Page 1

Ope ra ting In struc tions

Two com po nent pro por tio ning val ve

SKW

046-3MS

Ster ling Ma te rial Pro cess ing

Page 2

Sterling Material Processing

5200 West Clinton Ave.

Milwaukee, WI 53223

Telephone (414) 354-0970

Fax: (414-354-6421

www.sterlco.com

Parts & Service:

Telephone (800) 423-3183

Edition: 04/97

SKW

These operating instructions are for:

*

Se ri al num ber:

Built in:

Date of de li very:

Num ber of de li very:

Date of com mis sio ning:

Lo ca ti on:

046-3MS

Group of ma chi nes:

2

Page 3

SKW

Sterling Material Processing retains all rights to change the information in these

operating instructions at any time without notice.

We assume no liability for any errors or direct or indirect damage resulting in

context with these operating instructions.

Copying, translation or publication in any form except for personal use of

046-3MS

purchaser requires approval from Sterling Material Processing.

All rights reserved.

3

Page 4

SKW

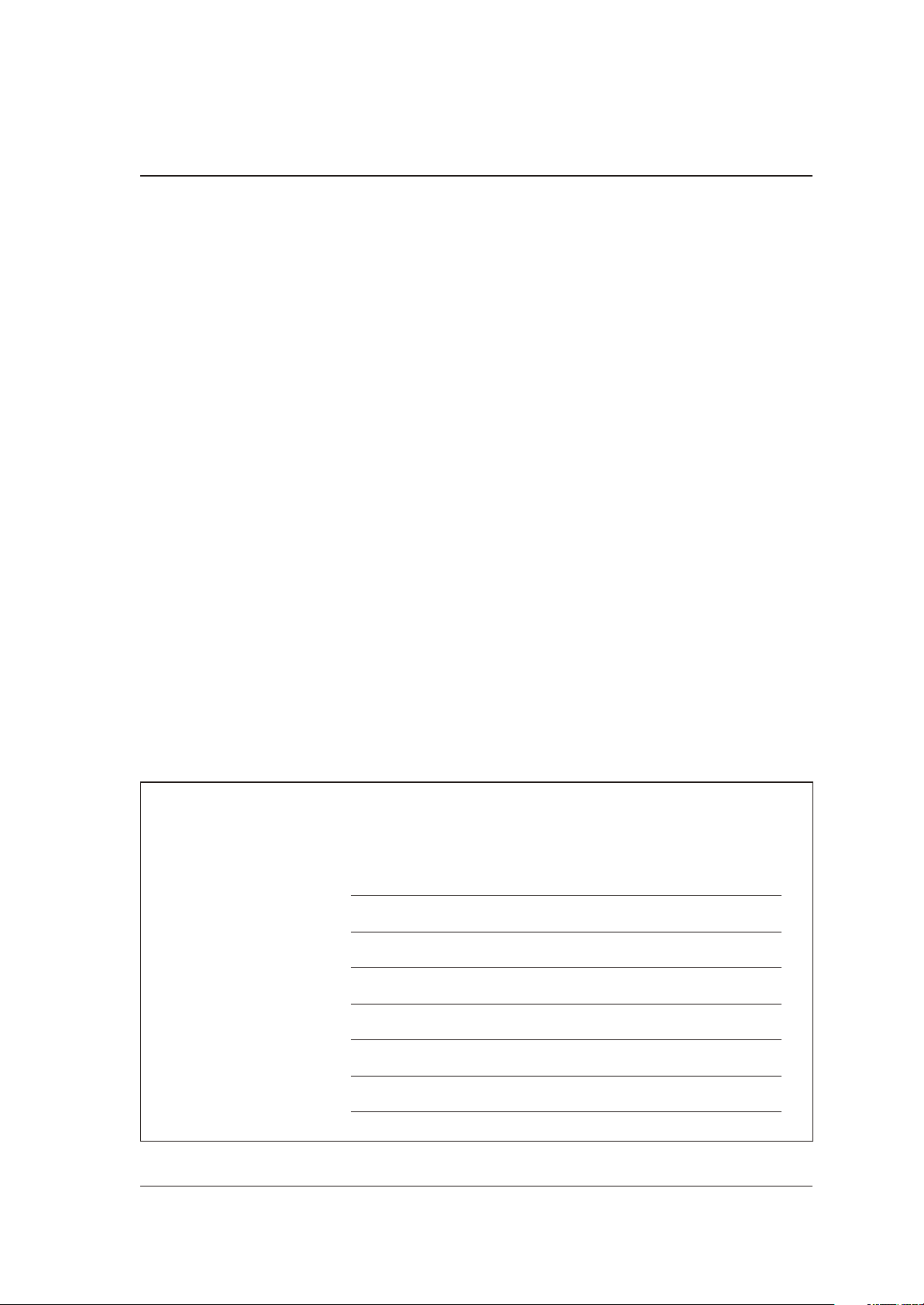

Tab le of con tents

1. Sa fe ty in struc tions ............................................6

1.1. War nings and sym bols ..................................7

1.2. Ex pla na tions and in for ma ti on .............................8

1.3. For your sa fe ty ........................................9

1.4. For the ope ra ting sa fe ty of the equip ment..................13

2. In stal la ti on in struc tions .......................................15

2.1. In stal la ti on ...........................................17

2.2. Elec tri cal con nec ti on ...................................18

2.2.1. Con nec ti on to a sing le con vey or unit

SSE 2&5 ....................................18

2.2.2. Con nec ti on to a vac uum receiver unit

SSK 05, 1, 3, 5 & 30 ...........................19

2.2.3. Con nec ti on to a con vey ing sys tem control .........19

2.3. Com pres sed air supp ly .................................20

3. Functio nal des crip ti on ........................................21

3.1. Ge ne ral in for ma ti on ...................................22

3.2. Con trol ..............................................23

3.2.1. SKW Ver si on 1 ...............................23

3.2.1.1. Con vey ing ra tio .......................24

3.2.1.2. Swit ching cy cles ......................25

3.2.2. SKW Ver si on 2 ...............................26

4. Start-up.....................................................27

4.1. Ad ju sting the con vey ing ra tio ............................28

4.2. De ter mi ning the swit ching cy cle du ra ti on ..................29

4.3. Set ting the swit ching cy cles .............................32

046-3MS

Table of contents 4

Page 5

SKW

5. Main ten an ce.................................................33

5.1. Main ten an ce in ter vals ..................................35

5.2. Chec king for smooth ope ra ti on ..........................36

6. Tech ni cal data ...............................................37

6.1. Di men si on sheet SKW 40/50 ............................38

6.2. Di men si on sheet SKW 65...............................39

7. Ap pen dix ...................................................40

7.1. Spa re parts list .......................................41

046-3MS

Table of contents 5

Page 6

1. Sa fe ty in struc tions

These safety instructions apply to all persons within the

»

range of action of the equipment.

Please inform all persons within the range of action of the

equipment of the direct and indirect hazards connected

with the equipment.

These operating instructions are to be used by all persons

assigned activities connected with the equipment.

Knowledge of the English language is prerequisite.

Ensure in each case that the operating personnel are

familiar with the operating instructions and the function of

the equipment.

