Page 1

Alpha FXM350/ Micro350 UPS

Installation and Operation

Manual

Part # 017-241-B0

Effective 11/11

member of The Group

™

Your Power Solutions Partner

Page 2

Page 3

Alpha FXM350 and Micro350 UPS

Installation and Operation Manual

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual

before proceeding. If there are questions regarding the safe operation of this powering

system, contact Alpha Technologies or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power

supplies, generators, batteries, or other hardware if used or operated in any manner or

subject to any condition inconsistent with its intended purpose, or if installed or operated in an unapproved manner, or improperly maintained.

For technical support, contact Alpha Technologies:

Canada and USA: 1-888-462-7487

International: +1-604-436-5547

Email: support@alpha.ca

Copyright

Copyright © 2011 Alpha Technologies Ltd. All rights reserved. Alpha is a registered trademark of Alpha Technologies.

No part of this documentation shall be reproduced, stored in a retrieval system, translated, transcribed, or

transmitted in any form or by any means manual, electric, electronic, electromechanical, chemical, optical, or

otherwise without prior explicit written permission from Alpha Technologies.

This document, the software it describes, and the information and know-how they contain constitute the proprietary, confidential and valuable trade secret information of Alpha Technologies, and may not be used for

any unauthorized purpose, or disclosed to others without the prior written permission of Alpha Technologies.

The material contained in this document is for information only and is subject to change without notice.

While reasonable efforts have been made in the preparation of this document to assure its accuracy, Alpha

Technologies assumes no liability resulting from errors or omissions in this document, or from the use of the

information contained herein. Alpha Technologies reserves the right to make changes in the product design

without reservation and without notification to its users.

Page 4

Table of Contents

1. Safety ....................................................................................................................................7

1.1 Safety Symbols .................................................................................................................... 7

1.2 General Warnings ................................................................................................................ 8

1.3 Battery Safety ....................................................................................................................... 8

1.4 Work Environment Safety .................................................................................................... 9

1.5 Certications and Compliances .......................................................................................... 10

2. General Description ............................................................................................................11

2.1 Alpha FXM350 .....................................................................................................................11

2.2 Micro350/ Alpha FXM350 ....................................................................................................11

2.3 FXM350 Front Panel .......................................................................................................... 13

2.4 Micro350 Top Panel ........................................................................................................... 16

3. Site Planning .......................................................................................................................17

3.1 Safety Precautions ............................................................................................................. 17

3.2 Electromagnetic Compatibility (EMC) Requirements ......................................................... 18

3.3 Mounting Options for the Micro350 (XL and XL3) .............................................................. 18

3.4 Options for Communicating with the FXM .......................................................................... 22

4. Unpacking the Equipment ...................................................................................................23

4.1 Alpha FXM350/Micro350 Conguration ............................................................................. 23

4.2 Unpacking .......................................................................................................................... 23

4.3 Optional Items .................................................................................................................... 23

5. Installation ..........................................................................................................................24

5.1 Installation of the Micro350 ................................................................................................ 24

5.2 Mounting and Wiring the FXM350 as a standalone device ................................................ 31

5.3 Wiring the External Batteries and Optional Battery Heater Mats ....................................... 33

5.4 Start-Up .............................................................................................................................. 35

6. Theory of Operation ............................................................................................................36

6.1 Block Diagram .................................................................................................................... 36

6.2 Modes of Operation ............................................................................................................ 36

2

017-241-B0 Rev B

Page 5

7. Operating the FXM350........................................................................................................40

7.1 Switching the Alpha FXM On and Off ................................................................................. 40

7.2 Operating from the Control Panel Interface ....................................................................... 42

7.3 Operating via the FXM Communication Module (Intranet or Internet) ............................... 49

7.4 The Alpha UPS Monitor Interface ....................................................................................... 73

7.5 HyperTerminal Interface ..................................................................................................... 76

8. Maintenance .......................................................................................................................89

8.1 Updating the Software ........................................................................................................ 89

8.2 Testing and Replacing the Batteries ................................................................................... 92

8.3 Preventive Maintenance ..................................................................................................... 95

9. Troubleshooting ..................................................................................................................96

9.1 Procedure ........................................................................................................................... 96

10. Specications ....................................................................................................................98

11. Warranty ..........................................................................................................................101

