Page 1

Installation and Servicing

Instructions

Alpha FlowSmart 25 and 50

Hot Water System incorporating a Flue Gas Heat

Recovery Device, Primary Store and an Alpha CD

Condensing Combination Boiler

For Technical help or for Service call ...

ALPHA HELPLINE

Tel: 0870 3001964

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

Building Regulations Approved

Certificate No. ETC12908

Zenex SuperFlow Technology

Patent Protected No. 2420174

Other Patents Pending

Leave these instructions with the User

Page 2

CONTENTS

1 Introduction ....................................... 2

2 Technical data................................... 3

3 General information........................... 5

4 Installation......................................... 8

5 Commissioning ................................. 10

6 Routine inspection............................. 11

7 Short parts list ................................... 11

8 Inspection history .............................. 12

1 INTRODUCTION

The Alpha FlowSmart system is a domestic hot water system designed to provide a high level of performance more

efficiently.

The combination boiler will provide both central heating and domestic hot water at mains pressure.

The complete FlowSmart package consists of an Alpha CD35C condensing combination boiler, GasSaver, primary

storage cylinder (25 or 50 litre), expansion vessel and fittings kit. A cylinder thermostat and a 'Y' or 'S' plan control

system kit will also be required for the installation (not supplied).

IMPORTANT

The Alpha FlowSmart system must be installed as detailed in these instructions. The boiler and GasSaver must be

installed in accordance with the installation instructions supplied with them. Failure to do so will negate the warranty

supplied with this unit.

The FlowSmart system has been approved to the relevant requirements of the Building Regulations for primary hot water

storage systems and to the UK Water Regulations.

It is the law that all gas appliances are installed by a competent person, ie CORGI registered personnel, in accordance

with the following recommendations:-

Current Gas Safety (Installation and Use) Regulations

All current Building Regulations issued by the Department of the Environment, i.e. Approved Document L1.

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department

UK Water Regulations/Byelaws (Scotland)

Health & Safety Document No. 635 (The Electricity At Work Regulations 1989)

The installation should also be in accordance with the following British Standard Codes of Practice:BS 5440:1:2000 Flues

BS 5449:1990 Forced circulation hot water systems

BS 5546:2000 Installation of hot water supplies for domestic purposes

BS 6700:1997 Design, installation, testing and maintenance of services supplying water

BS 6798:2000 Installation of gas fired hot water boilers

BS 6891:1998 Gas installation

BS 7593:1992 Code of Practice for treatment of water in heating systems

BS 7671:2001 Requirements for electrical installations, IEE Wiring Regulations

Failure to install any part of the FlowSmart system correctly could lead to prosecution. It is in your own interest and that

of safety to ensure that the law is complied with.

Manufacturer's instructions must NOT be taken in anyway as over-riding statutory obligations.

Notes: 1. Alpha CD condensing flue components must be used when the GasSaver is used with an Alpha CD boiler.

2. It is essential that the primary system is thoroughly cleaned and flushed when fitting the FlowSmart system.

All cleaning agent must be removed and inhibitor added to the system - failure to do so will invalidate the warranty.

Alpha FlowSmart 25 and 50 - Contents/Introduction

2

Page 3

2 TECHNICAL DA T A

2.1 GENERAL

Cylinder External Dimensions 25 L

50 L

Outer Case

Cylinder Insulation Material

Cylinder Insulation Thickness

Standing Energy Loss of Cylinder 25 L

50 L

2.2 DHW SYSTEM

Maximum Inlet Water Pressure

Minimum Inlet Water Pressure

Maximum Water Flow Rate

Minimum Water Flow rate

Outlet Water Temperature (approx. max.)