SKW

046-3MS

Sa fe ty in struc tions 6

Page 7

SKW

1.1. War nings and sym bols

The following warnings and symbols are used in these operating instructions:

This symbol indicates danger to life! Fatal or serious injury

»

is possible if the corresponding instructions, regulations or

warnings are not observed.

L

F

&

$

This symbol indicates that serious injury is possible if the

corresponding instructions, regulations or warnings are not

observed.

This symbol indicates that extensive damage to equipment

is possible if the corresponding instructions, regulations or

warnings are not observed.

This symbol indicates information important for becoming

familiar with the equipment, i.e. technical correlations.

This symbol indicates that a technical term is explained at

this point.

046-3MS

Sa fe ty in struc tions 7

Page 8

SKW

1.2. Ex pla na tions and in for ma ti on

Various terms and designations are used frequently in these operating

instructions to ensure clarity. Therefore please note that the terms used in the

text stand for the corresponding explanations listed below.

Equipment

·

“Equipment” can mean an individual unit, a machine or an installation.

Operating personnel

·

The “operating personnel” are persons operating the equipment on their own

responsibility or according to instructions (minimum age: 16).

Operator

·

The “operator” of the equipment (production manager, foreman, etc.) is the

person responsible for all production sequences. The operator instructs the

operating personnel of what is to be done.

Operating instructions

·

The “plant operating instructions” describe the interaction of the equipment,

production sequences or methods. The plant operating instructions must be

compiled by the operator of the equipment.

Equipment foreman

·

When several operating personnel work on one machine, the “equipment

foreman” coordinates the sequences. The equipment foreman must be

appointed by the operator.

Trained personnel

·

“Trained personnel” are persons who, due to their training, are authorized to carry

out the required work in good practice.

046-3MS

Sa fe ty in struc tions 8

Page 9

1.3. For your sa fe ty

The operating personnel of this equipment must be at least 16 years old.

·

Please read these operating instructions carefully before taking into operation for

·

the first time. All points are to be observed. Contact us should questions arise.

This avoids injury and damage to equipment!

These operating instructions must be kept available at all times at the place of

·

operation of the equipment.

Improper operation results in danger of accidents!

Please note that, for reasons of clarity, not all conceivable cases regarding

·

operation or maintenance of the equipment can be covered in these operating

instructions.

SKW

Please observe all safety instructions and warnings on the equipment.

·

This avoids injury and damage to equipment!

All work on the equipment is to be carried out by persons whose qualifications are

·

specified in the pertaining chapters of the operating instructions.

Improper operation results in danger of accidents!

The proper working clothes are to be worn during any work on the equipment.

·

This avoids injury!

Compare the connected loads with those of the mains supply.

·

Danger of injury through electrical shock!

When using lifting gear, please observe the pertaining regulations.

·

Caution: Danger of accidents!

Please note that all installation, start-up and maintenance procedures are to be

·

carried out by qualified, trained personnel only.

046-3MS

Improper operation results in danger of accidents!

Sa fe ty in struc tions 9

Page 10

The local regulations and requirements pertaining to the equipment must be

·

observed.

The “5 safety rules” as provided in DIN VDE 0105, Section 1, must be observed

·

for all work carried out on the equipment.

Disconnect electrical components from the mains supply before work is carried

·

out on these components.

Caution: Danger to life through electrical shock!

Do not modify, add other equipment or change the design of the equipment

·

without the approval of the manufacturer.

Caution: Danger of accidents!

Compile detailed plant operating instructions based on the supplied operating

·

instructions for the sequence of procedures to be carried out on this equipment.

Improper operation results in danger of accidents!

SKW

Appoint an equipment foreman to be responsible for the equipment.

·

Ensure that the operating personnel are thorough training in the operation of the

·

equipment.

Improper operation results in danger of accidents!

When the main switch is switched off for reasons pertaining to safety, it must be

·

secured against unauthorized activation.

Caution: Danger of accidents!

Before starting maintenance work, appoint a supervisor.

·

Inform the responsible personnel before maintenance work on the system is

·

started.

Caution: Danger of accidents!

046-3MS

Sa fe ty in struc tions 10

Page 11

Disconnect the equipment from mains supply before starting maintenance

·

procedures to ensure that it cannot be switched on unintentionally.

Caution: Danger of accidents!

Repair work may be carried out by trained personnel only.

·

Caution: Danger of accidents!

Never operate the equipment when partially dismantled.

·

Caution! Limbs may be caught in machinery; danger of electrical shock!

In case of malfunction, shut down the equipment immediately. Have malfunctions

·

corrected immediately.

Caution: Danger of accidents!

The equipment is intended only for conveying granulated plastics and regrinds.

·

Other use of the equipment is contrary to its specifications.

SKW

This equipment is not suitable for food processing.

·

Please observe that sound levels exceeding 85 dB(A) may lead to health

·

problems after prolonged exposure. Use suitable ear protection.

This prevents ear damage!

Attachments not supplied by Sterling must be manufactured in accordance with

·

safety instruction EN 294.

Caution: Danger of accidents!

Check all pipes, hoses and screwed connections for leaks and damage on a

·

regular basis. Correct such damages immediately.

Caution: Danger of accidents!

Depressurize all compressed air piping before maintenance work.

·

Danger! Limbs may be caught in machinery!

046-3MS

Never operate the equipment without elbows.

·

Danger! Limbs may be caught in machinery!

Sa fe ty in struc tions 11

Page 12

The equipment may only be operated when all appertaining components are

·

connected properly and comply with applicable regulations.

The equipment may only be operated in conjunction with a conveyor unit.

·

Observe the safety instructions for connected equipment.

·

SKW

046-3MS

Sa fe ty in struc tions 12

Page 13

1.4. For the ope ra ting sa fe ty of the equip ment

Never change settings if the consequences are not precisely known.

·

Use only original Sterlingspare parts.

·

Observe the maintenance instructions.

·

Keep record of all maintenance and repair procedures.

·

Please note that electronic components may be damaged by static discharge.

·

Check all electrical connections for secure fit before the equipment is taken into

·

operation and at regular intervals.

SKW

Never adjust sensors without exact knowledge of their function.

·

Please note that the maximum ambient temperature must not exceed 45 °C

·

(113°F).

Align the suction tubes of the individual components equally.

·

Please note that the set conveying ratio determines the conveying time.

·

Please note that compressed air supply is required for the operation of the SKW.

·

Never set a higher operating pressure than 6 bar (87.02 PSI) for the SKW (system

·

overpressure).

Check whether the regrind is connected to the left-hand intake port (1) of the

·

SKW.

046-3MS

Install VA-steel pipe bends when conveying abrasive material (SKW 40,

·

SKW 50).

Sa fe ty in struc tions 13

Page 14

Please note that SKW 65 may not be used for conveying abrasive materials.

·

Please note that the SKW can only be used in conjunction with a conveyor unit.

·

Please observe the operating instructions of the connected conveyance control

·

system.

SKW

046-3MS

Sa fe ty in struc tions 14

Page 15

2. In stal la ti on in struc tions

These installation instructions are intended for persons

»

with skills in electrical and mechanical areas due to their

training, experience and received instructions.

Personnel using these installation instructions must be

instructed in the regulations for the prevention of

accidents, the operating conditions and safety regulations

and their implementation.

