Page 1

PA Series

1kW Powered & Unpowered Audio Consoles

SERVICE INFORMATION

Publication AP5288

Page 2

Introduction

This publication provides technical information on servicing the Allen & Heath PA Series consoles.

Included are system block diagram, internal layout drawing and circuit schematics with board

layouts and spare parts lists. Whilst we believe this information to be reliable we do not assume

responsibility for inaccuracies. We also reserve the right to make changes in the interest of further

product development.

Additional Resources

Allen & Heath web site www.allen-heath.com Product information

Technical downloads

Distribution contacts

Company contacts

Technical support support@allen-heath.com

See web for local contact

Effects editor software PA-FX Editor Download from web site

PA-CP user guide AP4956 Operating instructions

Performance specification

PA user guide AP5195 Operating instructions

Performance specification

PA Series Service Information

Issue status: pa_series_ap5288_6.doc

Print date: 08 December 2004

Copyright © 2004 Allen & Heath. All rights reserved

Allen & Heath Limited

Kernick Industrial Estate, Penryn, Cornwall, TR10 9LU, UK

http://www.allen-heath.com

2 pa_series_ap5288_6.doc

Page 3

Servicing Precautions – General Notes

Service personnel: Service work should be carried out by technically qualified service personnel only.

Mains power is dangerous and can kill. Do not attempt to work on a linear or switched

mode power supply if you are not suitably qualified to do so. Do not attempt to repair

surface mount circuit assemblies unless you are suitably qualified and have the

necessary facilities to do so. Replacement circuit assemblies can be ordered.

Service facilities: Ensure a suitably sized work surface is available. Ensure this is clear of dirt, debris

and obstructions which may damage the equipment surfaces. Ensure adequate

lighting. Use the correct tools for the job and ensure they are in good working order.

Ensure all workshop safety requirements are adhered to.

Service information: Check that you have all the information you need before starting the service job. Refer

to the Allen & Heath web site or contact Allen & Heath technical support for details on

the latest information. Full technical information can be downloaded from the web site

Distributor Zone (password required).

Mains power: Connect the equipment to mains power only of the type described in the user guide

and marked on the rear panel. The power source must provide a good ground

connection. Ensure you always use an isolation transformer when working on any

mains power supply unit.

Mains cord and fuse: Use the correct power cord as supplied with the equipment. Do not remove or tamper

with the ground connection in the power cord. Heed the Important Mains Plug Wiring

Instructions printed in the user guide if it is necessary to rewire the mains cord.

Always replace the equipment mains fuse with the correct type and rating as

described in the user guide and marked on the equipment panel.

Opening the unit: Switch off and remove the mains power cord before opening the equipment. Ensure

all power supply covers and safety shields are in place before applying power with the

unit open for diagnostic fault finding.

Closing the unit: Before finishing, check the quality and accuracy of the service work carried out.

Remove any dirt or debris as this may cause equipment failure in the future. Ensure all

assemblies, harnesses and connectors are correctly aligned and plugged in. Ensure

that jumper settings and control configurations are correctly set according to the

requirements of the customer.

Testing the unit: Before operating the equipment, read and adhere to the Important Safety Instructions

printed in the user guide. Test that the service work has been successfully carried out.

Shipping the unit: Use adequate packing such as the original packaging or purpose designed flight case

if you need to ship the unit. To avoid injury to yourself or damage to the equipment

take care when lifting, moving or carrying the equipment.

Servicing Notes – PA-CP

User maintenance: There are no user serviceable parts inside. It should not be necessary for the user to

Technology:

remove the cover or access internal parts.

The PA-CP uses conventional thru-hole and SMT (surface mount) PCB technology. It

has a built-in linear regulated power supply which should be serviced by suitably

qualified personnel only.

Operation: To test the console make sure it is connected as described in the user guide. Check

that the voltage setting marked on the rear panel is correct for the local mains supply.

Fault finding: For effective fault diagnosis trace the signal flow through the circuit path. Refer to the

system block diagram. Replacement circuit assemblies are available from Allen &

Heath.

pa_series_ap5288_6.doc 3

Page 4

Contents Log

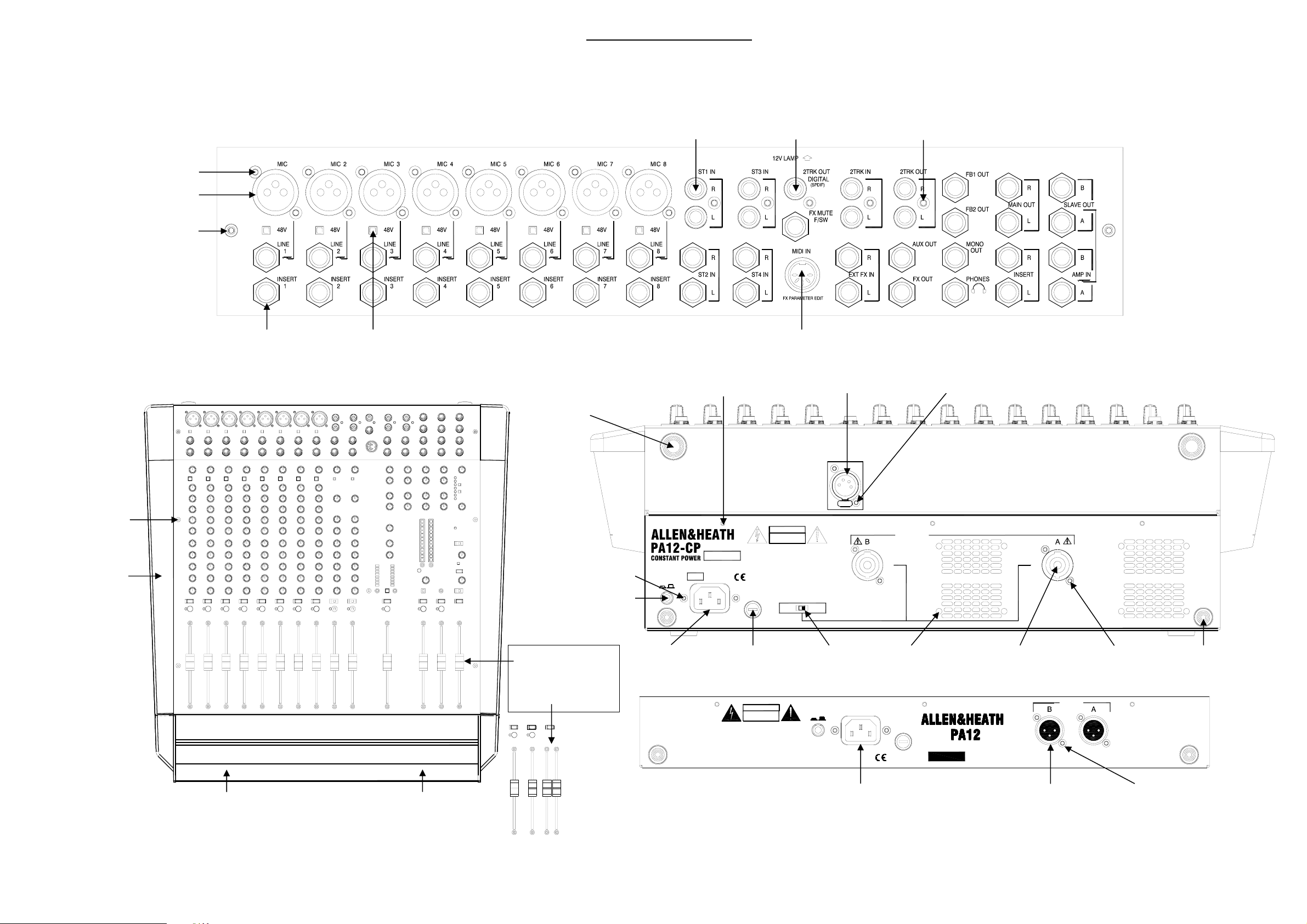

Internal Layout drawing ........................................... pa_series_layout_3.pdf

Surface and Main Parts.............................................. pa_series_parts_4.pdf

PA-CP System Block Diagram........................... pa-cp_blockdiagram_2.pdf

PA System Block Diagram...................................... pa_blockdiagram_2.pdf

