Alpha FS50 Installation And Servicing Instructions

1

Installation and Servicing

Instructions

Alpha FlowSmart FS50

Hot Water System incorporating an Alpha Condensing Combination

Boiler with GasSaver - Flue Gas Heat Recovery Device and floor

standing 50L Primary Store.

Leave these instructions with the User

For Technical help or for Service call ...

ALPHA HELPLINE

Tel: 0344 871 8764

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

2

CONTENTS

1.0 Introduction

2.0 System Operation

3.0 Important Information

4.0 Technical Data

5.0 Cylinder Connections & Clearances

6.0 FlowSmart System Options

7.0 Installation

7.1 Flushing

7.2 Secondary circulation (optional)

7.3 InTec 40GS2 + Alpha Diverter + Alpha Controls + 1CH zone

7.4 InTec 40GS2 + Alpha Diverter + Alpha Controls + 2CH zone

7.5 InTec 40GS2 + S Plan / S Plan Plus

7.6 E-Tec Combi + Alpha Diverter + Alpha Controls + 1CH zone

7.7 E-Tec Combi + S Plan / S Plan Plus

8.0 Commissioning

8.1 Final Commissioning

8.2 Routine inspection

8.3 Short parts list

9.0 Product Data Sheet (ErP)

3

1.0 INTRODUCTION

The Alpha FlowSmart system is a domestic hot water system designed to provide a

high level of heating and hot water performance more efficiently. The combination

boiler provides high volume and flow of instantaneous hot water using a patented preheat system and central heating via a sealed heating system.

