Aiwa D27U Service Manual

D27U

English

SERVICE MANUAL

VIDEO MECHANISM

BASIC NAME

D27

NAME

P4LRN045B

P4ERN048C

N4ERN025C

N4ERN028C

S/M Code No. 09-986-264-4N3

DATA

TABLE OF CONTENTS

VCR TEST TAPE INTERCHANGEABILITY TABLE ...................................................................................................................3

STANDARD MAINTENANCE .....................................................................................................................................................4

SERVICE JIGS AND TOOLS/ALIGNMENT TAPES FOR ADJUSTMENT .................................................................................5

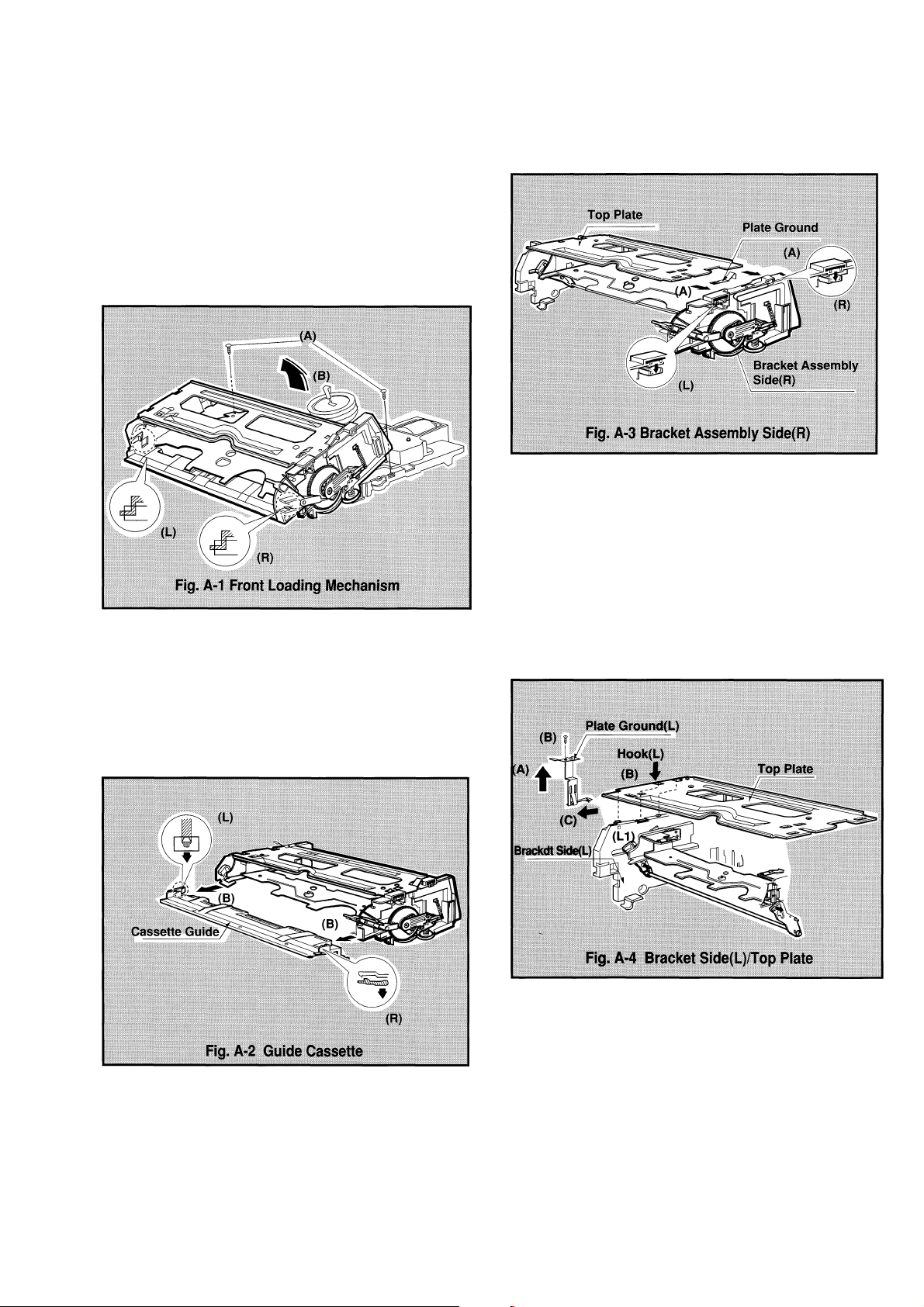

FRONT LOADING MECHANISM DISASSEMBLY ................................................................................................................. 6-8

• Front Loading Mechanism Assembly, Parts Location ...................................................................................................................................6

1. Front Loading Mechanism Assembly .....................................................................................................................................................7

2. Guide Cassette.......................................................................................................................................................................................7

3. Bracket Assembly Side (R).....................................................................................................................................................................7

4. Bracket Side (L)/Top Plate .....................................................................................................................................................................7

5. Holder Assembly Cassette .....................................................................................................................................................................8

6. Arm Assembly F/L ..................................................................................................................................................................................8

7. Spring Stopper........................................................................................................................................................................................8

8. Plate Reflector ........................................................................................................................................................................................8

DECK MECHANISM DISASSEMBLY................................................................................................................................... 9-19

• Deck Mechanism Parts Location ...................................................................................................................................................................9

1. Auto Head Cleaner Assembly ..............................................................................................................................................................10

2. Drum and Base Assembly ....................................................................................................................................................................10

3. Drum Sub Assembly and Motor Assembly ...........................................................................................................................................10

4. A/C (Audio/Control) Head Assembly ................................................................................................................................................... 11

5. FE (Full Erase) Head Assembly ...........................................................................................................................................................11

6. Plate Up/Supply Main Brake/Take up Main Brake/Body Prism Led Assembly ................................................................................... 11

7. Tension Arm/Lever Assembly Tension.................................................................................................................................................12

8. TAB Lever.............................................................................................................................................................................................12

