Alcatel OmniSwitch 6250-24, OmniSwitch 6250-P24, OmniSwitch 6250-24M, OmniSwitch 6250-24MD, OmniSwitch 6250-8M operation manual

Part No. 060303-10, Rev. F

September 2015

OmniSwitch 6250

Hardware Users Guide

enterprise.alcatel-lucent.com

This user guide documents the OmniSwitch 6250 for AOS Release 6.7.1.

This user guide documents OmniSwitch 6250 hardware, including chassis and associated components.

The specifications described in this guide are subject to change without notice.

enterprise.alcatel-lucent.com Alcatel-Lucent and the Alcatel-Lucent Enterprise logo are trademarks of

Alcatel-Lucent. To view other trademarks used by affiliated companies of ALE Holding, visit:

enterprise.alcatel-lucent.com/trademarks. All other trademarks are the property of their respective owners.

The information presented is subject to change without notice. Neither ALE Holding nor any of its affiliates

assumes any responsibility for inaccuracies contained herein. (July 2015)

26801 West Agoura Road

Calabasas, CA 91301

(818) 880-3500 FAX (818) 880-3505

Service & Support Contact Information

North America: 800-995-2696

Latin America: 877-919-9526

EMEA: +800 00200100 (Toll Free) or +1(650)385-2193

Asia Pacific: +65 6240 8484

Web: service.esd.alcatel-lucent.com

Email: esd.support@alcatel-lucent.com

Contents

About This Guide ..............................................................................................................ix

Supported Platforms ..........................................................................................................ix

Who Should Read this Manual? ........................................................................................xi

When Should I Read this Manual? ....................................................................................xi

What is in this Manual? .....................................................................................................xi

What is Not in this Manual? ..............................................................................................xi

How is the Information Organized? ................................................................................. xii

Documentation Roadmap ......................................................................................... .... ... .xii

Related Documentation ...................................................................................................xiv

Product Documentation ....................................................................................................xv

Technical Support ............................................................................................................xv

Documentation Feedback .................................................................................................xv

Chapter 1 OmniSwitch 6250 ............................................................................................................ 1-1

Chassis Configurations ....................................................................................................1-2

OmniSwitch 6250 Feature Overview ..............................................................................1-3

Security Features .............................................................................................................1-3

Applications ....................................................................................................................1-3

Availability Features .......................................................................................................1-4

Software Rollback ................................................................. .... ...............................1-4

Hot Swapping ...........................................................................................................1-4

Hardware Monitoring ............................................. .... ..............................................1-5

Backup Power Supplies ............................................................................................1-5

Chapter 2 Getting Started ...............................................................................................................1-1

Installing the Hardware ...................................................................................................1-1

Items Required ........................................................... .... ..........................................1-1

Site Preparation ........................................................................................................1-1

Environmental Requirements ............................................................................1-1

Electrical Requirements .....................................................................................1-1

Unpacking and Installing the Switch .......................................................................1-2

Items Included ........................................................................................ .... .......1-2

Weight Considerations ......................................................................................1-2

Airflow Considerations .....................................................................................1-3

Mounting the Switch .......................................................................................................1-3

OmniSwitch 6250 Hardware Users Guide September 2015 iii

Contents

Connections and Cabling ................................................................................................1-4

Serial Connection to the Console Port ...............................................................1-4

Serial Connection Default Settings ...................................................................1-4

Booting the Switch ..........................................................................................................1-5

Component LEDs ..............................................................................................1-5

Your First Login Session ................................................................................................1-6

Logging In to the Switch ..........................................................................................1-6

Unlocking Session Types .............................................................. .... .... ...................1-7

Changing the Login Password ..................................................................................1-8

Setting the System Time Zone .................................................................................1-8

Setting the Date and Time ........................................................................................1-8

Setting Optional Parameters ................... ..................................................................1-9

Specifying an Administrative Contact ........................................ .... .... .... ...........1-9

Specifying a System Name ................................................................................1-9

Specifying the Switch’s Location ......................................................................1-9

Viewing Your Changes ............................................................................................1-9

Saving Your Changes ...............................................................................................1-9

Chapter 3 OmniSwitch 6250 Chassis and Hardware Components ................................................3-1

OmniSwitch 6250-8M .....................................................................................................3-3

OmniSwitch 6250-8M Rear Panel .................................................... .... .... ...............3-5

OmniSwitch 6250-24M/24MD .......................................................................................3-7

OmniSwitch 6250-24M/24-MD Rear Panel ............................................................3-9

OmniSwitch 6250-24 ....................................................................................................3-12

OmniSwitch 6250-24 Rear Panel ...........................................................................3-14

OmniSwitch 6250-P24 ..................................................................................................3-16

OmniSwitch 6250-P24 Rear Panel .........................................................................3-18

LED Status ............................................................................................................3-20

OS6250 - Power Supplies .............................................................................................3-21

Internal AC Power Supply .....................................................................................3-22

Internal DC Power Supply .....................................................................................3-23

PS-42W-AC Power Brick ......................................................................................3-24

PS-30W-DC Power Brick ......................................................................................3-25

PS-225W-AC-P PoE Power Supply Module .........................................................3-26

Power Supply Tray .................................................................................................3-27

AC Power Cords ...........................................................................................................3-28

Specifications .........................................................................................................3-28

DC Power Specifications ..............................................................................................3-29

OS6250-24MD Internal DC Power Supply ...........................................................3-29

Backup DC Power Brick ........................................................................................3 -29

Stacking Cables .............................................................................................................3-30

Console Port ..................................................................................................................3-31

iv OmniSwitch 6250 Hardware Users Guide September 2015

Contents

Port Pinouts .................................................................................. .................................3-32

RJ-45 Console Port – Connector Pinout ................................................................3-32

10/100 Ethernet Port – RJ-45 Pinout (non-PoE) .................................................... 3-32

Gigabit Ethernet Port – RJ-45 Pinout .....................................................................3-32

10/100/1000 Mbps Power over Ethernet Port – RJ-45 Pinout ..............................3-33

Overtemp Condition ................... ... .... ....................................................... .... .................3-33

Dying Gasp ....................................................................................................................3-34

Scenarios ................................................................................................................3-34

SNMP Trap ......................................................................................................3-34

Syslog Message ...............................................................................................3-34

Link OAM PDU ..............................................................................................3-35

Chapter 4 Mounting OS6250 Switches ............................................................................................4-1

Chassis Components ................................................................................................4-1

Available Mounting Kits ..........................................................................................4-2

General Installation Recommendations ..........................................................................4-3

Cooling Recommendations ......................................................................................4-3

Recommended Clearances .......................................................................................4-4

Mechanical Loading .................................................................................................4-4

Circuit Overloading ..................................................................................................4-4

Reliable Earthing ......................................................................................................4-4

Power Supply Information ..............................................................................................4-5

Assembling OS6250 Switches ........................................................................................4-6

Assembly Guidelines ................................................................................................4-6

Attaching the Power Supply Tray on Side of Chassis .............................................4-6

OS6250-RM-19 - Power supply tray side installation ......................................4-6

OS6250-DUAL-MNT - Attaching Two Chassis Side-by-Side ..............................4-10

Attaching Power Supply Tray to Rear of Chassis ..................................................4-12

Securing Power Supplies in Power Supply Tray ...................................................4-13

Power Supply Brick Installation ......................................................................4-13

Power Supply Module Installation ..................................................................4-14

Mounting OS6250 Switches .........................................................................................4-15

Rack-Mounting OS6250 Switches .........................................................................4-15

General Rack-Mounting Guidelines ................................................................4-15

