Page 1

Alpha FXM 650, 1100, 2000 UPS

Installation & Operation Manual

Part # 017-230-B4

Effective: 07/2013

member of The Group

™

Your Power Solutions Partner

Page 2

Page 3

Alpha FXM 650, 1100, 2000 UPS

Installation and Operation Manual

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual

before proceeding. If there are questions regarding the safe operation of this powering

system, contact Alpha Technologies or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power

supplies, generators, batteries, or other hardware if used or operated in any manner or

subject to any condition inconsistent with its intended purpose, or if installed or operated in an unapproved manner, or improperly maintained.

For technical support, contact Alpha Technologies:

Canada and USA: 1-888-462-7487

International: +1-604-436-5547

Copyright

Copyright © 2013 Alpha Technologies Ltd. All rights reserved. Alpha is a registered trademark of Alpha Technologies.

No part of this documentation shall be reproduced, stored in a retrieval system, translated, transcribed, or transmitted in any form or by any means manual, electric, electronic, electromechanical, chemical, optical, or otherwise without prior explicit written permission from Alpha Technologies.

This document, the software it describes, and the information and know-how they contain constitute the proprietary, confidential and valuable trade secret information of Alpha Technologies, and may not be used for any

unauthorized purpose, or disclosed to others without the prior written permission of Alpha Technologies.

The material contained in this document is for information only and is subject to change without notice. While

reasonable efforts have been made in the preparation of this document to assure its accuracy, Alpha Technologies assumes no liability resulting from errors or omissions in this document, or from the use of the information

contained herein. Alpha Technologies reserves the right to make changes in the product design without reservation and without notification to its users.

Page 4

Table of Contents

1. Safety ....................................................................................................................................4

1.1 Safety Symbols .................................................................................................................... 4

1.2 General Warnings and Cautions .......................................................................................... 5

1.3 Certications and Compliances ............................................................................................ 6

2. General Description ..............................................................................................................7

2.1 Overview .............................................................................................................................. 7

2.2 Front Panel ........................................................................................................................... 7

3. Site Planning ....................................................................................................................... 11

3.1 Safety Precautions ..............................................................................................................11

3.2 Communicating with the Alpha FXM .................................................................................. 12

3.3 Electromagnetic Compatibility (EMC) Requirements ......................................................... 13

4. Unpacking Alpha FXM ........................................................................................................14

5. Installation ...........................................................................................................................15

5.1 Tools and Equipment Required for Installation ................................................................... 15

5.2 Mounting the Alpha FXM .................................................................................................... 16

5.3 Wiring the External Batteries .............................................................................................. 17

5.4 UATS and (UGTS) Option .................................................................................................. 19

6. Operating the Alpha FXM....................................................................................................20

6.1 Switching the Alpha FXM On and Off ................................................................................. 20

6.2 Operating from the Control Panel Interface ....................................................................... 21

6.3 Operating via the FXM Communication Module (Intranet or Internet) ............................... 30

6.4 The Alpha UPS Monitor Interface ....................................................................................... 56

6.5 HyperTerminal Interface ..................................................................................................... 60

7. Maintenance .......................................................................................................................72

7.1 Upgrading the FXM Firmware ............................................................................................ 72

7.2 Testing and Replacing the Batteries ................................................................................... 74

7.3 Preventative Maintenance .................................................................................................. 77

8. Troubleshooting ..................................................................................................................78

8.1 Procedure ........................................................................................................................... 78

2

017-230-B4 Rev B

Page 5

9. Specications ...................................................................................................................... 80

10. Warranty ...........................................................................................................................83

11. Emergency Shutdown Procedure .....................................................................................84

Appendix A - Peukert Number and Battery Capacity ................................................................ 85

A.1 Introduction ....................................................................................................................... 85

A.2 Determining the Peukert’s Number and Peukert’s Capacity ............................................. 85

A.3 Determining Peukert’s Capacity for Series Parallel Combinations ................................... 85

A.4 Example ............................................................................................................................ 86

A.5 Using the Spreadsheet ......................................................................................................87

Appendix B - Types of Triggers ................................................................................................88

B.1 Edge trigger ...................................................................................................................... 88

B.2 Level Toggle ...................................................................................................................... 88

017-230-B4 Rev B

3

Page 6

1. Safety

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions that

must be followed during the installation, servicing, and maintenance of the product. Keep it in a safe place. Review the drawings and illustrations contained in this manual before proceeding. If there are any questions regarding the safe installation or operation of this product, contact Alpha Technologies or the nearest Alpha representative. Save this document for future reference.

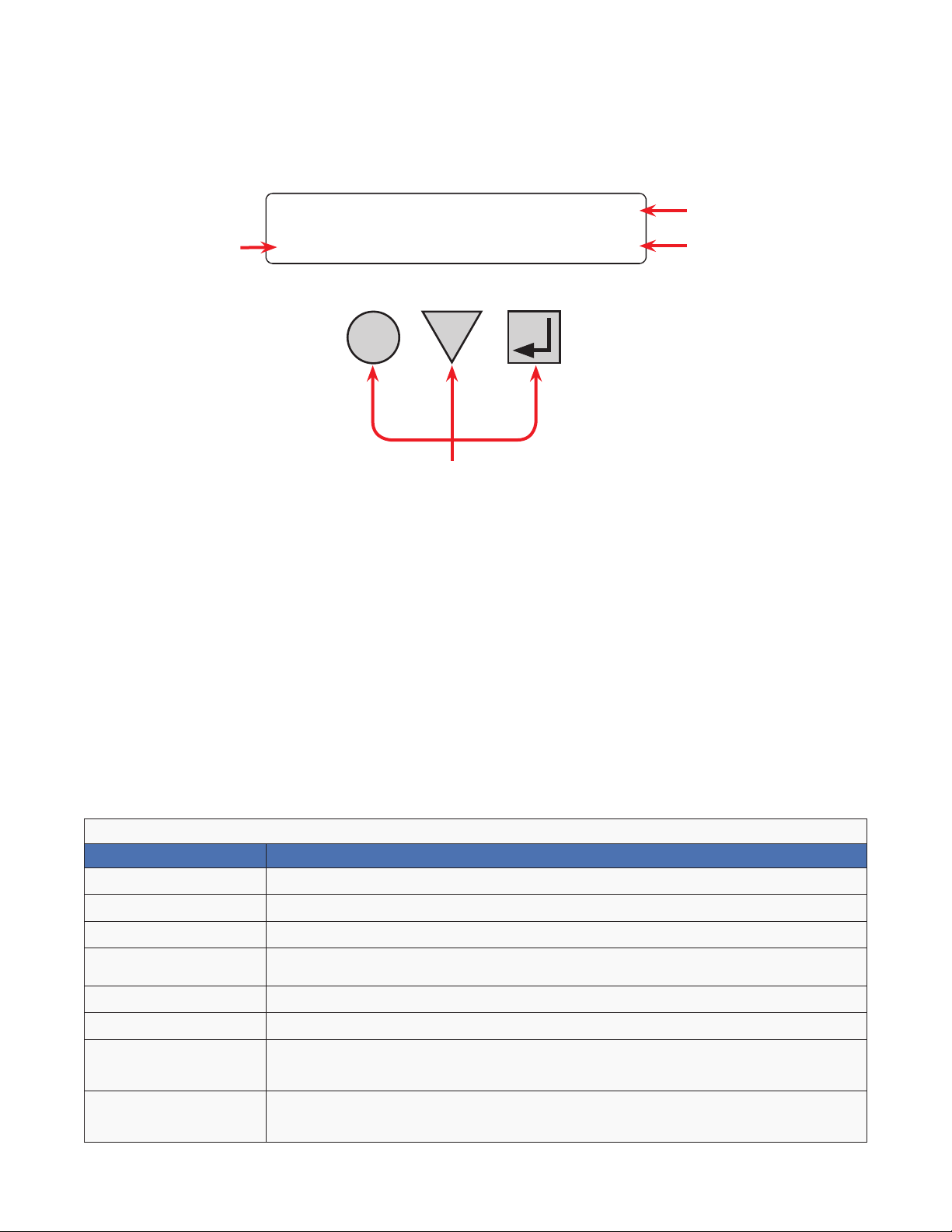

1.1 Safety Symbols

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and attention.

The use of ATTENTION indicates specic regulatory/code requirements that may affect the

placement of equipment and /or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure.

Notes are designated with a checkmark, the word NOTE, and a rule beneath which the

information appears.

CAUTION!

CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment. Cautions are designated with a yellow warning triangle, the word CAUTION,

and a rule beneath which the information appears.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to personnel.

Warnings are indicated by a shock hazard icon, the word WARNING, and a rule beneath

which the information appears.

HOT!

The use of HOT presents safety information to PREVENT BURNS to the technician or

user.

4

017-230-B4 Rev B

Page 7

1.2 General Warnings and Cautions

You must read and understand the following warnings before installing the Alpha FXM and its components. Failure to do so could result in personal injury or death.

• Read and follow all instructions included in this manual.

• Do not work alone under hazardous conditions.

• Only qualified personnel are allowed to install, operate and service this system and its components.

• Use proper lifting techniques whenever handling equipment, parts, or batteries.

• Always assume electrical connections or conductors are live. Switch off all circuit breakers and double-

check connections with a voltmeter before performing installation or maintenance.

• Place warning label(s) on the utility panel to tell emergency personnel a UPS is installed.

• The Alpha FXM uses more than one live circuit. AC power may be present at the outputs even if the system

is disconnected from line or battery power.

• The Alpha FXM surface can be very hot to the touch.

• Battery installation and servicing should be done or supervised by personnel knowledgeable about batteries

and their safety procedures.

• If electrolyte splashes on your skin, immediately wash the affected area with water. If electrolyte gets into

your eyes, wash them for at least 10 minutes with clean running water or a special neutralizing eye wash

solution. Seek medical attention at once.

• Neutralize spilled electrolyte with special neutralizing solutions in a “spill kit” or a solution of 1 lb. (0.45 kg) of

baking soda (bicarbonate of soda) in 1 gallon (3.8 L) of water.

• Be extra cautious when connecting or adjusting battery cabling. An improperly connected battery cable or

an unconnected battery cable can result in arcing, fire, or explosion.

• Use new batteries when installing a new unit. Verify that all batteries are the same type with identical date

codes.

• Always replace batteries with ones of identical number, type and rating. Never install old or untested batteries. One sealed lead-acid battery is rated to a maximum voltage of 12 Vdc.

• A battery that shows signs of cracking, leaking or swelling must be replaced immediately by authorized personnel using a battery of identical type and rating.

• Keep the chassis area clear and dust-free during and after installation.

• Keep tools away from walk areas where you or others could fall over them.

• Wear safety glasses when working under any conditions that might be hazardous to your eyes.

• Do not work on the unit or connect or disconnect cables during periods of lightning activity.

• Do not smoke or introduce sparks in the vicinity of a battery.

• Never open or damage the batteries. Released electrolyte is harmful to the skin and eyes. It may be toxic

and hazardous to the environment.

• A battery can present a risk of electrical shock and high short-circuit current. The following precautions

should be observed when working on batteries:

a. Remove watches, rings, or other metal objects.

b. Use tools with insulated handles.

c. Wear rubber gloves and boots.

d. Do not lay tools or metal parts on top of batteries.

e. Disconnect the charging source before connecting or disconnecting battery terminals.

f. Determine if the battery is inadvertently grounded. If inadvertently grounded, remove the source from the

ground. Contact with any part of a grounded battery can result in electrical shock. The likelihood of such

shock can be reduced if the grounds are removed during installation and maintenance (applicable to

equipment and remote battery supplies not having a grounded supply circuit).

017-230-B4 Rev B

5

Page 8

• Never let live battery wires touch the Alpha FXM, the enclosure or any other metal objects. This can cause a

fire or explosion.

• Never dispose of batteries in a fire. The batteries may explode. Follow the manufacturer’s directions and

check with your local jurisdictions for safe battery disposal.

• Before attaching the batteries to the Alpha FXM, make sure that the polarity is correct.

• If the batteries have been in storage for more than 3 months, recharge them for at least 24 hours and then

test them with a load before installation.

