Page 1

INSTALLATION INSTRUCTIONS

seamless

pipe

M192-NAV Transducer

Installed in Lloyd’s Type Approved, Tank, CS235

IMPORTANT: Please read the instructions completely before

proceeding with the installation. These directions supersede

instructions in your instrument manual if they differ.

WARNING: NEVER USE SOLVENTS!

Cleaners, gasoline, paints, sealants, and other products may

17-174-01 rev. 1 2/99

contain strong solvents, such as acetone, which can attack many

plastics dramatically reducing their strength.

Tools and Materials Needed

Water-based antifouling paint (mandatory in salt water)

Cable gland

Junction box

Underwater lubricant such as Aqualube

Hex wrench: 8M

Marine sealant

NOTE: The terms tank and housing are used interchangeably.

Antifouling Paint

Surfaces exposed to salt water must be coated with

antifouling paint. Paint the housing with an appropriate

antifouling, corrosion inhibiting coating. Use only water-

based antifouling paint on the radiating face of the

transducer. Never use ketone-based paint on the

transducer’s face since ketones can attack many plastics

possibly damaging the transducer. It is easier to apply

antifouling paint before installation, but allow for sufficient

drying time.

Installing the Transducer and Cable

Caution: Never pull, carry, or hold the transducer by the

cable as this may sever internal connections.

1. Inspect the transducer, cable, and connectors carefully

before installing. All parts must be clean and free of oil,

grease, paint, solvents, and other foreign material that

may hinder performance.