FlowSmart Cylinder

Mains Water Inlet Pipe Connection

Mains Water Outlet Pipe Connection

Coil Material

DHW Coil Water Capacity 25 L

50L

Secondary Circulation Connections 50L only

Secondary Circulation Coil Capacity 50L only

345 mm Dia. x H530 mm

470 mm Dia. x H650 mm

Steel - White paint

PUR foam

50 mm

0.6 kW/24hr (0.8 Watts/litre)

1.1 kW/24hr (0.8 Watts/litre)

*5 bar

0.2 bar

18 l/min

2.5 l/min

62°C

3/4" BSP to 15 mm (fitting supplied)

3/4" BSP to 15 mm (fitting supplied)

Copper

2 L

3.5 L

3/4" BSP

0.28 L

* Note: If inlet water

pressure is above 5

bar a pressure

reducing valve must

be fitted

2.3 PRIMARY SYSTEM

Maximum Working Pressure

Minimum System Pressure

Maximum System Temperature (approx.)

Boiler Pressure relief Valve Setting

Boiler Exp. Vessel (pre-charge press.)

Recommended System Pressure (cold)

FlowSmart Cylinder

Flow and Return Connections

Cylinder Material

Cylinder Capacity 25 L

50 L

Plugged Connection (immersion heater if required)

3/4" BSP to 22 mm (fittings supplied)

