Page 1

Hydraulic Downforce

To create a conguration, make the following button presses to start the Conguration Wizard and then follow the

instructions given on the display.

Enter Settings

Planting

Conguration Product

Planting

Press to Highlight Conguration

8360,1770,3dr

Gauge Wheel Load Alarm

Start of Conguration Wizard

Down

Force

Select planter type (drop down menu)

If using uplift springs, enter value as dened

in installation instructions

Places an upper limit on the amount of

supplemental down force

Alarm will trigger if any monitored gauge wheel

load is below this value for a duration of time

Alarm will trigger if any monitored gauge wheel

load is below Minimum Load for this amount of

time

Down Force Control Mode (drop down menu)

Monitor Only: Select this option if only using gauge wheel sensors in conjunction with other

supplemental down force products (i.e. manually adjusted springs or airbags)

Control: Select this option is using Ag Leader hydraulic down force actuator and gauge

Control Settings

Note: Some planters may have a combination of long and short parallel arms depending on accessories. In this case use

the value that represents the majority of the rows.

wheel sensors. This option allows for active down force control

Enabling this option will disengage active control (hold) when any portion of the planter enters

a no plant zone, such as boundaries, or previously planted areas. Use caution with this option if

planting long point rows. Alarms are disabled when system is in hold.

Value must be entered for your specic planter and parallel arm combination

Kinze 3000 series 4.2 PSI/lb

John Deere Max Emerge/XP with short parallel arms

John Deere Max Emerge/XP with long parallel arms 3.8 PSI/lb

4.5 PSI/lb

Quick Reference Guide

AL: 2006350 ENG Rev B

1

Page 2

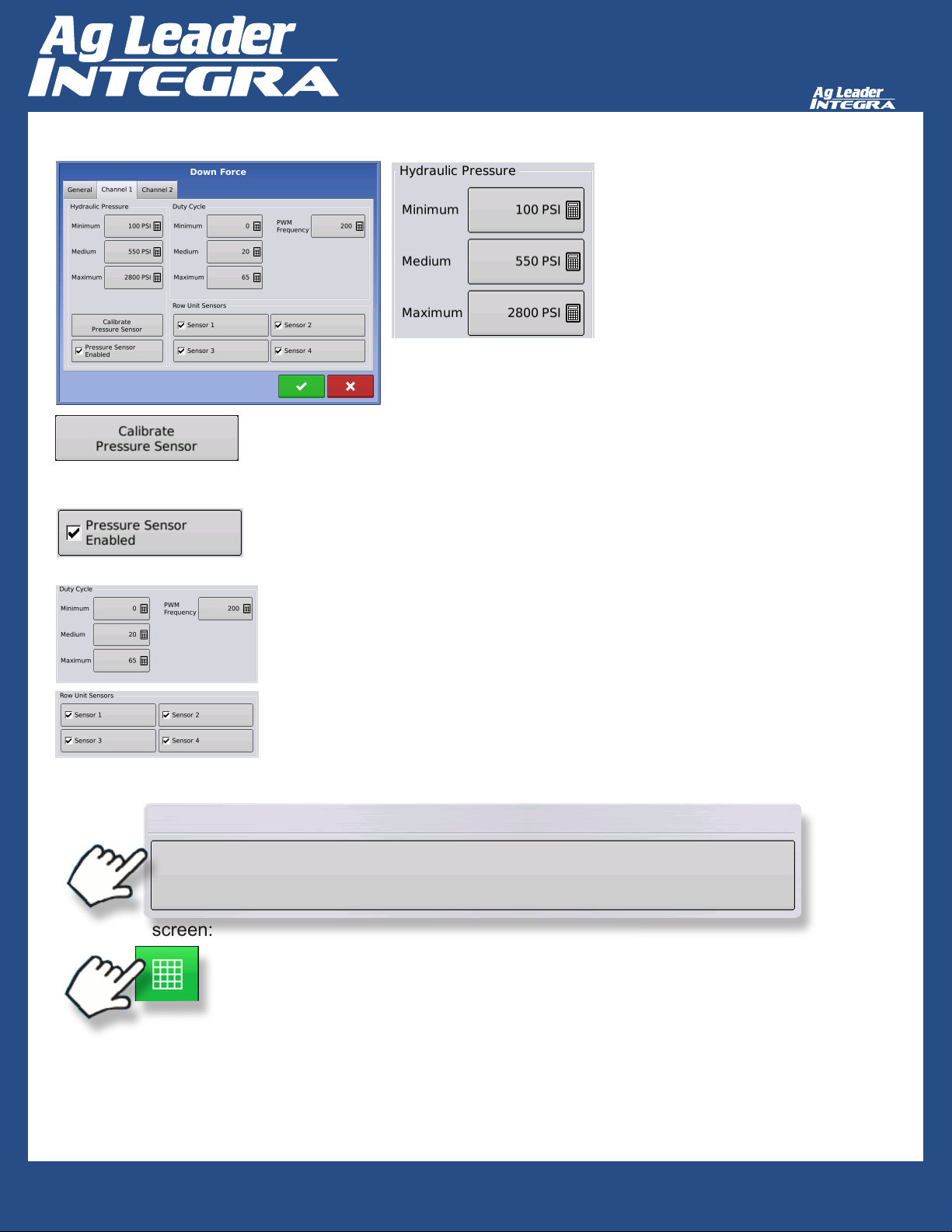

Hydraulic Downforce

Manually entered values depicting

tractor’s hydraulic pressure. Values shown

are for a 3000 PSI system (most common)

Select Channel to Calibrate

1. Set Point: Enter value here that matches value displayed on the corresponding channel’s

mechanical gauge attached to Ag Leader Down Force valve. (This can be done at 0 PSI)

2. Slope: value is dependent on manufacture of pressure transducer. Use 0.75 PSI/mV for

transducer supplied with valve.

Pressure Sensor Enabled: must be enabled to display “Down Force” on run screen.

Duty Cycle

Minimum/Medium/Maximum: Manually entered values correlating PWM duty cycle to

hydraulic pressure supplied to Down Force actuators. Values shown are for the Ag

Leader supplied hydraulic down force valve.

PWM Frequency: Number of PWM signals per second (Hz)

Row Unit Sensors

Enabled sensors will be used to calculate required supplemental down force

To start the Field Operation Wizard and load a conguration:

Conguration

To view run screen:

Quick Reference Guide

Start Field Operation

AL: 2006350 ENG Rev B

2

Page 3

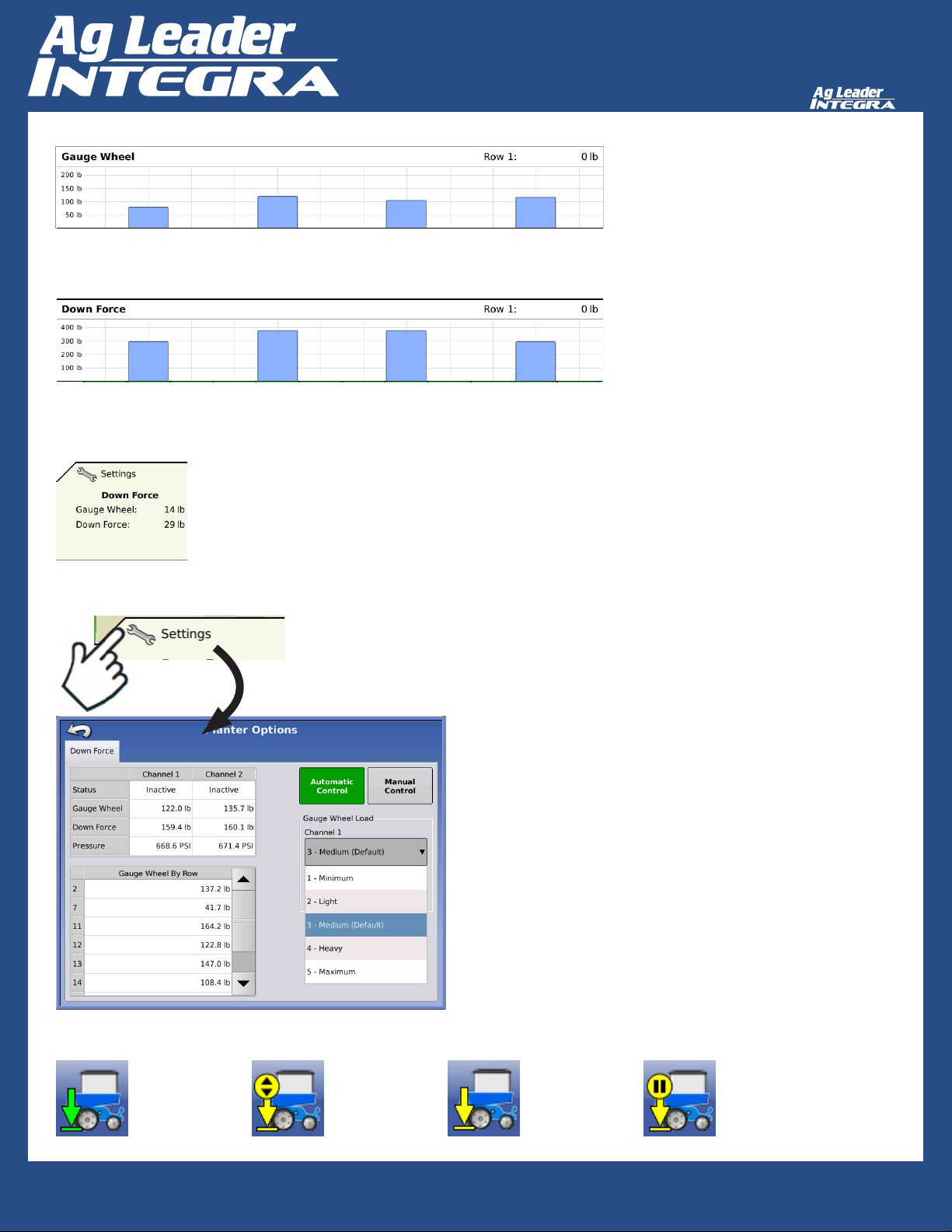

Hydraulic Downforce

Gauge Wheel (bar graph): Each bar displays gauge wheel load for monitored rows

Down Force (bar graph): Each bar displays supplemental down force for monitored

rows

Down Force

a. Gauge Wheel: Planter average gauge wheel load

b. Down Force: Planter average supplemental down force

Planter Options - Down Force tab

Status: displays current status of control system

Active: System is actively controlling down force

Inactive: System is not actively controlling down force

Hold: Pressure is being held constant due to manual hold or

automatic hold

Gauge Wheel: Instantaneous channel average gauge wheel

load

Down Force: Instantaneous hydraulic pressure

Pressure: Pressure reading from corresponding channel

pressure transducer

Gauge Wheel By Row (table): Instantaneous gauge wheel load

for each monitored row

Automatic Control (button): Active down force control mode.

Gauge Wheel Load: User selected aggressiveness. Higher

aggressiveness will equate to higher gauge wheel loads

Manual Control (button): Allows user to manually adjust

pressure supplied to down force actuators across planter. Active

down force is disabled when in this mode.

