Page 1

AT-x210-24GT

1357

2468

9111315R

10 12 14 16R

17 19 21 23R

18 20 22 24R

AT-x210-24GT

Gigabit Ethernet Switch

15 16 23 24

L/A

2 4 6 8 10 12 14 16R 18 20 22 24R

MODE

L/A

MODE

CONSOLE

RS-232

FAULT

STANDBY

RESET

POWER

SELECT

1 3 5 7 9 11 13 15R 17 19 21 23R

15

16

23

24

SPEED

DUPLEX

MODE

MODE

SPEED / DUPLEX

L/A

LINK / ACT

L/A

LINK / ACT

SFP

CLASS 1

LASER PRODUCT

1357

2468

9111315R

10 12 14 16R

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

SELECT

SPEED

DUPLEX

2 4 6 8 10 12 14 16R

13579111315R

L/A

MODE

L/A

MODE

15

16

15 16

AT-x210-16GT

Gigabit Ethernet Switch

MODE

SPEED / DUPLEX

L/A

LINK / ACT

MODE

L/A

LINK / ACT

SFP

CLASS 1

LASER PRODUCT

1357

2468

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

MODE

SPEED

DUPLEX

SELECT

2468

1357

L/A

MODE

L/A

MODE

9

AT-x210-9GT

Gigabit Ethernet Switch

CLASS 1

LASER PRODUCT

MODE

SPEED / DUPLEX

L/A

LINK / ACT

L/A

LINK / ACT

SFP

AT-x210-16GT

AT-x210-9GT

Gigabit Ethernet Switches

Installation Guide

613-001769 Rev A

Page 2

Copyright © 2013 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis,

Inc.

Allied Telesis and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated. All other product names,

company names, logos or other designations mentioned herein are trademarks or registered trademarks of their respective

owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document

without prior written notice. The information provided herein is subject to change without notice. In no event shall Allied

Telesis, Inc. be liable for any incidental, special, indirect, or consequential damages whatsoever, including but not limited

to lost profits, arising out of or related to this manual or the information contained herein, even if Allied Telesis, Inc. has

been advised of, known, or should have known, the possibility of such damages.

Page 3

Electrical Safety and Emissions Standards

This product meets the following standards.

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses , and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

RFI Emissions EN 55022:2010

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN 62233:2008

EN 62311:2008

FCC Class A

FCC Part 15 (47 CFR 15)

ICES-003

VCCI-A

VCCI-B

2004/108/EC EMC Directive

Warning: In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Environmental 2011/65/EU RoHS Directive

Compliance

Electrical Safety C-TICK

CE

2006/95/EC Low Voltage Directive

EN 60950-1:2006+A11:2009+A1:2010+A12:2011

IEC 60950-1 (ed.2)

UL 60950 (

CULUS

)

Laser Safety EN 60825-1:2007

Immunity EN 55024:2010

i

Page 4

Translated Safety Statements

Important: The indicates that a translation of the safety statement is available in a PDF

document titled Translated Safety Statements posted on the Allied Telesis website at

www.alliedtelesis.com.

ii

Page 5

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Contents

Preface............................................................................................................................................................... 1

Symbol Conventions..................................... ... ... .... ... ... ... .... ... ... .................................................................. 2

Contacting Allied Telesis.............................................................................................................................. 3

Chapter 1: Overview

Features ............................................................................................................................................................. 6

Twisted Pair Ports ................................................................................................................................. 6

SFP Slots............................................................................................................................................... 6

LEDs...................................................................................................................................................... 7

Installation Options................................................................................................................................ 7

Power Conservation.............................................................................................................................. 7

MAC Address Table .............................................................................................................................. 7

Package Contents........................................................................................................................................ 8

Front and Back Panels................................................................................................................................. 9

Management Software............................................................................................................................... 11

Twisted Pair Ports...................................................................................................................................... 12

LEDs .......................................................................................................................................................... 13

POWER/FAULT/STANDBY LEDs....................................................................................................... 13

10Base-T/100Base-TX/1000 Base-T Link Activity LEDs..................................................................... 15

SFP LEDs............................................................................................................................................ 17

Power Supply............................................................................................................................................. 19

Chapter 2: Installation

Reviewing Safety Precautions.......................................................................................................................... 22

Selecting a Site for the Switch ................................................................................................................... 24

Cable Specifications................................................................................................................................... 25

Unpacking the Switch................................................................................................................................. 26

Installing the Switch on a Table or a Desktop............................................................................................ 27

Installing the Switch in an Equipment Rack............................................................................................... 28

Installing Optional SFP Transceivers......................................................................................................... 35

Cabling the Switch ..................................................................................................................................... 39

Powering On the Switch............................................................................................................................. 41

Monitoring the Initialization Processes....................................................................................................... 43

Chapter 3: Troubleshooting

Appendix A:

Physical Specifications..................................................................................................................................... 52

Dimensions.......................................................................................................................................... 52

Weight ................................................................................................................................................. 52

Environmental Specifications.............. .... ... ... ... ... .... ... ... .................................................... ... ...................... 52

Power Specifications.................................................................................................................................. 53

Electrical Safety and Electromagnetic Emissions Certifications ................................................................ 53

Connectors and Port Pinouts..................................................................................................................... 54

iii

Page 6

Contents

iv

Page 7

Figures

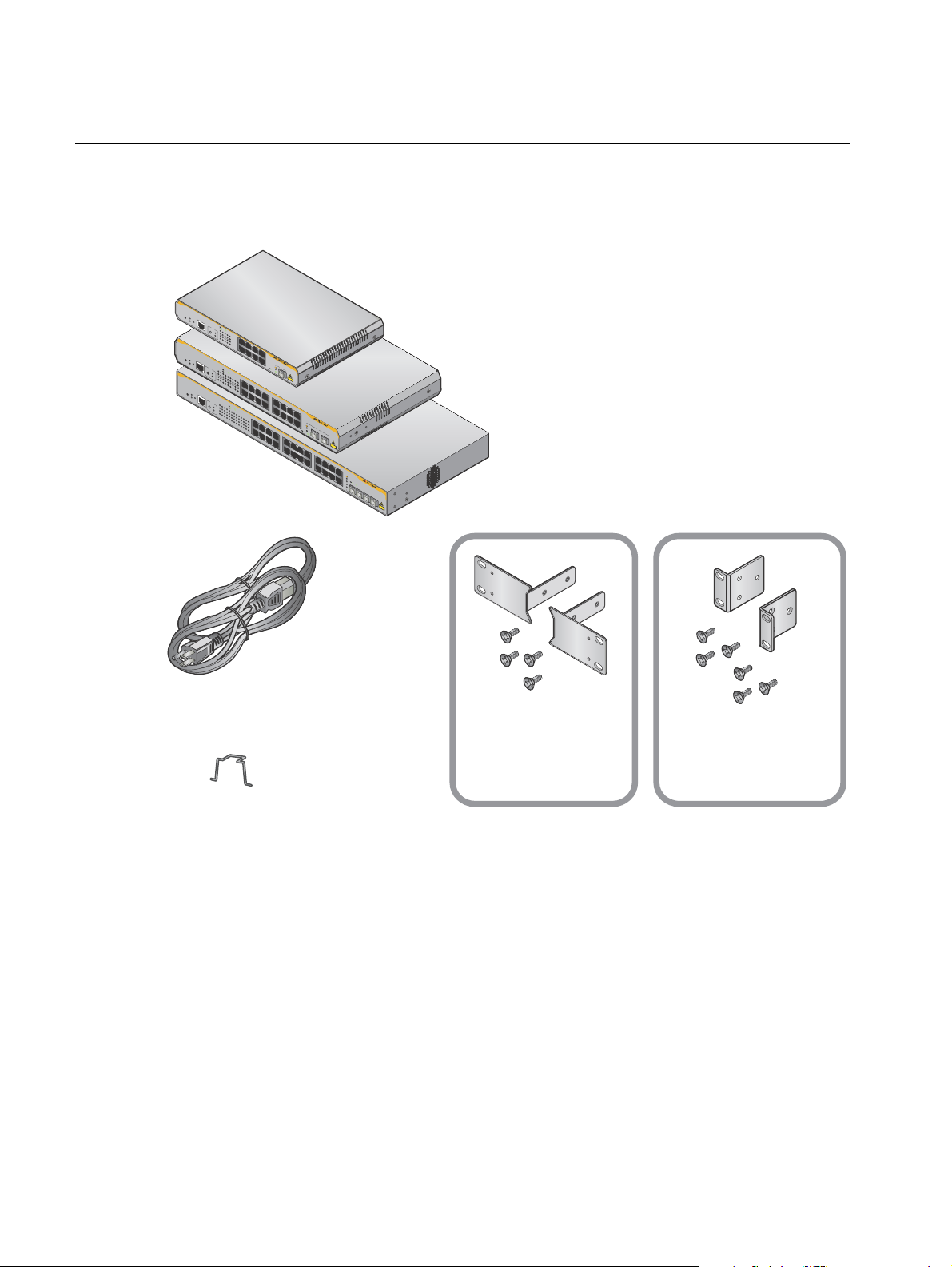

Figure 1: AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT packaging.............................................................................. 8

