Page 1

®

查询EPM7128SLC84-10供应商

June 2003, ver. 6.6 Data Sheet

MAX 7000

Programmable Logic

Device Family

Features...

■ High-performance, EEPROM-based programmable logic devices

(PLDs) based on second-generation MAX

■ 5.0-V in-system programmability (ISP) through the built-in

®

architectu re

IEEE Std. 1149.1 Joint Test Action Group (JTAG) interface available in

MAX 7000S devices

– ISP circuitry compatible with IEEE Std. 1532

■ Includes 5.0-V MAX 7000 devices and 5.0-V ISP-based MAX 7000S

devices

■ Built-in JTAG boundary-scan test (BST) circuitry in MAX

7000S

devices with 128 or more macrocells

■ Complete EPLD family with logic densities ranging from 600 to

5,000 usable gates (see Tables 1 and 2)

■ 5-ns pin-to-pin logic delays with up to 175.4-MHz counter

frequencies (including interconnect)

■ PCI-compliant devices available

f

For information on in-system programmable 3.3-V MAX 7000A or 2.5-V

MAX 7000B devi ces, see th e MAX 7000 A Programma ble Logi c Device F amily

Data Sheet or the MAX 7000B Programmable Logic Device Family Data

Sheet.

Table 1. MAX 7000 Device Features

Feature EPM7032 EPM7064 EPM7096 EPM7128E EPM7160E EPM7192E EPM7256E

Usable

gates

Macrocells 32 64 96 128 160 192 256

Logic array

blocks

Maximum

user I/O pins

(ns) 6 6 7. 5 7.5 10 12 12

t

PD

(ns)5566777

t

SU

t

(ns)2.5 2.533333

FSU

t

(ns)444.54.5566

CO1

f

(MHz) 151.5 151.5 125.0 125.0 100.0 90.9 90.9

CNT

600 1,250 1,800 2,500 3,200 3,750 5,000

2468101216

36 68 76 100 104 124 164

Altera Corporation 1

DS-MAX7000-6.6

Page 2

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Table 2.MAX 7000S Device Features

Feature EPM7032S EPM7064S EPM7128S EPM7160S EPM7192S EPM7256S

Usable gates 600 1,250 2,500 3,200 3,75 0 5,000

Macrocells 32 64 128 160 192 256

Logic array

blocks

Maximum

user I/O pins

(ns)55667.57.5

t

PD

t

(ns) 2.9 2.9 3.4 3.4 4.1 3.9

SU

(ns) 2.5 2.5 2.5 2.5 3 3

t

FSU

t

(ns) 3.2 3.2 4 3.9 4.7 4.7

CO1

f

(MHz) 175.4 175.4 147.1 149.3 125.0 128.2

CNT

2 4 8 10 12 16

36 68 100 104 124 164

...and More

Features

■ Open-drain output option in MAX 7000S devices

■ Programmable macrocell flipflops with individual clear, preset,

clock, and clock enable controls

■ Programmable power-saving mode for a reduction o f over 50% in

each macrocell

■ Configurable expander product-term distribution, allowing up to

32 product terms per macrocell

■ 44 to 208 pins avail ab le in pla stic J-lead chip carr ier (P L CC), ceramic

pin-grid array (PGA), plastic quad flat pack (PQFP), p ower q uad flat

pack (RQFP), and 1.0-mm thin quad flat pack (TQFP) packages

■ Programmable security bit for protection of proprietary designs

■ 3.3-V or 5.0-V operation

– MultiVolt

TM

I/O interface operation, allowing devices to

interface with 3.3-V or 5.0-V devices (M ultiVolt I/O ope ration is

not avai lable in 44-pin packages)

– Pin compatible with low-voltage MAX 7000A and MAX 7000B

devices

■ Enhanc ed features availabl e in MAX 7000E and MAX 7000 S devices

– Six pin- or logic-driven output enable signals

– Two global clock signals with optional inversion

– Enhanced interconnect resources for improved routability

– Fast input setup times provided by a dedicated path from I/O

pin to macrocell registers

– Programmable output slew-rate control

■ Software design s upport and au tomatic plac e-and-ro ute provided by

Altera’s development system for Windows-based PC s and Sun

SPARCstation, and HP 9000 Series 700/800 workstations

2 Altera Corporation

Page 3

MAX 7000 Programmabl e Log i c Dev ic e Fam ily Data Sheet

■ Additional design entry and simula tion support pr ovide d by EDIF

2 0 0 and 3 0 0 netlist files, library of parameterized modules (LPM),

Verilog HDL, VHDL, and other interfa ces to popular EDA tools from

manufacturers such as Cadence, Exemplar Logic, Mentor Graphics,

OrCAD, Synopsys, and VeriBes t

■ Programming support

– Altera’s Master Programming Unit (MPU) and programming

hardware from third-party manufacturers program all

MAX 7000 devices

TM

–The BitBlaster

parallel port download cable, and MasterBlaster

serial download cable, By te Bl as terMVTM

TM

serial/universal serial bus (USB) download cable program MAX

7000S devices

General

Description

The MAX 7000 family of high-density, high-performance PLDs is based

on Altera’s second-generation MAX architecture. Fabricated with

advanced CMOS technology, the EEPROM-based MAX7000 family

provides 600 to 5,000 usable gates, ISP, pin-to-pin delays as fast as 5 ns,

and counter speeds of up to 175.4 MHz. MAX 7000S devices in the -5, -6,

-7, and -10 spe ed g ra d es as we l l as MAX7000 and MAX7000E devices in

-5, -6, -7, -10P, and -12P speed grades comply with the PCI Special Interest

Group (PCI SIG) PCI Local Bus Specification, Revision 2.2. See Table 3

for available speed grades.

Table 3.MAX 7000 Speed Grades

Device Speed Grade

-5 -6 -7 -10P -10 -12P -12 -15 -15T -20

EPM7032

EPM7032S

EPM7064

EPM7064S

EPM7096

EPM7128E

EPM7128S

EPM7160E

EPM7160S

EPM7192E

EPM7192S

EPM7256E

EPM7256S

vvv v

vvv v

vv v vvv

vvvvv

vvvv

vvvvvv

vv v v

vv vv v

vv v v

vv v

vv v

vvv v

vvv v

Altera Corporation 3

Page 4

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

The MAX 7000E devices—including the EPM7128E, EPM7160E,

EPM7192E, and EPM7256E de v ices —have several enhanced features:

additional global clocking, additional output enable controls, enhanced

interconnect resources, fast input registers, and a programmabl e slew

rate.

In-system programmable MAX 7000 devices—called MAX7000S

devices—include the EPM7032S, EPM7064S, EPM7 12 8S , EPM7160S,

EPM7192S, and EPM7256S devices. MAX7000S devices have the

enhanced fea tures of MAX7000E device s as well as JTAG BST circu itry in

devices with 128 or more macrocells, ISP, and an open-drain output

option. See Table 4.

Table 4. MAX 7000 Device Features

Feature EPM7032

EPM7064

EPM7096

ISP via JTAG interface

JTAG BST circuitry

Open-drain output option

Fast input registers

Six global output enables

Two global clocks

Slew-rate control

MultiVolt interface (2)

Programmable register

Parallel expanders

Shared expanders

Power - saving mode

Security bit

PCI-compliant devices avai lable

Notes:

(1) Available only in EPM7128S, EPM7160S, EPM7192S, and EPM7256S devices only.

(2) The Mul t iVolt I/O interf ace is not available in 44-pin packages.

vvv

vvv

vvv

vvv

vvv

vvv

vvv

All

MAX 7000E

Devices

All

MAX 7000S

Devices

v

v(1)

v

vv

vv

vv

vv

4 Altera Corporation

Page 5

MAX 7000 Programmabl e Log i c Dev ic e Fam ily Data Sheet

The MAX 7000 architecture supports 100% TTL emulation and

high-density integration of SSI, MSI, and LSI logic functions. The

MAX 7000 architecture easily integrates multiple devices ranging from

PALs, GALs, and 22V10s to MACH and pLSI devices. MAX 7000 devices

are available in a wide ran ge of packages, includin g P LCC, PGA, PQFP,

RQFP, and TQFP packages. See Table 5.

Table 5. MAX 7000 Maximum User I/O Pins Note (1)

Device 44-

PLCC

EPM7032 36 36 36

EPM7032S 36 36

EPM7064 36 36 52 68 68

EPM7064S 36 36 68 68

EPM7096 52 64 76

EPM7128E 68 84 100

EPM7128S 68 84 84 (2) 100

EPM7160E 64 84 104

EPM7160S 64 84 (2) 104

EPM7192E 124 124

EPM7192S 124

EPM7256E 132 (2) 164 164

EPM7256S 164 (2) 164

Notes:

(1) When the JTAG inte r face in M AX 7000S devices is used for ei the r b ound ary-scan testing or for ISP, four I/O pins

become JTAG pins.

(2) Perform a complete thermal analysis before committing a design to this device package. For more information, see

the Operating Requirements for Altera Devices Data Sheet.

Pin

44Pin

PQFP

44Pin

TQFP

68Pin

PLCC

84Pin

PLCC

100-

Pin

PQFP

100-

Pin

TQFP

160-

Pin

PQFP

160-

Pin

PGA

192-

Pin

PGA

208-

Pin

PQFP

208-

Pin

RQFP

MAX 7000 devices use CMOS EEPROM cells to implement logic

functions. The user-configurable MAX 7000 architecture accommodates a

variety of independe nt c omb inat orial and se qu ent ial l ogic func tions . T he

devices can be reprogrammed for quick and efficient iterations during

design development and debug cycles, and can be programme d and

erased up to 100 times.

