Page 1

INSTALLATION INSTRUCTIONSOWNER’S GUIDE &

Transom Mount with Kick-up Bracket 20-035

Transducer or TRIDUCER® Multisensor

Model: P52

Follow the precautions below for optimal product

performance and to reduce the risk of property

damage, personal injury, and/or death.

WARNING: Always wear safety goggles and a dust

mask when installing

WARNING: When the boat is placed in the water,

immediately check for leaks around the screws and

17-002 rev. 04 04/12/11

any other holes drilled in the hull.

CAUTION:

impact only.

CAUTION: Never pull, carry, or hold the sensor by the

cable as this may sever internal connections.

CAUTION: Never strike the sensor.

CAUTION: Never use solvents. Cleaners, fuel, paint,

sealants, and other products may contain strong

solvents, such as acetone, which attack many plastics

greatly reducing their strength.

IMPORTANT: Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

Applications

• Not recommended for boat with large inboard engine(s).

• Good operation up to 40kn (46MPH).

Requires experimentation at higher speeds.

• Vertically orients the sound beam on hull with deadrise angle up

°

to 22

• Adjusts to transom angles up to 20°.

Tools & Materials

Safety goggles

Dust mask

Water-based antifouling paint (mandatory in salt water)

Screwdrivers

Adjustable wrench

Pencil

Electric drill

Drill bits and hole saw or spade bit:

Bracket holes 4mm, #23, or 9/64"

Fiberglass hull chamfer (preferred), 6mm, or 1/4"

Transom hole (optional) 20mm or 13/16"

Cable clamp holes

Masking tape

Marine sealant (suitable for below waterline)

Straight edge

Line (optional)

Zip-ties

The bracket protects the sensor from frontal

3mm or 1/8"

P52 TRIDUCER® Multisensor

Identifying Your Model

The model name is printed on the cable tag.

Antifouling Paint

Aquatic growth can accumulate rapidly on the sensor’s surface

reducing performance within weeks. Surfaces exposed to salt

water that do not interlock must be coated with antifouling paint.

Use water-based antifouling paint only. Never use ketone based

paint, since ketones can attack many types of plastic possibly

causing damage to the transducer. It may be easier to apply paint

before installing the sensor, but allow drying time. Reapply paint

every 6 months or at the beginning of each boating season.