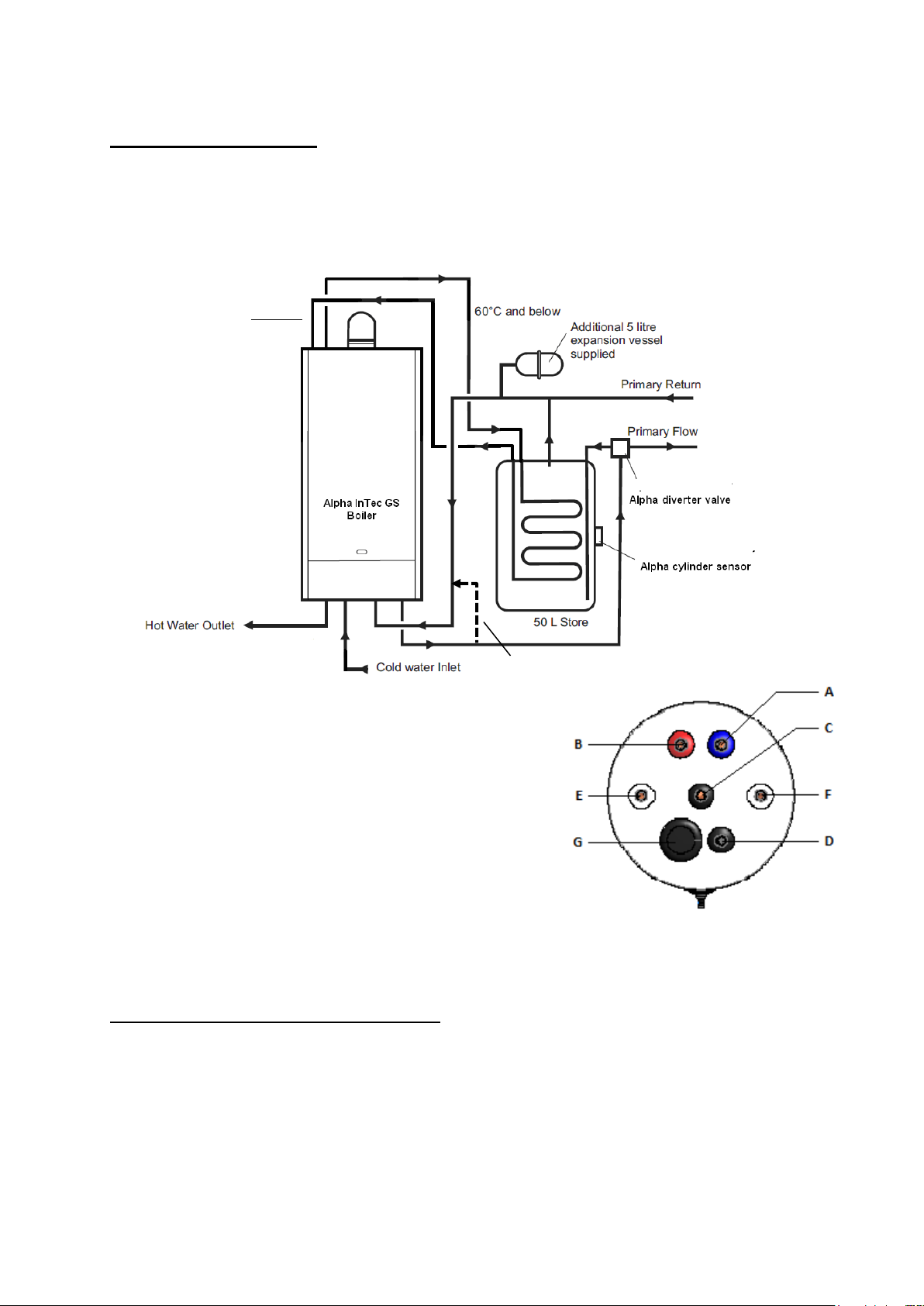

2.0 SYSTEM OPERATION

The Alpha FlowSmart system has been designed to deliver domestic hot water at a

high level of performance more efficiently, for example up to 18 l/min for temperatures

of 50°C and above for long periods of demand using less energy than a typical hot water

storage system utilizing a large cylinder.

The cold water supply first passes through the GasSaver where the reclaimed heat

from the hot flue gasses is used to pre-heat the cold water supply. This pre-heated

water then enters the coil in the primary store where it is heated to a higher

temperature.

This hot water is then blended into the inlet of the combination boiler at a temperature

of approximately 30°C to give a constant pre-heated supply to the boiler. The boiler

then further heats the water to the required outlet temperature. When the flow of hot

water is stopped, the FlowSmart store is reheated and then the system is ready to

provide the same performance again.

3.0 IMPORTANT INFORMATION

The Alpha FlowSmart must be installed as described in these instructions. The Alpha

boiler must be installed in accordance with the instructions supplied with it. Failure to

do so will negate the warranty supplied with this unit.

The FlowSmart system has been approved to the relevant requirements of the building

regulations for primary hot water storage systems and the UK Water Regulations. It is

the law that all gas appliances are installed by a competent person, i.e. Gas Safe

registered engineer, in accordance with Current Gas Safety (Installation and use)

Regulations and all current Building Regulations.

Failure to install any part of the FlowSmart system correctly could lead to prosecution.

It is in your own interest and that of safety to ensure that the law is complied with.

Manufacturer’s instructions must not be taken in any way as over-riding statutory

obligations.

It is essential that the central heating system is thoroughly cleaned and flushed before

fitting an Alpha FlowSmart system. Failure to do so will invalidate the warranty.

If it is not possible to clean the system before fitting the new boiler, the system should

be cleaned using a proprietary cleaner and a magnetic filter connected in the return

before the boiler as this is the most effective method of ensuring that any magnetite and

rust particles are prevented from entering and damaging the boiler. Once the system

condition has been restored, an effective magnetic filter and strainer should be fitted

permanently to the system as a method of collecting any magnetite and rust from the

system during operation.

4

Before installation, check that the incoming mains water supply is adequate to provide

the required flow rate. High outlet flow rates can only be achieved with a good mains

supply pressure and flow. In certain high flow demands serving many outlets

simultaneously, a boosted supply may be required.

IMPORTANT! The incoming mains water pressure should be between 1 and 5 Bar to

ensure efficient operation. If the pressure is above 5 Bar a pressure reducing valve

must be fitted. A small expansion device should also be added to supply circuit to take

up any thermal expansion of the water within the pipes.

Consideration should be given to correct pipe sizing to and from the FlowSmart system to

ensure optimum performance. All pipe runs should be as short as possible using

suitably sized pipes to enable sufficient flow rates, the pipework should also be

insulated to reduce heat loss. Before the mains water supply pipe is connected to the

boiler, it should be thoroughly flushed out to avoid the danger of dirt or foreign matter

entering the boiler.