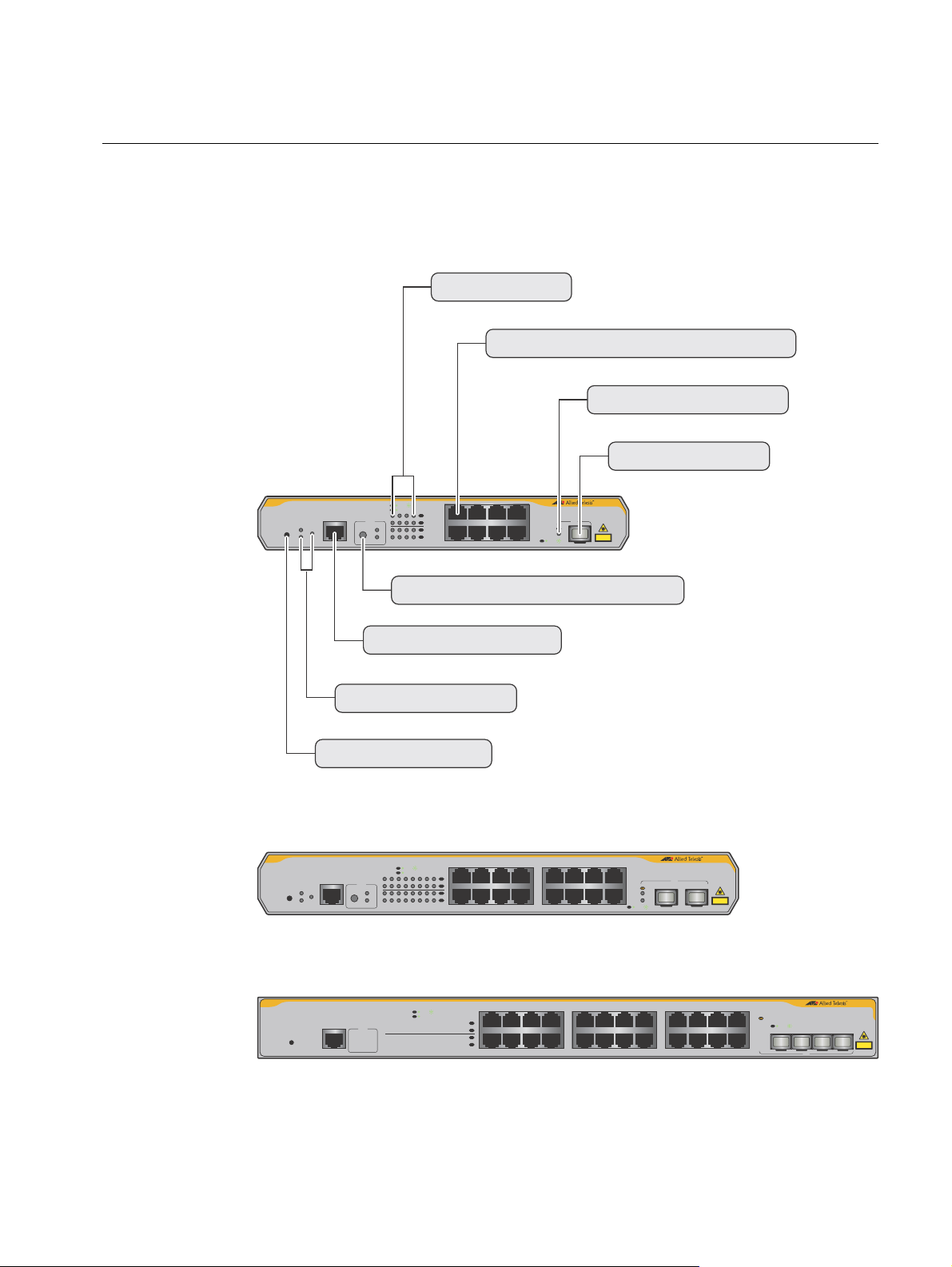

Figure 2: AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Front Panels.......................................................................... 9

Figure 3: MODE LED Toggle button.................................................................................................................................... 10

Figure 4: AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Back Panels........................................................................ 10

Figure 5: POWER LED on AT-x210-9GT............................................................................................................................ 13

Figure 6: FAULT LED on AT-x210-9GT.............................................................................................................................. 14

Figure 7: FAULT LED on AT-x210-16GT............................................................................................................................ 14

Figure 8: AT-x210-9GT Link/Activity and Speed LEDs........................................................................................................ 15

Figure 9: AT-x210-16GT Link/Activity/Speed LEDs............................................................................................................. 16

Figure 10: AT-x210-24GT Link/Activity/Speed Port LED..................................................................................................... 16

Figure 11: AT-x210-9GT SFP Speed and Link/Activity LEDs.............................................................................................. 17

Figure 12: AT-x210-16GT SFP Status LEDs....................................................................................................................... 18

Figure 13: AT-x210-24GT SFP Status LEDs....................................................................................................................... 18

Figure 14: Attaching the Rubber Feet ................................................................................................................................. 27

Figure 15: Turning the Switch Upside Down ....................................................................................................................... 28

Figure 16: Attaching brackets to an AT-x210-24GT............................................................................................................ 28

Figure 17: Mounting an AT-x210-24GT Switch in an Equipment Rack ............................................................................... 29

Figure 18: Attaching the brackets level with the front of an AT-x210-16GT............................. ... ........................................ 30

Figure 19: Close up showing a bracket positioned for an AT-x210-9GT............................................................................. 30

Figure 20: Mounting an AT-x210-16GT Switch in an Equipment Rack ............................................................................... 31

Figure 21: Fitting rack mount handles to the brackets for an AT-x210-9GT........................................................................ 32

Figure 22: Fitting brackets to the mounting for an AT-x210-9GT ........................................................................................ 32

Figure 23: Attaching cable tray brackets for an AT-x210-9GT ............................................................................................ 33

Figure 24: Mounting an AT-x210-9GT Switch in an Equipment Rack ................................................................................. 33

Figure 25: Mounting an AT-x210-9GT Switch in an Equipment Rack ................................................................................. 34

Figure 26: Securing cables to the cable tray for an AT-x210-9GT ...................................................................................... 34

Figure 27: Removing the Dust Plug from an SFP Slot .............................................................................

Figure 28: Inserting the SFP on an AT-x210-24GT............................................................................................................. 36

Figure 29: Inserting the SFP on an AT-x210-16GT............................................................................................................. 36

Figure 30: Positioning the SFP Handle in the Upright Position ........................................................................................... 37

Figure 31: Ejecting an SFP transceiver after lowering the SFP Handle to the Downwards Position................................... 37

Figure 32: Lifting the AC Power Cable Hook on an AT-x210-16GT Switch......................................................................... 41

Figure 33: Plugging in the AC Power Cord on an AT-x210-16GT Switch ............................................................ ............... 41

Figure 34: Switch Initialization Messages............................................................................................................................ 43

Figure 35: Switch Initialization Messages (Continued )........................................................................................................ 44

Figure 36: Switch Initialization Messages (Continued )........................................................................................................ 45

Figure 37: RJ-45 Connector and Port Pin Layout................................................................................................................ 54

........................... 35

v

Page 8

List of Figures

vi

Page 9

Tables

Table 1. AT-x210-9GT POWER LED Functional Descriptions ..........................................................................................13

Table 2. AT-x210-16GT and AT-x210-24GT FAULT LED Functional Descriptions ..........................................................14

Table 3. AT-x210-16GT and AT-x210-24GT STANDBY LED Functional Descriptions .....................................................14

Table 4. AT-x210-9GT LINK/ACT and SPEED/DUPLEX LED Descriptions .....................................................................15

Table 5. AT-x210-16GT and AT-x210-24GT LINK/ACT and SPEED/DUPLEX LED Descriptions ....................................17

Table 6. SFP Link/Activity LED Functional Descriptions ....................................................................................................18

Table 7. Twisted Pair Cabling and Distances .....................................................................................................................25

Table 8. Chassis Dimensions .............................................................................................................................................52

Table 9. Chassis Weight .....................................................................................................................................................52

Table 10. Environmental Specifications ..............................................................................................................................52

Table 11. Power Specifications ..........................................................................................................................................53

Table 12. Safety and Electromagnetic Emissions Certifications .........................................................................................53

Table 13. MDI Pin Signals (10Base-T or 100Base-TX) ......................................................................................................54

Table 14. MDI-X Pin Signals (10Base-T or 100Base-TX) ..................................................................................................54

Table 15. RJ-45 1000Base-T Connector Pinouts ...............................................................................................................55

vii

Page 10

List of Tables

viii

Page 11

Preface

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

This guide contains the installation instructions for the AT-x210-9GT, ATx210-16GT, and AT-x210-24GT Gigabit Ethernet Switches. This preface

contains the following sections:

“Symbol Conventions” on page 2

“Contacting Allied Telesis” on page 3

1

Page 12

Symbol Conventions

Note

Caution

Warning

Warning

This document uses the following conventions:

Notes provide additional information.

