Page 1

Page 2

Page 3

Precision Farming System

PF3000 Cotton Yield Monitor

Operators Manual

Page 4

Page 5

PF3000 Cotton Yield Monitor

1-1

Ag Leader Technology

Welcome

System Upgrades

Limited Warranty

Welcome to the Ag Leader Technology family. Ag Leader Technology is

dedicated to the development of advanced, yet practical and cost-effective

tools for agricultural production. Above all, however, we are dedicated to

meeting your needs for support of existing products and development of

product improvements.

We want to hear from you! Feel free to call any time to discuss:

• Operational problems with your system

• Features you don’t like about your system

• Features you would like added to your system

We will do our best to ensure that you are happy with your current system

and that it is upgraded in the future to better meet your needs.

Ag Leader Technology will periodically provide free operating program

upgrades that will improve the performance of your PF3000.

To receive free upgrades and new product news, you must send in or fax

(515-232-3595) the Registration Form that is at the beginning of the

operator’s manual. Our mailing address is:

Ag Leader Technology will repair or replace at no charge any component of

the PF3000 system that fails during normal service on the equipment model

that the system was intended for use within two years from the date of first

use.

Warranty is not provided for damage resulting from abuse, neglect,

accidents, vandalism, acts of nature, or any other causes that are outside the

normal, intended use of the PF3000 system.

General

Ag Leader Technology

2202 South Riverside Drive

P.O. Box 2348

Ames, IA 50010

Internet

http://www

.agleader.com

March 2002

Page 6

1-2

PF3000 Cotton Yield Monitor

General

Service

Copyright Notice

Proprietary

Technology Notice

Ag Leader Technology

Ag Leader Technology shall not be liable for indirect, incidental, or

consequential damages to the dealer, end user, or third parties arising from

the sale, installation, or use of the PF3000 system.

If you have a problem with your system, call your Ag Leader Technology

dealer or call us directly at the phone number below. If we determine you

have a hardware failure, we will ship replacement hardware immediately.

Our mailing address and phone numbers are:

Ag Leader Technology

2202 South Riverside Drive

P.O. Box 2348

Ames, IA 50010

Phone: 515-232-5363

Fax: 515-232-3595

Note: Return failed hardware to us by UPS (preferred) or US mail.

Ag Leader Technology has copyrighted (1998) the contents of this

manual and the operating program for the PF3000 system. No reproductions

of this material may be made without first obtaining the consent of Ag

Leader Technology.

The PF3000 system has patents or licensing agreements on its design and

operational features. Copying features of this system relating to

measurement and calculation of cotton flow and weight, or organization of

field and load data may result in patent licensing infringement.

March 2002

Page 7

PF3000 Cotton Yield Monitor

1-3

Ag Leader Technology

General

Description

Fields and Loads

Keypad

The PF3000 is a universal monitor/controller for crop production that is

GPS compatible. In the cotton harvester it functions as a yield monitor and

accurately measures and records pounds per acre, weight of current load and

volume in bales.

The PF3000 has its own internal memory for recording field and load data.

GPS data, however, is not recorded in the internal memory, and must

be logged to a memory card.

The PF3000 must be setup and calibrated to record accurate information.

All the information recorded by the PF3000 must be recorded in a field and

load. The operator must manually select or change the field and load on the

PF3000 during field operation. A load is used to subdivide a field into

smaller sections. The monitor load is not associated with the cotton picker

basket, wagon, or truck load. It is recommended to use different loads for

different hybrids or varieties or field conditions (like a wet hole).

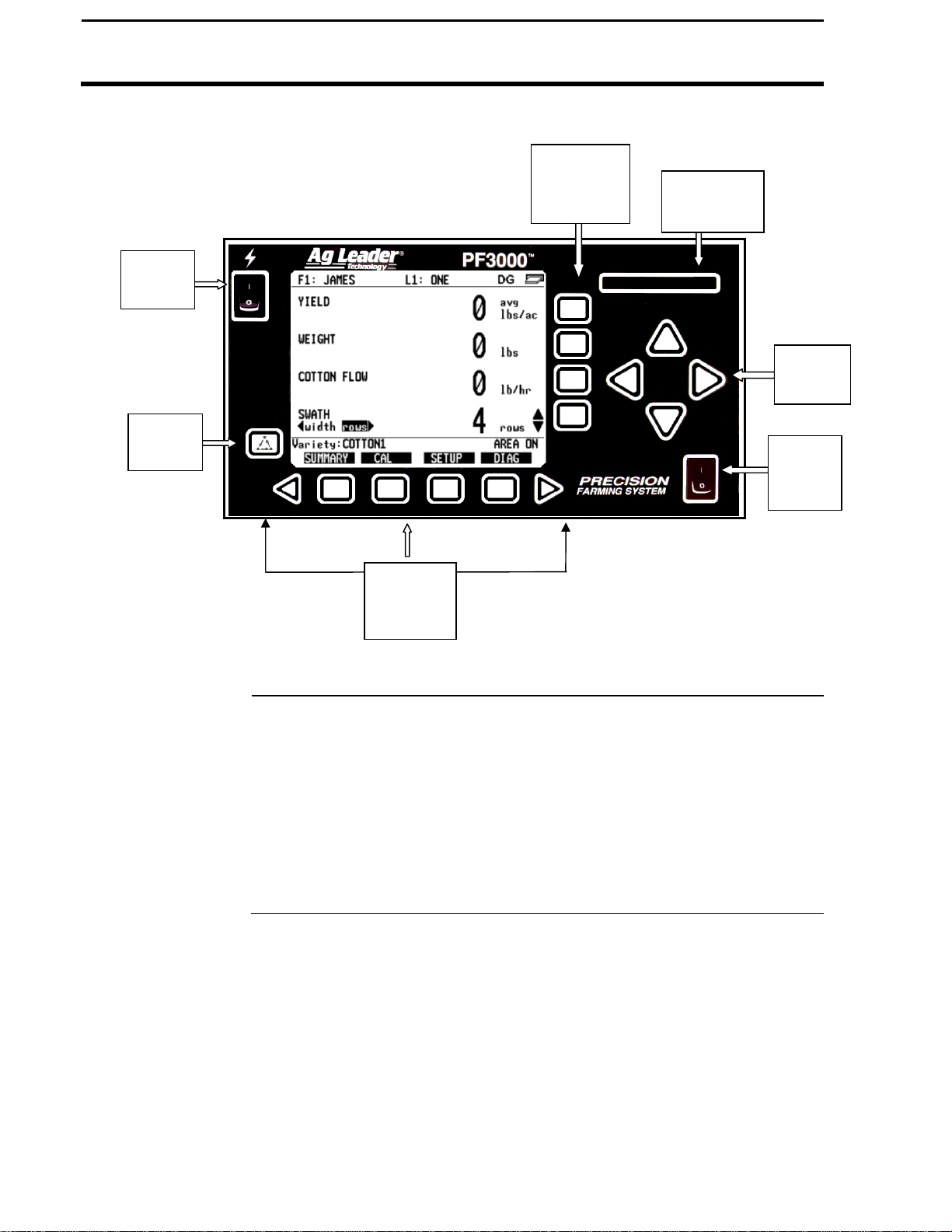

The monitor has "soft" keys which do not have labels on the keys to identify

the function of the key. The labels for the keys will appear on the display

screen next to the key. However, there are four major groups of the keys:

arrow keys, display selection keys, menu key, menu selection keys.

General

March 2002

Page 8

1-4

Switch

PF3000 Cotton Yield Monitor

General

Power

Switch

Menu

Key

Arrow Keys

Ag Leader Technology

Display

Selection

Keys

Menu

Selection

Keys

Figure 1: Front panel of the PF3000

The UP, DOWN, LEFT and RIGHT ARROW keys on the right side of the

keypad are used to select and change a setting. The bottom LEFT and

RIGHT ARROW keys are only used to view more menu or display items.

They are never used to select or change a setting.

On the main operating screen, you may see an up and down arrow symbol

that will be to the right of one of the display lines. This symbol indicates

what item the UP or DOWN ARROW keys will change if pressed.

Memory

Card Slot

Arrow

Keys

Area

Count

March 2002

Page 9

PF3000 Cotton Yield Monitor

1-5

Ag Leader Technology

Display and

Display Selection

Keys

Selection

Box

The PF3000 has four display lines for viewing items on the main operating

screen. You can choose which items you see on the display and the position

that the items appear on the display.

To change a display item on a display line you must select the line. The four

display selection keys to the right of the display each select a display line. A

rectangular box surrounds the display line to show that it is selected.

When the display line is selected the four menu items on the bottom change

and show items you can select for display. Press a key below one of the

four display items to put a different display item in place of the selected

display item. There are more than four display items to choose for viewing.

Press the bottom LEFT or RIGHT ARROW keys to scroll to the right or left

and view other display items on the bottom.

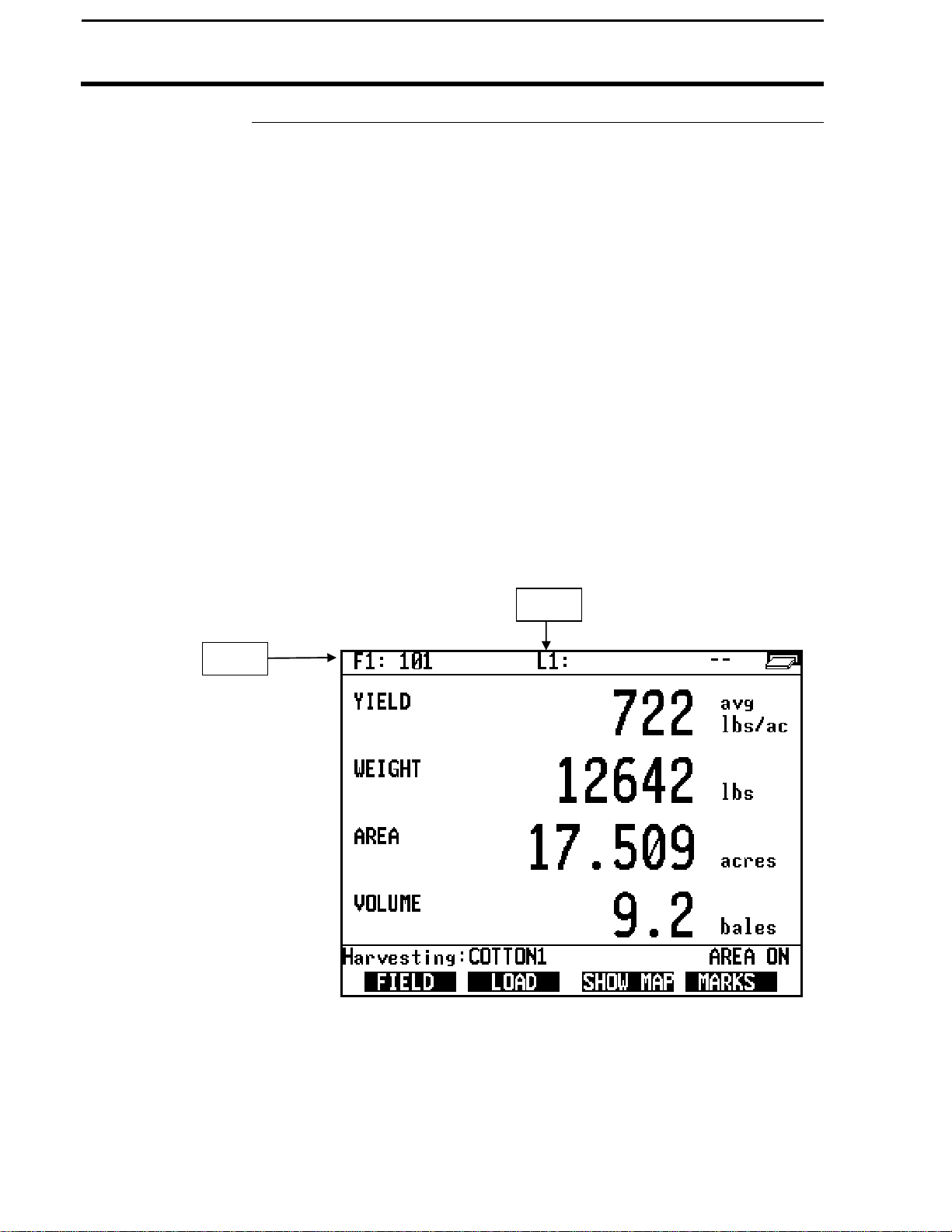

Figure 2: Main operating screen

When arrows present,

press bottom arrow keys

to display additional

menu or display items

General

Card

Symbol

Up and

Down

Arrow

Symbol

March 2002

Page 10

1-6

PF3000 Cotton Yield Monitor

General

Menu Key

Menu Selection

Keys

Ag Leader Technology

When some display items (like swath) are selected, an up and down arrow

symbol will appear on the right of the display line. This indicates you can

change the setting of the item with the UP or DOWN ARROW keys. After

you have made the change you must press the key to the right of the display

line to deselect the line.

The MENU key switches the menus on the bottom of the display. There are

two main menus that you can view by pressing the MENU key. They are

shown below.

It is recommended to display the FIELD, LOAD, menu during normal

operation of the monitor, unless you are marking and therefore need to

display marks on the bottom.

Main Menus:

SUMMARY

FIELD

The name above the four menu selection keys on the bottom of the display

will change depending on what you are doing on the monitor.

The bottom RIGHT and LEFT ARROW keys are used to view additional

menu or display items. If you see a right and left arrow symbol on the

display above the bottom RIGHT and LEFT ARROW keys, this indicates

you can press the bottom RIGHT and LEFT ARROW keys to view more

menu or display items. Refer to Figure 2.

LOAD

CAL

SHOW MAP

SETUP

MARKS

DIAG

March 2002

Page 11

PF3000 Cotton Yield Monitor

1-7

25-Pin Connector

Port 1

Port 2

Port 3

Ag Leader Technology

Area Count Switch

Connectors

The area count switch manually turns area counting on and off. When the

switch is in the up position area is counting. When the switch is in the

down position, area is not counting. The monitor will display either "AREA

ON" or "AREA OFF" on the bottom right corner of the display to indicate

the status of area counting.

The PF3000 has four connectors on the bottom side of the console. The

large 25-pin connector is for power and sensor connections. The three 9-pin

ports (Port 1, Port 2 and Port 3) are for connecting a GPS receiver (Port 1)

and as yet to be determined functions for Ports 2 and 3.

General

Figure 2: PF3000 Connectors

March 2002

Page 12

1-8

Emitter

Detector

PF3000 Cotton Yield Monitor

General

Flow Sensor

Ag Leader Technology

Below is an example of a flow sensor. On all cotton pickers, the flow

sensor installs on the basket duct. The flow sensor measures the cotton

weight in pounds as the cotton passes between the emitter and detector.

Figure 4: Flow Sensor

March 2002

Page 13

PF3000 Cotton Yield Monitor

1-9

Ag Leader Technology

Header Height

Sensor

Header Sensor

Below is an example of a header height sensor installed underneath a picker

cab. The header height sensor tells the monitor the position of the header so

that when the head is raised on the end rows, the monitor stops counting

area.

