Page 1

Alpha Industrial Power

Spill Control Barrier System

Installation Manual

Battery Acid Spill ControlBarrier

with Acidsafe Floor Coating

Battery AcidSpillControlBarrier

without AcidsafeFloor Coating

AlphaIndustrial Power

1075Satellite Blvd,Suite100 678-475-3995

Suwanee, GA30024 800-996-6104

www.alpha.com

Page 2

Alpha Industrial Power Spill Control Barrier System

Spill Control Barrier System

Installation Manual

TABLEOFCONTENTS

1. Introduction .......................................................................... 1

2. Safety Precautions............................................................... 2

3. Initial Conditions .................................................................. 4

4. Floor Preparation................................................................. 5

5. Barrier Installation................................................................. 7

6. Coating Application............................................................... 12

7. Leak Test ............................................................................. 14

8. Coating Maintenance........................................................... 15

9. MSDS Section...................................................................... 16

Installation Manual Page 1 of 25

Page 3

Alpha Industrial Power Spill Control Barrier System

1. Introduction

1.1 The Battery Acid Spill Control Barrier without floor coating is intended to

contain battery electrolyte in the event of a spill or leak from a stationary

lead-acid battery. The Spill Control Barrier surrounds the battery rack with a

4 inch steel enclosure. It is bonded permanently to the floor with Acidsafe

Adhesive Gel and sealed against leakage. The Battery Acid Spill Control

Barrier with floor coating also includes Acidsafe Floor Coating, which covers

the entire floor surface within the enclosureandprotectsthefloor fromthe

corrosive effects of batteryacid. Both theCoating and Adhesive are based

on modified novolac epoxy resins with polyaminecuratives andhave been

tested to be impervious to 70%sulfuricacid in continuous immersion and up to

98% sulfuric acid in splash and spill exposure. The system may be installed

around existing battery racks without removal of the batteries and without

interruption of facility operations.

1.2 The highly adaptable design of the system allows configuration to suit a

wide range of battery room layouts. This manual covers all of the procedures

necessary in most anticipated battery room applications. If a specific

application is encountered that is not addressed in this manual, contact

Alpha Industrial Power at 678-475-3995 for additional information of

supplementary procedures

1.3 Neutra-Mats (part number 5NMB0010) inside the containment area absorb

and neutralize the acid immediately upon exposure thus greatly reducing the

risk of personal injury and structural damage or contamination. The mats are

placed side by side to completely cover the floor beneath the racks. A single

Neutra-Mat will fully absorb and neutralize one quart of battery electrolyte (pH

between 7.0- 9.0). Each individual Neutra-Mat may be quickly and easily

replaced as necessary. Additionally, Neutra-Mats turn pink upon exposure to

acid, indicating a leak and the needforreplacement. If Neutra-Matswerenot

ordered for this installation, they may be obtained from Alpha Industrial

Power.

1.4 Despite the Spill Control Barrier and Coating’s strength and durability, failure

to conscientiously follow these instructions may result in inadequate

coverage, performance,or protection.Carefullyread and understand the entire

instructionmanual before beginning assembly.

Installation Manual Page 2 of 25

Page 4

Alpha Industrial Power Spill Control Barrier System

2.SafetyPrecautions

2.1 Examine all shipping containers for signs of external damage. Also look for

indications of coating spillage during shipment. In the event that coating

material has been spilled, consult the Material Safety Data Sheet for spill

handling instructions and personal protective equipment requirements.

2.2 Make note of any damage on the bill of lading before signing for delivery.

If system components have been damaged or lost in transit, contact the

shippingcarrier for instructions concerning filing a claim.

2.3 Wear steel toed shoes and safety glasses when assembling the Spill

Control Barrier.

2.4 Wear chemical resistant gloves and safety goggles when handling

Adhesive, Coating or Joint/Crack Filler. In areas where ventilation is

insufficient, a respirator may also be required. Read the Material Safety Data

Sheets supplied with this kit and be familiar with the safety precautions listed

therein.

2.5 Observe and obey all caution notes contained in the following instructions.

Installation Manual Page 3 of 25

Page 5

Alpha Industrial Power Spill Control Barrier System

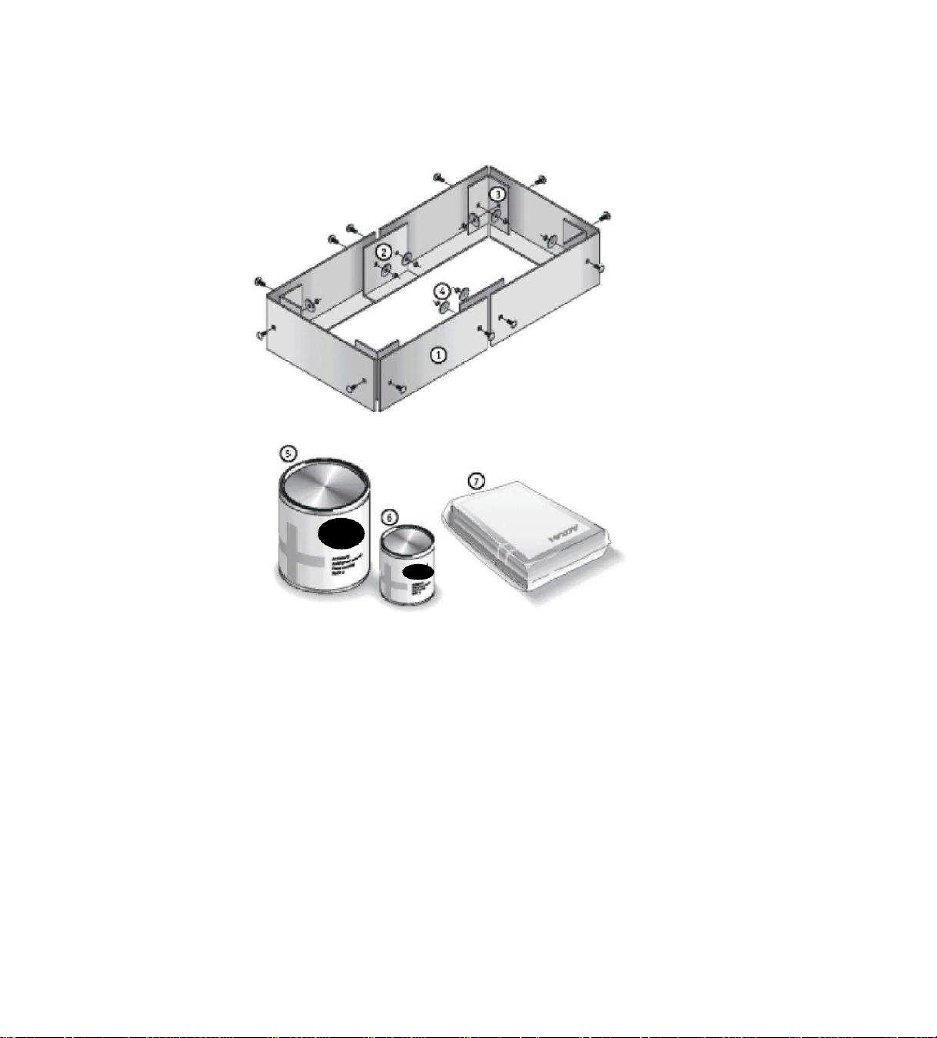

Figure 3.1 – Spill Control Barrier Components

1. B arr i er Stri p s

2. S p lice P l a tes

3. C o rner P l a te

4. Ass embly Hardw are

5. Acidsafe Coating (Part A) – floor coating version only

6. Acidsafe Coating (Part B) – floor coating version only

7. Acids afe Adh esive

Installation Manual Page 4 of 25

Page 6

Alpha Industrial Power Spill Control Barrier System

3. Initial Conditions

3.1 For maximum effectiveness of the Spill Control Barrier, the floor surface

should be flat, smooth and reasonably level. An uneven surface can

cause gaps between the Spill Control Barrier and the floor, which may

require additional Adhesive during final assembly. Unlevel or sloped floors

may require additional Coating to achieve minimum film thickness.