Altera Corporation 5

Page 6

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

MAX 700 0 d evices contain fro m 32 to 256 ma cr ocells th at are combined

into groups of 16 macrocells, called logic array blocks (LABs). Each

macrocell has a programmable-AND/fixed-OR array and a configurable

register with ind epend ently prog rammabl e clock, clock enable, cle ar, an d

preset functions. To bu ild compl ex logic functions, each macrocell can be

supplemented with both shareable expander product terms and highspeed parallel expand er product terms to provide up to 32 product terms

per macrocell.

The MAX 7000 family provides programmable speed/power

optimization. Speed-critical portions of a design can run at high

speed/full power, while the remaining portions run at reduced

speed/low power. This speed/power optimization feature enables the

designer to configure one or more macrocells to operate at 50% or lower

power while adding only a nominal timing delay. MAX 7000E and

MAX 7000S devices also provide an option that reduces the slew rate of

the output buffers, minimizing noise transients when non-speed-critical

signals are switc hing. The output drive rs of all M AX 7000 devices (except

44-pin devices) can be set for either 3.3-V or 5.0-V operation, allowing

MAX 7000 devices to be used in mixed-voltage systems.

The MAX 7000 family is supported byAltera deve lopment systems, which

are integrated packages that offer schematic, text—including VHDL,

Verilog HDL, and the Altera Hardware Descr ipt i on Langu age (AHDL)—

and waveform design entry, compilation and logic synthesis, simulation

and timing analysis, and device programming. The software provides

EDIF 2 0 0 and 3 0 0, LPM, VHDL, Verilog HDL, and other interfaces for

additional design entry and simulation support from other industrystandard PC- and UNIX-workst ation-based EDA tools . The software run s

on Windows-based PC s, as well a s Sun SPARCsta tion, and H P 9000 Series

700/800 workstations.

f

Functional

Description

6 Altera Corporation

For more information on development tools, see the MAX+PLUS II

Programmable Logic Development System & Software Data Sheet and the

Quartus Programmable Logic Development System & Software Data Sheet.

The MAX 7000 architecture includes the following elements:

■ Logic array blo cks

■ Macrocells

■ Expander product terms (shareable and parallel)

■ Programmable interconnect arra y

■ I/O control blocks

Page 7

MAX 7000 Programmabl e Log i c Dev ic e Fam ily Data Sheet

The MAX 7000 architecture includes four dedicated inputs that can

be used as general-purpose inputs or as high-speed, global control

signals (clock, clear, and two output enable signals) for each

macrocell and I/O pin. Figure1 shows the ar chite cture of EPM7032 ,

EPM7064, and EPM7096 devic es .

Figure 1. EPM7032, EPM7064 & EPM7096 Device Block Diagram

INPUT/GLCK1

INPUT/GCLRn

INPUT/OE1

INPUT/OE2

LAB A LAB B

8 to 16

I/O pins

8 to 16

I/O pins

I/O

Control

Block

I/O

Control

Block

8 to 16

8 to 16

LAB C

Macrocells

1 to 16

Macrocells

33 to 48

16

8 to 16

16

8 to 16

LAB D

8 to 16

8 to 16

I/O

Control

Block

I/O

Control

Block

8 to 16

I/O pins

8 to 16

I/O pins

36

36

PIA

36

36

16

8 to 16

16

8 to 16

Macrocells

17 to 32

Macrocells

49 to 64

Altera Corporation 7

Page 8

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

I

s

s

Figure2 shows the architecture of MAX 7000E and MAX 7000S devices.

Figure 2. MAX 7000E & MAX 7000S Device Block Diagram

INPUT/GCLK1

NPUT/OE2/GCLK2

INPUT/OE1

INPUT/GCLRn

6 Output Enables

6 Output Enables

Macrocells

17 to 32

Macrocells

49 to 64

LAB B

LAB D

6 to16

6 to16

6 to16

6 to16

I/O

Control

Block

I/O

Control

Block

6 to 16 I/O Pin

6

6 to 16 I/O Pin

6

LAB A

6 to16

6 to16

6 to 16 I/O Pins

6 to 16 I/O Pins

I/O

Control

Block

I/O

Control

Block

6

6 to16

6 to16

6

LAB C

Macrocells

1 to 16

Macrocells

33 to 48

36 36

16

6 to16

36 36

16

6 to16

PIA

16

6 to16

16

6 to16

Logic Array Blocks

The MAX 7000 device architecture is based on the linking of highperformance, flexible, logic array modules called logic array blocks

(LABs). LABs consist of 16-macr ocell array s, as shown in Figures 1 and 2.

Multiple LABs are linked together via the programmable interconnect

array (PIA), a global bus that is fed by all dedicated inputs, I/O pins, and

macrocells.

8 Altera Corporation

Page 9

MAX 7000 Programmabl e Log i c Dev ic e Fam ily Data Sheet

-

er

S

M

x

f

er

y

a

(

)

S

Each LAB is fed by the following signals:

■ 36 signals from the PIA that are used for general logic inputs

■ Global controls that are used for secondary register functions

■ Direct input paths from I/O pins to the registers that are used

for fast setup times for MAX 7000E and MAX 7000S devices

Macrocells

The MAX 7000 macrocell can be individual ly configur ed for either

sequential or combinatorial logic operation. The macrocell consists

of three functional blocks: the logic array, the product-term select

matrix, and the programmable register. The macrocell of EPM7032,

EPM7064, and EPM7096 devic es i s s hown in Figure 3.

Figure 3. EPM7032, EPM7064 & EPM7096 Device Macrocell

Logic Arra

Product

elect

atri

rallel Logic

Expanders

from other

macrocells

Global

Clear

Clear

Select

Global

Clocks

2

VCC

Clock/

Enable

Select

Fast Input

Select

PRN

D/T Q

ENA

CLRN

Programmable

Register

Register

Bypass

From

I/O pin

To I/O

Control

Block

to PIA

36 Signals

rom PIA

16 Expander

Product

hared Logic

Expanders

ms

Altera Corporation 9

Page 10

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Figure4 shows a MAX 7000E and MAX 7000 S device macrocell.

Figure 4. MAX 7000E & MAX 7000S Device Macrocell

Logic Array

Product-

Term

Select

Matrix

Parallel Logic

Expanders

(from other

macrocells)

Global

Clear

Clear

Select

Global

Clocks

2

VCC

Clock/

Enable

Select

Fast Input

Select

PRN

D/T Q

ENA

CLRN

Programmable

Register

Register

Bypass

from

I/O pin

to I/O

Control

Block

36 Signals

from PIA

16 Expander

Product T erms

Shared Logic

Expanders

to PIA

Combinatorial logic is implemented in the logic array, which provides

five product terms per macroce ll. The product-term select matrix allocates

these product terms for use as either primary logic inputs (to the OR and

XOR gates) to implement combinatorial functions, or as secondary inputs

to the ma crocell’s register clear, preset, clock, and clock enable control

functions. Two kinds of expander product terms (“expanders”) are

available to supplement macrocell logic resources:

■ Sharea ble expanders, which a re inverted product ter ms that are fed

back into the logic array

■ Parallel expanders, which are product terms borrowed from adjacent

macrocells

The Altera developm en t sys te m aut omatically optimizes pro du ct-term

allocation according to the logic requirements of the design.

For registered functions, each macrocell flipflop can be individually

programmed to implement D, T, JK, or SR operation with prog rammable

clock control. The flipflop can be bypassed for combinatorial operation.

During design entry, the designer specifies the desired flipflop type; the

Altera development software then selects the most efficient flipflop

operation for each registered function to optimize resource utilization.

10 Altera Corporation

Page 11

MAX 7000 Programmabl e Log i c Dev ic e Fam ily Data Sheet

Each programmable regist er can be clock ed in th ree differe nt mo des:

■ By a global clock signal. This mode achieves th e fastest clock-to -

output performance.

■ By a glo b al clock signal and enabled by an act iv e-high cl ock

enable. This mode provides an enable on each flipflop while still

achieving the fast clock-to-output performance of the global

clock.

■ By an array clock implemented with a product term. In this

mode, the flipflop can be clocked by signals from buried

macrocells or I/O pins.

In EPM7032, EPM7064, and EPM7096 devices, the global clock signal

is available from a dedicated clock pin, GCLK1, as shown in Figure 1.

In MAX 70 00E a n d M A X 7000S devices, two glob al cl ock signals ar e

available. As show n in Figure 2, these global clock signals can be the

true or the complement of either of the global clock pins, GCLK1 or

GCLK2.

Each register also suppor ts asynchr onous prese t and clear functions.

As shown in Figures 3 and 4, the product -term select matrix al locates

product terms to control these operations. Although the

product-term-driven preset and clear of the register are active high,

active-low control c an be obta ined by inve rting t he signal within t he

logic array. In addition, each regist er c l ea r function can be

individually driven by the active-low dedica te d global clea r pin

(GCLRn). Upon power-up, each register in the device will be set to a

low state.

All MAX 7000E and MAX 70 00S I/O pins h ave a f a st input path to a

macrocell registe r . T his ded ica te d pat h a llows a s ig nal to by pas s t he

PIA and combinatorial logic and be driven t o an input D flipflop w ith

an extremely fast (2.5 ns) input setup time.

Expander Product Terms

Although most logic functions can be implemented with the five

product terms available in each macrocell, the more complex logic

functions require additional product terms. Another macrocell can

be used to supply the required logic resources; however, the

MAX 7000 architecture also allows both shareable and parallel

expander product terms (“expanders”) that provide additional

product terms directly to any macrocell in the same LAB. These

expanders help ensure that logic is synthesized with the fewest

possible logic resources to obtain the fastest possible speed.