Active Manual Inactive Manual

Hold

Quick Reference Guide

AL: 2006350 ENG Rev B

3

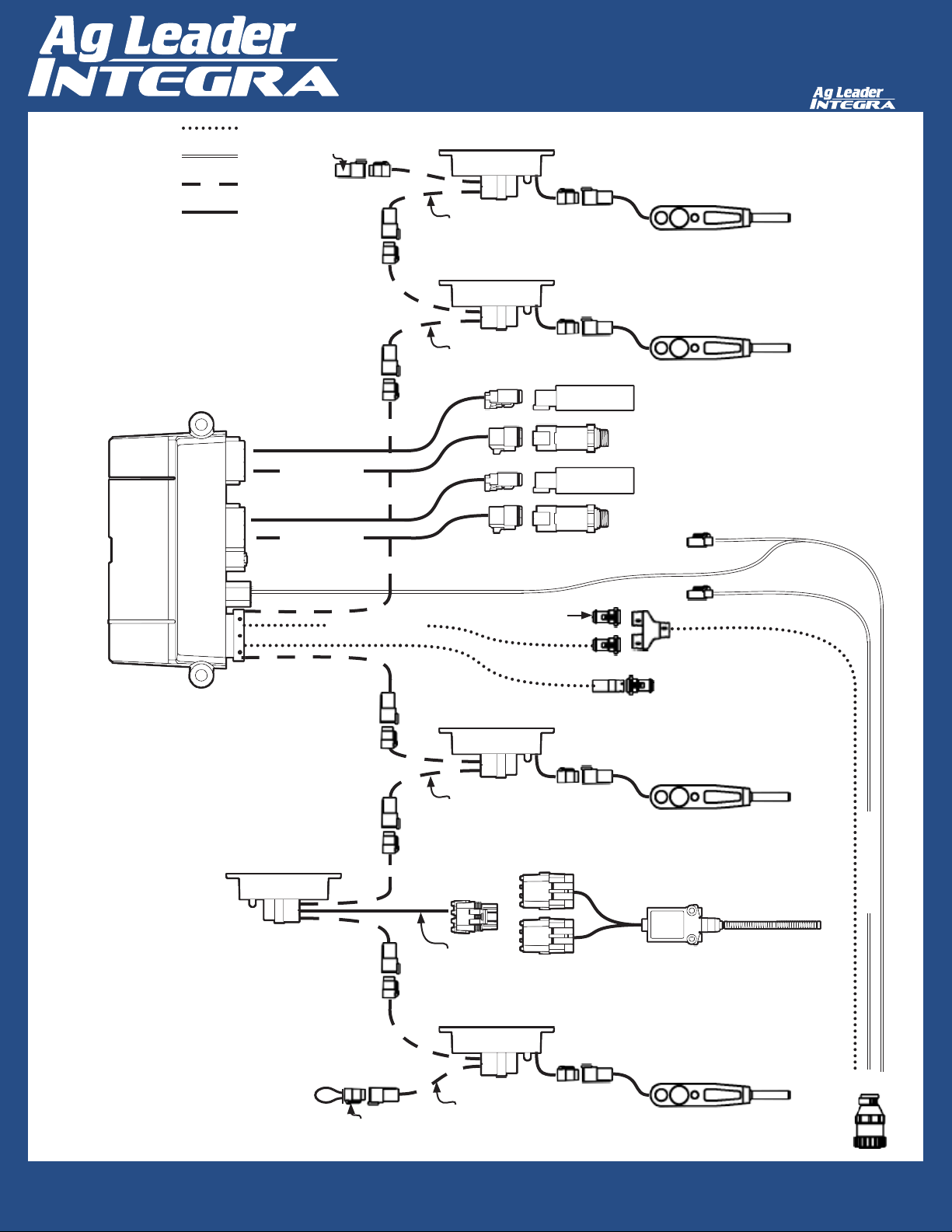

Page 4

Hydraulic Downforce

CAN A

HIGH POWER

LOCAL CAN BUS

SIGNAL/CONTROL

At least one implement switch must be installed on the

Seed Command system.

Terminator

P/N 4002871

Right End of Planter

Terminating

Plug P/N

4002871 must

be installed on

the right end of

the planter.

Channel Cable

Channel Cable

Row Module

P/N 4002912-1

Row Module Breakout

Row Module

P/N 4002912-1

Row Module Breakout

Cable Diagram

Load Sensor

Load Sensor

Channel 2 Solenoid Valve

Channel 2 Pressure

Channel 1 Solenoid Valve

Channel 1 Pressure

Down Force Control Module

Control module and Implement Switch module(s) can

be placed anywhere in series on the local CAN Bus.

