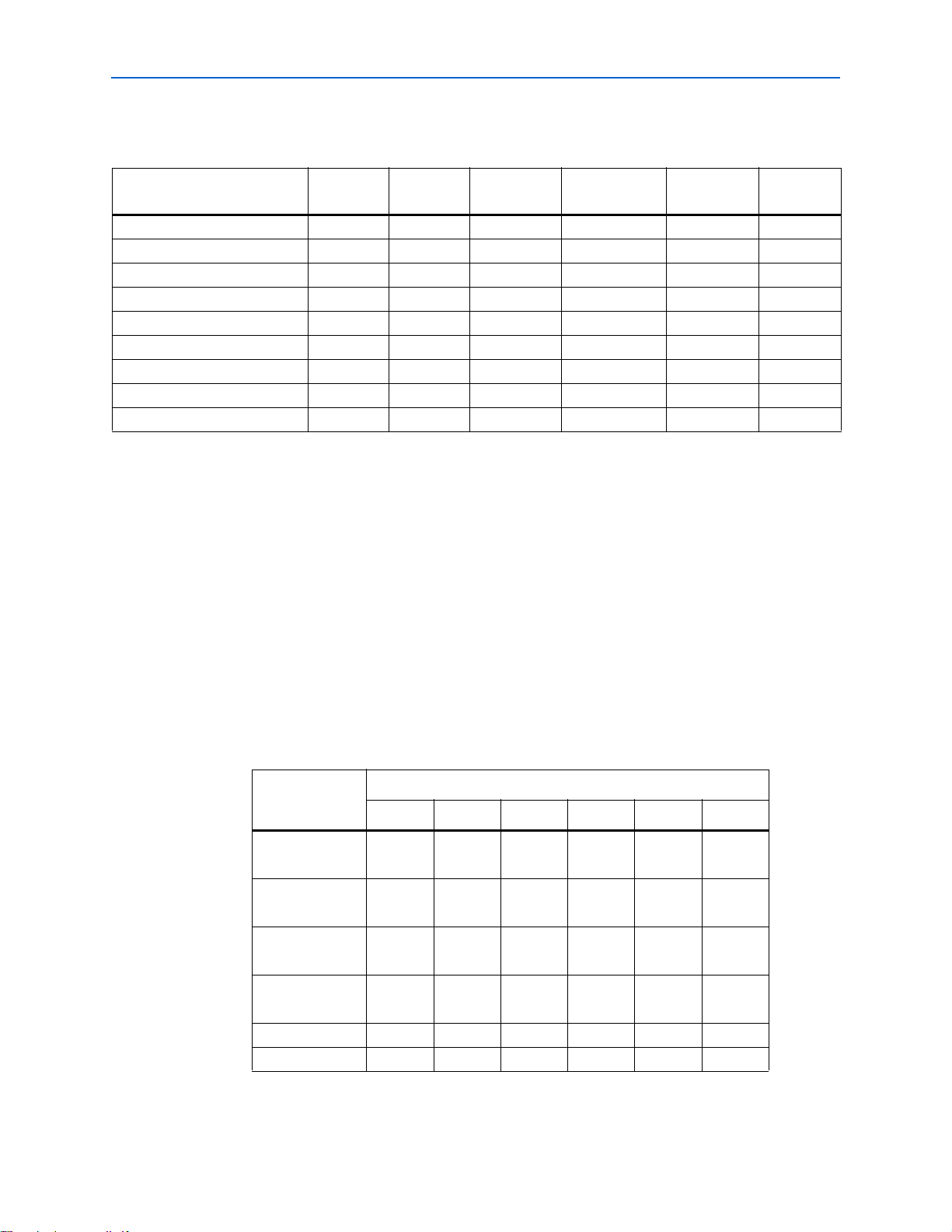

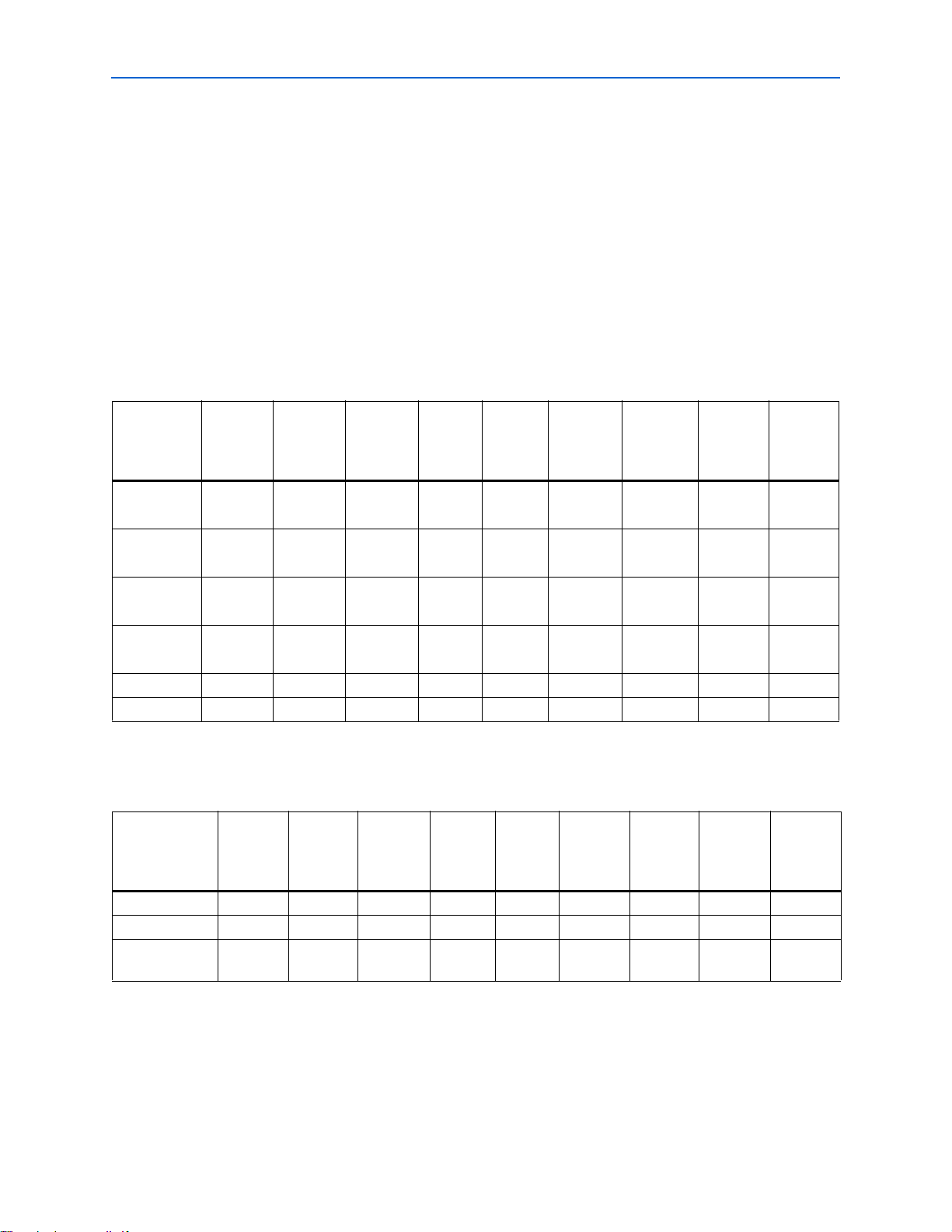

Table 1–1 shows the MAX II family features.

Tab le 1 –1 . MAX II Family Features

Feature

EPM240

EPM240G

EPM570

EPM570G

EPM1270

EPM1270G

EPM2210

EPM2210G EPM240Z EPM570Z

LEs 240 570 1,270 2,210 240 570

Typical Equivalent Macrocells 192 440 980 1,700 192 440

Equiv alent Macrocell Range 128 to 240 240 to 570 570 to 1,270 1,270 to 2,210 128 to 240 240 to 570

UFM Size (bits) 8,192 8,192 8,192 8,192 8,192 8,192

Maximum User I/O pins 80 160 212 272 80 160

(ns) (1) 4.7 5.4 6.2 7.0 7.5 9.0

t

PD1

(MHz) (2) 304 304 304 304 152 152

f

CNT

(ns) 1.7 1.2 1.2 1.2 2.3 2.2

t

SU

(ns) 4.3 4.5 4.6 4.6 6.5 6.7

t

CO

Notes to Ta bl e 1– 1:

(1) t

represents a pin-to-pin delay for the worst case I/O placement with a full diagonal path across the device and combinational logic

PD1

implemented in a single LUT and LAB that is adjacent to the output pin.

(2) The maximum frequency is limited by the I/O standard on the clock input pin. The 16-bit counter critical delay will run faster than this number.

f For more information about equivalent macrocells, refer to the MAX II Logic Element to

Macrocell Conversion Methodology white paper.

MAX II and MAX IIG devices are available in three speed grades: –3, –4, and –5, with

–3 being the fastest. Similarly, MAX IIZ devices are available in three speed grades: –6,

–7, and –8, with –6 being the fastest. These speed grades represent the overall relative

performance, not any specific timing parameter. For propagation delay timing

numbers within each speed grade and density, refer to the DC and Switching

Characteristics chapter in the MAX II Device Handbook.

Table 1–2 shows MAX II device speed-grade offerings.

