Page 1

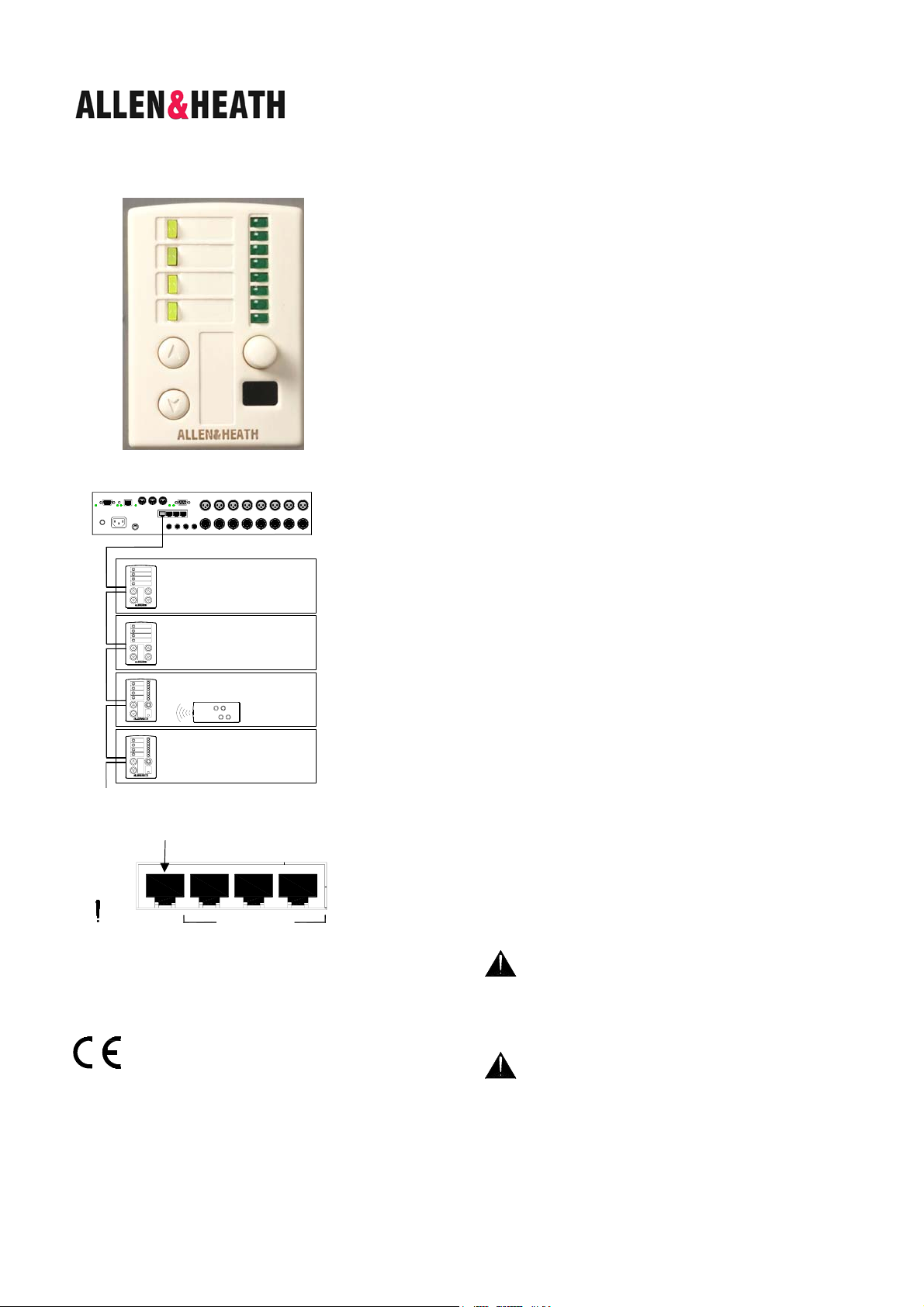

PL-4 Wall Plate AP5082

User Guide

Introduction The PL-4 is one of several remote control devices available

for the iDR audio mix processor system. It is part of the Allen & Heath PL

Series of wall plates and remote controllers. It is a wall plate or furniture

mounted module comprising plastic control panel and attached circuit

assembly. It can be mounted in a single unit wall box using a standard face

plate (UK, EU or US version supplied). A suitable template with cutting details

is provided for custom application. The PL-4 interfaces with the Allen & Heath

PL-Anet serial port. Multiple PL-4 units can be daisy chained together along

with other PL-Anet devices using CAT5 cable. For information on the full range

of PL products available visit http://www.idrseries.com. The wall plate control

and indicator functions are programmed using the iDR System Manager

software. Space is provided on the control panel for custom labelling. The PL-

4 is ideal as a wall mounted room remote controller in installed audio systems.

The installer can program the unit so that the non-technical operator has local

control of volume, mute, source select, and preset changes which reconfigure

the room for different functions, as well as the convenience of the PL-5 infra-

red remote controller.

2 switches can be assigned for level up or down control (input, output,

crosspoint or group), mute toggle, audio monitor select, or preset recall. 4

LED indicators can be assigned as audio meters (choice of 8x points in the

signal path), mute status, or as preset related static display. They can display

four states: off, green, yellow or red. Rotary control can be assigned as a

continuous level control (input, output, crosspoint or group). An 8 LED meter

bar displays the control position. Infra-red controller allows wireless local

control using the hand-held PL-5 remote controller. Each of the 14 keys on the

PL-5 can be assigned in the same way as the switches described above. The

PL-4 can be used without the IR controller. Custom labels Recessed areas

are provided for fitting custom adhesive labels. Recommended maximum label

sizes are 6x14mm and 26x9mm.

iDR

EXAMPLE

PL-Anet SERIAL PORT

PL-3

PL-3