Cautions inform you that performing or omitting a specific action

may result in equipment damage or loss of data.

Warnings inform you that performing or omitting a specific action

may result in bodily injury.

Warnings inform you that an eye and skin hazard exists due to the

presence of a Class 1 laser device.

2

Page 13

Contacting Allied Telesis

If you need assistance with this product, you may contact Allied Telesis

technical support by going to the Support & Services section of the Allied

Telesis web site at www.alliedtelesis.com/support. You can find links for

the following services on this page:

24/7 Online Support - Enter our interactive support center to

search for answers to your questions in our knowledge database,

check support tickets, learn about RMAs, and contact Allied

Telesis technical experts.

USA and EMEA phone support - Select the phone number that

best fits your location and customer type.

Hardware warranty information - Learn about Allied Telesis

warranties and register your product online.

Replacement Services - Submit a Return Merchandise

Authorization (RMA) request via our interactive support center.

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Documentation - View the most recent installation guides, user

guides, software release notes, white papers and data sheets for

your product.

Software Updates - Download the latest software releases for your

product.

For sales or corporate contact information, go to

www.alliedtelesis.com/purchase and select your region.

3

Page 14

4

Page 15

Chapter 1

Overview

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

This chapter provides descriptions of the AT-x210-9GT, AT-x210-16GT,

and AT-x210-24GT Gigabit Ethernet Switches and contains the following

sections:

“Features” on page 6

“Package Contents” on page 8

“Front and Back Panels” on page 9

“Management Software” on page 11

“Twisted Pair Ports” on page 12

“LEDs” on page 13

“Power Supply” on page 19

5

Page 16

Chapter 1: Overview

Note

Note

Features

Here are the hardware features of the AT-x210-9GT, AT-x210-16GT and

AT-x210-24GT Gigabit Ethernet Switches.

Twisted Pair

Ports

Here are the basic features of the 10/100/1000 Mbps twisted-pair ports:

9, 16, or 24 ports per switch

10Base-T (IEEE 802.3i), 100Base-TX (IEEE 802.3u) and

1000Base-T (IEEE 802.3ab) compliant

IEEE 802.3u Auto-Negotiation compliant

Auto-MDI/MDIX

100 meters (328 feet) maximum operating distance

IEEE 802.3x Flow Control in 10Base-T/100Base-TX full-duplex

operation

IEEE 802.3x Back Pressure in 10Base-T/100Base-TX half-duplex

operation

IEEE803.3z 1000Base-T Flow Control

Support for Jumbo frames up to 10KB

RJ-45 connectors

SFP Slots All three switches support both 100Base-FX and 1000Base-SX/LX

transceivers. The switches support either two or four slots for SFPs:

One SFP slot on the AT-x210-9GT Switch

Two SFP slots on the AT-x210-16GT Switch

Four SFP slots on the AT-x210-24GT Switch

You must purchase SFP transceivers separately. For a list of

supported transceivers, contact your Allied Telesis distributor or

reseller.

See the product data sheets for the specific ATI SFP modules

supported by the AT-x210 series switches.

6

Page 17

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

LEDs Here is a brief description of the port LEDs:

Power LED/Fault/Standby LEDs; refer to “POWER/FAULT/

STANDBY LEDs” on page 13.

Speed and link/activity LEDs for the twisted pair ports; see

“10Base-T/100Base-TX/1000 Base-T Link Activity LEDs” on

page 15.

Link/activity LEDs for the SFP slots; see “SFP LEDs” on page 17.

Installation

Options

Power

Conservation

MAC Address

Table

The AT-x210-9GT switch can be installed in the following way:

Mounted on a Desk or tabletop

The AT-x210-16GT and AT-x210-24GT switches can be installed in the

following ways:

Rack mounted in a19-inch equipment rack

Mounted on a Desk or tabletop

Wall mounted

The AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT switches have the

following power conservation features:

High-efficiency power supply

Power scaling based on traffic loads on ports operating at 1000

Mbps (Port power scaling not available at 10 or 100 Mbps)

Power shutdown on unused ports

Here are the basic features of the MAC address table:

Storage capacity up to 8KB MAC address entries

Automatic learning and aging

7

Page 18

Chapter 1: Overview

1 Power Cable (1.8m)

AT-x210-16GT/AT-x210-24GT

1 x 19” rack mount kit

1 Power cable hook

AT-x210-16GT

2 Brackets

4 Bracket screws

(M3×6mm pan head screws)

AT-x210-24GT

2 Brackets

6 Bracket screws

(M4×6mm countesunk screws)

AT-x210-9GT

AT-x210-16GT

AT-x210-24GT

5

7

6

8

9

11

13

15R

10

12

14

16R

17

19

21 23R

18

20

22

24R

15

16

23

24

2

4

6

8

RS-232

F

AU

LT

STANDBY

SELECT

1

3

5

7

9

11

15R

17

15

16

23

24

SPEED

MODE

M

O

DE

L/

A

LI

NK

/

ACT

L/

A

LINK /

ACT

SFP

1

3

5

7

2

4

6

8

9

11

13

15R

10

12

14 16R

17

19

21

23R

18

20

22

24R

AT-x210-24GT

Gigabit Ether

net Sw

itc

h

15

16 23

24

L

/A

2

4

6

8

10

12

14

16R

18

20

22

24

R

MODE

L/A

M

O

DE

CON

S

O

L

E

RS-23

2

FAUL

T

STANDBY

RESET

POWE

R

SELECT

1

3

5

7

9

11

13 15R

17

19

21

23R

15

16

23

24

SPEED

DUP

L

EX

M

O

DE

M

ODE

SPEED / DU

P

L

E

X

L

/A

L

IN

K

/

AC

T

L/

A

LINK

/

ACT

SFP

C

L

ASS

1

L

A

S

E

R

PROD

U

C

T

13

57

246

8

9

11 13

15R

10 12

14

16R

FAULT

STANDBY

R

E

SET

P

OWE

R

CONS

OLE

R

S-23

2

SELEC

T

SPEED

DUPLE

X

2

4

6

8

10

12

14

16R

1

3

5

7

9

11

13

1

5

R

L/

A

MOD

E

L

/A

MODE

1

5

16

1

5

16

AT-x210-16GT

Giga

bit Ethe

r

net Sw

itch

M

OD

E

SPEED /

D

UPLEX

L/

A

LIN

K

/

ACT

MODE

L/A

LIN

K

/

AC

T

SFP

C

LAS

S

1

LA

S

E

R

P

R

O

D

U

C

T

1

3

5

7

2

4

6

8

FAU

LT

STAN

D

BY

R

ESE

T

POW

E

R

CONSOLE

RS-

2

32

M

ODE

SP

E

E

D

D

UP

L

EX

SELEC

T

2

4

6

8

1

3

5

7

L

/A

M

O

D

E

L/A

MOD

E

9

AT-x210-9GT

Giga

b

i

t

Et

h

e

r

ne

t

Switch

C

LA

S

S

1

L

A

S

E

R

P

RO

D

U

CT

M

O

D

E

S

P

EED

/

DU

PL

E

X

L

/

A

LINK

/

A

C

T

L/A

L

I

N

K

/

A

C

T

S

FP

1 Console Cable (2m)

Package Contents

Figure 1 illustrates the package contents for the AT-x210-9GT,

AT-x210-16GT, and AT-x210-24GT Gigabit Ethernet Switches.