• Each AlphaCell™ battery has a date code, found on the warning label, which must be recorded in the maintenance log. If non-Alpha batteries are used, see the manufacturer’s documentation for date code type and

placement.

1.3 Certifications and Compliances

The Alpha FXM has been designed, manufactured, and tested to the requirements of the following national and

international safety standards:

• CAN/CSA-C22.2 No. 107.3-05 – Uninterruptible Power Systems; additional requirements (RD): CAN/CSAC22.2 No. 60950-1-03 - Information Technology Equipment - Safety.

• UL 1778 (Edition 4) – Uninterruptible Power Systems; additional requirements (RD): UL 60950-1 (Edition 1) Information Technology Equipment - Safety.

• FCC CFR47 Part 15 Class A – This equipment has been tested and found to comply with the limits for a

Class A digital device pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

• Industry Canada - This Class A digital device apparatus complies with Canadian ICES-003.

• Industry Canada - Cet appareil numrique de la Classe A est conforme la norme NMB-003 du Canada.

6

017-230-B4 Rev B

Page 9

2. General Description

2.1 Overview

The Alpha FXM is available in 3 models – FXM 650, FXM 1100 and FXM 2000. The FXM 650 and the FXM

1100/2000 look different, but all of the front panel connectors and circuit breakers operate in the same way. However the circuit breakers for each unit have different ratings. See Chapter "9. Specifications" for details. All units

operate in the same way unless stated otherwise in this manual.

• FXM 650-24Vdc – with a 24 Vdc battery string voltage.

• FXM 650-48Vdc – with a 48 Vdc battery string voltage.

• FXM 1100-48Vdc – with a 48 Vdc battery string voltage.

• FXM 2000-48Vdc – with a 48 Vdc battery string voltage.

2.2 Front Panel

Figure 1 shows the front panel connectors and circuit breakers, which are described in detail in the following

sections.

2

1

3

1

4

4

6

7

6

5

5

8

10

C6

8

11

10

9

12

13

14

12

2

017-230-B4 Rev B

3

Figure 1 — FXM 650 (top) and FXM 1100/2000 front panel description

7

11

13

149

7

Page 10

Battery breaker

1

This circuit breaker provides over-current protection and is used as an on/off switch for the battery power. It must

be switched on for proper Alpha FXM operation.

Battery connector

2

The battery connector connects the external batteries to the Alpha FXM.

Replaceable fan assembly

3

This microprocessor-controlled fan turns on at a programmable temperature to lower the Alpha FXM internal temperature. It must not be blocked. An Alarm is generated if the fan fails; a failed fan can be replaced in the field.

RJ45 communication module connector

4

The RJ-45 connector is the Alpha FXM Ethernet connector.

LCD control panel and menu navigation buttons

5

The LCD control panel together with the cancel, scroll and select buttons are used to monitor and control the

Alpha FXM.

Battery voltage test points

6

These test points accept 2 mm diameter test probe tips. The battery circuit breaker must be on to measure the

voltage.

The battery voltage test points are not to be used as a power outlet.

RS-232

7

This DE-9 connector allows a straight-through DE-9 to DE-9 connector cable to be used to connect the

Alpha FXM to a computer for remote control and monitoring.

Battery temperature sensor connector

8

The battery charging voltage is temperature dependant when compensation is not set to 0 mV/°C/cell. A battery

temperature sensor connects to the Alpha FXM so the Alpha FXM microprocessor can adjust the charging voltage for optimum charging. Refer to "UPS Maintenance > Battery" on page 38.

The sensor MUST be attached to the Alpha FXM for normal operation. If the sensor is not attached, a “Temperature Probe Unplugged” alarm appears on the LCD.

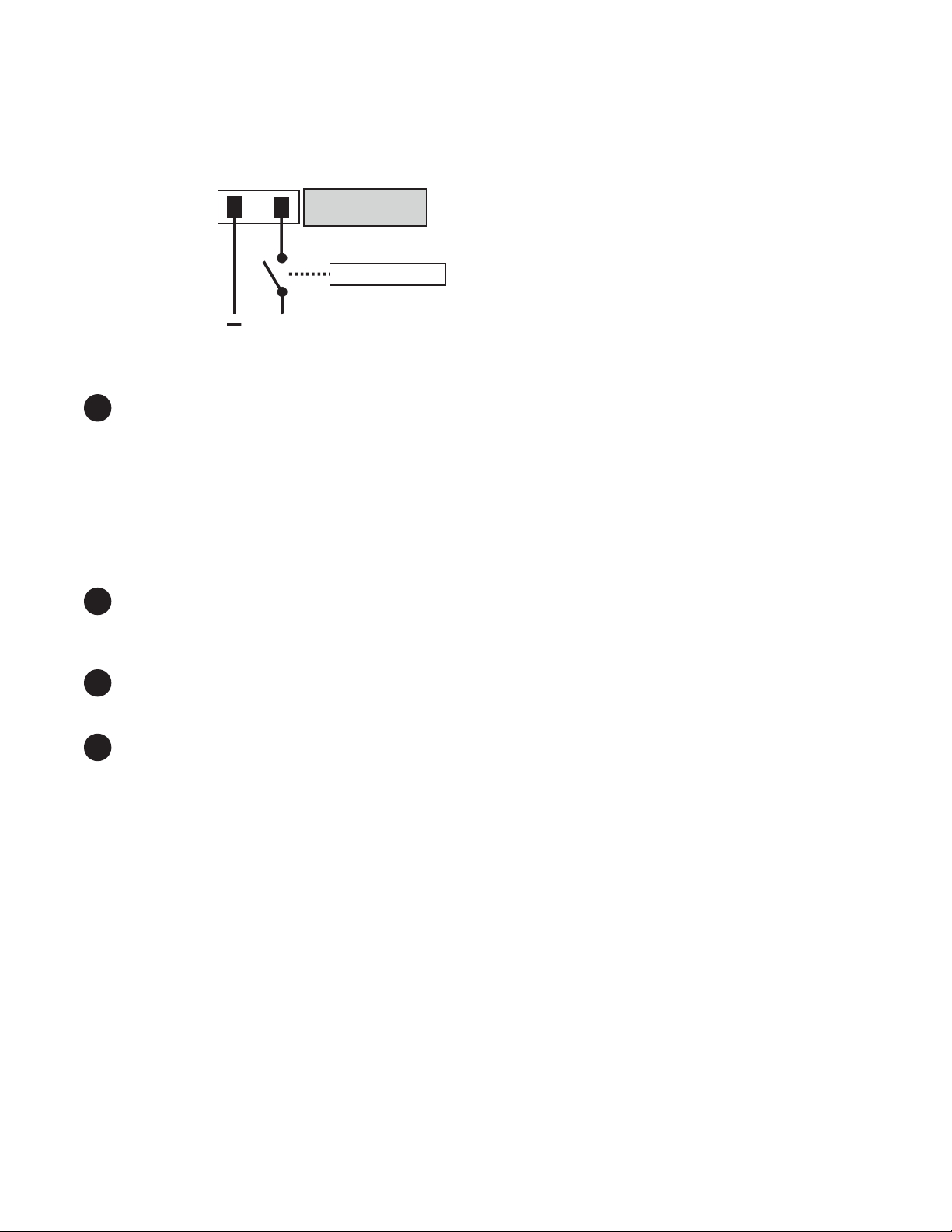

9

Contacts C1 to C6

Contacts C1 to C5 allow the Alpha FXM to be connected to an external monitoring panel or to traffic control

equipment.

The factory default settings can be reprogrammed to meet your requirements. Each contact can only be programmed for one function at a time and cannot show multiple conditions. See "UPS Maintenance > Relay & Load

Shed" on page 41 and section 6.5.7 on page 66 for the HyperTerminal interface.

For Contact C6, the default factory configuration is +48 Vdc output (FXM 650-24 is +24 Vdc), but it can be factory configured as a dry contact. Figure 2 shows the contact’s layout while Figure 3 shows the +48 Vdc or +24

Vdc terminal block layout.

Microprocessor

UPS

The contacts have

a maximum rating

of 1A at 250V.

Interior

Normally

Open (NO)

Common(C)

Figure 2 — Contact Layout (Standard for C1 to C5, Factory Option for C6)

8

Normally

Closed (NC)

017-230-B4 Rev B

Page 11

C1: The C1 contact is energized when line power is unqualified and the Alpha FXM provides backup battery

power to the load(s). It can be used to generate an “On Battery” contact.

C2, C3: These contacts are energized when the battery drops below a pre-set voltage level. They can be used to

generate a Low Battery alarm. To change the pre-programmed level to match the batteries used and the actual

operating conditions, see Low Battery Warning in "UPS Maintenance > Battery" on page 38.

C4: This contact is energized after the Alpha FXM has been in Inverter mode for 2 hours.

To change the pre-programmed 2 hours to match your operating conditions, see Load Shed Timer Configura-

tion in "UPS Maintenance > Relay & Load Shed" on page 41.

C5: The C5 contact is energized when any alarm is generated—see "Table P — Alarm Submenu" on page 78.

C6: The factory default layout for the C6 contact is a relay that is energized when the Alpha FXM is in Line or

Inverter modes and is de-energized when in Standby mode. It provides 48 Vdc (500 mA) from the external batteries to an external fan or other equipment. C6 can be factory-configured as a dry contact.

Microprocessor

+48Vdc, 500mA

(FXM 1100/2000, 650-

48) or +24Vdc (FXM

650-24) from the

external batteries.

Contact

C6

16 17

Figure 3 — 48 Vdc Contact Layout (De-energized Shown, Factory Default for C6)

Optically isolated user inputs C7 and contacts C8

10

18

The optically isolated user inputs are used to attach an external switch panel for remote control of the Alpha FXM

or to allow the Alpha FXM to control optional Alpha Off-Line Automatic Transfer Switch (ATS).

User Input (C7): This relay has three contacts that are used to control the Alpha FXM:

19 (S1) : Shorting this contact starts the Alpha FXM self test. See "UPS Maintenance > Battery" on page 38.

20 (S2): Shorting this contact activates an alarm. See "UPS Maintenance > User Input" on page 46.

21 (S3): Shorting this contact disables the AC output. There is no AC output power, but the Alpha FXM is still

energized. A manual restart is required to put the Alpha FXM back to normal operation.

22 (C): Isolated return for contacts S1, S2 and S3.

017-230-B4 Rev B

19

S1:Self Test20S2:Alarm21S3:Shutdown22Common

Figure 4 — User Input Layout

9

Page 12

ATS (C8): When the Alpha FXM is in the Inverter mode, this normally open relay closes sending 48 Vdc (FXM

650-48, 1100, 2000) or 24 Vdc (FXM 650-24) from the external batteries to this dry contact (Figure 5). If the optional Alpha Off-Line Automatic Transfer Switch (ATS) is connected, it will cause the ATS to switch the load from

line power to the Alpha FXM battery backup power.

Contact C8

48Vdc from the

external batteries

Microprocessor

+

23

Figure 5 — ATS Layout

11

Status and Alarm LEDs

Status:

Green LED solidly illuminated: the Alpha FXM is in Line mode and line power is provided to the load.

Green LED flashing: the unit is in Inverter mode and backup battery power is provided to the load.

Alarm:

Red LED solidly illuminated: fault in the Alpha FXM. (See "Table Q — Fault Submenu" on page 79.)

Red LED flashing indicates an alarm. (See "Table P — Alarm Submenu" on page 78.)

24

AC Input Circuit Breaker

12

This circuit breaker is an on/off switch for the line power into the Alpha FXM that also provides input protection. It

must be switched on for proper Alpha FXM operation.

13

Input Terminal Block

This terminal block is the Alpha FXM AC line power input.

14

Output Terminal Block

This terminal block is the Alpha FXM AC power output.

10

017-230-B4 Rev B

Page 13

3. Site Planning

WARNING!

Restricted Access: The Alpha FXM must be installed in a restricted area accessible only

by qualied service personnel.

The Alpha FXM is intended for permanent AC connection only. The only exception is the

FXM650(U) model.

The Alpha FXM must be correctly grounded for proper operation. Older facilities may

have inadequate electrical grounding. Inspection must be performed by a qualied electrician before installation to ensure that grounding meets the local electrical code.