General

Figure 5: Header Height Sensor

March 2002

Page 14

Page 15

PF3000 Cotton Yield Monitor

2-1

Ag Leader Technology

Important Notices

Section Contents

Using Power

Supply

The PF3000 must be set up before field operation, but before you begin the

setup procedures, read the following notices:

• The PF3000 is a software upgradeable monitor. Ag Leader Technology

will periodically offer free operating program upgrades to increase the

capabilities of the PF3000. To receive the program upgrade, you

must send in the registration form found at the beginning of the

Operator’s Manual.

• If you plan to make yield maps on your own computer, you will need to

use a mapping program that can process data from the PF3000. Memory

cards can be ordered through your Ag Leader Technology dealer.

This setup section contains instructions for the following items. The

operating modes that the instructions pertain to are also listed.

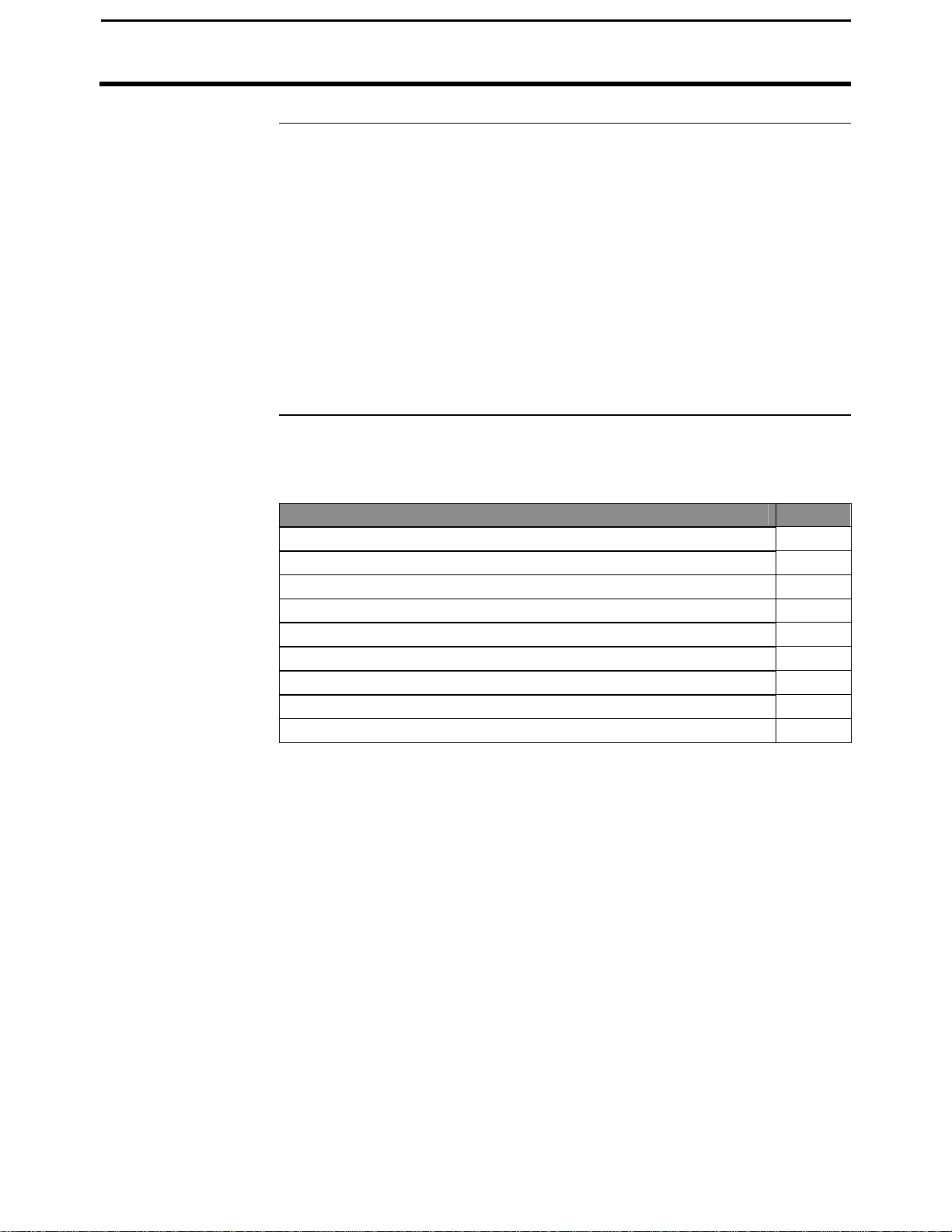

Item Page

Console Setup 2-3

Vehicle Setup 2-5

Cal Set Setup (see calibration section)

Card Setup 2-10

Swath Setup 2-15

Marker Setup 2-17

Creating, Naming Fields & Loads (1st & 2nd Pick) 2-19

Memory Setup 2-24

Sensor Setup 2-26

The PF3000 console does not need to be in the vehicle to set it up. You can

use the provided power supply (plugs into 120v outlet) to power up the

console inside your home or shop.

Setup Overview

March 2002

Page 16

2-2

PF3000 Cotton Yield Monitor

Setup Overview

Order of Keys

(Harvest Mode)

Ag Leader Technology

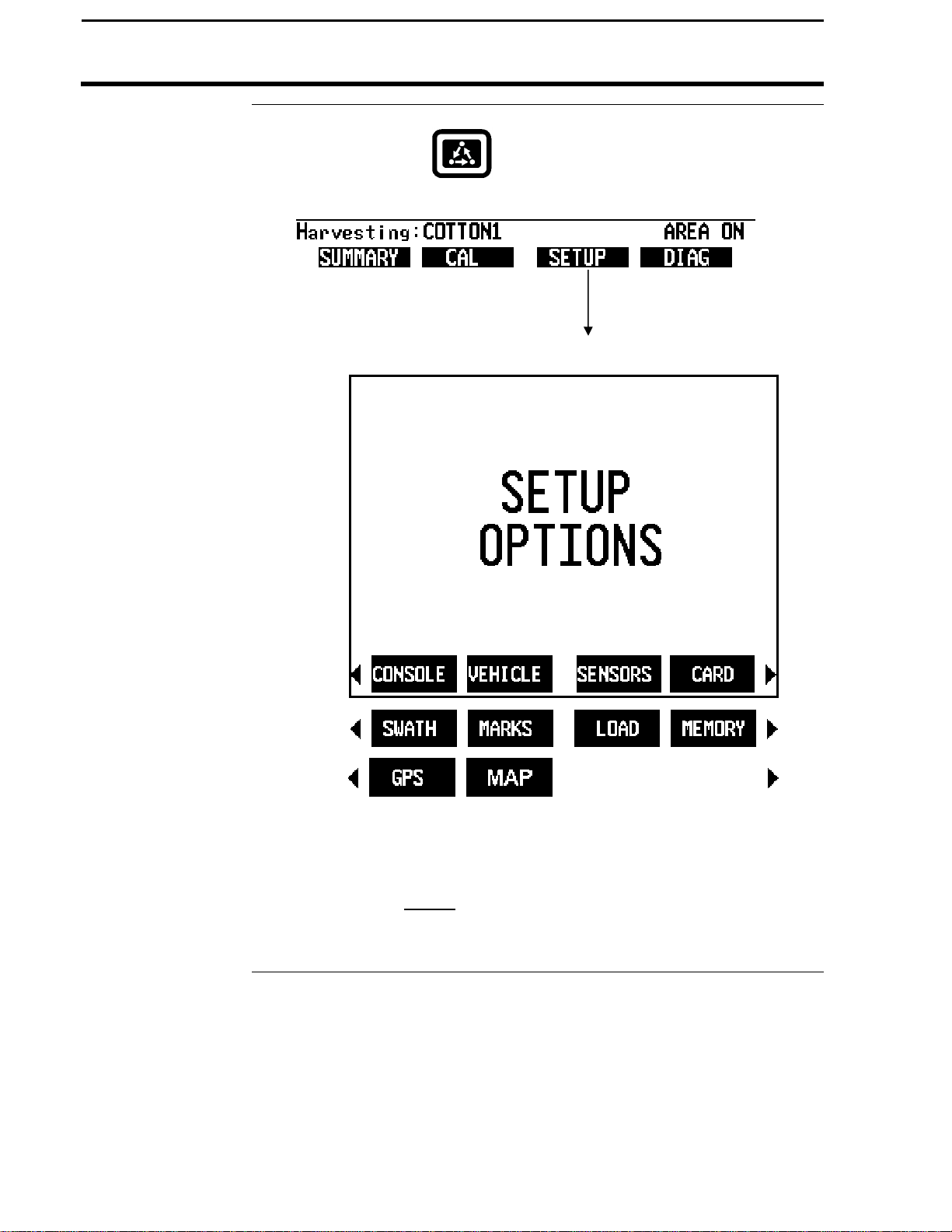

Press the MENU key until you see the following keys on

the display.

Press the SETUP key

to view the following

setup menu items.

NOTE: Instructions for GPS Setup are located in the Add-On GPS

3000/3050/3100 Installation and General Instructions

Press the bottom LEFT or RIGHT ARROW keys to

switch between and view the setup menu items

shown above.

* * *

March 2002

Page 17

PF3000 Cotton Yield Monitor

2-3

Changing a Setting

Ag Leader Technology

Introduction

Console Setup

Screen

The console settings are general settings that apply to all operating modes

and uses of the PF3000.

To view the console setup screen press the:

Example of console setup screen:

Console Setup

MENU key

SETUP key

CONSOLE key

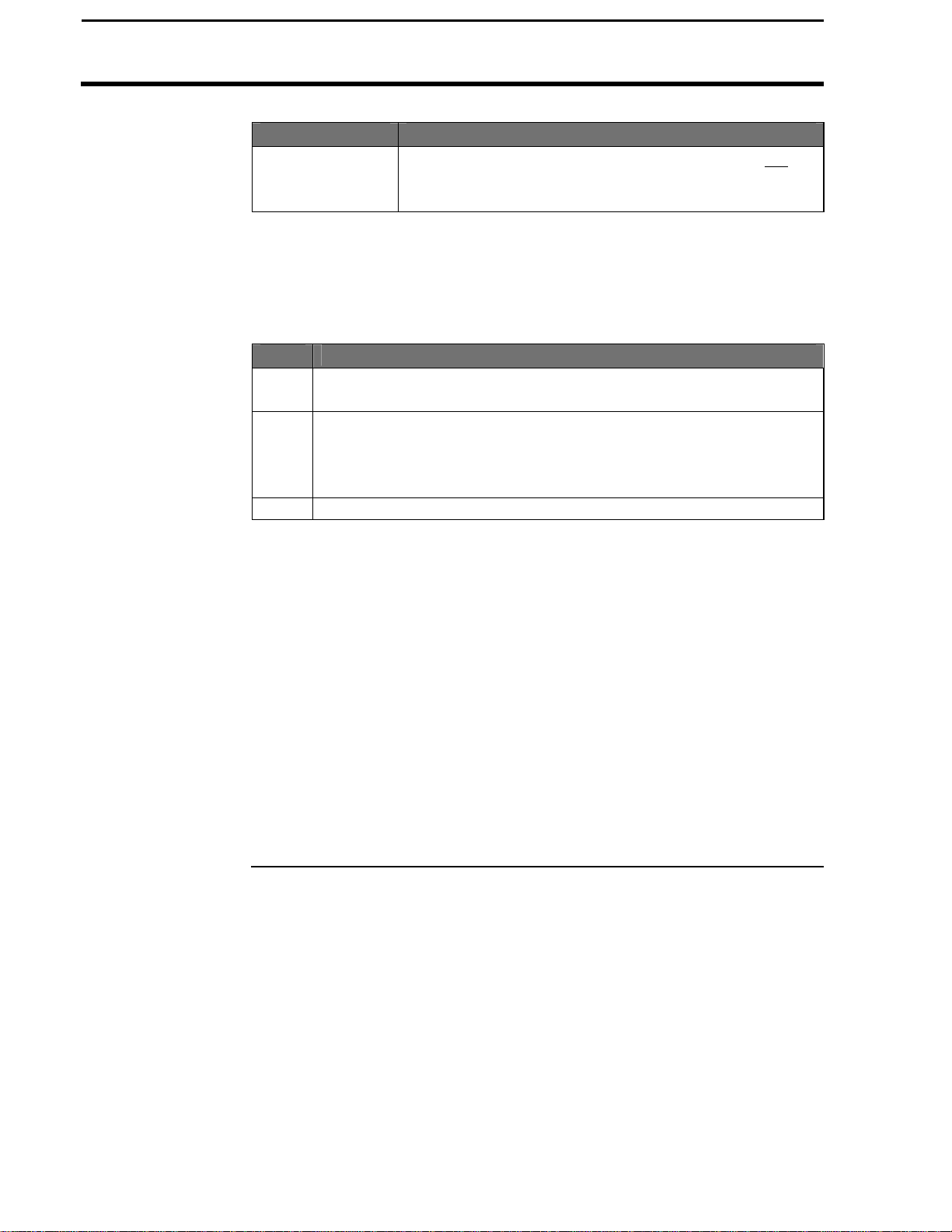

Step Action

1 Use the UP or DOWN ARROW keys to select the item you want

to change. The item is selected when a black filled rectangular

box surrounds the entire line.

2 Press the EDIT key and then use the UP or DOWN ARROW keys

to change the number or setting.

3 Once you have changed a setting press the ACCEPT key. Press

the EXIT key once you have made all the settings.

March 2002

Page 18

PF3000 Cotton Yield Monitor

2-4

Voltage calibration

Field Marke

r

Console Setup

Operating mode

Units of measure

Month/Day/Year

Time

Serial number,

Box calibration,

GPS Check Sum

Ag Leader Technology

At this time, Cotton Harvest and Site Verification is the only operating

mode available with the PF3000 Cotton Yield Monitor System. To use the

PF3000 for grain harvest or app rate, a different operating program is

available.

The units of measurement for the PF3000 Cotton Yield Monitor are

Imperial or Metric.

Use the LEFT or RIGHT ARROW keys to move from month to day to year.

Use the UP or DOWN ARROW keys to change the value. The whole

month, day or year is highlighted and only the last digit increments. Press

LEFT or RIGHT ARROW to set to item to be edited.

12 Hour Clock with AM/PM. The whole hour (2 digits) or minutes value (2

digits is highlighted when editing. AM changes to PM when incrementing

by 12. Press LEFT or RIGHT ARROW to set to item to be edited. If you

are using metric units of measure the 24 hour clock is used.

The serial number, box calibration number and voltage calibration number

can be found on the bottom side of the monitor. These numbers should be

set correctly from the factory.

If you are using a GPS receiver with the PF3000 the GPS Check Sum setting

is used to enable or disable data string error checking.

NOTE: For all Ag Leader receivers (GPS 2000/2100, Add-on GPS

3000/3100), and Trimble 120,122,132 receivers the GPS Check Sum should

be set to ON.

For most other brands of GPS receivers the GPS Check Sum should also be

set to ON. If you can not get a "D" and "G", though, set this setting to OFF.

If you are… Select

Marking field points with the PF3000’s internal

INTERNAL

marker selection keys.

Marking field points with an external Ag Leader

EXTERNAL

Field Marker.