Rack-Mounting Installation .............................................................................4-15

Power Supply Tray - Removeable Section ...................................................... 4 -17

OS6250-RM-19-L - Mounting Instructions ....................................................4-18

OS6250-REAR-MNT - Mounting Instructions ...............................................4-19

Steps ......................................................................................................................4-19

Completed Assembly .............................................................................................4-20

Table-Mounting OS6250 Switches ........................................................................4-21

General Table-Mounting Guidelines ............................................................... 4-21

Table-Mounting Installation ............................................................................4-21

Wall-Mounting the OS6250-8M ............................................................................4-23

General Wall-Mounting Guidelines ................................................................4-23

OS6250-WALL-MNT - Wall-Mounting Installation ......................................4-24

OmniSwitch 6250 Hardware Users Guide September 2015 v

Contents

Connecting Chassis to Power Source ............................................................................4-26

AC Power Supply Connections ..............................................................................4-26

Powering On a Chassis .................................... .... ............................................4-26

OS6250-24MD Internal DC Power Supply Connections ................................4-27

Backup DC Power Brick Connections ............................................................4-27

Securing the Redundant DC Power Supply Connector ...................................4-28

Installing DC Power Source Wire Leads .........................................................4-29

Hot-Swapping Power Supplies ...................................................................... .........4-31

Chapter 5 Booting 6250 Switches ....................................................................................................5-1

Booting an OmniSwitch 6250 ..................................................................................5-1

Console Port ....................................................................................................................5-2

Serial Connection Default Settings ..........................................................................5-2

Modifying the Serial Connection Settings ...............................................................5-2

Viewing the Power Supply Status ..................................................................... 5-4

Monitoring the Chassis ...................................................................................................5-5

Checking the Overall Chassis Status ........................................................................5-5

Checking the Temperature Status ............................................................................5-5

Checking the Fan Status ...........................................................................................5-6

Checking the Power Supply Status ..........................................................................5-6

Additional Monitoring Commands ..........................................................................5-6

Using LEDs to Visually Monitor the Chassis ..........................................................5-7

Installing SFP and XFP Transceivers .......................................................................5-7

Chapter 6 Managing Power over Ethernet (PoE) ...........................................................................6-1

In This Chapter ................................................................................. .... .... .... ...................6-2

Power over Ethernet Specifications ................................................................................6-3

Viewing PoE Power Supply Status .................................................................................6-4

Configuring Power over Ethernet Parameters .................................................................6-5

Power over Ethernet Defaults ..................................................................................6-5

Understanding and Modifying the Default Settings .................................................6-5

Setting the PoE Operational Status ....................................................................6-5

Configuring the Total Power Available to a Port ............................... ...............6-6

Configuring the Total Power Available to a Switch .........................................6-6

Setting Port Priority Levels ...............................................................................6-7

Understanding Priority Disconnect .................................................................................6-8

Setting Priority Disconnect Status ............................................................................6-8

Disabling Priority Disconnect ...........................................................................6-8

Enabling Priority Disconnect ............................................................................6-8

Monitoring Power over Ethernet via CLI .....................................................................6-11

vi OmniSwitch 6250 Hardware Users Guide September 2015

Contents

Chapter 7 Managing OmniSwitch 6250 Stacks ............................................................................... 7-1

In This Chapter ................................................................................. .... .... .... ...................7-2

OmniSwitch 6250 Stacking Specifications .....................................................................7-3

Changing Stacking Mode on Metro Models ............................................................7-3

OmniSwitch 6250 Stack Overview .................................................................................7-4

Roles Within the Stack ....................................................................................................7-4

Primary and Secondary Management Modules .......................................................7-4

Primary Management Module Selection ...........................................................7-7

Secondary Management Module Selection ..................................................... 7-10

Idle Module Role ....................................................................................................7-12

Pass-Through Mode ...............................................................................................7-13

Recovering from Pass-Through Mode (Duplicate Slot Numbers) ..................7-14

Stack Cabling ............................. ... .... .... ................................................... .... .... .............7-17

Redundant Stacking Cable Connection ..................................................................7-18

Checking Redundant Stacking Cable Status ..........................................................7-19

Slot Numbering .............................................................................................................7-20

Dynamic Slot Number Assignment ........................................................................7-21

Manual Slot Number Assignment ..........................................................................7-23

Reverting to the Dynamic Slot Numbering Model ..........................................7-24

Hot-Swapping Modules In a Stack ...............................................................................7-25

Removing Switches from an Existing Stack ..........................................................7-25

Inserting Switches Into an Existing Stack ..............................................................7-25

Merging Stacks .......................................................................................................7-26

Reloading Switches .......................................................................................................7-27

Reloading the Primary Management Module ........................................................7-27

Reloading the Secondary Management Module ....................................................7-29

Reloading Switches with Idle Roles .......................................................................7-31

Reloading Switches in Pass-Through Mode ..........................................................7-31

Reloading All Switches in a Stack .........................................................................7-32

Software Synchronization During a Full Reload .............................................7-32

Effects of Saved Slot Number Information on the Reload Process .................7-32

Avoiding Split Stacks .............................................................................................7-34

Changing the Secondary Module to Primary ................................................................7-35

Synchronizing Switches in a Stack ...............................................................................7-37

Automatic Synchronization During a Full Reload .................................................7-37

Stack Split Detection (SSP) ..........................................................................................7-38

Stack Split Key Components and Terms ................................................................7-38

Basic Operation .............................................................. ... .... .................................7-39

Protection States .....................................................................................................7-39

Stack Split Recovery .......................................................................................7-39

Monitoring the Stack .....................................................................................................7-41

Visually Monitoring the Stack ...............................................................................7-42

OmniSwitch 6250 Hardware Users Guide September 2015 vii

Contents

Appendix A Regulatory Compliance and Safety Information ................................................... .........A-1

Declaration of Conformity: CE Mark .............................................. .... .... ......................A-1

China RoHS: Hazardous Substance Table .....................................................................A-2

California Proposition 65 Warning ................................................................................A-3

Waste Electrical and Electronic Equipment (WEEE) Statement ...................................A-4

Standards Compliance ....................................................................................................A-5

Safety Agency Certifications ..................................................................................A-5

EMI/EMC Standards ...............................................................................................A-5

FCC Class A, Part 15 ..............................................................................................A-6

Canada Class A Statement ............................................. ... ......................................A-6

JATE ........................................................................................................................A-6

CISPR22 Class A warning ......................................................................................A-6

Korean Emission Statement .................................................................................... A-7

VCCI .......................................................................................................................A-7

Class A Warning for Taiwan and Other Chinese Markets ......................................A-7

Network Cable Installation Warning .............................................................................A-8

Translated Safety Warnings ...........................................................................................A-8

Chassis Lifting Warning .................. .................................................................A-8

Electrical Storm Warning ................................................................................. A-8

Installation Warning .........................................................................................A-9

Invisible Laser Radiation Warning ...................................................................A-9

Power Disconnection Warning .........................................................................A-9

Proper Earthing Requirement Warning ..........................................................A-10

Read Important Safety Information Warning ................................................. A-11

Restricted Access Location Warning .............................................................A-11

Wrist Strap Warning .......................................................................................A-12

Instrucciones de seguridad en español .........................................................................A-13

Advertencia sobre el levantamiento del chasis ...............................................A-13

Advertencia de las tapaderas en blanco ..........................................................A-13

Advertencia en caso de tormenta eléctrica ..................................................... A-13

Advertencia de instalación .............................................................................A-13

Advertencia de radiación láser invisible .........................................................A-13

Advertencia de la batería de litio ....................................................................A-13

Advertencia sobre la tensión de operación .....................................................A-13

Advertencia sobre la desconexión de la fuente ..............................................A-13

Advertencia sobre una apropiada conexión a tierra .......................................A-14

Leer “información importante de seguridad” ................................................. A-14

Advertencia de acceso restringido ..................................................................A-14

Advertencia de pulsera antiestática ................................................................A-14

Clase de seguridad ............................... ....................................................... ....A-14

viii OmniSwitch 6250 Hardware Users Guide September 2015

About This Guide

This OmniSwitch 6250 Hardware Users Guide describes your switch hardware components and basic

switch hardware procedures.