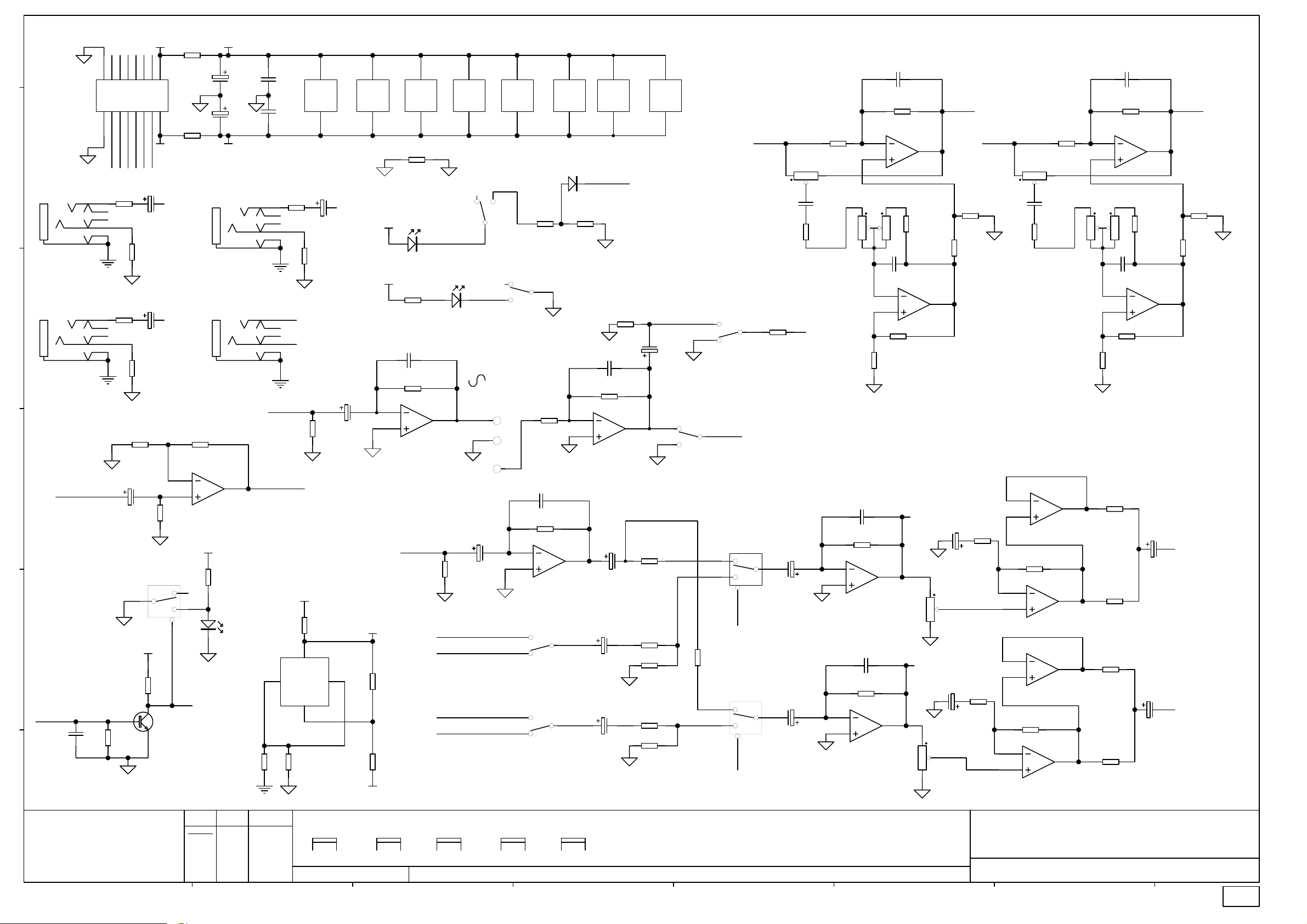

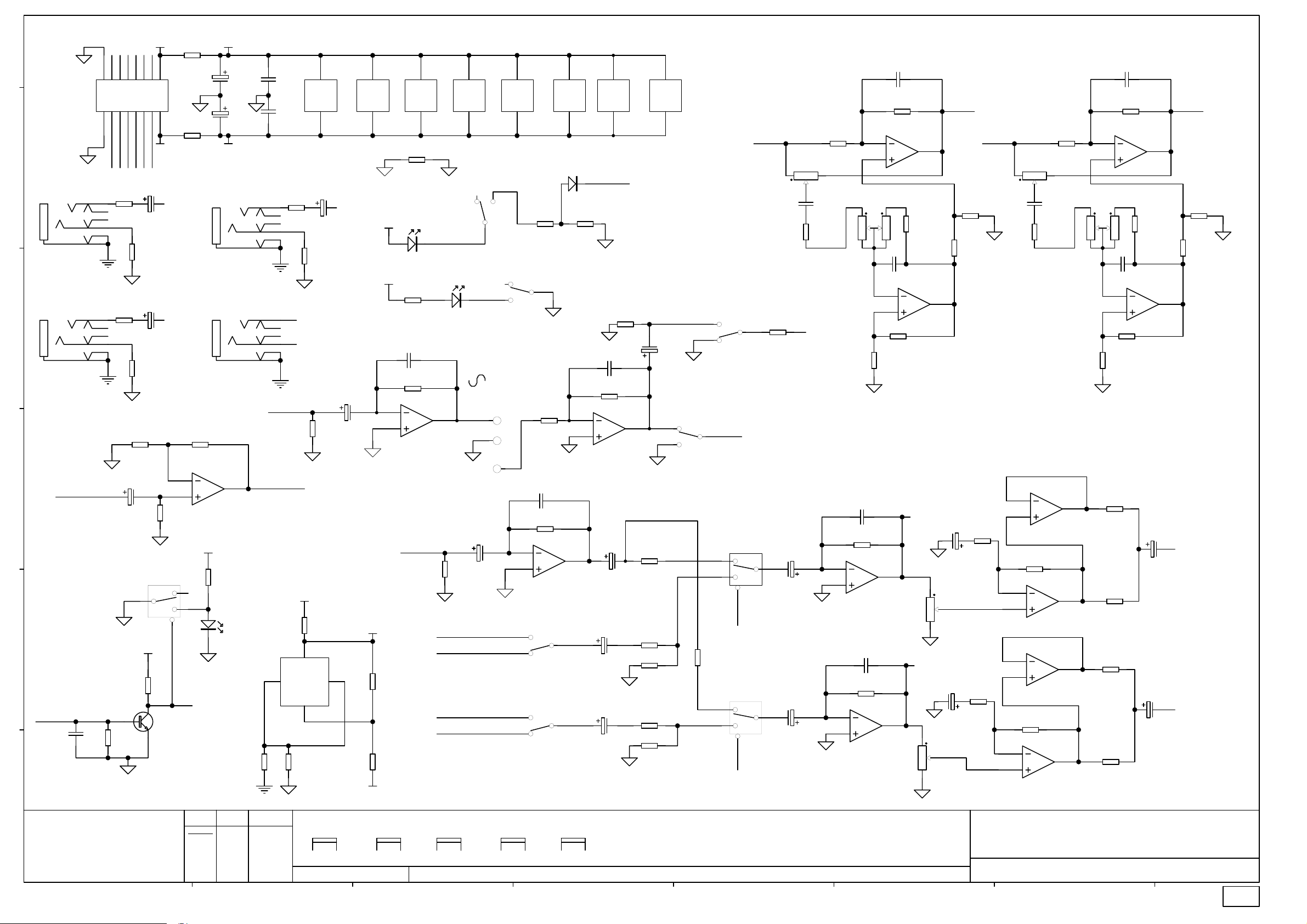

PA-CP Mono Input Pcb.........................pa-cp_003-034_monoinput_1.1.pdf

PA Series Stereo Input PCB ..........pa_series_003-035_stereoinput_2.1.pdf

PA Series Aux / FX PCB...........................pa_series_003-036_auxfx_2.1.pdf

PA Series Sub 1 PCB............................... pa_series_003-037_sub1_1.1.pdf

PA Series FB1 / Phones PCB .........pa_series_003-038_fb1phones_2.1.pdf

PA Series FB2 PCB..................................... pa_series_003-039_fb2_1.1.pdf

PA-CP LR Master PCB ................................. pa-cp_003-040_lrmaster_3.pdf

PA-CP Distribution PCB .......................... pa-cp_003-041_distribution_2.pdf

PA Series Effects PCB ............................. pa_series_003-042_effects_2.pdf

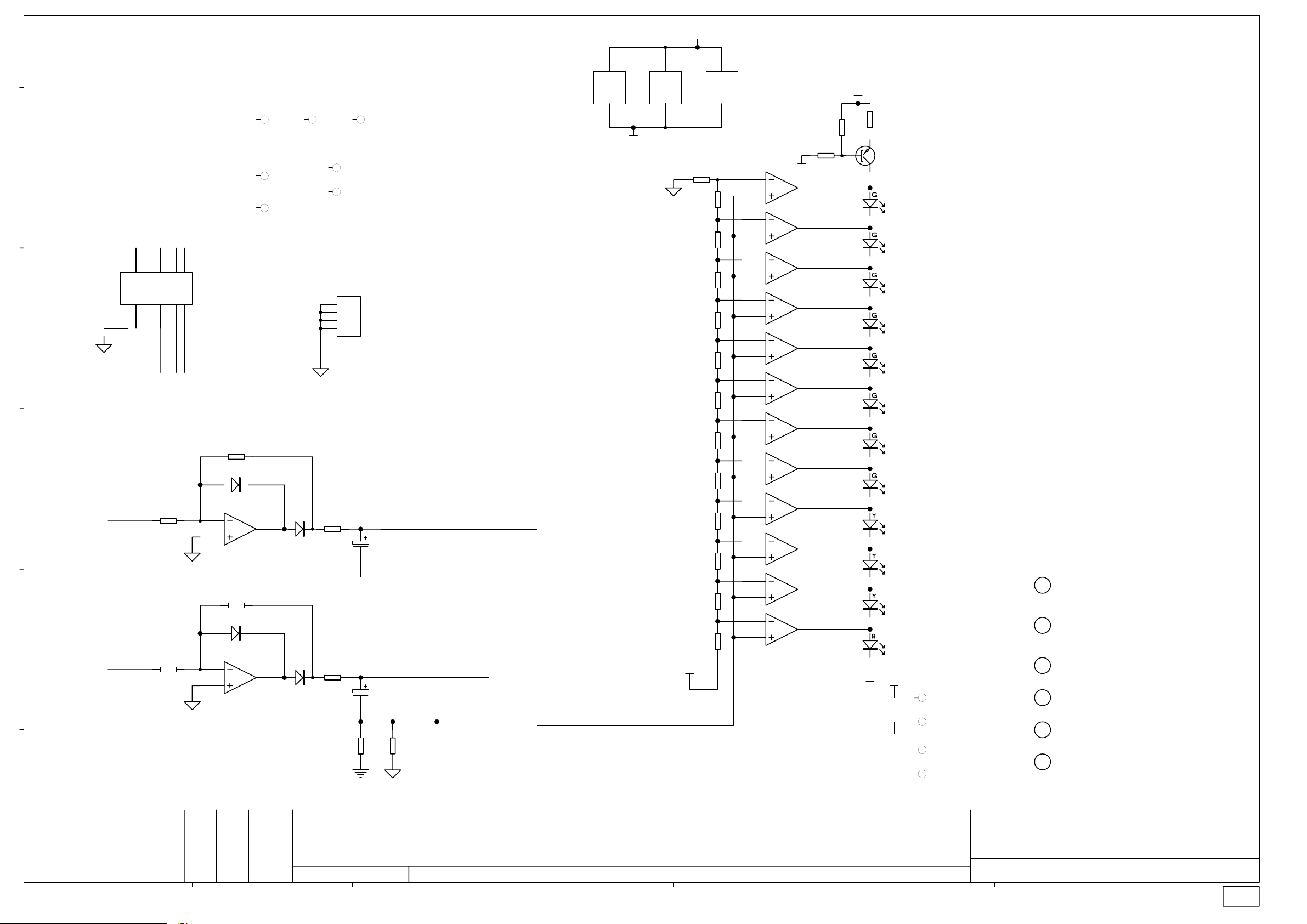

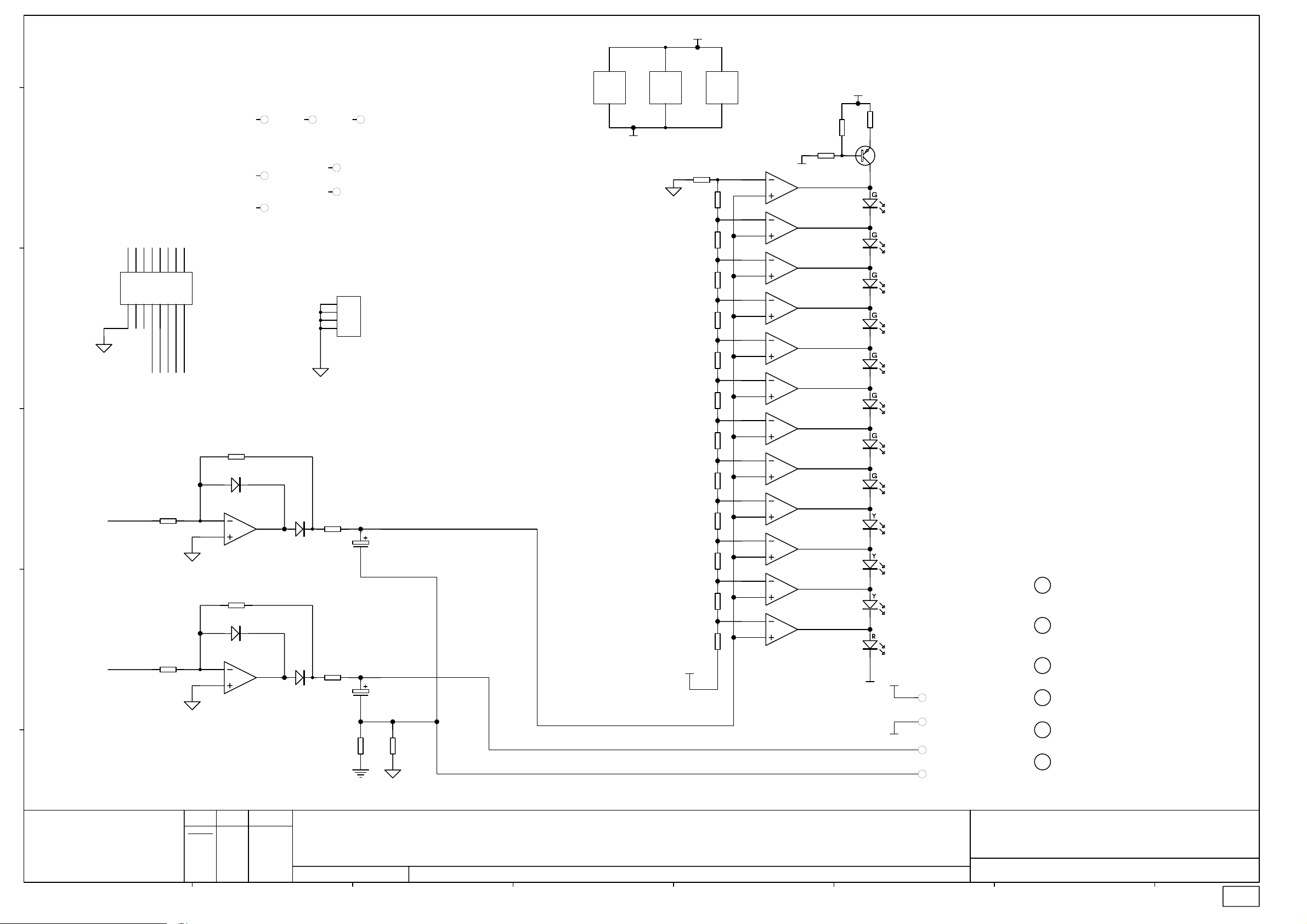

PA-CP Amplifier PCB .................................. pa-cp_003-043_amplifier_4.pdf

PA-CP Power Supply PCB...................... pa-cp_003-069_linearpsu_3.2.pdf

PA-CP Power Supply PCB...................... pa-cp_003-069_linearpsu_3.3.pdf

PA Series FX LED PCB ............................ pa_series_003-070_fxled_2.1.pdf

PA Mono Input PCB ................................... pa_003-091_monoinput_1.2.pdf

PA LR Master PCB ............................................ pa_003-092_lrmaster_1.pdf

PA Distribution PCB ..................................... pa_003-093_distribution_1.pdf

PA Switched Mode Power Supply PCB ..............pa_003-094_smpsu_2.pdf

PA Switched Mode Power Supply PCB ..............pa_003-094_smpsu_4.pdf

4 pa_series_ap5288_6.doc

Page 5

PA Series – Historical Change Log

The following list identifies historical changes to the PA Series. The effective dates, serial

numbers and related change note documentation are included for reference to help identify

the correct issue circuit boards and components. Whilst we believe this information to be

reliable we do not assume responsibility for inaccuracies. We also reserve the right to make

changes in the interest of further product development.

