Installation and Servicing

Instructions

Alpha SolarSmart 90

Pre-Heat Drain Back Solar System and Wall Mounted

Unvented Hot Water Solar Cylinder

for use with an Alpha Combination Boiler

For Technical help or for Service call ...

ALPHA HELPLINE

Tel: 0870 3001964

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

Building Regulations Approved

Certificate No. ETC11206

THE NATIONAL FEDERATION OF

SOLAR Key Mark Certificated

Leave these instructions with the User

ROOFING CONTRACTORS LIMITED

CONTENTS

1 Introduction ....................................... 2

2 Technical data................................... 3

3 General information...........................6

4 Installation......................................... 12

5 Commissioning ................................. 18

6 System operation .............................. 20

7 Routine inspection.............................22

8 Component replacement ................... 22

9 Wiring diagram.................................. 24

10 Diagnostics and fault codes ............... 25

11 Checklist for unvented storage........... 26

12 Parts list ............................................ 27

13 Inspection history .............................. 28

1 INTRODUCTION

The Alpha SolarSmart 90 system is a pre-heat drain back solar collector system which includes a wall mounted 90 litre

unvented cylinder to store water heated by the solar collector. The system must be used in conjunction with an Alpha

combination boiler fitted with the Alpha Solar valve which is supplied with the system.

The SolarSmart 90 system consists of a 90 litre cylinder, a 2.5 m² flat plate drain back solar collector, drain back unit,

unvented kit and solar valve. The 90 litre unvented cylinder is fitted with a pump, control box and temperature sensors.

The drain back unit is fitted with a heat exchanger and pump.

The unvented kit must be fitted in the mains water supply to the cylinder. The kit includes a pressure reducing valve,

expansion vessel, expansion relief valve, check valve and a tundish. The solar valve must be fitted directly to the mains

water inlet of the Alpha combination boiler.

Note: In the northern hemisphere solar collectors should ideally face South. For more information see Section 3.6.

IMPORTANT

This System has been approved to the Building Regulations for unvented hot water storage systems and the Local

Authority must be notified of the intention to install. Therefore the installation must be carried out by a person competent

to install unvented hot water systems.

The installation must be carried out in accordance with the following recommendations:All current Building Regulations issued by the Department of the Environment, i.e. Approved Document L1

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department

UK Water Regulations/Byelaws (Scotland)

Health & Safety Document No. 635 (The Electricity At Work Regulations 1989)

The installation should also be in accordance with the following British Standard Codes of Practice:-

BS 5449:1990 Forced circulation hot water systems

BS 5546:2000 Installation of hot water supplies for domestic purposes

BS 5918:1989 Solar heating systems for domestic hot water

BS 6700:1997 Design, installation, testing and maintenance of services supplying water

Failure to install this appliance correctly could lead to prosecution and will invalidate the guarantee. It is in your own

interest and that of safety to ensure that the law is complied with.

Manufacturer's instructions must NOT be taken in anyway as over-riding statutory obligations.

This appliance meets the requirements of IPX4D, i.e. degree of protection against moisture.

Reference should be made to Criteria for gas fired combination boilers used as after heaters in solar thermal systems

and BRE Solar heating UK:1981.

Note: 1) The Alpha SolarSmart system was a ClearSkies recognised product and is now a product recognised in the UK

Microgeneration Product Certification Scheme.Therefore the system is eligible for renewable energy grants.

2) The SolarSmart collector has been tested to DIN EN12975 and CEN Keymark certificated for Solar Thermal

Products.

Alpha SolarSmart 90 - Contents/Introduction

2

2 TECHNICAL DA T A

2.1 DHW SYSTEM

Solar Cylinder

Max. Hot Water Working Pressure

Max. Mains Inlet Pressure

Min. Mains Water Pressure

Mains Inlet Connection

DHW Outlet Connection

DHW Cylinder Capacity

Expansion Vessel Size (pre-charge press.)

Pressure Reducing Valve Setting

Temperature and Pressure Relief Valve

Expansion Relief Valve Setting

Flow Rate L/min

Max. Outlet Water Temp. (Approx.) °C

Reference to WRC-NSF Test Procedure 1.50.220 using a 30 kW boiler. Time to reheat water store by 55°C - 25 minutes. Reheat time for 70% of store - 18 minutes

(inlet of pressure reducing valve)

gal/min

°F

5.5 bar

12 bar

0.1 bar

15 mm

15 mm

8 L at 2.5 bar

2.5 bar

90°C/7 bar

Max.18.0

Max. 4.0

Max. 70

Max. 158

91 L

6 bar

Min. 1.0

Min. 0.22

Min. 5

Min. 41

Drain Back Unit (DBU)

