Page 1

ALLEN&H

EATH

WARNING – HIGH VOLTAGES

Power Supply Unit (PSU) work should only

e carried out by qualified personnel.

b

We recommend that you use an approved Allen & Heath

service centre for all power supply work.

Please contact your local Allen & Heath distributor for more details.

http://www.allen-heath.com/

Page 2

ALLEN&HEATH

ML5000

Dual Function Live Sound Console

SERVICE MANUAL

Publication AP3737

Page 3

Introduction

This service manual provides technical information on the Allen & Heath ML5000 audio console.

Included is the technical specification, system block diagram, circuit schematics with board layouts,

and a spare parts list. Information on the power supply is available in a separate publication. Only

technically qualified service personnel should carry out service work on the console and its power

supply.

Whilst we believe the information in this manual to be reliable we do not assume responsibility for

inaccuracies. We also reserve the right to make changes in the interest of further product

development.

We are able to offer further product support through our world-wide network of approved dealers

and service agents. You can also access our Web site on the Internet for information on our

product range and further technical support. To help us provide the most efficient service please

keep a record of the console serial number, and date and place of purchase to be quoted in any

communication regarding this product. The serial number is located on the rear panel.

Check out our home site for information on the company and its pedigree, our full product range

and our design philosophy.

www.allen-heath.com

ML5000 Service Manual AP3737 Issue 2

Copyright © 2002 Allen & Heath. All rights reserved

This product complies with the European Electromagnetic

Compatibility directives 89/336/EEC & 92/31/EEC and the

European Low Voltage Directives 73/23/EEC & 93/68/EEC.

This product has been tested to EN55103 Parts 1 & 2 1996 for use in

Environments E1, E2, E3, and E4 to demonstrate compliance with the

protection requirements in the European EMC directive 89/336/EEC. During

some tests the specified performance figures of the product were affected.

This is considered permissible and the product has been passed as

acceptable for its intended use.

Allen & Heath has a strict policy of ensuring all products are tested to the

latest safety and EMC standards. Customers requiring more information

about EMC and safety issues can contact Allen & Heath.

NOTE: Any changes or modifications to the console not approved by Allen &

Heath could void the compliance of the console and therefore the users

authority to operate it.

Manufactured in the United Kingdom by Allen & Heath

Kernick Industrial Estate, Penryn, Cornwall, TR10 9LU, UK

http://www.allen-heath.com

2 ML5000 Service Manual

Page 4

Contents

Important Safety Instructions ............................4

Mains Plug Wiring Instructions .........................5

General Precautions ......................................... 5

ML5000 Key Features ...................................... 6

Front Panel Layout............................................7

Rear Panel Layout ............................................ 8

Functional Description ......................................9

Installing the Console......................................10

The Expander Sidecar ....................................11

The MPS14 Power Supply.............................. 14

Technical Specifications .................................16

System Block Diagram....................................17

Connector Types and Wiring .......................... 19

Gain Structure.................................................20

Internal Jumper Options .................................21

MIDI ................................................................22

Operating Software Technical Support........... 24

Servicing the Input Faders..............................25

Servicing the Master Faders........................... 27

Base Removal and Internal Assemblies......... 29

Removing a Mono Input Assembly ................. 30

Removing the Master Distribution................... 31

Servicing the Meterbridge............................... 32

Servicing the MPS14 Power Supply............... 33

Ordering Consoles and Accessories ..............34

Ordering Assemblies.......................................35

Ordering Spare Parts...................................... 37

Channel Cue Sheet (Blank) ............................42

Master Cue Sheet (Blank) ..............................43

Service Notes (Blank) ..................................... 44

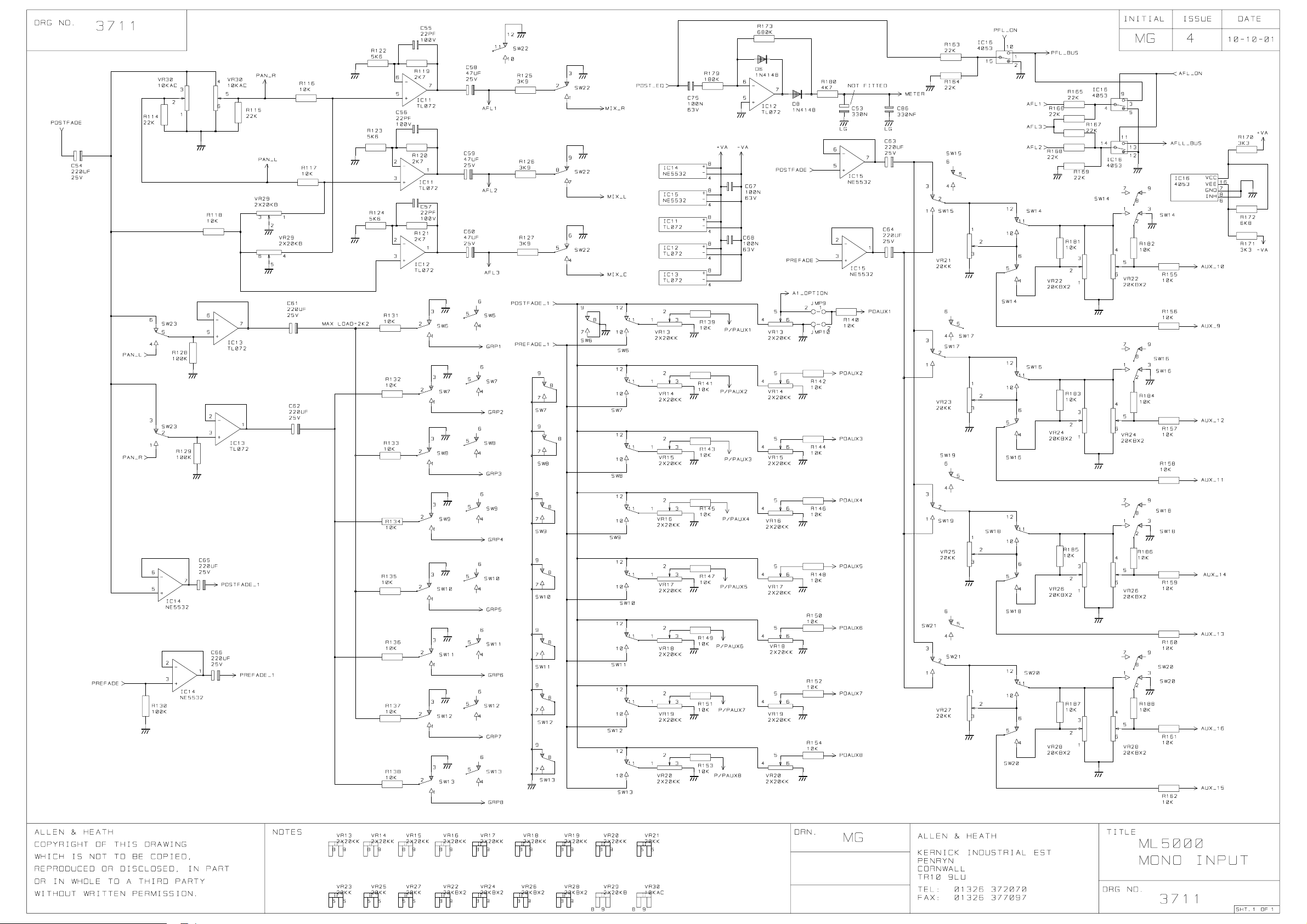

TECHNICAL DRAWINGS .................. Section D

ML5000 Service Manual 3

Page 5

Important Safety Instructions

WARNINGS - Read the following before proceeding :

CAUTION

ATTENTION: RISQUE DE CHOC ELECTRIQUE – NE PAS OUVRIR

Read instructions: Retain these safety and operating instructions for future reference. Adhere to

all warnings printed here and on the console power unit. Follow the operating

instructions printed in the user guide and the power unit user guide.

Do not remove covers: Operate the power unit with its covers correctly fitted. Refer any service work

to competent technical personnel only.

Power sources: Connect the power unit to a mains power only of the type described in the

User Guide and marked on the rear panel. Use the power cord with sealed

mains plug appropriate for your local mains supply as provided with the

console. If the provided plug does not fit into your outlet consult your service

agent for assistance.

Power cord routing: Route the power cord so that it is not likely to be walked on, stretched or

pinched by items placed upon or against it.

Grounding: Do not defeat the grounding and polarisation means of the power cord plug.

Do not remove or tamper with the ground connection in the power cord.

WARNING: This equipment must be earthed.

Water and moisture: To reduce the risk of fire or electric shock do not expose the power unit or

console to rain or moisture or use it in damp or wet conditions. Do not place

containers of liquids on it which might spill into any openings.

Ventilation: Do not obstruct the ventilation slots or position the console or power unit

where the air flow required for ventilation is impeded. If the console is to be

operated in a flightcase ensure that it is constructed to allow adequate

ventilation.

Heat and vibration: Do not locate the power unit in a place subject to excessive heat or direct

sunlight as this could be a fire hazard. Locate the console and its power unit

away from any equipment which produces heat or causes excessive

vibration.

Servicing: Switch off the equipment and unplug the power cord immediately if it is

exposed to moisture, spilled liquid, objects fallen into the openings, the power

cord or plug become damaged, during lightening storms, or if smoke, odour

or noise is noticed. Refer servicing to qualified technical personnel only.

Installation: Install the console in accordance with the instructions printed in the User

Guide. Do not connect the output of power amplifiers directly to the console.

Use audio connectors and plugs only for their intended purpose.

4 ML5000 Service Manual

Page 6

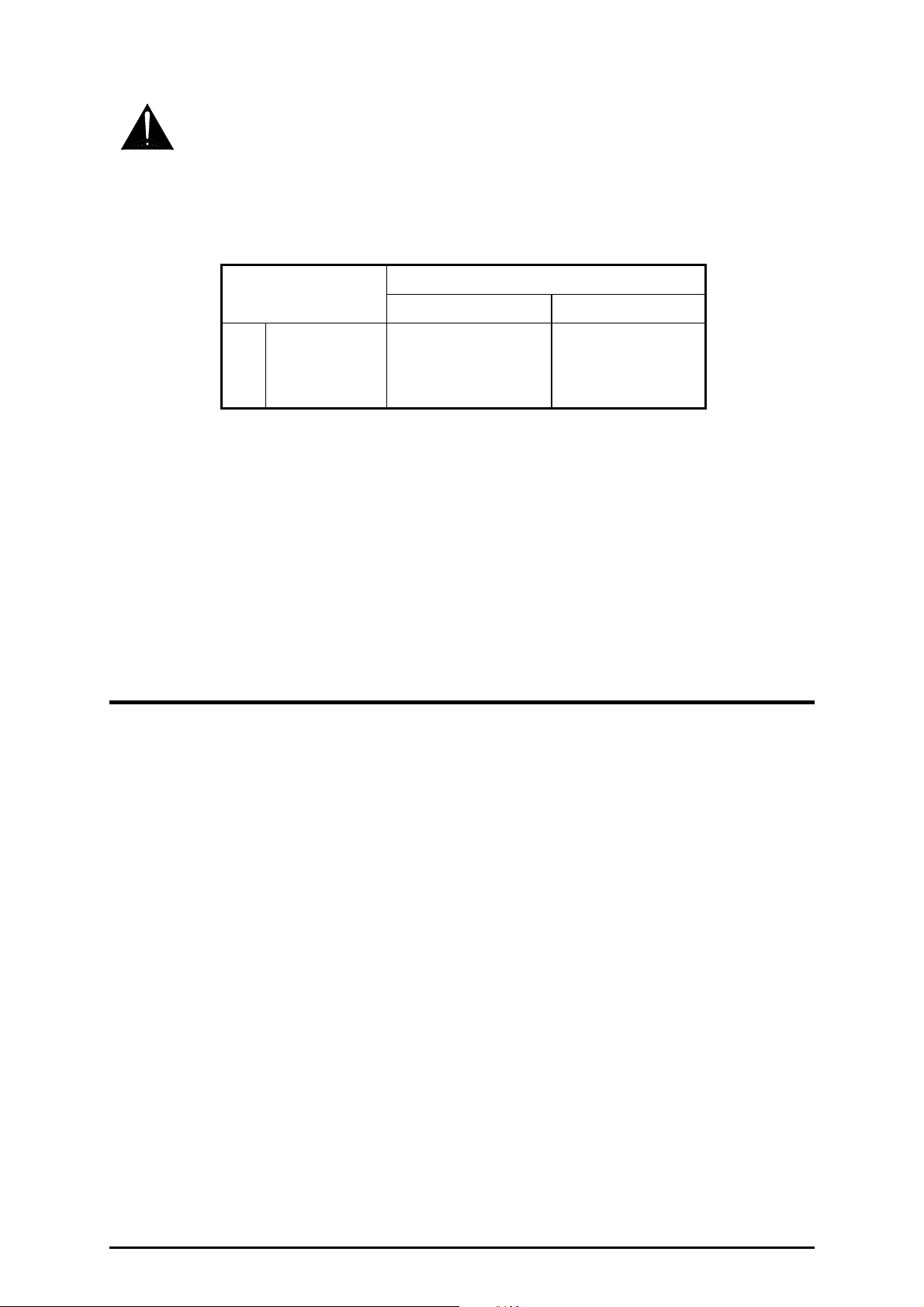

Important Mains Plug Wiring Instructions.

The power unit is supplied with a moulded mains plug fitted to the AC mains

power lead. Follow the instructions below if the mains plug has to be

replaced.

The mains lead wires are coloured in accordance with the following code:

TERMINAL

L

LIVE BROWN BLACK

N

NEUTRAL BLUE WHITE

E

EARTH GND GREEN & YELLOW GREEN

The wire which is coloured Green and Yellow must be connected to the

terminal in the plug which is marked with the letter E or with the Earth symbol.

This appliance must be earthed.

The wire which is coloured Blue must be connected to the terminal in the plug

which is marked with the letter N.

The wire which is coloured Brown must be connected to the terminal in the

plug which is marked with the letter L.

Ensure that these colour codes are followed carefully in the event of the plug

being changed.

General Precautions

WIRE COLOUR

European USA/Canada

Damage : To prevent damage to the controls and cosmetics avoid placing heavy

objects on the control surface, scratching the surface with sharp objects, or

subjecting the console to rough handling and vibration.

Environment : Protect from excessive dirt, dust, heat and vibration when operating and

storing. Avoid tobacco ash, smoke, drinks spillage, and exposure to rain and

moisture. If the console becomes wet, switch off and remove mains power

immediately. Allow to dry out thoroughly before using again.

Radiation : To avoid induced noise and interference pickup do not operate the console

close to strong sources of electromagnetic radiation such as power supplies,

video monitors, lighting cables and dimmers.

Cleaning : Avoid the use of chemicals, abrasives or solvents. The control panel is best

cleaned with a soft brush and dry lint-free cloth. Stubborn marks can be

removed using a cloth dampened with isopropyl alcohol. Do not leave

marking tape stuck to the console for long periods of time as the adhesive

can degrade and leave a sticky residue. The faders, switches and

potentiometers are lubricated for life. The use of electrical lubricants on these

parts is not recommended. Refer to the power unit user guide for instructions

on cleaning its ventilation filters.

Transporting : The console should be transported in the original packing or purpose built

foam lined flightcase. Protect the control surface from damage during transit.

The console is a large and heavy item. To avoid injury ensure adequate man

power and precaution when lifting or moving the console.

ML5000 User Guide 5

Page 7

ML5000 Key Features

The Allen & Heath ML5000 is a large format VCA equipped dual function live sound console. It

can be quickly configured for front-of-house (FOH) or stage monitor mixing. As one console

suitable for both applications it is equally well suited to installation, rental and touring. It offers an

IO capability and feature set that satisfies the latest trends in live sound engineering, in particular

the growing number of inputs and outputs for multi-speaker house and monitor systems, demands

of stereo in-ear monitoring, 3 speaker LCR imaging, advanced grouping and automation. The

design ensures on-the-road durability, a clear layout for easy walk up and go operation, and no

compromise audio performance.

