Page 1

MAX 3000A

®

Programmable Logic

Device Family

September 2000, ver. 1.1 Data Sheet

High-performance, low-cost CMOS EEPROM-based programmable

Features...

■

logic devices (PLDs) built on a Multiple Array MatriX (MAX®)

architecture (see Table 1)

3.3-V in-system programmability (ISP) through the built-in

■

IEEE Std. 1149.1 Joint Test Action Group (JTAG) interface with

advanced pin-locking capability

Built-in boundary-scan test (BST) circuitry compliant with

■

IEEE Std. 1149.1-1990

Enhanced ISP features:

■

– Enhanced ISP algorithm for faster programming

– ISP_Done bit to ensure complete programming

– Pull-up resistor on I/O pins during in-system programming

High-density PLDs ranging from 600 to 5,000 usable gates

■

4.5-ns pin-to-pin logic delays with counter frequencies of up to

■

227.3 MHz

MultiVoltTM I/O interface enabling the device core to run at 3.3 V,

■

while I/O pins are compatible with 5.0-V, 3.3-V, and 2.5-V logic

levels

Pin counts ranging from 44 to 208 in a variety of thin quad flat pack

■

(TQFP), plastic quad flat pack (PQFP), and plastic J-lead chip carrier

(PLCC) packages

■

Hot-socketing support

Programmable interconnect array (PIA) continuous routing structure

■

for fast, predictable performance

PCI compatible

■

Bus-friendly architecture including programmable slew-rate control

■

■

Open-drain output option

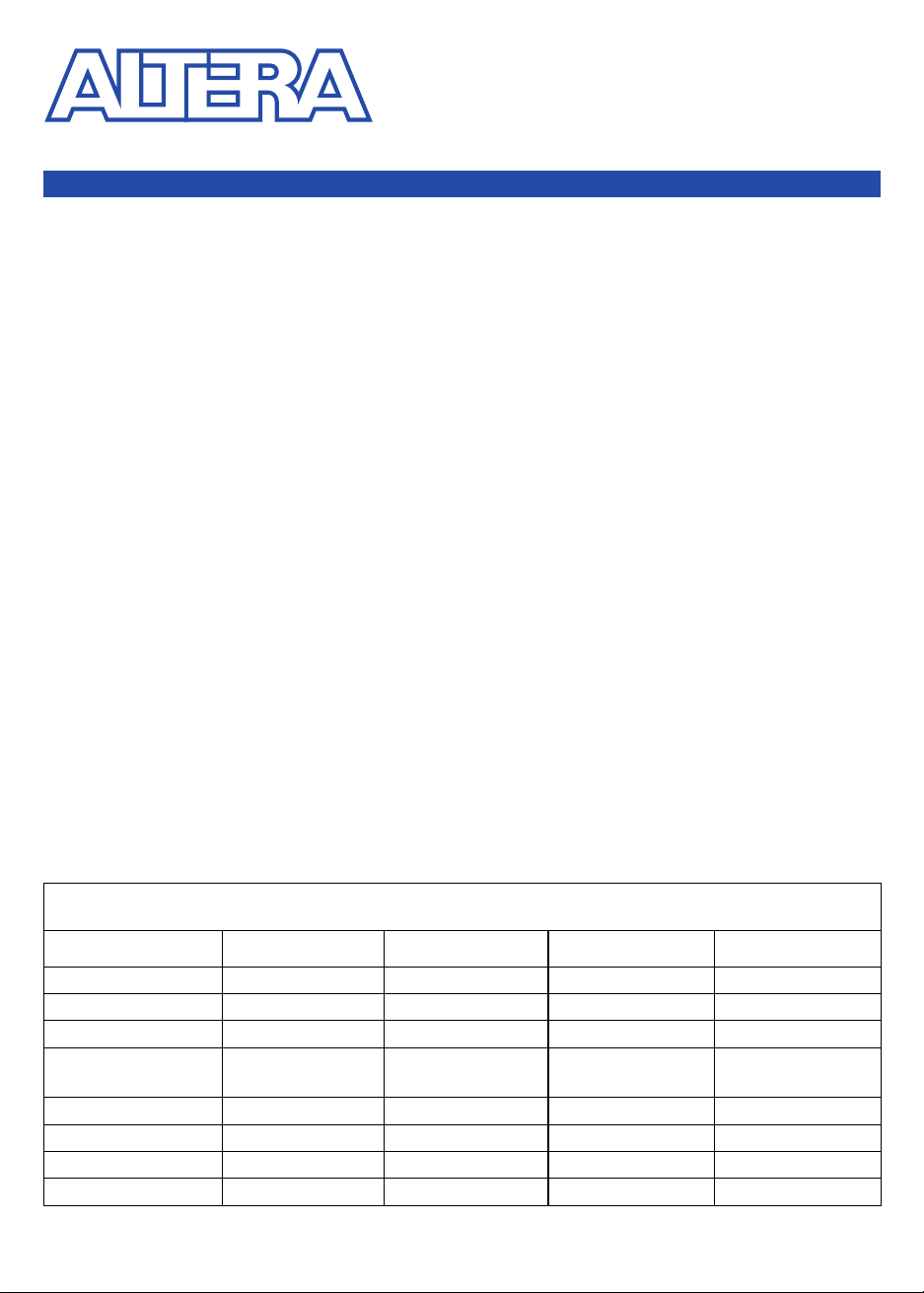

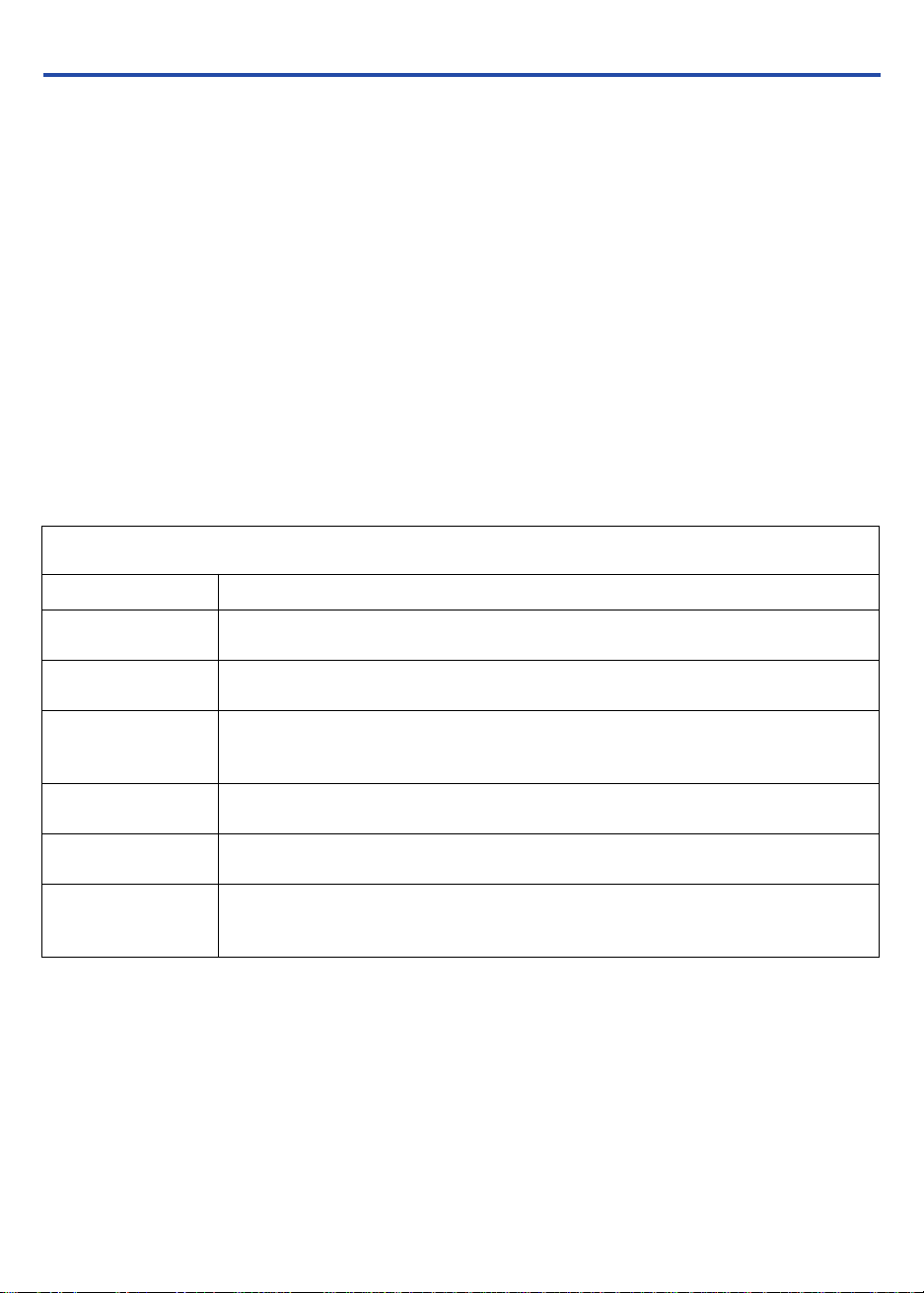

Table 1. MAX 3000A Device Features

Feature EPM3032A EPM3064A EPM3128A EPM3256A

Usable gates 600 1,250 2,500 5,000

Macrocells 32 64 128 256

Logic array blocks 2 4 8 16

Maximum user I/O

pins

(ns) 4.5 4.5 5.0 5.5

t

PD

tSU (ns) 2.9 2.8 3.3 3.9

t

(ns) 3.0 3.1 3.4 3.5

CO1

f

(MHz) 227.3 222.2 192.3 172.4

CNT

Altera Corporation 1

A-DS-M3000A-01.1

34 66 96 158

Page 2

MAX 3000A Programmable Logic Device Family Data Sheet

Programmable macrocell flipflops with individual clear, preset,

...and More Features

■

clock, and clock enable controls

■

Programmable power-saving mode for a power reduction of over

50% in each macrocell

■

Configurable expander product-term distribution, allowing up to

32 product terms per macrocell

■

Programmable security bit for protection of proprietary designs

■

Enhanced architectural features, including:

– 6 pin- or logic-driven output enable signals

– Two global clock signals with optional inversion

– Enhanced interconnect resources for improved routability

– Programmable output slew-rate control

■

Software design support and automatic place-and-route provided by

the Altera® MAX+PLUS® II development system for Windows-based

PCs and Sun SPARCstations, HP 9000 Series 700/800, and IBM RISC

System/6000 workstations

■

Additional design entry and simulation support provided by EDIF

2 0 0 and 3 0 0 netlist files, library of parameterized modules (LPM),

Verilog HDL, VHDL, and other interfaces to popular EDA tools from

third-party manufacturers such as Cadence, Exemplar Logic, Mentor

Graphics, OrCAD, Synopsys, Synplicity, and VeriBest

■

Programming support with the Altera master programming unit

(MPU), MasterBlasterTM communications cable, ByteBlasterMVTM

parallel port download cable, BitBlasterTM serial download cable as

well as programming hardware from third-party manufacturers and

any in-circuit tester that supports JamTM Standard Test and

Programming Language (STAPL) Files (

Files (

.jbc

), or Serial Vector Format Files (

.jam

), Jam STAPL Byte-Code

.svf

)

General Description

2 Altera Corporation

MAX 3000A devices are low-cost, high-performance devices based on the

Altera MAX architecture. Fabricated with advanced CMOS technology,

the EEPROM-based MAX 3000A devices operate with a 3.3-V supply

voltage and provide 600 to 5,000 usable gates, ISP, pin-to-pin delays as

fast as 4.5 ns, and counter speeds of up to 227.3 MHz. MAX 3000A devices

in the -4, -5, -6, -7, and -10 speed grades are compatible with the timing

requirements of the PCI Special Interest Group (PCI SIG)

Specification, Revision 2.2

. See Table 2.

PCI Local Bus

Page 3

MAX 3000A Programmable Logic Device Family Data Sheet

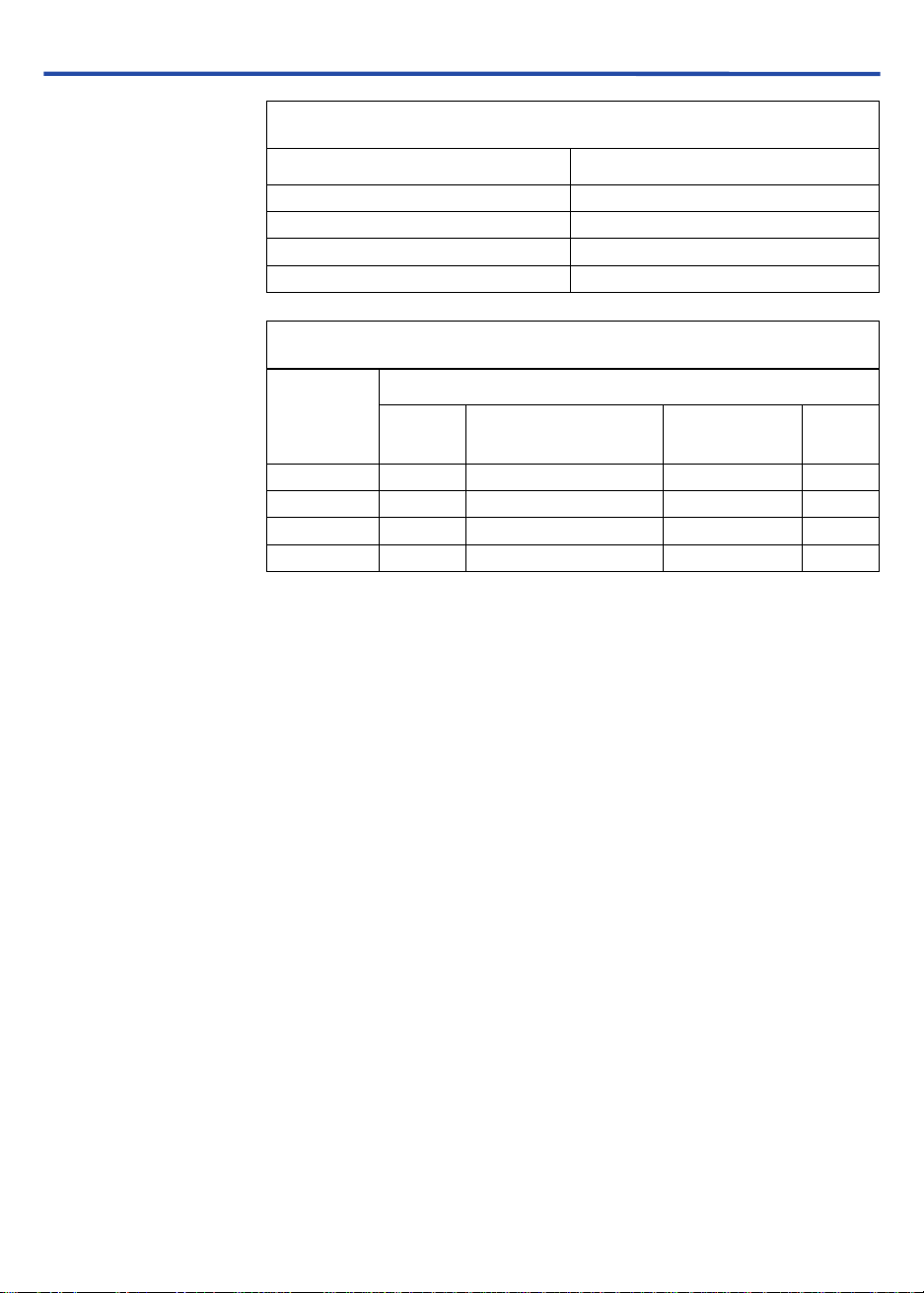

Table 2. MAX 3000A Speed Grades

Device Speed Grade

-4 -5 -6 -7 -10

EPM3032A

EPM3064A

EPM3128A

EPM3256A

Note:

(1) Contact Altera for up-to-date information on the availability of this speed grade.

vvv

vvv

vvv

v (1)

vv

The MAX 3000A architecture supports 100% transistor-to-transistor logic

(TTL) emulation and high-density small-scale integration (SSI),

medium-scale integration (MSI), and large-scale integration (LSI) logic

functions. The MAX 3000A architecture easily integrates multiple devices

ranging from PALs, GALs, and 22V10s to MACH, and pLSI devices.