Ensure in each case that the personnel are informed.

The installation instructions provided in the corresponding

operating instructions apply for all connected equipment.

Observe safety regulations with regard to lifting gear

handling

SKW

All installation work must be carried out with the equipment

disconnected from electrical power and compressed air

supply.

L

046-3MS

For installation work taking place at heights of over

approx.1829mm (6 ft), use only ladders or similar

equipment and working platforms intended for this

purpose. At greater heights, the proper equipment for

protection against falling must be worn.

Use only suitable lifting gear which is in proper working

order and load suspension devices with sufficient carrying

capacity. Do not stand or work under suspended loads!

Use suitable workshop equipment.

In stal la ti on in struc tions 15

Page 16

F

SKW

Install the equipment such that all parts are easily

accessible; this facilitates maintenance and repair work.

046-3MS

In stal la ti on in struc tions 16

Page 17

SKW

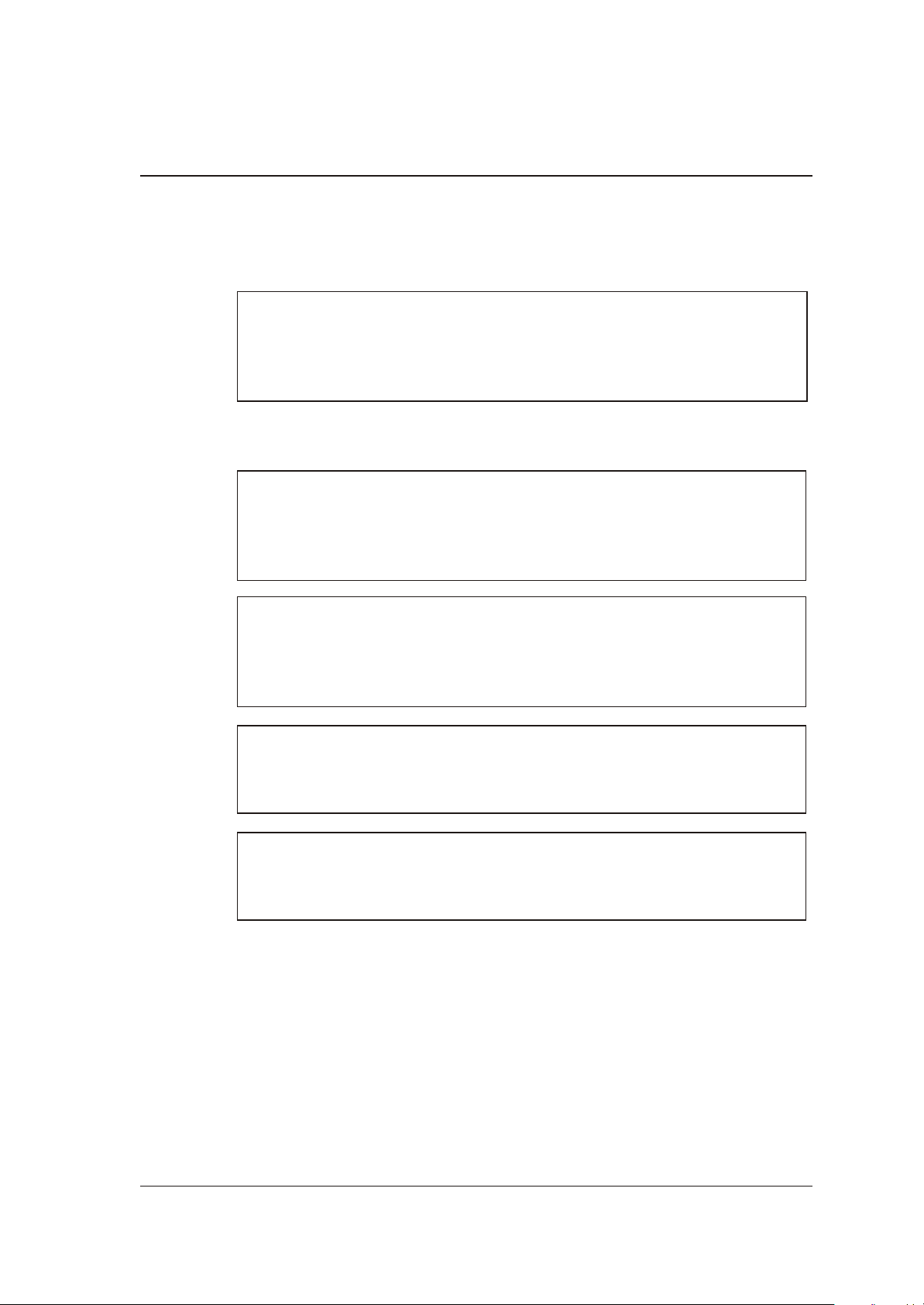

2.1. In stal la ti on

Installation is possible in any position. A mounting bracket is already attached.

The control unit must be accessible at any time

»

Install VA-steel pipe bends (SKW 40, SKW 50) when

conveying abrasive materials.

SKW 65 may not be used for conveying abrasive

materials.

Install the SKW in such manner that differences in conveying distances for the

two components are avoided.

Please note that the maximum ambient temperature near the SKW must not

exceed 45 °C (113°F).