Supported Platforms

The information in this guide applies to the following products:

• OmniSwitch 6250-8M

• OmniSwitch 6250-24M

• OmniSwitch 6250-24MD

• OmniSwitch 6250-24

• OmniSwitch 6250-P24

OmniSwitch 6250 Hardware Users Guide September 2015 page ix

Supported Platforms About This Guide

Unsupported Platforms

The information in this guide does not apply to the following products:

• OmniSwitch (original version with no numeric model name)

• OmniSwitch 6400 Series

• OmniSwitch 6600 Series

• OmniSwitch 6800 Series

• OmniSwitch 6850 Series

• OmniSwitch 6855 Series

• OmniSwitch 7700

• OmniSwitch 7800

• OmniSwitch 8800

• OmniSwitch 9000 Series

• OmniStack

• OmniAccess

page x OmniSwitch 6250 Hardware Users Guide September 2015

About This Guide Who Should Read this Manual?

Who Should Read this Manual?

The audience for this users guide is network administrators and IT support personne l who need to configure, maintain, and monitor switches and routers in a live network. However, anyone wishing to gain

knowledge on the OmniSwitch 6250 hardware will benefit from the material in this guide.

When Should I Read this Manual?

Read this guide as soon as you are ready to familiarize yourself with your switch hardware components.

You should have already stepped through the first login procedures and read the brief hardware overviews

in the OmniSwitch 6250 Getting Started Guide.

You should already be familiar with the very basics of the switch hardware, such as module LEDs and

module installation procedures. This manual will help you understand your switch hardware components

(e.g., chassis, stacking and cables, backup power supplies, etc.) in greater depth.

What is in this Manual?

This users guide includes the following hardware-related information:

• Descriptions of switch configurations.

• Descriptions of “availability” features.

• Descriptions of chassis types (e.g., the OS6250-24).

• Instructions for mounting the chassis.

• Descriptions of hardware components (status LEDs, chassis, cables, backup power supplies, etc.).

• Managing a chassis.

• Hardware-related Command Line Interface (CLI) commands

What is Not in this Manual?

The descriptive and procedural information in this manual focuses on switch hardware. It includes information on some CLI commands that pertain directly to hardware configuration, bu t it is not intended as a

software users guide. There are several OmniSwitch 6250 users guides that focus on switch software

configuration. Consult those guides for detailed information and examples for configuring your switch

software to operate in a live network environment. See “Documentation Roadmap” on page -xii and

“Related Documentation” on page -xiv for further information on software configuration guides available

for your switch.

OmniSwitch 6250 Hardware Users Guide September 2015 page xi

How is the Information Organized? About This Guide

How is the Information Organized?

This users guide provides an overview of OmniSwitch 6250 switches, specificat ions of the hardware

components, steps for setting up and managing OmniSwitch 6250 switches, and an overview and procedures for managing Power over Ethernet (PoE).

Documentation Roadmap

The OmniSwitch user documentation suite wa s design ed to supply you with information at several critical

junctures of the configuration process.The following section outlines a roadmap of the manuals that will

help you at each stage of the configuration process. Under each stage, we point you to the manual or

manuals that will be most helpful to you.

Stage 1: Using the Switch for the First Time

Pertinent Documentation: Getting Started Guide

Release Notes

The Getting Started Guide provides all the information you need to get your switch up and running the

first time. This guide provides information on unpacking the switch, installing power supplies, unlocking

access control, setting the switch’s IP address, and setting up a password. It also includes succinct overview information on fundamental aspects of the switch, such as hardware LEDs, the software directory

structure, stacking, CLI conventions, and web-based management.

At this time you should also familiarize yourself with the Release Notes that accompanied your switch.

This document includes important information on feature limitations that are not included in other user

guides.

Stage 2: Gaining Familiarity with Basic Switch Functions

Pertinent Documentation: Hardware Users Guide

Switch Management Guide

Once you have your switch up and running, you will want to begin investigating basic aspects of its hard

ware and software. Information about switch hardware is provided in the Hardware Users Guide. This

guide provide specifications, illustrations, and descriptions of all hardware components—e.g., chassis,

backup power supplies, etc.

The Switch Management Guide is the primary user guide for the basic software features on a switch. This

guide contains information on the switch directory structure, basi c fi le and directory utilities, switc h access

security, SNMP, and web-based management. It is recommended that you read this guide before connecting your switch to the network.

page xii OmniSwitch 6250 Hardware Users Guide September 2015

About This Guide Documentation Roadmap

Stage 3: Integrating the Switch Into a Network

Pertinent Documentation: Network Configuration Guide

When you are ready to connect your switch to the network, you will need to learn how the OmniSwitch

implements fundamental softwa re features, such as 802.1Q, VLANs, and Spanning Tree. The Network

Configuration Guide contains overview information, procedures and examples on how standard networking technologies are configured in the OmniSwitch 6250.

Anytime

The OmniSwitch CLI Reference Guide contains comprehensive information on all CLI commands

supported by the switch. This guide includes syntax, default, usage, example, related CLI command, and

CLI-to-MIB variable mapping information for all CLI commands supported by the switch. This guide can

be consulted anytime during the configuration process to find detailed and specific information on each

CLI command.

OmniSwitch 6250 Hardware Users Guide September 2015 page xiii

Related Documentation About This Guide

Related Documentation

The following are the titles and descriptions of all the OmniSwitch 6250 user manuals:

• OmniSwitch 6250 Getting Started Guide

Describes the hardware and software procedures for getting an OmniSwitch 6250 switch up and

running. Also provides information on fundamental aspects of OmniSwitch software.

• OmniSwitch 6250 Hardware Users Guide

Detailed technical specifications and procedures for the OmniSwitch 6250 chassis and components.

This manual also includes comprehensive information on assembling and managing stacked configurations.

• OmniSwitch 6250/6450 CLI Reference Guide

Complete reference to all CLI commands supported on the OmniSwitch Series of products. Includes

syntax definitions, default values, examples, usage guidelines and CLI-to-MIB variable mappings.

• OmniSwitch 6250/6450 Switch Management Guide

Includes procedures for readying an individual switc h for integ ration into a ne twork. To pics in clud e the

software directory architecture, image rollback protections, authenticated switch access, managing

switch files, system configuration, using SNMP, and using web management software (WebView).

• OmniSwitch 6250/6450 Network Configurat ion Guide

Includes network configuration procedures and descriptive information on all the major software

features and protocols included in the base software package. Chapters cover Layer 2 information

(Ethernet and VLAN configuration), Layer 3 information (routing protocols, such as RIP), security

options (authenticated VLANs), Quality of Service (QoS), and link aggregation.

• OmniSwitch 6250/6450 Transceivers Guide

Includes SFP and XFP transceiver specifications and product compatibility information.

• Technical Tips, Field Notices

Includes information published by Alcatel-Lucent’s Customer Support group.