2.4 COMPONENTS

Blending Valve Setting (boiler inlet) - Required temperature setting

Blending Valve Connections

Additional Primary System Expansion Vessel Capacity

Connection

Pre-Charge Pressure

2.5 bar

0.5 bar

82°C

3 bar

8 L at 0.8 bar

1.0 bar

Mild Steel

24 L

50 L

1 1/4" BSP

30°C

15 mm

5 L

1/2" BSP

1 bar

Alpha FlowSmart 25 and 50 - Technical Data

3

Page 4

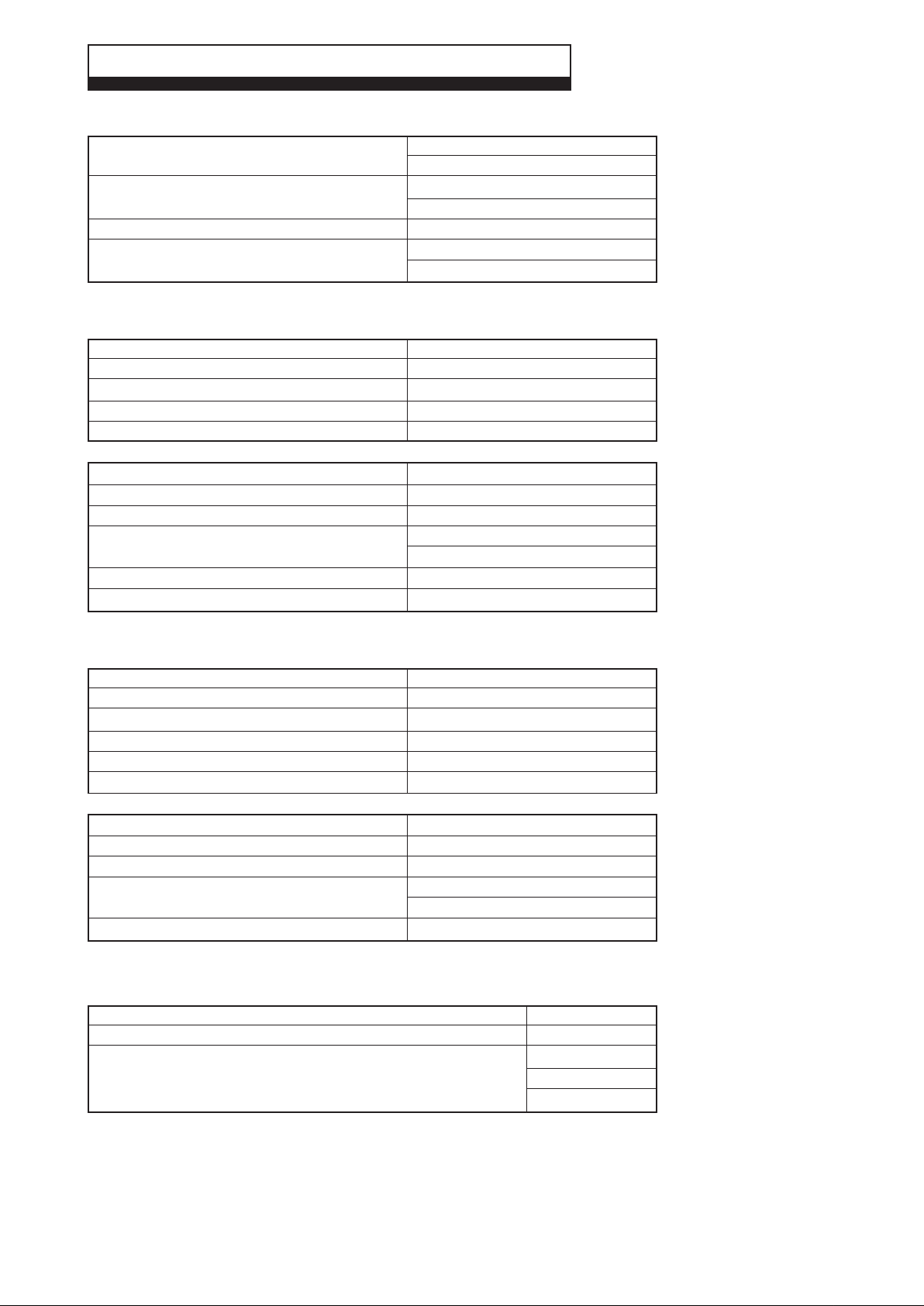

2.5 INSTALLATION

Minimum Clearances for Servicing Top

(Refer to Fig. 1) Drain Point Side only

Lifting Weight (empty) 25 L

50 L

Weight (full) including DHW and Primary Circuit 25 L

50 L

* 150 mm

100 mm

16 kg

29 kg

42 kg

82 kg

2.6 FLOWSMART CYLINDER LOCATION and CONNECTIONS

* Note: If an immersion heater is fitted,

sufficient top clearance must be

allowed to enable the immersion

heater to be replaced

*

Minimum

clearances

150 mm

470 mm Dia.

50 L

100 mm 100 mm

E

G

D

F

38 mm

650 mm

C

B

A

Minimum

*

clearances

Drain PointDrain Point

150 mm

345 mm Dia.

25 L

E

D

38 mm

530 mm

C

B

A

Connections - 50 L Connections - 25 L

- Mains Water Inlet 3/4" BSP (Blue collar)

A

- Hot Water Outlet 3/4" BSP (Red collar)

B

- Primary Return 3/4" BSP(Black collar)

C

- Primary Flow 3/4" BSP (Black collar)

D

- Secondary Circulation 3/4" BSP (White collar)

E

- Secondary Circulation 3/4" BSP (White collar)

F

- Plugged Immersion Heater Connection 11/4" BSP

G

2.7 ELECTRICAL CONNECTIONS

Remove link to connect

external control

2

1

Earth

(Green/Yellow Wire)

Neutral

NL

Permanent Live

Fuse

F2A

Alpha FlowSmart 25 and 50 - Technical Data

4

- Always fit fast blow 2A

- Mains Water Inlet 3/4" BSP (Blue collar)

A

- Hot Water Outlet 3/4" BSP (Red collar)

B

- Primary Return 3/4" BSP (Black collar)

C

- Primary Flow 3/4" BSP (Black collar)

D

- Plugged Immersion Heater Connection 11/4" BSP

E

Fig. 1

230/240V Switched Live from S or Y plan wiring junction box

(Blue Wire)

(Brown Wire)