12. Emergency Shutdown Procedure ...................................................................................102

List of Figures

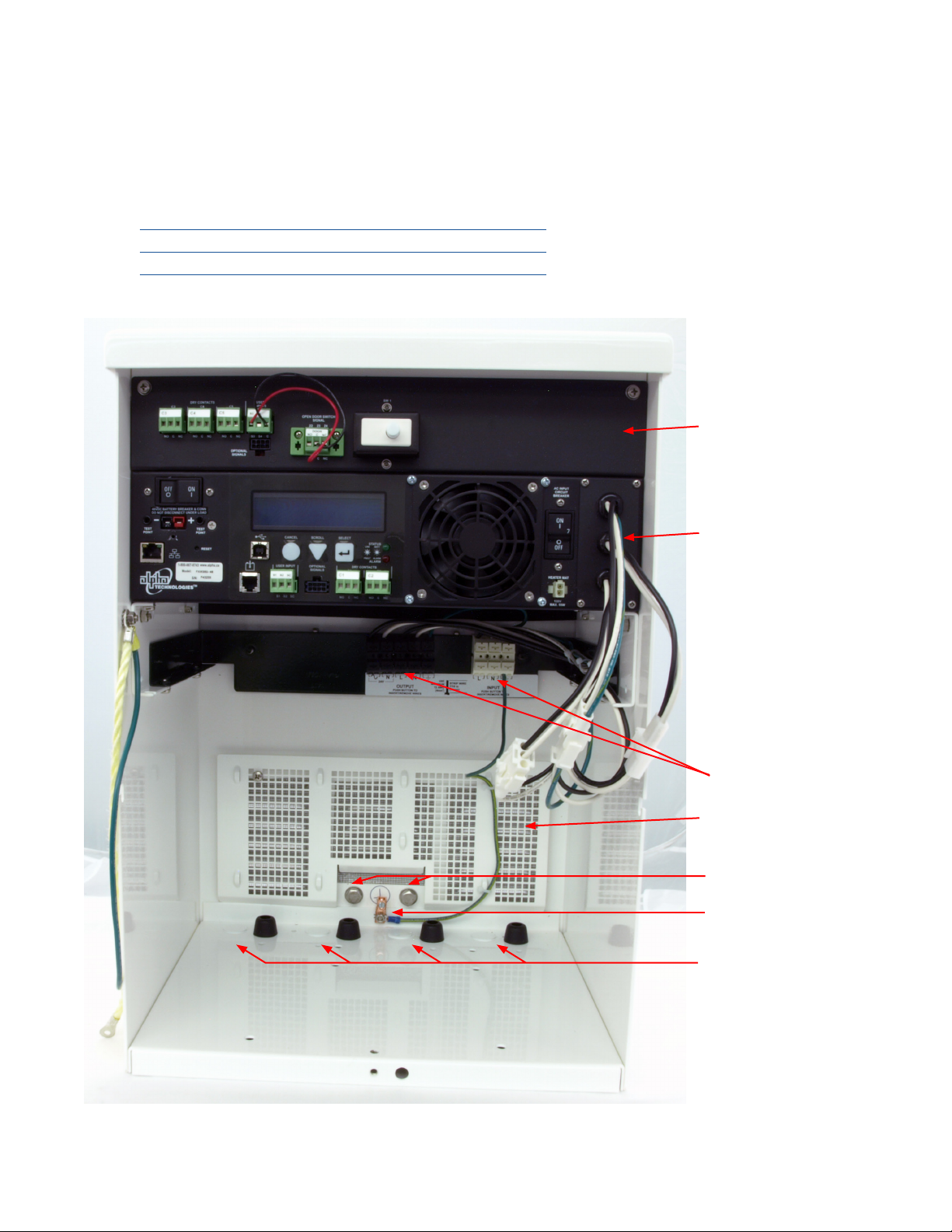

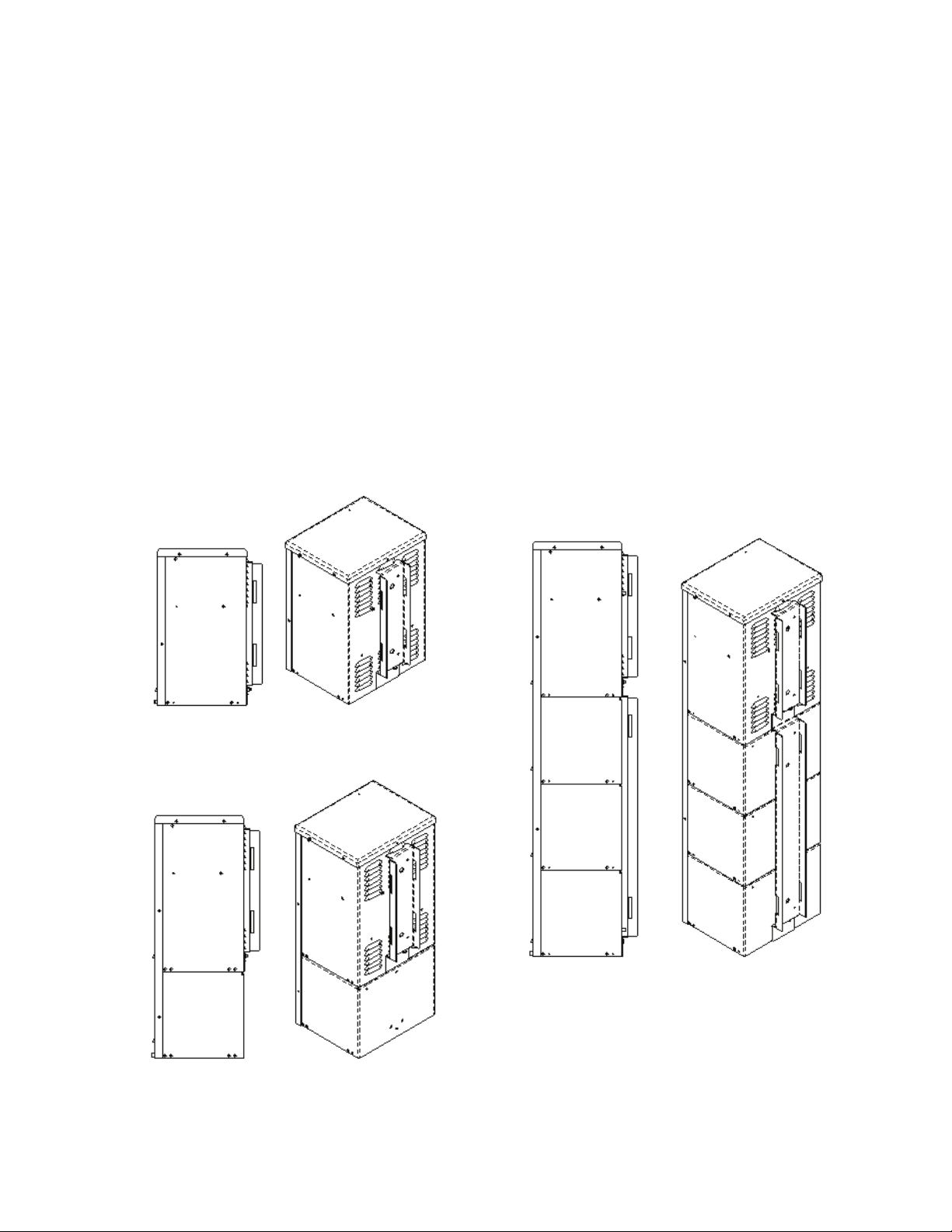

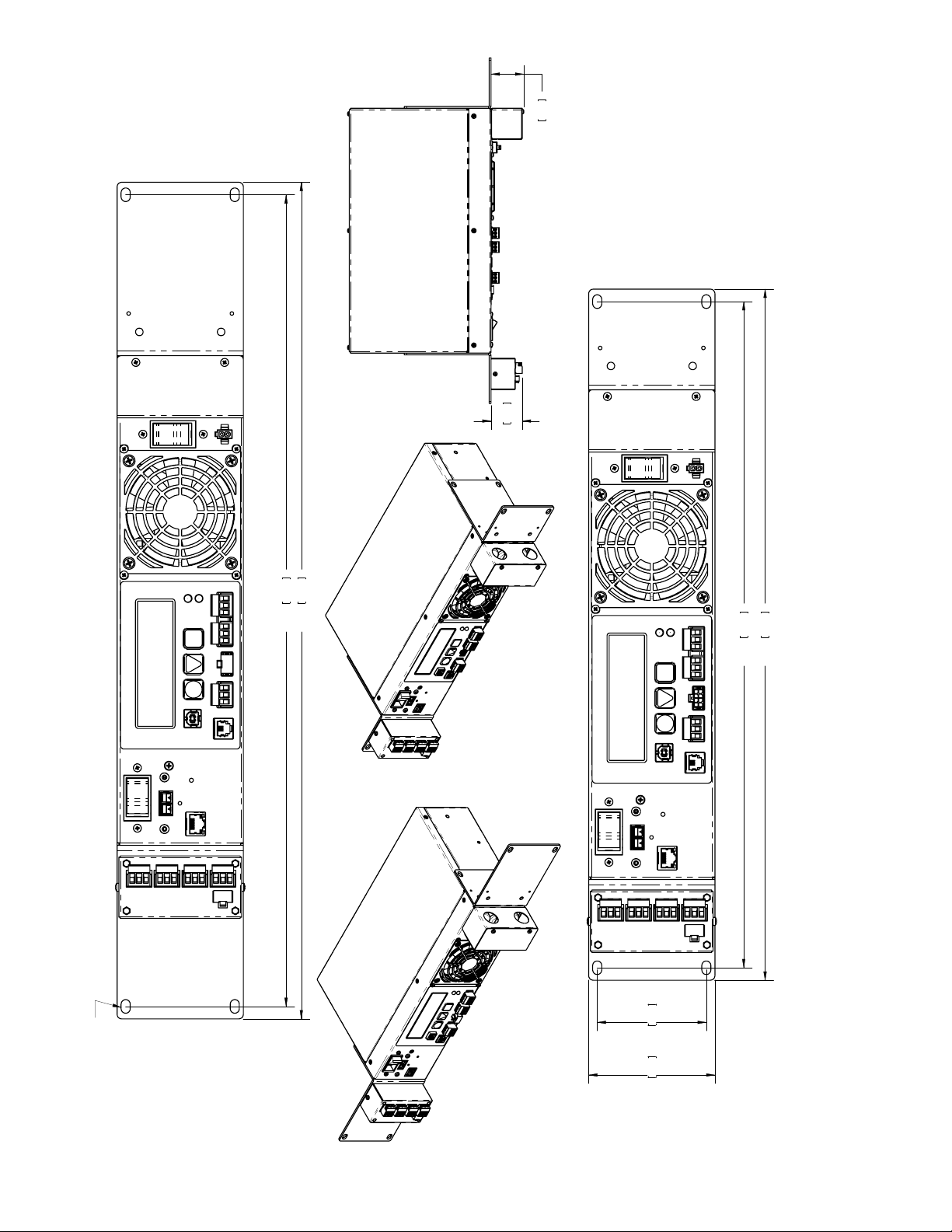

Figure 1 — Micro350 cabinets ..................................................................................................11

Figure 2 — FXM350 mounted in a standard Micro350 cabinet................................................. 12

Figure 3 — FXM 350 front panel description ............................................................................ 13

Figure 4 — User input layout ................................................................................................... 14

Figure 5 — Contact Layout (Standard for C1 and C2) .............................................................. 15

Figure 6 — Micro350 Top Panel ................................................................................................ 16

Figure 7 — Mounting the Micro350 ........................................................................................... 18

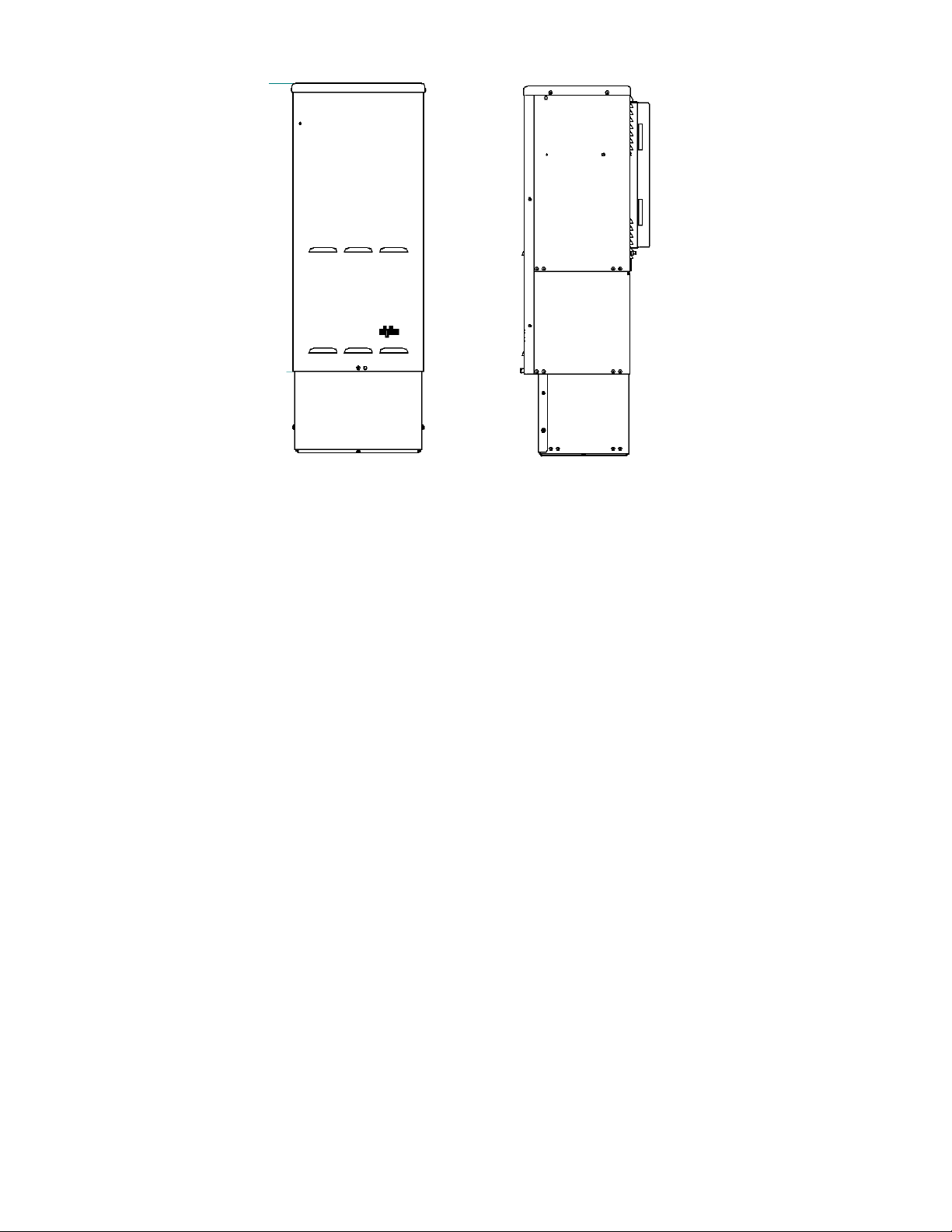

Figure 8 — Mounting on optional pedestal ............................................................................... 19

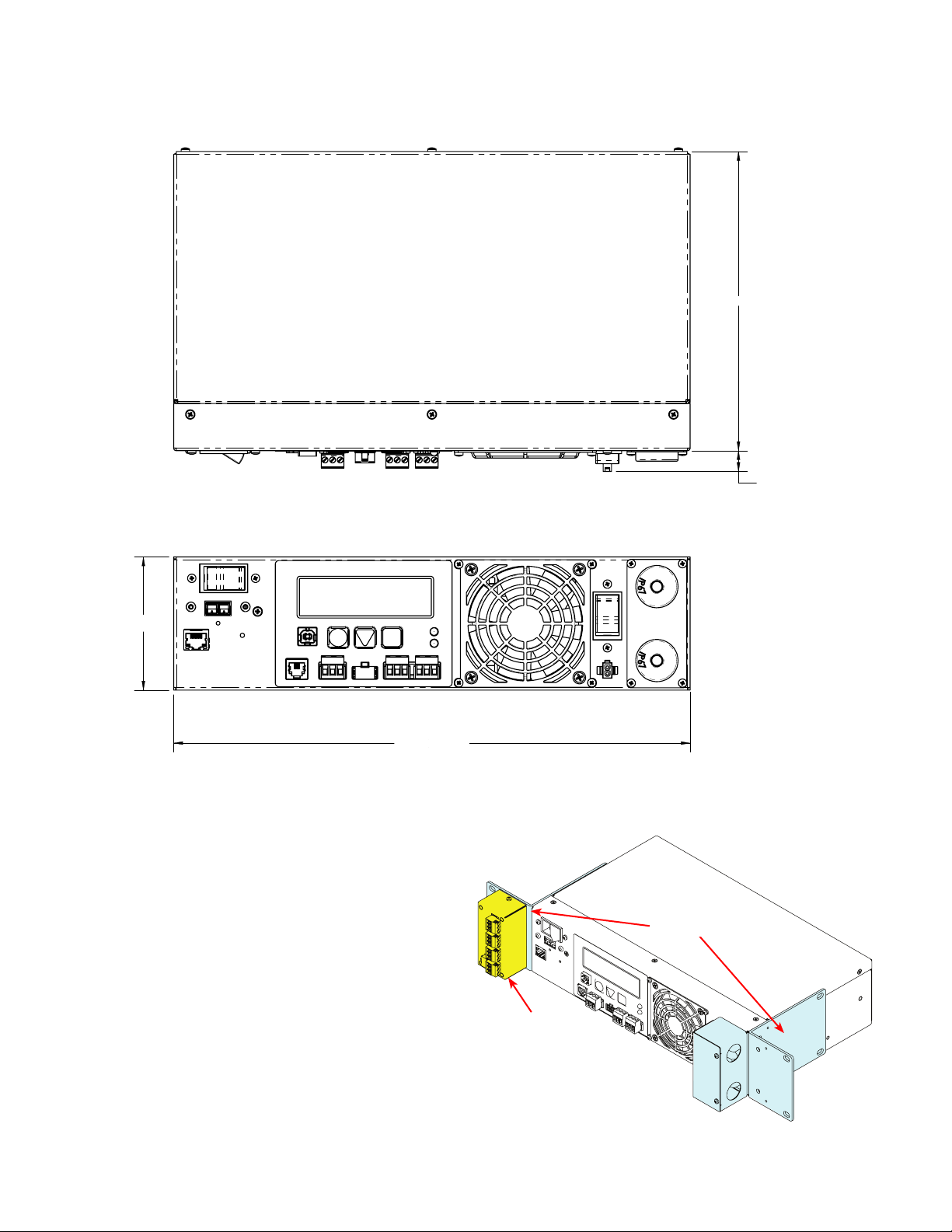

Figure 9 — FXM350 Mounting Dimensions .............................................................................. 20

Figure 10 — Rack-mount options ............................................................................................. 20

Figure 11 — FXM350 with ears for rack mounting .................................................................... 21

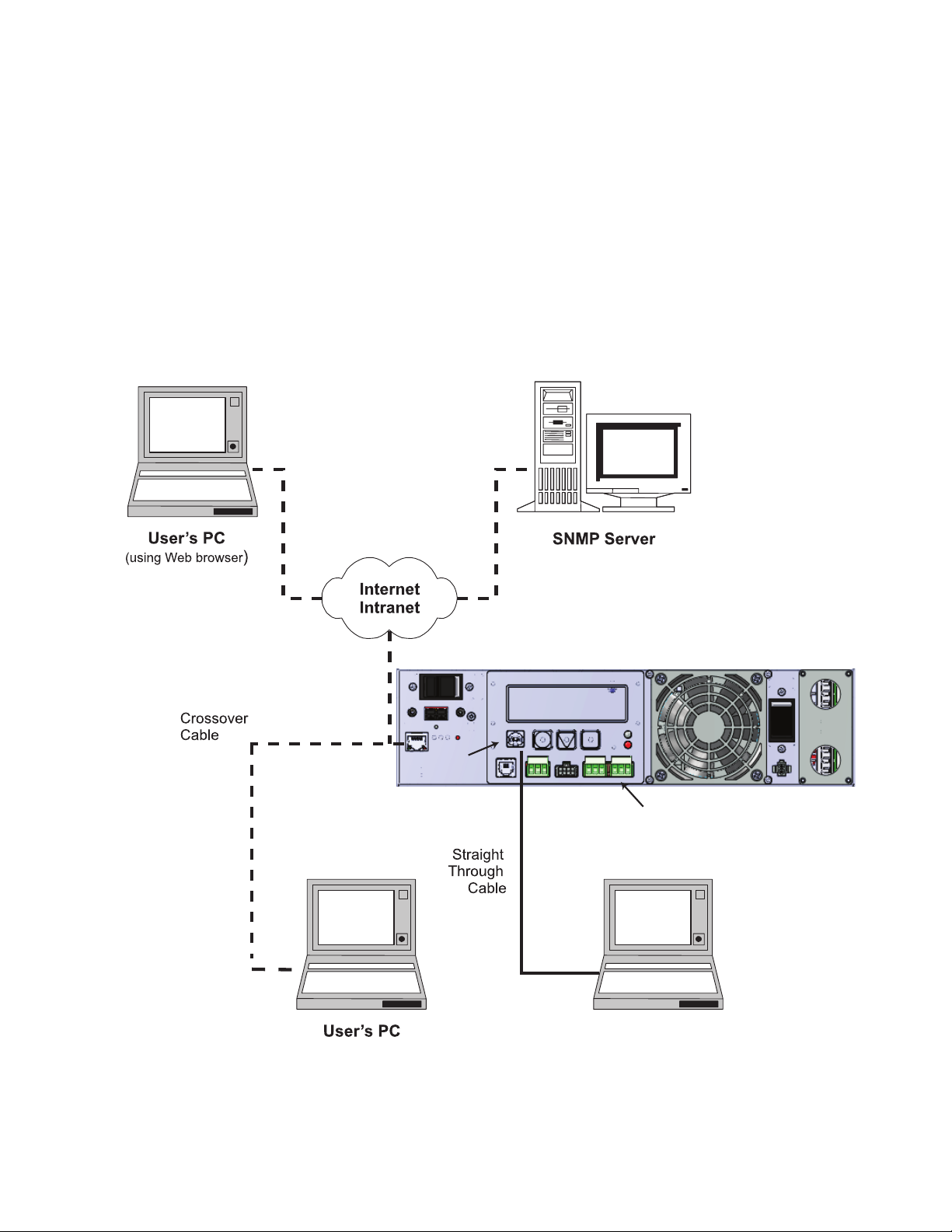

Figure 12 — Alpha FXM Communication Options .................................................................... 22