CAN Implement Switch

P/N 4002911

P/N 4002920-008

Dust Cap

Row Module

P/N 4002912-1

Row Module Breakout

P/N 4002658

Row Module

P/N 4002912-1

Load Sensor

P/N 4000726-12

Implement Switch

Terminator

P/N 4002870

Left End of Planter

Row Module Breakout

Terminating Plug P/N 4002870 must be

installed on the left end of the planter.

Quick Reference Guide

AL: 2006350 ENG Rev B

Load Sensor

4

Page 5

Hydraulic Downforce

Installation: Hydraulic Down Force FAQ

Where do I plug in an implement switch?

Generation 1 modules will broadcast the implement switch status over the CAN bus. No additional

implement switch is needed.

What if I don’t have any other generation 1 modules?

You will use the Ag Leader CAN implement switch module P/N 4002911 and cable P/N 4002658 in

conjunction with the standard implement switch.

What if my cables don’t reach the rows for which I have installed gauge wheel

sensors?

It may be acceptable to choose rows the cables will reach, as long as channel 2 sensors are on the

center 6 rows, and channel 1 sensors are outside that.

What if I don’t have any free SCV connections for the down force valve?

Teeing into existing lines is acceptable. Do not tee into the vacuum fan line if adjusting fan RPM

on the tractor with a knob or dial. Teeing into the line before a ow limiter on the planter would be

acceptable. Teeing into the hydraulic drive supply line would be the best option. Do not tee into

Rawson Drive supply line.

What if my hydraulic oil gets too hot?

Ag Leader sells a Load Sense kit (P/N 4101225) to help manage oil temperatures. Note: This

system will not help if using SCV to control hydraulic drives. In this case, an auxiliary oil cooler

may need to be installed.

What if my hydraulic actuator does not extend far enough to reach the lower bracket

with row unit at bottom travel?

Purchase one spacer kit (P/N 4101201) per row. This will install at the bottom of the ram.

(Commonly used on John Deere long parallel arms)

My Kinze planter has rows that are offset 4” back, causing the upper actuator bracket

to not line up with the lower actuator bracket.

Purchase one spacer kit (P/N 4101204) per row. This will move the upper bracket 4” rearward.

How does the system know the difference between the row modules on channel 1 and

those on channel 2?

The Channel 1 row modules will connect to the cable labeled “Type 1” while channel 2 row modules

will connect to “Type 2” cables.

Quick Reference Guide

AL: 2006350 ENG Rev B

5

Page 6

Hydraulic Downforce

Installation: Hydraulic Down Force FAQ

Am I missing something to plug into the 3 pin connector on the master hydraulic down

force module?

This connector is not used.

Why is the gauge wheel load bar graph constantly spiking and then going to 0?

This can happen if the Channel 1 pressure lines are routed to channel 2 sensors. Ensure channel

1 components (Down force pressure, and gauge wheel load sensor wiring) are on the wings,

and channel 2 components are on the center 6 rows. Ensure channel hoses are going to correct

channel of down force valve. Ensure PWM/pressure sensor cables are going to correct channel of

Down Force Module and Down Force Valve.

What are the red knobs on the down force valve?

This allows for manual adjustment of down force in the event of electronics failure. Push and twist

the knob to move between automatic adjustment (inner position) and manual adjustment (outer

position).

Why does the system need 3 hydraulic lines (Pressure, Return and Tank)

Under normal operation, pressure in the down force system is increased through the Pressure line

and relieved through the Return line. When the planter runs over a terrace or a water way, the

access pressure is released through the Tank line. All three lines MUST be connected.

Quick Reference Guide

AL: 2006350 ENG Rev B

6

Page 7

Hydraulic Downforce

Hydraulic Down Force

Alarm Explanation and Resolution

Down Force Inadequate

Problem: System is at maximum hydraulic pressure, but does not achieve an acceptable gauge

wheel load. Often times this alarm occurs when down force actuators are lifting the planter tool

bar.

Resolution: Add weight to planter. If planter tool bar is not lifting, increase maximum down force set-

ting in conguration setup.

Hydraulic Pressure too low

Problem: Hydraulic pressure is at 0 and the system is demanding more pressure.