Altera Corporation 11

Page 12

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

m

m

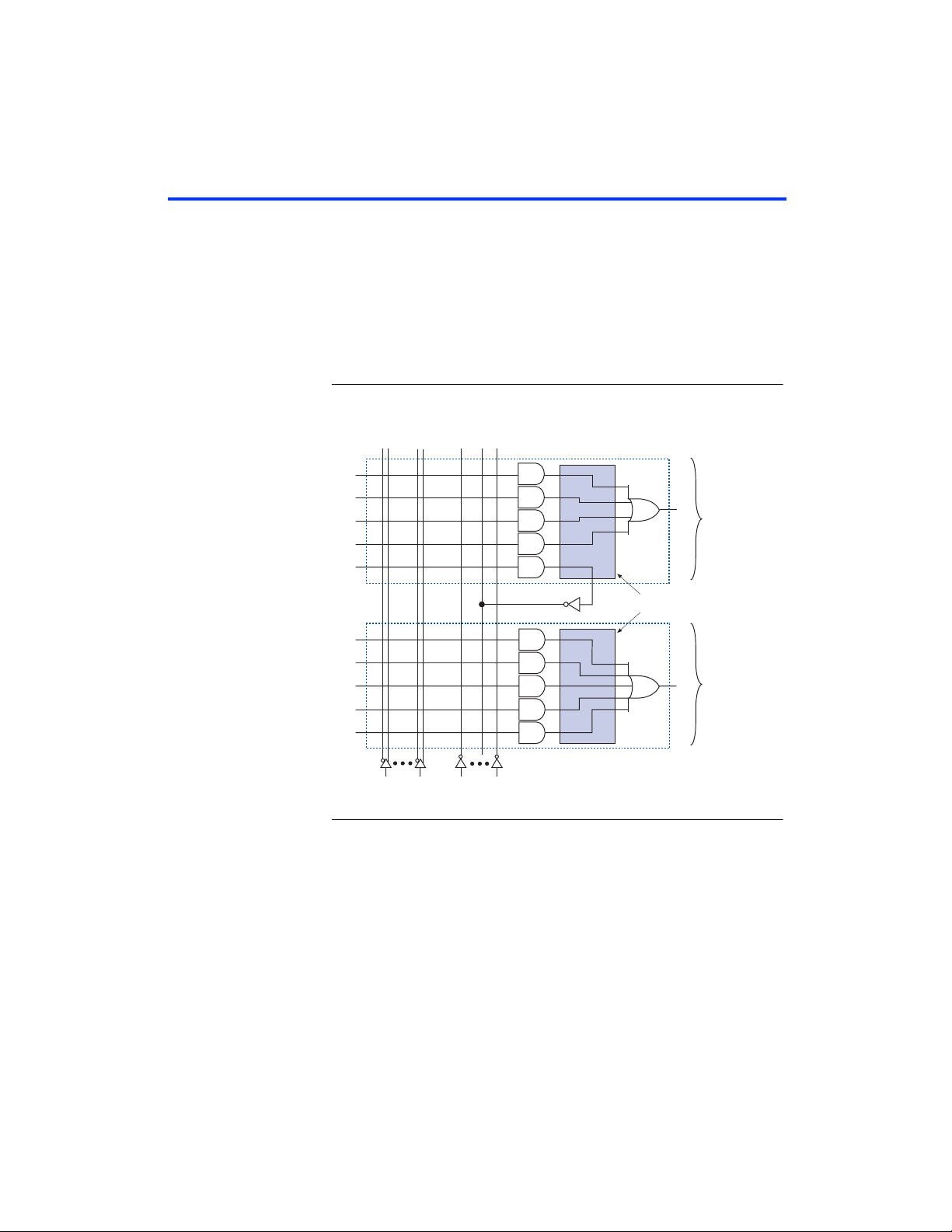

Shareable Expanders

Each LAB has 16 shareable expanders that can be viewed as a pool of

uncommitted single product terms (one from each macrocell) with

inverted outputs that feed back into the logic array. Each shareable

expander can be used and shared by any or all macrocells in the LAB to

build complex logic functions. A small delay (t

shareable expanders are used. Figure 5 shows how shareable exp anders

can feed multiple macrocells.

Figure 5. Shareable Expanders

Shareable expanders can be shared by any or all macrocells in an LAB.

) is incurred when

SEXP

Product-Term Select Matrix

Macrocell

Product-Ter

Logic

Macrocell

Product-Ter

Logic

36 Signals

from PIA

16 Shared

Expanders

Parallel Expanders

Parallel expanders are unused product terms that can be allocated to a

neighboring macrocell to implement fast, complex logic functions.

Parallel expanders allow up to 20 product terms to directly feed the

macrocell OR logic, with five product te rms provided by the macrocell and

15 parallel expanders provided by neighboring macrocells in the LAB.

12 Altera Corporation

Page 13

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

From

The compile r can allocate up t o three sets of up to f iv e parallel expa nd ers

automatically to the macrocells that require additional product terms.

Each set of five parallel expanders incurs a small, incremental timing

delay (t

). For example, if a macrocell requires 14 product terms, the

PEXP

Compiler use s the five dedicated pr oduct terms within the macroce ll a nd

allocates two se ts of parallel expande rs; the first set includ e s fiv e p rodu ct

terms and th e secon d set includ es fo ur product terms , inc reasing the to tal

delay by 2 × t

PEXP

.

Two groups of 8 macrocells within each LAB (e.g., macrocells

1 through 8 and 9 through 16) form two chains to lend or borrow parallel

expanders. A macrocell borrows parallel expanders from lowernumbered macrocells. For example, macrocell 8 can borrow parallel

expanders from macrocell 7, from macrocells 7 and 6, or from macrocells

7, 6, and 5. Within each group of 8, the lowest-numbered macrocell can

only lend parallel expanders and the highest-numbered macrocell can

only borrow them. Figure 6 shows how parallel ex pa nd er s ca n be

borrowed from a neighboring macrocell.

Figure 6. Parallel Expanders

Unused product terms in a macrocell can be allocated to a neighboring macrocell.

Previous

Macrocell

Preset

36 Signals

from PIA

16 Shared

Expanders

Product-

Term

Select

Matrix

Product-

Term

Select

Matrix

Clock

Clear

Preset

Clock

Clear

To Next

Macrocell

Macrocell

ProductTerm Logic

Macrocell

ProductTerm Logic

Altera Corporation 13

Page 14

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Programmable Int er co nnec t A rray

Logic is routed between LABs via the programmable interconnect array

(PIA). This global bus is a programmable path that connects any signal

source to any destination on the device. All MAX 7000 dedicated inputs,

I/O pins, and macrocell outputs feed the PIA, which makes the signals

available thro ugh out t he e ntire device. Only the sig nals required by eac h

LAB are actually routed from the PIA into the LAB. Figure 7 shows how

the PIA signals are routed into the LAB. An EEPROM cell controls one

input to a 2-input AND gate, which selects a PIA signal to drive into the

LAB.

Figure 7. PIA Ro ut ing

PIA

Signals

To LAB

While the routing dela ys of cha nne l-b ased r outi ng sche me s in ma sk ed or

FPGAs are cumulativ e, vari able, and path-d epen dent, the MAX 7000 PI A

has a fixed delay. The PIA thus eliminates skew between signals and

makes timing performance easy to predict.

I/O Control Blocks

The I/O control block allows each I/O pin to be individually configured

for input, output, or bidirectional operation. All I/O pins have a tri-state

buffer that is individually controlled by one of the global output enable

signals or directly connected to ground or V

control block for the MAX 7000 family. The I/O control block of EPM7032,

EPM7064, and EP M7096 device s has two global outp ut enable signal s that

are driven by t wo dedicate d active-low ou tput ena ble pins ( OE1 and OE2).

The I/O control block of MAX 7000E and MAX 7000S devices has six

global output enab le signa ls that are d riven by the true or complemen t of

two output enable sig na ls, a s ubse t of t he I /O pin s, o r a sub set of the I /O

macrocells.

14 Altera Corporation

. Figure 8 shows the I/O

CC

Page 15

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

E

M

F

Figure 8. I/O Control Block of MAX 7000 Devices

PM7032, EPM7064 & EPM7096 Devices

VCC

OE1

OE2

GND

rom Macrocell

To PIA

AX 7000E & MAX 7000S Devices

Six Global Output Enable Signals

PIA

VCC

To Other I/O Pins

From

Macrocell

Fast Input to

Macrocell

Register

To PIA

GND

Open-Drain Output (1)

Slew-Rate Control

Note:

(1) The open- d r ain o utput option is available only in MAX 7000S d ev i ces.

Altera Corporation 15

Page 16

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

When the tri-state buffer control is connected to ground, the output is

tri-stated (high impedance) and the I/O pin can be used as a dedicated

input. When the tri-sta te buffer cont r ol is con ne cted to V

enabled.

The MAX 7000 architecture provides dual I/O feedback, in which

macrocell and pin feedbacks are independent. When an I/O pin is

configured as an input, the associated macrocell can be used for buried

logic.

, the output is

CC

In-System

Programmability (ISP)

MAX 7000S devices are in-system programmable via an

industry-standard 4-pin Joint Test Action Group (JTAG) interface (IEEE

Std. 1149.1-1990). ISP allows quick, efficient iterations during design

development and debugging cycles. The MAX 7000S architecture

internally generates the high programming voltage required to program

EEPROM cells, allowing in-syst em programming wit h only a sing le 5.0 V

power supply. Du ring in-system pr ogramming, the I /O pins are tri- stated

and pulled-up to eliminate boa rd conflicts. The pull-up value is nomi nally

50 k¾.

