Page 1

MAX 10 Power Management User Guide

Subscribe

Send Feedback

UG-M10PWR

2015.02.09

101 Innovation Drive

San Jose, CA 95134

www.altera.com

Page 2

TOC-2

Contents

MAX 10 Power Management Overview..............................................................1-1

MAX 10 Power Management Features and Architecture.................................. 2-1

Power Supply Device Options....................................................................................................................2-1

Single-Supply Device.......................................................................................................................2-1

Dual-Supply Device.........................................................................................................................2-1

Comparison of the MAX 10 Power Supply Device Options......................................................2-2

Power Supply Design.......................................................................................................................2-3

Power-On Reset Circuitry.......................................................................................................................... 2-4

Power Supplies Monitored and Not Monitored by the POR Circuitry................................... 2-4

Instant-On Support......................................................................................................................... 2-6

Power Management Controller Scheme...................................................................................................2-6

Power Management Controller Architecture.............................................................................. 2-6

Hot Socketing............................................................................................................................................... 2-8

Hot-Socketing Specifications......................................................................................................... 2-8

Hot-Socketing Feature Implementation.......................................................................................2-9

Power Management Controller Reference Design.............................................3-1

Clock Control Block.................................................................................................................................... 3-2

I/O Buffer......................................................................................................................................................3-2

Internal Oscillator........................................................................................................................................3-2

Power Management Controller................................................................................................................. 3-3

Entering State....................................................................................................................................3-3

Sleep State..........................................................................................................................................3-3

Exiting State......................................................................................................................................3-3

Awake State.......................................................................................................................................3-3

Entering or Exiting Sleep Mode.................................................................................................................3-4

Entering Sleep Mode........................................................................................................................3-4

Exiting Sleep Mode..........................................................................................................................3-4

Timing Parameters.......................................................................................................................... 3-5

Hardware Implementation and Current Measurement.........................................................................3-5

Additional Information for MAX 10 Power Management User Guide ...........A-1

Document Revision History for MAX 10 Power Management User Guide...................................... A-1

Altera Corporation

Page 3

2015.02.09

www.altera.com

101 Innovation Drive, San Jose, CA 95134

MAX 10 Power Management Overview

1

UG-M10PWR

Subscribe

Send Feedback

MAX® 10 devices offer the following power supply device options:

• Single-supply device—requires 1 external power supply of 3.0 V or 3.3 V whilst offering maximum

convenience and board simplicity.

• Dual-supply device—requires 2 external power supplies of 1.2 V and 2.5 V whilst offering the most

features, highest performance, and when coupled with high-efficiency Enpirion® PowerSoCs, the

lowest power solution.

Related Information

MAX 10 Power Management Features and Architecture on page 2-1

Provides information about power management features and architecture

©

2015 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, ENPIRION, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos are

trademarks of Altera Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. Altera warrants performance

of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any

products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information,

product, or service described herein except as expressly agreed to in writing by Altera. Altera customers are advised to obtain the latest version of device

specifications before relying on any published information and before placing orders for products or services.

ISO

9001:2008

Registered

Page 4

MAX 10 Power Management Features and

VCC_ONE/VCCA

Voltage

Regulator

3.3 V/3.0 V

1.2 V

Max 10 Single-Supply Device

www.altera.com

101 Innovation Drive, San Jose, CA 95134

2015.02.09

UG-M10PWR

Subscribe

Send Feedback

MAX 10 power optimization features are as follows:

• Single-supply or dual-supply device options

• Power-on reset (POR) circuitry

• Power management controller scheme

• Hot socketing

Power Supply Device Options

This section covers the single-supply and dual-supply device options supported in MAX 10 devices.