* * *

March 2002

Page 19

PF3000 Cotton Yield Monitor

2-5

Ag Leader Technology

Introduction

Vehicle Setup

Screen

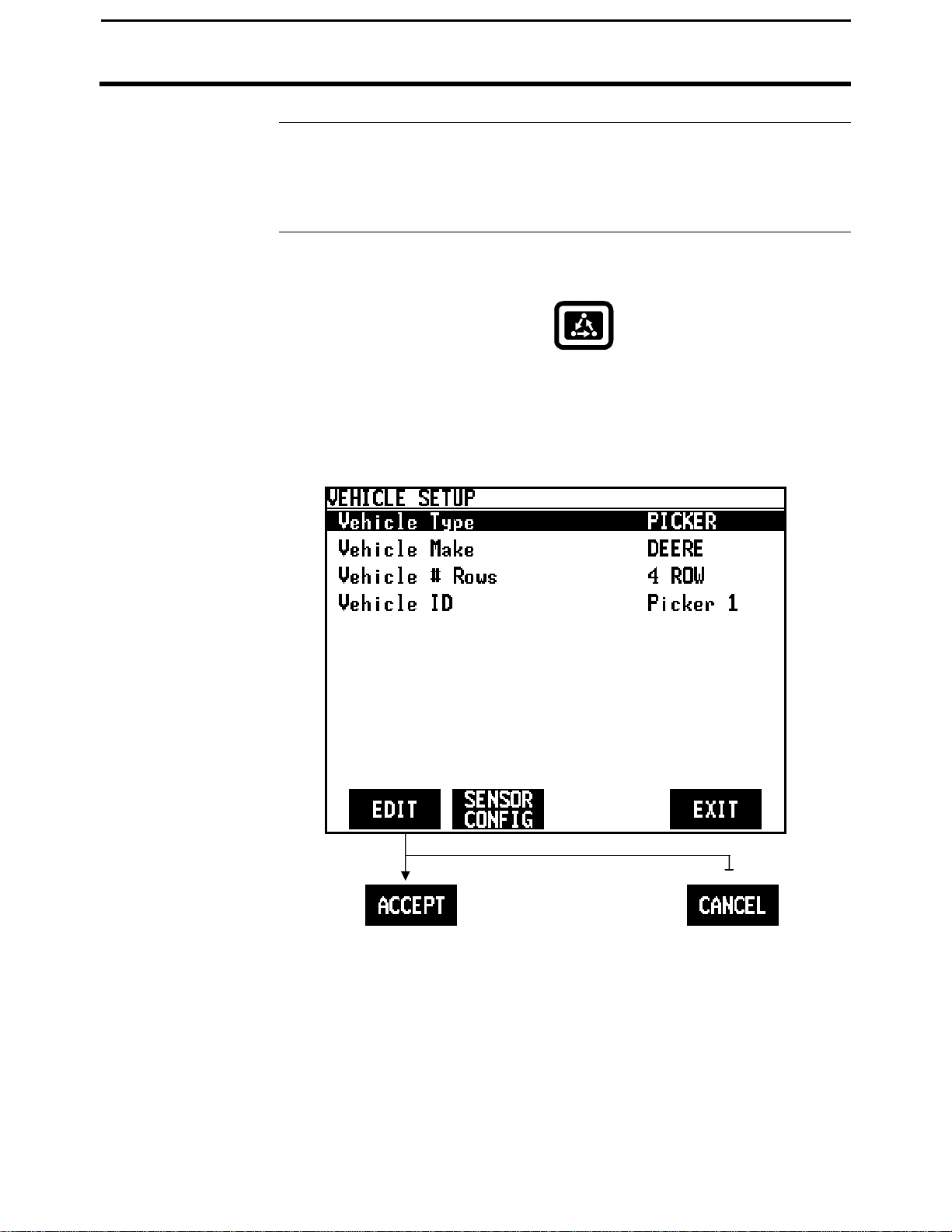

For each operating mode, there are different items to setup in the vehicle

setting screen. Below are the setup items for the cotton mode. Refer to

your Initial Calibration Sheet to make the correct settings.

To view the vehicle setup screen press the:

Example of vehicle setup screen:

Vehicle Setup

MENU key

SETUP key

VEHICLE key

March 2002

Page 20

PF3000 Cotton Yield Monitor

2-6

Changing a Setting

Vehicle Setup

Vehicle Type

Vehicle Make

Vehicle Nuber of

rows

Vehicle I.D.

Step Action

1 Use the UP or DOWN ARROW keys to select the item you want

to change. The item is selected when a black filled rectangular

box surrounds the entire line.

2 Press the EDIT key and then use the UP or DOWN ARROW keys

to change the number or setting.

3 Once you have changed a setting press the ACCEPT key. Press

the EXIT key once you have made all the settings.

This is currently set as picker.

At this time Deere and CASE-IH are the only selections. CASE-IH is the

default setting.

Set the number of picking units that are on your picker. The number of rows

must be set before completing Swath Setup later in this section. The

settings range from 2 to 6 rows.

Enter a name for the vehicle. The name of a driver or simply a unique name

or number for each machine is recommended.

Ag Leader Technology

March 2002

Page 21

PF3000 Cotton Yield Monitor

2-7

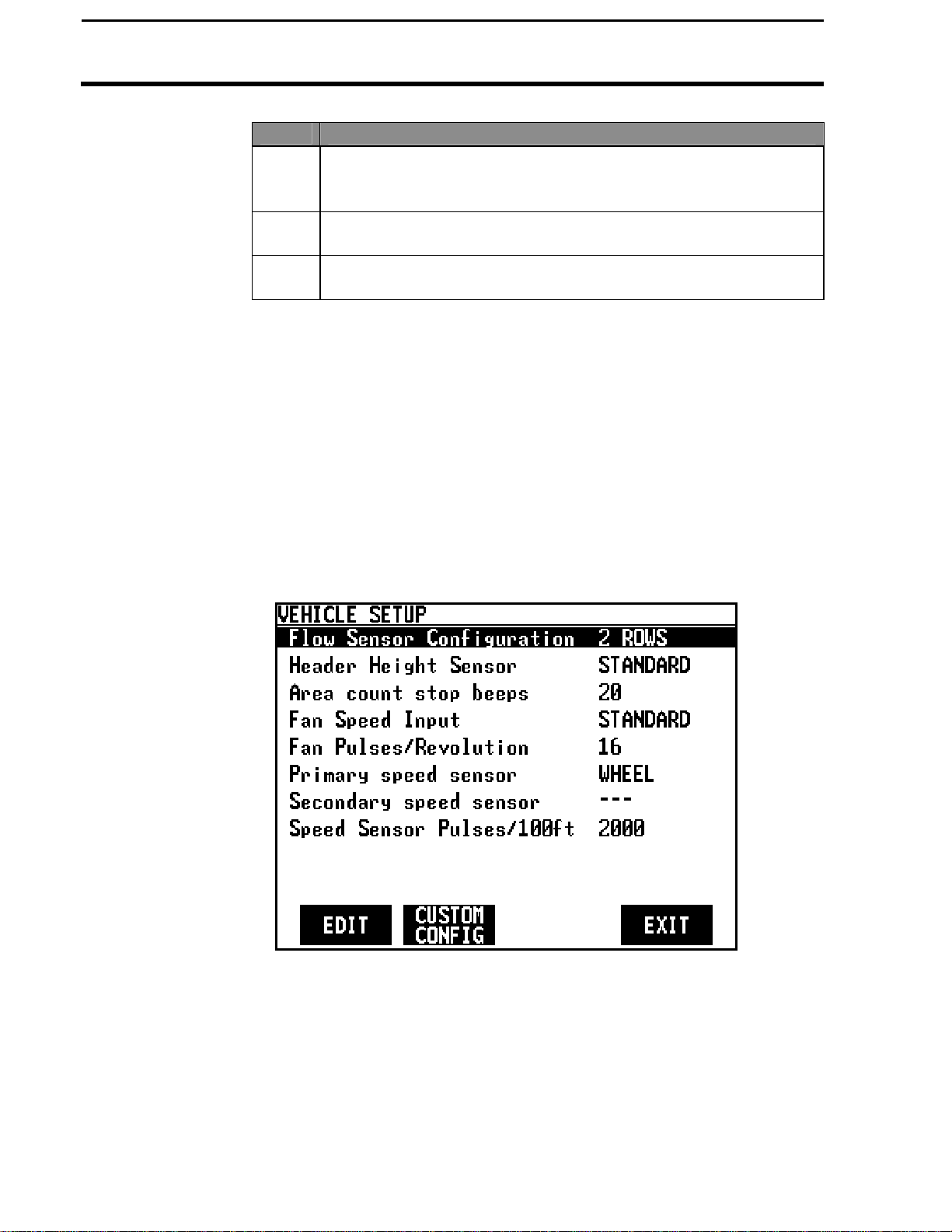

Set the number of flow sensors installed on the picker. 2 rows is the default.

Beeps

Ag Leader Technology

Flow Sensor

Configuration

Header Height

Area Count Stop

Fan

Pulses/Revolutions

Primary and

Secondary Speed

Sensor

Speed sensor pulses

/ 100 ft.

All rows will assign the appropriate number of sensors for each row. Cotton

strippers are fixed at 3 sets of sensors regardless of the number of rows

harvested.

Set as either STANDARD or OPTIONAL. Standard is the only header

height sensor available at this time.

The range for setting area count is 1 through 100. The default setting is 20.

This is the number of times the monitor beeps when the head is raised.

Sets the number of pulses per revolution to correctly display fan speed on

the PF3000. The default setting for CASE-IH pickers is 30. For John Deere

pickers 16.

The monitor has four different primary speed settings. They are listed

below.

Ground Speed Sensor Primary Speed Sensor

Speed sensor on transmission WHEEL

Speed sensor on tracks TRACK

Radar gun RADAR

GPS receiver (must be rated for accurate

ground speed: GPS2000/2100, Add-On

GPS3000/3100 and Trimble AgGPS receivers)

If you choose GPS as your primary speed sensor, you need to set the

secondary speed sensor to WHEEL, TRACK, or RADAR. If the GPS signal

is lost, the monitor will use the secondary speed sensor. If you do not

choose GPS as your primary speed sensor you can not set the secondary

speed sensor.

It is not recommended that you change this setting. This number is the

distance calibration number that is set when you perform a distance

calibration for WHEEL, TRACK or RADAR. Refer to the calibrating

distance instructions in the Calibration section. You must calibrate distance

for a WHEEL, TRACK or RADAR setting for accurate ground speed.

Vehicle Setup

GPS

March 2002

Page 22

PF3000 Cotton Yield Monitor

2-8

Vehicle Setup

Custom

Configuration

Ag Leader Technology

NOTE: If you want to use a radar gun, contact an Ag Leader Technology

dealer and purchase a special adapter cable for your radar gun.

This screen allows you to define where the sensors are located. On the

Vehicle Setup screen you defined the make, configuration and the number

of rows sensed. The CUSTOM configuration is defined on this screen.

The number of rows displayed on this screen is defined by the Picker

Configuration. The choices are limited by the Picker Make. Options will

vary between picker and cotton strippers.

The Picker Configuration & Flow Sensor Configuration define the default

sensor locations. For example:

4-Row Picker / 2 Rows: Row 1 and 4 are defined as FRONT/REAR.

5-Row Picker / 2 Rows: Row 1 and 5 are defined as FRONT/REAR.

6 Row Picker / 2 Rows: Row 2 and 5 are defined as FRONT/REAR.

2, 4, 5, 6 Row Picker / All Rows: All Rows are defined as FRONT/REAR.

NOTE: For CASE-IH Pickers the choices are NONE,

FRONT/REAR and FRONT ONLY. For Deere Pickers the choices

are NONE and INSTALLED.

March 2002

Page 23

PF3000 Cotton Yield Monitor

2-9

Ag Leader Technology

Vehicle Setup

* * *

March 2002

Page 24

2-10

PF3000 Cotton Yield Monitor

Card Setup

Introduction

Card Setup Screen

Ag Leader Technology

If you are using a GPS receiver, all the GPS data must be logged to a

memory card. If you are not using a GPS receiver, you do not need a card.

The memory card must be formatted with a DOS format. Cards rarely need

to be formatted since they are usually DOS formatted before they are

shipped. If formatting is required, format the card in your PC before using.

If you will be using multiple PF3000 monitors, label the memory cards to

identify them to a specific monitor. This will help prevent confusion when

you download the card information to your PC.

IMPORTANT: You must copy memory to every log file you

create and log to before you read the card into your computer.

This is automatically performed on startup and shutdown.

To view the card setup screen press the:

MENU key

SETUP key

CARD key

Example of card setup screens:

March 2002

Page 25

PF3000 Cotton Yield Monitor

2-11

Changing a Setting

Ag Leader Technology

Card Setup

Step Action

1 Use the UP or DOWN ARROW keys to select the item you want

to change. The item is selected when a black filled rectangular

box surrounds the entire line.

2 Press the EDIT key and then use the UP or DOWN ARROW keys

to change the number or setting.

3 Once you have changed a setting press the ACCEPT key. Press

the EXIT key once you have made all the settings.

Logging Device

If you are using a GPS receiver with the PF3000 you must use a memory

card to save the instantaneous GPS data.

If you... Select

Logging Interval

This setting determines how often the GPS information is saved to the

Do not have a GPS receiver. NONE

Do have a GPS receiver. MEMORY CARD

memory card. It also affects how large an area each GPS record will

represent on a map and how many logging hours are available before the

memory card becomes full.

There are three possible settings for the logging interval. 1, 2 or 3 seconds

The recommended setting is either two or three seconds.

3 mph

5 mph

20 M SANDISK ATA

1 sec 2 sec 3 sec

4.4 8.8 13.2

7.3 14.6 21.9

Approximate Logging Hours Until Card is Full

1 sec 2 sec 3 sec

25.8 47.2 65.2

Distance Traveled (ft)

Flash Card

32 M SANDISK ATA

41.2 75.5 104.3

Flash Card

NOTE: The logging hours available can vary from the numbers shown

above due to a variety of operating conditions. The number of fields

and loads, the number of separate files on the card and the number of

times the memory is copied to the card all affect the log file size.

.

March 2002

Page 26

2-12

Log File Format

PF3000 Cotton Yield Monitor

Card Setup

Log File

Logging Shutoff

Delay

Ag Leader Technology

The PF3000 requires a log file to store data on a memory card. The log file

will always have a ".PFL" extension and be named with the date the file was

created. Example: 98081502.PFL, second file created on 08/15/98.

If you have multiple PF3000 monitors, the monitors will create the same log

file name for each day’s harvest. Before downloading the card information,

create a separate file directory on your PC for each monitor and download

card data to these directories.

IMPORTANT: You must copy memory to every log file you create and

log to before you remove the card from your monitor. If you power the

monitor down before you remove the card, this will be done

automatically.

Type of Card Log file criteria

SANDISK ATA

FLASH card

A new log file must be created for each day. Can not add

to an old log file after a new file has been created. Can

store multiple log files on one card.

In order to log instantaneous GPS data or copy field and load data to a

memory card, a log file must be selected. Every time you turn on the monitor,

the monitor will prompt you to select or create a log file. Refer to the steps

below to select or create a log file after the monitor has been turned on.