3.2 Permanent floor coverings such as vinyl, linoleum, composite or asbestos tiles

will not affect the ability of the Spill Control Barrier or Acidsafe Floor Coatings to

contain acid spills, provided that the coverings are in good condition and

securelyfastenedto the floor. Loose or broken tilesshould be removed and voids

filled using Joint/Crack Filler Kit (part number 5CFK0001).

CAUTION:

All asbestos handling precautions should be observed when handling loose

or broken asbestos tiles, including respiratory protection, protective clothing

and specialized disposal. Consult with the local authority having

jurisdiction for asbestos abatement requirements.

3.3 Concrete should be completely dry and properly cured (minimum of 28

days after poured). Concrete slabs installed on or below grade or otherwise

exposed to weather may transmit water vapor, causing pinholes in the floor

coating during cure. Evening (after 7 PM) is the most suitable time of day for a

ground-floor installation as the effects of concrete off-gassing will be

minimized.

3.4 Failure to properly clean and prepare the surface of the floor prior to applying

the Adhesive and Coating can cause adhesion failure or degraded chemical

resistance over time. Appropriate floor cleaning and other surface preparatory

procedures are described in Section 4.

3.5 Local amb ien t a ir temp era ture mu st be grea ter tha n 5 0˚F when ap plying

and curing the Adhesive and Coating materials. As ambient air

temperature decreases, the time necessary to set and cure the Acidsafe

Ad hesive and Co ating incr ease s. Cold co nditio ns (bel ow 50˚F) will also

impair the Coating’s application characteristics.

Installation Manual Page 5 of 25

Page 7

Alpha Industrial Power Spill Control Barrier System

3.6 The following tools and supplies are recommended for a quick and

thorough Barrier installation:

7/16 inch box end or combination wrench

putty knife

tape measure

several sheets of sandpaper, 100 grit

roll of 1 inch masking tape

goggles,chemicalresistantgloves andrespirator (asneeded)for

installers’ paper towels or shop rags

rubbing alcohol

3.6.1 Additional supplies needed for Spill Barrier with floor coating version

only:

small metal ruler with 1/64” increments or wet film thickness gauge.

The Coating Installation standard Tool Kit (part number

5BNK0001) contains: small rotary stirring tool, two v-notch trowels,

four v-notch spreaders, onemaskingtape, twobrushes,two gloves,

tworags, twoputty knives, one 3-piece extension, one 1-1/2 inch

spiked pin roller, one pair goggles, and two sheets sandpaper.

(Other kits available upon request)

4.FloorPreparation

4.1 The installer or site/equipment engineer must ensure that sufficient aisle space

will remain once the Barriers have been installed. There should be a minimum

of 30 inches between Barriers. Aisle spacing at the end of each rack may be as

little as 24 inches, providing no conflict exists with battery maintenance

requirements. The aisle spacing,includingthe space between the surrounding

Barriers, should be sufficienttopermitallrequired maintenance (includingbattery

installationandremoval). SeetheNationalElectric Codeorcontactthelocalauthority

having jurisdiction for further clarification regarding aisle clearances.

4.2 After clearances have been verified, locate and mark the outline of the

Barrierusing the Barrier’s dimensionsand a tape measure.TheBarriershould

becentered around the rack with at least 1 inch clearance in all directions

to meet 1995 Uniform Fire Code article 64 requirements.

Installation Manual Page 6 of 25

Page 8

Alpha Industrial Power Spill Control Barrier System

4.3 Completely clean and prepare the portion of flooring which will have Adhesive

or Coating applied during installation. For Barrier System versions without

floor coating, this area is a strip approximately 3 inches wide inside the

outline of the Barrier perimeter. For Barrier System versions with floor

coating, this includes the entire area inside the outline of the Barrier

perimeter. Prepare the flooring according to the following guidelines.

All Floor Types: Remove all oil, grease, dirt, efflorescence, laitance,

chemicals, hardeners,curing membranes,wax, previouslyapplied coatings or

othersurfacecontainments. Floors may be cleaned with an alkaline detergent

dissolvedin hot water, scrubbed with a non-metallic stripping pad and rinsed

several times. Alternatively, clean using steam, water (low pressure), air

blast, vacuum, and broom cleaning methods as described in ASTM D 4258

and SSPC-SP-1.

Concrete Floors: Roughen surface by abrading or etching. Concrete may

be etched with a 20% phosphoric acid solution, mechanically scrubbed, and

rinsed with a neutralizing solution (2 lb. Sodium bicarbonate and 1 gal.

Water) and followed by a clean water rinse. Alternatively, abrade by steel

shot blasting, sandblasting, water jetting with abrasive, power tool cleaning, or

scarifying as described in ASTM D 4258 and NACE RP-01-72.

4.4 Perform a check for cleanliness by rubbing the floor with a clean, white cloth.

If the cloth appears dirty, perform Step 4.3 again. Also check surface

preparation by performing the following ‘water-break’ test: pour a small

amount of clean water onto the surface and observe. If water evenly wets

the surface, the cleaning is adequate.If the water forms beads on the

surface,performStep 4.3 again. Allow surfaces to completely dry before

applying Adhesive or Coating.

4.5 Use 100 grit aluminum oxide or silicon carbide sandpaper to lightly sand the

underside of the Barrier Strips and the mating surfaces of the connector

plates. Wipe all sanding debris from the Barrier Strips with a clean rag.

4.6 Inspect the floor inside the containment area for any progressive cracks

greater than 1/8 inch in width, as well as for control/expansion joints. Such

surface defects must be repaired or filled with a Joint/Crack Filler before

progressing any further with the Spill Control System installation. Smaller

defects may be filled using Adhesive and a putty knife. A Joint/Crack Filler

Kit is available from Alpha Industrial Power.