MAX 3000A devices are available in a wide range of packages, including

PLCC, PQFP, and TQFP packages. See Table 3.

Table 3. MAX 3000A Maximum User I/O Pins

Device 44-Pin

PLCC

EPM3032A 34 34

EPM3064A 34 34 66

EPM3128A 80 96

EPM3256A 116 158

Notes:

(1) Contact Altera for up-to-date information on available device package options.

(2) When the IEEE Std. 1149.1 (JTAG) interface is used for in-system programming or

boundary-scan testing, four I/O pins become JTAG pins.

44-Pin

TQFP

Notes (1), (2)

100-Pin

TQFP

144-Pin

TQFP

208-Pin

PQFP

MAX 3000A devices use CMOS EEPROM cells to implement logic

functions. The user-configurable MAX 3000A architecture accommodates

a variety of independent combinatorial and sequential logic functions.

The devices can be reprogrammed for quick and efficient iterations

during design development and debug cycles, and can be programmed

and erased up to 100 times.

Altera Corporation 3

Page 4

MAX 3000A Programmable Logic Device Family Data Sheet

MAX 3000A devices contain 32 to 256 macrocells, combined into groups

of 16 macrocells called logic array blocks (LABs). Each macrocell has a

programmableindependently programmable clock, clock enable, clear, and preset

functions. To build complex logic functions, each macrocell can be

supplemented with shareable expander and high-speed parallel expander

product terms to provide up to 32 product terms per macrocell.

MAX 3000A devices provide programmable speed/power optimization.

Speed-critical portions of a design can run at high speed/full power,

while the remaining portions run at reduced speed/low power. This

speed/power optimization feature enables the designer to configure one

or more macrocells to operate at 50% or lower power while adding only a

nominal timing delay. MAX 3000A devices also provide an option that

reduces the slew rate of the output buffers, minimizing noise transients

when non-speed-critical signals are switching. The output drivers of all

MAX 3000A devices can be set for 2.5 V or 3.3 V, and all input pins are

2.5-V, 3.3-V, and 5.0-V tolerant, allowing MAX 3000A devices to be used

in mixed-voltage systems.

MAX 3000A devices are supported by the MAX+PLUS II development

system, an integrated package that offers schematic, text—including

VHDL, Verilog HDL, and the Altera Hardware Description Language

(AHDL)—and waveform design entry, compilation and logic synthesis,

simulation and timing analysis, and device programming. The

MAX+PLUS II software provides EDIF 2 0 0 and 3 0 0, LPM, VHDL,

Verilog HDL, and other interfaces for additional design entry and

simulation support from other industry-standard PC- and UNIXworkstation-based EDA tools. The MAX+PLUS II software runs on

Windows-based PCs, as well as Sun SPARCstation, HP 9000 Series

700/800, and IBM RISC System/6000 workstations.

AND

/fixed-OR array and a configurable register with

f

Functional Description

4 Altera Corporation

For more information on development tools, see the

Programmable Logic Development System & Software Data Sheet

The MAX 3000A architecture includes the following elements:

■

Logic array blocks (LABs)

■

Macrocells

■

Expander product terms (shareable and parallel)

■

Programmable interconnect array (PIA)

■

I/O control blocks

The MAX 3000A architecture includes four dedicated inputs that can be

used as general-purpose inputs or as high-speed, global control signals

(clock, clear, and two output enable signals) for each macrocell and I/O

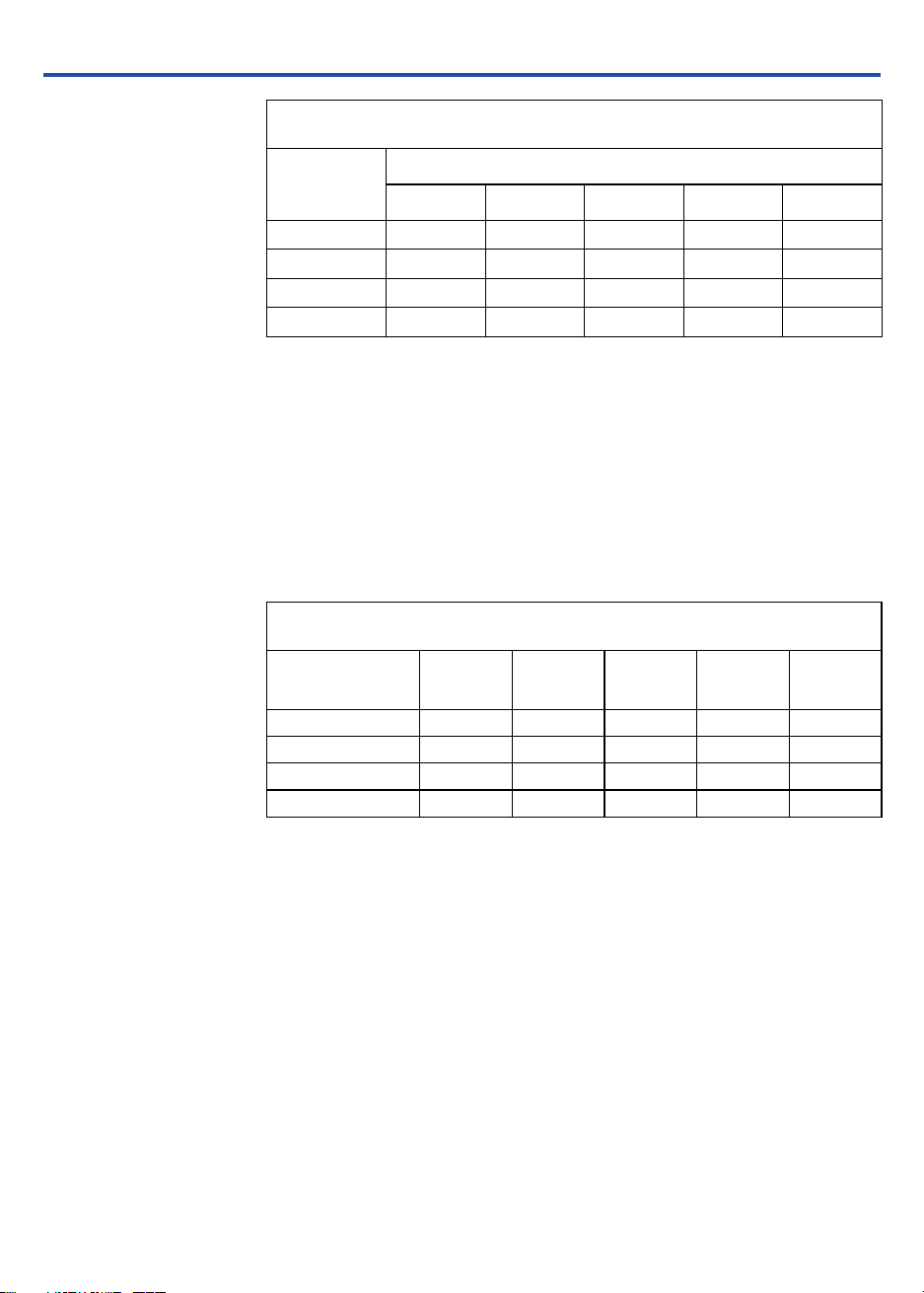

pin. Figure 1 shows the architecture of MAX 3000A devices.

MAX+PLUS II

.

Page 5

Figure 1. MAX 3000A Device Block Diagram

INPUT/GCLK1

INPUT/OE2/GCLK2

INPUT/OE1

MAX 3000A Programmable Logic Device Family Data Sheet

INPUT/GCLRn

6 to 16 I/O

6 to 16 I/O

6 Output Enables

6 to 16

I/O

Control

Block

6

6 to 16

I/O

Control

Block

6

LAB A

LAB C

Macrocells

1 to 16

Macrocells

33 to 48

36 36

16

6 to 16

36 36

16

6 to 16

16

6 to 16

PIA

16

6 to 16

Macrocells

17 to 32

Macrocells

49 to 64

6 Output Enables

LAB B

6 to 16

Control

LAB D

6 to 16

Control

I/O

Block

I/O

Block

6 to 16 I/O

6

6 to 16 I/O

6

Logic Array Blocks

The MAX 3000A device architecture is based on the linking of

high-performance LABs. LABs consist of 16-macrocell arrays, as shown in

Figure 1. Multiple LABs are linked together via the PIA, a global bus that

is fed by all dedicated input pins, I/O pins, and macrocells.

Each LAB is fed by the following signals:

■

36 signals from the PIA that are used for general logic inputs

■

Global controls that are used for secondary register functions

Macrocells

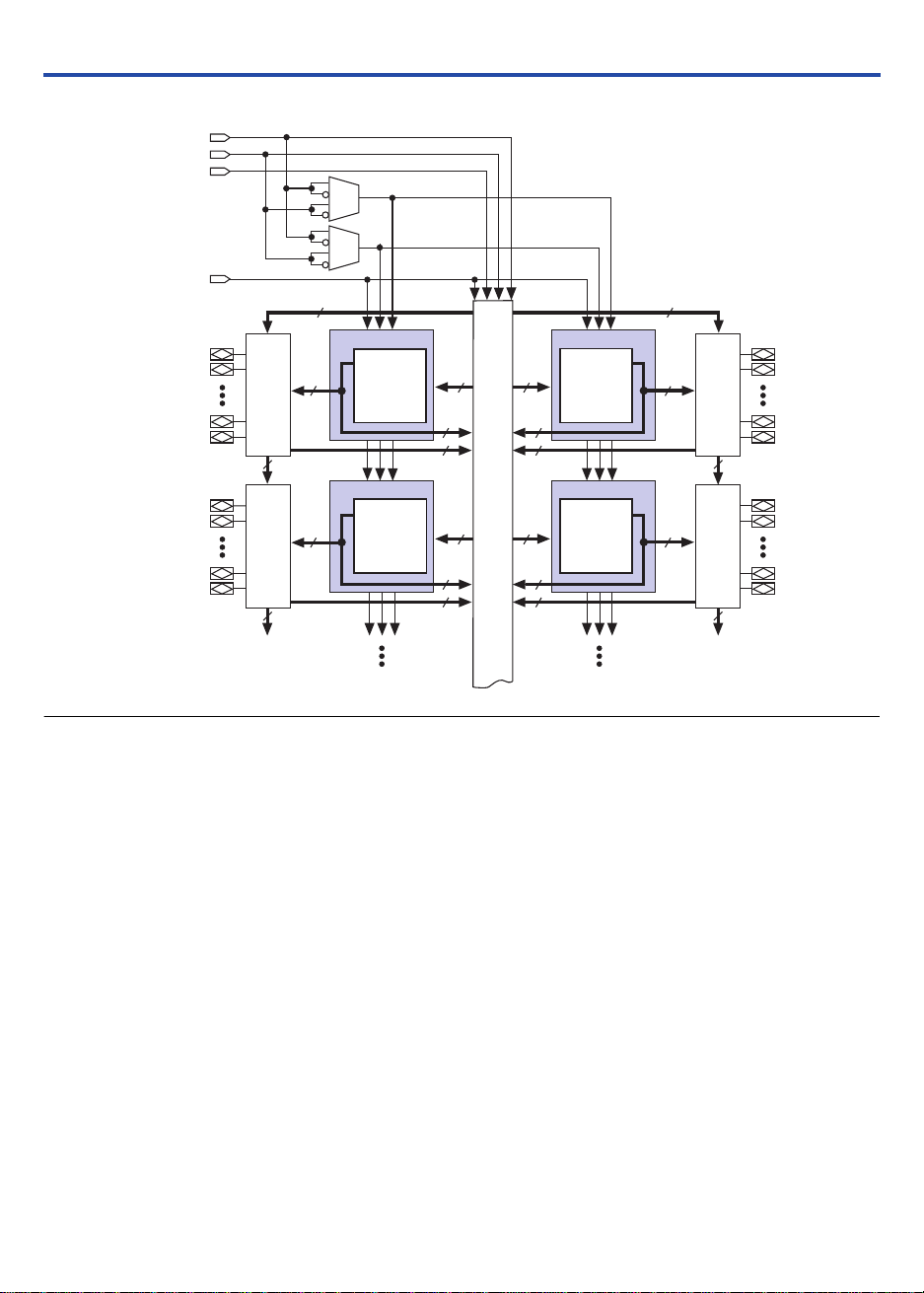

MAX 3000A macrocells can be individually configured for either

sequential or combinatorial logic operation. Macrocells consist of three

functional blocks: logic array, product-term select matrix, and

programmable register. Figure 2 shows a MAX 3000A macrocell.

Altera Corporation 5

Page 6

MAX 3000A Programmable Logic Device Family Data Sheet

Figure 2. MAX 3000A Macrocell

LAB Local Array

Product-

Term

Select

Matrix

Parallel Logic

Expanders

(from other

macrocells)

Global

Clear

Clear

Select

Global

Clocks

2

VCC

Clock/

Enable

Select

D/T

ENA

PRN

CLRN

Programmable

Register

Register

Bypass

Q

to I/O

Control

Block

36 Signals

from PIA

16 Expander

Product T erms

Shared Logic

Expanders

to PIA

Combinatorial logic is implemented in the logic array, which provides

five product terms per macrocell. The product-term select matrix allocates

these product terms for use as either primary logic inputs (to the OR and

XOR

gates) to implement combinatorial functions, or as secondary inputs

to the macrocell’s register preset, clock, and clock enable control

functions.