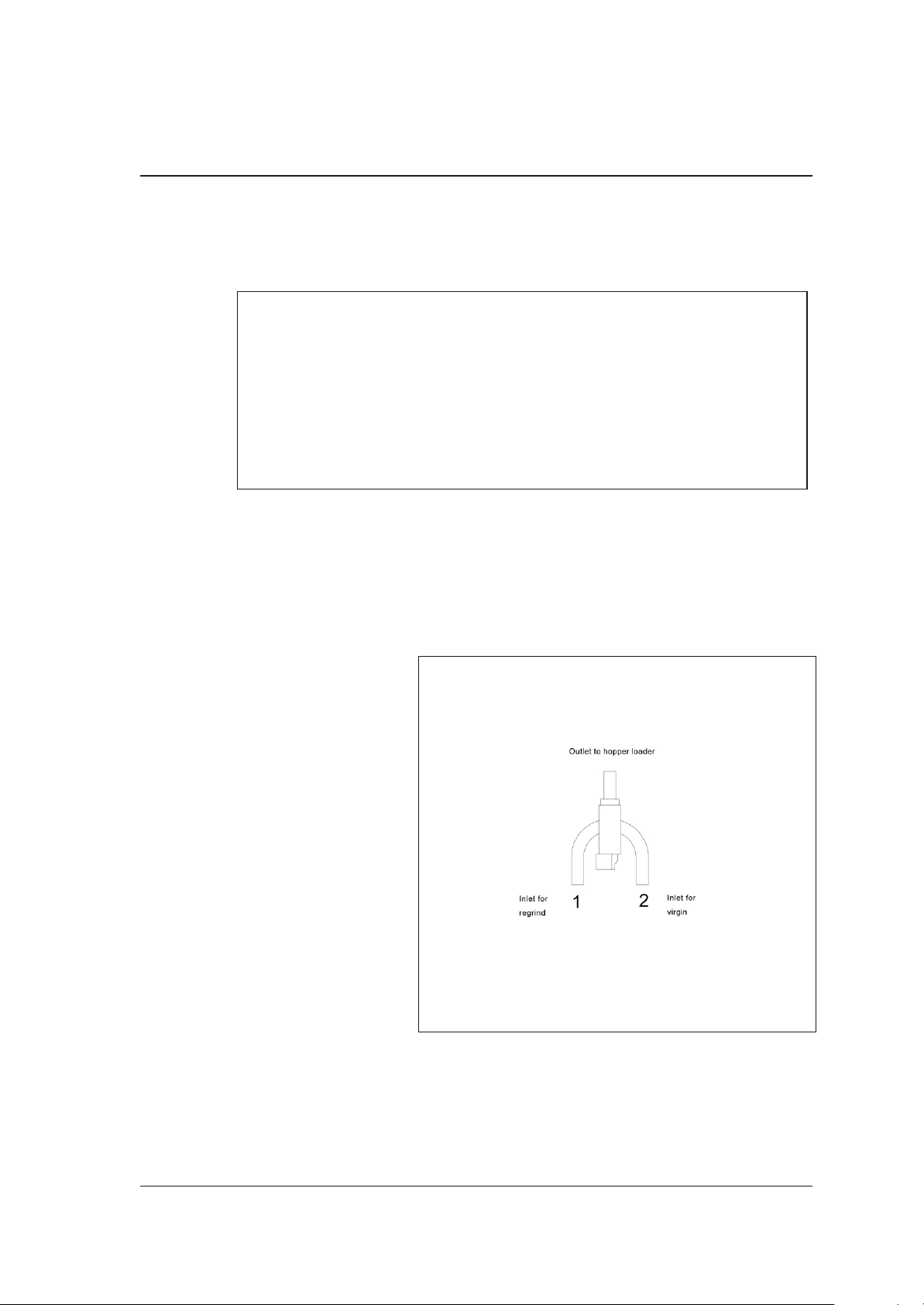

Remove the plugs from the

pipe bends.

Install the regrind line at intake

port 2 of the SKW.

Install the virgin material line

at intake port 1 of the SKW.

Install the feed line to the

hopper loader at the outlet port

of the SKW.

Align both suction pipes

equally in order to avoid

inaccurate percentage

preselection results.

Assembly SKW

046-3MS

In stal la ti on in struc tions 17

Page 18

2.2. Elec tri cal con nec ti on

2.2.1. Con nec ti on to a sing le con vey or unit CSE 2/CSE 5

Electrical connections are to be made by trained personnel

»

only.

Observe the regulations of your local Electricity Board.

All work is to be carried out with the equipment

disconnected from electric power and compressed air

supply.

SKW

The power consumption value of the SKW is approx. 15 Watts.

The operating voltage of the SKW is 100 V/60 Hz.

Special voltage on request.

Lay a cable (min. 3 x 1 mm2) from the single conveyor unit to the SKW.

Install the supplied plugs.

Install the plug of the SKW at the plug connector of the single conveyor control

unit.

Observe the operating instructions of the single conveyor unit.

046-3MS

In stal la ti on in struc tions 18

Page 19

2.2.2. Con nec ti on to a vac uum receiver unit SSK-05 1, 3, 5, & 30

Electrical connections are to be made by trained personnel

»

The power consumption value of the SKW is approx. 15 Watts.

The operating voltage of the SKW is 24 V.

only.

Observe the regulations of your local Electricity Board.

All work is to be carried out with the equipment

disconnected from electric power and compressed air

supply.

SKW

Lay a cable (min. 3 x 1 mm2) from the single conveyor unit to the SKW.

Install the supplied plugs.

Install the plug of the SKW at the plug connector of the single conveyor control

unit.

Observe the operating instructions of the vacuum receiver unit.

2.2.3. Con nec ti on to a con vey ing sys tem controller

The electrical connection to a conveying system controller

»

046-3MS

may only be made by skilled personnel authorized by

Sterling.

Other persons are not permitted to install electrical

connections.

In stal la ti on in struc tions 19

Page 20

2.3. Com pres sed air supp ly

For actuating the piston in the SKW

a compressed air supply

connection (1/4 inch) is required.

Check compressed air piping for

correct installation and assembly.

Check fittings, length and quality of

the hose connections for

agreement with requirements.

The operating pressure of the SKW

is 5-6 bar (72.52-87.02 PSI)

(system overpressure).

Check the compressed air supplied

by the plant’s supply network.

Adjust compressed air pressure to

5-6 bar(72.52-87.02 PSI) (system

overpressure).

SKW

Maintenance unit

Compressed air must be dewatered and oiled.

Install a maintenance unit (pressure reducer with water separator and oiler) if

required.

Connect the SKW to the plant’s supply network by means of a hose.

L

F

046-3MS

Depressurize compressed air supply lines which must be

opened.

Compressed air must be dewatered and oiled.

Adjust pressure to a max. value of 6 bar (87.02 PSI)

(system overpressure).

In stal la ti on in struc tions 20

Page 21

3. Functio nal des crip ti on

This functional description is intended for the operating

»

personnel of the equipment.

Prerequisite for this functional description is general

knowledge of conveyor systems operation.

Ensure in each case that the operating personnel are

sufficiently informed.

The SKW can only be operated in conjunction with a

conveyor unit.

F

SKW

046-3MS

Functio nal des crip ti on 21

Page 22

SKW

3.1. Ge ne ral in for ma ti on

The SKW has 2 elbows (virgin material intake port, regrind intake port) and an

outlet pipe socket leading to the conveyor unit.

With the SKW it is possible to convey two components to a hopper loader.

The SKW works in dependence on the conveying cycles of the conveyor unit. It is

only in operation when material is conveyed.

The SKW is available in 2 versions:

Version 1

·

Operation on SKW

SKW for connection to a single conveyor unit CSE 2/5;

Version 2

·

Operation on the conveying control

SKW for connection to a conveying control.

046-3MS

Functio nal des crip ti on 22

Page 23

SKW

3.2. Con trol

3.2.1. SKW Ver si on 1

The control unit is installed at the housing of the SKW.

The conveying ratio as well as the switching cycles are set by means of the keys

on the front side of the control system.

Per cen ta ge key Ar row key Dis play

SKW control system

046-3MS

Functio nal des crip ti on 23

Page 24

SKW

3.2.1.1. Con vey ing ra tio

The conveying ratio between component 1 (= regrind) and component 2 (= virgin

material) can be freely selected.

The control setting refers to the conveying time of component 1 (= regrind).

The conveying time of component 1 can be set from 0 to 99 % of total conveying

time.

Example

Proportioning valve setting: 22 %

Conveying ratio: 22 % component 1 and 78 % component 2

&

Conveying ratio relates to conveying time, not to the

amount of material conveyed.

046-3MS

Functio nal des crip ti on 24

Page 25

SKW

3.2.1.2. Swit ching cy cles

During each switching cycle, the SKW switches back and forth one time. The

pre-set conveying ratio is not affected by this. In order to prevent strong formation

of layers in the conveyed material, the number of switching cycles per conveying

procedure can be freely selected. Setting takes place by entry of one cycle

period. The cycle period can be set between 5 and 50 seconds. The setting is

carried out in five seconds.