Tab le 1 –2 . MAX II Speed Grades

Speed Grade

Device

EPM240

–3 –4 –5 –6 –7 –8

vvv———

EPM240G

EPM570

vvv———

EPM570G

EPM1270

vvv———

EPM1270G

EPM2210

vvv———

EPM2210G

EPM240Z — — — vvv

EPM570Z ———vvv

MAX II Device Handbook © August 2009 Altera Corporation

Page 19

Chapter 1: Introduction 1–3

Features

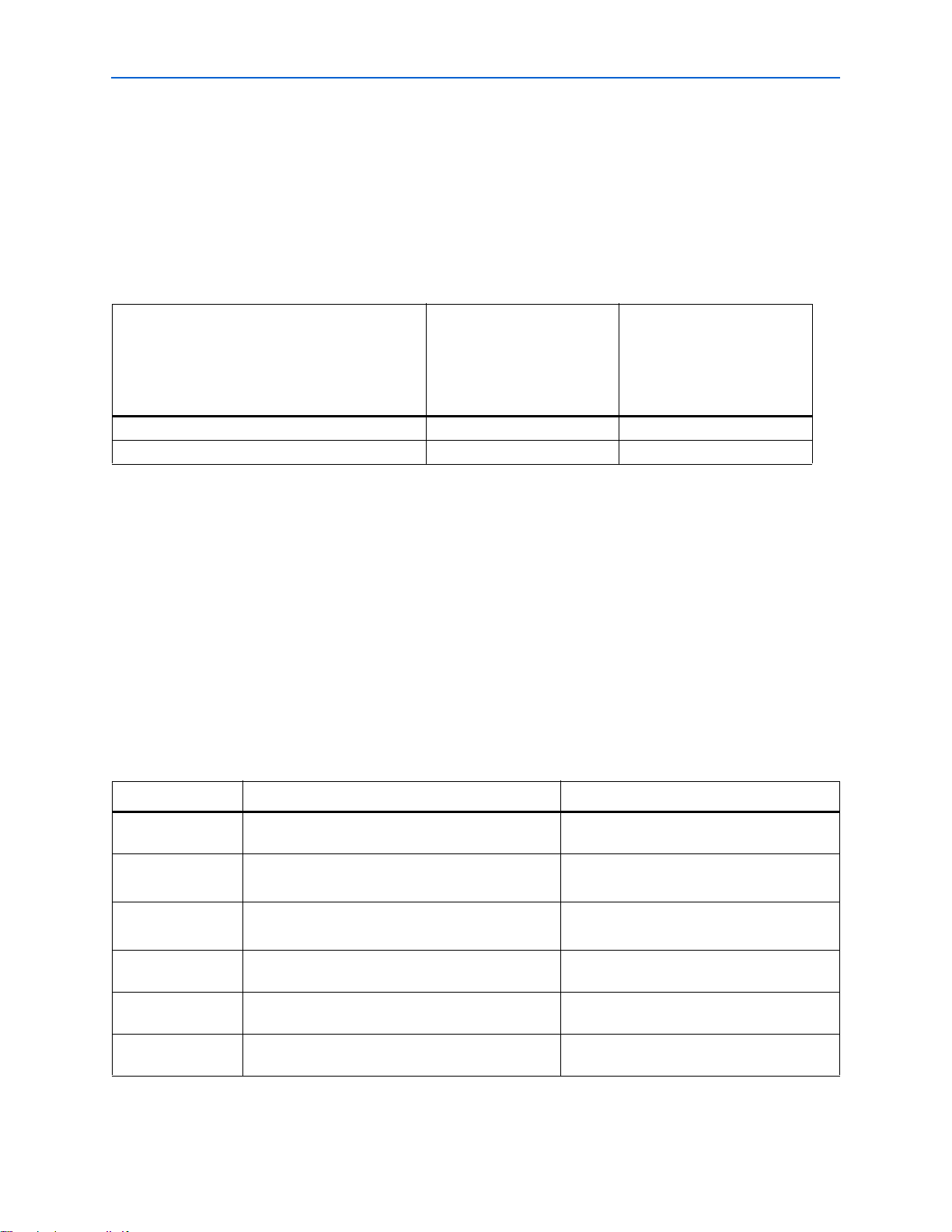

MAX II devices are available in space-saving FineLine BGA, Micro FineLine BGA,

and thin quad flat pack (TQFP) packages (refer to Table 1–3 and Table 1–4). MAX II

devices support vertical migration within the same package (for example, you can

migrate between the EPM570, EPM1270, and EPM2210 devices in the 256-pin

FineLine BGA package). Vertical migration means that you can migrate to devices

whose dedicated pins and JTAG pins are the same and power pins are subsets or

supersets for a given package across device densities. The largest density in any

package has the highest number of power pins; you must lay out for the largest

planned density in a package to provide the necessary power pins for migration. For

I/O pin migration across densities, cross reference the available I/O pins using the

device pin-outs for all planned densities of a given package type to identify which

I/O pins can be migrated. The Quartus® II software can automatically cross-reference

and place all pins for you when given a device migration list.

Tab le 1 –3 . MAX II Packages and User I/O Pins

144-Pin

Micro

FineLine

BGA (1)

144-Pin

Micro

FineLine

BGA

BGA

100-Pin

Micro

FineLine

BGA (1)

100-Pin

Micro

FineLine

BGA

100-Pin

FineLine

BGA

100-Pin

FineLine

BGA

100-Pin

TQFP

100-Pin

TQFP

144-Pin

TQFP

144-Pin

TQFP

68-Pin

Micro

FineLine

Devi ce

EPM240

EPM240G

EPM570

EPM570G

EPM1270

EPM1270G

EPM2210

EPM2210G

EPM240Z 54 80 — — — — — — —

EPM570Z — 76 — — — 116 160 — —

Note to Ta b le 1 –3 :

(1) Packages available in lead-free versions only.

Tab le 1 –4 . MAX II TQFP, FineLine BGA, and Micro Fi neLine BGA Package Sizes

Package

Pitch (mm) 0.5 0.5 1 0.5 0.5 0.5 0.5 1 1

Area (mm2) 25 36 121 256 484 49 121 289 361

Length × width

(mm × mm)

BGA (1)

—808080—— ———

— 76 76 76 116 — 160 160 —

— — — — 116 — 212 212 —

— — ———— —204272

68-Pin

Micro

FineLine

5 × 5 6 × 6 11 × 11 16 × 16 22 × 22 7 × 7 11 × 11 17 × 17 19 × 19

256-Pin

Micro

FineLine

BGA (1)