Figure 13 — Mounting to a wooden pole .................................................................................. 25

Figure 14 — Securing the enclosure to the mounting bracket .................................................. 25

017-241-B0 Rev B

3

Page 6

Figure 15 — Attaching the mounting bracket to the wall studs ................................................. 27

Figure 16 — AC Power distribution terminal blocks .................................................................. 28

Figure 18 — Terminal block wiring ............................................................................................ 29

Figure 17 — Wiring the Micro350 ............................................................................................. 29

Figure 19 — Ferrite ring installed on RJ45 network cable ........................................................ 30

Figure 20 — FXM350 with rack-mount ears and signal assembly option (wiring box not shown)

........................................................................................................................................ 31

Figure 21 — FXM350 Electrical Connections ........................................................................... 32

Figure 22 — External Battery Wiring (for 48 VDC string (top) and 24 VDC string) ................... 33

Figure 23 — Securing the batteries with the optional restraining bar ....................................... 34

Figure 24 — FXM 350 block diagram ....................................................................................... 36

Figure 25 — Battery charging in line mode ............................................................................... 38

Figure 26 — Back up power from batteries ............................................................................... 38

Figure 27 — LCD Control Panel Logo Screen .......................................................................... 42

Figure 28 — LCD Menu Tree .................................................................................................... 44

Figure 29 — Web GUI (UPS Specication Screen shown) ....................................................... 49

Figure 30 — Alpha UPS Monitor: UPS Communications screen .............................................. 50

Figure 31 — Web GUI: UPS Specication screen .................................................................... 51

Figure 32 — Web GUI: Input & Output screen .......................................................................... 52

Figure 33 — Web GUI: Battery & Inverter screen ..................................................................... 52

Figure 35 — Web GUI: User Input Status screen ..................................................................... 53

Figure 34 — Web GUI: Relay & Load Shed screen .................................................................. 53

Figure 36 — UPS Maintenance: Unit Conguration screen ...................................................... 54

Figure 37 — Restore all default commands .............................................................................. 54

Figure 38 — UPS Maintenance: Battery screen ....................................................................... 56

Figure 39 — UPS Maintenance: Inverter screen ...................................................................... 57

Figure 40 — UPS Maintenance: Relay & Load Shed screen.................................................... 58

Figure 41 — Programmable Timer Operation ........................................................................... 59

Figure 42 — Time Of Day Action Operation .............................................................................. 59

Figure 43 — Time Of Day Conguration ................................................................................... 60

Figure 44 — Time Of Day Action Status ................................................................................... 60

Figure 45 — Assigning the Temperature trigger function to a dry contact – Alpha UPS Monitor

4

017-241-B0 Rev B

Page 7

........................................................................................................................................ 61

Figure 46 — Setting the Temperature trigger value .................................................................. 61

Figure 47 — UPS Maintenance: Time & Date screen ............................................................... 62

Figure 48 — UPS Maintenance: Password screen ................................................................... 62

Figure 49 — User Input Conguration: Setting the Trigger Type .............................................. 63

Figure 50 — User Input Conguration: Setting the Logic Level ................................................ 63

Figure 51 — User Input Conguration: Setting an Action ......................................................... 64

Figure 52 — User Input Current Status ..................................................................................... 64

Figure 53 — User Input Current Status ..................................................................................... 64

Figure 54 — Alarms & Faults screen ........................................................................................ 65

Figure 55 — Event History screen ............................................................................................ 65

Figure 56 — Event Log Monitor screen .................................................................................... 66

Figure 57 — Event Log Monitor, Open Event File window........................................................ 67

Figure 58 — Alpha UPS Monitor: Upgrade Firmware ............................................................... 67

Figure 59 — Upgrade Communication Module ......................................................................... 68

Figure 60 — Alpha UPS Monitor: Congure Site Information ................................................... 68

Figure 61 — Congure SNMP screen ....................................................................................... 69

Figure 62 — Email Notication screen ...................................................................................... 69

Figure 63 — Test email feature ................................................................................................. 70

Figure 64 — Alpha UPS Monitor (UPS Specication Screen shown) ....................................... 73

Figure 65 — Add or Remove Programs Window ...................................................................... 74

Figure 66 — HyperTerminal communication parameters ......................................................... 76

Figure 67 — Main Menu Screen ............................................................................................... 77

Figure 68 — Menu Tree ............................................................................................................ 78

Figure 69 — Temperature trigger function via HyperTerminal ................................................... 84

Figure 70 — Typical Discharge Characteristics for Lead Acid Batteries ................................... 92

Figure 71 — Battery string example ........................................................................................ 104

Figure 72 — Edge Trigger ....................................................................................................... 106

Figure 73 — Level Trigger ....................................................................................................... 106

Figure 74 — Level Alternative ................................................................................................ 107

017-241-B0 Rev B

5

Page 8

List of Tables

Table A — UPS Operating Modes ......................................................................................................... 43

Table B — Control Menu ....................................................................................................................... 45

Table C — System Status Menu ........................................................................................................... 47

Table D — List of Parameters ............................................................................................................... 55

Table E — Line Status (see Figure 67) ................................................................................................. 79

Table F — Output Status (see Figure 67) ............................................................................................. 79

Table G — Faults (see Figure 67) ......................................................................................................... 80

Table H — Alarms (see Figure 67) ........................................................................................................ 80

Table I — Maintenance Submenu ......................................................................................................... 81

Table J — Dry Contact Conguration Settings...................................................................................... 82

Table K — Setting the Timer Contact .................................................................................................... 83

Table L — Setting the Date and Time ................................................................................................... 85

Table M — Event Codes ....................................................................................................................... 87

Table N — Battery Temperature Compensation Values ........................................................................ 93

Table O — Alarm Submenu .................................................................................................................. 96

Table P — Fault Submenu .................................................................................................................... 97

Table Q — Problems Not Reported by System..................................................................................... 97

Table R — Mechanical Specications ................................................................................................... 98

Table S — Electrical Specications....................................................................................................... 99

Table T — Boost/Buck/Line Transfer Thresholds ................................................................................ 100

Table U — Regulatory ......................................................................................................................... 100

6

017-241-B0 Rev B

Page 9

1. Safety

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions

that must be followed during the installation, servicing, and maintenance of the product. Keep it in a safe

place. Review the drawings and illustrations contained in this manual before proceeding. If there are any

questions regarding the safe installation or operation of this product, contact Alpha Technologies or the nearest Alpha representative. Save this document for future reference.

1.1 Safety Symbols

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and attention.

The use of ATTENTION indicates specic regulatory/code requirements that may affect the

placement of equipment and /or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure.

Notes are designated with a checkmark, the word NOTE, and a rule beneath which the

information appears.

CAUTION!

CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment. Cautions are designated with a yellow warning triangle, the word CAUTION,

and a rule beneath which the information appears.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to personnel.

Warnings are indicated by a shock hazard icon, the word WARNING, and a rule beneath

which the information appears.

HOT!

The use of HOT presents safety information to PREVENT BURNS to the technician or

user.

017-241-B0 Rev B

7

Page 10

1.2 General Warnings

You must read and understand the following warnings before installing the product. Failure to do so could

result in personal injury or death.

• Read and follow all instructions included in this manual.

• Only qualified personnel are allowed to install, operate and service this system and its components.

CAUTION!

Risk of Electric Shock. See Installation Instruction before connecting to the supply.

• The FXM350/ Micro350 is only intended for restricted access locations

• The UPS shall be connected only to a dedicated branch circuit.

CAUTION!

To reduce the risk of re, connect only to a maximum branch circuit overcurrent protection in accordance with the National Electrical Code, ANSI/NFPA 70.

• Always assume electrical connections or conductors are live. Switch all circuit breakers and double

check connections with a voltmeter before performing installation or maintenance.

• A disconnect switch shall be provided by others for the AC input and AC output circuits.

• The branch circuit overcurrent protection for the AC input and AC output circuit shall be provided in the

end installation.

• Place warning label(s) on the utility panel to tell emergency personnel that a UPS is installed.

• Use only proper lifting techniques whenever handling equipment, parts, or batteries.

• Ferules or the equivalent must be used when stranded wire is used on the AC input and output terminal

blocks.

WARNING!

The Alpha FXM350/ Micro350 have more than one live input circuit. AC power may be

present at the outputs even if the system is disconnected from line or battery power.

CAUTION!

The Alpha FXM350/ Micro350 metal surfaces can be very hot to the touch.

1.3 Battery Safety

• Battery Installation and servicing should be performed or supervised by personnel knowledgeable about

batteries and the required precautions performed.

• Be extra cautious when connecting or adjusting battery cabling. An improperly connected battery cable

or an unconnected battery cable can result in arching, fire or explosion.

• Before attaching the batteries to the Alpha FXM350/ Micro350, make sure that the polarity is correct.

• Use new batteries when installing a new unit. Verify that all batteries are the same type with identical

date codes.

• When replacing batteries, use sealed lead acid batteries, rated 12 V. Never install old or untested batteries.

• Batteries that show signs of cracking, leaking or swelling must be replaced immediately by authorized

personnel using a battery of identical type and rating.

8

017-241-B0 Rev B

Page 11

CAUTION!

Never open, damage or mutilate batteries. Released Electrolyte is harmful to the skin

and eyes. It may be toxic and hazardous to the environment.

• Never dispose of batteries in a fire. The batteries may explode. Follow the manufacturer’s directions and

check with your local jurisdictions for safe battery disposal.

• If electrolyte splashes on your skin, immediately wash the affected area with water. If electrolyte gets into

your eyes, wash them for at least 10 minutes with clean running water or special neutralizing eye wash

solution. Seek medical attention at once.

• Neutralize spilled electrolyte with special neutralizing solution and a “spill kit” or solution of 1 lbs

(0.45KG) of baking soda (bicarbonate of soda) in 1 gallon (3.8 L) of water.

CAUTION!

A battery can present a risk of electrical shock and high short-circuit current. The following precautions should be observed when working on batteries:

a. Remove watches, rings, or other metal objects.

b. Use tools with insulated handles.

c. Wear rubber gloves and boots.

d. Do not lay tools or metal parts on top of batteries.

e. Disconnect the charging source before connecting or disconnecting battery terminals.

f. Determine if the battery is inadvertently grounded. If inadvertently grounded, remove the source from

the ground. Contact with any part of a grounded battery can result in electrical shock. The likelihood

of such shock can be reduced if the grounds are removed during installation and maintenance

(applicable to equipment and remote battery supplies not having a grounded supply circuit).Never

let live battery wires touch the Alpha FXM350/ Micro350, the enclosure or any other metal objects.

This can cause a fire or explosion.

• Do not smoke or introduce sparks in the vicinity of a battery.

• If the batteries have been in storage for more than 3 months, recharge them for at least 24 hours and

then test them with a load before installation.

• Each AlphaCellTM battery has a date code found on the warning label which must be recorded in the

maintenance log. If non-Alpha batteries are used, see the manufacturer’s documentation for date code

type and placement.

1.4 Work Environment Safety

• Do not work alone under hazardous conditions.

• Keep the chassis area clear and dust-free during and after the installation.

• Keep tools away from walk areas where you or others could fall over them.

• Wear safety glasses when working under any conditions that might be hazardous to your eyes.

• Do not work on the unit or connect or disconnect cables during periods of lightning activity.

017-241-B0 Rev B

9

Page 12

1.5 Certifications and Compliances

The Alpha FXM350 and Micro350, has been designed, manufactured, and tested to the requirements of the

following national and international safety standards:

• CAN/CSA-C22.2 No. 107.3-05 – Uninterruptible Power Systems; additional requirements (RD): CAN/

CSA-C22.2 No. 60950-1-03 - Information Technology Equipment - Safety.

• UL 1778 (Edition 4) – Uninterruptible Power Systems; additional requirements (RD): UL 60950-1 (Edition

1) - Information Technology Equipment - Safety.

