Page 1

Alcatel-Lucent

VPN Firewall Brick

®

Model 1200 Security Appliance

User’sGuide

032360-00 REV A

Issue1

June2008

Alcatel-Lucent - Proprietary

This document contains proprietary information of Alcatel-Lucent and

is not to be disclosed or used except in accordance with applicable agreements.

Copyright © 2008 Alcatel-Lucent

Unpublished and Not for Publication

All Rights Reserved

See notice on first age

Page 2

Alcatel, Lucent, Alcatel-Lucent and the Alcatel-Lucent logo are trademarks of Alcatel-Lucent. All other trademarks

are the property of their respective owners.

The information presented is subject to change without notice. Alcatel-Lucent assumes no responsibility for

inaccuracies contained herein.

Copyright © 2008 Alcatel-Lucent. All Rights Reserved.

Notice

Every effort was made to ensure that this information product was complete and accurate at the time of printing.

However, information is subject to change.

Conformance statements

Federal Communications Commission (FCC) Notification and Repair Information This equipment has been tested and

found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy. If the equipment is

not installed and used in accordance with the guidelines in this document, the equipment may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at the expense of the user.

Alteration or modifications carried out without appropriate authorization may invalidate the user’s right to operate

the equipment.

Security statement

In rare instances, unauthorized individuals make connections to the telecommunications network through the use of

remote access features. In such an event, applicable tariffs require the customer to pay all network charges for

traffic. Lucent Technologies cannot be responsible for such charges and will not make any allowance or give any

credit for charges that result from unauthorized access.

Trademarks

VPN Firewall Brick is a registered trademark of Alcatel-Lucent.

Limited warranty

For terms and conditions of sale, contact your Alcatel-Lucent Account Team.

Ordering Information

The ordering number for this information product is 260-100-041

Thepartnumberforthisinformationproductis032360-00REVA

Technical Support

Alcatel-Lucent Customer Technical Support provides a technical assistance telephone number that is monitored 24

hours. For technical support (continental U.S.) call 1-866-582-3688 and select appropriate prompt. For international

support, please call +1 630-224-4672.

See notice on first age

Page 3

Contents

Overview ................................................................................................................................................................... 11

Structure of hazard statements

......................................................................................................................... 22

Introduction

.............................................................................................................................................................. 44

To Install a Model 1200 Brick Device

......................................................................................................... 99

To Change the SFP Module for a Model 1200 Brick Device Gigabit Only Port

................... 1212

Illustrations

............................................................................................................................................................. 1515

Specifications

........................................................................................................................................................ 1818

Safety Instructions

............................................................................................................................................... 2121

Laser Safety Guidelines

.................................................................................................................................... 2424

Maintenance

........................................................................................................................................................... 2828

Air Filter

................................................................................................................................................................. 2929

To Perform a Hot Swap of a Power Module

.......................................................................................... 3030

To Replace the Chassis Fan Filter

............................................................................................................... 3232

To Perform a Hot Swap of a Fan Unit

...................................................................................................... 3434

Index

39

...................................................................

iii

Page 4

Page 5

List of figures

Rack Mounting Brackets 10

SFP Module (Top, Bottom, Side, and Front Views) 13

Front View of 1200 Brick and 1200 HS Brick Devices 15

Rear View of 1200 Brick Device (AC version) 15

Rear View of 1200 HS Brick Device (AC version) 15

Rear View of 1200 HS Brick Device (DC version) 16

Rear Port View of 1200 Brick Device (AC version) 16

Rear Port View of 1200 HS Brick Device (AC and DC versions) 17

Hot Swap Power Module 31

Fan Filter Replacement 33

Brick Fan Units (Front View) 34

Brick Fan Units (Rear View) 35

Using Fan Filter Cover Hooks to Remove Fan Unit 37

Inserting the Replacement Fan Unit 38

...................................................................

v

Page 6

Page 7

Overview

.........................................................................................................................................................................................

Purpose

This document provides a detailed description of the Alcatel-Lucent VPN Firewall Brick

®

Model 1200 Security Appliance, including:

• General information about the Brick device hardware and features

• Instructions on how to install the Brick device

• Illustrations of the Brick device hardware components and interfaces

• Detailed specifications

• Safety instructions

• Maintenance procedures

Contents

Structure of hazard statements 2

Introduction 4

To Install a Model 1200 Brick Device 9

To Change the SFP Module for a Model 1200 Brick Device

Gigabit Only Port

12

Illustrations 15

Specifications 18

Safety Instructions 21

Laser Safety Guidelines 24

Maintenance 28

Air Filter 29

To Perform a Hot Swap of a Power Module 30

To Replace the Chassis Fan Filter 32

To Perform a Hot Swap of a Fan Unit 34

...................................................................

1

Page 8

Structure of hazard statements

.........................................................................................................................................................................................

Overview

Hazard statements describe the safety risks relevant while performing tasks on

Alcatel-Lucent products during deployment and/or use. Failure to avoid the hazards may

have serious consequences.

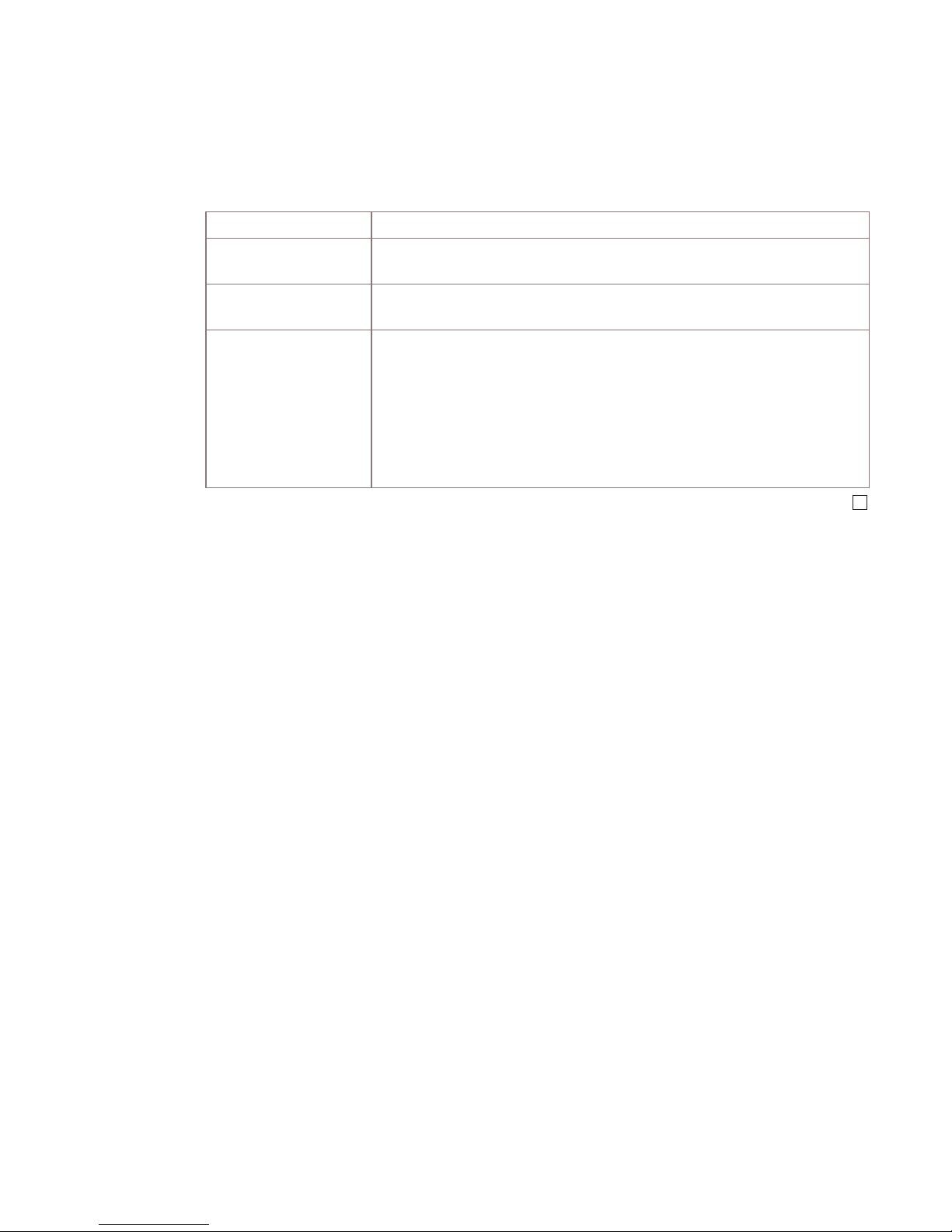

General structure

Hazard statements include the following structural elements:

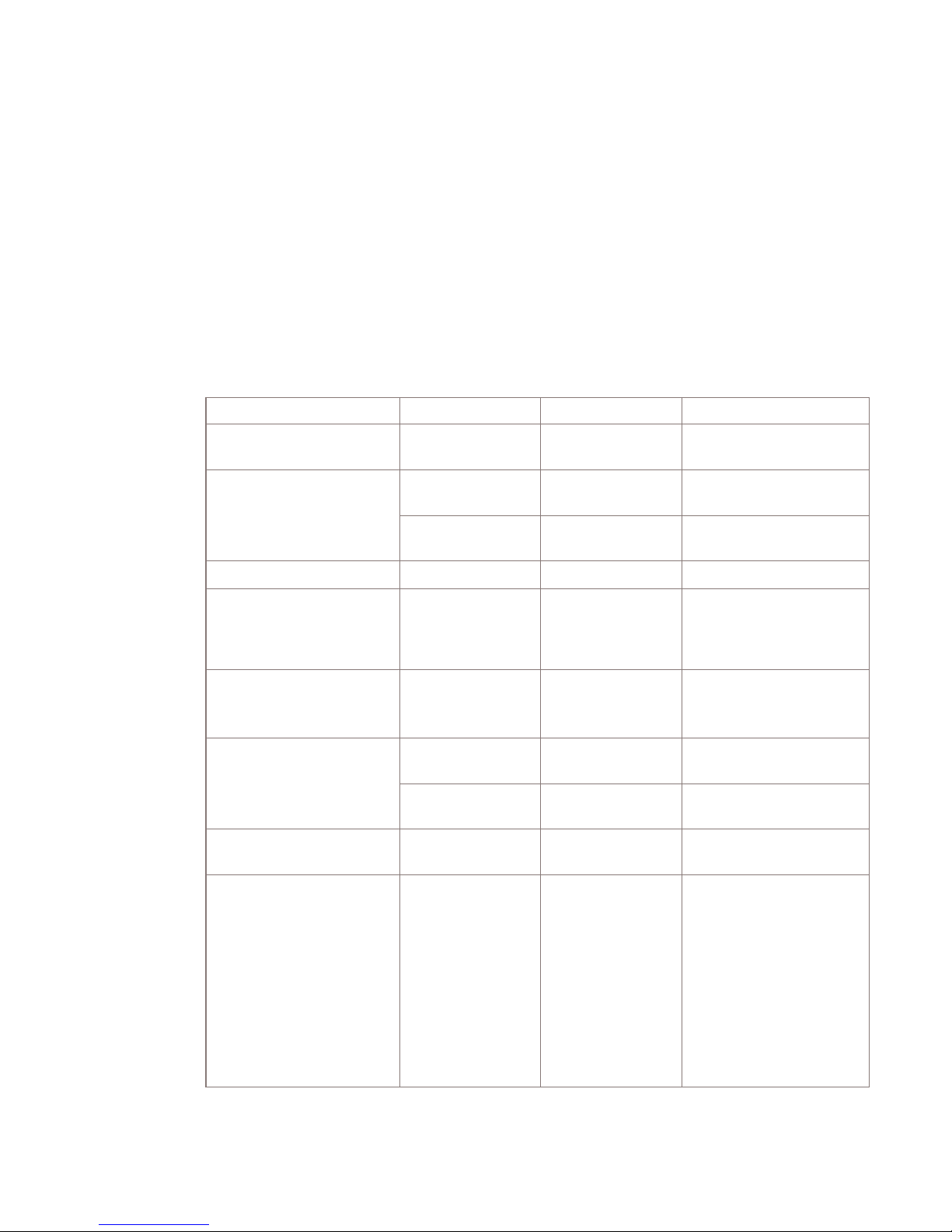

Item Structure element Purpose

1 Personal-injury symbol Indicates the potential for personal injury

(optional)

2 Hazard-type symbol Indicates hazard type (optional)

3 Signal word Indicates the severity of the hazard

4 Hazard type Describes the source of the risk of damage or

injury

5 Damage statement Consequences if protective measures fail

6 Avoidance message Protective measures to take to avoid the hazard

7 Identifier The reference ID of the hazard statement

(optional)

...................................................................

2

Page 9

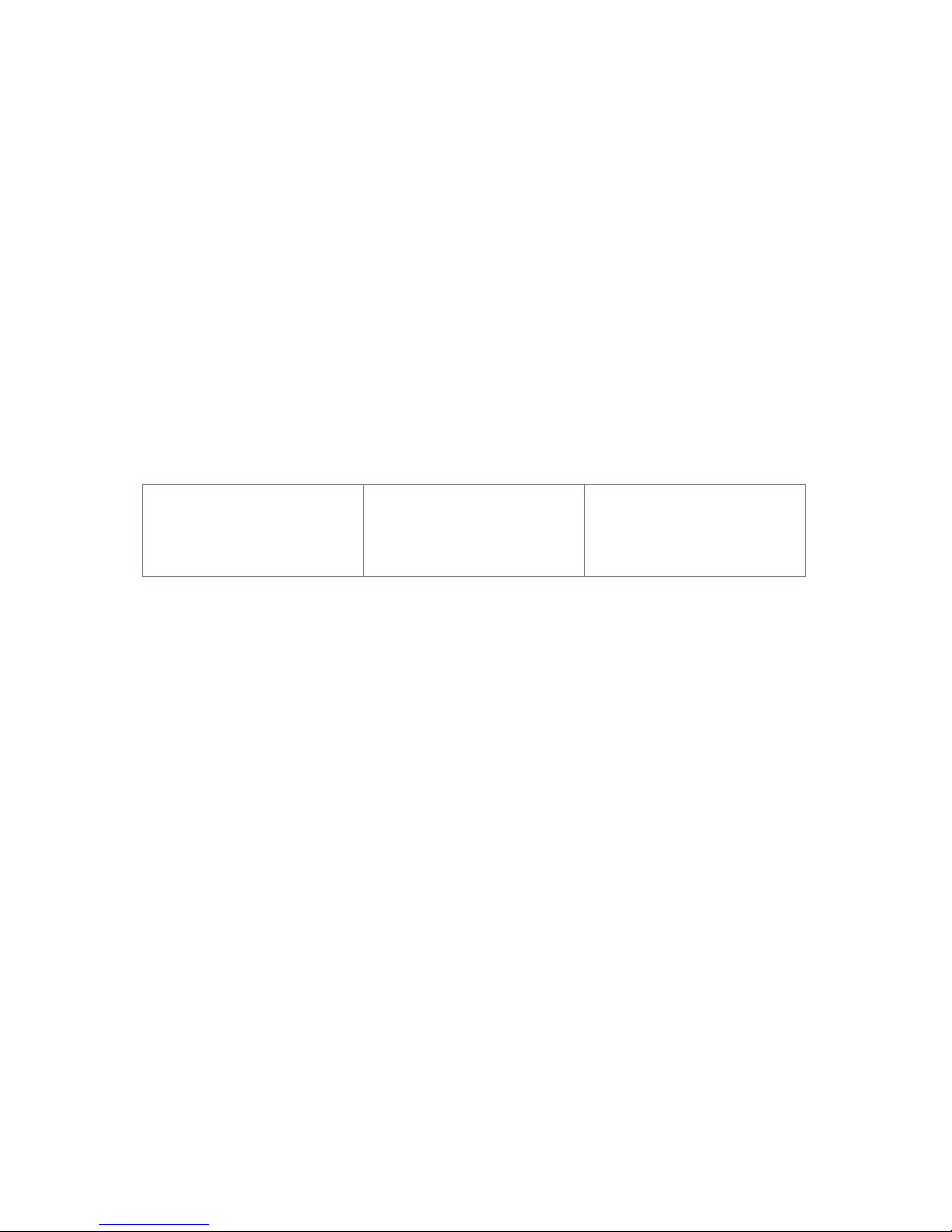

Signal words

The signal words identify the hazard severity levels as follows:

Signal word Meaning

DANGER Indicates an imminently hazardous situation (high risk) which, if not

avoided, will result in death or serious injury.

WARNING Indicates a potentially hazardous situation (medium risk) which, if

not avoided, could result in death or serious injury.

CAUTION When used with the personal injury symbol:

Indicates a potentially hazardous situation (low risk) which, if not

avoided, may result in personal injury.

When used without the personal injury symbol:

Indicates a potentially hazardous situation (low risk) which, if not

avoided, may result in property damage, such as service interruption

or damage to equipment or other materials.

Structure of hazard statements

...................................................................

3

Page 10

Introduction

.........................................................................................................................................................................................

General

A Model 1200 Brick device measures approximately 17″ (W)x19″ (D) x 3.5″(H) and is

intended to be installed on a standard 19-inch rack. It comes with two optional

rack-mounting brackets that can be attached to the sides to secure it to the rack.

There are two basic Brick 1200 models:

• The 1200 Brick (AC version only)

• The 1200 HS Brick (AC and DC versions)

Ports

The following table summarizes the number and type of ports that are supported on each

Brick 1200 model:

Port Type 1200 Brick Device 1200 HS Brick Device

10/100/1000BaseTX 8 14

Gigabit only interfaces

1

26

Notes:

1. The Gigabit only ports operate solely at the 1 Gigabit rate and are not 10/100/1000baseTX

auto-switchable. These ports are activated when the user inserts a Small Form-factor Pluggable

(SFP) module, which is ordered separately.

Power supply

The Model 1200 Brick device utilizes hot swappable mini-redundant power supplies for

both AC and DC versions.

Gigabit only interfaces

The Gigabit only ports on the Model 1200 Brick are configurable for copper/fiber

connections via Small Form-factor Pluggable (SFP) modules, which are sometimes referred

to as “mini-GBICs”.

The SFP module design is based on the GBIC interface, which is a standard for

transceivers that commonly use Gigabit copper Ethernet and fiber channels. The SFP is a

standard, hot swappable electrical interface that supports the full range of physical media,

from copper to optical fiber (multi mode or single mode) through the use of the appropriate

SFP module. These SFP modules can be easily interchanged, which allow networks to have

ports added or changed as the administrator wishes.

...................................................................

4

Page 11

Hardware encryption

A hardware-based Encryption Accelerator (AES) Card is standard on the DC version and

AC version of the Model 1200 Brick.

Front view

The front of the Model 1200 Brick device has a chassis fan filter replacement panel on the

left side, with light-emitting diode (LED) activity lights, Power, Audible Cut-Off (ACO),

and Unit ID LEDs/buttons, and two USB ports on the right side.

The following table describes the function, label, color and operation of each LED activity

light/button on the front panel.

Function LED/Button Label Color Operation

Power LED/button

(front)

1

Pwr GRN Steady ON=unit is

powered

Power Module Status PS1 GRN Steady ON=module 1 is

operating

PS2 GRN Steady ON=module 2 is

operating

Hard Disk Activity FD Act GRN Flashing=HDD activity

Encrypt Active EA Act GRN Steady ON=encryption

card active.

Flashing=data passing

through encryption card

Failover active FO Act GRN Steady ON=unit is in

failover mode and active

Flashing=unit in standby

Fan Bank Failure Fan1 GRN Steady ON=fan in

bank1 has failed

Fan2 GRN Steady ON=fan in

bank2 has failed

Fault

2

Fault YEL Steady ON=unit is in

the alarm state

ACO Active LED/button

3

ACO Act GRN Steady ON=the ACO

switch has been pressed

during an alarm state.

Steady OFF=no alarm

state is present or the

ACO button has not

been pressed during an

alarm state. The ACO

LED self-clears when

the offending alarm is

removed.

Introduction

...................................................................

5

Page 12

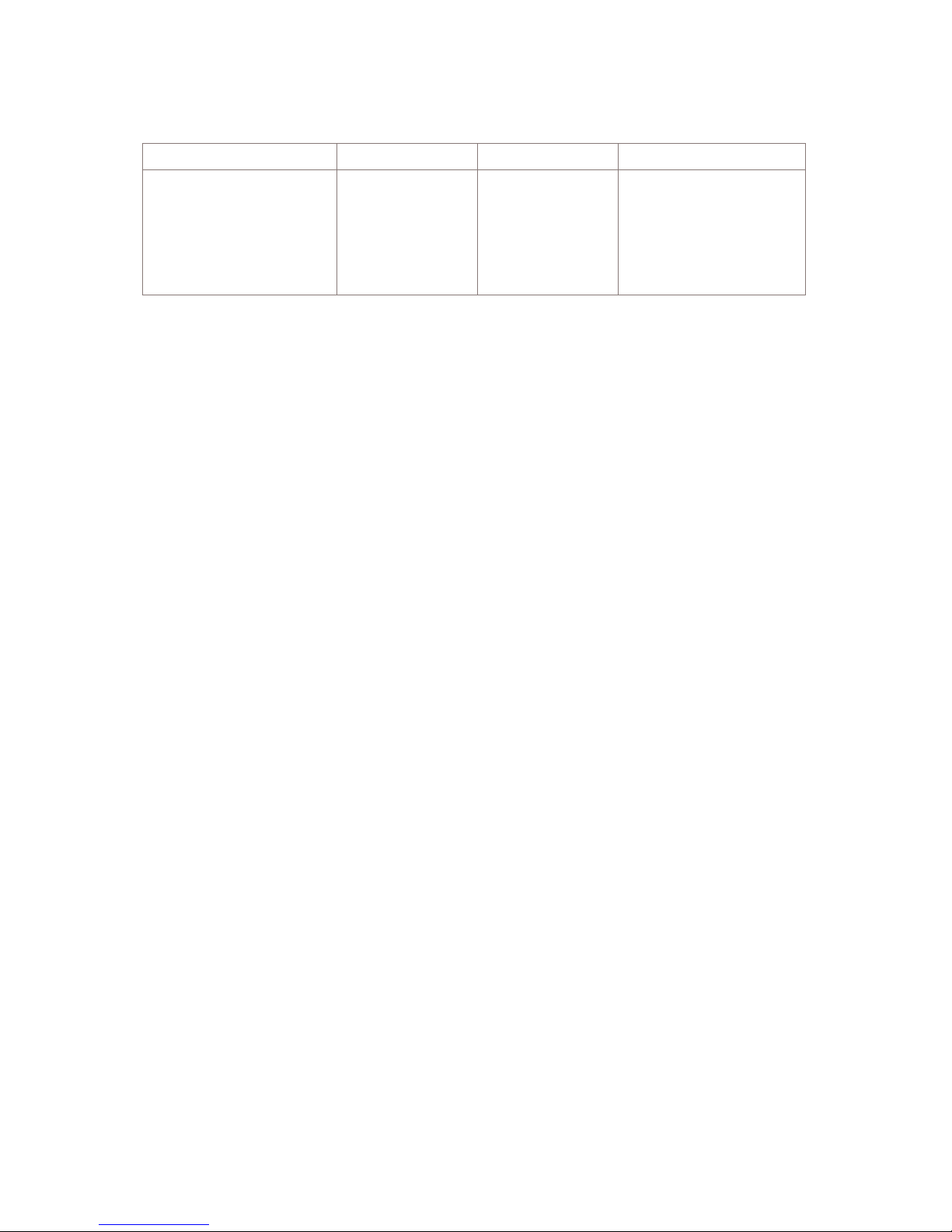

Function LED/Button Label Color Operation

Unit Indicator

LED/button

Unit ID BLU Steady ON=highlights a

particular unit in a rack

of equipment. LED

Indicator is on front

(button) and rear of

unit.

