Page 1

TV-AN2010

NH

SERVICE MANUAL

COLOR TELEVISION

This Service Manual is the "Revision Publishing" and replaces "Simple Manual"

(S/M Code No. 09-003-340-3T1).

S/M Code No. 09-003-340-3R1

REVISION

DATA

Page 2

NOTICES BEFORE REPAIRING

To make the best use of this equipment, make sure to

obey the following items when repairing (or mending).

1. Do not damage or melt the tunicate of the leading

wire on the AC1 side, including the power supply

cord.

2. Do not soil or stain the letters on the spec.

inscription plates, notice labels, fuse labels, etc.

3. When repairing the part extracted from the

conducted side of the board pattern, fix it firmly

with applying bond to the pattern and the part.

4. Restore the following items after repairing.

1) Conditions of soldering of the wires (especially,

the distance on the AC1 side).

2) Conditions of wiring, bundling of wires, etc.

3) Types of the wries.

4) Attachment conditions of all types of the insulation.

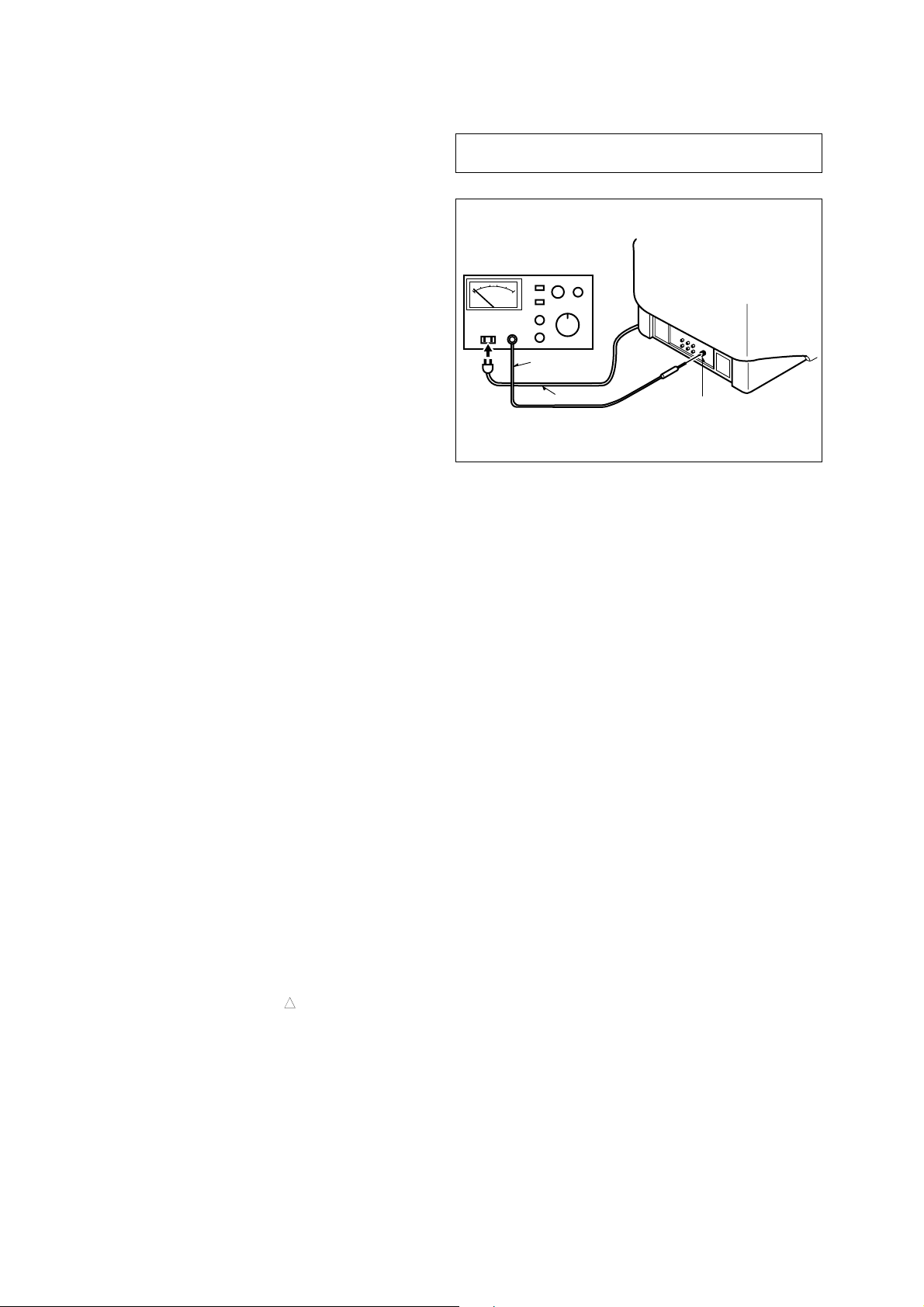

5. After repairing, always measure the insulation

resistance and perform the voltage-withstand test

(See Fig-1).

1) The insulation resistance must be 7.0 to 9.5 MΩ

when applying 500V per second.

2) In the voltage withstand test, apply 1.0 kV for 1

minute and check that the GO lamp lights.

Insulation resistance: 7.0 to 9.5 MΩ (500 V/s)

Voltage-withstand: 1.0 kV for 1 minute.

Safety checker (Model7110,etc.)

Earth cable

AC cable

Connect the earth cable

to the outside metal part

terminal.

Fig-1

* Breaking current set to 10 mA.

* Connect the safety checker as shown in Fig-1,

then measure the resistance and perform the test.

* Do not touch the equipment during testing.

* For details of the safety checker, refer to the supplied

Operation manual.

When servicing and checking on the TV, note the followings.

1. Keep the notices.

As for the places which need special attentions, they

are indicated with labels or seals on the cabinet,

chassis and parts. Make sure to keep the indications

and notices in the operation manual.

2. Avoid an electric shock.

There is a high voltage part inside. Avoid an electric

shock while the electric current is flowing.

3. Use the designated parts.

The parts in this equipment have the specific

characteristics of incombustibility and withstand voltage

for safety.

Therefore, use a part which has the same character

as the replaced part. Especially as to the important

parts for safety which is indicated in the circuit

diagram or the table of parts with a mark, the

designated parts must be used.

4. Put parts and wires in the original position after

assembling or wiring.

There are parts which use the insulation material such

as a tube or tape for safety, or which are assembled so

that these parts do not make contact with the printed

!

board. The inside wiring is designed not to get close to

the pyrogenic parts and high voltage parts. Therefore,

put these parts in the original positions.

5. Take care of the cathode-ray tube.

By setting an explosion-proof cathode-ray tube in this

equipment, safety is secured against implosion.

However, when removing it or servicing from the

back, it gives out shock that is dangerous. Take

enough care to deal with it.

6. Avoid an X-ray.

Safety is secured against an X-ray by giving

considerations to the cathode-ray tube and the high

voltage peripheral circuit, etc. Therefore, when

repairing the high voltage peripheral circuit, use the

designated parts and do not change the circuit.

Repairing, except indicates, causes rising of high

voltage, and the cathode-ray tube emits an X-ray.

7. Perform a safety check after servicing.

Confirm that the screws, parts and wiring which were

removed in order to service are put in the original

positions, or whether there are deteriorated portions

around the places serviced.

2

Page 3

SPECIFICATIONS

Tuner System Frequency synthesized tuner

TV System NTSC-M

Channel Coverage VHF: 2 to 13

Program Memory 181

Antenna Input 75 ohms, unbalanced

Picture Tube 20’’

Screen Size 404 (W) x 303 (H) mm (16 x 12 in.)

Video Input 1 Vp-p 75 ohms

Audio Input 0.5 Vrms., 33 k ohms more

Speaker 120 x 60 mm (43/4 x 2 3/8 in.)

Operating Voltage 110 - 240 V, 50/60 Hz

Power Consumption 105 W

Phone Jack Stereo-mini jack

Operating Temperature 5°C - 40°C

Operation Humidity 35% - 80%

Dimensions 610 (W) x 440 (H) x 483 (D) mm

Weight 19.5 kg (42.9 lbs.)

• Design and specifications are subject to change without notice.

UHF: 14 to 69

CATV: 5A, A-1 to A-5, A to W, W+1 to W+84

480 mm (Visible diagonal) (19 in.)

1

(24

/8 x 173/8 x 191/8 in.)

ACCESSORIES LIST

REF. NO PART NO. KANRI DESCRIPTION

1 8Z-JAK-901-010 IB,NH (E) -AN2110/ 2010/1410

2 8Z-JAE-951-010 RC UNIT,RC-ZVT18

3 87-A90-702-010 ANT ASSY,TV 5 SEC (NTSC)

! 4 87-A91-015-010 PLUG,CONVERSION JT-0475A

NO.