9. Supply Reel/Take Up Reel Assembly...................................................................................................................................................12

10. Gear Pulley/Belt Capstan .....................................................................................................................................................................13

11. Gear H1, H2/Lever H1......................................................................................................................................................................... 13

12. Arm Assembly Idler ..............................................................................................................................................................................13

13. Mode S/W.............................................................................................................................................................................................13

14. Capstan Motor Assembly .....................................................................................................................................................................14

15. CAM Bracket Assembly....................................................................................................................................................................... 14

16. Cam Bracket/Lever Jog/Gear Jog ........................................................................................................................................................14

17. Gear Cam L/D ......................................................................................................................................................................................14

18. Gear PS/Plate Slider ............................................................................................................................................................................15

19. Gear Assembly P2/P3 ......................................................................................................................................................................... 15

20. Base Assembly P2/P3 ......................................................................................................................................................................... 15

21. Guide Roller Assembly .........................................................................................................................................................................16

22. Clutch Assembly S27 ...........................................................................................................................................................................16

23. Clutch Assembly T27............................................................................................................................................................................16

24. Lever Assembly F/R & Arm F/R ...........................................................................................................................................................16

25. Holder Pinch Assembly ....................................................................................................................................................................... 17

26. Pinch Arm Assembly ............................................................................................................................................................................17

27. L/D Motor Bracket Assembly ................................................................................................................................................................17

28. Worm Wheel .........................................................................................................................................................................................17

29. L/D Motor Assembly & Worm L/D Motor & L/D Motor Bracket .............................................................................................................18

30. Gear CNT .............................................................................................................................................................................................18

31. Gear Pinch........................................................................................................................................................................................... 18

32. T/Up Arm Assembly..............................................................................................................................................................................18

33. Gear Pinch Cam .................................................................................................................................................................................. 19

MECHANISM ADJUSTMENT ............................................................................................................................................. 20-30

1. Mechanism and Mode Switch Alignment Check ..................................................................................................................................20

2. Preparation for Adjustment (To set VCR (VCP) to the loading state without inserting a cassette.) .................................................... 21

3. Tension Post Position and Tension Adjustment ...................................................................................................................................21

4. Checking Torque ..................................................................................................................................................................................22

5. Guide Roller Height Adjustment ...........................................................................................................................................................23

6. Audio/Control (A/C) Head Adjustment........................................................................................................................................... 24, 25

7. X-Value Adjustment ..............................................................................................................................................................................25

8.

Adjustment after Replacing Drum Assembly (Video Heads)....................................................................................................................................................

9.

Check the Tape Travel after Reassembling Deck Assembly ...........................................................................................................................................................

10. Maintenance/Inspection Procedure ................................................................................................................................................ 28-30

26

26, 27

EXPLODED VIEW .............................................................................................................................................................. 31-33

PARTS LIST..............................................................................................................................................................................34

REFERENCE NAME LIST ........................................................................................................................................................35