Inputs and Outputs

• 3 Standard frame sizes: 32+4, 40+4, 48+4 (mono + stereo channels)

• 32, 40, 48 mono mic/line inputs with inserts and direct outputs

• 4 dual stereo line inputs

• 24 input sidecar to expand to a maximum 96 inputs

• Main Left, Right and Centre outputs with inserts, C configurable as the engineers monitor

• 8 Groups, 16 Auxes: Group/Aux 1-8 and Aux 9-16 with faders and inserts, Aux 1-8 with rotaries

• Matrix 1-8 with inserts and external inputs

• 2-Track monitor input and recording send

• Stereo headphones and local monitors

• Dual mic talkback input

• ClearCom compatible intercom interface

Groups and Automation

• 8 VCA groups with mutes and PAFL monitoring

• 8 audio groups with LCRplus™ subgrouping

• 8 mute groups

• 128 snapshot memories for mute and/or VCA assignment store, recall and preview

• Solo-in-place with all-clear and toggle-last

• MIDI mute on/off, snapshot recall and dump in/out control

• Channels can be made safe independently from the automation and solo-in-place

Processing and Control

• 4-Band full sweep mono EQ with fully parametric mids, 4-band fixed frequency stereo EQ

• Sweepable high pass filter

• LCRplus™ 3 speaker imaging system

• Protected mode switching to configure the console for FOH or monitor application

• Intelligent PAFL system with all-clear, PFL/in-place AFL, priority, auto-cancel/add mode…

• Assignable talkback and intercom

• 1kHz tone and pink noise generator for system line-up and testing

• Full console monitoring and extensive metering of inputs, mix busses and outputs

6 ML5000 Service Manual

Page 8

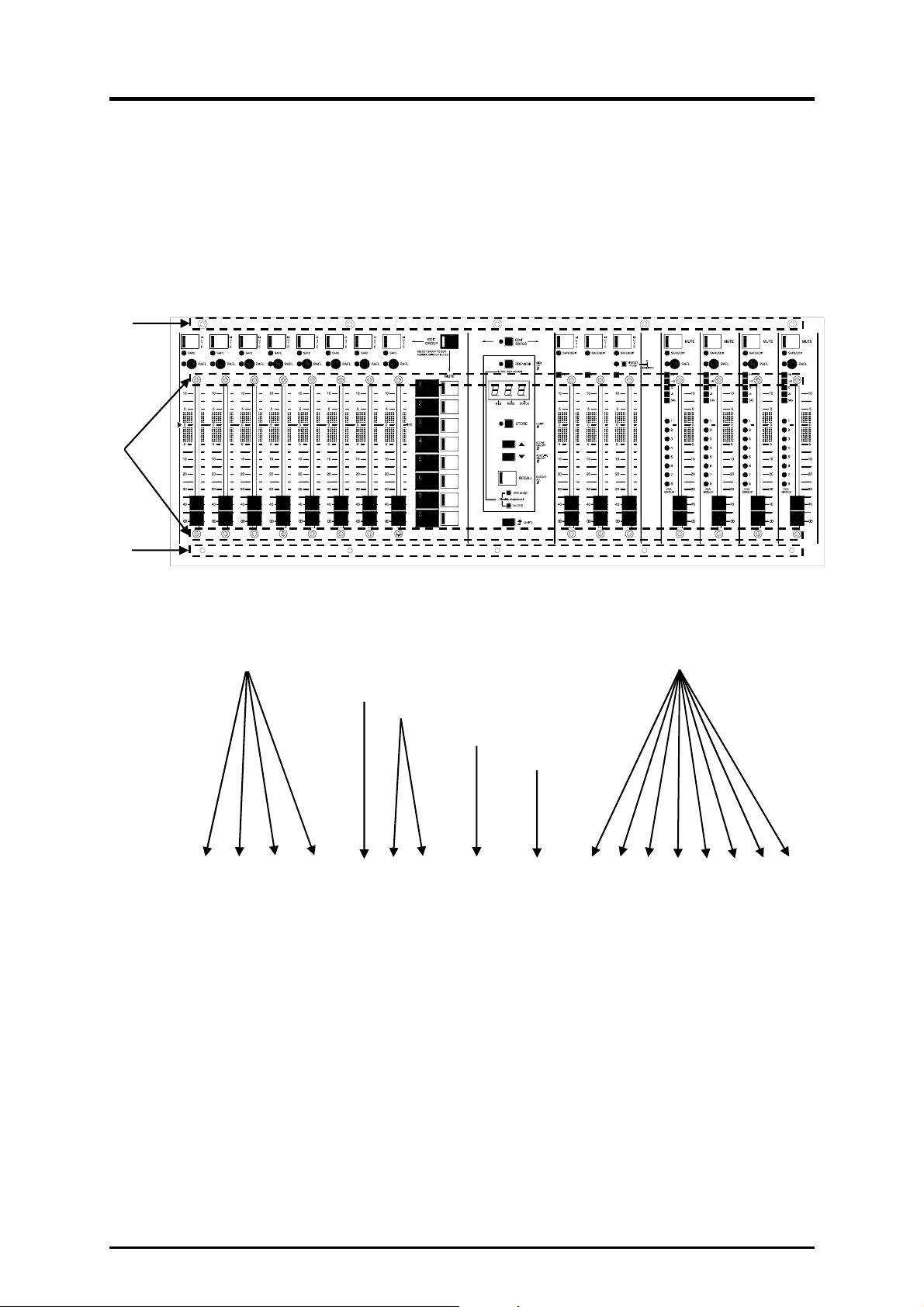

Front Panel Layout

ML5000 Service Manual 7

Page 9

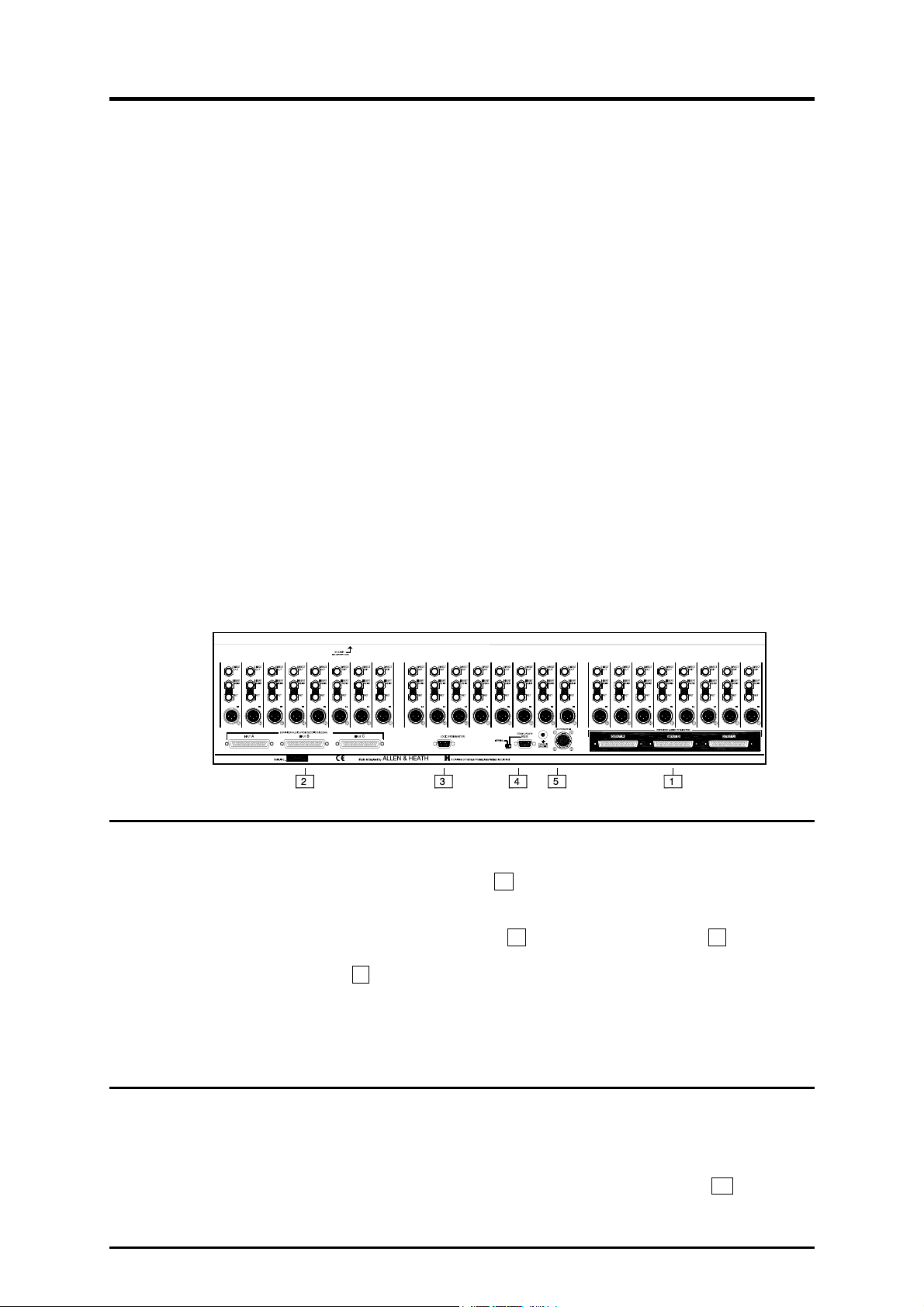

Rear Panel Layout

8 ML5000 Service Manual

Page 10

MONO INPUT and EQ. The input preamp

matches microphone or line level signals to the

console. The sweepable high pass filter removes

unwanted low frequency sounds below the selected

frequency. The channel insert is post filter, pre EQ.

A swept frequency 4 band equaliser provides

shelving high and low bands with adjustable shelf

frequency, and fully parametric high and low mid

bands with adjustable centre frequency and Q. The

filter and EQ can be independently switched in or

out.

GRP/AUX SENDS. This section provides controls

for the group routing and auxiliary sends. Controls

1-8 function according to the setting of the mode

switches in the master section. These configure

group routing switches and independent post-fade

aux sends for FOH (front-of-house) application, or

pre/post switchable sends for stage monitor

application. Controls 9-16 can be configured as

mono or stereo pre/post aux sends.

MAIN MIX SENDS. A single switch routes the

channel signal to the main L, R and C outputs. The

balance between the three outputs is determined by

the LCRplus pan and blend controls. Pan can also

be switched in or out of the group routing for stereo

or mono groups.

INPUT FADERS. Includes the channel fader,

mute, signal meter and PAFL monitoring. The 8

VCA group assignments are displayed. VCA and

mute group editing and channel safe selection is

performed using the mute switch with green

safe/edit indicator below.

STEREO INPUT and EQ. The input preamp

accepts two stereo sources with independent

control of each. This allows selection of either or

mixing together both sources. A fixed frequency 4

band equaliser provides shelving high and low

bands and two bell mid bands. The EQ can be

switched in or out.

GRP/AUX 1-8 MASTERS. These are the fader

masters for channel sends 1-8, configurable using

mode switches as fixed level groups or as variable

level pre or post-fade auxes. The output can be

routed to the main mix through LCRplus controls to

create sub groups. Led meters display the pre-fade

mix levels.

AUX 9-16 MASTERS. These are the fader

masters for channel sends 9-16.

ROTARY AUX MASTERS. These are the rotary

masters for channel post-fade aux sends 1-8. They

provide the independent effects sends when the

fader masters are configured as groups. They still

function when the fader masters are configured as

pre/post auxes but would not normally be required.

MAIN MIX FADERS. Provides separate master

faders and mutes for the main L, R and C outputs.

A mode switch configures the C output as the

engineers wedge monitor feed for the stage monitor

application.

MATRIX. This section provides all the controls for

the 8 matrix outputs, including the source and

master rotaries.

VCA GROUPS. These are the VCA group master

faders, mutes and PAFL monitor switches.

Channels are assigned to the groups using the edit

key. The normal fader operating level is marked ‘0’.

MUTE GROUPS. These are the master keys that

mute all channels assigned to the group. Channels

are assigned using the edit key.

SNAPSHOT MEMORIES. Provides the controls to

store, recall and preview the 128 onboard

memories, and edit channel safes. Mute settings

and/or VCA assignments can be disabled from the

snapshots.

HEADPHONES / MONITOR. Provides source

selection and independent control of the

headphones and local monitor outputs.

SOLO-IN-PLACE. Pressed with the shift key this

puts the console into SIP mode ready to solo any

channel when its mute key is pressed.

PAFL CONTROL. This section controls how the

intelligent PAFL system functions and provides the

clear all key.

OSC/NOISE GENERATOR. Enables and selects

a 1kHz tone or pink noise which can be routed to

any output for line up or system testing.

INTERCOM. The console talkback mic and

headphones can be interfaced to a ClearCom

compatible intercom system so eliminating the need

for a separate intercom headset.

TALKBACK. Pressing the talk switch routes the

talkback mic to any output with its TB enable switch

selected. The mic input is duplicated on the rear

panel for plugging in hand held microphones.

GRP/AUX 1-8 METERS. These moving coil VU

meters display the grp/aux 1-8 outputs.

LRC/PAFL METERS. The main L,R and C outputs

are simultaneously displayed on both VU and led

bar meters. These switch to display any PFL or

AFL when selected. The display is mono or mono +

stereo depending on source. The large call lamp

lights to warn when the intercom is signalled.

AUX 9-16 / MTX 1-8 METERS. These meters

display either the aux 9-16 outputs or matrix 1-8

levels according to the setting of the meter select

switch near section.

ML5000 Service Manual 9

Page 11

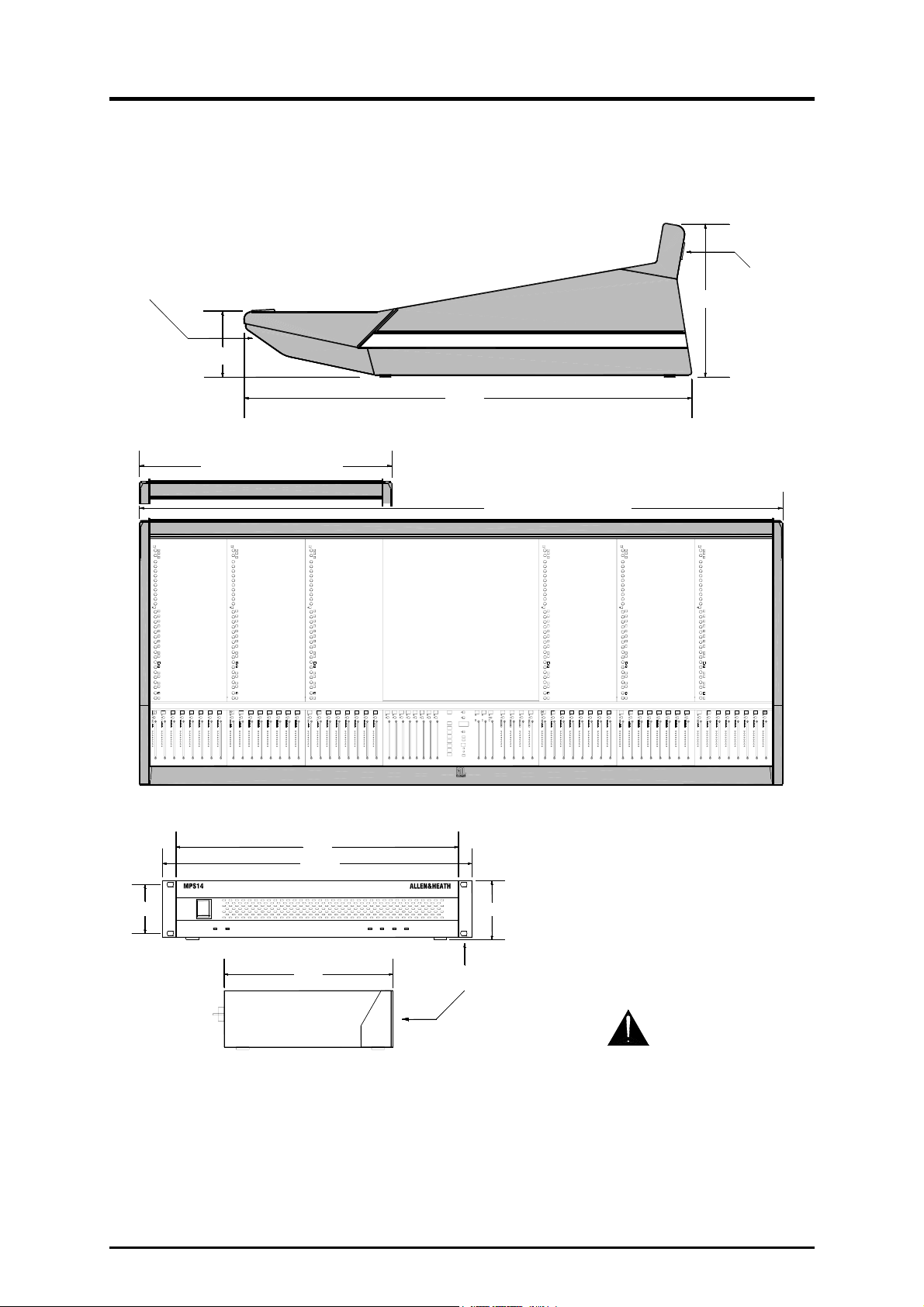

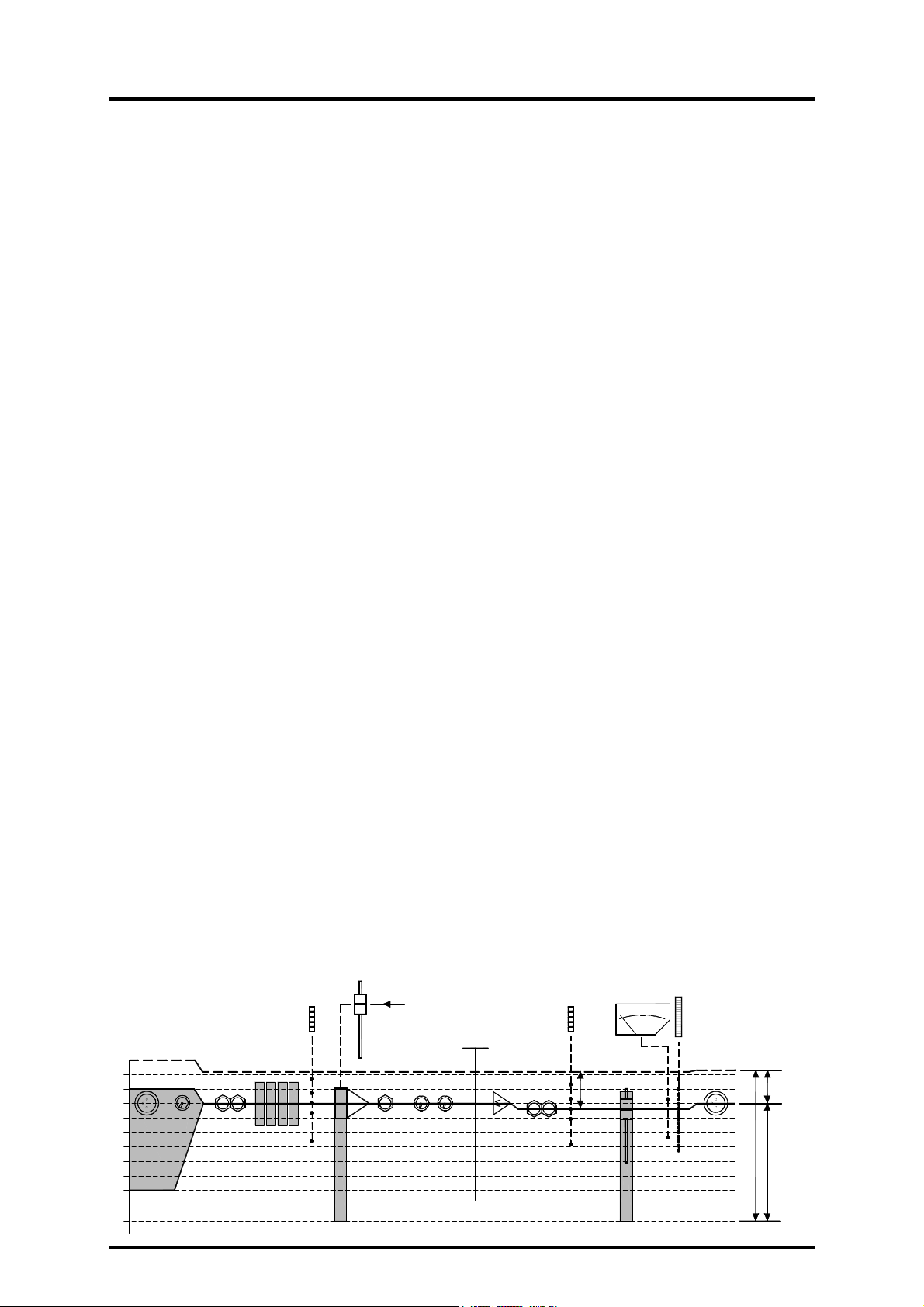

Installing the Console

Weights 32 Channel 84 kg (185 lbs)

40 Channel 96 kg (211 lbs)

48 Channel 110 kg (242 lbs)

24 Channel sidecar 45 kg (95 lbs)

MPS14 psu 6 kg (13 lbs)

HEADPHONES SOCKETS

UNDER ARMREST

130

ML5000-24SC = 831

LAMP SOCKETS

298

872

ML5000-32 = 1596

ML5000-40 = 1851

ML5000-48 = 2106

440

FC 76.2

482.6

263

90

REMOVABLE RACK EARS

2U HEIGHT

Refer to the power supply user guide

for safety and installation instructions.