• Release Notes and Upgrade Instructions

Includes open problem reports, feature exceptions, and other important information on the features

supported in the current release and any limitations to their support.

page xiv OmniSwitch 6250 Hardware Users Guide September 2015

About This Guide Product Documentation

Product Documentation

All products are shipped with a Product Documentation Card that prov ides details for downloading documentation for all OmniSwitch and other Alcatel-Lucent data enterprise products. All user guides for the

OmniSwitch Series are included on the Alcatel-Lucent public website. This website also includes user

guides for other Alcatel-Lucent Enterprise products. The latest user guides can be found on our website at:

http://enterprise.alcatel-lucent.com/UserGuides

Technical Support

An Alcatel-Lucent service agreement brings your company the assurance of 7x24 no-excuses technical

support. You’ll also receive regular software updates to maintain and maximize your Alcatel-Lucent product’s features and functionality and on-site hardware replacement through our global network of highly

qualified service delivery partners. Additionally, with 24-hour-a-day access to Alcatel-Lucent’s Service

and Support web page, you’ll be able to view and update any case (open or closed) that you have reported

to Alcatel-Lucent’s technical support, open a new case or access helpful release notes, technical bulletins,

and manuals. For more information on Alcatel-Lucent’s Service Programs, see our web page at

service.esd.alcatel-lucent.com, call us at 1-800-995-2696, or email us at esd.support@alcatel-lucent.com.

Documentation Feedback

Alcatel-Lucent values comments on the quality and usefulness of the documentation. To send comments

on the OmniSwitch documentation use the following email address: feedback.osdocs@alcatel-lucent.com.

For document identification it's helpful to include the Document Title, Part Number and Revision (which

can be found on the title page) with any comments.

OmniSwitch 6250 Hardware Users Guide September 2015 page xv

Documentation Feedback About This Guide

page xvi OmniSwitch 6250 Hardware Users Guide September 2015

1 OmniSwitch 6250

OS6250-24

OS6250-8M

OS6250-P24

OS6250-24M

OS6250-24MD

The Alcatel-Lucent OmniSwitch 6250 is a set of stackable switches designed for Enterprise and Metro

applications providing Fast Ethernet connectivity with Advanced Layer 2 software and basic routing.

OS6250 Switches

OmniSwitch 6250 Hardware Users Guide September 2015 page 1-1

Chassis Configurations OmniSwitch 6250

Chassis Configurations

OmniSwitch 6250 (OS6250) switches offer port densities of up to 24 Fast Ethernet ports. The following

OS6250 chassis configurations are available:

Metro Models

• OS6250-8M: Provides eight (8) Fast Ethernet ports, two (2) combo ports, two (2) non-combo fiber

ports, and an internal AC power supply.

• OS6250-24M: Provides twenty-four (24) Fast Ethernet ports, two (2) combo ports, two (2) non-combo

fiber ports, an internal AC power supply, and optional redundant external power supply.

• OS6250-24MD: Provides twenty-four (24) Fast Ethernet ports, two (2) combo ports, two (2) non-

combo fiber ports, an internal DC power supply, and optional redundant external power supply.

Enterprise Models

• OS6250-24: Provides twenty-four (24) Fast Ethernet ports, two (2) combo ports, two HDMI stacking

ports, an internal AC power supply, and optional external redundant power supply.

• OS6250-P24: Provides twenty-four (24) PoE Fast Ethernet ports, two (2) combo ports, two (2) HDMI

stacking ports, and external primary and redundant power supplies.

Combo Ports

Combo ports are individually configurable to be 10/100/1000BaseT or 100/1000X that can support SFP

transceivers for short, long and very long distances.

Non-combo Fiber Ports

The non-combo fiber ports provide uplink or stacking capability through the use of the SFP+ ports.

HDMI Ports

The HDMI ports provide stacking capability through the use of Alcatel-Lucent proprietary stacking cables.

page 1-2 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 OmniSwitch 6250 Feature Overview

OmniSwitch 6250 Feature Overview

Security Features

OmniSwitch 6250 switches offer extensive security features for network access control, policy enforcement and attack containment, enabling fully secure networks and OmniVista Network Management

System (NMS) support.

Applications

Well-suited for traditional enterprise network applications as well as Metro deployments.

• Small and Medium sized Enterprise (SME)

• Metro Ethernet Access

• Residence and business deployments

• Carrier Ethernet (e.g., Telco, CityNets, Metro access)

OmniSwitch 6250 Hardware Users Guide September 2015 page 1-3

Availability Features OmniSwitch 6250

Availability Features

OmniSwitch 6250 switches incorporate advanced Alcatel-Lucent Operating System (AOS) protocol s to

ensure high availability for mission critical applications. Availability features are hardware- and softwarebased safeguards that help to prevent the loss of data flow in the unlikely event of a subsystem failure.

In addition, some availability features allow users to maintain or replace hardware components without

powering off the switch or interrupting switch operations. Combined, these features provide added

resiliency and help to ensure that the switch or virtual chassis is consistently available for high-impact

network operations.

Hardware-related availability features include:

• Software Rollback

• Hot Swapping

• Hardware Monitoring

• Backup Power Supplies

Software Rollback

Software rollback (also referred to as image rollback) essentially allows the switch to return to a prior “la st

known good” version of software in the event of a system software problem. The switch controls software

rollback through its resilient directory structure design

(i.e., /flash/working and /flash/certified).

For detailed information on the software rollback feature, as well as the switch’s /flash/working and

/flash/certified directories, refer to the “Managing CMM Directory Content” chapter in the Switch

Management Guide.

Hot Swapping

Hot swapping refers to the action of adding, removing, or replacing components without powering off

switches or disrupting other components.This feature facilitates hardware upgrades and maintenance and

allows users to easily replace components in the unlikely event of hardware failure.

The following components can be hot swapped:

• Backup power supplies

• Power supply connector cables

• SFPs

Note. For instructions on hot swapping backup power supplies, refer to Chapter 4, “Mounting OS6250

Switches” For instructions on hot swapping combo connector SFPs, refer to the instruction card provided

with the SFP.

page 1-4 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Availability Features

Hardware Monitoring

Automatic Monitoring

Automatic monitoring refers to the switch’s built-in sensors that automatically monitor operations. If an

error is detected (e.g., over-threshold temperature), the switch immediately sends a trap to the user. The

trap is displayed on the console in the form of a text error message.

LEDs

LEDs, which provide visual status information, are provided on the chassis front panel. LEDs are used to

indicate conditions such as hardware and software status, temperature errors, link integrity, data flow, etc.

For detailed LED descriptions, refer to Chapter 3, “OmniSwitch 6250 Chassis and Hardware Compo-

nents.”

User-Driven Monitoring

User-driven hardware monitoring refers to CLI commands that are entered by the user in order to access

the current status of hardware components. The user enters “show” commands that output information to

the console. Monitoring information for chassis components, such as the optional back up power supply,

chassis temperature sensor, and chassis fans is provided in Chapter 3, “OmniSwitch 6250 Chassis and

Hardware Components.” The show commands for all the features are described in detail in the OmniS-

witch CLI Reference Guide.

Backup Power Supplies

Some OmniSwitch 6250 switches support an optional backup power supply. Backup power supplies operate in active standby mode. If the primary power supply fails unexpectedly, the backup power supply automatically takes up the full power load without disrupting the switch.

Note. For more information on power supplies, refer to Chapter 3, “OmniSwitch 6250 Chassis and Hard-

ware Components.”