Notes:

1. The Power LED/button works like a momentary switch. To power up the Brick device, press the

button in and a steady green LED light indicates that the Brick is powered up. To power down

the Brick device, press and hold the button in again for at least 3 seconds.

2. If lit, there is an alarm fault in either the power supplies or fans. Observe the Fan1 and Fan2

LEDs to determine if it is a Fan alarm, or the PS1 and PS2 LEDs to determine if it is a power

supply alarm.

3. The Audible Cut Out (ACO) LED/button works like a momentary switch. Press the button in to

turn off an audible alarm and the ACO LED.

4. The Unit ID LED/button works like a momentary switch. Press and hold the button in to activate

the front and rear Unit ID LEDs. When pressed in for about 6 seconds, the Unit ID button starts

on-demand diagnostics (refer to the section “Hardware diagnostics” (p. 6)).

In addition to the activity lights described above, the DC version of the Model 1200 Brick

also has a Fault light, which is amber when power is lost to the A or B power connector.

Hardware diagnostics

When the Model 1200 Brick is powered on and boots up, it performs a Power On Self Test

(POST) diagnostics check of the motherboard, during which its memory, circuitry, and

peripherals are tested and configured. If the boot up of the motherboard is successful, the

motherboard LEDs, which are visible through four holes located in the rear of the chassis

near the bottom center of the Brick, flash green or red and then go out. If the boot up of

the motherboard is unsuccessful, each LED on the motherboard displays a steady green or

red. Should this occur, contact Alcatel-Lucent Customer Technical Support and indicate the

locked color status of each LED on the motherboard, from left to right, which can be used

to help determine the problem encountered during the POST diagnostics check.

The Model 1200 Brick also allows you to perform an on-demand diagnostics check of the

front panel alarms hardware (controlled by the Brick Alarm card installed in the front

chassis of the Brick), or to confirm a fault that might have occurred during normal

operations.

To perform an on-demand diagnostics check, do the following:

1. Confirm that the Brick is connected to an active power source.

2. Press and hold the Unit ID LED/button for five seconds.

...................................................................

6

Page 13

The Brick’s front alarm card initially performs a program self-check. If this fails, all front

panel LEDs and the audible alarm buzzer cycle together through three blinks/audible alarms

and the on-demand diagnostics is terminated.

If the diagnostics program self-check passes, the Brick turns off all LEDs or audible alarms

that are active, then cycles through each alarm indicator on and off 3 times, one cycle per

second, sequentially.

The alarm indicators are activated in the following sequence:

1. PS1 LED

2. PS2 LED

3. FD Act

4. FO Act LED

5. Fan1 LED

6. Fan2 LED

7. Fault LED

8. ACO LED

9. Unit ID LED

10. Audible alarm (buzzer)

11. Remote Visual Alarm relay

12. Remove Audible Alarm relay

After the on-demand diagnostics run is completed, the front panel alarm indicators return to

their original state.

Rear view

The rear of the Model 1200 Brick device provides access to two hot swappable redundant

power supplies. There is an alarm interface terminal block with dry contact closures for

Visual and Audible alarms that can be connected to a local alarm system. There are two

10/100/1000baseTX interfaces on the motherboard. In addition, there are six

10/100/1000BaseTX interfaces on both versions of the Model 1200 Brick, with 1Gigabit

only ports (two on the Standard version and six on the HS version) where SFP modules

can be inserted. The rear also contains a keyboard port, a monitor port, the console port,

two USB ports, and the Unit ID LED light.

Important! For installation into networks that are subject to surges, a shielded Ethernet

cable and/or serial port cable may be needed for regulatory compliance.

Alcatel-Lucent Security Management Server (SMS) software

The Model 1200 Brick device is supported by a patch release of SMS Release 9.0 (and

later SMS releases). To upgrade SMS R9.0 with a software patch that incorporates the

Model 1200 Brick software, or to obtain the latest software patches for R9.0 in the future,

download the software patches from the VPN Firewall Product Registration and Support

website: (https://www.lucent-ipsec.com). On the VPN Firewall Product Registration and

Introduction

...................................................................

7

Page 14

Support web page, enter your User Name and Password (which are established during the

product registration process).

If you are a registered customer, the VPN Firewall Registration web page is displayed.

Click on the link on the left side of the page labeled

Downloads to access the Downloads

page. The Downloads page has a series of buttons which allow you to select and download

the required software release/patch. For additional instructions on how to download and

install the required SMS software release/patch, refer to the SMS product Release Notes.

CAUTION:

CAUTION

Electric shock hazard

Risk of shock

Before connecting power on the DC version of the Model 1200 Brick device, the Brick

device chassis must be properly grounded. Two 10-32 threaded studs, spaced 0.625 inches

apart, are provided at the rear of the chassis for grounding purposes.

Alarm outputs

Visual and Audible Alarm outputs are available from the rear of the Model 1200 Brick

device. Each Form C relay provides NO (Normally Open), C (Common), and NC

(Normally Closed) contacts. The designations NO, C, and NC represent the powered

″good″ state of the Brick device.

All contacts are limited to ±60V and 0.75A.

Visual Alarm Output - indicates the Alarm state of the Brick device and remains until the

alarm is gone.

Audible Alarm Output - indicates the Alarm state of the Brick device but can be disabled

with the ACO (Audible Cut Out) and will not reactivate until the existing alarm has been

cleared and a new alarm has been generated.

Handling Brick device components

To prevent damage to components from electrostatic discharge, always follow the proper

guidelines for equipment handling and storage. Adapter cards and semiconductor devices in

general can be easily and permanently damaged due to electrostatic discharge during

installation and removal.

In order to reduce the static potential, the user should be properly grounded through the use

of an approved antistatic wrist strap when installing, removing or handling Brick devices.

...................................................................

8

Page 15

To Install a Model 1200 Brick Device

.........................................................................................................................................................................................

When to use

Use this procedure to install a 1200 Brick device. It includes special handling instructions

for the AC and DC versions of the Model 1200 Brick device.

Task: installing a Model 1200 Brick device

Complete the following steps to install a Model 1200 Brick device.

.........................................................................................................................................................................

1

Remove the Brick device from the carton in which it was shipped.

.........................................................................................................................................................................

2

If additional support is needed (other than the two front brackets), use the additional side

mounted brackets. Slide the two adjustable rear mounting brackets into the mounting guide.

Depending on the rack mounting requirements, the rear brackets can be inserted in the

guide in either position shown in Figure 1, “ Rack Mounting Brackets” (p. 10).

The General Devices slide rails (part number C300-S-122) can be used for cabinet

mounting applications.

.........................................................................................................................................................................

3

Position the Brick device in the rack and fasten the Brick device to the rack using the front

brackets on either side of the device with two #2 Phillips head screws per bracket. If the

...................................................................