DHW Circuit:

Flow Connection

Return Connection

Max. Working Pressure

Heat Exchanger Coil Content

Collector Circuit:

Flow Connection

Return Connection

Max. Working Pressure

Vessel Size

Max. Filled Content

Heat Transfer Capacity

2.2 SOLAR COLLECTOR SYSTEM

Type:

Dimensions

Total Surface Area m²

Aperture Area m²

Length x Width x Thickness mm

Water Content L

Lift Weight kg

Profile of collector when fitted using an Alpha flashing kit protrudes approximately 30 mm to 60 mm

above the tiles (depends upon type of tile used)

Hydraulics

Maximum Pressure bar

Absorber

Aluminium Cover and Copper Pipe

(Length x Width x Depth) mm

Spectral Selective Layer

Absorption Coefficient %

Emission f %

Glass

Transparent, Hardened - Thickness mm

Collector Housing

Material

Insulation

Thickness mm

Thermal conduction coefficient W/mk

Cover Frame

Material

Temperature Sensor

Type - NTC Ohm

Connections

Pre-mounted Flexible Hoses Return to DBU mm

Flow from DBU mm

Minimum Roof Slope

Energy Performance (System with 90L tank)GJ/yr

Zero Loss Collector Efficiency (No)

Collector Heat Loss Coefficient (a1) W/m²k

Aperture to Gross Collector Area Ratio

Portrait

2230 x 1120 x 92

1.16

2140 x 1030 x 0.5

Aluminium Pressing

0.037

Aluminium Black Powder Coated

12 mm

15 mm

20°

3.629

Landscape

2.5

2.26

1120 x 2230 x 92

40

8

1030 x 2140 x 0.5

94

5

4

50

10 k

3.5

74%

0.9

1.10

30°

15 mm

15 mm

8 bar

0.32 L

15 mm

12 mm

6 bar

3.6 L

2.8 L

110 W/kg

Alpha SolarSmart 90 - Technical Data

3

2.3 INSTALLATION

Solar Cylinder Min. Clearances for Servicing Top

Bottom

Sides

Front

DBU Min. Clearances for Servicing Top

Bottom

Side

Front

Lift Weight - Cylinder Assembly

Lift Weight DBU

Weight Full and Operational - Cylinder Assemby

Weight Full and Operational - DBU

Supply

External Fuse

Power Consumption Max.

Min.

230/240 V ~ 50 Hz

3 A

165 W

5 W

100 mm

300 mm

10 mm

450 mm

100 mm

100 mm

10 mm

450 mm

22 kg

6 kg

113 kg

8.8 kg

2.5 GENERAL2.4 ELECTRICAL

Solar Cylinder Dimensions Height

Width

Depth

DBU Dimensions Height

Width

Depth

Solar Cylinder - Material

DBU Heat Exchanger - Material

Covers/Insulation Material

Solar Cylinder Insulation Thickness

Standing Energy Loss of Solar Cylinder

1110 mm

540 mm

530 mm

460 mm

365 mm

270 mm

Stainless Steel

Copper

EPP Foam

50 mm

0.92 kWh/24hr

0.43 watts/litre

2.6 LOCATION

Max. Height Between Top of Solar Collector and Bottom of DBU (see Note below)

Max. Distance Between DBU and Bottom of Solar Cylinder

Max. Distance Between Top of Solar Collector and Bottom of Solar Cylinder

Note: Whenever possible, always fit the DBU to the flexible hoses from the solar collector. If this is not possible, do not

use more than 2 m of 15 mm pipe for each of the flow and return between the DBU and collector.