• FCC CFR47 Part 15 Class A – This equipment has been tested and found to comply with the limits for a

Class A digital device pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

• Industry Canada - This Class A digital device apparatus complies with Canadian ICES-003.

• Industry Canada - Cet appareil numrique de la Classe A est conformé la norme NMB-003 du Canada.

10

017-241-B0 Rev B

Page 13

2. General Description

2.1 Alpha FXM350

The Alpha FXM350 is available in 24Vdc and 48Vdc models. It provides up to 350W of regulated AC Power

to the load, when utility power is available, and provides back up power from the batteries in case of a utility

power failure. Noteworthy features include:

• Local or remote monitoring and control via USB and SNMP communication

• Small footprint for wall, rack or enclosure mounting

• Dependable operation in extreme operating environments (-40 to 74°C or -40 to 165°F)

• Powerful firmware with enhanced features such as battery run-time information

2.2 Micro350/ Alpha FXM350

The Micro350 contains a standard FXM350 along with batteries—Figure 1 shows three options for the enclosure. These enclosures are designed with a NEMA 3R rating for outdoor applications.

Figure 2 shows the FXM350 installed in a standard-sized Micro350 cabinet. Power is distributed through

terminal blocks mounted on a DIN rail.

(a)Standard Micro350

(1 battery tray)

017-241-B0 Rev B

(b) Micro350 XL

(2 battery trays)

Figure 1 — Micro350 cabinets

(c) Micro350 XL3

(4 battery trays)

11

Page 14

In addition to the FXM350 standard features, the unit also includes the following:

• Three additional user-configurable dry contacts and two additional user inputs (top panel in Figure 2)

• Door sensor switch for increased security

• AC Input and outputs on an easy to install terminal block

• Flexible dual AC and DC output for multiple loads up to 350W with distribution

AC input Battery bus voltage AC output (dual)

120Vac 48V or 24V 120/24Vac

230Vac 24V 230/24Vac

Micro350 top panel

FXM350 front panel

AC power distribution

terminal blocks

Wire management

panel

Attachment holes for

mounting bracket

Ground stud

Knockouts for wiring

12

Figure 2 — FXM350 mounted in a standard Micro350 cabinet

017-241-B0 Rev B

Page 15

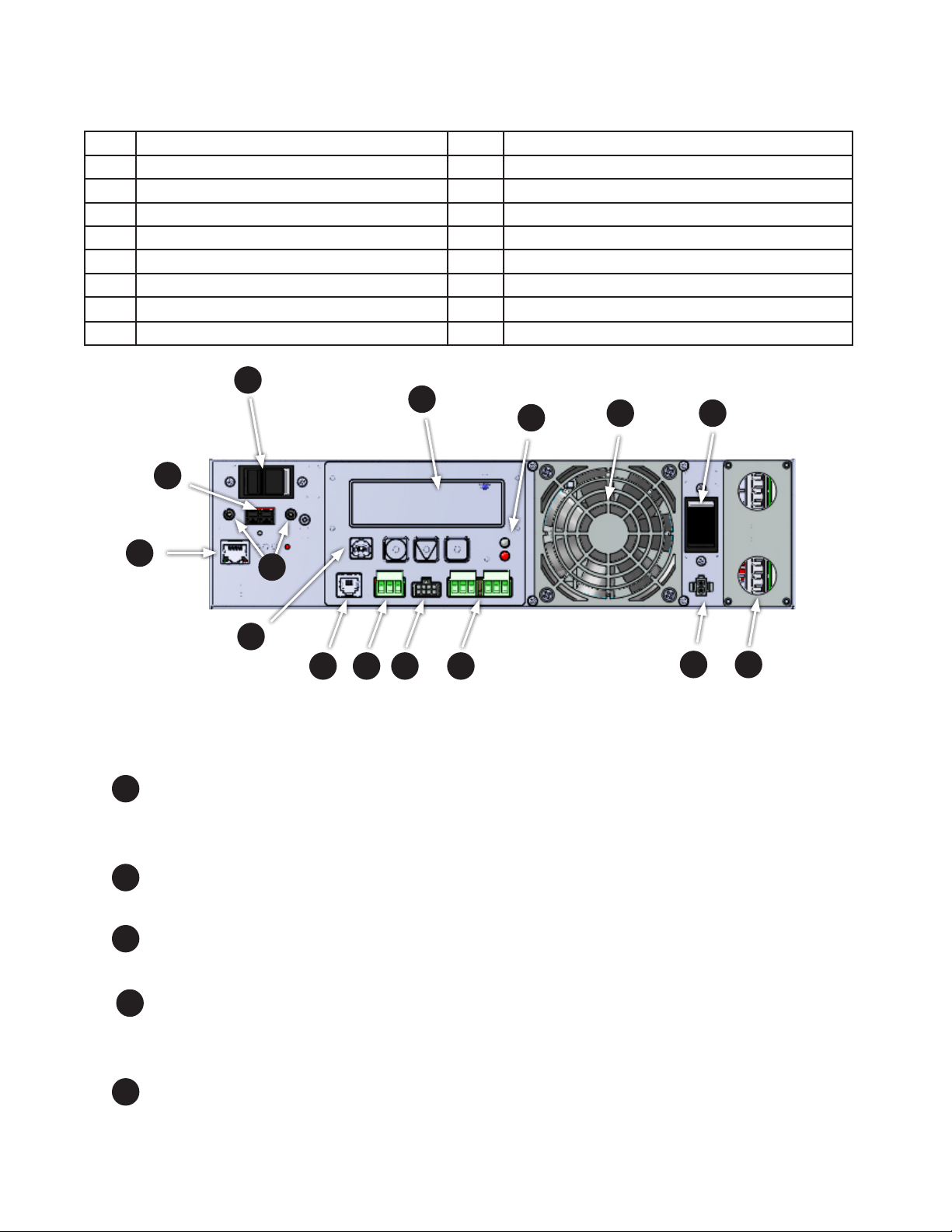

2.3 FXM350 Front Panel

The following table and Figure 3 identify the main features of the FXM350 which are described in detail in the

following pages.

Item Description Item Description

1 Battery breaker 8 Optically isolated user inputs

2 Battery connector 9 Additional user inputs and dry contacts connector

3 RJ45 communication module connector 10 Status and alarm LEDs

4 LCD control panel and menu navigation buttons 11 Configurable dry contacts, C1 and C2

5 USB communication connector 12 Replaceable fan assembly

6 Battery temperature sensor connector 13 AC input circuit breaker

7 Battery voltage test points 14 Battery heater mat connector

15 AC input/output connections

1

4

10

12

2

13

3

7

5

6

1

Battery breaker

This circuit breaker provides over-current protection and is used as an on/off switch for the battery power. It

must be switched on for proper Alpha FXM operation.

Battery connector

2

The battery connector connects the external batteries to the Alpha FXM.

RJ45 communication module connector

3

This RJ-45 connector is the Alpha FXM Ethernet connector.

9

8

Figure 3 — FXM 350 front panel description

11

14

15

4 LCD control panel a nd menu navigation buttons

The LCD control panel together with the cancel, scroll and select buttons are used to monitor and control the

Alpha FXM350.

USB communication connector

5

This USB communication connector provides a direct connection to the USB port of a standard computer

USB port (USB 2) for remote monitoring.

017-241-B0 Rev B

13

Page 16

Battery temperature sensor connecto r

6

The battery charging voltage is temperature dependant. A battery temperature sensor connects to the Alpha

FXM so that the Alpha FXM microprocessor can adjust the charging voltage for optimum charging.

The sensor MUST be attached to the Alpha FXM for normal operation. If the sensor is not attached, a “Temperature Probe Unplugged” alarm appears on the LCD.

7

Battery voltage test points

These test points let you measure the battery voltage. They accept 2 mm diameter test probe tips. The battery circuit breaker must be on to measure the voltage.

The battery voltage test points are not to be used as a power outlet.

8

Optically isolat ed user inputs

These optically isolated inputs are used to attach an external switch panel for remote control of the

Alpha FXM.

The User Input connector has three contacts (Figure 4) that are used to control the Alpha FXM. The default

settings for the user inputs are as follows:

1 (S1): Shorting this contact to Common starts the Alpha FXM battery test. See "Battery Test" on page 95.

2 (S2): Shorting this contact to Common activates an alarm. See "7.3.4.9 Maintenance > User Input" on

page 63.

3 (SC): Isolated return for contacts S1, and S2.

1 2 3

SC:CommonS1:Self Test S2:Alarm

Figure 4 — User input layout

9

Additional user inputs and dry contacts connector

Enables connection to 3 dry contacts and 2 user inputs on the Micro350 top panel or to optional rack mounting ears (see Figure 20).

10

Status and Alarm LEDs

Status:

Green LED solidly illuminated: the Alpha FXM is in Line mode and line power is provided to the load.

Green LED flashing: the unit is in Inverter mode and backup battery power is provided to the load.

Alarm:

Red LED solidly illuminated: fault in the Alpha FXM. (See "Table P — Fault Submenu" on page 97.)

Red LED flashing indicates an alarm. ( See "Table O — Alarm Submenu" on page 96.)

14

017-241-B0 Rev B

Page 17

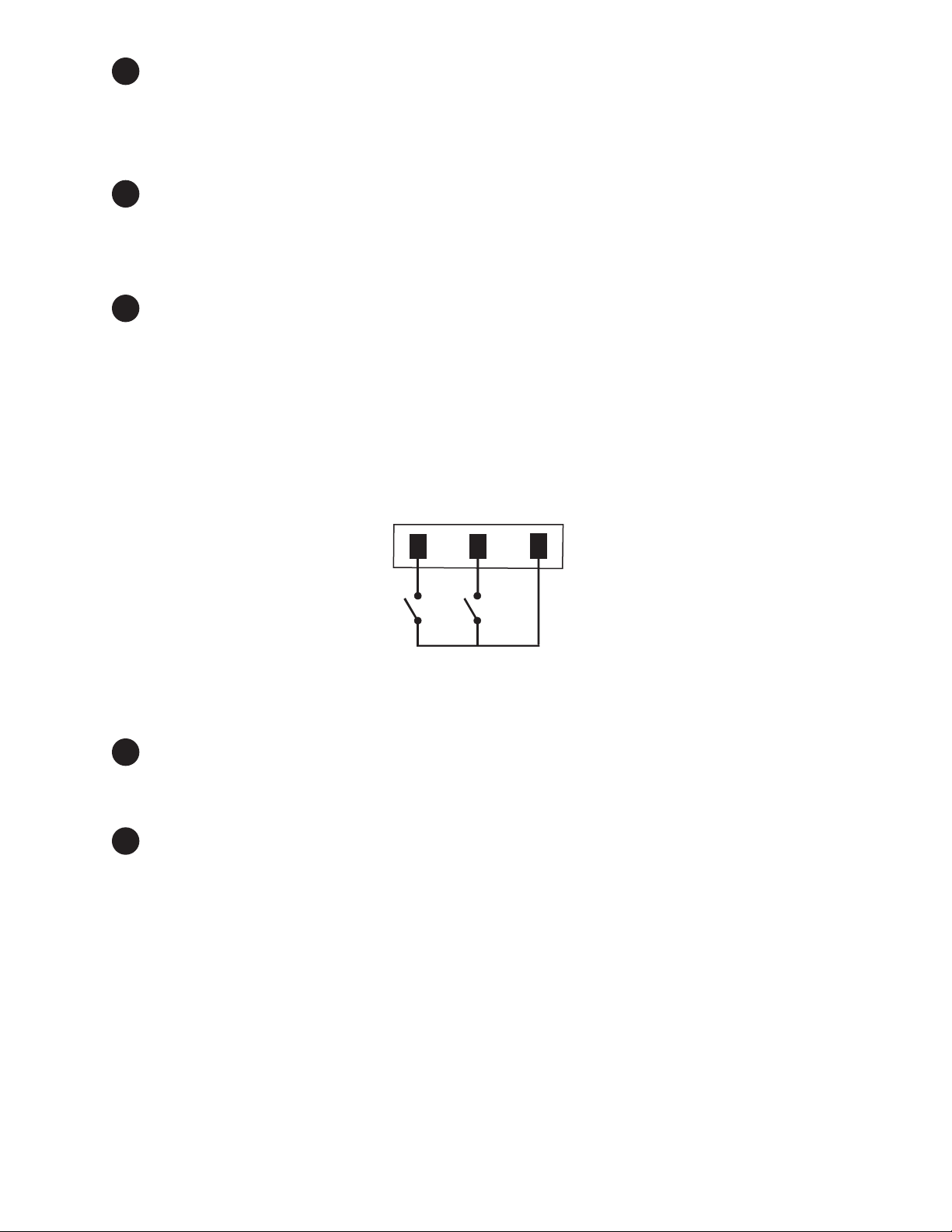

11

Configurabl e dry contacts, C1 and C2

Contacts C1 and C2 allow the Alpha FXM to be connected to an external monitoring panel or to traffic control

equipment.