8

Figure 1. AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT packaging

Page 19

Front and Back Panels

1357

2468

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

MODE

SPEED

DUPLEX

SELECT

2468

1357

L/A

MODE

L/A

MODE

9

AT-x210-9GT

Gigabit Ethernet Switch

CLASS 1

LASER PRODUCT

MODE

SPEED / DUPLEX

L/A

LINK / ACT

L/A

LINK / ACT

SFP

1357

2468

9111315R

10 12 14 16R

17 19 21 23R

18 20 22 24R

AT-x210-24GT

Gigabit Ethernet Switch

15 16 23 24

L/A

2 4 6 8 10 12 14 16R 18 20 22 24R

MODE

L/A

MODE

CONSOLE

RS-232

FAULT

STANDBY

RESET

POWER

SELECT

1 3 5 7 9 11 13 15R 17 19 21 23R

15

16

23

24

SPEED

DUPLEX

MODE

MODE

SPEED / DUPLEX

L/A

LINK / ACT

L/A

LINK / ACT

SFP

CLASS 1

LASER PRODUCT

1357

2468

9 11 13 15R

10 12 14 16R

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

SELECT

SPEED

DUPLEX

246810121416R

13579111315R

L/A

MODE

L/A

MODE

15

16

15 16

AT-x210-16GT

Gigabit Ethernet Switch

MODE

SPEED / DUPLEX

L/A

LINK / ACT

MODE

L/A

LINK / ACT

SFP

CLASS 1

LASER PRODUCT

AT-x210-24GT

AT-x210-16GT

⑦ Status LED

⑥ Console port

⑤ MODE LED Toggle button

④ SFP Slot

②

10/100/1000BASE-T

Ports

③ SFP Slot LED

① Port LED

AT-x210-9GT

⑧ Reset button

Figure 2 illustrates the front panels of the AT-x210-9GT, AT-x210-16GT,

and AT-x210-24GT Gigabit Ethernet Switches.

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Figure 2. AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Front Panels

9

Page 20

Chapter 1: Overview

135

246

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

SELECT

SPEED

DUPLEX

246810121416R

13579111315R

L/A

MODE

L/A

MODE

MODE

SPEED / DUPLEX

L/A

LINK / ACT

MODE

15

16

15

AT-x21

Gigabit Ethern

L/A

LINK / ACT

SFP

MODE LED Toggle button

AT-x210-16GT

AT-x210-24GT

AT-x210-9GT

⑨ Power connector

⑩ Power cable hook

⑪ Power cable hook mount

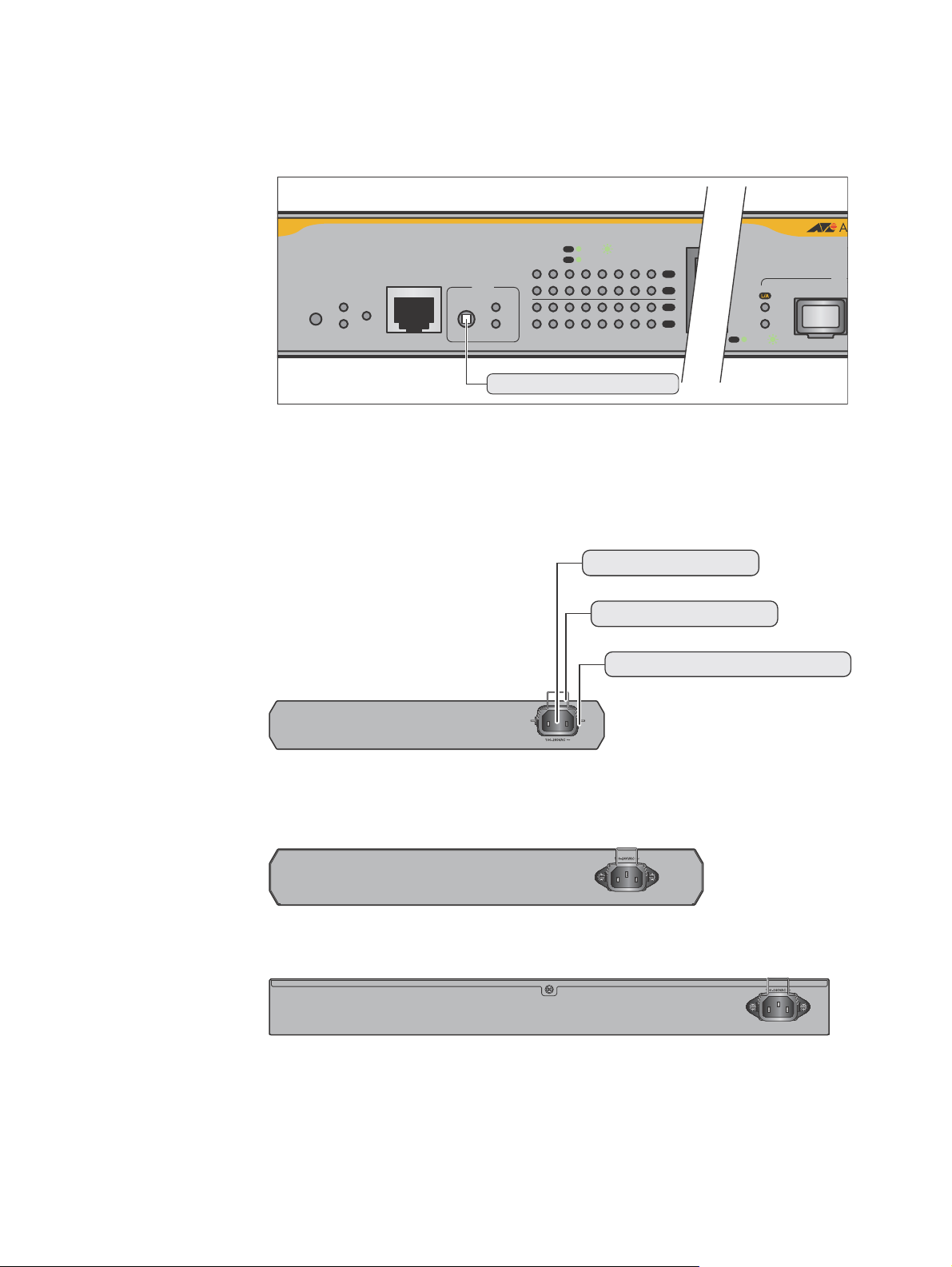

Figure 3 illustrates the MODE LED toggle button on the front panel of the

of the AT-x210-9GT and AT-x210-16GT Gigabit Ethernet Switches. This

button changes front panel LEDs for SPEED, DUPLEX, or turns off LEDs.

Figure 3. MODE LED Toggle button

Figure 4 illustrates the front panels of the AT-x210-9GT, AT-x210-16GT,

and AT-x210-24GT Gigabit Ethernet Switches.

10

Figure 4. AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Back Panels

Page 21

Management Software

The switches are shipped with the management software pre-installed.

The software provides a command line interface and a GUI (Graphical

User Interface) for in-band, over-the-network management. Refer to the:

AlliedWare Plus Software Reference for x210 Series Switches

In the unlikely event that the management software becomes corrupted or

damaged on the switch, you can download the software from the Allied

Telesis corporate web site and reinstall it on the switch. For instructions on

how to install new management software, see the product documentation.

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

11

Page 22

Chapter 1: Overview

Note

Twisted Pair Ports

The AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Layer 2 Gigabit

Ethernet Switches feature 9, 16, and 24 twisted pair ports, respectively. All

ports are 10Base-T, 100Base-TX, and 1000Base-T compliant. You can

set the port speeds and duplex modes either automatically with IEEE

802.3u Auto-Negotiation or manually with the management software.

The twisted pair ports feature 8-pin RJ-45 connectors. For the port

pinouts, see “Connectors and Port Pinouts” on page 54.

The ports have a maximum operating distance of 100 m (328 feet). For 10

Mbps operation, the ports require Category 3 or better 100 ohm shielded

or unshielded twisted pair cabling. For 100 or 1000 Mbps operation, the

ports require Category 5 or Enhanced Category 5 (5E) 100 ohm shielded

or unshielded twisted pair cabling.

The ports feature auto-MDI, which automatically configures the ports as

MDI or MDI-X. This feature allows you to use straight-through twisted pair

cables regardless of the wiring configurations of the ports on the end

nodes.

A switch port connected to an end node that is not using AutoNegotiation should not use Auto-Negotiation to set the speed and

duplex mode, because a duplex mode mismatch may occur. In this

case, disable Auto-Negotiation and set the port’s speed and duplex

mode manually.

12

Page 23

LEDs

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

MODE

SP

DU

SELECT

POWER LED

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

MODE

SPEED

DUPLEX

SELECT

2468

1357

L/A

MODE

L/A

MODE

MODE

SPEED / DUPLEX

L/A

LINK / ACT

FAULT LED

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

There are four types of LEDs on the AT-x210 switches:

“POWER/FAULT/STANDBY LEDs” on page 13

“10Base-T/100Base-TX/1000 Base-T Link Activity LEDs” on page 15

“SFP LEDs” on page 17

POWER/

FAULT/

STANDBY LEDs

The POWER LED reports the status of AC power and is located on the left

side of the front panel of the AT-x210-9GT switch. See Figure 5.

Figure 5. POWER LED on AT-x210-9GT

Table 1 describes the POWER LED for the AT-x210-9GT switch.