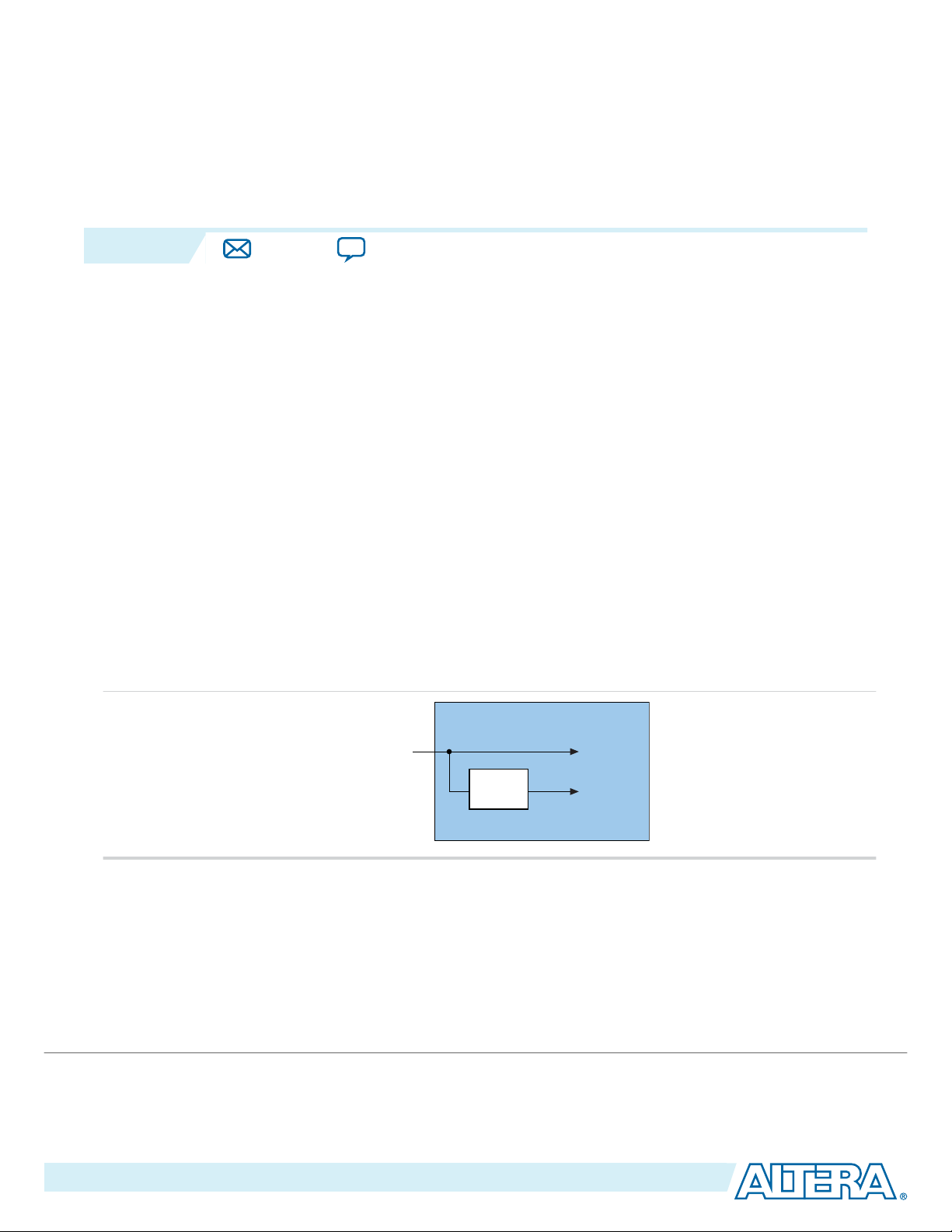

Single-Supply Device

MAX 10 single-supply devices only need either a 3.0- or 3.3-V external power supply. The external power

supply serves as an input to the MAX 10 device VCC_ONE and VCCA power pins. This external power supply

is then regulated by an internal voltage regulator in the MAX 10 single-supply device to 1.2 V. The 1.2-V

voltage level is required by core logic operation.

Architecture

2

Figure 2-1: MAX 10 Single-Supply Device

Dual-Supply Device

MAX 10 dual-supply devices require 1.2 V and 2.5 V for the device core logics and periphery operations.

©

2015 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, ENPIRION, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos are

trademarks of Altera Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. Altera warrants performance

of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any

products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information,

product, or service described herein except as expressly agreed to in writing by Altera. Altera customers are advised to obtain the latest version of device

specifications before relying on any published information and before placing orders for products or services.

ISO

9001:2008

Registered

Page 5

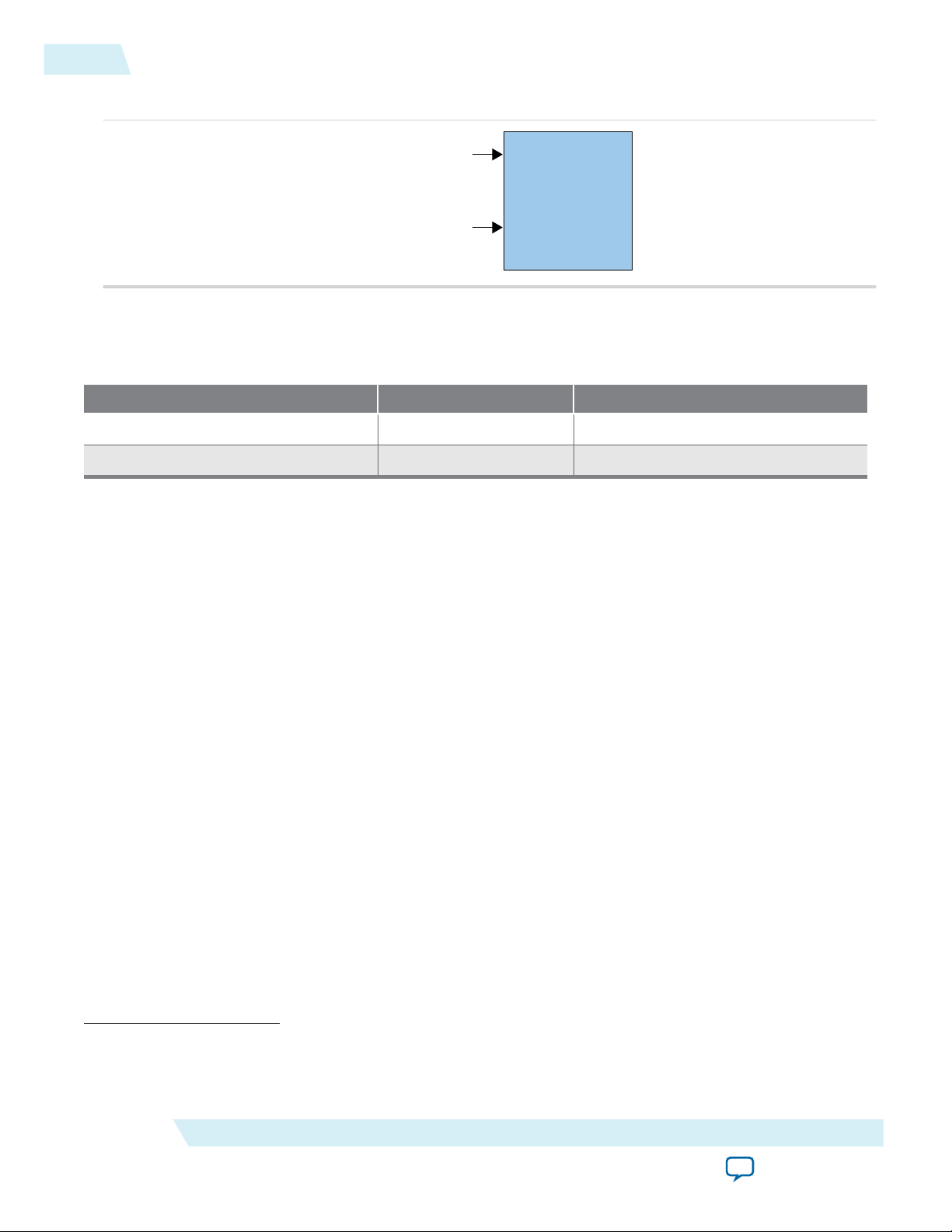

MAX 10

Dual-Supply Device

(1.2 V)

VCCA, VCCA_ADC

(2.5 V)