ROOM 1

ROOM 2

PL-4

PL-4

TERMINATION

PL-ANET

CAUTION 20V DC

TO AVOID DAMAGE ONLY CONNECT

COMPATIBLE REMOTE CONTROL

EQUIPMENT TO THE PL-ANET PORT.

This product complies with the European

Electromagnetic Compatibility directives 89/336/EEC &

92/31/EEC.

NOTE: Any changes or modifications to the

equipment not approved by Allen & Heath could void

the compliance of the equipment. Whilst we believe

the information in this guide to be reliable we do not

assume responsibility for inaccuracies. We also reserve

the right to make changes in the interest of further

product development.

Copyright© 2004 Allen & Heath Ltd. All rights reserved.

ROOM 3

PL-5

ROOM 4

PL-5

DR-LINK AUDIO OUTAUDIO IN

DIGITAL EXPANDER

Number and addressing of devices The maximum number of

PL devices that can be connected depends on their type and the cable

lengths. Up to 12x PL-4 devices (more if using half speed scan) may be

connected in an iDR system, with or without the PL-9 hub. Fewer devices may

be connected if long distances or other PL types are also involved. To check

this refer to the PL Combinations Calculator spreadsheet available from our

web site. The iDR allocates the device addresses automatically per PL type in

the order they appear in the chain.

PL-Anet is the proprietary Allen & Heath system for daisy chaining remote

controllers. It is an RS485 serial connection that uses CAT5 STP cable to

communicate between devices over long distances. PL-Anet only works with

Allen & Heath PL devices. The connection includes +20V DC to power the

connected devices. The iDR-8 port is shown here.

IMPORTANT :

Observe the local standards which may apply

to the installation. To ensure operator safety

ensure that any exposed metal plates are correctly

bonded to ground. Do not install the equipment

where it is subject to moisture, heat or vibration.

Connect this equipment to the Allen & Heath

PL-Anet port only. Test for correct wiring and

installation before switching the equipment on.

NOTE: Do not install the PL-4 in a position subject

to bright sunlight. This may reduce the

effectiveness of the IR signal. If you are using the

IR function we recommend that you install only one

PL-4 per room to avoid multiple pickup from the

same hand set.