Step Action

1 Select Log File and press the EDIT key.

2 Select a log file or press CREATE FILE key to create a new log file.

3 With the desired file selected, press the ACCEPT key.

NOTE: After you read all the log files on your card into your

computer (and make backup copies of files), it is recommended to

erase the log file(s) on the card.

For the PF3000 Cotton Yield Monitor, this option is not selectable.

The shutoff delay range is from 0 to 30 seconds. The default setting is 3

seconds.

March 2002

Page 27

PF3000 Cotton Yield Monitor

2-13

Ag Leader Technology

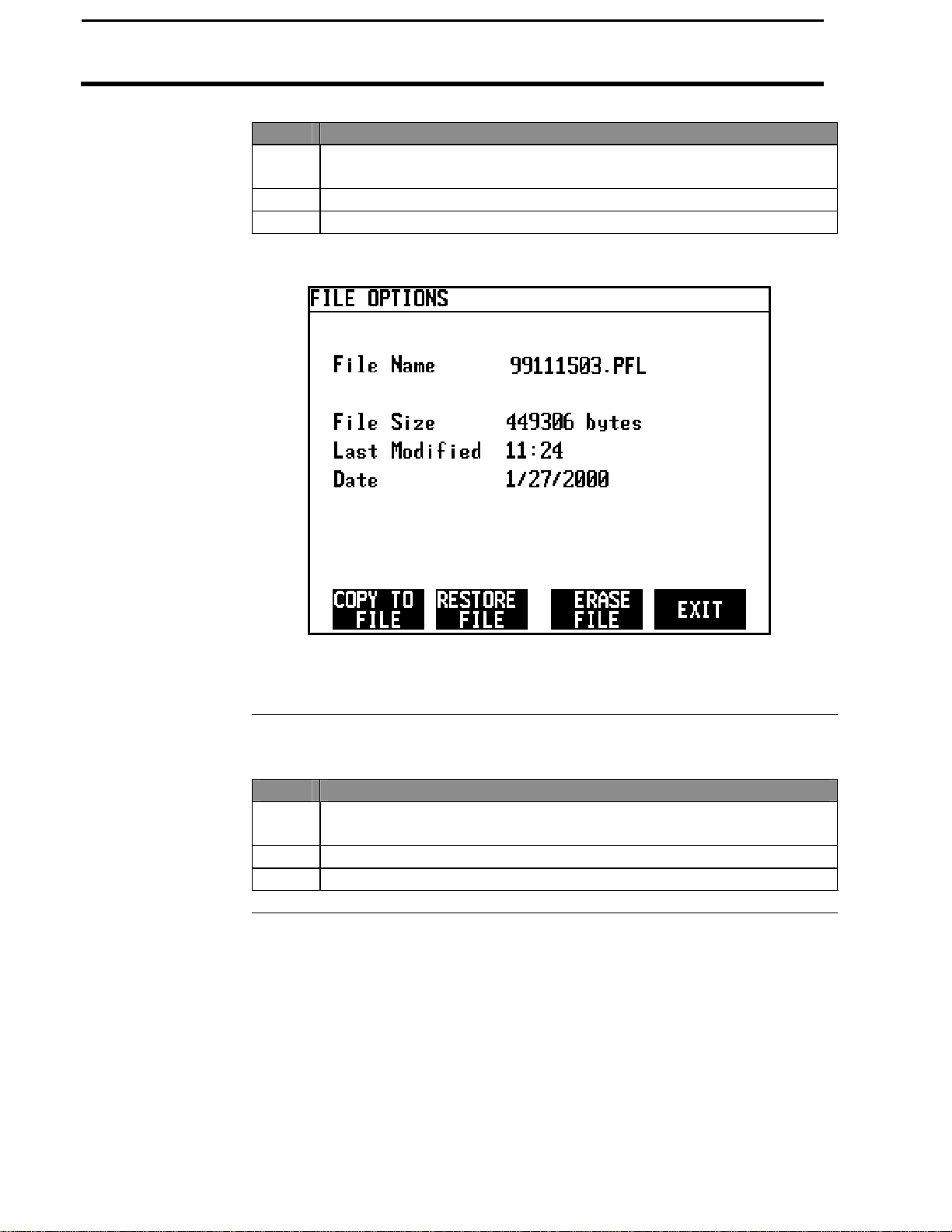

Copying Data to

Log File

Restoring from

File

To copy memory to log files that are not set as the current log file, press the

SHOW FILES key and select one of the log files. Press the FILE OPTIONS

key and press the COPY TO FILE key. At the card setup screen, press the

COPY TO CARD key to copy memory to the file set as the log file (this is the

same copy to card function that you are prompted to do during shut down).

You can restore field and load data into the monitor’s memory from a log file

on a memory card..

IMPORTANT: Before you remove the memory card from the

monitor, you must copy memory to every log file that you have

logged to, otherwise your data could be lost. Every time you turn

off the monitor, it will automatically copy memory to card (this

copies memory only to the file set as the log file).

IMPORTANT: It is dangerous to restore memory from a card

because the current data in the monitor will be replaced with the

data on card.

Card Setup

March 2002

Page 28

2-14

PF3000 Cotton Yield Monitor

Card Setup

Ag Leader Technology

Step Action

1 Press the SHOW ALL FILES key. Select the log file and press the

FILE OPTIONS key. Press the RESTORE FILE key.

Erasing File

2 Press the RESTORE key again if you really want to restore the data.

3 Press the EXIT key once you are finished.

You can erase individual log files from a memory card

Step Action

1 Press the SHOW ALL FILES key. Select the log file and press the

FILE OPTIONS key. Press ERASE FILE key.

2 Press the ERASE key again if you really want to erase the file.

3 Press the EXIT key once you are finished.

* * *

March 2002

Page 29

PF3000 Cotton Yield Monitor

2-15

The swath setup screen is used to set the permanent, full swath of your head.

Swath Setup

Screen

Ag Leader Technology

Introduction

Do not adjust the swath setting on this screen when you encounter a partial

swath while harvesting. Refer to the Swath Setting instructions in

Operation Section and select swath as a display item and set a partial swath.

To view the swath setup screen press the:

Example of swath setup screen:

NOTE: Ensure you have set the number of rows for your cotton

picker on the Picker Configuration line of the Vehicle Setup screen

before completing Swath Setup.

Swath Setup

MENU key

SETUP key

Bottom RIGHT ARROW key

SWATH key

March 2002

Page 30

2-16

Center

PF3000 Cotton Yield Monitor

Swath Setup

Ag Leader Technology

Changing a Setting Step Action

1 Use the UP or DOWN ARROW keys to select type of spacing to

be set.

2 Press the EDIT key to change the spacing. Use the UP or DOWN

ARROW keys to change the number. Press the ACCEPT key after

you have changed the number.

Full Swath

3 Press the EXIT key once you have made all the settings.

Adjustable in 1 inch increments. The range of settings is from 30 to 500

inches. Set the full swath in the monitor to the full swath of your header.

For broadcast headers it is advisable to set the swath to 6” to 12” less than

the actual swath width of the header because you can rarely maintain a full

swath while harvesting. In some cases, the number of rows the header can

harvest will exceed the limit of the monitor. If this happens, the full swath

is what you should be concerned with. It does not matter if the number of

rows or the width of each row in the monitor does not exactly match your

true situation.

Row to Row

Spacing

Selecting this option changes the line selected to only highlighting the

spacing value. The UP or DOWN ARROW keys will adjust the value by

whole number increments. When swath is edited, all row spacings become

equal to the full swath divided by the number of rows. The default is 40

inches. The limits are from 10 to 100.

Row 1 to Vehicle

Adjustable in 1 inch increments. Limits are from 0 to full swath value.

This accounts for offset headers.

Refer to the Swath Setting instructions in the Operation Section for more

information about partial swath.

* * *

March 2002

Page 31

PF3000 Cotton Yield Monitor

2-17

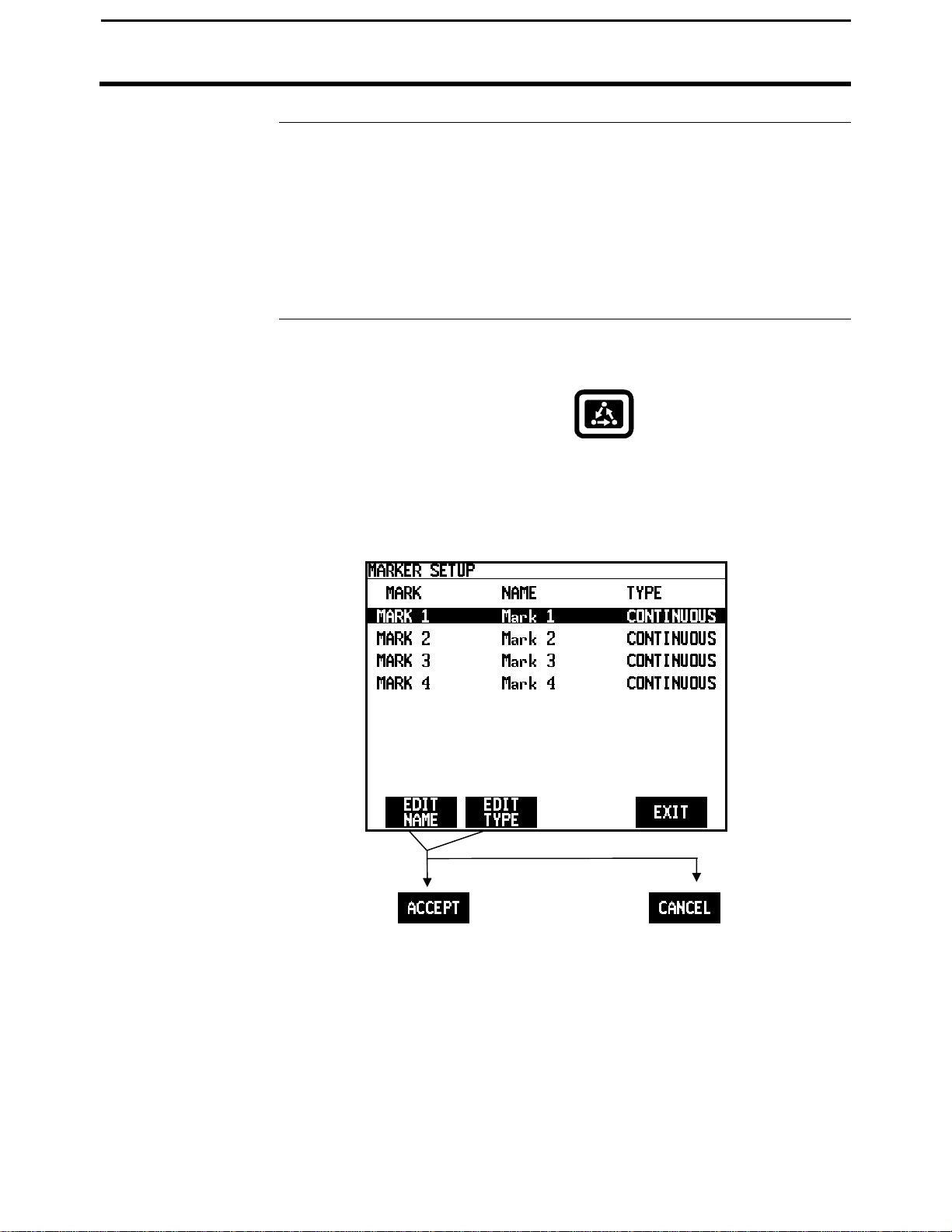

Marker Setup

Ag Leader Technology

Introduction

Screen

If you are using an external Field Marker ignore the instructions below. The

marker setup screen is only used for making settings for the Internal marker

selection keys. You may make up to 4 marks on the internal setting.

IMPORTANT:

If you are using the external field marker, make sure that under the

CONSOLE key you set Field Marker to EXTERNAL.

To view the marker setup screen press the:

Example of marker setup screen:

Marker Setup

MENU key

SETUP key

BOTTOM right arrow key

MARKS key

March 2002

Page 32

PF3000 Cotton Yield Monitor

2-18

Changing a Setting

Marker Setup

Step Action

1 Use the UP or DOWN ARROW keys to select the mark. The mark

is selected when a black filled rectangular box surrounds the entire

line.

2 Press the EDIT NAME key to rename an existing mark. Use the

UP or DOWN ARROW keys to change a character in the name.

Use the LEFT or RIGHT ARROW keys to move the cursor over

another character within the name. Press the ACCEPT key after

you have changed the name.

3 Press the EDIT TYPE key to set the mark for continuous or spot

marking. Use the UP or DOWN ARROW keys to change the

setting. Press the ACCEPT key after you have changed the setting.

4 Press the EXIT key once you have made all the settings.

Continuous marking

Set the marking type to continuous if the item in the field you are marking

requires you to make several marks in a row (for example: marking large

weed patches or tile lines).

When you press a mark key that is set for continuous marking, the mark will

remain on until you press the mark key again to turn off the mark.

Spot marking

Set the marking type to spot if the item in the field you are marking requires

just one mark (for example: marking a rock or tile hole).

When you press a mark key that is set for spot marking, the mark will

remain on only for a few seconds and then will automatically go off.

* * *

Ag Leader Technology

March 2002

Page 33

PF3000 Cotton Yield Monitor

2-19

Ag Leader Technology

Recommendations

All the information recorded by the PF3000 must be recorded in a field and

load. The field and load that the monitor is set on is located on the top line

of the display on the main operating screen.

Fields

You should at least create all the fields and name them before you begin to

use the PF3000. You should choose field names that you can use year after

year.

If you are unable to properly set-up your monitor before harvest, you may

create fields as you harvest. If there are errors made by the operator in that

the fields did not get changed at the proper time or did nor get changed at

all, you may use a sort feature in the SMS software that allows you to

automatically sort the data into the correct field. This is only possible if you

have created boundaries for each of the fields.

Second Pick Option: The second pick feature is available so if you second

pick a field, you can separate the data from the first pick which allows for

further analysis. The second pick feature also allows there to be one

calibration set for all second pick fields and loads.

Loads

It also recommended to create and name loads within fields before you use

the PF3000. Each operating mode of the PF3000 will have its own set of

loads for each field.

Definition:

Load: A load is used to subdivide a field into smaller sections. The

monitor load is not associated with the picker basket, wagon, or

truck load.

