F

A

U

L

T

C

O

D

E

S

FOR:

ALLISON, CATERPILLAR, CUMMINS,

ICU 3, ICU 3 C2, MERCEDES, WABCO, PCM

CONTENTS

ALLISON 1000 & 2000…………………………………………………..……..page 4

ALLISON 3000 MH…………………………………….………………….……page 7

ICU 3 J-1587 MID, PID, SID CODES…………………………………………..page 18

ICU 3 J1587 & J1939 FOR C2……………………………………………………page 23

CATERPILLAR…………………………………………………………………...page 31

CUMMINS…………………………………………………………..…………….page 53

MERCEDES 900………………………………………………………………......page 61

WABCO…………………………………………………………….….………….page 74

PCM………..………………………………………………………………………page 85

A

Page 4

L

L

I

S

O

N

FAULT CODES

1000 TRANSMISSIONS

2000 TRANSMISSIONS

ALLISON 1000/2000/24000 SERIES ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

Check

Page 5

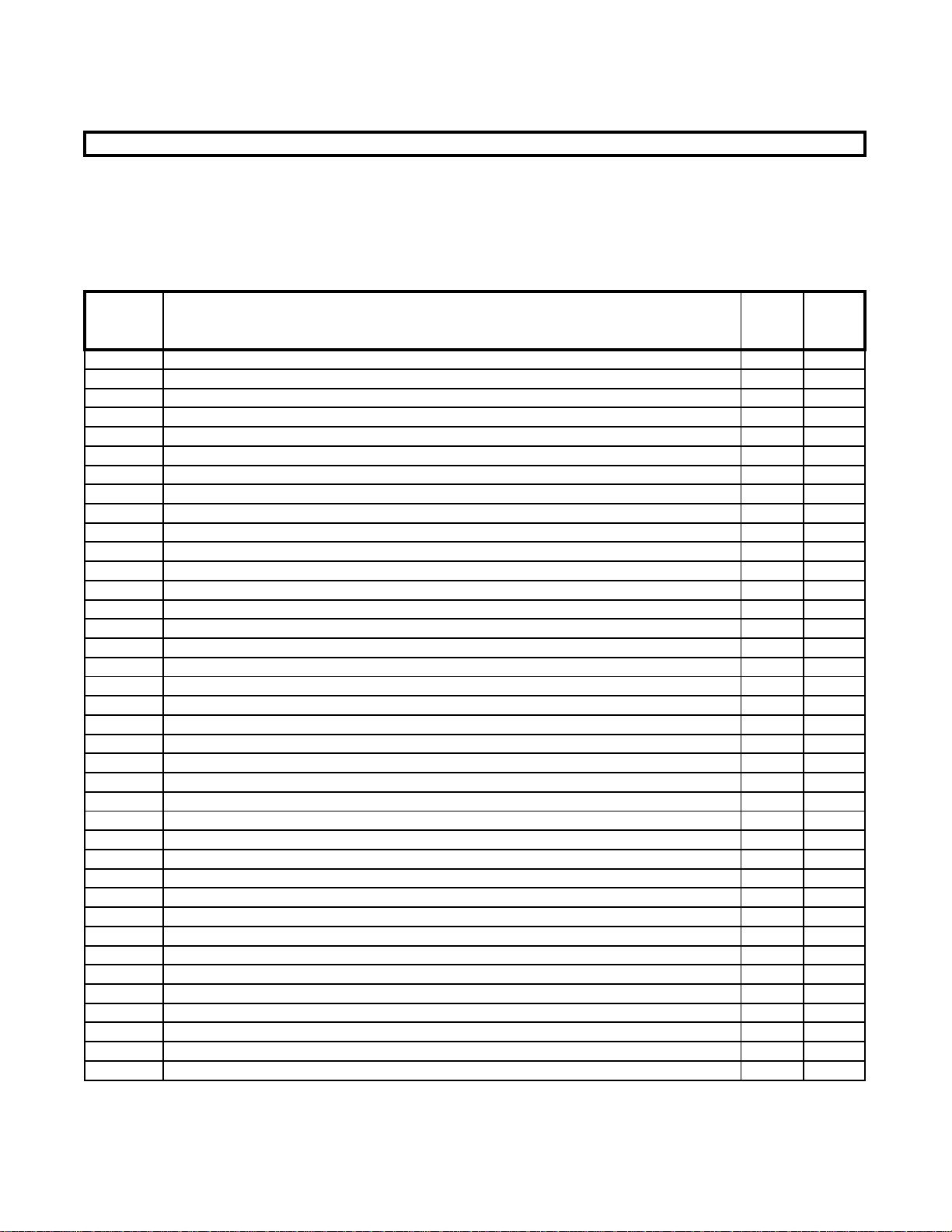

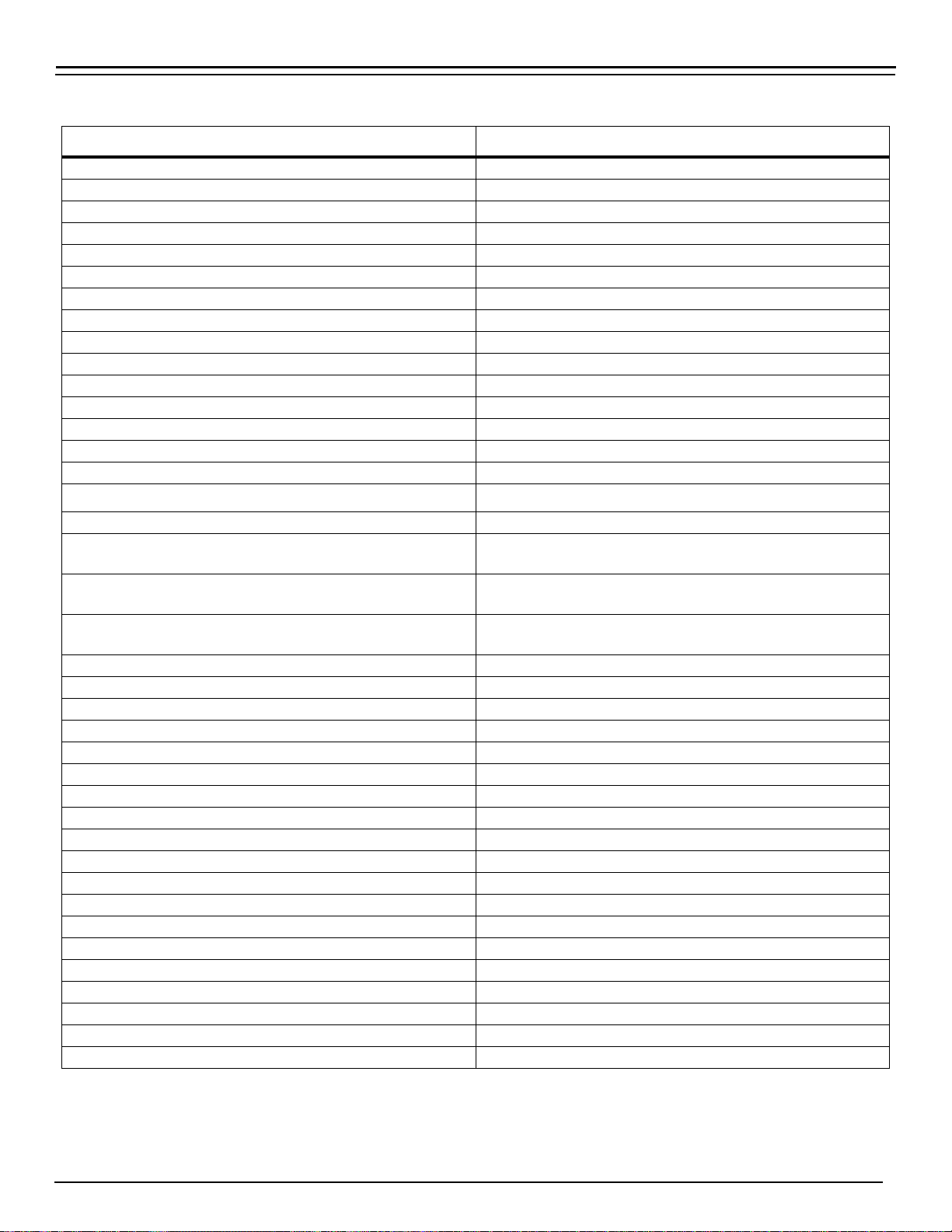

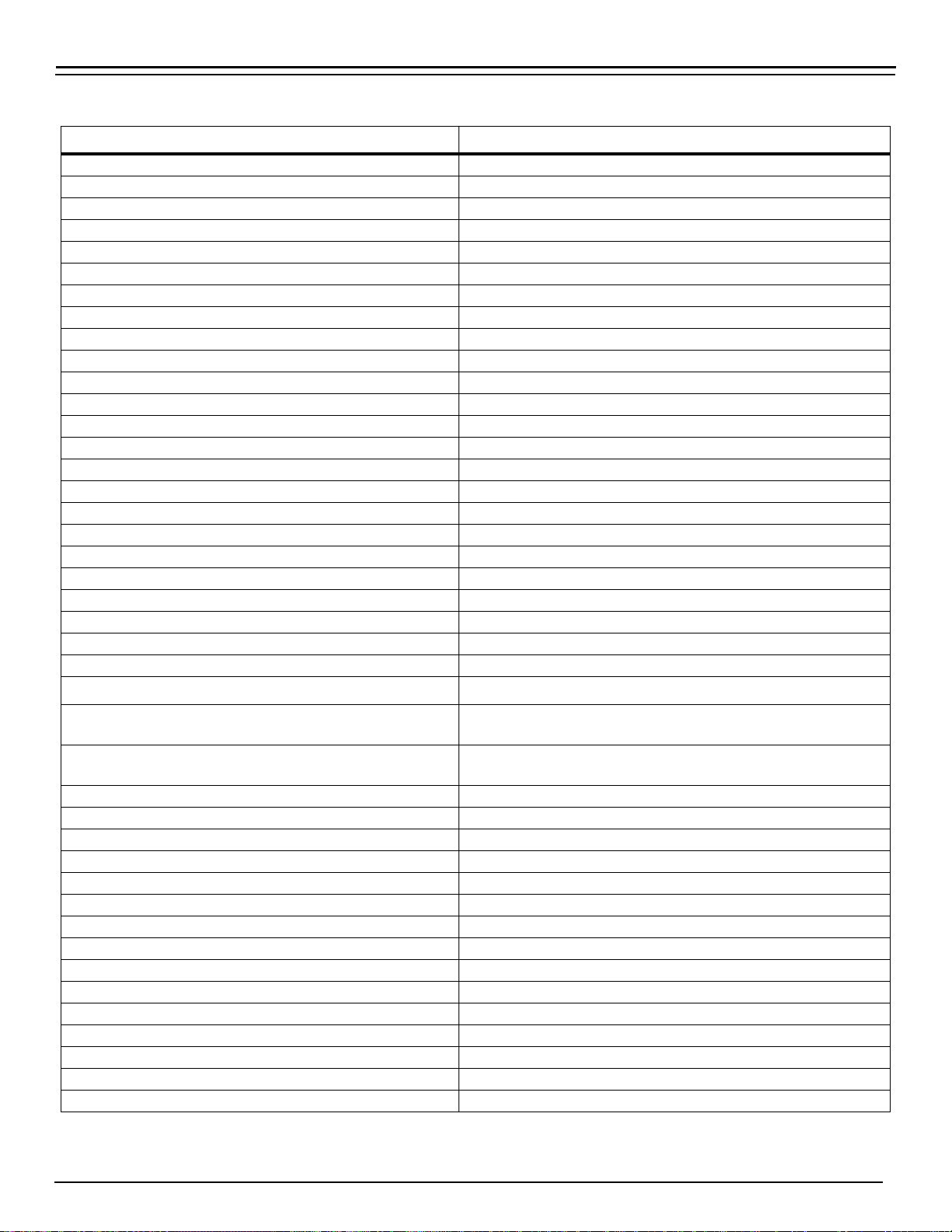

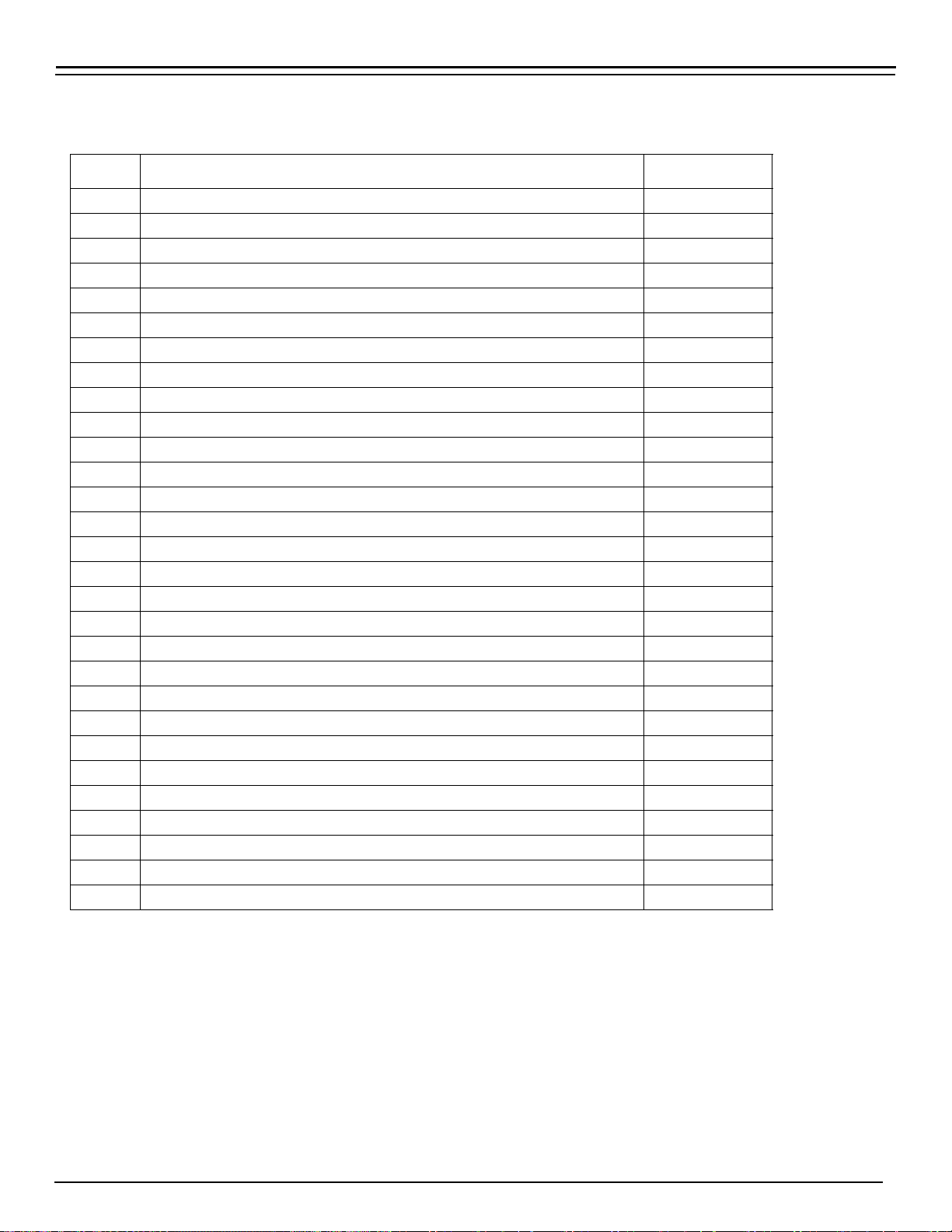

DIAGNOSTIC TROUBLE COPDES (DTC)