PL-4 User Guide AP5082 issue 4 1

Page 2

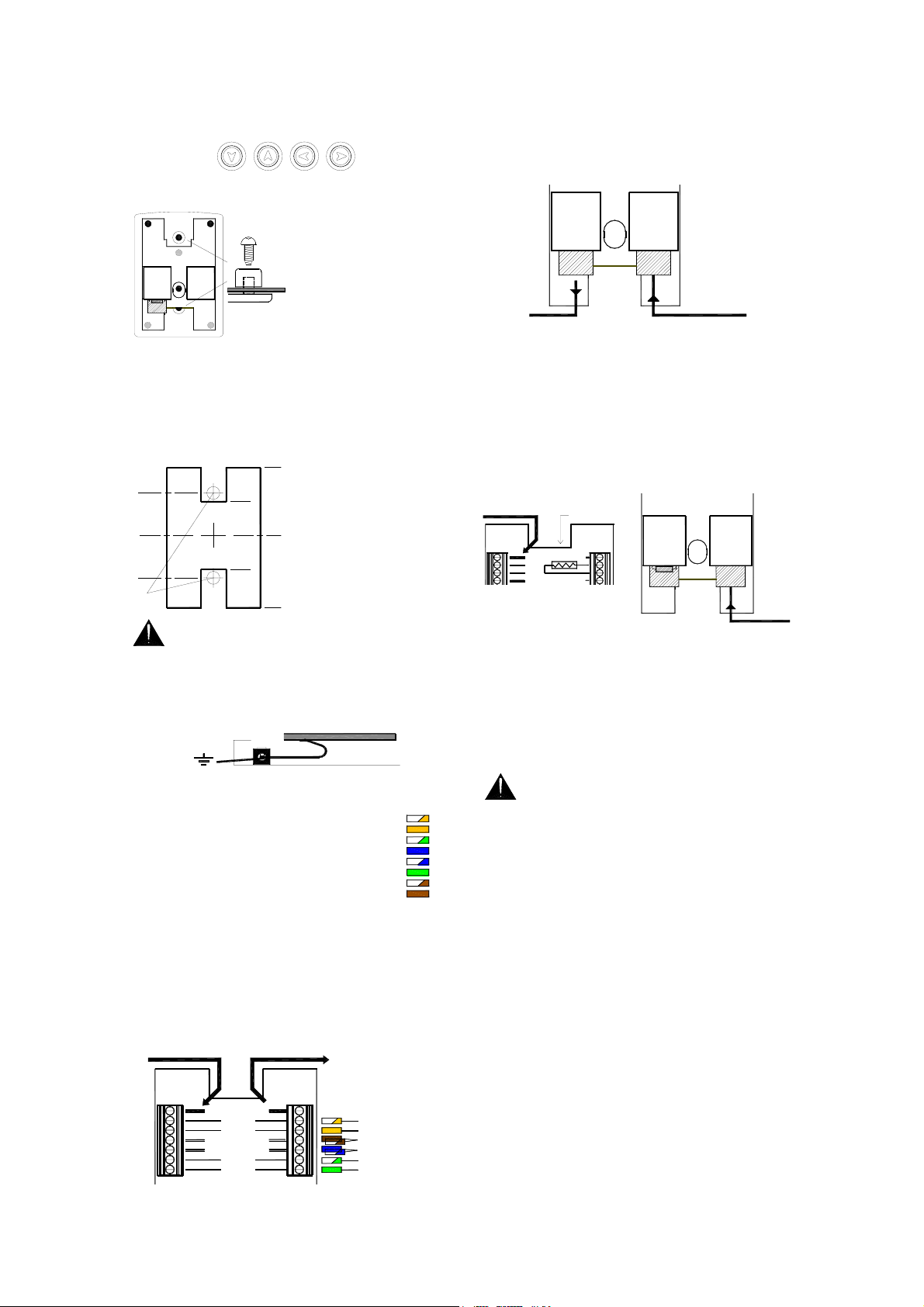

Aligning the arrow keys The two switch

caps can be rotated so that the arrow faces up, down,

left or right. Decide which way you want them to face

according to function, for example volume or source

select.

To change them, first

remove the three screws

A

BB

C

B

OUT

IN

C C

(B) and unplug the top

PCB. Remove the three

screws (C) and lift the

lower PCB away. Rotate

the switch caps into the

required position.