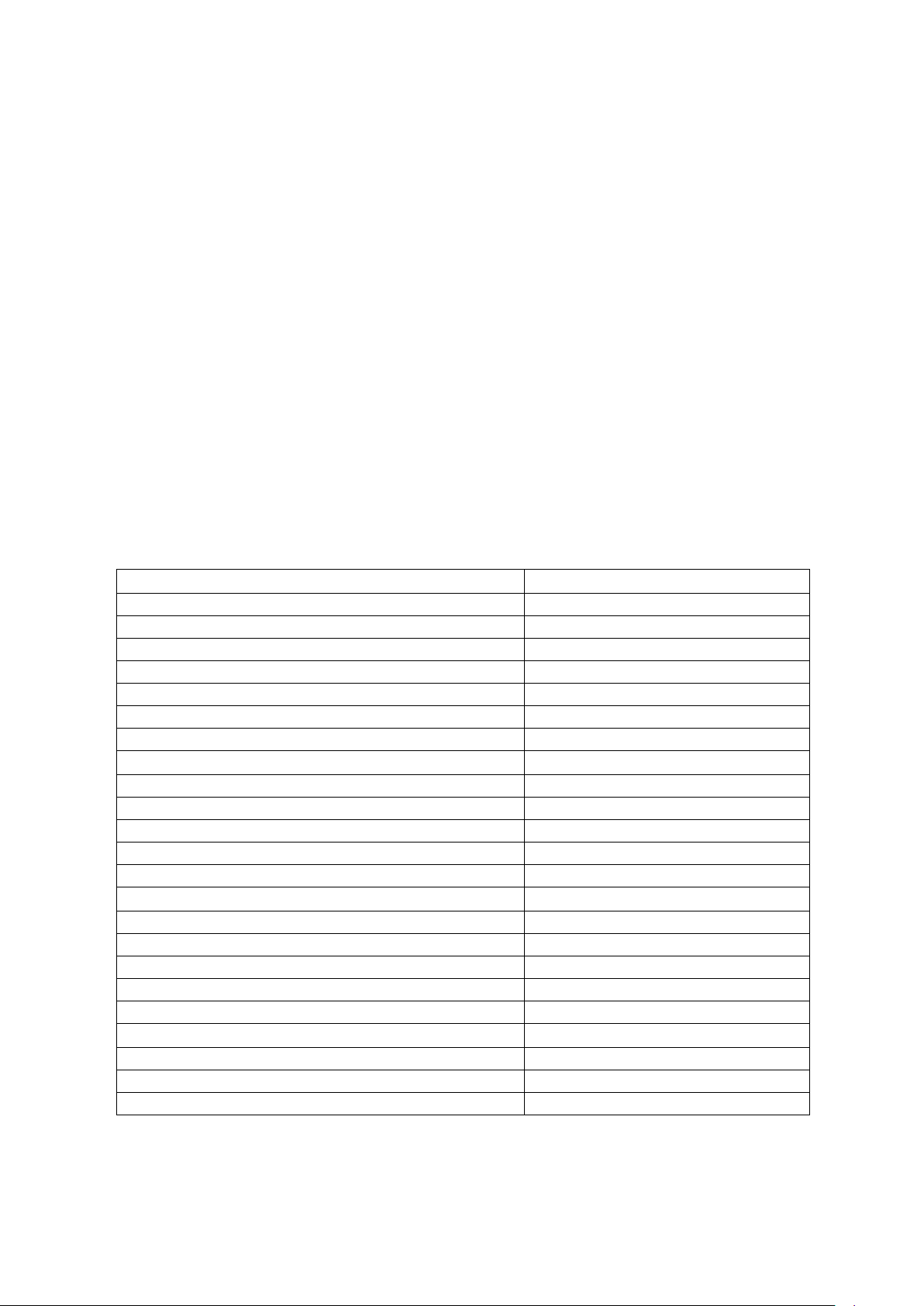

4.0 TECHNICAL DATA

Cylinder dimensions (mm)

H650 x D463

Cylinder insulation material

injected polyurethane

Cylinder insulation thickness

30 mm

Standing energy loss

0,68 kWh/24h

Max inlet water pressure

5 Bar

Min inlet water pressure

1 Bar

Recommended inlet water pressure

2-4 Bar

Recommended incoming cold mains flow rate

20 litres per minute

Outlet water temperature (approx. max.)

62⁰C

Mains water inlet pipe connection

3/4" BSP to 15mm (fitting supplied)

Mains water outlet pipe connection

3/4" BSP to 15mm (fitting supplied)

Coil material

copper

Secondary Circulation connections

3/4" BSP

Maximum Working Pressure Central Heating

2.5 Bar

Minimum System Pressure Central Heating

0.5 Bar

Maximum System Temperature (approx.) Heating

82°C

Boiler Pressure relief Valve Setting

3 Bar

Boiler Exp. Vessel (pre-charge press.)