3 m

6 m

6 m

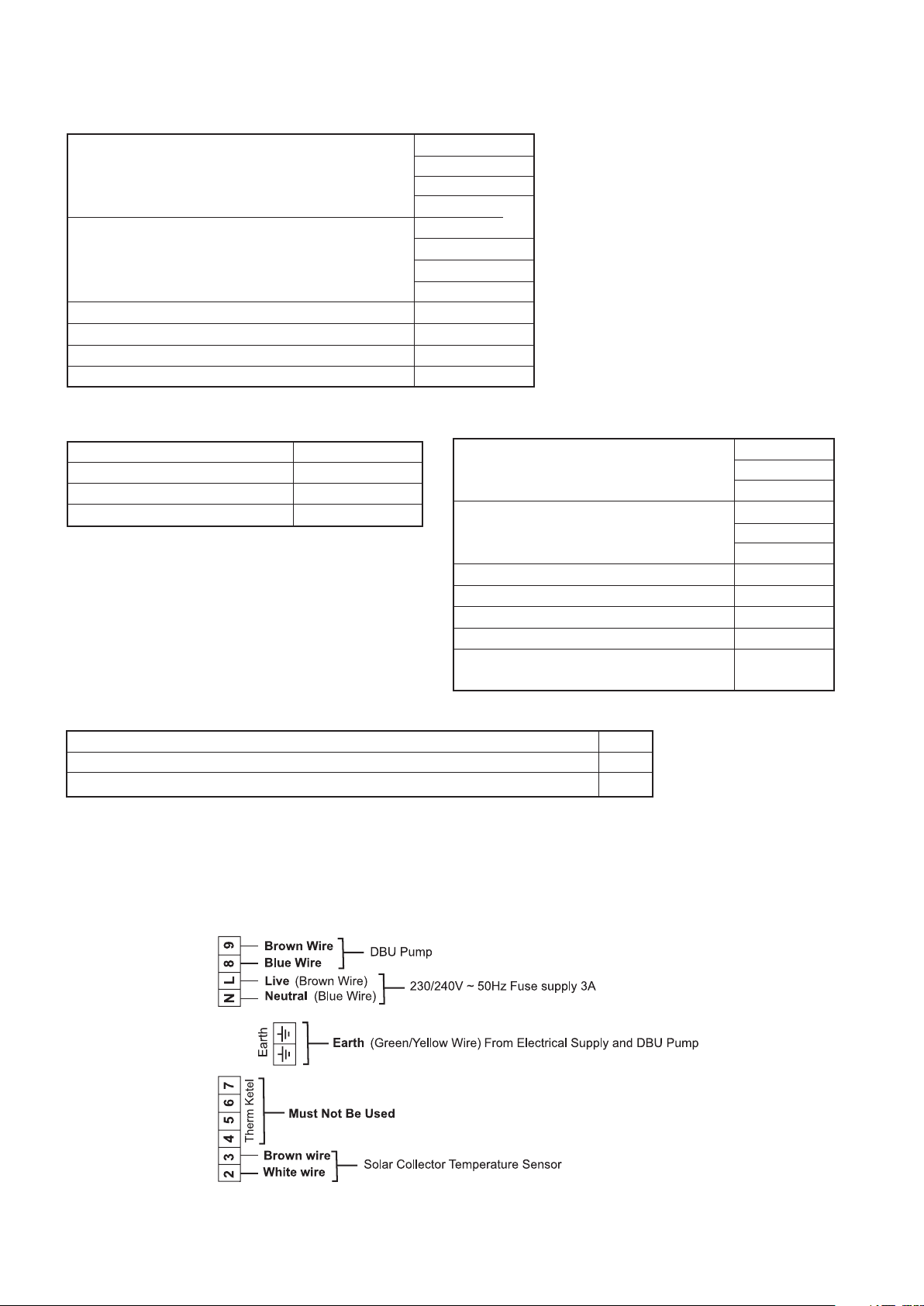

2.7 ELECTRICAL CONNECTIONS

Notes: This Appliance Must Be Earthed.

Do Not Connect Any Other Controls.