5-5. DIAGNOSTIC TROUBLE CODES (DTCs)

DTC LIST AND DESCRIPTIONS INDEX

Trans

DTC Description

P0121 Pedal Postion Sensor Performance Problem No 5-15

P0122 Pedal Postion Sensor Circuit Low Voltage No 5-16

P0123 Pedal Postion Sensor Circuit High Voltage No 5-19

P0218 Transmission Fluid Over Temperature No 5-22

P0562 System Voltage Low Yes 5-26

P0563 System Voltage High Yes 5-29

P0602 TCM Not Programmed Yes 5-33

P0606 Controller Internal Performance Yes 5-34

P0701 Transmission Control System Performance No 5-35

P0703 Brake Switch Circuit No 5-37

P0705 Transmission Range Sensor Circuit (PRNDL Input) No 5-41

P0706 Transmission Range Sensor Circuit Performance Yes 5-45

P0708 Transmission Range Sensor Circuit High Input Yes 5-49

P0710 Transmission Fluid Temperature Sensor Malfunction No 5-53

P0711 Transmission Fluid Temperature Sensor Circuit Performance Yes 5-57

P0712 Transmission Fluid Temperature Sensor Circuit Low Input (High Temperature) Yes 5-61

P0713 Transmission Fluid Temperature Sensor Circuit Low Input (Low Temperature) Yes 5-65

P0716 Turbine Speed Sensor Circuit Performance Yes 5-69

P0717 Turbine Speed Sensor Circuit No Signal Yes 5-73

P0721 Output Speed Sensor Circuit Performance Yes 5-77

P0722 Output Speed Sensor Circuit No Signal Yes 5-81

P0726 Engine Speed Input Circuit Performance Yes 5-85

P0727 Engine Speed Sensor Circuit No Signal Yes 5-89

P0731 Incorrect 1st Gear Ratio Yes 5-93

P0732 Incorrect 2nd Gear Ratio Yes 5-97

P0733 Incorrect 3rd Gear Ratio Yes 5-101

P0734 Incorrect 4th Gear Ratio Yes 5-105

P0735 Incorrect 5th Gear Ratio Yes 5-109

P0736 Incorrect Reverse Ratio Yes 5-113

P0741 Torque Converter Clutch System Stuck Off Yes 5-117

P0742 Torque Converter Clutch System Stuck On Yes 5-120

P0748 Pressure Control Solenoid A Electrical Yes 5-123

P0763 Shift Solenoid C Electrical Yes 5-127

P0768 Shift Solenoid D Electrical Yes 5-131

P0773 Shift Solenoid E Electrical Yes 5-135

P0778 Pressure Control Solenoid B Electrical Yes 5-139

P0840 Transmission Pressure Switch Solenoid C Circuit Yes 5-143

P0841 Transmission Pressure Switch Solenoid C Circuit Stuck Open Yes 5-147

Light

Page

ALLISON 1000/2000/24000 SERIES ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

CHECK

Page 6

DIAGNOSTIC TROUBLE COPDES (DTC)

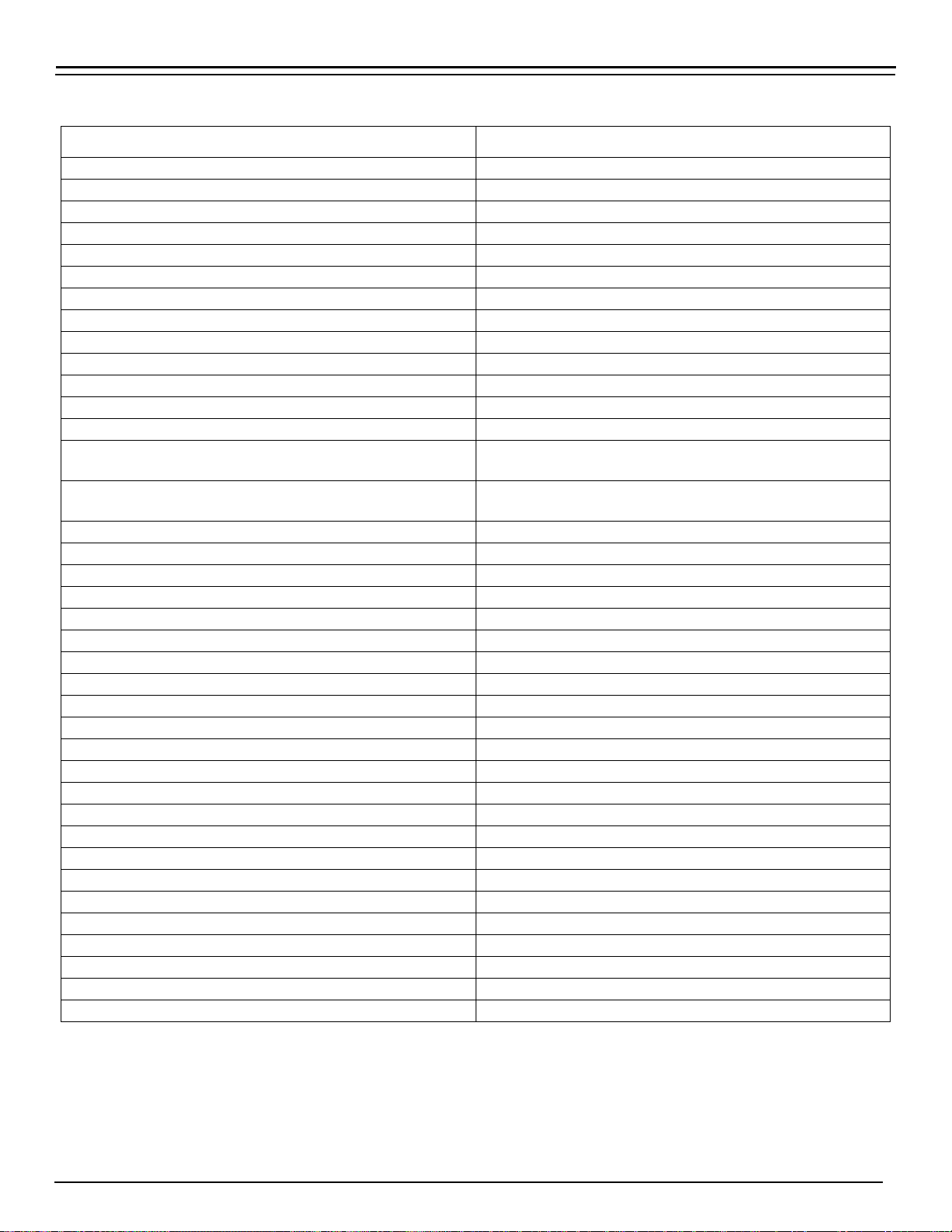

DTC LIST AND DESCRIPTIONS INDEX (cont'd )

TRANS

DTC Description

P0842 Transmission Pressure Switch Solenoid C Circuit Stuck Closed Yes 5-151

P0843 Transmission Pressure Switch Solenoid C Circuit High Yes 5-155

P0845 Transmission Pressure Switch Solenoid D Circuit Yes 5-159

P0846 Transmission Pressure Switch Solenoid D Circuit Yes 5-163

P0847 Transmission Pressure Swtich Solenoid D Circuit Yes 5-167

P0848 Transmission Pressure Switch Solenoid D Circuit Yes 5-171

P1688 Unmanaged Engine Torque Delivered to TCM Yes 5-175

P1709 Transmission Pressure Switch Solenoid E Circuit Yes 5-177

P1710 Transmission Pressure Switch Solenoid E Circuit Stuck Open Yes 5-181

P1711 Transmission Pressure Switch Solenoid E Circuit Stuck Closed Yes 5-185

P1712 Transmission Pressure Switch Solenoid E Circuit High Yes 5-189

P1713 Transmission Pressure Switch Reverse Circuit Yes 5-193

P1714 Transmission Pressure Switch Reverse Circuit Stuck On Yes 5-197

P1716 Transmission Pressure Switch Reverse Circuit High no 5-201

P1718 Incorrect Neutral Gear Ration No 5-205

P1720 Solenoid A Controlled Clutch Not Engaged Yes 5-209

P1721 Solenoid B Controlled Clutch Not Engaged Yes 5-213

P1723 Solenoid A Controlled Clutch Engaged Yes 5-217

P1724 Solenoid B Controlled Clutch Engaged Yes 5-221

P1726 Shift Solenoid D Controlled Clutch Engaged No 5-225

P1727 Shift Controlled E Clutch Engaged No 5-229

P1760 TCM Supply Voltage No 5-233

P1779 Engine Torque Delivered To ECM Yes 5-236

P1835 Kickdown Circuit Yes 5-238

P1860 Torque Converter Clutch PWM Solenoid Circuit --Electrical Yes 5-241

P1875 4WD Low Switch Circuit Yes 5-245

P1891 Throttle Postion Sensor Pulse Width Modulation (PWM) Signal Low Input No 5-249

P1892 Throttle Postion Sensor Pulse Width Modulation (PWM) Signal High Input No 5-252