8 L at 1.0 Bar

Recommended Heating System Pressure (cold)

1.0 Bar

Flow and Return Connections

3/4" BSP to 22 mm (fittings supplied)

Cylinder Material

Mild Steel

Plugged Connection (immersion heater if required)

1 1/4" BSP

Blending Valve Connections

15 mm

Additional Primary System Expansion Vessel Capacity

5 L at 1 Bar

5

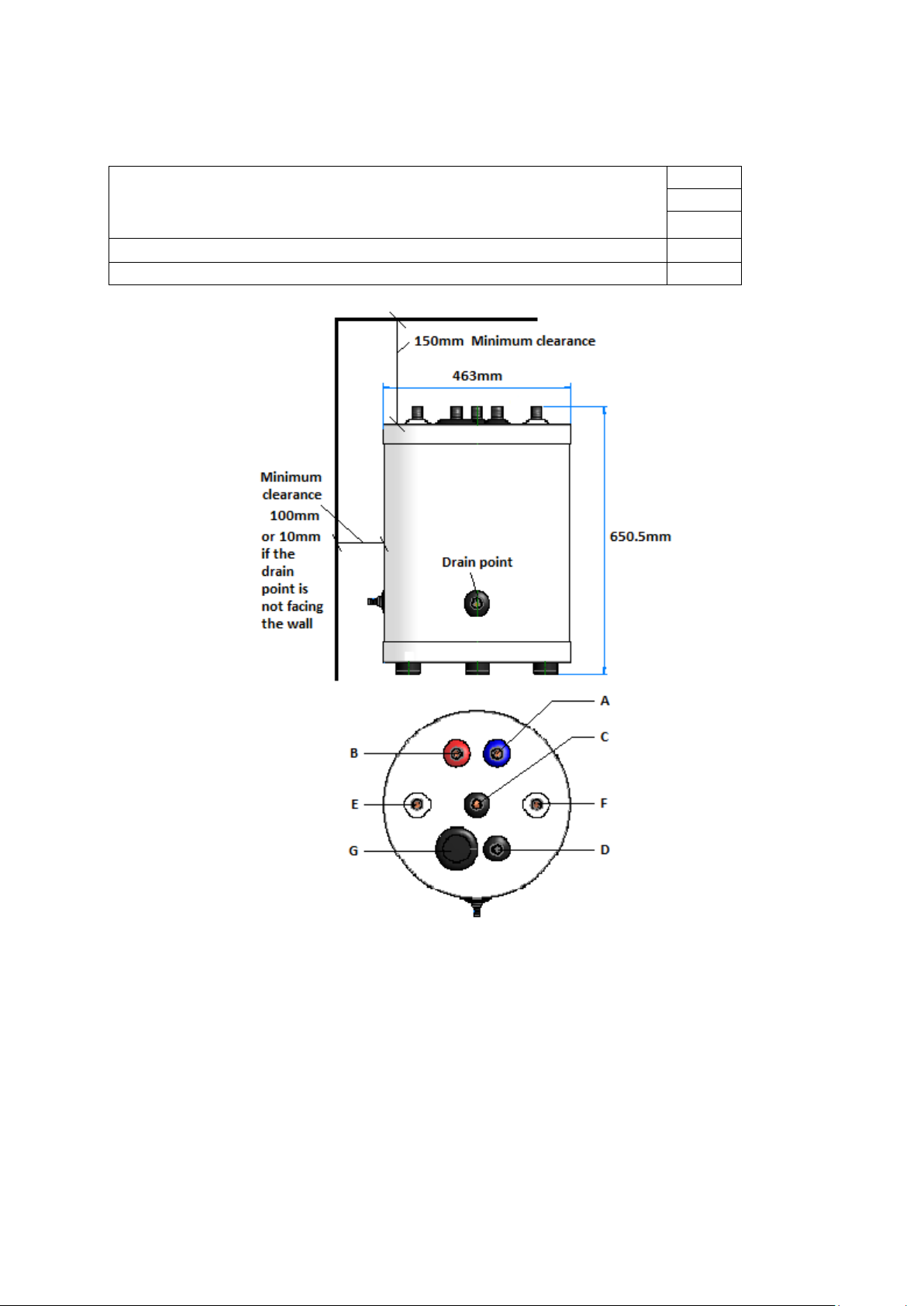

5.0 FLOWSMART CYLINDER CONNECTIONS + CLEARANCES

Minimum clearances for servicing

Top

Side

Side at drain point position

150mm

10mm

100mm

Lift weight empty

24 Kg

Weight full Inc. DHW and Primary circuits

80 Kg

A Mains water inlet ¾ BSP (Blue collar)

B Hot water outlet ¾ BSP (Red collar)

C Primary Return ¾ BSP (Black collar)

D Primary Flow ¾ BSP (Black collar)

E Secondary circulation ¾ BSP (White collar)

F Secondary circulation ¾ BSP (White collar)

G Plugged connection 11/4” BSP (for optional immersion)

Note: It is recommended that the drain point and thermostat/sensor are easily accessible for servicing

and adjustment.

6

6.0 FLOWSMART SYSTEM OPTIONS

The floor standing* FlowSmart system is available in two options:

1.) An Alpha InTec 40GS2 combination boiler with built in GasSaver, and floor mounted

50L thermal store

Or

2.) An Alpha E-Tec combination boiler**, separate GasSaver and floor mounted 50L

thermal store.