ISP simplifies the man ufacturing flow by allowi ng devices to be mou nted

on a printed circuit board with standard in-circuit test equipment before

they are programmed. MAX 7000S devices can be programmed by

downloading the information via in-circuit teste rs (ICT), embedde d

processors, or the Altera MasterBlaster, ByteBlasterMV, ByteBlaster,

BitBlaster download cables. (The ByteBlaster cable is obsolete and is

replaced by the ByteBlast erMV cable, which can program and configure

2.5-V, 3 .3-V, and 5.0-V devi ces.) Prog ramming the devices after they are

placed on the board eliminates lead damage on high-p in-cou nt pa ck ages

(e.g., QFP packages) due to device handling and allows devices to be

reprogrammed after a system has already shipped to the field. For

example, product upgrades can be performed in the field via software or

modem.

In-system programming can be accomplished with either an adaptive or

constant algorithm. An adaptive algorithm reads information from the

unit and adapts subsequent programming steps to achieve the fastest

possible programming time for that unit. Because some in-circuit testers

cannot support a n adaptive alg or ithm, Altera o ff ers d evic es te sted with a

constant algorithm. Devices tested to the constant algorithm have an “F”

suffix in the ordering code.

TM

The Jam

used to program MAX 7000S devices with in-circuit testers, PCs, or

embedded processor.

16 Altera Corporation

Standard Test and Programming Lang uage (STAPL) can be

Page 17

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

f

For more information on using the Jam language, see Application Note 88

(Using the Jam Language for ISP & ICR via an Embedded Processor).

The ISP circuitr y in MAX 7000S devices is compa tible wit h IEEE Std. 1532

specification. The IEEE Std. 1532 is a standard developed to allow

concurrent ISP between multiple PLD vendors.

Programming Seque nce

During in-system programming, instructions, addresses, and data are

shifted into the MAX 7000S device through the TDI input pin. Data is

shifted out through the TDO output pin and compared against the

expected data.

Programming a pattern into the device requires the following six ISP

stages. A stand-alon e verification of a programmed pa ttern invo lves only

stages 1, 2, 5, and 6.

1. Enter ISP. The enter ISP stage ensures that the I/O pins transition

smoothly from user mode to ISP mode. The enter ISP stage requires

1ms.

2. Check ID. Before any program or verify process, the silicon ID is

checked. The time required to read this silicon ID is relatively small

compared to the overall programming time.

3. Bulk Erase. Erasing the device in-system involves shifting in the

instructions to erase the device and applying one erase pulse of

100 ms.

4. Program. Programming the device in-system involves shifting in the

address and data and then applying the programming pulse to

program the EEPROM cells. This process is repeated for each

EEPROM address.

5. Verify. Verifying an Altera device in-system involves shifting in

addresses, applying the read pulse to verify the EEPROM cells, and

shifting out the data for comparison. This process is repeated for

each EEPROM address.

6. Exit ISP. An exit ISP stage ensures that the I/O pins transition

smoothly from ISP mode to user mode. The exit ISP stage requires

1ms.

Altera Corporation 17

Page 18

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

t

K

-- -

t

Cycle

---

Programming Times

The time required to implement each of the six programming stages can

be broken into the following two elements:

■ A pulse time to erase, program, or read the EEPROM cells.

■ A shifting time based on the test clock (TCK) frequency and the

number of TCK cycles to shift instructions, address, and data into the

device.

By combining the pulse and shift times for each of the programming

stages, the prog ram or v erify t ime ca n be d er ived as a fu nct ion of the TCK

frequency, the number of devices, and specific target device(s). Because

different ISP-capable devices have a different number of EEPROM cells,

both the total fix ed and total var iable tim es are unique for a si ngle d evice.

Programming a Single MAX 7000S Device

The time required to program a single MAX 7000S device in-system can

be calculated from the following formula:

Cycle

PTC

+=

PROGtPPULSE

--------- --------------- -----

f

TCK

where: t

PROG

t

PPULSE

= Programming time

= Sum of the fixed times to erase, program, and

verify the EEPROM cells

Cycle

f

TCK

=Number of TCK cycles to program a device

PTCK

= TCK frequency

The ISP tim es for a stand-alone veri fica tion of a single M AX 7000S device

can be calculated from the following formula:

VTCK

+=

VERtVPULSE

where: t

VER

t

VPULSE

Cycle

18 Altera Corporation

---------- --------------- ----

f

TCK

=Verify time

= Sum of the fixed times to verify the EEPROM cells

=Number of TCK cycles to verify a device

VTCK

Page 19

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

The programming times described in Tables 6 through 8 are ass o ciated

with the worst-case method using the enhanced ISP algorithm.

Table 6.MAX 7000S t

PULSE

& Cycle

TCK

Values

Device Programming Stand-Alone Verification

(s) Cycle

t

PPULSE

EPM7032S 4.02 342,000 0.03 200,000

EPM7064S 4.50 504,000 0.03 308,000

EPM7128S 5.11 832,000 0.03 528,000

EPM7160S 5.35 1,001,000 0.03 640,000

EPM7192S 5.71 1,192,000 0.03 764,000

EPM7256S 6.43 1,603,000 0.03 1,024,000

PTCK

t

(s) Cycle

VPULSE

VTCK

Tables 7 and 8 show the in-system programming and stand alone

verification times for several common test clock frequencies.

Table 7. MAX 7000S In-Sy stem Programming Times for Different Test Clock Frequencies

Device f

TCK

10 MHz 5 MHz 2 MHz 1 MHz 500 kHz 200 kHz 100 kH z 50 kHz

EPM7032S 4.06 4.09 4.19 4.36 4.71 5.73 7.44 10.86 s

EPM7064S 4.55 4.60 4.76 5.01 5.51 7.02 9.54 14.58 s

EPM7128S 5.19 5.27 5.52 5.94 6.77 9.27 13.43 21.75 s

EPM7160S 5.45 5.55 5.85 6.35 7.35 10.35 15.36 25.37 s

EPM7192S 5.83 5.95 6.30 6.90 8.09 11.67 17.63 29.55 s

EPM7256S 6.59 6.75 7.23 8.03 9.64 14.45 22.46 38.49 s

Units

Table 8.MAX 7000S Stand-Alone Verification Times for Different Test Clock Frequencies

Device f

TCK

Units

10 MHz 5 MHz 2 MHz 1 MHz 500 kHz 200 kHz 100 kHz 50 kHz

EPM7032S 0.05 0.07 0.13 0.23 0.43 1.03 2.03 4.03 s

EPM7064S 0.06 0.09 0.18 0.34 0.64 1.57 3.11 6.19 s

EPM7128S 0.08 0.14 0.29 0.56 1.09 2.67 5.31 10.59 s

EPM7160S 0.09 0.16 0.35 0.67 1.31 3.23 6.43 12.83 s

EPM7192S 0.11 0.18 0.41 0.79 1.56 3.85 7.67 15.31 s

EPM7256S 0.13 0.24 0.54 1.06 2.08 5.15 10.27 20.51 s

Altera Corporation 19

Page 20

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Programmable

Speed/Power

Control

Output

Configuration

MAX 7000 devices offer a power-saving mode that supports low-power

operatio n across user-define d signal paths or the ent ire device. This

feature allows total power dissipation to be reduced by 50% or more,

because most logic app lications requir e only a small fr action of all ga tes to

operat e at maximum frequency.

The designer can program each individual macrocell in a MAX 7000

TM

device for either high-speed (i.e., with the Turbo Bit

option turned on)

or low-power (i.e., with the Turbo Bit option turned off) operation. As a

result, speed-critical paths in the design can run at high speed, while the

remaining paths ca n operate at re duced power . Macrocells t hat run at low

power incur a nominal timing delay adder (t

t

EN

, and t

SEXP

, t

ACL

, and t

parameters.

CPPW

) for the t

LPA

LAD

, t

, tIC,

LAC

MAX 7000 device outputs can be programmed to meet a variety of

system-level requ ir eme nts.

MultiVolt I/O Interface

MAX 7000 devices—except 44-pin devices—support the MultiVolt I/O

interface feature, which allo ws MAX 7000 devices to interfac e with

systems that have differing supply voltages. The 5.0-V devices in all

packages can be set for 3.3-V or 5.0-V I/O pin operation. These devices

have one set of VCC pins for internal operation and input buffers

(VCCINT), and another set for I /O output drivers (VCCIO).

The VCCINT pins must always be connected to a 5.0-V power supply.

With a 5.0-V V

are therefore compatible with both 3.3-V and 5.0-V inputs.

level, input voltage thre shold s are at TTL levels, and

CCINT

The VCCIO pins can be connected to either a 3.3-V or a 5.0-V power

supply, depending on th e output require ments. When the VCCIO pins are

connected to a 5.0-V supply, the output levels are compatible with 5.0-V

systems. When V

is connected to a 3.3-V supply, the output high is

CCIO

3.3 V and is therefore compatible with 3.3-V or 5.0-V systems. Devices

operating with V

timing delay of t

levels lower than 4.75 V incur a nominally greater

CCIO

instead of t

OD2

OD1

.

Open-Drain Output Option (MAX 7000S Devic es Only )

MAX 7000S devices provide an optional open-drain (functionally

equivalent to open-collector) output for each I/O pin. This open-drain

output enables the device to provide system-level control signals (e.g.,

interrupt and write enable signals) that can be asserted by any of several

devices. It can also provide an additional wired-OR plane.

20 Altera Corporation

Page 21

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

By using an external 5.0-V pull-up resistor, output pins on MAX

7000S devices can be set to meet 5.0-V CMOS input vol tages. When

is 3.3 V, setting the open drain option will turn off the output

V

CCIO

pull-up transistor, allowing the external pull-up resistor to pull the

output high enough to meet 5.0-V CMOS input voltages. When

is 5.0 V, setting the output drain option is not necessary

V

CCIO

because the pull-up transistor will already turn off when the pin

exceeds appr oximately 3.8 V, allowing the external pull-up r esistor to

pull the output high enough to meet 5.0-V CMOS input voltages.