Installation Manual Page 7 of 25

Page 9

Alpha Industrial Power Spill Control Barrier System

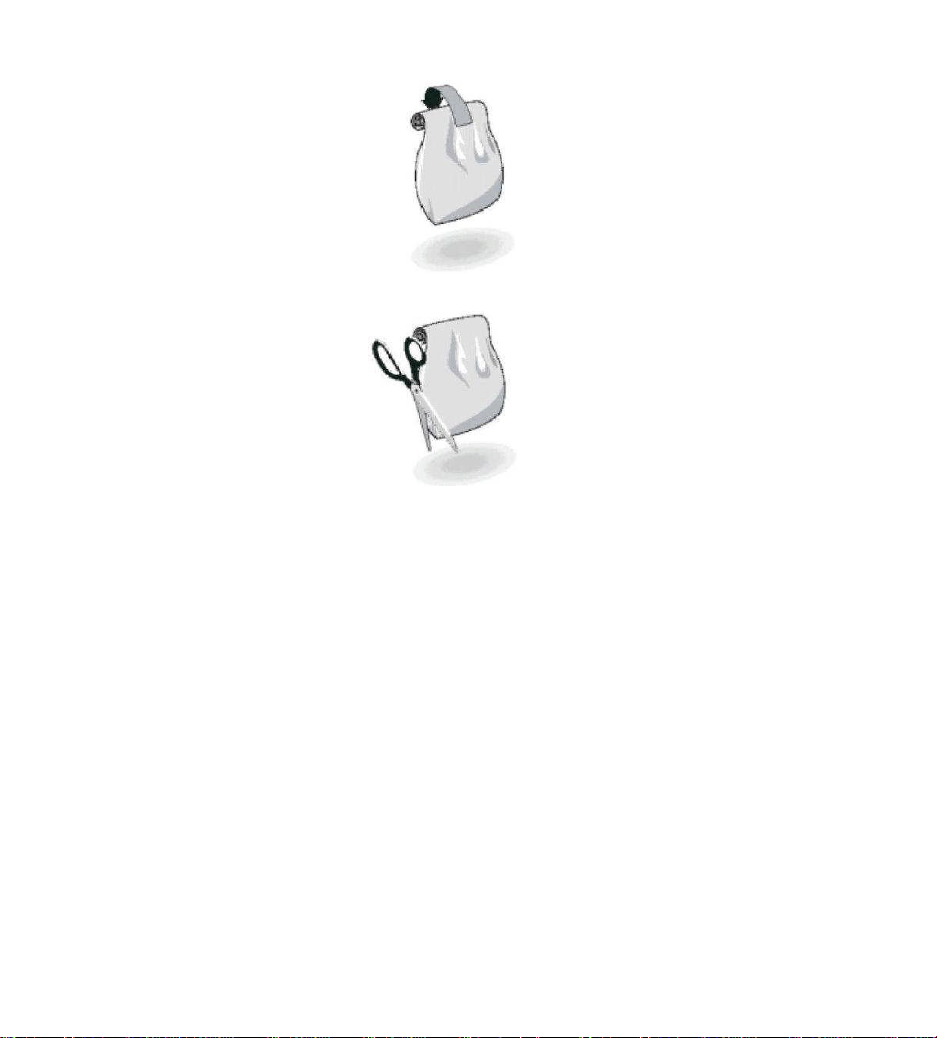

Figure 5.1 – Mixing the Adhesive

Figure 5.2 – Preparing Mixing Bag for Application

5. Barrier Installation

5.1 Lay out the Barrier Strips on the floor around the battery stand location in the

order demonstrated in Figure 3.1 and lightly bolt the pieces together using

carriage bolts, washers, nuts and the appropriate connector plates. Position

the barrier around the batterystand location to provide equal clearances on all

sides between the battery stand and the barrier. Note that the horizontal

flange on all of the barrier strips faces the battery stand (Figure 3.1). This

orientation is important both for barrier clearance and liquid-tight integrity.

CAUTION:

Barrier strips and connectorsareconstructed fromsteelandcoatedwith an acid

resistant epoxy. These strips should be handled with care near all electric

power sources. Contact with an electrical source could result in severe shock

or death. This product should only be installed by trained professionals

familiar with the electrical hazards of high energy DC back up power systems.

Installation Manual Page 8 of 25

Page 10

Alpha Industrial Power Spill Control Barrier System

5.2 After assembling and positioning the barrier system, mark the outer

perimeter of the barrier on the floor using 1 inch masking tape. This will

mark the proper placement of the Barrier and will help keep the floor clean

from adhesive overage or coating splatters and drips.

5.3 Check for uneven flooring by measuring the gap between the bottom of the

barrier and the floor. Gaps greater than 1/8 inch should be marked for the

application of additional Adhesive material during the barrier assembly

process. After marking large gaps, disassemble the parts for application of

Adhesiveand final assembly.

5.4 Prepare Adhesive by removing the separator between Part A and Part B

in the two part pouch. Knead the package vigorously and work the material

from end to end until the epoxy appears thoroughly mixed. To ensure complete

and thorough mixing,continue kneading for severalminutes after the Adhesive

material has achieved an even consistency and color. Poorly mixed Adhesive

will not fully cure, resultingin a failure to bond the Barrier securely to the floor

and to poor chemical resistance.

CAUTION:

The Adhesive and Coating materials are immediate eye irritants and, after

prolonged exposure, skin and lung irritants. Wear safety goggles, long

sleeved shirt, chemical resistant gloves and a NIOSH/MSHA TC-23C

approved respirator (respirator requiredfor inadequate ventilation situations

only) when mixing and applying these compounds. See the MSDS for

additional safety and handling instructions.

NOTE:

Once prepared, the Adhesive and Coating materials should be applied without

delay. Interaction between Part A and Part B of the Adhesive generates heat

that will acceleratethehardening process.Always grasp pouch by the rolled end

to avoid discomfort due to heat generation.

5.5 Roll the end of the bag such that the empty space has been taken up

(Figure 5.1). Diagonally cut one of the bottom corners so that the bag may

be used as an applicator (Figure 5.2). Squeezing the bag will apply a bead

of Adhesive.

5.6 Use the Adhesive to fill any defects in the floor inside the containment area that

havenotbeen previously filledusing the Joint/CrackFiller Kit. Use a puttyknife

to scrape the filled areas flush with the surrounding surface.

Installation Manual Page 9 of 25

Page 11

Alpha Industrial Power Spill Control Barrier System

5.7 In facilities where a battery rack is already installed, use a spreader or putty

knife to sealthebase of the batteryrackwithAdhesive as shown in Figure 5.3.

Usinga brush, apply Adhesive to the battery rack anchoring hardware as shown

in Figure 5.4.

5.8 Starting at one corner, apply a thick bead of Adhesive to the bottom

surface of two of the Barrier Strips and spread evenly over the flange with a

3/16 inch v-notch trowel. Use the 1/4 inch v-notch trowel if additional adhesive

is required for filling gaps. Press the strips into place on the floor and align

them to the markings made in Step 4.3.

5.9 Apply Adhesive to the mating surfaces of the Corner Plate, spread the

Adhesive evenly over the surface using a 1/8 inch v-notch trowel, and press

the plate into place over the joint (Figure 5.5). Lightly bolt the Corner Plate to

the Strips using a carriage bolt, flat washer and hex bolt arrangement.

5.10 Proceed along the Barrier perimeter while repeating steps 5.6 and 5.7.

Use a Splice Plate where joining Strips is required (Figure 5.6).

Figure 5.3 – Sealing Rack Frames

Installation Manual Page 10 of 25

Page 12

Alpha Industrial Power Spill Control Barrier System

Figure 5.4 – Coating Rack Hardware

5.11 At each corner joint, apply a bead of Adhesive over the mitered seam

and spread the material flush with a putty knife.

5.12 Recheck the alignment and position of the barrier and its components

and tighten all of the assembly hardware using a 7/16 inch box-end or

combination wrench. The hardware has been properly tightened when

Adhesive material starts to squeeze out evenly around the edges of the

connector plates. Avoid over tightening as this will cause an Adhesivestarved joint. Use a putty knife to scrape away the excess adhesive and

use it to fill any voids under the Barrier Strips.

5.13 Clean any Adhesive that hasbeenspilledusing a cloth lightlydampened

withdenatured or rubbing alcohol.