The utility line attached to the Alpha FXM input MUST be protected by a circuit breaker

certied for this use in accordance with the local electrical code. The UPS must be connected only to a dedicated branch circuit.

The UPS equipment that is powered by this service panel requires the neutral to be permanently bonded to the ground. Always disconnect the batteries before servicing the

circuit breaker panel.

The input and output lines to and from the Alpha FXM MUST have disconnect devices

attached.

The Alpha FXM is suitable for installations in Network Telecommunication Facilities and locations where the

National Electrical Code applies.

Grounding: The Alpha FXM is suitable both for installation as part of a common bonding network and an isolated bonding network.

For installations above 1400 m (4500 ft) elevation, additional cooling may be needed to reduce the operating

temperature of the Alpha FXM. The maximum allowable operating temperature must be reduced by 2°C (3.5

°F) for every 300 m (1000 ft) above 1400 m (4500 ft).

3.1 Safety Precautions

• Install the Alpha FXM on a surface that can support its weight. See Chapter "9. Specifications".

• The input wiring must reach a suitably grounded power outlet and the load wiring must reach the

Alpha FXM output terminal blocks.

• Place the Alpha FXM in a properly sheltered location or inside a weather-proof enclosure to protect the

electronics from water, dust and other possible contamination.

• Alpha Technologies offers a wide range of outdoor enclosure systems. Visit our website at www.alpha.ca,

or call customer service for more information.

• Backup Generator (If used)

Use Generator mode so that noise tolerance is increased to accept the fluctuations created by a generator. See Sense Type in Table B on page 24 .

Use a generator with electronic speed and voltage controls which produces less than 10% voltage total harmonic distortion (THD). Mechanical governors can force the Alpha FXM to run continuously in the

Inverter mode.

Before installation, make sure the generator’s output voltage is compatible with the Alpha FXM input voltage requirements. To make sure the system runs smoothly, use a generator that supplies twice as much

power as drawn by the total load.

017-230-B4 Rev B

11

Page 14

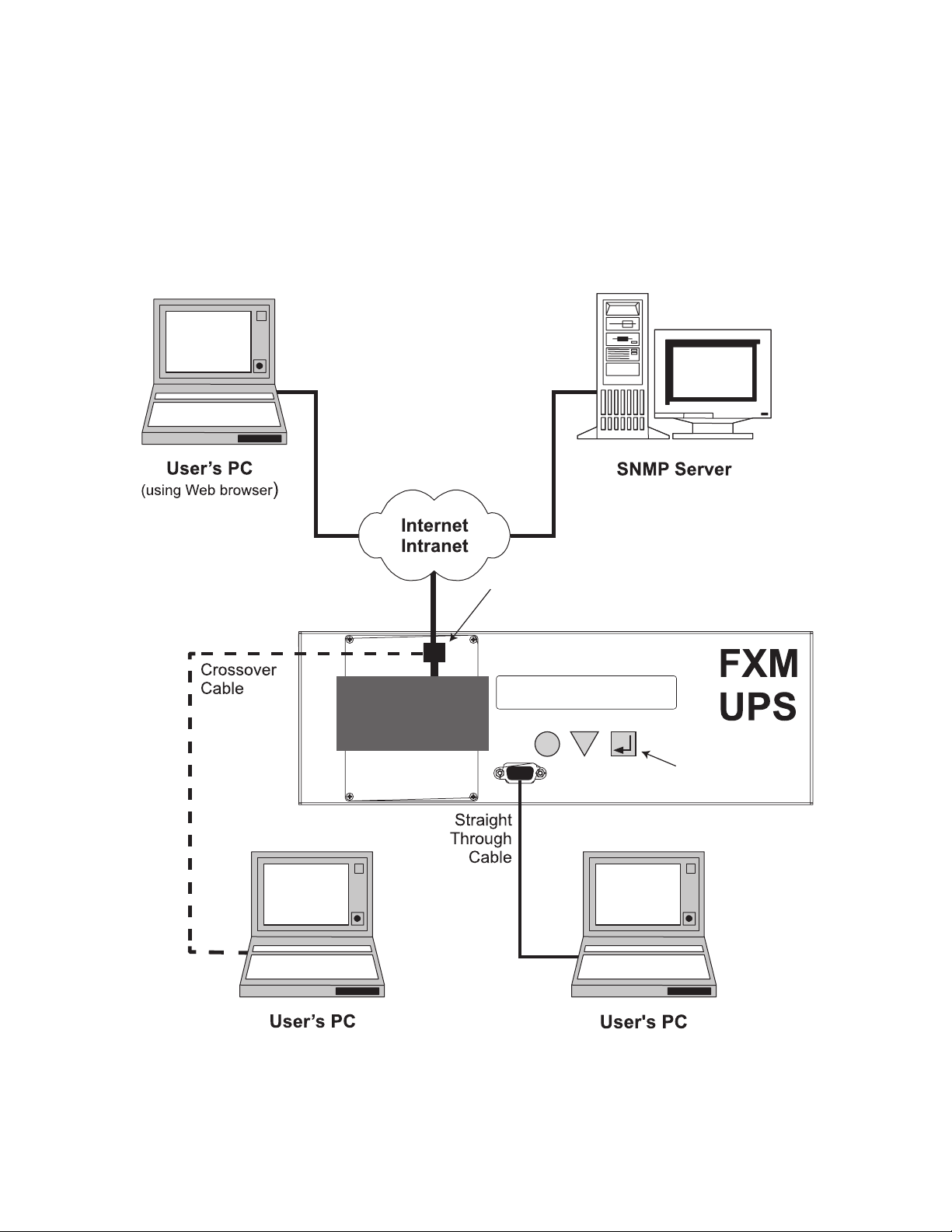

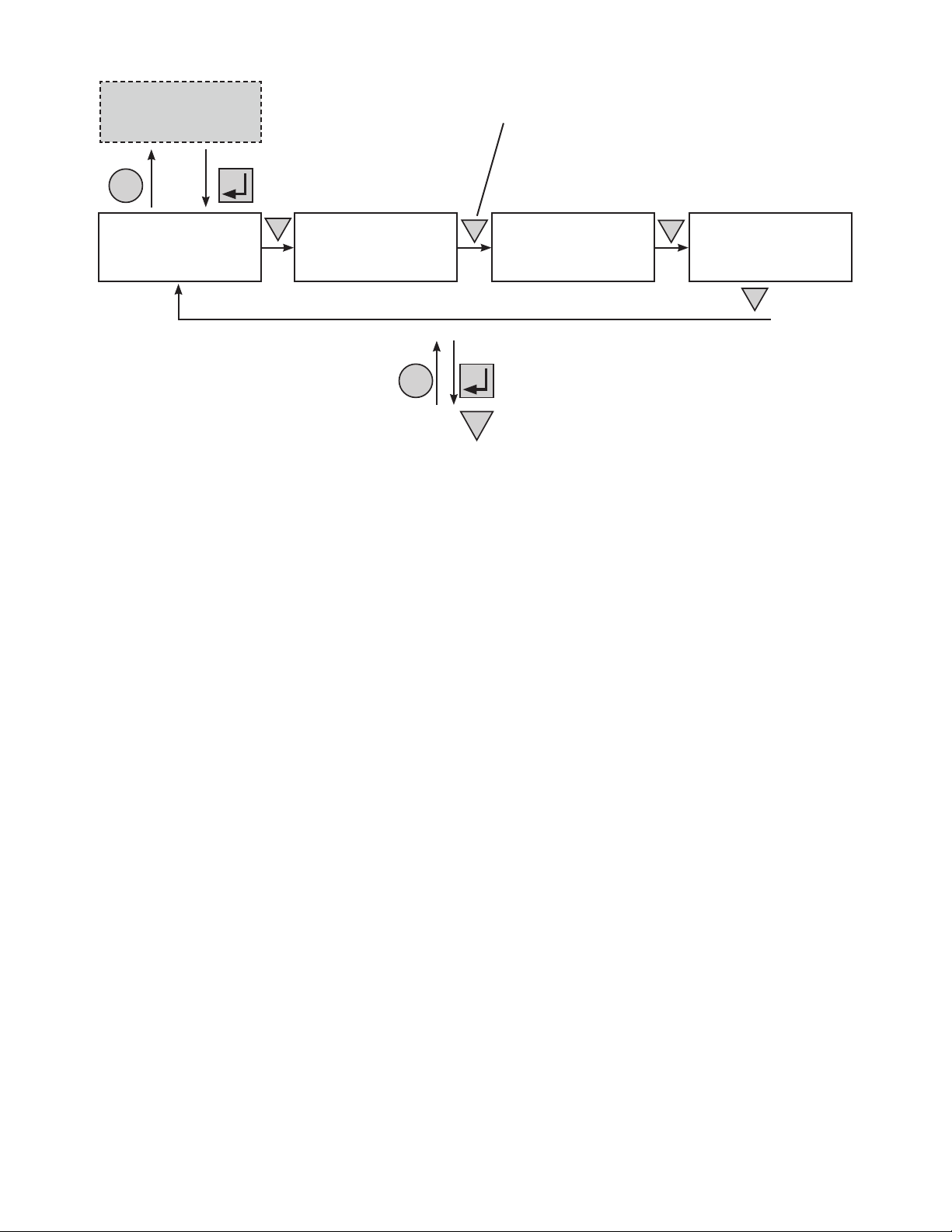

3.2 Communicating with the Alpha FXM

There are several ways you can communicate with the Alpha FXM UPS:

1. Using the control panel.

2. Using an RS-232 interface, you can access the UPS command line system with Windows HyperTerminal or

other terminal emulation program.

3. Using an RS-232 serial connection via the Alpha UPS Monitor installed on your computer. The

Alpha UPS Monitor software can be downloaded from www.alpha.ca/downloads/.

4. Using the optional factory-installed FXM communication module, you can communicate with the Alpha FXM

over a company intranet or the internet using a web browser or with SNMP communications.

Option 4

Option 4

On-Site

Ethernet Connection

Option 4

FXM

Communication

Module

Ethernet Port

Note: FXM Communication Module

is a factory-installed option

SCROLL

120/60/N

LINE

SELECT

Alpha

FXM 2000

CANCEL

RS-232 Port

Options

2 & 3

Option 1:

Control Panel

12

(Using Web browser for

Ethernet connection

to on-site computer)

Figure 6 — Alpha FXM Communication Options

(Using HyperTerminal or Alpha UPS Monitor

available at www.alpha.ca)

017-230-B4 Rev B

Page 15

3.3 Electromagnetic Compatibility (EMC) Requirements

Observe the following EMC requirements when setting up the Alpha FXM and its internal equipment:

• All AC mains and external supply conductors must be enclosed in a metal conduit or raceway when specified by local, national, and/or other applicable government codes and regulations.

• The customer facilities must provide suitable surge protection.

017-230-B4 Rev B

13

Page 16

4. Unpacking Alpha FXM

WARNING!

The Alpha FXM is heavy, up to 16 kg (35 lb). Use proper lifting techniques. The lifting

and moving should be done by at least two people to avoid injury.

Follow these guidelines for unpacking the Alpha FXM.

1. Select a suitable area for unpacking.

2. Store all the packing material and boxes for possible equipment returns.

3. Compare the packing slip and the list of parts with the items you received: make sure the standard items as

well as purchased options are included:

Standard items

1 Alpha FXM

1 Alpha FXM operator manual

Terminal blocks and labels for the dry contacts

8

1 Temperature sensor cable

Purchased options

• Batteries, if ordered from Alpha, will be shipped separately.

• Enclosure (with optional mounting hardware kit)

• Battery heating mats

• Network Interface card

• In-line fuse

4. If the list of parts on your packing slip does not match the items you received, or any items appear damaged,

immediately notify your carrier agent and the supplier who prepared your shipment.

14

017-230-B4 Rev B

Page 17

5. Installation

WARNING!

The Alpha FXM module MUST be correctly grounded for proper operation.

The input and output lines to and from the Alpha FXM MUST have disconnect devices

attached.

The Alpha FXM must be installed in a restricted area accessible only by qualied service personnel.