Two kinds of expander product terms (“expanders”) are available to

supplement macrocell logic resources:

Shareable expanders, which are inverted product terms that are fed

■

back into the logic array

Parallel expanders, which are product terms borrowed from adjacent

■

macrocells

The MAX+PLUS II development system automatically optimizes

product-term allocation according to the logic requirements of the design.

For registered functions, each macrocell flipflop can be individually

programmed to implement D, T, JK, or SR operation with programmable

clock control. The flipflop can be bypassed for combinatorial operation.

During design entry, the designer specifies the desired flipflop type; the

MAX+PLUS II software then selects the most efficient flipflop operation

for each registered function to optimize resource utilization.

6 Altera Corporation

Page 7

MAX 3000A Programmable Logic Device Family Data Sheet

Each programmable register can be clocked in three different modes:

■

Global clock signal mode, which achieves the fastest clock-to-output

performance.

■

Global clock signal enabled by an active-high clock enable. A clock

enable is generated by a product term. This mode provides an enable

on each flipflop while still achieving the fast clock-to-output

performance of the global clock.

Array clock implemented with a product term. In this mode, the

■

flipflop can be clocked by signals from buried macrocells or I/O pins.

Two global clock signals are available in MAX 3000A devices. As shown

in Figure 1, these global clock signals can be the true or the complement

of either of the two global clock pins,

GCLK1

or

GCLK2

.

Each register also supports asynchronous preset and clear functions. As

shown in Figure 2, the product-term select matrix allocates product terms

to control these operations. Although the product-term-driven preset and

clear from the register are active high, active-low control can be obtained

by inverting the signal within the logic array. In addition, each register

clear function can be individually driven by the active-low dedicated

global clear pin (

GCLRn

).

Expander Product Terms

Although most logic functions can be implemented with the five product

terms available in each macrocell, highly complex logic functions require

additional product terms. Another macrocell can be used to supply the

required logic resources. However, the MAX 3000A architecture also

offers both shareable and parallel expander product terms (“expanders”)

that provide additional product terms directly to any macrocell in the

same LAB. These expanders help ensure that logic is synthesized with the

fewest possible logic resources to obtain the fastest possible speed.

Shareable Expanders

Each LAB has 16 shareable expanders that can be viewed as a pool of

uncommitted single product terms (one from each macrocell) with

inverted outputs that feed back into the logic array. Each shareable

expander can be used and shared by any or all macrocells in the LAB to

build complex logic functions. A small delay (

shareable expanders are used. Figure 3 shows how shareable expanders

can feed multiple macrocells.

t

) is incurred when

SEXP

Altera Corporation 7

Page 8

MAX 3000A Programmable Logic Device Family Data Sheet

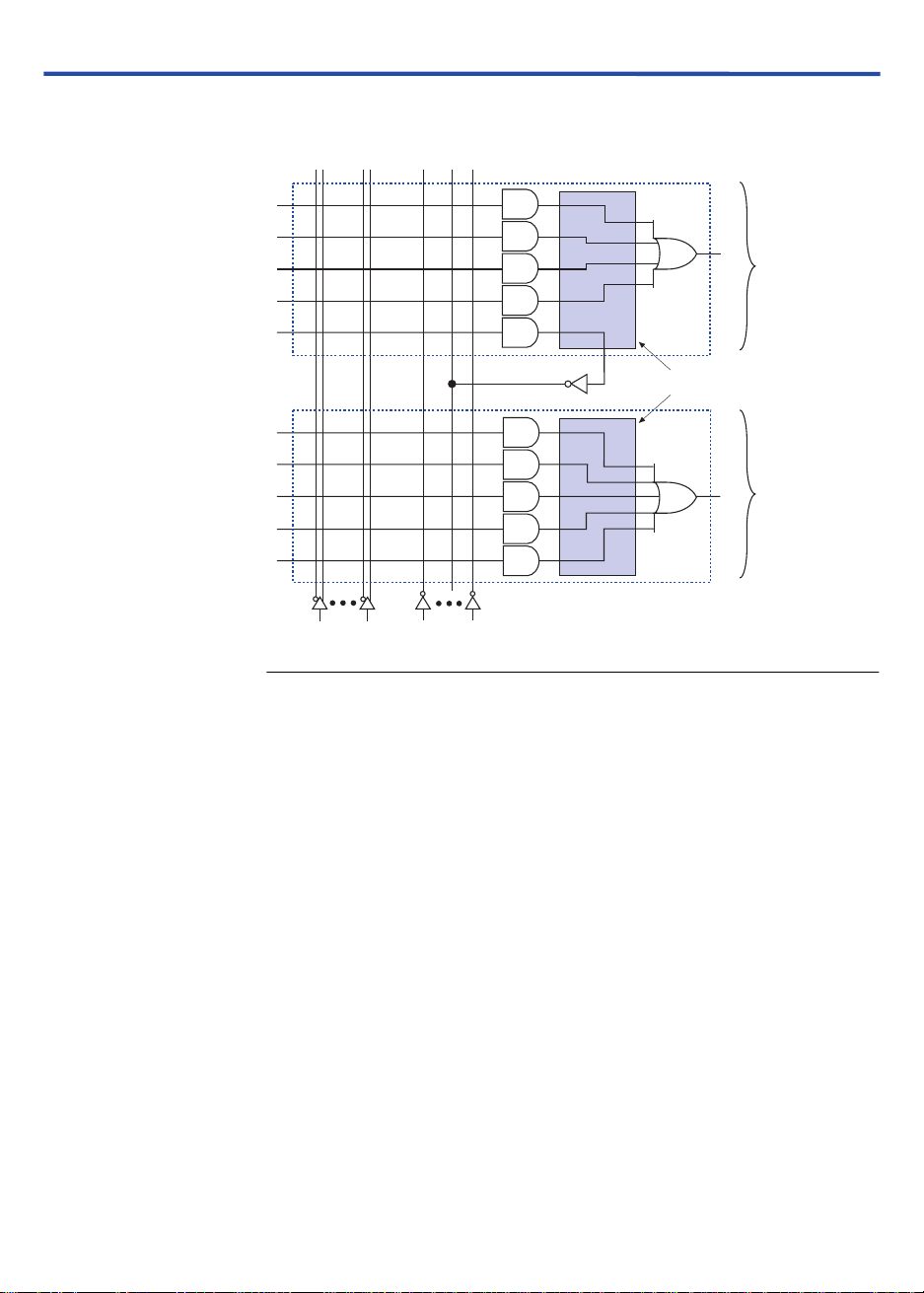

Figure 3. MAX 3000A Shareable Expanders

Shareable expanders can be shared by any or all macrocells in an LAB.

Macrocell

Product-Term

Logic

Product-Term Select Matrix

Macrocell

Product-Term

Logic

36 Signals

from PIA

16 Shared

Expanders

Parallel Expanders

Parallel expanders are unused product terms that can be allocated to a

neighboring macrocell to implement fast, complex logic functions.

Parallel expanders allow up to 20 product terms to directly feed the

macrocell OR logic, with five product terms provided by the macrocell and

15 parallel expanders provided by neighboring macrocells in the LAB.

The MAX+PLUS II Compiler can automatically allocate up to three sets of

up to five parallel expanders to the macrocells that require additional

product terms. Each set of five parallel expanders incurs a small,

incremental timing delay (

product terms, the MAX+PLUS II Compiler uses the five dedicated

product terms within the macrocell and allocates two sets of parallel

expanders; the first set includes five product terms, and the second set

includes four product terms, increasing the total delay by 2 ×

t

). For example, if a macrocell requires 14

PEXP

t

PEXP

.

8 Altera Corporation

Page 9

MAX 3000A Programmable Logic Device Family Data Sheet

Two groups of eight macrocells within each LAB (e.g., macrocells 1

through 8 and 9 through 16) form two chains to lend or borrow parallel

expanders. A macrocell borrows parallel expanders from lowernumbered macrocells. For example, macrocell 8 can borrow parallel

expanders from macrocell 7, from macrocells 7 and 6, or from macrocells

7, 6, and 5. Within each group of eight, the lowest-numbered macrocell

can only lend parallel expanders and the highest-numbered macrocell can

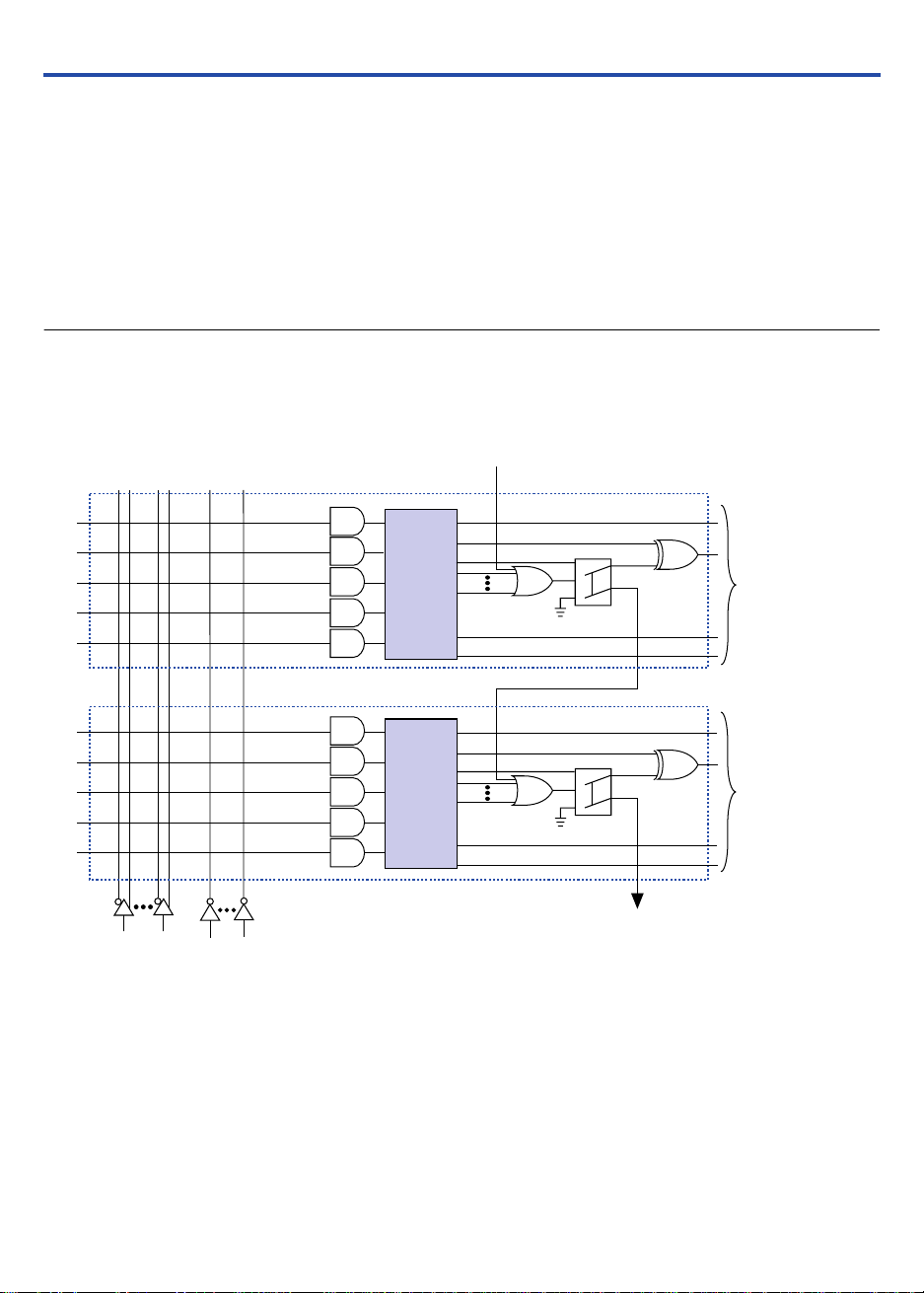

only borrow them. Figure 4 shows how parallel expanders can be

borrowed from a neighboring macrocell.

Figure 4. MAX 3000A Parallel Expanders

Unused product terms in a macrocell can be allocated to a neighboring macrocell.