The factory default settings can be reprogrammed to meet your requirements. See "7.3.3.3 Monitoring > Relay & Load Shed" on page 53 for web and Alpha UPS Monitor, and "7.5.4 Programming the Dry Contacts" on

page 82 for HyperTerminal.

C1: The C1 contact is energized when line power is unqualified and the Alpha FXM provides backup battery

power to the load(s). Can be used to generate an “On Battery” alarm.

C2 : This contact is energized when the battery drops below a pre-set voltage level. Can be used to generate

a “Low Battery” alarm. You can change the pre-programmed level to match the batteries used and the actual

operating conditions. See "Adjusting and Controlling the Alpha FXM" on page 81: #35 Low Battery Warning

Voltage.

Microprocessor

UPS

The contacts have

a maximum rating

of 1A at 250V.

Interior

Normally

Closed (NC)

Replaceable fan assembly

12

Normally

Open (NO)

Common (C)

Figure 5 — Contact Layout (Standard for C1 and C2)

This microprocessor-controlled fan regulates the Alpha FXM internal temperature for optimum performance.

Microprocessor-control of the fan speed increases the life of the internal electronics and the fan.

Take care that the fan is not blocked. Failure of the fan generates an alarm; the internal fan assembly is designed so it can be replaced if it fails.

13

AC input circuit breaker

This circuit breaker is an on/off switch for the line power into the Alpha FXM ,which also provides input protection. It must be switched on for proper Alpha FXM operation.

14

Battery heater mat connector

This connector plugs into a 55W heater mat (optional). The Alpha FXM senses the battery temperature

through the battery temperature sensor (explained in 6 above) and controls the battery heater mat. The

heater mat is set to turn on at 5°C or less and turns off at 15°C.

15

AC input/output conn ections

The terminal blocks provide connections to the AC input and loads for dual outputs.

017-241-B0 Rev B

15

Page 18

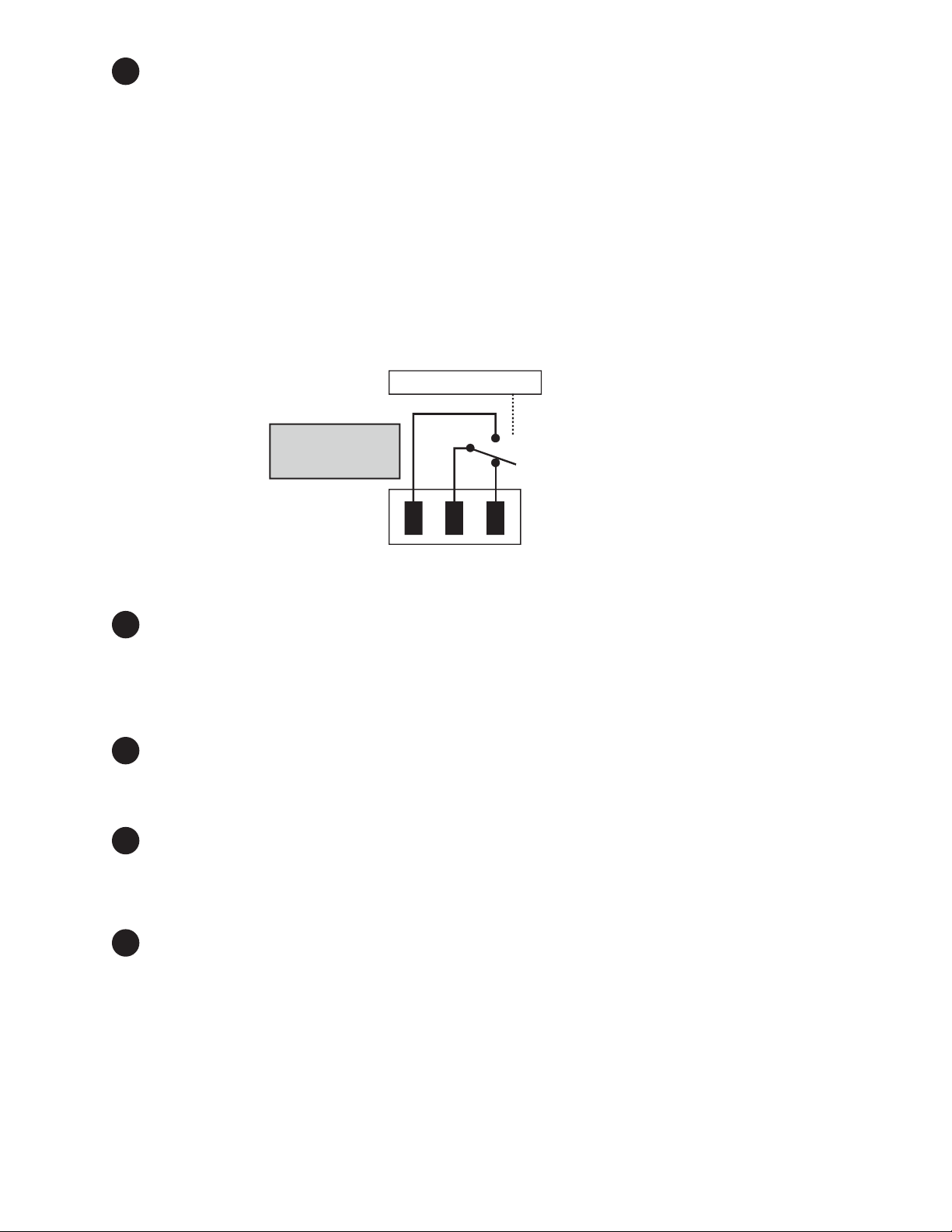

2.4 Micro350 Top Panel

The Micro350 top panel has three additional dry contacts and two user inputs.

The panel also has a door interlock and auxiliary contacts, which can be wired to a user input to generate an

alarm when the door is open.

Dry contacts

C3, C4, and C5

Additional signals connector.

Connects to #9 of gure 3

User inputs

S3 and S4

Door interlock

Open door

switch signal

Figure 6 — Micro350 Top Panel

16

017-241-B0 Rev B

Page 19

3. Site Planning

WARNING!

Restricted Access: The Alpha FXM350 and Micro350 must be installed in a restricted

area accessible only by qualied service personnel.

The Alpha FXM350 and Micro350 are intended for permanent AC connection only.

The Alpha FXM350 and Micro350 must be correctly grounded for proper operation.

Older facilities may have inadequate electrical grounding. Inspection must be performed

by a qualied electrician before installation to ensure that grounding meets the local

electrical code.

The utility line attached to the Alpha FXM input MUST be protected by a circuit breaker

certied for this use in accordance with the local electrical code. The UPS must be connected only to a dedicated branch circuit.

The UPS equipment that is powered by this service panel requires the neutral to be permanently bonded to the ground. Always disconnect the batteries before servicing the

circuit breaker panel.

The input and output lines to and from the Alpha FXM MUST have disconnect devices

attached.

The Alpha FXM is suitable for installations in network telecommunication facilities and locations where the

National Electrical Code applies.

Grounding: The Alpha FXM is suitable both for installation as part of a common bonding network (CBN) and

an isolated bonding network.

For installations above 1400 m (4500 ft) elevation, additional cooling may be needed to reduce the operating temperature of the Alpha FXM. The maximum allowable operating temperature must be reduced by 2°C

(3.5 °F) for every 300 m (1000 ft) above 1400 m (4500 ft).

3.1 Safety Precautions

• Install the Alpha FXM350 and Micro350 and batteries on a surface that can support the total weight. See

Chapter "10. Specifications" on page 98.

• The input wiring must reach a suitably grounded power outlet and the load wiring must reach the

Alpha FXM350 and Micro350 output terminal blocks.

• Place the Alpha FXM350 in a properly sheltered location or inside a weather-proof enclosure to protect

the electronics from water, dust and other possible contamination.

• Backup Generator (If used)

In Generator mode, the Alpha FXM range of acceptable input frequency and voltage is expanded to

accept the fluctuations created by a generator. See "7.2.2 The LCD Control Menu" on page 45, Table B,

Sense Type.

Use a generator with electronic speed and voltage controls which produces less than 10% voltage total

harmonic distortion (THD). Mechanical governors can force the Alpha FXM to run continuously in Battery

mode. Before installation, make sure the generator’s output voltage is compatible with the Alpha FXM

input voltage requirements. To make sure the system runs smoothly, use a generator that supplies twice

as much power as drawn by the total load.

017-241-B0 Rev B

17

Page 20

3.2 Electromagnetic Compatibility (EMC) Requirements

Micro XL Micro XL3

Micro XL3

Observe the following EMC requirements when setting up the Alpha FXM and its internal equipment:

• All AC mains and external supply conductors must be enclosed in a metal conduit or raceway when

specified by local, national, and/or other applicable government codes and regulations.

• The customer facilities must provide suitable surge protection.

• To meet FCC Class B requirements, follow the instructions in section 5.1.4 to attach a ferrite ring to the

connector end of your RJ45 network cable.