The cycle period may not be longer than the conveying

time.

F

&

Example

Conveying time: 90 seconds, cycle period = 15 seconds

Calculation of switching cycles:

conveying time

cyc l e period

The shorter the cycle period, the higher the number of

switching cycles.

The higher the number of switching cycles, the less

significant is the zoning effect in the hopper loader.

s

switching cycles

Cycle period must always be high enough that both virgin

material and regrind are conveyed properly.

90

15

6 itching cycles

s

F

sw= =

046-3MS

Functio nal des crip ti on 25

Page 26

SKW

3.2.2. SKW Ver si on 2

On the SKW housing, a terminal box is installed (optional: terminal box with 3

light-emitting diodes = LEDs for limit position monitoring).

&

The conveying ratio and the switching cycles are entered into the control system

of the conveying control.

Observe the operating manual of the conveying control.

The two green LEDs indicate the limit positions of the

rotary piston. The red LED goes on in case of a

disturbance.

046-3MS

Functio nal des crip ti on 26

Page 27

4. Start-up

»

SKW

This chapter is intended for operating personnel.

Prerequisite for this chapter is general knowledge of the

operation of conveying units.

Also prerequisite for this chapter is that the functional

description has been read and understood.

Ensure in each case that the operating personnel are

sufficiently informed.

F

&

Check the compressed air supply (max. 6 bar system

overpressure). (87.02 PSI)

Check the connections of the conveying lines.

Check the suction pipe adjustment.

The SKW can only be operated in conjunction with a

conveying system.

046-3MS

Start-up 27

Page 28

4.1. Ad ju sting the con vey ing ra tio

Adjust the conveying ratio according to your specific requirements.

SKW Version 1

By means of the arrow key, set the percentage of

component 1 (= regrind).

Ex am ple

Desired conveying ratio: 40 % regrind and 60 % raw material.

Press the arrow key until “40" appears on the display.

When conveying poorly flowing components, set higher

values.

F

SKW

SKW Version 2

Set the percentage of component 1 (= regrind) by means of the control system of

the conveying control.

Observe the operating manual of the conveying control.

046-3MS

Start-up 28

Page 29

SKW

4.2. De ter mi ning the swit ching cy cle du ra ti on

Measure the conveying time of the respective hopper.

Take out the table.

Look for the value in the column “conveying time”.

Select a number of switching cycles.

Press the percentage key.

By means of the arrow key, select the desired switching cycle.

Carry through one conveying procedure.

If you are not satisfied with the result, check the setting and correct, if necessary.

No thick layers may form in the hopper loader.

F

Ex am ple

Conveying time: 50 s

Conveying ratio: 40 % regrind, 60 % virgin material

Setting options for a conveying time of 50 s:

Con vey ing

time

(se conds)

50

Num ber of swit ching cy cles at cy cle pe ri od (se conds)

50 45 40 35 30 25 20 15 10 5

1 1,1 1,3 1,4 1,7 2 2,5 3,3 5 10

046-3MS

a.) Setting 50 seconds = 1 switching cycle per conveying procedure

Start-up 29

Page 30

SKW

The SKW switches twice; it conveys

regrind for 20 seconds and virgin

material for 30 seconds.

Sig ni fi cant zo ning.

b.) Setting 10 = 5 switching cycles per

conveying procedure

The SKW switches ten times; it

conveys regrind for 4 seconds and

virgin material for 6 seconds.

In sig ni fi cant zo ning.

046-3MS

Start-up 30

Page 31

c.) Setting 5 = 10 switching cycles per conveying cycle

The SKW switches 20 times; it

conveys regrind for 2 seconds

and virgin material for 3 seconds.

This process is repeated 10

times.

No cor rect con vey an ce pos si ble.

With a conveying time of 2 to 3

seconds the material cannot be

conveyed properly.

SKW

046-3MS

Start-up 31

Page 32

4.3. Set ting the swit ching cy cles

SKW Ver si on 1

Press the percentage key.

By means of the arrow key, set the determined switching cycle.

Check the result.

If the result is not satisfactory, correct the setting.

SKW

&

SKW Version 2

Set the determined value by means of the control system of the conveying

control.

Observe the operating manual of the conveying control.

Check the result.

If the result is not satisfactory, correct the setting.

If there are too many switching cycles, proper conveying is

not possible.

046-3MS

Start-up 32

Page 33

5. Main ten an ce

This chapter is intended for persons with skills in electrical

»

and mechanical areas due to their training, experience and

received instructions.

Personnel using the instructions in this chapter must be

instructed of the regulations for the prevention of

accidents, the operating conditions and safety regulations

and their implementation.

SKW

Ensure in each case that the personnel are informed

accordingly.

For maintenance work taking place at heights of over

approx.1829 mm (6 ft), use only ladders or similar

equipment and working platforms intended for this

purpose. At greater heights, the proper equipment for

protection against falling must be worn.

Use only suitable lifting gear which is in proper working

order and load suspension devices with sufficient carrying

capacity. Do not stand or work under suspended loads!

Ensure that the electric motors/switch cabinets are

sufficiently protected against moisture.

Use only suitable workshop equipment.

Before starting maintenance work, appoint a supervisor.

Inform the responsible personnel before maintenance work

046-3MS

on the system is started.

Main ten an ce 33

Page 34

Never operate the equipment when partially dismantled.

All maintenance and repair work not described in this

chapter may only be carried out by Sterlingservice

personnel or authorized personnel (appointed by Sterling).

SKW

L

F

Disconnect the equipment from mains supply before

starting maintenance procedures to ensure that it cannot

be switched on unintentionally.

Depressurize all compressed air piping of the equipment

before starting maintenance work.

Please observe the maintenance intervals.

Before starting maintenance work, clean the equipment of

oil, fuel or lubricants.

Ensure that materials and incidentals required for

operation as well as spare parts are disposed of properly

and in an environmentally sound manner.

Use only original Sterling spare parts.

Keep record of all maintenance and repair procedures.

046-3MS

Main ten an ce 34

Page 35

SKW

5.1. Main ten an ce in ter vals

Dai ly: Check war ning signs on equip ment for good

le gi bi li ty and com ple te ness.

Check the oil le vel in the oi ler.

Emp ty the wa ter se pa ra tor.

Check ope ra ting pres su re of the plant’s supp ly

net work (5-6 bar (72.52-87.02 PSI) sys tem over

pres sure).

Every three months: Check the SKW for smooth ope ra ti on.

Every six months: Check all elec tri cal and me cha ni cal con nec tions

for se cu re fit.

F

In case of soiled material and material with a high dust

content equipment should be checked monthly for smooth

operation.

046-3MS

Main ten an ce 35

Page 36

5.2. Chec king for smooth ope ra ti on

Disconnect the equipment from mains power supply to

»

Unscrew the plug at the solenoid valve.

Remove the hose from the hopper loader

outlet port.

ensure that it cannot be switched on unintentionally.

In order to check for smooth operation compressed air

supply to the SKW must be maintained.

Danger! Limbs may be caught in machinery!

SKW

Move the manual actuator of the solenoid

valve from position B to position A and

back

Observe the piston through the pipe

socket at the “hopper loader outlet port”.

The piston must move back and forth

quickly.