U1000 Serial Data Communication Link Malfunction (Class2) No* 5-255

U1016 Class 2 Powertrain Controller State of Health Failure No* 5-258

U1041 Class 2 ABS Controller State of Health Failure No* 5-261

U1064 Class 2 TBC Controller State of Health Failure No* 5-264

U1096 Class 2 IPC Controller State of Health Failure No* 5-267

U1300 Serial Data Communication Link Low (Class2) No 5-270

U1301 Serial Data Communication Link High (Class2) No 5-273

U2104 Can Bus Rest Counter Overrun Yes 5-276

U2105 Can Bus Error ECM Yes 5-279

LIGHT

Page

A

Page 7

L

L

I

S

O

N

FAULT CODES

3000 MH

TRANSMISSIONS

Code Listings And Procedures

Page 8

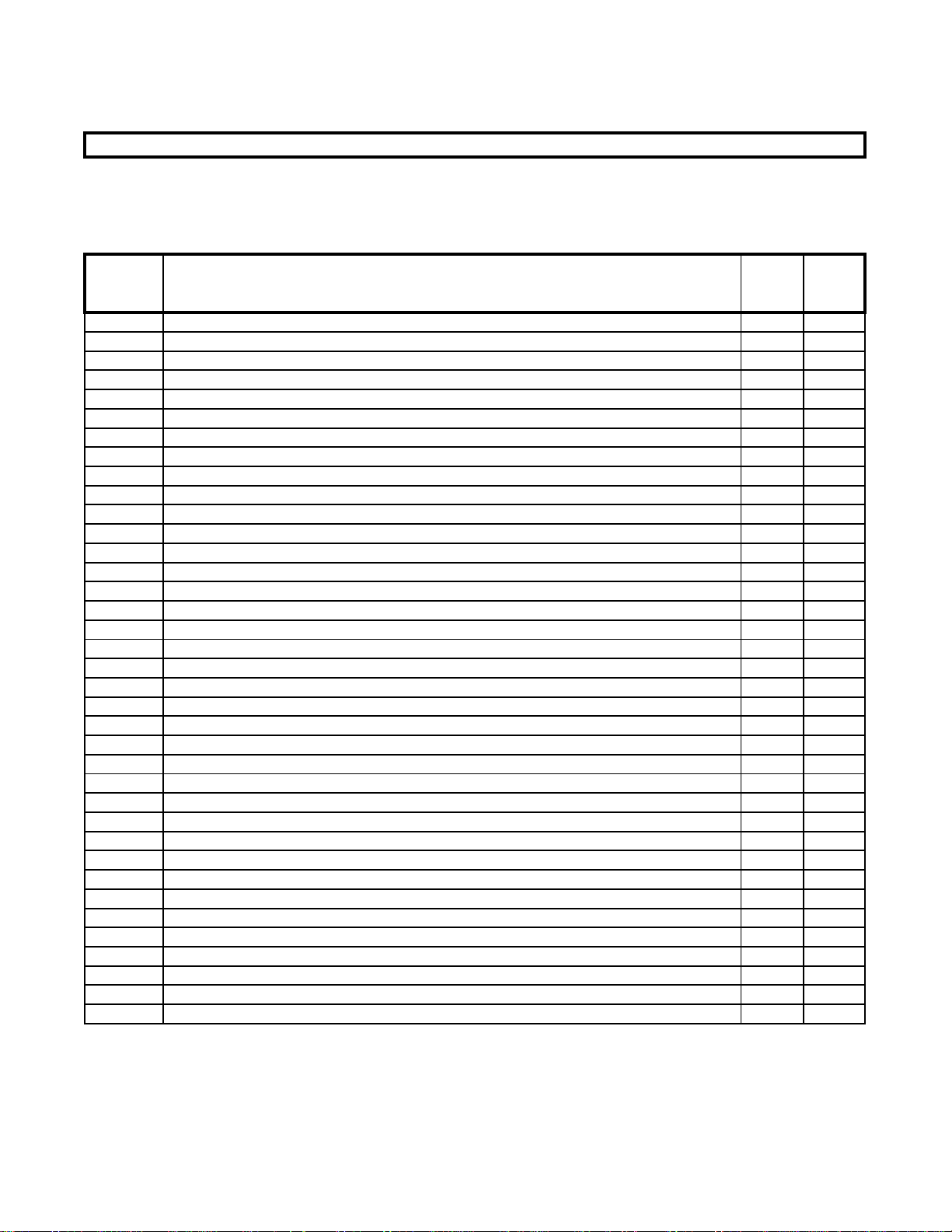

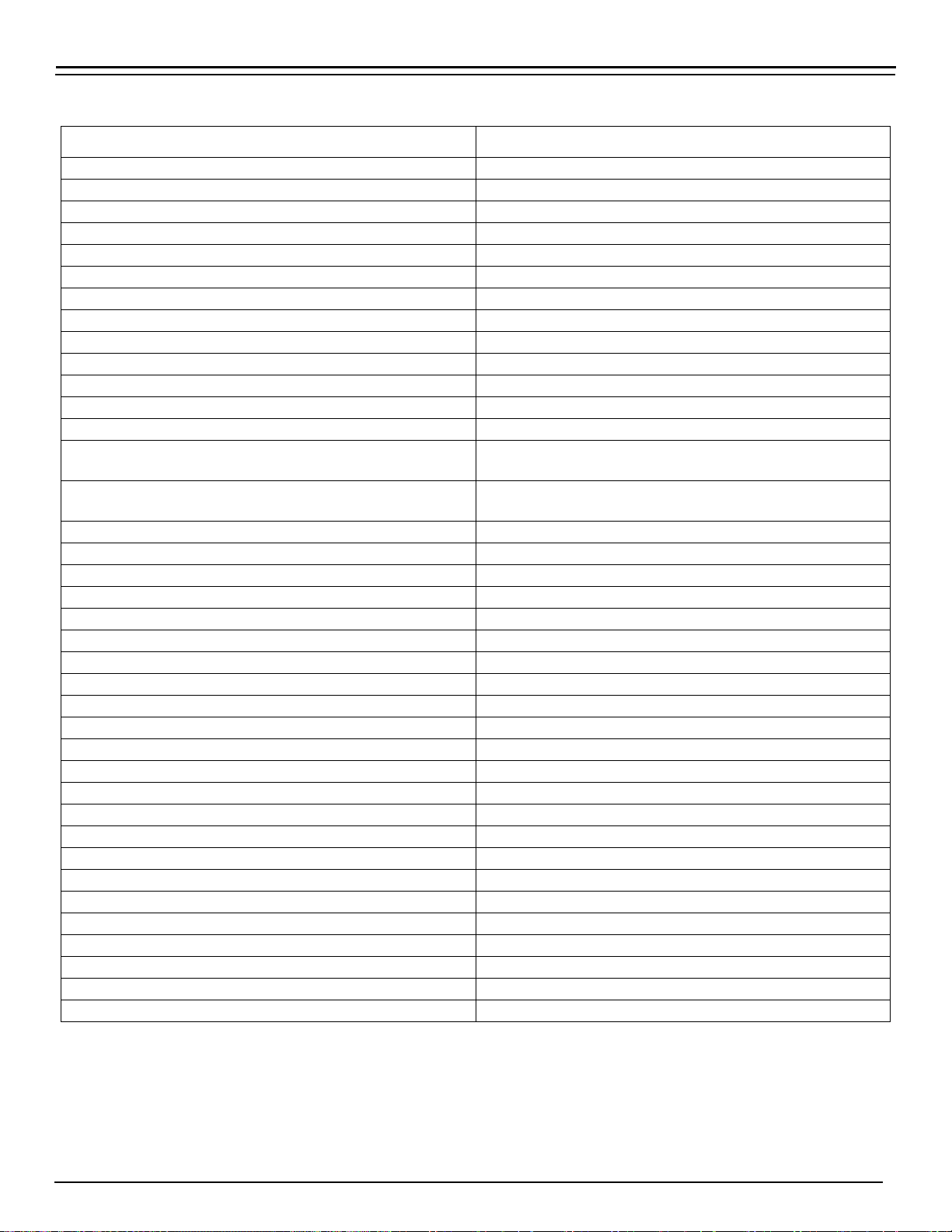

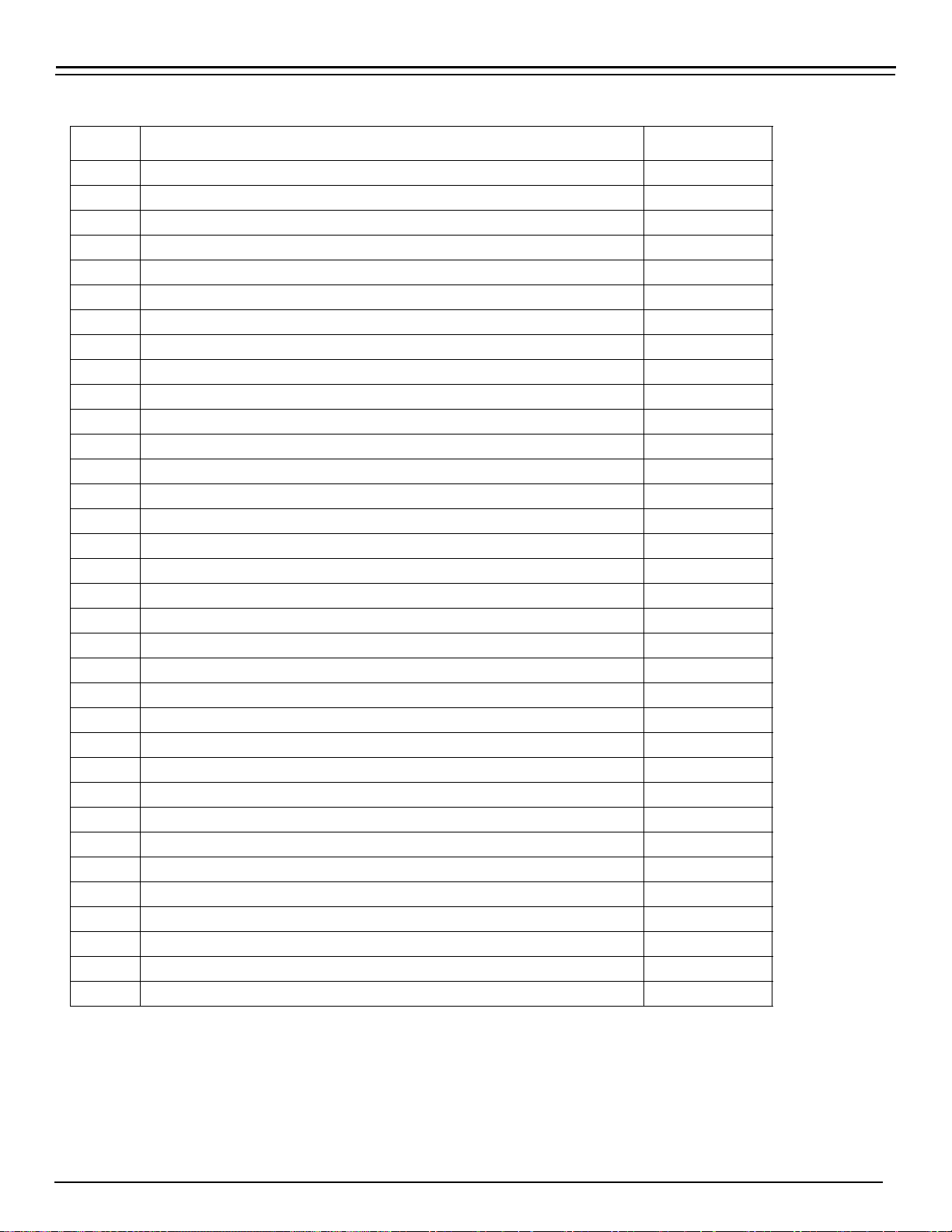

CODES QUICK CHECKS

MAIN

CODE

13 12 Check:

SUB

CODE

ECU Input Voltage

Low

13 13

ECU Input Voltage

Medium Low

13 23

ECU Input Voltage

High

14 12, 23 Check:

Oil Level Sensor

21 12, 23 Check:

a. Battery direct ground and power connections are

tight and clean.

b. Vehicle batteries are charged.

c. Vehicle charging system is not over- or

under-charging.

d. VIM fuse is good.

e. VIM connections are tight, clean, and undamaged.

f. Vehicle manufacturer supplied wiring is correct.

g. ECU connectors are tight, clean, and undamaged.

a. Is transmission equipped with oil level sensor?

b. Engine speed sensor, output speed sensor,

temperature sensor, and oil level sensor are

working correctly.

c. Wiring harness has no opens, shorts to ground, or

shorts to battery.

a. TPS connector is properly connected.

Throttle Position

Sensor

b. End of TPS cable is pulled out properly.

c. Engine fuel lever is in idle position.

d. Engine fuel lever provides proper amount of

stroke on TPS cable.

e. Wiring harness to TPS has no opens, shorts

between wires, or shorts to ground.

f. TPS for proper operation and resistance readings.

55

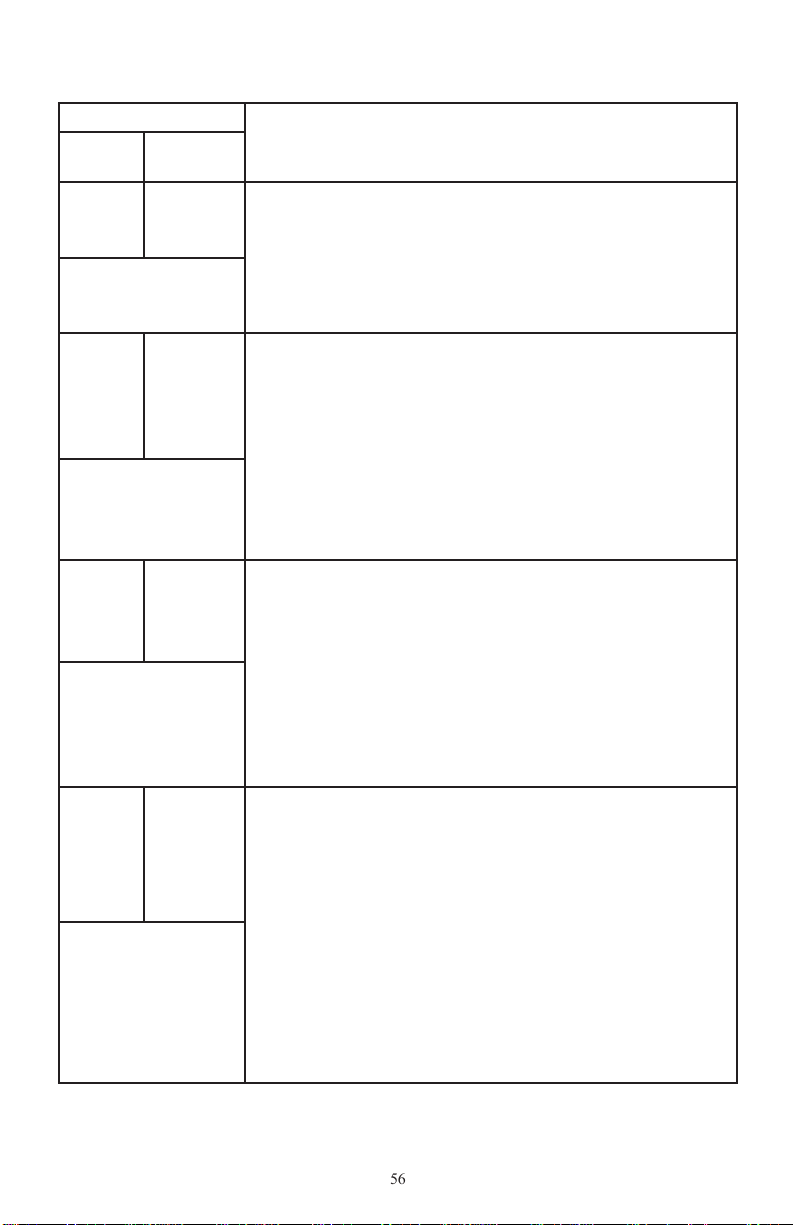

Code Listings And Procedures

Page 9

CODES QUICK CHECKS

MAIN

CODE

22 14, 15, 16 Check:

Speed Sensors

23 12, 13, 14,

Shift Selectors

24 12 Check:

Sump Fluid

Temperature Cold

SUB

CODE

15, 16

a. Speed sensors and connectors are tight, clean, and

undamaged.

b. Wiring harness to sensors has no opens, shorts

between wires, or shorts to ground.

Check:

a. ECU connectors are tight, clean, and undamaged.

b. Shift selector connector is tight, clean, and

undamaged.

c. Wiring harness has no opens, shorts between

wires, or shorts to ground.

d. Shift selector(s) for proper operation.

a. Air temperature is below –32°C (–25°F)

• If yes, this is a correct response for

temperature.

• If no, check that main transmission connector is

tight, clean, and undamaged.

(cont’d)

b. ECU connectors are tight, clean, and undamaged.

24 23 Verify the overheat situation. Check:

a. Correct dipstick is installed.

b. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

Sump Fluid

Temperature Hot

• If fluid level is incorrect—correct fluid level.

• If fluid level is correct—check for cause of

overheating.

c. Check if ECU and transmission connectors are

tight, clean, and undamaged.

56

Code Listings And Procedures

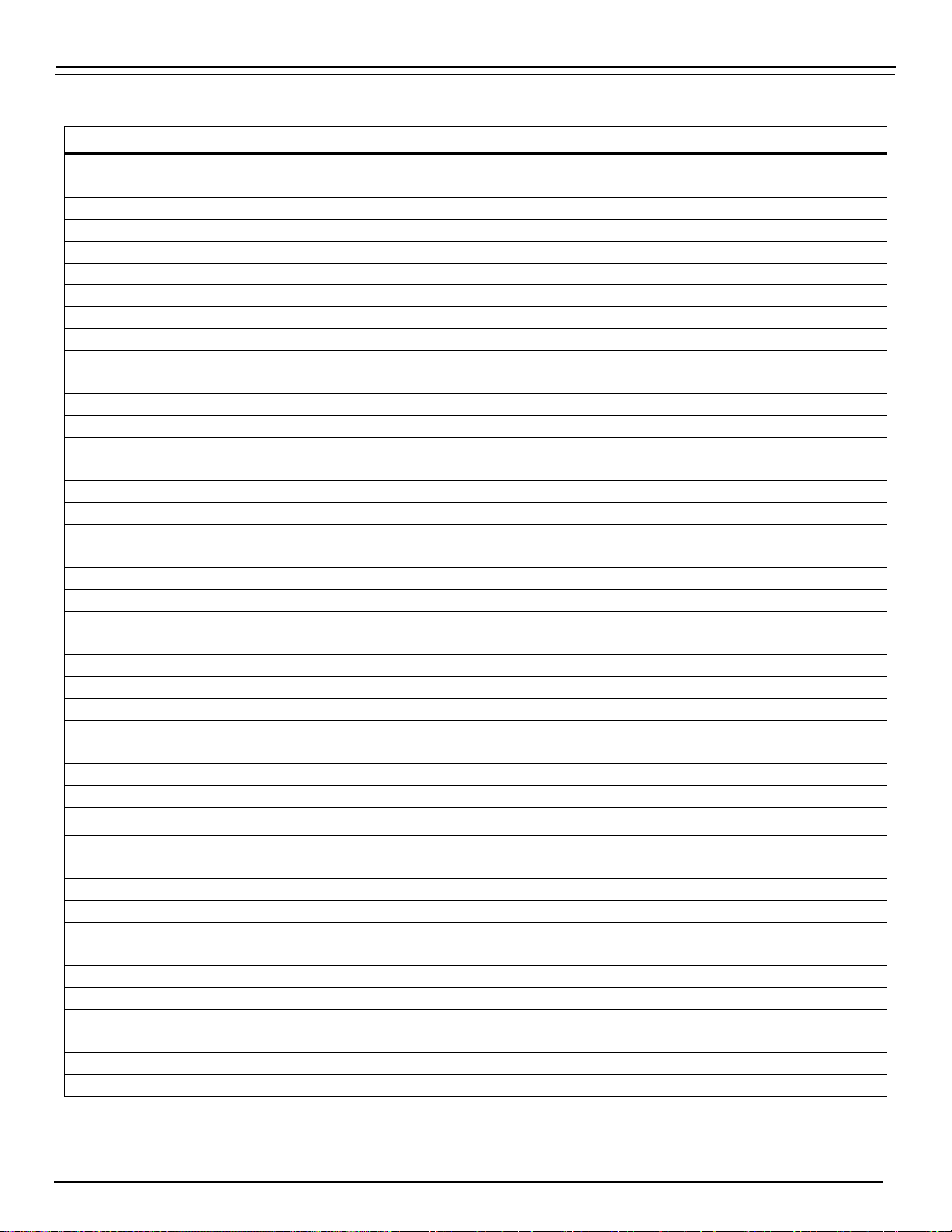

Page 10

CODES QUICK CHECKS

MAIN

CODE

25 00, 11, 22,

SUB

CODE

33, 44, 55,

66, 77

Check:

a. Speed sensor connector is tight, clean, and

undamaged.

b. ECU connectors are tight, clean, and undamaged.