9

Page 16

rear brackets are used, slide the bracket to the frame and fasten with two screws per

bracket.

.........................................................................................................................................................................

4

For AC models, take the two power cords that come with the unit and connect them to the

two power supply connectors on the back. See Figure 4, “Rear View of 1200 Brick Device

(AC version)” (p. 15)and Figure 5, “Rear View of 1200 HS Brick Device (AC version)”

(p. 15)for the location of the connectors.

.........................................................................................................................................................................

5

For DC models, make the following power connections (see Figure 6, “Rear View of 1200

HS Brick Device (DC version)” (p. 16) for the location of the connections):

-48VDC Power

Figure 1 Rack Mounting Brackets

...................................................................

10

Page 17

Two 12 foot power cables are provided. These cables consist of a pair of 12 AWG wires

and Faston connectors, which fasten directly into a field wiring terminal block on the

power supply. The other end of the cable is pre-stripped (3/8″) for connection to a fuse

panel or other source of -48VDC power. Observe proper polarity when connecting to a fuse

panel. The BLACK wire is ground and the RED wire is -48VDC.

The battery return conductor is an Isolated DC Return (DC-1).

Primary Ground

The product has been designed to be installed in a Common Bonding Network (CBN). The

Brick device has a primary ground connection on the rear of the unit. The connection point

is identified with the earth connection point symbol. This connection utilizes two 10-32

studs on 0.625″ centers. Lock washers and nuts for fastening a terminal lug are provided.

The primary ground must be utilized and the wire and lug must be selected in accordance

with NEC, state, local and customer guidelines.

.........................................................................................................................................................................

6

Connect the SMS to one of the Ethernet interfaces on the back (refer to Figure 4, “Rear

View of 1200 Brick Device (AC version)” (p. 15) through Figure 8, “Rear Port View of

1200 HS Brick Device (AC and DC versions)” (p. 17)). The following explains the type of

Ethernet cable to use:

Direct connection

If you are connecting the SMS directly to the Brick device, use a crossover Ethernet cable.

Hub/Switch

If you are connecting the Brick device to the SMS by means of a hub or switch, use

regular Ethernet cables from the SMS to the hub/switch, and from the hub/switch to the

interface on the back.

.........................................................................................................................................................................

7

Connect the LANs to the Brick device. Insert the Ethernet cable from the LANs into the

remaining Ethernet interfaces (see Figures 4 through 9).

Keep a record of the interfaces to which the SMS and the various LANs are connected.

You will need this information later when you create security zones and assign them to

interfaces.

.........................................................................................................................................................................

8

Power up the Brick device. It is now ready to be configured using the SMS (refer to the

Configuring and Activating an Alcatel-Lucent VPN Firewall Brick® Security Appliance

chapter in the SMS Administration Guide for instructions).

E ND OF STEPS

.............................................................................................................................................................................................

To Install a Model 1200 Brick Device

...................................................................

11

Page 18

To Change the SFP Module for a Model 1200 Brick Device

Gigabit Only Port

.........................................................................................................................................................................................

When to use

Use the following tasks to install an SFP module or to remove an SFP module for a

Gigabit only port on a Model 1200 Brick device.

Important! There are a variety of SFP modules that are commercially available.

However, Alcatel-Lucent only qualifies that the SFP modules that can be ordered from

Alcatel-Lucent will work properly. The user assumes all liability when using SFP

modules other than those available from Alcatel-Lucent. Contact your sales

representative for additional information.

Task: installing an SFP module

Complete the following steps to install an SFP module:

.........................................................................................................................................................................

1

Remove the SFP module from its protective packaging, and verify that the SFP module is

the correct model for your network configuration.

Note: you can identify SFP modules by the SFP module label, which also lists the SFP

model number and wavelength (if fiber).

Refer to Figure 2, “SFP Module (Top, Bottom, Side, and Front Views)” (p. 13) to

locate the SFP module label.

...................................................................

12

Page 19

.........................................................................................................................................................................

2

Verify that the bale clasp on the front of the SFP module is closed before inserting the SFP

module (refer to Figure 2, “SFP Module (Top, Bottom, Side, and Front Views)” (p. 13)).

.........................................................................................................................................................................

3

CAUTION

Possible Equipment Damage

Do not remove the dust plugs from the optical bore of the SFP module or the dust caps

from the fiber-optic cable until you are ready to connect the cable. The plugs and caps

protect the SFP module optical ports and cable connectors from contamination.

Align the SFP module in front of the slot opening with its connection pins in the upward

position (the SFP module label will face in a downward position), and slide the SFP

Figure 2 SFP Module (Top, Bottom, Side, and Front Views)

To Change the SFP Module for a Model 1200 Brick Device Gigabit Only Port

...................................................................

13

Page 20

module into the slot until you feel the connector on the module snap into place in the rear

of the slot.

Task: removing an SFP module

Complete the following steps to remove an SFP module from a Model 1200 Brick device:

.........................................................................................................................................................................

1

Disconnect the Ethernet or fiber-optic connector cable from the SFP module.

.........................................................................................................................................................................

2

Pivot the bale up to release the SFP module latching mechanism.

If the bale-clasp latch is obstructed and you cannot use your index finger to open it, use a

small, flat-blade screwdriver or other long, narrow instrument to open the bale-clasp latch.

.........................................................................................................................................................................

3

Grasp the SFP module between your thumb and index finger and carefully slide the module

out of the receptacle.

.........................................................................................................................................................................

4

Close the SFP bale clasp and insert the dust plug into the optical bores (if fiber).

.........................................................................................................................................................................

5

Place the SFP module in an antistatic bag or other protective environment.

E ND OF STEPS

.............................................................................................................................................................................................

...................................................................

14

E

ND OF STEPS

.........................................................................................................................................................................

Page 21

Illustrations

.........................................................................................................................................................................................

Purpose

This section provides a series of illustrations of the front and rear views of the Model 1200

Brick device.

Illustrations

The following illustrations provide front and rear views of the 1200 Brick and 1200 HS

Brick devices.

Figure 3 Front View of 1200 Brick and 1200 HS Brick Devices

Figure 4 Rear View of 1200 Brick Device (AC version)

Figure 5 Rear View of 1200 HS Brick Device (AC version)

...................................................................

15

Page 22

Figure 6 Rear View of 1200 HS Brick Device (DC version)

Figure 7 Rear Port View of 1200 Brick Device (AC version)

...................................................................

16

Page 23

Figure 8 Rear Port View of 1200 HS Brick Device (AC and DC versions)

Illustrations

...................................................................

17

Page 24

Specifications

.........................................................................................................................................................................................

Overview

This section provides detailed specifications for the Model 1200 Brick device hardware and

performance.

Dimensions

Height: 3.5 inches (8.89 cm)

Width: 17 inches (43.18 cm)

Depth: 19 inches (48.26 cm)

Weight: 33 lbs. (14.97 kg)

Shipping Weight: 41 lbs. (18.60 kg)

Rack Mountable

Processor Memory

The following processor memory specifications apply to each Brick 1200 model:

• 3.2 GHz Processor with 1G of RAM (1200 Brick)

• 3.6 GHz Processor with 2G of RAM (1200 HS Brick)

LAN Interfaces

The following LAN interfaces are available on the 1200 Brick device:

• Eight 10/100/1000base TX ports

• 2 Gigabit only ports

• One encryption accelerator card

The following LAN interfaces are available on the 1200 HS Brick device:

• 14 10/100/1000base TX ports

• Six Gigabit only ports

• One encryption accelerator card

Performance

For information on the 1200 Brick device performance specifications, please access the

following website: (http://www.alcatel-lucent.com)

Click on the

Products & Services link at the top of the page. The Products & Services

web page is displayed. Click on the

Product Catalog link. The Product Catalog web page

is displayed.

...................................................................