Assembly Description

Main

003-094

003-069

003-094

003-034

Fader change to add extra master

fader

PA SMPSU PCB Minimum current

increase for TL783

PA-CP Linear PSU PCB +/- 15V rail

fuse value changes

PA SMPSU PCB post regulation

added – up-issue to issue 4

PA CP Mono Input 48V 22R type

change

From Serial

Number

019388

018930

018780

-

-

Date

16/06/03 917

23/09/03 949

23/09/03 950

13/11/03 966

25/02/04

Change Note

Number

990

pa_series_ap5288_6.doc 5

Page 6

PA Series Surface Parts

9MM POT NUT AB8050

GREY-RED KNOB AJ2074

14MM 5KRDx2 POT AI8174

GREY PUSH BUTTON AJ2864

LATCHING SWITCH AL0162

GREY-L/BLUE KNOB AJ2076

11MM 20KB C/D POT AI8004

GREY-GREEN KNOB AJ2077

11MM 200KCx2 POT AI8005

11MM 20KB C/D POT AI8004

11MM 20KB C/D POT AI8004

11MM 20KB C/D POT AI8004

GREY-GREY KNOB AJ2078

11MM 20KK POT AI8003

11MM 20KK POT AI8003

GREY-BLUE KNOB AJ2075

11MM 20KK POT AI8003

GREY-YELLOW KNOB AJ2079

11MM 20KK POT AI8003

GREY-BROWN KNOB AJ2080

14MM 10KACx2 C/D POT AI8008

RED TOMBSTONE LED AE4863

WHITE PUSH BUTTON AJ2962

LATCHING SWITCH AL0162

RED LED AE0086

ROUND GREY PUSH BUTTON AJ2864

LATCHING SWITCH AL0162

LINE

12kHz

250Hz

60Hz

MIC

-10 -5

FB1

FB2

AUX

PAN

-5

0

350Hz

0

20

10

100Hz

-15

1k5

-15 +15

-15

-15

O

O

O

OOO

O

O

=

-5

30

63 25

+15

7k

+15

+15

+6

+6

+6

+6

RL

-10

-20

-30

OO

-10

-20

-30

OO

-15 +15

-15

OO

OO

OO

OO

L R

0

14MM 20KKx2 POT AI8007

9-10

LR

5

10

LATCHING SWITCH AL0162

11MM 200KCx2 POT AI8005

11MM 20KB C/D POT AI8004

0

14MM 20KKx2 POT AI8007

5

10

11MM 200KCx2 POT AI8005

11MM 20KB C/D POT AI8004

14MM 20KBx2 C/D POT AI8006

-10

0

14MM 20KBx2 C/D POT AI8006

+15

11MM 20KK POT AI8003

+6

11MM 20KK POT AI8003

+6

11MM 20KK POT AI8003

+6

GREEN TOMBSTONE LED AE4864

11MM 20KK POT AI8003

+6

=

MOMENTARY SWITCH AL0374

14MM 10KACx2 C/D POT AI8008

LATCHING SWITCH AL0162

LATCHING SWITCH AL0162

14MM 20KKx2 POT AI 8007

11MM 20KK POT AI8003

11MM 20KK POT AI8003

M3x5 SCREW AB4661

LATCHING SWITCH AL0162

LATCHING SWITCH AL0162

STAGE

ROOM

HALL

PLATE

CHAMBER

CATHEDRAL

ARENA

GATED REV

PK !

3

O 10O

+6OO

+6

OO

KARAOKE

PING PONG

CHORUS

SLAP+REV

DLY+REV

ECHO+REV

CH+REV

PH+REV

70

10030

200

20Hz

+10

-10

70

100

30

200

20Hz

-10

12WAY LED BAR AE2701

4ABx5/16 SCREWAB0059

5MM RED LED AE0001

14MM 20KKx2 POT AI8007

LATCHING SWITCH AL0162

M3x5 SCREW AB4661

LATCHING SWITCH AL0162

LATCHING SWITCH AL0162

200

-10

120Hz

-10

500

500Hz120Hz

1k

500Hz

5k

10k

+10

-10

2k5

5k

10k

+10

-10

1k 1k200

2k

+10

500

1k

2k

+10+10

7k2k5

2k5

10k

1k5

-10

7k

2k5

1k5

MIN

20k

LIM

SIG

SPK

+10

OFF

TMP

SPK

OFF

SIG

LIM

20k

11MM 20KK POT AI8003

MAX

GREEN LED AE0085

LATCHING SWITCH AL0162

FB1

FB1L

YELLOW LED AE0084

FB2

L R+R

LATCHING SWITCH AL0162

11MM 20KK POT AI8003

MIN

+10

-10

MAX

BLUE LED AE4041

LATCHING SWITCH AL0162

11MM 20KK POT AI8003

+6OO

LATCHING SWITCH AL8065

POST-LR

LATCHING SWITCH AL8065

PRE-LR

TO

OOMAXMIN

14MM 20KKx2 POT AI8007

+6

GREEN TOMBSTONE LED AE4864

POST-LR FADER

LATCHING SWITCH AL0162

LATCHING SWITCH AL0162

10

40

50

3k600

12kHz

60Hz

PK !PK !

M3x5 SCREW AB4661

WHITE-BLACK FADER KNOB AJ8078

100MM 10KD FADER AI8117

BLUE-BLACK FADER KNOB AJ8081

100MM 10KDx2 FADER AI8118

YELLOW-BLACK FADER KNOB AJ8080

100MM 10KDx2 FADER AI8118

BLACK-WHITE FADER KNOB AJ3503

100MM 10KD FADER AI8117

PA series products up to serial

number 019388 have x1 stereo

MASTER LR FADER

PA series products from serial

number 019388 have x2 mono

MASTER L & R FADERS

RED-BLACK FADER KNOB AJ8079

100MM 10KDx2 FADER AI8118

RED-BLACK FADER KNOB AJ8079

100MM 10KD FADER AI8117

pa_series_parts_4.doc Sheet 1 of 2

Page 7

PA Series Surface Parts

A

4x5/16 SCREW AB2810

FEMALE XLR AL2412

M3x5 SCREW AB5344

1

JACK NUT AL4715

JACK SOCKET AL4713

LATCHING SWITCH AL0162

20DIA P4x5 FAST FOOT AK0102

5WAY FEMALE DIN SOCKET AL3962

M3x6 SCREW AB0072

SINGLE PHONO AL4895DUAL PHONO AL0577

4x5/16 SCREW AB2810

M3x10 SCREW AB0093 4PIN FEMALE XLR AL8104

M3x5 SCREW AB5344

SIDE MOULDIING AA4920-L/R

OR RACK EARS AA5013

HANDLE AA4922 FRONT EXTRUSION AA4923

M3x10 SCREW AB0076

BLACK BUTTON AJ2887

MAINS SWITCH

PA series products up to serial

number 019388 have x1 stereo

MASTER LR FADER

PA series products from serial

number 019388 have x2 mono

MASTER L & R FADERS

L3338

ON/OFF

0

I

ENGINEERED IN ENGLAND BY ALLEN & HEATH Ltd.

MAINS IEC AL5118

SERIAL NUMBER

MAINS INPUT

V AC ~ 47- 63 Hz

1600W MAX

FUSE HOLDER AL3178

10A FUSE AL3455

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

DO NOT OBSTRUCT VENTILATION OPENINGS.

NO USER SERVICEABLE PARTS INSIDE.

WARNING: TO REDUCE THE RISK OF ELECTRIC SHOCK

DO NOT EXPOSE THIS APPARATUS TO RAIN OR MOISTURE.

THIS APPARATUS MUST BE EARTHED BY THE POWER CORD.

RISK OF HAZARDOUS ENERGY! MAKE PROPER SPEAKER CONNECTIONS.

SEE OPERATING MANUAL BEFORE USING.

CAUTION: FOR C ONTINUED PROTECTI ON AGAINST RISK OF FIRE

ATTENTION: REMPLACER LE FU SIBLE AVEC UN DES MEMES CARACTERISTIQUES.

100-240V T10A L

FUSE

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

NO USER SERVICEABLE PARTS INSIDE.

WARNING: TO REDUCE THE RISK OF ELECTRIC SHOCK

DO NOT EXPOSE THIS APPARATUS TO RAIN OR MOISTURE.

THIS APPARATUS MUST BE EARTHED BY THE POWER CORD.

SEE OPERATING MANUAL BEFORE USING.

CAUTION: FOR CONTINUED PROTECT ION AGAINST RISK OF FIRE

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CONSTANT POWER SW ITCH

12V LAMP

REPLACE FUSE WITH SAME TYPE AND RATING.

8 OHMS4 OHMS

SET SWITCH TO MATCH SPEAKER IMPEDANCE

SPEAKER OUTPUTS

500W + 500W RMS

4 OHM LOAD MINIMUM

CONNECT SPEAKER BETWEEN PIN 1+ AND PIN 1-

SLIDE SWITCH AL5071 SPEAKON CONNECTOR AL8126

ON/OFF

I 0

REPLACE FUSE WITH SAME TYPE AND RATING.

75W MAX

FUSE

100-240V T1A L

SERIAL NUMBER

ENGINEERED IN ENGLAND BY ALLEN & HEATH Ltd.

MAINS INPUT

100 - 240 V AC ~ 47- 63 Hz

MAINS IEC AL3458

M3x10 SCREW AB0093

MAIN OUTPUT

BALANCED PIN2 = +

15DIA 9MM HIGH FAST FOOT AK5069M4x8 SCREW AB0332

MALE XLR AL2411 4x5/16 SCREW AB2810

pa_series_parts_4.doc Sheet 2 of 2

Page 8

)

FB1 PHONES PCB

003-038

SUB 1 PCB

003-037

PA-CP Powered version

DISTRIBUTION PCB

003-041

FB2 PCB

003-039

COPPER EARTH STRIP

L/R MASTER PCB

003-040

FB2 FADER

FB1 PHONES FADER

PA series products from

serial number 019388

have x2 mono MASTER

L & R FADERS

PA series products up

to serial number 019388

have x1 stereo

MASTER LR FADER

AL4875

AUX FX

FADER

FRONT EXTRUSION

EFFECTS PCB

003-042

STEREO INPUT PCBs

003-035 x 2

AUX FX PCB

-

FX LED PCB

003-070

STEREO

INPUT

FADERS

MONO INPUT PCBs

003-034 x 16

MONO INPUT FADERS

Product .............................PA12-CP/100

.........................................PA12-CP/120

.........................................PA12-CP/220

.........................................PA12-CP/240

.........................................PA20-CP/100

.........................................PA20-CP/120

.........................................PA20-CP/220

.........................................PA20-CP/240

PA12-CP Pack Assembly......... 003-030

PA12-CP Main Assembly ......... 003-031

PA12-CP Top Panel Assy. ....... 003-032

PA12-CP Base Panel Assy. ..... 003-033

PA12-CP Rack Ear Assy.......... 003-071

PA20-CP Pack Assy................. 003-083

HANDLE

PA-CP Front Panel assembly Front view (20ch. shown

AMPLIFIER HEATSINK x2

LINEAR PSU PCB

003-069

TRANSFORMER

FAN FAN

LINEAR PSU

HEATSINK

PA20-CP Main Assy................. 003-084

PA20-CP Top Panel Assy. ....... 003-085

PA20-CP Base Panel Assy. ..... 003-086

Mono Input PCB ....................... 003-034

Stereo Input PCB ..................... 003-035

Aux FX PCB ............................. 003-036

Sub 1 PCB................................ 003-037

FB1 Phones PCB ..................... 003-038

FB2 PCB .................................. 003-039

Master L/R PCB ....................... 003-040

Distribution PCB ....................... 003-041

Effects PCB .............................. 003-042

Amplifier PCB ........................... 003-043

Linear PSU PCB....................... 003-069

AMPLIFIER PCB

003-043

FX LED PCB ............................ 003-070

AL4877

pa_series_layout_3.doc Sheet 1 of 2

PA-CP Chassis assembly Front view

Page 9

FB1 PHONES PCB

003-038

SUB 1 PCB

003-037

PA unpowered version

DISTRIBUTION PCB

003-093

FB2 PCB

003-039

COPPER EARTH STRIP

L/R MASTER PCB

003-092

FB2 FADER

FB1 PHONES FADER

PA series products from

serial number 019388

have x2 mono MASTER

L & R FADERS

PA series products up

to serial number 019388

have x1 stereo

MASTER LR FADER

AL4875

AUX FX

FADER

FRONT EXTRUSION

EFFECTS PCB

003-042

STEREO INPUT PCBs

003-035 x 2

AUX FX PCB

-

FX LED PCB

003-070

STEREO

INPUT

FADERS

MONO INPUT PCBs

003-091 x 16

MONO INPUT FADERS

Product ...................................PA12/100

...............................................PA12/120

...............................................PA12/220

...............................................PA12/240

...............................................PA20/100

...............................................PA20/120

...............................................PA20/220

...............................................PA20/240

...............................................PA28/100

...............................................PA28/120

...............................................PA28/220

...............................................PA28/240

PA12-CP Rack Ear Assy.......... 003-071

PA12 Top Panel Assy. ............. 003-095

PA12 Base Panel Assy. ........... 003-096

PA12 Pack Assembly ............... 003-097

HANDLE

PA Front Panel assembly Front view (20ch. shown)