Creating, Naming Fields, & Loads

March 2002

Page 34

2-20

Field

PF3000 Cotton Yield Monitor

Creating, Naming Fields, & Loads

Creating and

Naming Fields

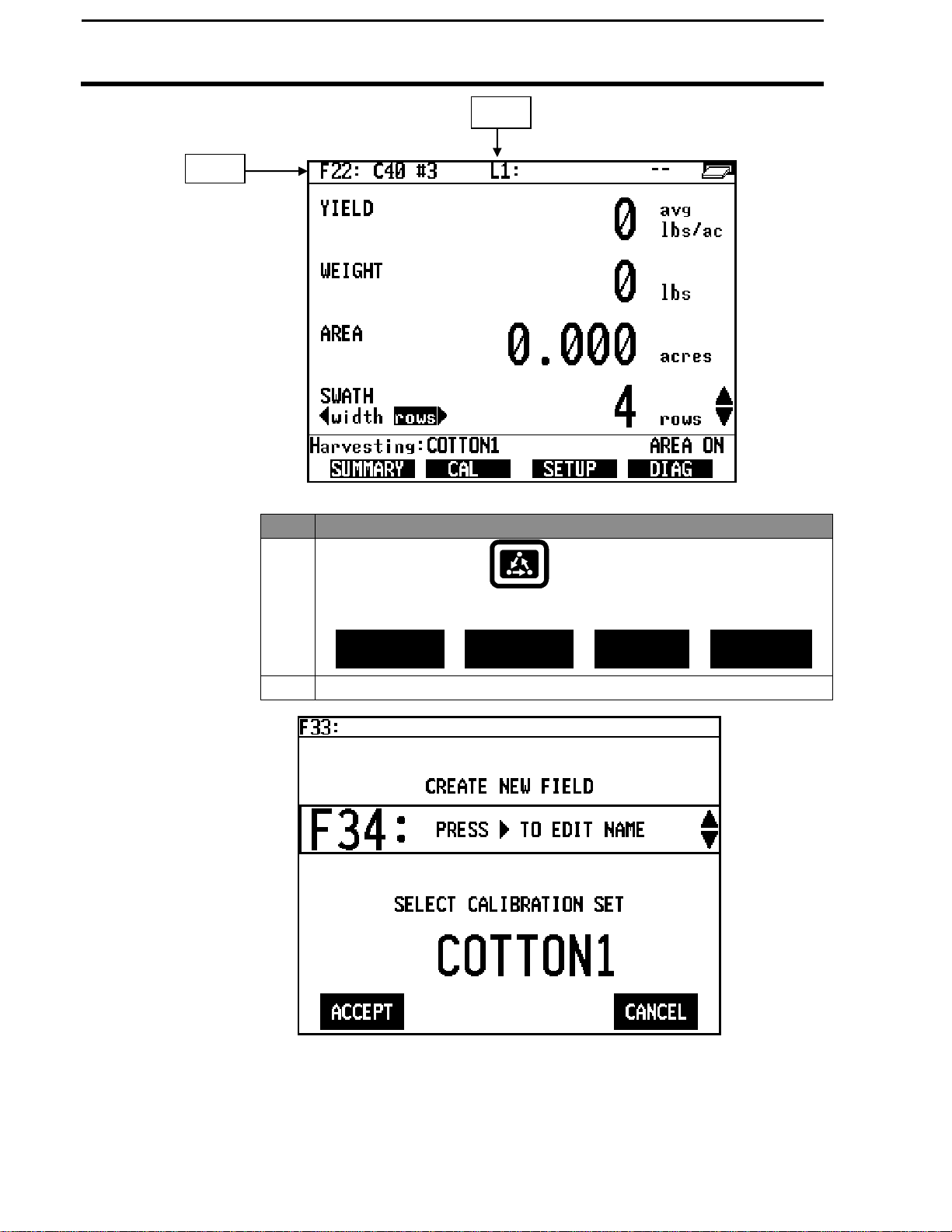

Step Action

1

Press the MENU key until the following is displayed on

the bottom of the display.

FIELD

2 Press the FIELD key twice to view the screen below.

Load

Ag Leader Technology

LOAD

SHOW MAP

MARKS

March 2002

Page 35

PF3000 Cotton Yield Monitor

2-21

Ag Leader Technology

Step Action

3

Naming Field

With the line displaying the field number selected (rectangular box

surrounds line), press the RIGHT ARROW key to move the cursor to

the right to enter a name. Use the UP or DOWN ARROW keys to scroll

through letters, numbers and other characters. After you have set the

character, move the cursor to the right by pressing the RIGHT ARROW

key and set a new character. You can enter up to a 10-character name.

Press the ACCEPT key once you have entered a name.

4

Creating Fields

Press the UP ARROW key to scroll through all the fields. Once you

scroll past the last field, "Create New Field" will be displayed. Name

the field and set the variety then with "Create New Field" displayed

above the field number press the ACCEPT key to create the new field.

5 When creating fields you have the option to change the calibration set.

You would want to do this if you know you will calibrate this field (or

set of data) different from other fields (or sets of data). Refer to the

calibration section for further details. Field calibration sets can be

modified at a later date as well.

6 Repeat Step 5 and create and name all your fields.

Creating, Naming Fields & Loads

Changing to Second

Pick:

The second pick option is available so first and second picking can be

separated and calibrated differently. In addition, SMS mapping software

allows you to do analysis of each picking or merge the two together. Due to

the extreme difference in harvesting and yield conditions from first and

second pick, it is required to calibrate the second pick separate from the first

pick.

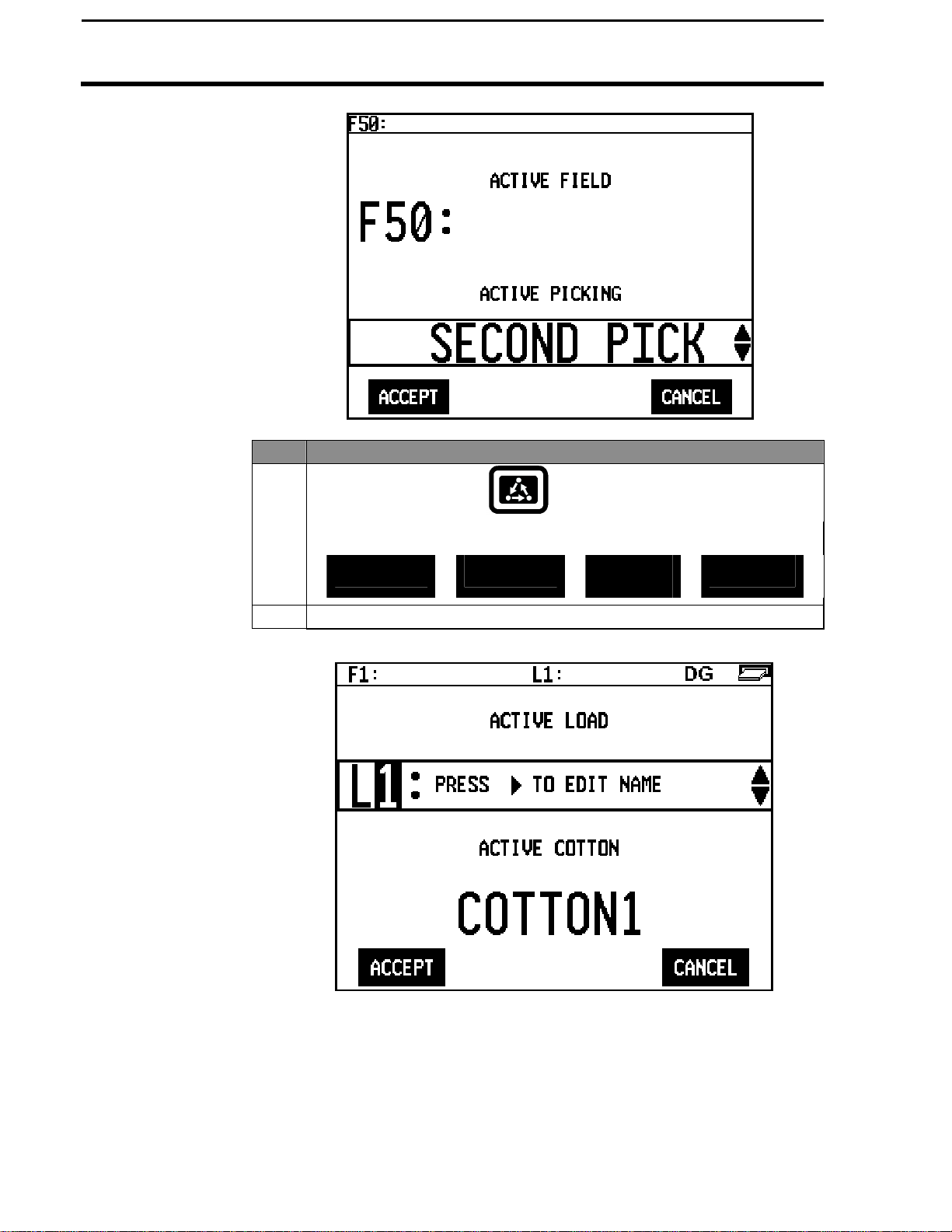

At the change field screen indicated below, the active picking indicates first

pick or second pick. The field below has already been toggled to the second

pick option. Select the item by pressing the key to the right of the item. A

rectangular box will be drawn around the item, indicating it is selected. Use

the arrow keys at the right to toggle the options. Press accept after the

second pick option has been selected. You will be required to change the

second pick instance for each field you wish to second pick.

If this is the first second pick field and a calibration set has not been created,

a new calibration set will automatically be created to be used by all second

pick fields. Refer to the calibration section for further details on calibration.

March 2002

Page 36

2-22

MAP

PF3000 Cotton Yield Monitor

Creating, Naming Fields, & Loads

Creating and

Naming Loads

Step Action

1

Press the MENU key until the following is displayed on

the bottom of the display.

FIELD

2 Press the LOAD key twice to view the screen below.

Ag Leader Technology

LOAD

SHOW

MARKS

March 2002

Page 37

PF3000 Cotton Yield Monitor

2-23

Ag Leader Technology

Step Action

3

Changing Fields

and Loads

Note: Refer to Load Setup to change variety, product or site type for an

existing load.

Changing Field

Press the FIELD key twice to display current field. Press the UP or DOWN

ARROW keys to scroll through the fields. Press the ACCEPT key to

change to the different field.

Changing Load

Press the LOAD key twice to display the current load. Press the UP or

DOWN ARROW keys to scroll through the loads. Press the ACCEPT key

to change to the different load.

Naming Load

With the line displaying the load number selected (rectangular box

surrounds line), press the RIGHT ARROW key to move the cursor to

the right to enter a name. Use the UP or DOWN ARROW keys to

scroll through letters, numbers and other characters. After you have

set the character, move the cursor to the right by pressing the RIGHT

ARROW key and set a new character. You can enter up to an 10character name. Press the ACCEPT key once you have entered a

name.

4 When creating loads you have the option to change the calibration set.

You would want to do this if you know you will calibrate this load (or

set of data) different from other loads (or sets of data). Refer to the

calibration section for further details. A Load's calibration sets can be

modified at a later date.

Step Action

5

Creating Loads

Press the UP ARROW key to scroll through all the loads in the field

for the variety. Once you scroll past the last load, "Create New

Load" will be displayed above the load number and name. Name the

load and set the variety, then with "Create New Load" displayed

above the load number press the ACCEPT key to create the new

load.

6 Repeat step 4 and create and name all your loads.

Creating, Naming Fields & Loads

* * *

March 2002

Page 38

PF3000 Cotton Yield Monitor

2-24

Memory Setup

Introduction

Memory Screen

Ag Leader Technology

The PF3000 has its own internal memory which stores all the field and load

summary data and setup and calibration settings. The internal memory does

not store any GPS data. All GPS data must be logged to a memory card.

To view the memory screen press the:

MENU key

SETUP key

bottom RIGHT ARROW key

MEMORY key

Example of memory screen:

March 2002

Page 39

PF3000 Cotton Yield Monitor

2-25

Card

Ag Leader Technology

Available Memory

Clear Load

Erase Memory

Restoring Data

from a Memory

The monitor does not have a pre-determined number of fields and loads that

it can store. It is only limited by memory. Instead, you should look at the %

memory used to get a relative idea of how many more fields and loads you

can create.

If you want to clear one load or all loads in a field, press CLEAR LOADS

key. Press EDIT key use the UP or DOWN ARROW to select the field

where loads are to be cleared and press ACCEPT key. Scroll down to

LOAD and press EDIT key use the UP or DOWN ARROW key to highlight

a specific load from a field and press ACCEPT key. Press the CLEAR

LOAD key to remove a specific load. The next screen will advise you to

press ACCEPT key to clear the load or CANCEL to abort. To remove all

loads from a field press CLEAR ALL key. The next screen will advise you

to press ACCEPT to clear all loads or CANCEL to abort.

If you want to clear all the setup, calibration and field and load data in the

monitor press the ERASE MEMORY key. The monitor will warn you that

you will lose all the data. Press the ACCEPT key to remove all the data.

You should normally only clear all the data at the beginning of the season.

You can restore field and load data from a memory card. The field and load

data can be from another PF3000 Cotton Yield Monitor or PF3000 Pro

Cotton Monitor. Refer to the card setup instructions in the setup section.

Memory Setup

* * *

March 2002

Page 40

PF3000 Yield Monitor

2-26

Sensor Setup

Introduction

Ag Leader Technology

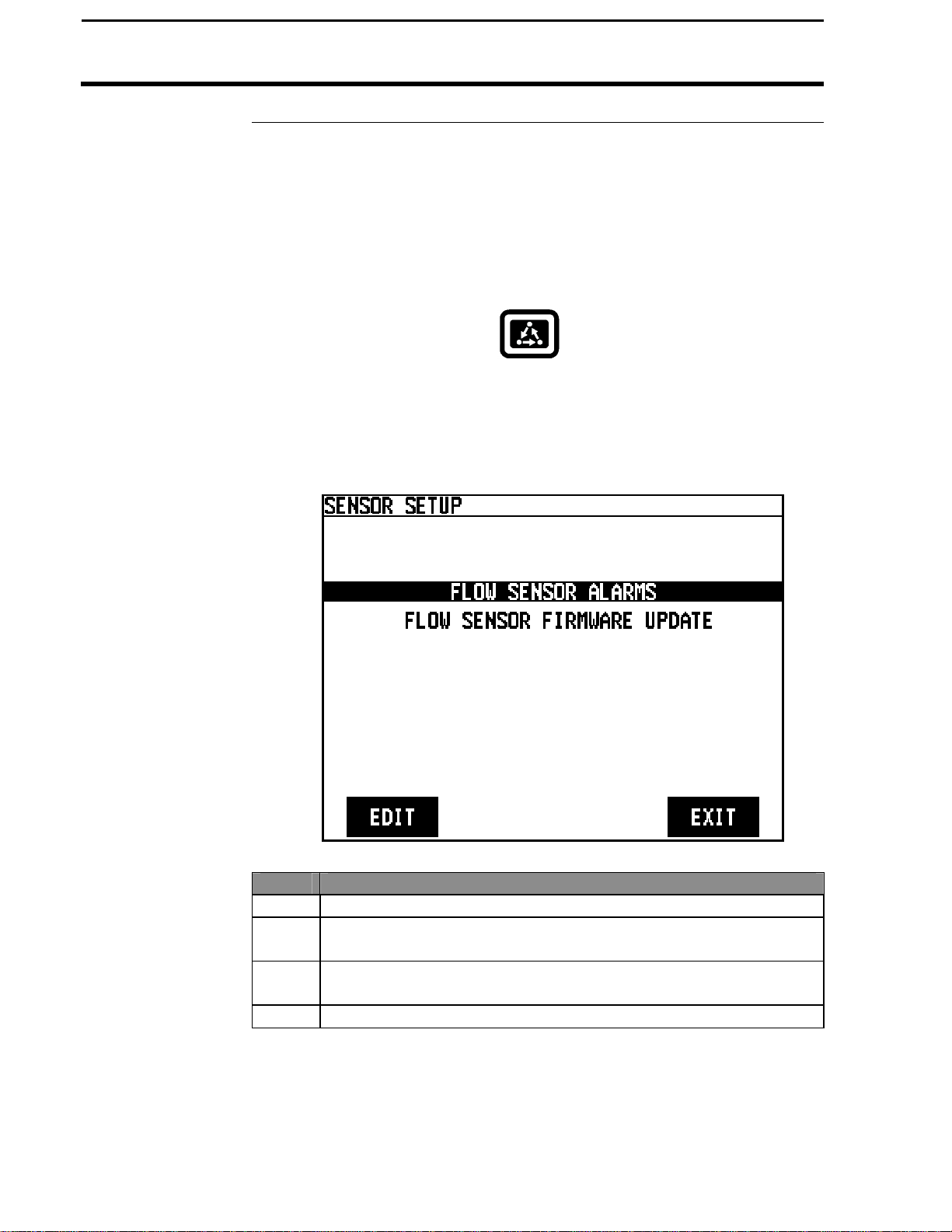

The flow sensor setup screen will allow you to set the sensitivity of the flow

sensor alarms. The sensor alarms warn you that one or more flow sensors

are not operating correctly and no yield data can be obtained from that

sensor.