2-2

Comparison of the MAX 10 Power Supply Device Options

Figure 2-2: MAX 10 Dual-Supply Device

Comparison of the MAX 10 Power Supply Device Options

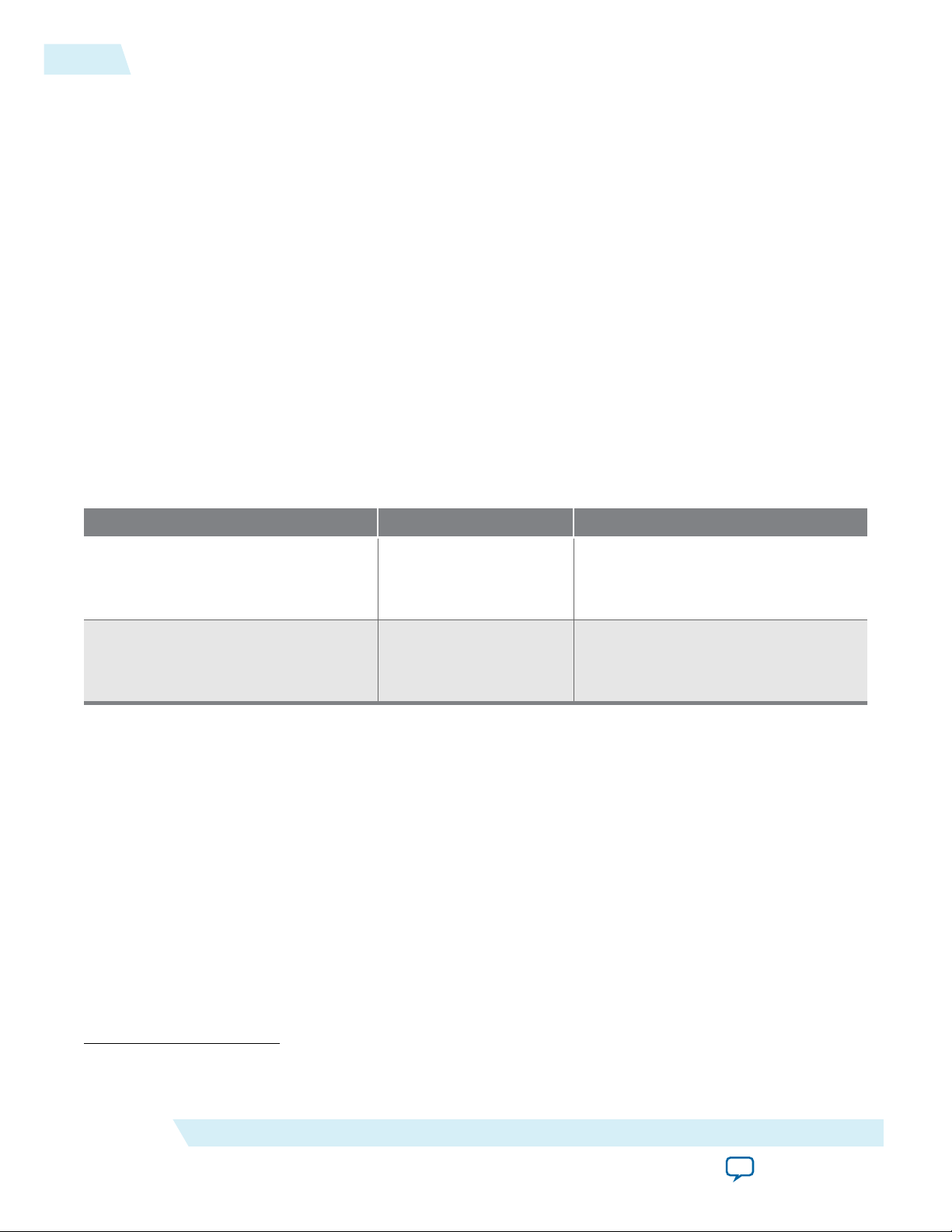

Table 2-1: Comparison of the MAX 10 Power Supply Device Options

Characteristics Single-Supply Device Dual-Supply Device

Voltage regulator count

Core and I/O performance Low High

(1)

1 2

UG-M10PWR

2015.02.09

For MAX 10 single-supply devices, only one power supply is required—3.0 V or 3.3 V to power the core

of the FPGA. The same power supply can be used to power the I/O if the same 3.0 V or 3.3 V voltage is

required. If different I/O voltage is used, then additional voltage regulators will be needed.

For MAX 10 dual-supply devices, two power supplies are required to supply power to the device core,

periphery, phase-locked loop (PLL), and analog-to-digital converters (ADC) blocks—1.2 V and 2.5 V.

Depending on the I/O standard voltage requirement, you may use two or more voltage regulators.

As the power rails for the FPGA core are supplied externally in the MAX 10 dual-supply devices, the

design can be optimized for power by using high efficiency switching power supplies on the board. The

power savings will be equal to the increased efficiency of the regulators used compared to the internal

linear regulators of the MAX 10 single-supply devices. If linear regulators are used to power the MAX 10

dual-supply devices, the power consumption of the MAX 10 dual-supply devices will be approximately

equal to the MAX 10 single-supply devices.

The device performance of the single-supply device is lower than that of the dual-supply device. For the

performance difference in terms of LVDS, pseudo-LVDS, digital signal processing (DSP), and internal

memory performance, refer to the MAX 10 FPGA device datasheet.

Related Information

MAX 10 FPGA Device Datasheet

Provides details about the MAX 10 performance difference in terms of LVDS, pseudo-LVDS, DSP, and

internal memory performance.

(1)

Altera Corporation

This shows the number of power supplies required by the core and periphery of the MAX 10 devices. You

may need additional voltage regulators to supply power to the VCCIO if the VCCIO does not have the same

voltage level as the core and periphery supply.

MAX 10 Power Management Features and Architecture

Send Feedback

Page 6

UG-M10PWR

2015.02.09

Power Supply Design

Designing a power tree for a MAX 10 single- or dual-supply device will vary depending on the static and

dynamic power, as well as I/O and other feature utilization, for each specific use case.

Altera® Enpirion portfolio of power management solutions, combined with comprehensive design tools,

enable optimized MAX 10 device power supply design. The Enpirion portfolio includes power

management solutions that are compatible with all MAX 10 variants.

The MAX 10 FPGA Device Family Pin Connection Guidelines provides a more detailed recommendation

about how to group inputs in order to power a MAX 10 device. The PowerPlay Early Power Estimators

(EPE) tool for MAX 10 devices provides input rail power requirements and specific device recommenda‐

tions based on each specific MAX 10 use case.