256-Pin

Micro

FineLine

BGA

256-Pin

FineLine

BGA

256-Pin

FineLine

BGA

324-Pin

FineLine

324-Pin

FineLine

BGA

BGA

© August 2009 Altera Corporation MAX II Device Handbook

Page 20

1–4 Chapter 1: Introduction

Referenced Documents

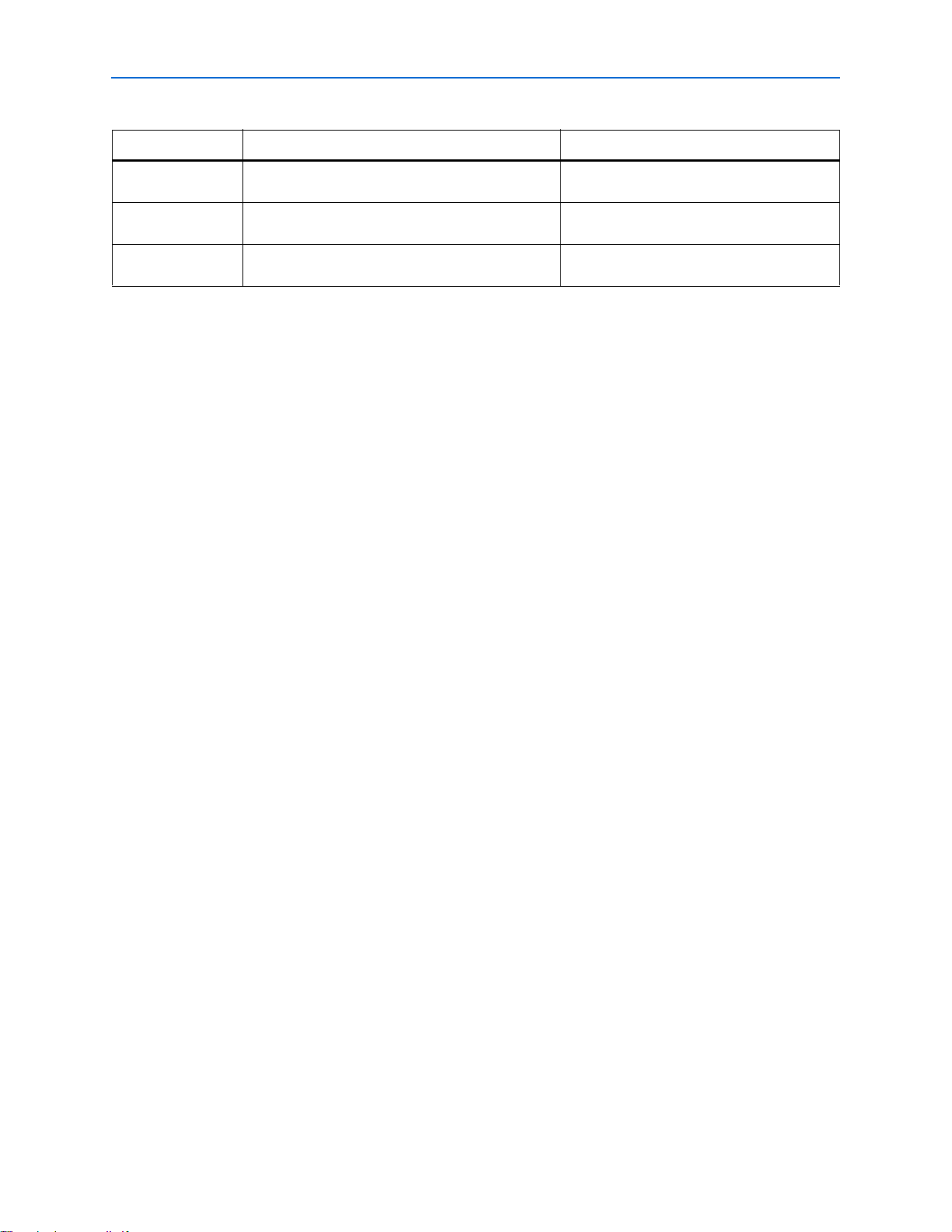

MAX II devices have an internal linear voltage regulator which supports external

supply voltages of 3.3 V or 2.5 V, regulating the supply down to the internal operating

voltage of 1.8 V. MAX IIG and MAX IIZ devices only accept 1.8 V as the external

supply voltage. MAX IIZ devices are pin-compatible with MAX IIG devices in the

100-pin Micro FineLine BGA and 256-pin Micro FineLine BGA packages. Except for

external supply voltage requirements, MAX II and MAX II G devices have identical

pin-outs and timing specifications. Ta b le 1 –5 shows the external supply voltages

supported by the MAX II family.

Tab le 1 –5 . MAX II External Supply Voltages

EPM240G

EPM570G

EPM240

EPM570

EPM1270

Devices

MultiVolt core external supply voltage (V

MultiVolt I/O interface voltage levels (V

Notes to Ta bl e 1– 5:

(1) MAX IIG and MAX IIZ devices only accept 1.8 V on their VCCINT pins. The 1.8-V V

(2) MAX II devices operate internally at 1.8 V.

) (2) 3.3 V, 2.5 V 1.8 V

CCINT

) 1.5 V, 1.8 V, 2.5 V, 3.3 V 1.5 V, 1.8 V, 2.5 V, 3.3 V

CCIO

EPM2210

external supply powers the device core directly.

CCI NT

EPM1270G

EPM2210G

EPM240Z

EPM570Z (1)

Referenced Documents

This chapt er references the following documents:

■ DC and Switching Characteristics chapter in the MAX II Device Handbook

■ MAX II Logic Element to Macrocell Conversion Methodology white paper

Document Revision History

Table 1–6 shows the revision history for this chapter.

Tab le 1 –6 . Document Revision History

Date and Revision Changes Made Summary of Changes

August 2009,

version 1.9

October 2008,

version 1.8

December 2007,

versi on1.7

December 2006,

version 1.6

August 2006,

version 1.5

July 2006,

version 1.4

■ Updated Ta bl e 1– 2. Added information for speed grade –8

■ Updated “Introduction” section.

■ Updated new Document Format.

■ Updated Table 1–1 through Table 1–5.

■ Added “Referenced Documents” section.

■ Added document revision history. —

■ Minor update to features list. —

■ Minor updates to tables. —

Updated document with MAX IIZ information.

—

MAX II Device Handbook © August 2009 Altera Corporation

Page 21

Chapter 1: Introduction 1–5

Document Revision History

Tab le 1 –6 . Document Revision History

Date and Revision Changes Made Summary of Changes

June 2005,

■ Updated timing numbers in Table 1-1. —

version 1.3

December 2004,

■ Updated timing numbers in Table 1-1. —

version 1.2

June 2004,

■ Updated timing numbers in Table 1-1. —

version 1.1

© August 2009 Altera Corporation MAX II Device Handbook

Page 22

1–6 Chapter 1: Introduction

Document Revision History

MAX II Device Handbook © August 2009 Altera Corporation

Page 23

MII51002-2.2

Introduction

2. MAX II Architecture

This chapter describes the architecture of the MAX II device and contains the

following sections:

■ “Functional Description” on page 2–1

■ “Logic Array Blocks” on page 2–4

■ “Logic Elements” on page 2–6

■ “MultiTrack Interconnect” on page 2–12

■ “Global Signals” on page 2–16

■ “User Flash Memory Block” on page 2–18

■ “MultiVolt Core” on page 2–22

■ “I/O Structure” on page 2–23

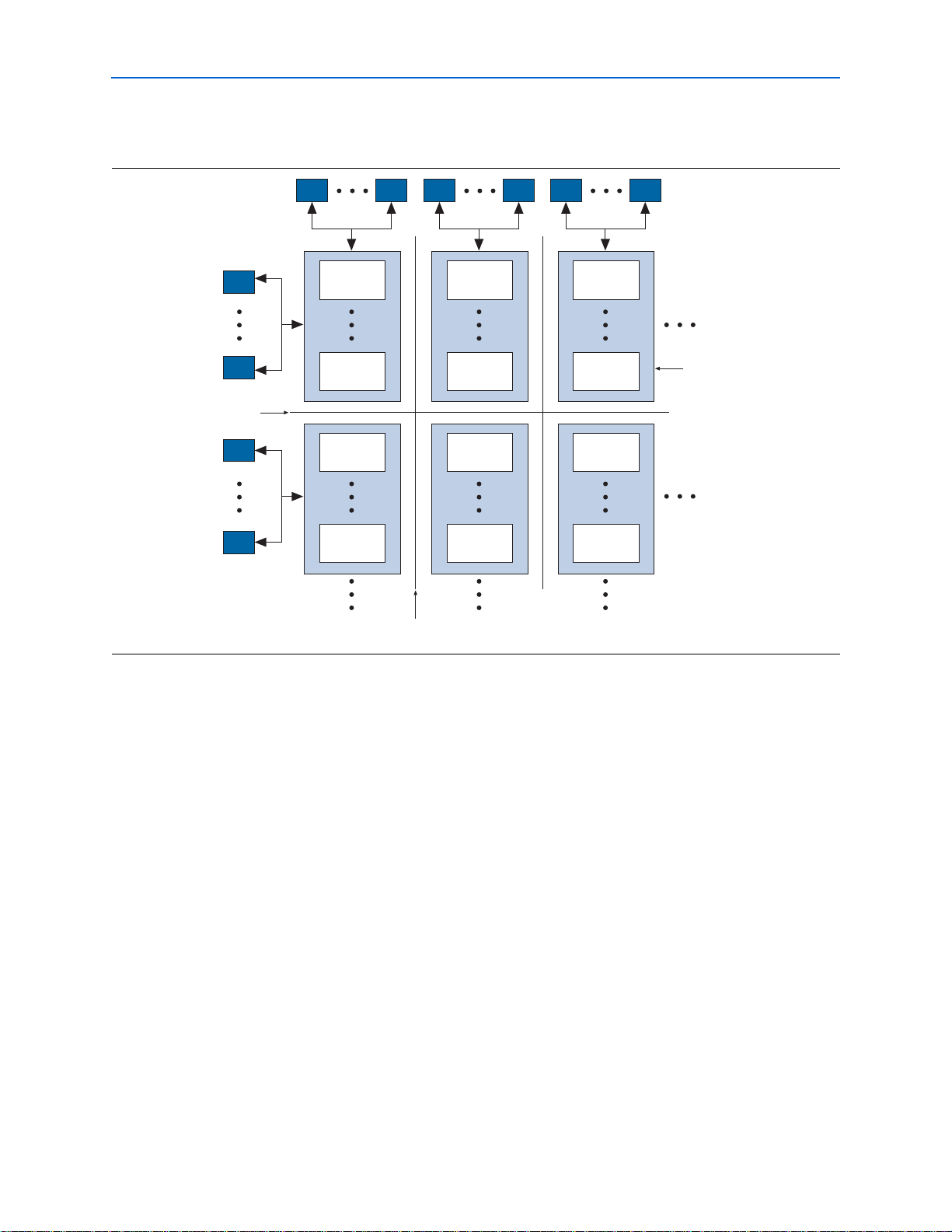

Functional Description

MAX® II devices contain a two-dimensional row- and column-based architecture to

implement custom logic. Row and column interconnects provide signal interconnects

between the logic array blocks (LABs).

The logic array consists of LABs, with 10 logic elements (LEs) in each LAB. An LE is a

small unit of logic providing efficient implementation of user logic functions. LABs

are grouped into rows and columns across the device. The MultiTrack interconnect

provides fast granular timing delays between LABs. The fast routing between LEs

provides minimum timing delay for added levels of logic versus globally routed

interconnect structures.

The MAX II device I/O pins are fed by I/O elements (IOE) located at the ends of LAB

rows and columns around the periphery of the device. Each IOE contains a

bidirectional I/O buffer with several advanced features. I/O pins support Schmitt

trigger inputs and various single-ended standards, such as 66-MHz, 32-bit PCI, and

LVTTL.

MAX II devices provide a global clock network. The global clock network consists of

four global clock lines that drive throughout the entire device, providing clocks for all

resources within the device. The global clock lines can also be used for control signals

such as clear, preset, or output enable.

© October 2008 Altera Corporation MAX II Device Handbook

Page 24

2–2 Chapter 2: MAX II Architecture

Logic Array

BLock (LAB)