(cont’d)

Output Speed

Sensor

26 00, 11 Check:

Throttle/Engine

Coolant Source Not

Detected

32 00, 33, 55,77Check:

C3 Pressure Switch

Open

33 12, 23 Check:

c. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

d. Wiring harness to sensor has no opens, shorts

between wires, or shorts to ground.

a. TPS for proper operation, related harness for

opens and shorts.

b. Serial connection to engine is tight, clean, and

undamaged.

c. SCI wiring harness has no opens or shorts.

a. Correct dipstick is installed.

b. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

c. Main transmission connector is tight, clean, and

undamaged.

d. ECU connectors are tight, clean, and undamaged.

e. Wiring harness has no opens, shorts between

wires, or shorts to ground.

Sump Oil

Temperature Sensor

Failure

a. Main transmission connector is tight, clean, and

undamaged.

b. ECU connectors are tight, clean, and undamaged.

c. Wiring harness has no opens, shorts between

wires, or shorts to ground.

57

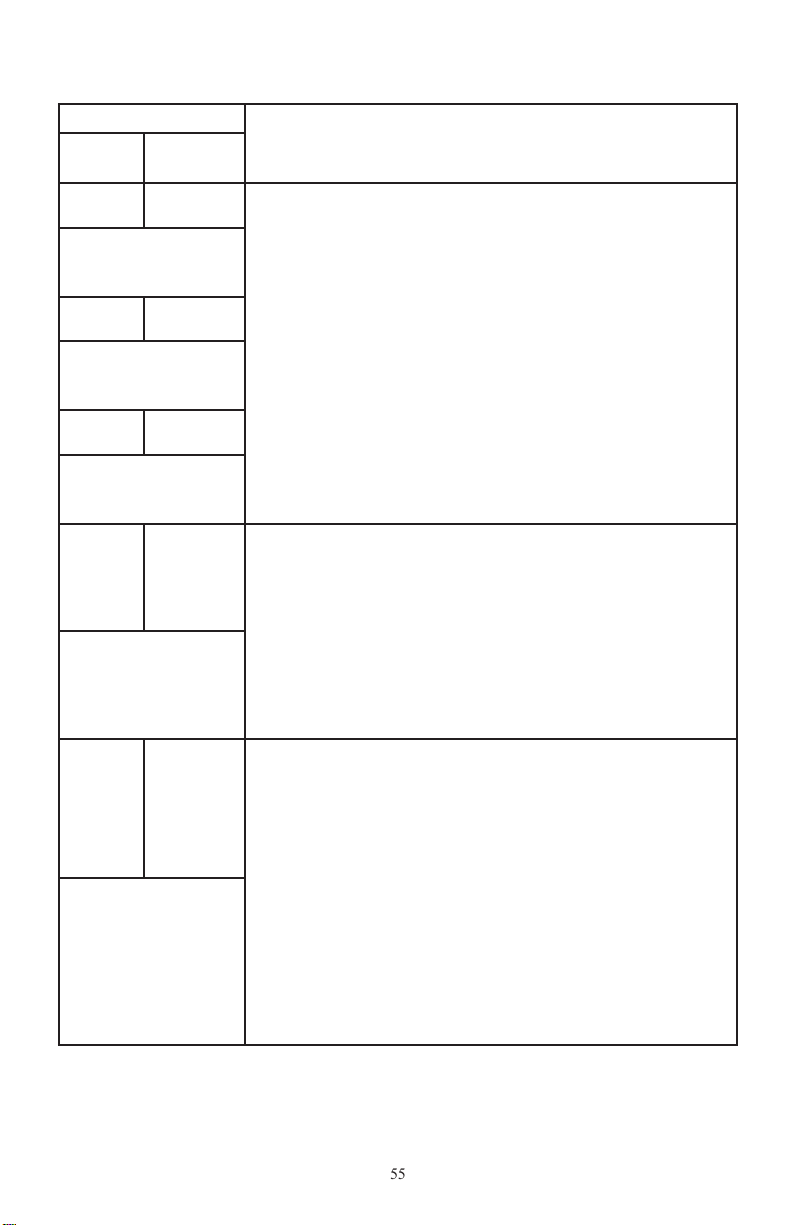

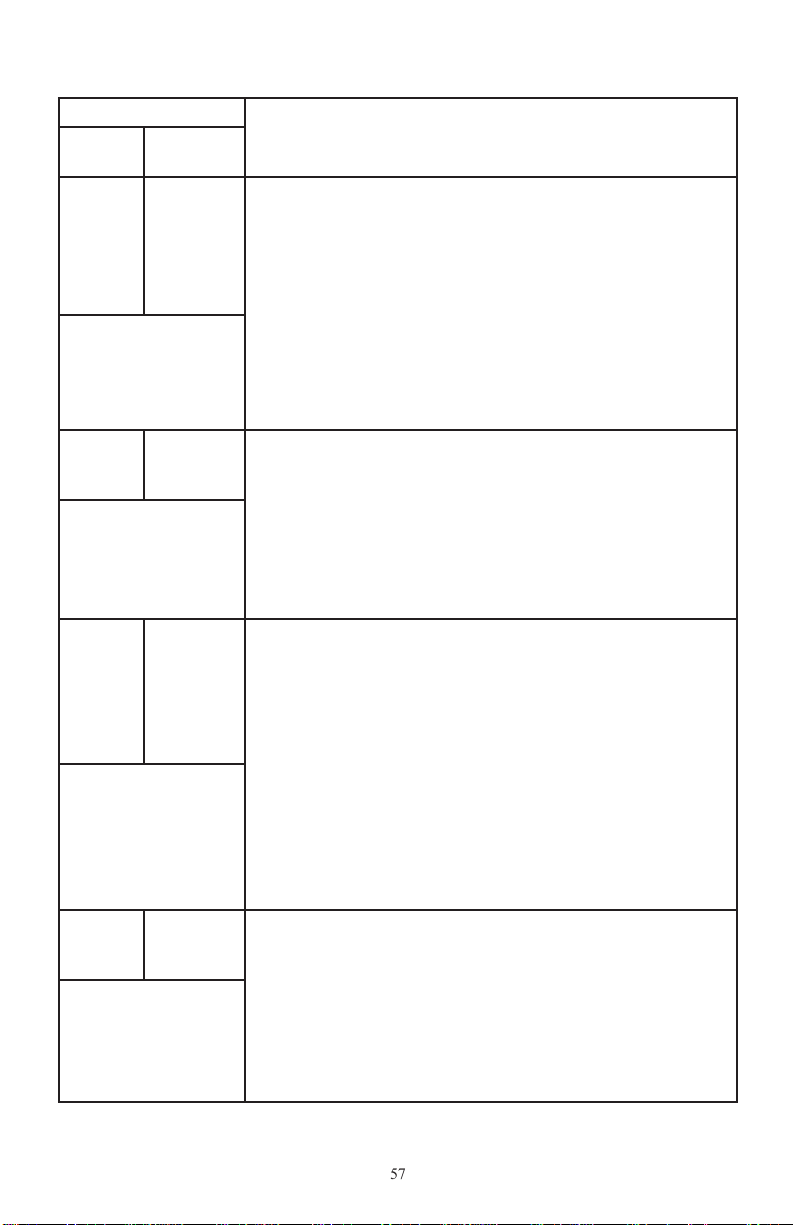

Code Listings And Procedures

Page 11

CODES QUICK CHECKS

MAIN

CODE

34 12, 13, 14,

EEPROM

35 00, 16 Check:

SUB

CODE

15, 16, 17

a. Recalibrate ECU, if possible.

b. Replace ECU if not possible to recalibrate.

a. ECU connectors are tight, clean, and undamaged.

b. VIM connectors are tight, clean, and undamaged.

(cont’d)

Power Interruption

Real Time Write

Interruption

36 00, 01, 02

Hardware/Software

Not Compatible

42 12, 13, 14,

15, 16, 21

22, 23, 24,

26

Short to Battery in

Solenoid Circuit

c. Vehicle manufacturer supplied wiring has correct

power and ground connections.

d. Power connections are battery direct.

e. Ground connections are battery direct.

f. Ignition switch connections are correct.

a. If able, recalibrate ECU; if not, replace ECU.

b. Check that ECU is compatible with TransID level

(36 01).

c. Troubleshoot TransID wire and circuit for short to

battery (36 02).

Check:

a. Main transmission connector is tight, clean, and

undamaged.

b. ECU connectors are tight, clean, and undamaged.

c. Wiring harness is not pulled too tight, and there is

no damage, chafing, or screws through harness.

d. Wiring harness has no opens, shorts between

wires, or shorts to ground.

e. Unauthorized repairs have not been made.

f. Change harness (optional).

58

Code Listings And Procedures

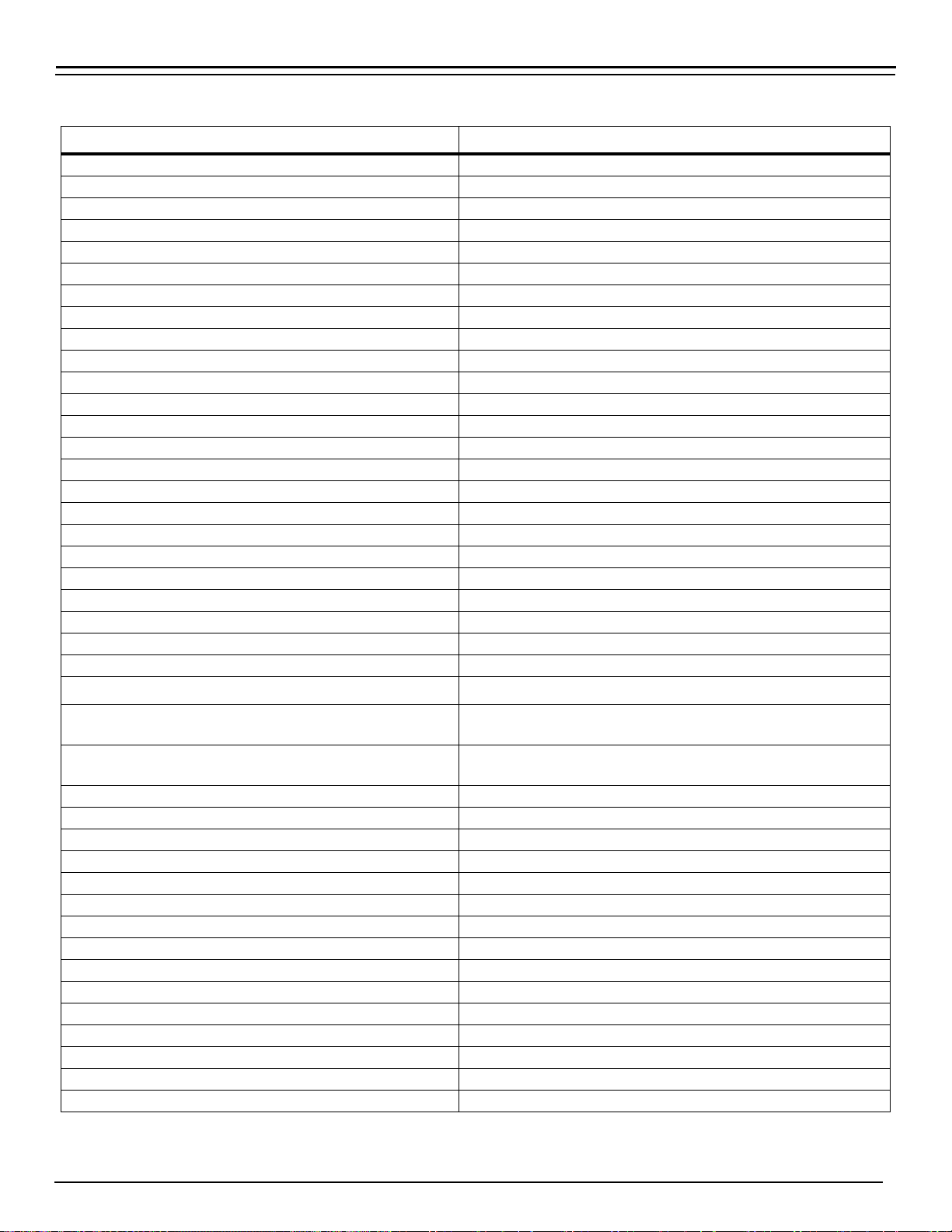

Page 12

CODES QUICK CHECKS

MAIN

CODE

44 12, 13, 14,

Solenoid Circuit

Short to Ground

45 12, 13, 14,

Solenoid Circuit

Open

46 21, 26, 27 Check:

SUB

CODE

15, 16, 21,

22, 23, 24,

26

15, 16, 21,

22, 23, 24,

26

Check:

a. Main transmission connector is tight, clean, and

undamaged.

b. ECU connectors are tight, clean, and undamaged.

c. Wiring harness has no opens, shorts between

wires, or shorts to ground.

Check: a. b. c.

a. Main transmission connector is tight, clean, and

undamaged.

b. ECU connectors are tight, clean, and undamaged.

c. Wiring harness has no opens or shorts.

a. Main transmission connector is tight, clean, and

undamaged.