Slew-Rate Control

The output buffer for each MAX 7000E and MAX 7000S I/O pin has

an adjustable output slew rate that can be configured for low-noise

or high-speed performance. A faster slew r ate provid es high-sp eed

transit ions for high-performance sy stems. However, these fast

transitions may introduce noise transients into the system. A slow

slew rate reduces s ystem noise, b ut adds a nominal de lay of 4 to 5 ns.

In MAX 7000E devices, when the Turbo Bit is turned off, the slew

rate is set for low noise performance. For MAX 7000S devices, each

I/O pin has an individual EEPROM bit that controls the slew rate,

allowing designers to specify the slew rate on a pin-by-pin basis.

Programming wi th

External Hardware

f

f

Altera Corporation 21

MAX 7000 devices can be programmed on Windows- based PCs with

the Altera Logic Programmer card, the Master Pro gramming Unit

(MPU), and the appropriate device adapter. The MPU performs a

continuity check to ensure adequate electrical contact between the

adapter and the dev ice.

For more information, see the Altera Programming Hardware Data

Sheet.

The Altera development system can use text- or waveform-format

test vectors created with the Text Editor or Waveform Editor to test

the programmed device. For added de sign verification, designers

can perform functional te sting to compare the functional beha vior of

a MAX 7000 device with the results of simulation. Moreover, Data

I/O, BP Microsystems, and other programming hardware

manufacturers also provide programming support for Altera

devices.

For more information, see the Programming Hardware Manufacturers.

Page 22

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

IEEE Std.

1149.1 (JTAG)

Boundary-Scan

Support

MAX 7000 devices support JTAG BST circuitry as specified by IEEE Std.

1149.1-1990. Table 9 describes the JTAG instructions supported by the

MAX 7000 family. The pin-out tables (see the Altera web site

(http://www.altera.com) or the Altera Digital Library for pin-out

information) show the location of the JTAG control pins for each device.

If the JTAG interface is not requir ed, the JTAG pins are available as us er

I/O pins.

Table 9. MAX 7000 JTAG Inst ructions

JTAG Instruction Dev ice s Description

SAMPLE/PRELOAD EPM7128S

EPM7160S

EPM7192S

EPM7256S

EXTEST EPM7128S

EPM7160S

EPM7192S

EPM7256S

BYPASS EPM7032S

EPM7064S

EPM7128S

EPM7160S

EPM7192S

EPM7256S

IDCODE EPM7032S

EPM7064S

EPM7128S

EPM7160S

EPM7192S

EPM7256S

ISP Instructions EPM7032S

EPM7064S

EPM7128S

EPM7160S

EPM7192S

EPM7256S

Allows a snapshot of signals at the device pins to be captured and

examined during normal dev ic e operation, and permits an initial data

pattern output at the device pins.

Allows the external circuitry and board-level interconnections to be

tested by forcing a test pattern at the out put pins and c apt uring test

results at the input pins.

Places the 1-bit bypass register between the TDI and TDO pins, which

allows the BST data to pass synchronously through a selected device

to adjacent devices during normal device operation.

Selects the IDCODE registe r and plac es it be tween TDI and TDO,

allowing the IDCODE to be serially shifted out of TDO.

These instructions are used whe n programming MAX 7000S devices

via the JTAG ports with the MasterBlaster, ByteBlasterMV, BitBlaster

download cable, or using a Jam File (.jam), Jam Byte -Co de f ile (.jbc),

or Ser ial Vect or F ormat file (.svf) via an embedded proc es s or or te st

equipment.

22 Altera Corporation

Page 23

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

The instruction r egist er len gt h of MAX 7000S d evices is 10 bits . Tables 10

and 11 show the boundary-scan register length and device IDCODE

information for MAX 7000S devices.

Table 10. MAX 7000S Boundary-Scan R egister Length

Device Boundary-Scan Register Length

EPM7032S 1 (1)

EPM7064S 1 (1)

EPM7128S 288

EPM7160S 312

EPM7192S 360

EPM7256S 480

Note:

(1) This device does not support JTAG boundary-scan testing. Selecting either the

EXTEST or SAMPLE/PRELOAD instruction will select the one-bit bypass register.

Table 11.32-Bit MAX 7000 Device IDCODE Note (1)

Device IDCODE (32 Bits)

Version

(4 Bits)

EPM7032S 0000 0111 0000 0011 0010 00001101110 1

EPM7064S 0000 0111 0000 0110 0100 00001101110 1

EPM7128S 0000 0111 0001 0010 1000 00001101110 1

EPM7160S 0000 0111 0001 0110 0000 00001101110 1

EPM7192S 0000 0111 0001 1001 0010 00001101110 1

EPM7256S 0000 0111 0010 0101 0110 00001101110 1

Notes:

(1) The most significant bit (MSB) is on the left.

(2) The least si gnificant bi t (L SB) for all JTAG IDCODEs is 1.

Altera Corporation 23

Part Number (16 Bi t s) Manufacturer’s

Identity (11 Bits)

1 (1 Bit)

(2)

Page 24

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Figure9 shows the timing requirements for the JTAG signals.

Figure 9. MAX 7000 JTAG Waveforms

TMS

TDI

t

JCP

JCH

t

JCL

t

TCK

t

JPSU

t

JPH

t

JPXZ

TDO

Signal

to Be

Captured

Signal

to Be

Driven

t

t

JPZX

JSZX

t

JSSU

t

JPCO

t

JSH

t

JSCO

t

JSXZ

Table12 shows the JTAG timing parameters and values for MAX 7000S

devices.

Table 12. JTAG Timing Parameters & Values for MA X 7000S Devices

Symbol Parameter Min Max Unit

t

t

t

t

t

t

t

t

t

t

t

t

t

TCK clock period 100 ns

JCP

TCK clock high time 50 ns

JCH

TCK clock low time 50 ns

JCL

JTAG port setup time 20 ns

JPSU

JTAG port hold time 45 ns

JPH

JTAG port clock to output 25 ns

JPCO

JTAG port high impedance t o val id out put 25 ns

JPZX

JTAG port valid output to high im pedance 25 ns

JPXZ

Capture register setup time 20 ns

JSSU

Capture register hold time 45 ns

JSH

Update register clock to output 25 ns

JSCO

Update register high impedance to valid output 25 ns

JSZX

Update register valid output to high impedance 25 ns

JSXZ

f

For more information, see Application Note 39 (IEEE 1149.1 (JTAG)

Boundary-Scan Testing in Altera Devices).

24 Altera Corporation

Page 25

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

VCC

Design Security

Generic Testing

All MAX 7000 devices contain a programmable security bit that controls

access to the data programmed into the device. When this bit is

programmed, a proprietary design implemented in the devi ce cannot be

copied or retrieved. This feature provides a high level of design security

because programmed data wit hin EEPROM cells is invisible . The security

bit that controls this function, as well as all other programmed data, is

reset only when the device is reprogrammed.

Each MAX 7000 device is functionally tested. Complete testing of each

programmable EEPROM bit a nd a ll in te rnal logi c e lements e nsur es 1 00 %

programming yield . AC test measurements are taken under conditions

equivalent to those sh own in Figure 10. Test patt erns c an be u sed an d the n

erased during early stages of the production flow.

Figure 10 . MAX 7000 AC Test Conditions

Power supply transients can affect AC

measurements. Simultaneous

transitions of m ulti pl e out put s sh ould be

avoided for accurate measurement.

Threshold tes ts must not be performed

under AC condit ions. Large-ampli tude,

fast ground- current transients normally

occur as the device outputs discharge

the load capacitances. When these

transients flow through the parasitic

inductance be tween the device grou nd

pin and the test system ground,

significant reductions in observable

noise immunity can result. Numbers in

brackets are for 2.5-V devices and

outputs. Numbers without brackets are

for 3.3-V devices and outputs.

464 Ω

[703 Ω]

Device

Output

250

[8.06 ]

KΩ

Device input

rise and fall

times < 3 ns

To Test

System

Ω

C1 (includes JIG

capacitance)

QFP Carrier &

Development

Socket

MAX 7000 and MAX 7000E de vices in QFP package s with 100 or more

pins are shipped in special plastic carriers to protect the QFP leads. The

carrier is used with a prototype development socket and special

programming hardware available from Altera. This carrier technology

makes it possible to prog ram, tes t, erase, a nd reprogra m a device without

exposing the leads to mechanical stress.

f

For detailed information and carrier dimensions, refer to the QFP Carrier

& Development Socket Data Sheet.

1 MAX 7000S devices are not shipped in carriers.

Altera Corporation 25

Page 26

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Operating

Conditions

Tables 13 through 18 provide information about absolute maximum

ratings, recommended operating conditions, operating conditions, and

capacitance for 5.0-V MAX 7000 devices.