Put the hose at the hopper loader outlet

port back in place.

Screw the plug to the solenoid valve.

046-3MS

6. Tech ni cal data

Tech ni cal data 36

Page 37

SKW

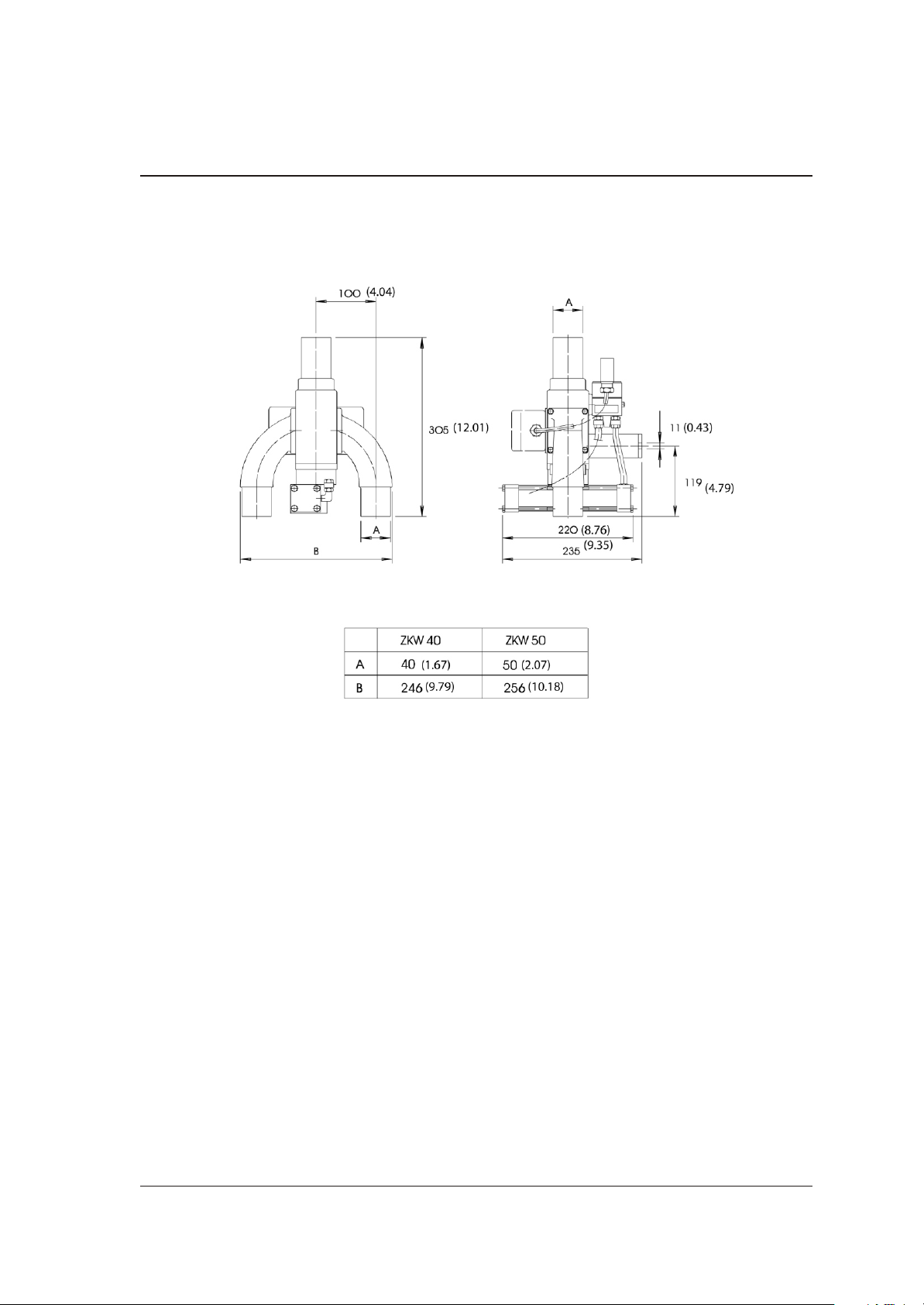

Ver sions: SKW 40

SKW 50

SKW 65

SKW 40

Height: 305 mm (12.01 in.)

Width: 246 mm (10.79 in.)

Depth: 235 mm (9.35 in.)

Weight: 7.5 kg (16.53 lbs.)

Com pres sed air supp ly: 5-6 bar (72.52-87.02 PSI) sys tem over pres su re

Pi ping sys tem: Æ 40 mm (1.67 in.)

SKW 50

Height: 305 mm (12.01 in.)

Width: 256 mm (10.18 in.)

Depth: 235 mm (9.35 in.)

Weight: 7.5 kg (16.53 lbs.)

Com pres sed air supp ly: 5-6 bar (72.52-87.02 PSI) sys tem over pres su re

Pi ping sys tem: Æ 50 mm ((2.07 in.)

SKW 65

Height: 340 mm (13.49 in.)

Width: 290 mm (11.42 in.)

Depth: 245 mm (10.7 in.)

Weight: 12.5 kg (27.66 lbs.)

Com pres sed air supp ly: 5-6 bar (72.52-87.02 PSI) sys tem over pres su re

Pi ping sys tem: Æ 65 mm (0.36 in.)