(cont’d)

Solenoid

Overcurrent

Offgoing Ratio Test

(During Shift)

51 01, 10, 12,

21, 23, 24,

35, 42, 43,

45, 46, 53,

64, 65,

XY*

b. ECU connectors are tight, clean, and undamaged.

c. Wiring harness has no opens, shorts between

wires, or shorts to ground.

d. Replace ECU.

Check:

a. Output and turbine speed sensor connectors are

tight, clean, and undamaged.

b. Speed sensor wiring harness has no opens, shorts

between wires, or shorts to ground.

c. Correct dipstick is installed.

d. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

59

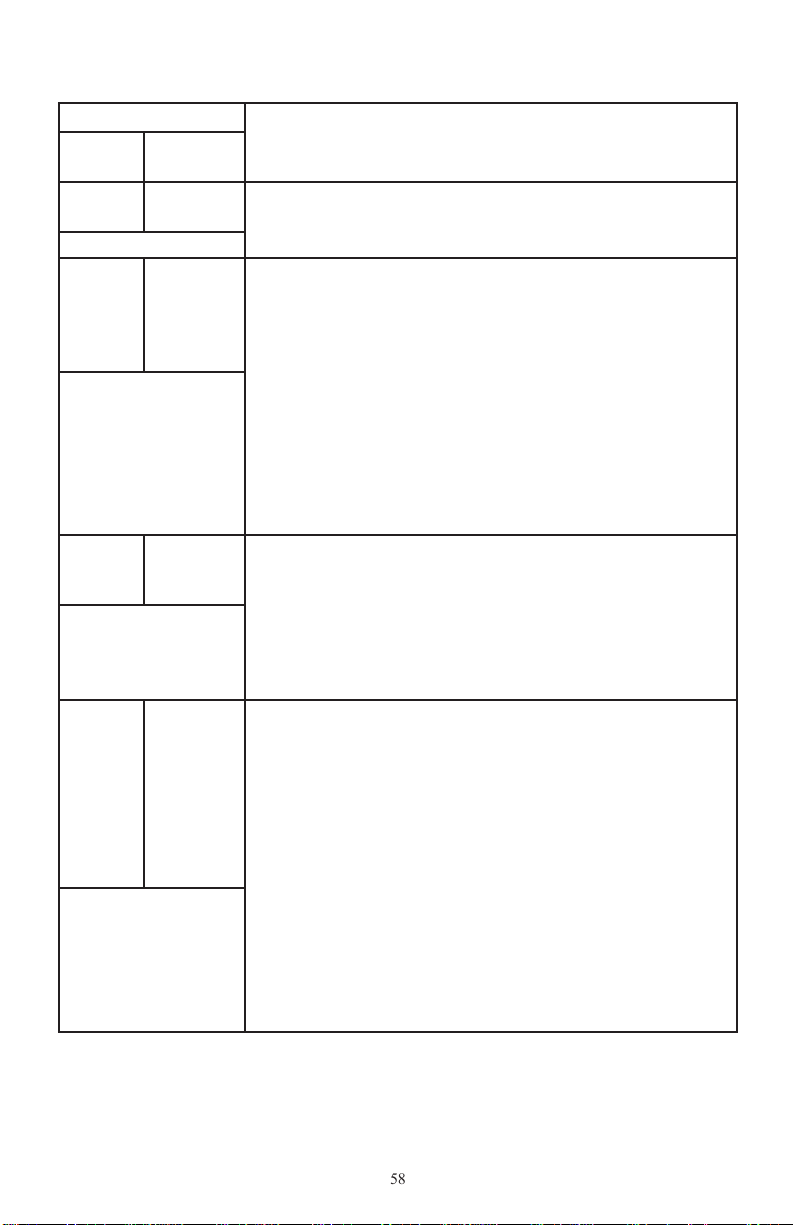

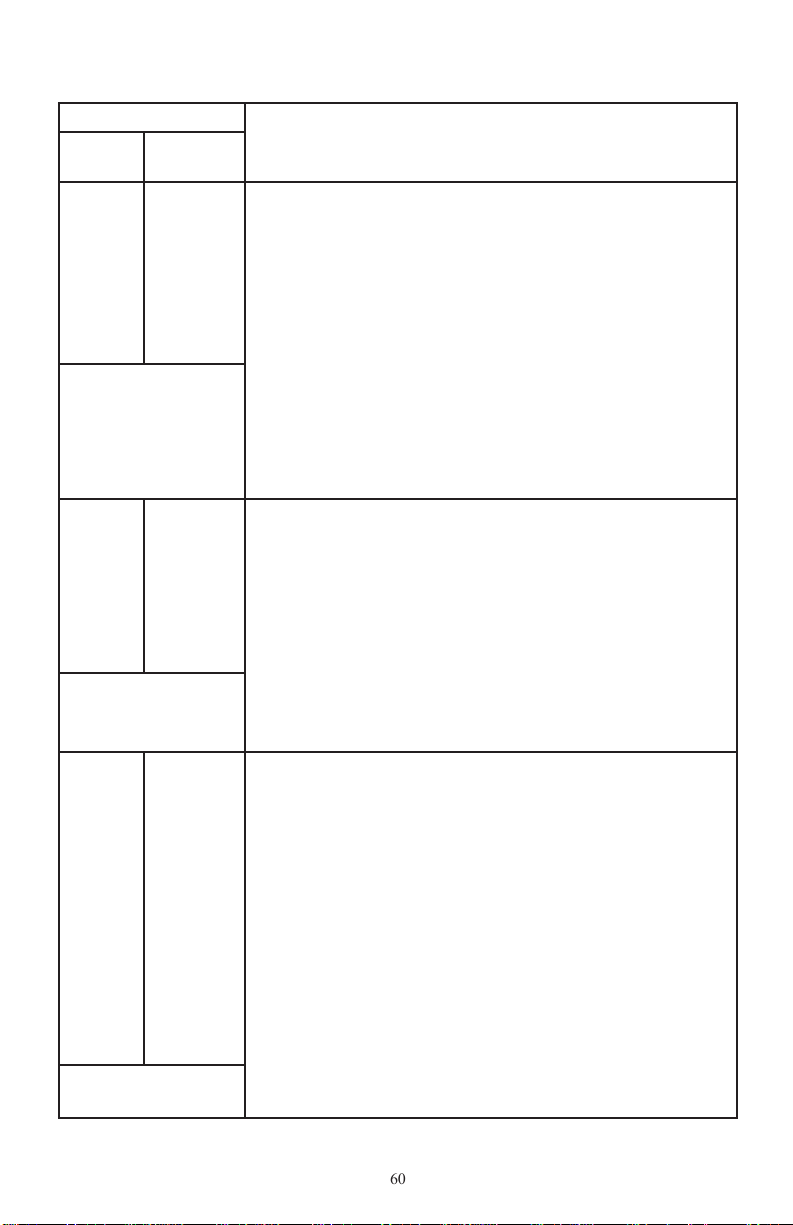

Code Listings And Procedures

Page 13

CODES QUICK CHECKS

MAIN

CODE

52 01, 08, 32,

SUB

CODE

34, 54, 56,

71, 72, 78,

79, 99,

XY*

Check:

a. Output and turbine speed sensor connectors are

tight, clean, and undamaged.

b. Speed sensor wiring harness has no opens, shorts

between wires, or shorts to ground.

(cont’d)

Offgoing C3

Pressure Switch Test

(During Shift)

53 08, 09, 18,

19, 28, 29,

38, 39, 48,

49, 58, 59,

68, 69, 78,

99, XY*

Offgoing Speed Test

(During Shift)

54 01, 07, 10,

12, 17, 21,

23, 24, 27,

32, 34, 35,

42, 43, 45,

46, 53, 54,

56, 64, 65,

70, 71, 72,

80, 81, 82,

83, 85, 86,

87, 92, 93,

95, 96,

XY*

Oncoming Ratio

Test (After Shift)

c. Main wiring harness to transmission has no shorts

between wires or shorts to ground.

d. Correct dipstick is installed.

e. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

Check:

a. Turbine and engine speed sensor connectors are

tight, clean, and undamaged.

b. Speed sensor wiring harness has no opens, shorts

between wires, or shorts to ground.

c. Correct dipstick is installed.

d. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

Check:

a. Turbine and output speed sensor connectors are

tight, clean, and undamaged.

b. Speed sensor wiring harness has no opens, shorts

between wires, or shorts to ground.

c. Correct dipstick is installed.

d. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

e. EEPROM calibration is correct for the

transmission.

60

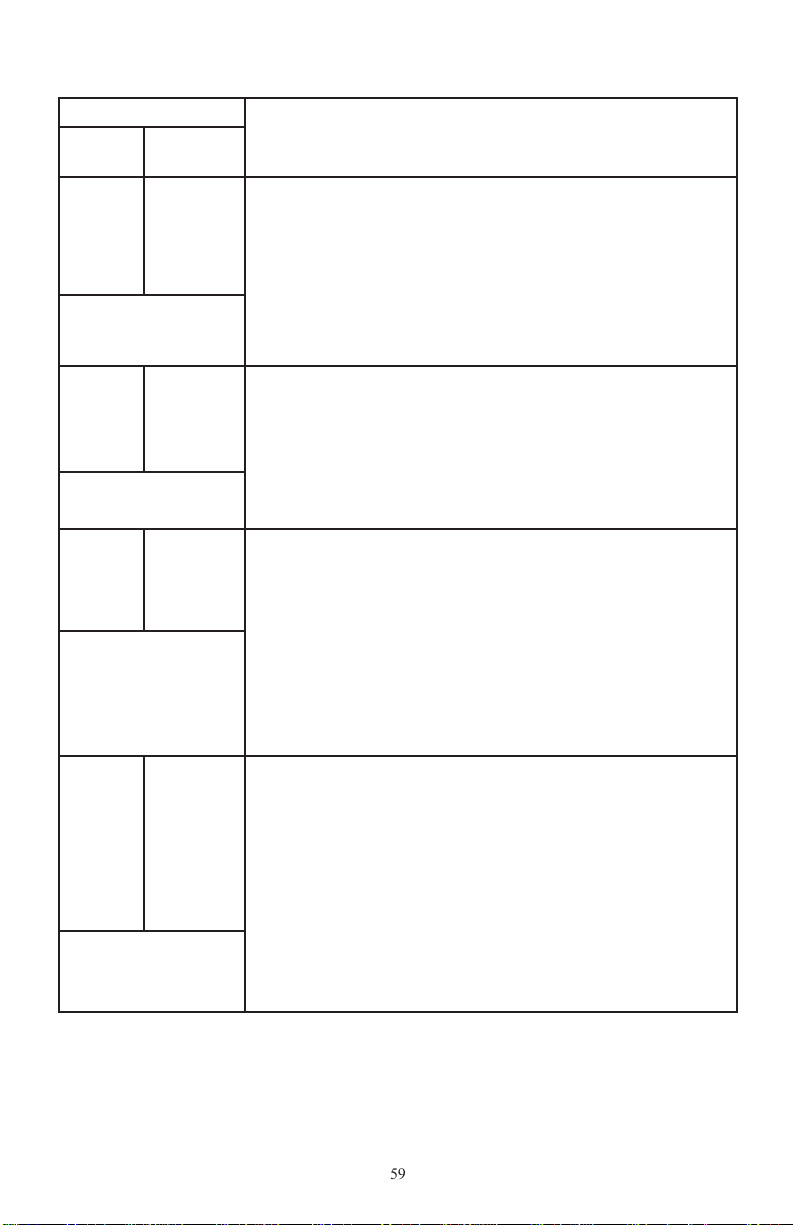

Code Listings And Procedures

Page 14

CODES QUICK CHECKS

MAIN

CODE

55 07, 17, 27,

SUB

CODE

87, 97,

XY*

Check:

a. Correct dipstick is installed.

b. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

c. Output and turbine speed sensor connectors are

tight, clean, and undamaged.

(cont’d)

Oncoming C3

Pressure Switch Test

(After Shift)

56 00, 11, 22,

33, 44, 55,

66, 77

Range Verification

Ratio Test

d. Speed sensor wiring harness has no opens, shorts

between wires, or shorts to ground.

e. Transmission connector is tight, clean, and

undamaged.

f. ECU connectors are tight, clean, and undamaged.

g. C3 pressure switch wiring has no opens, shorts

between wires, or shorts to ground.

Check:

a. Turbine and output speed sensor connectors are

tight, clean, and undamaged.

b. Speed sensor wiring harness has no opens, shorts

between wires, or shorts to ground.

c. Transmission connector is tight, clean, and

undamaged.

d. ECU connectors are tight, clean, and undamaged.

e. Correct dipstick is installed.

f. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

61

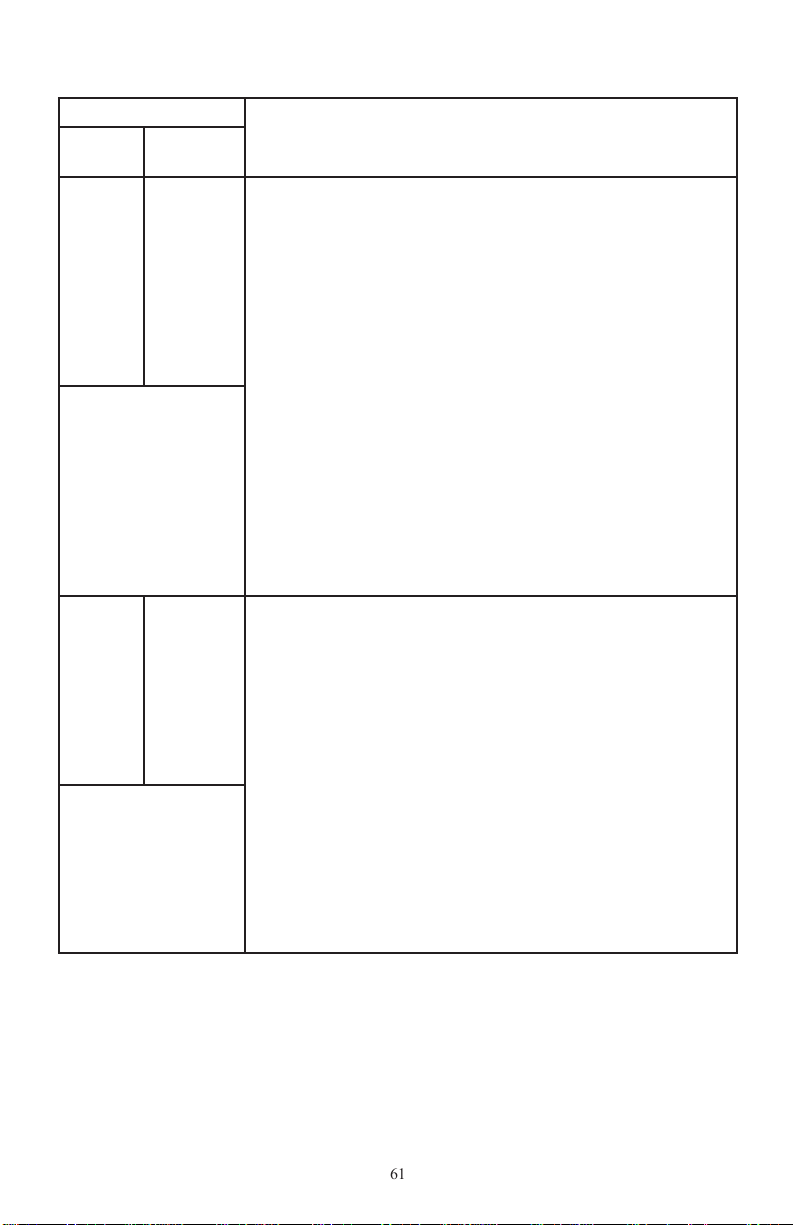

Code Listings And Procedures

Page 15

CODES QUICK CHECKS

MAIN

CODE

57 11, 22, 44,

SUB

CODE

66, 88, 99

Check:

a. Correct dipstick is installed.

b. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

c. Output and turbine speed sensor connectors are

tight, clean, and undamaged.