3

Page 4

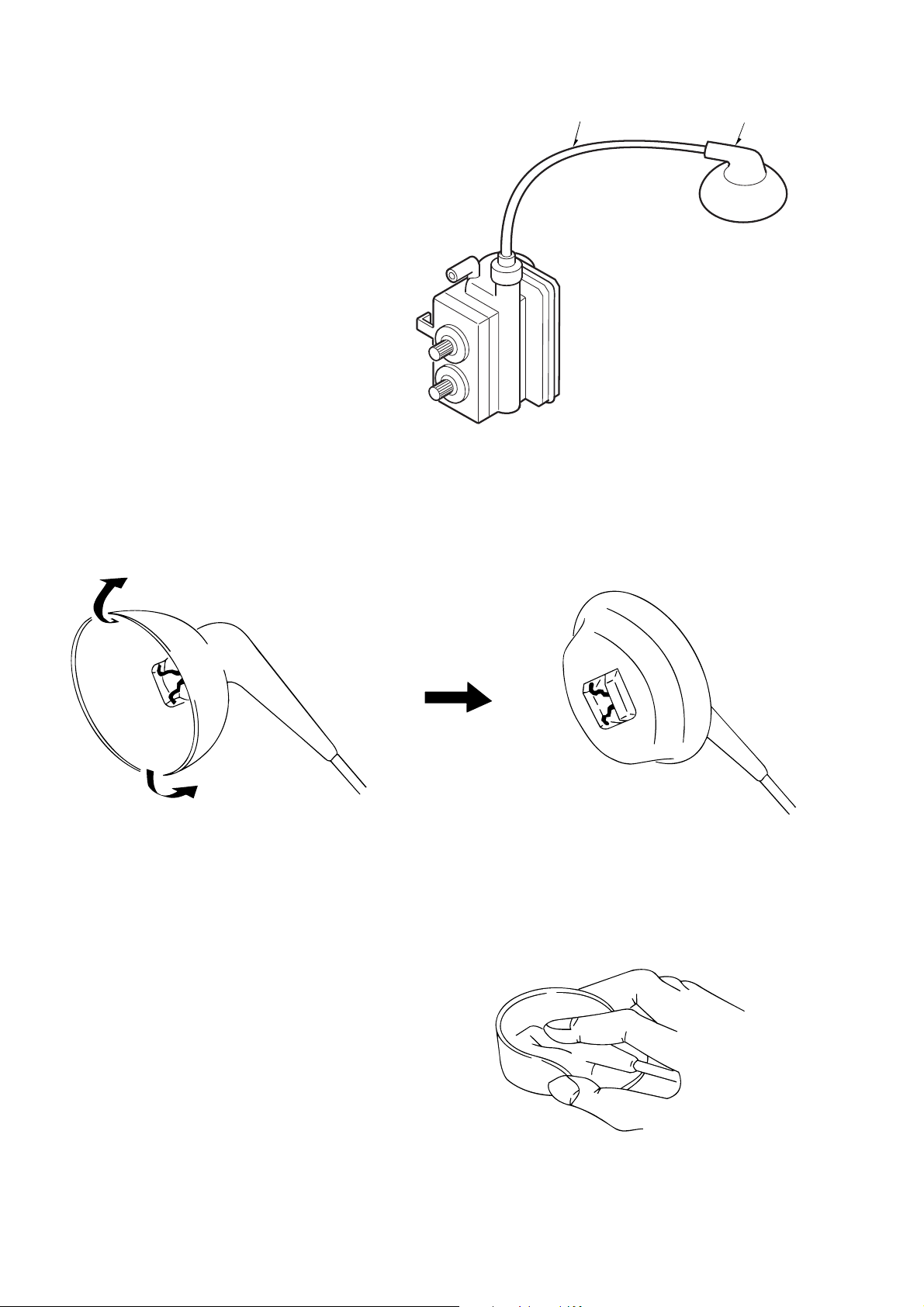

Anode cap

CRT GND

Hook

CRT

CRT GND

Grip

DISASSEMBLY INSTRUCTIONS

Front cabinet

Rear cabinet

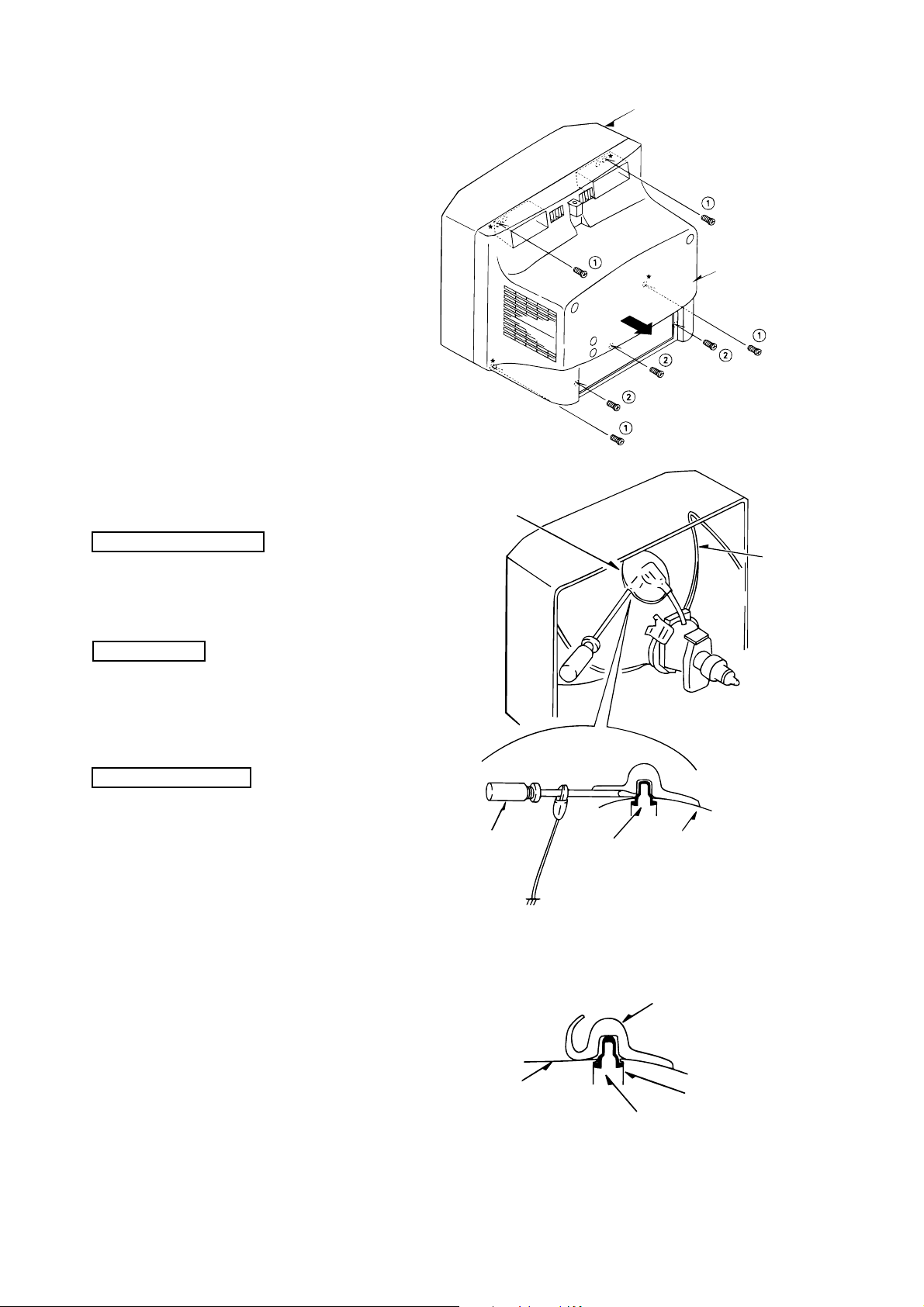

1. REAR CABINET REMOVAL

(1) Remove four screws 1 and three screws 2, then remove

the rear cabinet in the direction of the arrow. (See Figure1-

1)

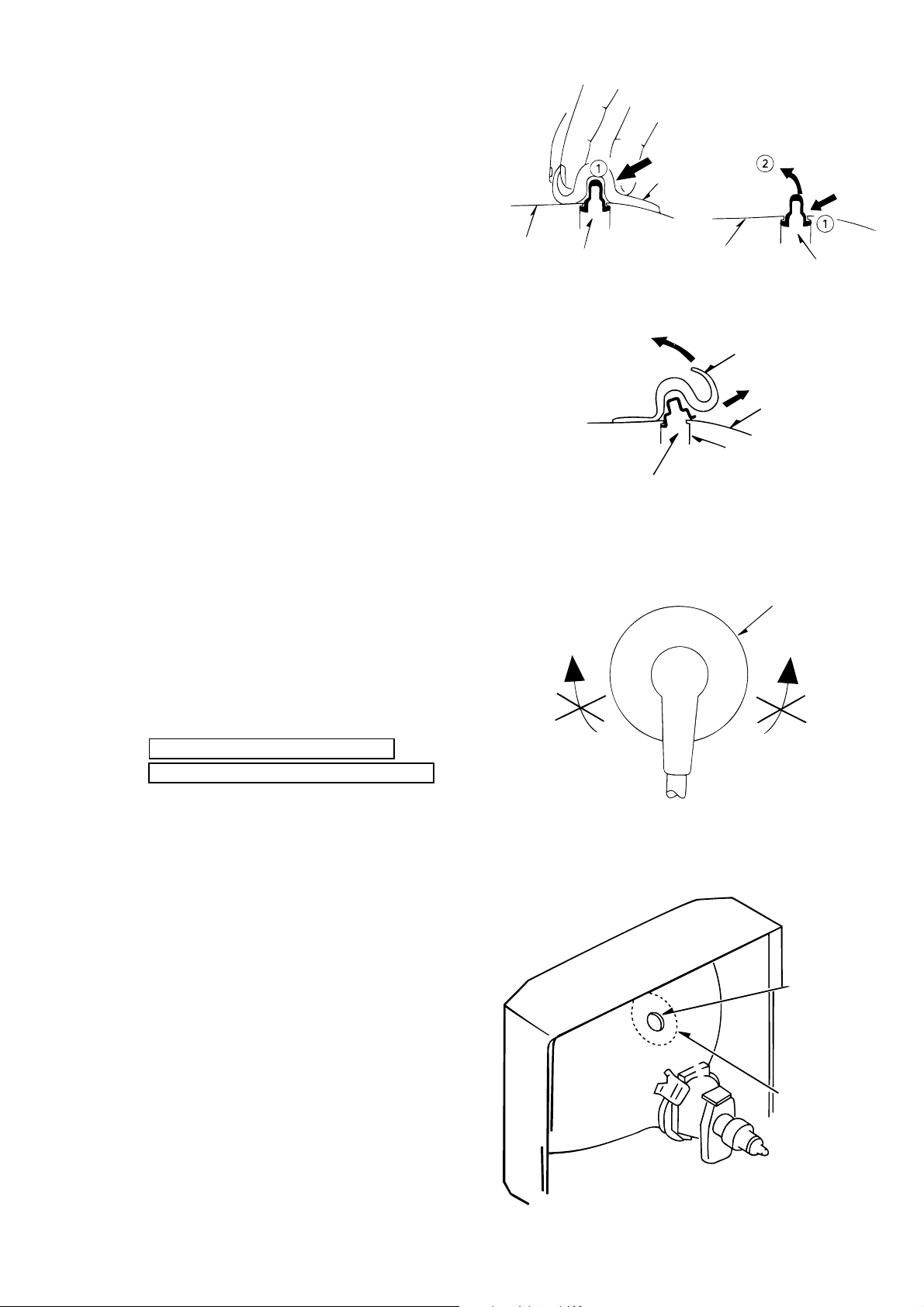

2. HIGH-VOLTAGE CAP (ANODE CAP) REMOVAL

Figure 1-1

2-1. Cautions before Removing

Discharge the anode voltage

(1) The anode voltage is not discharged completely from the

CRT of this unit even after the power is turned off. Be

sure to discharge the residual anode voltage before

removing the anode cap.

Do not use pliers

(2) Do not use pliers, etc. to remove the anode cap. If you

used pliers and bent the hook to remove the cap, the spring

characteristics of the hook could be lost, and when

reinstalled, the cap would come off from the CRT anode

button easily, causing an accident.

Do not turn the anode cap

(3) If the anode cap is turned in the direction of its

circumference, the hook is likely to come off.

2-2. Anode Cap Removal

Discharge the anode voltage. (See Figure 2-1)

(1) Connect a flat-bladed screwdriver to the CRT GND via

an alligator clip.

(2) Use a tester to check the end of the screwdriver and ground

of the TV for continuity.

(3) Touch the hook with the end of the screwdriver.

Caution : Be careful not to damage the anode cap.

(4) Turn over the anode cap.

Caution : Be careful not to damage the anode cap.