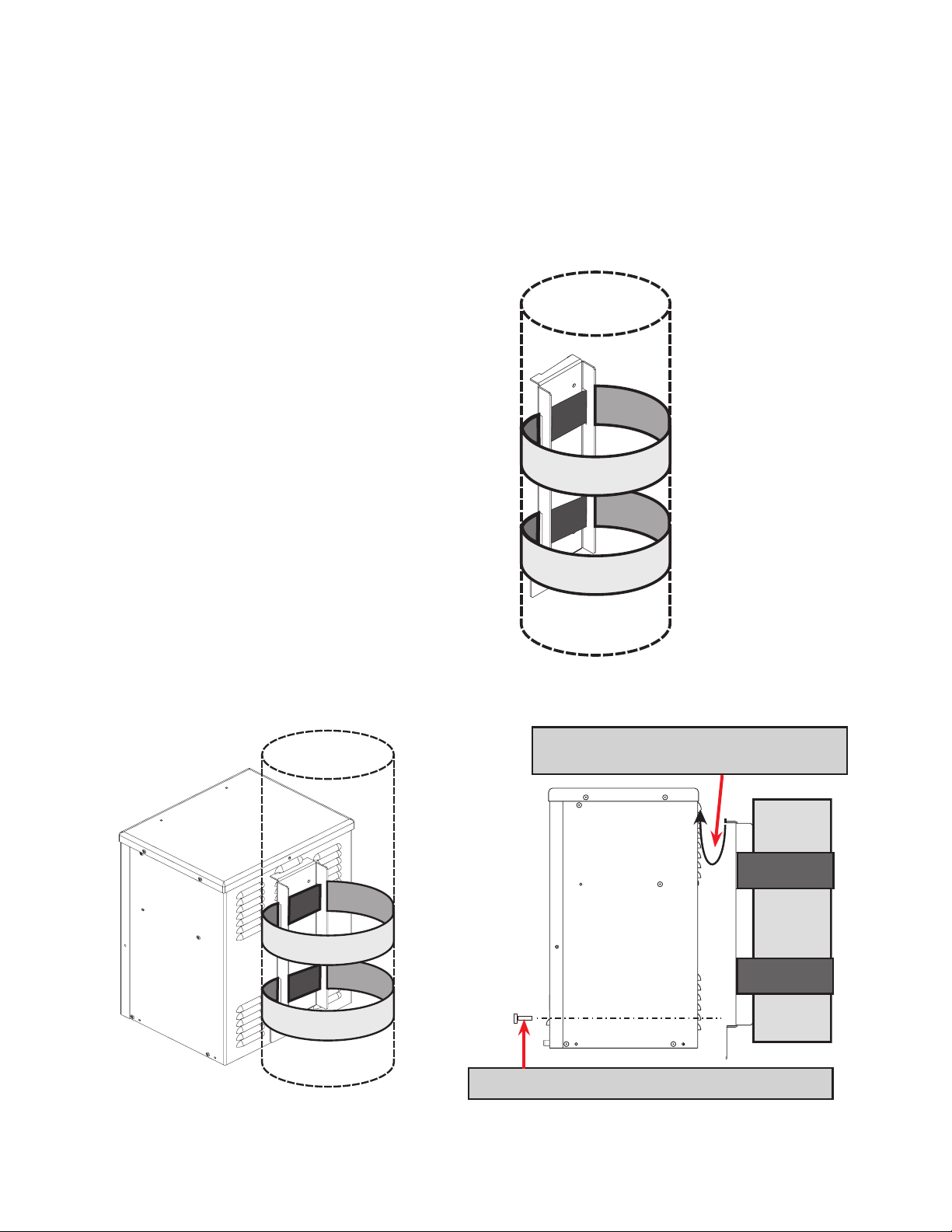

3.3 Mounting Options for the Micro350 (XL and XL3)

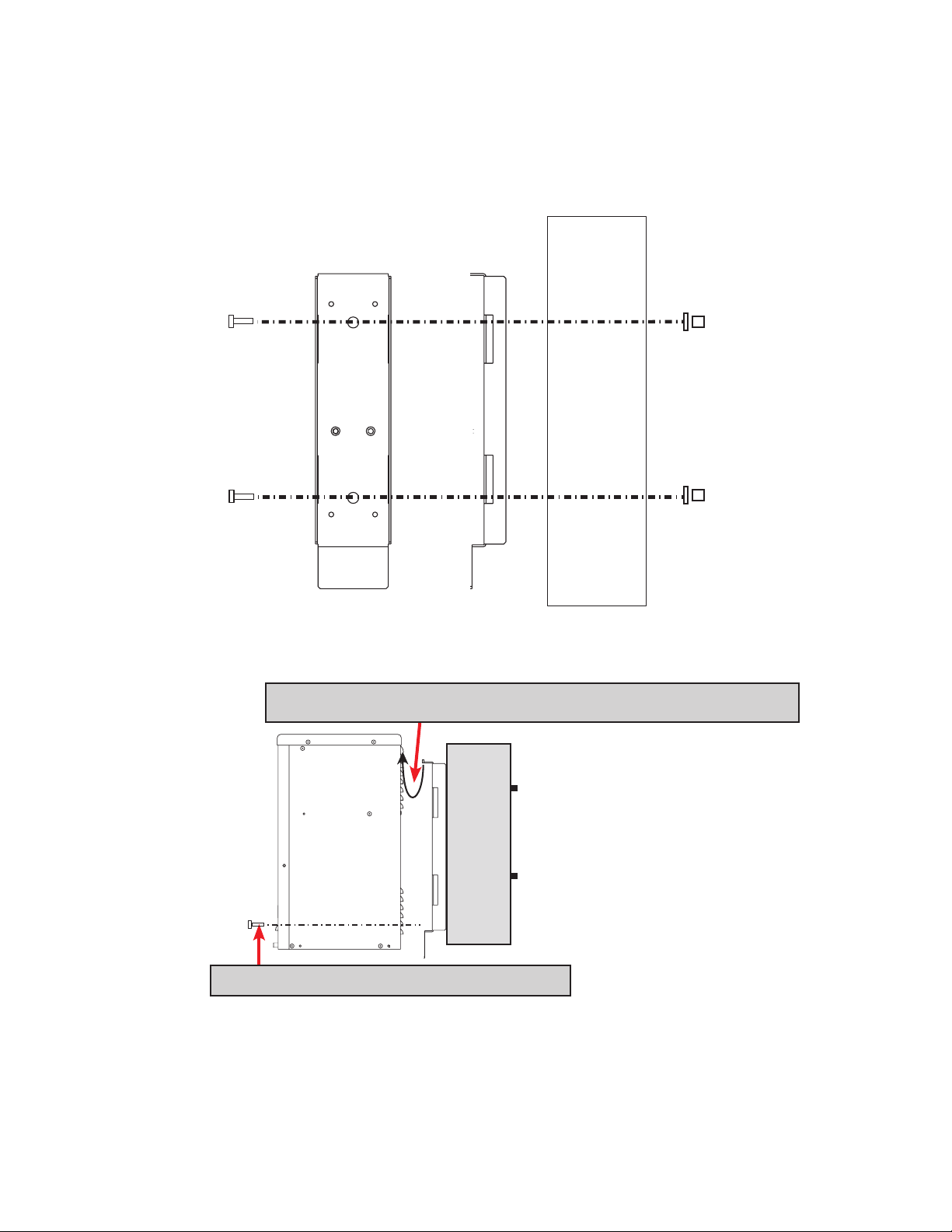

Figure 7 shows the mounting hardware for the various configurations of the Micro350.

Choose from the following options for mounting the Micro350:

• Mounting to a wooden pole, 5.1.1.1 on page 24.

• Mounting to a steel or concrete pole, 5.1.1.3 on page 26.

• Mounting to a wall, 5.1.1.4 on page 27.

Optional pedestal mounting is shown in Figure 8.

18

Micro Standard

Micro XL3

NOTE: To install a Micro XL3 enclosure, rst attach

the XL to an XL3 kit.

Micro XL

Figure 7 — Mounting the Micro350

017-241-B0 Rev B

Page 21

Figure 8 — Mounting on optional pedestal

3.3.1 Battery Heater Mats

The FXM350 and Micro350 allow connection, on its front panel, of a battery heater mat without a thermostat

(#14 in Figure 3). Maximum power of the battery heater mat for use with the FXM350 connector is 55W. The

FXM turns the heater mat on when the temperature measured by the battery temperature sensor senses a

temperature < 5°C. It turns the heater mat off when the temperature raises to >15°C. For the Micro350XL or

bigger systems needing more than one heater mat, it is recommended to use the heater mats with built in

thermostat and daughter heater mats that can be daisy chained. These heater mats may be wired to the AC

in the terminal block on the distribution panel. Ensure that the input breaker is appropriately rated.

017-241-B0 Rev B

19

Page 22

3.3.2 Mounting options for the FXM350

Figure 9 and Figure 11 provide dimensions for mounting the FXM350 UPS as a standalone device.

198

[7.8]

13.7

[0.5]

[3.5]

88

Figure 9 — FXM350 Mounting Dimensions

3.3.2.1 Standalone Configurations:

• Wall mounted, with front access, onto a 19"

mounting tray that includes a battery cabinet

• Rack mounted in a 19" or 23" rack with add-on

ears and a wiring box (Figure 10). An optional

signals assembly can be ordered, which provides two user inputs and three dry contacts.

342

[13.5]

Standard

ears and

wiring box

Optional signals

assembly

20

Figure 10 — Rack-mount options

017-241-B0 Rev B

Page 23

43.7 1.72

46.0 1.81

9.53[0.375]

X

OBROUND THRU

6.35[0.250]

TYP.

566.7 22.31

584.1 23.00

& OPTIONAL EXTERNAL DRY CONTACTS MODULE

FXM 350 w/RACK MOUNT KIT CONFIGURED FOR A 19" RACK

88.1 3.47 76.2 3.00

& OPTIONAL EXTERNAL DRY CONTACTS MODULE

FXM 350 w/RACK MOUNT KIT CONFIGURED FOR A 23" RACK

465.1 18.31

482.5 19.00

Figure 11 — FXM350 with ears for rack mounting

017-241-B0 Rev B

21

Page 24

3.4 Options for Communicating with the FXM

There are several ways to communicate with the Alpha FXM UPS:

1. The control panel page 42).

2. Window®’s HyperTerminal or other terminal emulation program to access the UPS command line system

over the USB interface (page 76).

3. Alpha UPS Monitor installed on your computer and connected to the FXM over the USB interface . The

Alpha UPS Monitor software can be downloaded from www.alpha.ca./downloads/.

4. Factory-installed FXM communication module to communicate with the Alpha FXM using any of the

following:

• On site PC

• Company intranet or the internet using a web browser (page 49).

• SNMP communications

Option 4

Option 5

On-Site

Ethernet Connection

Ethernet

Port

USB Port

Option 4

(Use a Web browser for

Ethernet connection

to on-site computer)

FXM350 UPS

Option 1:

Control Panel

Options

2 and 3

User’s PC

(Use Alpha UPS Monitor

or HyperTerminal)

22

Figure 12 — Alpha FXM Communication Options

017-241-B0 Rev B

Page 25

4. Unpacking the Equipment

4.1 Alpha FXM350/Micro350 Configuration

The Alpha FXM is factory installed inside the Micro350 prior to shipping.

WARNING!

The Alpha FXM350/Micro350 combination is heavy, up to 12 kg (26 lb). Use proper lifting

techniques.

4.2 Unpacking

1. Select a suitable area for unpacking.

2. Store all the packing material and boxes for possible equipment returns.

4.2.1 FXM350 Standalone or Micro350 (XL)

1. Check the contents in your product package. The following standard items are shipped together in a

plastic bag:

• Terminal blocks and labels for the dry contacts

• Temperature sensor cable

• Battery clip with screws

• AC plate with screws and bushing

• Ferrite ring

• Cable tie

• Operator’s manual

• USB cable

2. Compare the packing slip and the list of parts with the items you received. If the list of parts on your

packing slip does not match the items you received, or any items appear damaged, immediately notify

your carrier agent and the supplier who prepared your shipment.

4.3 Optional Items

Optional items may include:

• Battery heating mats

• Battery cable kit

• Rack mount ears and wiring box kit for mounting in a 19" or 23" rack (Figure 10)

• Optional signals assembly for FXM350 (Figure 20)

• Distribution panel

Batteries, if ordered from Alpha, will ship separately.

017-241-B0 Rev B

23

Page 26

5. Installation

WARNING!

To avoid personal injury or damage to the equipment, always use at least two installation personnel to remove the unit from its container.

5.1 Installation of the Micro350

WARNING!

Batteries or other components (with the exception of factory-installed components)

must not be installed until the Micro350 cabinet has been securely set in place at its permanent location. Transporting the unit with batteries installed may cause a short circuit,

re, explosion, and/or damage to the battery pack, enclosure and installed equipment.

Damage caused by improper shipping or transporting a unit with batteries installed is

not covered by the warranty.

5.1.1 M ounting the Micro350 Enclosure

5.1.1.1 Mounting to a wooden pole

Have the following tools and materials on hand:

• 13 mm nut driver for the bolts that attach the cabinet to the mounting bracket.

• Two 5/8 inch diameter machine bolts (UNC tread); SAE (Grade 5 or better), length to suit the pole (not

provided).

• Two 5/8 inch diameter zinc-plated flat washers.

• Two 5/8 inch diameter hex nuts (UNC thread).

• Auger or drill for boring 3/4 inch diameter holes in the wood pole.

24

017-241-B0 Rev B

Page 27

5.1.1.2 Procedure:

1. Using the mounting bracket as a template, drill 2 holes into the pole to accept the machine bolts.

2. Secure the mounting bracket to the pole with the machine bolts as shown in Figure 13.

3. Secure the Micro350 cabinet to the mounting bracket with the supplied bolts (Figure 14).

Front Side Wood

Pole

Figure 13 — Mounting to a wooden pole

a. Hook the top of the mounting bracket under the case’s attachment tting.

b. Secure the cabinet to the mounting bracket.

Figure 14 — Securing the enclosure to the mounting bracket

017-241-B0 Rev B

25

Page 28

5.1.1.3 Mounting to a Steel or Concrete Pole

Have the following tools and materials on hand:

• 13 mm nut driver for the bolts that attach the cabinet to the mounting bracket.

• Two pole mount straps that fit the pole. Straps must be stainless or galvanized.

• C001 Band-It tool or equivalent.

• C206 3/4 inch stainless steel Band-It band or equivalent.

• C256 3/4 inch stainless steel Band-It buckles or equivalent.

Procedure:

1. Secure the mounting bracket to the pole with

the straps.

Steel or Concrete

Pole

2. Secure the Micro350 cabinet to the mounting bracket with the supplied bolts.

26

a. Hook the top of the mounting bracket under

the case’s attachment tting.

b. Secure the cabinet to the mounting bracket.

017-241-B0 Rev B

Page 29

5.1.1.4 Mounting to a Wall

Have the following tools and materials on hand:

• 13 mm nut driver for the bolts that attach the cabinet to the mounting bracket.

• Four 1/4" x 1-1/8" lag bolts.

• Four 1/4" diameter flat washers.

• Drill with 1/8" bit for drilling pilot holes.

• Assorted sockets and wrenches.