18

Page 25

Enter VPN Firewall Brick in the Product Search field on the right side of the web page and

press the Enter key. A web page is displayed with a list and descriptions of the current

Brick models.

Click on the hyperlink name

VPN Firewall Brick® 1200. A product page is displayed with

a general description of the Model 1200 Brick devices, with links to their benefits, features,

technical details, and related documents.

Under the

Resources section of the web page, click on the link to the Brick 1200

datasheet.

Hardware Assisted Encryption

Encryption Accelerator Modules are provided on the Model 1200 Brick device for AES-256

encryption.

Other Ports

Other port interfaces supported on the Brick device are:

• SVGA video

• DB9 serial

• PS/2 keyboard

Cooling

Active cooling is provided for the following hardware components:

• CPU

• Chassis

• Power Supply

Altitude

Up to 13,123 feet (4,000 m.)

Environmental

The following are environmental/operational specifications for the Brick:

Operating

Temperature: -5 to 55 C.

Shock: 2.5g. at 15 - 20 ms on any axis

Relative Humidity: 5 - 95% at 40 C. (non-condensing)

Vibration: 5g. at 2 - 200 Hz on any axis

Non-Operating

Temperature: 0 to 70 C.

Specifications

...................................................................

19

Page 26

Shock: 35g. at 15 - 20 ms on any axis

Relative Humidity: 5 - 95% at 40 C. (non-condensing)

Vibration: 5g at 2 - 200 Hz on any axis

Power

The following power supply configurations are supported on the Brick device:

AC Model:

Hot Swappable Internal AC to DC Power Supply: Rated 500 watts max

Auto-ranging: 90 to 254 VAC, 47 to 63 Hz

Typical Consumption: 8A @ 120VAC; 5A @ 240VAC

DC Model:

Hot Swappable Internal DC to DC Power Supply: Rated 500 watts max

Input Range: -4 to -60 VDC

Typical Consumption: 10A @ -48VDC, 8A @ -60VDC

Product Safety and Emissions Certifications

Safety Listings/EMC Certifications

Safety Listings

USA/Canada: ULR60950-1, First Edition and CAN/CSA C22.2 No. 60950-1-03

EU - CE, CB Scheme: EN/IEC 60950-1

EMC Certifications

USA: FCC Part 15, Class A

Canada: IC-ES003

EU: EN 300386-2; EN 55022, Class A; RoHS-compliant

Japan: VCCI-A

ICSA Certification

ICSA V4.0 Firewall Certified

ICSA V1.0B IPSec Certified

...................................................................

20

Page 27

Safety Instructions

.........................................................................................................................................................................................

Safety symbols

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the product.

When installing, operating, or maintaining this equipment, basic safety precautions should

always be followed to reduce the risk of fire, electric shock, and injury to persons,

including the following:

• Read and understand all instructions.

• Follow all warnings and instructions marked on this product.

• For information on proper mounting instructions, consult the User’s Manual provided

with this product.

• Do not place this product on an unstable cart, stand or table. The product may fall,

causing serious damage to the product.

• Do not place this product on an unstable cart, stand or table. The product may fall,

causing serious damage to the product.

• Install only equipment identified in the User’s Manual provided with this product. Use

of other equipment may result in improper connection of circuitry leading to fire or

injury to persons.

• This product should be operated only from the type of power source indicated on the

marking label. If you are not sure of the type of power supply, consult your dealer or

local Power Company.

• Disconnect up to two (2) power supply connections when removing power from this

system.

• Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or

aerosol cleaners. Use a damp cloth for cleaning.

• Do not use this product near water, for example, in a wet basement.

• Never push objects of any kind into this product through slots as they may touch

dangerous voltage points or short-out parts that could result in a risk of fire or

electrical shock. Never spill liquids of any kind on the product.

• Slots and openings in the unit are provided for ventilation, to protect it from

overheating; these openings must not be blocked or covered. This product should not

be placed in a built-in installation unless proper ventilation is provided.

• To reduce the risk of electrical shock, do not disassemble this product. Service should

be performed by trained personnel only. Opening or removing covers and/or circuit

boards may expose you to dangerous voltages or other risks. Incorrect reassembly can

cause electric shock when the unit is subsequently used.

• Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries

according to the instruction.

...................................................................

21

Page 28

• This product is equipped with a three-wire grounding type plug, a plug having a third

(grounding) pin. This plug is intended to fit only into a grounding type power outlet.

This is a safety feature. If you are unable to insert the plug into the outlet, contact your

electrician to replace your obsolete outlet. Do not defeat the safety purpose of the

grounding type plug. Do not use a 3-to-2-prong adapter at the receptacle. Use of this

type adapter may result in risk of electrical shock and/or damage to this product.

• Do not allow anything to rest on the power cord. Do not locate this product where the

cord will be abused by persons walking on it.

• Do not overload wall outlets and extension cords as this can result in the risk of fire or

electric shock.

• Other precautions follow:

Unplug this product from the wall outlet and refer servicing to qualified service

personnel under the following conditions:

1. When the power supply cord or plug is damaged or frayed.

2. If liquid has been spilled into the product.

3. If the product has been exposed to rain or water.

4. If the product does not operate normally by following the operating instructions.

Adjust only those controls that are covered by the operating instructions because

improper adjustment of other controls may result in damage and will often require

extensive work by qualified technician to restore the product to normal operation.

5. If the product has been dropped or the cabinet has been damaged.

6. If the product exhibits a distinct change in performance.

• For a unit intended to be powered from -48 V dc voltage sources, read and understand

the following:

– This equipment must be provided with a readily accessible disconnect device as

part of the building installation.

– Ensure that there is no exposed wire when the input power cables are connected to

the unit.

– Installation must include an independent frame ground drop to building ground.

Refer to User’s Manual.

This symbol is marked on the product, adjacent to the ground (earth) area for

the connection of the ground (earth) connector.

– This Equipment is to be Installed Only in Restricted Access Areas on Business and

Customer Premises Applications in Accordance with Articles 110-16, 110-17, and

110-18 of the National Electrical Code, ANSI/NFPA No. 70. Other Installations

Exempt from the Enforcement of the National Electrical Code May Be Engineered

According to the Accepted Practices of the Local Telecommunications Utility.

Save these instructions for future reference.

...................................................................

22

Page 29

Scandanavian power module notification

CAUTION:

• Apparatet må tilkoples jordet stikkontakt (Denmark)

• Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan (Finland)

• Apparatet må tilkoples jordet stikkontakt (Norway)

• Apparaten skall anslutas till jordat uttag (Sweden)

Safety Instructions

...................................................................

23

Page 30

Laser Safety Guidelines

.........................................................................................................................................................................................

General Laser Information

Optical fiber telecommunication systems, their associated test sets, and similar operating

systems use semiconductor laser transmitters that emit infrared (IR) light at wavelengths

between approximately 800 nanometers and 1600 nanometers. The emitted light is above

the red end of the visible spectrum, which is normally not visible to the human eye.

Although radiant energy at near-IR wavelengths is officially designated invisible, some

people can see the shorter wavelength energy even at power levels several orders of

magnitude below any that have been shown to cause injury to the eye.

Conventional lasers can produce an intense beam of monochromatic light. The term

monochromaticity means a single wavelength output of pure color that may be visible or

invisible to the eye. A conventional laser produces a small-size beam of light, and because

the beam size is small the power density (also called irradiance) is very high. Consequently,

lasers and laser products are subject to federal and applicable state regulations as well as

international standards for their safe operation.

A conventional laser beam expands very little over distance, or is said to be very well

collimated. Thus, conventional laser irradiance remains relatively constant over distance.

However, lasers used in lightwave systems have a large beam divergence, typically 10 to

20 degrees. Here, irradiance obeys the inverse square law (doubling the distance reduces

the irradiance by a factor of (4) and rapidly decreases over distance.