230/240V ~ 50Hz

Fuse supply 3A

Fig. 2 - Boiler terminal block

Page 5

3 GENERAL INFORMATION

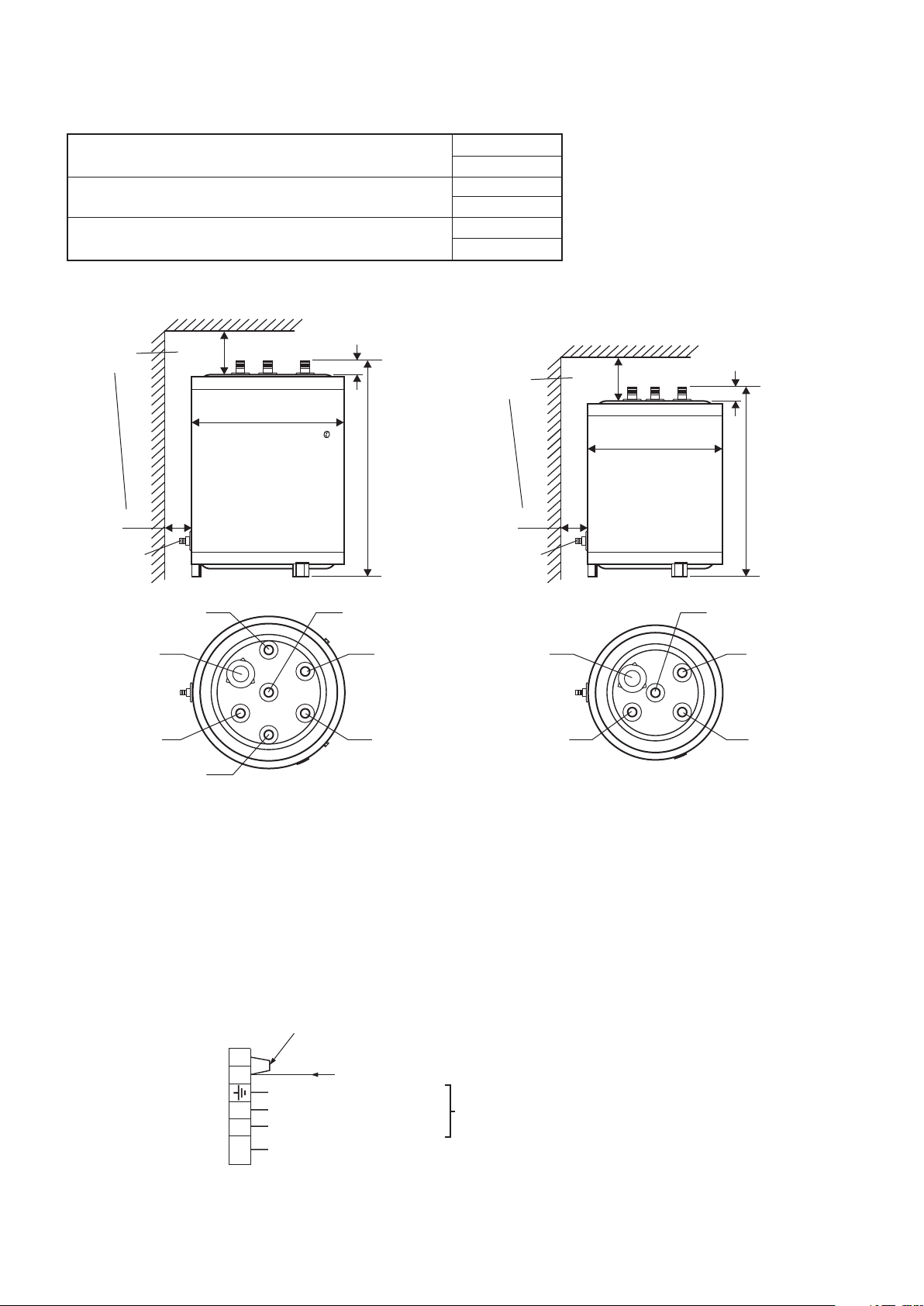

Hot Outlet Temp °C FlowSmart 50

Hot Outlet Temp °C FlowSmart 25

Hot Outlet Temp °C 200 L Store

Hot Outlet Temp °C 200 L Store Blended

3.1 HOW DOES THE FLOWSMART SYSTEM WORK

The Alpha FlowSmart system has been designed to deliver domestic hot water at a high level of performance more

efficiently, for example 18 l/min for temperatures of 50°C and above for long periods of demand using less energy than a

typical hot water storage system utilising a large cylinder.