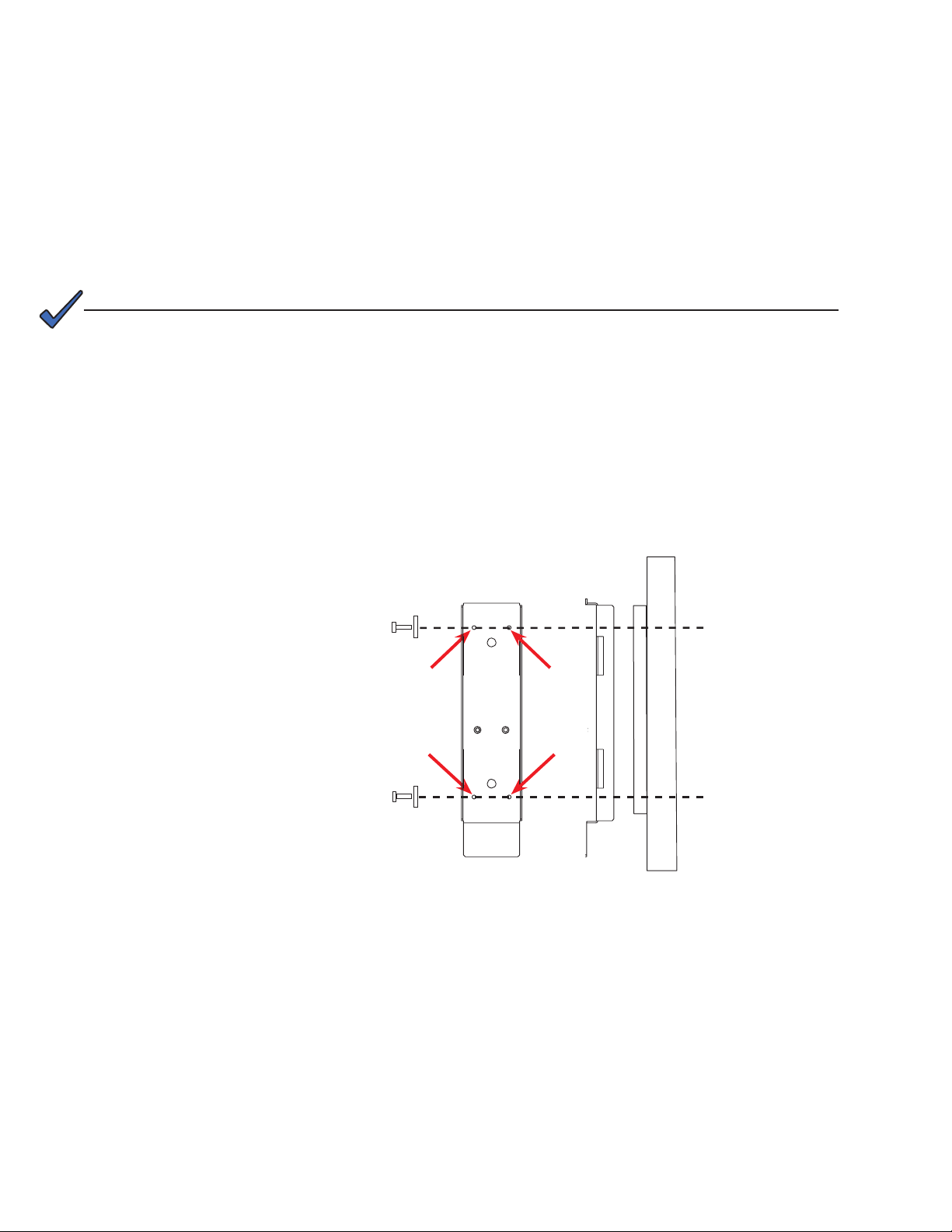

Procedure:

NOTE:

If the wall structure is not strong enough to support the weight of the Micro350 enclosure and batteries, use a wooden backing plate that has a minimum thickness of 1-1/4"

and a maximum width of 4" that is securely mounted to a wall stud or studs.

1. Using the mounting bracket as a template, drill 4 pilot holes (indicated by the arrows in the following

diagram) into the wall to accept 1/4" bolts.

2. Secure the mounting bracket to the wall with the 4 bolts and washers.

3. Secure the Micro350 enclosure to the mounting bracket with the supplied bolts.

NOTE:

To install a Micro XL3 enclosure,

rst attach the XL to an XL3 kit.

Figure 15 — Attaching the mounting bracket to the wall studs

Front Side

Wall or

studs

017-241-B0 Rev B

27

Page 30

5.1.2 Wiring the Micro350

OUTPUT

PUSH BUTTON TO

INSERT/REMOVE WIRES

INPUT

PUSH BUTTON TO

INSERT/REMOVE WIRES

L

N

STRIP WIRE

7/16 in

(11mm)

USE

MAXIMUM

12 AWG

2

(4mm )

L

24V

N

WARNING!

Before starting, disconnect the Line power.

If stranded wires are used for connection at the input terminal block, ferrules or equivalent crimping terminals must be used.

Separate the AC input power cables from the output power cables within the Alpha FXM

enclosure. Route them through separate conduit openings in the enclosure.

Separate the DC Battery cable from the AC Input and Output power cables. Route the

cable through its own opening.

The AC power distribution terminal blocks in the Micro350 enclosure are located in the below the FXM350

(see Figure 16). Refer to Table S for detailed electrical specifications.

Figure 16 — AC Power distribution terminal blocks

Have the following tools and materials on hand:

• Hammer for removing the knockouts

• Slot head screwdriver, 3/16 or smaller, to attach wires to the terminal blocks for the dry contacts / user

inputs on the front panel

• Slot head screwdriver, 1/4 or larger, for removing the knockouts

• DC voltmeter

• Battery terminal corrosion inhibitor such as NOCO Company’s NCP-2 or Sanchem Inc. No-Ox ID Grease

“A”

• Maximum of 12 AWG wire for wiring the input and output terminal blocks

• If used, 1/2" conduit connectors to fit the knockouts (7/8" diameter) and armored conduit to fit

• Optional battery heater mats

28

017-241-B0 Rev B

Page 31

5.1.2.1 Procedure

1. Remove the front cover of the enclosure – lift

the cover up and then pull out at the bottom.

2. If necessary, remove the knockouts with a

hammer and screwdriver.

3. If used, install conduits into the openings.

4. Install the wires into the cabinet. Make sure

that the wiring is long enough to reach the

terminal blocks.

5. Strip the ends of the wires by 7/16" (11 mm).

6. Run the ground wire to the ground terminal

shown in Figure 17.

7. Push in the button on the terminal block and

then insert each wire into the corresponding

terminal. See Figure 18.

8. Secure the wiring to the wiring management

panel with tie-wraps provided with the

Micro350.

9. Remove the packaging around the door

switch after completing the wiring.

Factory installed

ground wire.

Connect ground

wire to copper-

ground terminal.

Remove knockouts for wiring.

Figure 17 — Wiring the Micro350

WARNING!

The input and output wiring must NOT touch the cabinet except for the wiring management panel.

The input terminal block has two inputs for each pole (line, neutral and ground). Make

sure you have inserted each wire into the correct position and not accidentally connected the line and neutral to the same pole.

Verify the line wire is attached to the line terminal block, the ground wire is attached to

the ground terminal block and the neutral wire is attached to the neutral terminal block

to prevent accidental shocks or electrocutions.

CORRECT

INCORRECT

017-241-B0 Rev B

Figure 18 — Terminal block wiring

29

Page 32

5.1.3 Options

If applicable, connect the following—see Figure 3 on page 13.

• USB cable

• Dry contact alarms

• User inputs

5.1.4 Ferrite Ring for Network Cable

Remove the ferrite ring and cable tie from the plastic bag of small parts that were part of your shipment.

Attach the ferrite ring to the connector end of your RJ45 network cable as shown in Figure 19.

Figure 19 — Ferrite ring installed on RJ45 network cable

5.1.5 Battery Heater Mats

For installation and connection of option battery heater mats, refer to section "5.3 Wiring the External Batteries

and Optional Battery Heater Mats" on page 33.

30

017-241-B0 Rev B

Page 33

5.2 Mounting and Wiring the FXM350 as a standalone device

5.2.1 Mounting

The FXM 350 UPS module, which is approximately 13.5 in wide, can be mounted in several ways:

• Wall mounted, with front access onto a 19" mounting tray that includes a battery cabinet

• 19" or 23" rack mounted (with the addition of the optional ears shown in Figure 20). The signal assembly

option provides additional user inputs and dry contacts.

Optional ears

Optional signal

assembly

Figure 20 — FXM350 with rack-mount ears and signal assembly option (wiring box not shown)

5.2.1.1 Rack Mounting the FXM

STEP 1: Install Ears

1. Install the ears at both ends of the FXM.

2. Mount the FXM in the rack.

STEP 2: Install Wiring Box

1. Remove the AC I/O connections cover.

Keep the screws to attach the wiring box.

2. Thread the wires through the wiring box.

3. Attach the wiring box with the four screws

removed in the first step.

4. Complete the wiring as described in

section 5.2.2.

Optional signal

assembly cable

connection

Wiring box instal-

lation location

5. Screw the cover onto the wiring box.

STEP 3: Install Signal Assembly Option

1. Attach the signal assembly to the left ear.

2. Connect the signals connector cable from

the signal assembly to the FXM Figure 20.

017-241-B0 Rev B

AC I/O connections cover

Wiring box

31

Page 34

5.2.2 Wiring the AC Input and Output

WARNING!

Make sure the line power is off and tagged. Switch off all input and output circuit breakers on the FXM350 before making any electrical connections.

The electrical connectors are located on the right

side of the FXM350.

AC Input – 120/230Vac

(#14 AWG)

Ensure that the

cables are routed

AC Output 2 – 24Vac

(#12 AWG)

through the AC

cover plate and/or

wiring box and suitably strain relieved.

AC Output 1 – 120/230Vac

(#14 AWG)

Figure 21 — FXM350 Electrical Connections

5.2. 3 Ferrite Ring for Network Cable

Remove the ferrite ring and cable tie from the plastic bag of small parts that were part of your shipment.

Attach the ferrite ring to the connector end of your RJ45 network cable as shown.

32

017-241-B0 Rev B

Page 35

5.3 Wiring the External Batteries and Optional Battery Heater Mats

WARNING!

The batteries must be installed by qualied personnel trained in the safe use of highenergy power supplies and their batteries. Refer to the safety section in this manual.

• Use new batteries when installing a new unit. Verify that all batteries are the same type with identical

date codes.

• Use appropriate battery voltage string for 24 and 48V versions of the products.

• If you are making your own battery wiring harness, use at least 10 AWG wires.

• The battery return connection is to be treated as an Isolated DC return (DC-I) as defined in GR-1089CORE.

5.3.1 Procedure

1. Place the battery heat mat(s) on the battery shelves. Refer to the manual that ships with the battery heat

mat to connect it to a power source.

2. For FXM350-48 (48V battery string), number the batteries from 1 to 4 with labels or tape. For FXM350-24

(24V battery string), number the batteries from 1 to 2 as shown in the Figure 22.

3. Coat the battery terminals with the corrosion inhibitor.

To positive terminal

Battery #4 Battery #3 Battery #2 Battery #1

To positive terminal

Optional in-line fuse

Optional in-line fuse

Battery #2 Battery #1

To negative terminal

To negative terminal

017-241-B0 Rev B

Figure 22 — External Battery Wiring (for 48 VDC string (top) and 24 VDC string)

33

Page 36

CAUTION!

Torque the battery terminals according to the manufacturer’s specications as given on

the name plate or data sheet.

4. Place the batteries into the enclosure. Orient them so that connecting cable lengths are minimized.

5. If the optional battery restraining bar is used, install it as shown in Figure 23.

6. Connect the batteries as shown in Figure 22. If used, install the in-line fuse.

7. If the Micro XL or XL3 is used, connect and install the extra shelves of batteries.

8. Connect the black battery cable to the negative terminal of the battery string, and the red battery cable to

the positive terminal of the battery string.

9. When the batteries are wired, measure the voltage at the battery connection terminals. It should read 2127V for a 24V battery string and 42-54 for a 48V battery string.

10. Note the polarity and ensure it is correct.

11. Ensure that the DC breaker if OFF.

12. Connect the battery connectors to the FXM350 and install the battery clip.

CAUTION!

Failure to install the battery clip could result in overheating of the battery connectors

and possible damage to the FXM350.

13. Route the sensor end of the battery temperature cable to the batteries.

14. Attach the battery temperature sensor to the body of the battery, about 2 to 3" (5 to 7.5 cm) from the base

of the battery.

1: Hook

the bar

under the

restraining

screw.

34

2: Secure the bar

to the chassis

Figure 23 — Securing the batteries with the optional restraining bar

017-241-B0 Rev B

Page 37

5.4 Start-Up

1. Switch on the FXM battery circuit breaker. The LCD displays STANDBY.

2. Switch on the AC utility breaker at the main power panel. Switch on the AC Input circuit breaker on the

FXM. If qualified, LINE appears on the LCD.

3. Allow the batteries to charge for approximately 8 hours.

4. The load should be receiving power, If not, perform troubleshooting.

017-241-B0 Rev B

35

Page 38

6. Theory of Operation

6.1 Block Diagram

Figure 24 shows the eight PCBs in the FXM350 and the communication path between them.

HEATER

MAT OUTPUT

COMM

MODULE

USER

INTERFACE

DC INPUT

DC EMI

BOARD

HEATER MAT

RELAY BOARD

MAIN BOARD

MICROCONTROLLER

BOARD

LINE FREQUENCY

TRANSFORMER

132

120

108

N

DRY CONTACTS

120

INV

BOARD

AC INPUT

& OUTPUT

AC EMI

BOARD

DRY CONTACTS & EXTERNAL

LCD DISPLAY

Figure 24 — FXM 350 block diagram

SIGNALS OUTPUTS AND USER &

BATTERY TEMPERATURE INPUTS

6.2 Modes of Operation

The following list of operation modes is explained in the following sections.

• Line mode

• Backup mode

• Standby

• Shutdown

• Fault

36

017-241-B0 Rev B

Page 39

6.2.1 Line Mode

132

AC EMI

Output(s)

Input

Grid relay

120

108

120

INV

Inverter/

Charger

N

Battery

In line mode, the voltage input equals the voltage output. The FXM350 has Automatic Voltage Regulation

(AVR) to maintain the output voltage within the regulation range.

6.2.1.1 Boost Mode

When the input voltage drops, a reduction

in output voltage is prevented by increasing the ratio of primary to secondary

windings in the transformer. The ratio is

increased by using a relay to change the

transformer taps.

Input

Grid relay

132

120

108

120

INV

6.2.1.2 Buck Mode

When the input voltage increases, an

increase in output voltage is prevented by

decreasing the ratio of primary to secondary windings in the transformer. The ratio

is decreased by using a relay to change

the transformer taps.