5.14 Retain any mixed Adhesive that is left over for leak repair during the

coating process. If leak repair is not necessary, allow the Adhesive to

harden in its container and dispose of in accordance with local, state and

federal regulations.

5.15 If installing a Barrier System without floor coating, remove masking and

proceed to Section 7 for information on performing a leak test of the Barrier.

Installation Manual Page 11 of 25

Page 13

Alpha Industrial Power Spill Control Barrier System

Figu

re 5.5–Assembling Barrier

Figure 5.6 – Assembling Barrier Splices

Installation Manual Page 12 of 25

Page 14

Alpha Industrial Power Spill Control Barrier System

6. Coating Application (Barrier System with floor coating version only)

6.1 Verify that the proper quantities of Acidsafe Floor Coating Part A and Part B

are matched up properly in preparation for mixing. A 1 gallon kit will be

comprised of one 1 gallon can of Part A and a 1 quart can of Part B.

6.2 Pour all of Part B into a corresponding container of Part A and blend with a

rotary stirrer and an electricdrillon moderate speed (approximately700 rpm).

Keep the stirring vanes well below the surface of the Coating to avoid

entraining air bubbles into the mixture. Continue to stir the Coating

compound for several minutes after the mixture has achieved an even color

and pay special attention to unmixed material at the sides and bottom of the

container. Mix additional Coating as necessary during the coating process to

complete the installation. Improperly mixedCoating willnotcompletelycure,

resulting in reduced chemicalresistance and poor performance.

6.3 Pour and spread the Coating evenly over the floor inside the containment

area using a plastic spreader or putty knife (Figure 6.2). If installing the coating

under an existing rack, try to allocate equal amounts of coating material

betweeneachset of rackframes.Spread thecoatingusinga 1/4inch v-notch

spreader to obtain a uniform thickness. Figure 6.1 shows coating being

applied under a rack. Note thatthebatteries are not illustratedforreasons of

clarity;batteries DO NOT need to be removed in order to apply the coating.

Figure 6.1 – Spreading Acidsafe Around Existing Racks

Installation Manual Page 13 of 25

Page 15

Alpha Industrial Power Spill Control Barrier System

Figure 6.2 – Spreading Acidsafe in New Installations

6.4 Check that Coating thickness in all areas is at least 5/64 inches using a

small metal ruler or 80 mils on a film gauge. Spread the Coating as

necessary to achieve a uniform thickness. If the film thickness in an area

is insufficient, pour additional Coating or use the spreader to redistribute

the Coating as necessary.

6.5 Use a spiked pin roller (available in the Coating Installation Tool Kit) to

rupture any air bubbles. If no spiked pin roller is available or in places that

the spiked pin roller is unable to reach, break the surface of any bubbles

seen by probing them with an unfolded paper clip.

6.6 Inspect the perimeter of the barrier for seepage. If Coating is seeping under

the barrier, use a spreader or gloved finger to force some remaining Adhesive

under the Barrierin the area of the leak until the flow stops. If no usable

Adhesive remains,a piece of Coating-saturatedpaper towel may also be used.

6.7 Remove the masking tape from the floor around the barrier.

Installation Manual Page 14 of 25

Page 16

Alpha Industrial Power Spill Control Barrier System

6.8 Any mixed Coating that has been spilled may be absorbed with cat litter box

filler and wiped up with a cloth moistened with denatured or rubbing alcohol.

Allow remaining Coating material to harden in its container and dispose of

in accordance with local, state and federal regulations.

6.9 In installations where Coating is installed before the battery system, racks may

be positioned only after the Coating has been completely cured. If a leak test

is to be performed, it also must be satisfactorily completed prior to rack

installation. Do not load the racks with batteries until the Coating has had at

least one week to completely cure. Once the battery racks have been

installed, obtain a Leak Repair Kit (part number 5LRK0001) and use it to seal

the frames (Figure 5.3) and anchors (Figure 5.4).

7. Leak Test

7.1 The barrier leak test is an optional procedure to verify the liquid-tight integrity

of the Spill Control System. After the Coating and the Adhesive have been

permitted to cure for 24 hours, perform a leak test by filling the Barrier system

with water and allowing it to stand while checking for leaks. If any leakage

occurs, identify and mark the unsealed location.

7.2 Drain the barrier and make sure the floor is clean and dry. In most cases, a

wet/dryshop vacuum is the quickest and easiest method to remove the water

from the barrier.

7.3 If leakage is found, obtain a Leak Repair Kit from Alpha Industrial Power.

Follow the enclosed instructions to mix an appropriate quantity of Adhesive

and brush it over the area of the leak until the crack or seam is no longer

evident. Allow the repair 24 hours to cure before retesting.

Installation Manual Page 15 of 25

Page 17

Alpha Industrial Power Spill Control Barrier System

8. Coating Maintenance

8.1 Coating integrity is important to the effectiveness of the Barrier system. The

elastic nature of the Coating typically resists cracking and chipping in a

conventional battery room environmentandnoreapplicationsarelikelytobe

required for the lifetime of the batterysystem.However,extremeconditionsor

circumstancesmaydamage the surface of the Coating. For that reason, it must

undergo periodic inspection and occasional repair.

8.2 If the battery facility has experienced an earthquake or other event in which

damage to the floor has occurred in the area of the Barrier, remove the

Neutra-Mats and perform an inspection of the floor inside the barrier to

detect any cracks or breaks in the Coating. Fill a one quart atomizing bottle

with at least 16 ounces of distilled water, 1 to 2 fluid ounces of food dye and 6

to 8 drops of a surfactant such as Dawn or Ivory liquid dish soap. Shake well

and mist the suspect area. Wipe the sprayed area with a damp rag and any

fractures will appear as dye-colored lines. If cracks or defects are found,

repair as follows:

8.3 Obtain a Leak Repair Kit (part number 5LRK0001) from Alpha Industrial

Power. Ensure that the area is completely dry. Sand an area at least 1 inch

on all sides of the crack or chip for the entire length of the defect using 100

grit aluminum oxide or silicon carbide sandpaper. Remove any sanding

debris.

8.4 Mix the Adhesive in the Leak Repair Kit and brush the repair material over

the sanded area untilthecrackis no longer evident.Allow the repair 24 hours to

cure before placing anything on top of it, such as Neutra-Mats.

8.5 For cracks larger than 1/8 inch in width, ensure that no structural damage

has occurred that will endanger the battery facility. Obtain a Joint/Crack

Filler Kit from Alpha Industrial Power and repair the crack in accordance

with the enclosed instructions.

Installation Manual Page 16 of 25

Page 18

Alpha Industrial Power Spill Control Barrier System

Revision Date: March 18, 2008 MSDS No. AAG (A)

MATERIAL SAFETY DATA SHEET

Product Name:

ChemicalFamily: EpoxyResinMixture

CompanyName: EasternResinsCorp.

ADHESIVEGEL(RESIN),PART-A

1174River Street Woonsocket,RI

02895,USA

BUSINESS PHONE:

EMERGENCYPHONE:

(401)769-6700

(800)255-3924

2. COMPOSITION

1. MATERIAL IDENTIFICATION

ExposureLimits

ChemicalName Wt % TLV-TWA PEL

EpoxyresinMixture >70 N/E N/E

TitaniumDioxide * <10 10 mg/m3 15 mg/m3

Carbonblack* <1 3.5 mg/m3 3.5 mg/m3

Fumedsilica* <10 20 mppcf 20mppcf

Specific ingredients are considered aTradeSecret

Abbreviations:N/E -NOT ESTABLISHED

* - Materialsarein

Non-Airborne

form

ACGIH OSHA

3. HEALTH HAZARDS

PrimaryRoutesofExposure:

EyeContact

SkinContact

and temporary orpermanent sensitization.