Table 1. AT-x210-9GT POWER LED Functional Descriptions

LED State Description

POWER Off Indicates either the switch is not receiving

AC power or the AC input power is operating

outside the normal range.

Steady

Green

The switch is receiving AC input power and is

operating normally.

13

Page 24

Chapter 1: Overview

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

SELECT

SPEED

DUPLEX

2 4 6 8 10 12 14 16R

13579111315R

L/A

MODE

L/A

MODE

MODE

SPEED / DUPLEX

L/A

LINK / ACT

MODE

FAULT LED

Figure 6. FAULT LED on AT-x210-9GT

Table 2 describes the functions for the FAULT LED for the AT-x210-9GT

and AT-x210-16GT switches.

Table 2. AT-x210-16GT and AT-x210-24GT FAULT LED Functional

Descriptions

LED State Description

FAULT Off The switch is receiving AC input power and is

operating normally

6 flashes in

2 seconds

Steady

Flashing indicates the switch is overheating.

Contact Allied Telesis for support and advice.

Indicates the system is experiencing failure.

Green

Figure 7. FAULT LED on AT-x210-16GT

Table 3 describes the functions for the STANDBY LED for the AT-x2109GT and AT-x210-16GT switches.

Table 3. AT-x210-16GT and AT-x210-24GT STANDBY LED Functional

Descriptions

LED State Description

STANDBY Off STANDBY is not supported. The LED is not lit.

14

Page 25

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Speed

Link/Activity

2468

1357

L/A

MODE

L/A

MODE

MODE

SPEED / DUPLEX

L/A

LINK / ACT

(LINK/ACT)

(SPEEDDUPLEX)

10Base-T/

100Base-TX/1000

Base-T Link

Activity LEDs

The Link Activity (L/A) LEDs provide information about the 10Base-T/

100Base-TX/1000Base-T ports.

AT-x210-9GT Link/Activity and Speed LEDs

The AT-x210-9GT switch indicates LINK/ACT (link/activity) and SPEED/

DUPLEX (speed/duplex) with two LEDs for each port. See Figure 8.

Figure 8. AT-x210-9GT Link/Activity and Speed LEDs

See Table 4 for a description for the AT-x210-9GT Link/Activity and Speed

LEDs.

Table 4. AT-x210-9GT LINK/ACT and SPEED/DUPLEX LED Descriptions

LED State Description

Link/Activity

(LINK/ACT)

Off The port has not established a link with a

network device, or the ecofriendly

feature is enabled with the MODE LED

button to turn off the front panel LEDs.

Use the MODE LED button to turn off the

front panel LEDs and conserve electricity

when you are not monitoring the switch.

Speed/Duplex

(SPEED/

DUPLEX)

Blinking

Green

Steady

Green

Off The maximum operating speed of the

The port is transmitting or receiving

network packets.

The port has established a link with a

network device and is active.

port is 10 or 100 Mbp, or the ecofriendly

feature is enabled with the MODE LED

button to turn off the front panel LEDs.

Steady

Green

The maximum operating speed of the

port is 1000 Mbps.

.

15

Page 26

Chapter 1: Overview

246810121416R

1 3 5 7 9 11 13 15R

L/A

MODE

L/A

MODE

MODE

SPEED / DUPLEX

L/A

LINK / ACT

Speed and

Link/Activity

(LINK/ACT)

Speed and

Link/Activity

LINK/ACT)

AT-x210-16GT Link/Activity LEDs

The AT-x210-16GT switch has two LEDs per port on the front panel to

indicate link, activity, duplex, and speed status. See Figure 9.

Figure 9. AT-x210-16GT Link/Activity/Speed LEDs

AT-x210-24GT Link/Activity LEDs

The AT-x210-24GT switch has two LEDs per port to indicate port’s link,

activity, duplex, and speed status. See Figure 10.

L/A

LINK / ACT

MODE

SPEED / DUPLEX

1 3 5 7 9 11 13 15R 17 19 21 23R

2 4 6 8 10 12 14 16R 18 20 22 24R

L/A

MODE

L/A

MODE

Figure 10. AT-x210-24GT Link/Activity/Speed Port LED

16

Page 27

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

9

AT-x210-9GT

Gigabit Ethernet Switch

CLASS 1

LASER PRODUCT

L/A

LINK / ACT

SFP

Speed and

Link/Activity

SFP LEDs

See Table 5 for a description for the AT-x210-16GT and AT-x210-24GT

Link/Activity and Speed LEDs.

Table 5. AT-x210-16GT and AT-x210-24GT LINK/ACT and SPEED/

DUPLEX LED Descriptions

LED State Description

Link/Activity

(LINK/ACT)

Speed/Duplex

(SPEED/

DUPLEX)

Off The port has not established a link with a

network device, or the ecofriendly

feature is enabled with the MODE LED

button to turn off the front panel LEDs.

Use the MODE LED button to turn off the

front panel LEDs and conserve electricity

when you are not monitoring the switch.

Blinking

Green

Steady

Green

The port is transmitting or receiving

network packets.

The port has established a link with a

network device and is active.

Off The maximum operating speed of the

port is 10 or 100 Mbp, or the ecofriendly

feature is enabled with the MODE LED

button to turn off the front panel LEDs.

Use the MODE LED button to turn off the

front panel LEDs and conserve electricity

when you are not monitoring the switch.

Steady

Green

The maximum operating speed of the

port is 1000 Mbps.

.

SFP LEDs The SFP LEDs indicate the Link/Activity and Speed status of each SFP

slot.

The AT-x210-9GT and AT-x210-16GT switches have the SFP LEDs on

the front panel. See Figure 11 and Figure 12.

Figure 11. AT-x210-9GT SFP Speed and Link/Activity LEDs

17

Page 28

Chapter 1: Overview

15

16

15 16

AT-x210-16GT

Gigabit Ethernet Switch

L/A

LINK / ACT

SFP

CLASS 1

LASER PRODUCT

Speed and

Link/Activity

SFP LEDs

Speed and

Link/Activity

SFP LEDs

Figure 12. AT-x210-16GT SFP Status LEDs

The AT-x210-24GT SFP LEDs can be found on between the upper and

lower SFP slots. See Figure 13.

AT-x210-24GT

15

L/A

LINK / ACT

16

15 16 23 24

23

24

Gigabit Ethernet Switch

SFP

CLASS 1

LASER PRODUCT

Figure 13. AT-x210-24GT SFP Status LEDs

Table 6 describes the Link/Activity LEDs for the SFP slots.

Table 6. SFP Link/Activity LED Functional Descriptions

LED State Description

SFP Off The port on the SFP transceiver has not

established a link with an end node or the

transceiver slot is empty, or the ecofriendly

feature is enabled with the MODE LED

button to turn off the front panel LEDs.

Use the MODE LED button to turn off the

front panel LEDs and conserve electricity

when you are not monitoring the switch.

Blinking

Green

Steady

Green

The SFP transceiver is transmitting or

receiving network packets (Activity).

The SFP transceiver has established a link

with a network device, but is not transmitting

or receiving network packets (Link).

18

Page 29

Power Supply

Note

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Each switch has an internal power supply with a single AC power supply

socket on the back panel. To power the switch on or off, connect or

disconnect the power cord provided with the switch. A power cord is

supplied with the switch.

For the power requirements, see the “Power Specifications” on

page 53.

19

Page 30

Chapter 1: Overview

20

Page 31

Chapter 2

Installation

This chapter contains the following sections:

“Reviewing Safety Precautions” on page 22

“Selecting a Site for the Switch” on page 24

“Cable Specifications” on page 25

“Unpacking the Switch” on page 26

“Installing the Switch on a Table or a Desktop” on page 27

“Installing the Switch in an Equipment Rack” on page 28

“Installing Optional SFP Transceivers” on page 35

“Cabling the Switch” on page 39

“Powering On the Switch” on page 41

“Monitoring the Initialization Processes” on page 43

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

21

Page 32

Chapter 2: Installation

Note

Warning

Warning

Warning

Warning

Caution

Reviewing Safety Precautions

Please review the following safety precautions before you begin to install

the chassis or any of its components.

The indicates that a translation of the safety statement is

available in a PDF document titled Translated Safety Statements.