Reassemble the module

taking care to correctly

align the inter-PCB

connector.

Mounting into the face plate A pre-cut

brushed aluminium UK (part number AA5029), EU

(AA5250) or US (AA5030) plate is supplied. A backing

box for the UK plate can be ordered (AA5220).

TOP

The assembled module

fits into an ‘H’ shaped

cutout in the centre of the

32

mounting plate. The

module is held using the

two screws with plastic

clamps provided (A).

34

Unscrew these from the

module first. Dimensions

are in millimetres below.

DIA 6

20

16

c

20

16

16

12

16

Grounding a metal plate If the face

plate is metal ensure that it is correctly grounded to

ensure operator safety. The plate should be connected

to a local safety ground, not the PL-Anet screen

connection. Use a ground wire or physical contact with

a grounded back box.

Wiring standards Use flame

retardent CAT5 STP (shielded twisted

pair) cable. The connection follows

the EIA/TIA 568B wiring colour

scheme. Ensure all ports and cables

in the system are wired to this

scheme. The RJ45 connector wiring

is shown here.

1 WH/OR

2 OR

3 WH/GN

4 BL

5 WH/BL

6 GN

7 WH/BN

8 BN

PL-Anet connection – early version

Screw terminal blocks are provided for the serial port

IN and OUT connections on early version PL-4

modules. Use a small flat bladed screwdriver. Ensure

the wires are correctly stripped and formed to allow

sufficient service loop in the backing box. Note that

some wires are twisted together in the same terminal.

INPUT OUTPUT

CABLE SCREEN

WH/OR

OR

BN + WH/BN

BL + WH/BL

WH/GN

GN

0V

+20V DC

PL-Anet connection – later version

RJ45 sockets are provided for the serial port IN and

OUT connections on more recent PL-4 modules. Use

unbooted plugs to ensure the cables can fit into the

backing box. Use a small bladed screwdriver to lever

up the plug retaining clips when unplugging the cables

if the clips are against the circuit card.

OUT

IN

OR TERMINATOR

FROM PREVIOUS PL DEVICETO NEXT PL DEVICE

End of chain termination As with any

RS485 system, the last PL device needs to have a

terminating resistor fitted to its output port. Early

version PL-4 modules are shipped with a 100 ohm

resistor already fitted. Leave this fitted only if the unit is

the last in the chain. Later version PL-4 modules are

supplied with a terminating RJ45 plug (Allen & Heath

part number 003-082).

OUT

PL-Anet

IN

INPUT OUTPUT

100 ohms

TERMINATION

100 ohms TERMINATOR

FROM PREVIOUS PL DEVICE

Connection to the iDR The PL-Anet network

plugs into the iDR unit using an RJ45 connector. This

is wired to the 568B scheme. The PL-Anet port

provides the RS485 serial communication and +20V

DC power to the chain of PL modules. The device

addresses are automatically allocated per type in the

order they appear in the PL-Anet chain.

Testing the wiring Before powering

up the system make sure all the wiring is inspected and

continuity tested. This is important as wiring errors

may result in damage to the equipment.

Powering up the PL system Ensure that

the iDR PL-Anet port is active. Its green ‘active’ LED

should be lit. If not, use the iDR System Manager

software Communications Option menu to activate the

port. Plug in the PL-Anet cable. The iDR System

Manager screen should display icons on the right hand

toolbar for each PL device it recognises. The rotary

control on the powered PL-4 should work immediately

with the LED level bar. Refer to the Help file for details

on programming the PL functions.

Diagnostics If a fault is suspected check the two

diagnostics LEDs on the PL-4 connector PCB. Both

the red and green LEDs should be lit once

communication with the iDR is established. Also

measure the PL-Anet +20V supply feed between the

blue wires (+20V) and the brown wires (0V). For

reliable operation this voltage should not drop below

+11V with all PL LED displays turned on. If a fault is

found, first check for correct wiring. If further

assistance is required contact Allen & Heath technical

support.

2 PL-4 User Guide AP5082 issue 4

Loading...

Loading...