2

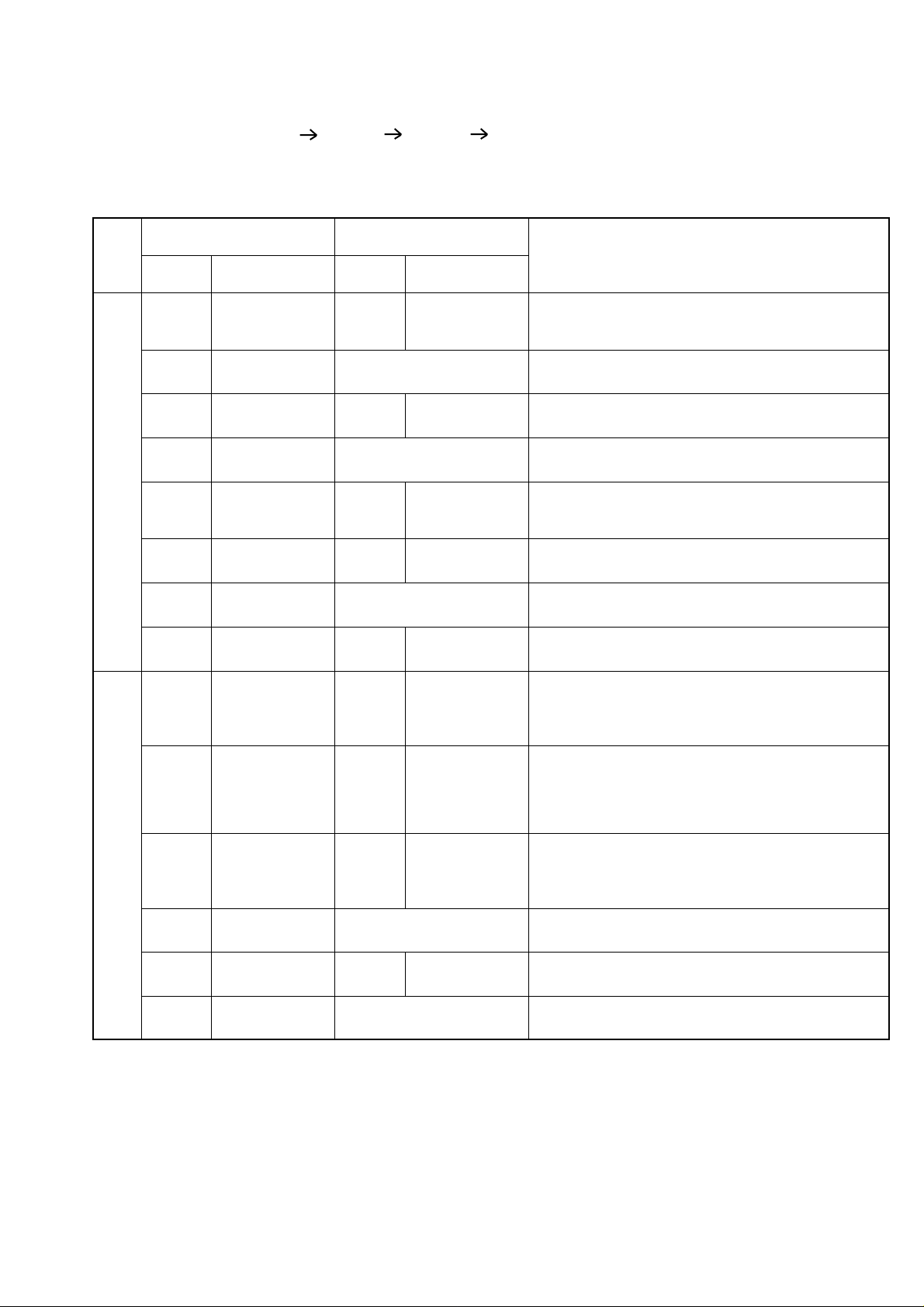

VCR TEST TAPE INTERCHANGEABILITY TABLE

There are two types of the new allgnment tape CH-1B (for NTSC) and CH-2 (for PAL). On each tape four signals (1)-(4)

are recorded for the times and in the order shown below.

(1) : 8min. (2) : 2min. (3) : 5min. (4) : 5min.

The TTV-MP1 (for M-PAL), TTV-MS1 (for MESECAM) and TTV-S1 (for SECAM) allgnment tapes have the same

contents as the previous tapes.

Method

NTSC

Now in use TYPE

Model Contents *1

TTV-N1

TTV-NS1

TTV-N1E

TTV-NS6E

TTV-N2

TTV-N12

(SCV-1998)

TTV-N6

(TTV-N06T)

TTV-N7A

NTSC, Color bar,

1kHz, SP

NTSC, Color bar,

1kHz, SP

NTSC, Color bar,

1kHz, EP

NTSC, Color bar,

No sound, EP

NTSC, Stairsteps,

7kHz, SP

NTSC, Color bar,

1kHz, SP

NTSC, Mono scope,

7kHz, SP

NTSC, Stairsteps,

1kHz, SP, HiFi 400Hz

New TYPE

Model Contents *1

CH-1B(2)

CH-1B(4)

*2

CH-1B(1)

CH-1B(4)

CH-1B(3)

NTSC, Stairsteps,

1kHz, SP

No Changed.

NTSC, Color bar,

1kHz, EP

No Changed.

NTSC, Stairsteps,

7kHz, SP

NTSC, Color bar,

1kHz, EP

No Changed.

NTSC, Color bar,

No sound SP,

HiFi 400Hz

Application

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

For S-VHS (SQPB) check

Switching position ADJ.

For S-VHS (SQPB) check

Head ACE Azimuth ADJ.

FM Envelope ADJ.

X-V alue ADJ.

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

Switching position ADJ.

PB-Y Level/General electrical ADJ.

Head ACE Height/Tilt ADJ.

Switching position. (LP Model)

FM Envelope ADJ. (LP Model)

X-Value ADJ. (LP Model)

HEAD ACE Azimuth ADJ.

FM Envelope ADJ. (SP Model)

X-Value ADJ. (SP Model)

For total picture quality check (resolution, etc)

HiFi Audio PB Level ADJ.

FM Filter ADJ.

PAL

TTV-P1

TTV-P1L

TTV-P2

TTV-P6

(TTV-N06T)

TTV-P7

TTV-P16

PAL, Color bar,

1kHz, SP

PAL, Color bar,

1kHz, LP

PAL, Stairsteps,

6kHz, SP

PAL, Monoscope,

6kHz, SP

PAL, Stairsteps,

1kHz, SP,

HiFi 1kHz

PAL, Color bar,

400Hz,

SP, HiFi 1kHz

CH-2(2)

* 3

CH-2(4)

CH-2(1)

CH-2(3)

PAL, Stairsteps,

1kHz, SP

PAL, Color bar,

1kHz, LP

PAL, Stairsteps,

6kHz, SP

No Changed.

PAL, Color bar,

No sound

SP, HiFi400Hz

No Changed.

* 1. Described in the order of color format. video signal. linear audio. tape speed and Hi-Fi audio.

* 2. Use CH-1B (1)-(3) with models used exclusively in the SP mode.

* 3. Use CH-2 (3) and (4) when it is necessary to observe the chroma signal.