CRT

Figure 2-1

Anode cap

Anode button

Hook

Figure 2-2

4

Page 5

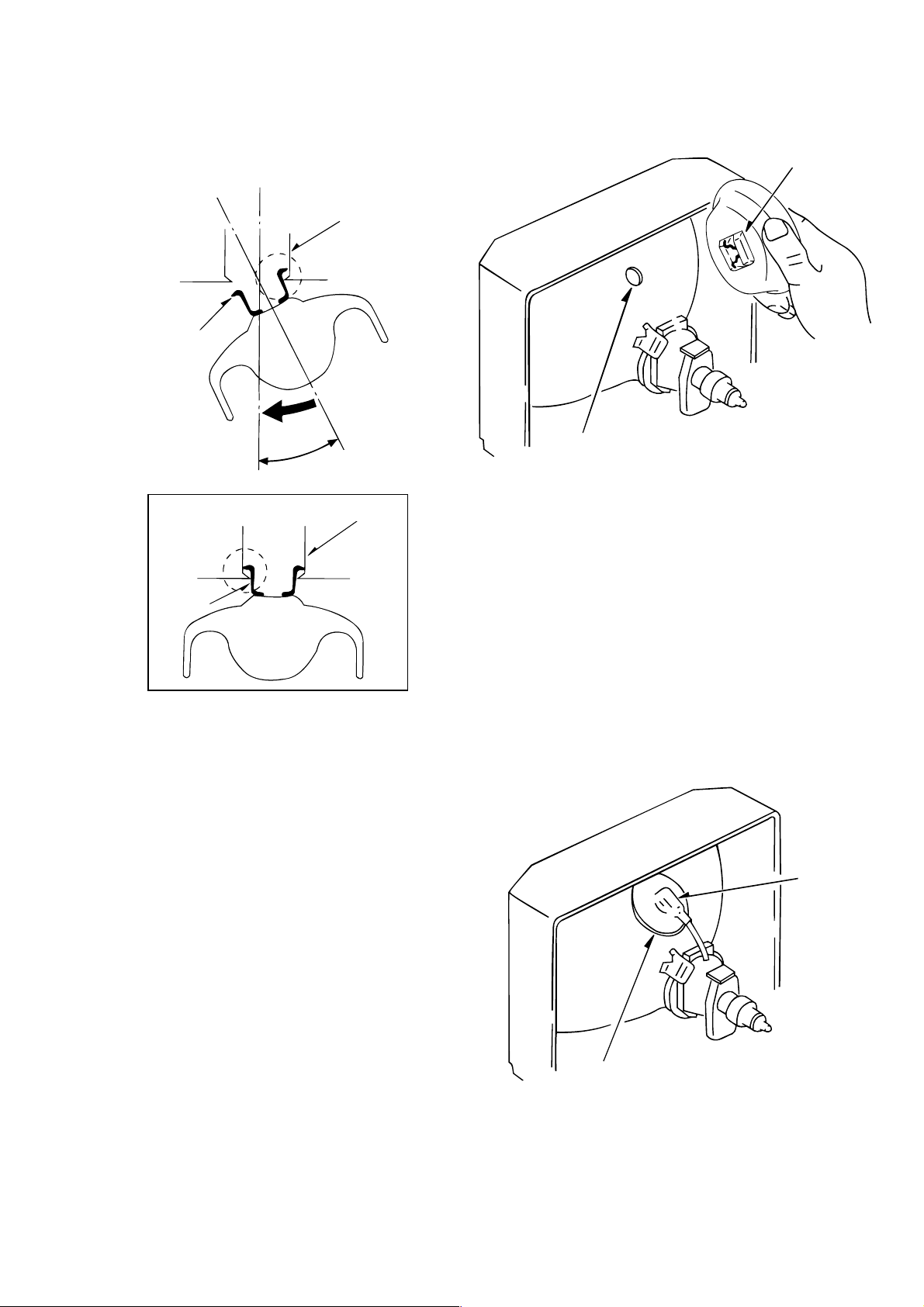

(5) Push the anode cap with your thumb in the direction of

CRT

CRT

Anode cap

Hook

Hook

Anode cap

Hook

Anode button

CRT

Left

Right

Anode cap

Anode button

Installation

section

arrow 1 as shown in the figure, then lift the cap in the

direction of arrow 2 to release the hook on one side. (See

Figure 2-3)

(6) Turn over the anode cap on the side where the hook was

released and pull out the cap in the direction opposite to

that on which the cap was pushed. (See Figure 2-4)

Caution : Do not pull out the anode cap straight up.

: Do not pull the cap forcibly. After removing

the cap, check that the hook is not deformed.

Figure 2-3

Figure 2-4

3. ANODE CAP REINSTALLTION

Observe the cautions carefully so that no accident occurs

due to a defect in installing the anode cap and so it does

not come off.

3-1. Caution before Reinstalling

Never turn the anode cap after installing it

Never re-use the hook when it has been deformed

(1) If the anode cap is turned after it is installed, it may come

off. Therefore, arrange the high-voltage cable before

attaching the anode cap. (See Figure 3-1)

(2) If you have attached the anode cap before arranging the

high-voltage cable, arrange the cable carefully so the cap

does not turn.

3-2. Anode cap reinstallation

(1) Use a clean cloth moistened slightly with alcohol to clean

the installation section. (See Figure 3-2)

Caution : Check that the installation section is free from

dust, foreign matter, etc.

(2) Coat the anode cap installation circumference with an

appropriate amount of the specified silicone grease (KS650N).

Caution : Be careful that silicone grease does not enter

the anode button.

Figure 3-1

Figure 3-2

5

Page 6

(3) Eliminate twisting, etc. of the high-voltage cable and

arrange it so that no twisting occurs. (See Figure 3-3)

Caution : If the cable is not arranged correctly, the anode

cap could turn and cause an installation defect.

(4) Turn over the rubber cap symmetrically on the left and

right. (See Figure 3-4)

Caution : Take great care not to damage the anode cap.

High-voltage cable

Anode cap

Figure 3-3

(5) Fit your forefinger over the projection at the center of the

cap and hold the cap between your thumb and middle

finger. (See Figure 3-5)

Figure 3-4

Figure 3-5

6

Page 7

(6) Apply the hook on one side to the anode button as shown

Anode button

Skirt

on the figure. (See Figure 3-6)

Caution : Check that the hook is held securely.

(7) Apply the hook on the other side to the anode button as

shown in Figure 3-7.

Anode button

Hook

Hook

Anode button

30°

Anode button

Hook

Figure 3-7

(8) Pull the anode cap slightly with the rubber cap turned

over and visually check that the hook is engaged securely.

(9) Release your hand from the rubber cap of the anode cap.

Caution : Cover the anode cap so that it does not lift.

(10) Hold the skirt of the andoe cap slightly to improve the

close contact between the cap and CRT.

(11) Check that the anode cap is in close contact with the CRT.

(See Figure 3-8)

Figure 3-6

Figure 3-8

7

Page 8

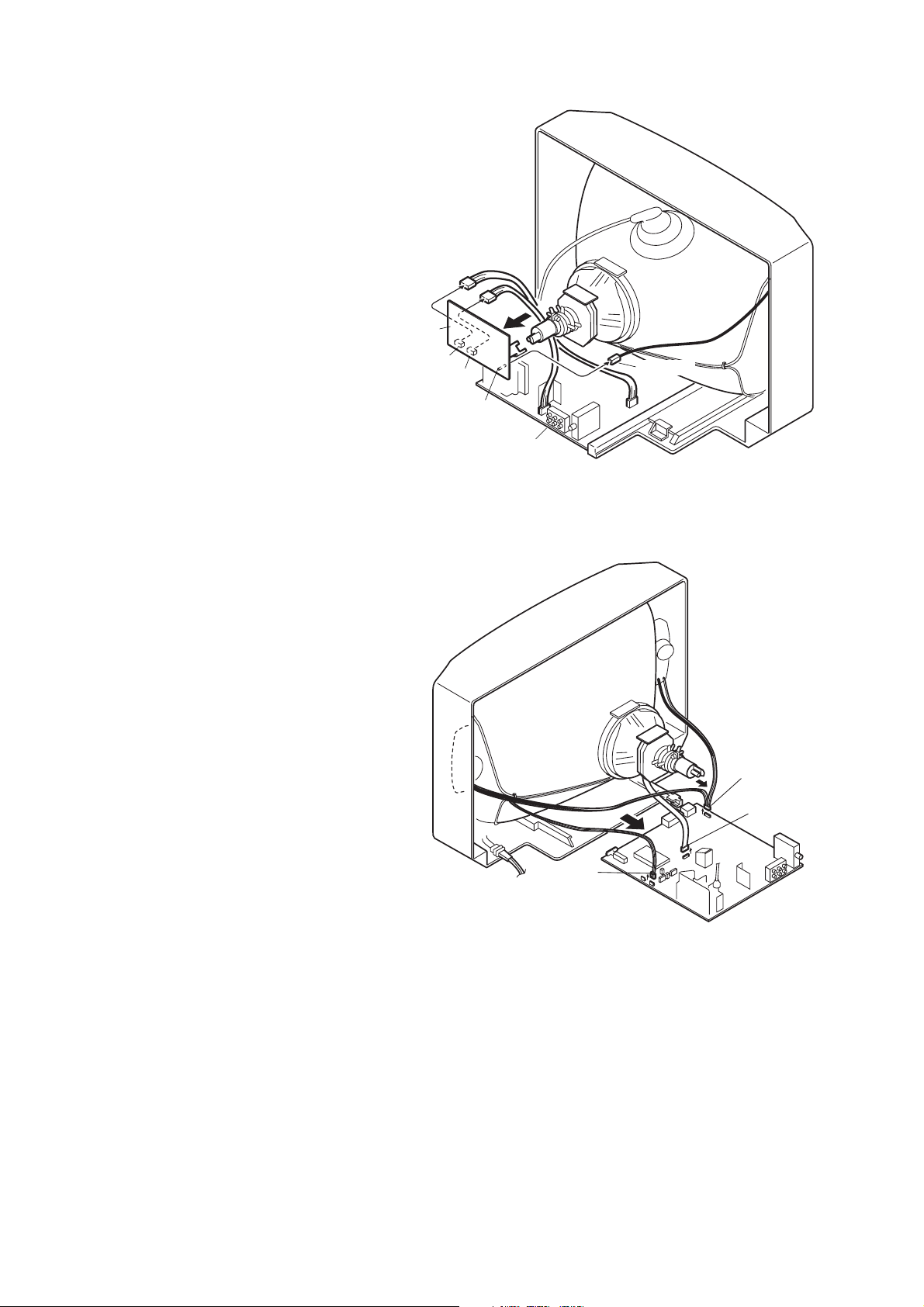

4. NK C.B REMOVAL

(1) Disconnect CN903 (CRT GND).

(2) Disconnect CN901, CN902.

(3) Pul out the NK C.B. in the direction of arrow.

(See Figure 4)

BT301

BT601

NK C.B

5. MAIN C.B REMOVAL

(1) Disconnect CNA401, CN601 and CN802.

(2) Pull out the Main C.B. in the direction of the arrow.

(See Figure 5)

CN902

CN901

CRT GND

CN903

MAIN C.B

Figure 4

CNA401

CN601

CN802

Figure 5

8

Page 9

ELECTRICAL MAIN PARTS LIST

REF. NO PART NO. KANRI DESCRIPTION

IC

87-A20-364-010 IC,KIA7809PI

87-027-666-010 IC,TC4052BP

87-A20-312-010 IC,M62420SP

87-070-237-010 IC,LA7832

87-A30-041-110 TR,SE115N

87-A20-611-080 IC,M51943BSL-700A

8Z-JAD-621-010 IC,M37272M8-165SP

87-A91-538-010 RCR UNIT,SBX1981-72P

87-A21-433-010 IC,KS24C041I

87-A21-299-010 IC,LA6458SLL

8Z-JBJ-605-010 IC,TA1268N

87-002-421-010 IC,NJM2233BL

87-A21-283-010 IC,AN5277

87-A21-259-010 IC,MM1454XD

87-A21-169-010 IC,MM1124B

87-A21-345-010 IC,NJM2150

87-A21-344-010 IC,STR-F6656

TRANSISTOR

89-337-794-580 TR,2SC3779 D/E

87-A30-091-080 FET,2SJ460

87-A30-114-080 TR,2SD1207T

89-208-922-380 TR,2SB892 ST

87-026-269-080 TR,DTA114ES

89-327-854-080 TR,2SC2785F

89-111-755-080 TR,2SA1175F

87-A30-121-080 TR,DTC 323 TS

87-A30-090-080 FET,2SK2541

87-A30-176-010 TR,2SC1573A P/Q/R

89-320-012-080 TR,2SC2001L

87-A30-095-010 TR,2SD2333LS/C202

DIODE

87-017-654-060 DIODE,GBU6JL6131

87-070-111-060 DIODE,RU30A

87-017-352-090 DIODE,RU3YX

87-070-112-060 DIODE,RU4YX

87-017-931-080 ZENER,MTZJ5.6B

87-002-743-080 ZENER,MTZJ 33B

87-070-136-080 ZENER,MTZJ5.1B

87-A40-523-080 ZENER,MTZJ9.1B

87-A40-348-080 ZENER,MTZJ3.3A

87-020-465-080 DIODE,1SS133 (110MA)

87-A40-286-080 DIODE,RGP10JE-5025

87-070-274-080 DIODE,1N4003 SEM

87-017-932-080 ZENER,MTZJ6.2B

87-A40-450-090 DIODE,RU 1P

87-A40-611-080 ZENER,MTZJ3.9B

87-A40-249-080 ZENER,MTZJ 15A

MAIN C.B

BT301 87-JBC-625-010 CONN ASSY,5P V WHT TV-NK

BT401 8Z-JAE-615-110 CONN ASSY,4P V GRAY JK

BT601 87-JBC-626-010 CONN ASSY,4P V WHT TV-NK

C1 87-016-624-080 CAP,E 10-16 SSL

C2 87-018-134-080 CAPACITOR,TC-U 0.01-16

C3 87-018-134-080 CAPACITOR,TC-U 0.01-16

C5 87-016-633-080 CAP,E 1-50 SSL

C6 87-018-134-080 CAPACITOR,TC-U 0.01-16

C7 87-016-621-080 CAP,E 220-10 SSL

C10 87-018-119-080 CAP, CER 100P-50V

C15 87-018-123-080 CAP, CER 220P-50V

C16 87-016-633-080 CAP,E 1-50 SSL

C17 87-018-131-080 CAP, CER 1000P-50V

C18 87-018-128-080 CAP, CERA-SOL SS 560P

NO.

