Page 1

!

Installation

Fast Ethernet

®

Switches

AT-8316F/MT

AT-8316F/VF

AT-8316F/SC

AT-8324

Guide

PN 613-10813-00 Rev B

Page 2

Copyright 2003 Allied Telesyn, Inc.

960 Stewart Drive Suite B, Sunnyvale, CA 94086 USA

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesyn, Inc.

CentreCom is a registered trademark of Allied Telesyn, Inc.

All other product names, company names, logos or other designations mentioned herein are trademarks or registered trademarks of

their respective owners.

Allied Telesyn, Inc. reserves the right to make changes in specifications and other information contained in this document without

prior written notice. The informati on provided h erein is su bject to cha nge without n otice. In n o event sha ll Allied Telesyn, Inc. be liable

for any incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising out of or

related to this manual or the information contained herein, even if Allied Telesyn, Inc. has been advised of, known, or should have

known, the possibility of such damages.

Page 3

Electrical Safety and Emission Compliance

Statement

STANDARDS: This product meets the following standards

U.S. Federal Communications Commission

RADIATED ENERGY

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with this instruction manual, may cause harmful int erfer enc e to radio comm unication s. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Note: Modifications or changes not expressly approved by the manufacturer or the FCC can void your right to operate this

equipment.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

RFI Emission EN55022 Class A

WARNING: In a domestic environment this product may cause radio interference in which case the user may be required t o take

adequate measures.

Immunity EN50082-1 1997

Electrical Safety EN60950, UL 1950, CSA 950

Laser EN60825

IMPORTANT: Appendix A contains translated safety statements for installing this equipment. When you see the ", go to Appendix A

for the translated safety statement in your language.

WICHTIG: Anhang A enthält übersetzte Sicherheitshinweise für die Installation dieses Geräts. Wenn Sie

Anhang A den übersetzten Sicherheitshinweis in Ihrer Sprache nach.

VIGTIGT: Tillæg A indeholder ove rsatte sikkerhedsadvarsler, der vedrører installation af dette udstyr. Når De ser symbolet

slå op i tillæg A og finde de oversatte sikkerhedsadvarsler i Dere s eget sprog.

BELANGRIJK: Appendix A bevat vertaalde veiligheidsopmerkingen voor het installeren van deze apparatuur. Wanneer u de

raadpleeg Appendix A voor vertaalde veiligheidsinstructies in uw taal.

IMPORTANT : L'annexe A contient les instructions de sécurité relatives à l'installation de cet équipement. Lorsque vous voyez le

symbole

", reportez-vous à l'annexe A pour consulter la traduction de ces instructions dans votre langue.

TÄRKEÄÄ: Liite A sisältää tämän laitteen asentamiseen liittyvät käännetyt turvaohjeet. Kun näet

turvaohjetta liitteestä A.

IMPORTANTE: l’Appendice A contiene avvisi di sicurezza tradotti per l’ins tallaz ione di questa apparecchiatura. Il simbolo

di consultare l’Appendice A per l’avviso di sicurezza nella propria lingua.

VIKTIG: Tillegg A inneholder oversatt sikkerhetsinformasjon for installering av dette utstyret. Når du ser

å finne den oversatte sikkerhetsinformasjonen på ønsket språ k.

" 2

" 1

" 3

" 4

" 5

" sehen, schlagen Sie in

", skal De

" ziet,

"-symbolin, katso käännettyä

", indica

", åpner du til Tillegg A for

IMPORTANTE: O Anexo A contém advertências de segurança traduzidas para instalar este equipamento. Quando vir o símbolo

leia a advertência de segurança traduzida no seu idioma no Anexo A.

IMPORT ANTE: El Apéndice A contiene mensajes de seguridad traducidos para la instalación de este equipo. Cuando vea el símbolo

",

", vaya al Apéndice A para ver el mensaje de seguridad traducido a su idioma.

OBS! Bilaga A innehåller översatta säkerhetsmeddelanden a vseende installationen av den na utrustning. När du ser

Bilaga A för att läsa det översatta säkerhetsmeddelandet på ditt språk.

", skall du gå till

3

Page 4

Page 5

Table of Contents

Preface ......................................................................................................................................................................................................................7

Purpose of This Guide ... .................................................. ......................................................................................................................................7

How This Guide is Organiz ed ................................................................................ .............................................................................................7

Document Conventions ......................................................................................................................................................................................8

Where to Find Related Guides ..................................................... ......................................................................................................................9

Chapter 1

Hardware Description .....................................................................................................................................................................................11

The Switch Models . ..............................................................................................................................................................................................12

Features and Components ...............................................................................................................................................................................13

Physical Description ............................................................................................................................................................................................14

Data Ports ................................................................................................................................................................................................................15

Switch LEDs ............................................................................................................................................................................................................16

RS232 Connector ..................................................................................................................................................................................................18

Stacking Ports ........................................................................................................................................................................................................19

Stacking Module Expansio n Slo t ....................................................................................................................................................................20

Stack ID Switch ............................................................................................... .......................................................................................................20

Expansion Module Slots ....................................................................................................................................................................................21

Optional Expansion Mo du le s................................................................................................. ................................................................. 21

R.P.S Input Connector ................................................................. ........................................................................................................................23

Reset Button ...........................................................................................................................................................................................................24

AC Power Connector ...........................................................................................................................................................................................25

AT-S25 Management Software and Omega Management Interface ......... .......................................................................................25

Network Topology ...............................................................................................................................................................................................26

Where to Go Next ................................................ .................................................................................................................................................28

Chapter 2

Planning the Installation ...............................................................................................................................................................................29

AT-8316F and AT-8324 Switch Cabling Specifications .................... .......................................................................................................30

Switch Stacks .........................................................................................................................................................................................................31

Stack of Two or Three Switc hes....................................... ....................................................................................................................... 3 1

Stack of Four to Eight Switches.................................................................................................................. ............................................ 32

Expansion Modules .............................................................................................................................................................................................33

Port Trunking .........................................................................................................................................................................................................35

Guideline 1: Number of Port s in a Tru nk............................................................................................................................................. 35

Guideline 2: Using Ports from the Same Group .............................................. ................................................. ................................ 35

Guideline 3: Creating Onl y One Trunk Per Group................................................................................................ ............................ 36

Guideline 4: Using Consecu ti v e Ports.. .................................................. .................................................. ............................................ 36

5

Page 6

Guideline 5: Cabling Based on Port Number..................................................................................................................................... 37

Guideline 6: Using Expansio n M odules.... ........................................................................................................................................... 37

Where to Go Next ................................................ .................................................................................................................................................38

Chapter 3

Installing the Switch .........................................................................................................................................................................................39

Verifying the Package Contents .....................................................................................................................................................................40

Reviewing Safety Precaut io ns .... .....................................................................................................................................................................41

Selecting a Site for the Switc h ............................. ............................................................................................................................................42

Installing the Switch as a Standalone Unit ............................................... ...................................................................................................43

Installing the Switch in a Rack ......................................... ................................................................................................................................45

Building a Stack of Two Switche s ....................... ............................................................................................................................................46

Building a Stack of Three Switc he s ........................ ........................................................................................................................................49

Building a Stack of Four to Eight Swit che s .................................................................................................................................................52

Powering On a Stack . ................................................................................................... .......................................................................................57

Setting Up a Terminal for Loc a l M anagement ...........................................................................................................................................59

Installing an Expansion Module ......................................................................................................................................................................60

Resetting a Stack .................... ..............................................................................................................................................................................62

Where to Go Next ................................................ .................................................................................................................................................63

Chapter 4

Troubleshooting ................................................................................................................................................................................................65

At the First Sign of a Proble m .................................. ................................................. .......................................................................................66

Network Cabling Proble ms ...................... ........................................................................... ..............................................................................67

Calling Technical Suppo rt ........................ ........................................................................... ..............................................................................67

How the Switch Reports Problems ................................................................................................................................................................68

Common Problems .............................................................................................................................................................................................70

Link /Activity LED on Any Port is OFF............................................................................................... .................................................... 70

Power LED is OFF......................................................................................................................................................................................... 71

Fault LED is ON........................................................................................................................ ..................................................................... 71

Appendix A

Translated Electrical Safety and Emission Information ..................................................................................................................73

Appendix B

Technical Specifications .................................................................................................................................................................................85

Appendix C

Switch Default Settings ..................................................................................................................................................................................89

Index ........................................................................................................................................................................................................................91

6

Page 7

Preface

Purpose of This Guide

This guide is intended for network administrators who are

responsible for installing and maintaining AT-8316F and AT-8324

Ethernet switches.

How This Guide is Organized

This guide contains the following chapters and appendices:

Chapter 1, Hardware Description, describes the features and

functions of the switches and the expansion modules. The chapter

also describes several network topologies that use the fast Ethernet

switches.

Chapter 2, Planning the Installation, contains cabling specifications

for the switches and expansion modules, and lists the rules to

observe when creating a port trunk.

Chapter 3, Installing the Switch, contains the procedures for

installing the switch, building a stack of switches, and installing the

expansion modu les.

Chapter 4, Troubleshooting, describes how to troubleshoot the

switch in case of a problem.

Appendix A, Translated Electrical Safety and Emission

Information, contains translations of the safety warnings

documented throughout this guide.

Appendix B, Technical Specifications, presents in tabular form

switch and expansion module specifications.

7

Page 8

Preface

Appendix C, Switch Default Settings, lists the switch’s factory

default software settings.

An Index, at the end of this guide, is according to subject matter.

Document Conventions

The conventions used in this guide are as follows:

# Notes:

Note

A note provides additional information.

# Warnings:

Warning

A warning indicates that performing or omitting a specific action

may result in bodily injury.

# Cautions:

Caution

A caution indicates that performing or omitting a specific action

may result in equipment damage or loss of data.

8

Page 9

Where to Find Related Guides

After you have performed the procedures in this guide and installed

the switch on your network, go to the Allied Telesyn web site at

www.alliedtelesyn.com and download the following guide:

AT-S25 Management Software User’s Guide

PN 613-10844-00

This manual explains how to use the Omega management software

and the AT-S25 software to configure and manage the device.

AT-8316F and AT-8324 Installation Guide

9

Page 10

Page 11

Chapter 1

Hardware Description

The AT-8316F and the AT-8324 switches are designed to provide

your network with Ethernet, Fast Ethernet, and Gigabit Ethernet

connectivity over fiber optic and twisted pair cabling.

The switches can operate as standalone units or can be

interconnected together through special stacking ports to form

logical switches. Logical switches, also referred to as s tacks, can make

it easier for you to manage your network because you can manage

all of the switches as one unit. Logical switches are also easy to

customize. You can add or remove switches from a logical switch so

that the unit always has the number and types of ports that your

network requires.

Two expansion slots on the front of the switches further add to the

flexibility of the systems. You can use the slots to install 10Base-T,

100Base-TX, 100Base-FX, and 1000Base-FX expansion modules.