from

Previous

Macrocell

Preset

36 Signals

from PIA

16 Shared

Expanders

Product-

Term

Select

Matrix

Product-

Term

Select

Matrix

Macrocell

ProductTerm Logic

Clock

Clear

Preset

Macrocell

ProductTerm Logic

Clock

Clear

to Next

Macrocell

Altera Corporation 9

Page 10

MAX 3000A Programmable Logic Device Family Data Sheet

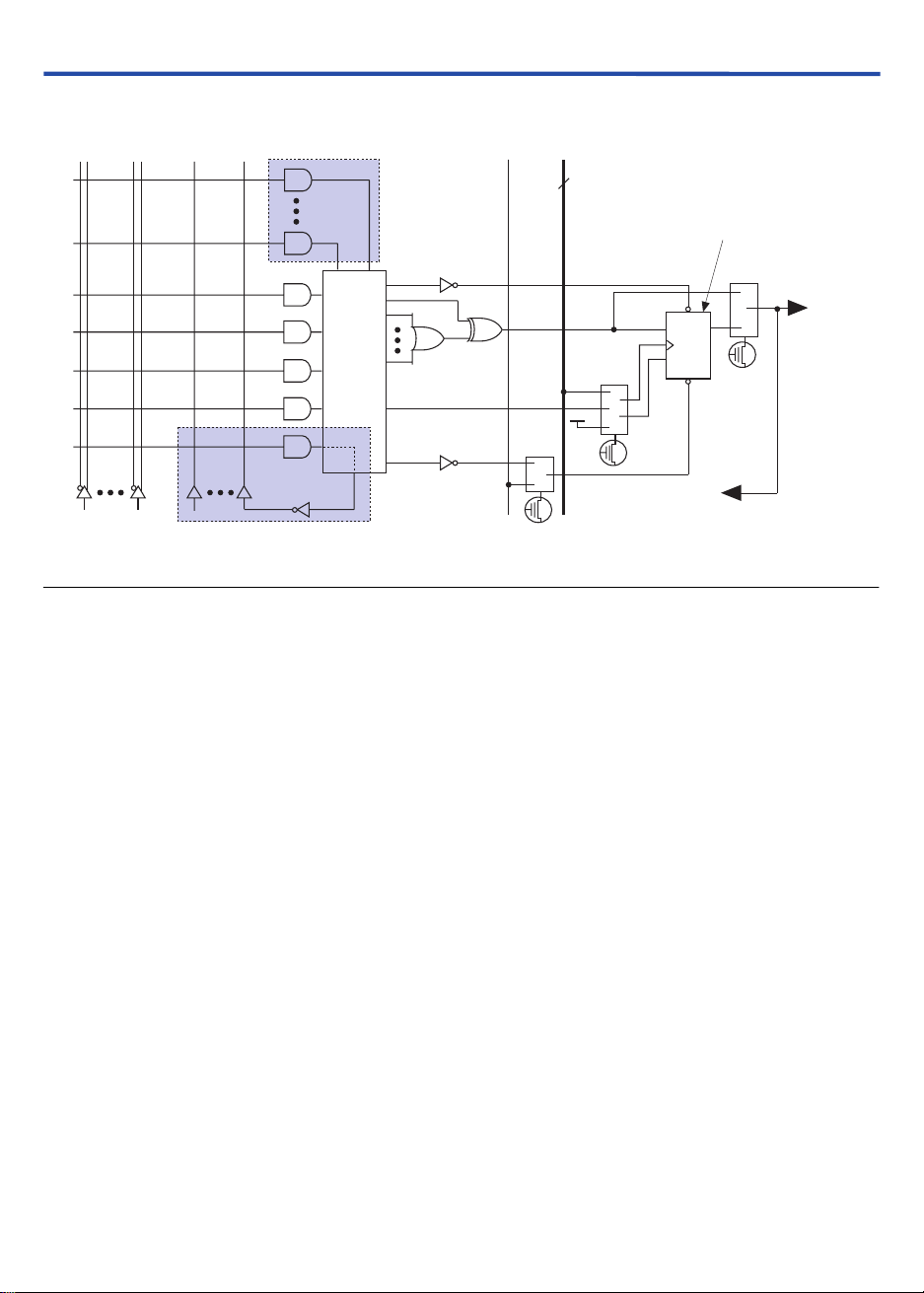

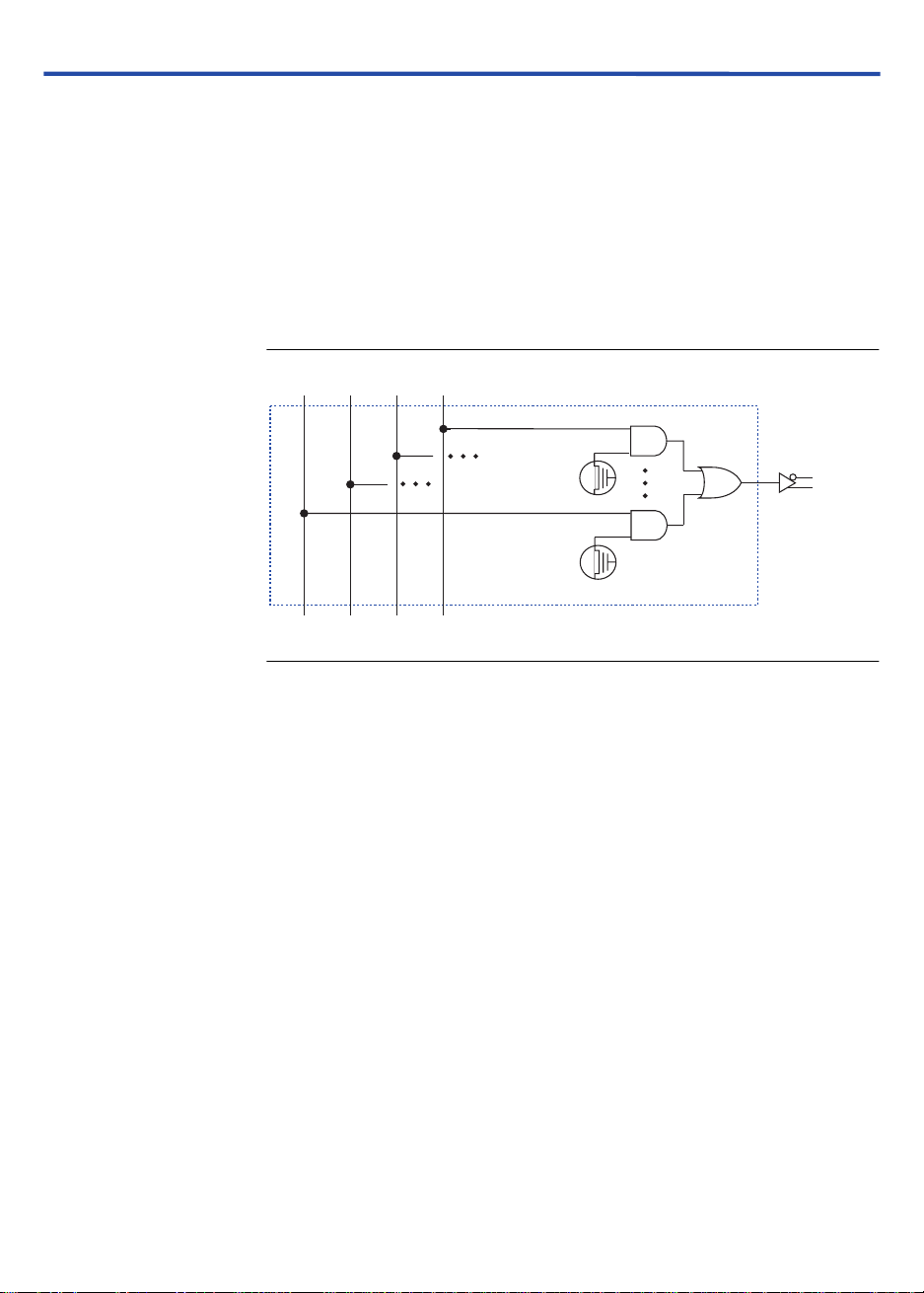

Programmable Interconnect Array

Logic is routed between LABs on the PIA. This global bus is a

programmable path that connects any signal source to any destination on

the device. All MAX 3000A dedicated inputs, I/O pins, and macrocell

outputs feed the PIA, which makes the signals available throughout the

entire device. Only the signals required by each LAB are actually routed

from the PIA into the LAB. Figure 5 shows how the PIA signals are routed

into the LAB. An EEPROM cell controls one input to a 2-input

which selects a PIA signal to drive into the LAB.

Figure 5. MAX 3000A PIA Routing

AND

gate,

to LAB

PIA Signals

While the routing delays of channel-based routing schemes in masked or

field-programmable gate arrays (FPGAs) are cumulative, variable, and

path-dependent, the MAX 3000A PIA has a predictable delay. The PIA

makes a design’s timing performance easy to predict.

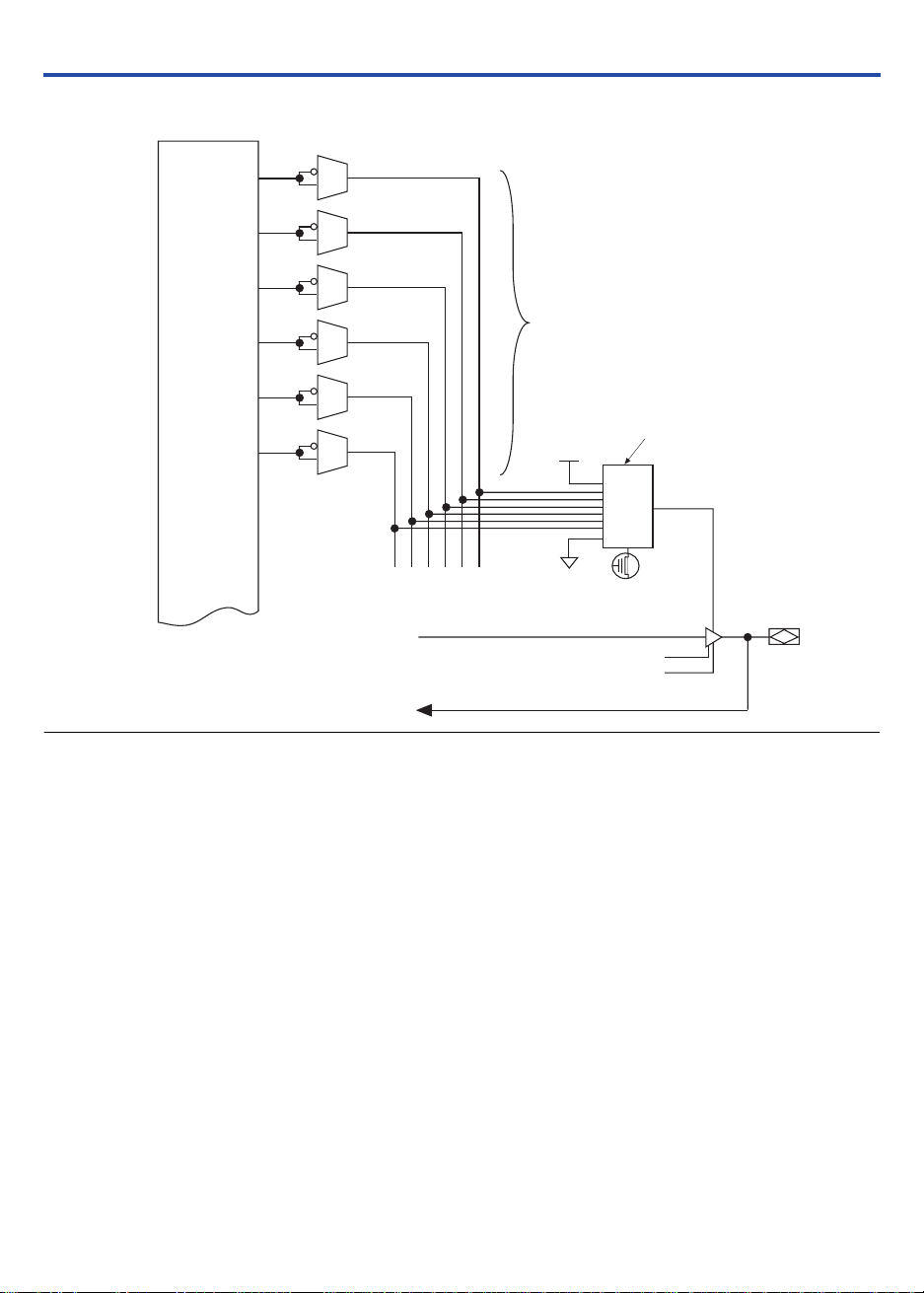

I/O Control Blocks

The I/O control block allows each I/O pin to be individually configured

for input, output, or bidirectional operation. All I/O pins have a tri-state

buffer that is individually controlled by one of the global output enable

signals or directly connected to ground or VCC. Figure 6 shows the I/O

control block for MAX 3000A devices. The I/O control block has

six global output enable signals that are driven by the true or complement

of two output enable signals, a subset of the I/O pins, or a subset of the

I/O macrocells.

10 Altera Corporation

Page 11

MAX 3000A Programmable Logic Device Family Data Sheet

Figure 6. I/O Control Block of MAX 3000A Devices

PIA

6 Global

Output Enable Signals

OE Select Multiplexer

to Other I/O Pins

from

Macrocell

to PIA

VCC

GND

Open-Drain Output

Slew-Rate Control

When the tri-state buffer control is connected to ground, the output is

tri-stated (high impedance) and the I/O pin can be used as a dedicated

input. When the tri-state buffer control is connected to VCC, the output is

enabled.

The MAX 3000A architecture provides dual I/O feedback, in which

macrocell and pin feedbacks are independent. When an I/O pin is

configured as an input, the associated macrocell can be used for buried

logic.

Altera Corporation 11

Page 12

MAX 3000A Programmable Logic Device Family Data Sheet

In-System

Programmability (ISP)

MAX 3000A devices can be programmed in-system via an industrystandard 4-pin IEEE Std. 1149.1-1990 (JTAG) interface. In-system

programmability (ISP) offers quick, efficient iterations during design

development and debugging cycles. The MAX 3000A architecture

internally generates the high programming voltages required to program

its EEPROM cells, allowing in-system programming with only a single

3.3-V power supply. During in-system programming, the I/O pins are tristated and weakly pulled-up to eliminate board conflicts. The pull-up

value is nominally 50 kΩ.

MAX 3000A devices have an enhanced ISP algorithm for faster

programming. These devices also offer an ISP_Done bit that ensures safe

operation when in-system programming is interrupted. This ISP_Done

bit, which is the last bit programmed, prevents all I/O pins from driving

until the bit is programmed.

ISP simplifies the manufacturing flow by allowing devices to be mounted

on a printed circuit board (PCB) with standard pick-and-place equipment

before they are programmed. MAX 3000A devices can be programmed by

downloading the information via in-circuit testers, embedded processors,

the MasterBlaster communications cable, the ByteBlasterMV parallel port

download cable, and the BitBlaster serial download cable. Programming

the devices after they are placed on the board eliminates lead damage on

high-pin-count packages (e.g., QFP packages) due to device handling.

MAX 3000A devices can be reprogrammed after a system has already

shipped to the field. For example, product upgrades can be performed in

the field via software or modem.

The Jam STAPL can be used to program MAX 3000A devices with incircuit testers, PCs, or embedded processors.

f

Programming with External Hardware

f

12 Altera Corporation

For more information on using the Jam STAPL language, see Application

Note 88 (Using the Jam Language for ISP & ICR via an Embedded Processor)

and Application Note 122 (Using Jam STAPL for ISP & ICR via an Embedded

Processor).

MAX 3000A devices can be programmed on Windows-based PCs with an

Altera Logic Programmer card, MPU, and the appropriate device adapter.

The MPU performs continuity checking to ensure adequate electrical

contact between the adapter and the device.

For more information, see the Altera Programming Hardware Data Sheet.

Page 13

MAX 3000A Programmable Logic Device Family Data Sheet

The MAX+PLUS II software can use text- or waveform-format test vectors

created with the MAX+PLUS II Text Editor or Waveform Editor to test the

programmed device. For added design verification, designers can

perform functional testing to compare the functional device behavior with

the results of simulation.

Data I/O, BP Microsystems, and other programming hardware

manufacturers also provide programming support for Altera devices.

f

IEEE Std.

1149.1 (JTAG)

Boundary-Scan

Support

Table 4. MAX 3000A JTAG Instructions

JTAG Instruction Description

SAMPLE/PRELOAD Allows a snapshot of signals at the device pins to be captured and examined during

EXTEST Allows the external circuitry and board-level interconnections to be tested by forcing a

BYPASS Places the 1-bit bypass register between the TDI and TDO pins, which allows the BST

IDCODE Selects the IDCODE register and places it between the TDI and TDO pins, allowing the

USERCODE Selects the 32-bit USERCODE register and places it between the TDI and TDO pins,

ISP Instructions These instructions are used when programming MAX 3000A devices via the JTAG ports

For more information, see Programming Hardware Manufacturers.

MAX 3000A devices include the JTAG BST circuitry defined by IEEE Std.