Alpha SolarSmart 90 - Technical Data

4

Fig. 1

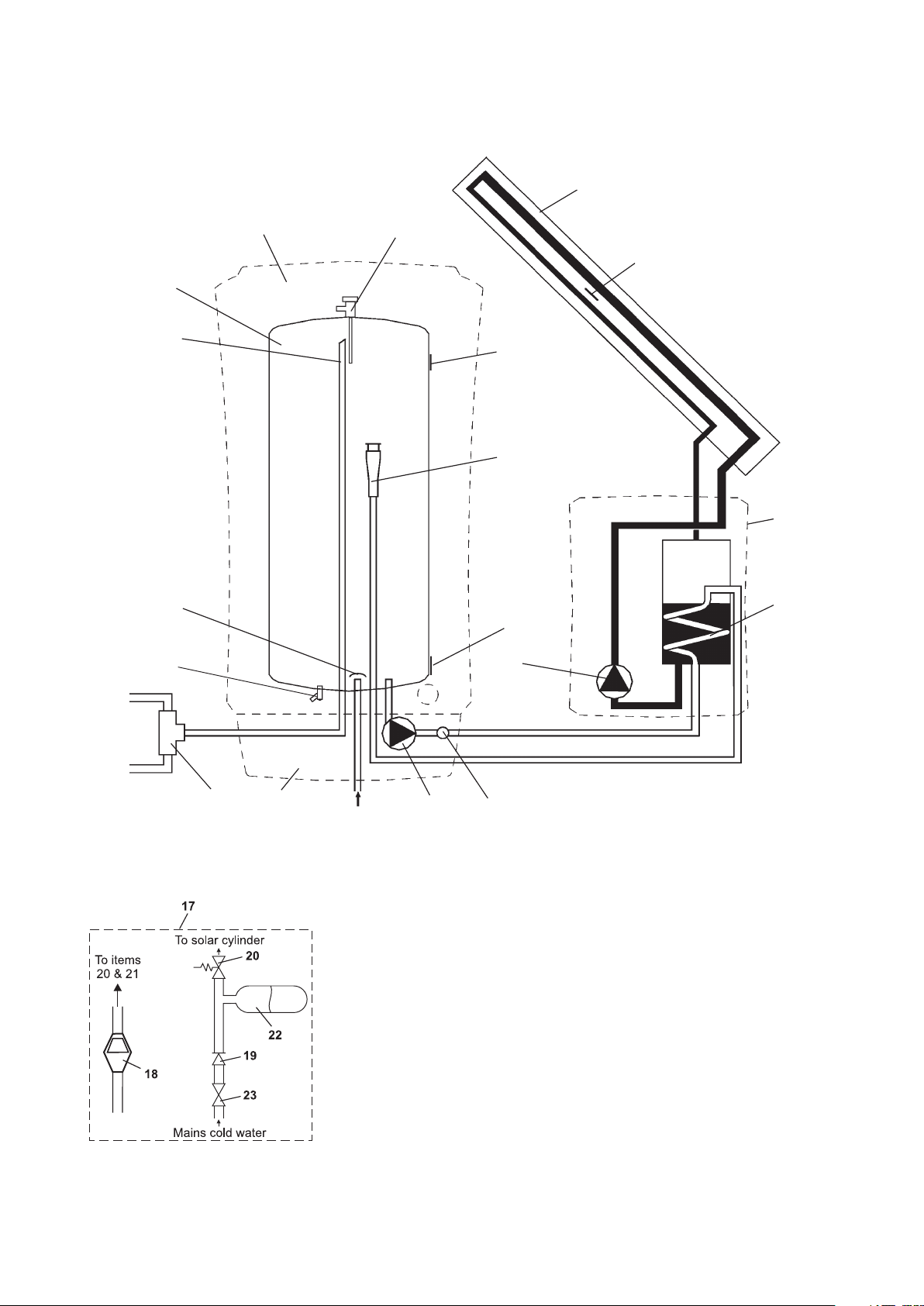

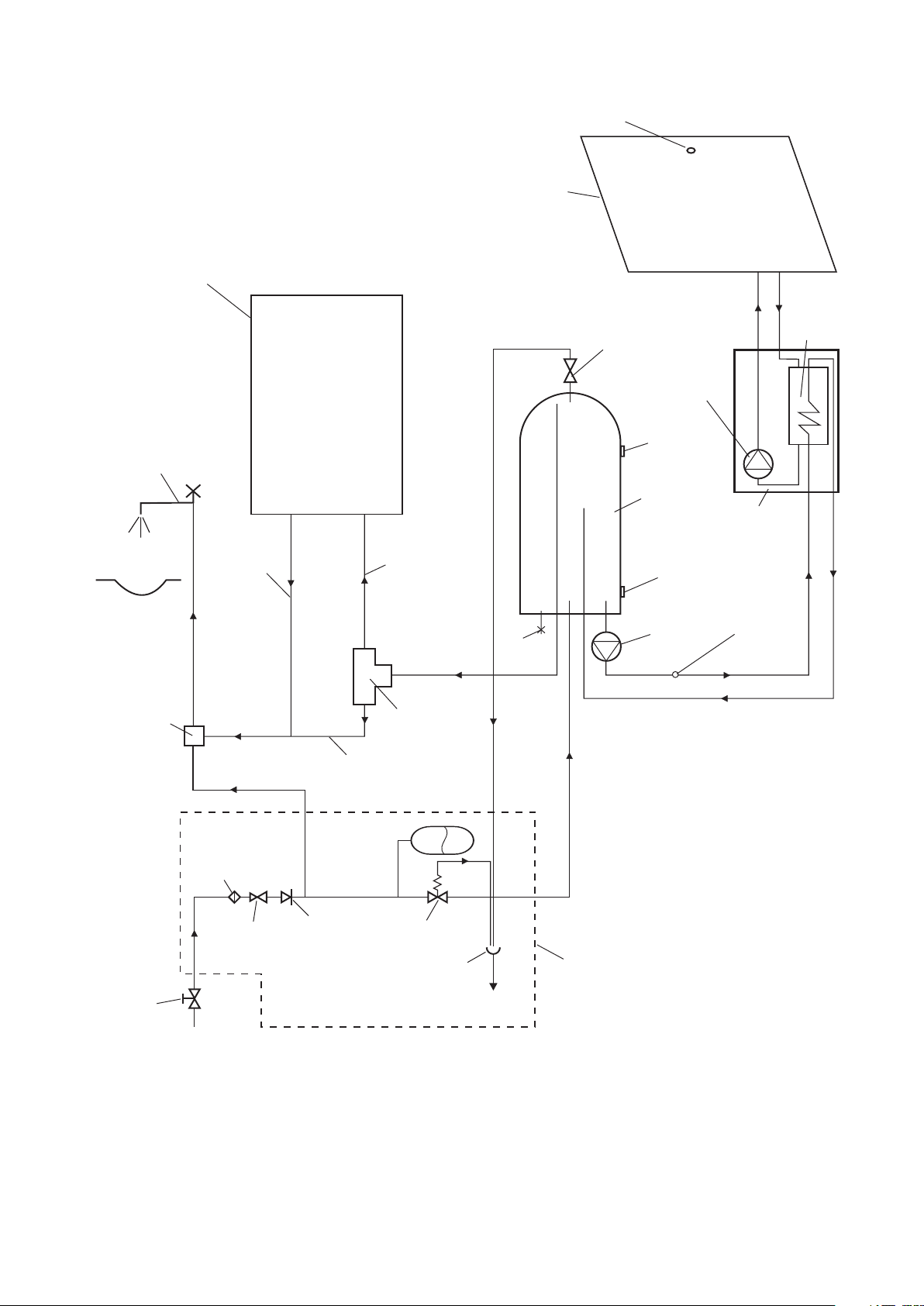

2.8 SOLAR SYSTEM SCHEMATIC

1

24

10

15

21

5

6

14

9

2

8

4

14

3

12

13

11

16

Cold water

7

inlet

1 Solar collector

2 Drain back unit (DBU)

3 DBU pump

4 DBU heat exchanger

5 Collector temperature sensor

6 Solar cylinder

7 Solar cylinder pump

8 Filter

9 Diffuser

10 DHW outlet pipe

11 Solar valve

12 Flow to boiler

25

13 Flow to tap

14 Temperature sensors

15 Insulation/casing

16 Bottom tray

17 Unvented kit

18 Tundish

19 Non-return valve

20 Expansion relief valve

21 Temperature and pressure relief valve

22 Expansion vessel

23 Pressure reducing valve with filter

24 Drain point for cylinder

25 Overheat thermostat

Fig. 2

Alpha SolarSmart 90 - Technical Data

5

3 GENERAL INFORMATION

3.1 ELECTRICAL SUPPLY

The Solar system requires a 230/240 V ~ 50 Hz mains supply, fused at 3 A - The system must be earthed.

There must only be one common isolator, providing complete electrical isolation, for the Solar system.

This system has been fitted with a supply cable, however, if it is necessary to fit a cable use PVC insulated cable not less

than 0.75 mm² (24 x 0.2 mm) to BS 6500 Table 16. The system should be connected to a fused three pin plug and

unswitched shuttered socket outlet (both complying with BS 1363), or a fused double pole switch with a contact

separation of at least 3 mm in both poles.

Note: There is no electrical connections between the boiler and the Solar system. Therefore, it is recommended that the

Solar system electrical isolation is completely separate to the boiler and any external controls isolation.