Heed all warnings printed in the user

guide and on the power unit.

Refer to the sidecar user guide for

instructions on connecting the sidecar

expander to the console.

CAUTION: Ensure adequate

ventilation around the power supply

unit. Do not operate it where it is

subject to excessive heat, for

example in direct sunlight or next to

power amplifiers. Use forced air

cooling such as rack fans if it is

operated in a confined or hot space.

10 ML5000 Service Manual

Page 12

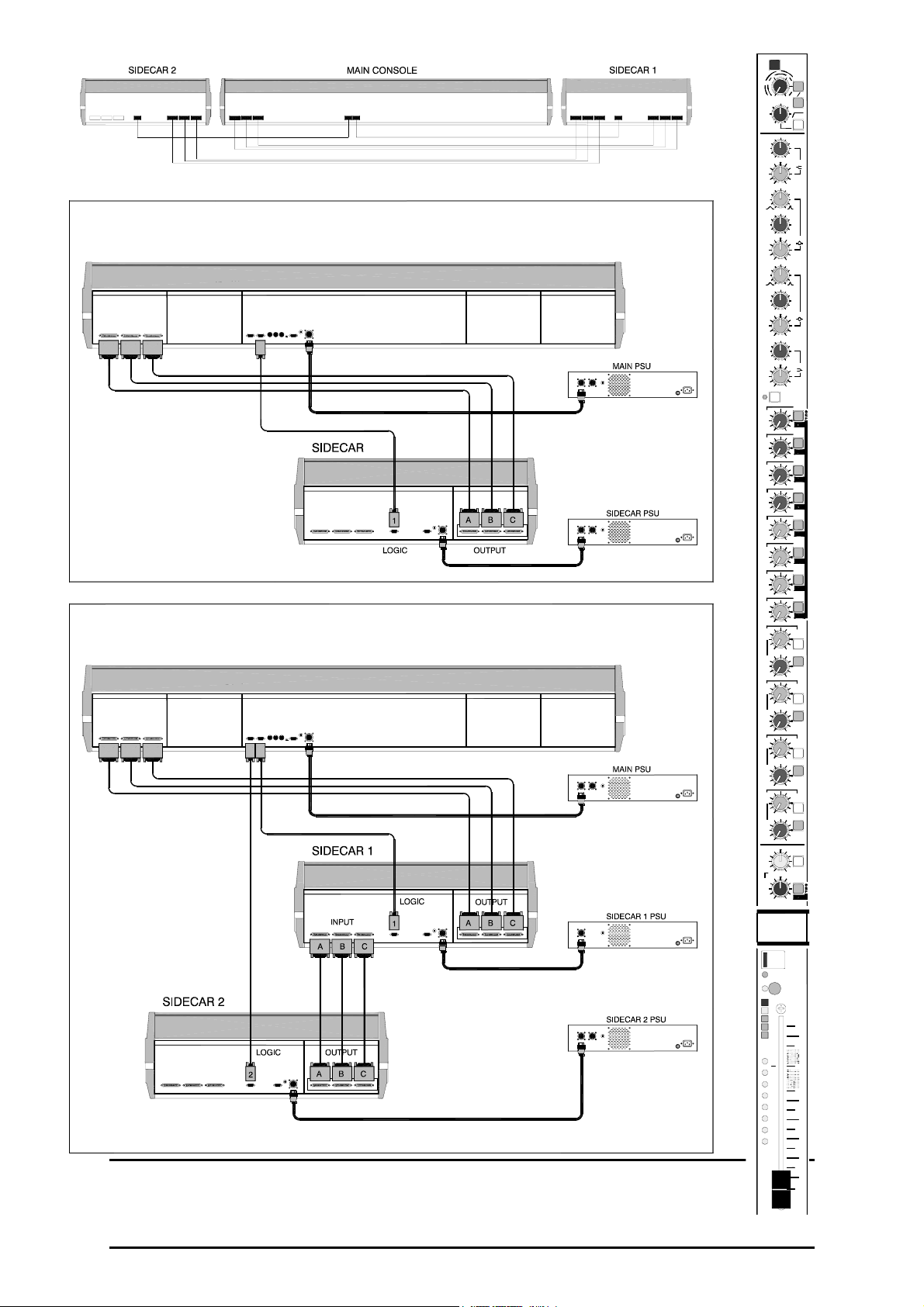

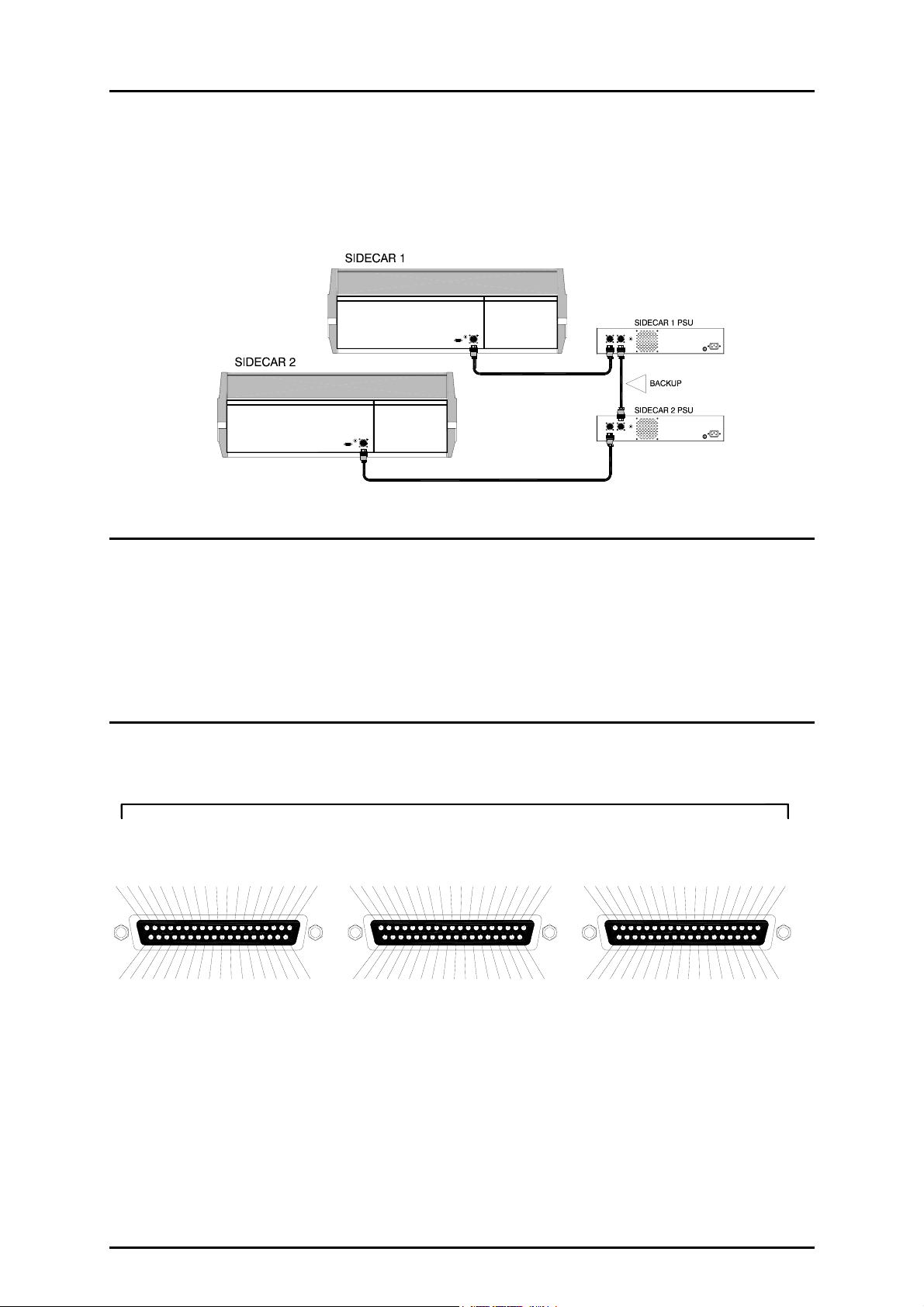

The Expander Sidecar

channels. Do not connect more than two sidecars.

The following is supplied with each sidecar:

1x MPS14 Power Supply Unit with User Guide MPS14/n

1x Mains cord with moulded plug suitable for your local supply n = volts

1x DC power cable 2.8 metres long 002-583

3x 37way Audio Cables 2.8 metres long 002-617

1x 9way Logic Cable 2.8 metres long AL4155

The Allen & Heath ML5000-24SC Sidecar is the 24

mono input channel expander for the ML5000

console. It is free standing and does not need to be

mechanically fixed to the main console.

Interconnection is by means of multiway cables to

link the audio signals and control logic. It is supplied

with its own power supply unit independent of the

console. The input channel strip is identical to the

main console with all functions available. The

groups and snapshots are controlled from the main

console. Up to two gooseneck lamps (part AL4061)

may be plugged into the rear of the meterbridge.

Note: This sidecar may be used with the ML5000

only. It is not suitable for use with other consoles or

as a stand alone console. One or two sidecars may

be connected allowing a maximum 96 input

Connecting the Sidecar to the Console

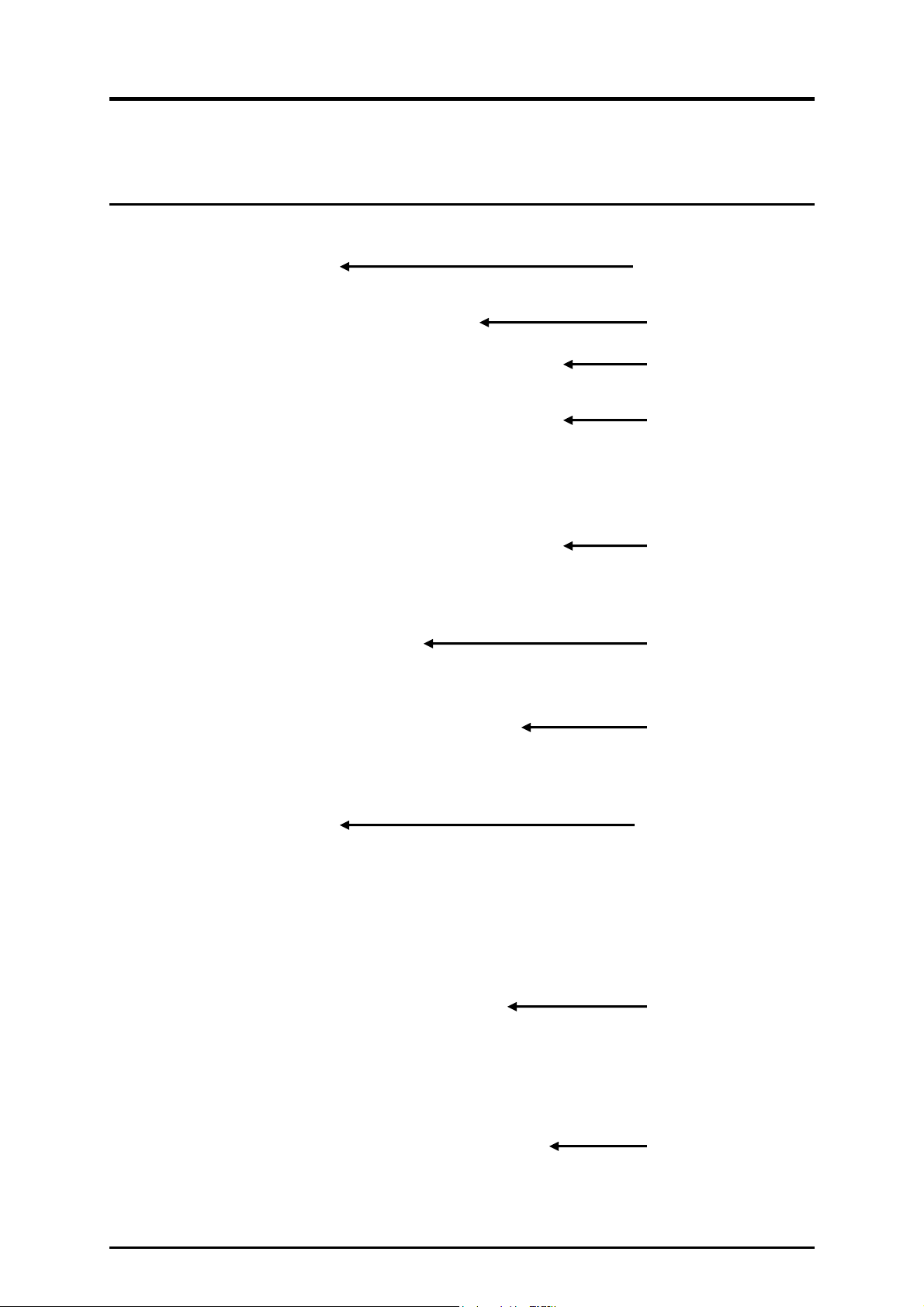

Diagram 1 shows the cable routing for connecting the sidecars to the ML5000. Refer to Diagram

2 for connecting one sidecar. Refer to Diagram 3 for connecting two sidecars.

Connect the three audio OUTPUT connectors 1 to the main console EXPANDER INPUT using

the three 37way 1 to 1 shielded cables provided. We recommend that you label the cables A, B

and C to avoid them being swapped if replugged. If you are connecting a second sidecar plug its

OUTPUT into the first sidecar INPUT connectors 2 . Plug the LOGIC connector 3 into the main

console LOGIC connector 1 for one sidecar, or 1 and 2 for two sidecars. Plug the power supply

DC cable into connector 5 .

Note: To maintain correct channel assignment do not reverse the interconnecting cables. Make

sure the cable plug locking screws are correctly tightened.

Turning the Console and Sidecars On and Off

Make sure the DC power cables and audio and logic interconnecting cables are correctly plugged

in and locked. Turn all power supplies on or off together. Alternatively, turn the sidecar supplies

on first followed by the main console, and turn the console off first followed by the sidecars. Do not

turn off any supply during normal console operation.

Note: For normal console operation make sure the rear panel RS232 switch 4 is set to its

NORMAL position. It will not function correctly if left in its RS232 position.

ML5000 Service Manual 11

Page 13

Diagram 1

Diagram 2

MAIN CONSOLE

INPUT LOGIC

ABC 1

Diagram 3

MAIN CONSOLE

INPUT LOGIC

ABC 1

INPUT 1 OUTPUT2OUTPUT INPUT

CONNECTING ONE SIDECAR

ML5000

POWER

CONNECTING TWO SIDECARS

ML5000

POWER

2

20

GAIN

- 10 10

100

50 200

30

20Hz

7kHz

3k

2kHz 20kHz

-15 +15

1.2

0.6 2.5

2kHz

1k

500 5k

400Hz 20kHz

-15 +15

1.2

0.6 2.5

100Hz

60

30 250

20Hz 1kHz

-15 +15

100Hz

50

20Hz 200Hz

-15 +15

AUX

1

OO +6

AUX

2

OO +6

AUX

3

OO +6

AUX

4

OO +6

AUX

5

OO +6

AUX

6

OO +6

AUX

7

OO +6

AUX

8

OO +6

LEV

9

OO +6

PAN

10

OO +6

LEV

11

OO +6

PAN

12

OO +6

LEV

13

OO +6

PAN

14

OO +6

LEV

15

OO +6

PAN

16

OO +6

+

LCR

BLEND

LR C

PAN

LR

24

+48V

PAD

40

20dB

O

4060

HPF

400

10k

HF

Q

3k

HM

Q

120

LM

150

LF

EQ IN

PRE

PRE

PRE

PRE

PRE

PRE

PRE

PRE

9-10

STEREO

PRE

11-12

STEREO

PRE

13-14

STEREO

PRE

15-16

STEREO

PRE

=

MAIN

MIX

=

MUTE

SAFE/EDIT

PAFL

PK

+6

0

10

-6

SIG

5

1

0

2

3

5

4

5

10

6

20

7

8

VCA

30

GROUP

40

OO

12 ML5000 Service Manual

Page 14

Combining Sidecar Power Supplies for Backup

If you are connecting two sidecars then you can link the power supplies together for redundant

supply backup. One MPS14 supply is capable of running both sidecars together should the other

fail. You need to order the short 0.7 meter DC power cable (part 002-584) for linking.

Note: Do not link the main console power supply to the sidecar supply in this way. One supply is

not capable of running both the main console and its sidecar should the other fail. You should

order a spare power supply with your console in this case. Make sure the power supplies are

positioned next to each other and using the same mains distribution.

RS232 Code Update

A rear panel RS232 port is provided. This is used for loading new operating software into the

sidecar from a PC. It is not used for any other function. Check our Web site www.allen-heath.com

for details on the latest version of ML5000 operating software and instructions on loading it into the

console.