1149.1-1990. Table 4 describes the JTAG instructions supported by

MAX 3000A devices. The pin-out tables starting on page 39 of this data

sheet show the location of the JTAG control pins for each device. If the

JTAG interface is not required, the JTAG pins are available as user I/O

pins.

normal device operation, and permits an initial data pattern output at the device pins

test pattern at the output pins and capturing test results at the input pins

data to pass synchronously through a selected device to adjacent devices during normal

device operation

IDCODE to be serially shifted out of TDO

allowing the USERCODE value to be shifted out of TDO

with the MasterBlaster, ByteBlasterMV, or BitBlaster cable, or when using a Jam STAPL

file, JBC file, or SVF file via an embedded processor or test equipment

The instruction register length of MAX 3000A devices is 10 bits. The

IDCODE and USERCODE register length is 32 bits. Tables 5 and 6 show

the boundary-scan register length and device IDCODE information for

MAX 3000A devices.

Altera Corporation 13

Page 14

MAX 3000A Programmable Logic Device Family Data Sheet

Table 5. MAX 3000A Boundary-Scan Register Length

Device Boundary-Scan Register Length

EPM3032A 96

EPM3064A 192

EPM3128A 288

EPM3256A 480

Table 6. 32-Bit MAX 3000A Device IDCODE Value Note (1)

Device IDCODE (32 bits)

f

Version

(4 Bits)

EPM3032A 0001 0111 0000 0011 0010 00001101110 1

EPM3064A 0001 0111 0000 0110 0100 00001101110 1

EPM3128A 0001 0111 0001 0010 1000 00001101110 1

EPM3256A 0001 0111 0010 0101 0110 00001101110 1

Notes:

(1) The most significant bit (MSB) is on the left.

(2) The least significant bit (LSB) for all JTAG IDCODEs is 1.

Part Number (16 Bits) Manufacturer’s

Identity (11 Bits)

1 (1 Bit)

(2)

See Application Note 39 (IEEE 1149.1 (JTAG) Boundary-Scan Testing in Altera

Devices) for more information on JTAG BST.

14 Altera Corporation

Page 15

MAX 3000A Programmable Logic Device Family Data Sheet

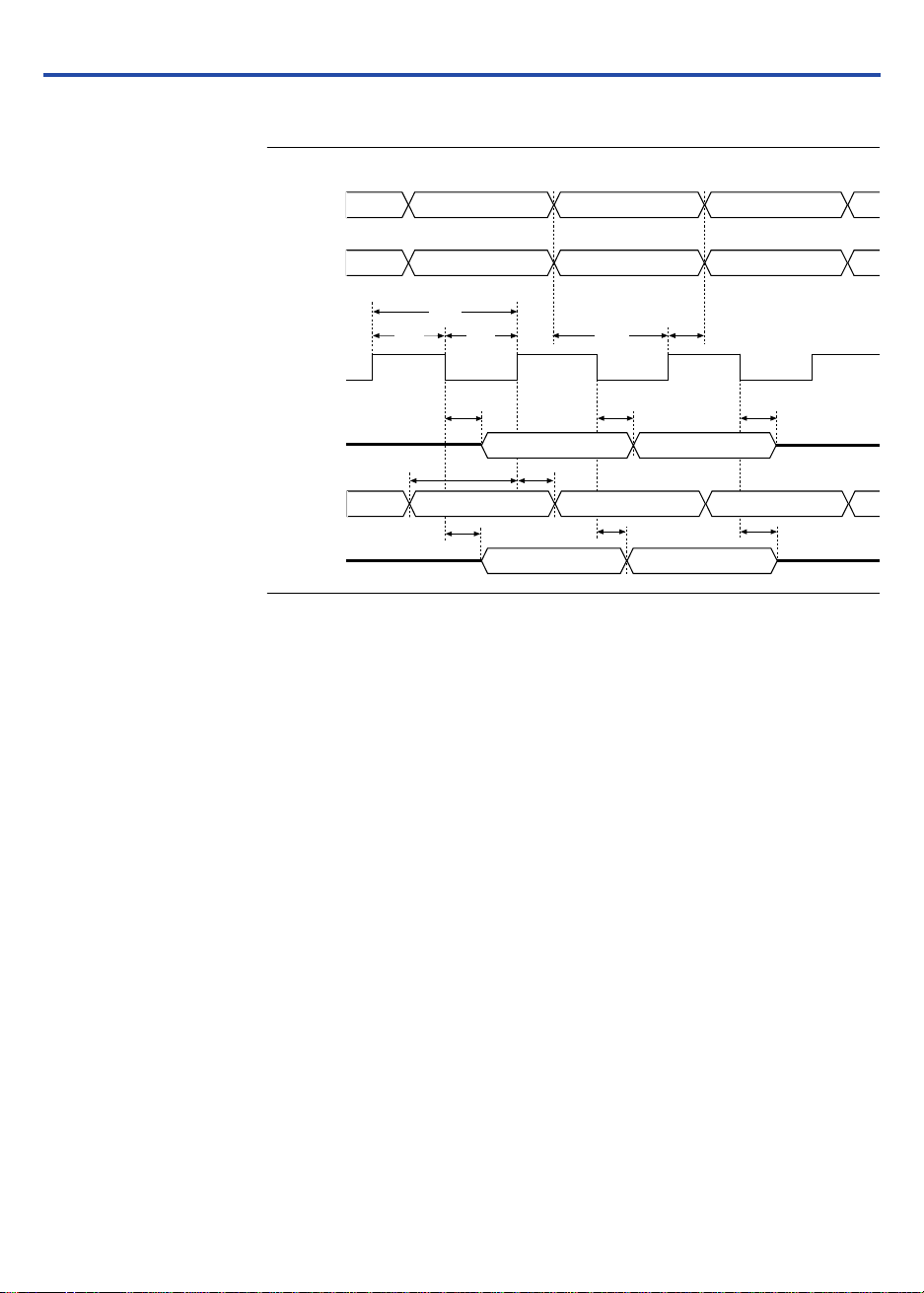

Figure 7 shows the timing information for the JTAG signals.

Figure 7. MAX 3000A JTAG Waveforms

TMS

TDI

t

JCP

t

JCL

t

JPSU

t

JPH

TCK

t

JCH

t

JPZX

t

JPCO

t

JPXZ

TDO

t

JSH

t

JSCO

t

JSXZ

Signal

to Be

Captured

Signal

to Be

Driven

t

JSZX

t

JSSU

Table 7 shows the JTAG timing parameters and values for MAX 3000A

devices.

Altera Corporation 15

Page 16

MAX 3000A Programmable Logic Device Family Data Sheet

Table 7. JTAG Timing Parameters & Values for MAX 3000A Devices

Symbol Parameter Min Max Unit

t

JCP

t

JCH

t

JCL

t

JPSU

t

JPH

t

JPCO

t

JPZX

t

JPXZ

t

JSSU

t

JSH

t

JSCO

t

JSZX

t

JSXZ

TCK clock period 100 ns

TCK clock high time 50 ns

TCK clock low time 50 ns

JTAG port setup time 20 ns

JTAG port hold time 45 ns

JTAG port clock to output 25 ns

JTAG port high impedance to valid output 25 ns

JTAG port valid output to high impedance 25 ns

Capture register setup time 20 ns

Capture register hold time 45 ns

Update register clock to output 25 ns

Update register high impedance to valid output 25 ns

Update register valid output to high impedance 25 ns

Programmable Speed/Power Control

Output

Configuration

MAX 3000A devices offer a power-saving mode that supports low-power

operation across user-defined signal paths or the entire device. This

feature allows total power dissipation to be reduced by 50% or more

because most logic applications require only a small fraction of all gates to

operate at maximum frequency.

The designer can program each individual macrocell in a MAX 3000A

device for either high-speed or low-power operation. As a result, speedcritical paths in the design can run at high speed, while the remaining

paths can operate at reduced power. Macrocells that run at low power

incur a nominal timing delay adder (t

t

CPPW

and t

parameters.

SEXP

) for the t

LPA

LAD

, t

LAC

, tIC, t

ACL

, tEN,

MAX 3000A device outputs can be programmed to meet a variety of

system-level requirements.

MultiVolt I/O Interface

The MAX 3000A device architecture supports the MultiVolt I/O interface

feature, which allows MAX 3000A devices to connect to systems with

differing supply voltages. MAX 3000A devices in all packages can be set

for 2.5-V, 3.3-V, or 5.0-V I/O pin operation. These devices have one set of

VCC pins for internal operation and input buffers (VCCINT), and another

set for I/O output drivers (VCCIO).

16 Altera Corporation

Page 17

MAX 3000A Programmable Logic Device Family Data Sheet

The VCCIO pins can be connected to either a 3.3-V or 2.5-V power supply,

depending on the output requirements. When the VCCIO pins are

connected to a 2.5-V power supply, the output levels are compatible with

2.5-V systems. When the VCCIO pins are connected to a 3.3-V power

supply, the output high is at 3.3 V and is therefore compatible with 3.3-V

or 5.0-V systems. Devices operating with V

incur a nominally greater timing delay of t

levels lower than 3.0 V

CCIO

instead of t

OD2

OD1

. Inputs can

always be driven by 2.5-V, 3.3-V, or 5.0-V signals.

Table 8 summarizes the MAX 3000A MultiVolt I/O support.

Table 8. MAX 3000A MultiVolt I/O Support

Voltage Input Signal (V) Output Signal (V)

V

CCIO

2.5 3.3 5.0 2.5 3.3 5.0

2.5

3.3

Note:

(1) When V

tolerant inputs.

CCIO

vvvv

(1)

vvv

is 3.3 V, a MAX 3000A device can drive a 2.5-V device that has 3.3-V

v

vv

Open-Drain Output Option

MAX 3000A devices provide an optional open-drain (equivalent to

open-collector) output for each I/O pin. This open-drain output enables

the device to provide system-level control signals (e.g., interrupt and

write enable signals) that can be asserted by any of several devices. It can

also provide an additional wired-OR plane.

Slew-Rate Control

The output buffer for each MAX 3000A I/O pin has an adjustable output

slew rate that can be configured for low-noise or high-speed performance.

A faster slew rate provides high-speed transitions for high-performance

systems. However, these fast transitions may introduce noise transients

into the system. A slow slew rate reduces system noise, but adds a

nominal delay of 4 to 5 ns. When the configuration cell is turned off, the

slew rate is set for low-noise performance. Each I/O pin has an individual

EEPROM bit that controls the slew rate, allowing designers to specify the

slew rate on a pin-by-pin basis. The slew rate control affects both the

rising and falling edges of the output signal.

Altera Corporation 17

Page 18

MAX 3000A Programmable Logic Device Family Data Sheet

CC

Design Security

Generic Testing

All MAX 3000A devices contain a programmable security bit that controls

access to the data programmed into the device. When this bit is

programmed, a design implemented in the device cannot be copied or

retrieved. This feature provides a high level of design security because

programmed data within EEPROM cells is invisible. The security bit that

controls this function, as well as all other programmed data, is reset only

when the device is reprogrammed.

MAX 3000A devices are fully functionally tested. Complete testing of

each programmable EEPROM bit and all internal logic elements ensures

100% programming yield. AC test measurements are taken under

conditions equivalent to those shown in Figure 8. Test patterns can be

used and then erased during early stages of the production flow.

Figure 8. MAX 3000A AC Test Conditions

Power supply transients can affect AC

measurements. Simultaneous transitions

of multiple outputs should be avoided for

accurate measurement. Threshold tests

must not be performed under AC

conditions. Large-amplitude, fast-groundcurrent transients normally occur as the

device outputs discharge the load

capacitances. When these transients flow

through the parasitic inductance between

the device ground pin and the test system

ground, significant reductions in

observable noise immunity can result.

Numbers in brackets are for 2.5-V

outputs. Numbers without brackets are for

3.3-V devices or outputs.

703 Ω

[521 Ω]

Device

Output

620 Ω

[481 Ω]

Device input

rise and fall

times < 2 ns

V

to Test

System

C1 (includes JIG

capacitance)

Operating Conditions

Tables 9 through 12 provide information on absolute maximum ratings,

recommended operating conditions, DC operating conditions, and

capacitance for MAX 3000A devices.

Table 9. MAX 3000A Device Absolute Maximum Ratings Note (1)

Symbol Parameter Conditions Min Max Unit

V

V

I

OUT

T

T

T

18 Altera Corporation

Supply voltage With respect to ground (2) –0.5 4.6 V

CC

DC input voltage –2.0 5.75 V

I

DC output current, per pin –25 25 mA

Storage temperature No bias –65 150 ° C

STG

Ambient temperature Under bias –65 135 ° C

A

Junction temperature PQFP and TQFP packages, under bias 135 ° C

J

Page 19

MAX 3000A Programmable Logic Device Family Data Sheet

Table 10. MAX 3000A Device Recommended Operating Conditions

Symbol Parameter Conditions Min Max Unit

V

V

V

V

V

T

T

t

R

t

F

Supply voltage for internal logic and

CCINT

input buffers

Supply voltage for output drivers,

CCIO

3.3-V operation

Supply voltage for output drivers,

3.0 3.6 V

3.0 3.6 V

2.3 2.7 V

2.5-V operation

Supply voltage during ISP 3.0 3.6 V

CCISP

Input voltage (3) –0.5 5.75 V

I

Output voltage 0 V

O

Ambient temperature For commercial use 0 70 ° C

A

For industrial use –40 85 ° C

Junction temperature For commercial use 0 90 ° C

J

For industrial use –40 105 ° C

Input rise time 40 ns

Input fall time 40 ns

CCIO

V

Table 11. MAX 3000A Device DC Operating Conditions Note (4)

Symbol Parameter Conditions Min Max Unit

V

V

V

V

I

I

I

OZ

R

High-level input voltage 1.7 5.75 V

IH

Low-level input voltage –0.5 0.8 V

IL

3.3-V high-level TTL output voltage IOH = –8 mA DC, V

OH

3.3-V high-level CMOS output

voltage

2.5-V high-level output voltage I

3.3-V low-level TTL output voltage IOL = 8 mA DC, V

OL

3.3-V low-level CMOS output

voltage

2.5-V low-level output voltage I

Input leakage current VI = V

Tri-state output off-state current VO = V

Value of I/O pin pull-up resistor

ISP

when programming in-system or

= –0.1 mA DC, V

I

OH

= –100 µA DC, V

OH

= –1 mA DC, V

I

OH

= –2 mA DC, V

I

OH

= 0.1 mA DC, V

I

OL

= 100 µA DC, V

OL

= 1 mA DC, V

I

OL

= 2 mA DC, V

I

OL

or ground –10 10 µA

CCINT

or ground –10 10 µA

CCINT

V

= 2.3 to 3.6 V (7) 20 74 kΩ

CCIO

= 3.00 V (5) 2.4 V

CCIO

= 3.00 V (5) V

CCIO

= 2.30 V (5) 2.1 V

CCIO

= 2.30 V (5) 2.0 V

CCIO

= 2.30 V (5) 1.7 V

CCIO

= 3.00 V (6) 0.4 V

CCIO

= 3.00 V (6) 0.2 V

CCIO

= 2.30 V (6) 0.2 V

CCIO

= 2.30 V (6) 0.4 V

CCIO

= 2.30 V (6) 0.7 V

CCIO

– 0.2 V

CCIO

during power-up

Altera Corporation 19

Page 20

MAX 3000A Programmable Logic Device Family Data Sheet

Table 12. MAX 3000A Device Capacitance Note (8)

Symbol Parameter Conditions Min Max Unit

C

C

Notes to tables:

(1) See the Operating Requirements for Altera Devices Data Sheet.