3

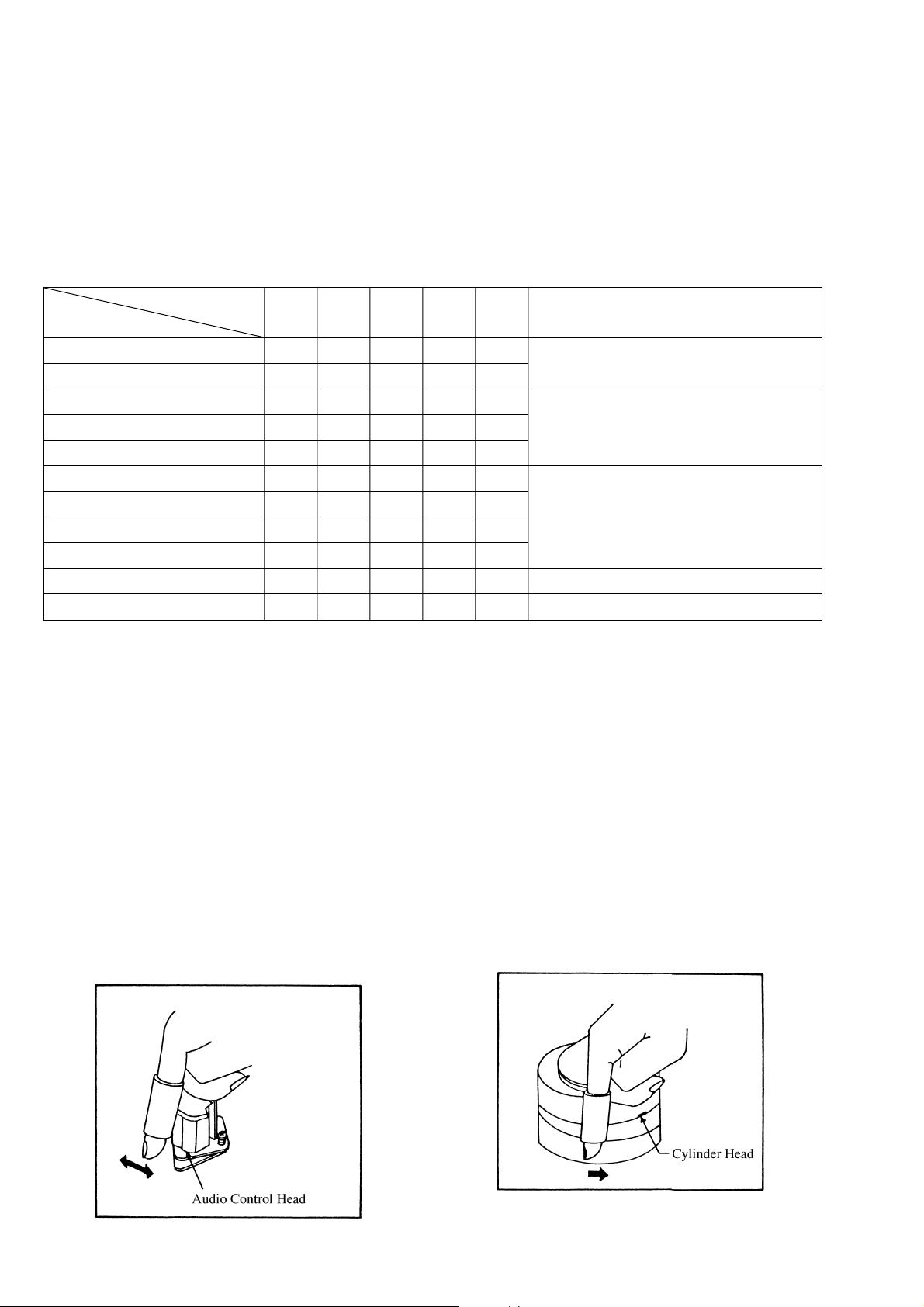

STANDARD MAINTENANCE

1. SERVICE SCHEDURE

The standard list is shown as follows which is heavily

dependent on the environmental conditions and operating

method. If maintenance is not properly executed, the

problem will grow over time into other parts of the machine

which will shorten the maintenance period as shown in the

list. If the machine is not used for long period of time or

incorrectly used, the rubber parts can be deformed and worn

out of their lives. The following list shows a reference time

for maintenance and can differ from actual time of the

required maintenance.

Inspection Time

Parts Name

Audio Control Head

Full Erase Head

Reel Belt

Front Loading Belt

Pinch Roller

Capstan DD Unit

Loading Motor

Tension Band Ass’y

Capstan Shaft

Tape Run Mechanism Guide Posts

Cylinder Unit

500

Hours

1,000

Hours

9

9

9

9

9

9

9

9

9

9

9

9

9

9 0

1,500

Hours

9

9

9

9

9

9

2,000

Hours

9

9

0

0

9

9

9

9 0

3,000

Hours

9

9

9 0

0

0

0

9

9

9 0

0: Replace 9: Cleaning

Notes

Clean the parts which contact tape.

Clean the rubber parts and the parts which

contact rubber.

If abnormal rotation is found, replace it.

Clean the heads.

2. CLEANING

Note:

• If a part is cleaned using alchol, dry it completely before

tape is run in the mechanism. If drying is incomplete,

alchol will stick on the tape and will damage that portion

of the tape.

(1) Audio Control Head

• Wrap the cleaning cloth or chamois around finger and

soak it with alcohl. Move it horizontally over the audio

control head. Clean the full erase head in the same way.

(See the illustration below.)

(2) Tape Run Mechanism

• Clean the tape run mechanism with gauze soaked with

alchol.

(3) Cylinder

• Put on glove (thin glove) so that the upper drum or

lower drum must be touched by naked hand.

• Apply a few drops of alchol into the cleaning cloth or

chamois. Bring it in contact with the head tip and rotate

the upper drum in the counterclockwise direction.

Note:

• Though the video head is made from the very hard

material, it is very thin and fragile. Never move the

cleaning cloth or chamois in vertical direction or clean it

vertically. It can easily break the head.

• Do not operate the machine before the cleaned portion is

completely dried.

• The stained chamois or the stained head cleaning cloth

must not be re-used.