The system is controlled using either an optional Alpha E-Tec system diverter kit (plus

optional Alpha Climatic controller recommended) or a standard S plan controls kit can

be used.

It is important to purchase the correct FlowSmart system components and controls to

ensure the system works efficiently and as intended.

Note: Please ensure you have all kit components and controls BEFORE

commencing installation.

* Wall hung FlowSmart is a separate product and has separate installation instructions.

** For FlowSmart systems using other Alpha combination boilers please see previous

installation instructions

7.0 INSTALLATION

When delivered on site do not unpack until ready for installation and store in a dry

area. Depending on the system type you have, FlowSmart should be installed as

shown in the sections below.

Note: Please ensure you have all kit components and controls BEFORE

commencing installation.

7.1 FLUSHING

If it is not possible to clean the system before fitting the new boiler, the system should

be cleaned using a proprietary cleaner and a magnetic filter connected in the return

before the boiler as this is the most effective method of ensuring that any magnetite and

rust particles are prevented from entering and damaging the boiler. Once the system

condition has been restored, an effective magnetic filter and strainer should be fitted

permanently to the system as a method of collecting any magnetite and rust from the

system during operation.

7

7.2 SECONDARY CIRCULATION (OPTIONAL)

Note: Additional fittings will be required to connect to the cylinder secondary

circulation connections – 3.019591 x 2no. (3/4" BSP to 15mm)

The FlowSmart 50 cylinder incorporates a secondary circulation coil in the store

(connections E & F)

A DHW expansion vessel (not included) of the correct size must be fitted to the

secondary circulation system.

The vessel must be a minimum of 10% of the secondary pipe work volume. e.g. if the

secondary circulation circuit has a water volume of 20 litres then the vessel size must

be 2 litres.

The vessel pre-charge must be set to the same pressure as the static mains water

supply.

The secondary circulation pump should be controlled by a timer and correspond with

the timer settings of the FlowSmart system i.e. do not operate the pump when the store

is not heated.

A thermostat should also be used on the secondary circulation pump control and set

such that it does not exceed the FlowSmart cylinder thermostat setting.

Ensure there are no dead legs or areas where there is no circulation within the pipe

work of the secondary circulation system.

Optional Secondary Circulation Example.

8

7.3 SYSTEM TYPE 1

InTec 40GS2 boiler with floor standing cylinder + Alpha Diverter +

Alpha Controls (1 CH zone)

Cylinder connections

A From top boiler connection ¾ BSP (Blue collar)

B Back to top boiler connection ¾ BSP (Red collar)

C Primary Return ¾ BSP (Black collar)

D Primary Flow ¾ BSP (Black collar)

E Secondary circulation ¾ BSP (White collar)

F Secondary circulation ¾ BSP (White collar)

G Plugged immersion heater connection 11/4 BSP

For optional DHW secondary circuit schematic (if

required), see page 7

Recommended Alpha Equipment List

Alpha Intec 40GS2 boiler (3.028276)

FlowSmart 50 (6.2003020) floor standing cylinder c/w cylinder connection kit.

Boiler top pipework connection kit (3.022913)

Alpha E-Tec diverter kit (6.5500048) complete with 3-port valve and cylinder sensor

Controls:

Alpha Climatic controller (3.022143 Wireless or 3.022144 hard wired)

Optional Alpha external weather compensation probe (3.022383)