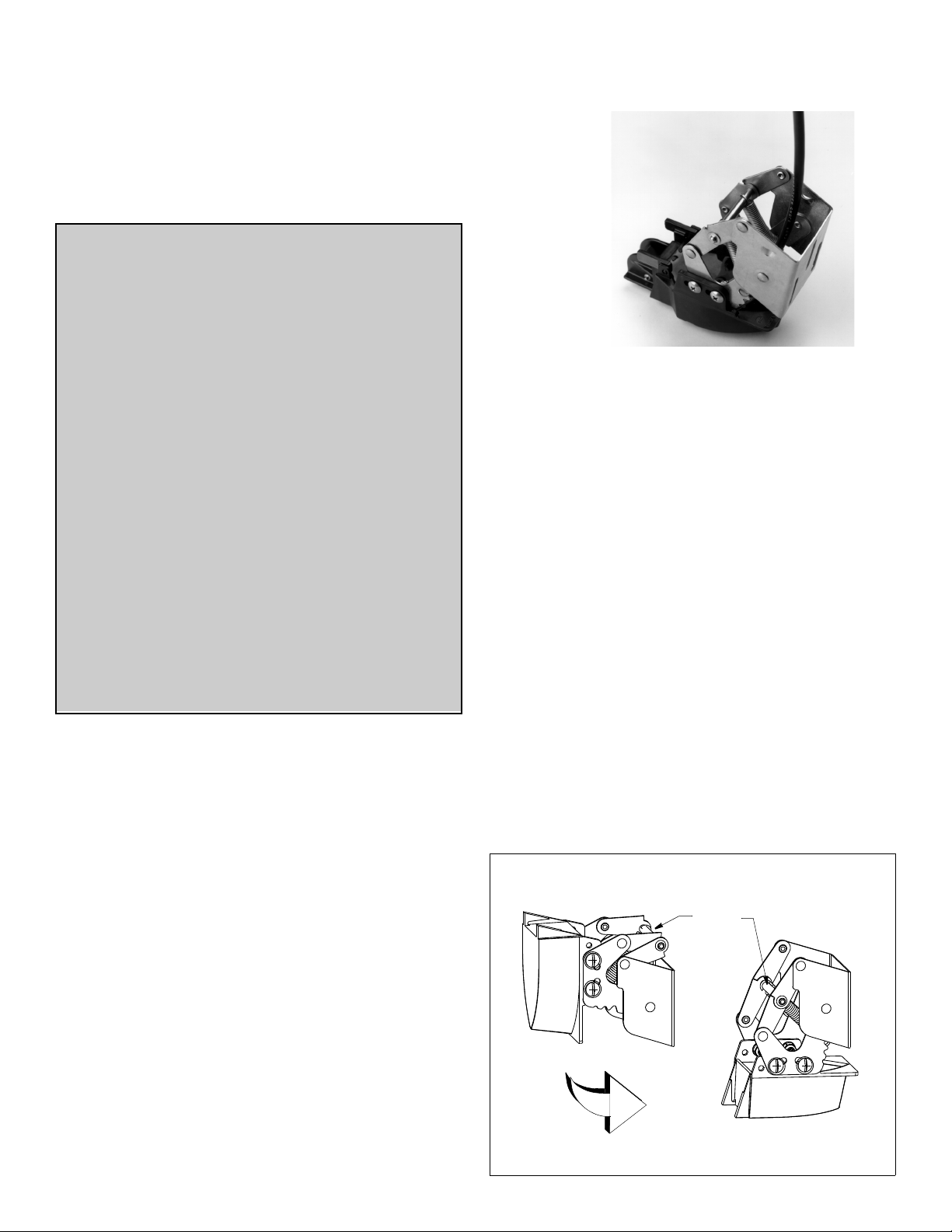

Assembling

1. The bracket is shipped in the “up” (released) position. Before

attaching the sensor, set the bracket in the “down” (operating)

position by grasping the cross bar and pulling outward in an arc

(see Figure 1).

2. Run the cable through the bracket between the cross bar and

the transom (see photo on front page).

3. Attach the sensor to the bracket with the four #10-32 x 5/8"

machine screws, washers, and lock nuts. Tighten the screws so

the sensor remains in place, but can be adjusted (see Figure 2).

P52—Place the bracket inside the mounting tabs (see photo on

front page).

“up” (released) “down” (operating)

cross bar

Figure 1. Bracket positions (P37 shown)

Page 2

transom

lock nut (4)

flat washer (8)

mounting tabs

#10-32 x 5/8"

screw (4)

Figure 2. Transducer and bracket assembly (P37 shown)

Mounting Location

CAUTION: Do not mount in an area of turbulence or bubbles:

near water intake or discharge openings; behind strakes, struts,

fittings, or hull irregularities

CAUTION: Avoid mounting the sensor where the boat may be

supported during trailering, launching, hauling, or storage.

• For the best performance, the sensor must be in contact with

smooth water. To identify an area of clean water, observe the

water flow off the transom while the boat is underway.