Resolution: Check hydraulic hoses for proper connections. Ensure SCV remote is set for continuous

ow. Zero each channel’s pressure sensor only when mechanical gauge reads 0 psi.

Low Gauge Wheel Load

Problem: Down force system is not achieving an acceptable gauge wheel load.

Resolution: Increase aggressiveness for problematic channel under settings button from run screen.

This alarm may be followed by Down Force Inadequate, in which case consult that alarm resolution section.

Pressure Sensor Failure

Problem: Pressure sensor is outside voltage range.

Resolution: swap cables with other channel (if applicable), re-zero pressure sensors. If problem

persists on same channel, replace pressure sensor. If problem is now on other channel, inspect/

replace cable.

Row Module Communication Lost

Problem: Row module communication lost.

Resolution: Inspect cabling of row module. Replace row module.

Row Module Failure

Problem: Row module is not sensing inputs. Row module is power cycling at intervals of less than 2

seconds

Resolution: Swap module with different row. If problem follows, replace module. If problem exists on

same row, inspect or replace load sensor.

# Row Modules does match the display conguration

Problem: Conguration was set to a number of sensors that was not detected by the system.

Resolution: Create a conguration that matches the number of sensors used. Check that all row

modules are communicating. Flashing green LED on the row module indicates proper communication.

Quick Reference Guide

AL: 2006350 ENG Rev B

7

Page 8

Hydraulic Downforce

Troubleshooting Step 1A: Hydraulic Down Force

Start

Latest

Display

rmware?

Yes

Down

Force icon

present on lower right

run screen.

Yes

Enter 5 mph manual ground

speed.

Is

arrow icon

green when planter is

lowered?

Yes

Is

arrow icon

yellow when planter is

raised?

No

No

No

Implement Switch

No

Implement Switch

Upgrade

rmware

Go to Step 3:

Connections

Go to Step 3:

Connections

Down

Force Module

Communicating?

Yes

Operating

Conguration set to

control?

Yes

Restart eld operation, select

Down Force on Product

Selection screen accept

Down Force Warning

No

Cables and Power

No

Go to Step 2:

Set Operating conguration

to Control instead of

Monitor Only

Yes

Go to Step 1B:

Hydraulic Down

Force

Quick Reference Guide

AL: 2006350 ENG Rev B

8

Page 9

Hydraulic Downforce

Troubleshooting Step 1B: Hydraulic Down Force

Continued from Step 1A:

Hydraulic Down Force

Engage down force

hydraulics.

In

Manual

Control click the

increase arrow several

times. Does pressure

increase?

Yes

Put planter in down position

with load on gauge wheels.

Place in manual control at

maximum pressure.

No

Go to Step 4:

Hydraulics

Enter

down

force module

diagnostics. Do all row

sensors register a load

reading?

Yes

Decrease

pressure

in manual control.

Does the pressure

displayed go

down.

Yes

Return system to desired

control mode. Manual/

Automatic

Troubleshooting Complete.

System should be in eld-ready

state.

With planter still in down

position with load on gauge

No

wheels and in manual control

at maximum pressure

Move to softer ground or

pull forward. The opening

discs are not digging into the

No

Go to Step 4:

Hydraulics

ground.

Can

the gauge

wheels on the monitored

rows be turned by hand?

Yes

No

Cables and Power

Go to Step 2:

Quick Reference Guide

AL: 2006350 ENG Rev B

9

Page 10

Hydraulic Downforce

Troubleshooting Step 2: Power and Cables

Start

Lights

present on Down

Force Module?

Yes

Are all lights

green?

Yes

Are row module

lights green?

Yes

Does

cabling match

the Figure 1: Cable

Diagram?

Yes

No

No

No

No

Go to Step 5:

Indicator Lights

Go to Step 5:

Indicator Lights

Correct cabling errors to

match Figure 1: Cable

Diagram.

Display powered

on?

Yes

Is

CAN A

connected?

Yes

Check power control relay.

No

No

Power on Display

Connect CAN A

Troubleshooting Complete.