4

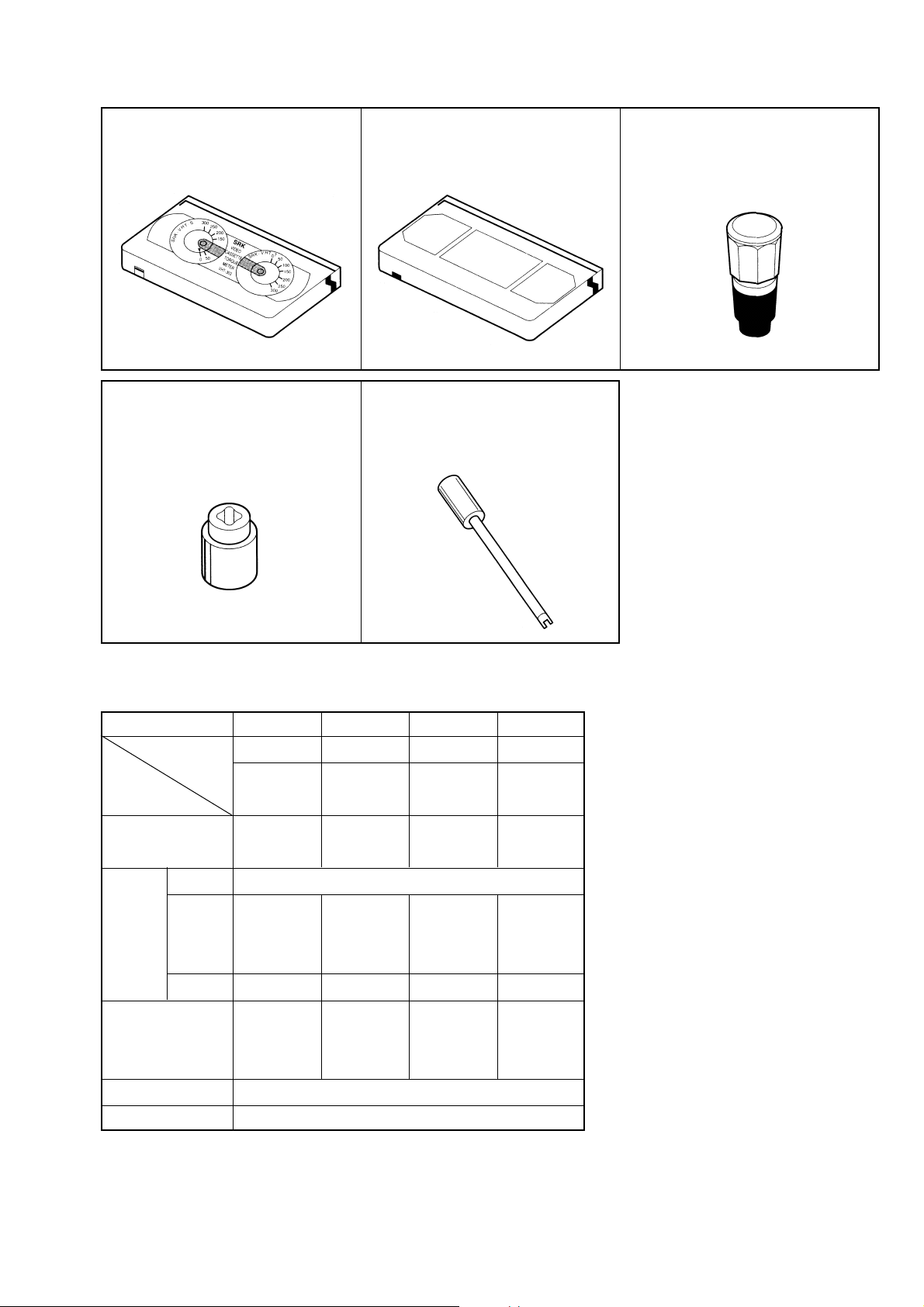

SERVICE JIGS AND TOOLS

• Tools and Fixtures for Deck

1. Cassette Torque meter 2. Alignment tape 3. Torque gauge

Parts No: SRX-VHT-103 (See figure below) Parts No: D00-D002

4. Torque gauge adaptor 5. Post height adjusting driver

Parts No: D09-R001 Parts No:

SV-TG0-030-000 (SMALL)

SV-TG0-020-000 (LARGE)

ALIGNMENT TAPES FOR ADJUSTMENT

Derivation No. A B C D

Mechanism PAL PAL NTSC NTSC

SP/LP SP SP/LP/EP SP

Adjustment Items

FM Envelope TTV-P2L TTV-P2

Slantness A commercially available tape

A/C TTV-P1

Head

RG Post Inclination A commercially available tape

Tape Back Tension SRK-VHT-103

Height

Azimuth TTV-P2 TTV-P2 TTV-N2 TTV-N2

X-value

2/4 Head 2 Head 2/4 Head 2 Head

TTV-N1

(TTV-N12)

TTV-N1

(TTV-P1L)

TTV-P2

(TTV-P2L)

TTV-P1 (TTV-N12)

(TTV-N1E)

TTV-N2

TTV-P2 TTV-N2E TTV-N2

TTV-N12

TTV-N2

TTV-N1

(TTV-N12)

* The numbers in ( ) parenthesis can be used as the substitute.