Table 13. MAX 7000 5.0-V Device Absolute Maxi mum Ratings Note (1)

Symbol Parameter Conditions Min Max Unit

V

V

I

T

T

T

OUT

Supply voltage With respect to ground (2) –2.0 7.0 V

CC

DC input voltage –2.0 7.0 V

I

DC output current, per pin –25 25 mA

Storage temperature N o bias –65 150 ° C

STG

Ambient temperature Under bias –65 135 ° C

AMB

Junction temperature C eramic packages, under bias 150 ° C

J

PQFP and RQFP packages, under bias 135 ° C

Table 14. MAX 7000 5.0-V Device Recommended Op erating Conditions

Symbol Parameter Conditions Min Max Unit

V

V

V

V

V

T

T

t

R

t

F

Supply voltage for internal logic and

CCINT

input buffers

Supply voltage for output drivers,

CCIO

5.0-V operation

Supply voltage for output drivers,

3.3-V operation

Supply voltage during ISP (7) 4.75 5.25 V

CCISP

Input voltage –0.5 (8) V

I

Output voltage 0V

O

Ambient temperature For commercial use 0 70 ° C

A

Junction temperature For commercial use 0 90 ° C

J

Input rise time 40 ns

Input fall time 40 ns

(3), (4), (5) 4.75

(4.50)

(3), (4) 4.75

(4.50)

(3), (4), (6) 3.00

(3.00)

For industrial use –40 85 ° C

For industrial use –40 105 ° C

5.25

(5.50)

5.25

(5.50)

3.60

(3.60)

CCINT

CCIO

+ 0.5 V

V

V

V

V

26 Altera Corporation

Page 27

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

Table 15.MAX 7000 5.0-V Device DC Operating Conditions Note (9)

Symbol Parameter Conditions Min Max Unit

V

V

V

V

I

I

I

OZ

High-level input voltage 2.0 V

IH

Low-level input voltage –0.5 (8) 0.8 V

IL

5.0-V high-level TTL output voltage IOH = –4 mA DC, V

OH

3.3-V high-level TTL output voltage I

3.3-V high-level CMOS output

voltage

5.0-V low-level TTL output voltage IOL = 12 mA DC, V

OL

3.3-V low-level TTL output voltage I

3.3-V low-level CMOS output

voltage

Leakage current of dedicated input

= –4 mA DC, V

OH

I

= –0.1 mA DC, V

OH

= 12 mA DC, V

OL

I

= 0.1 mA DC, V

OL

VI = –0.5 to 5.5 V (11) –10 10 µA

= 4.75 V (10) 2.4 V

CCIO

= 3.00 V (10) 2.4 V

CCIO

= 3.0 V (10) V

CCIO

= 4.75 V (11) 0.45 V

CCIO

= 3.00 V (11) 0.45 V

CCIO

= 3.0 V(11) 0.2 V

CCIO

– 0.2 V

CCIO

pins

I/O pin tri-state output off-state

VI = –0.5 to 5.5 V (11), (12) –40 40 µA

current

CCINT

+ 0.5 V

Table 16.MAX 7000 5.0-V Device Capacitance: EPM7032, EPM7064 & EPM7096 Devices Note (13)

Symbol Parameter Conditions Min Max Unit

C

C

Input pin capacitance VIN = 0 V, f = 1.0 MHz 12 pF

IN

I/O pin capacitance V

I/O

= 0 V, f = 1.0 MHz 12 pF

OUT

Table 17.MAX 7000 5.0-V Device Capacitance: MAX 7000E Devices No te (13)

Symbol Parameter Conditions Min Max Unit

C

C

Input pin capacitance VIN = 0 V, f = 1.0 MHz 15 pF

IN

I/O pin capacitance V

I/O

= 0 V, f = 1.0 MHz 15 pF

OUT

Table 18.MAX 7000 5.0-V Device Capacitance: MAX 7000S Devices Note (13)

Symbol Parameter Conditions Min Max Unit

C

C

Altera Corporation 27

Dedicated input pin capacitance VIN = 0 V, f = 1.0 MHz 10 pF

IN

I/O pin capacitance V

I/O

= 0 V, f = 1.0 MHz 10 pF

OUT

Page 28

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

T

O

C

Notes to tables:

(1) See the Operating Requirements for Altera Devices Data Sheet.

(2) Minimu m DC input volta ge on I/O pins is –0 . 5 V a n d on 4 dedicated input pins is –0 . 3 V. D ur ing transit ions, the

inputs may undershoot to –2.0 V or overshoot to 7.0 V for input currents less than 100 mA and periods shorter than

20 ns.

(3) Numbers in parentheses are for industrial-te mperatur e-ra nge devices.

(4) V

(5) The POR time for all 7000S devices does not exceed 300 µs. The sufficient V

(6) 3.3-V I/O operation is n ot avail able for 44-pin packages.

(7) The V

(8) During in-system pro gr a mming, the minimum DC input voltage is –0.3 V.

must rise monotonically.

CC

device is fully initialized within the POR time after V

parameter applies only t o MA X 7000S devices.

CCISP

voltage level for POR is 4.5 V. The

reaches the sufficient POR voltage level.

CCINT

CCINT

(9) The se values are specified under the MAX 7000 recommended operating conditions in Table 14 on page 26.

(10) The parameter is measured with 50% of the outputs each sourcing the specified current. The I

to high-level TTL or CMOS output current.

(11) The parameter is measured with 50% of the outputs each sinking the specified current. The I

low-level T T L, PCI, or CM OS output current.

parameter refers

OH

parameter refers to

OL

(12) When the JTAG interface is enabled in MAX 7000S devices, the input leakage current on the JTAG pins is typically

–60 µA.

(13) Capacitan c e is measured at 25° C and is sample-tested only. The

OE1 pin has a maximum capacitance of 20 pF.

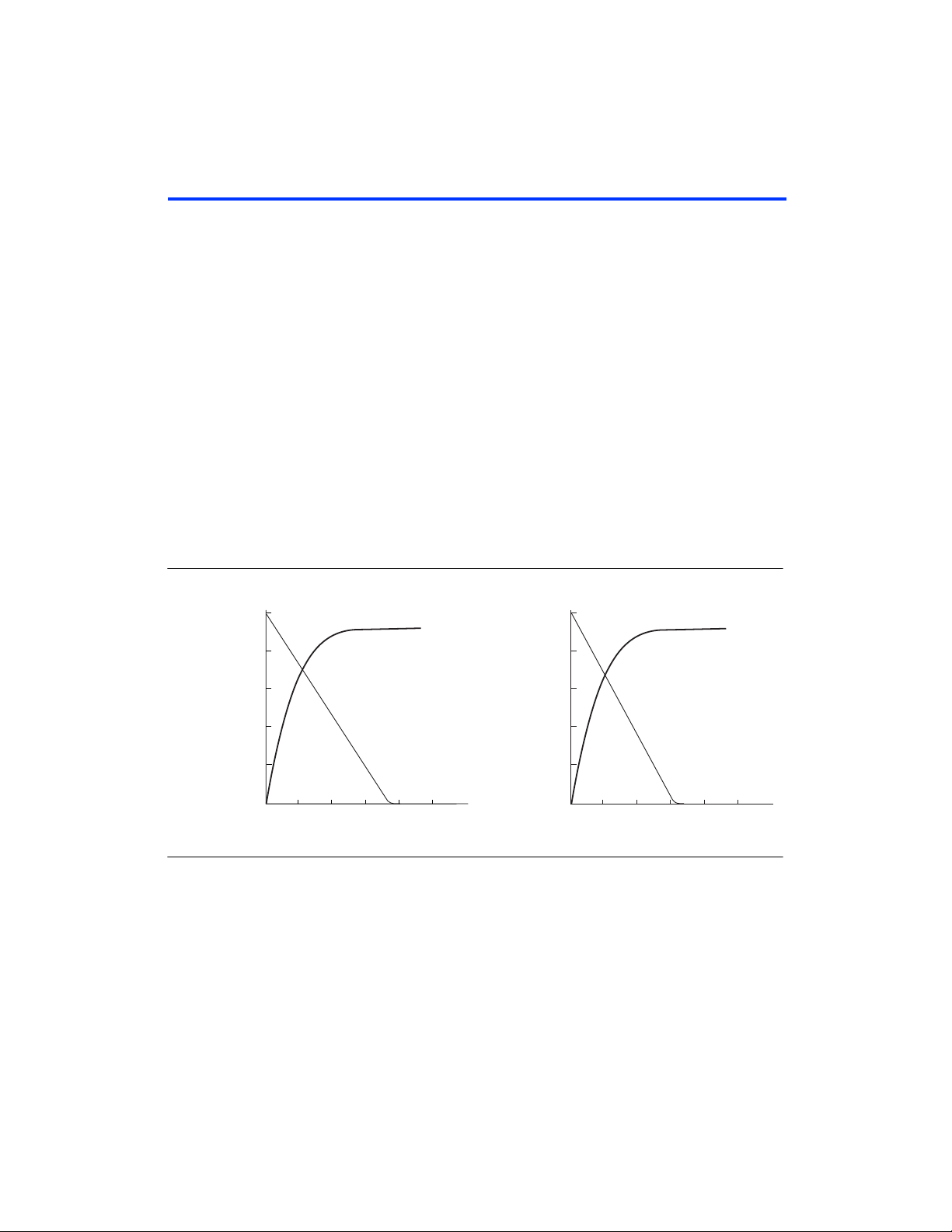

Figure 11 shows the typical output drive characteristics of MAX 7000

devices.

Figure 11. Output Drive Characteristics of 5.0-V MAX 7000 Devices

150

120

90

I

ypical

O

utput

urrent (mA)

60

30

Timing Model

I

OL

Typical

V

= 5.0 V

CCIO

Room T emperature

I

OH

12345

Output

Current (mA)

VO Output Voltage (V)

MAX 7000 de vice timi ng ca n be an aly zed wi th the Alt era so ftwa re, with a

variety of popula r industry-standard EDA simulators and timing

150

120

90

I

O

60

30

12345

I

OL

V

= 3.3 V

CCIO

Room T emperature

I

OH

3.3

VO Output Voltage (V)

analyzers, or with the timing model shown in Figure 12. MAX 7000

devices have fixed internal delays that enable the designer to determine

the worst-case ti ming of any design . The Alt era sof tware provid es timin g

simulation, point-to-point delay prediction, and detailed timing analysis

for a device-wide performance evaluation.

28 Altera Corporation

Page 29

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

Figure 12 . MAX 7000 Timing Model

Internal Output

Enable Delay

t

(1)

IOE

Input

Delay

t

IN

PIA

Delay

t

PIA

Global Control

Delay

t

GLOB

Logic Array

Delay

t

LAD

Register

Control Delay

t

LAC

t

IC

t

EN

Shared

Expander Delay

t

SEXP

Notes:

(1) Only available in M A X 7000E and MAX 7000S devi ces.