Sensor Screen

To view the sensor setup screen press the:

MENU key

SETUP key

bottom RIGHT ARROW key

SENSOR key

Changing a Setting Step Action

1 Highlight the setting to be changed and press the EDIT key.

2 Press the UP or DOWN ARROW keys to select the setting to be

changed and press the EDIT key.

3 Use the UP or DOWN ARROW keys to change the number value

and press the ACCEPT key.

4 Press the EXIT key when the sensors are set.

March 2002

Page 41

PF3000 Cotton Yield Monitor

2-27

Ag Leader Technology

Choke Sensitivity

Stringer Sensitivity

Low Signal

Threshold

The choke alarm is to alert you when one or more conveyors have

blockages, which could damage your picking drums. The sensitivity

of this alarm can be adjusted from 0 to 100 percent. A sensitivity of

zero means that the alarm is disabled. The zero flow threshold sets a

maximum amount of flow which a conveyor is considered blocked.

The best setting varies widely with yield and the consistency of the

yield throughout the field.

NOTE: If your picker is equipped with a factory-installed choke

alarm system, we recommend using the factory-installed system for

choke alarms.

The stringer alarm is to alert you when one or more conveyors have

strings or ropes of cotton hanging in them which will cause large false

flow readings. The sensitivity of this alarm can be adjusted from 0 to

100 percent. A sensitivity of zero means that the alarm is disabled.

The zero flow threshold sets a minimum amount of flow which a

stringer must cause before the alarm is activated. The recommended

setting is 50 percent, but the best setting varies with field conditions.

The low signal alarm is to alert you to sensors which are too dirty or

are misaligned, causing the yield data to be inaccurate. The threshold

of this alarm can be adjusted from 0 to 60 percent of the full-strength

signal. A threshold of zero means that the alarm is disabled. The

recommended setting is 20 percent.

NOTE: The monitor will still measure yield very accurately even at

signal strengths as low as 20 percent.

Sensor Setup

March 2002

Page 42

PF3000 Cotton Yield Monitor

2-28

Sensor Setup

Zero Flow

Threshold

Flow Sensor

Firmware

Ag Leader Technology

The zero flow threshold affects both the stringer and choke alarms. It

can be adjusted from 0 to 65000, but typical settings are within the

range of 50 to 500. The zero flow threshold sets the amount of flow

which is considered negligible. When driving your picker around, you

may see very small but non-zero flow readings in the Sensor Data

Diagnostics. This threshold should be set larger than the average of

these non-zero readings to avoid false stringer and choke alarm

activations.

To view the flow sensor firmware version, highlight the Flow Sensor

Firmware Update line and press EDIT. Highlight the setting to be

changed and press the EDIT key. Press the UP or DOWN ARROW

keys to select the setting to be changed and press the EDIT key. Use

the UP or DOWN ARROW keys to change the number value and

press the ACCEPT key. Press the EXIT key when the sensors are set.

March 2002

Page 43

PF3000 Cotton Yield Monitor

3-1

Ag Leader Technology

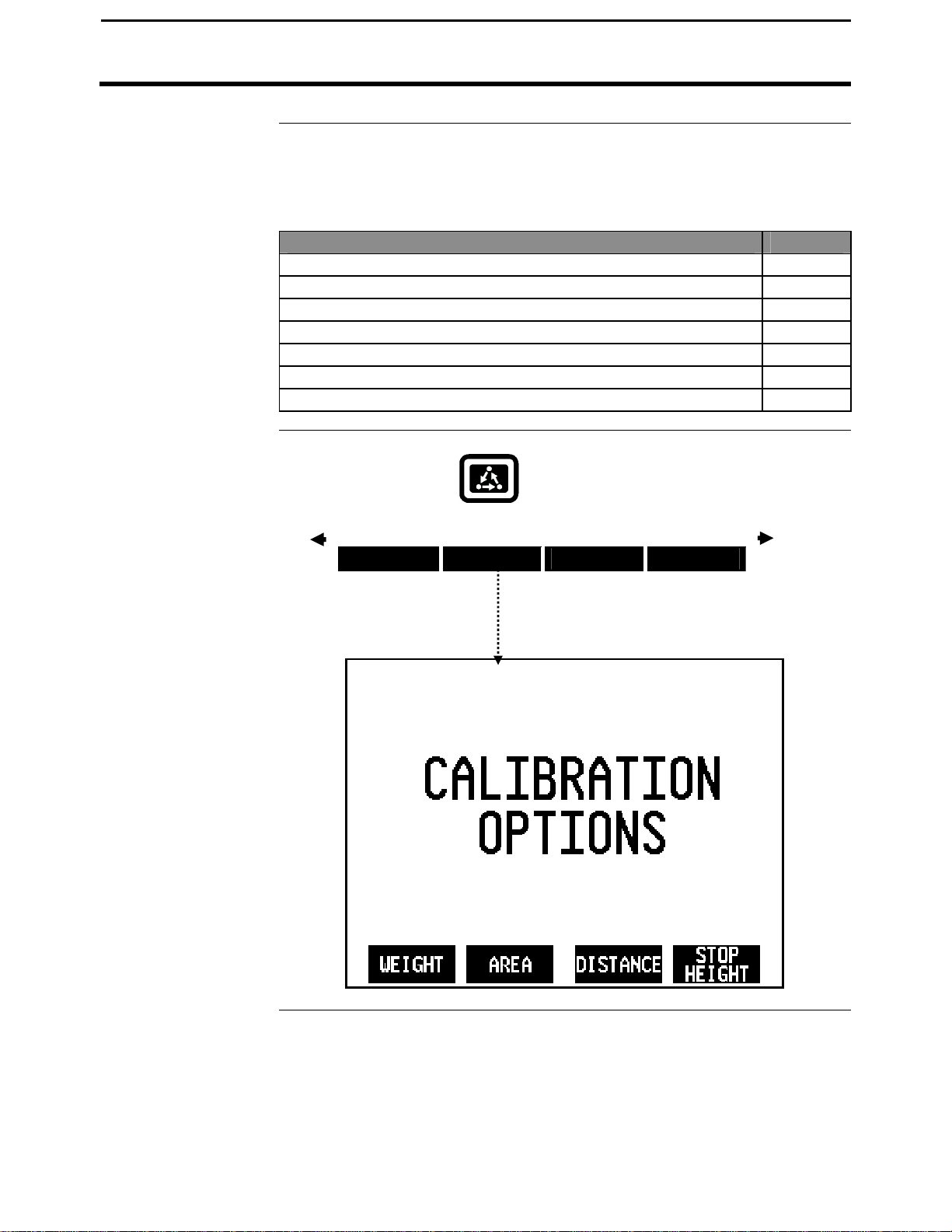

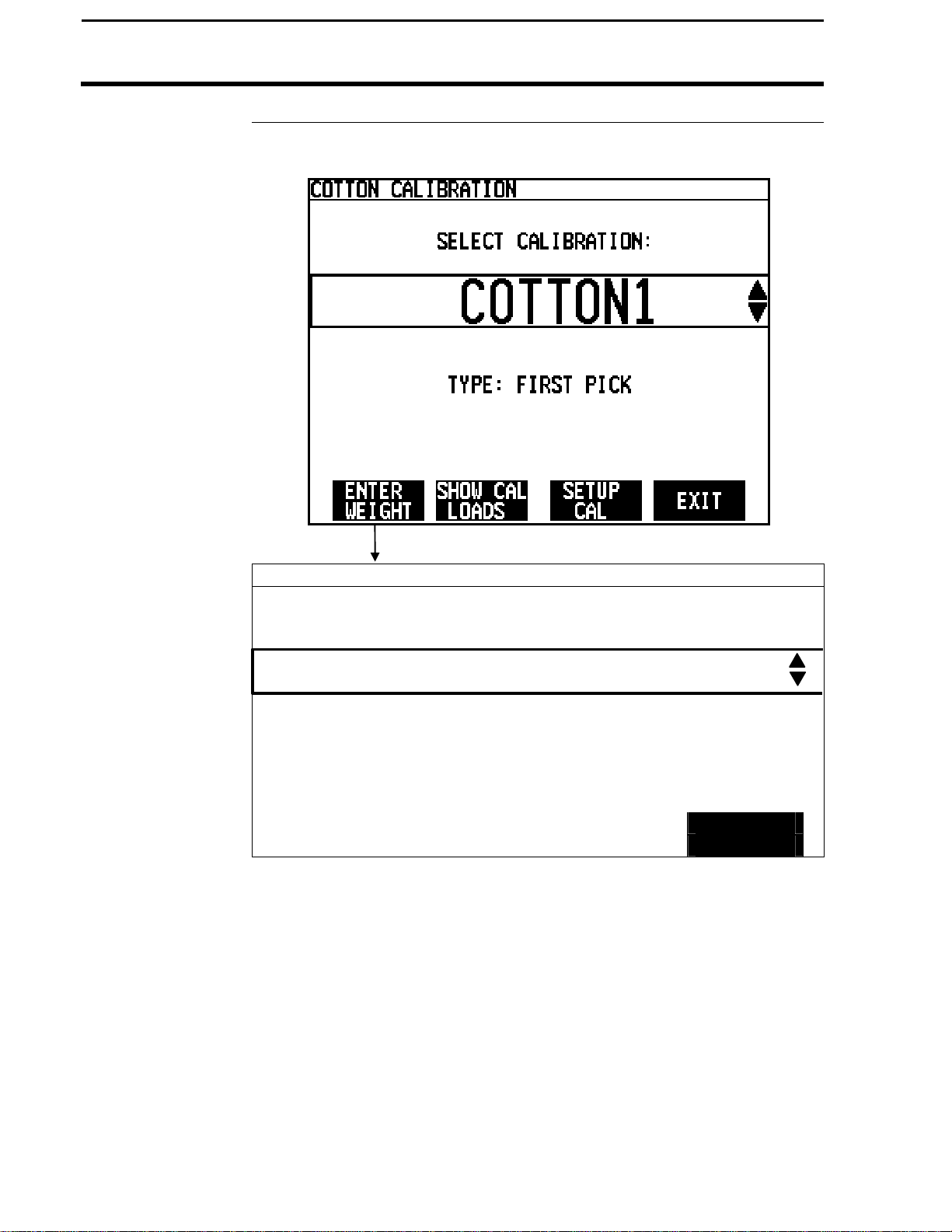

Introduction

Order of Keys

Press the CAL key to view

the following calibration

menu items.

You must calibrate the monitor for it to be accurate.

The calibration section contains instructions for the following items:

Cal Set Setup 3-2

Calibrating Seed Cotton Weight 3-6

Calibrating Area 3-12

Calibrating Distance 3-14

Calibrating Stop Height 3-17

Calibrating Vibration 3-19

Log Sheets (At the end of this section)

Press the MENU key until you see the following on

the display.

SUMMARY CAL SETUP DIAG

Calibration Overview

Item Page

* * *

March 2002

Page 44

PF3000 Cotton Yield Monitor

3-2

Setup Screen

Cal Set Setup

Introduction

Cotton Cal Set

Ag Leader Technology

The Calibration Set is used to create categories of different types of cotton,

different harvest conditions, or any other crop condition unique to your

operation you wish to identify. Your monitor is calibrated based on the

harvested loads of these calibration sets in a field. For example, in the

screen below, Cal Set 1 could be named for a specific type of cotton, or

could be a Cal Set you create during harvest because of changes observed

(post rain, green cotton, etc) in the cotton.

Many users of the PF3000 Cotton Yield Monitor believe it is important to

have the monitor calibrated as accurately as possible at all times.

When the physical characteristics of the cotton change, there could be a shift

in the accuracy of the yield monitor. This means that if the average error

was at 1% (ranging from +3 to –1%) and you moved to a new field and the

error shifts to 15% it would also have the same range 17% to 13%. The

point is within each characteristic change, the yield monitor will be very

consistent. If you goal is to make a yield map showing the variability

relative to other areas within that field, you generally should not need to recalibrate. This is assuming that most physical characteristics of the cotton

are generally similar within a field. In addition, you will have the

opportunity to scale the data in SMS mapping software and correct any

error.

Create a name for an actual variety of cotton planted or for different harvest

conditions. To view the cotton Cal Set setup screen press the:

MENU key

CAL key

WEIGHT key

SETUP CAL key

March 2002

Page 45

PF3000 Cotton Yield Monitor

3-3

Edit Name

Changing a Setting

Ag Leader Technology

Example of cal set setup screen:

Step Action

1 Press EDIT NAME key.

2 Use the UP or DOWN ARROW keys to change the letter. Use the

LEFT or RIGHT ARROW keys to add letters or numbers to the

name.

3 Press the ACCEPT key to complete the name change.

Step Action

1 Press the EDIT SETTINGS key to move to another screen and

change the settings of the default bale size, lint percent, and C

values. Refer to the screen below. See section below for further

details on editing the C values.

2 Press the EDIT key to change the desired item. Use the UP or

DOWN ARROW keys to change the value. Once you have

changed the value press the ACCEPT key.

3 Press the EXIT key once you have made all the settings.

Cal Set Setup

Type indicating

picking instance

March 2002

Page 46

3-4

PF3000 Cotton Yield Monitor

Cal Set Setup

Bale size

Lint percent

Setting Initial C

Numbers

Ag Leader Technology

Example of cal set setup screen:

Bale size can be set between 200 and 800 pounds

Sets the percent of lint per bale. (Lint turn out.)

The three C Numbers, C1, C2 and C3 determine the pounds of cotton the

monitor calculates. At first, the C1, C2 and C3 will be set to default value,

these initial numbers will change and become more accurate after you have

calibrated.

The C values: C1, C2, and C3 represent the following:

March 2002

Page 47

PF3000 Cotton Yield Monitor

3-5

Ag Leader Technology

C1: C1 is the vibration cal number. This number represents some

minimum value that the sensors must output before cotton flow is

calculated. Any signal below this value will not be recorded and cannot

be modified by post calibration. This is the number to be adjusted if a

significant amount of cotton is accumulating when sitting still in

logging mode. (this value should only be adjusted after all other

possible sources are ruled out.) Increase the value to decrease the

influence of vibration.

C2: This value is a scaling value that should never be changed.