5

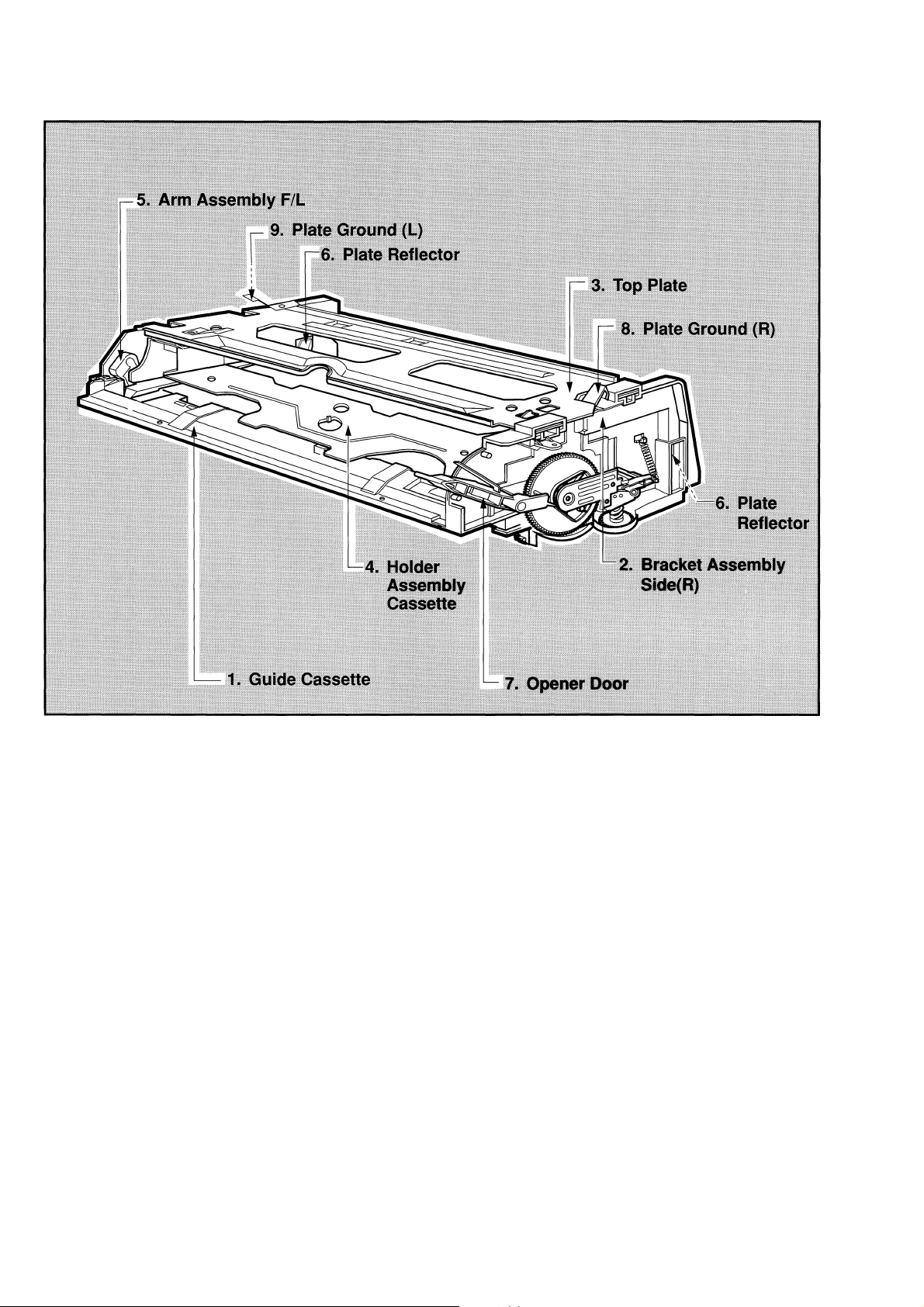

FRONT LOADING MECHANISM DISASSEMBLY

• Front Loading Mechanism Assembly, Parts Location

• Component list below will be discribed as if the top and bottom covers, front panel and deck

mechanism assembly have already been removed.

1. Guide Cassette 5. Arm Assembly F/L

2. Bracket Assembly Side (R) 6. Plate Reflector

3. Top Plate 7. Opener Door

4. Holder Assembly Cassette 8. Plate Ground (R)

9. Plate Ground (L)

6

1. Front Loading Mechanism Assembly (Fig.

A-1)

1) Remove the Top and Bottom Covers and Front Panel.

2) Remove two screws (A).

3) Lift up the Front Loading Mechanism Assembly in the

direction of arrow (B).

NOTE)

When disassembling and reassembling:

1 Give special attention to removal and to reassembly

because two hooks (L), (R) are engaged.

3. Bracket Assembly Side (R) (Fig. A-3)

1) Push the hooks (L), (R) of Bracket Assembly Side (R)

to disengage with the Top Plate and remove it in the

direction of arrow (A).

4. Bracket Side (L)/Top Plate (Fig. A-4)

2. Guide Cassette (Fig. A-2)

1) Push hook (R) of the Cassette Guide and disengage

with Bracket Side (R) and push hook (L) of the

cassette Guide which is engaged with Bracket Side

(L) and remove it in the direction of arrow (B).

1) Remove the screw (B).

2) Remove the plate Ground (L), in the direction of

arrow (A).

3) Push the locking tab (L1) and then remove the

Bracket Side (L) in the direction of arrow (B).

4) The Top Plate can be removed by Separating the

Bracket Side (L).