OmniSwitch 6250 Hardware Users Guide September 2015 page 1-5

Availability Features OmniSwitch 6250

page 1-6 OmniSwitch 6250 Hardware Users Guide September 2015

2 Getting Started

Installing the Hardware

Items Required

• Grounding wrist strap

• Phillips screwdriver

• Flat-blade screwdriver

Site Preparation

Environmental Requirements

OmniSwitch 6250 switches have the following environmental and airflow requirements:

• The installation site must maintain a temperature between 0° and 45° Celsius (32° and 113° Fahrenhe it)

and not exceed 95 percent maximum humidity (non-condensing) at any time.

• Be sure to allow adequate room for proper air ventilation at the front, back, and sides of the switch.

Refer to “Airflow Considerations” on page 2-3 for minimum clearance requirements. No clearance is

necessary at the top or bottom of the chassis.

Electrical Requirements

Note. Alcatel-Lucent switches must be installed by a professional installer. It is the responsibility of the

installer to ensure that proper grounding is available and that the installation meets applicable local and

national electrical codes.

OmniSwitch 6250 switches have the following general electrical requirements:

• Each switch requires one grounded electrical outlet for the chassis power supply. OmniSwitch 6250

switches offer AC power supply support only. Refer to the following chapters for

more information.

• Each supplied AC power cord is 2 meters (approx. 6.5 feet). Do not use extension cords.

Redundant AC Power. It is recommended that each AC outlet resides on a separate circuit. With

redundant AC, if a single circuit fails, the switch’s remaining power supplies (on separate circuits)

can remain operational.

OmniSwitch 6250 Hardware Users Guide September 2015 page 2-1

Installing the Hardware Getting Started

Unpacking and Installing the Switch

To protect your switch components from damage, read all unpacking recommendation s and instructions

carefully before beginning.

Unpack your OmniSwitch 6250 chassis as close as possible to the location where it will be in stalled.

Items Included

Your OmniSwitch 6250 includes the following items:

• OmniSwitch chassis

• Transceivers, per order

• Rack mount brackets

• Country-specific power cord(s)

• Assorted instructional cards, anti-static bags and additional packaging

Weight Considerations

The OmniSwitch 6250 chassis weighs approximately 1.72 kg (3.80 lb).

page 2-2 OmniSwitch 6250 Hardware Users Guide September 2015

Getting Started Mounting the Switch

}

}

Rear. 6 inches minimum

at rear of chassis.

Front. 6 inches minimum

at front of chassis.

Sides. 2 inches minimum

at left and right sides.

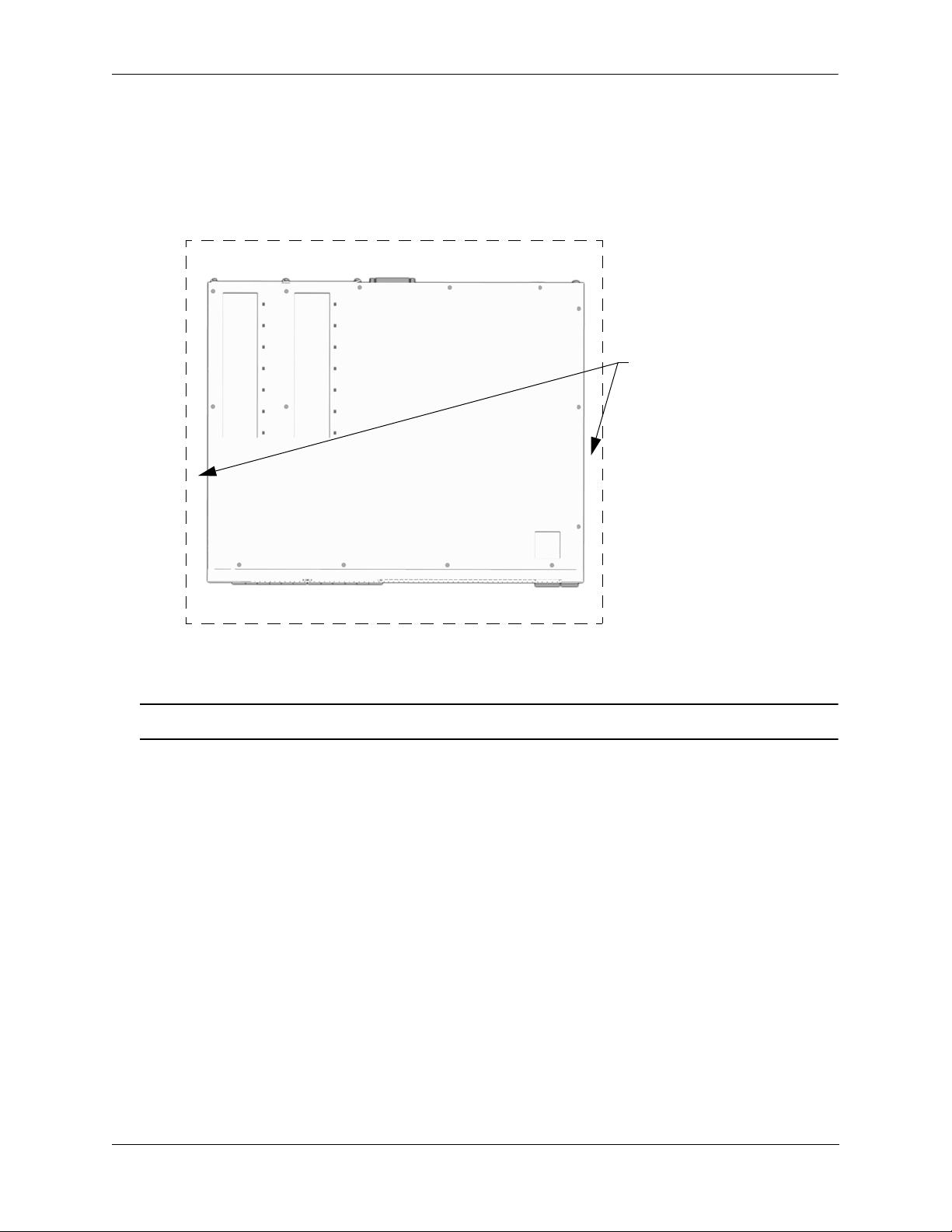

Airflow Considerations

To ensure proper airflow, be sure that your switch is placed in a well-ventilated area and provide minimum

recommended clearance at the front, back and sides of the switch.

Never obstruct chassis air vents.

Chassis Top View

Note. Clearance is not required at the top and bottom of the chassis.

Mounting the Switch

For information on mounting OmniSwitch 6250 switches, refer to Chapter 3, “OmniSwitch 6250 Chassis and

Hardware Components.”

OmniSwitch 6250 Hardware Users Guide September 2015 page 2-3

Connections and Cabling Getting Started

Connections and Cabling

Once your switch is properly installed, you should connect all network and management cables required for

your network applications. Connections may include:

• DB9-to-RJ-45 cable to the console connector

• Cables to 10/100/1000 Ethernet or SFP ports

Note. For additional information on cabling connections, refer to the OmniSwitch AOS Release 6 Switch

Management Guide.

Serial Connection to the Console Port

The console port provides a serial connection to the switch using a USB connector and is required when

logging into the switch for the first time. By default, this connector provides a DCE console connection.

Serial Connection Default Settings

baud rate 9600

parity none

data bits (word size) 8

stop bits 1

For information on modifying these settings, refer to the OmniSwitch AOS Release 6 Switch

Management Guide.

page 2-4 OmniSwitch 6250 Hardware Users Guide September 2015

Getting Started Booting the Switch

Booting the Switch

Now that you have installed the switch components and connected network and management cables, you can

boot the switch. To boot the switch, plug the po wer supply cord into an easily-accessible, properly grounded

power outlet. (Do not use extension cords.) The switch will power on and boot automatically.

