Page 1

Instructions for adjusting a

replacement printed circuit board

Alpha HE/CB/SY Boiler Range

1. GENERAL

When the Printed Circuit Board (PCB) is replaced the following adjustments must be carried out:a. Adjust the central heating maximum and minimum output.

b. Ensure that the JP1 plug is correctly positioned for the type of gas the boiler is being used with.

MET - Natural Gas LPG - Liquefied Petroleum Gas

d. Ensure that all electrical plugs and connectors are pushed fully home and soundly connected.

Note: Before fitting a new PCB ensure the polarity of the electrical supply is correct by testing the supply, using a

suitable multimeter, as follows:-

Live to Neutral 240 Volts AC

Live to Earth 240 Volts AC

Neutral to Earth zero Volts AC

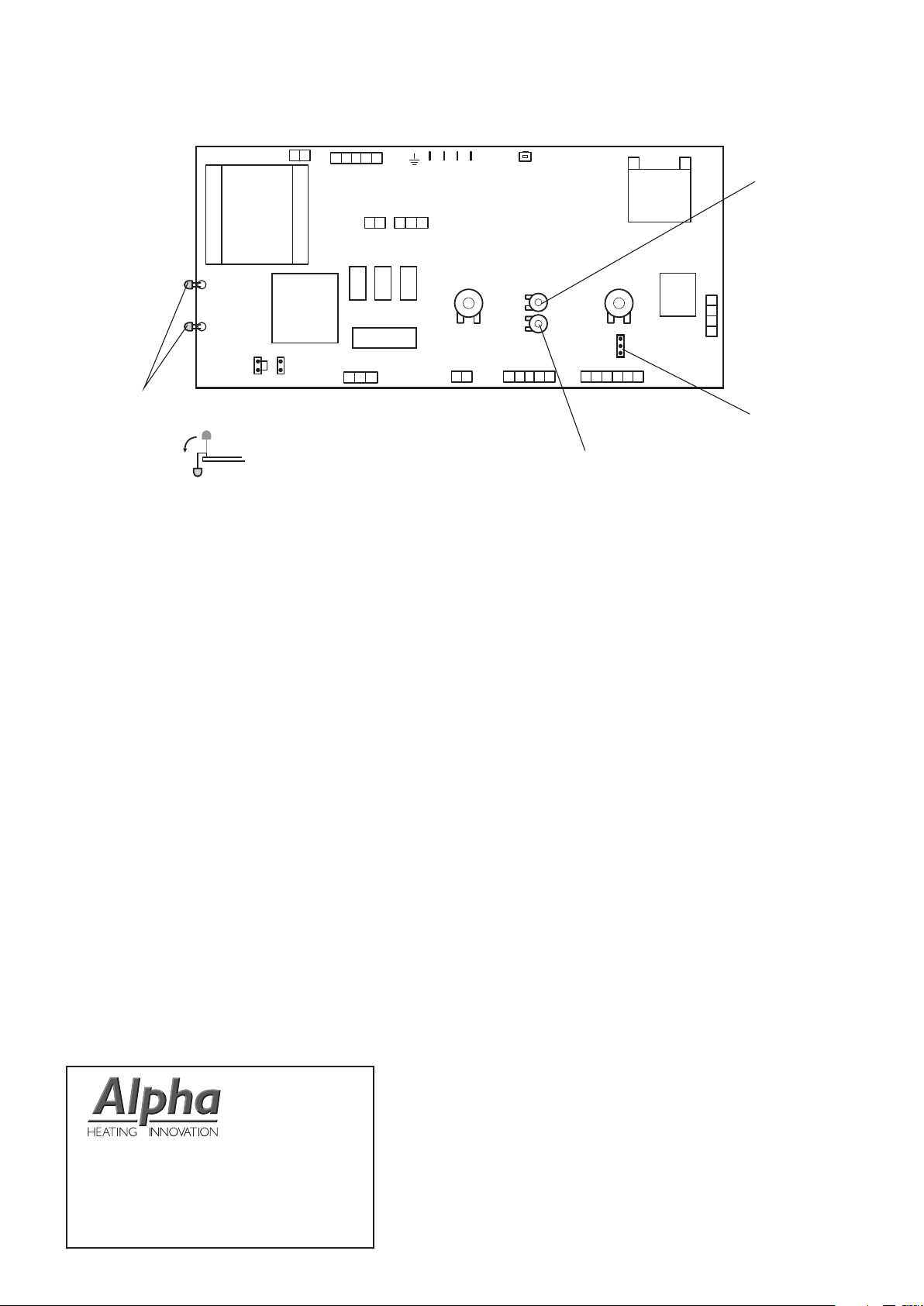

Note: i) Before fitting the PCB, carefully bend the red and yellow neons through 180° so that they locate into the

control panel - see Fig. 1.

ii) When the selector switch is turned to the reset position, there will be a delay of approximately 30 seconds

before the PCB will reset.

iii) Ignition rate is pre-set and is not adjustable.

2. FIT AND ADJUST THE REPLACEMENT PCB

Refer to the Installation and Servicing instructions for gaining access to and for replacement of the PCB. To adjust the

PCB the gas valve burner pressures must be measured. Loosen the burner test point screw on the gas valve and

connect a pressure gauge. After adjusting the PCB disconnect the pressure gauge, tighten the test point screw and

test for gas soundness using a suitable leak detection fluid.

Set the Minimum Central Heating Output

a. Turn the selector switch to CH and the central heating thermostat to maximum.

b. When the burner has ignited, take a small flat headed insulated screw driver and insert it into the slot in the CH

CAP (potentiometer P4) and turn it ant-clockwise to its minimum setting.