7

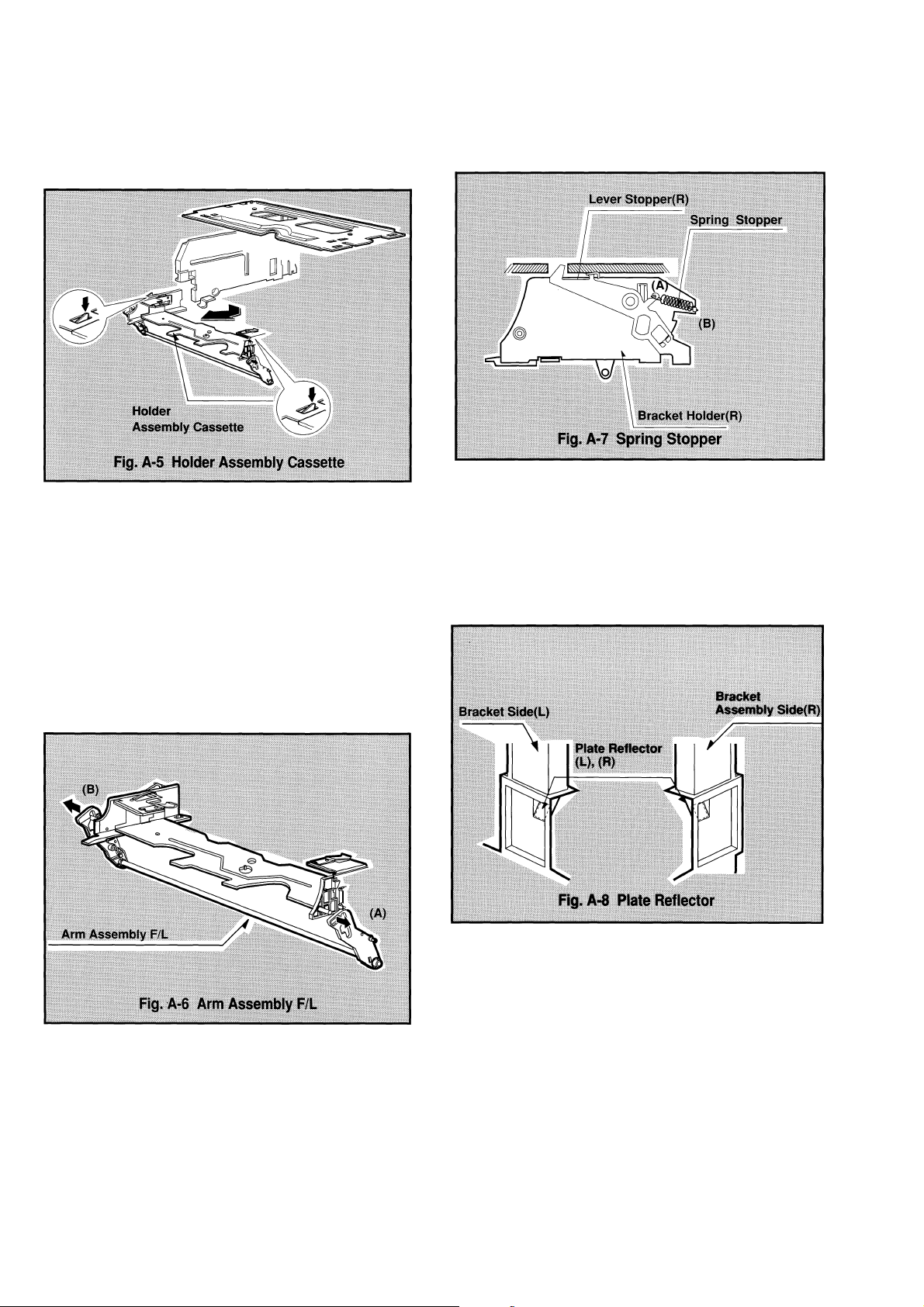

5. Holder Assembly Cassette (Fig. A-5)

7. Spring Stopper (Fig. A-7)

1) Separate the Bracket Assembly Side (R).

2) Push the two lever hooks (L), (R) down and separate

the Holder Assembly Cassette and the Arm Assembly

F/L from the Top Plate.

6. Arm Assembly F/L (Fig. A-6)

1) Remove by pulling the Arm F/L (R) from the Bracket

Holder (R) Boss in the direction of arrow (A).

2) Separate the Arm Assembly F/L from Cassette Holder

Boss in the direction of arrow (B).

1) Remove the Spring Stopper which is connected to the

Hooks (A), (B) of the Lever Stopper (R) and the

Bracket Holder (R).

8. Plate Reflector (Fig. A-8)

1) Detach the Plate Reflector (L) from the Top Plate by

using a knife.

2) Detach the Plate Reflector (R) from the Bracket

Assembly Side (R) by using a knife

NOTE)

When disassembling and reassembling:

1 Be sure to remove the Arm F/L (R) first. If not the

Arm Assembly F/L can be damaged.

8

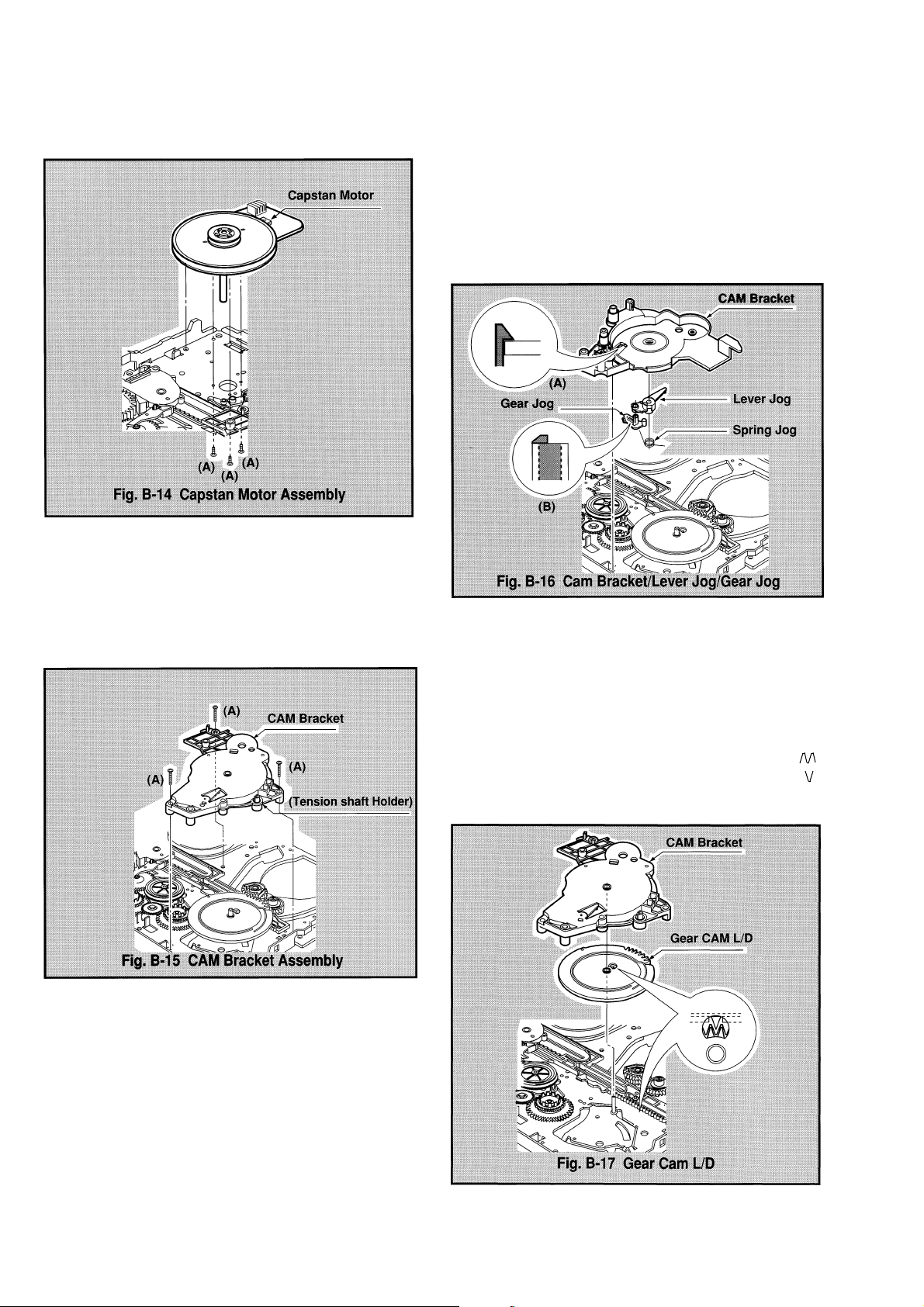

14. Capstan Motor Assembly (Fig. B-14)

1) Remove three Screws (A) on the top side and remove

the Capstan Motor Assembly.