Component LEDs

During the boot process, component LEDs will flash and change color, indi cating different stages of the boot.

Following a successful boot, chassis LEDs should display as follows:

OK1 Solid Green

PRI Solid Green

PWR Solid Green

Note. If the LEDs do not display as indicated, make sure the boot process is complet e. If t he LEDs do not

display as indicated following a complete boot sequence, contact Alcatel-Lucent Customer Support. For

information on LED states, refer to “Chassis Status LEDs” on page 3-19.

Once the switch has completely booted and you have accessed your computer’s terminal emulation software

via the console port, you are ready to lo g in to the switch’s Command Line Interface (CLI) and configure basic

information. Continue to “Your First Login Session” on page 2-6.

OmniSwitch 6250 Hardware Users Guide September 2015 page 2-5

Your First Login Session Getting Started

Your First Login Session

In order to complete the setup process for the switch, you must complete the following steps during your first

login session:

• Log in to the switch

• Unlock session types

• Change the login password

• Set the date and time

• Set optional system information

• Save your changes

Important. You must be connected to the switch via the console port before initiating your first

login session.

Logging In to the Switch

When you first log in to the switch, you will be prompted for a login name and password. Use the switch’s

default settings:

• Login: admin

• Password: switch

The default welcome banner, which includes informatio n such as the current software version and system date,

is displayed followed by the CLI command prompt:

Welcome to the Alcatel-Lucent OmniSwitch 6250

Software Version 6.7.1.80.R01 Development, July 08, 2015.

Copyright(c), ALE USA Inc., 2015. All Rights reserved.

OmniSwitch(TM) is a trademark of Alcatel-Lucent Enterprise registered

in the United States Patent and Trademark Office.

->

Note. A user account includes a login name, password, and user privileges. Privileges determine whether

the user has read or write access to the switch and which commands the user is authorized to execute. For

detailed information on setting up and modifying user accounts, refer to the OmniSwitch AOS Release 6

Switch Management Guide.

page 2-6 OmniSwitch 6250 Hardware Users Guide September 2015

Getting Started Your First Login Session

Unlocking Session Types

Security is a key feature on OmniSwitch 6250 switches. As described on page 2-6, when you access the switch

for the first time, you must use a direct console port connection. All other session types (Telnet, FTP,

WebView, and SNMP) are locked out until they are manually unlocked by the user.

The CLI command used to unlock session types is aaa authentication.

Note. When you unlock session types, you are granting switch access to non-local sessions (e.g., Telnet).

As a result, users who know the correct user login and password will have remote access to th e switc h. For

more information on switch security, refer to the OmniSwitch AOS Release 6 Switch Management Guide.

Unlocking All Session Types

To unlock all session types, enter the following command syntax at the CLI prompt:

-> aaa authentication default local

Unlocking Specified Session Types

You can also unlock session types on a one-by-one basis. For example, to unlock Telnet sessions only, enter

the following command:

-> aaa authentication telnet local

To unlock WebView (HTTP) sessions only, enter the following command:

-> aaa authentication http local

You cannot specify more than one session type in a single command line. However, you can still unlock

multiple session types by using the aaa authentication command in succession. For example:

-> aaa authentication http local

-> aaa authentication telnet local

-> aaa authentication ftp local

Refer to the OmniSwitch CLI Reference Guide for complete aaa authentication command syntax options.

OmniSwitch 6250 Hardware Users Guide September 2015 page 2-7

Your First Login Session Getting Started

Changing the Login Password

Change the login password for admin user sessions by following the steps below:

1 Be sure that you have logged into the switch as user type admin (see “Logging In to the Switch” on

page 2-6).

2 Enter the keyword password and press Enter.

3 Enter your new password at the prompt.

Note. Be sure to remember or securely record all new passwords; overriding configured passwords on an

OmniSwitch is restricted.

4 You will be prompted to re-enter the password. Enter the password a second time.

New password settings are automatically saved in real time to the local user database; the user is not required

to enter an additional command in order to save the password information. Also note that new password

information is retained following a reboot. All subsequent login sessions, including those through the console

port, will require the new password to access the switch.

For detailed information on managing login information, including user names and passwords, refer to the

OmniSwitch AOS Release 6 Switch Management Guide.

Setting the System Time Zone

The switch’s default time zone is UTC. If you require a time zone that is spe cifi c to y ou r region , or if you nee d

to enable Daylight Savings Time (DST) on the switch, you can configure these settings via the system

timezone and system daylight-savings-time commands.

For detailed information on configuring a time zone for the switch, refer to the OmniSwitch AOS Release 6

Switch Management Guide.

Setting the Date and Time

Set the current time for the switch by entering system time, followed by the current time in hh:mm:ss.

To set the current date for the switch, enter system date, followed by the current date in mm/dd/yyyy.

page 2-8 OmniSwitch 6250 Hardware Users Guide September 2015

Getting Started Your First Login Session

Setting Optional Parameters

Specifying an Administrative Contact

An administrative contact is the person or department in charge of the switch. If a contact is specified, users

can easily find the appropriate network administrator if they have questions or comments about the switch.

To specify an administrative contact, use the system contact command.

Specifying a System Name

The system name is a simple, user-defined text description for the switch.

To specify a system name, use the system name command.

Specifying the Switch’s Location

It is recommended that you use a physical labeling system for locating and identifying your switch(es).

Examples include placing a sticker or placard with a unique identifier (e.g., the switch’s default IP address) on

each chassis.

However, if no labeling system has been implemented or if you need to determine a switch’s location from a

remote site, entering a system location can be very useful.

To specify a system location, use the system location command.

Viewing Your Changes

To view your current changes, enter show system at the CLI prompt.

Saving Your Changes

Once you have configured this basic switch information, save your changes by entering write memory at the

CLI command prompt.

OmniSwitch 6250 Hardware Users Guide September 2015 page 2-9

Your First Login Session Getting Started

page 2-10 OmniSwitch 6250 Hardware Users Guide September 2015

3 OmniSwitch 6250

Chassis and Hardware

Components

OmniSwitch 6250 switches are available in the chassis configurations as shown in the table below:

• OmniSwitch 6250-8M

(OS6250-8M)

• OmniSwitch 6250-24M

(OS6250-24M)

• OmniSwitch 6250-24MD

(OS6250-24MD)

• OmniSwitch 6250-24

(OS6250-24)

• OmniSwitch 6250-P24

(OS6250-P24)

Eight port stackable Metro model.

Twenty-four port stackable Metro model.

Twenty-four port stackable Metro model with DC power.

Twenty-four port stackable Enterprise model.

Twenty-four port stackable Enterprise model with PoE.

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-1

OmniSwitch 6250 Chassis and Hardware Components

This chapter includes detailed information on these chassis types. Topics include:

• OmniSwitch 6250 chassis descriptions

• Technical specifications

• Power Supplies

• Stacking cables and power cords

• Console port and pinout specifications

page 3-2 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-8M

OmniSwitch 6250-8M

The OS6250-8M chassis contains the following major components:

• System status LEDs

• (8) Unshared 10/100Base-T ports

• (2) Non-combo 100/1000BaseX or SFP+ Stacking ports

• (2) Combo 10/100/1000Base-T or 100/1000BaseX ports

• Internal AC Power Supply

• Console port (RJ-45)

• USB port (USB 2.0)

Note. USB port is not supported in this release.