DISTRIBUTION PCB

003-093

PSU ASSEMBLY

003-100

SM PSU PCB

003-094

PA12 Main Assembly ............... 003-098

PA PSU Assy. .......................... 003-100

PA20 Pack Assembly ............... 003-101

PA20 Main Assy. ...................... 003-102

PA20 Base Panel Assy. ........... 003-103

PA20 Top Panel Assy. ............. 003-104

PA28 Pack Assembly ............... 003-105

PA28 Main Assembly ............... 003-106

PA28 Base Panel Assy. ........... 003-107

PA28 Top Panel Assy. ............. 003-108

Stereo Input PCB ..................... 003-035

Aux FX PCB ............................. 003-036

PSU HEATSINK

Sub 1 PCB................................ 003-037

FB1 Phones PCB ..................... 003-038

FB2 PCB .................................. 003-039

Effects PCB .............................. 003-042

FX LED PCB ............................ 003-070

Mono Input PCB ....................... 003-091

Master L/R PCB ....................... 003-092

Distribution PCB ....................... 003-093

SM PSU PCB ........................... 003-094

PA Chassis assembly Front view

pa_series_layout_3.doc Sheet 2 of 2

Page 10

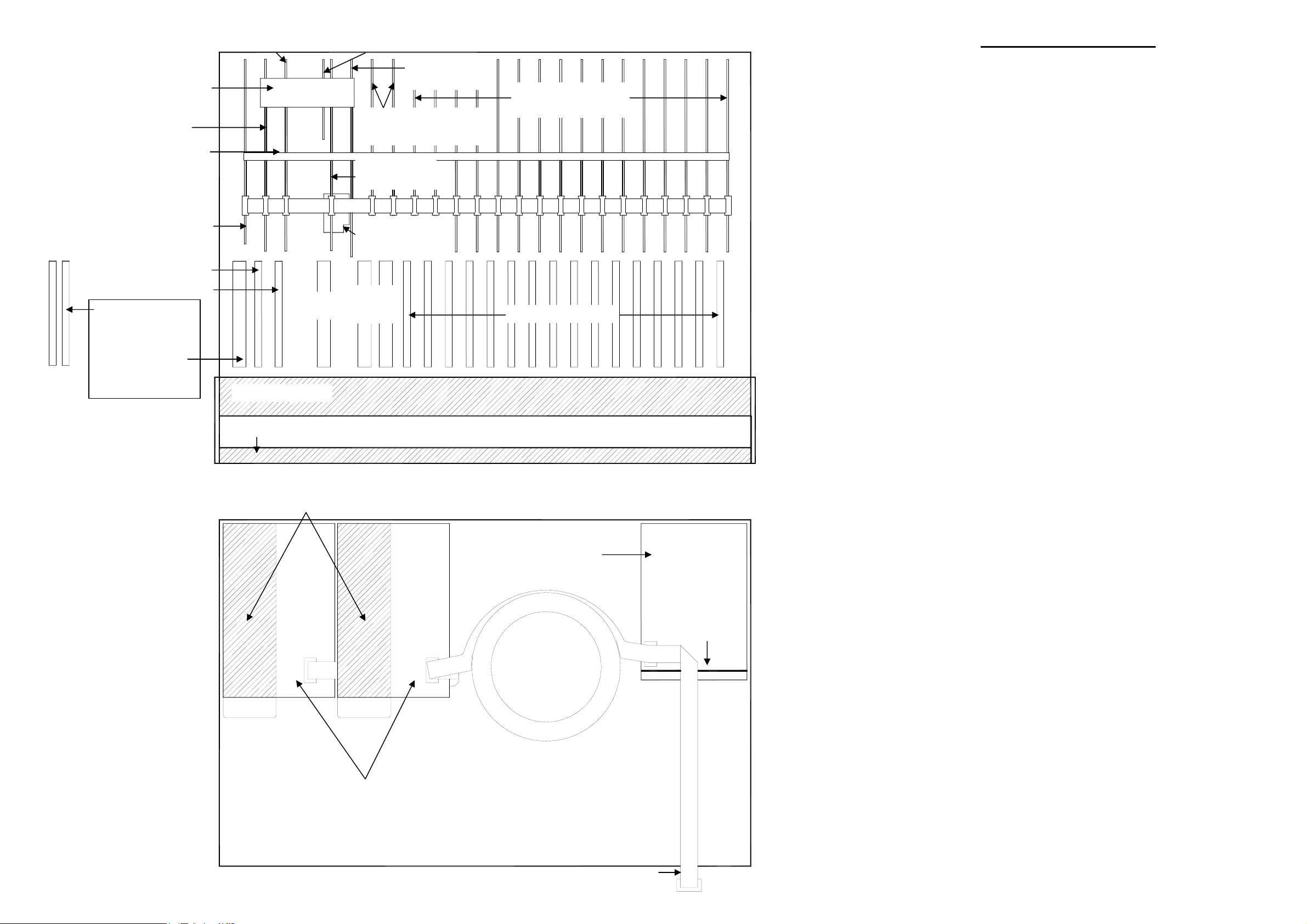

Products from serial number 019388

PA-CP SERIES BLOCK DIAGRAM

METERS

PFLFXAUX

FB2

FB1RL

PEAK

MUTE

PFL

FADER

PAN

PFL

MONITOR

LR / 2TRK

PFL/AFL

PHONES

L

R

HEADPHONES

MIC IN

PP

+

-

+48V

GAIN

LINE IN

MONO CHANNEL

HPF

100Hz

+

-

INSERT

4 BAND EQUALISER

LM HM HF

LF

ST1/3

ST2/4

EXT FX IN

L

R

L

R

L

R

INTERNAL FX

SELECT 1-16 / OFF

GAIN

SEL

CHAN

GAIN

GAIN

DIR OUT

FX

AUX

FB2

FB1

PEAK

MUTE

SUM

FADER

PFL

+

MUTE

FADER

SUM

SUM

BAL

+

+

FX

AUX

FB2

FB1

FB2

FB1

FB1

FB2

FADER

FADER

AUX

FX

LR

STEREO CHANNEL

2 BAND EQUALISER

SUM

+

LF

FX CHANNEL

SUM

+

FX MUTE FOOTSWITCH

+

SUM

PEAK

PFL

SUM

HF

L INSERT

R INSERT

AFL

MUTE

AFL

MUTE

2TRK IN

L

R

MAIN LR

FB1 OUT

FB2 OUT

AUX OUT

FX OUT

2TRK

FADERS

2TRK TO LR

BGM

SUM

+

SUM

+

SOURCE SELECT

SPK A SPK B

PRE POST

100Hz

ADC

MUTE

SUB

FB1LFB1

FB2R+L R

STANDBY

MONO

RELAY

SPDIF DIGITAL

2TRK OUT

L

ANALOG

R

LEV

LM HM HFLF

4 BAND EQUALISER

LM HM HF

LF

AMP A

LIMITER

SIGNAL

PROTECT

TEMP

PROTECT

SIGNAL

LIMITER

AMP B

L

MAIN OUT

R

MONO OUT

A

SLAVE OUT

B

LEV

A

AMP IN

LEV

B

pa-cp_blockdiagram_2.doc Sheet 1 of 1

8 OHM4 OHM

Page 11

Products from serial number 019388

PA SERIES BLOCK DIAGRAM

METERS

PFL

FX

AUX

FB2

FB1

R

L

PEAK

MUTE

PFL

FADER

PAN

PFL

MONITOR

LR / 2TRK

PFL/AFL

PHONES

L

R

HEADPHONES

MIC IN

PP

+

-

+48V

GAIN

LINE IN

MONO CHANNEL

HPF

100Hz

+

-

INSERT

4 BAND EQUALISER

LM HM HF

LF

ST1/3

ST2/4

EXT FX IN

DIR OUT

FX

AUX

FB2

FB1

PFL

PEAK

MUTE

SUM

FADER

PFL

+

MUTE

FADER

SUM

BAL

+

FX

AUX

FB2

FB1

FB1

FB2

AFL

FADER

AFL

FADER

L

R

L

R

L

R

GAIN

CHAN

GAIN

GAIN

LR

STEREO CHANNEL

2 BAND EQUALISER

SUM

+

LF

HF

SUM

PEAK

FX CHANNEL

SUM

+

L INSERT

R INSERT

MUTE

MUTE

2TRK IN

L

R

MAIN LR

FB1 OUT

FB2 OUT

2TRK

FADERS

2TRK TO LR

BGM

SUM

SUM

+

SOURCE SELECT

PRE POST

+

100Hz

ADC

MUTE

SUB

FB1LFB1

FB2R+L R

MONO

SPDIF DIGITAL

2TRK OUT

L

ANALOG

R

LEV

LM HM HFLF

4 BAND EQUALISER

LM HM HF

LF

A

L

MAIN OUT

R

MONO OUT

A

SLAVE OUT

B

LEV

INTERNAL FX

SELECT 1-16 / OFF

SEL

pa_blockdiagram_2.doc Sheet 1 of 1

FX MUTE FOOTSWITCH

+

+

SUM

SUM

FB2

FB1

AUX

FX

AUX OUT

FX OUT

A OUT B OUT

PEAK

SIGNAL

SIGNAL

PEAK

LEV

B

LEV

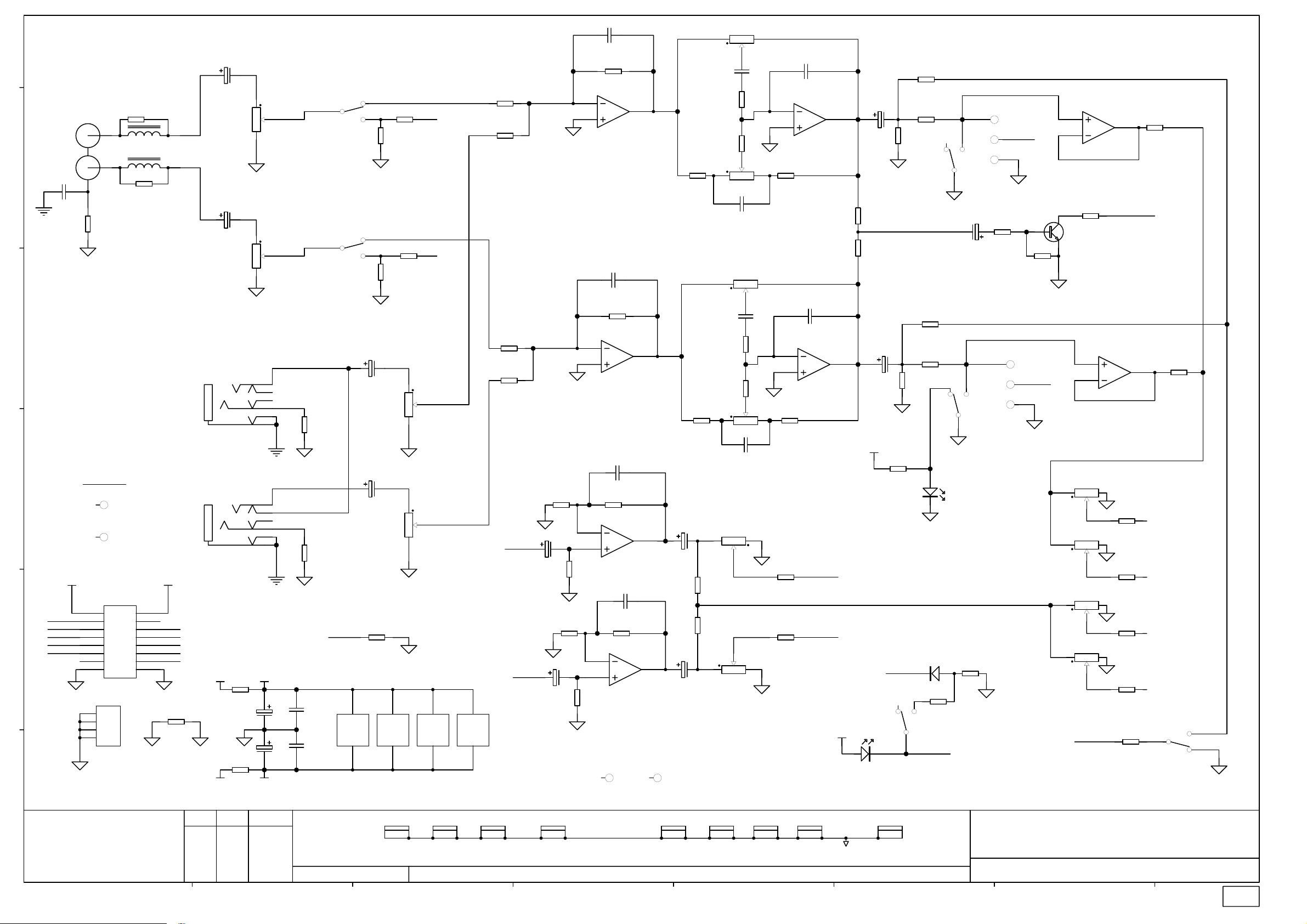

Page 12

SW1A

003-034/1

C2

47/63

C1

47/63

4

SW1B

6

SW2PCOL (SPUN)

1

3

R6

47K 0805

R5

47K 0805

-17VB

MIC-

D2

BAS16

-17VB

+48V

4K7 1% 0805 MELF

MIC+

D3

BAS16

R7

Q1

2SB737

R19

820R 1% 0805 MELF

1K2 1% 0805 MELF

R32

C6

1 6

220/10

POT14 5KRD X2

Q3

BC549

1K2 1% 0805 MELF

+17VB

VR1A

-17VB

4

Q4

BC549

R33

R21

68R 0805

820R 1% 0805 MELF

R8

4K7 1% 0805 MELF

MIC-

Q2

2SB737

R20

C11

33P 0805

C9

33P 0805

R22

2K7 1% 0805 MELF

U1B

6

5

NE5532 SMD

R23

2K7 1% 0805 MELF

LINE INPUT

CN2

JACK SLIMJACK SW6

C10

R

T

C15

R25

33K 1% 0805

47/25

C16

R24

33K 1% 0805

C18

7

47/25

R13

47K 0805

47/25

C12

15P 0805

15P 0805

R26

3K3 1% 0805

U1A

2

3

NE5532 SMD

R28

3K3 1% 0805

C7

220/10

R29

3K3 1% 0805

R27

3K3 1% 0805

3

R46

22R 0805

1

2 5

C17

47/25

VR1B

POT14 5KRD X2

AI1

HOLE-AI

FID1

FIDUCIAL

e

AI2

HOLE-AI

FID2

FIDUCIAL

3

1 2

0

R2

0R0 0805

CN1

XLR NC3FAHR20

C3

1N5_S

R1

0R0 0805

R10

1K8 0805

5

SW2PCOL (SPUN)

2

R4

6K8 1% 0805

R3

6K8 1% 0805

MIC INPUT

d

SW2A

SW2PCOL (SPUN)