Individual input rail voltage and current requirements are summarized on the Report tab while input rail

groupings and specific power supply recommendations can be found on the Main and Enpirion tabs,

respectively.

Power Supply Design

2-3

Warning: MAX 10 single-supply devices have maximum power consumption of V

following table. Running a design that goes beyond the maximum power consumption of

V

CC_ONE

of the MAX 10 single-supply device may cause functional issue on the device.

Therefore, ensure that your device does not exceed the maximum power consumption of

V

CC_ONE

when you analyze the power consumption of your design using the PowerPlay EPE

spreadsheet.

Table 2-2: Maximum Power Consumption of V

Device Maximum Power Consumption (W)

10M02S 0.778

10M04S 1.362

10M08S 1.362

10M16S 2.270

10M25S 2.943

10M40S 5.267

10M50S 5.267

Related Information

for MAX 10 Single-Supply Devices

CC_ONE

CC_ONE

, as listed in the

• Enpirion Power Management Solutions

Provides more information about Altera's Power Management IC and PowerSoC solutions designed

for powering FPGAs.

• MAX 10 FPGA Device Family Pin Connection Guidelines

Provides a more detailed recommendation about how to group inputs in order to power a MAX 10

device.

MAX 10 Power Management Features and Architecture

Send Feedback

Altera Corporation

Page 7

2-4

Power-On Reset Circuitry

Power-On Reset Circuitry

The POR circuitry keeps the MAX 10 device in the reset state until the POR monitored power supply

outputs are within the recommended operating range of the maximum power supply ramp time, t

UG-M10PWR

2015.02.09

.

RAMP

If the ramp time, t

, is not met, the MAX 10 device I/O pins and programming registers remain tri-

RAMP

stated, during which device configuration could fail.

The MAX 10 device POR circuit monitors the following power rails during power up regardless of the

power supply device options:

• V

• V

• V

The POR circuitry also ensures V

or regulated V

CC

of banks 1B and 8

CCIO

CCA

CC_ONE

(2)

level of I/O banks 1B and 8

CCIO

(2)

that contain configuration pins reach

an acceptable level before configuration is triggered.

Power Supplies Monitored and Not Monitored by the POR Circuitry

Table 2-3: Power Supplies Monitored and Not Monitored by the POR Circuitry

Power Supply Device Options Power Supplies Monitored Power Supplies Not Monitored

Single-supply device

Dual-supply device

• Regulated V

• V

CCA

CCIO

CC

CCA

CCIO

(3)

(3)

• V

• V

• V

• V

CC_ONE

• V

• V

• V

CCD_PLL

CCA_ADC

CCINT

—

The MAX 10 POR circuitry uses an individual POR-detecting circuitry to monitor each of the configura‐

tion-related power supplies independently. The main POR circuitry is gated by the outputs of all the

individual POR detectors. The main POR circuitry waits for all individual POR circuitries to release the

POR signal before allowing the control block to start programming the device. The main POR is released

after the last ramp-up power reaches the POR trip level followed by a POR delay.

By default, Quartus® II assigns POR delay time to standard POR delay. For some of the applications that

need fast wake-up to begin operation, you can enable fast POR delay time on the Quartus II programmer

user interface.

(2)

V

CCIO

(3)

For banks 1B and 8 for all MAX 10 devices and banks 1 and 8 for the 10M02 device.

Altera Corporation

of banks 1 and 8 for the 10M02 device.

MAX 10 Power Management Features and Architecture

Send Feedback

Page 8

Time

POR trip level

Volts

POR delay

configuration

time

t

RAMP

first power

supply

last power

supply

V

CCIO

Modular

Main POR

Main POR

V

CCA

V

CCIO

POR

V

CC

VCC POR

V

CCA

POR

V

CCIO

Modular

Main POR

Main POR

V

CCA

V

CCIO

POR

V

CC_ONE

VCC POR

V

CCA

POR

Voltage

Regulator

Single Supply Device Dual Supply Device

UG-M10PWR

2015.02.09

Power Supplies Monitored and Not Monitored by the POR Circuitry

2-5

Figure 2-3: Relationship Between t

and POR Delay

RAMP

MAX 10 Power Management Features and Architecture

Figure 2-4: Simplified POR Diagram for MAX 10 Devices

After the MAX 10 device enters user mode, the POR circuit continues to monitor the V

power supplies. This is to detect a brown-out condition during user mode. If either the V

CCA

CCA

and V

or V

voltages go below the POR trip point during user mode, the main POR signal is asserted. When the main

(3)

is monitored by the POR circuitry. In

CCIO

POR signal is asserted, the device is forced into reset state. V

the event of the V

However, if you are using instant-on features, the POR circuit does monitor the VCCIO voltage drop for

up to 9 ms after the last power rail reaches its trip point.

(3)

voltage drops during user mode, the POR circuit does not reset the device.

CCIO

Altera Corporation

CC

CC

Send Feedback

Page 9

I/O Power Down

Global Clock Gating

Sleep Mode

Finite

State

Machine

Internal

Oscillator

Power Management Controller

I/O Buffer

Global Clock Network

2-6

Instant-On Support

Instant-On Support

In some applications, it is necessary for a device to wake up very quickly to begin operation. The MAX 10

device offers the instant-on feature to support fast wake-up time applications. With instant-on feature,

MAX 10 device can directly enter configuration mode without any POR delay after the POR trips for the

monitored power supplies. Then your design can be configured from internal configuration flash memory

(CFM). This feature provides the shortest time to enter user mode as a whole.

In order to benefit from the instant-on feature of the MAX 10 device, there is a power-up sequence and

ramp time requirement to follow. The following table shows the power-up sequence requirement for

different power supply device options. For the minimum and maximum ramp time, refer to the

recommended operating conditions in the MAX 10 FPGA device datasheet.

Instant-On Requirement

Table 2-4: Instant-On Power-Up Sequence Requirement

Power Supply Device Options Power-Up Sequence

UG-M10PWR

2015.02.09

Single-supply device V

must ramp up to full rail before V

CCIO

CCA

and V

CC_ONE

start ramping.

Dual-supply device All power supplies must ramp up to full rail before VCC starts ramping.