The cold water supply first passes through the GasSaver where the reclaimed heat from the hot flue gasses is used to

pre-heat the cold water supply. This pre-heated water then passes through the coil in the primary store where it is heated

to a higher temperature. This hot water then passes to the blending valve where it is mixed with cold water direct from the

supply and enters the cold inlet of the combination boiler at a temperature of approximately 30°C. The boiler then heats

the water to the required temperature. See the performance graph Fig. 3.

When the flow of hot water is stopped, the FlowSmart store is reheated and then the system is ready to provide the same

performance again.

Outlet temperature for 30 mins at a flow rate of 18 L/min

Temp °C

80

70

60

50

40

30

20

10

0

0

5

10 15 20

Time Minutes

Hot Outlet Temp °C FlowSmart 50

Hot Outlet Temp °C FlowSmart 25

Hot Outlet Temp °C 200 L Store

Hot Outlet Temp °C 200 L Store Blended

25 30

Fig. 3 - FlowSmart vs 200 L store performance

3.2 TYPES OF INSTALLATION

Depending on the type of control system used the FlowSmart should be installed as shown in one of the following schematics.

The primary store should be positioned as close as possible to the boiler with the primary flow and return pipework to the store

no more than 1½ m in length. This pipework must be insulated.

Using the 'S' plan control system

Hot Water Outlet

Cold Water Out

GasSaver

Alpha

Combination

Boiler

30°C

Blending Valve

80°C and below

60°C and below

25 or 50 L Store

Fig. 4

Alpha FlowSmart 25 and 50 - General Information

Additional 5 litre

expansion vessel

supplied

Primary Return

Primary Flow

2 Port Zone

Valves

Cylinder

Thermostat

Cold water Inlet

5

Page 6

Using the 'Y' plan control system

60°C and below

Additional 5 litre

expansion vessel

supplied

Primary Return

Primary Flow

3 Port Zone

Valve

Cylinder

Thermostat

Cold water Inlet

Hot Water Outlet

Cold Water Out

30°C

Blending Valve

GasSaver

Alpha

Combination

Boiler

25 or 50 L Store

80°C and below

Fig. 5

3.3 DOMESTIC HOT WATER SYSTEM

Note: Before installation, check that the incoming mains water supply is adequate to provide the required flow rates.

The minimum flow rate needed for the flow switch and burner to operate is 2.5 litres/min.

The incoming mains water pressure should be between 0.2 and 5 bar to ensure efficient operation. If the pressure is

above 5 bar a pressure reducing valve must be fitted.

To ensure economic use, the pipe runs should, where possible, be in 15 mm copper pipe and be as short as possible,

also where possible the pipework should be insulated to reduce heat loss.

All taps and mixing valves used with the hot water system must be suitable for operating at a mains pressure of up to 8 bar.

Showers - A shower may be used with the boiler if required.

If a loose or flexible head type shower is used it may require the fitting of a double check valve, to comply with Water Bye Law 17.

Bidets - No anti-syphonage arrangements are necessary, provided the outlets are shrouded and it is not possible to

attach a temporary hand held spray. A supply of direct mains fed hot and cold water is permitted provided the appliance

is of the over-rim flushing type.

Before the mains water supply pipe is connected to the boiler, it should be thoroughly flushed out to avoid the danger of

dirt or foreign matter entering the boiler.

Alpha FlowSmart 25 and 50 - General Information

6

Page 7

3.4 FLUSHING THE HEATING SYSTEM

It is essential that the primary system is thoroughly cleaned and flushed when fitting the FlowSmart system. If a cleaning

agent is used, it must be flushed out before inhibitor is added to the primary system. Cleaning agent and inhibitor must be

applied in accordance with the manufacturers instructions. Only Fernox and Sentinel are acceptable for use. Further

information can be obtained from Fernox (Tel: 0179 9521133) or Sentinel (Tel: 0800 3894670).

All cleaning agent must be removed and inhibitor added to the system, failure to do so will invalidate the warranty.