Note: The sidecar settings are archived using a MIDI or RS232 dump from the main console.

There is no need to archive the sidecar settings separately.

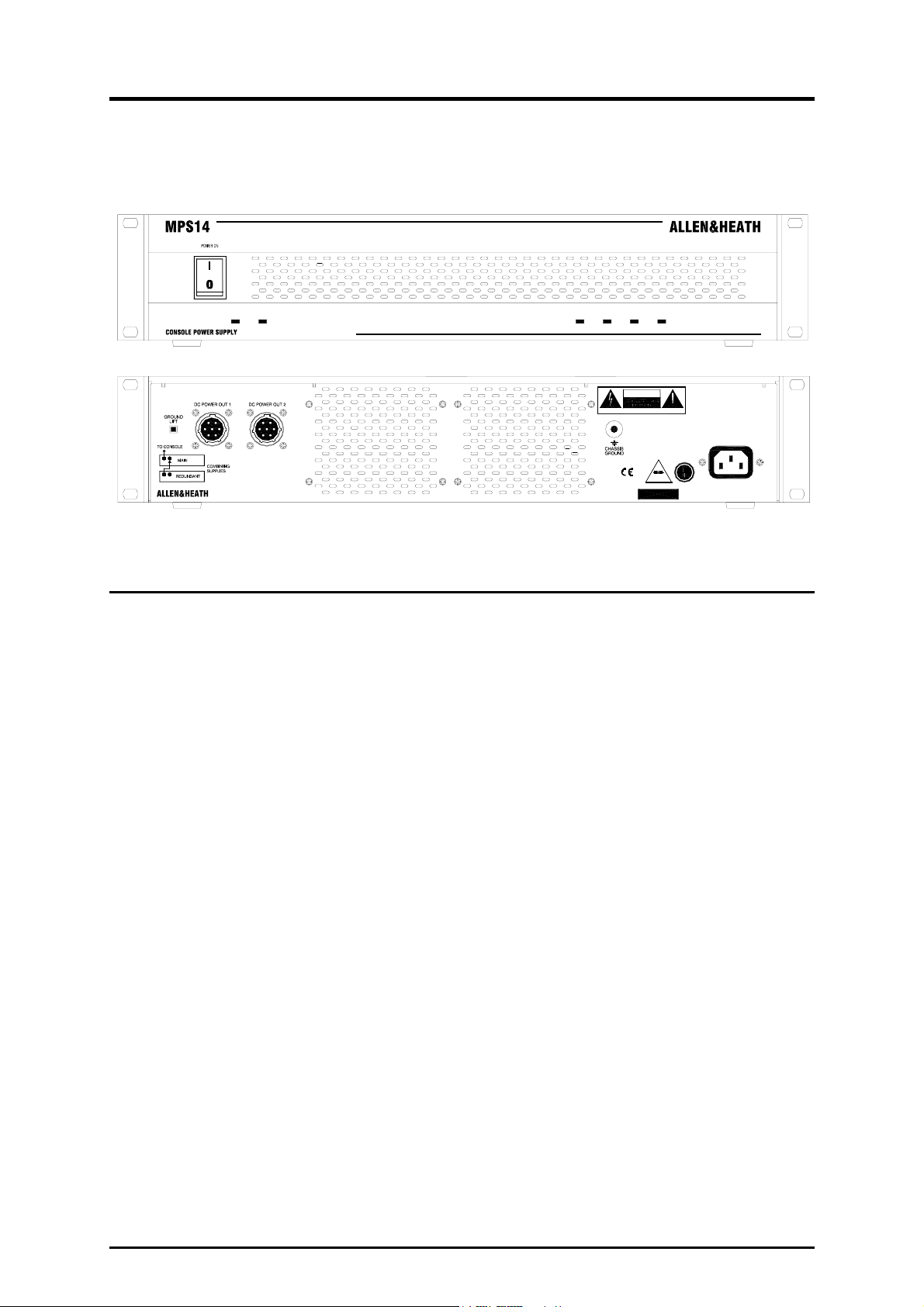

Sidecar Audio Connections

The following information is provided for reference only. It is not necessary to wire special cables

to connect the sidecar to the console. Standard 1 to 1 wired 37way cables are provided. The

audio signals are balanced and operate at a nominal –2dBu line level.

13 GRP 4+

12 AUX 1+

11 AUX 2+

10 AUX 3+

9 AUX 4+

8 AUX 5+

7 AUX 6+

6 PFL+

5 AFL+

4 nc

3 PFL DC

2 AFL DC

nc 23

nc 22

nc 21

1 0V (PAFL)

nc 20

18 L+

19 0V (CHS)

L- 37

R- 36

17 R+

GRP 1- 35

16 GRP 1+

GRP 2- 34

15 GRP 2+

GRP 3- 33

14 GRP 3+

GRP 4- 32

AUX 1- 31

AUX 2- 30

AUX 3- 29

AUX 4- 28

AUX 5- 27

AUX 6- 26

PFL- 25

AFL- 24

18 C+

19 0V (CHS)

C- 37

AFL L- 36

16 GRP 5+

17 AFL L+

GRP 5- 35

15 GRP 6+

GRP 7- 33

GRP 6- 34

14 GRP 7+

GRP 8- 32

13 GRP 8+

12 AUX 7+

AUX 7- 31

AUX 8- 30

11 AUX 8+

AUX 9- 29

10 AUX 9+

9 AUX 10+

AUX 10- 28

AUX 11- 27

8 nc

AUX 11+ 26

7 nc

AUX 12- 25

6 nc

AUX 12+ 24

5 nc

AUX 13- 23

CBA

13 nc

12 PAUX 1+

11 PAUX 2+

10 PAUX 3+

9 PAUX 4+

8 PAUX 5+

7 PAUX 6+

6 PAUX 7+

5 PAUX 8+

4 nc

3 nc

2 nc

nc 23

nc 22

nc 21

nc 20

1 nc

2 AUX 15+

AUX 16- 20

19 0V (CHS)

1 AUX 16+

nc 36

nc 35

nc 34

nc 33

nc 37

nc 32

PAUX 1- 31

PAUX 8- 24

PAUX 4- 28

PAUX 3- 29

PAUX 5- 27

PAUX 6- 26

PAUX 2- 30

PAUX 7- 25

4 AUX 13+

3 AUX 14+

AUX 15- 21

AUX 14- 22

14 nc

15 nc

16 nc

17 nc

18 nc

ML5000 Service Manual 13

Page 15

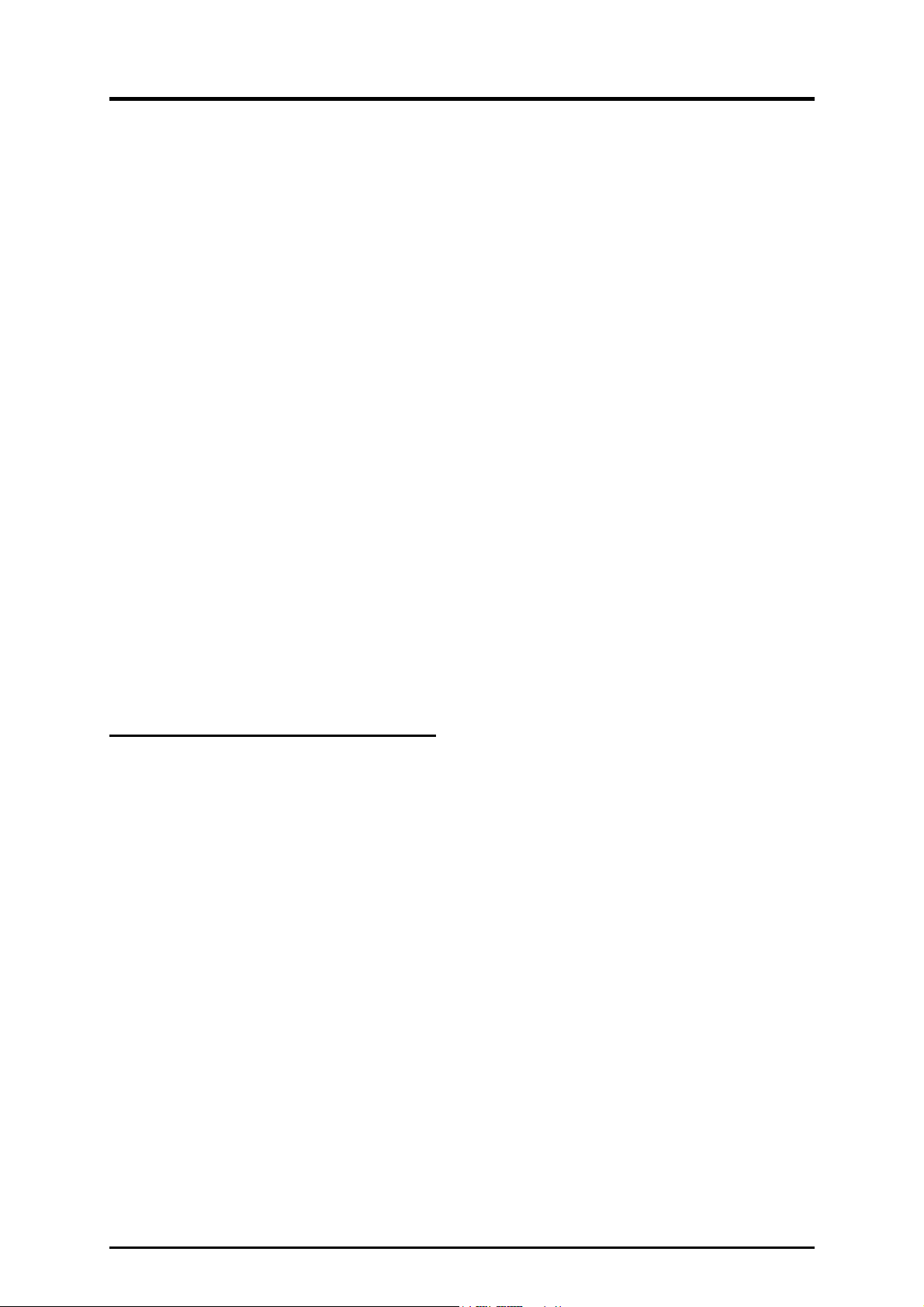

The MPS14 Power Supply

The slimline MPS14 power supply uses linear post-regulated switch mode technology to generate the DC

voltages required by the console. It will operate from a wide range of ac mains input voltages. Full protection and

thermally controlled fan cooling ensures the power unit will operate consistently. The MPS14 also has a built in

combiner for connection to a second supply for backup.

+18V -18V +10V +48VON PROTECT

ADVANCED TECHNOLOGY / HIGH POWER DELIVERY / AUTO COMBINING

T5A 250V

FUSE

T

MADE IN ENGLANDS/No

DO NOT OBSTRUCT VENTILATION OPENI NGS.

DO NOT OPEN. NO USER SERVICEABLE PARTS INSIDE.

THIS APPARATUS MUST BE EARTHED BY THE POWER CORD.

WARNING: TO REDUCE THE RISK OF ELECTRIC SHOCK

DO NOT EXPOSE THIS APPARATUS TO RAIN OR MOISTURE.

MAINS INPUT

500W MAX100V - 230V.AC 47-63 Hz ~

MPS14

CONSOLE POWER SUPPLY

PIN 1 = +10V @ 5A

PIN 2 = +17V @ 7A

PIN 3 = A GND

PIN 4 = A GND

PIN 5 = D GND

PIN 6 = +48V @ 1A

PIN 7 = -17V @ 7A

A DIVISION OF HARMAN INTERNATIONAL I NDUSTRIES LTD

CAUTION

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR.

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE REPLACE FUSE

WITH SAME TYPE AND RATING. DISCONNECT SUPPLY BEFORE CHANGING FUSE.

ATTENTION: REMPLACER LE FUSIBLE AVEC UN DES MEMES CARACTERISTIQUES.

COUPER L'ALIMENTA TION AVANT DE CHA NGER LE FUSIBLE.

Power Supply Installation

Free standing

The MPS14 can be operated as a free-standing unit without requiring any special cooling arrangement, but

should not be accidentally or deliberately covered in any way. Always stand the unit on a firm flat surface well

away from any soft furnishings or carpet.

Rack mounting

The MPS14 is designed as a 19 inch rack mount unit and will occupy 2U (3.5 inches) of rack space.

An important consideration when rack-mounting the unit is the need for natural convection of air flow over the

whole unit.

Good ventilation below the unit, in the floor or back of the rack, will ensure a path for continuous air flow.

Other equipment in the rack which is known not to produce a significant amount of heat should be mounted

below the unit. Equipment which also relies on good airflow within the rack (i.e. most power amplifiers and other

power supplies) should be given due consideration and some space should be provided between such units and

between the MPS14 unit. Forced convection, by means of a fan-tray, may be desirable in this situation.

Location

As with any power supply that contains switch mode technology, it is preferable to provide a degree of physical

isolation of the unit from other equipment, particularly that which carries low level audio signals, to avoid any

possible interference pick-up. For this reason the unit is provided with a long (2.9m) output cable to enable it to

be positioned away from the mixing console. For the same reason, when rack-mounting it is preferable to avoid

locating the unit adjacent to signal processing equipment.

Earthing

Finally, some consideration should be given to the earthing arrangement of the system, at the centre of which is

the console and the MPS14. The console chassis is earthed, to the mains earth, via the power supply. When

rack-mounting the MPS14 care should be taken to avoid any possible “ground loops” in the system which would

introduce audible hum or buzz to otherwise clean audio signals. Ground loops may occur where signal

processing equipment patched to the console, has its signal earth connected to the equipment chassis. A ground

loop is formed if the chassis of the signal processing equipment and the MPS14 chassis are in electrical contact

through the fixing rails they share in the rack. The MPS14 has audio 0V and mains earth connected internally. If

a ground loop is formed operation of the ground lift switch on the rear panel of the MPS14 may improve the

situation.

14 ML5000 Service Manual

Page 16

MPS14 Technical specifications

Mains Input Voltage Range 100 - 240 ± 10% VAC @ 47-63 Hz auto-sensing

Power consumption (max.) 500W

Mains Fuse: 100 - 240 V~ T 5.0A/250V

Internal Fuses:

PCB Ident Fuse type

F1 (+12V) T 6.3A 250V 20mm

F2 (+48V) T 2A 250V 20mm

F18 (aux psu) T 500mA 250V 20mm

DC Outputs

DC Voltage Rail Output Current

+17 VOLTS 7A Max.

-17 VOLTS 7A Max.

+12 VOLTS 5A Max.

+48 VOLTS 500mA Max.

CONSOLE POWER SUPPLYMPS14

ML5000

DIRECT

DIRECT

CHASSIS

GROUND

DIRECT

OUT

OUT

INSERT

INSERT

SEND

SEND

RET

RET

IN

IN

DC POWER IN

OUT

INSERT

SEND

RET

IN

RS232

DC Output Socket Pin Connections

Overall Dimensions

Front Panel: 482mm x 88mm 19 inch 2U

Width (excluding rack ears): 440mm 17.30 inches

Height including feet: 90mm 3.5 inches

Depth: 260mm 10.25 inches

Weight: 6Kg 13 pounds

PIN 1 = +10V @ 5A

PIN 2 = +17V @ 7A

PIN 3 = A GND

PIN 4 = A GND

PIN 5 = D GND

PIN 6 = +48V @ 1A

PIN 7 = - 17V @ 7A

Pin No: Connection

1 +12 Volts

2 +17 Volts

3 A GND

4 A GND

5 D GND

6 +48 Volts

7 -17 Volts

MPS14

MPS14

Cable Assemblies

Assembly Description A&H Part no:

DC cable

2.9m MPS14 to ML5000 console cable assembly

002-583

DC LINK cable 0.5m MPS14 to MPS14 PSU “LINKING” cable assembly 002-584

ML5000 Service Manual 15

Page 17

ML5000 Technical Specifications

0dBu = 0.775 Vrms, +4dBu = 1.23 Vrms

Operating Levels

Channels......................................... 0dBu Headroom +21dB

Mix .................................................. -2dBu Headroom +23dB

Frequency Response Referred to 1kHz at +4dBu

Mic to main output (+40dB)............. 20Hz to 30kHz +0/-0.5dB

Line to main output (0dB)................ 20Hz to 30kHz +0/-0.5dB

Distortion @1kHz +14dBu

THD+noise ...................................... < 0.01%

CMRR Common mode rejection @1kHz

Mic (+40dB)..................................... > 80dB

Mic + Pad (0dB) .............................. > 50dB

Crosstalk Referred to driven channel @1kHz

Channel to channel ......................... > -100dB

Mute shutoff .................................... > -85dB

Fader shutoff................................... > -90dB

Noise Performance Measured rms 22Hz to 22kHz unweighted

Mic EIN with 150 ohm source ......... -128dB

Residual output noise ..................... < -94dBu (-98dB SN)

Mix noise, nothing routed................ < -84dBu (-88dB SN)

Mix noise, 24 channels routed ........ < -80dBu (-84dB SN)

Metering

Reading 0................. +4dBu at XLR outputs

LED meters .............. Peak reading, 3 colours

VU meters ................ Ave reading, Illuminated moving coil

Peak indicators ........ 5dB before clip, multi-point sensing

Input meters ............. 5 bar LED (signal, -6, 0, +6, peak)

Group mix meters .... 5 bar LED (signal, -6, 0, +6, peak)

Group/Mtx meters .... VU

L,R,C meters............ VU and 16 bar LED

Lamp Connectors x4

Connector ....................................... XLR-F 4pin

Rating.............................................. 12V 400mA max

Channel Filters

Slope ............................................... 12dB/oct high pass

Frequency ....................................... 20Hz to 400Hz

variable

Mono Equaliser

HF................. +/-15dB, 2kHz to 20kHz shelf

HM................ +/-15dB, 500Hz to 15kHz bell, Q = 0.6 to 2.5

LM ................+/-15dB, 35Hz to 1kHz bell, Q = 0.6 to 2.5

LF ................. +/-15dB, 20Hz to 200Hz shelf

Stereo Equaliser

HF................. +/-15dB, 12kHz shelf

HM................ +/-15dB, 2.5kHz bell

LM ................+/-15dB, 250Hz bell

LF ................. +/-15dB, 60Hz shelf

Power Supply Model MPS14

Type ........................... External 2U rack or floor mount

Mains input................. 100-230V 50/60Hz universal input

Power consumption.... 500W

Full protection and fan cooling

Dimensions Width.............. Depth ...... .....Height

32 Channel 1596 (62.8”) ... 872 (34.3”) ....298 (11.7”)

40 Channel 1851 (72.9)..... 872.......... .....298

48 Channel 2106 (82.9”) ... 872.......... .....298

Sidecar 831 (32.7”) ..... 872.......... .....298

MPS14 psu 483 (19”) ........ 260 (10.2”) ....