All wiring must be in accordance with the current IEE Wiring Regulations (BS 7671).

3.2 DOMESTIC HOT WATER SYSTEM

The mains water supply must be first connected to the components detailed in Section 3.3 before the Solar cylinder. No

valves must be fitted between these components and the cylinder. The incoming mains water pressure to the cylinder is

regulated to 2.5 bar by the pressure reducing valve supplied in the unvented package. However, all taps and mixing

valves used with the hot water system must be suitable for operating at a pressure of up to 8 bar.

The Solar valve, supplied in the unvented package, must always be fitted directly to the cold water inlet of an Alpha

combination boiler.

Note: The hot water control thermostat on the combination boiler must always be turned to maximum.

To ensure economic use, the pipe runs to the Alpha combination boiler and taps should be in 15 mm copper pipe and be

as short as possible. Where possible the pipework should be insulated to reduce heat loss.

Before the mains water supply pipe is connected to the boiler, it should be thoroughly flushed out to avoid the danger of

dirt or foreign matter entering the boiler and the filter incorporated within the pressure reducing valve cleaned.

The stored water temperature is controlled to a maximum of 70°C.

To prevent high temperatures at the hot water taps, it is recommended that a thermostatically controlled mixing valve is fitted

after the boiler.

3.3 UNVENTED HOT WATER STORAGE SYSTEM

To comply with the Building Regulations for unvented hot water storage, it is required that the unvented kit components

detailed in Fig. 3 are fitted before the mains cold water inlet to the Solar cylinder. No isolating valves must be fitted

between these components and the cylinder.