Related Information

MAX 10 FPGA Device Datasheet

Provides details about the MAX 10 ramp time requirements, internal oscillator clock frequency, and hotsocketing specifications.

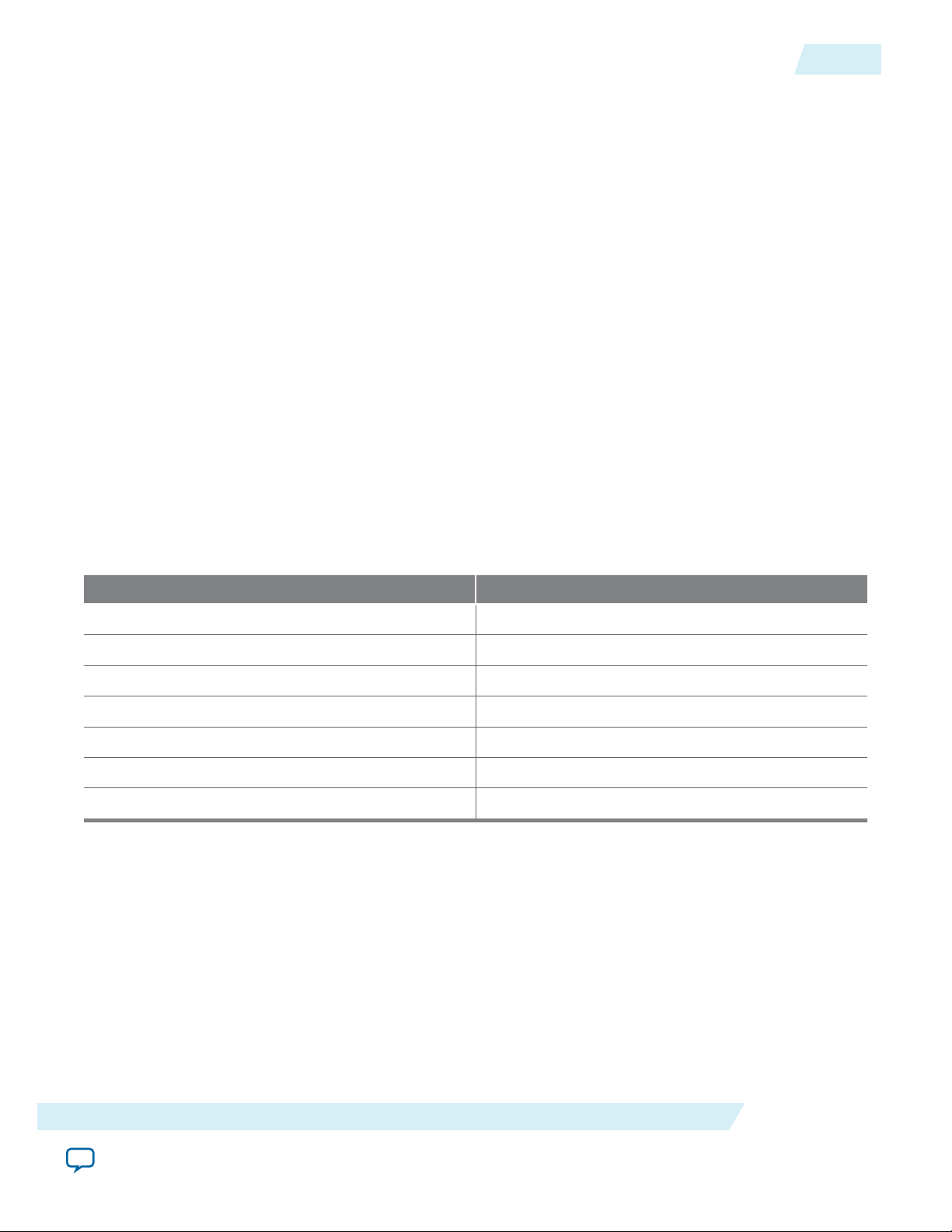

Power Management Controller Scheme

The power management controller scheme allows you to allocate some applications in sleep mode during

runtime. This enables you to to turn off portions of the design, thus reducing dynamic power consump‐

tion. You can re-enable your application with a fast wake-up time of less than 1 ms.

Power Management Controller Architecture

Figure 2-5: Power Management Controller Architecture

Altera Corporation

MAX 10 device contains hardware features that enable I/O power down and global clock (GCLK) gating

to manage low-power state during sleep mode. You can power down the I/O buffer dynamically when

your application is in idle or sleep mode. One example is the digital single lens reflex DSLR camera

MAX 10 Power Management Features and Architecture

Send Feedback

Page 10

UG-M10PWR

2015.02.09

Internal Oscillator

Internal Oscillator

2-7

application where the LVDS I/O needs to be powered down during the idle condition. Without touching

any buttons, the screen turns off while the camera is still powered on.

Altera provides a soft power management controller as reference design utilizing low-power features

implemented in the MAX 10 devices. You can modify the reference design based on your application. The

soft power management controller includes a simple finite state machine (FSM) to manage low-power

state mode by powering down the I/O buffer and GCLK gating during sleep mode.

All MAX 10 devices contain hardware feature for clock gating. The 10M16, 10M25, 10M40, and 10M50

devices contain hardware features for I/O power down. With hardware features, you can manage the lowpower state during sleep mode by using the soft power management controller that you define.

You can implement the power management controller in FPGA core fabric with minimum one I/O port

reserved for sleep mode enter and exit signals.

The internal oscillator clocks the power management controller operation. The internal oscillator is

routed from flash to the core. The internal oscillator enables the power management controller to detect

the wake-up event and the sleep mode event. In order to enable the internal oscillator clock when the

power management controller is enabled, you have to set oscena to 1. For the clock frequency of the

internal oscillator, refer to the MAX 10 FPGA device datasheet.

Related Information

MAX 10 FPGA Device Datasheet

Provides details about the MAX 10 ramp time requirements, internal oscillator clock frequency, and hotsocketing specifications.

I/O Buffer Power Down

The MAX 10 device has a dynamic power-down feature on some of the I/O buffers that have high-static

power consumption. The dynamic power-down feature is only applicable for the I/O buffers that have

been programmed for the I/O standards in the following table.