MultiTrack

Interconnect

MultiTrack

Interconnect

Logic

Element

Logic

Element

IOE

IOE

IOE IOE

Logic

Element

Logic

Element

IOE

IOE

Logic

Element

Logic

Element

IOE IOE

Logic

Element

Logic

Element

Logic

Element

Logic

Element

IOE IOE

Logic

Element

Logic

Element

Functional Description

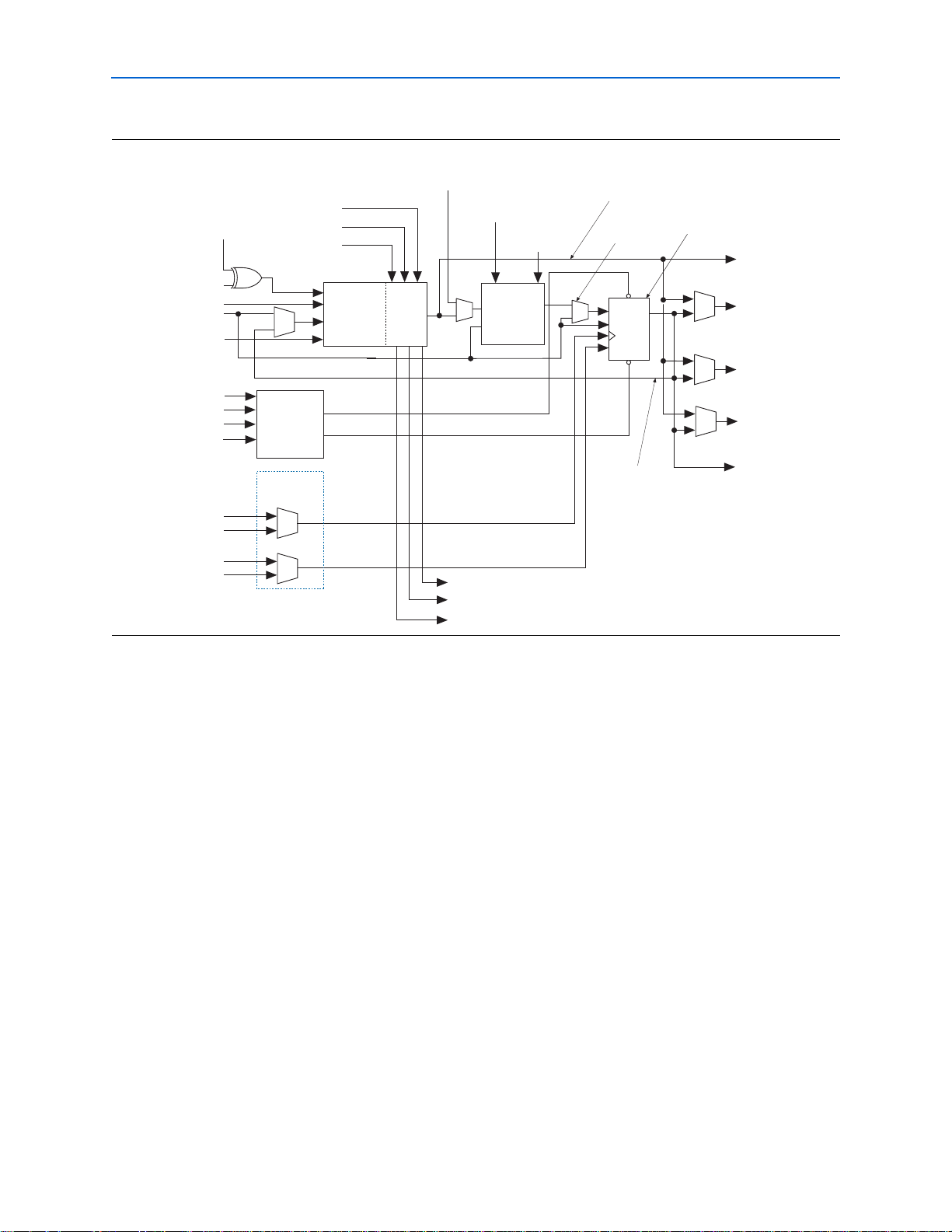

Figure 2–1 shows a functional block diagram of the MAX II device.

Figur e 2–1. MAX II Device Block Diagram

Each MAX II device contains a flash memory block within its floorplan. On the

EPM240 device, this block is located on the left side of the device. On the EPM570,

EPM1270, and EPM2210 devices, the flash memory block is located on the bottom-left

area of the device. The majority of this flash memory storage is partitioned as the

dedicated configuration flash memory (CFM) block. The CFM block provides the nonvolatile storage for all of the SRAM configuration information. The CFM

automatically downloads and configures the logic and I/O at power-up, providing

instant-on operation.

f For more information about configuration upon power-up, refer to the Hot Socketing

and Power-On Reset in MAX II Devices chapter in the MAX II Device Handbook.