046-3MS

Tech ni cal data 37

Page 38

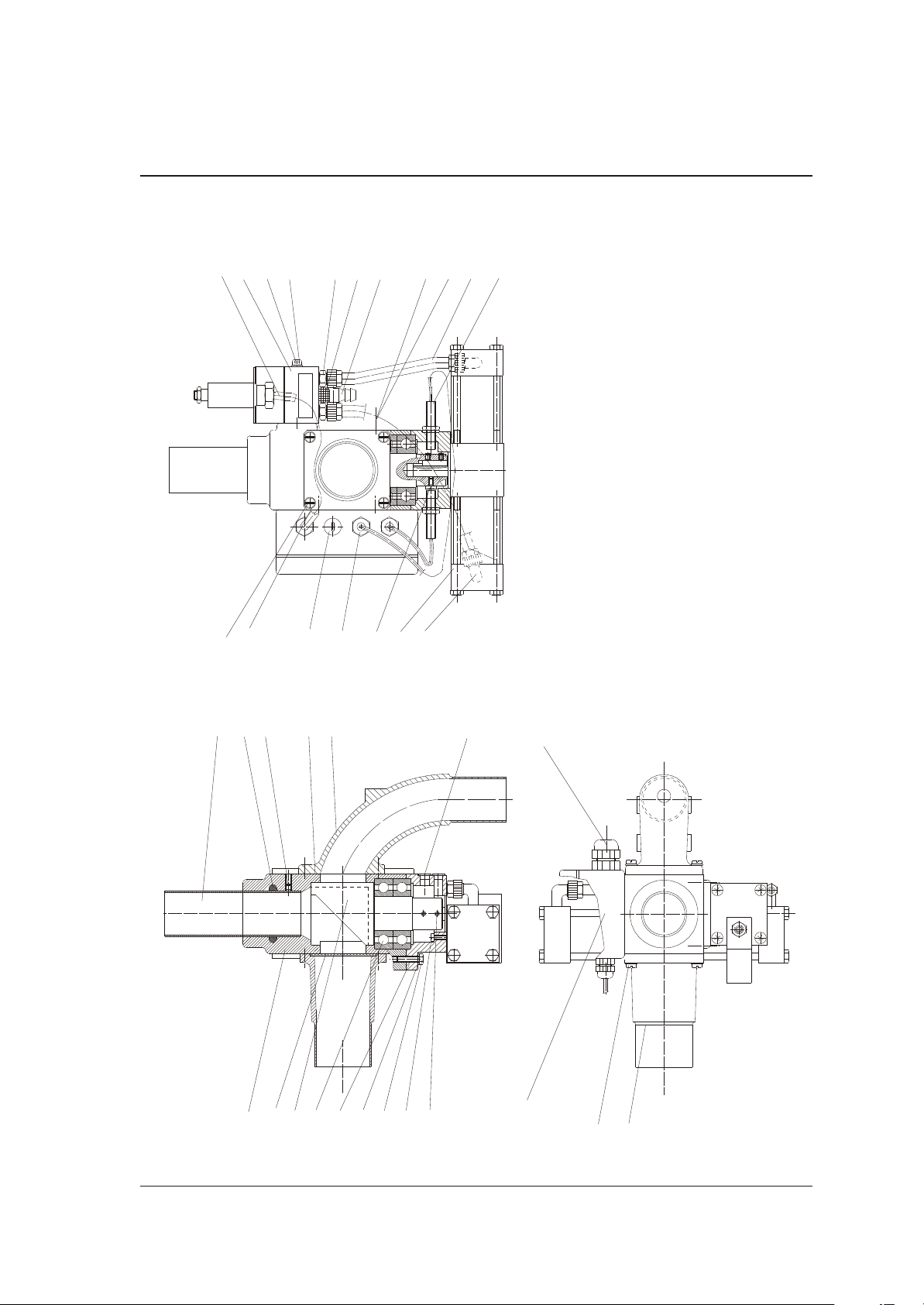

6.1. Di men si on sheet SKW 40/50

SKW

All di men sions in mm. (in.) Spec i fi ca tions may be sub ject to al te ra ti on.

6.2. Di men sion sheet SKW 65

(On next page)

046-3MS

Tech ni cal data 38

Page 39

SKW

All di men sions in mm (in.). Spec i fi ca tions may be sub ject to al te ra ti on.

046-3MS

Tech ni cal data 39

Page 40

7. Ap pen dix

SKW

046-3MS

Ap pen dix 40

Page 41

7.1. Spa re parts list

This spare parts list is intended to be used only by trained

»

personnel.

Other persons are not permitted to modify or repair the

equipment.

SKW

046-3MS

Ap pen dix 41

Page 42

SKW 40 (03596)

5 - 6 bar

1

2

3

4

7

8

6

13

19

21

5

23

24

252212

26

27

28

9

11

10

14

18,31,32

15

16

20

5

6

33

17

SKW

046-3MS

Ap pen dix 42

Page 43

03596

Pos. Or der no. De sig na ti on

0001 03546 Hou sing

0002 03576 Pis ton

0003 96366 Deep groo ve ball bea ring

0004 03575 Bea ring lid

0005 95944 Spring lock was her

0006 95842 Screw

0007 96043 Screw

0008 95840 Threa ded pin

0009 97706 Pipe so cket

0010 96384 Sea ling ring

0011 95839 Threa ded pin

0012 98167 Hose nozzle

SKW

0014 03573 Bend

0015 27603 Sup port

0016 95841 Screw

0018 96045 Screw

0019 96373 Ro ta ry dri ve

0020 98753 Coup ling pie ce

0021 96372 So le noid val ve

0022 95985 Screw

0023 98752 Coup ling pie ce

0024 98742 Si len cer

0025 03604 Bow

0026 95844 Screw

0027 95956 Disc

0028 98750 Hose

0029 95556 Screw

0031 95948 Disc

046-3MS

0032 93882 Nut

0033 15475 Sea ling

Ap pen dix 43

Page 44

SKW

5 - 6 bar

1

2

3

4

7

8

6

13

18,31,32

15

16

19

17

21

5

23

24

252212

26

27

28

9

10

11

14

5

6

20

50

SKW 50 (03597)

046-3MS

Ap pen dix 44

Page 45

03597

Pos. Or der no. De sig na ti on

0001 03547 Hou sing

0002 03576 Pis ton

0003 96366 Deep groo ve ball bea ring

0004 03575 Bea ring lid

0005 95842 Screw

0007 96043 Screw

0008 95840 Threa ded pin

0009 97704 Pipe so cket

0010 96383 Sea ling ring

0011 95839 Threa ded pin

0012 98167 Hose nozzle

0013 95955 Disc

SKW

0014 03574 Bend

0015 27603 Sup port

0016 95841 Screw

0018 96045 Screw

0019 96373 Ro ta ry dri ve

0020 98753 Coup ling pie ce

0021 96372 So le noid val ve

0022 95985 Screw

0023 98752 Coup ling pie ce

0024 98742 Si len cer

0025 03604 Bow

0026 95844 Screw

0027 95956 Disc

0028 98750 Hose

0031 95948 Disc

0032 93882 Nut

046-3MS

0033 15476 Sea ling

Ap pen dix 45

Page 46

SKW 65 (12446)

5 - 6 bar

1

2

3

4

8

9

14

6

13

19

20

21

5

23

24

25

22

12

26

27

28

15

16

5

6

18,31,32

7

50

51

17

SKW

046-3MS

Ap pen dix 46

Page 47

12446

Pos. Or der no. De sig na ti on

0001 12416 Hou sing

0002 12418 Pis ton

0003 92226 Deep groo ve ball bea ring

0004 12417 Bea ring lid

0005 95944 Spring lock was her

0006 95842 Screw

0007 96043 Screw

0008 95840 Threa ded pin

0009 17208 Pipe so cket

0012 98167 Hose nozzle

0013 95955 Disc

0014 12414 Bend

SKW

0015 27603 Sup port

0016 95841 Screw

0017 99931 Ca ble

0018 96045 Screw

0019 96373 Ro ta ry dri ve

0020 98753 Coup ling pie ce

0021 96372 So le noid val ve

0022 95985 Screw

0023 98752 Coup ling pie ce

0024 98742 Si len cer

0025 03604 Bow

0026 95844 Screw

0027 95956 Disc

0028 98750 Hose

0031 95948 Disc

0032 93882 Nut

046-3MS

0050 15477 Sea ling

0051 88141 Sea ling

Ap pen dix 47

Page 48

SKW

5 - 6 bar

6

13

19

20

17

21

5

23

242212

26

27

28

1

2

3

4

5

6

7

8

9

11

10

14

29

35

36

37

39

38,40

42

41

33

34

50

CLV 40 (10102)