Table 2-5: I/O Buffer Power Down

I/O Buffer I/O Standards Control Port Control Signal Capability

Input SSTL, HSTL, HSUL,

Output All I/O standards oe 1 per I/O buffer

During power-up and configuration modes, the soft power management controller is not yet configured

and the control signals are forced to 1 (inactive). After configuration mode, when the power management

controller is activated, the power management controller will default the control signals to 1. When

control signals are 0, the power management controller powers down or tri-states the I/O buffers.

Subsequently the I/O is put into the sleep mode.

and LVDS

nsleep 1 per I/O bank

(4)

The MAX 10 device I/O buffers need to maintain the previous states during the sleep mode operation.

The previous states in your core logics will still remain upon exiting the sleep mode.

(4)

I/O banks 1A and 1B share one control signal.

MAX 10 Power Management Features and Architecture

Send Feedback

Altera Corporation

Page 11

Power

Management

Controller

enout

clk1

clkn gclkin

lenout

gclkout

Clock Control Block

2-8

Global Clock Gating

Global Clock Gating

The dynamic power-down feature is available in GCLK networks only. You can use the power

management controller for the dynamic power-down of a GCLK network by controlling the active high

enout signal. The GCLK networks serve as low-skew clock sources for functional blocks such as logic

array blocks (LABs), DSP, embedded memory, and PLLs.

When a GCLK network is gated, all the logics fed by the GCLK network are in off-state. This reduces the

overall power consumption of the device. The dynamic power-down feature allows core logics to control

the following power-up and power-down conditions of the GCLK networks:

• Power down synchronously or asynchronously

• Power up asynchronously

Figure 2-6: GCLK Gating

UG-M10PWR

2015.02.09

Hot Socketing

The MAX 10 device offers hot socketing, which is also known as hot plug-in or hot swap, and power

sequencing support without the use of any external devices. You can insert or remove the MAX 10 device

on a board in a system during system operation. This does not affect the running system bus or the board

that is inserted into the system.

The hot-socketing feature removes some encountered difficulties when using the MAX 10 device on a

PCB that contains a mixture of devices with different voltage levels.

With the MAX 10 device hot-socketing feature, you no longer need to ensure a proper power-up sequence

for each device on the board. MAX 10 device hot-socketing feature provides:

• Board or device insertion and removal without external components or board manipulation

• Support for any power-up sequence

• Non-intrusive I/O buffers to system buses during hot insertion

Hot-Socketing Specifications

The MAX 10 device is a hot-socketing compliant device that does not need any external components or

special design requirements. Hot-socketing support in the MAX 10 device has the following advantages:

Altera Corporation

MAX 10 Power Management Features and Architecture

Send Feedback

Page 12

UG-M10PWR

2015.02.09

• You can drive the devices before power up without damaging the device.

• I/O pins remain tri-stated during power up. The device does not drive out before or during power up,

therefore not affecting other buses in operation.

Drive MAX 10 Devices Before Power Up

Before or during power up or power down, you can drive signals into I/O pins, dedicated input pins, and

dedicated clock pins without damaging the MAX 10 devices.

The MAX 10 device supports any power-up or power-down sequence to simplify system-level design.

I/O Pins Remain Tri-stated During Power up

The output buffers of the MAX 10 device are turned off during system power up or power down. The

MAX 10 device family does not drive out until the device is configured and working in recommended

operating conditions. The I/O pins are tri-stated until the device enters user mode with a weak pull-up

resistor to V

A possible concern for semiconductor devices in general regarding hot-socketing is the potential for latch

up. Latch up can occur when electrical subsystems are hot-socketed into an active system. During hotsocketing, the signal pins may be connected and driven by the active system. This occurs before the power

supply can provide current to the VCC of the device and ground planes. This condition can lead to latch

up and cause a low-impedance path from VCC to ground in the device. As a result, the device extends a

large amount of current, possibly causing electrical damage.

CCIO

.

Drive MAX 10 Devices Before Power Up

2-9

The design of the I/O buffers and hot-socketing circuitry ensures that the MAX 10 device family is

immune to latch up during hot-socketing.

Related Information

MAX 10 FPGA Device Datasheet

Provides details about the MAX 10 ramp time requirements, internal oscillator clock frequency, and hotsocketing specifications.

Hot-Socketing Feature Implementation

The hot-socketing feature tri-states the output buffer during the power-up (V

or power-down event. The hot-socketing circuitry generates an internal HOTSCKT signal when V

VCC is below the threshold voltage during power up or power down. The HOTSCKT signal cuts off the

output buffer to ensure that no DC current leaks through the pin (except for weak pull-up leaking). Each

I/O pin has the circuitry shown in the following figure. The hot-socketing circuit does not include

CONF_DONE and nSTATUS pins to ensure that these pins are able to operate during configuration. Thus, it is

an expected behavior for these pins to drive out during power-up and power-down sequences.

or VCC power supplies)

CCIO

CCIO

or

MAX 10 Power Management Features and Architecture

Send Feedback

Altera Corporation

Page 13

V

CCIO

PAD

R

Voltage

Tolerance

Control

Output Enable

Hot-Socket

Output

Pre-Driver

Power-On

Reset (POR)

Monitor

Weak

Pull-Up

Resistor

Input Buffer

to Logic Array

2-10

Hot-Socketing Feature Implementation

Figure 2-7: Hot-Socketing Circuitry for MAX 10 Devices

UG-M10PWR

2015.02.09

The POR circuit monitors the voltage level of power supplies and keeps the I/O pins tri-stated until the

device is in user mode. The weak pull-up resistor in MAX 10 device I/O elements (IOE) keeps the I/O

pins from floating. The voltage tolerance control circuit protects the I/O pins from being driven before

V

and VCC supplies are powered up. This prevents the I/O pins from driving out when the device is

CCIO

not in user mode.

Altera uses GND as reference for hot-socketing operation and I/O buffer designs. To ensure proper

operation, Altera recommends connecting the GND between boards before connecting the power

supplies. This prevents the GND on your board from being pulled up inadvertently by a path to power

through other components on your board. A pulled up GND can cause an out-of-specification I/O voltage

or current condition with the Altera device.