To prevent electric shock, do not remove the cover. No userserviceable parts inside. This unit contains hazardous voltages and

should only be opened by a trained and qualified technician. To

avoid the possibility of electric shock, disconnect electric power to

the product before connecting or disconnecting the cables. E1

Do not work on equipment or cables during periods of lightning

activity. E2

Power cord is used as a disconnection device. To de-energize

equipment, disconnect the power cord. E3

Class I Equipment. This equipment must be earthed. The power

plug must be connected to a properly wired earth ground socket

outlet. An improperly wired socket outlet could place hazardous

voltages on accessible metal parts. E4

Pluggable Equipment. The socket outlet shall be installed near the

equipment and shall be easily accessible. E5

Air vents must not be blocked and must have free access to the

room ambient air for cooling. E6

22

Operating Temperature. This product is designed for a maximum

ambient temperature of 40° degrees C. E7

Page 33

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Warning

Caution

Warning

All Countries: Install product in accordance with local and National

Electrical Codes. E8

Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect that

overloading of circuits might have on overcurrent protection and

supply wiring. Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern. E21

Mounting of the equipment in the rack should be such that a

hazardous condition is not created due to uneven mechanical

loading. E25

If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater than

the room ambient temperature. Therefore, consideration should be

given to installing the equipment in an environment compatible with

the manufacturer’s maximum rated ambient temperature (Tmra).

E35

Installation of the equipment in a rack should be such that the

amount of air flow required for safe operation of the equipment is not

compromised. E36

Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than

direct connections to the branch circuits (e.g., use of power strips).

E37

23

Page 34

Chapter 2: Installation

Selecting a Site for the Switch

Observe the following requirements when choosing a site for your switch:

If you plan to install the switch in an equipment rack, verify that the

rack is safely secured and will not tip over. Devices in a rack

should be installed starting at the bottom, with the heavier devices

near the bottom of the rack.

If you are installing the switch on a table, verify that the table is

level and secure.

The power outlet for the switch should be located near the unit and

should be easily accessible.

The site should provide for easy access to the ports on the front of

the switch. This will make it easier for you to connect and

disconnect cables, as well as view the switch’s LEDs.

Air flow around the unit and through its vents on the side and rear

should not be restricted so that the switch can maintain adequate

cooling.

Do not place objects on top of the switch.

Do not expose the switch to moisture or water.

Ensure that the site is a dust-free environment.

You should use dedicated power circuits or power conditioners to

supply reliable electrical power to the network devices.

24

Page 35

Cable Specifications

Note

Table 7 contains the cable specifications for the twisted pair ports.

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Table 7. Twisted Pair Cabling and Distances

Speed Type of Cable

Maximum

Operating

Distance

10 Mbps Standard TIA/EIA 568-B-compliant

Category 3 or better shielded or

unshielded cabling with 100 ohm

impedance and a frequency of 16

MHz.

100 Mbps Standard TIA/EIA 568-A-compliant

Category 5 or TIA/EIA 568-Bcompliant Enhanced Category 5

(Cat 5e) shielded or unshielded

cabling with 100 ohm impedance

and a frequency of 100 MHz.

1000 Mbps Standard TIA/EIA 568-A-compliant

Category 5 or TIA/EIA 568-Bcompliant Enhanced Category 5

(Cat 5e) shielded or unshielded

cabling with 100 ohm impedance

and a frequency of 100 MHz.

The twisted pair ports on the switch feature auto-MDI when

operating at 10, 100, or 1000 Mbps. A port is configured as MDI or

MDI-X when it is connected to an end node. Consequently, you can

use a straight-through twisted pair cable when connecting any type

of network device to a port on the switch.

100 m (328 ft)

100 m (328 ft)

100 m (328 ft)

25

Page 36

Chapter 2: Installation

Note

1 Power Cable (1.8m)

AT-x210-16GT/AT-x210-24GT

1 x 19” rack mount kit

1 Power cable hook

AT-x210-16GT

2 Brackets

4 Bracket screws

(M3×6mm pan head screws)

AT-x210-24GT

2 Brackets

6 Bracket screws

(M4×6mm countesunk screws)

AT-x210-9GT

AT-x210-16GT

AT-x210-24GT

5

7

6

8

9

11

13

15R

10

12

14

16R

17

19

21

23R

18

20

22

24R

15

16

23 24

2

4

6

8

RS-232

FAULT

STANDBY

SELECT

1

3

5

7

9

11

15R

17

15

16

23

24

SPEED

MODE

MO

D

E

L/

A

LINK /

ACT

L

/

A

LINK /

A

CT

SFP

1

3

5

7

2

4

6

8

9

11

13

15R

10

12

14

16R

17

19

21

23R

18

20

22

24R

AT-x210-24GT

Gigabit Ether

net Switch

15

16 23

24

L

/A

2

4

6

8

10

12

14

16R

18

20

22

24R

MO

D

E

L/A

MODE

C

ONS

OLE

RS-232

FAULT

STANDBY

RESET

POWER

SELECT

1

3

5

7

9

11

13 15R

17

19

21

23R

15

16

23

24

SPEED

DUPLEX

MODE

M

O

DE

SPEED / D

UPLEX

L/

A

LINK /

A

CT

L/

A

LINK /

ACT

SFP

C

L

A

SS

1

L

A

SE

R

PR

O

D

U

C

T

1357

24

6

8

9

11 13

15R

10 12

14

16R

FAULT

STANDBY

RESET

POWE

R

CONS

OLE

RS-232

S

E

LEC

T

SPEED

DUPLE

X

2

4

6

8

10

12

14

16R

1

3

5

7

9

11

13

15R

L/A

MODE

L/A

MODE

15

16

15

16

AT-x210-16GT

Giga

bit Ethe

r

net Sw

itch

M

OD

E

SPEED / DUPLEX

L/A

L

IN

K /

ACT

MODE

L

/A

LINK /

ACT

SFP

C

L

AS

S

1

LAS

E

R

P

R

OD

U

CT

1

3

5

7

2

4

6

8

FAULT

STAND

BY

RESET

POWER

CONSOLE

RS-232

MODE

SPEED

DUPLEX

SE

LECT

2

4

6

8

1

3

5

7

L/A

MOD

E

L

/A

M

OD

E

9

AT-x210-9GT

Gigab

it Ether

net

Switch

C

L

AS

S

1

LA

S

E

R

P

RO

D

U

C

T

MO

D

E

SPE

E

D

/ DU

PLE

X

L

/

A

LINK

/

ACT

L/A

LINK

/

ACT

SFP

1 Console Cable (2m)

Unpacking the Switch

To unpack the switch, perform the following procedure:

1. Remove all of the components from the shipping package.

2. Place the switch on a level, secure surface.

3. In addition to an AT-x210-9GT, AT-x210-16GT, or AT-x210-24GT

Store the packaging material in a safe location. You must use the

original shipping material if you need to return the unit to Allied

Telesis.

switch, verify that the shipping container includes the following items:

26

Page 37

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Installing the Switch on a Table or a Desktop

You can install AT-x210-16GT and AT-x210-24GT switches on a desktop,

or in a standard 19-inch equipment rack. To install AT-x210-16GT and ATx210-24GT switches in a rack, see “Installing the Switch in an Equipment

Rack” on page 28. The AT-x210-9GT is rack mountable using an optional

AT-x210-9GT rack mount kit (Part Number: 990-003904-00).Separate

installation instructions are included with the AT-x210-9GT rack mount kit.

Here are the guidelines to selecting a suitable site for desktop or table use:

The table should be level and stable and the power outlets should

be located near the switches and be easily accessible.

The site should allow for easy access to the ports on the front of

the switches, so that you can easily connect and disconnect

cables, and view the port LEDs.

The site should not expose the switches to moisture or water and

the site should be a dust-free environment.

The site should include dedicated power circuits or power

conditioners to supply reliable electrical power to the network

devices.

The rubber feet on the bottom of the switches should be left on for

table or desktop installation.

If you switch does not already have rubber feet fitted, fit these as follows:

1. Remove all equipment from the package and store the packaging

material in a safe place.

2. Turn the switch over and place it on a table.

3. Screw the four rubber feet to the bottom of the switch as shown below:

1971

Figure 14. Attaching the Rubber Feet

4. Turn the switch over again and place it on a flat, secure surface (such

as a desk or table) leaving ample space around the unit for ventilation.

5. Go to “Installing Optional SFP Transceivers” on page 35 or “Cabling

the Switch” on page 39.

27

Page 38

Chapter 2: Installation

5

7

6

8

91113

15R

10

12

14

16R

17

19 21

23R

18

20 22

24R

15 16

23

24

24

6

8

RS-232

FAULT

STANDBY

SELECT

13

57

9

11 15R

17

15

16

23

24

SPEED

MODE

MODE

L/A

LINK /

ACT

L/A

LINK /

ACT

SFP

1

3

5

7

2

46

8

9

11

13

15R

10

12 14

16R

17

19

21

23R

18

20

22

24R

AT-x210-24GT

Gigabit Ether

net Switch

15

16

23

24

L/A

24

6

8

10

12 14

16R

18

20

22

24R

MODE

L/A

MODE

CONSOLE

RS-232

FAULT

STANDBY

RESET

POWER

SELECT

1

3

57

911

13

15R

17

19

21 23R

15

16

23

24

SPEED

DUPLEX

MODE

MODE

SPEED / DUPLEX

L/A

LINK /

ACT

L/A

LINK /

ACT

SFP

CLASS 1

LASER PRODUCT

Installing the Switch in an Equipment Rack

Note: These instructions show you how to install an AT-x210-9GT,

AT-x210-16GT or AT-x210-24GT switch in an equipment rack. Rack

mount kit brackets are included with AT-x210-16GT and AT-x210-24GT

switches. The AT-x210-9GT switch is installed in a rack with the optional

AT-x210-9GT rack mount kit (Part Number 990-003904-00).