C3: The C3 value is the value that will change as a result of performing a

calibration on that cal set. This represents a mathematical value used to

calculate the yield, specific to that cal set.

The C values can be edited as described in the previous steps.

IMPORTANT: Do not change the C numbers after you have

calibrated. If you change the C number after calibration, the

accuracy of the monitor will be effected.

Cal Set Setup

March 2002

Page 48

PF3000 Cotton Yield Monitor

3-6

Calibrating Seed Cotton Weight

Calibration Procedure

Before You Begin

Harvesting

Calibration Loads

Before the monitor will accurately measure weight, you must calibrate the

monitor for seed cotton weight (lbs) before you harvest. You should be able

to calibrate the PF3000 for load weight to an average error of 3 percent to 5

percent.

Although it is recommended, you do not have to calibrate load weight at the

beginning of the season to get accurate results. When you calibrate the

monitor, it will automatically correct weights for all the loads of that cotton

calibration set that were previously harvested.

The monitor calibrates itself on the basis of actual weights you enter into the

monitor. You get the actual load weights by weighing the load on accurate

scales or by obtaining accurate module weights for a load from your gin.

IMPORTANT: For accurate calibration results, you should obtain at

least three calibration loads for each calibration set. Three calibration

loads should reflect the conditions present for the remainder of the

harvesting under that calibration set.

You will get the best results when conditions are the same throughout all

loads harvested within a cotton calibration set. So, it is best to harvest

calibration loads during the afternoon, when moisture is normally at its

lowest point of the day. Moisture variations will have an impact on scale

readings, although it will not in large affect the monitors estimated weight

or maps generated from the yield data. Keep in mind the optical flow

sensors are measuring volume and the scales are measuring weight. The

amount of volume the monitor reads is then matched with the scale weight,

thus calibrating the monitor.

Also, different varieties are more or less fluffy and have different seed mass

so they should not be mixed within a single calibration for maximum

accuracy.

Carefully follow these directions when harvesting your calibration loads.

The following procedure applies to both first and second pick calibrations.

Ag Leader Technology

March 2002

Page 49

PF3000 Cotton Yield Monitor

3-7

Calibration

Ag Leader Technology

Step Action

Seed Cotton

Weight

1 With the cotton picker stopped, the cotton basket completely empty,

and a hauling vehicle empty, set the monitor on a load that does not

have any data. Make sure the load is set on the correct cotton

calibration set.

2 Harvest cotton into the calibration load in the monitor.

NOTE: Harvest 3,000 or more lbs for calibration loads.

3 Unload one or more times into the hauling vehicle, finishing with the

following:

• Cotton basket again empty

• All the cotton from the calibration load on the hauling vehicle

• No cotton from any other picker on the hauling vehicle

4 Immediately change to another load that does not have any data.

5 Weigh the cotton on the hauling vehicle and record the actual load

weight on a log sheet in the back of this section of the manual.

NOTE: If you are using a weigh wagon to weigh the cotton, make

sure the wagon has been calibrated properly.

6 Repeat the above steps and harvest another calibration load. You

can also enter an actual weight and calibrate as you obtain each

actual weight.

To view the weight calibration screen press the:

Calibrating Seed Cotton Weight

Screen

MENU key

CAL key

WEIGHT key

March 2002

Page 50

PF3000 Cotton Yield Monitor

3-8

Procedure

Calibrating Seed Cotton Weight

Calibration

COTTON CALIBRATION

F1: North 80

Ag Leader Technology

L1: Corner E

ACT. WEIGHT:

MEASURED WEIGHT 13000 lb

% ERROR 2.5 %

CLEAR

WEIGHT

13325

EXIT

lb

March 2002

Page 51

PF3000 Cotton Yield Monitor

3-9

LOAD

ACT. WEIGHT

% ERROR

F2: 99B

-80AC

L2: 9352

21789

-0.4 %

L4: 9352

-

0.0 %

L5: -0.8 %

L2: 9281

22400

+0.1 %

WEIGHT

ON/OFF

CAL

Ag Leader Technology

Step Action

1 Use the UP or DOWN ARROW keys to select the cotton calibration

set. Press the ENTER WEIGHT key.

2 Refer to the next screen and change the load (and field if necessary)

to a load for which you want to enter an actual weight. Use the UP

or DOWN ARROW keys to change the field or load, depending on

which is selected.

You must have the field or load line selected (rectangular box

surrounds line) before you can change a field or load. To select

either field or load, press the key to the right of the field or load line.

If the Fields and loads do not appear that you feel should, check the

previous screen to verify you selected the correct cal set.

3 Press the key to right of the "Act. Weight" line to select that line.

4 Use the UP or DOWN ARROW keys and enter the actual weight for

the load. Press the ACCEPT key.

5 Repeat steps 2-4, and enter all the actual weights for all the

calibration loads.

6 Press the EXIT key once you have finished to return to the screen

where you selected the cal set.

7 Press the SHOW CAL LOADS key to view the screen below.

Example of calibration loads screen:

COTTON CALIBRATION : COTTON1

Calibrating Seed Cotton Weight

L3: 9352 +0.4 %

F4: SMITH

L1: 9281 20900 -0.2 %

EDIT

CAL

March 2002

PERFORM

EXIT

Page 52

PF3000 Cotton Yield Monitor

3-10

Calibrating Seed Cotton Weight

Step Action

8 The screen above allows you to include a load in the calibration or

exclude it by “unchecking” it and turning it off.

9 Press the PERFORM CAL key to start the calibration. The monitor

will start calibrating and then it will stop and display "Full

Calibration Complete".

NOTE: The calibration error is the percent difference between the

actual weight and the estimated weight. The maximum error is the

error of the calibration load that has the highest error.

Example:

Actual weight: 10,000 Lbs.

Estimated weight: 10,100 Lbs.

Error: + 1 %

10

Good Calibration Results:

If you have three or more calibration loads, your goal after

completing a calibration should be to achieve an average error of

less than 5 percent and a maximum error of 10 percent

If you have at least three calibration loads, and you find a load with a

high calibration error after completing the calibration, you should

remove the load as a calibration load by pressing the CAL ON/OFF

key. Press the PERFORM CAL key again to restart the calibration.

Once you are satisfied with your calibration results, press the EXIT

key until you return to the main operating screen.

Reasons for high calibration errors on loads

• Cotton calibration set is incorrectly set for the load

• Cotton moisture or density is considerably different between loads.

• Actual pounds value is not correct

• Cotton weighed is not the same amount of cotton that was harvested into

the load (for example: picker basket was not empty before starting the

load or forgot to change loads in the monitor and added more cotton into

the load (in the monitor) after cotton weighed or cotton spilled onto the

ground)

• Installation problem with flow sensor

Ag Leader Technology

March 2002

Page 53

PF3000 Cotton Yield Monitor

3-1

1

Ag Leader Technology

Recalibrating the

Monitor

Periodic Checks

for Accuracy

To improve the monitor’s calibration accuracy, you can add or eliminate a

calibration load and recalibrate the monitor at any time. If you have not

achieved satisfactory calibration results after entering 4 to 5 calibration

loads something is wrong. Refer to the Troubleshooting Section instead of

adding more actual weights.

Throughout the season you should occasionally check the monitor for

calibration accuracy by weighing a monitor load of cotton. If you find the

monitor is not accurate, enter that actual weight into the monitor and

calibrate the monitor again.

It is recommended you verify the calibration when you observe a change in

lint density or seed mass for example; when changing seed varieties or

continuing harvest after a heavy rain.

If a difference is found, you would want to create a new Cal Set, otherwise

previous data will be affected.

Calibrating Seed Cotton Weight

***

March 2002

Page 54

PF3000 Cotton Yield Monitor

3-12

Screen

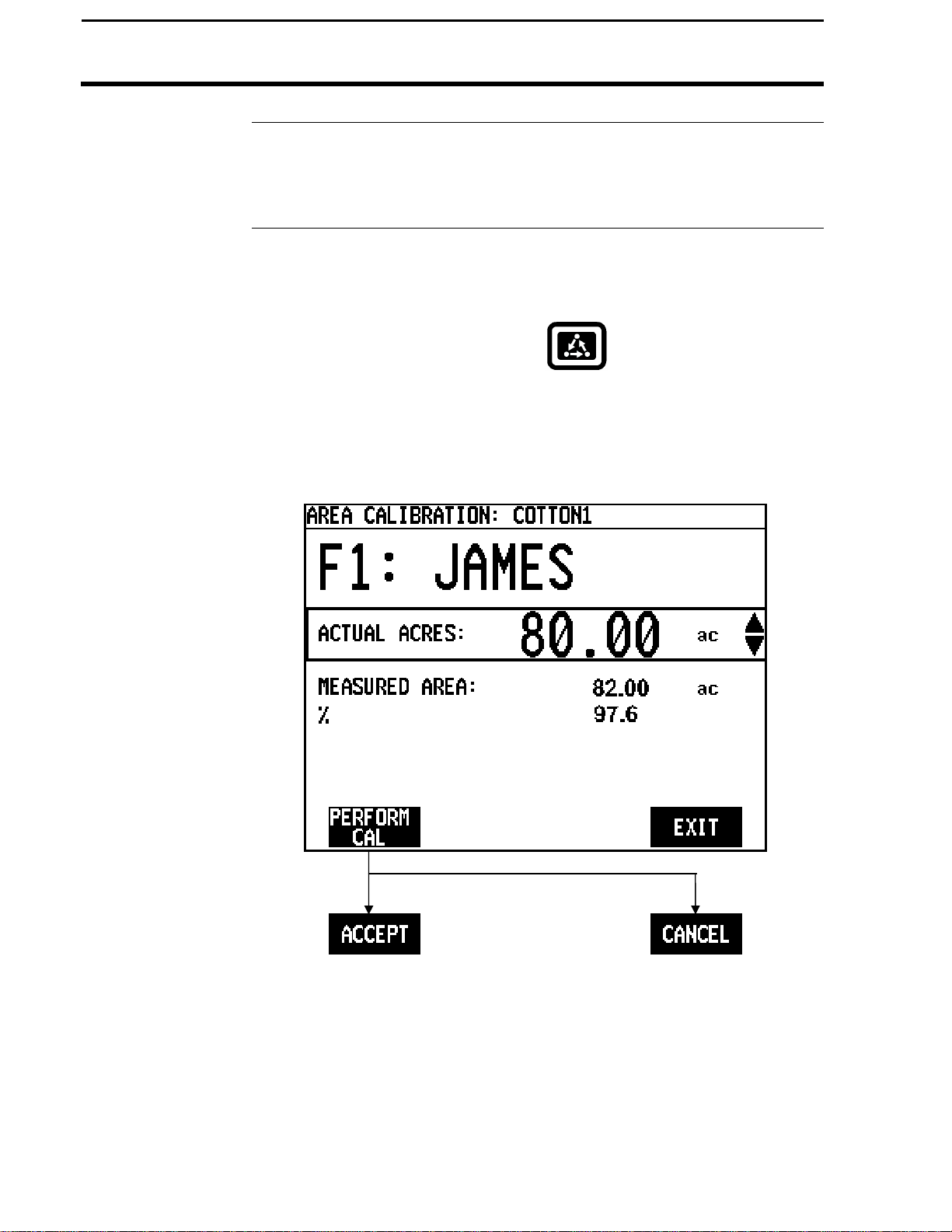

Calibrating Area

Adjusting Field

Area

Area Calibration

Ag Leader Technology

If you know the exact field area, you can adjust the monitor field area to the

correct value after you finish the field. Follow these steps to adjust the field

area:

To view the area calibration screen press the:

MENU key

CAL key

AREA key

Example of area calibration screen:

March 2002

Page 55

PF3000 Cotton Yield Monitor

3-13

Calibration

Ag Leader Technology

Step Action

Procedure

1 Change the field to a field for which you know the exact area. Select

(rectangular box surrounds line) the field by pressing the key to the

right of the line displaying field. Use the UP or DOWN ARROW

keys to change the field.

2 Select the "Actual Area" line by pressing the key to the right of the

line displaying actual area. Use the UP or DOWN ARROW keys to

set the actual area.

3 Press the PERFORM CAL key. Press the ACCEPT key.

4 Repeat steps 1-4 for all the fields for which you know the actual

area.

5 Press the EXIT key once you have finished.

NOTE:

• The monitor proportionally adjusts all the load areas so that the areas

from all the loads equal the total field area.

• The "Area Cal" number is the actual area divided by the area the

monitor originally counted. When you press the PERFORM CAL key,

the monitor determines the area calibration number and adjusts the

measured area accordingly.

• Usually the monitor slightly over counts area when turning on the ends

due to error in not turning on and off area counting exactly at the start

and end of a pass. It is suggested that you determine an average

percent error in counting area and adjust the field area accordingly,

even if you do not know the exact field area. Typical area calibration

numbers for harvesting row crops are 97-99%.

Calibrating Area

***

March 2002

Page 56

PF3000 Cotton Yield Monitor

3-14

Calibration

Calibrating Distance

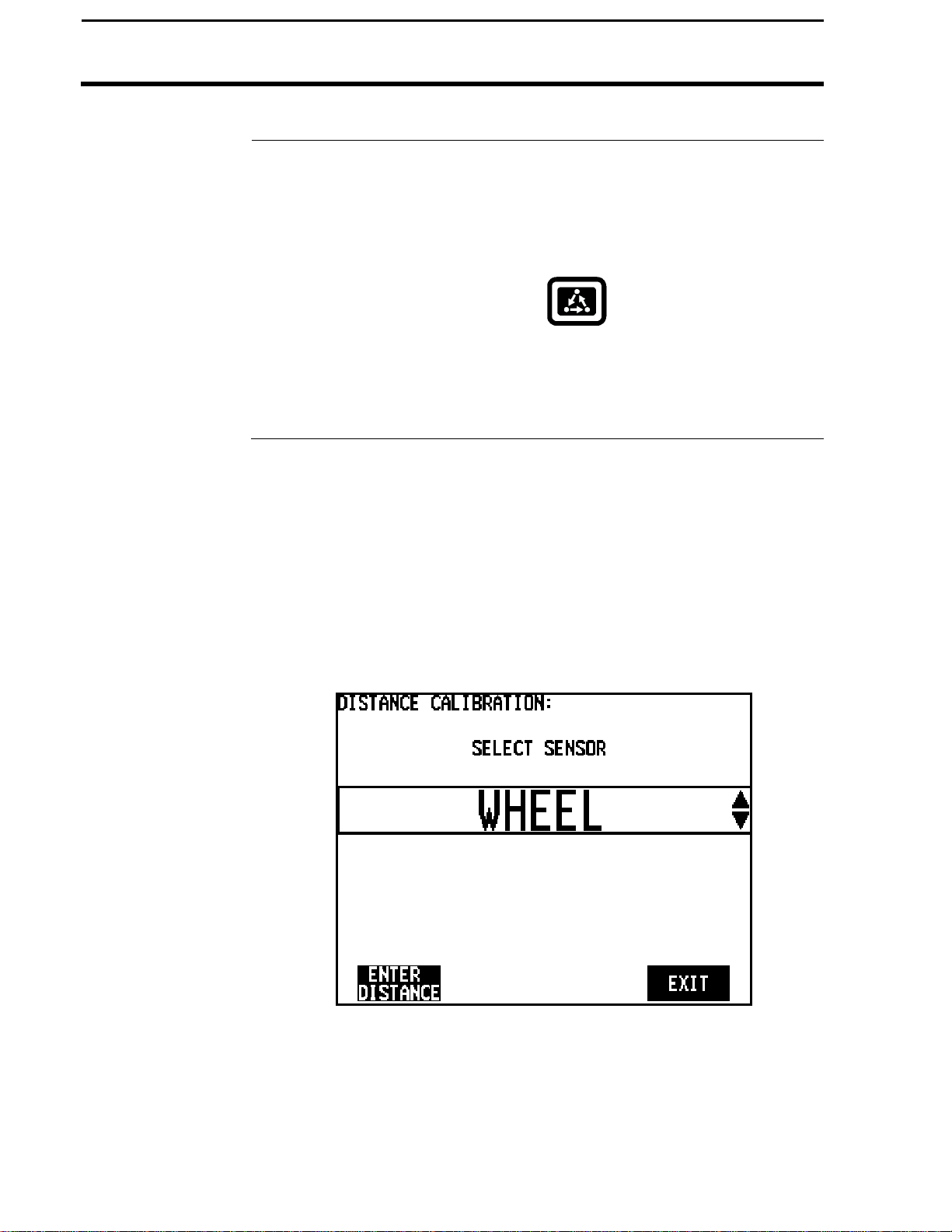

Introduction

Distance

Screen

Choosing Speed

Sensor

You must calibrate distance for a primary or secondary speed setting of

WHEEL, TRACK or RADAR.