(2) Not available in 44-pin d evices.

The timing characteristics of any signal path can be derived from the

timing model and parameters of a particular dev ice . Ex te rn al timing

parameters, which represent pin-to-pin timing delays, can be calculated

as the sum of internal parameters. Figure 13 shows the internal timing

relationship of internal and external delay parameters.

Parallel

Expander Delay

t

PEXP

Input Delay

Fast

t

FIN

(1)

Register

Delay

t

SU

t

H

t

PRE

t

CLR

t

RD

t

COMB

t

FSU

t

FH

Output

Delay

t

OD1

t

OD2

t

OD3

t

XZ

t

X1

Z

t

ZX2

t

ZX3

(2)

(2)

(1)

I/O

Delay

t

IO

f

For more infomration, see Application Note 94 (Understanding MAX 7000

Timing).

Altera Corporation 29

Page 30

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Figure 13. Swi t ch i ng W aveforms

tR & tF < 3 ns.

Inputs are driven at 3 V

for a logic high and 0 V

for a logic low. A ll timing

characteristics are

measured at 1.5 V.

Input Pin

I/O Pin

PIA Delay

Shared Expander

Parallel Expander

Delay

Logic Array

Input

Delay

Logic Array

Output

Output Pin

Global

Clock Pin

Global Clock

at Register

Data or Enable

(Logic Array Output)

Combinatorial Mode

t

IN

t

IO

Global Clock Mode

t

IN

tSUt

t

CH

t

GLOB

H

t

R

t

PIA

t

SEXP

t

, t

LAC

LAD

t

PEXP

t

COMB

t

OD

t

CL

t

F

Array Clock Mode

t

F

t

, t

CLR

PRE

t

PIA

t

OD

Input or I/O Pin

Clock into PIA

Clock into

Logic Array

Clock at

Register

Data from

Logic Array

Register to PIA

to Logic Array

Register Output

to Pin

t

R

t

ACH

t

IN

t

IO

t

PIA

t

ACL

t

IC

t

t

SU

H

t

RD

t

PIA

t

OD

30 Altera Corporation

Page 31

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

Tables 19 through 26 show the MAX 7000 and MAX 7000E AC

operating conditions.

Table 19.MAX 7000 & MAX 7000E External Timing Parameters Note (1)

Symbol Parameter Conditions -6 Speed Grade -7 Speed Grade Unit

Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

FSU

t

FH

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

ODH

t

CNT

f

CNT

t

ACNT

f

ACNT

f

MAX

Input to non-registered output C1 = 35 pF 6.0 7.5 ns

I/O input to non-registered output C1 = 35 pF 6.0 7.5 ns

Global clock setup time 5.0 6.0 ns

Global clock hold time 0.0 0.0 ns

Global clock setup time of fast input (2) 2.5 3.0 ns

Global clock hold time of fast input (2) 0.5 0.5 ns

Global clock to output delay C1 = 35 pF 4.0 4.5 ns

Global clock high time 2.5 3.0 ns

Global clock low time 2.5 3.0 ns

Array clock setup time 2.5 3.0 ns

Array clock hold time 2.0 2.0 ns

Array clock to output delay C 1 = 35 pF 6.5 7.5 ns

Array clock high time 3.0 3.0 ns

Array clock low time 3.0 3.0 ns

Minimum pulse width for clear and

(3) 3.0 3.0 ns

preset

Output data hold time after clock C1 = 35 pF (4) 1.0 1.0 ns

Minimum global clock period 6.6 8.0 ns

Maximum internal global clock

(5) 151.5 125.0 MHz

frequency

Minimum array clock period 6.6 8.0 ns

Maximum internal array clock

(5) 151.5 125.0 MHz

frequency

Maximum clock frequency (6) 200 166.7 MHz

Altera Corporation 31

Page 32

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Table 20. MAX 7000 & MAX 7000E Inter nal Timing Parameters Note (1)

Symbol Parameter Conditions Speed Grade -6 Speed Grade -7 Unit

Min Max Min Max

t

IN

t

IO

t

FIN

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

FSU

t

FH

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

t

PIA

t

LPA

Input pad and buffer delay 0.4 0.5 ns

I/O input pad and buffer delay 0.4 0.5 ns

Fast input delay (2) 0.8 1.0 ns

Shared expander delay 3.5 4.0 ns

Parallel expander delay 0.8 0.8 ns

Logic array delay 2.0 3.0 ns

Logic control array delay 2.0 3.0 ns

Internal output enable delay (2) 2.0 ns

Output buffer and pad delay

Slow slew rate = off, V

CCIO

Output buffer and pad delay

Slow slew rate = off, V

CCIO

Output buffer and pad delay

= 5.0 V

= 3.3 V

C1 = 35 pF 2.0 2.0 ns

C1 = 35 pF (7) 2.5 2.5 ns

C1 = 35 pF (2) 7.0 7.0 ns

Slow slew rate = on,

= 5.0 V or 3.3 V

V

CCIO

Output buffer enable delay

Slow slew rate = off, V

CCIO

Output buffer enable delay

Slow slew rate = off, V

CCIO

Output buffer enable delay

= 5.0 V

= 3.3 V

C1 = 35 pF 4.0 4.0 ns

C1 = 35 pF (7) 4.5 4.5 ns

C1 = 35 pF (2) 9.0 9.0 ns

Slow slew rate = on

= 5.0 V or 3.3 V

V

CCIO

Output buffer disable delay C1 = 5 pF 4.0 4.0 ns

Register setup time 3.0 3.0 ns

Register hold time 1.5 2.0 ns

Register setup time of fast input (2) 2.5 3.0 ns

Register hold time of fast input (2) 0.5 0.5 ns

Register delay 0.8 1.0 ns

Combinatorial delay 0.8 1.0 ns

Array clock delay 2.5 3.0 ns

Register enable time 2.0 3.0 ns

Global control delay 0.8 1.0 ns

Register preset time 2.0 2.0 ns

Register clear time 2.0 2.0 ns

PIA delay 0.8 1.0 ns

Low-power adder (8) 10.0 10.0 ns

32 Altera Corporation

Page 33

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

Table 21.MAX 7000 & MAX 7000E External Timing Parameters Note (1)

Symbol Paramet er Conditi ons Speed G rade Unit

MAX 7000E (-10P) MAX 7000 (-10)

MAX 7000E (-10)

Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

FSU

t

FH

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

ODH

t

CNT

f

CNT

t

ACNT

f

ACNT

f

MAX

Input to non-registered output C1 = 35 pF 10.0 10.0 ns

I/O input to non-registered output C1 = 35 pF 10.0 10.0 ns

Global clock setup time 7.0 8.0 ns

Global clock hold time 0.0 0.0 ns

Global clock setup time of fast input (2) 3.0 3.0 ns

Global clock hold time of fast input (2) 0.5 0.5 ns

Global clock to output delay C1 = 35 pF 5.0 5 ns

Global clock high time 4.0 4.0 ns

Global clock low time 4.0 4.0 ns

Array clock setup time 2.0 3.0 ns

Array clock hold time 3.0 3.0 ns

Array clock to output delay C1 = 35 pF 10.0 10.0 ns

Array clock high time 4.0 4.0 ns

Array clock low time 4.0 4.0 ns

Minimum pulse width for clear and

(3) 4.0 4.0 ns

preset

Output data hold time after clock C1 = 35 pF (4) 1.0 1.0 ns

Minimum global clock period 10.0 10.0 ns

Maximum internal global clock

(5) 100.0 100.0 MHz

frequency

Minimum array clock period 10.0 10.0 ns

Maximum internal array clock

(5) 100.0 100.0 MHz

frequency

Maximum clock frequency (6) 125.0 125.0 MHz

Altera Corporation 33

Page 34

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Table 22. MAX 7000 & MAX 7000E Inter nal Timing Parameters Note (1)

Symbol Parameter Conditio ns Speed Grade Unit

MAX 7000E ( -10P ) MAX 7000 (-10)

MAX 7000E (-10)

Min Max Min Max

t

IN

t

IO

t

FIN

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

FSU

t

FH

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

t

PIA

t

LPA

34 Altera Corporation

Input pad and buffer delay 0.5 1.0 ns

I/O input pad and buffer delay 0.5 1.0 ns

Fast input delay (2) 1.0 1 .0 ns

Shared expander delay 5.0 5.0 ns

Parallel expander delay 0.8 0.8 ns

Logic array delay 5.0 5.0 ns

Logic control array delay 5.0 5.0 ns

Internal output enable delay (2) 2.0 2.0 ns

Output buffer and pad delay

C1 = 35 pF 1.5 2.0 ns

Slow slew rate = off

V

= 5.0 V

CCIO

Output buffer and pad delay

C1 = 35 pF (7) 2.0 2.5 ns

Slow slew rate = off

V

= 3.3 V

CCIO

Output buffer and pad delay

C1 = 35 pF (2) 5.5 6.0 ns

Slow slew rate = on

V

= 5.0 V or 3.3 V

CCIO

Output buffer enable delay

C1 = 35 pF 5.0 5.0 ns

Slow slew rate = off

V

= 5.0 V

CCIO

Output buffer enable delay

C1 = 35 pF (7) 5.5 5.5 ns

Slow slew rate = off

V

= 3.3 V

CCIO

Output buffer enable delay

C1 = 35 pF (2) 9.0 9.0 ns

Slow slew rate = on

V

= 5.0 V or 3.3 V

CCIO

Output buffer disable delay C1 = 5 pF 5.0 5.0 ns

Register setup time 2.0 3.0 ns

Register hold time 3.0 3 .0 ns

Register setup time of fast input (2) 3.0 3.0 ns

Register hold time of fast input (2) 0.5 0.5 ns

Register delay 2.0 1.0 ns

Combinatorial delay 2.0 1.0 ns

Array clock delay 5.0 5.0 ns

Register enable time 5.0 5.0 ns

Global control delay 1.0 1.0 ns

Register preset time 3.0 3.0 ns

Register clear time 3.0 3.0 ns

PIA delay 1.0 1.0 ns

Low-power adder (8) 11.0 11.0 ns

Page 35

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

Table 23.MAX 7000 & MAX 7000E External Timing Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