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-3

OmniSwitch 6250-8M OmniSwitch 6250 Chassis and Hardware Components

A

B

C

D

E

F

G

OmniSwitch 6250-8M Front Panel

OS6250-8M Front Panel

Item Description

A

System Status LEDs

Provides status on hardware, software, stacking and power.

B

Console Port

RS-232 console port with an RJ-45 connector. Provides access to th e CLI for

configuration and management.

C

10/100BaseT RJ-45 Ports

10/100BaseT non-combo ports. Odd-numbered ports are on top row, evennumbered ports are on bottom row.

D

10/100/1000BaseT or 100/1000BaseX SFP Combo Ports

Two 10/100/1000BaseT or SFP combo ports for various supported SFP

transceivers.

E

SFP Uplink or SFP+ Stacking Ports

Two SFP or SFP+ ports to be used for uplink or stacking.

F

USB Port

High speed USB 2.0 port.

G

Push Button

When pushed all LEDs will turn of f and the LED of the S tack ID wil l remain

lit.

Refer to “LED Status” on page 3-20 for LED status information.

page 3-4 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-8M

A

B

OmniSwitch 6250-8M Rear Panel

Note. The figure shows a pre-production version of the chassis without product, safety, and compliance

information labels. All production versions of the chassis have these labels.

OS620-8M Rear Panel

Item Description

A

Grounding Block

Type LCD8-10A-L grounding lug

B

Power Supply Connector

Internal AC power supply.

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-5

OmniSwitch 6250-8M OmniSwitch 6250 Chassis and Hardware Components

OS6250-8M Specifications

Total unshared 10/100BaseT

8 (1-8)

ports per switch

Total combo ports per switch 2 (9-10)

Total non-combo SFP ports per

2 (11-12 in Uplink mode), (STK A, STK B Stacking mode)

switch

Total 802.3af PoE ports per

N/A

switch

Flash memory size 128 MB

RAM memory size 256 MB SDRAM

Chassis Width 8.5 inches (21.5 cm)

Chassis Height 1.73 inches (4.4 cm)

Chassis Height (rack units) 1 RU

Chassis Depth 11.5 inches (29.21 cm)

Weight 3.80 lbs (1.72kg)

Operating Humidity 5% to 95% non-condensing

Storage Humidity 10% to 95% non-condensing

Operating Temperature 0C to +45C

Storage Temperature -40C to +70C

Data rate (RJ-45) 10 or 100 Mbps (full or half duplex)

1 Gigabit per second (full duplex)

Upper Threshold Temperature 85C

Danger Threshold Temperature 90C

Data rate (SFP) 100/1000 Mbps (full duplex)

Maximum frame size 9216 bytes

Cable supported

(RJ-45)

10BaseT: unshielded twisted-pair (UTP)

100BaseTX: unshielded twisted-pair (UTP), Category 5, EIA/TIA 568

or shielded twisted-pair (STP), Category 5, 100 ohm

1000BaseT: unshielded twisted-pair (UTP), Category 5e

Maximum cable distance

100 meters

(RJ-45)

page 3-6 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-24M/24MD

OmniSwitch 6250-24M/24MD

The OS6250-24M chassis contains the following major components:

• System status LEDs

• (24) Unshared 10/100Base-T ports

• (2) Non-combo 100/1000BaseX or SFP+ Stacking Ports

• (2) Combo 10/100/1000Base-T or 100/1000BaseX

• Internal AC Power Supply (24M)

• Internal DC Power Supply (24MD)

• External BPS

• Console port (RJ-45)

• USB port (USB 2.0)

Note. USB port is not supported in this release.

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-7

OmniSwitch 6250-24M/24MD OmniSwitch 6250 Chassis and Hardware Components

A

B

C

OmniSwitch 6250-24M/24-MD Front Panel

OS6250-24M/24-MD Front Panel

Item Description

A

System Status LEDs

Provides status on hardware, software, primary and redundant power.

B

10/100/1000BaseT or 100/1000BaseX SFP Combo Ports

Two 10/100/1000BaseT or SFP combo ports for various supported SFP

transceivers.

C

10/100BaseT RJ-45 Ports

10/100BaseT non-combo ports. Odd-numbered ports are on top row, evennumbered ports are on bottom row.

Refer to “LED Status” on page 3-20 for LED status information.

page 3-8 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-24M/24MD

A

B

C

E FD

G

H

OmniSwitch 6250-24M/24-MD Rear Panel

Note. The figure shows a pre-production version of the chassis without product, safety, and compliance

information labels. All production versions of the chassis have these labels.

OS6250-24M Rear Panel

OS6250-24MD Rear Panel

Item Description

A

Push Button

When pushed all LEDs will turn off and the LED of the Stack ID

will remain lit.

B

Console Port

RS-232 console port with an RJ-45 connector. Provides access to

the CLI for configuration and management.

C

Grounding Block

Type LCD8-10A-L grounding lug

D

USB Port

High speed USB 2.0 port.

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-9

OmniSwitch 6250-24M/24MD OmniSwitch 6250 Chassis and Hardware Components

Item Description

E

SFP Uplink or SFP+ Stacking Ports

Two SFP or SFP+ ports to be used for uplink or stacking .

F

G

BPS Connector

Power Supply Connector

Internal AC power supply.

H

DC Power Supply Connector

Refer to “LED Status” on page 3-20 for LED status information.

page 3-10 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-24M/24MD

OS6250-24M/24-MD Specifications

Total unshared 10/100BaseT

24 (1-24)

ports per switch

Total combo ports per switch 2 (25-26)

Total non-combo SFP ports per

2 (27-28 in Uplink mode), (STK A, STK B Stacking mode)

switch

Total 802.3af PoE ports per

N/A

switch

Flash memory size 128 MB

RAM memory size 256 MB SDRAM

Chassis Width 8.5 inches (21.5 cm)

Chassis Height 1.73 inches (4.4 cm)

Chassis Height (rack units) 1 RU

Chassis Depth 11.5 inches (29.21 cm)

Weight 3.80 lbs (1.72 kg)

Operating Humidity 5% to 95% non-condensing

Storage Humidity 10% to 95% non-condensing

Operating Temperature 0C to +45C

Storage Temperature -40C to +70C

Upper Threshold Temperature 99C

Danger Threshold Temperature 105C

Data rate (RJ-45) 10 or 100 Mbps (full or half duplex)

1 Gigabit per second (full duplex)

Data rate (SFP) 100/1000 Mbps (full duplex)

Maximum frame size 9216 bytes

Cable supported

(RJ-45)

10BaseT: unshielded twisted-pair (UTP)

100BaseTX: unshielded twisted-pair (UTP), Category 5, EIA/TIA 568

or shielded twisted-pair (STP), Category 5, 100 ohm

1000BaseT: unshielded twisted-pair (UTP), Category 5e

Maximum cable distance

100 meters

(RJ-45)

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-11

OmniSwitch 6250-24 OmniSwitch 6250 Chassis and Hardware Components

OmniSwitch 6250-24

The front panel of the OS6250-24 chassis contains the following major components:

• System status LEDs

• (24) Unshared 10/100Base-T ports

• (2) Combo 10/100/1000Base-T or 100/1000BaseX

• (2) HDMI Stacking Ports

• Internal AC Power Supply

• External BPS

• Console port (RJ-45)

• USB port (USB 2.0)

Note. USB port is not supported in this release.

page 3-12 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-24

A

B

C

OmniSwitch 6250-24 Front Panel.

OS6250-24 Front Panel

Item Description

A

System Status LEDs

Provides status on hardware, software, primary and redundant power.

B

10/100/1000BaseT or 100/1000BaseX SFP Combo Ports

Two 10/100/1000BaseT or SFP combo ports for various supported SFP

transceivers.