(2) Minimum DC input voltage is –0.5 V. During transitions, the inputs may undershoot to –2.0 V or overshoot to

(3) All pins, including dedicated inputs, I/O pins, and JTAG pins, may be driven before V

(4) These values are specified under the recommended operating conditions, as shown in Table 10 on page 19.

(5) The parameter is measured with 50% of the outputs each sourcing the specified current. The I

(6) The parameter is measured with 50% of the outputs each sinking the specified current. The I

(7) This pull-up exists while devices are programmed in-system and in unprogrammed devices during power-up.

(8) Capacitance is measured at 25° C and is sample-tested only. The

Input pin capacitance VIN = 0 V, f = 1.0 MHz 8 pF

IN

I/O pin capacitance V

I/O

= 0 V, f = 1.0 MHz 8 pF

OUT

5.75 V for input currents less than 100 mA and periods shorter than 20 ns.

and V

powered.

CCINT

to high-level TTL or CMOS output current.

low-level TTL or CMOS output current.

OE1 pin (high-voltage pin during programming)

OL

has a maximum capacitance of 20 pF.

are

CCIO

parameter refers

OH

parameter refers to

Figure 9 shows the typical output drive characteristics of MAX 3000A

devices.

20 Altera Corporation

Page 21

MAX 3000A Programmable Logic Device Family Data Sheet

Figure 9. Output Drive Characteristics of MAX 3000A Devices

3.3 V

150

I

OL

Typical I

Output

O

Current (mA)

2.5 V

Typical I

Output

O

Current (mA)

100

150

100

V

= 3.3

= 3.3 V

I

OH

V

O

= 25 C

CCINT

V

CCIO

Temperature

50

0

0

1234

VO Output Voltage (V)

I

OL

V

= 3.3 V

CCINT

V

= 2.5 V

CCIO

Temperature

50

I

OH

0

0

1234

O

= 25 C

VO Output Voltage (V)

Power Sequencing & Hot-Socketing

Because MAX 3000A devices can be used in a mixed-voltage

environment, they have been designed specifically to tolerate any

possible power-up sequence. The V

CCIO

and V

power planes can be

CCINT

powered in any order.

Signals can be driven into MAX 3000A devices before and during

power-up without damaging the device. In addition, MAX 3000A devices

do not drive out during power-up. Once operating conditions are

reached, MAX 3000A devices operate as specified by the user.

Altera Corporation 21

Page 22

MAX 3000A Programmable Logic Device Family Data Sheet

Timing Model

MAX 3000A device timing can be analyzed with the MAX+PLUS II

software, with a variety of popular industry-standard EDA simulators

and timing analyzers, or with the timing model shown in Figure 10.

MAX 3000A devices have predictable internal delays that enable the

designer to determine the worst-case timing of any design. The software

provides timing simulation, point-to-point delay prediction, and detailed

timing analysis for device-wide performance evaluation.

Figure 10. MAX 3000A Timing Model

Input

Delay

t

IN

PIA

Delay

t

PIA

Internal Output

Enable Delay

t

IOE

Global Control

Delay

t

GLOB

Logic Array

Delay

t

LAD

Register

Control Delay

t

LAC

t

IC

t

EN

Shared

Expander Delay

t

SEXP

Parallel

Expander Delay

t

PEXP

Register

Delay

t

SU

t

H

t

PRE

t

CLR

t

RD

t

COMB

Output

Delay

t

OD1

t

OD2

t

OD3

t

XZ

t

X1

Z

t

ZX2

t

ZX3

I/O

Delay

t

IO

The timing characteristics of any signal path can be derived from the

timing model and parameters of a particular device. External timing

parameters, which represent pin-to-pin timing delays, can be calculated

as the sum of internal parameters. Figure 11 shows the timing relationship

between internal and external delay parameters.

22 Altera Corporation

Page 23

Figure 11. MAX 3000A Switching Waveforms

MAX 3000A Programmable Logic Device Family Data Sheet

tR & tF < 2 ns. Inputs are

driven at 3 V for a logic

high and 0 V for a logic

low. All timing

characteristics are

measured at 1.5 V.

Input Pin

I/O Pin

PIA Delay

Shared Expander

Parallel Expander

Delay

Logic Array

Input

Delay

Logic Array

Output

Output Pin

Global

Clock Pin

Global Clock

at Register

Data or Enable

(Logic Array Output)

Combinatorial Mode

t

IN

t

IO

Global Clock Mode

t

IN

tSUt

t

CH

t

GLOB

H

t

R

t

PIA

t

SEXP

t

, t

LAC

LAD

t

PEXP

t

COMB

t

OD

t

CL

t

F

Array Clock Mode

t

F

t

CLR

, t

PRE

t

PIA

t

OD

Input or I/O Pin

Clock into PIA

Clock into

Logic Array

Clock at

Register

Data from

Logic Array

Register to PIA

to Logic Array

Register Output

to Pin

t

R

t

ACH

t

IN

t

IO

t

PIA

t

ACL

t

IC

t

t

SU

H

t

RD

t

PIA

t

OD

Altera Corporation 23

Page 24

MAX 3000A Programmable Logic Device Family Data Sheet

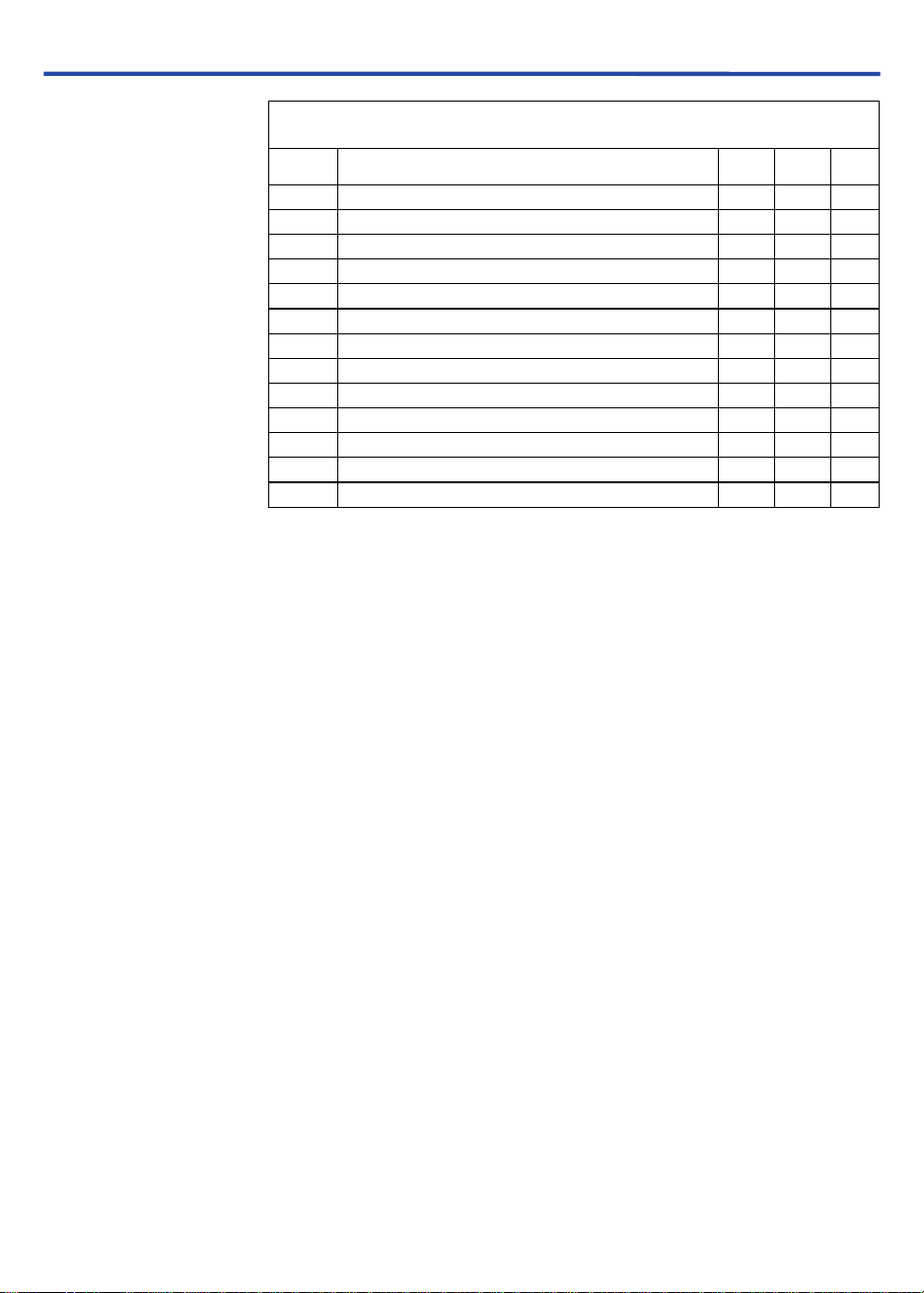

Tables 13 through 20 show EPM3032AE, EPM3064A, EPM3128A, and

EPM3256A timing information.

Table 13. EPM3032A External Timing Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

-4 -7 -10

Min Max Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

CNT

f

CNT

t

ACNT

f

ACNT

Input to nonregistered output

I/O input to nonregistered output

Global clock setup

C1 = 35 pF

4.5 7.5 10 ns

(2)

C1 = 35 pF

4.5 7.5 10 ns

(2)

(2) 2.9 4.7 6.3 ns

time

Global clock hold time (2) 0.0 0.0 0.0 ns

Global clock to output

C1 = 35 pF 1.0 3.0 1.0 5.0 1.0 6.7 ns

delay

Global clock high time 2.0 3.0 4.0 ns

Global clock low time 2.0 3.0 4.0 ns

Array clock setup time (2) 1.6 2.5 3.6 ns

Array clock hold time (2) 0.3 0.5 0.5 ns

Array clock to output

delay

C1 = 35 pF

(2)

1.0 4.3 1.0 7.2 1.0 9.4 ns

Array clock high time 2.0 3.0 4.0 ns

Array clock low time 2.0 3.0 4.0 ns

Minimum pulse width

(3) 2.0 3.0 4.0 ns

for clear and preset

Minimum global clock

(2) 4.4 7.2 9.7 ns

period

Maximum internal

(2), (4) 227.3 138.9 103.1 MHz

global clock frequency

Minimum array clock

(2) 4.4 7.2 9.7 ns

period

Maximum internal

(2), (4) 227.3 138.9 103.1 MHz

array clock frequency

24 Altera Corporation

Page 25

MAX 3000A Programmable Logic Device Family Data Sheet

Table 14. EPM3032A Internal Timing Parameters (Part 1 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-4 -7 -10

Min Max Min Max Min Max

t

IN

t

IO

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

Input pad and buffer delay 0.7 1.2 1.5 ns

I/O input pad and buffer

0.7 1.2 1.5 ns

delay

Shared expander delay 1.9 3.1 4.0 ns

Parallel expander delay 0.5 0.8 1.0 ns

Logic array delay 1.5 2.5 3.3 ns

Logic control array delay 0.6 1.0 1.2 ns

Internal output enable delay 0.0 0.0 0.0 ns

Output buffer and pad

C1 = 35 pF 0.8 1.3 1.8 ns

delay, slow slew rate = off

V

= 3.3 V

CCIO

Output buffer and pad

C1 = 35 pF 1.3 1.8 2.3 ns

delay, slow slew rate = off

= 2.5 V

V

CCIO

Output buffer and pad

C1 = 35 pF 5.8 6.3 6.8 ns

delay, slow slew rate = on

V

= 2.5 V or 3.3 V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.0 4.0 5.0 ns

slow slew rate = off

V

= 3.3 V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.5 4.5 5.5 ns

slow slew rate = off

V

= 2.5 V

CCIO

Output buffer enable delay,

C1 = 35 pF 9.0 9.0 10.0 ns

slow slew rate = on

= 2.5 V or 3.3 V

V

CCIO

Output buffer disable delay C1 = 5 pF 4.0 4.0 5.0 ns

Register setup time 1.3 2.0 2.8 ns

Register hold time 0.6 1.0 1.3 ns

Register delay 0.7 1.2 1.5 ns

Combinatorial delay 0.6 1.0 1.3 ns

Array clock delay 1.2 2.0 2.5 ns

Register enable time 0.6 1.0 1.2 ns

Global control delay 0.8 1.3 1.9 ns

Register preset time 1.2 1.9 2.6 ns

Register clear time 1.2 1.9 2.6 ns

Altera Corporation 25

Page 26

MAX 3000A Programmable Logic Device Family Data Sheet

Table 14. EPM3032A Internal Timing Parameters (Part 2 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-4 -7 -10

Min Max Min Max Min Max

t

t

PIA

LPA

PIA delay (2) 0.9 1.5 2.1 ns

Low-power adder (5) 2.5 4.0 5.0 ns

26 Altera Corporation

Page 27

MAX 3000A Programmable Logic Device Family Data Sheet

Table 15. EPM3064A External Timing Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

-4 -7 -10

Min Max Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

CNT

f

CNT

t

ACNT

f

ACNT

Input to nonregistered output

I/O input to nonregistered output

Global clock setup

C1 = 35 pF

4.5 7.5 10.0 ns

(2)

C1 = 35 pF

4.5 7.5 10.0 ns

(2)

(2) 2.8 4.7 6.2 ns

time

Global clock hold time (2) 0.0 0.0 0.0 ns

Global clock to output

C1 = 35 pF 1.0 3.1 1.0 5.1 1.0 7.0 ns

delay

Global clock high time 2.0 3.0 4.0 ns

Global clock low time 2.0 3.0 4.0 ns

Array clock setup time (2) 1.6 2.6 3.6 ns

Array clock hold time (2) 0.3 0.4 0.6 ns

Array clock to output

delay

C1 = 35 pF

(2)

1.0 4.3 1.0 7.2 1.0 9.6 ns

Array clock high time 2.0 3.0 4.0 ns

Array clock low time 2.0 3.0 4.0 ns

Minimum pulse width

(3) 2.0 3.0 4.0 ns

for clear and preset

Minimum global clock

(2) 4.5 7.4 10.0 ns

period

Maximum internal

(2), (4) 222.2 135.1 100.0 MHz

global clock frequency

Minimum array clock

(2) 4.5 7.4 10.0 ns

period

Maximum internal

(2), (4) 222.2 135.1 100.0 MHz

array clock frequency

Altera Corporation 27

Page 28

MAX 3000A Programmable Logic Device Family Data Sheet

Table 16. EPM3064A Internal Timing Parameters (Part 1 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-4 -7 -10