Altera Corporation

MAX 10 Power Management Features and Architecture

Send Feedback

Page 14

Power Management Controller Reference

PMC

(altera_pmc)

Internal Oscillator

(altera_int_osc)

sleep

rst_n

Clock Control Block

(clk_control_altclkctrl)

clk_osc

clk

I/O Buffer

(altera_gpio_lite)

User

Logic

sleep_status

gpio_pad_output[3:0]

cnt_enter_sleep[7:0]

cnt_value[7:0]

cnt_exit_sleep[7:0]

clk_gated

ioe

clk_ena

www.altera.com

101 Innovation Drive, San Jose, CA 95134

Design

2015.02.09

UG-M10PWR

Subscribe

This reference design utilizes the low-power feature supported in MAX 10 devices. The following figure

shows the related block diagrams in the power management controller reference design.

Figure 3-1: Power Management Controller Block Diagram

Send Feedback

3

The following table lists the input and output ports of the reference design.

Table 3-1: Input and Output Ports of the Power Management Controller Reference Design

Port Name Input/Output Description

sleep Input Sleep control.

rst_n Input Active low reset signal.

clk Input Clock signal.

sleep_status Output Sleep status of the system. This signal

is asserted high when the system is

entering the sleep mode condition.

This signal is de-asserted when the

system exits the sleep mode condition

completely.

gpio_pad_output[3:0] Output General-purpose I/O (GPIO) output

ports.

©

2015 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, ENPIRION, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos are

trademarks of Altera Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. Altera warrants performance

of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any

products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information,

product, or service described herein except as expressly agreed to in writing by Altera. Altera customers are advised to obtain the latest version of device

specifications before relying on any published information and before placing orders for products or services.

ISO

9001:2008

Registered

Page 15

3-2

Clock Control Block

Port Name Input/Output Description

cnt_value[7:0] Output Free-running counter value in user

logic.

cnt_enter_sleep[7:0] Output Counter value when the system is

entering sleep mode condition.

cnt_exit_sleep[7:0] Output Counter value when the system is

exiting sleep mode condition.

The power management controller design is a FSM showing the state of powering down and powering up

global clocks (GCLKs) and I/O buffers. The internal oscillator, clock control block, and I/O buffer are

intellectual property (IP) that are supported by the Quartus II software and you can instantiate the IPs

from the IP catalog. The user logic can be any logical circuitry that are implemented using logic element

(LE) and embedded component such as DSP and internal memory in your design. In this reference

design, the user logic used is a free-running 8-bit counter. The cnt_enter_sleep and cnt_exit_sleep

ports are used to ensure user logic can enter and exit sleep mode without data corruption. It is expected

for that cnt_enter_sleep[7:0] and cnt_exit_sleep[7:0] are at the same value after the user logic

enter and exit sleep mode. gpio_pad_output ports demonstrate tri-stated state of the GPIO when the

system is in sleep mode.

UG-M10PWR

2015.02.09

Related Information

PMC Reference Design

Clock Control Block

The clock control IP core (clk_control_altclkctrl) is an IP provided in the Quartus II software. This

IP is used to control the clock system in the device. The GCLKs that drive through the device can be

dynamically powered down by controlling the active high ena signal. The ena port is an input to the clock

control IP block. When this IP is instantiated, select the ena port to enable the controls of GCLKs.

I/O Buffer

Altera GPIO Lite IP core (altera_gpio_lite) is implemented as an input, output, or bidirectional I/O

buffer. You can control the power down of these I/O buffers by enabling the nsleep port of the input

buffer and the oe port of the output buffer. The oe and nsleep ports are pulled low by the power

management controller design to power down the I/O buffers during sleep mode. Altera recommends you

to use a separate Altera GPIO Lite IP when some of the I/O buffer is not required to be powered down.

Internal Oscillator

Internal Oscillator IP core (altera_in_osc) is a free-running oscillator once you enable it. This oscillator

will be running throughout the entire power management controller design.

Altera Corporation

Power Management Controller Reference Design

Send Feedback

Page 16

Awake

Sleep

EnteringExiting

Sleep = 1clk_ena = 1 &

ioe = 1

clk_ena = 0 &

ioe = 0

Sleep = 0

UG-M10PWR

2015.02.09

Power Management Controller

The power management controller implements a simple FSM to control the power-up and power-down

sequences of the GCLK networks and I/O buffer. The following figure shows the FSM of the power

management controller design.

Figure 3-2: FSM of the Power Management Controller

Power Management Controller

3-3

Entering State

When the power management controller detects a sleep event, the FSM transitions to the Entering state

and performs power-down operation on I/O buffers and GCLK networks. A sleep event is detected when

the sleep signal is asserted. A sleep event could be triggered by an internal or external request.

Sleep State

After the power-down operation on I/O buffers and GCLK networks, the FSM transitions to the Sleep

state and waits for the wake-up event. This state is the sleep mode state.

Exiting State

When the power management controller detects a wake-up event, the FSM transitions to the Exiting state

and performs power-up operation on I/O buffers and GCLK networks. A wake-up event is detected when

the sleep signal is de-asserted. A wake-up event could be triggered by an internal or external request such

as interruption or time-out on some counters..

Awake State

After the power-up operation on I/O buffers and GCLK networks, the FSM transitions to the Awake state.

This process repeats when a sleep event is initiated again.

Power Management Controller Reference Design

Send Feedback

Altera Corporation

Page 17

clk

sleep

current_state

ioe

clk_ena[15:0]

sleep_status

Awake Entering Sleep

16’hFFFF Disabling

16’h0000

T1

T2

3-4

Entering or Exiting Sleep Mode

Entering or Exiting Sleep Mode

During power-up and configuration modes, the sleep signal must be low. When the sleep signal is

asserted, the device immediately enters sleep mode. Upon entering sleep mode, the functionality of the

device such as GCLK networks and I/O buffers are dynamically powered down—to minimize dynamic

power dissipation. All configuration data is retained when the device is in the sleep mode.

Entering Sleep Mode

The following figure shows the timing diagram when the device enters sleep mode.

Figure 3-3: Entering Sleep Mode Timing Diagram

UG-M10PWR

2015.02.09

The following lists the sequence when the device enters sleep mode.

1. An internal or external request drives the sleep signal high, forcing the device to go into sleep mode.

2. After a delay of T1, the power management controller powers down all the I/O buffers by de-asserting

ioe signal that connects to oe and nsleep ports of the I/O buffers.