• Allow headroom space above the bracket for it to release and

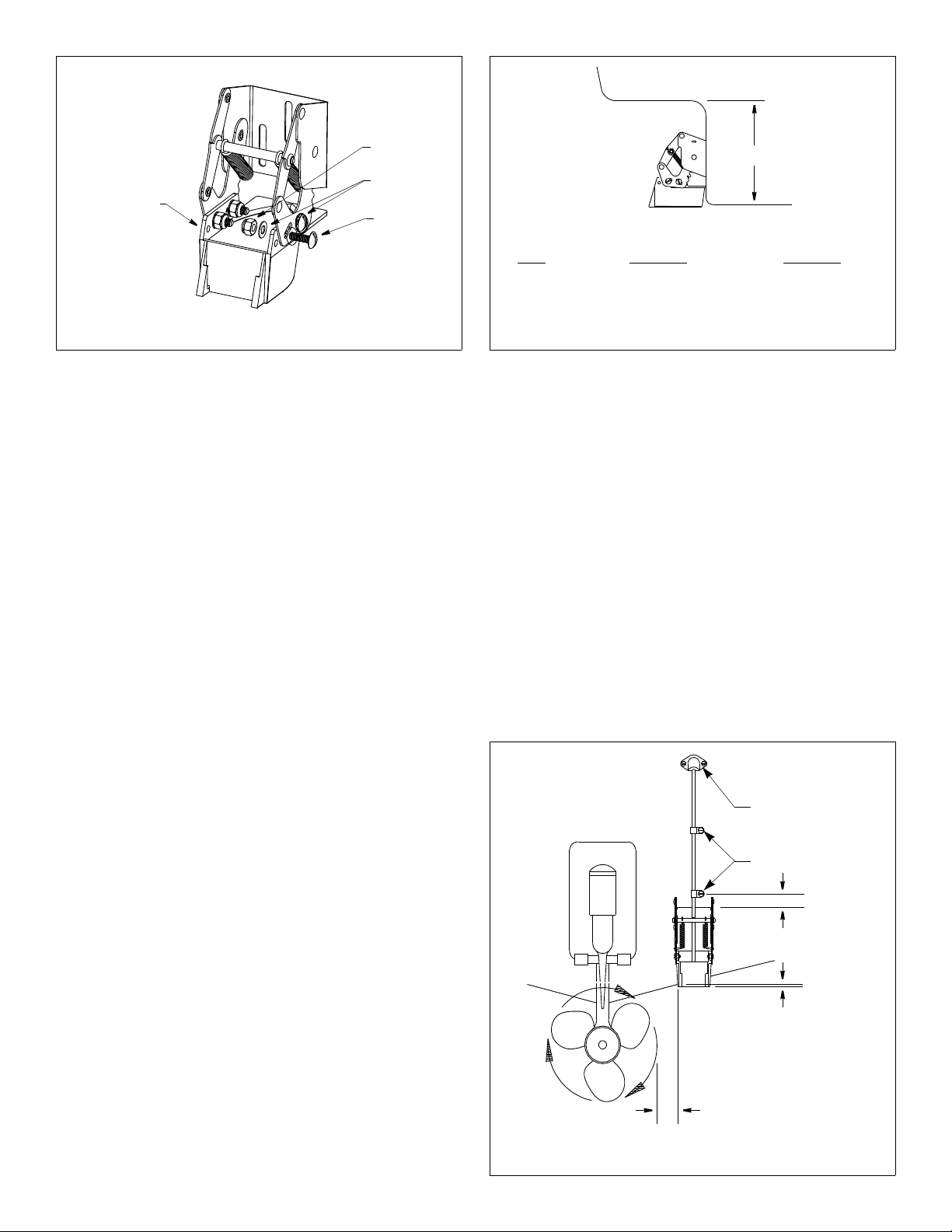

rotate the sensor upward (see Figure 3).

• Mount the sensor as close to the centerline (keel) of the boat as

possible to ensure the sensor remains in the water when the

boat is turning.

• Single drive boat—Mount at least 75mm (3") beyond the

swing radius of the propeller (see Figure 4). The starboard

side where the propeller blades are moving downward is

preferred.

• Twin drive boat—Mount the sensor between the drives.

height

Model

P52 175 mm (7-1/2") 215mm (9")

Height without Height with

paddlewheel paddlewheel

Figure 3. Height required at mounting location (P37 shown)

3. Using a 4mm, #23, or 9/64" bit, drill three holes 22 mm (7/8")

deep at the locations indicated.

4. Apply marine sealant to the threads of the three #10 x 3/4" selftapping screws to prevent water seepage into the transom.

Slide a flat washer onto each screw and fasten the assembly to

the hull. Do not tighten the screws completely at this time.

5. Using the vertical adjustment space on the bracket slots, slide

the sensor up or down to provide a projection of 6mm (1/4")

(see Figure 4). Tighten the screws.

6. Using a straight edge, adjust the angle of the transducer on the

bracket. Sight the underside of the transducer relative to the

underside of the hull (see Figure 6). Adjust the sensor on the

bracket so it is parallel to the bottom of the hull or at a slight

angle. For best results set the trailing edge of the transducer

1-3 mm (1/16 - 1/8") below the leading edge (see Figure 7).

Tighten the screws.

Installation

CAUTION: Do not position the leading edge of the sensor lower

than the trailing edge because aeration will occur.

CAUTION: Do not position the sensor deeper into the water than

necessary to avoid increasing drag, spray, and water noise and

reducing boat speed.

CAUTION: To prevent drilling too deeply, wrap masking tape

around the bit 22mm (7/8") from the point.