Min Max Min Max Min Max

t

IN

t

IO

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

Input pad and buffer delay 0.6 1.1 1.4 ns

I/O input pad and buffer

0.6 1.1 1.4 ns

delay

Shared expander delay 1.8 3.0 3.9 ns

Parallel expander delay 0.4 0.7 0.9 ns

Logic array delay 1.5 2.5 3.2 ns

Logic control array delay 0.6 1.0 1.2 ns

Internal output enable delay 0.0 0.0 0.0 ns

Output buffer and pad

C1 = 35 pF 0.8 1.3 1.8 ns

delay, slow slew rate = off

V

= 3.3 V

CCIO

Output buffer and pad

C1 = 35 pF 1.3 1.8 2.3 ns

delay, slow slew rate = off

V

= 2.5 V

CCIO

Output buffer and pad

C1 = 35 pF 5.8 6.3 6.8 ns

delay, slow slew rate = on

V

= 2.5 V or 3.3 V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.0 4.0 5.0 ns

slow slew rate = off

V

= 3.3 V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.5 4.5 5.5 ns

slow slew rate = off

V

= 2.5 V

CCIO

Output buffer enable delay,

C1 = 35 pF 9.0 9.0 10.0 ns

slow slew rate = on

V

= 2.5 V or 3.3 V

CCIO

Output buffer disable delay C1 = 5 pF 4.0 4.0 5.0 ns

Register setup time 1.3 2.0 2.9 ns

Register hold time 0.6 1.0 1.3 ns

Register delay 0.7 1.2 1.6 ns

Combinatorial delay 0.6 0.9 1.3 ns

Array clock delay 1.2 1.9 2.5 ns

Register enable time 0.6 1.0 1.2 ns

Global control delay 1.0 1.5 2.2 ns

Register preset time 1.3 2.1 2.9 ns

Register clear time 1.3 2.1 2.9 ns

28 Altera Corporation

Page 29

MAX 3000A Programmable Logic Device Family Data Sheet

Table 16. EPM3064A Internal Timing Parameters (Part 2 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-4 -7 -10

Min Max Min Max Min Max

t

PIA

t

LPA

PIA delay (2) 1.0 1.7 2.3 ns

Low-power adder (5) 3.5 4.0 5.0 ns

Altera Corporation 29

Page 30

MAX 3000A Programmable Logic Device Family Data Sheet

Table 17. EPM3128A External Timing Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

-5 -7 -10

Min Max Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

CNT

f

CNT

t

ACNT

f

ACNT

Input to nonregistered output

I/O input to nonregistered output

Global clock setup

C1 = 35 pF

5.0 7.5 10 ns

(2)

C1 = 35 pF

5.0 7.5 10 ns

(2)

(2) 3.3 4.9 6.6 ns

time

Global clock hold time (2) 0.0 0.0 0.0 ns

Global clock to output

C1 = 35 pF 1.0 3.4 1.0 5.0 1.0 6.6 ns

delay

Global clock high time 2.0 3.0 4.0 ns

Global clock low time 2.0 3.0 4.0 ns

Array clock setup time (2) 1.8 2.8 3.8 ns

Array clock hold time (2) 0.2 0.3 0.4 ns

Array clock to output

delay

C1 = 35 pF

(2)

1.0 4.9 1.0 7.1 1.0 9.4 ns

Array clock high time 2.0 3.0 4.0 ns

Array clock low time 2.0 3.0 4.0 ns

Minimum pulse width

(3) 2.0 3.0 4.0 ns

for clear and preset

Minimum global clock

(2) 5.2 7.7 10.2 ns

period

Maximum internal

(2), (4) 192.3 129.9 98.0 MHz

global clock frequency

Minimum array clock

(2) 5.2 7.7 10.2 ns

period

Maximum internal

(2), (4) 192.3 129.9 98.0 MHz

array clock frequency

30 Altera Corporation

Page 31

MAX 3000A Programmable Logic Device Family Data Sheet

Table 18. EPM3128A Internal Timing Parameters (Part 1 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-5 -7 -10

Min Max Min Max Min Max

t

IN

t

IO

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

Input pad and buffer delay 0.7 1.0 1.4 ns

I/O input pad and buffer

0.7 1.0 1.4 ns

delay

Shared expander delay 2.0 2.9 3.8 ns

Parallel expander delay 0.4 0.7 0.9 ns

Logic array delay 1.6 2.4 3.1 ns

Logic control array delay 0.7 1.0 1.3 ns

Internal output enable delay 0.0 0.0 0.0 ns

Output buffer and pad

C1 = 35 pF 0.8 1.2 1.6 ns

delay, slow slew rate = off

V

= 3.3 V

CCIO

Output buffer and pad

C1 = 35 pF 1.3 1.7 2.1 ns

delay, slow slew rate = off

V

= 2.5 V

CCIO

Output buffer and pad

C1 = 35 pF 5.8 6.2 6.6 ns

delay, slow slew rate = on

V

= 2.5 V or 3.3 V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.0 4.0 5.0 ns

slow slew rate = off

= 3.3 V

V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.5 4.5 5.5 ns

slow slew rate = off

V

= 2.5 V

CCIO

Output buffer enable delay,

C1 = 35 pF 9.0 9.0 10.0 ns

slow slew rate = on

V

= 2.5 V or 3.3 V

CCIO

Output buffer disable delay C1 = 5 pF 4.0 4.0 5.0 ns

Register setup time 1.4 2.1 2.9 ns

Register hold time 0.6 1.0 1.3 ns

Register delay 0.8 1.2 1.6 ns

Combinatorial delay 0.5 0.9 1.3 ns

Array clock delay 1.2 1.7 2.2 ns

Register enable time 0.7 1.0 1.3 ns

Global control delay 1.1 1.6 2.0 ns

Register preset time 1.4 2.0 2.7 ns

Register clear time 1.4 2.0 2.7 ns

Altera Corporation 31

Page 32

MAX 3000A Programmable Logic Device Family Data Sheet

Table 18. EPM3128A Internal Timing Parameters (Part 2 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-5 -7 -10

Min Max Min Max Min Max

t

t

PIA

LPA

PIA delay (2) 1.4 2.0 2.6 ns

Low-power adder (5) 4.0 4.0 5.0 ns

32 Altera Corporation

Page 33

MAX 3000A Programmable Logic Device Family Data Sheet

Table 19. EPM3256A External Timing Parameters Note (1)

Symbol Parameter Conditions Speed Grade Unit

-5 -7 -10

Min Max Min Max Min Max

t

PD1

t

PD2

t

SU

t

H

t

CO1

t

CH

t

CL

t

ASU

t

AH

t

ACO1

t

ACH

t

ACL

t

CPPW

t

CNT

f

CNT

t

ACNT

f

ACNT

Input to nonregistered output

I/O input to nonregistered output

Global clock setup

C1 = 35 pF

5.5 7.5 10 ns

(2)

C1 = 35 pF

5.5 7.5 10 ns

(2)

(2) 3.9 5.2 6.9 ns

time

Global clock hold time (2) 0.0 0.0 0.0 ns

Global clock to output

C1 = 35 pF 1.0 3.5 1.0 4.8 1.0 6.4 ns

delay

Global clock high time 2.0 3.0 4.0 ns

Global clock low time 2.0 3.0 4.0 ns

Array clock setup time (2) 2.0 2.7 3.6 ns

Array clock hold time (2) 0.2 0.3 0.5 ns

Array clock to output

delay

C1 = 35 pF

(2)

1.0 5.4 1.0 7.3 1.0 9.7 ns

Array clock high time 2.0 3.0 4.0 ns

Array clock low time 2.0 3.0 4.0 ns

Minimum pulse width

(3) 2.0 3.0 4.0 ns

for clear and preset

Minimum global clock

(2) 5.8 7.9 10.5 ns

period

Maximum internal

(2), (4) 172.4 126.6 95.2 MHz

global clock frequency

Minimum array clock

(2) 5.8 7.9 10.5 ns

period

Maximum internal

(2), (4) 172.4 126.6 95.2 MHz

array clock frequency

Altera Corporation 33

Page 34

MAX 3000A Programmable Logic Device Family Data Sheet

Table 20. EPM3256A Internal Timing Parameters (Part 1 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-5 -7 -10

Min Max Min Max Min Max

t

IN

t

IO

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

Input pad and buffer delay 0.7 0.9 1.2 ns

I/O input pad and buffer

0.7 0.9 1.2 ns

delay

Shared expander delay 2.1 2.8 3.7 ns

Parallel expander delay 0.3 0.5 0.6 ns

Logic array delay 1.7 2.2 2.8 ns

Logic control array delay 0.8 1.0 1.3 ns

Internal output enable delay 0.0 0.0 0.0 ns

Output buffer and pad

C1 = 35 pF 0.9 1.2 1.6 ns

delay, slow slew rate = off

V

= 3.3 V

CCIO

Output buffer and pad

C1 = 35 pF 1.4 1.7 2.1 ns

delay, slow slew rate = off

V

= 2.5 V

CCIO

Output buffer and pad

C1 = 35 pF 5.9 6.2 6.6 ns

delay, slow slew rate = on

V

= 2.5 V or 3.3 V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.0 4.0 5.0 ns

slow slew rate = off

V

= 3.3 V

CCIO

Output buffer enable delay,

C1 = 35 pF 4.5 4.5 5.5 ns

slow slew rate = off

V

= 2.5 V

CCIO

Output buffer enable delay,

C1 = 35 pF 9.0 9.0 10.0 ns

slow slew rate = on

V

= 2.5 V or 3.3 V

CCIO

Output buffer disable delay C1 = 5 pF 4.0 4.0 5.0 ns

Register setup time 1.5 2.1 2.9 ns

Register hold time 0.7 0.9 1.2 ns

Register delay 0.9 1.2 1.6 ns

Combinatorial delay 0.5 0.8 1.2 ns

Array clock delay 1.2 1.6 2.1 ns

Register enable time 0.8 1.0 1.3 ns

Global control delay 1.0 1.5 2.0 ns

Register preset time 1.6 2.3 3.0 ns

Register clear time 1.6 2.3 3.0 ns

34 Altera Corporation

Page 35

MAX 3000A Programmable Logic Device Family Data Sheet

Table 20. EPM3256A Internal Timing Parameters (Part 2 of 2) Note (1)

Symbol Parameter Conditions Speed Grade Unit

-5 -7 -10

Min Max Min Max Min Max

t

PIA

t

LPA

Notes to tables:

(1) These values are specified in Tables 13 through 20 under the recommended operating conditions shown in Table 9

(2) These values are specified for a PIA fan-out of one LAB (16 macrocells). For each additional LAB fan-out in these

(3) This minimum pulse width for preset and clear applies for both global clear and array controls. The t

(4) Measured with a 16-bit loadable, enabled, up/down counter programmed into each LAB.

(5) The t

PIA delay (2) 1.7 2.4 3.2 ns

Low-power adder (5) 4.0 4.0 5.0 ns

on page 18.

devices, add an additional 0.1 ns to the PIA timing value.

must be added to this minimum width if the clear or reset signal incorporates the t

path.

parameter must be added to the t

LPA

running in low-power mode.

LAD

, t

LAC

, tIC, tEN, t

SEXP

, t

, and t

ACL

parameter into the signal

LAD

parameters for macrocells

CPPW

parameter

LPA

Power Consumption

Supply power (P) versus frequency (f

, in MHz) for MAX 3000A

MAX

devices is calculated with the following equation:

P = P

+ PIO = I

INT

CCINT

× V

CC

+ P

IO

The PIO value, which depends on the device output load characteristics

and switching frequency, can be calculated using the guidelines given in

Application Note 74 (Evaluating Power for Altera Devices).

The I

logic. The I

I

CCINT

(A × MC

value depends on the switching frequency and the application

CCINT

value is calculated with the following equation:

CCINT

=

) + [B × (MC

TON

DEV

– MC

)] + (C × MC

TON

USED

× f

MAX

× tog

LC

)

Altera Corporation 35

Page 36

MAX 3000A Programmable Logic Device Family Data Sheet

The parameters in the I

MC

= Number of macrocells with the Turbo BitTM option turned

TON

CCINT

equation are:

on, as reported in the MAX+PLUS II Report File (.rpt)

MC

MC

= Number of macrocells in the device

DEV

= Total number of macrocells in the design, as reported in

USED

the RPT File

f

MAX

tog

LC

= Highest clock frequency to the device

= Average percentage of logic cells toggling at each clock

(typically 12.5%)

A, B, C = Constants (shown in Table 21)

Table 21. MAX 3000A I

Equation Constants

CC

Device A B C

EPM3032A 0.85 0.36 0.017

EPM3064A 0.85 0.36 0.017

EPM3128A 0.85 0.36 0.017

EPM3256A 0.85 0.36 0.017

The I

calculation provides an ICC estimate based on typical

CCINT

conditions using a pattern of a 16-bit, loadable, enabled, up/down

counter in each LAB with no output load. Actual ICC should be verified

during operation because this measurement is sensitive to the actual

pattern in the device and the environmental operating conditions.

36 Altera Corporation

Page 37

MAX 3000A Programmable Logic Device Family Data Sheet

Figures 12 and 13 shows the typical supply current versus frequency for

MAX 3000A devices.

Figure 12. ICC vs. Frequency for MAX 3000A Devices (Part 1 of 2)

EPM3032A

VCC = 3.3 V

70

60

Room Temperature

Typical I

CC

Active (mA)

EPM3064A

Typical I

CC

Active (mA)

40

140

120

100

80

50

30

20

10

0

High Speed

50 100

144.9 MHz

Non-Turbo

150

227.3 MHz

200 250

Frequency (MHz)

VCC = 3.3 V

Room Temperature

High Speed

60

40

20

125.0 MHz

Non-Turbo

222.2 MHz

0

50 100

150

200

250˚

Frequency (MHz)

Altera Corporation 37

Page 38

MAX 3000A Programmable Logic Device Family Data Sheet

)

Figure 13. ICC vs. Frequency for MAX 3000A Devices (Part 2 of 2)

EPM3128A

VCC = 3.3 V

Room Temperature

High Speed

Typical I

CC

Active (mA)

210

180

150

120

90

60

30

192.3 MHz

108.7 MHz

Non-Turbo

EPM3256A

Typical I

CC

Active (mA)

350

300

250

200

150

100

0

50 100

150

200 250

Frequency (MHz)

VCC = 3.3 V

Room Temperature

172.4 MHz

High Speed

102.0 MHz

Non-Turbo

50

0

50 100

150

200

Frequency (MHz

38 Altera Corporation

Page 39

MAX 3000A Programmable Logic Device Family Data Sheet

Device Pin-Outs

Tables 22 through 29 show the pin names and numbers for the pins in

MAX 3000A device packages.