This chapter describes the hardware features of the following

products:

# AT-8316F/MT switch

# AT-8316F/VF switch

# AT-8316F/SC switch

# AT-8324 switch

# The optional expansion modules: AT-A15/SX, AT-A15/LX,

AT-A16, AT-A17, AT-A18, and AT-A19

11

Page 12

Hardware Description

The Switch Models

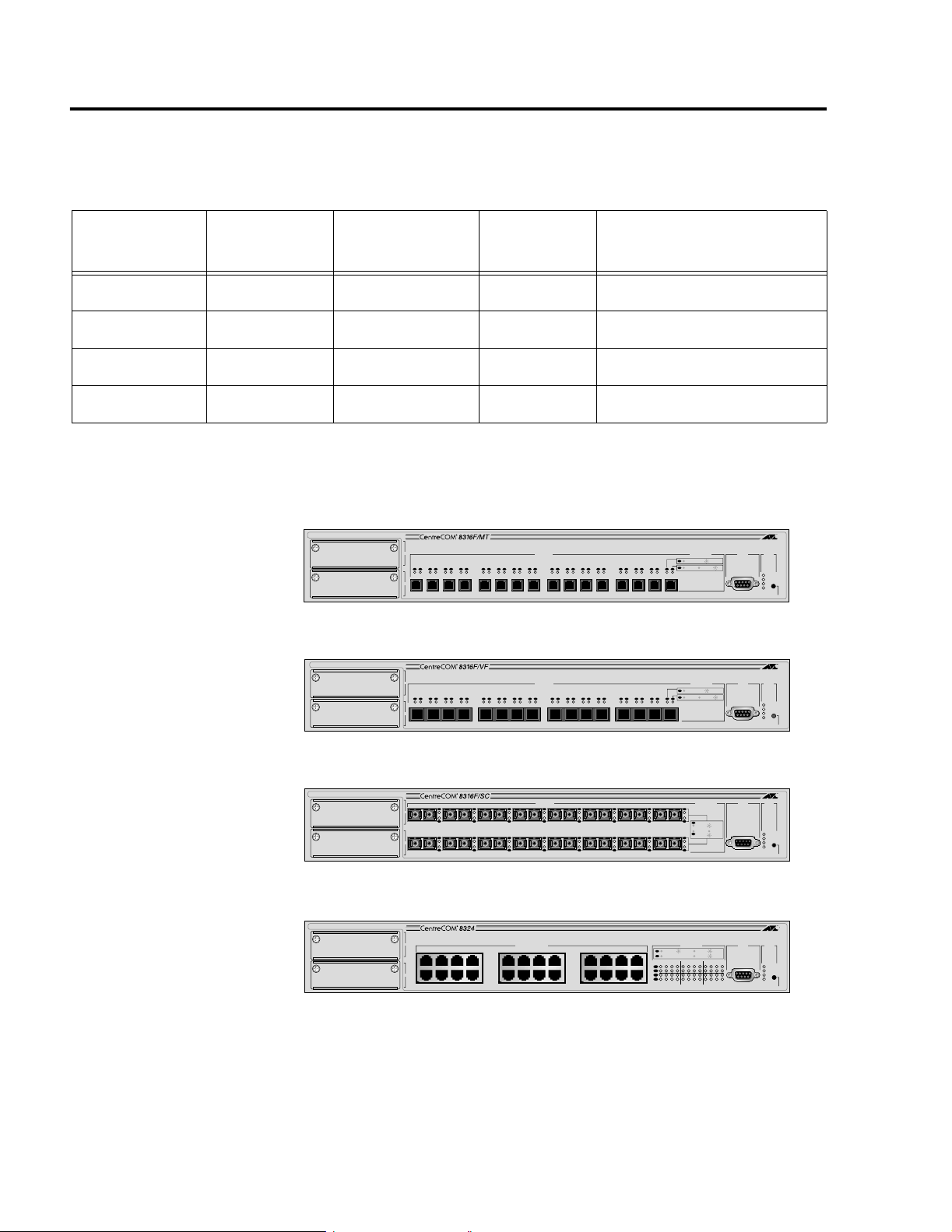

Table 1-1 lists the switch models.

Table 1-1 Switch Models

Model

1

Number of

Ports

Type of Port

Type of

Connector

Maximum Distance

AT-8316F/MT 16 100Base-FX MT-RJ 2 kilometers2 (1.25 miles)

AT-8316F/VF 16 100Base-FX VF-45 2 kilometers2 (1.25 miles)

AT-8316F/SC 16 100Base-FX SC 2 kilometers2 (1.25 miles)

AT-8324 24 10/100Base-TX RJ-45 100 meters (328 feet)

1. All models include two expansion slots.

2. Assumes 50/125 micron or 62.5/125 micron multimode fiber optic cabling and full-duplex operation.

Figure 1-1 shows the front panel of each switch.

100BASE-FX FAST ETHERNET SWITCH

A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

B

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

D/C

D/C

D/C

100BASE-FX

L/A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

D/C

D/C

D/C

D/C

L/A

L/A

L/A

D/C

D/C

D/C

AT-8316/MT

100BASE-FX FAST ETHERNET SWITCH

A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

B

1234 5678 9101112 13141516

D/C

D/C

D/C

100BASE-FX

L/A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

D/C

D/C

D/C

D/C

L/A

L/A

L/A

D/C

D/C

D/C

AT-8316F/VF

PORT ACTIVITY

L/A

ACTIVITY

100M LINK

D/C

FULL DUP

HALF DUP/ COL

L/A

L/A

D/C

D/C

PORT ACTIVITY

L/A

ACTIVITY

100M LINK

D/C

FULL DUP

HALF DUP/ COL

L/A

L/A

D/C

D/C

RS-232

TERMINAL PORT

RS-232

TERMINAL PORT

STATUS

FAULT

MASTER

RPS

PWR

RESET

STATUS

FAULT

MASTER

RPS

PWR

RESET

12

A

B

100BASE-FX FAST ETHERNET SWITCH

L/A

D/C

L/A

D/C

L/A

D/C

L/A

D/C

100BASE-FX

L/A

L/A

L/A

D/C

L/A

D/C

D/C

D/C

L/A

L/A

D/C

D/C

L/A

L/A

D/C

D/C

L/A

L/A

D/C

D/C

PORT ACTIVITY

87654321

L/A

D/C

L/A

RXTXRXTXRXTXRXTXRXTXRXTXRXTXRXTX

LINK / ACTIVITY

FULL DUP /

D/C

161514131211109

L/A

D/C

RXTXRXTXRXTXRXTXRXTXRXTXRXTXRXTX

AT-8316F/SC

10BASE-T / 100BASE-TX

FAST ETHERNET SWITCH

A

B

1X 3X 5X 7X

2X 4X 6X 8X

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

17X 19X 21X 23X

18X 20X 22X 24X

PORT ACTIVITY

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

HALF DUP/

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

AT-8324

Figure 1-1 AT-8316F and AT-8324 Swi tches

STATUS

RS-232

TERMINAL PORT

HALF DUP

COL

COL

FAULT

MASTER

RPS

PWR

RESET

STATUS

RS-232

TERMINAL PORT

FAULT

MASTER

RPS

PWR

24

RESET

Page 13

Features and Components

The switches have the following common hardware features:

# Half- or full-duplex operation on all switched ports delivering

up to 200 Mbps of bandwidth to servers, routers, workstations,

or other switches

# Auto-negotiation on all 10Base-T/100Base-TX ports for speed

and duplex in compliance with IEEE 802.3u specifications

(AT-8324 switch only)

# Non-blocking, clear-channel architecture delivers wire-speed

switching and up to 14 Gbps aggregate bandwidth

# Store-and-forward switching mode

# 8K MAC addresses per switch with automatic aging

# 4 MB SDRAM per eight 10Base-T/100Base-TX or 100Base-FX

ports

AT-8316F and AT-8324 Installation Guide

# 2 MB Flash memory for software upgrades

# In-band Telnet capability for remote switch management

# AT-S25 software and Omega management software

# Two stacking ports for interconnecting switches to create

logical switches

# One expansion slot for the optional AT-Stack8 Stacking Matrix

Module for creating logical switches of up to eight switches

# Two expansion slots for optional uplink expansion modules

# RS232 connector for local switch management

# IEEE 802.1Q compliant Virtual LAN (VLAN) tagging support

# IEEE 802.1P compliant Quality of Service

# Two priority queues/levels per-port based on tagging

information (IEEE 802.1P)

# IEEE 802.1d Spanning Tree Protocol

# SNMP Management Information Base (MIB) II, SNMP MIB

extensions, Bridge MIB (RFC 1493), Ethernet MIB (RFC 1643),

and Interface MIB (RFC 1573)

# BootP and DHCP support

# Port trunking for increased bandwidth to end nodes

13

Page 14

Hardware Description

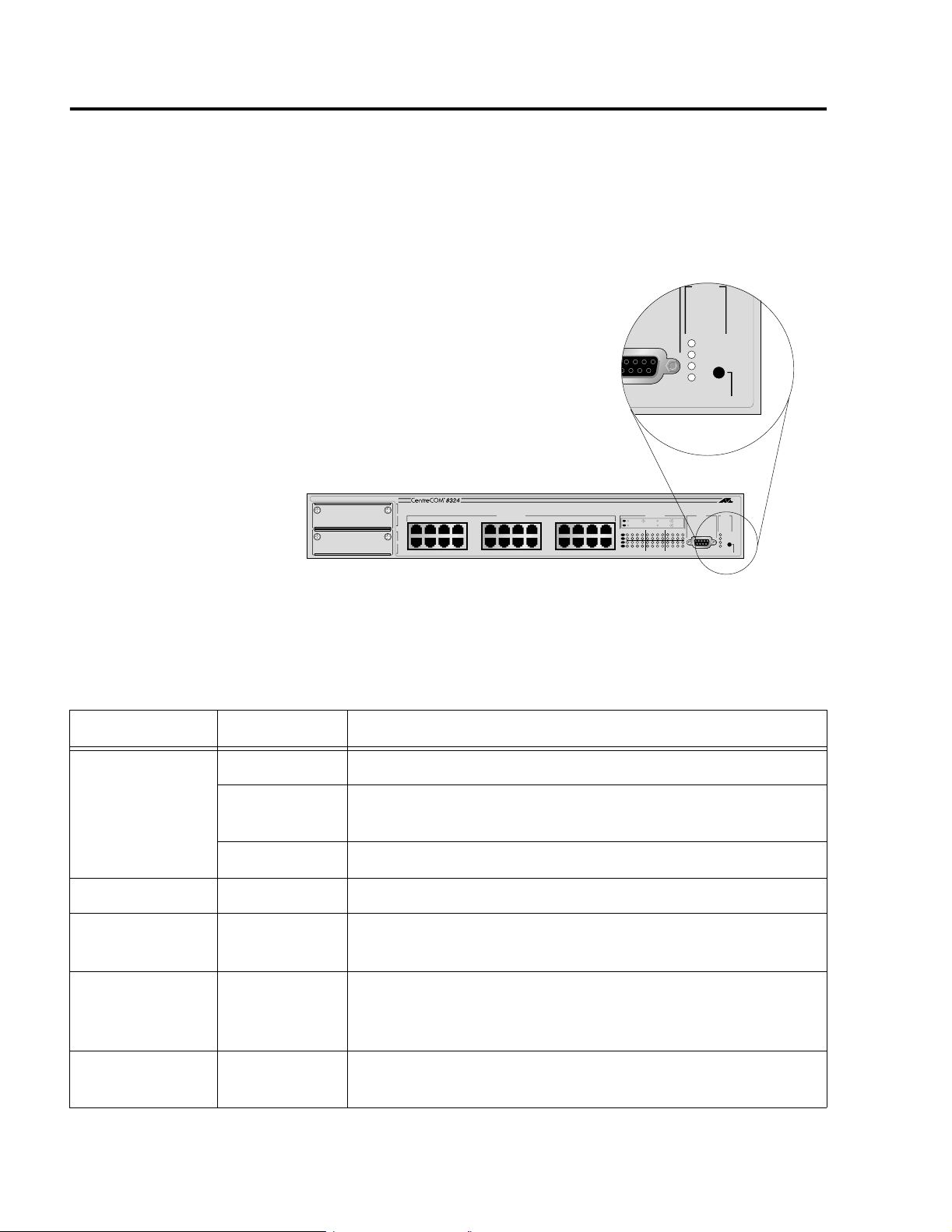

Physical Description

Figure 1-2 through Figure 1-4 illustrate the location of the switch

components.