Weights 32 Channel..... 84 kg (185 lbs)

40 Channel..... 96 kg (211 lbs)

48 Channel..... 110 kg (242 lbs)

24 Sidecar...... 45 kg (99 lbs)

MPS14 psu .... 6 kg (13 lbs)

INPUTS:

Mic (Pad out)................ XLR.................balanced, pin2+........ 2k ohm ..............variable -60 to -10dBu ........ Max +11dBu

Mic (Pad in).................. ........................ ................................. >20k ohm..........variable -40 to +10dBu .......Max +31dBu

Stereo A ...................... TRS jack .........balanced, tip+ ........... >20k ohm..........variable -18 to +6dBu ......... Max +27dBu

Stereo B ...................... XLR................. balanced, pin2+........ >20k ohm..........variable –18 to +6dBu ........ Max +27dBu

2-Track......................... TRS jack .........balanced, tip+ .......... >20k ohm..........+4dBu ................................. Max +25dBu

Matrix Ext in ................. TRS jack......... balanced, tip+........... >20k ohm..........+4dBu ................................. Max +25dBu

INSERTS:

Input send .................... TRS jack.........ground comp, tip+ .... <50 ohm............0dBu ...................................Max +21dBu

Input return................... TRS jack ......... balanced, tip+........... >20k ohm..........0dBu ...................................Max +21dBu

Output send ................. TRS jack.........ground comp, tip+ .... <50 ohm............-2dBu .................................. Max +21dBu

Output return................ TRS jack .........balanced, tip+........... >20k ohm..........-2dBu .................................. Max +21dBu

OUTPUTS:

L,R,C............................ XLR.................balanced, pin2+........ <75 ohm............+4dBu ................................. Max +26dBu

Grp/Aux 1-16................ XLR................. balanced, pin2+........ <75 ohm............+4dBu................................. Max +26dBu

Matrix 1-8 ..................... XLR................. balanced, pin2+........ <75 ohm............+4dBu ................................. Max +26dBu

Post Aux 1-8 ................ TRS jack.........ground comp, tip+ .... <50 ohm............-2dBu .................................. Max +21dBu

Direct out...................... TRS jack ......... ground comp, tip+ .... <50 ohm............0dBu ................................... Max +21dBu

2-Track......................... TRS jack .........ground comp, tip+ .... <50 ohm ............+4dBu ................................. Max +21dBu

Local Monitor ............... TRS jack.........ground comp, tip+ .... <50 ohm............0dBu ................................... Max +21dBu

Headphones................. TRS jack ......... tip left, ring right........ for stereo headphones >30 ohms

16 ML5000 Service Manual

Page 18

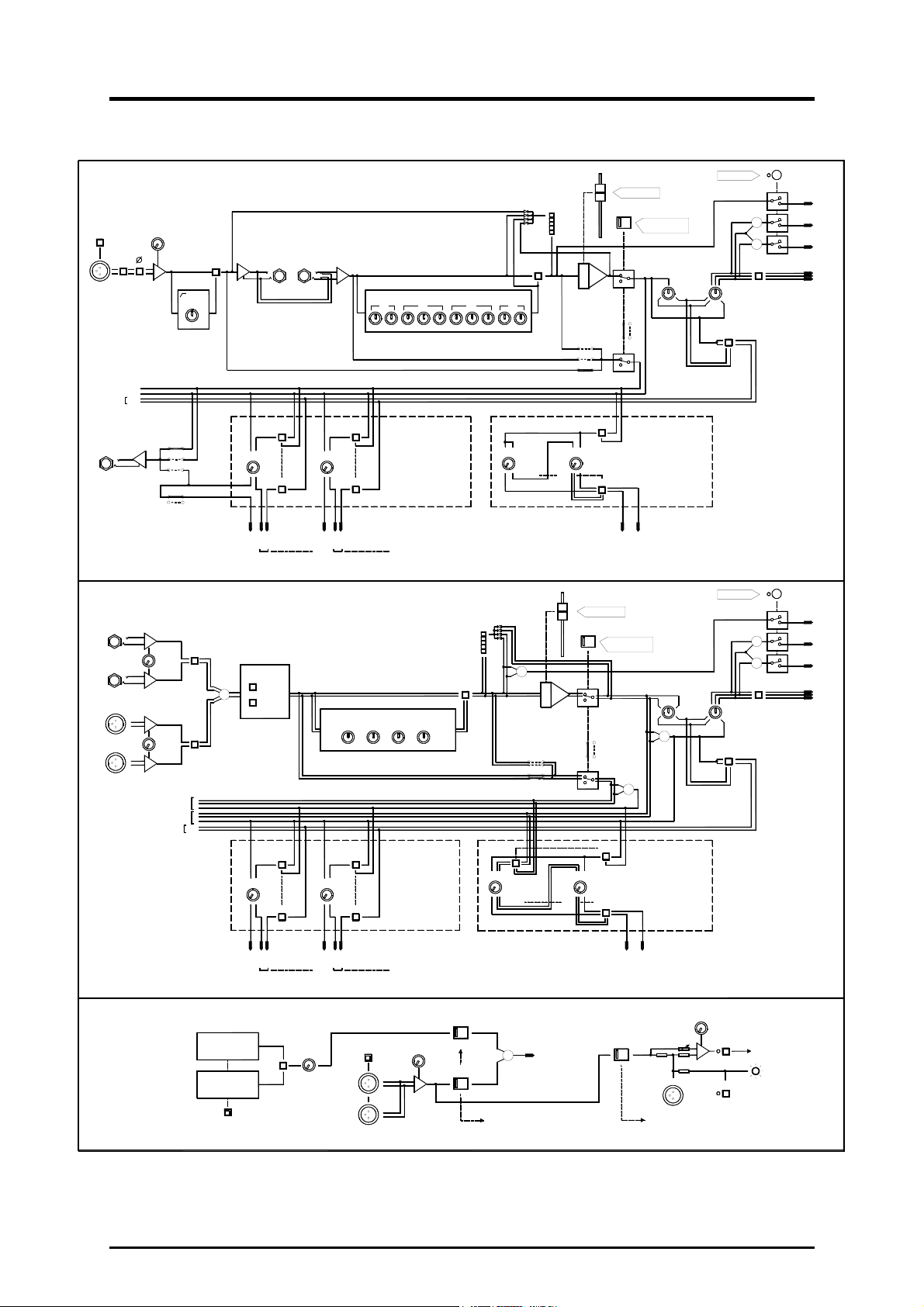

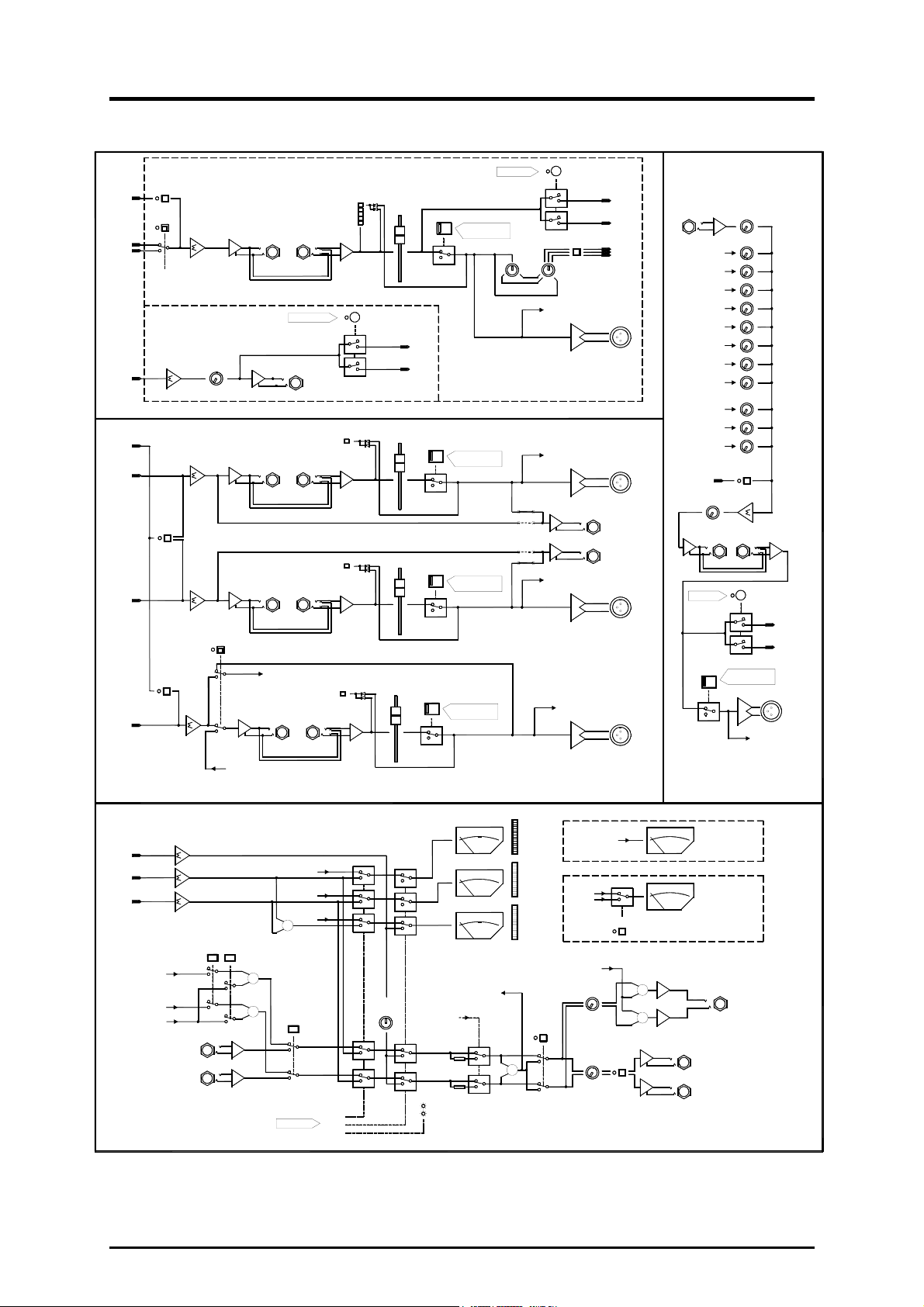

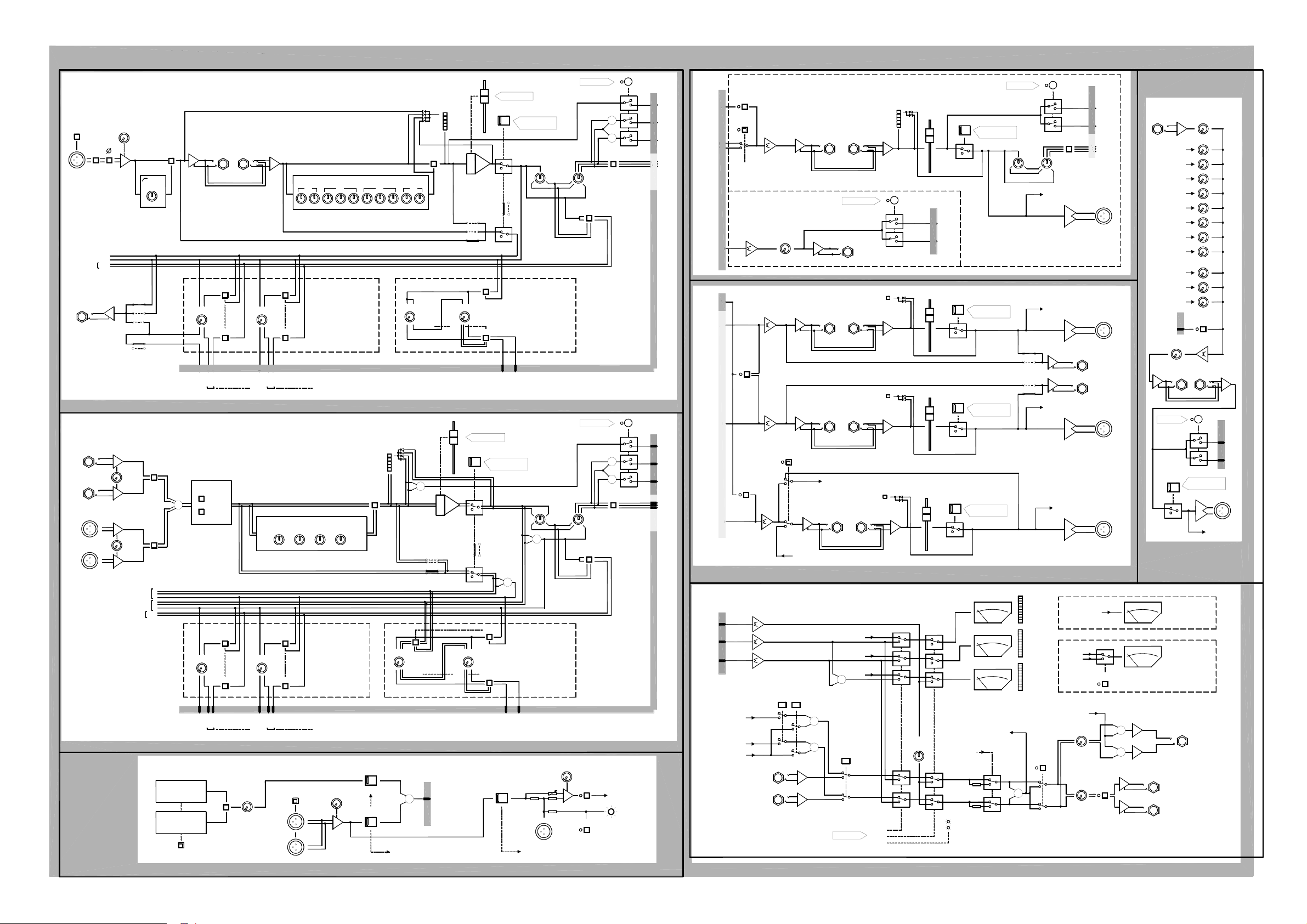

System Block Diagram (1 of 2)

MONO CHANNEL

PAD

PRE-FADE

POST-FADE

GRP

ODD

EVEN

GAIN

+

-

DIRECT OUT

OPTION LINKS

J5

POST-FADE

J4

PRE-FADE

J6

POST-TRIM

J9

J10

+48V

INPUT

DIRECT OUT

STEREO CHANNEL

+

L

-

INPUT A

R

L

INPUT B

R

+

+

+

-

-

-

GAIN

GAIN

PRE-FADE

POST-FADE

GRP

FREQ

FILTER

ON

ON

ODD

EVEN

HPF IN

(AUX1 ONLY)

L

R

M

L

R

M

FADER

VCA

POST-MUTE

PRE

STEREO

J3

J2

J1

VCA GROUPS

MUTE

J7

AUX9

MUTE GROUPS

SNAPSHOTS

PAN BLEND

L

J8

AUX 11 to 16

SAME AS 9,10 SHOWN

AUX10

AUX1

METER

PEAK

INSERT

SEND

RETURN

+

-

4 BAND EQUALISER

LF LM HM HF

AUX2

PRE

GRP/AUX 3 TO 8

SAME AS 1,2 SHOWN

GRP2

GRP2

AUX 2

POST AUX2

SET MASTER mode SWITCH

FOR EITHER AUX OR GROUP

PRE

GRP1

AUX1

GRP1

POST AUX1

AUX9

LEV 9-10

EQ IN

AUX10

PAN

PRE-FADE AUX

OPTION LINKS

POST-EQ

PRE-EQ

PRE-INSERT

FADER

VCA

POST-MUTE

R=J2

L=J1

PAN

AUX10

VCA GROUPS

MUTE

J3

PRE

STEREO

MUTE GROUPS

SNAPSHOTS

+

BAL BLEND

L RLRC

+

AUX 11 to 16

SAME AS 9,10 SHOWN

METER

PEAK

AUX9

9-10 LEV

+

PRE-FADE AUX

OPTION LINKS

POST-EQ

PRE-EQ

SOURCE

MONO L

+

MONO R

PRE

AUX1

GRP1

AUX2

4 BAND EQUALISER

LM HM HF

LF

PRE

GRP2

GRP/AUX 3 TO 8

SAME AS 1,2 SHOWN

EQ IN

PAFL LOGIC

LCR+

RLRC

GRP PAN ON

MONO

STEREO

PAFL LOGIC

LCR+

GRP BAL ON

MONO

STEREO

C

C

PAFL

PFL

L

+

R

+

MAIN

MIX

L AFL

R AFL

L MIX

R MIX

C MIX

PAFL

PFL

L

+

R

+

MAIN

MIX

L AFL

R AFL

L MIX

R MIX

C MIX

AUX1

GRP1

POST AUX1

OSC/NOISE/TALKBACK

PINK NOISE

1kHz OSC

TRIM

GRP2

AUX 2

POST AUX2

SET MASTER mode SWITCH

FOR EITHER AUX OR GROUP

OSC/NOISE TO TB

DIM

+48V

1

TRIM

TB

+

TALK TO TB

+

-

AUX9

INTERCOM

TALK TO INTERCOM

AUX10

INTERCOM IN/OUT

SIDETONE

TRIM

LISTEN

+

TO PHONES

LAMP

CALL

TB MIC

Disable

2

MONITOR DIM

MONITOR DIM

ML5000 Service Manual 17

Page 19

System Block Diagram (2 of 2)

POST AUX

L MIX

R MIX

C MIX

TB ENABLE

TB

mode

GRP

AUX

SET mode FOR EITHER:

GROUP = SWITCHED ROUTING

AUX = VARIABLE LEVEL+PRE/POST SWITCH

POST AUX 1-8

MIX

TB

TB

TB

MIX

MASTER

L MIX

R MIX

WEDGE mode

C MIX

GRP/AUX 1-16

INSERT

SEND

RETURN

AFL LOGIC

POST AUX OUT

LEFT

INSERT

SEND

RETURN

RIGHT

INSERT

SEND

RETURN

C

CENTRE

INSERT

SEND

RETURN

PEAK

PEAK

PEAK

PEAK

+

-

+

-

+

-

METER

+

-

LCR+

BLEND

GRP/AUX

L

AFL

MAIN

MIX

(1-8 ONLY)

BAL

BAL

L AFL

R AFL

L MIX

R MIX

C MIX

GRP/AUX

OUT

LEFT

OUT

EXT IN

MATRIX

+

-

GRP/AUX1

GRP/AUX 2

GRP/AUX 3

GRP/AUX 4

GRP/AUX 5

GRP/AUX 6

GRP/AUX 7

GRP/AUX 8

TB

L

R

C

TB ENABLE

AFL LOGIC

FADER

MUTE

MUTE GROUPS

SNAPSHOTS

PAN

L RLR C

AFL

L AFL

R AFL

FADER

MUTE

MUTE GROUPS

SNAPSHOTS

LEVEL

POST-FADE

FADER

FADER

MUTE

MUTE

MUTE GROUPS

SNAPSHOTS

MUTE GROUPS

SNAPSHOTS

J1

J2

J3

J4

PRE-INSERT

PRE-INSERT

POST-FADE

R

C METER

L

2TRK

OUT

R

RIGHT

BAL

OUT

CENTRE

BAL

OUT

AFL LOGIC

MUTE

SEND

INSERT

RETURN

MUTE GROUPS

SNAPSHOTS

+

-

AFL

L AFL

R AFL

BAL

OUT

MATRIX

L AFL

R AFL

WEDGE MON

TB DIM

INPUT PAFL

OUTPUT AFL

L METERS

R METERS

C METERS

WEDGE MON

METERS 1-8

METERS 9-16

GRP/AUX

MATRIX

GRP/AUX

METER SELECT

FROM INTERCOM

PHONES

MONO

LOCAL

+

MUTE

+

L

R

HEADPHONES

+

L

LOCAL

MONITOR

R

PFL

PFL MIX

L AFL MIX

R AFL MIX

MONITOR SOURCE

LR

C

L

R

C

L

2TRK

IN

R

+

+

+

-

+

-

+

2TRK

PAFL LOGIC

L

R

C

PFL

TRIM

AFL

PFL

MONITOR

18 ML5000 Service Manual

Page 20

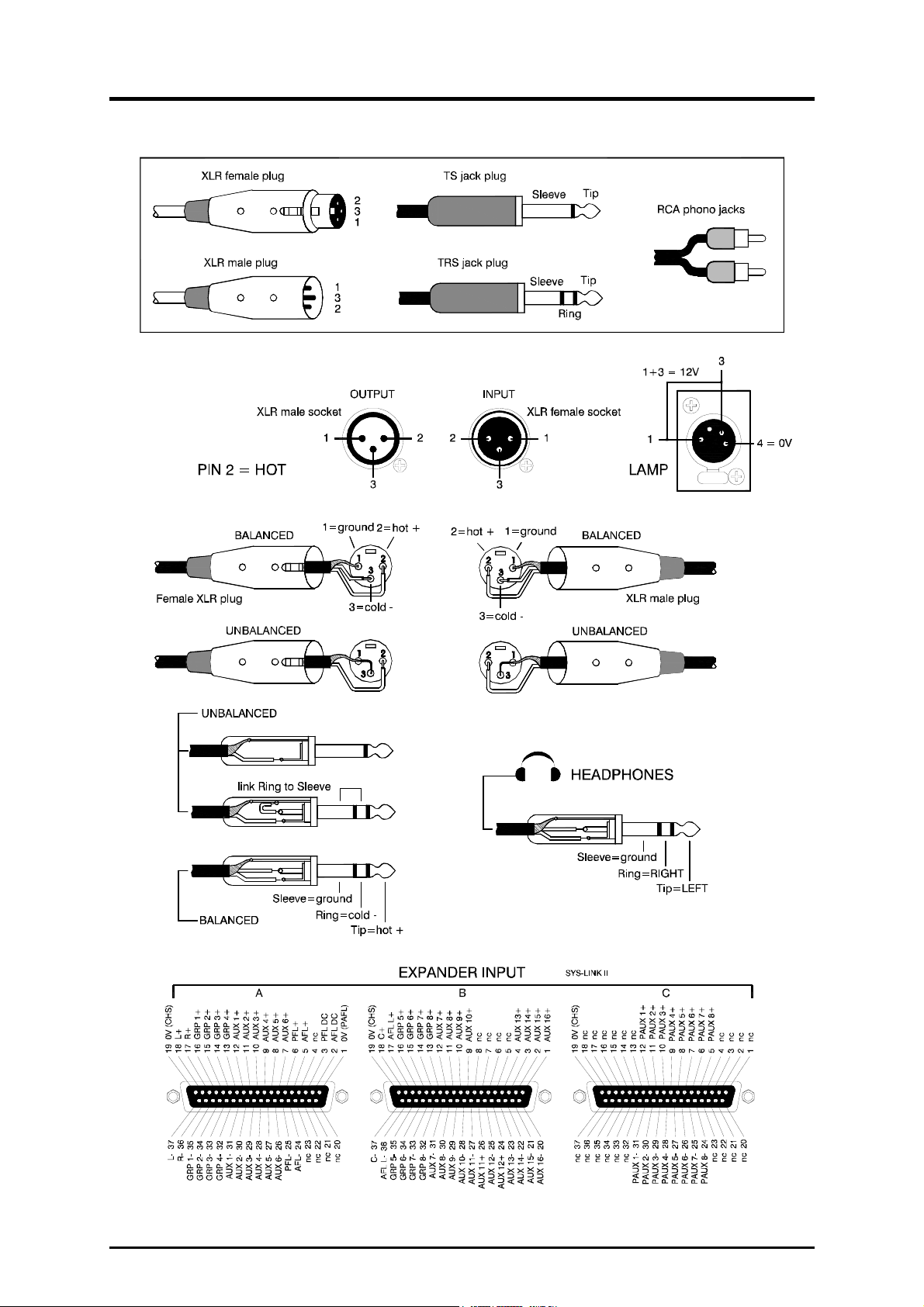

Connector Types and Wiring

ML5000 Service Manual 19

Page 21

Gain Structure (Reprinted from User Guide)

How the levels between the different signal stages

are set up is referred to as the gain structure. For

best performance it is important that the connected

source signals are matched to the ‘normal operating

level’ of the console. Similarly the levels of the

connected amplifiers and destination equipment

should be correctly matched to the console outputs.

If set too high then the signal peaks will be clipped

resulting in distortion, and if set too low then the

signal-to-noise performance will be degraded

resulting in excessive background hiss and noise.

Using the Meters. The ML5000 provides metering

at all important stages through the signal chain. For

best results operate the console with the LED bar

meters averaging around ‘0’ allowing the loudest

moments to reach ‘+6’. Reduce the gain if the red

peak LEDs start to flash. Note that the peak leds

light 5dB before actual clipping to warn that you are

nearing distortion and should reduce gain. The

LED bar meters have a peak response with fast

attack and slow release so that fast musical

transients are accurately displayed. The VU meters

have a slower attack so that the average levels are

better displayed. Both types of metering are useful

in live sound mixing.

Matching a Source to the Console. Start by

turning down the channel fader and send levels to

prevent unexpected loud volumes reaching the

main speakers and monitors. Adjust the GAIN

control for an average ‘0’ reading on the channel

meter. Press PAFL (in PFL mode) to listen to the

signal using headphones, local or wedge monitor,

and to view its level on the main LED and VU

meters. Once the gain is correctly set you can raise

the levels to bring the channel into the mix. Note

that you may need to adjust the gain if you make

significant changes to the EQ. Make sure that any

equipment inserted into the channel is set to

operate around 0dBu line level. It is best to first set

the gain with inserted signal processors such as

compressors switched to bypass.

Matching the Console to Destination Equipment.

The console produces a standard XLR output level

of 0dBu for a meter reading of ‘0’ and +22dBu

maximum to allow plenty of headroom for driving

equipment hotter. If you are connecting directly to a

sensitive power amplifier it is advisable to turn down

its input trim control if the normal console level is

too high. Simply turning down the console output

faders degrades the output stage noise

performance and reduces the resolution of the fader

movement. The output faders are best operated

around ‘-10’ to ‘0’ for loudest average volume

required. This allows plenty of additional headroom

if you need it. If you are connecting to crossovers

or speaker managers then set these for normal

0dBu operating level and use their level trimmers to

correctly match to the amplifiers.

Terminology. The normal operating level is the

optimum signal level for best console performance,

indicated by ‘0’ meter readings. The channels

operate at 0dBu and the mix stages at –2dBu for

extended headroom. Headroom is the extra level

available above normal to allow for loud peaks

before the signal becomes clipped resulting in

audible distortion. The signal-to-noise ratio (SNR)

is the difference measured in dB between normal

level and residual noise floor (hiss) produced by the

console electronics. The dynamic range is

headroom + SNR representing the maximum signal

range possible from quietest to loudest.

Using the VCA Groups. Assigning a channel to

one or more VCA groups lets those group faders

control the level of its VCA element. Each fader

provides up to +10dB boost. Note that the channel

VCA allows a maximum combined fader boost of

+10dB. Any more is simply ignored. It is best to

operate the VCA group faders around their nominal

‘0’ position. You can also use a VCA group to

reduce the overall level of a hot mix without having

to adjust all the channel faders.

Final word… A little care with setting gain

structure throughout the signal chain will give you

the very best performance and most manageable

control of the mix.

+30

+20

+10

0dBu

-10

-20

-30

-40

-50

-60

-90

INPUT

GAIN

INSERT

0dBu

EQUALISER

+/-15dB+60/-10 dB

CHANNEL

VCA

FADER

DIR OUT

0dBu

VCA GROUPS

PAN/BLEND

LRLR

-3dB law

MIXCHANNEL

MIX HEADROOM

MIX

INSERT

C

-2dBu

+23dB

VUMIX

FADER

OUTPUT

CLIPPING LEVEL

OUTPUT

DYNAMIC RANGE

112dB

NOISE FLOOR

+22dBu

HEADROOM

+22dB

0dBu

SNR

signal-to-noise

-90dB

-90dBu

20 ML5000 Service Manual

Page 22

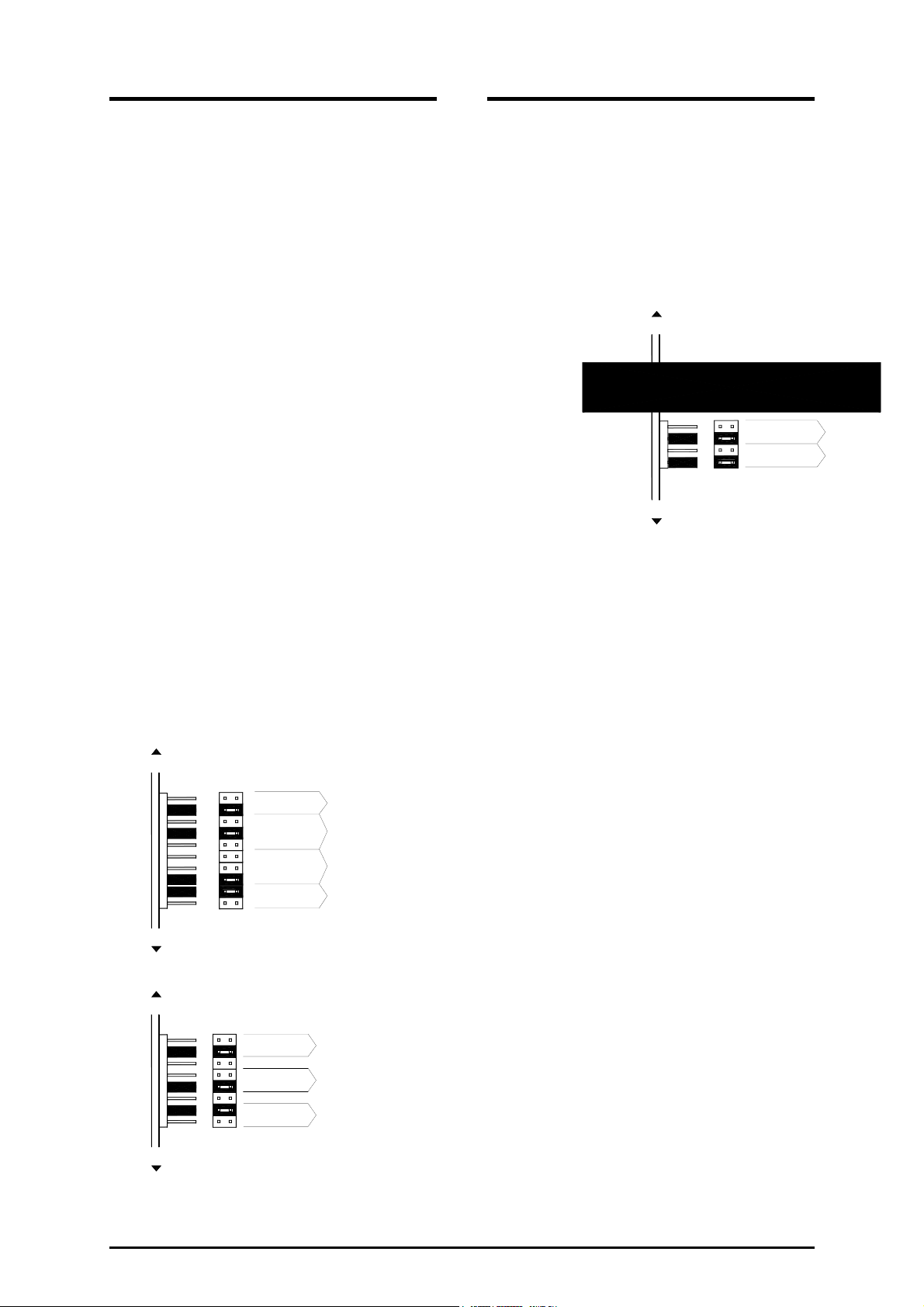

Channel Jumper Options

2-TRACK Jumper Options

Several link options are available to satisfy user

preferences. These require removal of the console

base panels and replugging of 2way jumpers on the

circuit boards. It is not necessary to remove

assemblies from the console. To avoid damage to

the internal assemblies this work should be carried

out by competent technical personnel.

Pre-fade Source. The source for the pre-fade aux

sends may be changed by repositioning jumper

links on each mono and stereo channel. The

default factory setting is pre-insert, pre-EQ, postmute. This is usually preferred when mixing

monitors from front-of-house. Select the source as

pre-insert, pre-EQ, or post-EQ by setting one

jumper. Select pre or post mute by setting another.

Set pairs of links on the stereo channels to affect

left and right signals.

Direct Output Source. The default factory setting

is post-fade. This can be changed to pre-fade.

Pre-fade follows the source as described above.

An additional option sources the output from the

AUX1 send control. This provides a post-fade

direct output with level trim. If preferred, the

channel feed to the AUX1 rotary master can be

disabled so that adjusting the direct output level

does not feed the mix. Note that this does not

affect the AUX1 send to the fader master when aux

mode is selected. Select the source as pre-fade,

post-fade, or post-fade with AUX1 trim by setting its

jumper. Set another jumper to turn the AUX1 feed

to the rotary master on or off as required.

The 2-track output is sourced from the main LR mix.

The factory default setting is post master LR faders.

If you want to source pre-insert, pre-fader then

replug the internal jumper links on the LR MIX

circuit board as shown below. For stereo recording

from a three channel LCR mix, or by creating a new

balance from the groups, use the MATRIX outputs

instead.