3. After a delay of T2, the power management controller turns off all GCLK networks by disabling

clk_ena[15:0] signal from LSB to MSB. After three clock cycles, the clk_ena[15:0] signal is fully

disabled and transits into the sleep state.

4. The power management controller remains in sleep state until the sleep signal is de-asserted.

5. User logic will latch the running counter value before entering the sleep state and output to

cnt_sleep_enter port. The running counter is then frozen.

6. gpio_pad_output (GPIO) is tri-stated when ioe is de-asserted.

Exiting Sleep Mode

The following figure shows the timing diagram when the device exits sleep mode.

Altera Corporation

Power Management Controller Reference Design

Send Feedback

Page 18

clk

sleep

current_state

ioe

clk_ena[15:0]

sleep_status

Sleep Exiting Awake

16’hFFFFEnabling

16’h0000

T4

T3

UG-M10PWR

2015.02.09

Timing Parameters

Figure 3-4: Exiting Sleep Mode Timing Diagram

The following lists the sequence when the device exits sleep mode.

1. An internal or external request drives the sleep signal low, forcing the device to exit sleep mode.

2. After a delay of T3, the power management controller turns on all GCLK networks by enabling

clk_ena[15:0] signal from LSB to MSB. After three clock cycles, the clk_ena[15:0] signal is fully

enabled and all GCLK networks are turned on.

3. After a delay of T4, the power management controller powers up all the I/O buffers by asserting the

ioe signal.

4. The power management controller remains in awake state until the sleep signal is asserted.

5. User logic will latch the running counter value before the awake state and output to cnt_sleep_exit

port. The running counter is then release from freeze.

6. gpio_pad_output (GPIO) is driving its output value when ioe is asserted.

3-5

Power Management Controller Reference Design

Timing Parameters

The following table lists the definition and minimum value of the T1, T2, T3, and T4 parameters in the

entering sleep mode timing diagram and exiting sleep mode timing diagram, respectively.

Table 3-2: T1, T2, T3, and T4 Parameters Minimum Value and Definition

Parameter Width (bits) Minimum Value

(Decimal)

T1 6 1 ioe disable timing.

T2 6 11 clk_ena disable timing.

T3 6 1 clk_ena enable timing.

T4 6 40 ioe enable timing.

T1, T2, T3, and T4 can be increased based on your system requirement.

Hardware Implementation and Current Measurement

This design is implemented using the 10M50DAF484C8 device. You can implement this design using any

MAX 10 device. This design runs on the MAX 10 Development Kit Board to show current and power

relative between user mode and sleep mode.

Send Feedback

Description

Altera Corporation

Page 19

3-6

Hardware Implementation and Current Measurement

UG-M10PWR

2015.02.09

The resource utilization of this design is as follows:

• 42,000 LEs (84% of total LEs)—gray counter top module utilizes most of the LEs in the device

• 33 I/O pins (9% of total pins)—covering 3 input pins and 30 output pins

The current in this design is measured using sensing resistor and current monitor component (LTC

2290). The measured current is further processed by a pre-programmed design in a MAX II device. The

measured current is shown on Altera power monitor GUI when the PowerMonitor.exe is launched. You

will see a current monitor for each of the main supplies to the MAX 10 device as follows:

• 2.5V_CORE

(5)

• 2.5V_VCCIO

• 1.5V_VCCIO

• 1.2V_VCC

For design demonstration purpose, the push button is used for sleep control and the LEDs are used for

sleep status. Thus, these signals have been inverted on the pin level. To enter sleep mode, press and hold

the push button USER_PB0. To release the design to user mode, release the push button USER_PB0.

LED0 indicates the sleep status of the device. LED0 is turned on when the device enters sleep mode and is

turned off when the device is in user mode. During sleep mode, gpio_pad_output ports connecting to

LED1–LED4 are tri-stated and then turned off.

The following figure shows the current monitor for each supply.

(5)

This is 2.5V_VCCA.

Altera Corporation

Power Management Controller Reference Design

Send Feedback

Page 20

User Mode

Sleep Mode

User Mode Sleep Mode

User Mode Sleep Mode

User Mode Sleep Mode

UG-M10PWR

2015.02.09

Figure 3-5: Current Monitor for Each Supply

Hardware Implementation and Current Measurement

3-7

The following table lists the comparison results of current and power consumption between user mode

and sleep mode of the design. In sleep mode, all GCLK networks are gated and all output buffers are

disabled.

Table 3-3: Comparison of Current and Power Consumption

Current and Power User Mode Sleep Mode

1.2V_ICC (mA) 160 11

2.5V_ICCA (mA) 28 28

1.5V_ICCIO (mA) 1.3 1.0

2.5V_ICCIO (mA) 2.7 1.2

Total power (mW) 270 88

The results show an approximate 93% reduction in the core current (1.2V_ICC) consumption and an

approximate 56% reduction in I/O current (2.5V_ICCIO) consumption in sleep mode relative to user

mode. The total power consumption reduction in this design in sleep mode is about 68%.

Power Management Controller Reference Design

Altera Corporation

Send Feedback

Page 21

Additional Information for MAX 10 Power

www.altera.com

101 Innovation Drive, San Jose, CA 95134

2015.02.09

UG-M10PWR

Subscribe

Management User Guide

Send Feedback

A

Document Revision History for MAX 10 Power Management User Guide

Date Version Changes

February 2015 2015.02.09 Added the MAX 10 Power Management Controller Reference Design.

December 2014 2014.12.15

September 2014 2014.09.22 Initial release.

• Updated the MAX 10 Power Management Overview section.

• Updated the Dual-Supply Device section to update details on

power consumption for dual-supply devices.

• Updated the Power Supply Design section to include the maximum

power consumption for each MAX 10 single-supply device.

• Updated the Power Management Controller Scheme section to

include updates on sleep mode.

©

2015 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, ENPIRION, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos are

trademarks of Altera Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. Altera warrants performance

of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any

products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information,

product, or service described herein except as expressly agreed to in writing by Altera. Altera customers are advised to obtain the latest version of device

specifications before relying on any published information and before placing orders for products or services.

ISO

9001:2008

Registered

Loading...

Loading...