All these components are supplied with the Solar system in a separate package and must be fitted by a competant

person in accordance with the instructions.

The installation is subject to Building Regulations approval and the Local Authority must be notified of the intention to install.

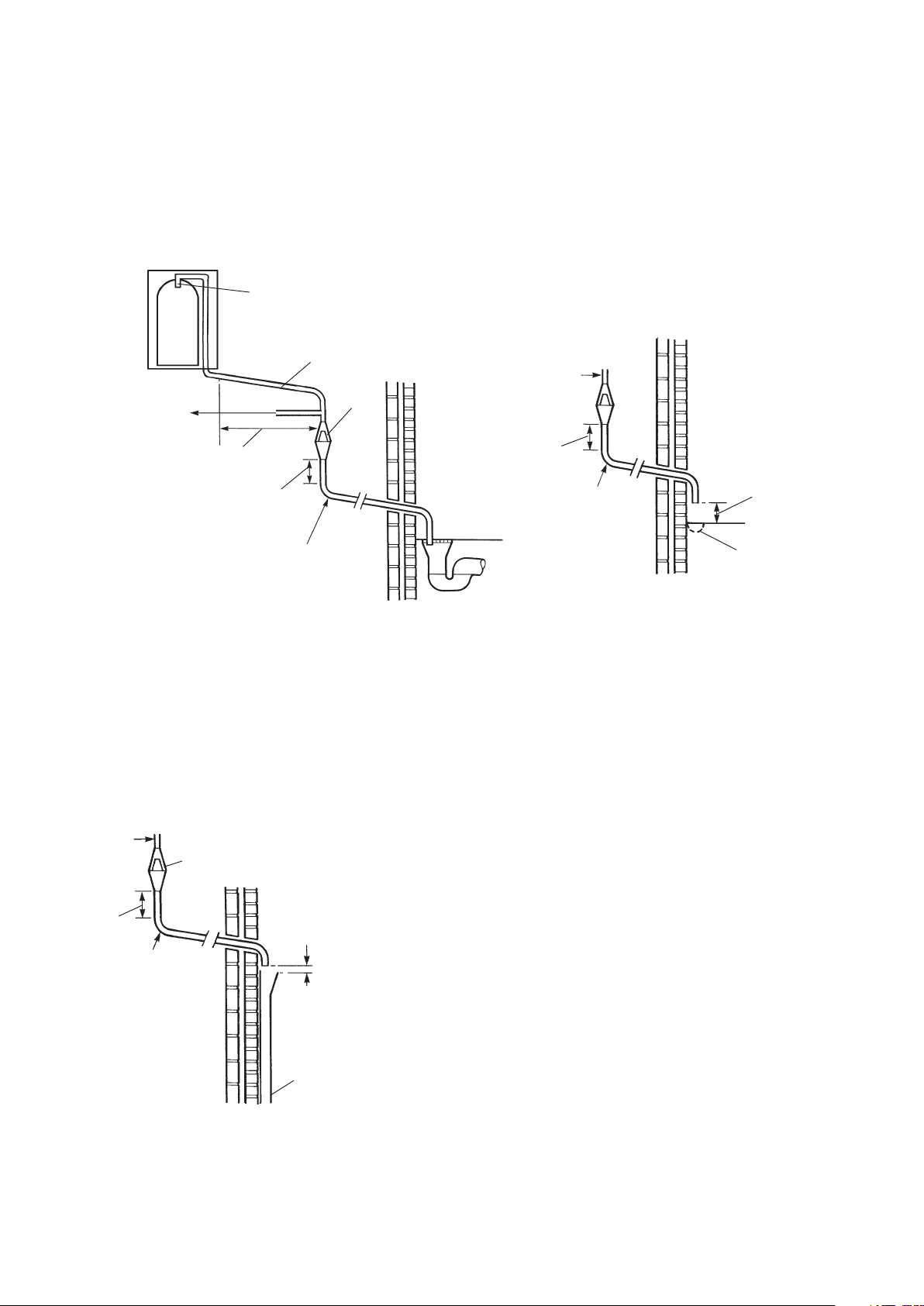

Discharge pipe - The discharge pipes from the temperature/pressure and expansion relief valves must be routed to the

tundish supplied and in 15 mm pipe. The discharge pipework from both relief valves may be joined together in the same

sized pipe, providing at least 22 mm pipework is connected downstream of the tundish.

Tundish - The tundish must be positioned within 500 mm of the appliance, so that it is visible to the User and away from

electrical devices. The minimum size of the discharge pipe downstream of the tundish is given in the following table.