FADER

LR MIX PCB

CONNECTORS

2-TRK SOURCE

GROUND

PRE-INSERT

POST-R FADER

PRE-INSERT

POST-L FADER

RIGHT

LEFT

FADER

CONNECTORS

FADER

CONNECTORS

MONO CHANNEL

AUX1>OFF

AUX1>ON

AUX1>DIR

POST-FADE

PRE-FADE

POST-EQ

PRE-EQ

PRE-INSERT

POST-MUTE

PRE-MUTE

AUX1 TO

ROTARY MASTER

DIR OUT SOURCE

PRE-FADE SOURCE

PRE-FADE MUTE

STEREO CHANNEL

POST-EQ

PRE-EQ R

POST-EQ

PRE-EQ L

POST-MUTE

PRE-MUTE

PRE-FADE SOURCE

RIGHT

PRE-FADE SOURCE

LEFT

PRE-FADE MUTE

ML5000 Service Manual 21

Page 23

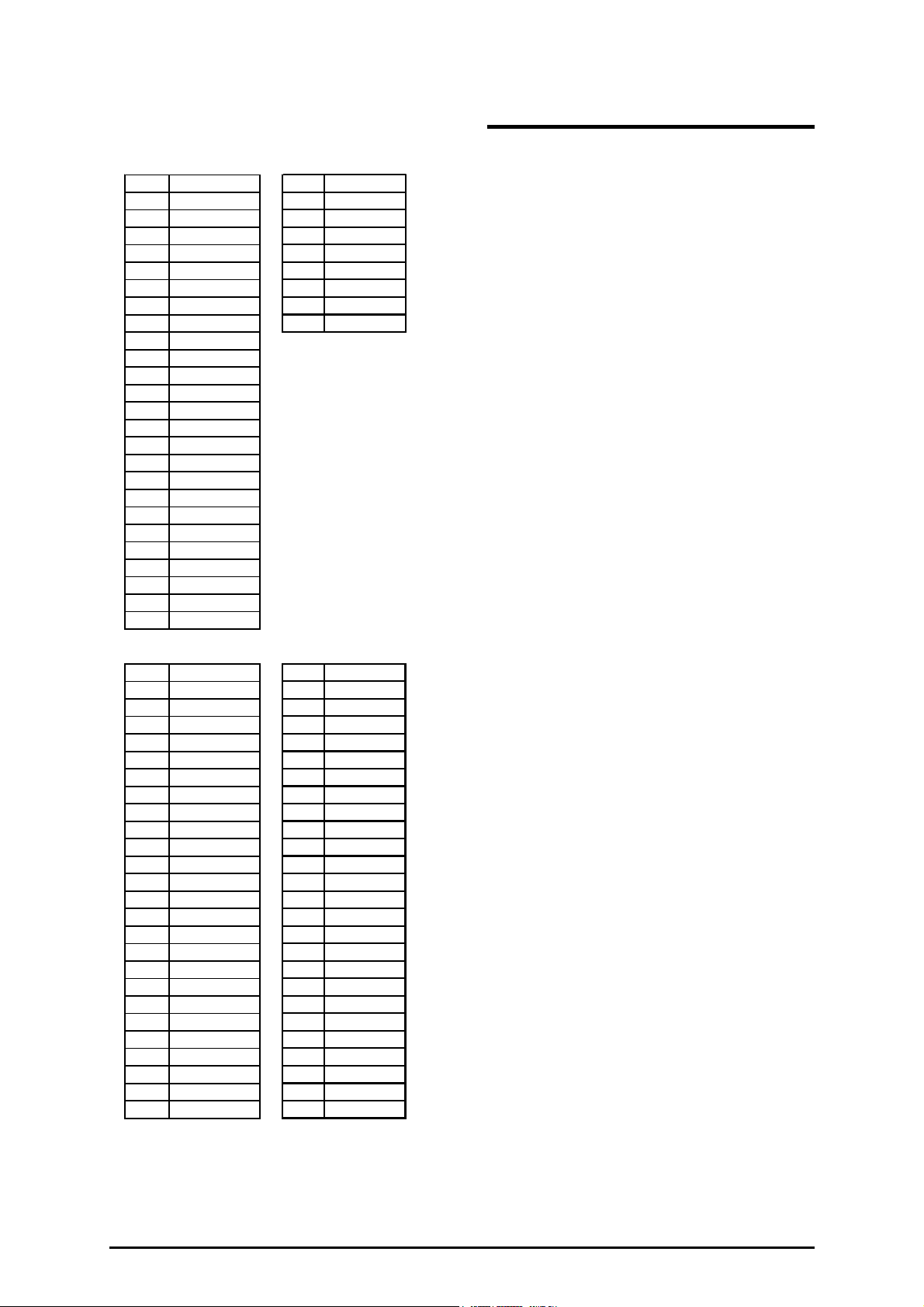

HEX MUTE HEX MUTE

00 GRP/AUX 1 50 STEREO 1

01 GRP/AUX 2 51 STEREO 2

02 GRP/AUX 3 52 STEREO 3

03 GRP/AUX 4 53 STEREO 4

04 GRP/AUX 5 54 MAIN L

05 GRP/AUX 6 55 MAIN R

06 GRP/AUX 7 56 MAIN C

07 GRP/AUX 8

08 AUX 9

09 AUX 10

0A AUX 11

0B AUX 12

0C AUX 13

0D AUX 14

0E AUX 15

0F AUX 16

10 MATRIX 1

11 MATRIX 2

12 MATRIX 3

13 MATRIX 4

14 MATRIX 5

15 MATRIX 6

16 MATRIX 7

17 MATRIX 8

MIDI Mutes

Pressing any input or output channel MUTE switch

transmits a MIDI Note On message. Similarly,

receiving a MIDI Note On message will turn the

associated channel mute on or off, unless the

channel has been made automation safe.

Console mutes are mapped to MIDI Note numbers

as shown in the table. Running status is supported

on receive and transmit.

Transmit. Pressing a channel MUTE switch

transmits the following Note On messages:

9n cc vv 9n cc 00

Where n = console MIDI channel number

cc = input or output channel number

vv = 3FH for mute off, 7FH for mute on

Receive. The console responds to the following

MIDI Note On message:

9n cc vv (00 is ignored)

Where vv < 40 = mute off,

40 <= vv <= 7F = mute on

Snapshot Memories

HEX MUTE HEX MUTE

20 CH 1 38 CH 25

21 CH 2 39 CH 26

22 CH 3 3A CH 27

23 CH 4 3B CH 28

24 CH 5 3C CH 29

25 CH 6 3D CH 30

26 CH 7 3E CH 31

27 CH 8 3F CH 32

28 CH 9 40 CH 33

29 CH 10 41 CH 34

2A CH 11 42 CH 35

2B CH 12 43 CH 36

2C CH 13 44 CH 37

2D CH 14 45 CH 38

2E CH 15 46 CH 39

2F CH 16 47 CH 40

30 CH 17 48 CH 41

31 CH 18 49 CH 42

32 CH 19 4A CH 43

33 CH 20 4B CH 44

34 CH 21 4C CH 45

35 CH 22 4D CH 46

36 CH 23 4E CH 47

37 CH 24 4F CH 48

Recalling a snapshot will transmit a MIDI Program

Change message. Receiving a Program Change

message will recall a snapshot.

Snapshot numbers 1 to 128 are mapped to MIDI

Program Change numbers 0 to 127. Running

status is supported on receive and transmit.

Transmit and Receive. The message format is:

Cn pp

Where n = console MIDI channel number

pp = console snapshot number 00 to 7F

MIDI AFL Messages

SysEx message strings are transmitted each time

an output channel AFL switch is selected or

released. These are for use with BSS and dbx

speaker management systems to automatically

select the remote control surface associated with

the output being AFL monitored.

BSS Omnidrive

F0 00 20 18 7F 20 tx_event F7

dbx Drive Rack

F0 00 01 1E 7F 7F 20 tx_event F7

These messages are subject to further development

and addition. Please check the Allen & Heath Web

site for the latest information.

22 ML5000 Service Manual

Page 24

Archiving the Console Settings

The console settings can be saved to an external

device such as a MIDI sequencer or data archiver

using the dump out facility. Saved settings can be

loaded back into the console using dump in. This is

ideal when you want to archive the settings to use

at a later date, for example a re-run of a previous

performance. You can also use the dump facility to

program additional ML5000 consoles, for example

when setting up duplicate shows or swapping

consoles around. Simply link MIDI OUT from one to

MIDI IN of the other and action the dump out facility.

Settings which are archived :

9 Current mute settings

9 Current Mute group assignments

9 Current VCA group assignments

9 Automation safes

9 Solo-in-Place safes

9 All snapshot memories

Settings which are not archived :

8 Current console operating mode

8 Current PAFL selection and settings

8 Store and auto-increment on/off

MIDI Dump Out

Connect the console to a suitable MIDI archiving

device. Set the same MIDI channel number on

both. Check the rear switch is set to MIDI. Hold

down SHIFT M9 and press STORE M4 . The

console dumps the current settings and memory

contents using a SysEx message string. During this

time dPo is displayed. Note that this operation

can take up to 10 seconds during which time the

console mutes, assignment, SIP and P/AFL

operations will be interrupted.

MIDI Dump In

Connect the console to the MIDI archiving device.

Set the same MIDI channel number on both. Check

the rear switch is set to MIDI. Start the process

using the MIDI archiver. The console current

settings and memory contents are overwritten.

During this time dPI is displayed. Note that this

operation can take a while during which time the

console mute, assignment, SIP and PAFL

operations will be interrupted.

MIDI Dump Message Format

The format for dump out and in is identical. The

dump data string is made up of multiple System

Exclusive messages (known as packets) which

contain the console information.

Transmit and Receive. The format for a single

packet is as follows:

F0 <SysEx header> <packet type> <packet

number> <data> <checksum> F7

<SysEx header> = 00 00 1A 50 07 VV vv nn

Where VV = software version number – unit

vv = software version number – decimal

nn = console MIDI channel number

<packet no.> = packet number from 0 to 127

<data> = block of console data (7-bit format)

<checksum> = checksum to allow error detection

MIDI Dump Errors

If the console or connected equipment fails to

respond to a MIDI dump then check:

• The MIDI cable is good and correctly plugged

• The same MIDI channel number is selected

• The rear panel switch is set to MIDI

• Try again

If a data error is detected during a dump out or in

the console display will show an error message

code:

Er1 Buffer overflow

Er2 Packet out of sequence / missing

Er3 Checksum error / corrupt data

Er4 Invalid packet length

Er5 Input timeout

Er6 Unsupported block type

Er7 Invalid scene number

Er8 Block size error

Allen & Heath ML Archiver

The ML Archiver Windows™ utility for the PC can

be downloaded from the Allen & Heath Internet site.

This can be used to archive data to and from the

PC via MIDI or RS232.

Check the Allen & Heath Web site for further details

and loading instructions.

If you are using a MIDI sequencer to record the

dump out data string then make sure you play it

back at the same speed you recorded it. If you

dump it back into the console faster than it was

recorded some data may not load correctly.

ML5000 Service Manual 23

Page 25

Operating Software Technical Support

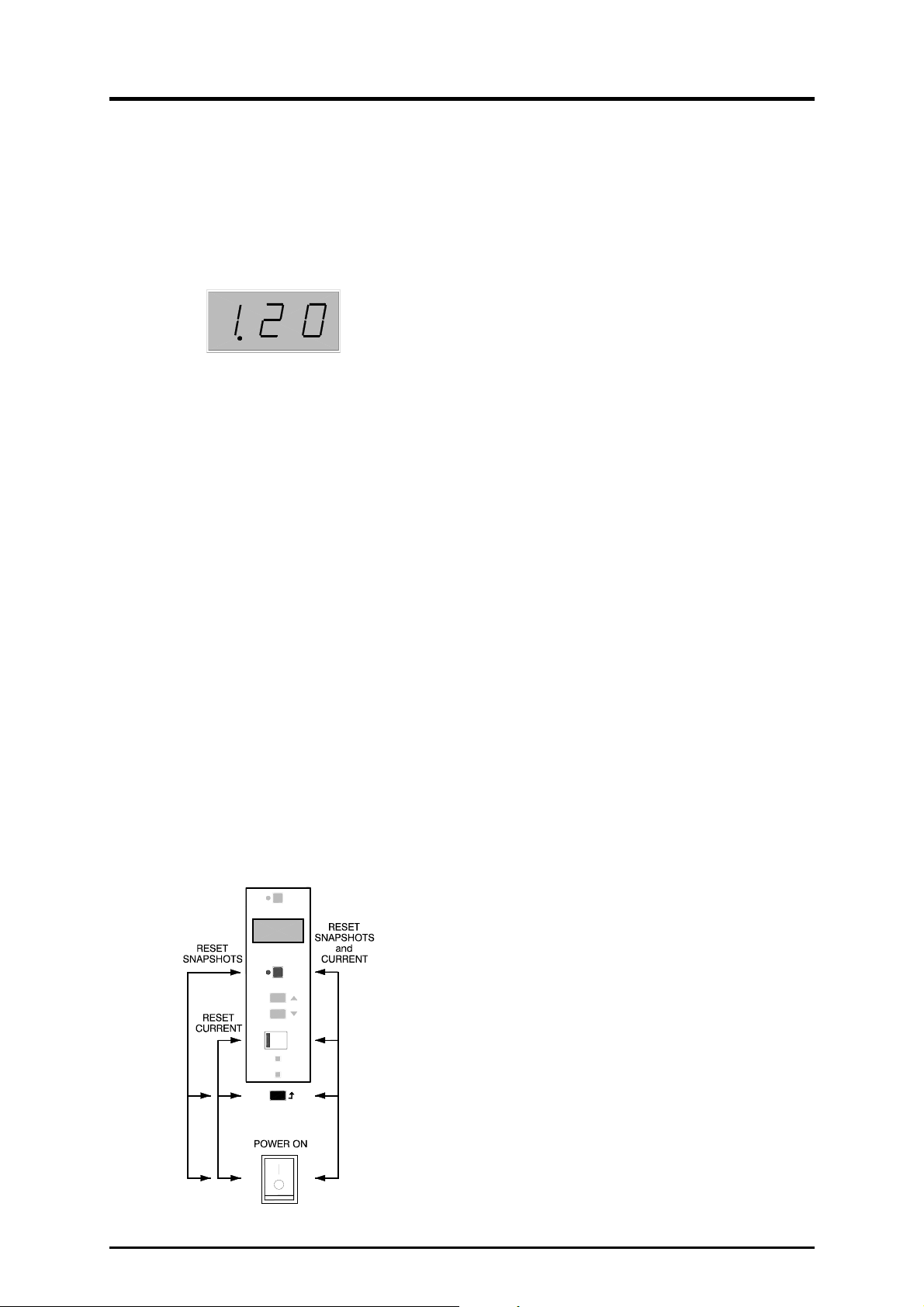

Operating Software Version Number

The version number is briefly shown on the

snapshot display on power up. Make sure the

system amplifiers are muted or turned off before

switching the console on or off. This example

displays version 1.20

Loading New Operating Software

Check the Allen & Heath Web site for the latest

version of console software. New software is

loaded from a PC via the RS232 port.

IMPORTANT ! The current console settings and

snapshots may be lost when you load new

operating software. If you wish to keep your

settings and snapshot contents, first archive them

using the dump out facility. Restore these after

loading the new software by using dump in.

Power Up and Power Down

The console settings are saved when power is

removed. On power up these settings are restored.

To Reset the Console Settings

Hold down SHIFT and RECALL while turning on the

console to reset all current settings. This does not

affect the contents of the snapshot memories. The

default settings are restored:

• Selects normal console operating mode

• Clears current P/AFL selections

• Clears all current Mute Group assignments

• Clears all current VCA Group assignments

• Clears all channel automation safes

• Restores the default SIP safes

• Enables the snapshot store function

• Turns off recall auto-increment

Download the software from the Allen & Heath Web

site to your PC computer. Connect the PC RS232

port to the console RS232 port using a standard

pin-to-pin (not null modem) 9-pin serial cable. Set

the console rear panel switch to the RS232 position.

Power up the console. The snapshot display

should read UPd (update) as the console awaits

data from the PC. Follow the instructions provided

on the Web site for loading the new software into

the console. When completed make sure you set

the console rear panel switch back to the MIDI

position.

STORE

RECALL

(SHIFT)

To Reset the Snapshot Memories

Hold down SHIFT and STORE while turning the

console on to clear all the snapshot memories. This

does not affect the current console settings. For all

snapshots:

• Clears all stored mutes

• Clears all stored VCA Group assignments

To reset all Settings and Memories

Hold down SHIFT, RECALL and STORE together

while turning the console on to clear all current

settings and the memories.

Contacting Allen & Heath

If you have any queries about the automation

system please quote the console model, serial

number and operating system version number in

any communication with Allen & Heath or your

appointed service agent. Technical support is

available through your dealer or by visiting the Allen

& Heath Internet Web site.

www.allen-heath.com

24 ML5000 Service Manual

Page 26

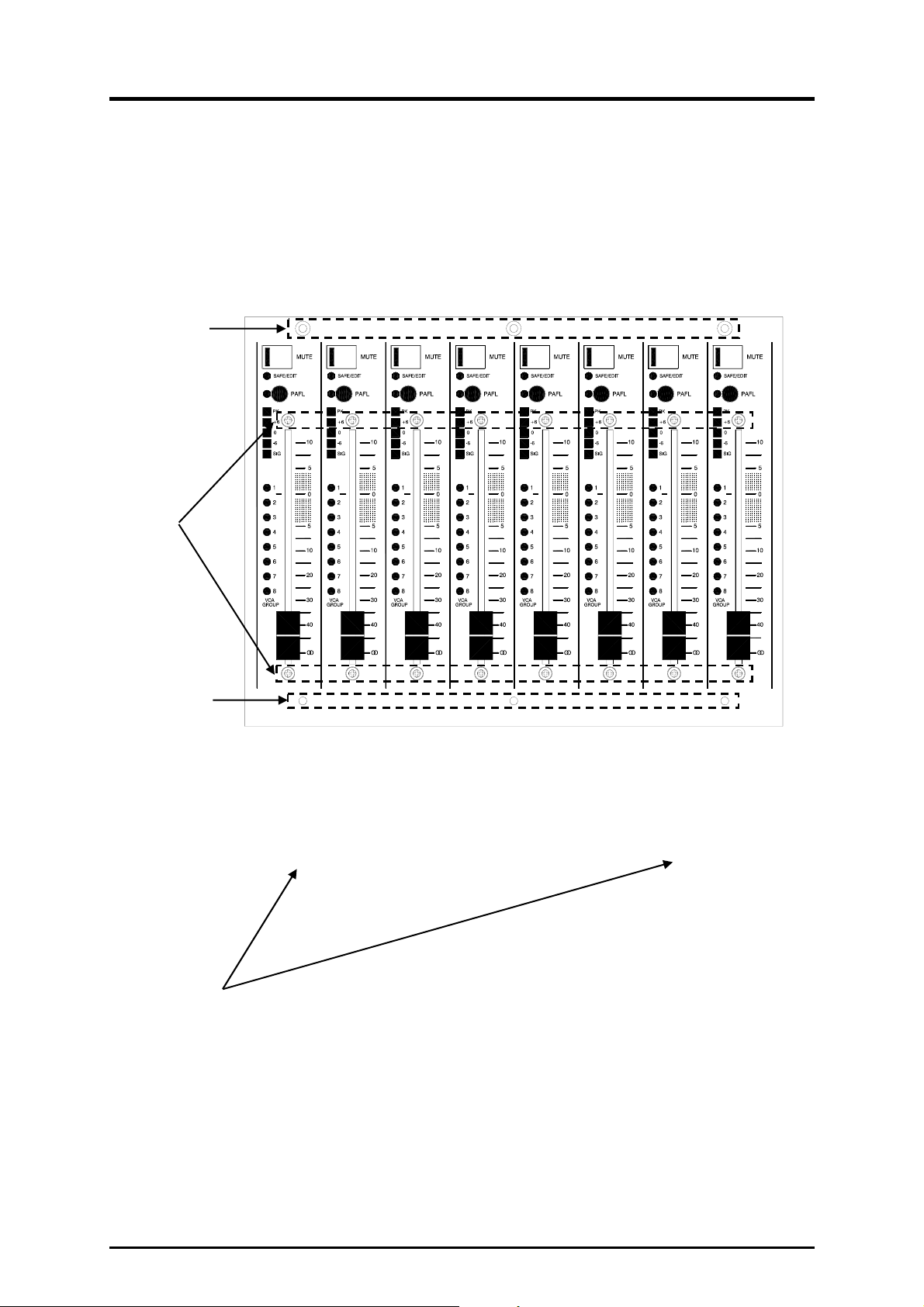

Servicing the Input Fader assembly

Before beginning any service work, remove all power to the unit and disconnect any signal cables

where necessary. Ensure adequate lighting and use the correct tools.

