Alpha FlowSmart Installation Guide

18 litres/minute from

a combi?

FlowSmart.

A step-by-step installation guide.

The perfect combination

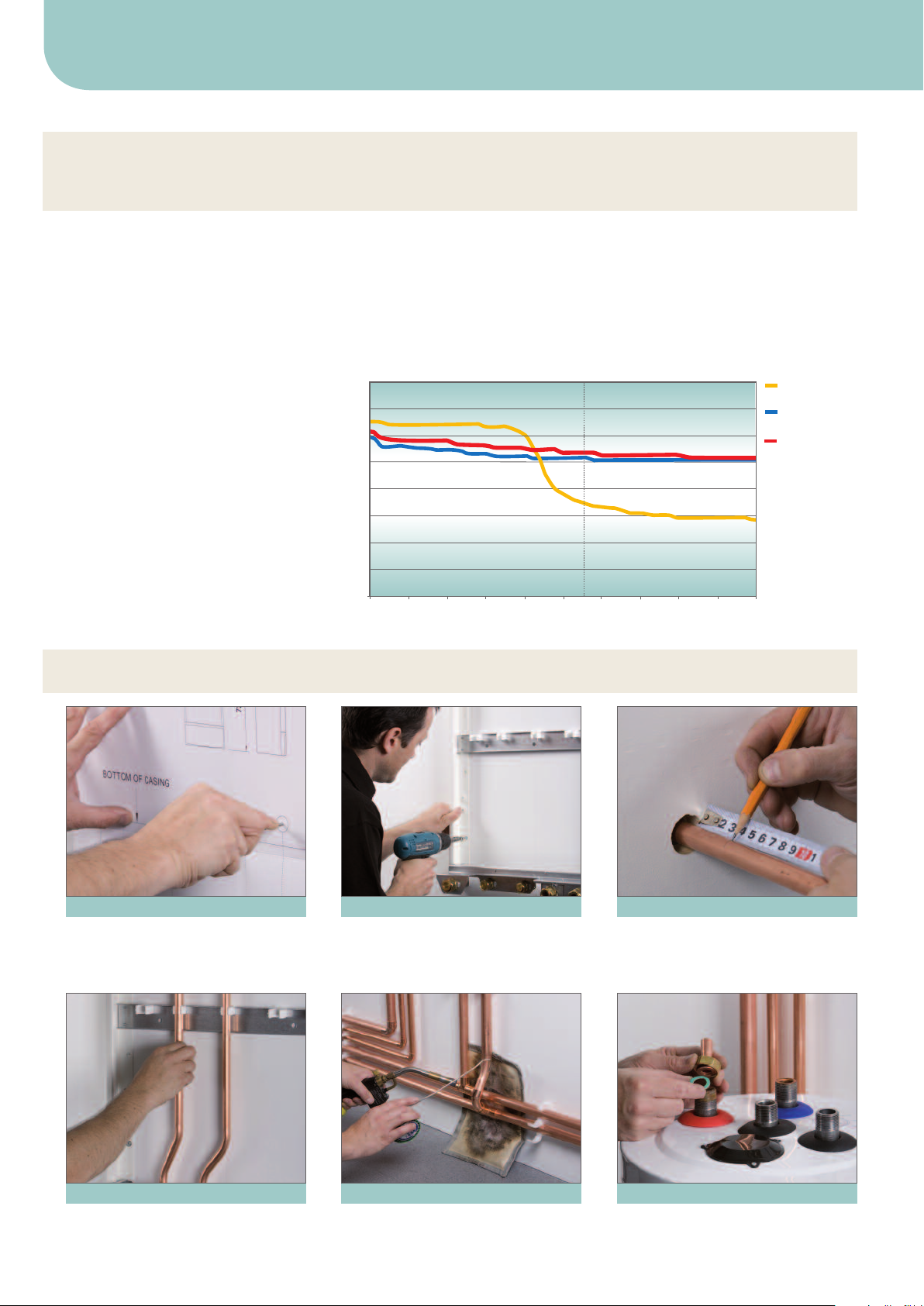

FlowSmart system v 200L unvented cylinder at flow rate 18 litres/minute

T

ime (minutes)

Te m p °C at flow rate 18L/min

D

HW output °C

200L unvented cylinder

D

HW output °C

F

lowSmart 25L store

80

70

60

5

0

40

3

0

20

1

0

0

2 4 6 8 10 12 14 16 18 20

D

HW output °C

F

lowSmart 50L store

ESS GAS USED*

L

%

lowSmart uses up to 25% less gas to provide DHW than a system boiler with a 200 litre unvented store

F

nd consumes less electricity.

25

By incorporating a GasSaver and small thermal store, FlowSmart allows a combi boiler to deliver a flow rate of 18

litres of hot water per minute, at 50ºC or above, for up to 30 minutes – more than three times longer than a typical

system boiler set-up.Together with its superior energy efficiency and ease of installation, this makes FlowSmart the

perfect combination.

a

Its thermal store recharges in just 5-7

minutes, compared to the 45 minutes a

200 litre cylinder can take to replenish

from empty.

The small thermal store takes up much

less space than a cylinder, enabling

FlowSmart to be more easily sited. If

required, the entire system can even be

installed together in a cupboard.

This, along with a limited pipework

requirement, means installation of

FlowSmart is also quicker and simpler.

18 steps to 18 litres/minute

FlowSmart system v 200L unvented cylinder at flow rate 18 litres/minute

STEP 1

Using a spirit level, tape the GasSaver and

PremierPack templates to wall. Mark all positions as

indicated on wall, drill holes and add rawlplugs. Mark

flue position and drill hole.

STEP 4

Remove tails from boiler and screw to PremierPack.

Measure, cut, bend and fit GasSaver mains inlet/outlet

pipework to PremierPack using the pipe clip plate.

Complete any other necessary pipework and fit using

pipe clips where required.

STEP 2

Screw PremierPack, GasSaver hanging bracket and

top fixing bolt assembly to wall.The boiler and

GasSaver can now be simply hung whenever you are

ready.

STEP 3

Drill hole in wall and push Expansion Relief Valve pipe

through. Pull back so that the rubber grommet

completes a seal, mark off and cut to required length.

STEP 5 STEP 6

ing that is necessary Position thermal store where required, and fit

Complete an

y solder

washers plus tails to connections shown on pipework

label on top of store

Loading...

Loading...