Top Connection

Kit

FROM B

TO A

External bypass

recommended

B A C D

9

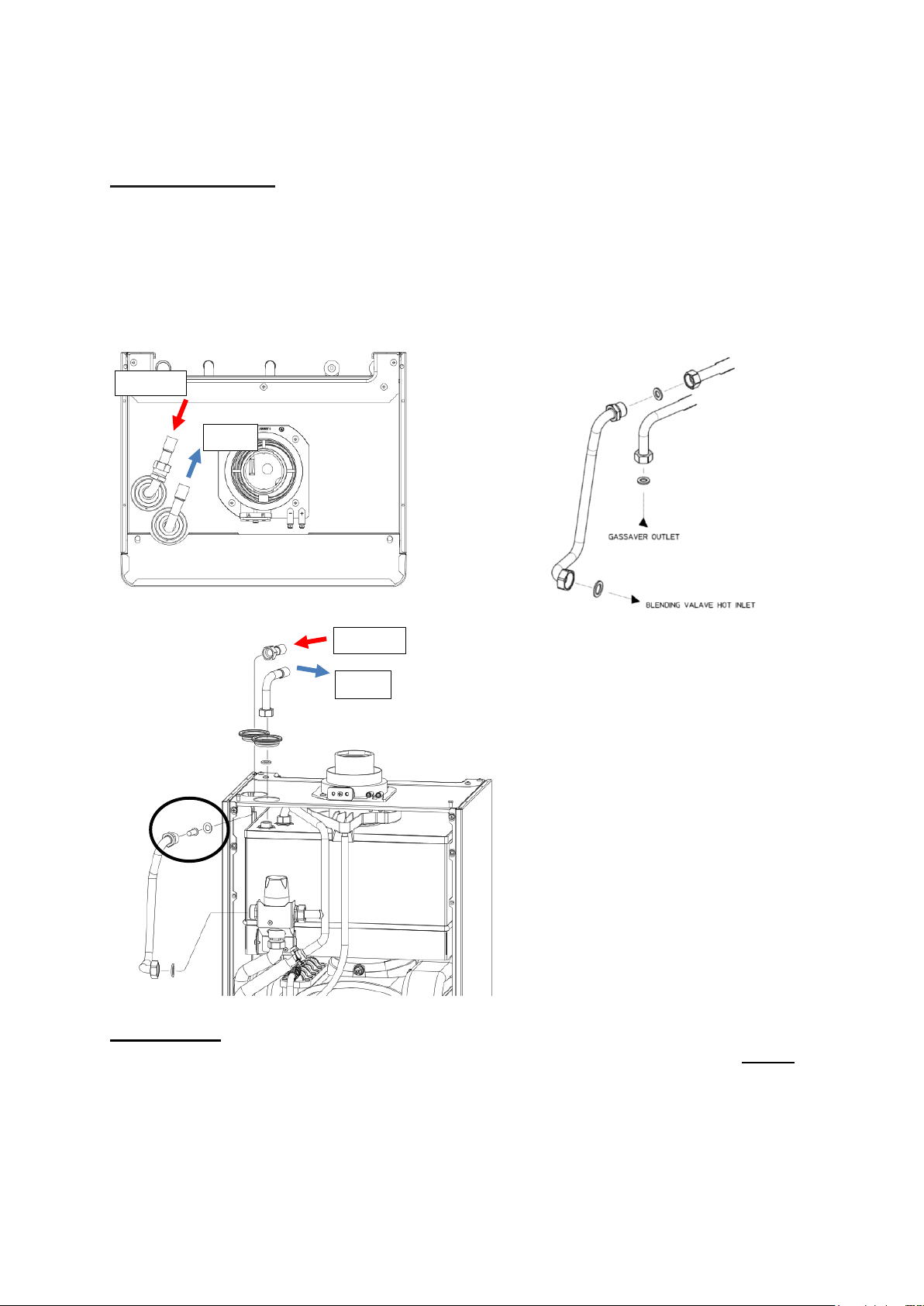

FITTING THE BOILER

Intec 40GS2 Boiler

The boiler and flue must be mounted as described in the instructions supplied with the

boiler.

When installing a floor standing cylinder to an InTec 40 GS2 boiler, a pipe kit MUST be

used to convert the top connections to connect 15mm copper pipe (part number

3.022913). Installation pipe work can be installed behind the boiler if required.

Fig 2 Top connection kit (3.022913)

IMPORTANT

To achieve maximum DHW flow rate the inlet mesh filter and flow regulator MUST be

removed from the brass inlet manifold of the boiler cold inlet connection (not shown).

The flow regulator should be discarded, and the mesh filter put into the top connection

kit joint as shown above.

TO A

FROM B

TO A

FROM B

10

FIT THE FLOWSMART PRIMARY STORE

1. Locate the primary store as close to the boiler as possible ensuring there are at least

the minimum clearances available.

2. The primary flow and return pipe work to the store should be no more than 1.5m in

length. The pipe work must be insulated.

3. Ensure the floor on which the store is mounted is capable of withstanding the weight

of the store, i.e. 80 kg.

Note: If an immersion heater is fitted, sufficient top clearance must be allowed to enable

the immersion heater to be replaced.

4. Fit the 3/4" BSP fittings supplied to the primary store connections using the washers

supplied as follows:-

a. The 3/4" BSP to 22 mm fittings to the primary flow and return connections (with the

black collars)

b. The 3/4" BSP to 15 mm fittings to the cold inlet (with the blue collar) and hot water

outlet connections (with the red collar).

5. Connect the pipework - Refer to the relevant schematic drawing for your installation

type.

6. Fit the 5 litre expansion vessel (using the 'T' connection supplied) to the primary

return pipework from the store.

7. Connect the Alpha E-Tec diverter kit 3-port valve as shown below.

Note: If a DHW secondary circulation circuit is used, see page 7.