The system should be flushed in accordance with BS 7593 and BS 5449. The following procedures are recommended:

1. Installing onto a new system:a.Fill the system, vent at high points, at pump and radiators.

b.Check for leaks.

c.Rapidly drain the system.

d.If required, chemically clean the system as instructed by the recommended cleaner manufacturer.

Note: Ensure that the system is flushed to remove any remains of the cleaner.

e.If chemical cleaner is not used to clean the system:-

i) Refill the system.

ii) Switch on the boiler and allow the system to heat up to the normal operating temperature.

iii) Rapidly drain the system while the water is still hot.

iv) Refill the system.

f. As required, add the recommended inhibitor to the system as instructed by the inhibitor manufacturer.

g.Recheck for leaks.

2. Installing onto an existing system, clean the system before fitting the new boiler:a.If the old boiler is still working:-

i) Switch on the boiler and allow the system to heat up to the normal operating temperature.

ii) Rapidly drain the system while the water is still hot.

iii) Refill and chemically clean the system as instructed by the recommended cleaner manufacturer.

iv) Ensure the system is flushed to remove any remains of the cleaner.

v) Fit the new boiler.

b.If the old boiler is not working:-

i) Rapidly drain the system.

ii) Remove the old boiler.

iii) Flush the system through.

iv) Fit the new boiler.

v) Refill and chemically clean the system as instructed by the recommended cleaner manufacturer.

vi) Ensure the system is flushed to remove any remains of the cleaner.

c.As required, add the recommended inhibitor to the system as instructed by the inhibitor manufacturer.

d.Check for leaks.

3.5 CENTRAL HEATING SYSTEM

Refer to the instructions supplied with the boiler for full information. However the FlowSmart has been supplied with a 5

litre expansion vessel for fitting to the primary return pipework between the FlowSmart primary store and the boiler (See

Figs. 4 and 5). This is to allow for the additional expansion required when fitting the FlowSmart primary store. The precharge of the expansion vessel should be 1 bar.

3.6 IMMERSION HEATER

If an immersion heater is fitted, it must incorporate a thermostat and thermal cut-out.

Note: Immersion heaters without thermal cut-outs must not be fitted.

The immersion heater must be installed in accordance to current electrical requirements for installation BS 7671 and

must be fused as stated on the heater. A label will be supplied with the immersion heater detailing the watts, voltage,

type, length and the BS or equivalent it complies with. This label must be fitted to the FlowSmart store.

Alpha FlowSmart 25 and 50 - General Information

7

Page 8

3.7 ALPHA FLOWSMART 50 - SECONDARY CIRCULATION - See Fig. 6

1. If a DHW secondary circulation circuit is required, you must use the FlowSmart 50 because it incorporates a secondary

circulation coil in the store.

2. A DHW expansion vessel the correct size must always be fitted to the secondary circulation system, eg. 5 litre expansion

vessel is suitable for capacities of the secondary circulation system upto 50 litres. This expansion vessel should be

charged to 3.5 bar.

3. The secondary circulation pump should be controlled by a timer, and correspond with the timer settings for the FlowSmart

system, i.e. do not operate the pump when the store is not heated.

4. Ensure the setting of the secondary circulation thermostat setting does not exceed the FlowSmart store temperature setting,

i.e. cylinder thermostat setting.

5. Ensure there are no dead areas or areas where there is no circulation within the pipework of the secondary circulation system.

GasSaver

Alpha CD35C

Combination

Boiler

Hot Water Outlet

From Boiler

Secondary Circulation Coil

Hot Water Tap

EF

FlowSmart 50 Store

Secondary Return

Loop (15 mm)

DHW Expansion Vessel

sized to suit water

capacity of secondary

circulation system

Non Return

Valve

Note: No valves must be

fitted between the expansion

vessel and the store

Secondary Circulation pump

controlled by Timer/Thermostat

Hot Water Tap

Hot Water Tap

Fig. 6

4 INST ALLATION

4.1 UNPACKING

Note: When delivered on site do not unpack until ready for installation and ensure to store in a dry area.