Table 22. EPM3032A Dedicated Pin-Outs

Dedicated Pin 44-Pin PLCC 44-Pin TQFP

INPUT/GCLK1 43 37

INPUT/GCLRn 139

INPUT/OE1 44 38

INPUT/OE2/GCLK2 240

TDI (1) 71

TMS (1) 13 7

TCK (1) 32 26

TDO (1) 38 32

GNDINT 22, 42 16, 36

GNDIO 10, 17, 30, 36 4, 11, 24, 30

VCCINT (3.3 V) 3, 23 17, 41

VCCIO (2.5 V or 3.3 V) 15, 35 9, 29

No Connect (N.C.) ––

Total User I/O Pins (2) 34 34

Altera Corporation 39

Page 40

MAX 3000A Programmable Logic Device Family Data Sheet

Table 23. EPM3032A I/O Pin-Outs

LAB MC 44-Pin

PLCC

A 1 4 42 B 17 41 35

2 5 43 184034

3 6 44 193933

47 (1) 1 (1) 20 38 (1) 32 (1)

5 8 2 21 37 31

693 22––

7 11 5 23 34 28

8 12 6 24 33 27

9 13 (1) 7 (1) 25 32 (1) 26 (1)

10 14 8 26 31 25

11 16 10 27 29 23

12 –– 28 28 22

13 18 12 29 27 21

14 19 13 30 26 20

15 20 14 31 25 19

16 21 15 32 24 18

Notes to tables:

(1) This pin may function as either a JTAG port or a user I/O pin. When the device is configured to use the JTAG ports

for in-system programming, this pin is not available as a user I/O pin.

(2) The user I/O pin count includes dedicated input pins and all I/O pins.

44-Pin

TQFP

LAB MC 44-Pin

PLCC

44-Pin

TQFP

40 Altera Corporation

Page 41

MAX 3000A Programmable Logic Device Family Data Sheet

Table 24. EPM3064A Dedicated Pin-Outs

Dedicated Pin 44-Pin

PLCC

INPUT/GCLK1 43 37 87

INPUT/GCLRn 13989

INPUT/OE1 44 38 88

INPUT/OE2/GCLK2 24090

TDI (1) 714

TMS (1) 13 7 15

TCK (1) 32 26 62

TDO (1) 38 32 73

GNDINT 22, 42 16, 36 38, 86

GNDIO 10, 17, 30, 36 4, 11, 24, 30 11, 26, 33, 43, 53,

VCCINT (3.3 V Only) 3, 23 17, 41 39, 91

VCCIO (2.5 V or 3.3 V) 15, 35 9, 29 3, 18, 34, 51, 66,

No Connect (N.C.) ––1, 2, 5, 7, 22, 24,

Total User I/O Pins (2) 34 34 66

44-Pin

TQFP

100-Pin

TQFP

59, 65, 74, 78, 95

82

27, 28, 49, 50, 55,

70, 72, 77

Altera Corporation 41

Page 42

MAX 3000A Programmable Logic Device Family Data Sheet

Table 25. EPM3064A I/O Pin-Outs

LAB MC 44-Pin

PLCC

A 1 12 6 14 C 33 24 18 40

2 ––13 34 ––41

3 11 5 12 35 25 19 42

49310 36262044

5829 37272145

6 ––838––46

7 ––639––47

87 (1) 1 (1) 4 (1) 40 28 22 48

9 ––100 41 29 23 52

10 ––99 42 ––54

11 6 44 98 43 ––56

12 ––97 44 ––57

13 ––96 45 ––58

145 4394 46312560

15 ––93 47 ––61

16 4 42 92 48 32 (1) 26 (1) 62 (1)

B 17 21 15 37 D 49 33 27 63

18 ––36 50 ––64

19 20 14 35 51 34 28 –

20 19 13 – 52 ––67

21 18 12 32 53 37 31 68

22 ––31 54 ––69

23 ––30 55 ––71

24 ––29 56 38 (1) 32 (1) 73 (1)

25 16 10 25 57 39 33 75

26 ––23 48 ––76

27 ––21 59 ––79

28 ––20 60 ––80

29 ––19 61 ––81

30148 17 62403483

31 ––16 63 ––84

32 13 (1) 7 (1) 15 (1) 64 41 35 85

Notes to tables:

(1) This pin may function as either a JTAG port or a user I/O pin. When the device is configured to use the JTAG ports

for in-system programming, this pin is not available as a user I/O pin.

(2) The user I/O pin count includes dedicated input pins and all I/O pins.

44-Pin

TQFP

100-Pin

TQFP

LAB MC 44-Pin

PLCC

44-Pin

TQFP

100-Pin

TQFP

42 Altera Corporation

Page 43

MAX 3000A Programmable Logic Device Family Data Sheet

Table 26. EPM3128A Dedicated Pin-Outs

Dedicated Pin 100-Pin TQFP 144-Pin TQFP

INPUT/GCLK1 87 125

INPUT/GCLRn 89 127

INPUT/OE1 88 126

INPUT/OE2/GCLK2 90 128

TDI (1) 44

TMS (1) 15 20

TCK (1) 62 89

TDO (1) 73 104

GNDINT 38, 86 52, 57, 124, 129

GNDIO 11, 26, 33, 43, 53, 59, 65,

74, 78, 95

VCCINT (3.3 V Only) 39, 91 51, 58, 123, 130

VCCIO (2.5 V or 3.3 V) 3, 18, 34, 51, 66, 82 24, 50, 73, 76, 95, 115, 144

No Connect (N.C.) – 1, 2, 12, 19, 34, 35, 36, 43,

Total User I/O Pins (2) 80 96

3, 13, 17, 26, 33, 59, 64, 77,

85, 94, 105, 114, 135

46, 47, 48, 49, 66, 75, 90,

103, 108, 120, 121, 122

Altera Corporation 43

Page 44

MAX 3000A Programmable Logic Device Family Data Sheet

Table 27. EPM3128A I/O Pin-Outs (Part 1 of 2)

LAB MC 100-Pin

TQFP

A1 2 143 C332532

2 –– 34 ––

3 1 142 35 24 31

4 – 141 36 – 30

5 100 140 37 23 29

6 99 139 38 22 28

7 –– 39 ––

8 98 138 40 21 27

9 97 137 41 20 –

10 –– 42 ––

11 96 136 43 19 25

12 – 134 44 – 23

13 94 133 45 17 22

14 93 132 46 16 21

15 –– 47 ––

16 92 131 48 15 (1) 20 (1)

B 17 14 18 D 49 37 56

18 –– 50 ––

19 13 16 51 36 55

20 – 15 52 – 54

21 12 14 53 35 53

22 10 11 54 – 45

23 –– 55 ––

249 10 563244

25 8 9 57 31 42

26 –– 58 ––

27 7 8 59 30 41

28 – 760– 40

29 6 6 61 29 39

30 5 5 62 28 38

31 –– 63 ––

32 4 (1) 4 (1) 64 27 37

144-Pin

TQFP

LAB MC 100-Pin

TQFP

144-Pin

TQFP

44 Altera Corporation

Page 45

Table 27. EPM3128A I/O Pin-Outs (Part 2 of 2)

MAX 3000A Programmable Logic Device Family Data Sheet

LAB MC 100-Pin

TQFP

E 65 40 60 G 97 63 91

66 –– 98 ––

67 41 61 99 64 92

68 – 62 100 – 93

69 42 63 101 ––

70 44 65 102 67 96

71 –– 103 ––

72 45 67 104 68 97

73 46 68 105 69 98

74 –– 106 ––

75 47 69 107 70 99

76 – 70 108 – 100

77 48 71 109 71 101

78 49 72 110 72 102

79 –– 111 ––

80 50 74 112 73 (1) 104 (1)

F81 52 – H 113 75 106

82 –– 114 ––

83 – 78 115 76 107

84 – 79 116 – 109

85 54 80 117 77 110

86 55 81 118 – 111

87 –– 119 ––

88 56 82 120 79 112

89 57 83 121 80 113

90 –– 122 ––

91 58 84 123 81 –

92 – 86 124 – 116

93 60 87 125 83 117

94 61 88 126 84 118

95 –– 127 ––

96 62 (1) 89 (1) 128 85 119

Notes to tables:

(1) This pin may function as either a JTAG port or a user I/O pin. When the device is configured to use the JTAG ports

for in-system programming, this pin is not available as a user I/O pin.

(2) The user I/O pin count includes dedicated input pins and all I/O pins.

144-Pin

TQFP

LAB MC 100-Pin

TQFP

144-Pin

TQFP

Altera Corporation 45

Page 46

MAX 3000A Programmable Logic Device Family Data Sheet

Table 28. EPM3256A Dedicated Pin-Outs

Dedicated Pin 144-Pin TQFP 208-Pin PQFP

INPUT/GCLK1 125 184

INPUT/GCLRn 127 182

INPUT/OE1 126 183

INPUT/OE2/GCLK2 128 181

TDI (1) 4 176

TMS (1) 20 127

TCK (1) 89 30

TDO (1) 104 189

GNDINT 52, 57, 124, 129 75, 82, 180, 185

GNDIO 3, 13, 17, 26, 33, 59, 64,

77, 85, 94, 105, 114, 135

VCCINT (3.3 V Only) 51, 58, 123, 130 74, 83, 179, 186

VCCIO (2.5 V or 3.3 V) 24, 50, 73, 76, 95, 115,

144

No Connect (N.C.) – 1, 2, 51, 52, 53, 54, 103,

Total User I/O Pins (2) 116 158

6, 14, 32, 40, 50, 72, 84,

94, 108, 116, 134, 142,

152, 174, 190, 200

5, 23, 41, 63, 85, 107, 125,

143, 165, 191

104, 105, 106, 155, 156,

157, 158, 207, 208

46 Altera Corporation

Page 47

MAX 3000A Programmable Logic Device Family Data Sheet

Table 29. EPM3256A I/O Pin-Outs (Part 1 of 4)

LAB MC 144-Pin

TQFP

A1 – 153 C 33 36 –

2 –– 34 ––

3 2 154 35 35 109

4 –– 36 ––

5 1 159 37 34 110

6 143 160 38 – 111

7 –– 39 ––

8 – 161 40 32 112

9 – 162 41 31 113

10 –– 42 ––

11 142 163 43 30 114

12 –– 44 ––

13 141 164 45 29 115

14 140 166 46 – 117

15 –– 47 ––

16 139 167 48 28 118

B17 – 141 D494492

18 –– 50 ––

19 10 – 51 43 93

20 –– 52 ––

21 9 144 53 42 95

22 – 145 54 41 96

23 –– 55 ––

24 8 146 56 40 97

25 7 147 57 – 98

26 –– 58 ––

27 6 148 59 39 99

28 –– 60 ––

29 5 149 61 38 100

30 – 150 62 – 101

31 –– 63 ––

32 4 (1) 151 64 37 102

208-Pin

PQFP

LAB MC 144-Pin

TQFP

208-Pin

PQFP

Altera Corporation 47

Page 48

MAX 3000A Programmable Logic Device Family Data Sheet

Table 29. EPM3256A I/O Pin-Outs (Part 2 of 4)

LAB MC 144-Pin

TQFP

E65 – 168 G 97 – 119

66 –– 98 ––

67 – 169 99 27 120

68 –– 100 ––

69 138 170 101 – 121

70 – 171 102 – 122

71 –– 103 ––

72 137 172 104 25 123

73 136 173 105 23 124

74 –– 106 ––

75 134 175 107 22 126

76 –– 108 ––

77 133 176 (1) 109 21 127 (1)

78 132 177 110 – 128

79 –– 111 ––

80 131 178 112 20 (1) 129

F81 – 130 H 113 – 79

82 –– 114 ––

83 19 131 115 54 80

84 –– 116 ––

85 18 132 117 53 81

86 – 133 118 ––

87 –– 119 ––

88 16 135 120 49 86

89 15 136 121 48 87

90 –– 122 ––

91 14 137 123 47 88

92 –– 124 ––

93 12 138 125 46 89

94 – 139 126 – 90

95 –– 127 ––

96 11 140 128 45 91

208-Pin

PQFP

LAB MC 144-Pin

TQFP

208-Pin

PQFP

48 Altera Corporation

Page 49

MAX 3000A Programmable Logic Device Family Data Sheet

Table 29. EPM3256A I/O Pin-Outs (Part 3 of 4)

LAB MC 144-Pin

TQFP

I 129 – 197 K 161 – 38

130 –– 162 ––

131 116 196 163 82 37

132 –– 164 ––

133 117 195 165 83 36

134 – 194 166 – 35

135 –– 167 ––

136 118 193 168 84 34

137 119 192 169 86 33

138 –– 170 ––

139 120 – 171 87 31

140 –– 172 ––

141 121 189 (1) 173 88 30 (1)

142 – 188 174 – 29

143 –– 175 ––

144 122 187 176 89 (1) 28

J 145 – 27 L 177 – 78

146 –– 178 ––

147 90 26 179 55 77

148 –– 180 ––

149 91 25 181 56 76

150 – 24 182 – 73

151 –– 183 ––

152 92 22 184 60 71

153 93 21 185 61 70

154 –– 186 ––

155 – 20 187 62 69

156 –– 188 ––

157 96 19 189 63 68

158 – 18 190 – 67

159 –– 191 ––

160 97 17 192 65 66

208-Pin

PQFP

LAB MC 144-Pin

TQFP

208-Pin

PQFP

Altera Corporation 49

Page 50

MAX 3000A Programmable Logic Device Family Data Sheet

Table 29. EPM3256A I/O Pin-Outs (Part 4 of 4)

LAB MC 144-Pin

TQFP

M 193 106 4 O 225 – 49

194 –– 226 ––

195 107 3 227 74 48

196 –– 228 ––

197 108 206 229 75 47

198 – 205 230 – 46

199 –– 231 ––

200 109 204 232 – 45

201 110 203 233 78 44

202 –– 234 ––

203 111 202 235 79 43

204 –– 236 ––

205 – 201 237 80 42

206 112 199 238 ––

207 –– 239 ––

208 113 198 240 81 39

N 209 – 16 P 241 66 65

210 –– 242 ––

211 98 15 243 67 64

212 –– 244 ––

213 99 13 245 68 62

214 – 12 246 69 61

215 –– 247 ––

216 100 11 248 – 60

217 101 10 249 70 59

218 –– 250 ––

219 102 9 251 – 58

220 –– 252 ––

221 103 8 253 71 57

222 – 7 254 – 56

223 –– 255 ––

224 104 (1) – 256 72 55

Notes to tables:

(1) This pin can function as either a JTAG pin or a user I/O pin. When the device is programmed to use the JTAG ports