CAUTION: Fiberglass hull—Minimize surface cracking by

running the drill in reverse until the gelcoat is penetrated.

Mounting & Adjusting

1. Position the assembly at the selected location with the

transducer face parallel to the water. Good results can be

achieved on most boats when the bottom of the transducer is

about 6mm (1/4") below the bottom of the hull and parallel to the

waterline (see Figure 4).

2. With a pencil, mark the outline of the bracket slots on the hull.

Mark the screw location at the bottom of each slot to allow for

adjusting the bracket (see Figure 5).

2

cable cover

cable clamps

50mm (2")

Hull projections:

fiberglass, wood 6mm (1/4")

Bottom parallel to water line

75mm (3") minimum beyond

swing radius of propeller

Figure 4. Mounting location on single drive boat

Page 3

correct incorrect

(cannot adjust)

YES

YES

Figure 5. Mounting the bracket

Setting the Bracket Release Point

There is considerable force on the bracket during normal

operation. The amount of force is proportional to the drag which is

created by the:

• Sensor—shape, size, weight, and amount of projection

below the transom.

• Speed—the square of the speed of the boat.

A larger and heavier transducer or TRIDUCER

®

multisensor

creates more drag as does a higher boat speed. For example, the

drag at 40kn (46MPH) is 4 times that at 20kn (23 MPH).

Set the springs in the appropriate notches on the pivot arms (see

Figure 7).

• Middle or lower notches if the top speed of the boat is more

than 30kn (34MPH).

Release Line

CAUTION: Be sure that both ends of the line are well secured to

eliminate the possibility of becoming entangled in the propeller.

To facilitate raising the sensor to the “up” (released) position, a

line can be attached to the bracket’s crossbar (see Figures 7 and

1). An upward jerk on this line will release the bracket.

Cable Routing

CAUTION: Do not remove the connector to ease cable routing. If

the cable must be cut and spliced, use Airmar’s splash-proof

Junction Box No. 33-035 and follow the instructions provided.

Removing the waterproof connector or cutting the cable, except

when using a water-tight junction box, will void the sensor

warranty.

Route the sensor cable(s) over the transom, through a drain hole,

or through a new hole drilled in the transom above the waterline.

1. If a hole must be drilled, choose a location well above the

waterline. Check for obstructions such as trim tabs, pumps, or

wiring inside the hull. Mark the location with a pencil. Drill a hole

through the transom using a 20 mm or 13/16” hole saw or spade

bit (to accommodate the connector).

2. Route the cable(s) over or through the transom. Be sure the

cable is between the cross bar and the transom (see photo

on page 1).

3. On the outside of the hull secure the cable(s) against the

transom using the cable clamps. Position a cable clamp 50mm

(2") above the bracket and mark the screw hole with a pencil

(see Figure 4).

4. Position the second cable clamp halfway between the first

clamp and the cable hole. Mark this mounting hole. If there are

two cables, repeat this step.

5. If a hole has been drilled through the transom, open the

appropriate slot(s) in the cable cover (see Figure 8). The cable

cover can accommodate two cables when there are separate

parallel

NO

angle too severe

slight angle

NO

Figure 6. Transducer angle adjustment (P37 shown)

cables for depth and speed/temperature functions. Position the

cover over the cable(s) where it enters the hull. Mark the two

mounting holes.

6. At each of the marked locations, use a 3 mm or 1/8" bit to drill a

hole 10mm (3/8") deep.

7. Apply marine sealant to the threads of the #6 x 1/2" (13mm)

self-tapping screws to prevent water from seeping into the

transom. If a hole has been drilled through the transom, apply

marine sealant to the space around the cable leading through

the transom.

8. Position the two cable clamps and screw them in place. If used,

push the cable cover over the cable(s) and screw it in place.

9. Route the cable(s) to the instrument(s), being careful not to tear

the cable jacket when passing it through the bulkhead(s) and

other parts of the boat. To reduce electrical interference,

separate the sensor cable(s) from other electrical wiring and

sources of noise. Coil any excess cable and secure it in place

with zip-ties to prevent damage.