To install AT-x210-9GT, AT-x210-16GT or AT-x210-24GT switches in a

19-inch equipment rack, follow these steps:

1. Place the unit upside down on a level, secure surface.

Figure 15. Turning the Switch Upside Down

2. Unscrew the rubber feet from the bottom and turn the switch over.

3. For AT-x210-24GT Switches, attach two rack mount brackets to the

sides of the switch using the bracket screws that come with the unit.

28

Figure 16. Attaching brackets to an AT-x210-24GT

Page 39

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

5

7

6

8

9

11

13

15R

10

12 14

16R

17

19 21

23R

18

20

22

24R

15

16

23

24

24

6

8

RS-232

FAULT

STANDBY

SELECT

1

3

5

7

9

11

15R

17

15

16

23

24

SPEED

MODE

MO

DE

L/A

LINK /

ACT

L/A

LINK /

ACT

SFP

13

5

7

2

4

6

8

91113

15R

10

12

14

16R

17 19 21

23R

18

20 22

24R

AT-x210-24GT

Gigabit Ether

net Switch

15 16

23

24

L/A

2

4

68

10

12

14

16R

18 20

22

24R

MODE

L/A

MODE

CONSOLE

RS-232

FAULT

STANDBY

RESET

POWER

SELECT

1

3

57

9

11 13

15R

17

19

21

23R

15

16

23

24

SPEED

DUPLEX

MODE

M

O

D

E

SPEED / DUPLEX

L/A

LINK /

ACT

L/A

LINK /

ACT

SFP

CLASS 1

LASER

P

R

O

DU

C

T

4. Mount an AT-x210-24GT switch in a 19-inch equipment rack using four

equipment rack screws (not provided with the switch).

Figure 17. Mounting an AT-x210-24GT Switch in an Equipment Rack

29

Page 40

Chapter 2: Installation

1

3

5

7

2

4

6

8

911

13

15R

10

12 14 16R

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

SELECT

SPEED

DUPLEX

2

4

6

8

10

12

14

16R

1

3

5

7

9

11

13

15R

L/A

MODE

L/A

MODE

15

16

15

16

AT-x210-16GT

Gigabit Ether

net Switch

MODE

SPEED / DUPLEX

L/A

LINK /

ACT

MODE

L/A

LINK /

ACT

SFP

CLASS

1

LASER PRODUCT

15

16

15

16

AT-x210-16GT

Gigabit Ether

net Switch

L/A

LINK /

ACT

SFP

CLASS 1

LASER PRODUCT

5. For AT-x210-16GT Switches, attach the two rack mount brackets to

the sides of the switch using the bracket screws that come with the

unit. See the bracket position as shown in Figure 18 and Figure 19.

Figure 18. Attaching the brackets level with the front of an AT-x210-16GT

Figure 19. Close up showing a bracket positioned for an AT-x210-9GT

30

Page 41

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

13

5

7

246

8

9

11

13

15R

10

12

14

16R

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

SELECT

SPEED

DUPLEX

2

4

6

8

10

12

14

16R

1

3

5

7

9

11

13

15R

L/A

MODE

L/A

MODE

15

16

15

16

AT-x210-16GT

Gigabit Ether

net Switch

MODE

SPEED / DUPLEX

L/A

LINK /

ACT

MODE

L/A

LINK /

ACT

SFP

CLASS 1

LASER PR

O

DUCT

6. Mount an AT-x210-16GT switch in a 19-inch equipment rack using the

provided spacer bracket mounts with four equipment rack screws (not

provided with the switch), as shown in Figure 20.

Figure 20. Mounting an AT-x210-16GT Switch in an Equipment Rack

31

Page 42

Chapter 2: Installation

7. For AT-x210-9GT switches, first fit the rack mount handles to the

brackets using the supplied M3x6mm pan head screws, as shown

below in Figure 21.

Figure 21. Fitting rack mount handles to the brackets for an AT-x210-9GT

8. After fitting the rack mount handles to the brackets using the supplied

M3x6mm pan head screws , as shown about in Figure 21, fit these

brackets with handles to the mounting for AT-x210-9GT switches

using the supplied M4x6mm countersunk screws, as shown below in

Figure 22.

Figure 22. Fitting brackets to the mounting for an AT-x210-9GT

32

Page 43

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

1

35

7

2

468

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

MODE

SPEED

DUPLEX

SELECT

2

4

6

8

1

3

5

7

L/A

MODE

L/A

MODE

9

AT-x210-9GT

Gigabit Ether

net Switch

CL

ASS 1

LASER PRODUCT

MODE

SPEED / DUPLEX

L/A

LINK /

ACT

L/A

LINK /

ACT

SFP

9. Next attach the cable tray brackets for AT-x210-9GT switches, as

shown below in Figure 23.

Figure 23. Attaching cable tray brackets for an AT-x210-9GT

10. Mount an AT-x210-9GT switch in a 19-inch equipment rack, as shown

below in Figure 24, using the screws from the rubber feet after

removing these screws, as shown earlier in Figure 15.

Figure 24. Mounting an AT-x210-9GT Switch in an Equipment Rack

33

Page 44

Chapter 2: Installation

1

35

7

2

46

8

FAULT

STANDBY

RESET

POWER

CONSOLE

RS-232

MODE

SPEED

DUPLEX

SELECT

2

4

6

8

1

3

5

7

L/A

M

ODE

L

/

A

MOD

E

9

AT-x210-9GT

Gigab

it Ether

net Switch

C

LA

S

S

1

LA

S

E

R PR

O

DU

CT

M

O

D

E

SPEED / DUPLEX

L

/

A

L

INK /

ACT

L/A

LI

NK /

ACT

SFP

11. Mount an AT-x210-9GT switch in a 19-inch equipment rack using the

provided spacer bracket mounts with four equipment rack screws, as

shown in Figure 25.

Figure 25. Mounting an AT-x210-9GT Switch in an Equipment Rack

12. Secure cables to the cable tray fitted earlier, as shown in Figure 26.

Figure 26. Securing cables to the cable tray for an AT-x210-9GT

34

Page 45

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Note

Note

Warning

1982

R

R

Installing Optional SFP Transceivers

To install an SFP transceiver, perform the following procedure:

The transceiver can be hot-swapped; you do not need to power off

the switch to install a transceiver. However, always remove the

cables before removing the transceiver.

You should always install the transceiver before connecting the fiber

optic cables to it.

1. Remove the transceiver from its shipping container and store the

packaging material in a safe location.

An SFP transceiver can be damaged by static electricity. Be sure to

observe all standard electrostatic discharge (ESD) precautions,

such as wearing an antistatic wrist strap, to avoid damaging the

transceiver.

2. Remove the dust plug from an SFP slot. See Figure 27.

Figure 27. Removing the Dust Plug from an SFP Slot

3. Position the SFP transceiver with the label facing up.

35

Page 46

Chapter 2: Installation

1981

R

R

15R

16R

15

16

15

16

AT-x210-16GT

Gigabit Ether

net Switch

L/A

LINK /

ACT

SFP

CLASS 1

LASER PRODUCT

4. For an AT-x210-24GT Switch, gently slide the transceiver into the SFP

slot until it clicks into place, as shown in Figure 28.

Figure 28. Inserting the SFP on an AT-x210-24GT

5. For an AT-x210-16GT Switch, gently slide the transceiver into the SFP

slot until it clicks into place, as shown in Figure 29.

Figure 29. Inserting the SFP on an AT-x210-16GT

36

Page 47

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

1983

R

R

SFP Transceiver

Handle

15R

16R

15

16

15

16

AT-x210-16GT

Gigabit Ether

net Switch

L/A

LINK /

ACT

SFP

CLASS 1

LASER PRODUCT

6. Verify that the handle on the transceiver is in the upright position, as

shown in Figure 30. This secures the transceiver and prevents it from

being dislodged from the slot.

Figure 30. Positioning the SFP Handle in the Upright Position

7. Eject SFP transceivers, as shown in Figure 31. First lower the SFP

Transceiver Handle, then gently remove the SFP Transceiver.