Expansion Module Slots

Expansion Module Slots

Port LEDs

100BASE-FX FAST ETHERNET SWITCH

A

L/A

L/A

L/A

L/A

L/A

L/A

B

D/C

D/C

D/C

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

D/C

D/C

100BASE-FX

L/A

L/A

L/A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

D/C

D/C

D/C

D/C

D/C

D/C

Sixteen 100Base-FX Ports

Figure 1-2 AT-8316F Switch (Model AT-8316F/MT)

10BASE-T / 100BASE-TX

FAST ETHERNET SWITCH

A

1X 3X 5X 7X

B

2X 4X 6X 8X

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

17X 19X 21X 23X

18X 20X 22X 24X

L/A

L/A

D/C

D/C

D/C

RS232 connector

Port LEDs

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

L/A

100M LINK

D/C

FULL DUP

PORT ACTIVITY

PORT ACTIVITY

HALF DUP/ COL

HALF DUP/

ACTIVITY

COL

24

Reset Button

STATUS

RS-232

TERMINAL PORT

FAULT

MASTER

RPS

PWR

System

LEDs

Reset Button

STATUS

RS-232

TERMINAL PORT

FAULT

MASTER

RPS

PWR

RESET

RESET

AC

Connector

R.P.S. Input

Connector

Twenty Four 10Base-T/100Base-TX Ports

RS232 connector

System

LEDs

Figure 1-3 AT-8324 Swi tch

STACK ID

IS-A IS-B

IS-A IS-B

Expansion Slot

Stacking Module

Stacking Ports

STACK ID

0

0

Stack ID

Switch

Figure 1-4 Switch Back Panel

14

Page 15

Data Ports

AT-8316F and AT-8324 Installation Guide

Each model of the AT-8316F switch features 16 fiber optic ports with

either MT-RJ, VF-45, or SC fiber optic connectors. The ports offer

100Base-FX performance and half- or full-duplex operation. Each

port can operate up to a maximum distance of 2 kilometers (1.25

miles), assuming 50/125 micron or 62.5/125 micron multimode fiber

optic cabling and full-duplex operation.

The AT-8324 switch has 24 twisted pair ports with RJ-45 connectors.

The ports, which feature auto-negotiation on both speed and duplex

mode, can operate as either 10Base-T or 100Base-TX ports and in

half- or full-duplex mode.

15

Page 16

Hardware Description

STATUS

RESET

FAULT

MASTER

RPS

PWR

RS-232

Switch LEDs

The Ethernet switch has a series of LEDs for monitoring the status of

the unit. There are system LEDs for monitoring the entire switch and

port LEDs for monitoring the individual data ports.

The system LEDs are Fault, Master, RPS (Redundant Power Supply),

and PWR. Figure 1-5 illustrates the location of the system LEDs. The

location of the system LEDs is the same on all switch models.

10BASE-T / 100BASE-TX

FAST ETHERNET SWITCH

A

B

1X 3X 5X 7X

2X 4X 6X 8X

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

17X 19X 21X 23X

18X 20X 22X 24X

PORT ACTIVITY

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

HALF DUP/

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

COL

STATUS

RS-232

TERMINAL PORT

FAULT

MASTER

RPS

PWR

24

RESET

Figure 1-5 System LEDs

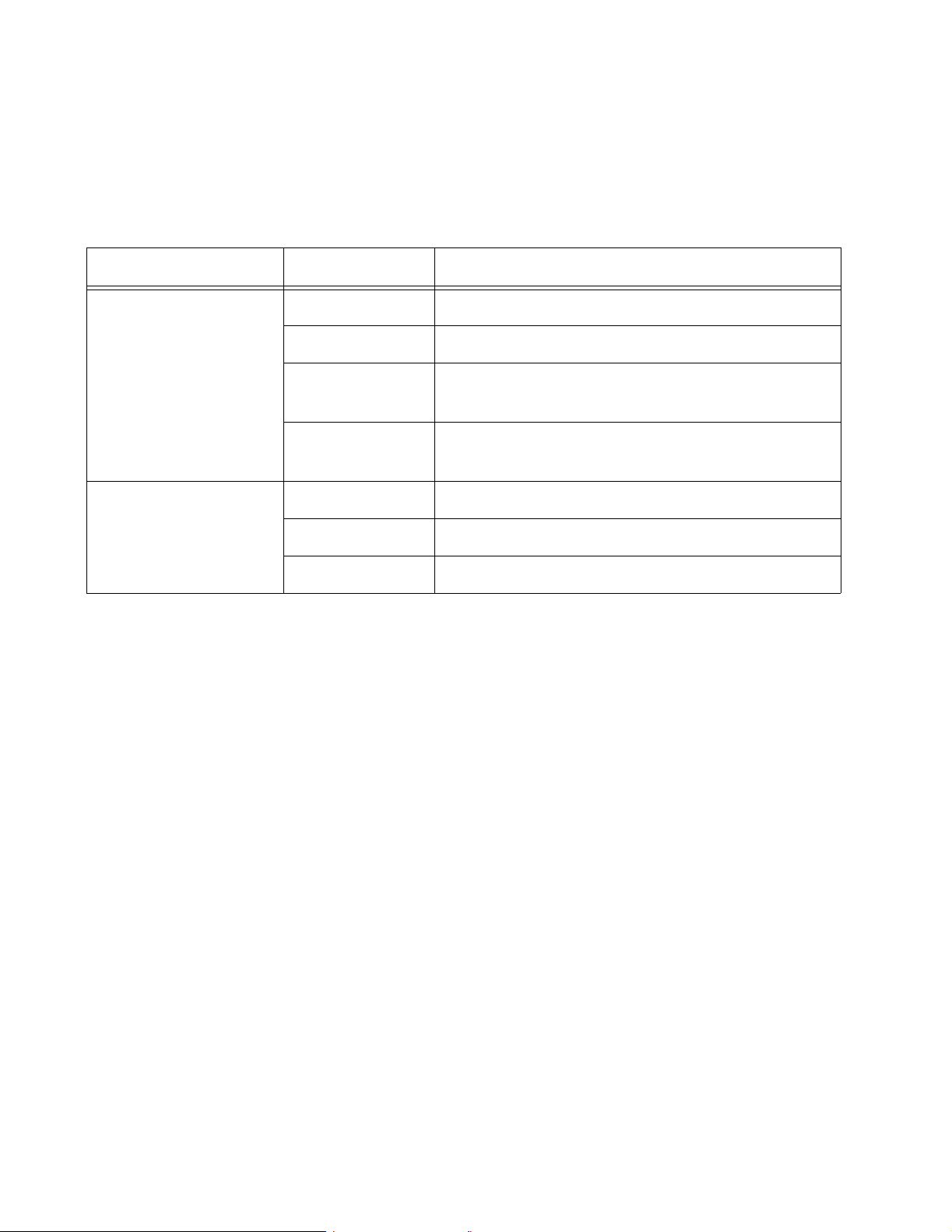

Table 1-2 describes the system LEDs on the Ethernet switch.

Table 1-2 Switch System LED Status

LED State Description

Fault Solid Red The switch or management software is malfunctioning.

Flashing Red The switch is booting, running diagnostic tests, writing

messages to FLASH, or transferring files using XMODEM.

OFF Normal operation.

Master Solid Amber The switch is functioning as the master switch of the stack.

Off The switch is functioning as a slave switch in the stack or is

not a part of a stack.

RPS (Redundant

Power Supply)

Solid Green The RPS is connected to the switch. To verify that the RPS is

operating correctly, refer to the instructions in the RPS

Quick Install Guide.

Power Solid Green The switch is receiving power, the voltage is within the

acceptable range, and the power supply is working.

16

Page 17

AT-8316F and AT-8324 Installation Guide

Each port has two LEDs that reflect the operating status of the port.

On the AT-8316F switch, the port LEDs are located directly above or

next to each port. On the AT-8324 switch, the port LEDs are grouped

together on the right side of the switch. Table 1-3 describes the port

LEDs on the Ethernet switch.

Table 1-3 Switch Port LED Status

LED State Description

L/A (Link/Activity) Solid Green This indicates a 100 Mbps link.

Flashing Green This indicates 100 Mbps activity.

Solid Amber This indicates a 10 Mbps link (AT-8324 switch

only).

Flashing Amber This indicates 10 Mbps activity (AT-8324 switch

only).

D/C (Duplex/Collision) Solid Green The port is operating at full-duplex.

Solid Amber The port is operating at half-duplex.

Flashing Amber Collisions are occurring on the line.