(cont’d)

Range Verification

C3 Pressure Switch

Test

61 00 Check:

Retarder Over

Temperature

d. Speed sensor wiring harness has no opens, shorts

between wires, or shorts to ground.

e. Transmission connector is tight, clean, and

undamaged.

f. ECU connectors are tight, clean, and undamaged.

g. C3 pressure switch wiring has no opens, shorts

between wires, or shorts to ground.

a. Fluid level is correct. Refer to CARE AND

MAINTENANCE section.

b. Retarder apply system is not allowing retarder and

throttle to be applied at the same time.

c. Fluid cooler is adequately sized for load.

62

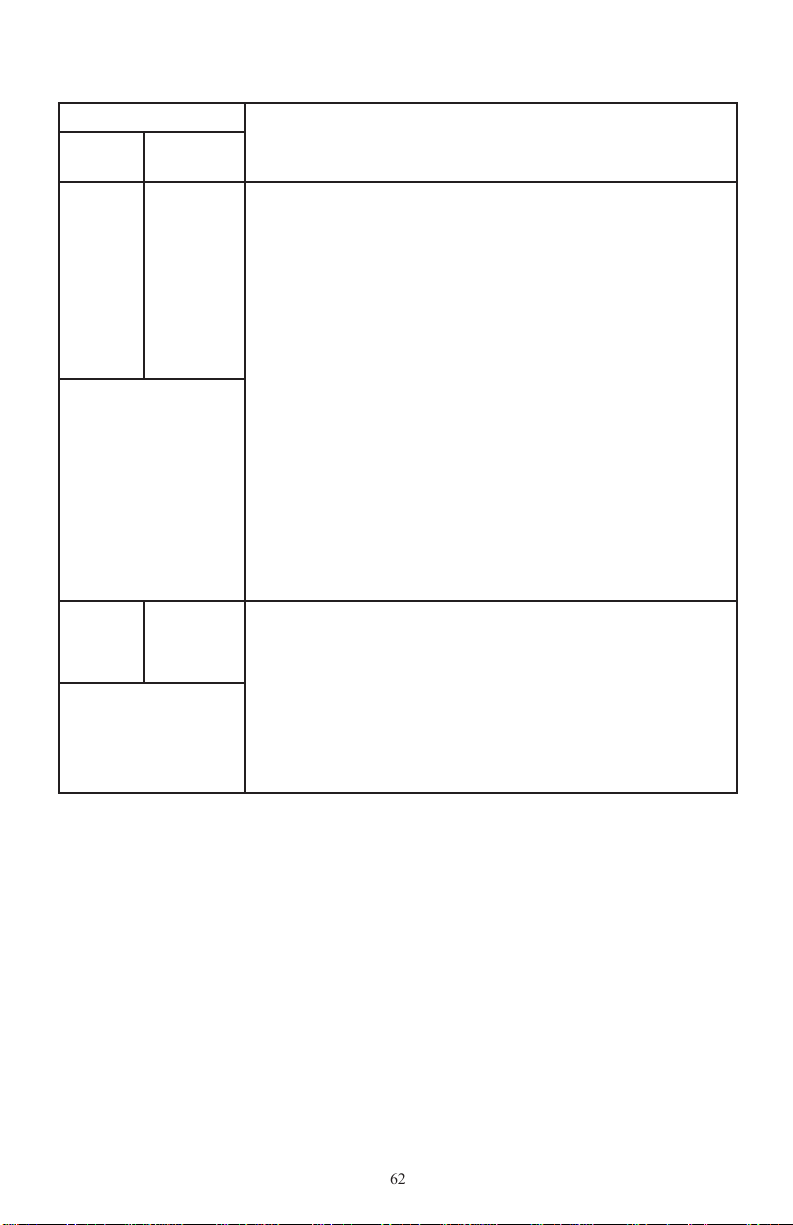

Code Listings And Procedures

Page 16

CODES QUICK CHECKS

MAIN

CODE

62 12, 23, 32,33Check:

Retarder

Temperature Sensor,

Engine Coolant

Sensor

63 00, 26, 40,

Input Function Fault

64 12, 23 Use diagnostic tool to read retarder counts and identify

Retarder Modulation

Request Device

Fault

66 00, 11, 22 Check: a. b. c.

SUB

CODE

41, 47

a. Retarder temperature measured with diagnostic

tool is consistent with code: or determine if code

is active using shift selector.

b. Sensor connector is tight, clean and undamaged.

c. ECU connectors are tight, clean, and undamaged.

d. Temperature sensor circuit has no opens, shorts

between wires, or shorts to ground.

e. Serial connection to engine computer is tight,

clean, and undamaged.

f. SCI wiring harness has no opens or shorts.

Check input wiring, switches, and connectors to

determine why input states are different.

problem wires. Check wiring for short to battery, ground

wire open, or short to ground.

(cont’d)

Serial

Communications

Interface Fault

ECU Malfunction

69 27, 28, 29,

33, 34, 35,

36, 39, 41,

42, 43

a. Serial connection to engine computer is tight,

clean, and undamaged.

b. SCI wiring harness has no opens, shorts, or shorts

to ground.

c. If diagnostic tool is not available, also be sure that

transmission ECU connections are tight, clean, and

undamaged.

d. Problem with CAN link or engine controls.

a. Clear diagnostic code and retry vehicle start.

b. If code recurs, reprogram or replace ECU.

63

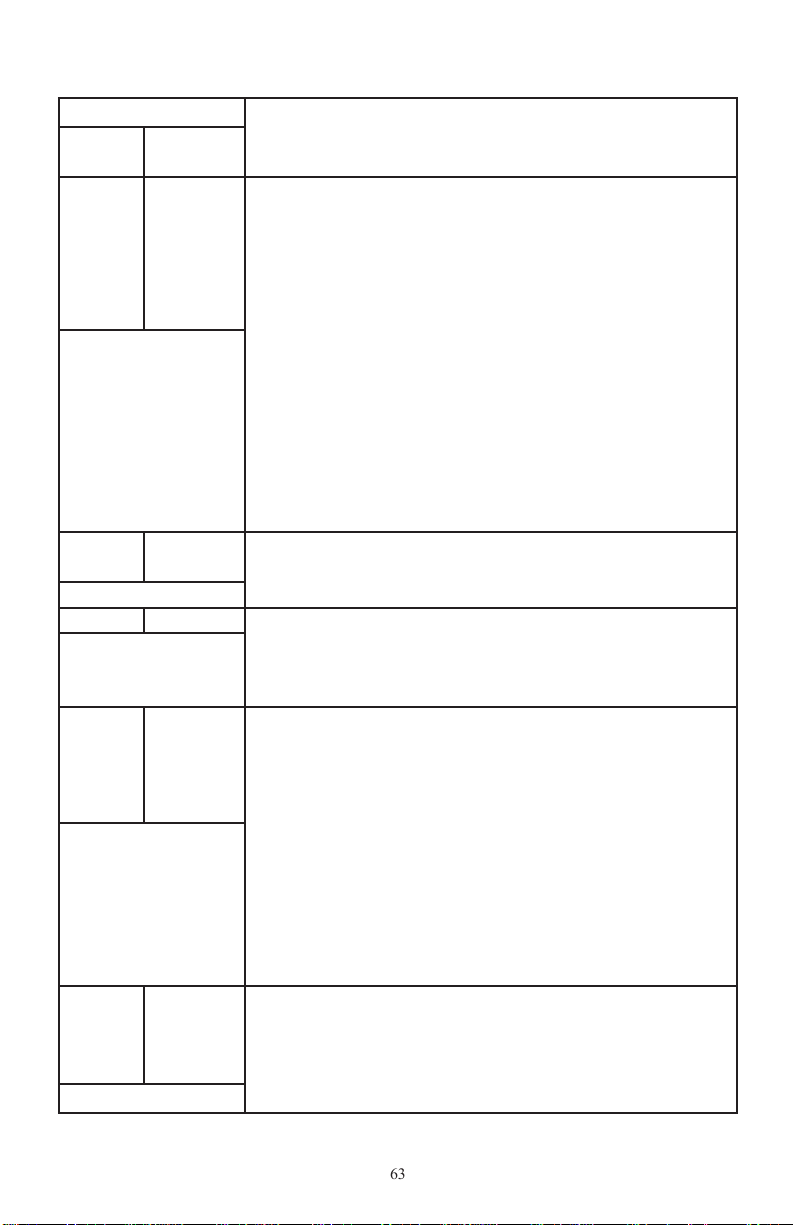

Code Listings And Procedures

Page 17

CODES QUICK CHECKS

MAIN

CODE

70 12, 13, 14 Reset ECU

Software Problem

* Additional codes could be logged for other shifts where X indicates range

shifted from and Y indicates range shifted to.

SUB

CODE

(cont’d)

64

I

Page 18

C

U

3

J

-

1

5

8

7

FAULT CODES

MID, PID, SID

Page 19

J-1587 ( MID, PID, SID CODES )

Fault Codes

MESSAGE IDENTIFIERS (MID CODES)

128 Engine 74 Maximum Road Speed Limit - MAXROADSPEED

130 Electronic Transmission 75 Steering Axle Temperature

136 Anti-Lock Brakes (ABS) 76 Axle Lift Air Pressure

140 Instrumentation Control Unit, Left 77 Forward-Rear Drive Axle Temperature

142 Instrumentation Control Unit, Right #1 78 Rearmost (Rear-Rear) Drive Axle Temperature

(becomes 234 with software ver. 8.4) 79 Road Surface Temperature

164 Bulkhead module 80 Washer Fluid Level

172 ServiceLink 81 Particulate Trap Inlet Pressure

179 Data Logging Unit 82 Air Start Pressure - AIRSTARTPRESS

181 Communications Unit-Satellite 83 Road Speed Limit Status - ROAD SPEED Lim

190 Air Conditioning Protection Unit - ACPU 84 Road Speed

219 Collision Avoidance Radar - VORAD 85 Cruise Control Status - Cruise Status

231 Communications Unit-Cellular 86 Cruise Control Set Speed - CRUISE SET

232 seat belt unit 87 Cruise Control High-Set Limit Speed

234 Instrumentation Control Unit, Right #2 88 Cruise Control Low-Set Limit Speed - CRUISE LO SET

PARAMETER IDENTIFIERS (PID CODES)

51 Throttle Position 90 PTO Oil Temperature - PTO OIL TEMP

52 Engine Intercooler Temperature - TEMP 91 Percent Accelerator Pedal Position - ACCEL PDL

53 Transmission Synchronizer Clutch Value - SYNCRO

CLUTCH

54 Transmission Synchronizer Brake Value - SYNCRO

BRAKE

55 Shift Finger Positional Status - SHFT FNGR POS 94 Fuel Delivery Pressure - FUEL DLVR PRSS

56 Transmission Range Switch Status - RANGE SWITCH 95 Fuel Filter Differential Pressure - FUEL FILTER

57 Transmission Actuator Status #2 - ACTTRSTATUS#2 96 Fuel Level

58 Shift Finger Actuator Status - SHFT FNGR ACT 97 Water in Fuel Indicator

59 Shift Finger Gear Position - SHFT FNGR GEAR 98 Engine Oil Level

60 Shift Finger Rail Position - SHFT FNGR RAIL 99 Engine Oil Filter Differential Pressure - Oil Fltr Pres

61 Parking Brake Actuator Status 100 Engine Oil Pressure

62 Retarder Inhibit Status - RETARDRINHIBIT 101 Crankcase Pressure

63 Transmission Actuator Status #1 - ACT STATUS #1 102 Boost Pressure

64 Direction Switch Status 103 Turbo Speed

65 Service Brake Switch Status 104 Turbo Oil Pressure

66 Vehicle Enabling Component Status 105 Intake Manifold Temperature - Intake Air TEMP

67 Shift Request Switch Status 106 Air Inlet Pressure

68 Torque Limiting Factor 107 Air Filter Differential Pressure - Air Filter

69 Two-Speed Axle Switch Status 108 Barometric Pressure

70 Parking Brake Switch 109 Coolant Pressure

71 Idle Shutdown Timer Status - IDLESHUTDWNTMR 110 Engine Coolant Temperature

72 Blower Bypass Valve Position - BLOWRBYPASSPOS 111 Coolant Level

73 Auxiliary Water Pump Pressure - Aux PUMP Press 112 Coolant Filter Differential Pressure - CoolFltDiffPrs

89 Power Takeoff Status - PTO STATUS

POS%

92 Percent Engine Load - ENG LOAD%

93 Output Torque - OUTPUT TORQUE

2-3af-T-Liner C2 02 Resources.fm 5/24/04

Saf-T-Liner C2

Page 20

J-1587 (MID, PID, SID ) CODES

Fault Codes (cont.)

PARAMETER IDENTIFIERS (PID CODES) (cont.)