REF. NO PART NO. KANRI DESCRIPTION

C19 87-016-629-080 CAP,E 0.1-50 SSL

C21 87-018-115-080 CAP, CER 47P-50V

C22 87-018-115-080 CAP, CER 47P-50V

C23 87-018-125-080 CAP, CER 330P-50V

C24 87-018-131-080 CAP, CER 1000P-50V

C25 87-016-629-080 CAP,E 0.1-50 SSL

C28 87-018-117-080 CAP,TC-U 68P-50 SL

C29 87-018-117-080 CAP,TC-U 68P-50 SL

C101 87-016-636-080 CAP,E 4.7-50 SSL

C104 87-016-621-080 CAP,E 220-10 SSL

C106 87-A10-576-010 CAP,CER 0.01-50 Z YF

C110 87-018-134-080 CAPACITOR,TC-U 0.01-16

C111 87-018-134-080 CAPACITOR,TC-U 0.01-16

C201 87-018-134-080 CAPACITOR,TC-U 0.01-16

C202 87-018-134-080 CAPACITOR,TC-U 0.01-16

C203 87-016-632-080 CAP,E 0.47-50 SSL

C204 87-018-134-080 CAPACITOR,TC-U 0.01-16

C205 87-016-577-080 CAP,E 470-16 SSL

C207 87-016-632-080 CAP,E 0.47-50 SSL

C208 87-018-134-080 CAPACITOR,TC-U 0.01-16

C209 87-016-576-080 CAP,E 330-16 SSL

C210 87-018-115-080 CAP, CER 47P-50V

C211 87-A11-080-080 CAP,TC U 47P-50 J CH

C214 87-016-627-080 CAP,E 47-16 SSL

C251 87-018-134-080 CAPACITOR,TC-U 0.01-16

C252 87-016-574-080 CAP,E 100-16 SSL

C253 87-A10-112-080 CAP,E 100-10 SSL

C254 87-015-464-080 CAP,E 4.7-16 BP

C255 87-015-464-080 CAP,E 4.7-16 BP

C301 87-016-624-080 CAP,E 10-16 SSL

C302 87-016-624-080 CAP,E 10-16 SSL

C303 87-016-624-080 CAP,E 10-16 SSL

C304 87-016-637-080 CAP,E 10-50 SSL

C305 87-018-134-080 CAPACITOR,TC-U 0.01-16

C306 87-016-574-080 CAP,E 100-16 SSL

C308 87-016-632-080 CAP,E 0.47-50 SSL

C310 87-018-119-080 CAP, CER 100P-50V

C311 87-A11-148-080 CAP,TC U 0.1-50 Z F

C312 87-A11-148-080 CAP,TC U 0.1-50 Z F

C313 87-A11-148-080 CAP,TC U 0.1-50 Z F

C314 87-018-134-080 CAPACITOR,TC-U 0.01-16

C315 87-018-131-080 CAP, CER 1000P-50V

C316 87-016-634-080 CAP,E 2.2-50 SSL

C317 87-016-634-080 CAP,E 2.2-50 SSL

C318 87-018-134-080 CAPACITOR,TC-U 0.01-16

C319 87-016-575-080 CAP,E 220-16 SSL

C320 87-016-587-090 CAP,E 1000-25 M SSL

C321 87-016-636-080 CAP,E 4.7-50 SSL

C323 87-016-625-080 CAP,E 22-16 SSL

C324 87-016-632-080 CAP,E 0.47-50 SSL

C328 87-016-624-080 CAP,E 10-16 SSL

C330 87-016-633-080 CAP,E 1-50 SSL

C332 87-018-134-080 CAPACITOR,TC-U 0.01-16

C333 87-018-125-080 CAP, CER 330P-50V

C334 87-018-134-080 CAPACITOR,TC-U 0.01-16

C335 87-016-574-080 CAP,E 100-16 SSL

C336 87-A11-148-080 CAP,TC U 0.1-50 Z F

C338 87-016-632-080 CAP,E 0.47-50 SSL

C342 87-010-529-080 CAP,E 1-50 BP

C343 87-018-131-080 CAP, CER 1000P-50V

C344 87-A11-080-080 CAP,TC U 47P-50 J CH

C346 87-016-622-080 CAP,E 470-10 SSL

C348 87-018-126-080 CAP,TC-U 390P-50 B

C401 87-018-134-080 CAPACITOR,TC-U 0.01-16

C402 87-016-627-080 CAP,E 47-16 SSL

!C403 87-010-399-090 CAP,E 3300-35 SME

C404 87-018-134-080 CAPACITOR,TC-U 0.01-16

C405 87-018-134-080 CAPACITOR,TC-U 0.01-16

C406 87-018-134-080 CAPACITOR,TC-U 0.01-16

C407 87-016-627-080 CAP,E 47-16 SSL

NO.

9

Page 10

REF. NO PART NO. KANRI DESCRIPTION

C408 87-016-574-080 CAP,E 100-16 SSL

C409 87-016-625-080 CAP,E 22-16 SSL

C410 87-016-624-080 CAP,E 10-16 SSL

C411 87-016-624-080 CAP,E 10-16 SSL

C412 87-016-624-080 CAP,E 10-16 SSL

C413 87-016-624-080 CAP,E 10-16 SSL

C414 87-016-624-080 CAP,E 10-16 SSL

C415 87-016-633-080 CAP,E 1-50 SSL

C416 87-016-633-080 CAP,E 1-50 SSL

C417 87-018-134-080 CAPACITOR,TC-U 0.01-16

C418 87-016-624-080 CAP,E 10-16 SSL

C419 87-A10-112-080 CAP,E 100-10 SSL

C428 87-016-627-080 CAP,E 47-16 SSL

C429 87-016-627-080 CAP,E 47-16 SSL

C430 87-018-134-080 CAPACITOR,TC-U 0.01-16

C435 87-016-627-080 CAP,E 47-16 SSL

C436 87-018-134-080 CAPACITOR,TC-U 0.01-16

C437 87-016-624-080 CAP,E 10-16 SSL

C440 87-016-627-080 CAP,E 47-16 SSL

C444 87-016-633-080 CAP,E 1-50 SSL

C445 87-016-591-080 CAP,E 100-35 SSL

C447 87-016-633-080 CAP,E 1-50 SSL

C449 87-016-588-090 CAP,E 2200-25 SSL

C450 87-016-588-090 CAP,E 2200-25 SSL

C453 87-016-574-080 CAP,E 100-16 SSL

C454 87-016-624-080 CAP,E 10-16 SSL

C455 87-016-624-080 CAP,E 10-16 SSL

C459 87-015-464-080 CAP,E 4.7-16 BP

C460 87-015-464-080 CAP,E 4.7-16 BP

C465 87-018-134-080 CAPACITOR,TC-U 0.01-16

C466 87-016-624-080 CAP,E 10-16 SSL

C473 87-018-118-080 CAP,TC-U 82P-50 B

C474 87-018-118-080 CAP,TC-U 82P-50 B

C475 87-018-117-080 CAP,TC-U 68P-50 SL

C476 87-018-117-080 CAP,TC-U 68P-50 SL

C477 87-015-464-080 CAP,E 4.7-16 BP

C478 87-015-464-080 CAP,E 4.7-16 BP

C487 87-016-633-080 CAP,E 1-50 SSL

C488 87-016-633-080 CAP,E 1-50 SSL

C495 87-018-115-080 CAP, CER 47P-50V

C496 87-018-115-080 CAP, CER 47P-50V

C502 87-A10-831-080 CAP,E 1000-25 M SMG

C503 87-016-633-080 CAP,E 1-50 SSL

C504 87-016-633-080 CAP,E 1-50 SSL

C508 87-A10-469-080 CAP,CER 2200P-500 K B DD10

C510 87-018-131-080 CAP, CER 1000P-50V

C511 87-016-591-080 CAP,E 100-35 SSL

C601 87-016-644-080 CAP,E 10-100 SSL

C604 87-016-593-080 CAP,E 470-35 M SSL

C606 87-A10-675-090 CAP,M/P 0.56-250 J

C608 87-A10-833-010 CAP,CER 1000P-2K K R LONG

C609 87-A11-047-090 CAP,M/P 8200P-1.25 H PHS

!C610 87-010-974-080 CAP,CER 220P-500 B

!C611 87-010-974-080 CAP,CER 220P-500 B

C612 87-016-624-080 CAP,E 10-16 SSL

C615 87-016-215-080 CAP,E 1-160 M TWSS

C616 87-A10-833-010 CAP,CER 1000P-2K K R LONG

!C801 87-A10-688-090 CAP,M/P 0.22-275 K (B81133)

!C803 87-A10-517-010 CAP,CER 3300P-4K M E KX

!C804 87-A10-517-010 CAP,CER 3300P-4K M E KX

C805 87-016-633-080 CAP,E 1-50 SSL

C806 87-A11-825-010 CAP,CER 120P-2K J SL

C807 87-018-127-080 CAP, CER 470P-50V

!C808 87-A11-992-090 CAP,E 330-400 105 KMH

C810 87-016-628-080 CAP,E 10-25 SSL

C811 87-016-582-080 CAP,E 47-25 SSL

C812 87-A11-302-090 CAP,M/P 0.01-630 J ECQF6(ZH)

C814 87-018-130-080 CAP,TC-U 820P-50 B

C815 87-A10-860-090 CAP,CER 470P-2K K R

C816 87-A10-731-090 CAP,E 220-160 M KMF

NO.