8. Connect all cold mains and hot water pipework as shown

9. Thoroughly flush out all water pipework.

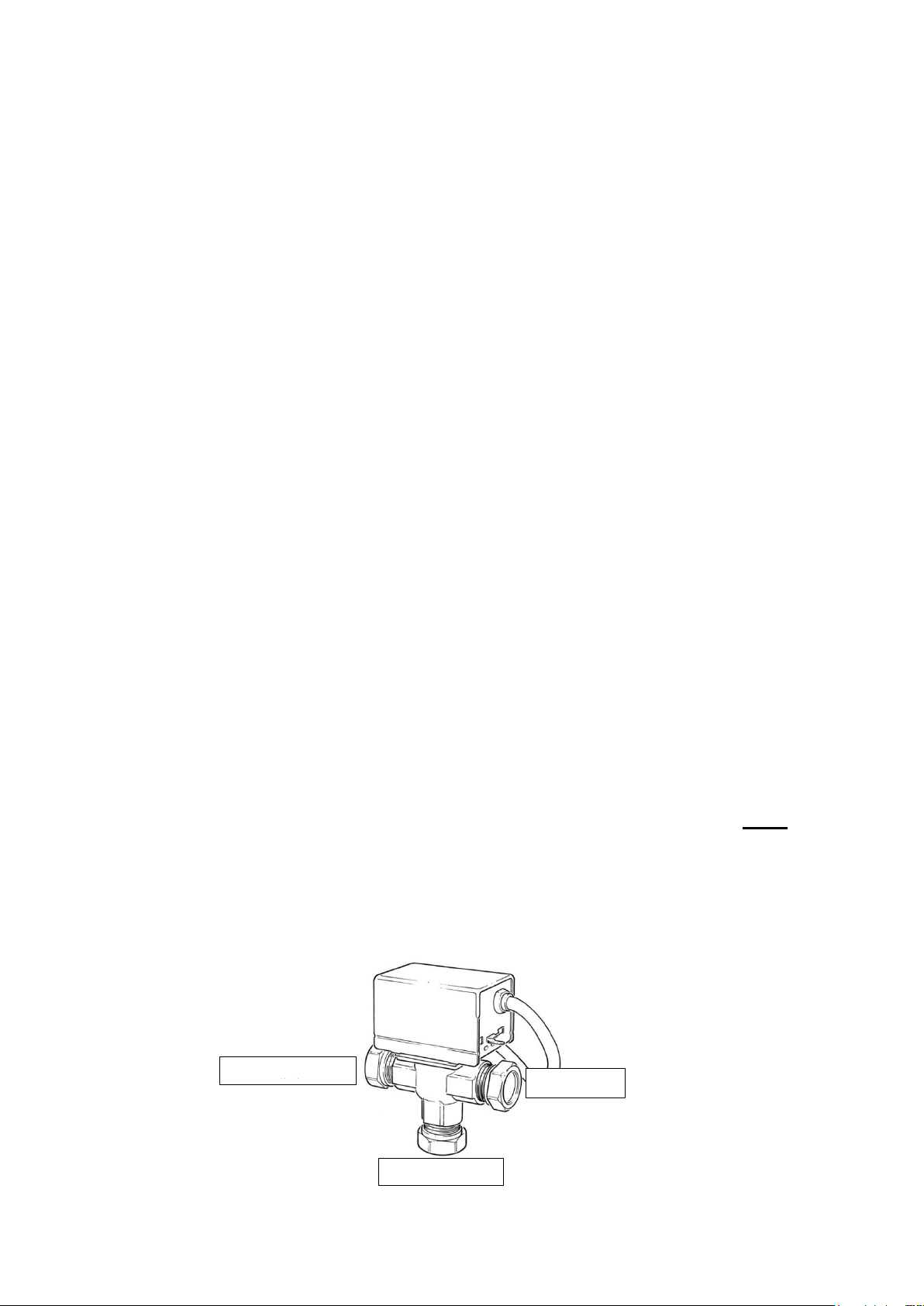

CONTROL VALVE INSTALLATION

Alpha E-Tec Diverter Kit (6.5500048)

Install 3 port valve supplied with Alpha E-Tec diverter kit according to instructions

provided.

Note: When using the optional Alpha E-Tec Diverter Kit, the valve must be

connected in the following way:

Connection AB to boiler flow

Connection A to heating flow

Connection B to FlowSmart cylinder primary flow (cylinder connection D)

Heating = A

B = Flowsmart

AB = Boiler Flow

11

EXTERNAL BYPASS

An external automatic type bypass is strongly recommended.

CYLINDER SENSOR

The FlowSmart cylinder insulation has a label indicating the location of the sensor

mounting position.