The discharge pipework from the tundish:-

Sizing of copper discharge pipe 'D2' - refer also to Fig. 4A and 4B

Valve

outlet size

G½

Minimum size of discharge

pipe 'D1' to tundish

15 mm

Minimum size of discharge

pipe 'D2' from tundish

22 mm

28 mm

35 mm

Maximum resistance allowed,

expressed as a length of straight

pipe (i.e. no elbows or bends)

up to 9 m

up to 18 m

up to 27 m

1. Shall fall continuously through its length.

2. Shall be of a heat resistant material, e.g. metal.

3. Shall not be fitted with any valves or taps.

4. Shall discharge to a safe visible position, e.g. into a gulley.

5. Shall have a minimum of 300 mm straight pipework directly from the tundish.

Note: Where children may play or otherwise come into contact with discharges, a wire cage or similar guard must be

positioned to prevent contact whilst maintaining visibility.

Resistance created

by each elbow

or bend

0.8 m

1.0 m

1.4 m

Alpha SolarSmart 90 - General Information

6

Combination boiler

Thermostat sensor

Solar collector

Hot tap

Thermostatically

controlled

mixing valve

Cold water

supply

Outlet water

temperature

60°C

Water temperature

less than 60°C

Solar valve

Water temperature

more than 60°C

Drain

point

Temperature/pressure

relief valve

Drain back

unit pump

Thermostat

sensor

Unvented

cylinder

Thermostat

sensor

Cylinder

pump

Heat

exchanger

Drain back

unit

Overheat

thermostat

Stop

valve

Filter

Mains water

supply

Pressure

reducing

valve

Check

valve

Expansion

vessel

Expansion

relief valve

Tundish

Discharge

pipe

Fig. 3

Unvented kit

Alpha SolarSmart 90 - General Information

7

Given below are suggested methods of terminating the discharge pipe safely.

Where a single pipe serves a number of discharges, such as in blocks of flats, the number served should be limited to not

more than 6 systems so that any installation can be traced reasonably easily. The single common discharge pipe should

be at least one pipe size larger than the largest individual discharge pipe to be connected.

If the system is installed where discharges from safety devices may not be apparent, i.e. in dwellings occupied by blind, infirm or disabled

people, consideration should be given to the installation of an electronically operated device to warn when discharge takes place.

a. Low level termination

Solar cylinder

temperature/pressure

relief valve

Metal discharge pipe (D1)

To expansion

relief valve

500 mm max.

from relief valve to tundish

Tundish

300 mm

minimum

D1

Pipe close to wall to

allow water to fan out

safely

300 mm

minimum

Metal discharge pipe (D2) from

tundish with continuous fall

D2

100 mm max.

70 mm min.

Ground level

Gulley if

available

Fig. 4a

b. High level termination

At high level, discharge onto a roof is acceptable providing the roof is capable of withstanding high temperatures and

there is a distance of 3 m from any plastic guttering systems that would collect such discharge.

Note: The discharge will consist of scalding water and steam. Asphalt, roofing felt and non-metallic rainwater goods may

be damaged by such discharges.

c. Termination into a hopper

300 mm

minimum

D1

D2

Tundish

Type 'A'

air gap

End of pipe to be

clearly visible

Worked example:-

The example below is for a G½ temperature relief valve with a discharge pipe (D2)

having four elbows and a length of 7 m from the tundish to the point of discharge.

From the table on page 6:-

Maximum resistance allowed for a straight length of 22 mm copper discharge pipe

(D2) from a G½ temperature relief valve is 9 m.

Subtract the resistance for four 22 mm elbows of 0.8 m each = 3.2 m.

Therefore the maximum permitted length equates to 9 - 3.2 = 5.8 m

5.8 m is less than the actual length of 7 m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of 28 mm pipe (D2) from a G½

temperature relief valve equates to 18 m.

Subtract the resistance for four 28 mm elbows at 1.0 m each = 4 m.

Therefore the maximum permitted length equates to 18 - 4 = 14 m

As the actual length is 7 m, a 28 mm (D2) copper pipe will be satisfactory.