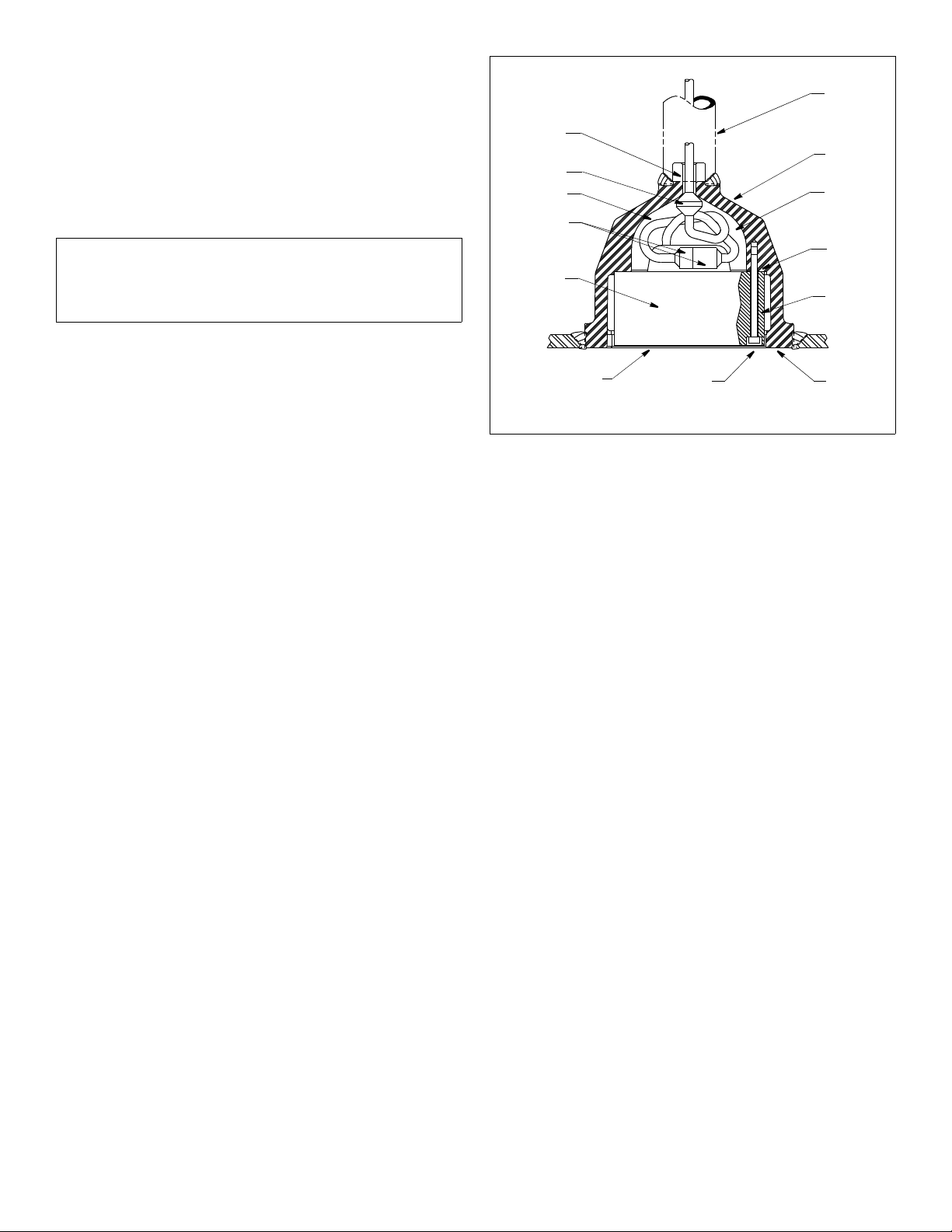

2. Pull the tagged end of the transducer cable

(P/N 22-136-01) through the housing cable passage

and the seamless pipe until the cable stop is seated

firmly against the cable passage opening (see Figure 1).

®

cable

passage

cable

stop

cable

loop

connectors

transducer

radiating face counterbore (3) flange

tank

(housing)

cable

storage

cavity

rubber

retaining

ring (3)

mounting

screw (3)

Figure 1. Installation

Approximately 305mm (12") of cable will remain in the

housing with the male connector attached.

3. Use a suitable cable gland at the top of the pipe to

support and clamp the cable.

4. Secure the free end of the cable in a junction box

located in a dry, gas free environment within the ship.

Caution: The transducer’s mounting screws utilize

rubber retaining rings to hold the screws in place

during installation. Do not remove them.

5. Carefully push the socket head end of each mounting

screw into the counterbore of the transducer to fully

expose the threaded end of the screw. Sparingly apply

a uniform coat of Aqualube

®

or other similar

underwater lubricant to the screw threads.

Caution: Lubrication is vital to the removal of these

screws should replacement of the transducer ever be

required.

6. Push the threaded end of each screw back into the

transducer until approximately 7mm (0.25") of the

lubricated threads are exposed and held in place by

the retaining ring.

7. While supporting the weight of the transducer, plug the

mating connectors together until they are fully

engaged. The connector faces must touch.

8. Slowly rotate the transducer approximately 1 to 2 turns

as it is raised into the housing to properly dress the

cable and joined connectors in the cable storage

cavity. The transducer face will be almost flush with the

flange of the housing when the cable is properly

stowed and the mounting screws are seated in the

threaded holes of the housing.

Page 2

Note: For diver installations, we suggest attaching the

hex wrench to a lanyard.