Once the installation location has been planned and prepared, you are ready to install the Alpha FXM. There are

three steps to setting up the Alpha FXM:

1. Mounting the Alpha FXM

2. Wiring the external batteries

3. Wiring the Alpha FXM

5.1 Tools and Equipment Required for Installation

• DC voltmeter.

• Labels or masking tape and marker.

• Torque wrench for input/output terminal blocks.

• Slot head screwdriver to fit the terminal blocks.

• Minimum #10 AWG copper wire for input/output terminal blocks.

• High strength, flame-proof tape such as duct tape.

• Battery terminal corrosion inhibitor such as NOCO Company NCP-2 or Sanchem Inc. No-Ox ID Grease “A”.

017-230-B4 Rev B

15

Page 18

5.2 Mounting the Alpha FXM

The Alpha FXM can be placed on a shelf with no other parts needed. Any version of the FXM can be rack or wall

mounted or secured to a shelf, such as on an outdoor enclosure shelf, with the optional mounting brackets as

shown in the figure below The brackets and the screws to attach them to the Alpha FXM case are available from

Alpha Technologies (part number 740-697-21).

CAUTION!

Terminal block covers and the battery harness restraining bracket MUST be used and

are available from Alpha Technologies (part number 740-698-21). If the Alpha FXM end

application is mounted inside an enclosure or in an area restricted to authorized personnel, then the covers and bracket may or may not be needed.

To meet NEBS Level 1 specifications when you are installing this unit in a rack or frame, do the following:

1. Before installation, clean all attachment points on the Alpha FXM, rack and mounting brackets and bring

them to a bright finish. Then coat them with an anti-oxidant such as Sanchem Inc. No-Ox ID “A-Special

Electrical Grade” or equivalent.

2. Attach the mounting brackets with the thread forming screws and the paint piercing washers provided with

the brackets to insure adequate grounding between the Alpha FXM chassis and the rack.

Figure 7 — Mounting the Alpha FXM Mounting brackets position for rack mounting. Rotate to fit either 19" or 23" racks.

For the FXM 1100/2000 units only, the control panel and the power connection panel can be rotated to suit

your needs. To rotate either one, unscrew the screws in each corner, remove the panel, rotate it and reinstall the

screws.

CAUTION!

Use care to avoid damaging or pulling out the wires or the ribbon cables when rotating

the panels.

16

017-230-B4 Rev B

Page 19

5.3 Wiring the External Batteries

WARNING!

The batteries must be installed by qualied personnel trained in the safe use of high-

energy power supplies and their batteries. Refer to the safety section in this manual.

• Use new batteries when installing a new unit. Verify that all batteries are the same type with identical date

codes.

• For the FXM 650-24, the battery string is 24 Vdc. For the FXM 650-48/1100/2000, the battery string is 48 Vdc.

• If you are making your own battery wiring harness, use at least 10 AWG (for FXM 650/1100) or 8 AWG (FXM

2000) wires.

• The battery return connection is to be treated as an Isolated DC return (DC-I) as defined in GR-1089-CORE.

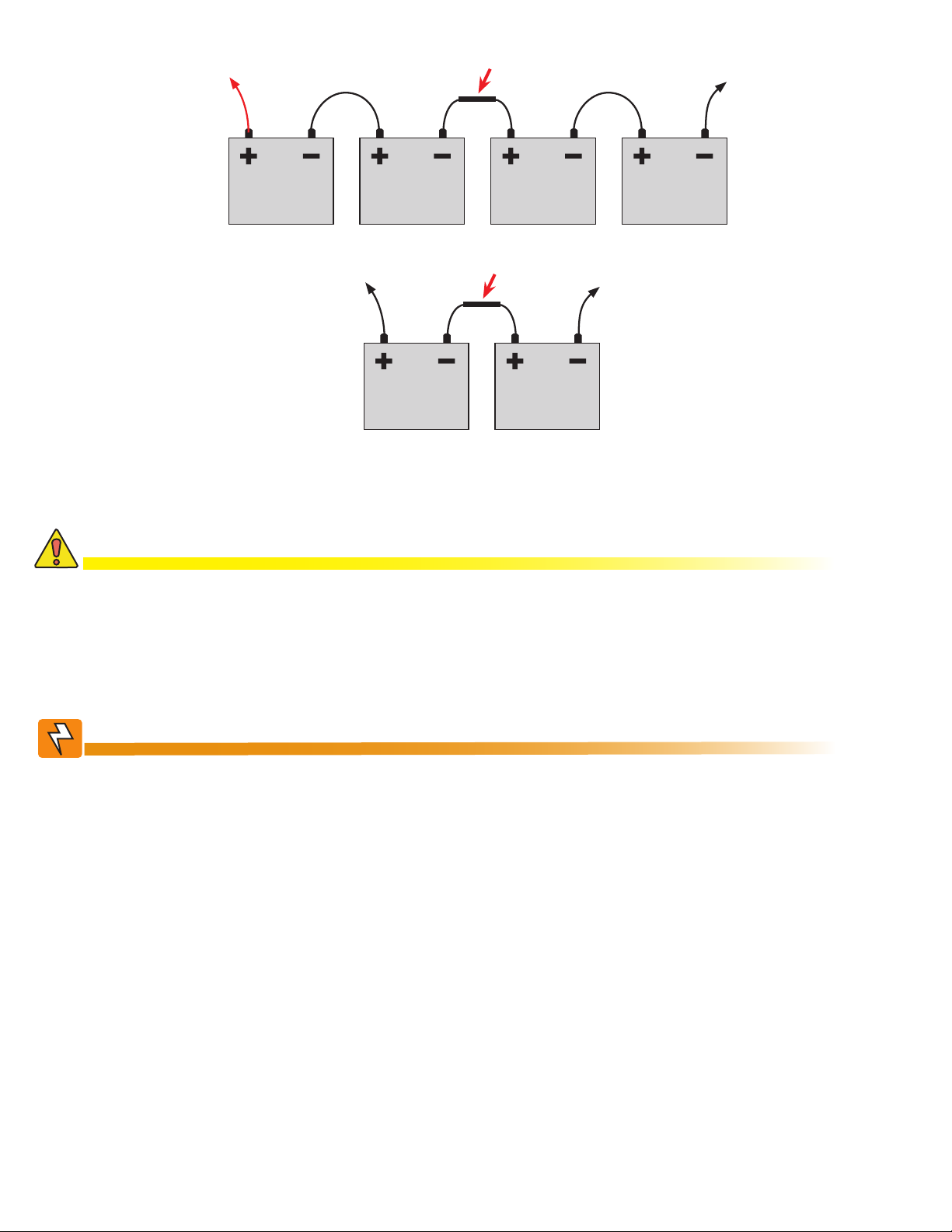

5.3.1 Procedure

NOTE: The optional in-line fuse option shown in Figure 8 on page 18, is available as part number SPB98-645-

1, Kit, FuseUpgrade, 100A.

1. For FXM 650-48/1100/2000 (48 V battery string), number the batteries from 1 to 4 with labels or tape. For

FXM 650-24 (24 V battery string), number the batteries from 1 to 2 with labels or tape.

2. Coat the battery terminals with the corrosion inhibitor.

3. Connect the batteries as shown in Figure 8 on page 18. If used, install the in-line fuse as shown.

4. Connect the black battery cable to the negative terminal of the battery string, and the red battery cable to the

positive terminal of the battery string.

5. When the batteries are wired, measure the voltage at the battery connection terminals. It should read

between 42 and 54V for the FXM 650-48/1100/2000 or 21 and 27V for the FXM 650-24.

6. Note the polarity and ensure it is correct.

7. Ensure that the DC breaker if OFF.

8. Connect the external batteries to the Battery connector—location 2 in Figure 1.

9. Route the sensor end of the battery temperature cable to the batteries.

10. Attach the battery temperature sensor to the body of the battery, about 2 to 3" (5 to 7.5 cm) from the base of

the battery.

11. If multiple battery strings are used, repeat steps 1 to 4 as required.

017-230-B4 Rev B

17

Page 20

To positive terminal

Battery #4 Battery #3 Battery #2 Battery #1

Optional in-line fuse

To negative terminal

To positive terminal

Battery #2 Battery #1

Figure 8 — External Battery Wiring (for 48 Vdc string (top) and 24 Vdc string)

Optional in-line fuse

To negative terminal

CAUTION!

Torque the battery terminals according to the manufacturer’s specications on the

battery name plate or data sheet.

5.3.2 Wiring the Alpha FXM

WARNING!

Make sure the line power is off. Switch off all circuit breakers on the Alpha FXM before

making any electrical connections.

If stranded wires are used to connect the input and output terminal blocks, ferules or

equivalent crimping terminals must be used.

18

017-230-B4 Rev B

Page 21

5.3.3 Procedure

1. If used, connect the following ports (see Figure 1 on page 7 for location of numbered elements):

• Ethernet port 4.

• RS-232 port 7.

• Dry contacts 9.

• User inputs 10.

2. Connect the load to the Alpha FXM Output terminal block 14. Torque to 1.4 N-m (12 lb-in).

3. Connect the line power to the Alpha FXM AC Input terminal block 13. Torque to 1.4 N-m (12 lb-in).

4. If needed, attach the terminal block covers and battery harness restraining bracket.

WARNING!

Before proceeding, verify that the line wire is attached to the line terminal block, the

ground wire is attached to the ground terminal block, and the neutral wire is attached to

the neutral terminal block to prevent accidental shocks or electrocutions.

5.4 UATS and (UGTS) Option

The Universal Automatic Transfer Switch (UATS) and Universal Generator Transfer Switch (UGTS) are the next

generation of Automatic Transfer Switch (ATS) and Generator Transfer Switch (GTS) products. They are optional

add-on switching units specifically designed for the FXM UPS family (FXM 650, 1100 and 2000), the Micro UPS

family (Micro 300 and 1000) and the Alpha FXM350/ Micro350 UPS. These switching units provide power and/or

bypass capacity (automatic or manual) so that the operator may safely disconnect the UPS from line or generator

power for easy removal and servicing. In bypass mode, the loads are directly connected to the line or generator

power without any conditioning. Depending on the use of one and/or the other, the UATS/UGTS allows the use

of up to 3 different back-up sources (line, batteries and generator). Refer to the UATS/UGTS Installation Manual

(Alpha P/N 020-165-B0) for details.

WARNING!

Make sure you have read and understood the instructions given in the UATS/UGTS Installation Manual before making any connection to the supply.

017-230-B4 Rev B

19

Page 22

6. Operating the Alpha FXM

6.1 Switching the Alpha FXM On and Off

Under normal operation, the Alpha FXM is always powered ON to supply uninterruptible power to the load.

Switching off the Alpha FXM will disconnect the power supply to the load. If for any reason you need to switch

off the Alpha FXM while maintaining power to your critical load, make sure that you have a plan that provides an

alternate source of power.

6.1.1 Switch Off Procedure

1. Switch off the AC input circuit breaker.

2. Switch off the battery circuit breaker.

The status LED turns off and the LCD panel goes blank. The Alpha FXM is now switched off and no backup

power is supplied to the load.

6.1. 2 Switch On Procedure (LINE mode)

Before you put the Alpha FXM back into commission, make sure that the line is qualified and the batteries are

fully charged.

1. Switch on the battery circuit breaker. The LCD displays STANDBY and the fan turns on for about a minute. If

the temperature is below –15ºC, the LCD display may not function. See Chapter "8. Troubleshooting".

2. Switch on the AC input circuit breaker. The Alpha FXM qualifies the line power. The LCD displays RETRAN,

then shows LINE, BUCK or BOOST. The status LED illuminates.

3. If there is no line power, the Alpha FXM remains in the STANDBY mode until the line power is qualified. To

provide backup battery power to the load, perform a manual start by using the Inverter command: From

the Control Menu, scroll till the LCD displays Inverter, press Select and select ON. (See Figure 11 on page

23).

The Alpha FXM uses auto-frequency detection. When it is first switched on, it senses the line frequency and adjusts its output frequency to match that of the input. The load should be receiving power, If not, perform troubleshooting.

6.1.3 Switching the Alpha FXM from Line mode to Inverter mode

You can force the Alpha FXM to operate in the Inverter mode by manually switching off the input circuit breaker.