113 Governor Droop 177 Transmission Oil Temperature - TRAN OIL TEMP

114 Net Battery Current - Battery AMPS 178 Front Axle Weight

115 Alternator Current - Alternator AMPS 179 Rear Axle Weight

116 Brake Application Pressure 180 Trailer Weight

117 Brake Primary Pressure - Primary Press 181 Cargo Weight

118 Brake Secondary Pressure - Sec. Press 182 Trip Fuel

119 Hydraulic Retarder Pressure - Retarder Press 183 Fuel Rate

120 Hydraulic Retarder Oil Temperature - Retdr Oil TEMP 184 Instantaneous Fuel Economy - Inst Fuel Icon

121 Engine Retarder Status - Retardr Status 185 Average Fuel Economy - AVG. Fuel Econ

122 Engine Retarder Percent -% Retarder 186 Power Takeoff Speed

123 Clutch Pressure 187 Power Takeoff Set Speed - PTO SET SPEED

124 Transmission Oil Level - Oil Level 188 Idle Engine Speed

125 Transmission Oil Level High/Low - Oil Level 189 Rated Engine Speed - Rated SPEED

126 Transmission Filter Differential Pressure -

FilterDifPress

127 Transmission Oil Pressure - Oil Pressure 191 Transmission Output Shaft Speed - TRAN OUT

154 Auxiliary Input and Output Status #2 232 DGPS Differential Correction - DGPS Correctn

155 Auxiliary Input and Output Status #1 233 Power Unit Number - POWER UNIT #

156 Injector Timing Rail Pressure 234 Software Identification

157 Injector Metering Rail Pressure 235 Total Idle Hours

158 Battery Potential (voltage)-Switched - Volts (BattSw) 236 Total Idle Fuel Used - Totl Idle Fuel

159 Gas Supply Pressure 237 Vehicle Identification Number

160 Main Shaft Speed 238 Velocity Vector

161 Input Shaft Speed 239 Vehicle Position

162 Transmission Range Selected 240 Change Reference Number

163 Transmission Range Attained 241 Tire Pressure

164 Injection Control Pressure 242 Tire Temperature

165 Compass Bearing - COMPASS Dir. 243 Component Identification

166 Rated Engine Power 244 Trip Distance

167 Alternator Potential (voltage) - Volts (Alt) 245 Total Vehicle Distance

168 Battery Potential (voltage) - Volts (Batt) 246 Total Vehicle Hours

169 Cargo Ambient Temperature - CARGO TEMP 247 Total Engine Hours

170 Cab Interior Temperature - CAB TEMP 248 Total PTO Hours

171 Ambient Air Temperature - Outside TEMP 249 Total Engine Revolutions

172 Air Inlet Temperature 250 Total Fuel Used

173 Exhaust Gas Temperature 251 Clock

174 Fuel Temperature - Fuel TEMP 252 Date

175 Engine Oil Temperature 253 Elapsed Time

176 Turbo Oil Temperature

190 Engine Speed

SPEED

02 Resources.fm 5/24/04 Saf-T-Liner C2 2 -33

Page 21

J-1587 ( MID, PID, SID, CODES )

Fault Codes (cont.)

SUB-SYSTEM IDENTIFIERS (SID CODES)

MID 128 - Engine 49 Injector Cylinder #19

1 Injector Cylinder #1 50 Injector Cylinder #20

2 Injector Cylinder #2 51 Auxiliary Output Device Driver #3

3 Injector Cylinder #3 52 Auxiliary Output Device Driver #4

4 Injector Cylinder #4 53 Auxiliary Output Device Driver #5

5 Injector Cylinder #5 54 Auxiliary Output Device Driver #6

6 Injector Cylinder #6 55 Auxiliary Output Device Driver #7

7 Injector Cylinder #7 56 Auxiliary Output Device Driver #8

8 Injector Cylinder #8 57 Auxiliary PWM Driver #1

9 Injector Cylinder #9 58 Auxiliary PWM Driver #2

10 Injector Cylinder #10 59 Auxiliary PWM Driver #3

17 Fuel Shutoff Valve 60 Auxiliary PWM Driver #4

18 Fuel Control Valve 61 Variable Swirl System Valve

19 Throttle Bypass Valve 62 Prestroke Sensor

20 Timing Actuator 63 Prestroke Actuator

21 Engine Position Sensor 64 Engine Speed Sensor #2

22 Timing Sensor 65 Heated Oxygen Sensor

23 Rack Actuator 66 Ignition Control Mode Signal

24 Rack Position Sensor 67 Ignition Control Timing Signal

25 External Engine Protection Input 68 Secondary Turbo Inlet Pressure

26 Auxiliary Output Device Driver #1 69 ACOC (Aftercooler/Oil Cooler) Coolant F

27 Variable Geometry Turbocharger Actuator 1 70 Inlet Air Heater Driver #1

28 Variable Geometry Turbocharger Actuator 2 71 Inlet Air Heater Driver #2

29 External Fuel Command Input 72 Injector Cylinder #21

30 External Speed Command Input 73 Injector Cylinder #22

31 Tachometer Signal Output 74 Injector Cylinder #23

32 Wastegate Output Device Driver 75 Injector Cylinder #24

33 Fan Clutch Output Device Driver 76 Knock Sensor

34 Exhaust Back Pressure Sensor 77 Gas Metering Valve

35 Exhaust Back Pressure Regulator Solenoid 78 Fuel Supply Pump Actuator

36 Glow Plug Lamp

37 Electronic Drive Unit Power Relay 1 Wheel Sensor ABS Axle 1 Left

38 Glow Plug Relay 2 Wheel Sensor ABS Axle 1 Right

39 Engine Starter Motor Relay 3 Wheel Sensor ABS Axle 2 Left

40 Auxiliary Output Device Driver #2 4 Wheel Sensor ABS Axle 2 Right

41 ECM 8 Volts DC Supply 5 Wheel Sensor ABS Axle 3 Left

42 Injection Control Pressure Regulator 6 Wheel Sensor ABS Axle 3 Right

43 Autoshift High Gear Actuator 7 Pressure Mod. Valve ABS Axle 1 Left

44 Autoshift Low Gear Actuator 8 Pressure Mod. Valve ABS Axle 1 Right

45 Autoshift Neutral Gear Actuator 9 Pressure Mod. Valve ABS Axle 2 Left

46 Autoshift Common Low Side (Return) 10 Pressure Mod. Valve ABS Axle 2 Right

47 Injector Cylinder #17 11 Pressure Mod. Valve ABS Axle 3 Left

48 Injector Cylinder #18

MID 136 ABS -

2-34 Saf-T-Liner C2 02 Resources.fm 5/24/04

Saf-T-Liner C2

Page 22

J-1587 (MID, PID, SID ) CODES

Fault Codes (cont.)

MID 136 ABS - (cont.)

12 Pressure Mod. Valve ABS Axle 3 Right 230 Idle Validation Switch

13 Retarder Control Relay 231 SAE J1939 Datalink

14 Relay Diagonal 1 232 5-Volt DC Supply

MID 190 ACPU - 233 Controller #2

1 Refrigerant Charge 234 Parking Brake ON Actuator

2 Refrigerant Moisture Level 235 Parking Brake OFF Actuator

3 Non-Condensable Gas in Refrigerant 236 Power Connect Device

4 Refrigerant Flow Control Solenoid 237 Start Enable Device

5 Low Pressure Switch 238 Diagnostic Light-Red

6 Refrigerant Clutch Circuit 239 Diagnostic Light-Amber

7 Evaporator Thermostat Circuit 240 Program Memory

MID 219 VORAD - 242 Cruise Control RESUME Switch

1 Forward Antenna 243 Cruise Control SET Switch

2 Antenna Electronics 244 Cruise Control ENABLE Switch

3 Brake Input Monitor 245 Clutch Pedal Switch #1

4 Speaker Monitor 246 Brake Pedal Switch #1

5 Steering Sensor Monitor 247 Brake Pedal Switch #2

6 Speedometer Monitor 248 Proprietary Datalink

7 Right Turn Signal Monitor 249 SAE J1922 Datalink

8 Left Turn Signal Monitor 250 SAE J1708 (J1587) Datalink

9 Control Display Unit 251 Power Supply

10 Right Side Sensor 252 Calibration Module

11 Left Side Sensor 253 Calibration Memory

12 Rear Sensor 254 Controller #1

GENERIC SIDs - FAILURE MODE IDENTIFIERS (FMI CODES)

151 System Diagnostic Code #1 00 Above normal operating range (temperature, pressure,

etc.)

152 System Diagnostic Code #2 01 Below normal operating range (temperature, pressure,

etc.)

153 System Diagnostic Code #3 02 Erratic, intermittent, or incorrect data

154 System Diagnostic Code #4 03 Voltage above normal or shorted high

155 System Diagnostic Code #5 04 Voltage below normal or shorted low

219 Start Signal Indicator 05 Current below normal or open circuit

220 Electronic Tractor/Trailer Interface 06 Current above normal or circuit shorted to gnd.

(ISO 11992) 07 Device not responding

221 Internal Sensor Voltage Supply 08 Abnormal frequency

222 Protect Light 09 Abnormal update rate

223 Ambient Light Sensor 10 Abnormal rate of change

224 Audible Alarm 11 Not identifiable

225 Green Light 12 Bad intelligent device or component

226 Transmission Neutral Switch 13 Out of calibration

227 Auxiliary Analog Input #1 14 Special instructions

228 High Pressure Switch 15 Reserved

229 Kickdown Switch

02 Resources.fm 5/24/04 Saf-T-Liner C2 2 -35

I

Page 23

C

U

3

J J

- -

1 & 1

5 9

8 3

7 9

FAULT CODES

FOR THE C2

Resources

Page 24

Fault Codes

MESSAGE IDENTIFIERS (MID CODES)

128 Engine 74 Maximum Road Speed Limit - MAXROADSPEED

130 Electronic Transmission 75 Steering Axle Temperature

136 Anti-Lock Brakes (ABS) 76 Axle Lift Air Pressure

140 Instrumentation Control Unit, Left 77 Forward-Rear Drive Axle Temperature

142 Instrumentation Control Unit, Right #1 78 Rearmost (Rear-Rear) Drive Axle Temperature

(becomes 234 with software ver. 8.4) 79 Road Surface Temperature

164 Bulkhead module 80 Washer Fluid Level

172 ServiceLink 81 Particulate Trap Inlet Pressure

179 Data Logging Unit 82 Air Start Pressure - AIRSTARTPRESS

181 Communications Unit-Satellite 83 Road Speed Limit Status - ROAD SPEED Lim

190 Air Conditioning Protection Unit - ACPU 84 Road Speed

219 Collision Avoidance Radar - VORAD 85 Cruise Control Status - Cruise Status

231 Communications Unit-Cellular 86 Cruise Control Set Speed - CRUISE SET

232 seat belt unit 87 Cruise Control High-Set Limit Speed

234 Instrumentation Control Unit, Right #2 88 Cruise Control Low-Set Limit Speed - CRUISE LO SET

PARAMETER IDENTIFIERS (PID CODES)

51 Throttle Position 90 PTO Oil Temperature - PTO OIL TEMP

52 Engine Intercooler Temperature - TEMP 91 Percent Accelerator Pedal Position - ACCEL PDL

53 Transmission Synchronizer Clutch Value - SYNCRO

CLUTCH

54 Transmission Synchronizer Brake Value - SYNCRO

BRAKE

55 Shift Finger Positional Status - SHFT FNGR POS 94 Fuel Delivery Pressure - FUEL DLVR PRSS

56 Transmission Range Switch Status - RANGE SWITCH 95 Fuel Filter Differential Pressure - FUEL FILTER

57 Transmission Actuator Status #2 - ACTTRSTATUS#2 96 Fuel Level

58 Shift Finger Actuator Status - SHFT FNGR ACT 97 Water in Fuel Indicator

59 Shift Finger Gear Position - SHFT FNGR GEAR 98 Engine Oil Level

60 Shift Finger Rail Position - SHFT FNGR RAIL 99 Engine Oil Filter Differential Pressure - Oil Fltr Pres

61 Parking Brake Actuator Status 100 Engine Oil Pressure

62 Retarder Inhibit Status - RETARDRINHIBIT 101 Crankcase Pressure

63 Transmission Actuator Status #1 - ACT STATUS #1 102 Boost Pressure

64 Direction Switch Status 103 Turbo Speed

65 Service Brake Switch Status 104 Turbo Oil Pressure

66 Vehicle Enabling Component Status 105 Intake Manifold Temperature - Intake Air TEMP

67 Shift Request Switch Status 106 Air Inlet Pressure

68 Torque Limiting Factor 107 Air Filter Differential Pressure - Air Filter

69 Two-Speed Axle Switch Status 108 Barometric Pressure

70 Parking Brake Switch 109 Coolant Pressure

71 Idle Shutdown Timer Status - IDLESHUTDWNTMR 110 Engine Coolant Temperature

72 Blower Bypass Valve Position - BLOWRBYPASSPOS 111 Coolant Level

73 Auxiliary Water Pump Pressure - Aux PUMP Press 112 Coolant Filter Differential Pressure - CoolFltDiffPrs

89 Power Takeoff Status - PTO STATUS

POS%

92 Percent Engine Load - ENG LOAD%

93 Output Torque - OUTPUT TORQUE

2-32 Saf-T-Liner C2 02 Resources.fm 5/24/04

Saf-T-Liner C2

Page 25

Fault Codes (cont.)

PARAMETER IDENTIFIERS (PID CODES) (cont.)

113 Governor Droop 177 Transmission Oil Temperature - TRAN OIL TEMP

114 Net Battery Current - Battery AMPS 178 Front Axle Weight

115 Alternator Current - Alternator AMPS 179 Rear Axle Weight

116 Brake Application Pressure 180 Trailer Weight

117 Brake Primary Pressure - Primary Press 181 Cargo Weight

118 Brake Secondary Pressure - Sec. Press 182 Trip Fuel

119 Hydraulic Retarder Pressure - Retarder Press 183 Fuel Rate

120 Hydraulic Retarder Oil Temperature - Retdr Oil TEMP 184 Instantaneous Fuel Economy - Inst Fuel Icon

121 Engine Retarder Status - Retardr Status 185 Average Fuel Economy - AVG. Fuel Econ

122 Engine Retarder Percent -% Retarder 186 Power Takeoff Speed

123 Clutch Pressure 187 Power Takeoff Set Speed - PTO SET SPEED

124 Transmission Oil Level - Oil Level 188 Idle Engine Speed

125 Transmission Oil Level High/Low - Oil Level 189 Rated Engine Speed - Rated SPEED

126 Transmission Filter Differential Pressure -

FilterDifPress

127 Transmission Oil Pressure - Oil Pressure 191 Transmission Output Shaft Speed - TRAN OUT

154 Auxiliary Input and Output Status #2 232 DGPS Differential Correction - DGPS Correctn

155 Auxiliary Input and Output Status #1 233 Power Unit Number - POWER UNIT #

156 Injector Timing Rail Pressure 234 Software Identification

157 Injector Metering Rail Pressure 235 Total Idle Hours

158 Battery Potential (voltage)-Switched - Volts (BattSw) 236 Total Idle Fuel Used - Totl Idle Fuel

159 Gas Supply Pressure 237 Vehicle Identification Number

160 Main Shaft Speed 238 Velocity Vector

161 Input Shaft Speed 239 Vehicle Position

162 Transmission Range Selected 240 Change Reference Number

163 Transmission Range Attained 241 Tire Pressure

164 Injection Control Pressure 242 Tire Temperature

165 Compass Bearing - COMPASS Dir. 243 Component Identification

166 Rated Engine Power 244 Trip Distance

167 Alternator Potential (voltage) - Volts (Alt) 245 Total Vehicle Distance

168 Battery Potential (voltage) - Volts (Batt) 246 Total Vehicle Hours

169 Cargo Ambient Temperature - CARGO TEMP 247 Total Engine Hours

170 Cab Interior Temperature - CAB TEMP 248 Total PTO Hours

171 Ambient Air Temperature - Outside TEMP 249 Total Engine Revolutions

172 Air Inlet Temperature 250 Total Fuel Used

173 Exhaust Gas Temperature 251 Clock

174 Fuel Temperature - Fuel TEMP 252 Date

175 Engine Oil Temperature 253 Elapsed Time

176 Turbo Oil Temperature

190 Engine Speed

SPEED

02 Resources.fm 5/24/04 Saf-T-Liner C2 2 -33

Resources

Page 26

Fault Codes (cont.)