1

3

C31

22N 0805

R67

0R0 0805

c

120K 1% 0805

C30

22N 0805

R47

100K 1% 0805

R31

R48

22K 0805

b

15

13

15

CN4

BOX 8X2 M 90 DEG

13

16

14

16

14

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

2

R30

100K 1% 0805

Ground

PFL_DET

11

5

7

9

5

7

9

11

6

8812

10

6

12

10

PFL_BUS

FB1 FB2

AUX1 AUX2

MIXL MIXR

4

5

1 2

C28

R50

120K 1% 0805

2

3

V+ +17VB

1

3

1

3

2

4

2

4

V-

+48V

10R PF RAD

ISSUE BY DATE

A MG 25-02-02

B MG 03-05-02

C MG 25-06-02

1 MG 22-7-02

SW2B

6

SW2PCOL (SPUN)

C40

22N 0805

22P_S

U2A

TL072D SMD

R54

+17VA

10R PF RAD

C24

47/25

C25

47/25

R56

-17VA

C20

1

47/25

C38

100N 0805

C39

100N 0805

FILE: C4788_1P1.Sch 15:59:16 26-Mar-2003

JACK SLIMJACK SW6

CN3

R58

47R 0805

R14

47K 0805

R55

10R PF RAD

R57

10R PF RAD

VR1C

POT14 5KRD X2

BRKT

8

INSERT

-17VB

C26

47/25

C27

47/25

R

T

C21

47/25

9

VR2A

POT11 20KB C/D

R51

6K8 1% 0805

R59

82K 0805

R15

47K 0805

R39

12K 0805

C32

47N 0805

1 3

VR5A

POT11 20KB C/D

2

2

13

12kHz

C29

1N0 0805

U2B

6

5

TL072D SMD

R40

12K 0805

R16

47K 0805

250Hz

CN5

EARTH SCREW TERMINAL NARROW

1

2

3

4

6

VR3B

200KC X2 D/G

BRKT

5

6

VR2B

POT11 20KB C/D

BRKT

5

PRINTED:

7

C33

47N 0805

+17VA

C34

100N 0805

-17VA

VR4B

POT11 20KB C/D

BRKT

5

6

R68

2K7 0805

120Hz

R60

27K 0805

300 - 6kHz

R52

10K 1% 0805

C4

2N2_S

1 3

VR4A

POT11 20KB C/D

8

V+

V-

4

VR5B

POT11 20KB C/D

BRKT

5

6

C37

330N 0805

VR6A

POT11 20KB C/D

2

R11

1K8 0805

U3A

2

3

TL072D SMD

2

U1C

NE5532 SMD

VR6B

POT11 20KB C/D

BRKT

5

13

C13

33P 0805

1

3

6

2

8

V+

V-

4

R69

2K7 0805

1

C5

2N2_S

VR3A

POT11 200KC X2 D/G

R53

10K 1% 0805

U2C

TL072D SMD

VR7B

POT11 20KK

BRKT

5

6

VR8B

POT11 20KK

BRKT

5

PEAK

C22

47/25

8

V+

V-

U3C

TL072D SMD

4

6

PRE EQ

POST EQ

POST MUTE

+17VB

R17

47K 0805

3

1

C35

100N 0805

VR9B

POT11 20KK

BRKT

5

6

JP3

JUMP 2 STRT

1 2

JP1

1 2

JUMP 2 STRT

JP2

1 2

JUMP 2 STRT

LED RECT 5X2.5MM TOMB RED

SW3B

SW2PCOL (SPUN)

4

6

SW4A

SW2PCOL (SPUN)

VR10B

POT11 20KK

BRKT

5

R36

6K8 1% 0805

PIN-SOLDER 1.2MM

2

6

JP4

JUMP 2 SKT

C19

47/25

5

PIN-SOLDER 1.2MM

PIN-SOLDER 1.2MM

R49

22K 0805

VR11C

POT14 10KAC C/D

BRKT

8

R34

2K2 1% 0805

LD1

RED

GRN

BLU

PFL_BUS

+17VB

9

R9

0R0 0805

1

3

SW3A

SW2PCOL (SPUN)

2

R35

4K7 1% 0805

C23

47/25

SW4B

SW2PCOL (SPUN)

LD2

LED T1 3MM RED

VR7A

6

5

R18

47K 0805

PFL_DET

TITLE:

POT11 20KK

VR8A

POT11 20KK

R41

10K 1% 0805

U3B

TL072D SMD

4

5

13

R37

2

13

2

C14

33P 0805

7

VR11A

POT14 10KAC C/D

D1

BAS16

R61

6

22K 0805

R65

4K7 1% 0805

FB1

8K2 1% 0805

R38

FB2

8K2 1% 0805

PIN-WIRE CRIMP 1.0MM

C8

220/10

4

R12

3K3 1% 0805

DIR OUT FEED

P2

PIN-WIRE CRIMP 1.0MM

P1

16

POT14 10KAC C/D

2 5

C36

PEAK

47/25

VR9A

POT11 20KK

2

VR10A

POT11 20KK

2

VR11B

3

R64

47K 0805

5K6 0805

PA SERIES MONO INPUT

PAGE:

DRG No: ISSUE: SHEET: OF

C4788 1 1

1

13

R44

10K 1% 0805

13

R45

10K 1% 0805

R42

10K 1% 0805

R43

10K 1% 0805

R66

MIXR

MIXL

AUX1

AUX2

Q5

BC549

R63

0R0 0805

Page 13

003-034

Page 14

Note: Description includes Allen and Heath part number in brackets

)

)

)

)

)

)

)

)

)

)

)

Designator Description Designator Description

C1 CAPACITOR ELECTROLYTIC 47uF 63V (AF0217) R30 RESISTOR METAL FILM SMD0805 100K 1% (AC2843)

C2 CAPACITOR ELECTROLYTIC 47uF 63V (AF0217) R31 RESISTOR SMD 120K 1% 0805 (AC5109)

C3 CAPACITOR CERAMIC SMD0805 1N5 (AF2991) R32 RESISTOR SMD MELF 1K2 1% 0805 METAL (AC5039)

C4 CAPACITOR CERAMIC SMD0805 2N2 (AF3548) R33 RESISTOR SMD MELF 1K2 1% 0805 METAL (AC5039)

C5 CAPACITOR CERAMIC SMD0805 2N2 (AF3548) R34 RESISTOR METAL FILM SMD0805 2K2 1% (AC0370)

C6 CAPACITOR ELECTROLYTIC 220uF 10V (AF0225) R35 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

C7 CAPACITOR ELECTROLYTIC 220uF 10V (AF0225) R36 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

C8 CAPACITOR ELECTROLYTIC 220uF 10V (AF0225) R37 RESISTOR METAL FILM SMD0805 8K2 1% (AC5017)

C9 CAPACITOR SMD0805 33P XXV (AF4887) R38 RESISTOR METAL FILM SMD0805 8K2 1% (AC5017)

C10 CAPACITOR CERAMIC SMD0805 15P 50V (AF5034) R39 RESISTOR CARBON SMD0805 12K 5% (AC4107)

C11 CAPACITOR SMD0805 33P XXV (AF4887) R40 RESISTOR CARBON SMD0805 12K 5% (AC4107)

C12 CAPACITOR CERAMIC SMD0805 15P 50V (AF5034) R41 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C13 CAPACITOR SMD0805 33P XXV (AF4887) R42 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C14 CAPACITOR SMD0805 33P XXV (AF4887) R43 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C15 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R44 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C16 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R45 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C17 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R46 RESISTOR SMD 22R 5% 0805 (AC4100)

C18 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R47 RESISTOR METAL FILM SMD0805 100K 1% (AC2843)

C19 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R48 RESISTOR CARBON SMD0805 22K 5% (AC3540)

C20 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R49 RESISTOR CARBON SMD0805 22K 5% (AC3540)

C21 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R50 RESISTOR SMD 120K 1% 0805 (AC5109)

C22 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R51 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

C23 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R52 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C24 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R53 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C25 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R54 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC0378)

C26 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R55 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC0378)

C27 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R56 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC0378)

C28 CAPACITOR SMD 22P CERAMIC 0805 (AF2992) R57 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC0378)

C29 CAPACITOR CERAMIC SMD0805 1N0 (AF5040) R58 RESISTOR CARBON SMD0805 47R 5% (AC3036)

C30 CAPACITOR CERAMIC SMD0805 22N (AF5035) R59 RESISTOR CARBON SMD0805 82K 5% (AC4894)

C31 CAPACITOR CERAMIC SMD0805 22N (AF5035) R60 RESISTOR CARBON SMD0805 27K 5% (AC4693)

C32 CAPACITOR SMD0805 47N XXV CERAMIC (AF4889) R61 RESISTOR CARBON SMD0805 22K 5% (AC3540)

C33 CAPACITOR SMD0805 47N XXV CERAMIC (AF4889) R63 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

C34 CAPACITOR CERAMIC SMD0805 100N (AF2851) R64 RESISTOR CARBON SMD0805 47K 5% (AC3035)

C35 CAPACITOR CERAMIC SMD0805 100N (AF2851) R65 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

C36 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R66 RESISTOR CARBON SMD0805 5K6 5% (AC4106)

C37 CAPACITOR CERAMIC SMD0805 330N (AF5070) R67 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C38 CAPACITOR CERAMIC SMD0805 100N (AF2851) R68 RESISTOR CARBON SMD0805 2K7 5% (AC4698)

C39 CAPACITOR CERAMIC SMD0805 100N (AF2851) R69 RESISTOR CARBON SMD0805 2K7 5% (AC4698)

C40 CAPACITOR CERAMIC SMD0805 22N (AF5035) SW1 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

CN1 XLR 3 PIN FEMALE WITH GROUND (AL2412) SW2 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

CN2 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713) SW3 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

CN3 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713) SW4 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

CN4 Connector IDC,Molex Type 0.1 Pitch 8x2 pins (AL4335)" U1 IC SMD NE5532 OP AMP (AE4699)

CN5 EARTH SCREW TERMINAL NARROW HORIZONTAL TYPE (AA9000) U2 IC SMD DUAL OP-AMP TL072 (AE3335)

D1 DIODE SIGNAL SMD BAS16 (AE3352) U3 IC SMD DUAL OP-AMP TL072 (AE3335)

D2 DIODE SIGNAL SMD BAS16 (AE3352) VR1 POT ALPS 14mm 5KRD x2 502RD (AI8174

D3 DIODE SIGNAL SMD BAS16 (AE3352) VR2 POT ALPS 11mm 20KB C/D 203B (AI8004

JP1 JUMP 2 OPTION LINK (AL8068) VR3 POT ALPS 11mm 200KC X2 DUAL GANG 204C (AI8005)

JP2 JUMP 2 OPTION LINK (AL8068) VR4 POT ALPS 11mm 20KB C/D 203B (AI8004

JP2 JUMPER SKT TWO WAY (AL0334) VR5 POT ALPS 11mm 20KB C/D 203B (AI8004

JP3 JUMP 2 OPTION LINK (AL8068) VR6 POT ALPS 11mm 20KB C/D 203B (AI8004

LD1 LED RED 5X2.5 TOMBSTONE (AE4863) VR7 POT ALPS 11mm 20KK 203K (AI8003

LD2 LED T1 3mm RED (AE0086

Q1 TRANSISTOR PNP 2SB737 (AE8069) VR9 POT ALPS 11mm 20KK 203K (AI8003

Q2 TRANSISTOR PNP 2SB737 (AE8069) VR10 POT ALPS 11mm 20KK 203K (AI8003

Q3 TRANSISTOR NPN BC549 (AE0020) VR11 POT ALPS 14mm 10KAC x2 C/D 103AC (AI8008

Q4 TRANSISTOR NPN BC549 (AE0020)

Q5 TRANSISTOR NPN BC549 (AE0020)

R1 RESISTOR SMD 22R 5% 0805 (AC4100)

R2 RESISTOR SMD 22R 5% 0805 (AC4100)

R3 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R4 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R5 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R6 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R7 RESISTOR SMD MELF 4K7 1% 0805 (AC5038)

R8 RESISTOR SMD MELF 4K7 1% 0805 (AC5038)

R9 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

R10 RESISTOR CARBON SMD0805 1K8 5% (AC3029)

R11 RESISTOR CARBON SMD0805 1K8 5% (AC3029)

R12 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

R13 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R14 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R15 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R16 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R17 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R18 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R19 RESISTOR SMD MELF 820R 1% 0805 METAL (AC5037)

R20 RESISTOR SMD MELF 820R 1% 0805 METAL (AC5037)

R21 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R22 RESISTOR SMD MELF 2K7 1% 0805 (AC5108)

R23 RESISTOR SMD MELF 2K7 1% 0805 (AC5108)

R24 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R25 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R26 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