C

10/100BaseT RJ-45 Ports

10/100BaseT non-combo ports. Odd-numbered ports are on top row, evennumbered ports are on bottom row.

Refer to “LED Status” on page 3-20 for LED status information.

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-13

OmniSwitch 6250-24 OmniSwitch 6250 Chassis and Hardware Components

A

B

C

E FD G

OmniSwitch 6250-24 Rear Panel

Note. The figure shows a pre-production version of the chassis without produ ct, safety, and compliance

information labels. All production versions of the chassis have these labels.

OS6250-24 Rear Panel

Item Description

A

Push Button

When pushed all LEDs will turn off and the LED of the Stack ID

will remain lit.

B

Console Port

RS-232 console port with an RJ-45 connector. Provides access to

the CLI for configuration and management.

C

Grounding Block

Type LCD8-10A-L grounding lug

D

USB Port

High speed USB 2.0 port.

E

HDMI Stacking Connectors

Connectors for use in stacking switches into a virtual chassis or as

an uplink port.

F

BPS Connector

G

Power Supply Connector

Internal AC power supply.

Refer to “LED Status” on page 3-20 for LED status information.

page 3-14 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-24

OS6250-24 Specifications

Total unshared 10/100BaseT

24 (1-24)

ports per switch

Total combo ports per switch 2 (25-26)

Total HDMI ports per switch 2 (Stack A, Stack B)

Total 802.3af PoE ports per

N/A

switch

Flash memory size 128 MB

RAM memory size 256 MB SDRAM

Chassis Width 8.5 inches (21.5 cm)

Chassis Height 1.73 inches (4.4 cm)

Chassis Height (rack units) 1 RU

Chassis Depth 11.5 inches (29.21 cm)

Weight 3.80 lbs (1.72 kg)

Operating Humidity 5% to 95% non-condensing

Storage Humidity 10% to 95% non-condensing

Operating Temperature 0C to +45C

Storage Temperature -40C to +70C

Upper Threshold Temperature 98C

Danger Threshold Temperature 105C

Data rate (RJ-45) 10 or 100 Mbps (full or half duplex)

1 Gigabit per second (full duplex)

Data rate (SFP) 100/1000 Mbps (full duplex)

Maximum frame size 9216 bytes

Cable supported

(RJ-45)

10BaseT: unshielded twisted-pair (UTP)

100BaseTX: unshielded twisted-pair (UTP), Category 5, EIA/TIA 568

or shielded twisted-pair (STP), Category 5, 100 ohm

1000BaseT: unshielded twisted-pair (UTP), Category 5e

Maximum cable distance

100 meters

(RJ-45)

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-15

OmniSwitch 6250-P24 OmniSwitch 6250 Chassis and Hardware Components

OmniSwitch 6250-P24

The front panel of the OS6250-P24 chassis contains the following major components:

• System status LEDs

• (24) Unshared 10/100Base-T PoE (802.3at first 6 ports and combo, 802.3af remaining ports) ports

• (2) Combo 10/100/1000Base-T or 100/1000BaseX

• (2) HDMI Stacking Ports

• External Power Supply

• External BPS

• Internal Fan

• Console port (RJ-45)

• USB port (USB 2.0)

Note. USB port is not supported in this release.

page 3-16 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-P24

A

B

C

OmniSwitch 6250-P24 Front Panel

OS6250-P24 Front Panel - Update

Item Description

A

System Status LEDs

Provides status on hardware, software, primary and redundant power.

B

10/100/1000BaseT or 100/1000BaseX SFP Combo Ports

Two 10/100/1000BaseT or SFP combo ports for various supported SFP

transceivers.

C

10/100BaseT RJ-45 Ports

10/100BaseT non-combo ports. Odd-numbered ports are on top row, evennumbered ports are on bottom row.

Refer to “LED Status” on page 3-20 for LED status information.

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-17

OmniSwitch 6250-P24 OmniSwitch 6250 Chassis and Hardware Components

A

B

C

E

F

D

G

OmniSwitch 6250-P24 Rear Panel

Note. The figure shows a pre-production version of the chassis without produ ct, safety, and compliance

information labels. All production versions of the chassis have these labels.

OS6250-P24 Rear Panel

Item Description

A

Push Button

When pushed all LEDs will turn off and the LED of the Stack ID

will remain lit.

B

Console Port

RS-232 console port with an RJ-45 connector. Provides access to

the CLI for configuration and management.

C

Grounding Block

Type LCD8-10A-L grounding lug

D

USB Port

High speed USB 2.0 port.

E

HDMI Stacking Connectors

Connectors for use in stacking switches into a virtual chassis or as

an uplink port.

F

G

Backup Power Supply Connector

Main Power Supply Connector

Refer to “LED Status” on page 3-20 for LED status information.

page 3-18 OmniSwitch 6250 Hardware Users Guide September 2015

OmniSwitch 6250 Chassis and Hardware Components OmniSwitch 6250-P24

OS6250-P24 Specifications

Total unshared 10/100BaseT

24 (1-24)

ports per switch

Total combo ports per switch 2 (25-26)

Total HDMI ports per switch 2 (StackA, StackB)

Total 802.3at PoE ports per

switch

Total 802.3af PoE ports per

switch

8 (1-6, 25-26) Ports 25 and 26 share PoE with 23 and 24. Only one set

of ports can have PoE operational at a time.

18 (7-24) Ports 23 and 24 share PoE with 25 and 26. Only one set of

ports can have PoE operational at a time.

Flash memory size 128 MB

RAM memory size 256 MB SDRAM

Chassis Width 8.5 inches (21.5 cm)

Chassis Height 1.73 inches (4.4 cm)

Chassis Height (rack units) 1 RU

Chassis Depth 11.5 inches (29.21 cm)

Weight 4.20 lbs (1.91kg)

Operating Humidity 5% to 95% non-condensing

Storage Humidity 10% to 95% non-condensing

Operating Temperature 0C to +45C

Storage Temperature -40C to +70C

Upper Threshold Temperature 86C

Danger Threshold Temperature 91C

Data rate (RJ-45) 10 or 100 Mbps (full or half duplex)

1 Gigabit per second (full duplex)

Data rate (SFP) 100/1000 Mbps (full duplex)

Maximum frame size 9216 bytes

Cable supported

(RJ-45)

10BaseT: unshielded twisted-pair (UTP)

100BaseTX: unshielded twisted-pair (UTP), Category 5, EIA/TIA 568

or shielded twisted-pair (STP), Category 5, 100 ohm

1000BaseT: unshielded twisted-pair (UTP), Category 5e

Maximum cable distance

100 meters

(RJ-45)

OmniSwitch 6250 Hardware Users Guide September 2015 page 3-19

OmniSwitch 6250-P24 OmniSwitch 6250 Chassis and Hardware Components

LED Status

LED State Description

OK Solid Green

Blinking Green

Solid Amber

PRI Solid Green

Solid Amber

Off

PWR Solid Green

Amber

Off

BPS Solid Green

Amber

Off

STK Green

Normal Operation.

Boot up/Remote Config Load in

Progress

Operating Temperature Exceeded.

Primary unit in a stack or standalone

switch.

Secondary unit in a stack.

Switch is idle. (not primary or

secondary)

P/S Normal Operation.

P/S Present and Bad (24-port models

only)

P/S Not Present or Bad.

P/S Normal Operation.

P/S Present and Bad (24-port models

only)

P/S Not Present or Bad.

Unit in Stacking Mode

Amber

Stack A/ Stack B Green

Amber

Off