017-241-B0 Rev B

Input

Grid relay

N

132

120

108

N

120

INV

37

Page 40

6.2.1.3 Battery Charging in Line Mode

The battery charging path is shown in Figure 25.

• Charging current of 4A for 48V battery

• Charging current of 6A for 24V battery

• No de-rating of load on AC outputs

AC EMI

Output(s)

Inverter/

Charger

Battery

Input

Grid relay

132

120

108

N

Figure 25 — Battery charging in line mode

120

INV

6.2.2 Back Up (Inverter) Mode

The FXM350 provides back up power from the batteries if utility power fails. The grid relay opens to prevent

power feedback to the grid.

38

Input

Grid relay

132

120

108

N

Figure 26 — Back up power from batteries

120

INV

AC EMI

Output(s)

Inverter/

Charger

Battery

017-241-B0 Rev B

Page 41

6.2.3 St andby Mode

The FXM350 displays STANDBY when the DC breaker is closed (unit is ON), but no AC is present. When the

AC input circuit breaker is switched on and line power is qualified, the Alpha FXM switches to LINE mode. If

AC is within specifications, the FXM provides automatic voltage regulation (AVR).

6.2.4 Shutdown Mode

The FXM/Micro350 can be shut down by switching off the AC breaker and the DC breaker.

The unit can also be shut down from the front panel LCD or remotely through the USB and SNMP.

If the Shutdown command is applied in Back Up mode, the unit shuts the inverter and opens the grid relay

(Figure 26).

If in Line mode, the grid relay is opened and the inverter disabled.

The FXM350 can be removed from Shutdown mode by manually resetting the AC and DC breakers or from

the LCD or the web pages.

6.2.5 Fault Mode

If a fault occurs on the FXM (red LED solidly illuminated), the unit goes into Shutdown mode until the fault is

cleared and reset. See Table P for a list of faults and to clear the fault, see Figure 28.

017-241-B0 Rev B

39

Page 42

7. Operating the FXM350

7.1 Switching the Alpha FXM On and Off

Under normal operation, the Alpha FXM is always powered ON to supply uninterruptible power to the load.

Switching off the Alpha FXM will disconnect the power supply to the load. If for any reason you need to

switch off the Alpha FXM while maintaining power to your critical load, make sure that you have a plan that

provides an alternate source of power.

7.1.1 Switch Off Procedure

1. Switch off the AC input circuit breaker.

2. Switch off the battery circuit breaker.

The status LED turns off and the LCD panel goes blank. The Alpha FXM is now switched off and no backup

power is supplied to the load.

7.1.2 Switch On Procedure (LINE mode)

Before you put the Alpha FXM back into commission, make sure that the line is qualified and the batteries are

fully charged.

1. Switch on the battery circuit breaker. The LCD displays STANDBY and the fan turns on for about a

minute. If the temperature is below –15ºC, the LCD display may not function. See Chapter 9.

2. Switch on the AC input circuit breaker. The Alpha FXM qualifies the line power. The LCD displays

RETRAN, then shows LINE, or BUCK or BOOST, depending on the line voltage. (See Table A on page

43). The status LED illuminates.

3. If there is no line power, the Alpha FXM remains in STANDBY mode until the line power is qualified. To

provide backup battery power to the load, perform a manual start by using the Inverter command:

From the Control Menu, scroll till the LCD displays Inverter, press Select and select ON. See("Figure

28 — LCD Menu Tree" on page 44).

The Alpha FXM uses auto-frequency detection. When it is first switched on, it senses the line frequency and

adjusts its output frequency to match that of the input. The load should be receiving power, If not, perform

troubleshooting.

7.1.3 Switching the Alpha FXM from Line mode to Inverter mode

You can force the Alpha FXM to operate in the Inverter mode by manually switching off the input circuit breaker when in Line mode. Doing so effectively disconnects any line power to the Alpha FXM simulating a power

outage which triggers the Alpha FXM to switch to the inverter mode of operation.

Procedure:

1. Switch off the input circuit breaker. The LCD shows INVERTER, the status LED starts flashing to show

that the Alpha FXM is running on backup battery power. Confirm that the load is receiving power.

40

017-241-B0 Rev B

Page 43

7.1.4 Switching the Alpha FXM from Standby mode to Inverter mode

When AC is not present and the loads need AC Power, the Alpha FXM can be forced to output AC using

energy from the batteries. To force the inverter on, refer to the CONTROL MENU, shown in Figure 28, and

INVERTER in Table B.

7.1.5 Switching the Alpha FXM from Inverter mode to Line mode

The Alpha FXM remains in the Inverter mode for as long as the input circuit breaker is switched off. Backup

power is provided to the load until the batteries are drained to a preset level which triggers the Alpha FXM

to shutdown automatically. If it is not necessary to operate the Alpha FXM in the Inverter mode, switch the

Alpha FXM back to the Line mode as soon as possible by closing the AC input circuit breaker.

Procedure

1. Switch on the AC input circuit breaker. The Alpha FXM qualifies the line power. The LCD displays

RETRAN, then shows LINE, or BUCK, or BOOST.(See Table A on page 43). The status LED illuminates

steadily.

If the Alpha FXM constantly switches between INVERTER and LINE modes because of frequent disturbances on the line, the Alpha FXM input parameters should be broadened from Normal to Generator. See Table B,

Sense Type. Also see the specifications: “Boost/Buck/ Line Transfer Thresholds”.

In the Generator mode, the range of acceptable input frequency and voltage are expanded to accept fluctuations and disturbances as created by a generator.

017-241-B0 Rev B

41

Page 44

7.2 Operating from the Control Panel Interface

The LCD control panel provides “at a glance” monitoring. This panel, when used along with the CANCEL,

SCROLL and SELECT buttons, allows you to program, make measurements, and troubleshoot the Alpha

FXM350. Figure 27 shows the layout.

The Alpha FXM350 is monitored and controlled with a series of menus and submenus. The Menu Tree is

shown in Figure 28.

Alpha

A

A Alpha FXM model name

Alpha FXM voltage conguration - 120 Vac or 230 Vac

B

Alpha FXM Frequency - 50 Hz or 60 Hz

Sense Type setting - Normal (N) or Generator (G); see "7.2.2 The LCD Control Menu" on page 45, Table B,

Sense Type.

C

Present operating mode - See (Table A). (LINE mode shown in Figure 27)

Control buttons:

D

SELECT - Pressing SELECT moves you down 1 level in the menu tree or accepts a change when

programming. Also scrolls through current alarm/fault list.

SCROLL - Pressing SCROLL moves you through the submenus

CANCEL - Pressing CANCEL moves you up one level in the menu tree.

FXM 350

CANCEL

Figure 27 — LCD Control Panel Logo Screen

SCROLL

D

120/60/N

LINE

SELECT

B

C

42

017-241-B0 Rev B

Page 45

7.2.1 Operating Modes

The Alpha FXM operating mode, (see Table A) automatically changes as a result of changes in the line. Refer

to Chapter 10, Specifications, for Boost/Buck/Line transfer thresholds. The LCD panel automatically updates

to reflect the change.

Table A — UPS Operating Modes

LCD display Description

SHUTDOWN The Alpha FXM inverter is switched off. Line power is disconnected from the load.

LINE The Alpha FXM is switched on. Line power is provided to the load.

BOOST1

BUCK1 The Alpha FXM lowers line voltage without using the batteries. AVR is enabled.

When the input voltage is lower than the nominal voltage, the Alpha FXM raises line voltage

without using the batteries. Automatic voltage regulation (AVR) is enabled.

INVERTER

RETRAN The Alpha FXM is transferring from INVERTER mode to Line mode.

TRAN The Alpha FXM is transferring from the state it is now in into Inverter mode.

STANDBY

BYPASS

The Alpha FXM is providing backup battery power to the load. See INVERTER in Table B

on page 45.

The Alpha FXM is switched on and waiting for the line power to be qualied or the user to

clear some faults.

CAUTION: Do not touch the AC output terminals; they may still be energized.

This mode is manually set from the Control Menu. See Figure 28, “Control Menu, INV

BYPASS”. This locks the unit into line mode and turns off the battery charger so the unit can

work with a manual break-before-make bypass switch. AVR will be disabled.

017-241-B0 Rev B

43

Page 46

Logo Screen

CANCEL

(Figure 27)

SELECT

Starting at the Logo

Screen, press the SELECT

button to go down one level.

Press the SCROLL button to move between the menus.

The SCROLL button moves only in one direction and is looped

within a submenu, so if you scroll past your selection, continue

to press the scroll till you reach it again.

Control Menu

(Table B))

The CONTROL

MENU (Table B) lets

you control, program

and adjust the Alpha

FXM for connection

to traffic intersection

equipment or other

applications. You

can control the:

• INVERTER

• DC CONNECT

• BYPASS

• BATT TEST

• BT TS DOD

• AUTO TEST

• SHUTDOWN

• SHUTDOWN AC

• SHUTDOWN DC

• SENSE TYPE

• FUNC MODE

• VOLTAGE

• FREQUENCY

• QUAL TIME

• BATT COMP

• DATE FRMT

• CLOCK FRMT

• INV RECORD

• CHGR CUR

• RELAY TEMP

• TEMP DISP

• DAYLIGHT

• CONFIGURE IP

SCROLL

Status Menu

(Table C)

CANCEL

SCROLL

SELECT

SCROLL

The SYSTEM STATUS

menu (Table C) lets

you measure various

inputs, outputs and

other values. The

available measurements are:

• VIN

• VOUT

• IOUT AC

• BATT TEMP

• FREQ IN

• OUTPUT PWR

• BATT VOLT

• CHGR CUR

• DATE

• TIME

• INV COUNT

• INV (min)

• SHED TIMER 1, 2

OR 3

• MAC Address

• IP Address

• kWh

• REMAIN TM

• SERIAL NUMBER

• VERSION

Alarm and Fault

Menus (If Active)

(Table O and Table P)

SCROLL

Event Status Menu

Press the SELECT button to enter the submenu. Then press

the SCROLL button to cycle through the submenu items. The

SCROLL button moves only in one direction, so if you overshoot,

you have to go all the way around the submenu again.

The ALARM and

FAULT menus that

display NO ALARMS

and NO FAULTS.

When the front panel

alarm LED is on or

flashing, press SELECT.

One of the malfunctions listed in Table

O and Table P will

appear on the LCD.

Press the SCROLL

button to see if more

than one malfunction

is present.

Fix the malfunction.

Press the SELECT

button to clear the

malfunction from the

screen.

If the malfunction is

fixed, the malfunction

is cleared from the

LCD. If it isn’t fixed, it

will reappear on the

screen.

The EVENT STATUS menu displays

the last Alpha FXM

event on the LCD.

For the event log,

see "7.2.5 Viewing

the 200-event Log"

on page 48.

Press the SELECT

button to access

the menu. Press

the SELECT then

the SCROLL button

to scroll through

the events. To see

what a specific

event was, press

the SELECT button.

Press the SCROLL

button to see what

malfunction triggered the event.

44

Figure 28 — LCD Menu Tree

017-241-B0 Rev B

Page 47

7.2.2 The LCD Control Menu

The control menu (Table B) lets you operate the Alpha FXM or program it to suit your operating conditions.

7.2.2.1 Procedure

1. From the Logo screen press the SELECT button to go down to the CONTROL menu.

2. Press the SELECT button to enter the submenu (Table B).

3. Press the SCROLL button to move between items in the submenu.

4. When you have reached the item you want to change, press the SELECT button. The item chosen will

blink.

5. To toggle between the choices, press the SCROLL button. Stop when you reach the choice you want.

6. To make the change, press the SELECT button. The blinking stops.

Table B — Control Menu

LCD display Meaning Description

When inverter mode is set to ON, the Alpha FXM provides backup battery power

INVERTER Inverter

DC CONNECT

BYPASS

DC Output

Connect

Voltage

Inverter

Bypass

to the load. This mode of operation is normally activated automatically when line

power becomes unavailable, or the line power is not qualied. You can also put

the Alpha FXM into this mode during initial startup in the absence of line power or

because of unqualied line power. See #31Inverter On/Off in Table I.

One of the dry contacts of the FXM350 can be programmed to operate as a

control for external DC disconnect and reconnect. (See LVD setting under "7.5.4

Programming the Dry Contacts" on page 82). The dry contact is energized when the

battery voltage is greater than the DC Connect set voltage and will de-energize if the

battery voltage drops below 42V for 48V system (21V for 24V system). The default

reconnect voltage is set to 48VDC and can be adjusted up to 51VDC.

This function can be enabled only when the Alpha FXM is in Line mode.

When enabled, the FXM locks into Line mode (no AVR) and disables the battery

charger. This mode is used when maintaining batteries.

OR

Allows the use of a break-before-make manual bypass switch so the Alpha FXM can

be shut off for maintenance without interrupting power to the load.

BATT TEST Battery Test

BT TS DOD

AUTO TEST Automatic Test Enable/Disable the scheduled self test.

SHUTDOWN

SHUTDOWN AC Shutdown AC