REF. NO PART NO. KANRI DESCRIPTION

!C817 87-A10-688-090 CAP,M/P 0.22-275 K (B81133)

C819 87-016-587-090 CAP,E 1000-25 M SSL

C821 87-010-446-010 CAP,E 2200-35 KME

C822 87-016-515-010 CAP,CER 1000P-1K KB

C827 87-016-587-090 CAP,E 1000-25 M SSL

C830 87-A11-824-010 CAP,CER 100P-2K J SL

C831 87-A10-858-090 CAP,CER 330P-2K KR

CF201 84-LB3-626-010 FLTR,TPS4.5MB2

CF202 87-008-574-080 FLTR,SFSH4.5MCB

CN1 87-009-195-010 CONN,5P B5BEH

CN401 87-049-469-010 CONN,4P V

CN601 87-A60-933-010 CONN,4P V B04(5-3)B-DVS-L

CN604 87-A60-485-010 CONN,2P V LV GRA

!CN801 87-099-674-010 CONN,2P VA V

!CN802 82-481-649-010 PLUG,2P MINI(*)

CNA401 87-JB8-601-010 CONN ASSY,4P SP-20

D1 87-070-110-010 LED,SLP-181B-51

D810 87-A90-965-010 VRIS,TNR15G471K

!F801 87-035-192-010 FUSE, 4AT

FB801 87-003-320-080 F-BEAD,FBR07HA121NB

FB803 87-003-320-080 F-BEAD,FBR07HA121NB

FB804 87-003-320-080 F-BEAD,FBR07HA121NB

FB805 87-003-320-080 F-BEAD,FBR07HA121NB

FB806 87-003-320-080 F-BEAD,FBR07HA121NB

FB807 87-003-320-080 F-BEAD,FBR07HA121NB

!FC801 87-033-213-080 CLAMP, FUSE

!FC802 87-033-213-080 CLAMP, FUSE

FR601 87-A00-063-060 RES,FUSE 2.2-1/2W J R-TYPE

FR602 87-A00-055-060 RES,FUSE 2.2-2WJ R-TYPE

FR604 87-A00-106-060 RES,FUSE 3.3-1W J R-TYPE

FR801 87-029-070-090 RESISTOR, FUSE 1/4W 2.2

HL1 84-LB3-216-010 HLDR,LED

J401 87-A60-856-010 JACK,PIN 3P

J402 87-A60-324-110 JACK,PIN 6P Y-W-R W/SW

J403 87-A60-858-010 JACK,3.5 BLK ST 2 SW

L2 87-005-614-080 COIL 100UH LAV35 J

L104 87-003-139-080 COIL,0.56UH

L201 8Z-JBR-612-010 COIL,SIF 4.5MHZ 504BN

L203 87-003-148-080 COIL BIAS 33UH

L204 87-003-282-080 COIL,12UH

L205 8Z-JBH-610-010 COIL,PIF-SQ57EL349A 45.75MHZ

L206 87-005-612-080 COIL,68UH J LAV35

L207 87-003-147-080 COIL, 22UH

L208 87-003-150-080 COIL, 68UH J LAL02

L251 87-005-610-080 COIL,47UH LAV35 J

L401 87-005-507-080 COIL,22UH FL0606 J

L402 87-005-507-080 COIL,22UH FL0606 J

L403 87-005-610-080 COIL,47UH LAV35 J

L404 87-005-507-080 COIL,22UH FL0606 J

L602 87-A50-040-010 COIL,2.2MH

L801 87-A50-176-080 COIL,33UH-PJ87

!LF801 87-JB8-651-010 FLTR,LINE SS24H-K15070

!LF802 8Z-JAD-610-010 FLTR,LINE FLF 15N022AV

!PR801 87-A90-090-080 PROTECTOR,1.5A 491SERIES 60V

!PR802 87-A90-195-080 PROTECTOR 7A 60V 491SERIES

!PR804 87-A90-195-080 PROTECTOR 7A 60V 491SERIES

!PS801 87-A91-407-010 P-COUPLER,ON3171-R

!PS802 87-A91-407-010 P-COUPLER,ON3171-R

!PT801 8Z-JAD-801-010 PT,SW ZJA-D

R107 87-A00-154-090 RES,M/F 18K-1W J RSF(S)

R110 87-A00-160-090 RES,M/F 33-2W J RSF(S)

R312 87-025-602-090 RES,M/O 39-2W J

R429 87-025-381-080 RES,M/F 18K-1/6W F

R430 87-025-424-080 RES,M/F 10K 1/6W F

R431 87-025-380-080 RES,M/F 15K-1/6W F

R432 87-025-381-080 RES,M/F 18K-1/6W F

R450 87-A00-624-090 RES,M/F 3.3-7W J RSV7

R505 87-A00-563-090 RES,M/F 1.5-1/2W J ERXS

R606 87-A00-196-090 RES,M/F 0.47-1/2W J RSF(S)

NO.

10

Page 11

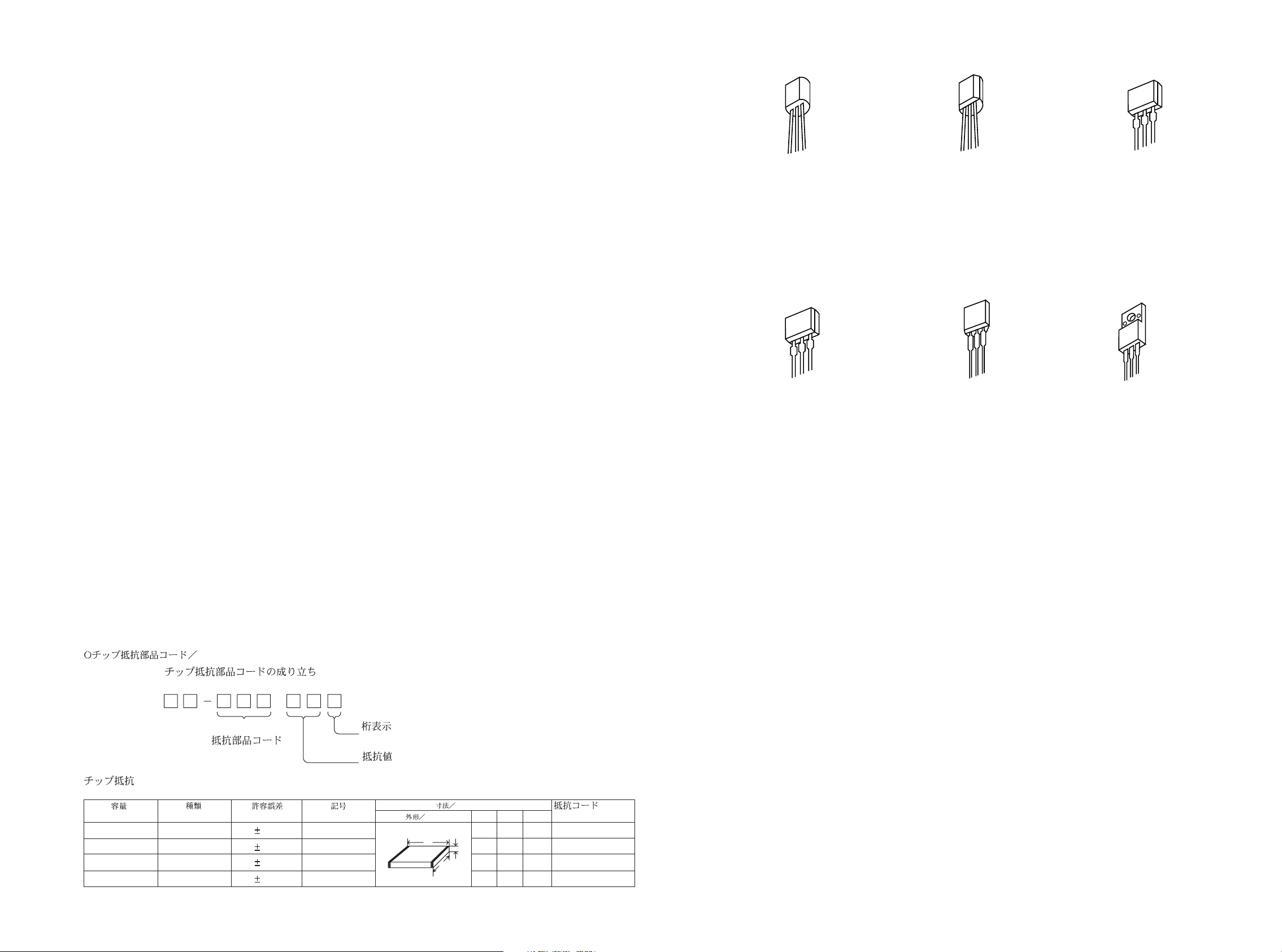

TRANSISTOR ILLUSTRATION

REF. NO PART NO. KANRI DESCRIPTION

R610 87-A00-123-090 RES,M/F 3.9K-2W J RSI-2S B

R611 87-A00-561-090 RES,M/F 4.7K-2W J ERGS

R624 87-A00-544-090 RES,M/F 220-3W J ERGS

R804 87-A00-543-080 RES,SD 8.2M-1W J RCR60

R806 87-A00-204-090 RES,CEM 0.18-5W K

R809 87-A00-552-010 RES,CEM 1.0-10W J MPC722

R810 87-A00-552-010 RES,CEM 1.0-10W J MPC722

R812 87-A00-576-090 RES,M/F 27K-5W J RSV5

R813 87-A00-577-090 RES,M/F 22K-2W J RSF(S)

R816 87-A00-411-090 RES,M/F 33K-1W J

R824 87-A00-577-090 RES,M/F 22K-2W J RSF(S)

SF201 8Z-JBH-633-010 FLTR,SAW M1969-US

SW2 87-A90-712-080 SW,TACT EVQ11L07K

SW3 87-A90-712-080 SW,TACT EVQ11L07K

SW4 87-A90-712-080 SW,TACT EVQ11L07K

SW5 87-A90-712-080 SW,TACT EVQ11L07K

SW6 87-A90-712-080 SW,TACT EVQ11L07K

SW7 87-A90-712-080 SW,TACT EVQ11L07K

!SW801 87-A90-364-010 SW,PUSH SDDLB1-C-D-2

!T601 8Z-JBS-605-010 FBT, HFT3608(SAN)20-C

!T602 8Z-JBH-615-010 TRANS,US ETH09K10AZ

!TH801 87-A91-405-010 POS-THMS,T209-B80-A10

TU101 8Z-JBE-610-010 TU UNIT,USA ENV56D74G3

X1 87-A70-124-080 VIB,CER 8.0MHZ

X301 87-A70-007-080 VIB,XTAL 3.58MHZ AQC-1001

X302 87-030-327-010 VIB,CER CSB503F30

NO.

REF. NO PART NO. KANRI DESCRIPTION

NK C.B

C901 87-012-372-010 CAP,CER 1000P-2K

C902 87-018-125-080 CAP, CER 330P-50V

C903 87-018-125-080 CAP, CER 330P-50V

C904 87-018-125-080 CAP, CER 330P-50V

!C905 87-010-976-080 CAP,CER 1000P-500 B

C907 87-016-577-080 CAP,E 470-16 SSL

C908 87-016-627-080 CAP,E 47-16 SSL

CN901 87-049-469-010 CONN,4P V

CN902 87-A60-622-010 CONN,5P V 2MM JMT

CN903 87-A60-485-010 CONN,2P V LV GRA

L901 87-005-615-080 COIL,120UH J LAV35

R904 87-A00-165-090 RES,M/F 15K-2W J RSF(S)

R905 87-A00-165-090 RES,M/F 15K-2W J RSF(S)

R906 87-A00-165-090 RES,M/F 15K-2W J RSF(S)

S901 86-LBU-670-010 SOCKET,CRT 9P CVT3326 1603

NO.