16. Cam Bracket/Lever Jog/Gear Jog

(Fig. B-16)

1) Remove the Cam Bracket Assembly.

2) Remove the Spring Jog.

3) Push the hook (A) and remove the Lever Jog.

4) Push the hook (B) and remove the Gear Jog.

NOTE)

1 The hook (B) on the Gear Jog should be in groove of

the Lever Jog.

15. CAM Bracket Assembly (Fig. B-15)

1) Remove three screws (A).

2) Remove the CAM Bracket Assembly.

17. Gear Cam L/D (Fig. B-17)

1) Remove the Cam Bracket Assembly.

2) Remove the Gear Cam L/D.

NOTE)

1) When assembling the Gear Cam L/D, the groove ( )

of Plate Slider should coincide with to the groove ( )

on the Gear Cam L/D.

14

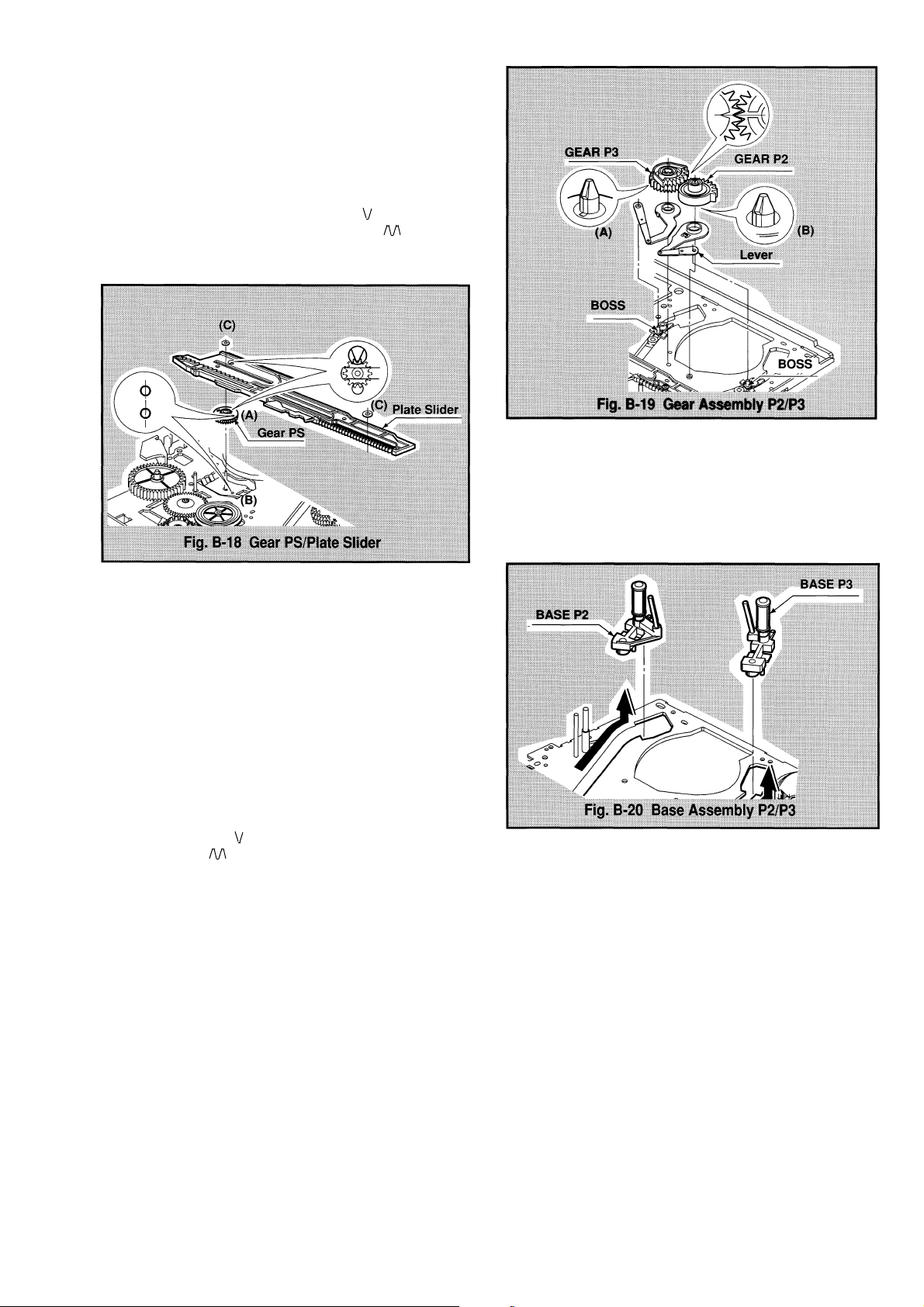

18. Gear PS/Plate Slider (Fig. B-18)

1) Remove two washers (C).

2) Remove the Plate Slider.

3) Remove the Gear PS.

NOTE)

1) When the hole (A) of the Gear PS is aligned to the

hole (B) of the chassis, the groove ( ) of the Plate

Slider should be aligned to the groove ( ) of the

Gear PS.

20. Base Assembly P2/P3 (Fig. B-20)

1) Remove the P2/P3 Gear Assembly.

2) Remove the P2/P3 Base Assembly.

19. Gear Assembly P2/P3 (Fig. B-19)

1) Remove the Plate Slider.

2) Remove by pushing one hook (B) on the top side of

Gear Assembly P3.

3) Remove by pushing one hook (A) on the top side of

Gear Assembly P2.

NOTES)

When disassembling and reassembling:

1 The P2 and P3 Gear Assembly should not be

interchanged.

2 The groove ( ), of Gear P2 should be aligned to the

groove ( ) of Gear P3.

3 Set the hole of Lever to the Boss of P2 and P3 Base

Assembly. (When assembling make sure that the

Lever is not bent.)

15

Loading...

Loading...