c. Insert the screw driver into the IGN CAP (potentiometer P3) and adjust it until the correct CH minimum setting is

obtained (refer to the instructions supplied with the boiler).

d. Turn the CH CAP back to maximum and check the pressure, re-adjust if required. The PCB is now set.

Adjustment of the Maximum Central Heating Output

The Central Heating Output will normally be set to maximum. However if required, adjust the CH output as follows:a. Set the selector switch to

b. Carefully locate a small insulated screwdriver into the potentiometer P4 (CH CAP) - see Fig. 1, which should be

fully clockwise.

c. To Range - Rate the heating output, the potentiometer can be turned anticlockwise to the required output.

Fully clockwise Maximum output

Fully anticlockwise Minimum output

Half way Approximately 16.1 kW (55 000 Btu/h) for CB24, CB24X, SY24 & HE25

and the heating thermostat to maximum to operate the boiler on central heating.

Approximately 20.5 kW (70 000 Btu/h) for CB28, CB28X, CB50 & HE33

Page 2

4

5

M2

T1

43 44 45 N

3

M1

M12

3536

37

38

40

32 31 30 29

M13

M10

P3 for

setting

T2

minimum

CH output

Main

PCB

LD2

LD1

JP3 JP2

Carefully bend the neon lamps

through 180° to t into the sockets

on the control panel.

DHW SET

M4

48

46

47

1213

IGN CAP

P3

P4

CH CAP

M5

CH SET

2P1P

MET

JP1

LPG

6M41M

41 4218 1920 2114 15 16 17

25

24

23

22

M7

JP1

MET/LPG

P4

CH CAP

Fig. 1

Alpha Therm Limited.

Nepicar House, London Road, Wrotham Heath,

Sevenoaks, Kent TN15 7RS

Tel: 0870 3001964

email: info@alphatherm.co.uk

website: www.alpha-innovation.co.uk

These instructions have been carefully prepared but we reserve the right to

alter the specification at any time in the interest of product improvement.

© Alpha Therm Limited 2008.

0112653 )07610( :leT - 0002 snoitacilbuP yb dengised dna delipmoc launaM 3/08/D217

Loading...

Loading...