E C B E C B

2SB892

2SC1573

B E C

2SC3779

2SD1207

2SA1175

2SC2785

2SC2001

S D G

2SJ460

2SK2541

E C B

DTA114ES

DTC323TS

B C E

2SD2333

CHIP RESISTOR PART CODE

Chip Resistor Part Coding

88

A

Resistor Code

Chip resistor

Wattage Type Tolerance

1/16W 1005 5% CJ

1/16W

1/10W

1/8W

1608

2125

3216

5%

5%

5%

Symbol

CJ

CJ

CJ

Figure

Value of resistor

Form

L

Dimensions (mm)

t

W

0.55

Resistor Code

108

118

128

LW t

1.0 0.5 0.35 104

1.6 0.8 0.45

2 1.25 0.45

3.2

1.6

: A

: A

1211

Page 12

SCHEMATIC DIAGRAM-1 (MAIN SECTION)

TP102

TP202

TP302

1413

Page 13

WIRING-1 (MAIN C.B SECTION)

1

A

B

C

D

234567

8

9

10

11 12 13

14

E

F

G

H

I

J

1615

Page 14

SCHEMATIC DIAGRAM-2 (NK SECTION)

WIRING-2 (NK C.B SECTION)

1

A

B

C

D

23456

7

E

F

G

H

I

J

1817

Page 15

WAVEFORM

IC1 Pin 17 (CV IN)

1

IC301 Pin 21 (B OUT)

5

1

IC1 Pin 20 (XOUT)

2

2

IC301 Pin 19 (R OUT)

3

500 mV/div

20 µs/div

1 V/div

50 ns/div

5

IC301 Pin 30 (FBP IN)

6

6

IC301 Pin 32 (H OUT)

7

1 V/div

20 µs/div

2 V/div

20 µs/div

3

IC301 Pin 20 (G OUT)

4

4

1 V/div

20 µs/div

1 V/div

20 µs/div

7

IC301 Pin 34 (32FH VCO)

8

8

1 V/div

20 µs/div

50 mV/div

500 ns/div

19

Page 16

IC301 Pin 43 (Y IN)

9

Between X301 & C309 (VCXO)

13

9

IC301 Pin 45 (CHROMA IN)

10

10

IC301 Pin 47 (TV DET OUT)

11

200 mV/div

20 µs/div

200 mV/div

20 µs/div

13

IC501 Pin 2 (V-OUT)

14

14

Q601 Collector

15

50 mV/div

100 ns/div

10 V/div

5 ms/div

11

IC301 Pin 54 (DE EMPHASIS)

12

12

500 mV/div

20 µs/div

200 mV/div

1 ms/div

15

Q602 Collector

16

16

200 V/div

20 µs/div

50 V/div

20 µs/div

20

Page 17

T601 Pin 8 (E24)

17

Q902 Collector (G) --- NK C.B

19

17

Q901 Collector (R) --- NK C.B

18

18

50 V/div

20 µs/div

20 V/div

20 µs/div

19

Q903 Collector (B) --- NK C.B

20

20

20 V/div

20 µs/div

20 V/div

20 µs/div

21

Page 18

IC DESCRIPTION

IC, M37272M8-165SP

Pin No. Pin Name I/O Description

1 HD I OSD horizontal synchronised signal input terminal. "L"= active.

2 VD I OSD vertical synchronised signal input terminal. "L"= active.

3 A MUTE

4 L MUTE

5 A DET OUT O Not used.

6 SW/SBASS O SBASS ON "L", OFF "H".

7 SEL1 O

8 SEL2 O

9 SP MUTE O Used to mute the speaker (sound) output.

10 REMOCON I Remote control signal is led to this pin.

O Used to mute line out sound and picture when no input signal is detected. "H" to mute.

Selecting tuner receiving band.

Pin 7 Pin 8

TUNER L L Reset start : Both of Pin 7, Pin 8 are "H".

VIDEO 1 L H

VIDEO 2 H L

11 SD I

12 EXT I I

13 PON O

Horizontal sync. detected input. The level of this pin will be sampled by µ-P to

determine whether there is picture signal detected.

2

C switching.

During standby mode, "H" level is inserted to switch off horizontal deflection and high

voltage.

14 A VCC – 5V supply.

15 HLF – Connected to filter.

16 V HOLD – Connected to condensor.

17 CV IN I Video signal input.

18 CNVSS – Connected to ground.

19 XIN I 8 MHz clock input.

20 XOUT O 8 MHz clock output.

21 VSS – Connected to ground.

22 VCC – 5 V supply.

23 BBE 1 O

Pin 23 Pin 24

OFF L L

LOW H L

24 BBE 2 O

HIGH H H

25 RST I Used to reset the µ-P when power up.

26 D DET A I Connected to ground through a resistor.

27 D DET F

I Fault detection. Detect as a fault when the voltage is more than 2.5V.

28 D DET R

29 AFTV I AFT voltage from IC301 is received by µ-P during channel tuning.

30 KEY I Input key is detected by monitor.

31 SDA2 I/O I

32 SDA1 I/O I

33 SCL2 I/O I

2

C bus CH2 data.

2

C bus CH1 data.

2

C bus CH2 clock.

34 SCL1 I/O I2C bus CH1 clock.

22

Page 19

Pin No. Pin Name I/O Description

35 S OUT O Not used.

36 QSUR O Surround ON "H", OFF "L".

37 LED O LED ON "L", OFF "H".

38 WP O E

2

PROM write protect.

39 FAST BLK O OSD blanking output.

40 B O OSD blue output.

41 G O OSD green output.

42 R O OSD red output.

IC, TA1268N

Pin No. Pin Name I/O Description

1 NC – Not connected.

2 AUDIO OUT O

Sound output. The maximum flew out current is 3.6mA.

So, the minimum load resistor is 1kΩ. (Not used)

3 RF AGC O RF AGC output.

4 SIF TANK – Tank coil connection for SIF detection circuit.

5 AGC FILT – PIF 2nd AGC filter.

6 PIF GND – GND for PIF circuit.

7 ~ 8 PIF IN I IF input. The typical input value is 90dBµV.

9 PIF VCC – VCC for PIF circuit.

10 LOOP FILT – PIF PLL loop filter.

11 APC FILT – APC filter of fsc oscillation.

12 VCXO I X'tal of 3.58MHz VCXO.

13 GND – V/C/D GND.

14 FAST BLANKING I Fast blanking of RGB input.

15 R IN I R signal input.

16 G IN I G signal input.

17 B IN I B signal input.

18 D VCC – VCC for digital circuit.

19 R OUT O R primary color signal output.

20 G OUT O G primary color signal output.

21 B OUT O B primary color signal output.

22 V OUT O Vertical pulse output.

23 NFB I NFB input.

24 V RAMP O Vertical ramp output.

25 V SEPA FILT – Vertical sync. separation filter.

26 H VCC – VCC for horizontal circuit.

23

Page 20

Pin No. Pin Name I/O Description

27 ~ 28 SCL, SDA I/O Input and output of I

Inputting of X-RAY protect circuit. The threshold voltage is 3.5V (typ.).

29 X RAY I If the voltage that is applied is more than the threshold voltage, the X-RAY

protect circuit make horizontal output a low.

2

C Bus.

30 FBP IN I

Fly-back pulse input. The Fly-back pulse is the reference of AFC circuit, gate pulse

and so on. The current needs to keep under 1mA.

31 SYNC OUT O Sync. pulse output.

32 H OUT O Horizontal pulse output.

33 H AFC –

Horizontal AFC filter. The AFC circuit fits the phase between inputted horizontal

sync. signal and horizontal pulse which is made by countdowning 32fH.

34 32FH VCO – Ceramic oscillator connection. That constitutes 32fH (503kHz) oscillation circuit.

35 D GND – GND for digital circuit.

36 ABL O ABL circuit.

37 TV IN I Inputting of PIF detected signal. The typical input amplitude is 1.0Vp-p.

38 ACL O ACL circuit.

39 EXT VIDEO I Inputting of external video signal.

40 BLANK DET – Filtering of black peak detection.

41 AV SW OUT O

Video switch output which selects TV signal or external video.

Amp gain: Min. 1.7, Typ. 1.9, Max. 2.1.

42 DC REST I Filtering of APL detection.

43 Y IN I Y signal input. The typical input amplitude is 1.0Vp-p.

AFT output. Monitor signal output can be selected via Bus.

B0 B1 OUTPUT

44 AFT O

0 0 AFT

0 1 TEST purpose only

10B

1 1 (RF AGC)/2

45 CHROMA IN I

Chrominance signal input. The typical input signal amplitude is 286mVp-p (at burst

signal). This IC will go to test mode when this terminal voltage is higher than 4.5V.

46 VCC – VCC for video, chroma and deflection circuit.

47 TV DET OUT O PIF detected signal output.

48 SIF VCC – VCC for SIF circuit.

49 ~ 50 PIF TANK – Tank coil connection for PIF detection circuit.

51 SIF GND – GND for SIF circuit.

52 LIMIT IN I Inputting of SIF limiter amplifier circuit.

53 AUDIO TV IN I Inputting of SIF detected signal. (Not used)

54 DE-EMPHASIS O Filtering of SIF de-emphasis.

55 EXT AUDIO IN I External audio input. (Not used)

56 NC – Not connected.

24

Page 21

IC BLOCK DIAGRAM

IC, MM1454XD

VCC

LIN

VREF

QF1

QF2

QF3

16 15 14 13 12 11 10 9

QSURROUND

BIAS

QF4

QF5

87654321

IC, TA1268N

RIN

PNR

B/Q

BET

QF6

ROUT

LOUT

GND

IC, SBX1981-72P IC, M51943BSL-700A

25

Page 22

IC, KS24C041I

IC, TC4052BP IC, M62420SP

IC, STR-F6656

26

Page 23

IC, MM1124B IC, NJM2233BL

1234567

GND

POMP UP

VERTICAL

DRIVE

VERTICAL

OUTPUT

THERMAL

PROTECT

V-OUT

PS

V-OUT

INPUT

OSC STEP

VCC

PULSE

GND

IC, NJM2150

IC, AN5277

IC, LA7832

27

Page 24

SET-UP FOR ADJUSTMENT

B

G

R

R/B

G

Because the video signal output from a pattern generator is used as

the adjustment signal input during adjustment, the video signal

output from the pattern generator must conform with the

specifications. Measure the output waveform across 75 Ω load.

Confirm that the synchronizing signal has an amplitude of about

0.3 V, the video signal portion has an amplitude of about 0.7 V and

the burst signal has an amplitude of about 0.3 V with flat envelope.

Confirm that ratio of the burst signal amplitude and the red signal

amplitude is 0.30 : 0.66. If the output signal does not conform with

the specifications, calibrate the pattern generator. (Refer to pattern

generator operation manual.)

Use the LEADER: LCG 404 for the pattern generator.

1. CRT ADJUSTMENT

1-1. Precautions

(1) Receive the white raster signal, and then perform aging for at

least 20 minutes.

(2) Demagnetize the area surronding the CRT with a degausser

before making adjustments.

(3) Set the picture quality for each mode to the factory setting.

(4) Position the front screen facing the east as much as possible.

1-2. Purpose

(1) Beam landing adjustment (purity magnet)

Set the left/right balance of beam landing. If there is a

discrepancy in this adjustment, a color irregularity will occur.

After completion of the landing adjustment, it is necessary to

perform convergence adjustment.

Approx. 0.7V

1 Vp-p

White (Approx.

Burst signal

75%)

Approx.

Approx. 0.3V

Cyan

Yellow

75% white

Green

Red

Magenta

Blue

Black

0.3V

TV display

Color bar signal of a pattern generator

Precautions before starting adjustment

Satisfy the following setting conditions before starting adjustment.

• Allow warm-up of 20 minutes or longer. (Do not turn off during

warm-up.)