A portion of the flash memory within the MAX II device is partitioned into a small

block for user data. This user flash memory (UFM) block provides 8,192 bits of

general-purpose user storage. The UFM provides programmable port connections to

the logic array for reading and writing. There are three LAB rows adjacent to this

block, with column numbers varying by device.

Table 2–1 shows the number of LAB rows and columns in each device, as well as the

number of LAB rows and columns adjacent to the flash memory area in the EPM570,

EPM1270, and EPM2210 devices. The long LAB rows are full LAB rows that extend

from one side of row I/O blocks to the other. The short LAB rows are adjacent to the

UFM block; their length is shown as width in LAB columns.

MAX II Device Handbook © October 2008 Altera Corporation

Page 25

Chapter 2: MAX II Architecture 2–3

y

Functional Description

Tab le 2 –1 . MAX II Device Resources

LAB Rows

Short LAB Rows

Devic es UFM Blocks LAB Columns

(Width) (1)

Total LA BsLong LAB Rows

EPM240 164—24

EPM570 11243 (3)57

EPM1270 1 16 7 3 (5) 127

EPM2210 1 20 10 3 (7) 221

Note to Ta b le 2 –1 :

(1) The width is the number of LAB columns in length.

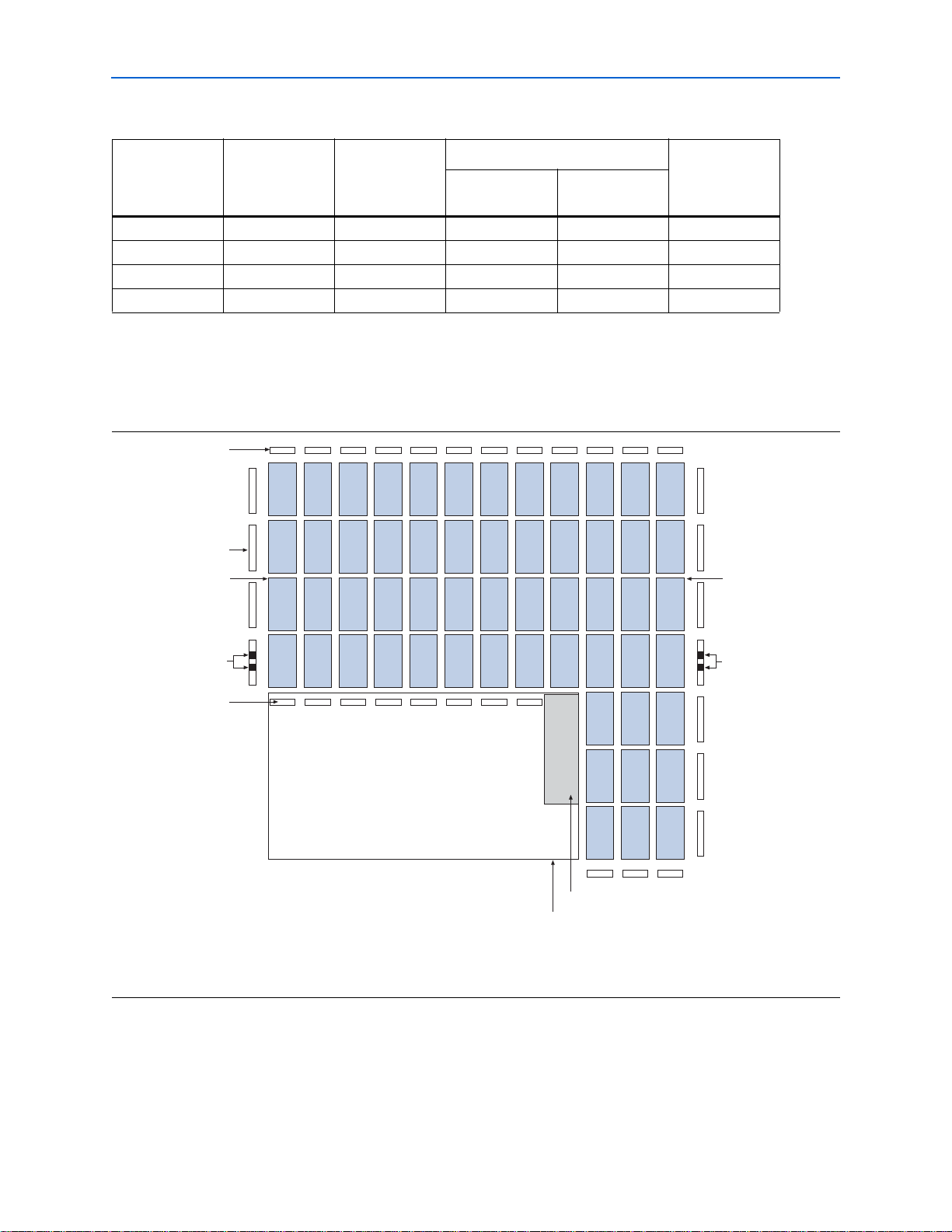

Figure 2–2 shows a floorplan of a MAX II device.