System should be in eld-ready

state.

Quick Reference Guide

AL: 2006350 ENG Rev B

10

Page 11

Hydraulic Downforce

Troubleshooting Step 3:

Implement Switch Connections

NOTE: A minimum of 1 implement switch (2 is recommended) must be installed

on planter for the down force system to work properly. If an implement switch is

already installed and connected to an existing SeedCommand module, no action is

required. If no implement switch is installed, action must be taken to install at least 1

implement switch and implement switch module on local down force CAN Bus.

When using the hydraulic down force module with existing Seed Command modules,

the implement switch must be connected to the module highest in the hierarchy

below:

Hydraulic Seed Rate Control Module

Clutch Control Module

Seed Tube Monitor Module

Implement switches connected to any non Seed Command related module will not

indicate planter up/down status for Hydraulic Down Force control. (App Rate Module

and Liquid Control Module included)

If none of the above 3 seed command modules are used then the Hydraulic Down

Force module must have a CAN implement switch installed.

Part numbers required for CAN implement switch installation:

Part Number Description

4002911 Module – CAN implement switch

4002658 Cable – CAN implement switch

4001507 Implement Switch

Implement Switch Kits (contain Implement Switch 4001507)

4100830 Kinze

4100831 John Deere

4100832 White

4100833 Case

Quick Reference Guide

AL: 2006350 ENG Rev B

11

Page 12

Hydraulic Downforce

Troubleshooting Step 4: Hydraulics

Start

Is Tractor

running with hydraulics

engaged?

Yes

At the down force control

valve, move the red circular

manual override knobs to

the other position (electronic

control override).

Is a pressure

displayed on the

valve’s gauge?

Yes

Move red circular override

knobs to the inner position

(automatic control).

From

the

display, Can

pressure be released

from the system using the

down arrow in manual

control?

Yes

From

the

display, Can

pressure be increased

in the system using the up

arrow in manual

control?

Start Tractor and engage

No

No

No

Ensure Pressure, Return and

No

system is set for continuous

hydraulics

Adjust manual override

pressure using allen head

adjustment just above the

electronic PWM valve.

pressure still

at 0?

Tank lines are completely

connected. Ensure SCV

remote is engaged in the

correct direction. Ensure

ow (motor mode).

No

Is

Yes

Yes

Troubleshooting Complete.

System should be in eld-ready

state.

Quick Reference Guide

AL: 2006350 ENG Rev B

12

Page 13

Hydraulic Downforce

Troubleshooting Step 5:

Indicator Lights

Light 2

(Proprietary CAN)

Light 1

(ISO CAN)

Power

Off Solid

Red

Boot No Power N/A No App Running N/A N/A N/A

Upgrade No Power N/A N/A N/A Running N/A N/A

Main

Application

No Power

High Current

Power Low

Flashing

Red

N/A N/A N/A Power OK N/A

Solid

Amber

Flashing

Amber

Solid

Green

Light 1 (ISO CAN)

Boot N/A N/A N/A N/A N/A N/A N/A

Upgrade Idle Bus Off N/A Bus Error

Passive

Main

Application

Idle Bus Off N/A Bus Error

Passive

Bus Error

Active

Bus Error

Active

N/A TX/RX

N/A TX/RX

Light 2 (Proprietary CAN)

Boot N/A N/A N/A N/A N/A N/A N/A

Upgrade N/A N/A N/A N/A N/A N/A N/A

Main

Application

Idle Bus Off N/A Bus Error

Passive

Bus Error

Active

N/A TX/RX

Power

Flashing

Green

Down Force

Row Unit Module

Local CAN

Off Solid

Red

Boot N/A N/A Upgrade

Main

Application

Idle Bus Off N/A Bus Error

Quick Reference Guide

AL: 2006350 ENG Rev B

Flashing

Red

State

Solid

Amber

N/A N/A N/A N/A

Passive

Flashing

Amber

Bus Error

Active

Solid

Green

N/A CAN OK

Flashing

Green

13

Loading...

Loading...