• Set all picture quality controls of users' setting to initial set-up,

unless otherwise specified.

• Picture quality reset

1. Select "Picture" on the screen menu and press enter button.

2. Select "Normal" and press enter button.

3. Select "Reset" and press enter button.

• Set the pattern generator’s output level to 1.0Vp-p (across 75Ω

load).

Before adjustment

Color

irregularity

After adjustment

Fig. 1-1

(2) Beam convergence adjustment (4-pole magnet)

Align the R beam with the B beam. The G beam does not

move with this adjustment.

(magenta)

Align the R beam with the B beam

Fig. 1-2

(3) Beam convergence adjustment (6-pole magnet)

With a 4-pole magnet align the G beam with the already aligned

R/B beam.

(magenta)

R/B

G

(white)

RGB

Align the G beam with the R/B beam

Fig. 1-3

28

Page 25

(4) The composition of each magnet is as shown in Fig. 1-4.

SN NS

NS SN

NN

SS

SS

NN

In making adjustments, rotate the lock ring clockwise (looking

from the CRT’s back screen) and disengage.

Be careful not to loose the lock ring too much. If the magnet

assembly has become shifted during adjustments, secure it to

the position in Fig. 1-4.

DY lock screw

Purity 4-pole 6-pole

CRT DY

Magnet assembly

1-3.Beam Landing Adjustment

(1) Receive the green raster signal from the pattern generator.

(2) Loosen the magnet lock screw, and shift the magnet assembly

backward (toward the neck).

(3) Loosen the DY lock screw, and shift the DY deflecting yoke

backward (toward the neck).

(4) After opening the two purity magnets to the same angle, adjust

the color width of the bands on both sides of the screen so that

they are equal. (refer to Fig. 1-5 (a)).

Lock ring

Magnet assembly

lock screw

Fig 1-4

(5) Gradually shift the deflecting yoke toward the front (toward

the CRT funnel). Stop movement at the point when the screen

has become completely green.

NK C.B

RGB

As shown in Fig. 1-5 (b), the purity magnet functions in relation

to the electron beam.

Fig 1-5 (a)

R=B

Fig 1-5 (b)

(6) Also, verify the respective monochromatics of red and blue.

(7) While looking at the screen, adjust the tilt of the deflecting

yoke and tighten the DY lock screw.

(8) Shift the magnet assembly to the front (toward the CRT funnel),

stop movement before the adjustment position and then tighten

the magnet lock screw.

At this time, be careful not to shift the position of the purity

magnet.

29

Page 26

As there is occurrence of convergence distortion after

GRB

N

N

N

S

S

S

S

N

N

S

GRB

S

N

completing the landing adjustments, be sure to carry out

convergence adjustments.

If the color irregularities in the screen’s corner section are

not improved, correct them with the landing magnet. After

using the landing magnet, be sure to demagnetize the CRT

with degausser and verify that there is no occurrence of color

irregularity. (refer to Fig. 1-6)

Landing magnet: 81-JTI-710-010

(two-sided adhesive tape) : 80-XVI-218-010 Cushion

Landing magnet

Cushion

Since the landing magnet is polarized,

check the screen’s improvement through

rotation, not only by position.

Fig 1-6

1-4. Beam Center Convergence Adjustment

Make adjustments on the convergence with 4-pole and 6-pole

magnets. Operate each magnet in relation to the electron beam

as shown in Figs. 1-7 and 1-8. When performing this

adjustment, verify whether there is distortion in the focus

adjustment. If necessary, carry out adjustments again.

In Fig. 1-7, two 4-pole magnets are stacked together so as to be of

the same polarity. Move the B and R beams to their respective

direction, by rotating the two 4-pole magnets together. By adjusting

the opening of the two magnets, it is possible to adjust the amount

of the beam’s movement.

Fig 1-8

In Fig. 1-8, the two 6-pole magnets are stacked together so as to be

of the same polarity. Move the B and R beams to their respective

direction, by rotating the two 6-pole magnets together. By adjusting

the opening of the two magnets, it is possible to adjust the amount

of the beam’s movement.

(1) Receive the dot pattern signal from the pattern generator.

(2) Pay attention to the center of the screen, and perform

adjustments with two 4-pole magnets so that the R beam and

B beam are perfectly aligned and become a magenta color.

(Refer to Fig. 1-2)

(3) In the same way, pay attention to the screen, and perform

adjustments with a 6-pole magnet so that the magenta beam

and G beam are aligned and become a white dot.

(Refer to Fig. 1-3)

(4) After adjustments are completed, secure all magnets with the

lock link. (Refer to Fig. 1-4)

1-5.The Surrounding Convergence Adjustment

Perform this adjustment after completion of adjustment 1-4.

(1) Shake the deflecting yoke up, down to the right and left, and

adjust any discrepancies in the screen’s surroundings.

(2) Insert wedges in three locations in the gap between the

deflecting yoke and the surface of the CRT funnel in order

to secure the deflecting yoke. (Refer to Fig. 1-9)

SN

BGR

NS

S

BGR

NN

S

Wedge

Wedge

Wedge

Position of wedge

Fig 1-7

30

Fig. 1-9

Page 27

IC BUS Data Setting Procedure

AGING AFT OK 000H

0123456789ABC D E F

1100101111110 1 0 0

Fig. 1

Fig. 2

1 MONO

2 IN-ST

3 ST

4 ST+S

5 SPARE

With this model, most parts of video and deflection blocks can be

adjusted using a jig remote control.

Preparations:

• Modify the hidden keys on the RC-6VT06 jig remote control

(TV-C142/86-LB4-951-010) so that they can easily be pressed.

2 keys to be modified (see the figure below):

ON/OFF

FINISH key

(hidden key

under the seal)

TV/VIDEO

SLEEP

12

45

78109

SYSTEM

CHANNEL VOLUME

3

6

TEST key

(hidden key

under the seal)

SYSTEM key

Aging mode operation method: Be sure to

check this after replacing EEPROM.

1. Press the TEST key on the remote control to set to the aging

mode. See Fig. 1.

2. Press the SYSTEM key to check the status of distinction switch.

See Fig. 2.

• If the contents are different, press the "1" key to select "IN-ST"

for destination.

• To modify the data, use the channel keys to move the cursor to

0-F, and then use the volume keys to change it to "0" or "1".

Starting service mode:

Hidden key TEST:

• Pressing the TEST key on the jig remote control once will set the unit

to the aging mode. See Fig. 1.

• Pressing TEST again will set the unit to the adjustment mode.

Hidden key FINISH:

• Pressing the FINISH key on the jig remote control will reset the

accumulated hours in the aging mode.

• Do not press FINISH during normal servicing.

Contents of aging mode:

1. Releasing auto power off function

Release the auto power off function when no input is supplied.

Use this mode for warming up (aging) during CRT adjustment.

2. AFT S-curve status display

OK, UP or DN (down) will appear to show whether the AFT

S-curve status is optimum, too high or too low.

AFT S-curve

UP: Deviation from standard value high.

OK: Normal value

DN: Deviation from standard value low.

31

Page 28

3. CRT ON accumulated hour display

The CRT usage hours accumulate every hour, and are displayed

using hexadecimal number.

Example of calculating displayed hexadecimal number:

AFT OK 1234H IN-ST

1x163 + 2x162 + 3x161 + 4x160 = 4660 hours

4th digit 3rd digit 2nd digit 1st digit

* When the accumulated hours exceed 7FFFH (32,768 hours), the

display will be reset to 0000H.

Adjustment mode operation method:

1. Press the SYSTEM key to restore the aging display, and press

the TEST key again to display the adjustment menu.

PAGE 1

1 H POS

2 V POS

3 V SIZE

4 OSD POS

5 PIF VCO

6 RF AGC

PUSH

1~6 KEY

PAGE 1

1 H POS

2 V POS

3 V SIZE

4 OSD POS

SD

AFT

PUSH

CH UP/DN KEY

Adjustment menu chart

PUSH

CH UP/DN KEY

PAGE 2

00

00

00

00

00

00

1 R CUTOFF

2 G CUTOFF

3 B CUTOFF

4 G DRIVE

5 B DRIVE

ENTER CONTRAST

PUSH

1~5 KEY

Press MENU to return. Press MENU to return. Press MENU to return. Press MENU to return.

PAGE 2

0~31

5 PIF VCO

SD

AFT

6 RF AGC

0~7

0~63

0~48

OK

0~127

OK

0~63

1 R CUTOFF

2 G CUTOFF

3 B CUTOFF

4 G DRIVE

5 B DRIVE

PUSH

CH UP/DN KEY

0~255

0~255

PUSH

CH UP/DN KEY

00

00

00

00

00

0~255

0~255

0~255

PAGE 3

1 SUB CONTRAST

2 SUB BRIGHT

3 SUB TINT

4 SUB COLOR

PUSH

1~4 KEY

PAGE 3

1 SUB CONTR...

2 SUB BRIGHT

3 SUB TINT

4 SUB COLOR

PUSH

CH UP/DN KEY

00

00

00

00

-63~+63

-63~+63

-63~+63

PUSH

CH UP/DN KEY

PUSH

1~4 KEY

-63~+63

PAGE 4

1 358 TRAP

2 BPF

3 H AFC

4 WPL

PAGE 4

1 358 TRAP

2 BPF CUTOFF

3 H AFC

4 WPL

PUSH

CH UP/DN KEY

(Inoperable)

0: ON

1: OFF

2: AUTO

PUSH

CH UP/DN KEY

00

00

00

00

0: +2

1: +1

0: OFF

1: ON

Each value in the adjustment menu can be modified using the volume adjustment keys (+, -).

*

Pressing the audio muting key, etc. during menu screen operation will clear the menu contents: Press the "0" key to restore the menu.

*

Fig.3

32

Page 29

ELECTRICAL ADJUSTMENT (adjustment menu screen)

J403

J401

IC303

IC403

IC1

IC402

IC405

IC407

IC251

IC406

TP302

BT301

3

TP201

(AFT)

IC301

C322

T601

(FBT)

R211

TP202

FORCUS

L205

P-IF

TP203

C213

L201

S-IF

R101

TP102

(IF)

TU101

T601

(FBT)

TP101

(RF AGC)

J402

SFR

S901

R903

R902

TP902

R901

R906

R904

SCREEN

R905

33

Page 30

PAGE 1

3 V SIZE 5

13~14

squares

Fig.1-3

• After replacing EEPROM, enter the following initial values before

proceeding with adjustment.

• During normal servicing, check the applicable items, and adjust

them if necessary.