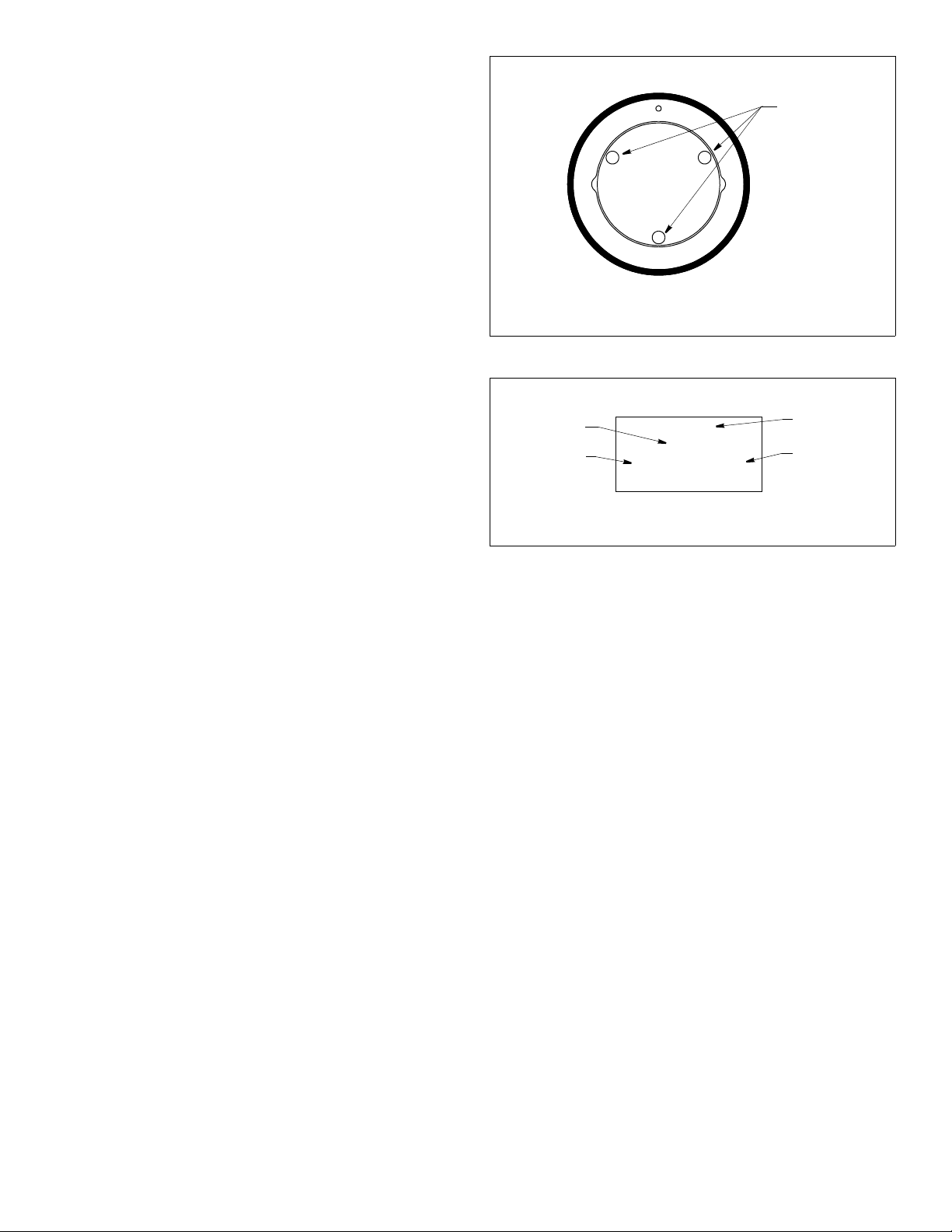

9. Tighten each of the mounting screws using the hex

wrench until the transducer is secured in the housing

and does not move. The recommended tightening

torque is 20N-m (15ft-lb). Fill the screw heads and

counterbores with marine sealant until they are flush

with the transducer’s radiating face. Remove any

excess sealant to ensure smooth water flow over the

transducer (see Figure 2).

Maintenance

counterbore

filled with

marine sealant

Aquatic growth can accumulate rapidly on the transducer’s

surface reducing the performance in weeks. Clean the

surface with a soft cloth and mild household detergent.

Reapply antifouling paint every 6 months.

Transducer Replacement

The information needed to order a replacement Airmar

transducer is printed on the vinyl tag affixed to the

transducer cable. Do not abrade the marking or remove

this tag. Contact your marine dealer or echosounder

manufacturer to obtain a replacement. When ordering,

specify the frequency, date code, and part number

(see Figure 3).

Figure 2. Bottom view including transducer’s radiation face

frequency

lot number

01-0797

120kH

KXQY9A/ XX-XXX

U.S.PAT.# XXXXXXX

date code

part number

Figure 3. Sample vinyl tag

®

AIRMAR

2

TECHNOLOGY CORPORATION

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

www.airmar.com

Loading...

Loading...