Lasers and Eye Damage

The optical energy emitted by laser and high-radiance LEDs in the 400-1400 nm range may

cause eye damage if absorbed by the retina. When a beam of light enters the eye, the eye

magnifies and focuses the energy on the retina magnifying the irradiance. The irradiance of

the energy that reaches the retina is approximately 105 or 100,000 times more than at the

cornea and, if sufficiently intense, may cause a retinal burn.

The damage mechanism at the wavelengths used in an optical fiber telecommunications is

thermal in origin, such as damage caused by heating. Therefore, a specific amount of

energy is required for a definite time to heat an area of retinal tissue. Damage to the retina

occurs only when one looks at the light sufficiently long that the product of the retinal

irradiance and the viewing time exceeds the damage threshold. Optical energies above 1400

nm cause corneal and skin burns but do not affect the retina. The thresholds for injury at

wavelengths greater than 1400 nm are significantly higher than for wavelengths in the

retinal hazard region.

Classification of Lasers

Manufacturers of lasers and laser products in the U.S. are regulated by the Food and Drug

Administration’s Center for Devices and Radiological Health (FDA/CDRH) under 21 CFR

1040. These regulations require manufacturers to certify each laser or laser product as

belonging to one of four major Classes I, II, IIa, IIIa, IIIb, or IV. The International

...................................................................

24

Page 31

Electro-technical Commission is an international standards body that writes laser safety

standards under IEC-60825. Classification schemes are similar with Classes divided into

Classes 1, 1M, 2, 2M, 3B, 3R and 4. Lasers are classified according to the accessible

emission limits and their potential for causing injury. Optical fiber telecommunication

systems are generally classified as Class I/1, because, under normal operating conditions,

all energized laser transmitting circuit packs are terminated on optical fibers which enclose

the laser energy with the fiber sheath forming a protective housing. Also, a protective

housing / access panel is typically installed in front of the laser circuit pack shelves. The

circuit packs themselves, however, may be FDA/CDRH Class I, IIIb, or IV or IEC Class 1,

1M, 3B, 3R or 4. State of the art Raman and EDFA optical amplifiers have now extended

into the Class IV/4 designations.

Laser Safety Precautions for Optical Fiber Telecommunications Systems

In its normal operating mode, an optical fiber telecommunication system is totally enclosed

and presents no risk of eye injury. It is a Class I/1 system under the FDA and IEC

classifications.

The fiber optic cables that interconnect various components of an optical fiber

telecommunication system can disconnect or break, and may expose people to laser

emissions. Also, certain measures and maintenance procedures may expose the technician to

emission from the semiconductor laser during installation and servicing. Unlike more

familiar laser devices, such as solid-state and gas lasers, the emission pattern of a

semiconductor laser results in a highly divergent beam. In a divergent beam, the irradiance

(power density) decreases rapidly with distance. The greater the distance, the less energy

will enter the eye, and the less potential risk for eye injury. Inadvertently viewing an

unterminated fiber or damaged fiber with the unaided eye at distances greater than 5 to 6

inches normally will not cause eye injury provided the power in the fiber is less than a few

milliwatts at the near IR wavelengths and a few tens of milliwatts at the far IR

wavelengths. However, damage may occur if an optical instrument such as a microscope,

magnifying glass or eye loupe is used to stare at the energized fiber end.

CAUTION

CAUTION

Possible radiation exposure

Possible personal injury

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Laser Safety Guidelines

...................................................................

25

Page 32

Laser Safety Precautions for Enclosed Systems

Under normal operating conditions, optical fiber telecommunication systems are completely

enclosed; nonetheless, the following precautions shall be observed:

1. Because of the potential for eye damage, technicians should not stare into optical

connectors or broken fibers.

2. Under no circumstance shall laser/fiber optic operations be performed by a technician

before satisfactorily completing training in laser safety.

3. Since viewing laser emissions directly in excess of Class I/1 limits with an optical

instrument such as an eye loupe greatly increases the risk of eye damage, appropriate

labels must appear in plain view, in close proximity to the optical port on the

protective housing/access panel of the terminal equipment.

Laser Safety Precautions for Unenclosed Systems

During service, maintenance, or restoration, an optical fiber telecommunication system is

considered unenclosed. Under these conditions, follow these practices:

1. Only authorized, trained personnel shall be permitted to do service, maintenance and

restoration. Avoid exposing the eye to emissions from unterminated, energized optical

connectors at close distances. Laser modules associated with the optical ports of laser

circuit packs are typically recessed, which limits the exposure distance. Optical port

shutters, Automatic Power Reduction (APR), and Automatic Power Shut Down (APSD)

are engineering controls that are also used to limit the emissions. However, technicians

removing or replacing laser circuit packs should not stare or look directly into the

optical port with optical instruments or magnifying lenses. (Normal eyewear or indirect

viewing instruments such as Find-R-Scopes are not considered magnifying lenses or

optical instru-ments.)

2. Only authorized, trained personnel shall use optical test equipment during installation

or servicing since this equipment contains semiconductor lasers. (Some examples of

optical test equipment are Optical Time Domain Reflectometers ( OTDR’s), Hand-Held

Loss Test Sets)

3. Under no circumstances shall any personnel scan a fiber with an optical test set

without verifying that all laser sources on the fiber are turned off.

4. All unauthorized personnel shall be excluded from the immediate area of the optical

fiber telecommunication systems during installation and service.

Consult ANSI Z136.2 - American National Standard for Safe Use of Optical Fiber

Communication Systems Utilizing Laser Diodes and LED Sources in the U.S. or outside

the U.S., IEC-60825, Part 2 for guidance on the safe use of optical fiber communication

systems in the workplace.

Recycling / take-back / disposal of product

Electronics products bearing or referencing the symbol below when put on the market

within the European Union, shall be collected and treated at the end of their useful life, in

compliance with applicable European Union and local registration. They shall not be

disposed of as part of unsorted municipal waste. Due to materials that may be contained in

...................................................................

26

Page 33

the product, such as heavy metals or batteries, the environment and human health may be

negatively impacted as a result of inappropriate disposal.

Note: In the European Union, a solid bar under the crossed-out wheeled bin indicates that

the product was put on the market after 13 August 2005.

Moreover, in compliance with legal requirements and contractual agreements, where

applicable, Alcatel-Lucent will offer to provide for the collection and treatment of

Alcatel-Lucent products at the end of their useful life, or products displaced by

Alcatel-Lucent equipment offers.

For information regarding take-back of equipment by Alcatel-Lucent, or for more

information regarding the requirements for recycling/disposal of product, please contact

your Alcatel-Lucent Account Manager or Alcatel-Lucent Takeback Support at

takeback@alcatel-lucent.com.

Laser Safety Guidelines

...................................................................

27

Page 34

Maintenance

.........................................................................................................................................................................................

Overview

This section describes maintenance procedures that may need to be performed periodically

to replace a defective part once a Model 1200 Brick device has been installed and is

operational.

...................................................................

28

Page 35

Air Filter

.........................................................................................................................................................................................

Periodic maintenance

The 1200 Brick device provides an air filter that is accessible at the front panel. The air

filter should be periodically (frequency is dependent on environment) inspected for

accumulation of dust/debris.

If dust/debris is present, the filter should be cleaned by washing it in a sink with liquid

soap and warm water (the filter is rugged) and shaken dry. The air filter can be removed,

cleaned and reinstalled while the Brick device is running.

...................................................................

29

Page 36

To Perform a Hot Swap of a Power Module

.........................................................................................................................................................................................

When to use

Use this hot swap procedure to remove and replace a defective power module. Refer to

Figure 9, “Hot Swap Power Module” (p. 31) while performing this procedure.

Alarm indicators

The yellow Fault LED on the front panel of the Brick is lit when one of the power

modules fails or both fan units fail. Observe the Fan1 and Fan2 LEDs to determine if it is

a fan unit alarm, or the PS1 and PS2 LEDs to determine if it is a power supply alarm.