MAX 7000E ( -12 P) MAX 7000 (-12)

MAX 7000E (-12)

Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

FSU

t

FH

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

ODH

t

CNT

f

CNT

t

ACNT

f

ACNT

f

MAX

Input to non-registered output C1 = 35 pF 12.0 12.0 ns

I/O input to non-registered output C1 = 35 pF 12.0 12.0 ns

Global clock setup time 7.0 10.0 ns

Global clock hold time 0.0 0.0 ns

Global clock setup time of fast input (2) 3.0 3.0 ns

Global clock hold time of fast input (2) 0.0 0.0 ns

Global clock to output delay C1 = 35 pF 6.0 6.0 ns

Global clock high time 4.0 4.0 ns

Global clock low time 4.0 4.0 ns

Array clock setup time 3.0 4.0 ns

Array clock hold time 4.0 4.0 ns

Array clock to output delay C1 = 35 pF 12.0 12.0 ns

Array clock high time 5.0 5.0 ns

Array clock low time 5.0 5.0 ns

Minimum pulse width for clear and

(3) 5.0 5.0 ns

preset

Output data hold time after clock C1 = 35 pF (4) 1.0 1.0 ns

Minimum global clock period 11.0 11.0 ns

Maximum internal global clock

(5) 90.9 90.9 MHz

frequency

Minimum array clock period 11.0 11.0 ns

Maximum internal array clock

(5) 90.9 90.9 MHz

frequency

Maximum clock frequency (6) 125.0 125.0 MHz

Altera Corporation 35

Page 36

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Table 24.MAX 7000 & MAX 7000E Internal Timi ng Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

MAX 7000E (-12P) MAX 7000 (-12)

MAX 7000E (-12)

Min Max Min Max

t

IN

t

IO

t

FIN

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

FSU

t

FH

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

t

PIA

t

LPA

36 Altera Corporation

Input pad and buffer delay 1.0 2.0 ns

I/O input pad and buffer delay 1.0 2.0 ns

Fast input delay (2) 1.0 1.0 ns

Shared expander delay 7.0 7.0 ns

Parallel expander delay 1 .0 1.0 ns

Logic array delay 7.0 5.0 ns

Logic control array delay 5.0 5.0 ns

Internal output enable delay (2) 2.0 2.0 ns

Output buffer and pad delay

C1 = 35 pF 1.0 3.0 ns

Slow slew rate = off

= 5.0 V

V

CCIO

Output buffer and pad delay

C1 = 35 pF (7) 2.0 4.0 ns

Slow slew rate = off

= 3.3 V

V

CCIO

Output buffer and pad delay

C1 = 35 pF (2) 5.0 7.0 ns

Slow slew rate = on

= 5.0 V or 3.3 V

V

CCIO

Output buffer enable delay

C1 = 35 pF 6.0 6.0 ns

Slow slew rate = off

= 5.0 V

V

CCIO

Output buffer enable delay

C1 = 35 pF (7) 7.0 7.0 ns

Slow slew rate = off

= 3.3 V

V

CCIO

Output buffer enable delay

C1 = 35 pF (2) 10.0 10.0 ns

Slow slew rate = on

= 5.0 V or 3.3 V

V

CCIO

Output buffer disable delay C1 = 5 pF 6.0 6.0 ns

Register setup time 1.0 4.0 ns

Register hold time 6.0 4.0 ns

Register setup time of fast input (2) 4.0 2.0 ns

Register hold time of fast input (2) 0.0 2.0 ns

Register delay 2.0 1.0 ns

Combinatorial delay 2.0 1.0 ns

Array clock delay 5.0 5.0 ns

Register enable time 7.0 5.0 ns

Global control delay 2.0 0.0 ns

Register preset time 4.0 3.0 ns

Register clear time 4.0 3.0 ns

PIA delay 1.0 1.0 ns

Low-power adder (8) 12.0 12.0 ns

Page 37

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

Table 25. MAX 7000 & MAX 7000E External Timing Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

-15 -15T -20

Min Max Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

FSU

t

FH

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

ODH

t

CNT

f

CNT

t

ACNT

f

ACNT

f

MAX

Input to non-registered output C1 = 35 pF 15.0 15.0 20.0 ns

I/O input to non-registered

C1 = 35 pF 15.0 15.0 20.0 ns

output

Global clock setup time 11.0 11.0 12.0 ns

Global clock hold time 0.0 0.0 0.0 ns

Global clock setup time of fast

(2) 3.0 – 5.0 ns

input

Global clock hold time of fast

(2) 0.0 – 0.0 ns

input

Global clock to output delay C1 = 35 pF 8.0 8.0 12.0 ns

Global clock high time 5.0 6.0 6.0 ns

Global clock low time 5.0 6.0 6.0 ns

Array clock setup time 4.0 4.0 5.0 ns

Array clock hold time 4.0 4.0 5.0 ns

Array clock to output delay C1 = 35 pF 15.0 15.0 20.0 ns

Array clock high time 6.0 6.5 8.0 ns

Array clock low time 6.0 6.5 8.0 ns

Minimum pulse width for clear

(3) 6.0 6.5 8.0 ns

and preset

Output data hold time after

C1 = 35 pF (4) 1.0 1.0 1.0 ns

clock

Minimum global clock period 13.0 13.0 16.0 n s

Maximum internal global clock

(5) 76.9 76.9 62.5 MHz

frequency

Minimum array clock period 13.0 13.0 16 .0 ns

Maximum internal array clock

(5) 76.9 76.9 62.5 MHz

frequency

Maximum clock frequency (6) 100 83.3 83.3 MHz

Altera Corporation 37

Page 38

MAX 7000 Programm ab le Logic D evi ce F ami ly Data Sheet

Table 26.MAX 7000 & MAX 7000E Internal Timi ng Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

-15 -15T -20

Min Max Min Max Min Max

t

IN

t

IO

t

FIN

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

FSU

t

FH

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

t

PIA

t

LPA

Input pad and buffer delay 2.0 2.0 3.0 ns

I/O input pad and buffer delay 2.0 2.0 3.0 ns

Fast input delay (2) 2.0 – 4.0 ns

Shared expander delay 8.0 10.0 9.0 ns

Parallel expander delay 1.0 1.0 2.0 ns

Logic array delay 6.0 6.0 8.0 ns

Logic control array delay 6.0 6.0 8.0 ns

Internal output enable delay (2) 3.0 – 4.0 ns

Output buffer and pad delay

C1 = 35 pF 4.0 4.0 5.0 ns

Slow slew rate = off

= 5.0 V

V

CCIO

Output buffer and pad delay

C1 = 35 pF (7) 5.0 – 6.0 ns

Slow slew rate = off

= 3.3 V

V

CCIO

Output buffer and pad delay

C1 = 35 pF (2) 8.0 – 9.0 ns

Slow slew rate = on

= 5.0 V or 3.3 V

V

CCIO

Output buffer enable delay

C1 = 35 pF 6.0 6.0 10.0 ns

Slow slew rate = off

V

= 5.0 V

CCIO

Output buffer enable delay

C1 = 35 pF (7) 7.0 – 11.0 ns

Slow slew rate = off

V

= 3.3 V

CCIO

Output buffer enable delay

C1 = 35 pF (2) 10.0 – 14.0 ns

Slow slew rate = on

V

= 5.0 V or 3.3 V

CCIO

Output buffer disable delay C1 = 5 pF 6.0 6.0 10.0 ns

Register setup time 4.0 4.0 4.0 ns

Register hold time 4.0 4.0 5.0 ns

Register setup time of fast input (2) 2.0 – 4.0 ns

Register hold time of fast input (2) 2.0 – 3.0 ns

Register delay 1.0 1.0 1.0 ns

Combinatorial delay 1.0 1.0 1.0 ns

Array clock delay 6.0 6.0 8.0 ns

Register enable time 6.0 6.0 8.0 ns

Global control delay 1.0 1.0 3.0 ns

Register preset time 4.0 4.0 4.0 ns

Register clear time 4.0 4.0 4.0 ns

PIA delay 2.0 2.0 3.0 ns

Low-power adder (8) 13.0 15.0 15.0 ns

38 Altera Corporation

Page 39

MAX 7000 Programmabl e Log i c Dev ic e Family Data Sheet

Notes to tables:

(1) These values are specified under the recommended operating conditions shown in Table 14 . See Figure 1 3 for more

information on switching waveforms.

(2) This parameter applies to MAX 7000E devices only.

(3) This minimum pulse width for preset and clear applies for both global clear and array controls. The t

must be added to this minimum width if the clear or reset signal incorporates the t

path.

parameter into the signal

LAD

parameter

LPA

(4) This parameter is a guideline that is sample-tested only and is based on extensive device characterization. This

parameter applies for both global and array clocking.

(5) These parameter s ar e measured with a 16-bit loa d ab le, en abled, up/down counter programmed int o eac h L AB .

(6) The f

(7) Operati ng con d iti o ns : V

(8) The t

running in the low-power mode.

values repr esent the highest fr eq uency for pi pelined data.

MAX

parameter must be added to the t

LPA

= 3.3 V ± 10% for commercial and industrial use.

CCIO

LAD