Ingestion:

Other

: May causeirritation and swelling.

:Maycause irritationandsensitization. Symptomscanbe immediate or delayedseveralhours.

Maycause irritation.

: Preexisting skin sensitization may be aggravated by exposureto thisproduct.

Eyes: Yes Skin: Yes Inhalation: Yes

Inhalation:

May cause irritation

4. FIRST AID MEASURES

Eyes:

Flusheyes thoroughly with waterfor atleast 15minutes while holdingeyelidsopen. Seekmedicalattention.

Skin:

Remove contaminatedclothing. Wipe excess from skin and wash the affectedareathoroughlywithsoap and water.Wash contaminated clothing thoroughly

beforereuse.

Inhalation:

Ingestion:

Remove tofreshair,andprovideoxygenor artificialrespiration if needed.Obtainmedicalattention;symptoms can be delayed upto several hours.

DO NOT inducevomiting. Give 1-2 cups of water or milk unlessthe personis drowsy,convulsing, or unconscious.Get medical attention.

5. FIREFIGHTING MEASURES

FlammableProperties:Flash Point

ExplosiveLimits:

HazardousDecompositionProducts

EXTINGUISHING MEDIA AND FIRE FIGHTING INSTRUCTIONS

full bunker gear, including a positive pressure, NIOSH approved, self-contained breathing apparatus. Extreme heat or water contamination may cause closed

containersto explode.

ExtinguishingMedia

: Use carbondioxide, dry chemicalor appropriate foam

: >300oF(PMCC)

: Carbonmonoxide, carbon dioxide, aldehydes, andother organic substances.

Notapplicable

Auto-IgnitionTemperature:

: When sufficiently large quantities are present, firefighters should be equipped with

Notapplicable

6. ACCIDENTAL RELEASE MEASURES

Ventilatethe spill area andevacuate if necessary. Removeall ignition sources. Dike and contain large spills. Clean-up personnel should use adequateprotective

equipment.

Storein acool;dry place, in closed containersat room temperature. Avoid contactwith incompatiblematerials. Wear protectiveeyewear,chemical-resistant gloves, and

otherprotective clothing asappropriate.

Installation Manual Page 17 of 25

7. HANDLING ANDSTORAGE

Page 19

Alpha Industrial Power Spill Control Barrier System

8.EXPOSURE CONTROLAND PERSONALPROTECTION

Engineering/Ventilation Controls:

worker exposure to all respiratory hazards. General ventilation, local ventilation, or isolation may prove adequate to keep airborne

concentrationsbelowexposurelimits.

RespiratoryProtection

SkinProtection

EyeProtection

: Not requiredunder normal conditions in a well-ventilatedworkplace.

: Imperviousglovesand protectiveclothingshouldbe worn asnecessary.

: Chemical splash goggles orsafety glasses withside shields should beworn asappropriate.

Effective engineering controls should be used whenever possible to eliminate and/or reduce

9. STABILITY ANDREACTIVITY

Chemical Stability

ConditionsandMaterialstoAvoid:

agents.

HazardousPolymerization

: Stable undernormal conditions anduse.

Reactswithaminesandstrongoxidizing

: Will not occur.

10.PHYSICALANDCHEMICALPROPERTIES

Appearance/Odor:

VaporPressure(mmHg

SpecificGravity:

): <1@25oC

GrayPaste,slightether odor

1.2-1.3

BoilingPoint

Vapor Density(air=1) :

SolubilityinWater:

: Not determined

None

11.TOXICOLOGICALINFORMATION

This section provides toxicological information with regard to the pure form of the componentindicated. It is suggested that

personstrained in its evaluation interpretthis information.

EpoxyResins: AcuteOral

AcuteDermal

(Rat): 11.4 g/kg

LD

50

(Rabbit): >20 g/kg

LD

50

12.DISPOSALCONSIDERATIONS

Keep out of surface waters, sewers, and waterways entering or leading to surface waters. Notify authorities if any exposure to the

environment occurs or is likely to occur. Utilize an appropriate disposal facility, in compliance with applicable federal, state, and

localenvironmental control regulations.

13.TRANSPORTATIONINFORMATION

DOT/IATAProperShippingName

TSCA:

Thechemicalcomponentsof this productareincludedinthe TSCA ChemicalSubstance Inventory,as required.

SARA TITLEIII:

Section313– ToxicChemicals

Section 311/312– HazardCategories

FireHazard:

SuddenReleaseofPressureHazard:

Delayed(Chronic)HealthHazard

OSHAHazardCommunicationStandardHazardClasses

NFPAHazards:

HMISHazards:

Health: 2 Flammability:1 Reactivity: 0

Health: 2 Flammability:1 Reactivity: 0

: Not Regulated

14. REGULATORYINFORMATION

: None

:

: No

No

No

:

ReactivityHazard:

Immediate(Acute)HealthHazard

: Yes

>1

No

This information is furnished without warranty, expressed or implied, except that it is accurate to the best of our knowledge. The

data on this sheet relates only to the specific material designated herein.

for use or reliance uponthese data.

Eastern Resins Corp.assumes no legal responsibility

Installation Manual Page 18 of 25

Page 20

Alpha Industrial Power Spill Control Barrier System

ExposureLimits

ACGIH

OSHA

Cycloaliphaticamine

50-70

N/E

N/E

Revision Date: March 18, 2008 MSDSNo. AAG (B)

MATERIAL SAFETY DATA SHEET

ProductName:

ChemicalFamily: AMINEMIXTURE

CompanyName:

ChemicalName Wt % TLV-TWA PEL

Aliphaticamine 30-50 N/E N/E

Specificingredientsareconsidereda TradeSecret

ADHESIVEGEL(HARDENER),PART-B

Eastern ResinsCorp.

1174RiverStreet

Woonsocket,RI02895,USA

1. MATERIAL IDENTIFICATION

BUSINESSPHONE:

EMERGENCYPHONE:

2. COMPOSITION

(401)769-6700

(800)255-3924

Abbreviations:N/E- NOTESTABLISHED

*-Materialsarein

Non-Airborne

form

3. HEALTH HAZARDS

PrimaryRoutesofExposure: Eyes

EyeContact

SkinContact:

Inhalation

Ingestion:

Other:

:Causesevereirritationandmaycauseburn.

Causeirritationandsensitization.Symptomscanbeimmediateordelayedseveralhours.

: Can causerespiratorytractirritation.

Cancause nausea,headache,andgastrointestinal irritation.

Preexistingskin sensitizationmaybeaggravated by exposuretothisproduct.

: Yes

Skin:

Yes

Inhalation:

Yes

4. FIRST AID MEASURES

Eyes:

Flush eyesthoroughly withwaterforat least15minuteswhile holdingeyelidsopen.Seekmedicalattention.

Skin:

Removecontaminatedclothing.Wipeexcessfromskinandwashtheaffectedareathoroughlywithsoapandwater.Wash

contaminatedclothing thoroughlybeforereuse.

Inhalation:

delayedup to severalhours.

Ingestion

medicalattention.