R27 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

R28 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

R29 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

VR8 POT ALPS 11mm 20KK 203K (AI8003

PA-CP Mono Input issue 1

Page 1 of 1

003−034

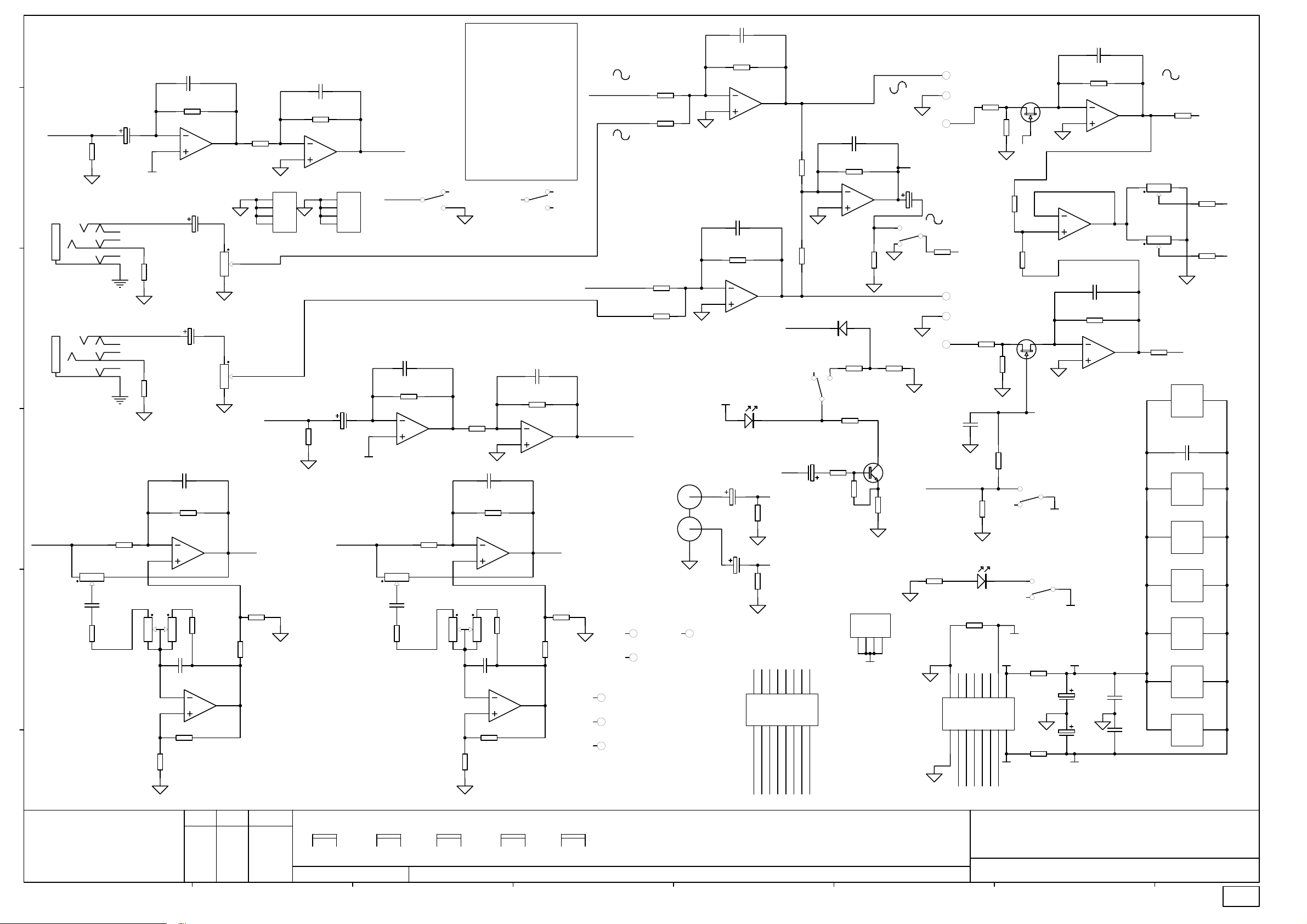

Page 15

CN1

003-035/1

RCA PHONO H2H

e

LEFT

RIGHT

C4

10N_S

IND EMI SUPP (WBCXX/R)

W

IND EMI SUPP (WBCXX/R)

R

R64

0R0 0805

d

c

GC

b

PFL_DET PFL_BUS

EARTH SCREW TERMINAL NARROW

AI HOLES

AI1

HOLE-AI

AI2

SLOT-AI

CN5

BOX 8X2 M 90 DEG

112

334

5

5

7

7

9

9

11

11

13

13

15

15

1

2

3

4

CN4

NF 0805

R3

R5 NF 0805

6

8

10

12

14

16

C20

33P 0805

C1

8

V+

V-

4

R27

10K 1% 0805

R26

10K 1% 0805

R32

10K 1% 0805

R31

10K 1% 0805

WIPER_L

WIPER_R

U6C

TL072D SMD

R6

4K7 1% 0805

C14

47/25

R7

4K7 1% 0805

C17

47/25

47/25

VR1A

POT14 20KK X2

L1

L2

C2

47/25

4

1 6

VR1B

POT14 20KK X2

3

2 5

SW1B

SW2PCOL (SPUN)

5

SW1A

SW2PCOL (SPUN)

2

4

R25

6

4K7 1% 0805

R1

NF 0805

1

R30

3

4K7 1% 0805

R2

NF 0805

C6

MIXL

MIXR

LEFT

T

R

CN3

JACK SLIMJACK MET SW6

R65

0R0 0805

47/25

C12

VR2A

POT14 20KK X2

4

1 6

RIGHT

T

R

CN2

JACK SLIMJACK MET SW6

V-V+

2

4

6

FB1FB2

8

AUXFX

10

MIXLMIXR

12

14

16

R70

10R PF RAD

10R PF RAD

R71

+17VA

-17VA

C15

47/25

C16

47/25

V+

R8

TCW

V-

R66

0R0 0805

C34

100N_S

C35

100N_S

GC

47/25

R46

0R0 0805

8

U3C

V+

V-

TL072D SMD

4

VR2B

POT14 20KK X2

2 5

8

U4C

V+

V-

TL072D SMD

4

3

8

U5C

V+

V-

TL072D SMD

4

6

5

2

3

2

3

R21

47K 0805

R22

47K 0805

R28

33K 1% 0805

U3B

TL072D SMD

C22

33P 0805

R33

33K 1% 0805

U3A

TL072D SMD

C24

R35

10K 1% 0805

U5A

TL072D SMD

C25

R36

10K 1% 0805

U5B

6

5

TL072D SMD

FID1

FIDUCIAL

7

33P 0805

33P 0805

1

1

7

FID2

FIDUCIAL

R14

C32

220/10

C33

220/10

3K9 0805

VR3B

POT14 20KB X2 C/D

3

R55

6K8 1% 0805

R10

3K9 0805

1 6

R50

2K2 1% 0805

R49

2K2 1% 0805

VR9B

POT14 10KAC C/D

3

VR4B

POT14 20KB X2 C/D

VR3A

POT14 20KB X2 C/D

VR4A

POT14 20KB X2 C/D

C30 150N 0805

VR9A

POT14 10KAC C/D

4

3

25

C31

2N7_S

R59

5K6 0805

25

C28 150N 0805

16

4

C3

2N7_S

R57

5K6 0805

R60

6K8 1% 0805

4

16

25

C26

22P_S

U4A

2

3

TL072D SMD

R43

3K9 0805

C29

22P_S

U4B

6

5

TL072D SMD

R44

3K9 0805

R37

8K2 1% 0805

R38

8K2 1% 0805

7

LD2

+17VA

SW4B

C5

47/25

C10

47/25

R61

6K8 1% 0805

PFL_DET

4

R11

47K 0805

R15

47K 0805

LD1

5

1

R68

1K0 1% 0805

R69

1K0 1% 0805

LED RECT 5X2.5MM TOMB RED

MIXL

MIXR

SW2PCOL (SPUN)

+17VA

LED T1 3MM RED

R62

3K3 1% 0805

R45

2K2 1% 0805

1

SW3A

SW2PCOL (SPUN)

R63

3K3 1% 0805

R48

2K2 1% 0805

D1

BAS16

6

R72

22K 0805

PEAK_LED

PIN-SOLDER 1.2MM

3

2

C11

47/25

4

6

SW3B

SW2PCOL (SPUN)

5

R74

3K3 1% 0805

P4

P6

WIPER_L

P5

R16

47K 0805

PIN-SOLDER 1.2MM

P1

P3

P2

R67

5K6 0805

WIPER_R

3

2

R4

4K7 1% 0805

Q1

BC848B

5

6

VR5A

POT11 20KK

2

VR6A

POT11 20KK

2

VR7A

POT11 20KK

2

VR8A

POT11 20KK

2

PFL_BUS

1

U6A

TL072D SMD

PEAK_LED

U6B

TL072D SMD

13

R40

10K 1% 0805

13

R41

10K 1% 0805

13

R39

6K8 1% 0805

13

R42

6K8 1% 0805

R73

22K 0805

R75

1K0 1% 0805

R76

1K0 1% 0805

7

FB1

FB2

AUX

FX

2

SW4A

SW2PCOL (SPUN)

3

1

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

ISSUE BY DATE

1 MG 23-07-02

2 AAT 25-09-02

BRKT

8

VR1C

POT14 20KK X2

FILE: C4789_2.Sch 16:54:05 26-Mar-2003

BRKT

9

8

VR2C

POT14 20KK X2

PRINTED:

BRKT

9

8

VR3C

POT14 20KB X2 C/D

9

BRKT

8

9

VR4C

POT14 20KB X2 C/D

BRKT

5

6

VR5B

POT11 20KK

BRKT

5

VR6B

POT11 20KK

6

POT11 20KK

BRKT

5

VR7B

6

5

VR8B

POT11 20KK

BRKT

6

POT_GND

BRKT

8

9

VR9C

POT14 10KAC C/D

TITLE:

PA SERIES STEREO INPUT CCT

PAGE:

DRG No: ISSUE: SHEET: OF

AG4789 1 1

2

Page 16

003-035

Page 17

Note: Description includes Allen and Heath part number in brackets

)

)

)

)

)

)

)

)

)

)

)

Designator Description Designator Description

C1 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R74 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

C2 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R75 RESISTOR METAL FILM SMD0805 1K0 1% (AC0369)

C3 CAPACITOR CERAMIC SMD0805 2N7 (AF2993) R76 RESISTOR METAL FILM SMD0805 1K0 1% (AC0369)

C4 CAPACITOR SMD 10N CERAMIC 0805 (AF2849) SW1 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

C5 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) SW3 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

C6 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) SW4 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

C10 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) U3 IC SMD DUAL OP-AMP TL072 (AE3335)

C11 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) U4 IC SMD DUAL OP-AMP TL072 (AE3335)

C12 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) U5 IC SMD DUAL OP-AMP TL072 (AE3335)

C14 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) U6 IC SMD DUAL OP-AMP TL072 (AE3335)

C15 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) VR1 POT ALPS 14mm 20KK x2 203K (AI8007

C16 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) VR2 POT ALPS 14mm 20KK x2 203K (AI8007

C17 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) VR3 POT ALPS 14mm 20KB x2 C/D 203B (AI8006

C20 CAP SM 33pF (AF4887) VR4 POT ALPS 14mm 20KB x2 C/D 203B (AI8006

C22 CAP SM 33pF (AF4887) VR5 POT ALPS 11mm 20KK 203K (AI8003

C24 CAP SM 33pF (AF4887) VR6 POT ALPS 11mm 20KK 203K (AI8003

C25 CAP SM 33pF (AF4887) VR7 POT ALPS 11mm 20KK 203K (AI8003

C26 CAPACITOR CERAMIC SMD0805 22P (AF2992) VR8 POT ALPS 11mm 20KK 203K (AI8003

C28 CAPACITOR CERAMIC SMD 150nF 25V (AF4888) VR9 POT ALPS 14mm 10KAC x2 C/D 103AC (AI8008

C29 CAPACITOR CERAMIC SMD0805 22P (AF2992)

C30 CAPACITOR CERAMIC SMD 150nF 25V (AF4888)

C31 CAPACITOR CERAMIC SMD0805 2N7 (AF2993)

C32 CAPACITOR ELECTROLYTIC 220uF 10V (AF0225)

C33 CAPACITOR ELECTROLYTIC 220uF 10V (AF0225)

C34 CAPACITOR CERAMIC SMD0805 100N (AF2851)

C35 CAPACITOR CERAMIC SMD0805 100N (AF2851)

CN1 RCA PHONO DUAL HORIZONTAL R/W (AL0577)

CN2 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713)

CN3 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713)

CN4 EARTH SCREW TERMINAL NARROW HORIZONTAL TYPE (AA9000)

CN5 Connector IDC,Molex Type 0.1 Pitch 8x2 pins (AL4335)

D1 DIODE SIGNAL SMD BAS16 (AE3352)

LD1 LED RECT 5x2.5MM TOMBSTONE RED (AE4863

LD2 LED T1 3mm RED (AE0086

Q1 TRANSISTOR NPN BC848B (AE3332)

R3 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

R4 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

R5 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

R6 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

R7 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

R8 TC LINK 22SWG (AH0070)

R10 RESISTOR CARBON SMD0805 3K9 5% (AC4105)

R11 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R14 RESISTOR CARBON SMD0805 3K9 5% (AC4105)

R15 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R16 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R21 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R22 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R25 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

R26 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R27 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R28 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R30 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

R31 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R32 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R33 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R35 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R36 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R37 RESISTOR METAL FILM SMD0805 8K2 1% (AC5017)

R38 RESISTOR METAL FILM SMD0805 8K2 1% (AC5017)

R39 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R40 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R41 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R42 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R43 RESISTOR CARBON SMD0805 3K9 5% (AC4105)

R44 RESISTOR CARBON SMD0805 3K9 5% (AC4105)

R45 RESISTOR METAL FILM SMD0805 2K2 1% (AC0370)

R46 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R48 RESISTOR METAL FILM SMD0805 2K2 1% (AC0370)

R49 RESISTOR METAL FILM SMD0805 2K2 1% (AC0370)

R50 RESISTOR METAL FILM SMD0805 2K2 1% (AC0370)