Remove the numbered Ident strip by placing a flat headed screwdriver under one end and prizing it

upwards. Remove the Ident strip by ‘peeling’ it from one end of the console to the other.

Remove the 3x 6Bx3/8 Countersunk Pozi Zinc Screws from the top of the fader panel (A) and the 3x

6Bx3/8 Flange Headed Pozi Black Screws from the bottom of the fader panel, taking care to retain the

plastic washers (B) (see fig.1). Carefully tilt the fader panel assembly out from the console and

remove all connecting IDC wireforms. The fader panel assembly can now be removed from the

console.

fig.1

3) Flip the fader panel over and remove the 2x 4ABx5/16 Countersunk Pozi Black Screws (D)

from the Fader Slave PCB (see fig.2)

fig.2

ML5000 Service Manual 25

Page 27

4) Carefully remove the Fader Slave PCB from the Mono Fader PCBs by pulling it upwards

from the fader boards.

5) Once removed, turn the Fader Slave PCB over (see fig.3)

To remove a Mono Fader PCB, use a 5.5mm spanner to remove the relevant M3x4 Taptite Hex

Headed Screws (E) that attach the Mono Fader PCBs to the Input Fader Bracket (see fig.3).

To remove a fader remove the two relevant M3x5 Countersunk Pozi Screws with under-head pips (C)

as shown in fig.1. Then unplug the fader wireform from the Fader Slave PCB, the fader can now be

removed. De-solder the three fader wireform wires from the fader, taking note of the wire positions for

refitting.

Note: A fader can be removed without removing the IDC wireforms and Slave PCB.

Fader Slave PCB

Fader Wireform

E

fig.3

To refit any of the PCB/Fader assemblies, follow the above procedure in reverse order. Ensure all

connectors and harnesses are correctly aligned and plugged on. Test for correct operation.

26 ML5000 Service Manual

Page 28

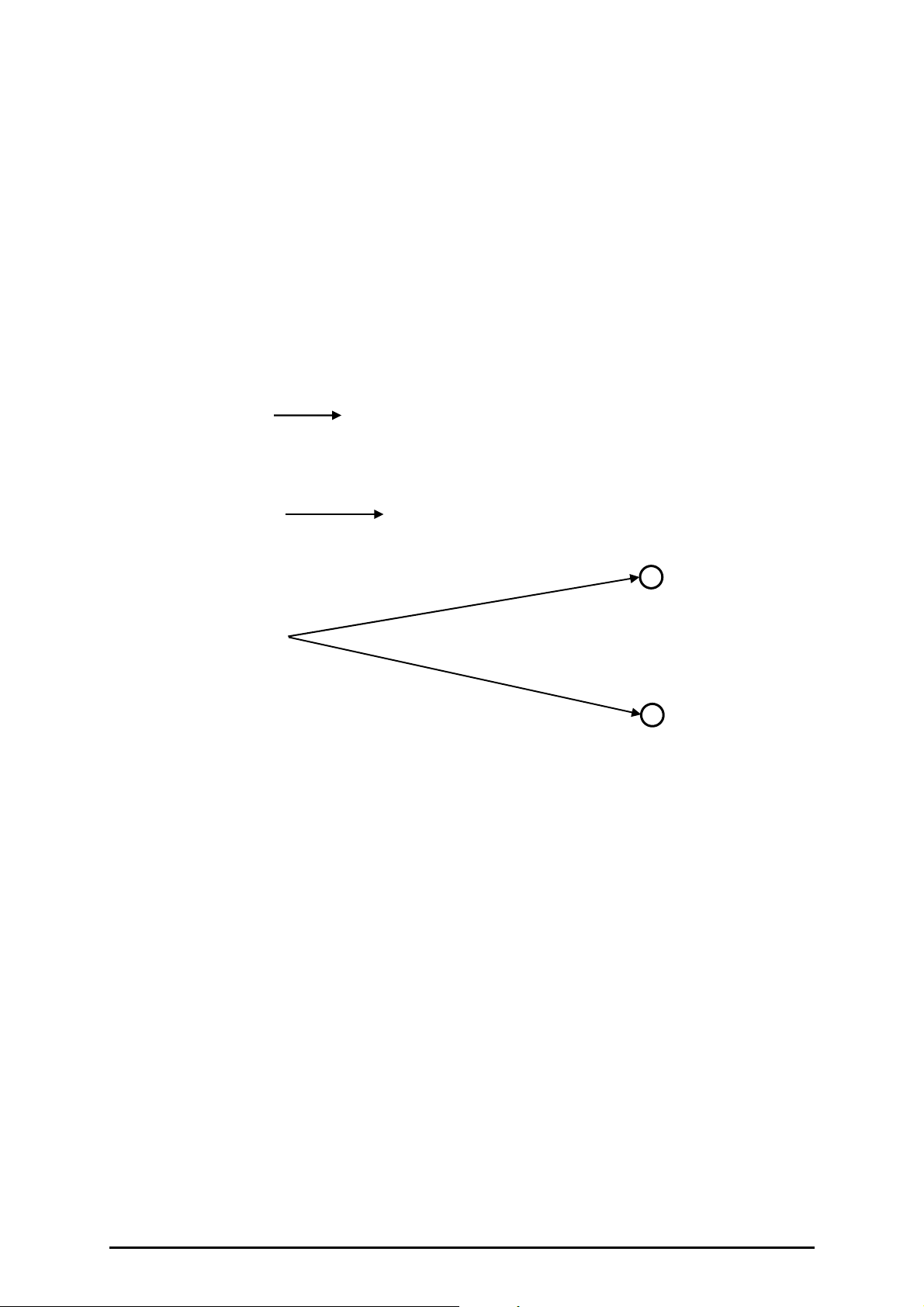

Servicing the Master Fader assembly

Before beginning any service work, remove all power to the unit and disconnect any signal cables

where necessary. Ensure adequate lighting and use the correct tools.

Remove the numbered Ident strip by placing a flat headed screwdriver under one end and prizing it

upwards. Remove the Ident strip by ‘peeling’ it from one end of the console to the other.

Remove the 5x 6Bx3/8 Countersunk Pozi Zinc Screws from the top of the fader panel (F) and the 5x

6Bx3/8 Flange Headed Pozi Black Screws from the bottom of the fader panel, taking care to retain the

plastic washers (G) (see fig.4). Carefully tilt the fader panel assembly out from the console and

remove all connecting IDC wireforms. The fader panel assembly can now be removed from the

console.

F

H

G

fig.4

Flip the fader panel over to reveal the PCB assemblies (see fig.5).

Stereo Fader PCBs

Master Fader Centre PCB

Master Fader L/R PCBs

Control Panel PCB

Mute Group PCB

Stereo Slave PCB

VCA Master Fader PCBs

VCA Master Slave PCB

fig.5

ML5000 Service Manual 27

Page 29

The Stereo Slave PCB must be removed before the following PCBs can be removed; Mono Fader,

Master Fader Centre, Master Fader L/R & Control Panel.

1) Cut the 2x Cable ties attaching the Stereo Slave PCB onto the Mono Fader & Control

Panel PCBs.

2) Carefully remove the Stereo Slave PCB by pulling it upwards.

3) Once removed, turn the Stereo Slave PCB over.

4) To remove a PCB, use a 5.5mm spanner to remove the relevant M3x4 Taptite Hex Headed

Screws that attach the PCBs to the Master Fader bracket.

5) To remove a fader, remove the two relevant M3x5 Countersunk Pozi Screws with underhead

pips (H) as shown in fig.4. Then unplug the fader wireform from the Stereo Slave PCB, the

fader can now be removed. De-solder the three fader wireform wires from the fader, taking

note of the wire positions for refitting.

6) Removal of the ‘H’ shaped Control Panel PCB can only be achieved once the vertical

section of PCB has been removed. Once the vertical section has been removed, remove the

2x M3x6mm Pan Pozi Black screws attaching the ‘H’ shaped Control Panel PCB to the fader

bracket. The ‘H’ shaped Control Panel PCB can then be removed.

10) To remove the Mute Group PCB, use a 5.5mm spanner to remove the two screws attaching

the PCB to the fader bracket.

The VCA Master Slave PCB must be removed before the Master Fader PCBs can be removed.

11) Cut the 2x Cable ties attaching the VCA Master Slave PCB onto the Master Fader PCBs.

12) Remove the 15way Flexi cable running between the VCA Master Slave PCB and the Mute

Group PCB.

13) Carefully remove the VCA Master Slave PCB by pulling it upwards.

14) Once removed, turn the VCA Master Slave PCB over.

15) To remove a PCB, use a 5.5mm spanner to remove the relevant M3x4 Taptite Hex Headed

Screws that attach the PCBs to the Master Fader Bracket.

16) To remove a fader, remove the two relevant M3x5 Countersunk Pozi Screws (H) from the

Master Fader front panel (see fig.4). Unplug the fader wireform from the Stereo Slave PCB,

the fader can now be removed. De-solder the three Fader wireform wires from the fader,

taking note of the wire positions for refitting.

Note: A fader can be removed without removing the IDC wireforms and Slave PCB.

17) To refit any of the PCB assemblies, follow the above procedure in reverse order. Make sure

all harnesses are aligned and plugged on. Test for correct operation.

28 ML5000 Service Manual

Page 30

Base removal and Internal PCB assemblies

Before beginning any service work, remove all power to the unit and disconnect any signal cables

where necessary. Ensure adequate lighting and use the correct tools.

Before you can access the internal PCB assemblies, invert the console and remove the screws

securing the base in place. Carefully lift the base off.

EARTH BUSS PCBS

MONO INPUT

PCBS

SYS-LINK II

OUT PCB

MIDI POWER

PCB

STEREO PCBs

AUX, GROUP

& LRC PCBs

MASTER

DISTRIBUTION

PCB

EARTH BUSS PCBS

MONO INPUT

PCBs

MONO INPUT

CONNECTOR

PCBs

Note that the Earth Strip has been removed for clarity.

ML5000 Service Manual 29

Page 31

Removing a Mono Input PCB assembly

Before beginning any service work, remove all power to the unit and disconnect any signal cables

where necessary. Ensure adequate lighting and use the correct tools.

1) Remove the screws attaching the relevant Earth Strip running the length of the Mono section

(see fig.6, right hand section only shown) then lift away the Earth Strip.

Earth Strip

50 way

IDC

wireform

SYS-LINK II

PCB

2) Carefully detach the 50way IDC wireform from the Mono Input PCBs and the SYS-LINK II

Input PCB as far as the relevant Mono Input PCB. Note: There are two different 50way IDC

wireforms on either side of the Master section. Remove the relevant IDC wireform according

to the side on which the particular Mono Input PCB lies.

3) Remove all the knob and switch caps from the required Mono Input PCB, then remove the

pot nuts underneath using an 11mm nutdriver.

4) The required Mono Input PCB can now be removed from the console.

5) To refit a Mono Input PCB assembly, follow the above procedure in reverse order. Make

sure all harnesses are correctly aligned and plugged on. Test for correct operation.

fig.6

30 ML5000 Service Manual

Page 32

Removing the Master Distribution PCB assembly

To access the Group and Auxiliary PCB assemblies it may be necessary to remove the Master

Distribution PCB.

Before beginning any service work, remove all power to the unit and disconnect any signal cables

where necessary. Ensure adequate lighting and use the correct tools.

1) Before removing the Master Distribution PCB assembly, the console base must first be

removed.

2) Locate the Master Distribution PCB assembly positioned near the centre of the console (see

fig.7).

Earth wire

Master

Distribution

PCB

LCR Option

links or

fig.7

3) Unplug all attaching IDC wireforms from the Master Distribution PCB assembly.

4) Desolder the Earth wire from the PCB then carefully remove the Master Distribution PCB by

pulling it away from the console.

5) To refit the Master Distribution PCB assembly, follow the above procedure in reverse order.

Use an inspection mirror to check that each connector and IDC harness is correctly aligned

and plugged on. Note: If a switch is fitted to the rear of the Master Distribution PCB rather

than solder links then make sure that it is set correctly. Test for correct operation.

ML5000 Service Manual 31

Page 33

Servicing the Meterbridge Assembly

Before beginning any service work, remove all power to the unit. Ensure adequate lighting and use

the correct tools.

1) Remove all the plastic snap-in rivets along the face of the meter panel with your fingernails or

other non-abrasive tool.

2) With a person standing at either end of the console, each using a small, thin screwdriver,

place the screwdriver through each of the endmost bottom rivet holes (see fig 8). Raise the

meter panel up with the screwdrivers so that the bottom becomes free of the extrusion.

3) The complete meter panel assembly can now be removed from the meter pod extrusion by

pulling it away from the extrusion, bottom first (see fig.9), allowing access to the Meter PCB

assemblies. Remove the two attaching IDC harnesses.

fig.8

fig.9

32 ML5000 Service Manual

Page 34

Servicing the MPS14 Power Supply

Cleaning and Replacing the fan filters.

At regular intervals, it is recommended that the foam fan filters are cleaned or replaced to ensure efficient

operation of the power unit. Failure to do so may reduce the efficiency or even damage the power unit.

To remove the fan filters, switch off and disconnect all power to the MPS14. Remove the rack ears and place to

one side. Remove the cover fixing screws and cover and place to one side.

The foam fan filters can now be removed by simply sliding out of the slots.

Either clean or fit new filters depending on their condition.

Replace the filters and reassemble the power unit. Check the fans are running unobstructed before completely

re-installing.

Replacing the mains fuse

The AC mains fuse is located on the rear of the MPS14 unit next to the AC mains connector. In the event of a

mains surge or under-rated fuse value, the mains input fuse will rupture. Switch off the power supply and remove

the mains lead plug from the “MAINS INPUT” socket on the rear of the unit.

Check the fuse and replace if necessary.

TO AVOID THE RISK OF FIRE REPLACE FUSE WITH THE CORRECT TYPE

ONLY, AS INDICATED ON THE UNIT

AC~ mains input voltage Fuse type

100V – 230V ± 10% T 5A 250V 20mm

In the event of repeated failure of the mains fuse, consult the local dealer from where the unit was purchased.

ML5000 Service Manual 33

Page 35

ORDERING A CONSOLE

To order a new console please specify the model number and AC mains voltage for the Power Supply.

MODEL DESCRIPTION ORDER CODE

ML5000-32

ML5000-40

ML5000-48

MPS14

* - Specify the voltage and mains plug requirement for your area.

32 Mono + 4 Stereo Input Channels ML5000-32

40 Mono + 4 Stereo Input Channels ML5000-40

48 Mono + 4 Stereo Input Channels ML5000-48

Power Supply for ML5000 MPS14/*

ORDERING AN ACCESSORY

To order an option please specify the model number required.

MODEL DESCRIPTION ORDER CODE

SIDECAR EXPANDER

DC POWER LEAD

DC COMBINER LEAD

SYS-LINK CABLE

LOGIC CABLE

GOOSENECK LAMP

32 CHANNEL DUSTCOVER

40 CHANNEL DUSTCOVER

OPTIONAL 24 MONO INPUT SIDECAR ML5000-24SC

2.9 METRE DC POWER LEAD 002-583

0.75 METRE DC COMBINER LEAD 002-584

2.8 METRE 37 WAY AUDIO CABLE 002-617

2.9 METRE 9 WAY LOGIC CABLE AL4155

18” GOOSENECK LAMP AL4061

32 CHANNEL VINYL DUSTCOVER AP4121

40 CHANNEL VINYL DUSTCOVER AP4122

48 CHANNEL DUSTCOVER

SIDE-CAR DUSTCOVER

48 CHANNEL VINYL DUSTCOVER AP4123

SIDECAR VINYL DUSTCOVER AP4234

MANUALS AND SUPPORT DOCUMENTATION

MODEL DESCRIPTION ORDER CODE

ML5000

ML5000 SIDECAR

MPS14 POWER SUPPLY

User Guide AP3736

User Guide AP4124

User Guide AP3898

SERVICE TOOLS

The tools required to service the ML5000 are standard to an electronics service workshop and are

easily obtainable. The following items are necessary for disassembly and service access:

TOOL USE ORDER CODE

4mm Hexagon (Allen) key M6 side trim AT0033

1-point Crosshead screwdriver M3, 4AB AT0004

2-point Crosshead screwdriver M4, 6AB, 8B AT0002

11mm AF Nutdriver Potentiometer and headphone nuts

12mm Nutdriver Jack nuts

1.27mm Hexagon (Allen) key PSU DC Leads AT4142

2.5MM hexagon (Allen) key M4 Sidetrim

5.5mm AF Spanner Fader PCB M3 Hex

5mm Nutspinner D-Type Screws

34 ML5000 Service Manual

Page 36

ORDERING AN ASSEMBLY

The following assemblies for the ML5000 are supplied fully tested. Please quote the description and

order code for the part required.

Printed circuit board (PCB) assemblies:

DESCRIPTION ORDER CODE

Mono Input PCB assembly 002-529

Stereo Input PCB assembly 002-564

Group 1, 3, 5, 7 PCB assembly 002-552

Group PCB assembly 002-553

Group 2, 4, 6, 8 PCB assembly 002-554

Aux 10 PCB assembly 002-545

Aux 12 PCB assembly 002-546

Aux 14 PCB assembly 002-547

Aux 16 PCB assembly 002-548

Master Distribution PCB assembly 002-556

LCR Mix PCB assembly 002-544

Mono Fader PCB assembly 002-530

Master Fader Centre PCB assembly 002-589

Master Fader L/R PCB assembly 002-588