Removetofreshair,andprovideoxygenorartificialrespirationifneeded.Obtainmedicalattention;symptomscanbe

:DONOTinducevomiting.Give1-2cupsofwaterormilkunlessthepersonisdrowsy,convulsing,orunconscious.Get

5. FIRE FIGHTING MEASURES

FlammableProperties:FlashPoint

ExplosiveLimits:

HazardousDecompositionProducts

EXTINGUISHING MEDIA AND FIRE FIGHTING INSTRUCTIONS

firefighters should be equipped with full bunker gear, including a positive pressure, NIOSH approved, self-contained breathing

apparatus.Extremeheatorwater contaminationmaycause closedcontainersto explode.

ExtinguishingMedia

:Usecarbondioxide, drychemicalor appropriatefoam.

: >200oF(PMCC)

Notapplicable

: oxidesofnitrogen, Carbon monoxide,carbon dioxideandotherorganicmaterials.

Auto-IgnitionTemperature:

: When sufficiently large quantities are present,

Notapplicable

6. ACCIDENTAL RELEASE MEASURES

Ventilatethespillareaandevacuateifnecessary.Removeallignitionsources.Dikeandcontainlargespills.Flushareawithwater

spray.Clean-uppersonnelshoulduseadequateprotectiveequipment.

Installation Manual Page 18 of 25

Page 21

Alpha Industrial Power Spill Control Barrier System

Revision Date: March 18, 2008 MSDS No. AAG (B)

7. HANDLING AND STORAGE

Storeina cool;dryplace,inclosedcontainersat roomtemperature.Avoidcontactwithincompatiblematerials.Wearprotective

eyewear,chemical-resistantgloves,and otherprotectiveclothingas appropriate.

8. EXPOSURE CONTROLANDPERSONAL PROTECTION

Engineering/Ventilation Controls:

worker exposure to all respiratory hazards. General ventilation, local ventilation, or isolation may prove adequate to keep airborne

concentrations belowexposurelimits.

RespiratoryProtection

SkinProtection

EyeProtection

:Notrequiredunder normalconditionsin awell-ventilatedworkplace.

:Imperviousglovesandprotectiveclothingshouldbe wornasnecessary.

:Chemicalsplashgogglesor safetyglasses withsideshieldsshouldbe wornasappropriate.

Effective engineering controls should be used whenever possible to eliminate and/or reduce

9. STABILITY AND REACTIVITY

ChemicalStability

ConditionsandMaterialstoAvoid:

Hazardous Polymerization:

: Stableundernormalconditionsanduse.

Reactswithepoxyandstrongoxidizingagents.

Will notoccur.

10.PHYSICALAND CHEMICALPROPERTIES

Appearance/Odor:

VaporPressure(mmHg

SpecificGravity:

Amberliquid,ammoniacalodor

): <1@25oC

1.04

BoilingPoint

Vapor Density(air=1):

SolubilityinWater:

: Notdetermined

>1

Slightly soluble

11.TOXICOLOGICAL INFORMATION

AcuteToxicityData:

Notavailable

ChronicToxicityData:

Notavailable

12.DISPOSALCONSIDERATIONS

Keep out of surface waters, sewers, and waterways entering orleadingto surface waters. Notify authorities ifany exposure tothe

environmentoccurs or is likelyto occur.Utilizean appropriate disposal facility,in compliancewithapplicable federal, state, and

localenvironmentalcontrolregulations.

DOT/IATAProperShippingName

13.TRANSPORTATION INFORMATION

:NotRegulated

14.REGULATORYINFORMATION

TSCA:

ThechemicalcomponentsofthisproductareincludedintheTSCAChemicalSubstanceInventory,asrequired.

SARATITLEIII:

Section313–ToxicChemicals

Section311/312– HazardCategories

FireHazard:

SuddenReleaseofPressureHazard:

Delayed(Chronic)HealthHazard

OSHAHazardCommunicationStandardHazardClasses

NFPAHazards:

HMISHazards:

Health:3 Flammability:1 Reactivity:0

Health:3 Flammability:1 Reactivity:0

: None

:

No

No

: No

ReactivityHazard:

Immediate(Acute)HealthHazard

:

No

: Yes

Thisinformationis furnished without warranty,expressedor implied,exceptthat it isaccurate to the bestof our knowledge. The

data on this sheet relates only to the specific material designated herein.

responsibilityforuseorrelianceupon thesedata.

Eastern Resins Corp.assumes no legal

Page 22

Alpha Industrial Power Spill Control Barrier System

ExposureLimits

TLV-TWA

PEL

Revision Date: March 18, 2008 MSDS No. ANFC (A)

MATERIALSAFETYDATASHEET

ProductName:

ChemicalFamily: EpoxyResinMixture

CompanyName:

ChemicalName Wt %

Epoxy resin Mixture

Titanium Dioxide *

Carbon black*

Specificingredients areconsidereda TradeSecret

Abbreviations:N/E- NOTESTABLISHED

PrimaryRoutesofExposure:

Eye Contact

SkinContact

Inhalation:

Ingestion:

Other

Eyes:

Skin:

contaminatedclothing thoroughlybeforereuse.

Inhalation:

delayedup to severalhours.

Ingestion:

medicalattention.

FlammableProperties:FlashPoint

ExplosiveLimits:

HazardousDecompositionProducts

EXTINGUISHING MEDIA AND FIRE FIGHTING INSTRUCTIONS

firefighters should be equipped with full bunker gear, including a positive pressure, NIOSH approved, self-contained breathing

apparatus.Extremeheatorwater contaminationmaycause closedcontainersto explode.

Extinguishing Media

Ventilatethespillareaandevacuateifnecessary.Removeallignitionsources.Dikeandcontainlargespills.Clean-uppersonnel

should useadequateprotectiveequipment.

:Maycauseirritationand swelling.

:Maycauseirritationandsensitization.Symptomscanbeimmediateordelayedseveralhours.

Maycauseirritation and temporaryorpermanentsensitization.

Maycauseirritation.

:Preexisting skinsensitization may be aggravatedby exposureto thisproduct.

Flusheyesthoroughlywithwater forat least15minuteswhileholding eyelids open.Seekmedical attention.

Removecontaminatedclothing.Wipeexcessfromskinandwashtheaffectedareathoroughlywithsoapandwater.Wash

Removetofreshair,andprovideoxygenorartificialrespirationifneeded.Obtainmedicalattention;symptomscanbe

DONOTinducevomiting.Give1-2cupsofwaterormilkunlessthepersonisdrowsy,convulsing,orunconscious.Get

NOVOLACFLOORCOATING(RESIN),PART-A

Eastern ResinsCorp.

1174 River Street

Woonsocket,RI02895,USA

*- Materialsarein

:Usecarbon dioxide,drychemical or appropriate foam

1. MATERIAL IDENTIFICATION

BUSINESSPHONE:

EMERGENCYPHONE:

(401) 769-6700

(800) 255-3924

2. COMPOSITION

Non-Airborne

form

>70

<10

<1

ACGIH

N/E

10 mg/m3

3.5mg/m3

OSHA

N/E

15mg/m3

3.5mg/m3

3. HEALTH HAZARDS

Eyes: Yes Skin: Yes Inhalation: Yes

4. FIRST AID MEASURES

5. FIRE FIGHTING MEASURES

: >300oF(PMCC)

Notapplicable

: Carbon monoxide,carbondioxide,aldehydes,andotherorganicsubstances.