Cut a slit in the insulation and fix the sensor directly to the cylinder metal surface

ensuring good contact. Fix into position using foil tape. Once fitted, cover sensor with

insulation if necessary.

Note: Do not simply push the sensor into the foam insulation as it will not read

temperature correctly.

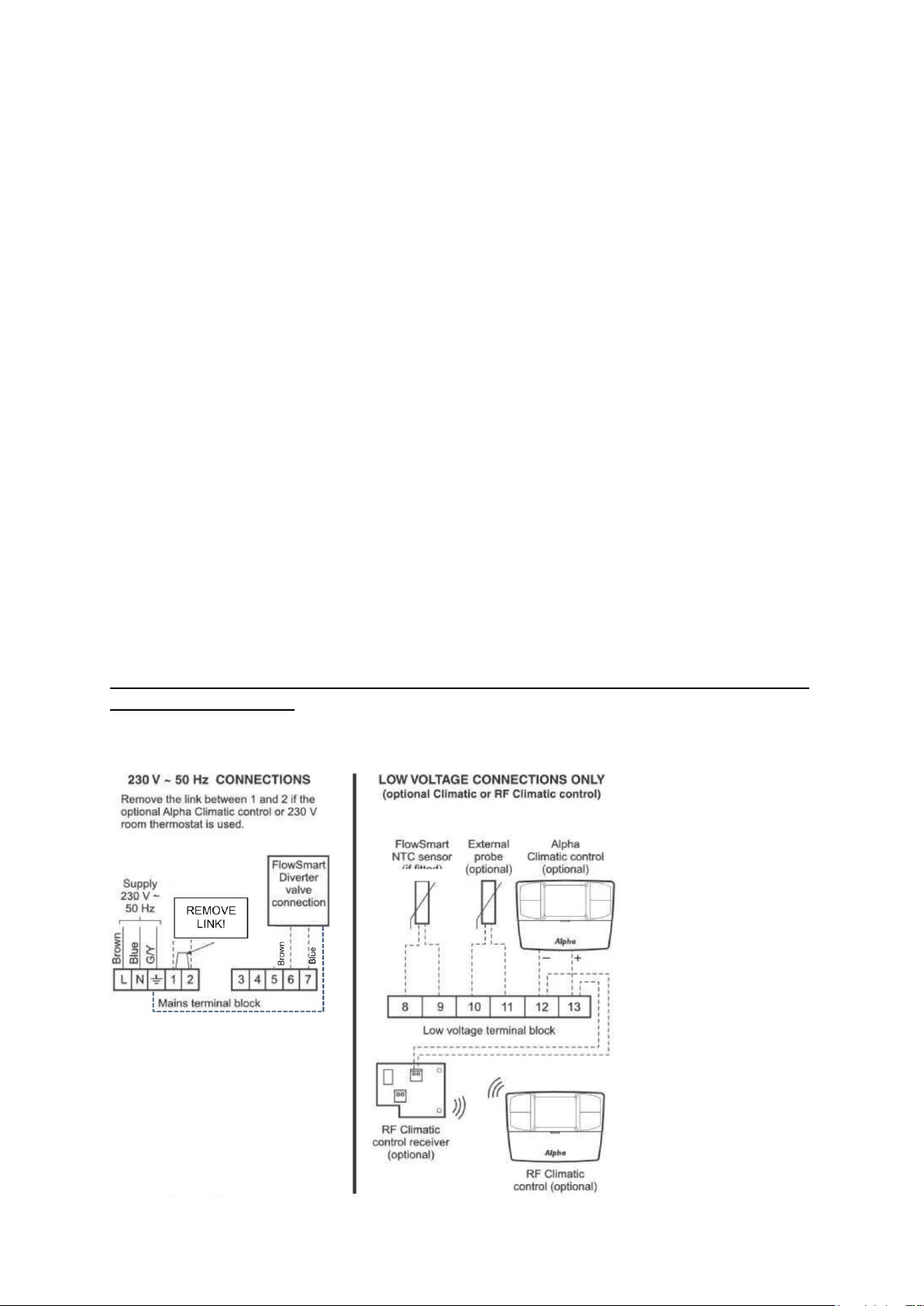

ELECTRICAL CONNECTIONS

All electrical wiring must be carried out by a competent person to BS 7671 Requirements for Electrical Installations, IEE Wiring Regulations.

Connect the mains supply to the boiler terminal block as described in the instructions

supplied with the boiler.

Note: An internal clock should not be fitted to the boiler when a FlowSmart

system is connected.

Alpha InTec 40GS2 boiler with floor standing cylinder + Alpha Diverter + Alpha

Controls (1 CH zone)

General wiring connections:

Loading...

Loading...