PAGE 1

1. H POS

2. V POS

3. V SIZE

4. OSD POS

5. PIF VCO

6. RF AGC

PAGE 2

1. R CUT OFF

2. G CUT OFF

3. B CUT OFF

4. G DRIVE

5. B DRIVE

PAGE 3

1. SUB CONTRAST

2. SUB BRIGHT

3. SUB TINT

4. SUB COLOR

PAGE 4

1. 3.58 TRAP

2. BPF

3. H AFC

4. WPL

Initial value

20

2

18

6

58

32

127

127

127

127

127

34

35

0

16

Specified value

ON

AUTO

+1

OFF

1-1. H POS Horizontal position adjustment/Adjustment menu

screen PAGE 1-1

Input signal: Crosshatch

Measuring instrument: Leader LCG-404 pattern generator

• Use the volume keys on the jig remote control to adjust so

that the dot mark at the center of crosshatch is positioned at

the horizontal center of screen and the squares on the left

and right are equal. Fig. 1-1

8~9 8~9

PAGE 1

1 H POS 18

Center

Fig.1-1

1-2. V POS Vertical position adjustment/Adjustment menu

screen PAGE 1-2

Input signal: Crosshatch

Measuring instrument: Leader LCG-404 pattern generator

• Use the volume keys on the jig remote control to adjust so

that the dot mark at the center of crosshatch is positioned at

the vertical center of screen. Fig. 1-2

1-3. V SIZE Vertical size adjustment/Adjustment menu screen

PAGE 1-3

Input signal: Crosshatch

Measuring instrument: Leader LCG-404 pattern generator

• Use the volume keys on the jig remote control to adjust so

that the number of crosshatch squares in the vertical direction

is 13-14. Fig. 1-3

1-4. OSD POS OSD position adjustment/Adjustment menu

PAGE 1-4

Input signal: Not specified

• Use the volume keys on the jig remote control to adjust so

that both sides of OSD characters are equal to the length of

edge of screen. A = B Fig. 1-4

PAGE 1

CRT center

mark

2 V POS 2

Fig.1-2

PAGE 1

OSD H 24

AB

Fig.1-4

34

Page 31

1 R CUTOFF

2 G CUTOFF

3 B CUTOFF

4 G DRIVE

5 B DRIVE

PAGE 2

127

127

127

127

127

Fig. 2-1

1-5. PIF VCO Video IF/VCO adjustment/Adjustment menu screen

PAGE 1-5

Input signal: ANT RF-INPUT

Color bar

• Measuring instruments: Leader LCG-404 pattern generator

Use the volume keys on the jig remote control to adjust so that

the AFT status on the screen is "OK". Fig. 1-5

• If there are several ranges where the AF status is acceptable,

select the center value.

* "NG" will appear for SD when no signal appears on the screen,

but this will not cause any problem for VCO adjustment

(example: No signal with video input). Even in this case,

adjustment is possible if there is a load on ANT.

White Balance Adjustment:

Adjustment menu screen PAGEs 2-1~5

* When the adjustment menu screen appears, the user picture

quality will be cleared.

Input signal: White raster

Details of adjustment: 1. R CUT OFF

2. G CUT OFF

3. B CUT OFF

4. G DRIVE

5. B DRIVE

* Perform aging for at least 20 minutes before adjustment.

* Repeat all processes of adjustment several times.

Measuring instrument: Leader LCG-404 pattern generator

Higher

OK

UP

58

Lower

OK

DN

52

PAGE 1

SD

AFT

5 PIF VCO

Optimum

OK

OK

58

Fig.1-5

1-6. RF AGC RF-AGC adjustment/Adjustment menu screen

PAGE 1-6

Input signal: ANT RF-INPUT

Color bar

Measuring instruments: Oscilloscope, Leader LCG-404 pattern

generator

1. Connect the oscilloscope to TP-101.

2. Use the volume keys on the jig remote control to adjust so

that the voltage at the test point is 3.5 ±0.3 V. Make sure

that "OK" appears for AFT on the adjustment menu screen

as shown in Fig. 1-6.

PAGE 1

Cutoff adjustment:

2-1. Use the pattern generator to input white raster signal.

2-2. Fix the cutoff value whose color seems to be most intense at

127, and use the volume keys on the jig remote control to adjust

the other two cutoff values so that a white picture appears.

Drive adjustment:

2-3. Use the volume keys on the jig remote control to increase the

4. G DRIVE value to 200 or more so that the picture is

greenish.

2-4. Decrease the value gradually until green disappears.

2-5. Use the volume keys on the jig remote control to increase the

5. B DRIVE value to 200 or more so that the picture is bluish.

2-6. Decrease the value gradually until blue disappears.

2-7. Perform steps 1-6 several times so that a white picture appears.

SD

AFT

6 RF AGC

Fig.1-6

OK

OK

32

Focus Adjustment:

Input signal: Dot signal

Adjustment point: Upper SFR of FBT (T601)

Measuring instrument: Leader LCG-404 pattern generator

• Adjust the upper SFR of FBT (T601) until the focus of dots in

the dot pattern is optimum.

35

Page 32

Screen Adjustment:

Fig. 3-3

One oblique line

Input signal: No signal (raster)

Adjustment point: Lower SFR of FBT (T601)

Measuring instrument: Leader LCG-404 pattern generator

1. Use the jig remote control to display the adjustment menu screen.

2. Press the "0" channel numeric key so that a horizontal single line

appears. Fig. 2-2

3. Adjust the lower SFR of FBT (T601) until the horizontal single

line starts to gleam.

4. Perform step (2) again to return to the adjustment menu screen.

3-3. SUB TINT Sub-tint adjustment/Adjustment menu screen

PAGE 3-3

Input signal: Color bar

VIDEO IN

Measuring instruments: Oscilloscope

Leader LCG-404 pattern generator

Test point: TP302/BT301 (wire connector) pin (3)

1. Connect the oscilloscope to TP302.

2. Use the volume keys on the jig remote control to adjust so

that the bottom edges of waveform are in one oblique line,

referring to Fig. 3-3.

Fig.2-2

3-1. SUB BRIGHT Sub-brightness adjustment / Adjustment menu

screen PAGE 3-2 (make sure of the order)

Input signal: Color bar (stairstep)

Measuring instrument: Leader LCG-404 pattern generator

1. Use the volume keys on the jig remote control to adjust until

the second step from the right gleams.

PAGE 3

3 SUB BRIGHT 37

2nd from right

Fig. 3-1

3-2. SUB CONTRAST Sub-brightness adjustment / Adjustment

menu screen PAGE 3-1

Input signal: Color bar (QIW) with chroma off

Measuring instruments: Oscilloscope

Leader LCG-404 pattern generator

Test point: TP902 on NK C.B.

1. Connect the oscilloscope to TP902.

2. Use the volume keys on the jig remote control to adjust so

that the voltage to the pedestal level from 100% white is

80 ± 2.0 V, referring to Fig. 3-2.

3-4. SUB COLOR Sub-color adjustment/Adjustment menu screen

PAGE 3-4

Input signal: Color bar

VIDEO IN

Measuring instruments: Oscilloscope

Leader LCG-401 pattern generator

Test point: TP302/BT301 (wire connector) pin (3)

1. Connect the oscilloscope to TP302.

2. Use the volume keys on the jig remote control to adjust so

that the peaks of waveform are in one straight line, referring

to Fig. 3-4.

Cyan

Horizontal straight line

Magenta

Fig. 3-4

1.0V

10 S

Pedestal level

80+2.0V

Fig. 3-2

75%white

100%white

36

Page 33

4. TV SETTING CHECK Settings check for different models/

1.0 V

0.5 ms

4.5 V

Fig.5-1

Adjustment menu screen PAGEs 4-1~4

The settings are fixed for each model: Do not change the

settings to those other than specified.

• Check to see if the settings on the adjustment menu screen

are the same as in Table 4.

If the settings are different, use the volume keys on the jig

remote control to reset them.

3.58 TRAP 0: ON

BPF 2: AUTO

H AFC 1: +1

WPL 0: OFF

* The 3.58 TRAP setting cannot be modified.

Table 4

PAGE 4

4 WPL

(Inoperable)

0: ON

2: AUTO

1: +1

0: OFF

Fig. 4

1 358 TRAP

2 BPF CUTOFF

3 H AFC

Check is possible even with a list of menus.

Tuner Adjustment:

If adjustment element has been replaced as a result of repair, perform

the following adjustments, and then proceed with adjustment using

the adjustment menu screens.

If this adjustment is not complete, correct adjustment will not be

possible with adjustment menu screens.

Components which cause the circuit status to change after repair:

• VCO coil

• SIF coil

• TRAP coil

• SEPARATION VR

5-1. VCO ADJUSTMENT VCO (PIF) adjustment/Video carrier

frequency free-running adjustment

Input signal: RF-NTSC color bar:

Input level: 90 dBµV

BROADCAST CH/fc=45.75MHz

Mode: TUNER

Test points: Input: TP-102 IF (TU101 pin 11)

Output: TP-201 AFT (IC301 pin 44)

Adjustment point: L205/P-IF

Measuring instruments: Oscilloscope

Leader LCG-404 pattern generator

1. Connect the oscilloscope to TP-201.

2. Supply a specified level RF signal to TP-102, and adjust

L205 so that the voltage at TP-201 is 2.8 ± 0.3 V DC.

5-2 SIF ADJUSTMENT Audio IF modulation adjustment

Input signal: AM/FM-SG RF OUT: 4.5MHz

MODE OFF

90 dBµV

With the smple adjustment method, receive an ordinary

broadcast signal with simple adjustment.

Mode: TUNER

Test points: Input/TP-202: IC301 pin 52

Output/TP-203: IC301 pin 54

Adjustment point: L201/S-IF

Measuring instruments: Oscilloscope

AM/FM signal generator

1. Connect the oscilloscope to TP-203.

2. Tune in TV channel 2.

3. Supply a specified signal to TP-202, and adjust L201 so

that the voltage at TP-203 is 4.5 ± 0.2 V DC.

37

Page 34

MECHANICAL EXPLODED VIEW 1/1

D

13

PCB

14

12

11

D

10

15

7

C

6

C

9

E

E

16

F

F

5

G

G

G

F

19

C

7

C

5

1

H

2

A

4

3

38

8

PCB

18

F

F

Page 35

MECHANICAL MAIN PARTS LIST 1/1

REF. NO PART NO. KANRI DESCRIPTION

1 87-054-086-010 BADGE,AIWA 52.5

2 8Z-JAK-003-010 PANEL,MAIN AN2010 NH

3 8Z-JBR-005-010 LENS,RC

4 8Z-JBR-006-010 LENS,LED

5 8Z-JBR-004-010 KEY,MAIN

6 8Z-JBS-001-010 CABI,FR

7 8Z-JB4-620-010 SPKR,6*12 8OHM 10W

! 8 8Z-JAD-620-010 AC CORD SET,NH BLK

9 8Z-JBR-201-010 HLDR,PCB 1

! 10 87-JBD-606-010 CRT,A48LRH94X02(W)

! 11 87-A50-557-010 DGC,20' 15 OHM-TYPE8

12 84-LB3-205-010 SPR-E,EARTH

13 84-LB2-633-110 CONN ASSY,1P CRT GND

14 8Z-JBR-002-010 CABI,REAR

15 8Z-JB5-010-010 PANEL,REAR SH

16 87-A90-332-010 HLDR,SF-2001 HV CABLE

18 8Z-JB5-007-010 BTN,POWER SH

19 84-LB3-216-010 HLDR,LED

A 87-067-680-010 BVI T3+3-10

C 87-078-070-010 BVIT3B+4-12

D 86-LBB-206-010 S-SCREW,ASSY TV5-40 W20

E 87-067-761-010 TAPPING SCREW, BVT2+3-10

F 87-067-579-010 TAPPING SCREW, BVT2+3-8

G 87-067-844-010 BVT2+4-16 BLK

H 87-067-690-010 TAPPING SCREW, BVIT3+3-12

NO.

COLOR NAME TABLE

Basic color symbol Color Basic color symbol Color Basic color symbol Color

B Black C Cream D Orange

G Green H Gray L Blue

LT Transparent Blue N Gold P Pink

R Red S Silver ST Titan Silver

T Brown V Violet W White

WT Transparent White Y Yellow YT Transparent Yellow

LM Metallic Blue LL Light Blue GT Transparent Green

LD Dark Blue DT Transparent Orange

39

Page 36

2–11, IKENOHATA 1–CHOME, TAITO-KU, TOKYO 110, JAPAN TEL:03 (3827) 3111

737004

Printed in Singapore

Loading...

Loading...