Auto-IgnitionTemperature:

: When sufficiently large quantities are present,

Notapplicable

6. ACCIDENTAL RELEASE MEASURES

Installation Manual Page 20 of 25

Page 23

Alpha Industrial Power Spill Control Barrier System

Storeina cool;dryplace,inclosedcontainersat roomtemperature.Avoidcontactwithincompatiblematerials.Wearprotective

eyewear,chemical-resistantgloves,and otherprotectiveclothingas appropriate.

7. HANDLING AND STORAGE

8. EXPOSURE CONTROLANDPERSONAL PROTECTION

Engineering/Ventilation Controls:

worker exposure to all respiratory hazards. General ventilation, local ventilation, or isolation may prove adequate to keep airborne

concentrations belowexposurelimits.

RespiratoryProtection

containedbreathingapparatusisrequired.

SkinProtection

EyeProtection

:Ifexposurelimitsareexceededandlocalventilationisunavailable,a supplied-airrespiratorora self-

:Imperviousglovesandprotectiveclothingshouldbe wornasnecessary.

:Chemicalsplashgogglesor safetyglasses withsideshieldsshouldbe wornasappropriate.

Effective engineering controls should be used whenever possible to eliminate and/or reduce

9. STABILITY AND REACTIVITY

ChemicalStability

ConditionsandMaterialstoAvoid:

HazardousPolymerization

: Stableundernormalconditionsanduse.

Reactswithaminesandstrongoxidizingagents.

:Willnotoccur.

10.PHYSICALAND CHEMICALPROPERTIES

Appearance/Odor:

VaporPressure(mmHg

SpecificGravity:

): <1@25oC

Grayliquid,slightetherodor

1.2

BoilingPoint

Vapor Density(air=1):

: Notdetermined

SolubilityinWater:

>1

None

11.TOXICOLOGICAL INFORMATION

Thissectionprovidestoxicologicalinformationwith regardtothepureformofthecomponentindicated.Itissuggestedthat

personstrainedin itsevaluation interpretthisinformation.

EpoxyResins: AcuteOral

AcuteDermal

(Rat): 11.4g/kg

LD50

(Rabbit): >20 g/kg

LD50

12.DISPOSALCONSIDERATIONS

Keep out of surface waters,sewers, and waterways entering or leadingto surface waters. Notify authorities ifany exposure to the

environmentoccurs or is likelyto occur.Utilizean appropriate disposal facility,in compliancewithapplicable federal, state, and

localenvironmentalcontrolregulations.

13.TRANSPORTATION INFORMATION

DOT/IATAProperShippingName

TSCA:

ThechemicalcomponentsofthisproductareincludedintheTSCAChemicalSubstanceInventory,asrequired.

SARATITLEIII:

Section313–ToxicChemicals

Section311/312– Hazard Categories

FireHazard:

SuddenReleaseofPressureHazard:

Delayed(Chronic)HealthHazard

OSHAHazard CommunicationStandardHazardClasses

NFPAHazards:

HMISHazards:

Health:2 Flammability:0 Reactivity:0

Health:2 Flammability:0 Reactivity:0

:NotRegulated

14.REGULATORYINFORMATION

: None

:

No

No

: No

ReactivityHazard:

Immediate(Acute)HealthHazard

:

No

: Yes

Thisinformationis furnishedwithoutwarranty, expressedorimplied,exceptthatit is accurateto the bestofour knowledge.

Thedata on this sheet relates only to the specific material designated herein.

legal responsibility for use or reliance upon these data.

Eastern ResinsCorp.assumes no

Installation Manual Page 21 of 25

Page 24

Alpha Industrial Power Spill Control Barrier System

Revision Date: March 18, 2008

MSDSNo.ANFC(B)

MATERIAL SAFETY DATA SHEET

ProductName:

ChemicalFamily: AMINE MIXTURE

CompanyName:

ChemicalName Wt% TLV-TWA PEL

Cycloaliphaticamine 50-70 N/E N/E

Aliphaticamine 30-50 N/E N/E

Specific ingredientsareconsidereda TradeSecret

Abbreviations:N/E- NOTESTABLISHED

PrimaryRoutesofExposure: Eyes

EyeContact

SkinContact:

Inhalation

Ingestion:

Other:

Eyes:

Skin:

contaminatedclothing thoroughlybeforereuse.

Inhalation:

delayedup to severalhours.

Ingestion

medicalattention.

FlammableProperties:FlashPoint

ExplosiveLimits:

HazardousDecompositionProducts

EXTINGUISHING MEDIA AND FIRE FIGHTING INSTRUCTIONS

firefighters should be equipped with full bunker gear, including a positive pressure, NIOSH approved, self-contained breathing

apparatus.Extremeheatorwater contaminationmaycause closedcontainersto explode.

ExtinguishingMedia

Ventilatethespillareaandevacuateifnecessary.Removeallignitionsources.Dikeandcontainlargespills.Flushareawithwater

spray.Clean-uppersonnelshoulduseadequateprotectiveequipment.

:Causesevereirritationandmaycauseburn.

Causeirritation andsensitization.Symptomscanbeimmediateordelayed severalhours.

: Can causerespiratorytractirritation.

Cancause nausea,headache,andgastrointestinal irritation.

Preexistingskin sensitizationmaybeaggravated by exposuretothisproduct.

Flush eyesthoroughly withwaterforat least15minuteswhile holdingeyelidsopen.Seekmedicalattention.

Removecontaminatedclothing.Wipe excessfromskinandwashtheaffectedareathoroughlywithsoapandwater.Wash

Removetofreshair,andprovide oxygenorartificialrespirationifneeded.Obtainmedicalattention;symptomscanbe

:DONOTinducevomiting.Give1-2cupsofwaterormilkunlessthepersonisdrowsy,convulsing,orunconscious.Get

NOVOLACFLOORCOATING(HARDENER),PART-B

Eastern ResinsCorp.

1174RiverStreet BUSINESSPHONE: (401) 769-6700

Woonsocket,RI02895, USA EMERGENCYPHONE:(800)255-3924

*- Materialsarein

:Usecarbondioxide, drychemicalor appropriatefoam.

1. MATERIAL IDENTIFICATION

2. COMPOSITION

ExposureLimits

ACGIH OSHA

Non-Airborne

form

3. HEALTH HAZARDS

: Yes

Skin:

Yes

Inhalation:

Yes

4. FIRST AID MEASURES

5. FIRE FIGHTING MEASURES

: >200oF(PMCC)

Notapplicable

: oxidesofnitrogen,Carbonmonoxide,carbon dioxideandotherorganicmaterials.

Auto-IgnitionTemperature:

: When sufficiently large quantities are present,

Notapplicable

6. ACCIDENTAL RELEASE MEASURES

Installation Manual Page 22 of 25

Page 25

Alpha Industrial Power Spill Control Barrier System

7. HANDLING AND STORAGE

Storeina cool;dryplace,inclosedcontainersat roomtemperature.Avoidcontactwithincompatiblematerials.Wearprotective

eyewear,chemical-resistantgloves,and otherprotectiveclothingas appropriate.

8. EXPOSURE CONTROL ANDPERSONAL PROTECTION

Engineering/Ventilation Controls:

worker exposure to all respiratory hazards. General ventilation, local ventilation, or isolation may prove adequate to keep airborne

concentrations belowexposurelimits.

RespiratoryProtection

containedbreathingapparatusisrequired.