1. The following items are supplied in the FlowSmart package:

a. An Alpha CD35C condensing combination boiler

b. An Alpha GasSaver GS-1 complete

c. A FlowSmart 25 or 50 primary store

e. A FlowSmart expansion vessel and fittings kit (Part No. 3.019505) which contains the items shown in Fig. 7

2 x 3/4" BSP to 22 mm fittings

2 x 3/4" BSP to 15 mm fittings

5 litre expansion vessel

Fig. 7 - Expansion vessel kit contents

Alpha FlowSmart 25 and 50 - General Information/Installation

8

2 x 1/2" wahers

'T' fitting

2 x 22 mm to 1/2" BSP

6 x 3/4" washers

Page 9

2. The following items are required in addition to the above.

a. The required flue terminal assembly for the boiler

b. A cylinder thermostat

c. An 'S' or 'Y' plan control system kit, including programmer and room thermostat.

4.2 FIT THE BOILER AND GASSAVER

The boiler, flue and GasSaver must be fitted as described in the instructions supplied with the boiler and the GasSaver.

4.3 FIT THE FLOWSMART PRIMARY STORE

1. Locate the primary store as close to the boiler as possible ensuring there are the minimum clearances available as given in

Section 2.5 and shown in Fig. 1.

Ensure the floor on which the store is mounted is capable of withstanding the weight of the store, i.e. 42 kg for 25 litre model

or 82 kg 50 litre model.

Note: If an immersion heater is fitted, sufficient top clearance must be allowed to enable the immersion heater to be replaced.

2. Connect the pipework - Refer to Figs. 1 and 4 or 5.

a. Fit the 3/4" BSP to 22 mm fittings and 3/4" BSP to 15 mm fittings supplied, to the primary store connections using the

washers supplied as follows:The 3/4" BSP to 22 mm fittings to the primary flow and return connections (with the black collar) and the 3/4" BSP to 15 mm

fittings to the cold inlet (with the blue collar) and hot water outlet connections (with the red collar).

Note: 50 L only - If a DHW secondary circulation circuit is used, the connections with the white collar (E and F) must be

connected to the circuit. Refer to Section 3.7 and Fig. 6.

b. Thoroughly flush out all water pipework. Refer to Section 3.4.

c. Connect all primary system pipework referring to Fig. 4 or 5. Ensure that the following are connected:-

Connect the 5 litre expansion vessel using the 'T' connection supplied, to the primary return pipework from the store.

Connect the 'S' or 'Y' plan valves as shown in Fig. 4 or 5.

d. Connect all cold mains and hot water pipework as shown in Fig. 4 or 5. Ensure that the blending valve is connected to

the hot water outlet pipework from the store also shown in Fig. 4 or 5.

4.4 FIT THE CYLINDER THERMOSTAT

1. Remove the six screws securing the 80 x 160 mm cover located on the side of the primary store, just above the drain tap

and remove the cover.

2. Cut away the insulation around the 80 x 160 mm hole until the metal side of the store is exposed.

3. The cylinder thermostat can then be located within the hole and secured as detailed in the instructions supplied with the

thermostat.

4.5 ADJUST THE SEASONALITY VALVE - See Fig. 8

Adjust the seasonality valve on the combination boiler by turning the adjusting screw fully clockwise, as shown in Fig. 8.

This will allow the maximum flow rate through the boiler.

Seasonality

valve adjusting

screw

Underneath the

combination boiler

Seasonality

valve

Wall

Fig. 8 - Location of seasonality valve

Alpha FlowSmart 25 and 50 - Installation

9

Page 10

4.6 ELECTRICALLY CONNECT ALL CONTROLS

Note: All electrical wiring must be carried out by a competent person to BS 7671 - Requirements for Electrical

Installations, IEE Wiring Regulations.

1. Connect the mains supply to the boiler terminal block as described in the instructions supplied with the boiler.

The boiler electrical connections are shown in Fig. 2 of these instructions.