17

Page 18

Hardware Description

STATUS

RE

FAULT

MASTER

RPS

PWR

212223

24

RS-232

TERMINAL PORT

ACTIVITY

COL

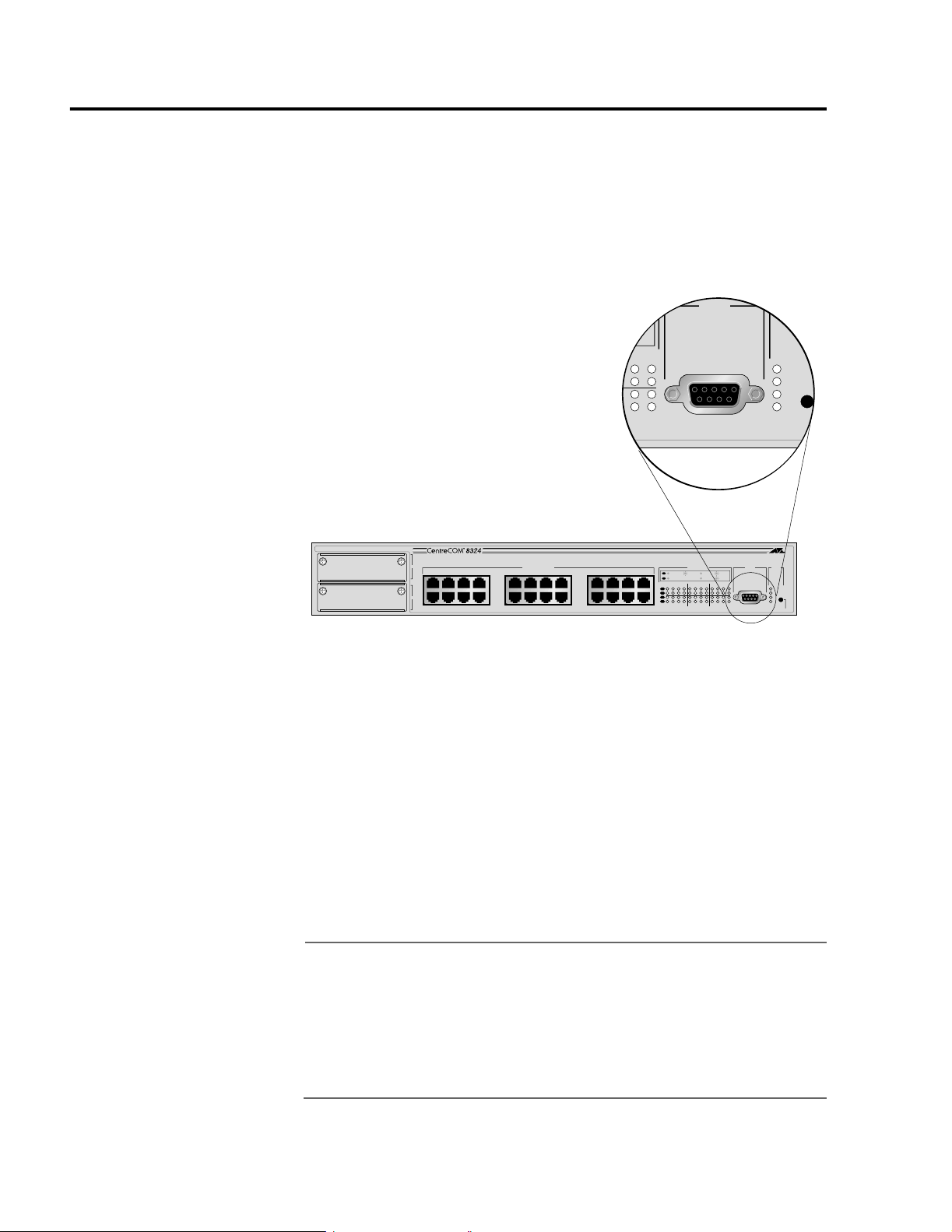

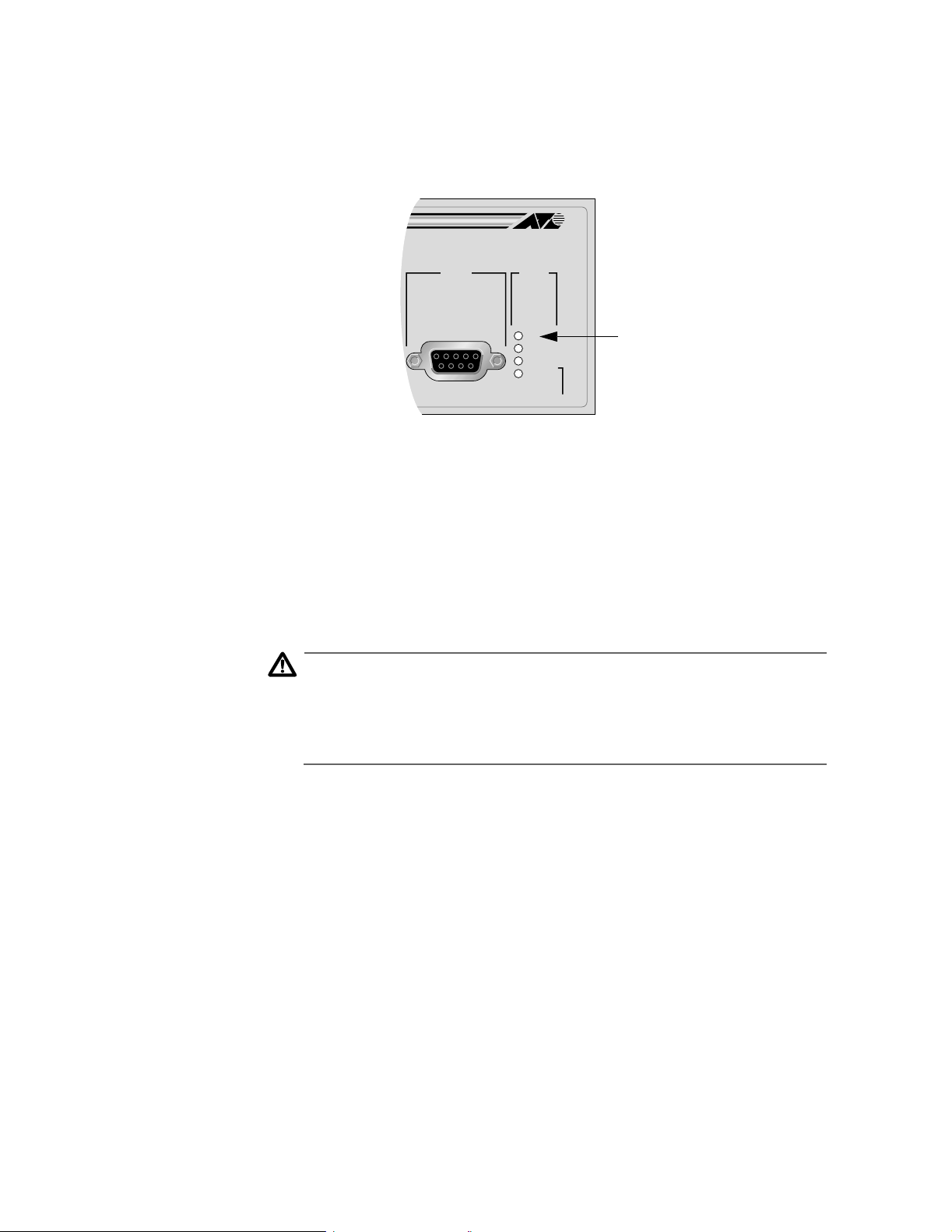

RS232 Connector

The RS232, DB-9 female port on the front of the switch (shown in

Figure 1-6) is used with a VT100 terminal to manage the system. By

connecting a terminal to the connector (or by using a personal

computer with a terminal emulation program, such as the MSWindows’ Hyper Terminal emulation program), you can access the

pre-installed Omega management program and configure the

switch.

18

10BASE-T / 100BASE-TX

FAST ETHERNET SWITCH

A

B

1X 3X 5X 7X

2X 4X 6X 8X

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

17X 19X 21X 23X

18X 20X 22X 24X

PORT ACTIVITY

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

HALF DUP/

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

COL

24

RS-232

TERMINAL PORT

STATUS

FAULT

MASTER

RPS

PWR

RESET

Figure 1-6 RS232 Port

This method for accessing the Omega program is referred to as “local

access” or “out-of-band” access. You can also access the program

over the web with a web browser or remotely via Telnet or an SNMP

management program.

In an IP environment, after you have initially installed the switch you

will be required to access the Omega program through the RS232

port in order to assign the switch its IP address and, if necessary, a

gateway address. Once these addresses have been assigned, you can

either continue to manage the switch through the RS232 port or

access the program via one of the other available methods.

Note

Only the RS232 port on the master switch in a stack can be used to

configure a stack locally. The RS232 ports on the slave switches are

inactive and cannot be used. (For an explanation of master and

slave switches, refer to , Chapter 3, Installing the Switch.)

Additionally, a straight-through cable is required in order to

connect a terminal to the RS232 port on the master switch.

Page 19

Stacking Ports

IS-A IS-B

STACK ID

0

AT-8316F and AT-8324 Installation Guide

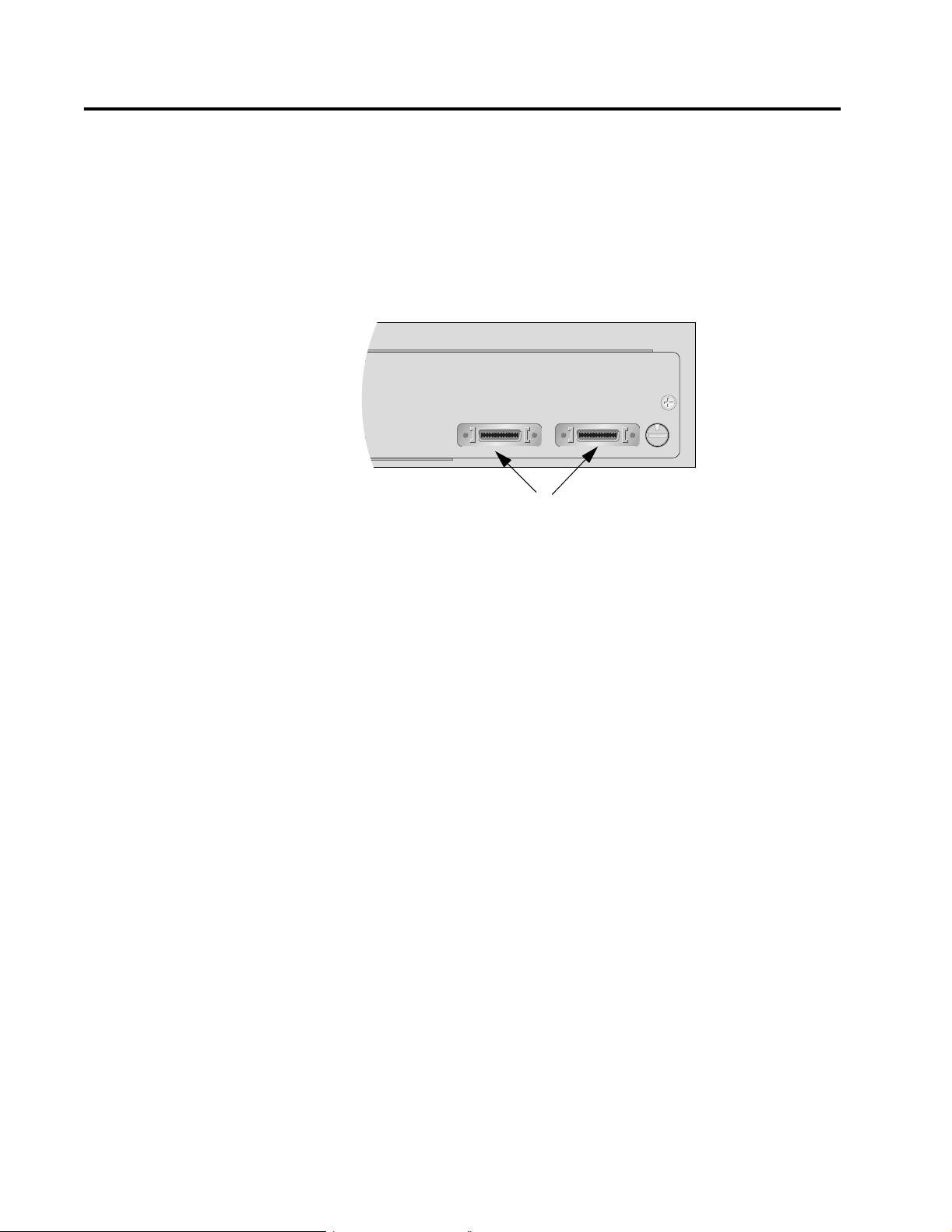

On the back of the switch are two stacking ports (Figure 1-7). The

ports are used to interconnect AT-8316F and AT-8324 switches to

form logical switches. A logical switch consists of two or more

individual switches that function as one unit. This feature allows you

to build a switch that is customized to the needs and requirements of

your network. It also makes it easier to manage them since, rather

than having to mange the switches individually, you can manage all

the switches as one unit.

Stacking Ports

Figure 1-7 Stacking Ports

Interconnecting two or more AT-8316F or AT-8324 switches creates

what is referred to as a stack. A stack can consist of either the same

type of Ethernet switches or different types of switches. For example,

a stack can consist of a combination of AT-8316F/MT and AT-8324

switches. The result would be one logical switch, where the

individual switches themselves were different in the number and

types of ports.

Each stacking port provides two gigabits of full-duplex bandwidth

between switches. A stack of two or three switches does not require

any additional hardware other than the switches and the

AT-CABLE-4 cables that comes with the units. Creating a stack of four

to eight switches requires the optional AT-Stack8 Stacking Matrix

Module.

19

Page 20

Hardware Description

STACK ID

1

Stacking Module Expansion Slot

The stacking module expansion slot on the back panel of the switch

is for the optional AT-Stack8 Stacking Matrix Module. This module

allows you build a logical switch of up to eight switches.

Stack ID Switch

Next to the stacking ports on the back panel of the switch is the Stack

ID switch (shown in Figure 1-8). You use this switch when you build a

stack to assign each switch a unique identification number.

IS-A IS-B

STACK ID

0

Figure 1-8 Stac k ID Switch

Note

While the Stack ID switch has the range of settings of 0 to 9, only

settings 1 through 8 are valid settings. Settings of 0 and 9 are

invalid and should not be used. For information on setting this

switch, refe r t o Chapter 3, Installing the Switch .