SkinProtection

EyeProtection

ChemicalStability

ConditionsandMaterialstoAvoid:

Hazardous Polymerization:

:Ifexposurelimitsareexceededandlocalventilationisunavailable,a supplied-airrespiratorora self-

:Imperviousglovesandprotectiveclothingshouldbe worn as necessary.

:Chemicalsplashgogglesor safetyglasses withsideshieldsshouldbe wornasappropriate.

: Stableundernormalconditionsanduse.

Effective engineering controls should be used whenever possible to eliminate and/or reduce

9. STABILITY AND REACTIVITY

Reactswithepoxyandstrongoxidizingagents.

Will notoccur.

10.PHYSICAL AND CHEMICALPROPERTIES

Appearance/Odor:

VaporPressure(mmHg

SpecificGravity:

): <1@25oC

Amberliquid,ammoniacalodor

1.0

BoilingPoint

Vapor Density(air=1):

: Notdetermined

SolubilityinWater:

>1

Slightly soluble

11.TOXICOLOGICAL INFORMATION

AcuteToxicityData:

Notavailable

ChronicToxicityData:

Notavailable

12.DISPOSAL CONSIDERATIONS

Keep out of surface waters,sewers, and waterways entering or leadingto surface waters. Notify authorities ifany exposure to the

environmentoccurs or is likelyto occur.Utilizean appropriate disposal facility,in compliancewithapplicable federal, state, and

localenvironmentalcontrolregulations.

13.TRANSPORTATIONINFORMATION

DOT/IATAProperShippingName

:NotRegulated

14.REGULATORYINFORMATION

TSCA:

ThechemicalcomponentsofthisproductareincludedintheTSCAChemicalSubstanceInventory,asrequired.

SARATITLEIII:

Section313–ToxicChemicals

Section311/312– Hazard Categories

FireHazard:

SuddenReleaseofPressureHazard:

Delayed(Chronic)HealthHazard

OSHA HazardCommunicationStandardHazardClasses

NFPAHazards:

HMISHazards:

Health:3 Flammability:1 Reactivity:0

Health:3 Flammability:1 Reactivity:0

: None

:

No

No

: No

ReactivityHazard:

Immediate(Acute)HealthHazard

:Corrosive

No

: Yes

Thisinformationis furnishedwithoutwarranty, expressedorimplied,exceptthatit is accurateto the bestofour knowledge.

Thedata on this sheet relates only to the specific material designated herein.

legal responsibility for use or reliance upon these data.

Eastern ResinsCorp.assumes no

Installation Manual Page 23 of 25

Page 26

Alpha Industrial Power Spill Control Barrier System

Neutra

-

Tube

MATERIALSAFETY DATASHEET

SectionI GeneralInformation

Manufacturer:

AcranSpill Containment, Inc.

105-D Snyder Road

South Plainfield,NJ 07080

DatePrepared: Telephone Number for Information:

8September2008 (908) 769-6915

SectionII Hazardous Ingredients and Identity Information

Neutralizer/Absorber Blend CAS #: Trade Secret Weight>99% NuisanceDust

OSHAPEL: 15mg/M3Totaldust,5 mg/M3Respirabledust ACGIHTLV:

10mg/M3Total dust

ColorChangeAgent CAS #: Trade Secret Weight <1%

Skin, Eye, and Respiratory Irritant

P/N 7NTA0006

(FCM00702)

Neutra-Mat

P/N5NMB0010

(FCM00703)

SectionIII Physical Data

BolingPoint:N/A Vapor Density: N/A

Melting Point: N/A Liquid Density: N/A

Volatiles:0%vol. 0%wt. Evaporation Rate: N/A

Specific Gravity: 2.5

Solubility: 3.5% wt in water.

Appearance& Odor: Pillow containinga lighttan powder. Odorless.

SectionIV Fireand Explosion Hazard Data

FlashPoint:Non-flammable LEL: None UEL: None

Extinguishing Media: Water, Carbon Dioxide, or Appropriate Foam

SpecialFirefighting Procedures: Iflarge quantities of product areinvolved,

significant levels of CO2may be generated making necessary the use of a

self contained breathing apparatus (CO2is an asphyxiant at levels over 5%).

Unusual Fire and Explosion Hazards: None

SectionV First Aidand Health HazardData

Acute and Chronic Effects of Overexposure:

EyeContact: Dusts mayirritatethe eyes.In caseof eyecontact,wash eyeswith

copious amounts of water for 15 minutes.

Skin Contact: Prolonged exposure may cause irritation. Irritant dose is 30 mg/3

days–mild irritation to human skin. In case of skin contact, immediately wash

skin with soap and water.

Inhalation: Nuisance dust can aggravate chronic bronchial difficulties. Breathing

dustmay irritate thenose andthroatand causecoughingor chestdiscomfort.If

inhaled, remove to fresh air. Give artificial respiration if not breathing. If

breathing is difficult, give oxygen.

Ingestion: Excessive oral doses (5g/kg) may produce gastrointestinal

disturbance, alkalosis, and expansion in extracellular fluid. Oral toxicity is

4.22 g/kg RatLD50. If swallowed andconscious, wash mouth withwater and

inducevomiting. Do not put anything inmouth of unconscious person. Seek

immediate medical attention.

Installation Manual Page 24 of 25

Page 27

Alpha Industrial Power Spill Control Barrier System

Neutra

-

Tube

SectionVI Reactivity Data

Stability:

Stable

Conditions toavoid:

Hazardous DecompositionProducts:

dangerous levels ofCO2gas.

SectionVII SpillorLeak Procedures

Steps To Be Taken In Case Material Is Released Or Spilled:

or damaged, avoid breathing dust.

WasteDisposalMethod:

of hazardous or toxicliquid,dispose ofin accordance withapplicablefederal,state andlocal regulations.

SectionVIII Special ProtectionInformation

RespiratoryProtection:

Ventilation:

SkinProtection:

EyeProtection:

Work/hygienicpractices:

No dust shouldbe produced innormal usage.If dustis created

duringhandling, keepdustlevelsbelow 10mg/M3LocalExhaust:

Mechanical(General):

workpractices. Always wash hands andface beforeeating,

drinking or smoking.

Hazardous Polymerization:

Excessiveheat,HFacid,magnesium withhydrogen,strongoxidizingagent.

If unused, not classified ashazardous forlandfill disposal (40CFR Part261). Afterabsorption

Dustmask should beused if dustlevelsexceedPEL.

Gloves and labcoat, apron or coveralls

Usegoggles orsafetyglassestoavoidirritation.

Establish good personalhygiene and

Combustion byproducts maybe CO, NOx, SOx. Heating mayrelease

Seeabove

Will not occur

Special:

N/A

Other:

N/A

Sweep or scoop up intoclean container.If bags are torn

Seeabove

SectionIX SpecialPrecautions

Precautions To Be Taken In Handling, Transportation, And Storage:

performance. Handlewith care not topuncturebags.

Other Precautions:

SectionX Additional Regulatory Information

Productnot regulated bythe DOT

None

This Product Safety Data Sheet is offeredsolely for your

information, consideration and investigation. ACRAN, Inc.

provides no warranties, either expressed or implied, and

assumes no responsibility for the accuracy and completeness of

the data contained herein.

Store in a dry place to protect productfrom lossof

P/N 7NTA0006

(FCM00702)

Neutra-Mat

P/N5NMB0010

(FCM00703)

Installation Manual Page 25 of 25

Loading...

Loading...