Alpha SolarSmart 90 - General Information

8

Fig. 4b

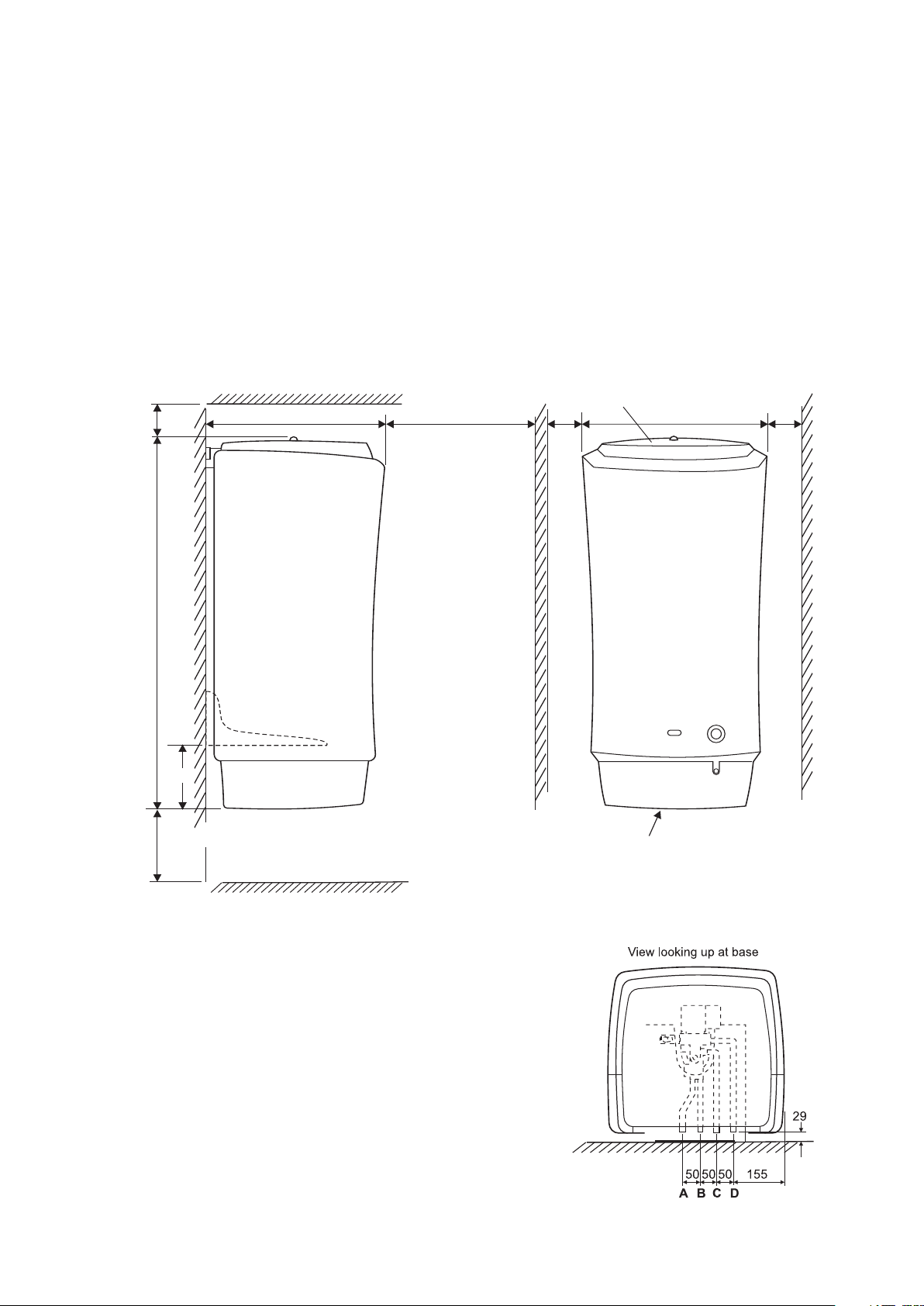

3.4 SOLAR CYLINDER INFORMATION - Figs. 5a and 5b

Positioning

The Solar cylinder must be installed on a flat vertical wall which is capable of supporting the weight of the cylinder when

full (113 kg).

The cylinder may be installed in any room or internal space, although particular attention is drawn to the requirements of

the current IEE Wiring (BS7671) Regulations, and in Scotland, the electrical provisions of the Building Regulations

applicable in Scotland, with respect to the installation of the cylinder in a room or internal space containing a bath or

shower. When the cylinder is installed in a room containing a bath or shower, it must not be possible for a person using

the bath or shower to touch any electrical switch or cylinder control utilising mains electricity.

The bottom of the Solar cylinder must be located within 6 metres of the top of the Solar collector and of the drain back

unit.

Dimensions

The dimensions of the cylinder and clearances required for servicing are shown in Fig. 5a.

Serial No. under cover

100

530

450

10

540

10

Side

1110

187

300

Fig. 5a

Water connections

The connections at the bottom of the cylinder are shown in Fig. 5b.

Note: Use compression fittings only on the cylinder connections.

Cylinder Connections

A Water outlet to boiler 15 mm

B Cold water inlet 15 mm

C Return from DBU 15 mm

D Flow from cylinder to DBU 15 mm

Front

Serial Number

Fig. 5b

Alpha SolarSmart 90 - General Information

9

Loading...

Loading...