20

Page 21

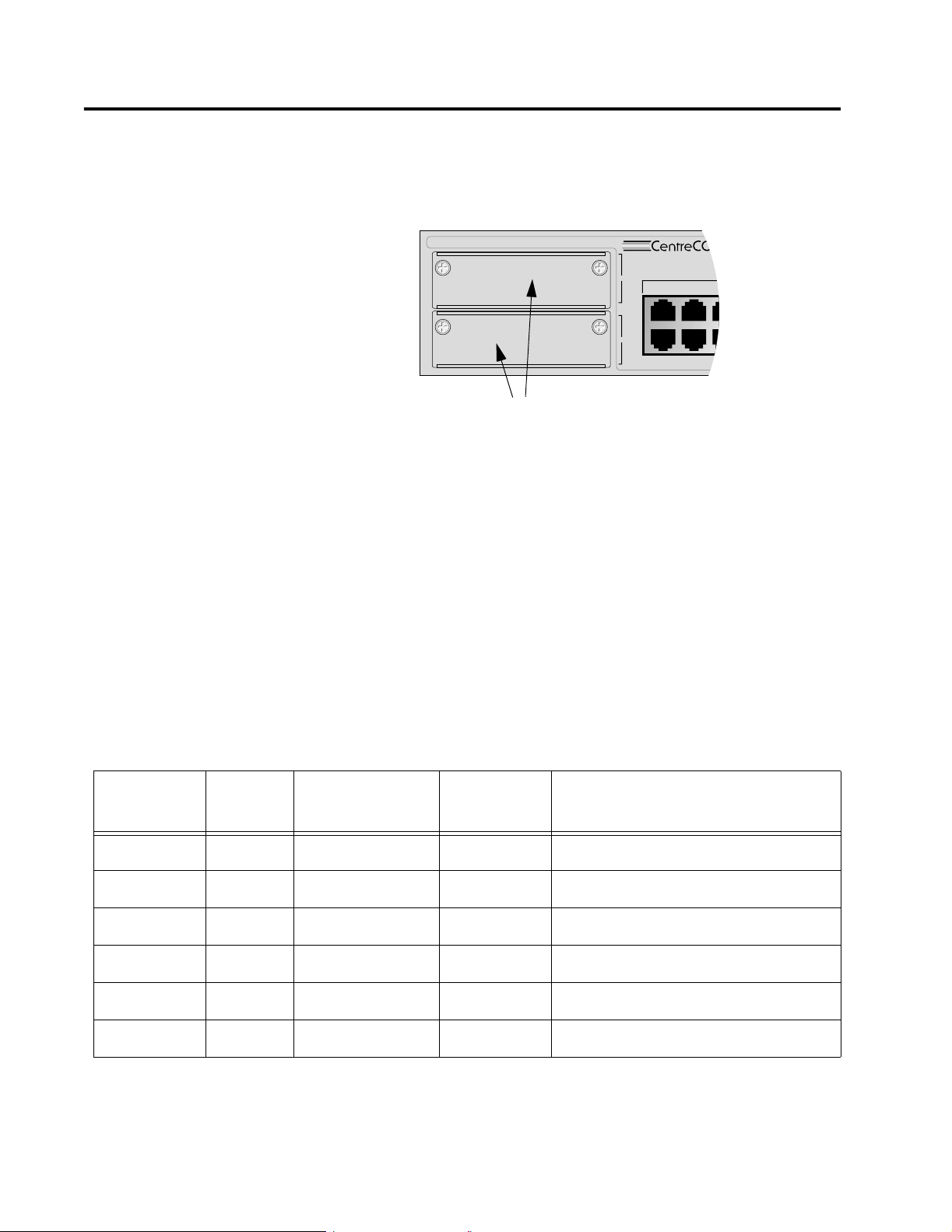

Expansion Module Slots

10BASE-T / 100BASE-TX

FAST ETHERNET SWITCH

1X 3X

2X 4X

A

B

The capabilities of the AT-8316F and AT-8324XL Ethernet switches

can be expanded by installing optional expansion modules in the

two expansion slots on the front of the switches (shown in Figure

1-9).

The modules offer you flexibility in building or expanding your

network. For example, you can use the modules to build a highspeed backbone network between different switches, to expand the

number of ports on a switch for additional nodes, or to provide a

high-speed connection to shared devices, such as servers or routers.

AT-8316F and AT-8324 Installation Guide

Expansion Slots

Figure 1-9 Expansion Slot s

Optional

Expansion

Modules

Table 1-4 lists the optional expansion modules for the AT-8316F and

AT-8324 Ethernet switches. The modules can be installed in any

combination in the switch. For example, you can install an AT-A15/LX

module in one expansion slot and an AT-A18 module in the second

expansion slot of the same switch.

Table 1-4 Optional Expansion Modules

Module

Number

of Ports

Type of Port

AT-A15/SX 1 1000Base-SX SC 550 meters

Type of

Connector

Maximum Distance

1

(1,804 feet)

AT-A15/LX 1 1000Base-LX SC 10 kilometers2 (6.2 miles)

AT-A16 2 100Base-FX VF-45 2 kilometers3 (6,600 feet)

AT-A17 2 100Base-FX SC 2 kilometers3 (6,600 feet)

AT-A18 4 10/100Base-TX RJ-45 100 meters (328 feet)

AT-A19 2 100Base-FX MT-RJ 2 kilometers

1. Assumes 50/125 micron multimode fiber optic cabling.

2. Assumes 9/125 micron single-mode fiber optic cabling.

3. Assumes 50/125 micron or 62.5/125 micron multimode fiber optic cabling and full-duplex operation.

3

(6,600 feet)

21

Page 22

Hardware Description

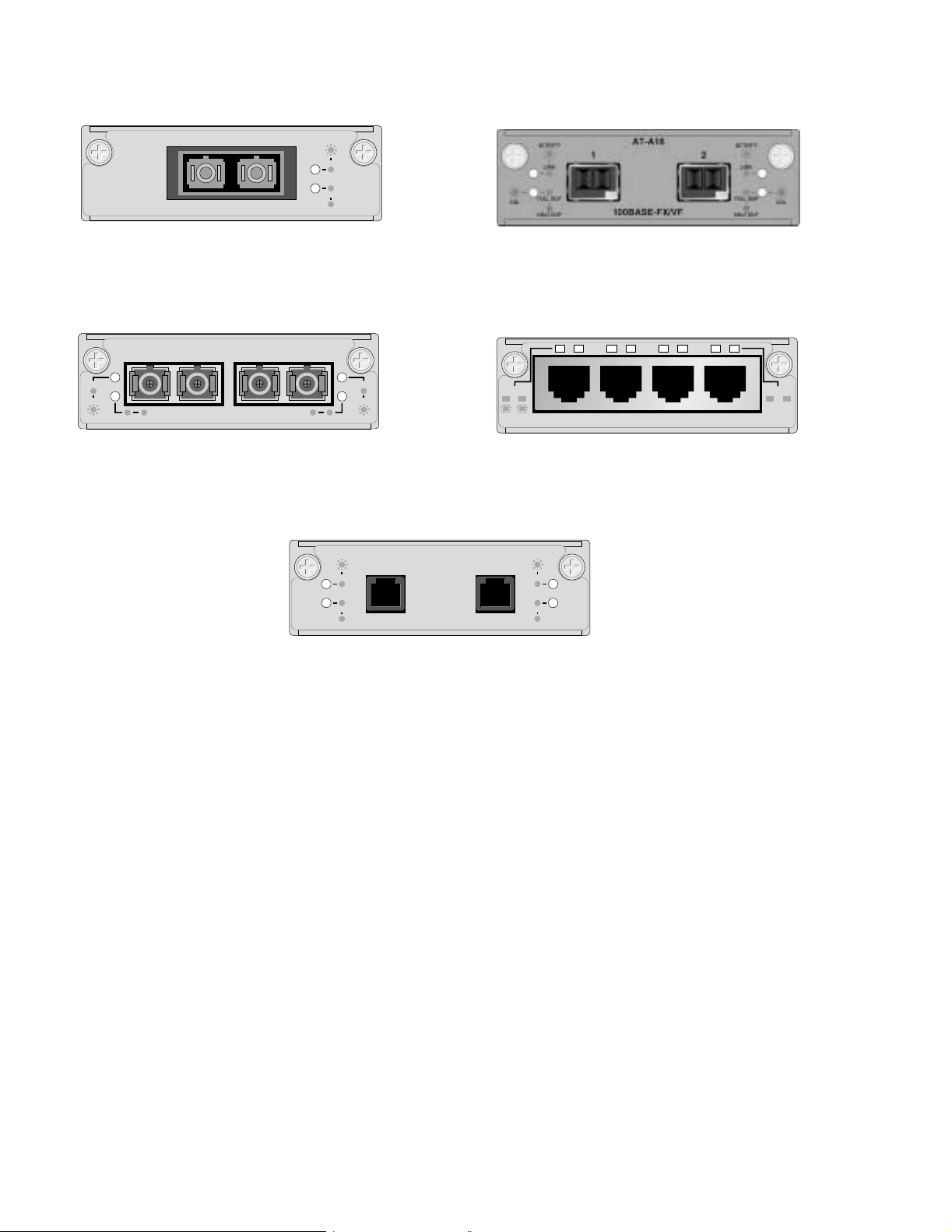

Figure 1-10 illustrates the front panels of the expansion modules.

LINK

ACTIVITY

AT-A15

1000BASE-X

AT-A15 (SX or LX)