Doing so will effectively disconnect any line power to the Alpha FXM, simulating a power outage which triggers

the Alpha FXM to switch to the inverter mode of operation.

Procedure

1. Switch off the input circuit breaker. The LCD shows INVERTER, the status LED starts flashing to show that

the Alpha FXM is running on backup battery power. Confirm that the load is receiving power.

6.1.4 Switching the Alpha FXM from Inverter mode to Line mode

The Alpha FXM remains in the Inverter mode for as long as the input circuit breaker is switched off. Backup power is provided to the load until the batteries are drained to a preset level which triggers the Alpha FXM to shutdown automatically. If it is not necessary to operate the Alpha FXM in the Inverter mode, switch the Alpha FXM

back to the Line mode as soon as possible.

Procedure

1. Switch on the input circuit breaker. The Alpha FXM qualifies the line power. The LCD displays RETRAN, then

shows LINE, BUCK or BOOST. The status LED illuminates.

If the Alpha FXM constantly switches between Inverter and Line modes because of a noisy line, broaden the

input parameter tolerances from Normal to Generator. See Sense Type in Table B on page 24.

20

017-230-B4 Rev B

Page 23

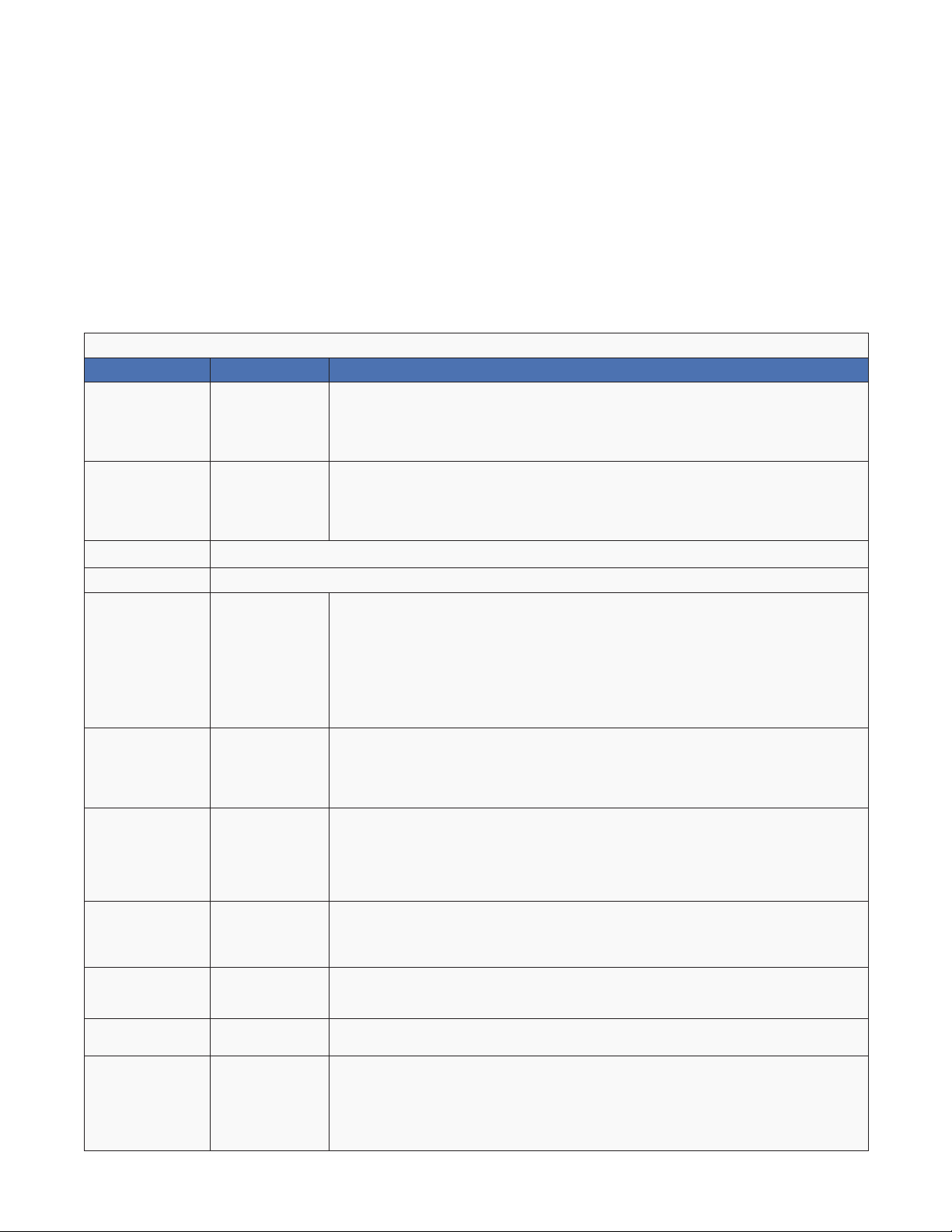

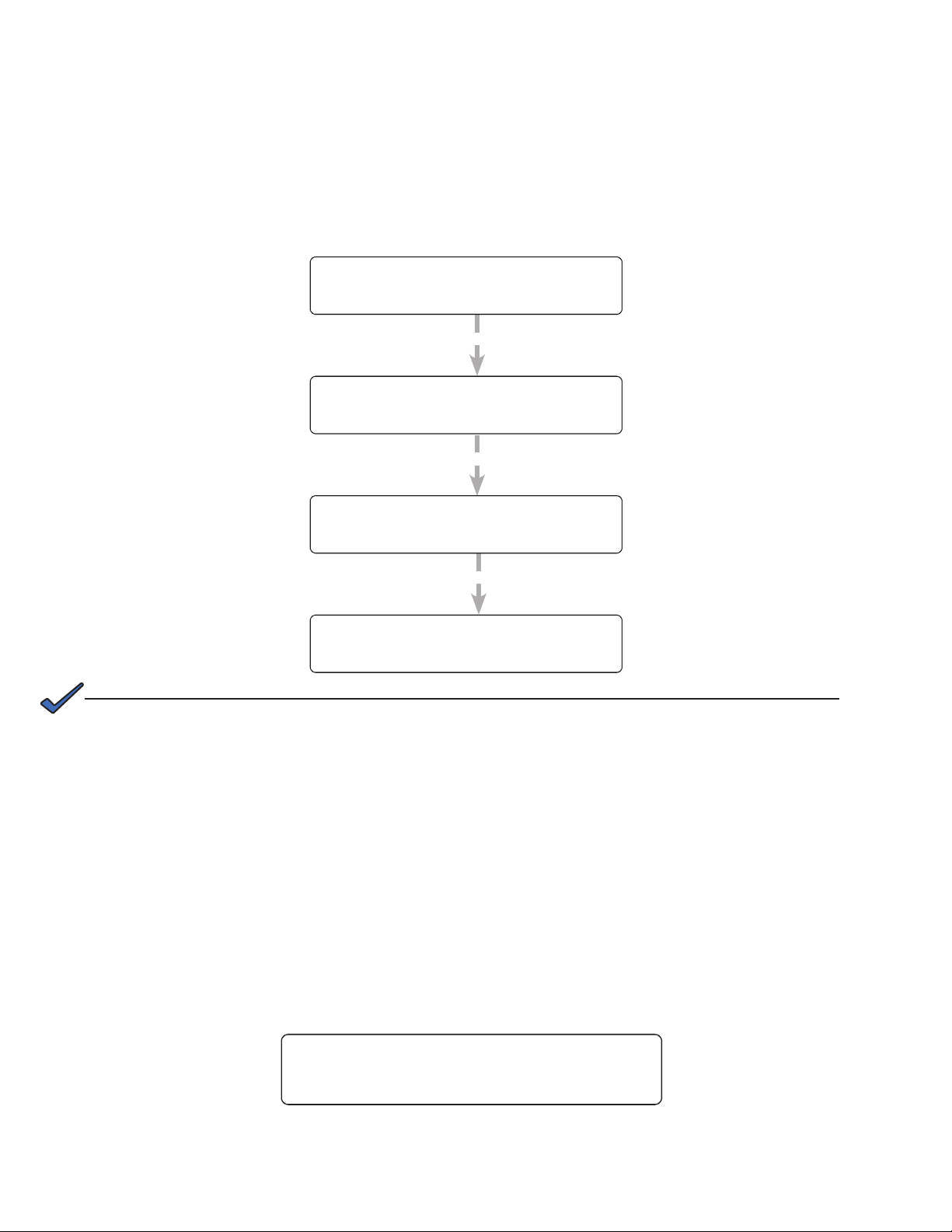

6.2 Operating from the Control Panel Interface

The LCD control panel provides “at a glance” monitoring. This panel, when used along with the CANCEL,

SCROLL and SELECT buttons, allows you to program, make measurements, and troubleshoot the Alpha FXM.

The layout of the LCD interface is shown in Figure 9.

The Alpha FXM is monitored and controlled with a series of menus and submenus.

Alpha

A

A Alpha FXM model name

Alpha FXM voltage conguration - 120 Vac or 230 Vac

B

Alpha FXM Frequency - 50 Hz or 60 Hz

Sense Type setting - Normal (N) or Generator (G); see Sense Type in Table B

C Present operating mode - (LINE mode shown) See Figure 10.

Control buttons:

SELECT - Pressing SELECT moves you down 1 level in the menu tree (Table C) or

accepts a change when programming.

D

SCROLL - Pressing SCROLL moves you through the submenus (Table C) or toggles

between choices when programming.

CANCEL - Pressing CANCEL moves you up one level in the menu tree (Table C).

FXM 2000

CANCEL

SCROLL

D

120/60/N

LINE

SELECT

B

C

Figure 9 — LCD Control Panel Logo Screen

The Alpha FXM operating mode automatically changes as a result of changes in the line or the Alpha FXM operating mode. (The LCD panel automatically updates to reflect the new mode. See Table A and also "Table V —

Boost/Buck/Line Transfer Thresholds" on page 82.

Table A — UPS Operating Modes

LCD display Description

SHUTDOWN The Alpha FXM inverter is switched off. Line power is disconnected from the load.

LINE The Alpha FXM is switched on. Line power is provided to the load.

BOOST1 OR BOOST2 The Alpha FXM transformer is raising line voltage without using the batteries. AVR is enabled.

BUCK1 OR BUCK2

INVERTER The Alpha FXM is providing backup battery power to the load.

RETRAN

STANDBY

BYPASS

The Alpha FXM transformer is lowering line voltage without using the batteries. AVR is

enabled.

The Alpha FXM is transferring from INVERTER mode to Line mode.

The Alpha FXM is switched on and waiting for the line power to qualify or the user to clear

some faults.

CAUTION: Do not touch the AC output terminals, which may still be energized.

This mode is manually set with the Control Menu. See Figure 11, “Control Menu, BYPASS”.

This locks the unit into line mode and turns off the battery charger so the unit can work with a

manual break-before-make bypass switch.

017-230-B4 Rev B

21

Page 24

CANCEL

Logo Screen

(Figure 9)

SELECT

Starting at the Logo

Screen, press the SELECT

button to go down one level.

Press the SCROLL button to move between

the menus. The SCROLL button moves only in one

direction, so if you overshoot, you have to go all the way

around the menu tree again.

Control Menu

(Tabl e B)

System Status Menu

SCROLL

Alarm and Fault

(Tabl e C)

CANCEL

SCROLL

SELECT

Menus (If Active)

(Tabl e P and Tab le Q)

Press the SELECT button to enter the submenu.

Then press the SCROLL button to cycle through the

submenu items. The SCROLL button moves only in

one direction, so if you overshoot, you have to go all

SCROLL

Figure 10 — LCD Menu Structure

the way around the submenu again.

SCROLL

Event Status Menu

22

017-230-B4 Rev B

Page 25

The CONTROL MENU

(Table B) lets you

control, program and

adjust the Alpha FXM

for connection to traffic

intersection equipment

or other applications.