10.Refer to the echosounder owner’s manual(s) to connect the

sensor to the instrument(s).

cross bar

spring

pivot arm

1-3mm (1/16 -1/8")

stern

cable

notch

bow

Figure 7. Transducer angle & release point setting (P37 shown)

Figure 8. Cable cover

3

Page 4

Figure 9. 33-105

shear

pins (4)

shear pins (4)

Figure 10. 33-110

To improve performance, try the following one at a time in the

order given.

a. Increase the sensor’s angle in the water.

b. Move the sensor deeper into the water in increments of

3mm (1/8").

c. Move the sensor closer to the centerline of the boat.

Fill unused screw holes with marine sealant.

NOTE: High-speed operation [above 35kn (40MPH)] may

require less projection in the water to improve performance and

reduce the chance that water pressure will cause the bracket to

release.

Checking for Leaks

When the boat is placed in the water, immediately check for

leaks around the screws that fasten the sensor to the hull. Note

that very small leaks may not be readily observed. Do not leave

the boat in the water unchecked for more than three hours.

Testing on the Water

Bracket Release Point

CAUTION: Do not set the bracket to withstand more force than

the minimum required to hold the sensor in the "down" (operating)

position, since this increases the chance that the bracket will not

release when the sensor is struck.

The correct bracket release setting has been found when the

sensor remains in the “down” (operating) position under normal

operating conditions. Gradually increase the boat speed and

observe the echosounder. When the bracket releases, there will

be an instantaneous loss of echo. Depending on conditions, the

bracket may either partially release and reset itself or fully release

rotating the sensor through an arc of 105

If the bracket releases before reaching top boat speed, set the

springs in the next lower notches and reset the bracket in the

“down” (operating) position. Repeat the test until the desired

result is obtained.

Echosounder Performance

1. If there is a temperature sensor, allow a few minutes for it to

respond to a major temperature change from the air to the water.

Check for an accurate reading.

2. Become familiar with your echosounder’s performance at a

speed of 4kn (5MPH).

3. Gradually increase the boat speed and observe the gradual

decline in performance due to turbulent water flowing over the

transducer’s active surface.

4. If the decline in performance is sudden (not gradual), identify

the boat speed at which the onset occurred. Return the boat to

this speed, then gradually increase speed while making

moderate turns in both directions.

5. If the performance improves while turning to the side on which

the sensor is installed, the transducer’s position probably needs

adjustment. It is probably in aerated water.

°.

Maintenance, Repair, & Replacement

Speed Sensor

Be sure to place the bracket in the “up” (released) position before

beaching, trailering, or hauling the boat since these are the main

causes of speed sensor breakage.

Cleaning

Clean the transducer’s surface with a Scotch-Brite® scour pad

and mild household detergent taking care to avoid making

scratches. If the fouling is severe, lightly wet sand with fine grade

wet/dry paper.

If the paddlewheel becomes fouled or inoperable, unsnap the

paddlewheel assembly from the main housing for cleaning.

Severe cases may require removal of the paddlewheel. Using a

small screwdriver, remove the paddlewheel shaft retainers. (If a

retainer is lost, a dab of RTV caulk on the end of the shaft will

secure it.) If necessary, use a stiff brush or putty knife to remove

the growth being careful to avoid scratching the transducer’s face.

Wet sanding is permissible with fine grade wet/dry paper.

Sensor Replacement & Parts

The information needed to order a replacement sensor is printed

on the cable tag. Do not remove this tag. When ordering, specify

the part number, date, and frequency in kHz.

Replace broken or worn parts immediately. The speed sensor

shear pins are designed to fracture upon impact. The water

lubricated paddlewheel bearings have a life of up to 5 years on

low-speed boats [less than 10kn (11MPH)] and 2 years on highspeed vessels. For a replacement paddlewheel carrier without a

cable, order the Airmar Snap-in Paddlewheel Carrier 33-105 (see

Figure 9); for an assembly with a cable, order a Transom

Paddlewheel Kit 33-110 (see Figure 10) from your marine dealer

or echosounder manufacturer.

This stainless steel bracket interchanges with the Plastic Release

Bracket 20-039 using the same mounting holes.

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco Tel: 803-693-0777

(USA) Fax: 803-693-0477

email: sales@gemeco.com

Airmar EMEA Tel: +33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax: +33.(0)2.23.52.06.49

email: sales@airmar-emea.com

®

AIRMAR

TECHNOLOGY CORPORATION

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

www.airmar.com

Copyright © 1995 2011 Airmar Technology Corp. All rights reserved.

4

Loading...

Loading...