SUB-SYSTEM IDENTIFIERS (SID CODES)

MID 128 - Engine 49 Injector Cylinder #19

1 Injector Cylinder #1 50 Injector Cylinder #20

2 Injector Cylinder #2 51 Auxiliary Output Device Driver #3

3 Injector Cylinder #3 52 Auxiliary Output Device Driver #4

4 Injector Cylinder #4 53 Auxiliary Output Device Driver #5

5 Injector Cylinder #5 54 Auxiliary Output Device Driver #6

6 Injector Cylinder #6 55 Auxiliary Output Device Driver #7

7 Injector Cylinder #7 56 Auxiliary Output Device Driver #8

8 Injector Cylinder #8 57 Auxiliary PWM Driver #1

9 Injector Cylinder #9 58 Auxiliary PWM Driver #2

10 Injector Cylinder #10 59 Auxiliary PWM Driver #3

17 Fuel Shutoff Valve 60 Auxiliary PWM Driver #4

18 Fuel Control Valve 61 Variable Swirl System Valve

19 Throttle Bypass Valve 62 Prestroke Sensor

20 Timing Actuator 63 Prestroke Actuator

21 Engine Position Sensor 64 Engine Speed Sensor #2

22 Timing Sensor 65 Heated Oxygen Sensor

23 Rack Actuator 66 Ignition Control Mode Signal

24 Rack Position Sensor 67 Ignition Control Timing Signal

25 External Engine Protection Input 68 Secondary Turbo Inlet Pressure

26 Auxiliary Output Device Driver #1 69 ACOC (Aftercooler/Oil Cooler) Coolant F

27 Variable Geometry Turbocharger Actuator 1 70 Inlet Air Heater Driver #1

28 Variable Geometry Turbocharger Actuator 2 71 Inlet Air Heater Driver #2

29 External Fuel Command Input 72 Injector Cylinder #21

30 External Speed Command Input 73 Injector Cylinder #22

31 Tachometer Signal Output 74 Injector Cylinder #23

32 Wastegate Output Device Driver 75 Injector Cylinder #24

33 Fan Clutch Output Device Driver 76 Knock Sensor

34 Exhaust Back Pressure Sensor 77 Gas Metering Valve

35 Exhaust Back Pressure Regulator Solenoid 78 Fuel Supply Pump Actuator

36 Glow Plug Lamp

37 Electronic Drive Unit Power Relay 1 Wheel Sensor ABS Axle 1 Left

38 Glow Plug Relay 2 Wheel Sensor ABS Axle 1 Right

39 Engine Starter Motor Relay 3 Wheel Sensor ABS Axle 2 Left

40 Auxiliary Output Device Driver #2 4 Wheel Sensor ABS Axle 2 Right

41 ECM 8 Volts DC Supply 5 Wheel Sensor ABS Axle 3 Left

42 Injection Control Pressure Regulator 6 Wheel Sensor ABS Axle 3 Right

43 Autoshift High Gear Actuator 7 Pressure Mod. Valve ABS Axle 1 Left

44 Autoshift Low Gear Actuator 8 Pressure Mod. Valve ABS Axle 1 Right

45 Autoshift Neutral Gear Actuator 9 Pressure Mod. Valve ABS Axle 2 Left

46 Autoshift Common Low Side (Return) 10 Pressure Mod. Valve ABS Axle 2 Right

47 Injector Cylinder #17 11 Pressure Mod. Valve ABS Axle 3 Left

48 Injector Cylinder #18

MID 136 ABS -

2-34 Saf-T-Liner C2 02 Resources.fm 5/24/04

Saf-T-Liner C2

Page 27

Fault Codes (cont.)

MID 136 ABS - (cont.)

12 Pressure Mod. Valve ABS Axle 3 Right 230 Idle Validation Switch

13 Retarder Control Relay 231 SAE J1939 Datalink

14 Relay Diagonal 1 232 5-Volt DC Supply

MID 190 ACPU - 233 Controller #2

1 Refrigerant Charge 234 Parking Brake ON Actuator

2 Refrigerant Moisture Level 235 Parking Brake OFF Actuator

3 Non-Condensable Gas in Refrigerant 236 Power Connect Device

4 Refrigerant Flow Control Solenoid 237 Start Enable Device

5 Low Pressure Switch 238 Diagnostic Light-Red

6 Refrigerant Clutch Circuit 239 Diagnostic Light-Amber

7 Evaporator Thermostat Circuit 240 Program Memory

MID 219 VORAD - 242 Cruise Control RESUME Switch

1 Forward Antenna 243 Cruise Control SET Switch

2 Antenna Electronics 244 Cruise Control ENABLE Switch

3 Brake Input Monitor 245 Clutch Pedal Switch #1

4 Speaker Monitor 246 Brake Pedal Switch #1

5 Steering Sensor Monitor 247 Brake Pedal Switch #2

6 Speedometer Monitor 248 Proprietary Datalink

7 Right Turn Signal Monitor 249 SAE J1922 Datalink

8 Left Turn Signal Monitor 250 SAE J1708 (J1587) Datalink

9 Control Display Unit 251 Power Supply

10 Right Side Sensor 252 Calibration Module

11 Left Side Sensor 253 Calibration Memory

12 Rear Sensor 254 Controller #1

GENERIC SIDs - FAILURE MODE IDENTIFIERS (FMI CODES)

151 System Diagnostic Code #1 00 Above normal operating range (temperature, pressure,

etc.)

152 System Diagnostic Code #2 01 Below normal operating range (temperature, pressure,

etc.)

153 System Diagnostic Code #3 02 Erratic, intermittent, or incorrect data

154 System Diagnostic Code #4 03 Voltage above normal or shorted high

155 System Diagnostic Code #5 04 Voltage below normal or shorted low

219 Start Signal Indicator 05 Current below normal or open circuit

220 Electronic Tractor/Trailer Interface 06 Current above normal or circuit shorted to gnd.

(ISO 11992) 07 Device not responding

221 Internal Sensor Voltage Supply 08 Abnormal frequency

222 Protect Light 09 Abnormal update rate

223 Ambient Light Sensor 10 Abnormal rate of change

224 Audible Alarm 11 Not identifiable

225 Green Light 12 Bad intelligent device or component

226 Transmission Neutral Switch 13 Out of calibration

227 Auxiliary Analog Input #1 14 Special instructions

228 High Pressure Switch 15 Reserved

229 Kickdown Switch

02 Resources.fm 5/24/04 Saf-T-Liner C2 2 -35

Resources

Page 28

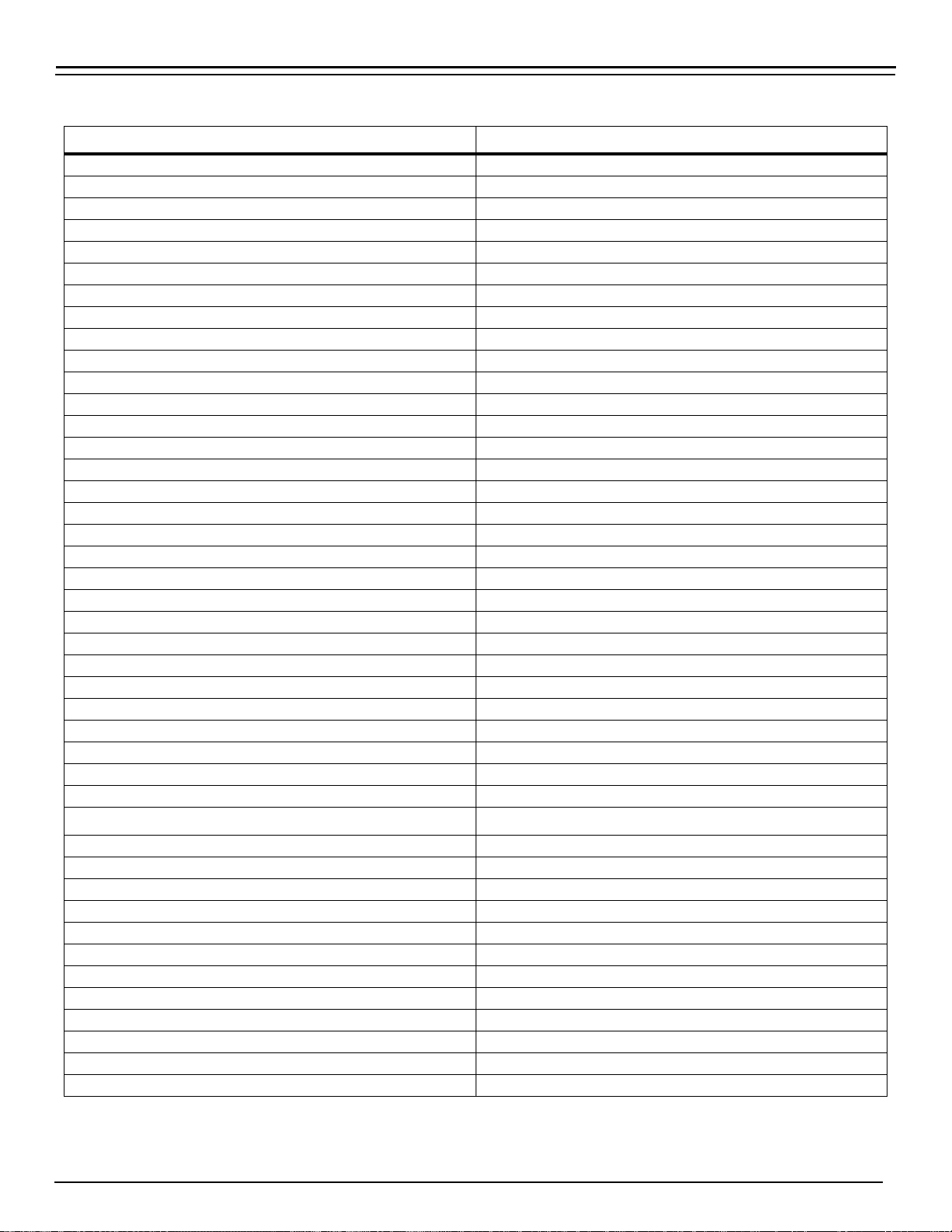

J1587 SIDs under BHM (MID 164)

SID Description Possible FMI

0 Backlighting Dimmer Switch Fault 7

1 Clutch Switch Fault 7

2 --- Reserved for Future --3 Headlight Switch Fault 7

4 ICU3-M2 High Beam Switch Fault 2

5 Ignition Switch Fault 7

6 Marker Interrupt Switch Fault 7

7 ICU3-M2 Wiper High / Low CAN Message Error 2

8 ICU3-M2 Wiper On / Off CAN Message Error 2

9 Wiper Park Input Fault 7

10 --- Reserved for Future --11 ICU3-M2 Left Turn Switch CAN Message Error 2

12 ICU3-M2 Right Turn Switch CAN Message Error 2

13 ICU3-M2 Washer Switch CAN Message Error 2

14 ICU3-M2 Wiper On / Off CAN Message Error 2

15 ICU3-M2 Wiper Low CAN Message Error 2

16 ICU3-M2 Wiper High CAN Message Error 2

17 Wheel Based Vehicle Speed CAN Message Error 2

18 Wake up Hardware Fault 7

19 Unknown Keep Awake Fault 7

20 Extra Smart Switch 7

21 Duplicate Smart Switch 7

22 Missing Smart Switch 7

23 Fifth Wheel Solenoid Unexpected Pressure Feedback 7

24 Fifth Wheel Solenoid No Pressure Feedback 7

25 End of Frame Air Unexpected Pressure Feedback 7

26 End of Frame Air No Pressure Feedback 7

27 Axle Lift Unexpected Pressure Feedback 7

28 Axle Lift No Pressure Feedback 7

2-36 Saf-T-Liner C2 02 Resources.fm 5/24/04

J1587 SIDs under BHM (MID 164) (cont.)

Page 29

SID Description Possible FMI

29 Suspension Dump Unexpected Pressure Feedback 7

30 Suspension Dump No Pressure Feedback 7

31 Suspension Proportioning Unexpected Pressure Feedback 7

32 Suspension Proportioning No Pressure Feedback 7

33 Cigar Lighter Output Fault 7

34 BHM / ICU3-M2 Ignition Mismatch 7

35 BHM / ICU3-M2 Hazard Switch Mismatch 2

36 BHM / ICU3-M2 Wiper Park Mismatch 2

37-49 --- Reserved for Future ---

50 BHM B1.A 3,4

51 BHM B1.F, B1.P, B2.K, B2.L, B6.A8 5,6

52 BHM B1.J 3,4

53 BHM B1.K, B5.C 5,6

54 BHM B1.L 5,6

55 BHM B1.N 3,4

56 BHM B1.R 5,6

57 BHM B2.M 5,6

58 BHM B3.D 3,4

59 BHM B3.E 3,4,5,6

60 BHM B3.F 5,6

61 BHM B3.G 5,6

62 BHM B3.H 5,6

63 BHM B4.B 5,6

64 BHM B4.E, B4.F 3,4,5,6

65 BHM B4.G 3,4

66 BHM B4.K 3,4

67 BHM B4.M, B5.E 3,4,5,6

68 BHM B5.A, B7.A12 5,6

69 BHM B6.A9, B6.A10 5,6

70 BHM B5.B 5,6

71 BHM B5.D 5,6

72 BHM B5.F 3,4,5,6

73 BHM B5.G 3,4,5,6

74 BHM B5.H, B7.A1 3,4,5,6

Saf-T-Liner C2

02 Resources.fm 5/24/04 Saf-T-Liner C2 2 -37

Loading...

Loading...