AT-A17

RXTX RXTX

100BASE-FX/SC

AT-A17

ACTIVITY

LINK

FULL

HALF

AT-A16

2X 3X 4X1X

LINK

ACTIVITY

FULL HALFFULL HALF

100M

LINK

ACTIVITY

10M

LINK

AT-A18

10BASE-T/100BASE-TX

FULL

DUPLEX

HALF

DUPLEX

AT-A18

ACTIVITY

LINK

AT-A19

ACTIVITY

LINK

FULL

HALF

100BASE-FX/MT

FULL

HALF

AT-A19

Figure 1-10 Optional Expansion Modules

22

Page 23

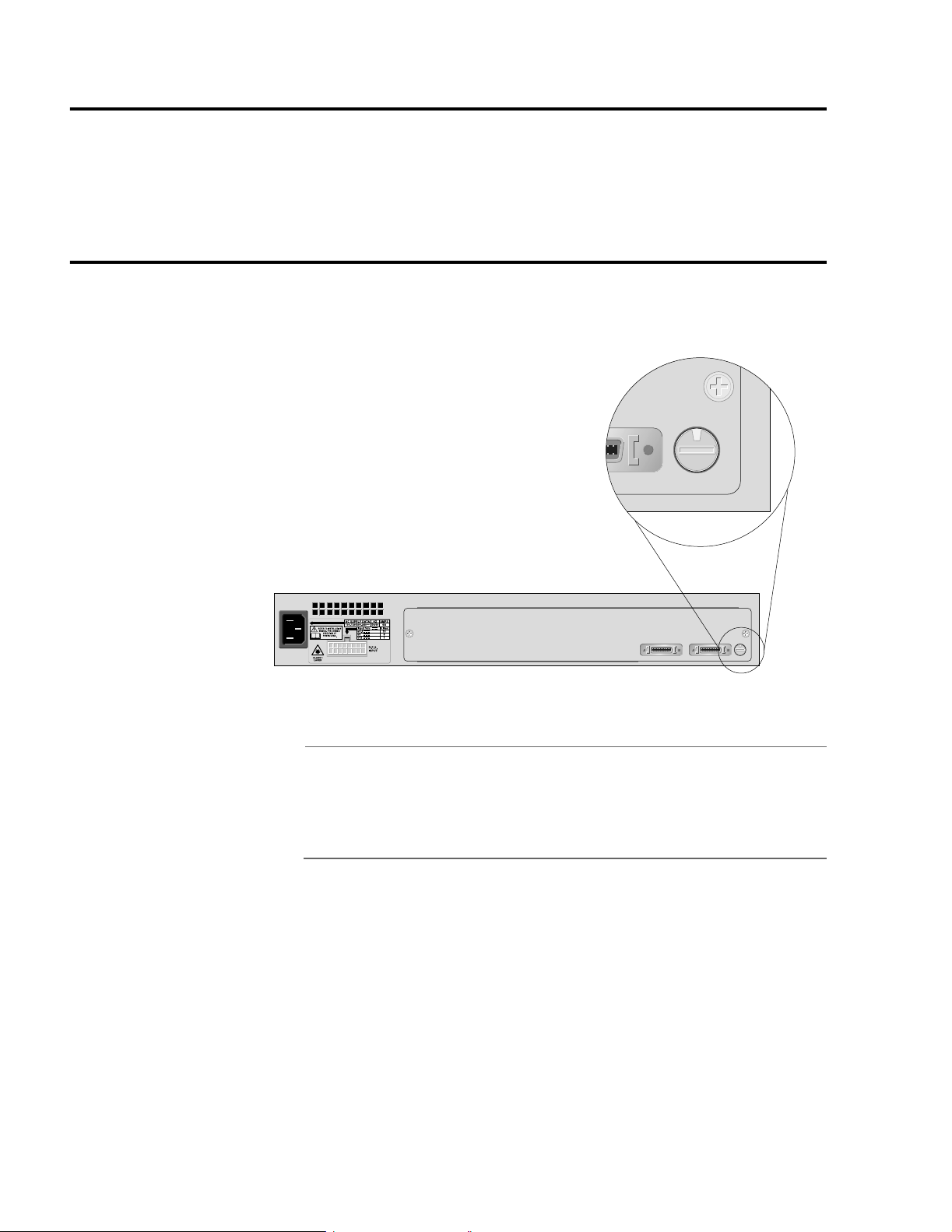

R.P.S Input Connector

On the back panel of the Ethernet switch is a connector labelled

R.P.S. Input (shown in Figure 1-11). This connector is used to connect

the switch to a redundant power supply (RPS) unit. The RPS shares

the load of powering the switch with the standard power supply that

comes with the Ethernet switch. If one power supply fails, the

remaining unit provides all power to the switch, thus protecting the

switch from a system failure.

AT-8316F and AT-8324 Installation Guide

R.P.S Input Connector

Figure 1-11 R.P.S Input Connector

Allied Telesyn offers the AT-RPS8000 redundant power supply

system for the AT-8316F and AT-8324 switches. The RPS system

comes with one redundant power module pre-installed that can

support one Ethernet switch. The AT-RPS8000 unit has three

expansion slots for three additional redundant power modules, each

of which can support an additional switch. Contact your Allied

Telesyn representative for more information about the AT-RPS8000

redundant power supply unit.

23

Page 24

Hardware Description

Reset Button

The Reset button on the front panel of the switch resets the switch. It

is primarily used for diagnostics or resetting the switch statistics

stored by the AT-S25 management software. You can also reset the

switch using the Omega management interface, as explained in the

AT-S25 Management Software User’s Guide. This guide is

available from the Allied Telesyn web site at www.alliedtelesyn.com/

techhome.htm.

Note

If it becomes necessary to reset a switch that is a part of a stack, you

must reset all of the switches in the stack. You cannot reset just one

switch in a stack. Additionally, you should reset the slave switches

first, then the master switch. For information on slave and master

switches, refer to Chapter 3, Installing the Switch.

24

Page 25

AT-8316F and AT-8324 Installation Guide

AC Power Connector

The switch has a single AC power supply socket on the back panel,

which has autoswitch AC inputs. The input voltage range is from

100-120/200-240 VAC, 4/2A, 50/60 Hz. The power cord acts as an ON/

OFF switch.

AT-S25 Management Software and Omega Management Interface

The AT-S25 software is the management program for the switch, and

it comes pre-installed on the unit. Included with the AT-S25 software

is the Omega management interface. This menu oriented interface

makes it easy for you to manage the system. With Omega, you can

perform all of the tasks necessary to configuring and monitoring the

system, such as creating VLANs, assigning operational parameters to

the switch, such as an IP address and gateway address, and viewing

switch statistics, all through menu selections and easy-to-use

windows.

In a network environment where you have created a stack of

Ethernet switches, you will use the Omega management interface to

manage all of the switches in the stack as a unit, that is, as one logical

switch. You will not manage each switch in a stack separately.

There are several different methods for accessing the Omega

management interface on an Ethernet switch:

# RS-232 connector on the switch

# Web browser

# Telnet program

# SNMP network management program

The Omega interface functions the same and has the same

capabilities regardless of the method you choose to access it. The

program has security features that allow you to disable one or more

of the access methods to prevent unauthorized access to a switch.

The program also has a password security feature.

Note

For instructions on how to access and how to use the Omega

management interface, refer to the AT-S25 Management

Software User’s Manual. This guide is available from the Allied

Telesyn web site at www.alliedtelesyn.com/techhome.htm.

25

Page 26

Hardware Description

Network Topology

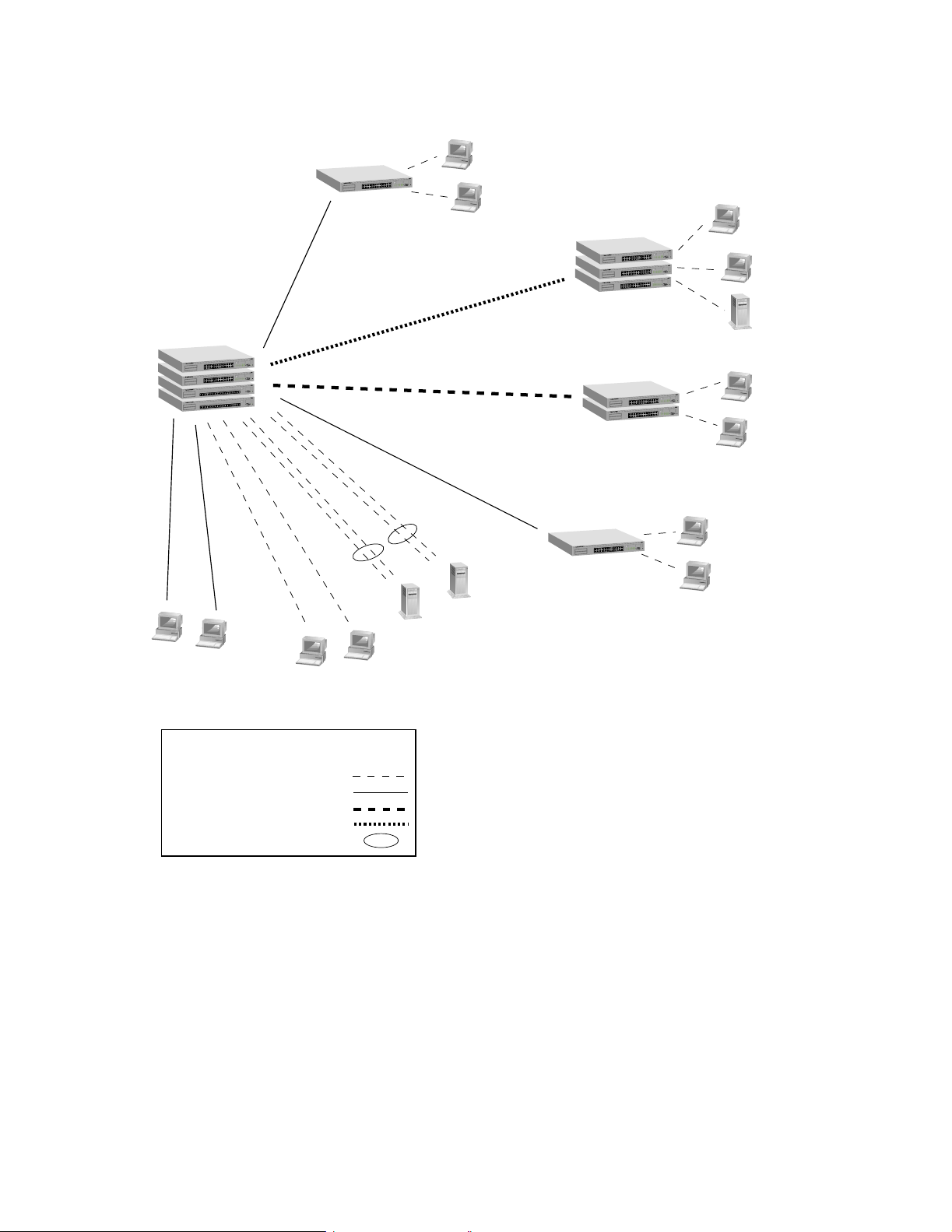

Figure 1-12 is an example of a network consisting of AT-8316F and

AT-8324 Ethernet switches. Some of the features of the network

include the following:

# Though the Sales and Technical Support workgroups are

distributed between several sites, the 802.1Q VLAN

capabilities of the switches allow you to easily separate their

traffic, improving network performance and enhancing

network security as well.

# The stack of four switches at site 1 are interconnected with an

AT-Stack8 stacking module.

# Port trunking at site 1 provides 200 Mbps of full-duplex

operation to the network servers in the server farm.

# Expansion modules in the switches provide interconnections

between the various sites. For example, site 1 and site 2 each

have AT-A15/LX expansion modules to provide 1000Base-LX

performance up to a maximum distance of 10 kilometers (6.2

miles).

26

Page 27

Site 1:

AT-8324 and

AT-8316F

stack

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

X

T

-

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

X

T

E

S

A

B

0

0

1

/

T

-

X

E

T

S

-

A

E

B

S

0

A

1

B

0

H

0

C

1

T

/

I

T

W

-

S

E

T

S

E

A

N

B

R

0

E

1

H

T

E

T

S

A

F

X

T

E

S

A

B

0

0

1

/

T

-

X

E

T

S

-

A

E

B

S

0

A

1

B

0

H

0

C

1

T

/

I

T

W

-

S

E

T

S

E

A

N

B

R

0

E

1

H

T

E

T

S

A

F

AT-8316F and AT-8324 Installation Guide

Site 2:

AT-8224XL switch

Y

T

I

V

I

T

C

A

T

R

O

P

X

T

E

S

A

0B

0

/ 1

T

-

E

S

A

B

0

1

X

T

E

S

A

B

0

0

1

/

T

-

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

R

E

T

Technical

Support

workgroup

Site 3:

AT-8324 stack

F

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

X

T

E

S

A

B

0

0

1

/

T

-

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

IN

M

Y

R

T

E

I

T

V

I

T

C

A

T

R

O

P

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

IN

M

Y

R

T

E

I

T

IV

T

C

A

T

R

O

P

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

R

E

T

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

IN

M

R

E

T

Site 4:

AT-8324 stack

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

Y

R

T

E

I

T

IV

T

C

A

T

R

O

P

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

Y

R

T

E

I

T

IV

T

C

A

T

R

O

P

X

T

-

E

S

A

B

0

0

1

/

T

-

E

S

A

B

0

1

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

Y

R

T

E

I

T

V

I

T

C

A

T

R

O

P

X

T

E

S

A

B

0

0

1

/

T

-

E

S

A

B

0

1

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

Y

R

E

IT

T

V

I

T

C

A

T

R

O

P

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

Production

workgroup

Sales

workgroup

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

Y

R

T

E

I

T

V

I

T

C

A

T

R

O

P

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

Site 5:

AT-8224XL switch

S

U

T

A

T

S

2

3

2

S

R

T

R

O

P

L

A

N

I

M

Y

R

T

E

I

T

V

I

T

C

A

T

R

O

P

X

T

E

S

A

B

0

0

1

/

T

E

S

A

B

0

1

X

T

E

S

A

B

0

0

1

/

T

-

E

S

A

B

0

1

H

C

T

I

W

S

T

E

N

R

E

H

T

E

T

S

A

F

Technical

Support

workgroup

Engineering

workgroup

Legend

10Base-T/100Base-TX link

100Base-FX link

1000Base-SX link

1000Base-LX link

Port trunk

Sales

workgroup

Figure 1-12 Topology Example

27

Page 28

Hardware Description

Where to Go Next

Proceed to Chapter 2 for information on how to plan the installation.