R55 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R57 RESISTOR CARBON SMD0805 5K6 5% (AC4106)

R59 RESISTOR CARBON SMD0805 5K6 5% (AC4106)

R60 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R61 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R62 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

R63 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

R64 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

R65 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

R66 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

R67 RESISTOR CARBON SMD0805 5K6 5% (AC4106)

R68 RESISTOR METAL FILM SMD0805 1K0 1% (AC0369)

R69 RESISTOR METAL FILM SMD0805 1K0 1% (AC0369)

R70 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC5077)

R71 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC5077)

R72 RESISTOR CARBON SMD0805 22K 5% (AC3540)

R73 RESISTOR CARBON SMD0805 22K 5% (AC3540)

PA-CP Stereo Input issue 2

Page 1 of 1

003−035

Page 18

C6

003-036/1

C1

100/6.3

e

FX

R1

100K 1% 0805

EXT FX LEFT

CN3

JACK SLIMJACK SW6

T

R

EXT FX RIGHT

d

CN2

JACK SLIMJACK SW6

T

R

c

2

C28

47N 0805

R48

15K 0805

R42

10K 1% 0805

13

POT11 200KC X2 D/G

LF_IN_A

VR2A

POT11 20KB C/D

b

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

6

5

GC

R34

68R 0805

R35

68R 0805

2

3

VR1A

2

1

R58

10K 1% 0805

C3

22P_S

R4

20K 1% 0805

7

U1B

TL072D SMD

C14

47/25

VR5A

POT14 20KK X2

1 6

C16

47/25

VR5B

POT14 20KK X2

2 5

C12

22P_S

R43

10K 1% 0805

1

U6A

TL072D SMD

3

R49

15K 0805

C26

47N 0805

6

5

TL072D SMD

R62

6K8 1% 0805

ISSUE BY DATE

7

U6B

A MG 25-02-02

B AAT 30-04-02

1 AAT 04-07-02

2 AAT 09-09-02

C4

22P_S

R7

R6

10K 1% 0805

CN8

1

2

3

4

EARTH SCREW TERMINAL NARROW

4

3

AUX

LF_OUT_A

R60

3K3 1% 0805

R56

10K 1% 0805

10K 1% 0805

6

5

U2B

TL072D SMD

CN9

1

2

3

4

EARTH SCREW TERMINAL NARROW

C2

R2

100/6.3

100K 1% 0805

LF_IN_B

VR1B

POT11 200KC X2 D/G

BRKT

5

6

FILE: C4790_2.1.SCH 09:14:03 27-Mar-2003

7

ENCODER

GC

POT11 20KB C/D

FX_OUT

SW3A

FX_SW

2

SW2PCOM (SPUN)

C9

22P_S

R5

20K 1% 0805

2

3

U1A

TL072D SMD

R44

VR4A

POT11 20KB C/D

VR2B

BRKT

5

10K 1% 0805

13

2

C29

47N 0805

R50

15K 0805

POT11 200KC X2 D/G

6

PRINTED:

EFFECTS PCB

1

3

R12

1

10K 1% 0805

C13

22P_S

R45

10K 1% 0805

U7A

2

3

TL072D SMD

VR3A

POT11 200KC X2 D/G

VR3B

BRKT

5

2

1

6

3

C27

47N 0805

U7B

6

5

R63

6K8 1% 0805

R59

10K 1% 0805

SW3B

5

SW2PCOM (SPUN)

C10

22P_S

R13

10K 1% 0805

2

3

TL072D SMD

1

R51

15K 0805

7

TL072D SMD

VR4B

POT11 20KB C/D

BRKT

5

6

U2A

R61

3K3 1% 0805

R57

10K 1% 0805

FROM_FX_L

4

6

FROM_FX_R

1

LF_OUT_B

VR5C

POT14 20KK X2

BRKT

8

9

33K 1% 0805

AUX_OUT

RCA PHONO H2H

FID1

FIDUCIAL

FID3

FIDUCIAL

AI1

HOLE-AI VTECH

AI2

SLOT-AI VTECH

AI3

SLOT-AI VTECH

R8

33K 1% 0805

R19

10K 1% 0805

R14

R20

10K 1% 0805

CN1

2

3

TL072D SMD

6

5

TL072D SMD

+17VA

C18

47/25

W

R

FID2

FIDUCIAL

TO DIST PCB

22P_S

R23

33K 1% 0805

U3A

C5

22P_S

R24

33K 1% 0805

U3B

LD2

LED T1 3MM RED

C19

47/25

15

15

16

16

FX_SW

1

R25

22K 1% 0805

R28

22K 1% 0805

7

PFL_DET

SW2B

SW2PCOL (SPUN)

C17

PEAK

2TRK_IN_L

R39

47K 0805

2TRK_IN_R

R40

47K 0805

13

11

13

14

14

12

FROM_FX_L FROM_FX_R

47/25

LF_OUT_BLF_IN_B

3

5

7

9

3

5

7

9

11

4

6

8812

10

4

6

10

FX_OUT AUX_OUT

LF_IN_A LF_OUT_A

FOOTSWITCH

C7

22P_S

R26

22K 1% 0805

6

5

U4B

TL072D SMD

47K 0805

D1

BAS16

R41

4

6

22K 0805

R21

5

4K7 1% 0805

R36

47K 0805

R52

5K6 0805

CN7

EARTH SCREW TERMINAL NARROW

1

CN5

1

BOX 8X2 M 90 DEG

2

2

2TRK_IN_L 2TRK_IN_R

R37

3K3 1% 0805

123

SGND

BOX 8X2 M 90 DEG

PEAK

C15

47/25

7

3

1

SW2A

SW2PCOL (SPUN)

R46

Q3

BC549

R55

0R0 0805

4

MAIN BUS

CN6

P1

RED

P2

GRN

P3

BLU

2

R38

47K 0805

P4

PNK

P5

GRN2

P6

VIO

C22

100N_S

FOOTSWITCH

100K 1% 0805

R22

6K8 1% 0805

LED RECT 5X2.5MM TOMB RED

15

16

R9

10K 1% 0805

22K 1% 0805

22K 1% 0805

PFL_BUS

22K 1% 0805

R16

10K 1% 0805

R15

22K 1% 0805

R47

470K 2% 0805

R3

LD1

R18

NF 0805

PFL_DET

13

11

7

9

7

9

15

13

11

16

14

8812

10

14

12

10

PFL_BUS

AUX FX

MIXL MIXR

R10

R27

5

6

FB1 FB2

3

5

6

4

+48V

R29

V+

3

4

V-

TITLE:

PAGE:

DRG No: ISSUE: SHEET: OF

C8

22P_S

2

3

6

5

5

-17VA

+17VA

-17VA

R30

33K 1% 0805

TL072D SMD

U4A

C11

22P_S

R31

33K 1% 0805

TL072D SMD

C20

47/25

C21

47/25

1

U5B

U5A

1

7

C24

100N_S

C25

100N_S

R11

10K 1% 0805

VR7A

POT11 20KK

2

VR8A

POT11 20KK

2

R17

10K 1% 0805

U7C

8

TL072D SMD

U1C

8

TL072D SMD

U2C

8

TL072D SMD

U3C

8

TL072D SMD

U4C

8

TL072D SMD

U5C

8

TL072D SMD

U6C

8

TL072D SMD

13

13

MIXR

V+

100N_S

V+

V+

V+

V+

V+

V+

Q1

J111N

MUTE

Q2

J111N

MUTE

SW1A

SW2PCOL (SPUN)

3

1

SW1B

SW2PCOL (SPUN)

6

4

GC

R53

10R PF RAD

1

1

2

2

R54

10R PF RAD

2

3

TL072D SMD

2

-17VA

PA SERIES AUX-FX PCB

C4790 1 1

2.1

V-

C23

V-

V-

V-

V-

V-

V-

MIXL

R32

12K 0805

R33

12K 0805

4

4

4

4

4

4

4

FB1

FB2

Page 19

003-036

Page 20

Note: Description includes Allen and Heath part number in brackets

)

)

)

)

)

)

)

Designator Description Designator Description

C1 CAPACITOR ELECTROLYTIC 100uF 6.3V (AF2984) R47 RESISTOR METAL FILM SMD0805 470K 2% (AC2844)

C2 CAPACITOR ELECTROLYTIC 100uF 6.3V (AF2984) R48 RESISTOR CARBON SMD0805 15K 5% (AC3486)

C3 CAPACITOR CERAMIC SMD0805 22P (AF2992) R49 RESISTOR CARBON SMD0805 15K 5% (AC3486)

C4 CAPACITOR CERAMIC SMD0805 22P (AF2992) R50 RESISTOR CARBON SMD0805 15K 5% (AC3486)

C5 CAPACITOR CERAMIC SMD0805 22P (AF2992) R51 RESISTOR CARBON SMD0805 15K 5% (AC3486)

C6 CAPACITOR CERAMIC SMD0805 22P (AF2992) R52 RESISTOR CARBON SMD0805 5K6 5% (AC4106)

C7 CAPACITOR CERAMIC SMD0805 22P (AF2992) R53 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC5077)

C8 CAPACITOR CERAMIC SMD0805 22P (AF2992) R54 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC5077)

C9 CAPACITOR CERAMIC SMD0805 22P (AF2992) R55 RESISTOR CARBON SMD0805 0R0 5% (AC2838)

C10 CAPACITOR CERAMIC SMD0805 22P (AF2992) R56 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C11 CAPACITOR CERAMIC SMD0805 22P (AF2992) R57 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C12 CAPACITOR CERAMIC SMD0805 22P (AF2992) R58 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C13 CAPACITOR CERAMIC SMD0805 22P (AF2992) R59 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

C14 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R60 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

C15 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R61 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

C16 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R62 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

C17 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) R63 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

C18 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) SW1 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

C19 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) SW2 SWITCH DPDT ALPS (SPUN) LATCHING (AL0162)

C20 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) SW3 SWITCH 2 POLE MOMENTARY (AL0374)

C21 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208) U1 IC SMD DUAL OP-AMP TL072 (AE3335)

C22 CAPACITOR CERAMIC SMD0805 100N (AF2851) U2 IC SMD DUAL OP-AMP TL072 (AE3335)

C23 CAPACITOR CERAMIC SMD0805 100N (AF2851) U3 IC SMD DUAL OP-AMP TL072 (AE3335)

C24 CAPACITOR CERAMIC SMD0805 100N (AF2851) U4 IC SMD DUAL OP-AMP TL072 (AE3335)

C25 CAPACITOR CERAMIC SMD0805 100N (AF2851) U5 IC SMD DUAL OP-AMP TL072 (AE3335)

C26 CAPACITOR CERAMIC SMD0805 47N (AF4889) U6 IC SMD DUAL OP-AMP TL072 (AE3335)

C27 CAPACITOR CERAMIC SMD0805 47N (AF4889) U7 IC SMD DUAL OP-AMP TL072 (AE3335)

C28 CAPACITOR CERAMIC SMD0805 47N (AF4889) VR1 POT ALPS 11mm 200KC X2 DUAL GANG 204C (AI8005)

C29 CAPACITOR CERAMIC SMD0805 47N (AF4889) VR2 POT ALPS 11mm 20KB C/D 203B (AI8004

CN1 RCA PHONO DUAL HORIZONTAL R/W (AL0577) VR3 POT ALPS 11mm 200KC X2 DUAL GANG 204C (AI8005)

CN2 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713) VR4 POT ALPS 11mm 20KB C/D 203B (AI8004

CN3 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713) VR5 POT ALPS 14mm 20KK x2 203K (AI8007

CN5 Connector IDC,Molex Type 0.1 Pitch 8x2 pins (AL4335) VR7 POT ALPS 11mm 20KK 203K (AI8003

CN6 Connector IDC,Molex Type 0.1 Pitch 8x2 pins (AL4335) VR8 POT ALPS 11mm 20KK 203K (AI8003

CN7 EARTH SCREW TERMINAL NARROW HORIZONTAL TYPE (AA9000)

CN8 EARTH SCREW TERMINAL NARROW HORIZONTAL TYPE (AA9000)

CN9 EARTH SCREW TERMINAL NARROW HORIZONTAL TYPE (AA9000)

D1 DIODE SIGNAL SMD BAS16 (AE3352)

LD1 LED RECT 5x2.5MM TOMBSTONE RED (AE4863

LD2 LED T1 3mm RED (AE0086

Q1 TRANSISTOR JFET N CHANNEL J111N (AE0083)

Q2 TRANSISTOR JFET N CHANNEL J111N (AE0083)

Q3 TRANSISTOR NPN BC549 (AE0020)

R1 RESISTOR METAL FILM SMD0805 100K 1% (AC2843)

R2 RESISTOR METAL FILM SMD0805 100K 1% (AC2843)

R3 RESISTOR METAL FILM SMD0805 100K 1% (AC2843)

R4 RESISTOR METAL FILM SMD0805 20K 1% (AC5057)

R5 RESISTOR SMD 20K 1% 0805 (AC5057)

R6 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R7 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R8 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R9 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R10 RESISTOR METAL FILM SMD0805 22K 1% (AC2842)

R11 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R12 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R13 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R14 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R15 RESISTOR METAL FILM SMD0805 22K 1% (AC2842)

R16 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R17 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R19 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R20 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R21 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

R22 RESISTOR METAL FILM SMD0805 6K8 1% (AC3064)

R23 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R24 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R25 RESISTOR METAL FILM SMD0805 22K 1% (AC2842)