If it is a power supply alarm, check the green LED on the back of each power module at

the rear of the Brick to determine which is the defective module. The green LED will not

be lit on the defective power module.

Important! Make sure that the correct power module is identified for removal.

Otherwise, removal of the wrong power module may cause a shutdown of the whole

system.

Task: performing a hot swap of a power module

Complete the following steps to perform a hot swap of a power module:

.........................................................................................................................................................................

1

Loosen the bracket screws of the defective power module.

.........................................................................................................................................................................

2

WARNING

Flammable-material hazard

The cover of the power module is used as a heat sink and is hot.

Wear gloves when handling the unit to avoid burning your hands and then set the module

aside to cool.

Remove the defective power module by pulling it out using the attached handle.

.........................................................................................................................................................................

3

Insert a new power module into the power system to the end, making sure it is seated

properly.

.........................................................................................................................................................................

4

Connect the power cord of the new power module.

.........................................................................................................................................................................

5

Check that the LED of the power module light is green.

...................................................................

30

Page 37

.........................................................................................................................................................................

6

Check the LED that indicates the total power system status.

.........................................................................................................................................................................

7

Tighten the screws of the power module bracket to secure it.

If the DC fan of the power module fails, you have to replace the power module.

Follow the hot swap procedures for replacement of the power module.

E ND OF STEPS

.............................................................................................................................................................................................

Figure 9 Hot Swap Power Module

To Perform a Hot Swap of a Power Module

...................................................................

31

Page 38

To Replace the Chassis Fan Filter

.........................................................................................................................................................................................

When to use

As needed, periodically clean or replace the chassis fan filter using the following

procedure. Refer to Figure 10, “Fan Filter Replacement” (p. 33) while performing this

procedure.

This procedure must also be followed to remove the chassis fan filter cover and filter

before performing a hot swap of a fan unit (refer to the procedure “To Perform a Hot Swap

of a Fan Unit” (p. 34)).

Task: replacing the chassis fan filter

Complete the following steps to replace the chassis fan filter:

.........................................................................................................................................................................

1

At the front of the Brick device, unscrew the thumbscrews over the tabs of the chassis fan

filter cover, pull the filter cover down and slightly forward, and remove it.

.........................................................................................................................................................................

2

Remove the fan filter and clean or discard it.

.........................................................................................................................................................................

3

Replace the cleaned (or new) filter .

...................................................................

32

Page 39

.........................................................................................................................................................................

4

Reinstall the chassis fan filter cover, so that the two hooks on the left of the cover are

positioned in the cutout slots on the left side of the Brick, and screw the thumbscrews over

the tabs of the fan filter cover.

E ND OF STEPS

.............................................................................................................................................................................................

Figure 10 Fan Filter Replacement

To Replace the Chassis Fan Filter

...................................................................

33

Page 40

To Perform a Hot Swap of a Fan Unit

.........................................................................................................................................................................................

When to use

Use this hot swap procedure to remove and replace a defective fan unit.

The fan units are individual single-fan and dual-fan plug-in units with a metal cage cover

(refer to Figure 11, “Brick Fan Units (Front View)” (p. 34) and Figure 12, “Brick Fan

Units (Rear View)” (p. 35)).

Figure 11 Brick Fan Units (Front View)

...................................................................

34

Page 41

While removing and replacing a fan unit, keep in mind that the single fan unit must always

be installed on the left side of the opening for the fan assemblies, and that the dual fan unit

must always be installed on the right side of the opening.

When a fan unit is removed while the Brick is running, a temperature sensor within the

CPU monitoring the internal operating temperature invokes the remaining fan(s) to run at

full speed and generates a visual fan alarm, indicating a missing fan unit. Once the

replacement fan unit is installed, the alarm is cleared and the fans return to normal

operating speed.

Figure 12 Brick Fan Units (Rear View)

To Perform a Hot Swap of a Fan Unit

...................................................................

35

Page 42

Task: performing a hot swap of a fan unit

CAUTION

Service-disruption hazard

Removing a fan unit while the Brick is in operation and not replacing it quickly may cause

an abnormally high CPU temperature and possible shutdown of the Brick to avoid

overheating.

When replacing a fan unit, do so promptly to avoid potential shutdown of the Brick device.

Complete the following steps to perform a hot swap of a fan unit:

.........................................................................................................................................................................

1

Remove the chassis fan filter cover and filter as described in the procedure “To Replace the

Chassis Fan Filter” (p. 32).

...................................................................

36

Page 43

.........................................................................................................................................................................

2

Use the hooks on the left side of the chassis fan filter cover to hook and pull the fan unit

out of the opening at the front of the Brick device (refer to Figure 13, “Using Fan Filter

Cover Hooks to Remove Fan Unit” (p. 37)).

Figure 13 Using Fan Filter Cover Hooks to Remove Fan Unit

To Perform a Hot Swap of a Fan Unit

...................................................................

37

Page 44

.........................................................................................................................................................................

3

Insert the replacement fan unit into the opening at the front of the Brick device (refer to

Figure 14, “Inserting the Replacement Fan Unit” (p. 38)).

.........................................................................................................................................................................

4

Reinsert the fan filter in front of the fan units in the opening of the Brick.

.........................................................................................................................................................................

5

Reinstall the chassis fan filter cover and secure it with the two thumbscrews as described in

the procedure “To Replace the Chassis Fan Filter” (p. 32).

E ND OF STEPS

.............................................................................................................................................................................................

Figure 14 Inserting the Replacement Fan Unit

...................................................................

38

Page 45

Index

.........................................................................................

A

Air filter

replacing, 29

Alarm interface terminal block

rear panel, 7

Alarm outputs, 8

Alcatel-Lucent Security Management

Server (SMS), 7

Audible alarm indicators, 7

.........................................................................................

B

Booting up

Brick device, 6

Brick devices

installing, 9

.........................................................................................

C

Chassis fan filter

replacing, 32

Cooling, 19

.........................................................................................

D

Diagnostics

front alarm card, 6

motherboard, 6

Dimensions

specifications, 18

.........................................................................................

E

Emissions certifications, 20

Encryption

hardware-assisted, 18

Encryption Accelerator (AES) card, 4

Environmental

specifications, 19

.........................................................................................

F

Fan unit

hot swapping, 34

Front alarm card

diagnostics, 6

Front panel, 5

LEDs, 5

Front view illustrations, 15

.........................................................................................

G

Gigabit only ports, 4

change SFP module for, 12

.........................................................................................

H

Handling Brick device components, 8

Hardware

dimensions, 4

encryption, 4

.........................................................................................

I

Illustrations

front view, 15

rear view, 15

Install

Brick devices, 9

.........................................................................................

L

Laser safety guidelines, 24

LEDs

front panel, 5

.........................................................................................

M

Maintenance procedures, 28

Models, 4

Motherboard

diagnostics, 6

.........................................................................................

P

Performance

specifications, 18

Ports, 4, 18

Gigabit only, 4

...................................................................

39

Page 46

Power module

hot swapping, 30

Power supply, 4, 20

Processor memory

specifications, 18

Product safety certifications, 20

.........................................................................................

R

Rear panel

alarm interface terminal block, 7

Rear view illustrations, 15

.........................................................................................

S

Safety instructions, 21

SFP modules

See: Small Form-factor Pluggable

(SFP) modules

Small Form-factor Pluggable (SFP)

modules

definition, 4

install, 12

remove, 12

Specifications

dimensions, 18

environmental, 19

performance, 18

processor memory, 18

weight, 18

Switches, 5

.........................................................................................

V

Visual alarm indicators, 7

.........................................................................................

W

Weight

specifications, 18

Index

...................................................................

40

Loading...

Loading...