28

Page 29

Chapter 2

Planning the Installation

This chapter contains information that will help you plan the

installation of the switch. The information includes:

# AT-8316F and AT-8324 Switch Cabling Specifications

# Switch stacks

# Expansion Modules

# Port Trunking

29

Page 30

Planning the Installation

AT-8316F and AT-8324 Switch Cabling Specifications

Table 2-1 contains the cabling specifications for the data ports on the

switches.

Table 2-1 Switch Cabling Specifications

Model Type of Cabling Maximum Distance

AT-8316F

(models MT, VF, and SC)

50/125 micron multimode or

62.5/125 micron multimode

AT-8324 10Base-T operation:

Category 3 or better

100Base-TX operation:

Category 5 or better

Note

To connect a workstation or server to a twisted pair port on an

AT-8324 switch, use a straight-through cable. To connect a hub,

router, or other switch to a twisted pair port on the AT-8324 switch,

use a crossover cable.

Full-duplex:

2 kilometers (1.25 miles)

Half-duplex:

412 meters (1,351 feet)

100 meters (328 feet)

100 meters (328 feet)

30

Page 31

Switch Stacks

AT-8316F and AT-8324 Installation Guide

On the back panel of the Ethernet switches are two stacking ports.

You use these ports to interconnect switches together to create a

stack. A stack of switches functions as one logical switch, rather than

as individual units.

A stack can consist of from two to eight switches. As explained in the

following sections, building a stack or two or three switches does not

require any additional hardware. A stack of from four to eight

switches requires the optional AT-St ac k8 module.

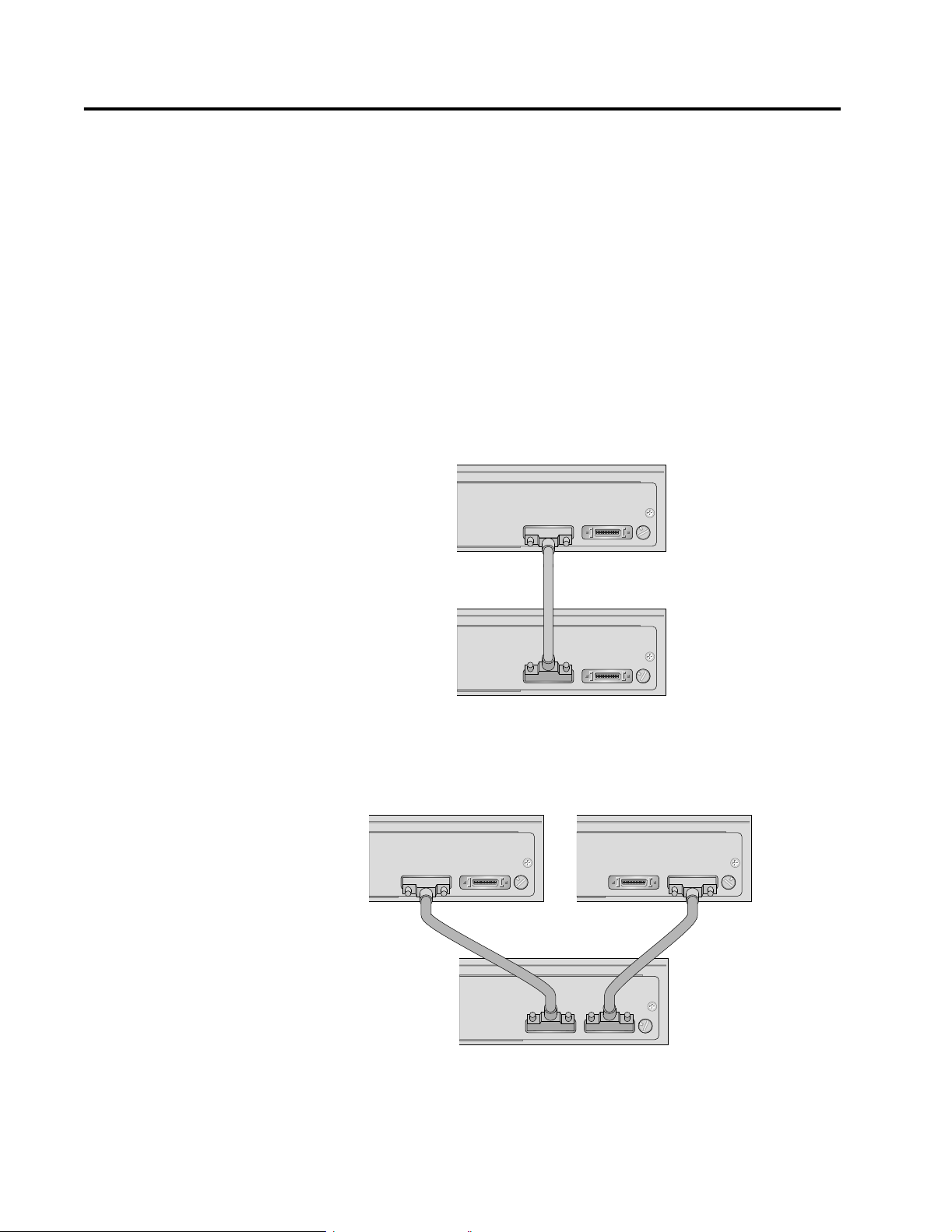

Stack of Two or

Three Switches

Creating a stack of two or three Ethernet switches requires no

additional hardware other than the AT-CABLE-4 cable that comes

with the switches. Figure 2-1 illustrates two Ethernet switches that

have been interconnected through the stacking ports to form a

logical switch.

IS-A IS-B

IS-A IS-B

STACK ID

STACK ID

2

0

1

Figure 2-1 Stack of Two Ethernet Switches

Creating a stack of three switches also does not require any

additional hardware, as illustrated in Figure 2-2.

IS-A IS-B

STACK ID

0

2

IS-A IS-B

IS-A IS-B

STACK ID

0

1

Figure 2-2 Stack of Three Ethernet Switches

STACK ID

0

3

31

Page 32

Planning the Installation

Stack of Four to

Eight Switches

In order to create a stack of from four to eight AT-8316F or AT-8324

Ethernet switches, you need the optional AT-Stack8 Stacking Matrix

Module (show in Figure 2-3). This module has eight ports, each

providing two gigabits of full-duplex bandwidth. Each stack requires

only one stacking module. You install the module into one of the

switches of the stack and then connect all of the switches to the

module using the AT-CABLE-4 cables.

8

K

C

A

T

-S

T

A

1

S

T

R

O

P

K

C

A

T

S

6

2

7

3

8

4

A

-

IS

5

D

I

K

C

A

T

S

B

-

IS

Figure 2-3 AT-Stack8 Stacking Matrix Module

32

Page 33

Expansion Modules

AT-8316F and AT-8324 Installation Guide

If you are building a stack of Ethernet switches, it is important to

know that the more switches in the stack, the fewer number of

expansion modules allowed. (This relates to the number of device

identification numbers that are available to the switches.)

Table 2-2 lists the number of expansion modules that you can install

in stacks of one to eight switches. For example, for a stack of six

switches you could install a total of eight expansion modules. The

expansion modules themselves can be installed in any switch in a

stack, and in any order.

Table 2-2 Permitted Number of Expansion Modules

Number of Switches

in the Stack

Total Number of

Expansion Slots in

the Stack

Permitted Number of

Expansion Modules

122

244

366

488

51010

6128

7144

8160

33

Page 34

Planning the Installation

Table 2-3 contains the cabling specifications for the expansion

modules.

Table 2-3 Expansion Module Cabling Specifications

Model Type of Cabling

1

Maximum Distance

AT-A15/SX 50/125 micron multimode fiber 550 meters2 (1,804 feet)

62.5/125 micron multimode fiber 275 meters (902 feet)

3

AT-A15/LX 9/125 micron single-mode fiber 10 kilometers (6.2 miles)

50/125 micron or 62.5/125 micron

550 meters (1,804 feet)

multimode fiber

AT-A16 50/125 micron or 62.5/125 micron

multimode fiber

Full-duplex:

2 kilometers (1.25 miles)

Half-duplex:

412 miles (1,351 feet)

AT-A17 50/125 micron or 62.5/125 micron

multimode fiber

Full-duplex:

2 kilometers (1.25 miles)

Half-duplex:

412 meters (1,351 feet)

2

AT-A18 10Base-T operation:

Category 3 or better

100Base-TX operation:

Category 5 or better

AT-A19 50/125 micron or 62.5/125 micron

multimode fiber

1. Refer to the IEEE 802.3 Standard for additional cable information.

2. Assumes a fiber optic cable rating of 500 Mhz/Km.

3. Assumes a fiber optic cable rating of 200 Mhz/Km

100 meters (328 feet)

100 meters (328 feet)

Full-duplex:

2 kilometers (1.25 miles)

Half-duplex:

412 meters (1,351 feet)

34

Page 35

Port Trunking

AT-8316F and AT-8324 Installation Guide

As explained in Chapter 1, port trunking, also referred to as “link

aggregation,” is an economical way for you to increase the

bandwidth between an AT-8316F or AT-8324 switch and another

network device, such as a server, router, workstation, or another

switch. A port trunk is two or more data ports that have been

grouped together to increase the bandwidth between a switch and a

network node. This increase in bandwidth can prove useful in

situations where a single connection between the switch and

another node is insufficient to handle the traffic load.

When ports are trunked together, they act as one logical path. The

increase in bandwidth is equal to the port speed times the number of

ports trunked together. For example, if you were to trunk together

four 100 Mbps ports, the result would be 400 Mbps of bandwidth.

The AT-8316F and AT-8324 switches allow you to trunk together two,

four, or eight ports, providing 200 Mbps, 400 Mbps, or 800 Mbps of

throughput. You can also trunk the ports on an expansion module to

increase the bandwidth from an expansion module to another

network device.

Guideline 1:

Number of

Ports in a Trunk

Guideline 2:

Using Ports

from the Same

Group

When implementing a port trunk, you will need to observe the

following guidelines:

The number of ports in a port trunk must be 2, 4, or 8 ports.

The ports on the Ethernet switches are divided into groups. When

choosing ports for a port trunk, the selected ports must be members

of the same group. You cannot create a port trunk consisting of ports

from different groups.

The ports on an AT-8324 switch are divided into five groups, as

illustrated in Figure 2-4.

10BASE-T / 100BASE-TX

FAST ETHERNET SWITCH

Group D

Group E

A

1X 3X 5X 7X

B

2X 4X 6X 8X

Group A

Ports 1 to 8

10BASE-T / 100BASE-TX

9X 11X 13X 15X

10X 12X 14X 16X

Group B

Ports 9 to 16

17X 19X 21X 23X

18X 20X 22X 24X

Group C

Ports 17 to 24

PORT ACTIVITY

L/A

100M LINK / ACTIVITY 10M LINK / ACTIVITY

D/C

HALF DUP/

FULL DUP

1234567891011121314151617181920212223

L/A

D/C

L/A

D/C

COL

STATUS

RS-232

TERMINAL PORT

FAULT

MASTER

RPS

PWR

24

RESET

Figure 2-4 Port Groupings on an AT-8324 Switch

35

Page 36

Planning the Installation

The ports on the AT-8316/MT and AT-8316/VF switches are divided

into four groups, as shown in Figure 2-5.