Figure 31. Ejecting an SFP transceiver after lowering the SFP Handle to

the Downwards Position

8. Repeat steps 2 through 6 to install additional SFP transceivers.

37

Page 48

Chapter 2: Installation

Note

Note

SFP transceivers are dust sensitive. Always keep the plug in the

optical bores when a fiber optic cable is not installed, or when

storing the SFP. When you do remove the plug, keep it for future

use.

Unnecessary removal and insertion of an SFP can lead to

premature failure.

For information on the cable specifications of the SFP, consult the

documentation shipped with the SFP.

9. Go to “Cabling the Switch” on page 39.

38

Page 49

Cabling the Switch

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Observe the following guidelines when connecting twisted pair and fiber

optic cables to the ports on the switch:

The connector on the cable should fit snugly into the port on the

switch. The tab on the connector should lock the connector into

place.

Because the twisted pair ports have auto-MDI/MDI-X, you may use

straight-through twisted pair cable to connect any type of network

device to the switch.

If your network topology contains a loop where two or more

network devices can communicate with each other over more than

one network path, do not connect the network cables that form the

loop until after you activate a spanning tree protocol on the switch.

Data loops can adversely affect network performance.

If you are creating a port trunk, do not connect the cables of the

trunk to the switch until after you have created the trunk in the

switch’s management software. Otherwise, a network loop will

result which can adversely affect network performance.

The default setting for the wiring configurations of the ports is auto-

MDI/MDI-X. The default setting is appropriate for switch ports that

are connected to 10/100Base-TX network devices that also

support auto-MDI/MDI-X.

The default auto-MDI/MDI-X setting is not appropriate for switch

ports that are connected to 10/100Base-TX network devices that

do not support auto-MDI/MDI-X and have a fixed wiring

configuration. For switch ports connected to those types of network

devices, you should disable auto-MDI/MDI-X and set the wiring

configurations manually.

The appropriate MDI/MDI-X setting for a switch port connected to a

10/100Base-TX network device with a fixed wiring configuration

depends on the setting of the network device and whether the

switch and network device are connected with straight-through or

crossover cable. If you are using straight-through twisted pair

cable, the wiring configurations of a port on the switch and a port

on a network device must be opposite each other, such that one

port uses MDI and the other MDI-X. For example, if a network

device has a fixed wiring configuration of MDI, you must disable

auto-MDI/MDI-X on the corresponding switch port and manually

set it to MDI-X. If you are using crossover twisted pair cable, the

wiring configurations of a port on the switch and a port on a

network device must be the same.

39

Page 50

Chapter 2: Installation

The default speed setting for the ports is Auto-Negotiation. This

setting is appropriate for ports connected to network devices that

also support Auto-Negotiation.

The default speed setting of Auto-Negotiation is not appropriate for

ports connected to 10/100Base-TX network devices that do not

support Auto-Negotiation and have fixed speeds. For those switch

ports, you should disable Auto-Negotiation and set the port’s

speed manually to match the speeds of the network devices.

The 10/100/1000Base-T ports must be set to Auto-Negotiation, the

default setting, to operate at 1000Mbps.

The default duplex mode setting for the ports is Auto-Negotiation.

This setting is appropriate for ports connected to network devices

that also support Auto-Negotiation for duplex modes.

The default duplex mode setting for the ports is Auto-Negotiation.

This setting is appropriate for ports connected to network devices

that also support Auto-Negotiation for duplex modes.

The default duplex mode setting of Auto-Negotiation is not

appropriate for ports connected to network devices that do not

support Auto-Negotiation and have a fixed duplex mode. You

should disable Auto-Negotiation on those ports and set their

duplex modes manually to avoid the possibility of duplex mode

mismatches. A switch port using Auto-Negotiation defaults to halfduplex if it detects that the end node is not using Auto-Negotiation,

which can result in a mismatch if the end node is operating at a

fixed duplex mode of full-duplex.

Do not attach cables to ports of static or LACP port trunks until

after you have configured the trunks on the switch. Otherwise, the

ports will form network loops that can adversely affect network

performance

40

Page 51

Powering On the Switch

Power cable hook

Power cable hook mount

Power cable

To power on the AT-x210-24GT, AT-x210-16GT, or AT-x210-9GT switch,

perform the following procedure:

1. Plug the power cord into the AC power connector, as shown in

Figure 32 on the back of an AT-x210-16GT Switch.

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Figure 32. Lifting the AC Power Cable Hook on an AT-x210-16GT Switch

2. Plug the power cord into the AC power connector as shown in

Figure 33 on the back of an AT-x210-16GT Switch.

Figure 33. Plugging in the AC Power Cord on an AT-x210-16GT Switch

3. Plug the other end of the power cord into a wall outlet.

41

Page 52

Chapter 2: Installation

Warning

Power cord is used as a disconnection device. To de-energize

equipment, disconnect the power cord. E3

Pluggable Equipment. The socket outlet shall be installed near the

equipment and shall be easily accessible. E5

4. Verify that the POWER LED is green. If the LED is OFF, see Chapter

3, “Troubleshooting” on page 47.

The switch is now powered on and ready for network operations. For

information on how to manage the switch, see the following manual:

AlliedWare Plus Software Reference for x210 Series Switches

42

Page 53

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Bootloader 2.0.10 loaded

Press <Ctrl+B> for the Boot Menu

Reading filesystem...

Loading flash:

x210-5.4.3.rel

Verifying release... OK

Booting...

Starting base/first... [ OK ]

Mounting virtual filesystems... [ OK ]

______________ ____

/\ \ / /______\

/ \ \_ __/ /| ______ |

/ \ | | / | ______ |

/ \ \ / / \ ____ /

/______/\____\ \/ /____________/

Allied Telesis Inc.

AlliedWare Plus (TM) v5.4.3

Current release filename:

x210-5.4.3.rel

Original release filename: x210-5.4.3.rel

Built: Tue Jul 9 18:20:42 NZST 2013 by: maker @m ak er 04 -bu il d

Mounting static filesystems... [ OK ]

Checking flash filesystem... [ OK ]

Mounting flash filesystem... [ OK ]

Checking NVS filesystem... [ OK ]

Mounting NVS filesystem... [ OK ]

Starting base/dbus... [ OK ]

Starting base/syslog... [ OK ]

Monitoring the Initialization Processes

It takes about thirty seconds for the switch to initialize its management

software programs and features, and load the default configuration.

You may also monitor the bootup sequence by connecting a terminal or

computer that has a terminal emulator program, to the Console port on the

master switch. You will see the messages in Figure 34 here to Figure 36

on page 45.

Figure 34. Switch Initialization Messages

43

Page 54

Chapter 2: Installation

Starting base/loopback... [ OK ]

Starting base/sysctl... [ OK ]

Received event poefw.done

Starting base/portmapper... [ OK ]

Received event syslog.done

Starting base/reboot-stability... [ OK ]

Starting base/autofs-card... [ OK ]

Checking system reboot stability... [ OK ]

Starting base/cron... [ OK ]

Starting base/appmond... [ OK ]

Starting hardware/openhpi... [ OK ]

Starting hardware/timeout... [ OK ]

Starting base/inet... [ OK ]

Starting base/modules... [ OK ]

Received event modules.done

Received event board.inserted

Received event hardware.done

Starting network/startup... [ OK ]

Starting network/stackd... [ OK ]

Starting network/election.timeout... [ OK ]

Received event network.enabled

Initializing HA processes:

openhpid, hostd, cntrd, nsm, auth, ep sr, hsl

imiproxyd, irdpd, lldpd, loopprot, mstp

rmon, sflowd, imi, lacp

Received event network.initialized

Assigning Active Workload to HA processes:

hsl, nsm, rmond, sflowd, irdpd, lacpd

lldpd, loopprotd, mstpd, authd, epsrd, imi, imiproxyd

Received event network.activated

Loading default configuration

Warning: flash:/default.cfg doe s no t exi st , lo ad ing fac to ry defaults.

..

Figure 35. Switch Initialization Messages (Continued)

44

Page 55

AT-x210-9GT, AT-x210-16GT, and AT-x210-24GT Switches Installation Guide

Assigning Active Workload to HA processes:

hsl, nsm, rmond, sflowd, vrrpd, irdpd, lacpd

lldpd, loopprotd, mstpd, authd, epsrd, imi, imiproxyd

Received event network.activated

Loading default configuration

Warning: flash:/default.cfg doe s no t exi st , lo ad ing fac to ry defaults.

..

done!

Received event network.configured

awplus login:

Figure 36. Switch Initialization Messages (Continued)

45

Page 56

Chapter 2: Installation

46

Page 57

Chapter 3

Note

Troubleshooting

This chapter contains information on how to troubleshoot the switch if a

problem occurs.

For further assistance, please contact Allied Telesis Technical