Note: An internal clock should not be fitted to the boiler when a FlowSmart system is connected. An external 2-channel

clock must be used instead.

2. Connect the cylinder thermostat, 2-channel programmer, room thermostat and zone valves as described in the

instructions supplied with the 'S' or 'Y' plan control system kits.

5 COMMISSIONING

1. Fill all the systems, i.e. primary and secondary circuits and check for leaks. Refer to the boiler instructions.

2. Refer to Section 3.4 in these instructions and ensure the primary system has been flushed and cleaned and inhibitor

added to the primary system.

Note: All cleaning agent must be removed and inhibitor added to the primary system, failure to do so will invalidate the

warranty.

3. Commission the boiler and GasSaver as described in the boiler and GasSaver installation instructions.

4. Ensure that the boiler hot water thermostat is set to position 9 (maximum) and the boiler central heating thermostat is set

to a position above 7 to max. as shown in Fig. 9.

Domestic

Hot Water Thermostat

SET TO 9 (MAXIMUM)

OFF

0

A

B

C

D

1

2

RESET

3

SELECTOR THERMOSTAT THERMOSTAT

1

2

9

3

4

8

5

7

6

SET ABOVE 7 UPTO 9 (MAXIMUM)

9

8

Central

Heating Thermostat

1

2

3

4

5

7

6

2

3

1

04

bar

Fig. 9

5. Ensure that the blending valve positioned between the FlowSmart store and the boiler water inlet is set to approximately

30°C, i.e. about the minimum setting.

6. Ensure that the cylinder thermostat is set at or below the boiler central heating thermostat temperature setting.

Alpha FlowSmart 25 and 50 - Installation/Commissioning

10

Page 11

6 ROUTINE INSPECTION

It is recommended that the FlowSmart cylinder should be subject to a general condition inspection at each boiler

maintenance interval.

If the system pressure exceeds 2.5 bar when operating at maximum temperature, the additional 5 litre expansion vessel

(refer to Fig. 4 or 5) as well as the boiler expansion vessel should be checked and re-pressurised, if necessary.

Notes: 1. Check the expansion vessel charge only when the system pressure is zero.

2. The expansion vessel pressure should be charged to 1 bar.

7 SHORT PARTS LIST

Item Qty. Part No.

5 litre expansion vessel

Drain tap

Connector ¾" BSP to 15 mm

Connector ¾" BSP to 22 mm

'T' connector 22 mm to ½" BSP

Plug 1¼" BSP

'O' ring for 1¼" BSP plug

Box spanner for 1¼" connection

1

1

2

2

1

1

1

1

1.026991

6.2003030

3.019591

3.019592

3.019539

6.0001140

6.2003040

6.2003045

Alpha FlowSmart 25 and 50 - Routine Inspection/Short Parts List

11

Page 12

8 INSPECTION RECORD

It is recommended that the FlowSmart is inspected regularly and that you complete the appropriate Inspection Record

below.

Service Provider: Before completing the appropriate Inspection Record below, please ensure you have carried out the

boiler service as described in the boiler instruction manual.

INSPECTION 1: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

INSPECTION 3: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

INSPECTION 5: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

INSPECTION 2: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

INSPECTION 4: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

INSPECTION 6: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

INSPECTION 7: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

Alpha Therm Limited.

Nepicar House, London Road, Wrotham Heath,

Sevenoaks, Kent TN15 7RS

Tel: 0870 3001964

email: info@alphatherm.co.uk

website:www.alpha-innovation.co.uk

INSPECTION 8: Date .................................................................

Engineers Name .........................................................................

Company Name ..........................................................................

Telephone No..............................................................................

CORGI ID card serial No. ...........................................................

Comments ...................................................................................

.....................................................................................................

Signature .....................................................................................

These instructions have been carefully prepared but we reserve the right to

alter the specification at any time in the interest of product improvement.

© Alpha Therm Limited 2008.

Manual compiled and designed by Publications 2000 - Tel: (01670) 356211 06/08/D215

Loading...

Loading...