You can control the:

• INVERTER Enable/

Disable

• INVERTER On/Off

• LVD DSCNNCT

• LVD CONNECT

• BYPASS

• BATT TEST

• BT TS DOD

• AUTO TEST

• SHUTDOWN

• SHUTDOWN AC

• SHUTDOWN DC

• SENSE TYPE

• FUNC MODE

• VOLTAGE

• AUTO FREQ

• FREQUENCY

• QUAL TIME

• INVERTER CUTOFF

Enable/Disable

• INVERTER CUTOFF

(voltage)

• CHARGER

• BATT FLOAT

• CHGR CUR

• BATT COMP

• DATE FRMT

• CLOCK FRMT

• INV RECORD

• RELAY TEMP

• TEMP DISP

• DAYLIGHT

• CONFIGURE IP

The SYSTEM STATUS

menu (Table C) lets you

measure various inputs,

outputs and other

values. The available

measurements are:

• VIN

• VOUT

• IOUT AC

• BATT TEMP

• FREQ IN

• OUTPUT PWR

• BATT VOLT

• CHGR CUR

• DATE

• TIME

• INV COUNT

• INV TIMER

• BUCK/BOOST

• SHED TIMER 1, 2

OR 3

• MAC Address

• IP Address

• kWh

• Remain Tm

• Serial Number

• VERSION

The ALARM and FAULT

menus in the Troubleshooting section are

invisible and disabled

until the Alpha FXM has

a malfunction.

When the front panel

alarm LED is on or

flashing, press SELECT.

One of the malfunctions

listed in Table R and

Table S will appear

on the LCD. Press the

SCROLL button to

see if more than one

malfunction is present.

Fix the malfunction.

Press the SELECT

button to clear the

malfunction from the

screen.

If the malfunction is

fixed, the malfunction

is cleared from the

LCD. If it isn’t fixed, it

will reappear on the

screen.

The EVENT STATUS

menu displays the last

200 Alpha FXM events

on the LCD.

Press the SELECT

button to access the

menu. Press SELECT

and then the SCROLL

button to scroll through

the events. To see what

a specific event was,

press the SELECT button. Press the SCROLL

button to see what

malfunction triggered

the event.

017-230-B4 Rev B

Figure 11 — LCD Menu Tree

23

Page 26

6.2.1 The LCD Control Menu

The control menu (Table B) lets you operate the Alpha FXM or program it to suit your operating conditions.

Procedure

1. From the Logo screen go to the Control menu.

2. Press the SELECT button to enter the submenu (Table B).

3. Press the SCROLL button to move between items in the submenu.

4. When you have reached the item you want to change, press the SELECT button. The item chosen is blinking.

5. To toggle between the choices, press the SCROLL button. Stop when you reach the choice you want.

6. To make the change, press the SELECT button. The blinking stops.

Table B — Control Menu

LCD display Meaning Description

INVERTER

INVERTER

LVD DSCNNCT Battery voltage value at which the LVD congured relay should open

LVD CONNECT Battery voltage value at which the LVD congured relay should close

BYPASS Inverter Bypass

Inverter

(Enabled/

Disabled)

Inverter (On/

Off)

When Disable is selected and AC is lost, the FXM will be in Standby mode. The

inverter cannot be started through the Inverter On/Off menu,

When Enable is selected and AC is lost, the FXM will be in Inverter mode. Turning

inverter on/off manually will work.

When inverter mode is set to ON, the Alpha FXM provides backup battery power

to the load. This mode of operation is normally activated automatically when line

power becomes unavailable, or the line power is not qualied. You can also put

the Alpha FXM into this mode during initial startup in the absence of line power or

because of unqualied line power.

This function can only be switched on when the Alpha FXM is in Line mode. When

switched on, it locks the Alpha FXM into the Line mode, switches off the battery

charger and makes the output voltage equal to the input voltage.

Used when:

• Replacing the batteries.

OR:

• To allow the use of a break-before-make manual bypass switch so the

Alpha FXM can be shut off for maintenance or replacement without interrupting

power to the load.

Available when CHARGER on the Control Menu is set to Standard method.

BATT TEST Battery Test

BT TS DOD

AUTO TEST Automatic Test

SHUTDOWN

SHUTDOWN AC

SHUTDOWN DC

24

Battery Test

Depth-ofDischarge

Shutdown AC

and DC (On/

Off)

Shutdown AC

(On/Off)

Shutdown DC

(On/Off)

Starts the battery test, which uses depth-of-discharge setting, the battery capacity,

Peukert number, and open-circuit voltage. This setting can be adjusted using BT TS

DOD menu. A battery test is also performed during the self test.

Available when CHARGER on the Control Menu is set to Standard method.

Sets the desired battery test depth-of-discharge to a value between 0 and 100%.

Make sure that the set time duration is shorter than the max back up time of your

battery bank. Otherwise, you will drain the battery and trigger a fault – Batt Volt Low.

The default value is set to 20% DoD.

Available when CHARGER on the Control Menu is set to Standard method.

If the GUI periodic self test is enabled, this starts the test when it is scheduled to

take place.

When this function is switched On, the Alpha FXM inverter is shut off. Neither Line

nor Inverter power is supplied to the load. If a dry contact was used as a LVD, the

LVD will open.

When this function is switched On, the Alpha FXM inverter is shut off. Neither Line

nor Inverter power is supplied to the load.

When this function is switched On, the LVD congured relay will be de-energized.

Applies when ANY programmable dry contact is programmed to be the Low Voltage

Disconnect indicator. See "UPS Maintenance > Relay & Load Shed" on page 41.

When the function is switched from On to Off, a 10 second delay occurs before the

LVD congured relay is re-energized.

017-230-B4 Rev B

Page 27

Table B — Control Menu

LCD display Meaning Description

This function can only be used when the Alpha FXM is in Standby or Shutdown

mode (Table A).

SENSE TYPE Sense Type

FUNC MODE Functional

VOLTAGE Voltage

AUTO FREQ Automatic

FREQUENCY Frequency

QUAL TIME

INV CUTOFF

INV CUTOFF

CHARGER

BATT FLOAT

BATT COMP

DATE FRMT

CLOCK FRMT

INV RECORD

CHGR CUR Charger current

Mode

Frequency

Detection

Line qualify

time

Inverter Cutoff

(Enabled/

Disabled)

Inverter Cutoff

Threshold

(Voltage)

Battery

charging

options

Battery

charging oat

options

Battery

temperature

compensation

Date Format

Selection

Clock display

format option

Inverter record

clear

Normal: The Alpha FXM can operate successfully with most line conditions.

OR:

Generator: This setting increases noise tolerance so the uctuations created by

a generator are acceptable. (A noisy line can cause the Alpha FXM to constantly

switch between inverter and line modes.)

The Functional mode can be changed when the Alpha FXM is in any mode (Table C

and "Table V — Boost/Buck/Line Transfer Thresholds" on page 82).

Automatic Voltage Regulation (AVR): Buck and boost modes are active.

OR:

Quality: Buck and boost modes are switched off; the input voltage is the Alpha FXM

output voltage.

Sets the Alpha FXM output voltage setting to one of the voltages specied in

"Specications" on page 80. Changing the voltage setting from factory default

should be done by a qualied technician acting under the instructions of Alpha

Technical Support (1 888 462 7487). Failure to contact Alpha Technologies before

performing this procedure could void your warranty.

Enable (default) allows the unit to detect and automatically congure the AC input

frequency (50Hz or 60Hz).

In cases where the AC input frequency can be out of range for long periods,

Disable prevents the unit from switching back and forth between 50Hz and 60Hz.

The frequency can only be changed when the Alpha FXM is in Standby mode—to

50 Hz or 60 Hz. This change should ONLY be done by a qualied technician acting

under the instructions of Alpha Technical Support (1 888 462 7487). Failure to

contact Alpha Technologies before doing this procedure could void your warranty.

Set how long it takes for the Alpha FXM to return to Line mode after the line has

become requalied to make sure the line is stable. The factory default setting

is 3 seconds. User adjustable in increments of 1 sec until 1 minute, and then in

increments of 1 minute to 15 minutes max.

When Disable is selected the default FXM inverter cutoff threshold is used.

When Enable is selected the user congured inverter cutoff threshold voltage is

used.

Denes the point where the unit will switch from Inverter to Standby when the

battery is considered to be low or in order to preserve the battery. See "UPS

Maintenance > Inverter" on page 40.

When Standard charger is selected, set BATT FLOAT to AUTO or Constant.

When Bulk charger is selected, set MAX VOLT and FLOAT VOLT. See section 6.2.2

When BATT FLOAT is set to Constant, the default max charge voltage is 54.6V

and oat is 54.2V, both at 25°C. Temperature compensation will be active

When BATT FLOAT is set to AUTO, the oat voltage is set to 1.8V below the max

charge voltage. The default max charge voltage is 54.6V and default oat is 52.8V,

both at 25°C

Sets the battery temperature compensation to match the batteries you are using. It

can be set from 0 to -6 mV/°C/Cell in increments of 0.5. The factory default setting

is -5 mV/°C/Cell.

Toggles the Alpha FXM date format between YY-MM-DD, MM-DD-YY, DD-MM-YY

YYYY-MM-DD, MM-DD-YYYY, DD-MM-YYYY, YY-TXT-DD, TXT-DD-YY, DD-TXTYY, YYYY-TXT-DD, TXT-DD-YYYY, DD-TXT-YYYY, YYYY-DD-TXT, YY-DD-TXT,

YYYY-DD-MM, YY-DD-MM. The factory default setting is MM-DD-YY.

Format to display time information: in 24 hour clock format or 12 hour clock (AM/

PM).

Clears the inverter counter and timer from the LCD system status menu.

Charging current can be set to 0A or any value between 2 and maximum in

increments of 1A, where maximum = 15A for FXM1100/FXM2000 and 10A for

FXM650. (Charging current cannot be set to 1A).

017-230-B4 Rev B

When charging current is set to 0A, the charger will stop charging.

25

Page 28

Table B — Control Menu

LCD display Meaning Description

RELAY TEMP

TEMP DISP

DAYLIGHT

CONFIGURE IP FXM IP Congure the FXM IP address

Relay

temperature

Temperature

display format

Daylight saving

option

Temperature setting to activate the specied dry contact. The congured dry contact

will activate when the set battery temperature is reached. Setting range: 20ºC to

55ºC in increments of 5ºC.

The temperature can be displayed in Celsius or Fahrenheit.

Switch ON this option to activate Daylight Saving time.

6.2.2 Battery Charging Options

CAUTION!

The adjustments to the charge algorithm must be made only by qualied personnel,

who understand the different charging modes and their suitability to the battery

chemistry.

Alpha

120/60/N

FXM2000 STANDBY

CANCEL

SCROLL

Standard Battery Charging

For more information on standard battery charging, refer to the web GUI description "UPS Maintenance > Battery"

on page 38.

1. Put the unit in STANDBY mode before starting this procedure.

2. Use a combination of the SCROLL and SELECT keys on the control panel interface to select

CHARGER in the Control menu.

3. Select Standard to charge the batteries in AUTO or Constant mode.

CONTROL

MENUS

SELECT

120/60/N

STANDBY

BATT FLOAT

Constant

When BATT FLOAT is set to Constant, the default max

charge voltage is 54.6V and float is 54.2V, both at 25°C.

Temperature compensation will be active.

120/60/N

STANDBY

26

CHARGER

Standard

120/60/N

STANDBY

BATT FLOAT

AUTO

When BATT FLOAT is set to AUTO, the float voltage is set to

1.8V below the max charge voltage. The default max charge

voltage is 54.6V and default float is 52.8V, both at 25°C.

120/60/N

STANDBY

017-230-B4 Rev B

Page 29

Bulk Battery Charging

Selecting Bulk allows programming of the max voltage and the float voltage. For more information on bulk battery

charging, refer to the web GUI description "UPS Maintenance > Battery" on page 38.

1. Put the unit in STANDBY mode before starting this procedure.

2. Use a combination of the SCROLL and SELECT keys on the control panel interface to select

CHARGER in the Control menu.

3. Select Bulk to set the max charge voltage and float voltage for charging the batteries (selectable in 0.1V

increments).

CONTROL

MENUS

CHARGER

Bulk

Selecting Bulk allows

programming of the

max charge voltage

and the float voltage.