Figur e 2–2. MAX II Device Floorplan (Note 1)

I/O Blocks

I/O Blocks

Logic Array

Blocks

2 GCLK

Inputs

I/O Blocks

UFM Block

CFM Block

Logic Arra

Blocks

2 GCLK

Inputs

Note to Fi gure 2–2:

(1) The device shown is an EPM570 device. EPM1270 and EPM2210 devices have a similar floorplan with more LABs. For EPM240 devices, the CFM

and UFM blocks are located on the left side of the device.

© October 2008 Altera Corporation MAX II Device Handbook

Page 26

2–4 Chapter 2: MAX II Architecture

Logic Array Blocks

Logic Array Blocks

Each LAB consists of 10 LEs, LE carry chains, LAB control signals, a local interconnect,

a look-up table (LUT) chain, and register chain connection lines. There are 26 possible

unique inputs into an LAB, with an additional 10 local feedback input lines fed by LE

outputs in the same LAB. The local interconnect transfers signals between LEs in the

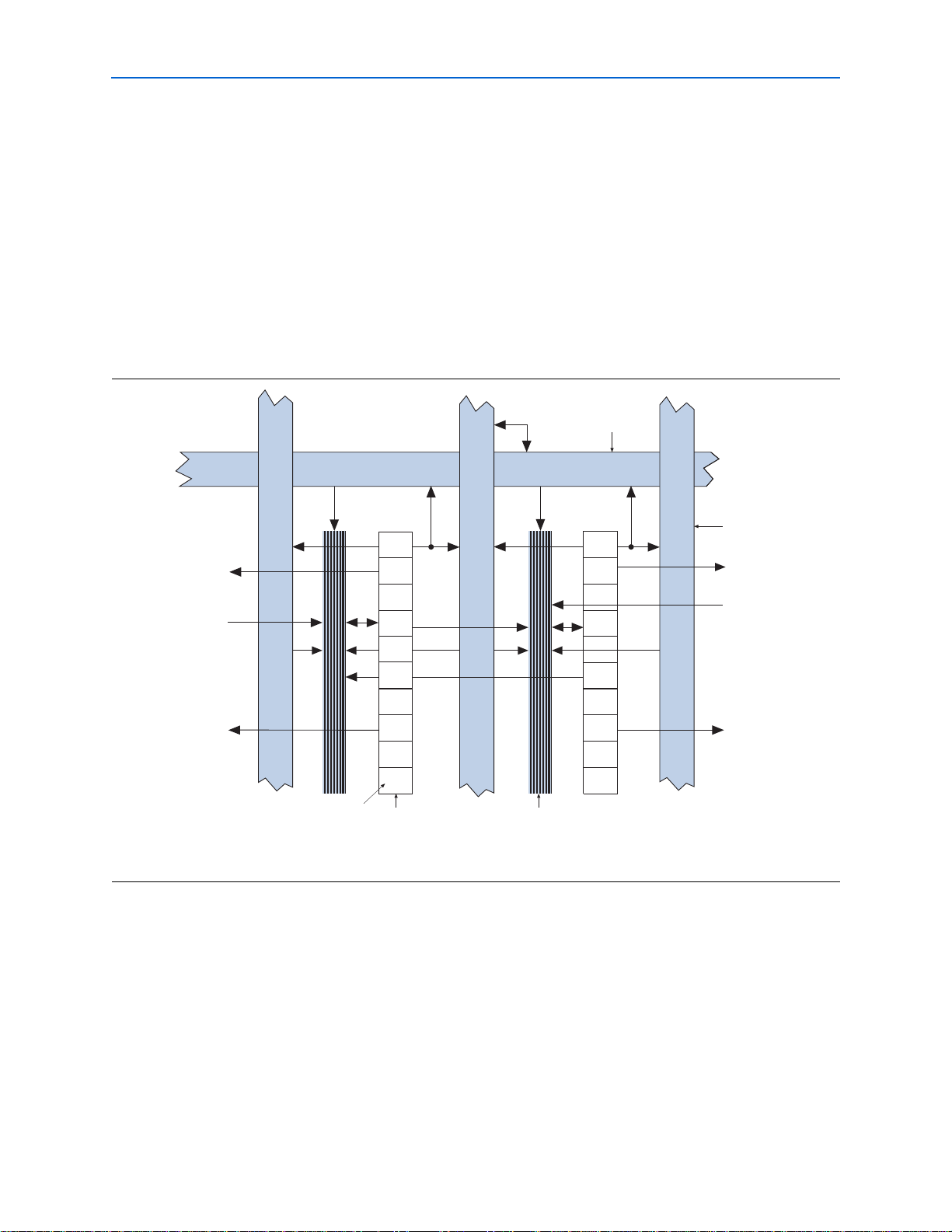

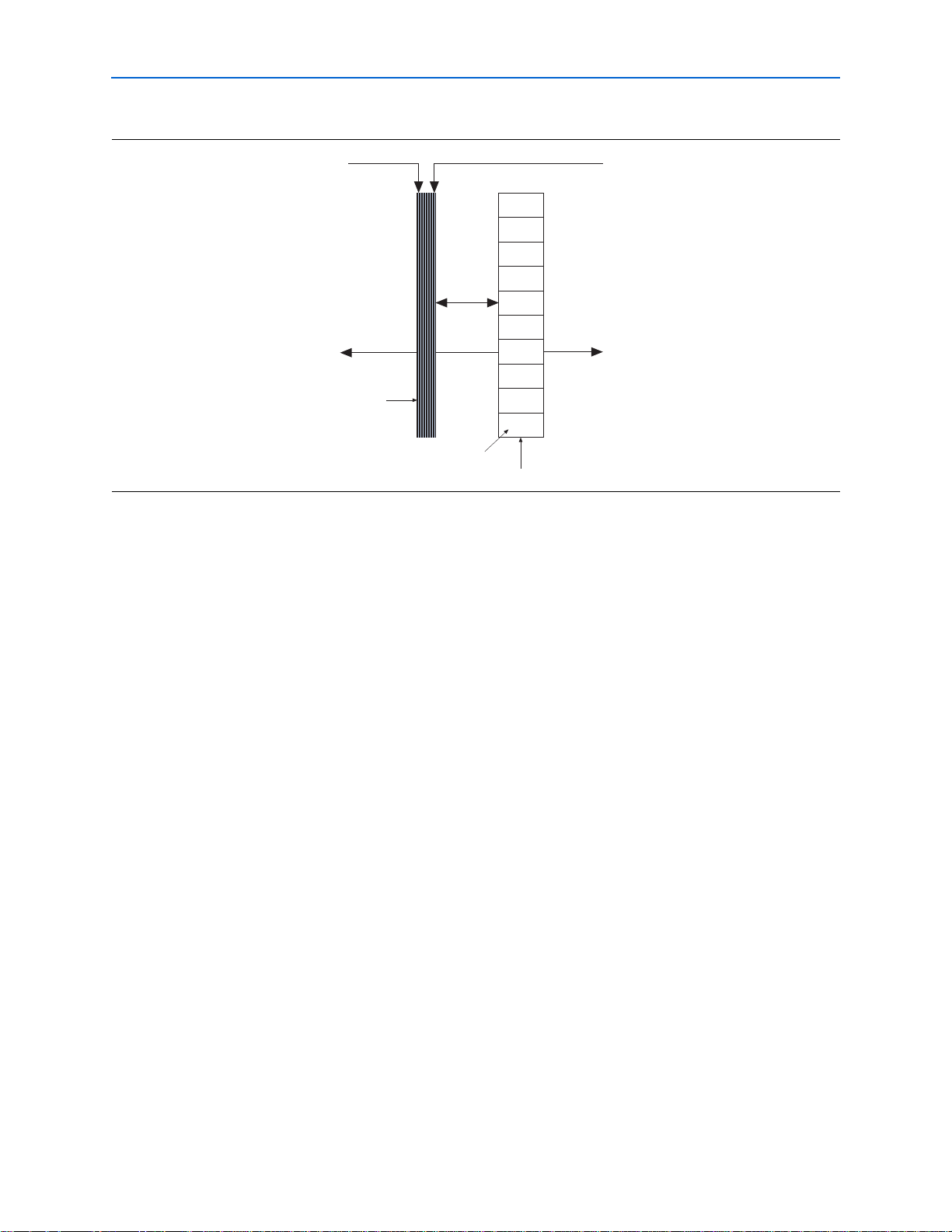

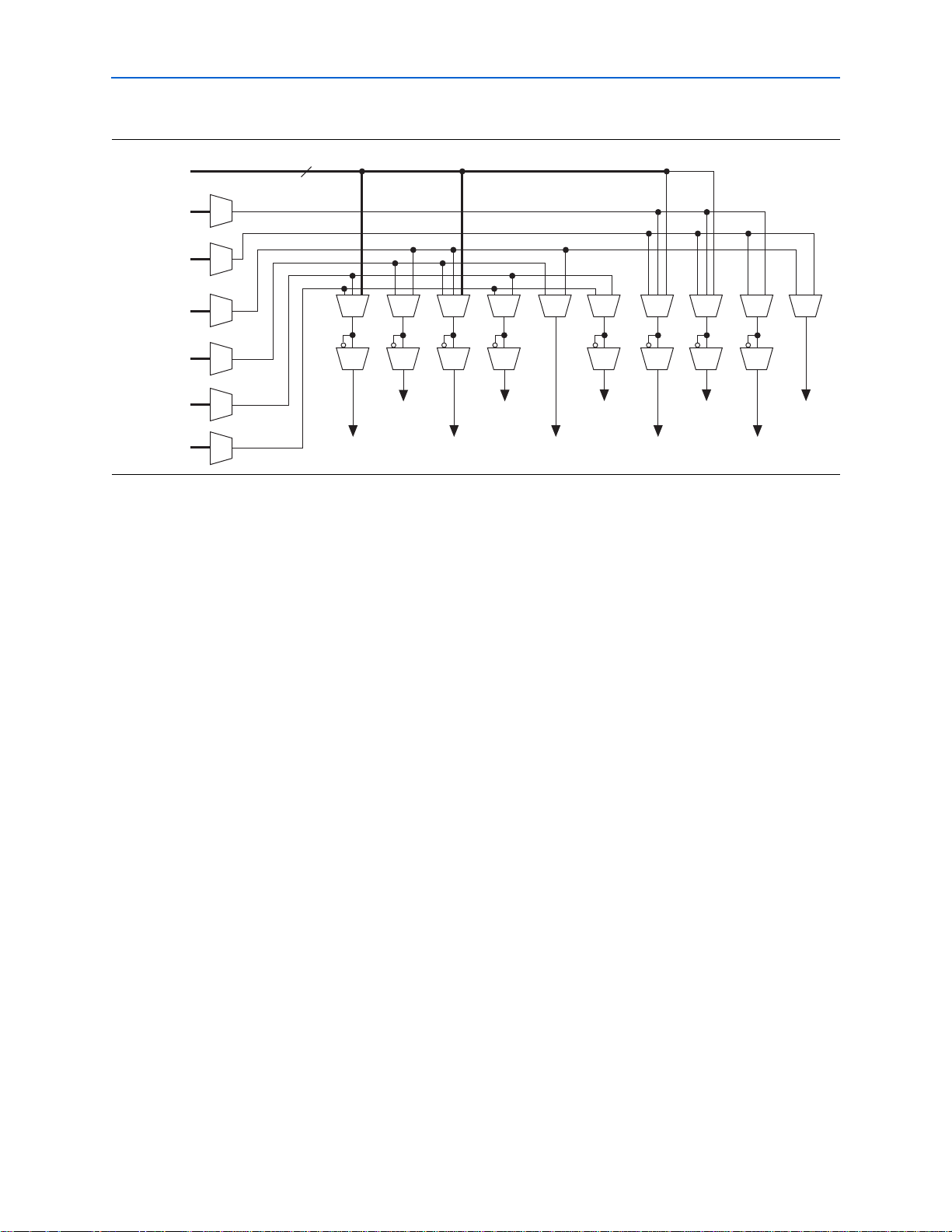

same LAB. LUT chain connections transfer the output of one LE’s LUT to the adjacent