046-3MS

Ap pen dix 48

Page 49

10102

Pos. Or der no. De sig na ti on

0001 03546 Hou sing

0002 09518 Pis ton with fi nal switch po si ti on check

0003 96366 Deep groo ve ball bea ring

0004 09519 Bea ring lid with fi nal switch po si ti on check

0005 95944 Spring lock was her

0006 95842 Screw

0007 96043 Screw

0008 95840 Threa ded pin

0009 97706 Pipe so cket

0010 96384 Sea ling ring

0011 95839 Threa ded pin

0012 98167 Hose nozzle

SKW

0013 95957 Disc

0014 03573 Bend

0017 99931 Ca ble

0019 96373 Ro ta ry dri ve

0020 98753 Coup ling pie ce

0021 96372 So le noid val ve

0022 95985 Screw

0023 98752 Coup ling pie ce

0024 98742 Si len cer

0026 95844 Screw

0027 95956 Disc

0028 98750 Hose

0029 96038 Screw

0033 97763 Co ni cal caps

0034 92477 3-wire -in itia tor with LED

0035 88071 Screw

046-3MS

0036 11503 Nozzle

0037 93228 Sie ve

Ap pen dix 49

Page 50

0038 11122 Hou sing

0039 99944 Coup ling pie ce

0040 92470 SKW-MLV con trol card

0041 98609 Coup ling pie ce

0042 93075 Welsh plug

0050 15475 Sea ling

0051 85982 Dis tan ce bolt

0052 95946 Spring lock was her

0053 95970 Nut

SKW

046-3MS

Ap pen dix 50

Page 51

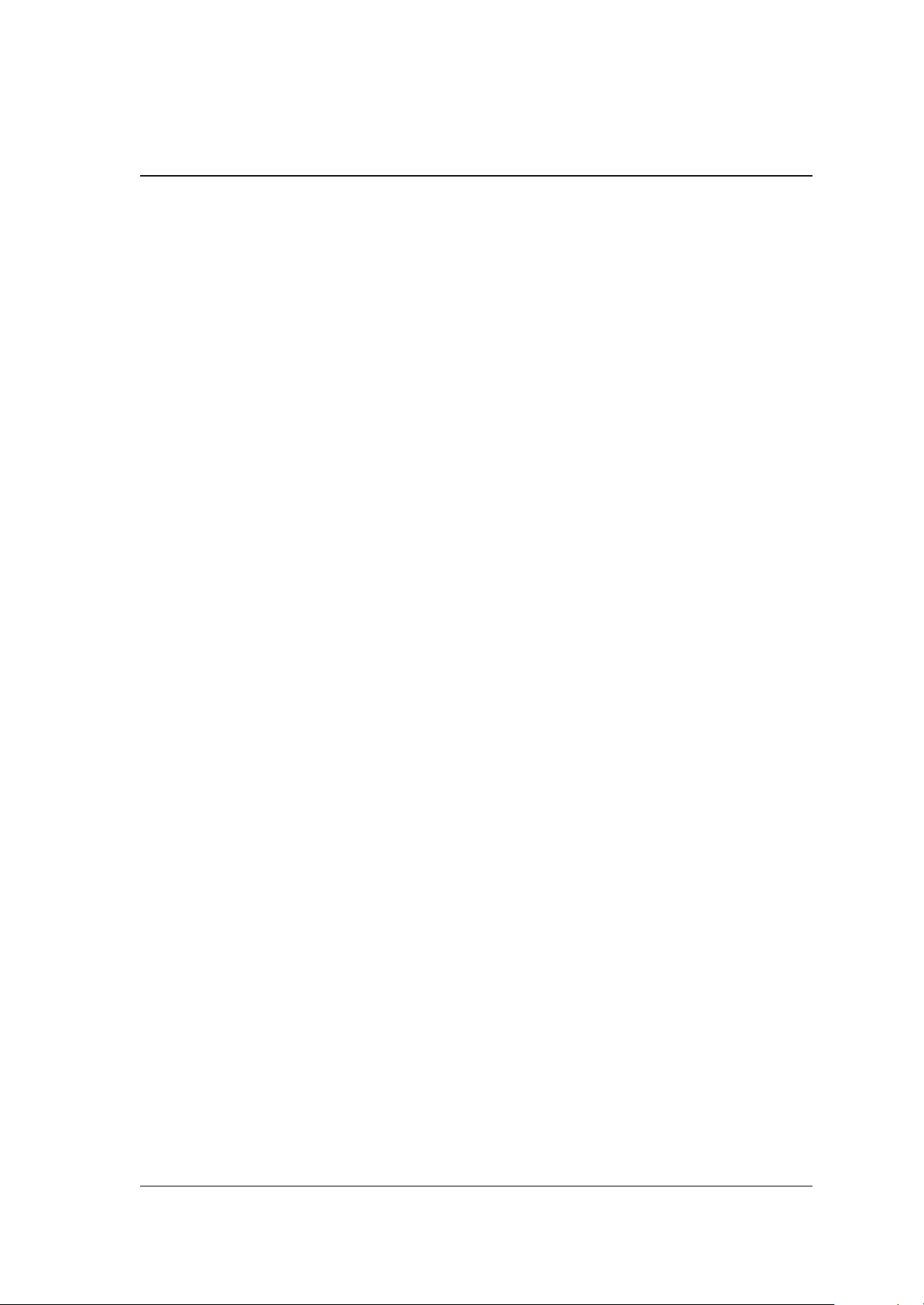

Con nec ti on dia gram

SKW

046-3MS

Ap pen dix 51

Page 52

Con vey ing

time

Num ber of swit ching cy cles at cy cle pe ri od (se conds)

(se conds)

5

10

15

20

25

30

35

40

45

50

55

60

65

50 45 40 35 30 25 20 15 10 5

* * * * * * * * * 1

* * * * * * * * 1 2

* * * * * * * 1 1,5 3

* * * * * * 1 1,3 2 4

* * * * * 1 1,3 1,7 2,5 5

* * * * 1 1,2 1,5 2 3 6

* * * 1 1,2 1,4 1,8 2,3 3,5 7

* * 1 1,1 1,3 1,6 2 2,7 4 8

* 1 1,1 1,3 1,5 1,8 2,3 3 4,5 9

1 1,1 1,3 1,4 1,7 2 2,5 3,3 5 10

1,1 1,2 1,4 1,6 1,8 2,2 2,8 3,7 5,5 11

1,2 1,3 1,5 1,7 2 2,4 3 4 6 12

1,3 1,4 1,6 1,9 2,2 2,6 3,3 4,3 6,5 13

70

75

80

85

90

95

100

105

110

115

120

* = Setting not permitted

1,4 1,5 1,8 2 2,3 2,8 3,5 4,7 7 14

1,5 1,7 1,9 2,1 2,5 3 3,8 5 7,5 15

1,6 1,8 2 2,3 2,7 3,2 4 5,3 8 16

1,7 1,9 2,1 2,4 2,8 3,4 4,3 5,7 8,5 17

1,8 2 2,3 2,6 3 3,6 4,5 6 9 18

1,9 2,1 2,4 2,7 3,2 3,8 4,8 6,3 9,5 19

2 2,2 2,5 2,9 3,3 4 5 6,7 10 20

2,1 2,3 2,6 3 3,5 4,2 5,3 7 10,5 21

2,2 2,4 2,8 3,1 3,7 4,4 5,5 7,3 11 22

2,3 2,6 2,9 3,3 3,8 4,6 5,8 7,7 11,5 23

2,4 2,7 3 3,4 4 4,8 6 8 12 24

Loading...

Loading...