R26 RESISTOR METAL FILM SMD0805 22K 1% (AC2842)

R27 RESISTOR METAL FILM SMD0805 22K 1% (AC2842)

R28 RESISTOR METAL FILM SMD0805 22K 1% (AC2842)

R29 RESISTOR METAL FILM SMD0805 22K 1% (AC2842)

R30 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R31 RESISTOR METAL FILM SMD0805 33K 1% (AC3532)

R32 RESISTOR CARBON SMD0805 12K 5% (AC4107)

R33 RESISTOR CARBON SMD0805 12K 5% (AC4107)

R34 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R35 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R36 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R37 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R38 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R39 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R40 RESISTOR CARBON SMD0805 47K 5% (AC3035)

R41 RESISTOR CARBON SMD0805 22K 5% (AC3540)

R42 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R43 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R44 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R45 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R46 RESISTOR METAL FILM SMD0805 3K3 1% (AC3061)

PA-CP Aux FX issue 2

Page 1 of 1

003−036

Page 21

+17VB

003-037/1

3

U(S)1E

LM339 SMD

V+

V-

12

-17VB

R(S)4

e

1 2

SGNDS

120R 1% 0805

R(S)5

120R 1% 0805

R(S)6

120R 1% 0805

R(S)7

120R 1% 0805

R(S)8

120R 1% 0805

d

R(S)9

330R 1% 0805

R(S)10

330R 1% 0805

R(S)11

560R 1% 0805

R(S)12

680R 1% 0805

c

R(S)13

1K2 1% 0805

R(S)14

1K2 1% 0805

R(S)15

3K9 0805

R(S)16

1K0 1% 0805

b

+17VB

P8

1

1

PIN

P9

1

1

PIN

P10

-17VB

1

1

PIN

P11

1

1

PIN

SGNDS

12

12

12

12

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

+17VB

3

V+

V-

12

4

5

6

7

8

9

10

11

4

5

6

7

8

9

10

11

4

5

6

7

8

9

10

11

U(S)2E

LM339 SMD

U(S)1A

LM339 SMD

U(S)1B

U(S)1C

LM339 SMD

U(S)1D

LM339 SMD

U(S)2A

U(S)2B

LM339 SMD

U(S)2C

LM339 SMD

U(S)2D

LM339 SMD

U(S)3A

LM339 SMD

U(S)3B

LM339 SMD

U(S)3C

LM339 SMD

U(S)3D

LM339 SMD

3

U(S)3E

LM339 SMD

V+

V-

12

-17VB

2

1

LM339 SMD

14

13

2

LM339 SMD

1

14

13

2

1

14

13

R(S)3

15K 0805

+17VB

R(S)2

4K7 1% 0805

1 2

-17VB

1 2

123456789101112131415161718192021222324

METER SUB PCB

R(S)1

1K2 1% 0805

Q(S)1

BC858B

LD(S)1

LED BAR

CN1

RCA PHONO H2H

LF_OUT_A

R2

68R 0805

W

R3

68R 0805

R

R1

68R 0805

VR2A

POT11 20KB C/D

2

C9

6N8_S

R14

12K 0805

R24

+VA

10R PF RAD

R25

-VA

10R PF RAD

C1

2TRK_OUT_L

47/25

C2

2TRK_OUT_R

47/25

R8

10K 1% 0805

13

2

3

VR1A

POT11 200KC X2 D/G

2

+17VA

C5

47/25

C6

47/25

-17VA

TL072D SMD

3

C10

1

6N8_S

6

5

R20

10K 1% 0805

R18

15K 0805

100N 0805

EXT FX RIGHT

CN2

JACK SLIMJACK SW6

C7

22P_S

R9

10K 1% 0805

1

U1A

R15

12K 0805

U1B

TL072D SMD

C13

100N 0805

C14

T

R

R22

2K7 0805

R12

10K 1% 0805

7

8

U1C

TL072D SMD

V+

V-

4

LMF_OUT_A

8

U2C

TL072D SMD

V+

V-

4

R4

68R 0805

R5

68R 0805

C3

47/25

LF_OUT_B

JACK SLIMJACK SW6

VR4A

POT11 20KB C/D

2

C11

6N8_S

R16

12K 0805

TO DIST PCB

+VA

-VA

EXT FX LEFT

CN3

T

R

R10

10K 1% 0805

13

POT11 200KC X2 D/G

LMF_OUT_A

15

13

11

7

9

9

15

13

11

16

14

10

16

14

12

10

LF_OUT_A

VR3A

2

LMF_OUT_B

5

7

8812

6

LF_OUT_B

2

3

1

R19

15K 0805

1

3

3

5

4

6

2

4

2TRK_OUT_L 2TRK_OUT_R

FX_OUT AUX_OUT

1

2

R6

68R 0805

R7

68R 0805

C8

22P_S

R11

10K 1% 0805

U2A

1

TL072D SMD

3

R17

12K 0805

C12

6N8_S

U2B

6

5

TL072D SMD

R21

10K 1% 0805

CN4

BOX 8X2 M 90 DEG

AI1

HOLE-AI VTECH

AI1_1

HOLE-AI VTECH

C4

47/25

LMF_OUT_B

R23

2K7 0805

R13

10K 1% 0805

7

FH1

HOLE-FIXING 3.5MM

FH2

HOLE-FIXING 3.5MM

FID1

FIDUCIAL

AI2

SLOT-AI VTECH

FX_OUTAUX_OUT

FID2

FIDUCIAL

FID1_1

FIDUCIAL

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

ISSUE BY DATE

A MG 25-02-02

B AAT 22-04-02

1 AAT 27-06-02

VR1B

POT11 200KC X2 D/G

BRKT

5

6

FILE: C4791_1P1.SCH 09:36:03 27-Mar-2003

VR2B

POT11 20KB C/D

BRKT

5

6

VR3B

POT11 200KC X2 D/G

BRKT

5

PRINTED:

6

VR4B

POT11 20KB C/D

BRKT

5

6

TITLE:

PA SERIES SUB 1 PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C4791 1 1

1

Page 22

003-037

Page 23

Note: Description includes Allen and Heath part number in brackets

)

)

Designator Description

C1 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208)

C2 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208)

C3 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208)

C4 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208)

C5 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208)

C6 CAPACITOR ELECTROLYTIC 47uF 25V (AF0208)

C7 CAPACITOR CERAMIC SMD0805 22P (AF2992)

C8 CAPACITOR CERAMIC SMD0805 22P (AF2992)

C9 CAPACITOR SMD 6N8 CERAMIC 0805 (AF2994)

C10 CAPACITOR SMD 6N8 CERAMIC 0805 (AF2994)

C11 CAPACITOR SMD 6N8 CERAMIC 0805 (AF2994)

C12 CAPACITOR SMD 6N8 CERAMIC 0805 (AF2994)

C13 CAPACITOR CERAMIC SMD0805 100N (AF2851)

C14 CAPACITOR CERAMIC SMD0805 100N (AF2851)

CN1 RCA PHONO DUAL HORIZONTAL R/W (AL0577)

CN2 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713)

CN3 JACK SOCKET HORIZONTAL 6 PIN MET HEADPHONE (AL4713)

CN4 Connector IDC,Molex Type 0.1 Pitch 8x2 pins (AL4335)

LD(S)1 LED BAR MB12 SQUARE LEDS IN HOUSING 8G,3Y,1R (AE2701)

Q(S)1 TRANSISTOR PNP BC858B (AE3042)

R1 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R2 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R3 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R4 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R5 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R6 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R7 RESISTOR CARBON SMD0805 68R 5% (AC4101)

R8 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R9 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R10 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R11 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R12 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R13 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R14 RESISTOR CARBON SMD0805 12K 5% (AC4107)

R15 RESISTOR CARBON SMD0805 12K 5% (AC4107)

R16 RESISTOR CARBON SMD0805 12K 5% (AC4107)

R17 RESISTOR CARBON SMD0805 12K 5% (AC4107)

R18 RESISTOR CARBON SMD0805 15K 5% (AC3486)

R19 RESISTOR CARBON SMD0805 15K 5% (AC3486)

R20 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R21 RESISTOR METAL FILM SMD0805 10K 1% (AC2841)

R22 RESISTOR CARBON SMD0805 2K7 5% (AC4698)

R23 RESISTOR CARBON SMD0805 2K7 5% (AC4698)

R24 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC5077)

R25 RESISTOR CARBON 10R PRE FORMED 1/4W 5% (AC5077)

R(S)1 RESISTOR METAL FILM SMD0805 1K2 1% (AC3059)

R(S)2 RESISTOR METAL FILM SMD0805 4K7 1% (AC3062)

R(S)3 RESISTOR CARBON SMD0805 15K 5% (AC3486)

R(S)4 RESISTOR METAL FILM SMD0805 120R 1% (AC3055)

R(S)5 RESISTOR METAL FILM SMD0805 120R 1% (AC3055)

R(S)6 RESISTOR METAL FILM SMD0805 120R 1% (AC3055)

R(S)7 RESISTOR METAL FILM SMD0805 120R 1% (AC3055)

R(S)8 RESISTOR METAL FILM SMD0805 120R 1% (AC3055)

R(S)9 RESISTOR METAL FILM SMD0805 330R 1% (AC3056)

R(S)10 RESISTOR METAL FILM SMD0805 330R 1% (AC3056)

R(S)11 RESISTOR METAL FILM SMD0805 560R 1% (AC3057)

R(S)12 RESISTOR METAL FILM SMD0805 680R 1% (AC3058)

R(S)13 RESISTOR METAL FILM SMD0805 1K2 1% (AC3059)

R(S)14 RESISTOR METAL FILM SMD0805 1K2 1% (AC3059)

R(S)15 RESISTOR CARBON SMD0805 3K9 5% (AC4105)

R(S)16 RESISTOR METAL FILM SMD0805 1K0 1% (AC0369)

U1 IC SMD DUAL OP-AMP TL072 (AE3335)

U2 IC SMD DUAL OP-AMP TL072 (AE3335)

U(S)1 IC LM339 COMPARATOR SMD (AE4890)

U(S)2 IC LM339 COMPARATOR SMD (AE4890)

U(S)3 IC LM339 COMPARATOR SMD (AE4890)

VR1 POT ALPS 11mm 200KC X2 DUAL GANG 204C (AI8005)

VR2 POT ALPS 11mm 20KB C/D 203B (AI8004

VR3 POT ALPS 11mm 200KC X2 DUAL GANG 204C (AI8005)

VR4 POT ALPS 11mm 20KB C/D 203B (AI8004

PA-CP Sub 1 issue 1

Page 1 of 1

003−037

Page 24

+17VB

003-037/1

3

U(S)1E

LM339 SMD

V+

V-

12

-17VB

R(S)4

e

1 2

SGNDS

120R 1% 0805

R(S)5

120R 1% 0805

R(S)6

120R 1% 0805

R(S)7

120R 1% 0805

R(S)8

120R 1% 0805

d

R(S)9

330R 1% 0805

R(S)10

330R 1% 0805

R(S)11

560R 1% 0805

R(S)12

680R 1% 0805

c

R(S)13

1K2 1% 0805

R(S)14

1K2 1% 0805

R(S)15

3K9 0805

R(S)16

1K0 1% 0805

b

+17VB

P8

1

1

PIN

P9

1

1

PIN

P10

-17VB

1

1

PIN

P11

1

1

PIN

SGNDS

12

12

12

12

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

+17VB

3

V+

V-

12

4

5

6

7

8

9

10

11

4

5

6

7

8

9

10

11

4

5

6

7

8

9

10

11

U(S)2E

LM339 SMD

U(S)1A

LM339 SMD

U(S)1B

U(S)1C

LM339 SMD

U(S)1D

LM339 SMD

U(S)2A

U(S)2B

LM339 SMD

U(S)2C

LM339 SMD

U(S)2D

LM339 SMD

U(S)3A

LM339 SMD

U(S)3B

LM339 SMD

U(S)3C

LM339 SMD

U(S)3D

LM339 SMD

3

U(S)3E

LM339 SMD

V+

V-

12

1K 1% 0805

-17VB

2

1

LM339 SMD

14

13

2

LM339 SMD

1

14

13

2

1

14

13

R(S)2

R(S)3

15K 0805

1 2

+17VB

1 2

123456789101112131415161718192021222324

-17VB

METER SUB PCB

R(S)1

180R 0805

Q(S)1

BC858B

LD(S)1

LED BAR

CN1

RCA PHONO H2H

LF_OUT_A

R2

68R 0805

W

R3

68R 0805

R

R1

68R 0805

VR2A

POT11 20KB C/D

2

C9

6N8_S

R14

12K 0805

R24

+VA

10R PF RAD

R25

-VA

10R PF RAD

C1

2TRK_OUT_L

47/25

C2

2TRK_OUT_R

47/25

R8

10K 1% 0805

13

2

3

VR1A

POT11 200KC X2 D/G

2

+17VA

C5

47/25

C6

47/25

-17VA

TL072D SMD

3

C10

1

6N8_S

6

5

R20

10K 1% 0805

R18

15K 0805

100N 0805

EXT FX RIGHT

CN2

JACK SLIMJACK SW6

C7

22P_S

R9

10K 1% 0805

1

U1A

R15

12K 0805

U1B

TL072D SMD

C13

100N 0805

C14

T

R

R22

2K7 0805

R12

10K 1% 0805

7

8

U1C

TL072D SMD

V+

V-