MAX VOLT

53.5V

FLOAT VOLT

52.5V

NOTE:

Temperature compensation defaults to 0 mv/ °C/ cell in this mode, but can be changed

to non-zero values.

120/60/N

STANDBY

120/60/N

STANDBY

120/60/N

STANDBY

120/60/N

STANDBY

Selectable in 0.1V steps: from

52 to 56V. (Default is 53.5V)

Selectable in 0.1V steps: from

52V to less than or equal to max

charge voltage. (Default is 53.5V)

If you set the max charging voltage to a value lower than currently set oat voltage, oat

voltage will be automatically adjusted to be equal to the new max charging voltage.

6.2.3 Controlling the external fan by temperature triggered dry contact

The Temperature trigger has a user configurable range of +20°C to +55°C (68 to 131 °F). When the battery

temperature (monitored by the Battery Temperature Probe) reaches the threshold, the assigned relay closes and

turns on the external fan.

Procedure

From the Logo screen, navigate to Control Menu > RELAY TEM P. Press the SELECT button and the current

temperature display will start flashing. Use the Scroll button to change the temperature in 5°C increments. Press

SELECT to accept the changes or CANCEL to abort.

RELAY TEMP

55

Dry contact functions are not programmable through the LCD. Use the Web GUI or HyperTerminal instead.

017-230-B4 Rev B

120/60/N

LINE

27

Page 30

6.2.4 Making Measurements

The System Status menu lets you make measurements of various Alpha FXM inputs, outputs, temperatures and

other values.

Procedure

1. From the Logo screen go to the System Status menu.

2. Press the SELECT button to enter the submenu (Table E).

3. Press the SCROLL button to move between items in the submenu. Stop at the item you want to measure. The

measurement is displayed on the LCD and automatically updated every 0.5 second.

Table C — System Status Menu

LCD display Meaning Description

VIN Input Voltage Line input voltage into the Alpha FXM

VOUT Output Voltage

IOUT AC

BATT TEMP

FREQ IN Input Frequency Frequency of line power into the Alpha FXM (Hz)

OUTPUT PWR Output Power Alpha FXM output power in VA (true RMS)

BATT VOLT Battery Voltage Battery output voltage (Vdc)

CHGR CUR Charger Current Alpha FXM battery charging current (Amps)

DATE Current date Displays in the format set by the user

TIME Current time

INV COUNT # of line failures

INV (min)

BUCK/BOOST

SHED TIMER1

SHED TIMER2

SHED TIMER3

Output Current

(AC)

Battery

Temperature

Amount of time

inverter was on

Buck/Boost

count

Amount of time

(in seconds) until

the dry contact is

activated.

Alpha FXM output voltage (true RMS)

Alpha FXM AC output current (true RMS)

Battery temperature (°C)

Displays in the format set by the user

Shows how many times the inverter has been active since the last time the

inverter counter was cleared. See INV RECORD description in Table B.

Shows total time in minutes the inverter has been active since the last time the

inverter timer was cleared. See INV RECORD description in Table B.

Number of times FXM goes into Buck and Boost mode

The factory default dry contact for this setting is contact C4. SHED TIMER2 and

SHED TIMER3 can be eld programmed. The factory default setting is 2 hours,

To change the setting see "UPS Maintenance > Relay & Load Shed" on page

41.

28

MAC Address FXM MAC

IP Address FXM IP FXM IP

kWh kWh Meter Accumulated output energy

Remain Tm

Serial Number

VERSION Software Version Software version used in this Alpha FXM

Remaining

Battery Runtime

Unit Serial

Number

FXM MAC address

Remaining runtime of the battery (standard charging method)

Unit serial number of the Alpha FXM

017-230-B4 Rev B

Page 31

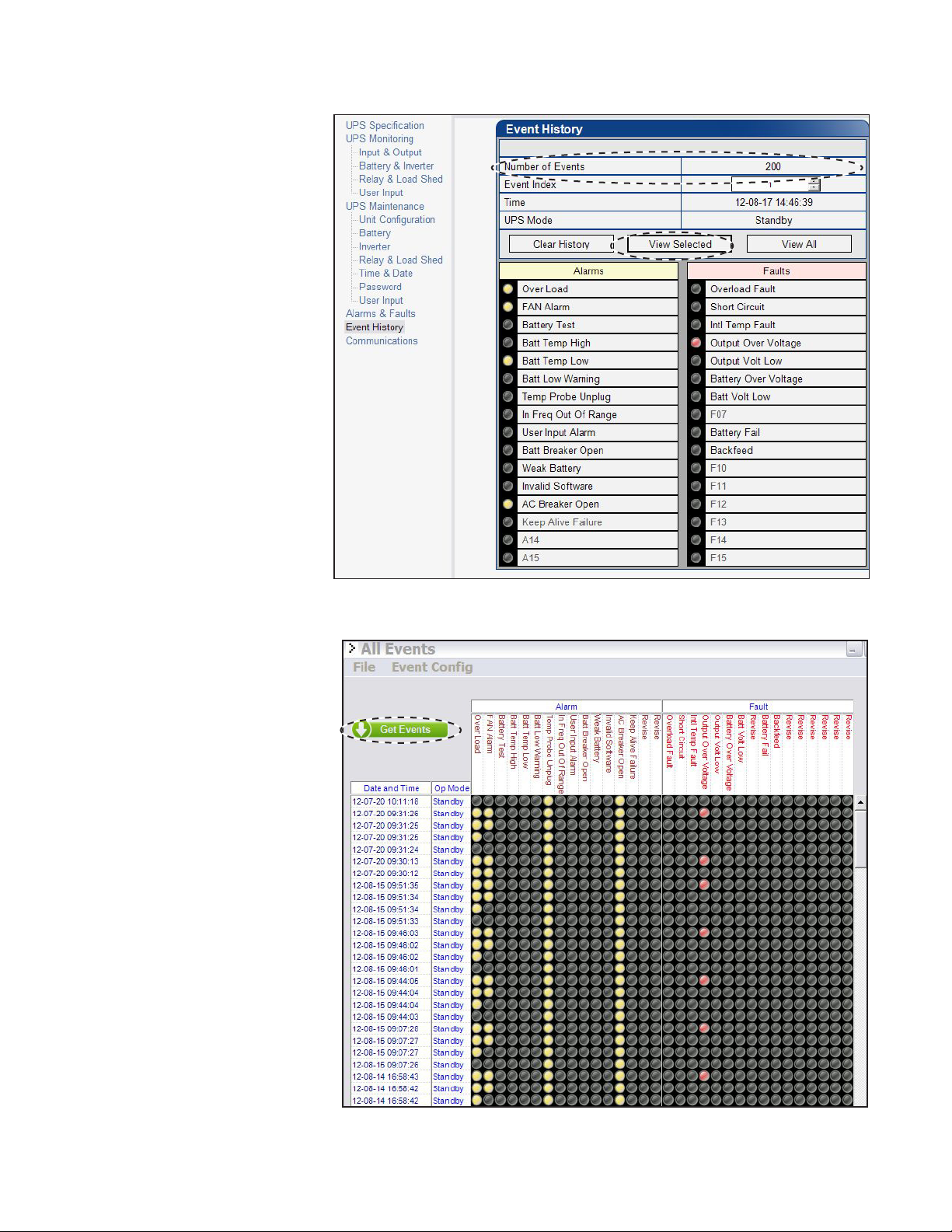

6.2.5 Viewing the 200-Event Log

Use the LCD display to view up to the last 200 events, and the malfunctions that triggered each of them. If more

than 200 events occurred, the oldest is overwritten. The 200-event log cannot be cleared in the LCD menus.

Procedure

1. From the Logo screen, navigate to the EVENT STATUS MENU.

EVENT STAT

MENUS

2. Press the SELECT button to enter the submenu.

3. The following log screen appears.

DATE EVENT HAPPENED

(YY:MM:DD) (Depends on

selected date format)

OPERATING MODE the

Alpha FXM was in when the

event happened (LINE shown)

06:11:29

16:23:56

TIME EVENT HAPPENED

(HH:MM:SS 24-hour clock)

(Depends on selected date format)

4. Press the SELECT button. The event counter flashes.

5. Press the SCROLL button to scroll through the event counter.

6. When you reach the event you want press the SELECT button.

7. The event loading screen appears and then the log screen reappears with the details for that event.

120/60/N

LINE

LINE

EVENT: 1

EVENT COUNTER

(Event #1 shown)

Event

Loading

ALARM STATUS

EVENT: 1

Over Load

8. Press the SCROLL button. One of the faults or alarms shown in Table Q and Table R is displayed and is the

malfunction that triggered the event.

017-230-B4 Rev B

29

Page 32

6.3 Operating via the FXM Communication Module (Intranet or Internet)

The internet or a company intranet can be used to communicate with the Alpha FXM through the factory-installed

FXM communication module.

B

A

A Screen selection menus

B Current UPS operating mode. Updates automatically.

Fault and alarm indicators – when a light in this bar is illuminated, move the mouse

C

cursor over the light to determine the malfunction. Double-clicking on the light will

send you to the Alarms & Faults screen.

D Readout screens

C

D

30

Figure 12 — Web GUI (UPS Specification screen shown)

017-230-B4 Rev B

Page 33

6.3.1 Installation and Set Up

The following tools and materials are needed:

• Computer with network card and web browser

• Cross over cable or hub

• The UPS Final IP Address and Subnet Mask and, if needed, the Default Gateway and the DNS Server ad-

dresses

CAUTION!

To successfully complete this procedure, you should have a working knowledge of

network protocols and how to congure them. Consult your network administrator for

details.

If multiple UPS are installed on the same network, congure each unit’s IP address

before the installation. (See "Figure 1 — FXM 650 (top) and FXM 1100/2000 front panel

description" on page 7.) Each UPS on the network MUST have its own unique IP address.

Procedure

1. Connect the Alpha FXM to a personal computer with either the cross over cable or through a hub.

2. Switch on the personal computer.

3. Configure the network card to talk to the FXM communication module. The module default address is

http://192.168.0.90.

4. Cut and paste the IP address into the browser and press ENTER.

5. Select Communications > Configure TCP/IP in the home screen (Figure 12).

6. Configure the TCP/IP properties according to your network requirements.

7. Click Apply Settings.

017-230-B4 Rev B

Figure 13 — Communications screen

31

Page 34

6.3.2 UPS Specifications

This screen displays the Alpha FXM2000 specifications.

Figure 14 — UPS Specification screen

6.3.3 UPS Monitoring

These read-only screens show the Alpha FXM current input and output values and other measurements.

UPS Monitoring > Input & Output

Shows the current line input and Alpha FXM output values and the Alpha FXM present operating mode.

Figure 15 — UPS Monitoring: Input & Output screen

32

017-230-B4 Rev B

Page 35

UPS Monitoring > Battery & Inverter

Shows the battery string status and how many times and for how long the inverter has been active.

The appearance of the Battery Parameters table depends on the choice of charging method—see "UPS Maintenance > Battery" on page 38.

Figure 16 — UPS Monitoring: Battery & Inverter screen—standard charging method

The Battery & Inverter monitoring page for bulk charger does not display a number of parameters: Runtime Remaining, Peukert Number, Capacity and Battery Open-Circuit Voltage.

Figure 17 — UPS Monitoring: Battery & Inverter screen—bulk charging method

017-230-B4 Rev B

33

Page 36

Monitoring > Relay & Load Shed

Shows how the front panel dry contacts are configured. If any relays are used for load shedding, the time setting

is shown.

Figure 18 — UPS Monitoring: Relay & Load Shed screen

Monitoring > User Input Status

Shows the current status of the user programmable inputs 1 to 4.

NOTE: User input 4 is only available on some models.

Figure 19 — UPS Monitoring: User Input Status screen

34

017-230-B4 Rev B

Page 37

6.3.4 UPS Maintenance Menus

Use the UPS Maintenance screens to configure and adjust the Alpha FXM to meet your operating needs.

To change parameters, either click the On/Off buttons or select an item from a drop down menu.

To execute the changes, click on the Update Configuration button.

UPS Maintenance > Unit Configuration

Sets the unit name, input, output and how often the Alpha FXM parameters update.