100BASE-FX FAST ETHERNET SWITCH

A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

B

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

D/C

D/C

D/C

100BASE-FX

L/A

L/A

L/A

L/A

L/A

L/A

D/C

D/C

D/C

D/C

D/C

D/C

L/A

L/A

L/A

D/C

D/C

PORT ACTIVITY

L/A

ACTIVITY

100M LINK

D/C

FULL DUP

HALF DUP/ COL

L/A

L/A

D/C

D/C

D/C

RS-232

TERMINAL PORT

STATUS

FAULT

MASTER

RPS

PWR

RESET

Group C

Group D

Group A

Ports 1 to 8

Group B

Ports 9 to 16

Figure 2-5 Port Groups on an AT-8316F/MT or AT-8316/VF Switch

The ports on the AT-8316/SC switch also are divided into four

groups, as shown in Figure 2-6.

Group A

Ports 1 to 8

Group C

Group D

A

B

100BASE-FX FAST ETHERNET SWITCH

L/A

D/C

L/A

D/C

L/A

D/C

L/A

D/C

100BASE-FX

L/A

L/A

D/C

D/C

L/A

L/A

D/C

D/C

Group B

Ports 9 to 16

87654321

L/A

L/A

L/A

D/C

D/C

L/A

L/A

D/C

D/C

L/A

D/C

D/C

RXTXRXTXRXTXRXTXRXTXRXTXRXTXRXTX

161514131211109

L/A

L/A

D/C

D/C

RXTXRXTXRXTXRXTXRXTXRXTXRXTXRXTX

L/A

LINK / ACTIVITY

FULL DUP /

D/C

HALF DUP

COL

TERMINAL PORT

FAULT

MASTER

RPS

PWR

RESET

STATUS

RS-232

PORT ACTIVITY

Figure 2-6 Port Groups on an AT-8316F/SC Switch

As mentioned previously, the ports for a port trunk must be

members of the same group. A port trunk cannot consist of ports

from different groups. For example, you could use ports 4 and 5 on

an AT-8324 switch as one port trunk, and this would be valid since

the ports are members of the same group. However, ports 7, 8, 9, and

10 cannot be combined to form one port trunk on an AT-8324 switch

because these ports belong to different groups.

Guideline 3:

Creating Only

One Trunk Per

Group

Guideline 4:

Using

Consecutive

Ports

36

Each group of ports on an Ethernet sw itch can suppo rt only one po rt

trunk. For example, the AT-8324 Ethernet switch has three port

groups, assuming no expansion modules. Consequently, this switch

can support three port trunks, one port trunk for each port group.

The addition of two expansion modules would enable the switch to

support two additional port trunks, one for each module.

The ports of a trunk must be consecutive. For example, you could use

ports 4, 5, 6, and 7 as one port trunk, and this would be valid because

the ports are consecutive. However, an invalid selection of ports for a

trunk would be 1, 3, 5, and 7 since these ports are not consecutive.

Page 37

AT-8316F and AT-8324 Installation Guide

Guideline 5:

Cabling Based

on Port Number

Guideline 6:

Using

Expansion

Modules

When cabling a trunk, it is important that the order of the

connections be identical on both nodes. The lowest numbered port

in a trunk must be connected to the lowest numbered port on the

trunk on the other device, the next lowest numbered port must be

connected to the next lowest numbered port on the other device,

and so on.

For example, assume that you were installing a trunk from an

AT-8316F/SC switch to an AT-8324 switch. On the AT-8316F/SC

switch you had decided to use ports 12, 13, 14, 15 from port group

two for the trunk. On the AT-8324 switch you had chosen ports 21,

22, 23, and 24 from port group 3. To maintain the order of the port

connections, you would connect port 12 on the AT-8316F/SC switch

to port 21 on the AT-8224XL, port 13 to port 22, and so on.

Expansion modules also support port trunking. That is, you can

group the ports on an expansion module together to increase the

bandwidth to the end-node, whether that happens to be another

switch, a server, or router. Table 2-4 lists the number of port trunks

that you can create for each expansion module.

Table 2-4 Trunked Ports on Expansion Modules

Model of Expansion Module Trunked Ports

AT-A15 (SX or LX) 0

AT-A16 2 ports

AT-A17 2 ports

AT-A18 2 or 4 ports

AT-A19 2 ports

37

Page 38

Planning the Installation

Where to Go Next

Go to Chapter 3 for instructions on how to install the switch as a

standalone unit or as part of a stack.

38

Page 39

Chapter 3

Installing the Switch

This chapter describes the following installation procedures:

# Verifying the Package Contents

# Reviewing Safety Precautions

# Selecting a Site for the Switch

# Installing the Switch as a Standalone Unit

# Installing the Switch in a Rack

# Building a Stack of Two Switches

# Building a Stack of Three Switches

# Building a Stack of Four to Eight Switches

# Setting Up a Terminal for Local Management

# Modifying an Existing Stack

# Installing an Expansion Module

39

Page 40

Installing the Switch

Verifying the Package Contents

Make sure the following hardware components are included in your

switch package. If any of the following items are missing or

damaged, contact your Allied Telesyn sales representative.

# One AT-8316F/MT, AT-8316F/VF, AT-8316F/SC, or AT-8324

switch

# Two mounting brackets

# Six flathead Phillips screws

# Power cord (Americas, EC, Australia, and UK only)

# One AT-CABLE-4 cable

# One AT-8316F/MT, AT-8316F/VF, AT-8316F/SC, and AT-8324

Quick Install Guide

# Warranty card

40

Page 41

Reviewing Safety Precautions

Please review the following safety precautions before you begin to

install the switch in your network. Refer to Appendix A for translated

safety statements in your language.

Laser

Class 1 laser product. " 6

Laser

Do not stare into the laser beam. " 7

Caution

Electric Shock Hazard: To prevent electric shock, do not remove

the cover. There are no user-serviceable parts inside. The unit

contains hazardous voltages and should only be opened by a

trained and qualified technician. " 8

Caution

Lightening Danger: Do not work on this equipment or cables

during periods of lightening activity. " 9

AT-8316F and AT-8324 Installation Guide

Caution

Power cord is used as a disconnection device: To de-energize

equipment, disconnect the power cord. " 10

Caution

Electrical-Type Class 1 Equipment: This equipment must be

earthed. The power plug must be connected to a properly wired

earth ground socket outlet. An improperly wired socket outlet

could place hazardous voltages on accessible metal parts. " 11

Caution

Pluggable Equipment: The socket outlet should be installed near

the equipment and should be easily accessible. " 12

Caution

Air vents: The air vents must not be blocked on the unit and must

have free access to the room ambient air for cooling. " 13

Caution

Operating Temperature: This product is designed for a maximum

ambient temperature of 40°C. " 14

Caution

All Cou ntries: Install this product in accordance with local and

National Electric Codes. " 15

41

Page 42

Installing the Switch

Selecting a Site for the Switch

Be sure to observe the following requirements when choosing a site

for your switch:

# Make sure that the switch’s power is accessible and cables can

be connected easily.

# Cabling must be away from sources of electrical noise such as

radios, transmitters, broadband amplifiers, power lines,

electric motors, and fluorescent fixtures.

# Air flow around the switch and through its vents on the side

and rear must not be restricted.

# If you are installing the switch on a desk, make sure it is placed

on a level, secure desktop.

# Do not place objects on top of the switch.

# Do not expose the switch to moisture or water.

# Make sure it is in a dust-free environment.

# Use dedicated power circuits or power conditioners to supply

reliable electrical power to the network devices.

Having selected a site to install the switch, go to one of the following

procedures:

# Installing the Switch as a Standalone Unit on page 3-43

# Building a Stack of Two Switches on page 3-46

# Building a Stack of Three Switches on page 3-49

# Building a Stack of Four to Eight Switches on page 3-52

42

Page 43

Installing the Switch as a Standalone Unit

This section contains the procedure for installing an AT-8316F or

AT-8324 switch as a standalone unit (not as part of a stack). To install

the switch as a standalone unit, perform the following steps:

1. Remove all components from their shipping package and store

the packaging material in a safe location.

2. Locate a level, secure surface for the switch.

3. If you purchased an expansion module for a switch, install the

module by performing the procedure Installing an Expansion

Module on page 3-60.

4. If you want to install the switch in a rack, perform the procedure

Installing the Switch in a Rack on page 3-45.

5. Apply AC power to the switch by plugging the power cord into

the AC power connector on the back panel of the unit (shown in

Figure 3-1) and plugging the other end into a wall outlet.

AT-8316F and AT-8324 Installation Guide

IS-A IS-B

IS-A IS-B

R.P.S. Input Connector

AC Power Connector

Figure 3-1 AT-8316F and AT-8324 Ethern et Switch Rear Panel

Caution

The power cord is used as a disconnect device. To de-energize

equipment, disconnect the power cord. "10

STACK ID

STACK ID

0

0

43

Page 44

Installing the Switch

As power is applied to the switch, the Fault LED (shown in

Figure 3-2) flashes as the switch runs a series of internal self

tests. After the switch has finished running its self tests, the

Fault LED will stop flashing and will remain OFF.

RS-232

TERMINAL PORT

STATUS

FAULT

MASTER

RPS

PWR

Fault LED

RESET

Figure 3-2 Fault LED

For information on all the switch LEDs, refer to the section

Switch LEDs on page 1-16.

6. If you purchased a redundant power supply (RPS) unit for the

Ethernet switch, connect the RPS unit to the R.P.S. Input

connector on the rear of the switch by following the directions

included with the RPS system.

Caution

If you intend to use a redundant power supply (RPS) with the

switch, check to be sure that the cable with the RPS unit is

compatible with the RPS Input Port on the switch. The pin

assignments for the port are provided in Appendix B.

44

7. Connect the data cables to the ports on the switch.

8. Go to the procedure Setting Up a Terminal for Local

Management on page 3-59 to access the Omega management

software on the switch.

Page 45

Installing the Switch in a Rack

To install the Ethernet switch in a standard 19-inch rack, perform the

following steps:

1. Remove all components from the shipping package and store the

packaging material in a safe location.

2. Locate a level, secure surface for the switch.

3. Remove the snap-on plastic feet from the bottom of the switch, as

shown in Figure 3-3.

AT-8316F and AT-8324 Installation Guide

Figure 3-3 Removing the Feet

4. Attach the rackmounting brackets to each side of the switch,

using the six flathead screws that came in the switch package as

shown in Figure 3-4.

M

IR

R

O

R

P

O

R

T

LINK

X

R

S

T

-2

E

R

3

2

M

IN

A

L

P

O

R

T

S

T

A

T

U

S

F

A

U

L

T

M

A

S

T

E

R

R

P

S

P

W

R

R

E

S

E

T

Figure 3-4 Attaching Rackmounting Brackets

Caution

Air vents must not be blocked and must have free access to the

room ambient air for cooling. " 13

5. Mount the switch in the rack using standard screws (not

provided).

45

Page 46

Installing the Switch

Building a Stack of Two Switches

To build a stack of two switches, perform the following steps:

1. Select one of the Ethernet switches to be the master switch of the

stack. The other switch will be slave switch. In selecting the master

switch, follow these guidelines:

# The master switch can be either an AT-8316F or AT-8324

switch.

# If the two switches have different versions of the AT-S25 agent

software, select the switch that has the most recent version of

the AT-S25 software as the master switch.

Note

During network operations, the master switch will overwrite the

AT-S25 software in the slave switches with its own version of the

management software. This occurs even if a slave switch contains a

more recent version of the AT-S25 software. For this reason, it is

important that the switch you select to be the master switch have

the most recent version of the management software of all the

switches in the stack.

2. Remove all components from the shipping package and store the

packaging material in a safe location.

3. Locate a level, secure surface for the switches.

Note

If you are building a stack from existing AT-8316F and AT-8324

switches, power OFF the Ethernet switches. If the switches are

connected to an AT-RPS8000 redundant power supply unit, power

OFF the AT-RPS8000 unit using the ON/OFF switch on the back

panel of the unit.

4. If you purchased expansion modules for the switches, install the