AC Output Shutdown

When this function is switched On, the Alpha FXM inverter is shut off. Neither line nor inverter power is supplied to the load.

DC Output Shutdown

When this function is switched On, the LVD configured relay will be de-energized (Off).

Applies when ANY programmable dry contact is programmed to be the Low Voltage Disconnect indicator.

See "UPS Maintenance > Relay & Load Shed" on page 41. When the function is switched from On to Off, a 10

second delay occurs before the LVD congured relay is energized.

Automatic Frequency Detection

This setting is enabled by default and allows the unit to detect and automatically configure the AC input

frequency (50Hz or 60Hz).

In cases where the AC input frequency can be out of range for long periods, disabling the automatic configuration prevents the unit from switching back and forth between 50Hz and 60Hz.

Figure 20 — Shown for 230Vac unit, Power set to AVR,

Power Quality or AVR

Figure 21 — Shown for 230Vac unit, Power set to Quality

AVR (Automatic Voltage Regulation) switches on the buck and boost modes.

Quality switches off the buck and boost modes. The input voltage is the Alpha FXM output voltage.

AVR boost/line/buck thresholds (field not available for 120Vac units)

For 230Vac units only, the AVR boost/buck thresholds can be configured (Figure 20). Select Reduced to

decrease the thresholds in order to be in Line mode when the AC input is between 195Vac and 239Vac.

Quality: line/inverter thresholds (field not available for 120Vac units)

For 230Vac units only, the Quality thresholds can be configured (Figure 21). Select Increased to increase the

thresholds by 7Vac in order to be in Line mode when the AC input is between 219Vac and 260Vac.

017-230-B4 Rev B

35

Page 38

Restoring All Parameters to Default Values

The purpose of this command is to reset the Alpha FXM to the factory default parameters in Table D. Battery

charger related defaults are reset according to the charging method selected at the time the defaults are applied.

CAUTION!

This command resets all parameters that are user-congurable. The command is password protected. All previously programmed operation will be lost.

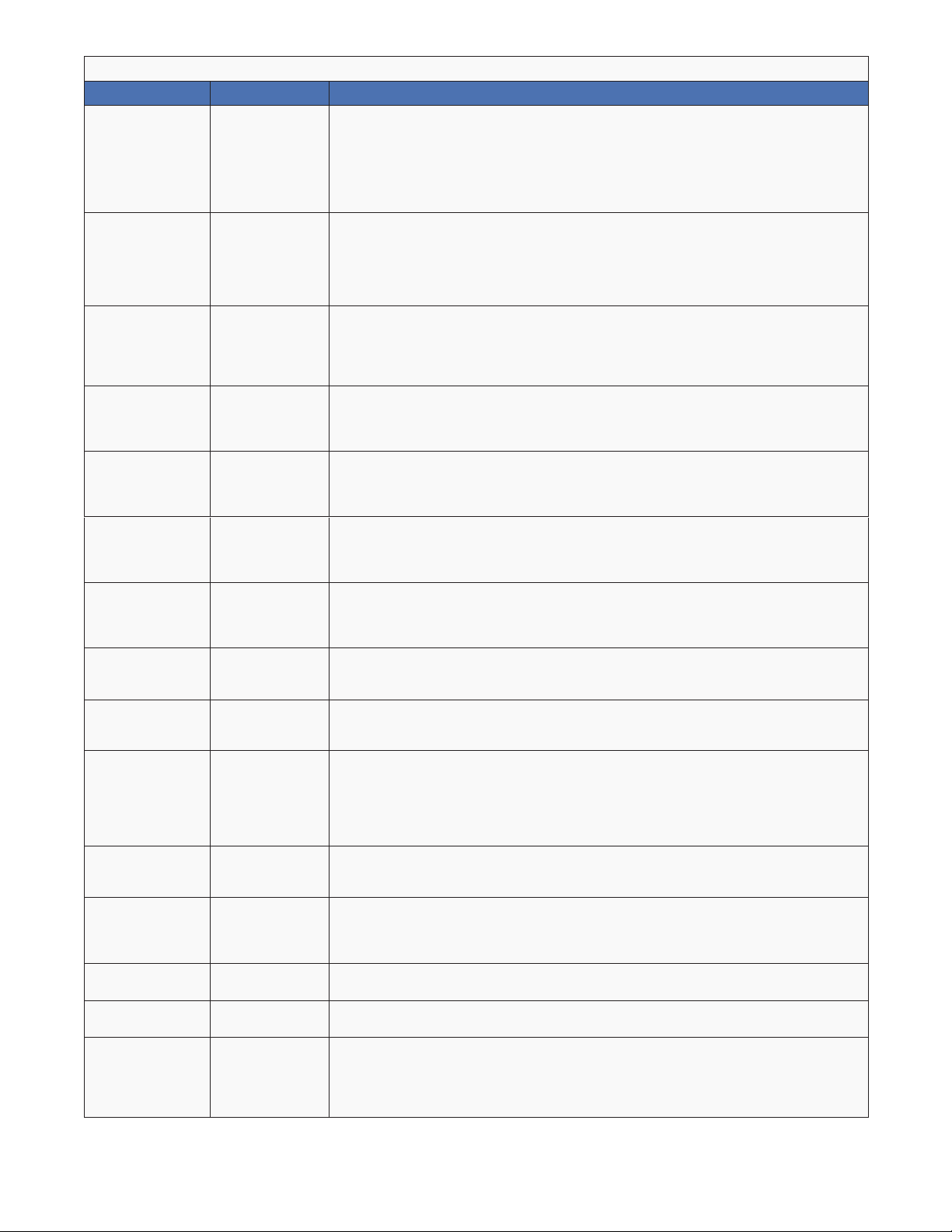

Table D — Parameters/ Default Settings

Parameters Default Settings

Battery charging current (Amps) 10

Temperature compensation of battery charging

(mV/°C/Cell)

Maximum charge voltage: Standard > Auto mode @25°C (V)

Maximum float voltage: Standard > Auto mode @25°C (V)

Maximum charge voltage: Standard > Constant mode @25°C (V)

Maximum float voltage: Standard > Constant mode @25°C (V)

Maximum charge voltage: Bulk mode (V) 53.5

Maximum float voltage: Bulk mode (V) 53.5

Default low battery warning Bulk mode (V) 44

Type setting of programmable user input #1 Edge trigger

Level setting of programmable user input #1 Low

Action #1 setting of programmable user input #1 Self test

Action #2 setting of programmable user input #1 None

Type setting of programmable user input #2

Level setting of programmable user input #2 Low

Action #1 setting of programmable user input #2 User alarm on

Action #2 setting of programmable user input #2 User alarm off

Type setting of programmable user input #3 Edge trigger

Level setting of programmable user input #3 Low

Action #1 setting of programmable user input #3 Shutdown on

Action #2 setting of programmable user input #3 Shutdown off

Type setting of programmable user input #4 Edge trigger

Level setting of programmable user input #4 Low

Action #1 setting of programmable user input #4 None

Action #2 setting of programmable user input #4 None

Start hour of rush hour of time of day action period #1 00

Start minute of rush hour of time of day action period #1 00

End hour of rush hour of time of day action period #1 00

End minute of rush hour of time of day action period #1 00

Start hour of rush hour of time of day action period #2 00

Start minute of rush hour of time of day action period #2 00

End hour of rush hour of time of day action period #2 00

Standard charging method: -5.0

Bulk charging method: 0

54.6

52.8

54.6

54.2

Level toggle

36

017-230-B4 Rev B

Page 39

Table D — Parameters/ Default Settings

End minute of rush hour of time of day action period #2 00

Format setting of date display on LCD YY-MM-DD

Line qualify time (sec)

Inverter off delay setting (sec) 0

Number of weeks setting of periodical self-test 4

Day of the week setting of periodical self-test Monday

Time of the day setting of periodical self-test

Battery low warning threshold setting: Standard charge mode (%) 40

Self test depth-of-discharge setting: Standard charge mode (%) 20

Temperature setting to turn on cooling fan (°C)

Load shed timer1 duration 2: 00:00

Load shed timer2 duration 2: 00:00

Load shed timer3 duration 2: 00:00

Programmable dry contact #1 setting On Batt

Programmable dry contact #2 setting Low Batt

Programmable dry contact #3 setting Low Batt

Programmable dry contact #4 setting Timer 1

Programmable dry contact #5 setting Alarms

Password setting 1111

3

00:00:00

55

017-230-B4 Rev B

37

Page 40

UPS Maintenance > Battery

Setting the Battery Charging Method to Standard or Bulk in the Battery Primary Configuration table

determines which parameters can be set or adjusted. See Figure 22 and Figure 23. The Standard charging

method is the default setting.

Standard Charging Method

Standard Charger Mode

Auto: Charger stops charging when the battery is

fully charged.

Constant: Charger switches to float mode when the

battery becomes charged. Float voltage is 0.4V lower

than maximum charging voltage and is temperature

compensated.

Temperature Compensation

Adjustable from 0 to -6.0 in increments of 0.5.

(Factory default is -5 mV/°C/Cell)

Max Charger Current

Charging current can be set to 0 or any value

between 2A and maximum in increments of 1A

(maximum = 15A for FXM1100/ FXM2000 and 10A for

FXM650). Charging current cannot be set to 1A.

When charging current is set to 0A, charger will stop

charging.

Low Battery Warning

Battery voltage value that activates the low battery

warning alarm. For the range of 24V and 48V

settings, refer to the Low Battery Warning entry in

Table I on page 65. The alarm is removed when

battery voltage is 2V above the warning setting for

a 48V battery, or 1V above the warning setting for a

24V battery.

Peukert Number

Refer to Appendix A to calculate the Peukert number.

Capacity

Rated capacity (Ah) of the battery shown on the

battery data sheet. Do not confuse the battery

capacity with the Peukert capacity.

Battery Open Circuit Voltage

Obtain this number from the battery data sheet. The

value is for a single battery, so for a 48V system with

4 batteries connected in series, multiply the number

by 4. For a 24V system with 2 batteries connected in

Figure 22 — UPS Maintenance: Battery,

Standard charging method

series, multiply by 2.

Low Voltage Disconnect and Low Voltage Reconnect are available when either standard or bulk charging method

is selected.

Parameter 48V 24V

Default Minimum Maximum Default Minimum Maximum

Low Voltage Disconnect (Vdc) 42 42 45 21 21 23

Low Voltage Reconnect (Vdc) 48 48 51 24 24 26

38

017-230-B4 Rev B

Page 41

NOTE:

The Battery Runtime Remaining algorithm attempts to calculate the health of the battery to get a more accurate

prediction of the remaining battery runtime. An accurate estimate of the battery health requires that at least one

battery discharge greater than 20% depth of discharge has taken place since the unit was switched on. When

the unit is powered up from an off state, the algorithm assumes that a new battery is connected to the unit. Each

discharge of greater than 20% will result in a new calculation for the relative battery health. This value is then

used in the Battery Runtime Prediction algorithm to compensate for an aging battery. We recommend that the

user set up a periodic (every 6 months) battery test with a depth of discharge of at least 20%.

The Battery Runtime Remaining algorithm relies heavily on the battery voltage to predict the remaining runtime.

This results in a less accurate predicted runtime during periods when the battery voltage is changing rapidly. The

battery voltage typically changes rapidly during the first few minutes of discharge when the unit switches from

charging to discharging while the unit is in the Inverter mode. The battery voltage may also change rapidly during

the last 20% of the discharge time when the battery is almost drained.

Bulk Charging Method

The Battery maintenance page has two tables: Battery Primary Configuration and Battery Configuration.

In the Battery Primary Configuration table, select Bulk battery charging method.

Figure 23 — UPS Maintenance: Battery, Bulk charging method

In the Battery Configuration table, Temperature Compensation (default 0.0mV/Cell/°C for bulk charger) and

Max Charger Current have the same function as the Standard charging method.

The following three parameters are only available when the Bulk battery charging method is selected:

Parameter 48V 24V

Default Minimum Maximum Default Minimum Maximum

Max Charger Voltage (Vdc) 53.5 52 56 26.8 26 28

Float Charger Voltage (Vdc) 53.5 52 56 26.8 26 28