To view the distance calibration screen press the:

You must choose the speed sensor you are using for ground speed before

you can calibrate distance. Use the UP or DOWN ARROW key to select

either:

• WHEEL

• TRACK

• RADAR

Press the ENTER DISTANCE key after you have set the ground speed

sensor.

Ag Leader Technology

MENU key

CAL key

DISTANCE key

March 2002

Page 57

PF3000 Cotton Yield Monitor

3-15

Calibrate Distance

Procedure

Ag Leader Technology

Preparing to

Calibration

You must accurately measure a known distance, setting flags or making a

mark at each end of the path.

NOTE:

• Use at least a 200 feet travel path to obtain an accurate calibration.

• For maximum accuracy, calibrate on a ground surface that is similar to

field conditions.

Example of distance calibration screen:

Calibrating Distance

March 2002

Page 58

PF3000 Cotton Yield Monitor

3-16

Calibrating Distance

NOTE:

• Upon pressing PERFORM CAL, the monitor automatically adjusts the

• You can manually change the "pulses / 100 ft" number. Select "pulses /

NOTE:

You should record the pulses/100 ft on the log sheet provided. If problems

with the monitor occur, you can enter this value and you will not have to

repeat the Distance Calibration. This value can also be accessed under the

"Vehicle Setup" screen, then "Sensor Config".

Ag Leader Technology

Step Action

1 Use the UP or DOWN ARROW keys to set the actual distance to

the known length of the travel path.

NOTE: The actual distance line must be selected (rectangular box

surrounds line) before you can set the actual distance. Press the

key to the right of the actual distance line to select it if it is not

already selected.

2 Position the vehicle at the beginning of the travel path. Pick a spot

on the vehicle and align it with the mark at the beginning of the

travel path. Press the START TRAVEL key.

3 Drive the length of the path stopping at the end marker and press

the STOP TRAVEL key.

4 Press the PERFORM CAL key to calibrate the distance. Press the

ACCEPT key to accept the calibration.

5 Press the CLEAR DISTANCE key and repeat steps 2-4 and drive

the travel path again to double check the accuracy of the distance

calibration.

6 Press the EXIT key twice after you have finished calibrating

distance.

"pulses / 100 ft" number so that the "Measured Distance" is equal to the

"Actual Distance".

100 ft" by pressing the key to the right of the line. Then use the UP or

DOWN ARROW keys to set the number. Do not change this number

after calibrating.

* * *

March 2002

Page 59

PF3000 Cotton Yield Monitor

3-17

Calibration

Ag Leader Technology

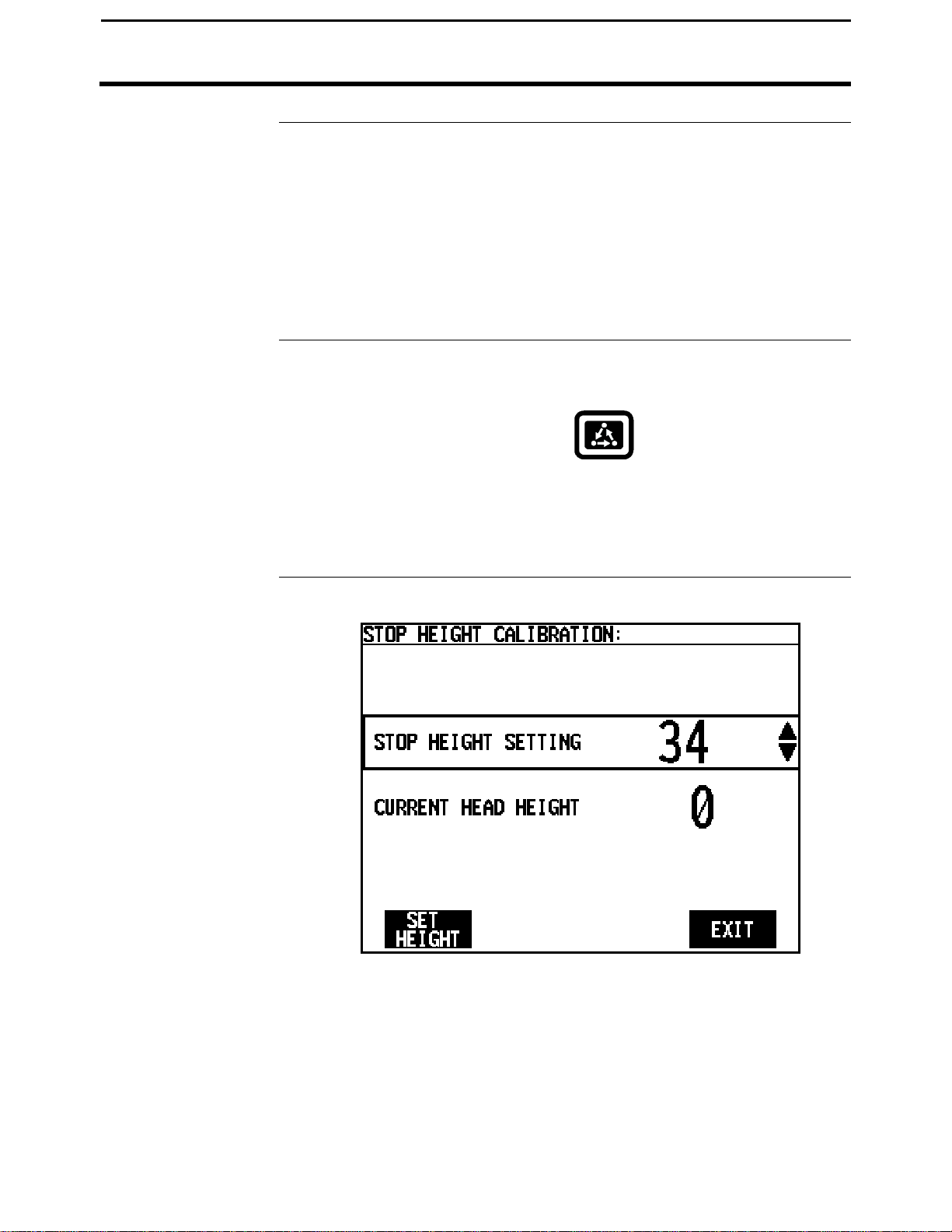

Introduction

Stop Height

Calibration

Screen

The stop height is the height at which the head must be raised at the end of a

pass to shut off area counting. The stop height number is a reference

number for the monitor to determine the height of the head. It does not

pertain to feet or inches of height.

The stop height number must be set.

You must have the monitor installed in the picker to set the stop height.

To view the stop height calibration screen press the:

Calibrating Stop Height

MENU key

CAL key

STOP HEIGHT key

March 2002

Page 60

PF3000 Cotton Yield Monitor

3-18

Calibrating Stop Height

Step Action

1 Use the UP or DOWN ARROW keys to select stop height setting.

2 Press the SET HEIGHT key.

Step Action

3 Move the picker head to the height at which you want the monitor to

4 Press the SET HEIGHT key. The monitor will automatically set the

5 Press the EXIT key twice to return to the main operating screen.

NOTE: You can manually adjust the stop height number by pressing the

UP or DOWN ARROW key when the screen above is displayed. Adjustment

of the sensor maybe needed to gain more range of motion. Adjust the point

at which the chain attaches to the threaded rod and/or adjust the location

that the chain is attached to the head.

Ag Leader Technology

stop counting area.

stop height setting equal to the current stop height. Press the

ACCEPT key.

* * *

March 2002

Page 61

PF3000 Cotton Yield Monitor

3-19

Ag Leader Technology

Calibrating for

Vibration

C Numbers

The vibration calibration is not automated at this time. If you suspect that

vibration is causing false cotton flow, call Ag Leader Technology Technical

Support at 515-232-5363.

Refer to the previous section on “Calibrating Seed Cotton Weight” where the

C Values are discussed.

The three C Numbers, C1, C2 and C3 determine the pounds that the monitor

calculates. You can display the C numbers by pressing the SET UP CAL

then EDIT SETTINGS at the cotton weight calibration screen where you

choose the cotton calibration set.

IMPORTANT: Do not change the C numbers after you have

calibrated.

Refer to the previous section on “Calibrating Seed Cotton Weight” where

the C Values are discussed.

Calibrating Vibration

* * *

March 2002

Page 62

Page 63

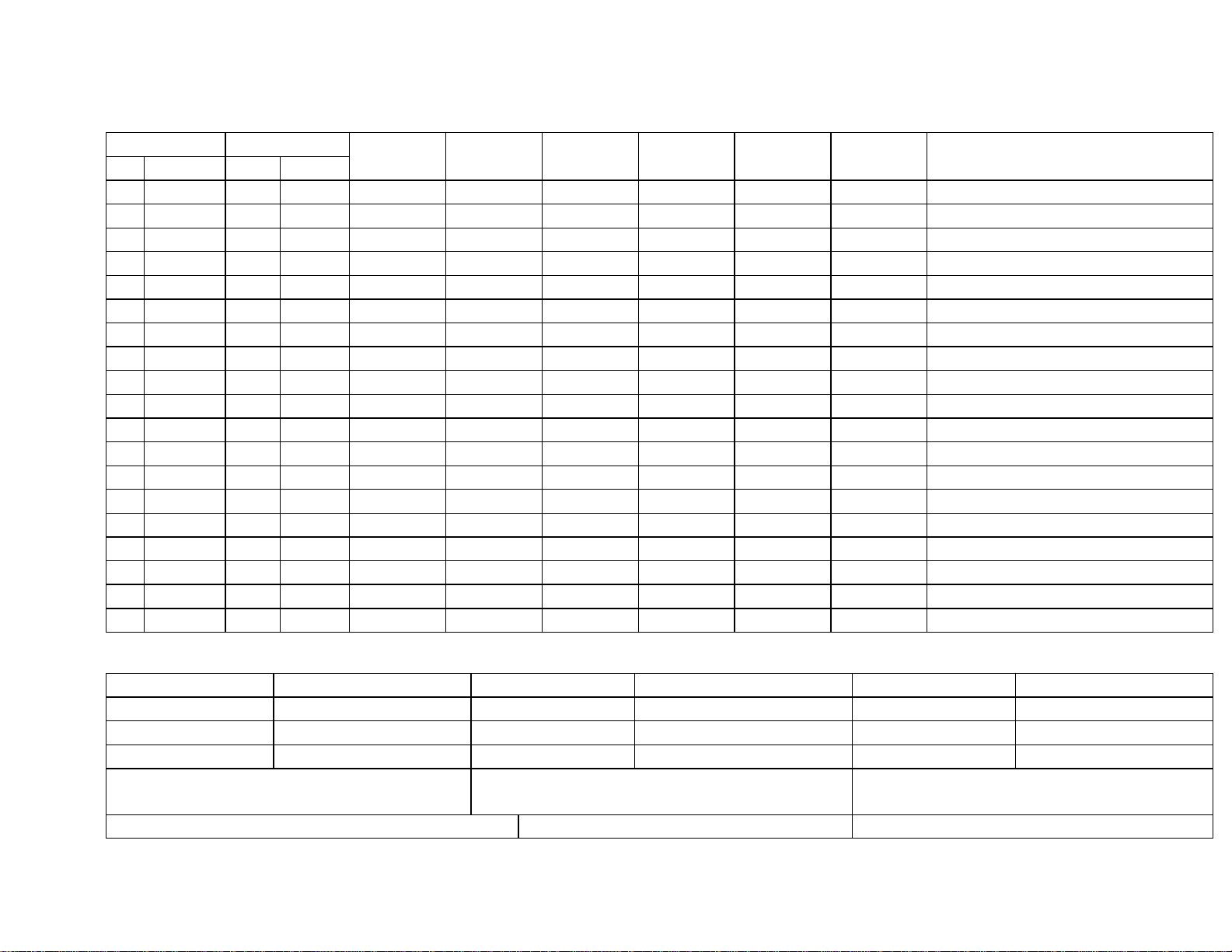

Calibration

Log Sheet

Field Load

# Name # Name

Set

After Calibration – Record C Values

Cal. Set Name:

C1 C1 C1

C2 C2 C2

C3 C3 C3

Comments:

Actual Indicated

Date Lbs Lbs Acres Yield Comments

Cal. Set Name:

Comments:

Cal. Set Name:

Comments:

Speed Sensor Pulses/Rev (under Vehicle Setup)

Page 64

Page 65

Calibration

Log Sheet

Field Load

# Name # Name

Set

After Calibration – Record C Values

Cal. Set Name:

C1 C1 C1

C2 C2 C2

C3 C3 C3

Comments:

Speed Sensor Pulses/Rev (under Vehicle Setup)

Actual Indicated

Date Lbs Lbs Acres Yield Comments

Cal. Set Name:

Comments:

Cal. Set Name:

Comments:

Page 66

Page 67

Calibration

Log Sheet

Field Load

# Name # Name

Set

After Calibration – Record C Values

Cal. Set Name:

C1 C1 C1

C2 C2 C2

C3 C3 C3

Comments:

Speed Sensor Pulses/Rev (under Vehicle Setup)

Actual Indicated

Date Lbs Lbs Acres Yield Comments

Cal. Set Name:

Comments:

Cal. Set Name:

Comments:

Page 68

Page 69

PF3000 Cotton Yield Monitor

4-1

Section Contents

Ag Leader Technology

Important Notices

The PF3000 Cotton Yield Monitor must be properly setup and calibrated.

Carefully read and follow the directions in the setup and calibration section

before using the PF3000.

This section contains instructions for the following items.

Fields and Loads 4-2

On Screen Mapping 4-4

Area Counting 4-6

Marking 4-8

Logging Map Data to a Card 4-10

Using a GPS Receiver 4-14

Using a Radar Gun 4-16

Diagnostic 4-17

Display Items 4-24

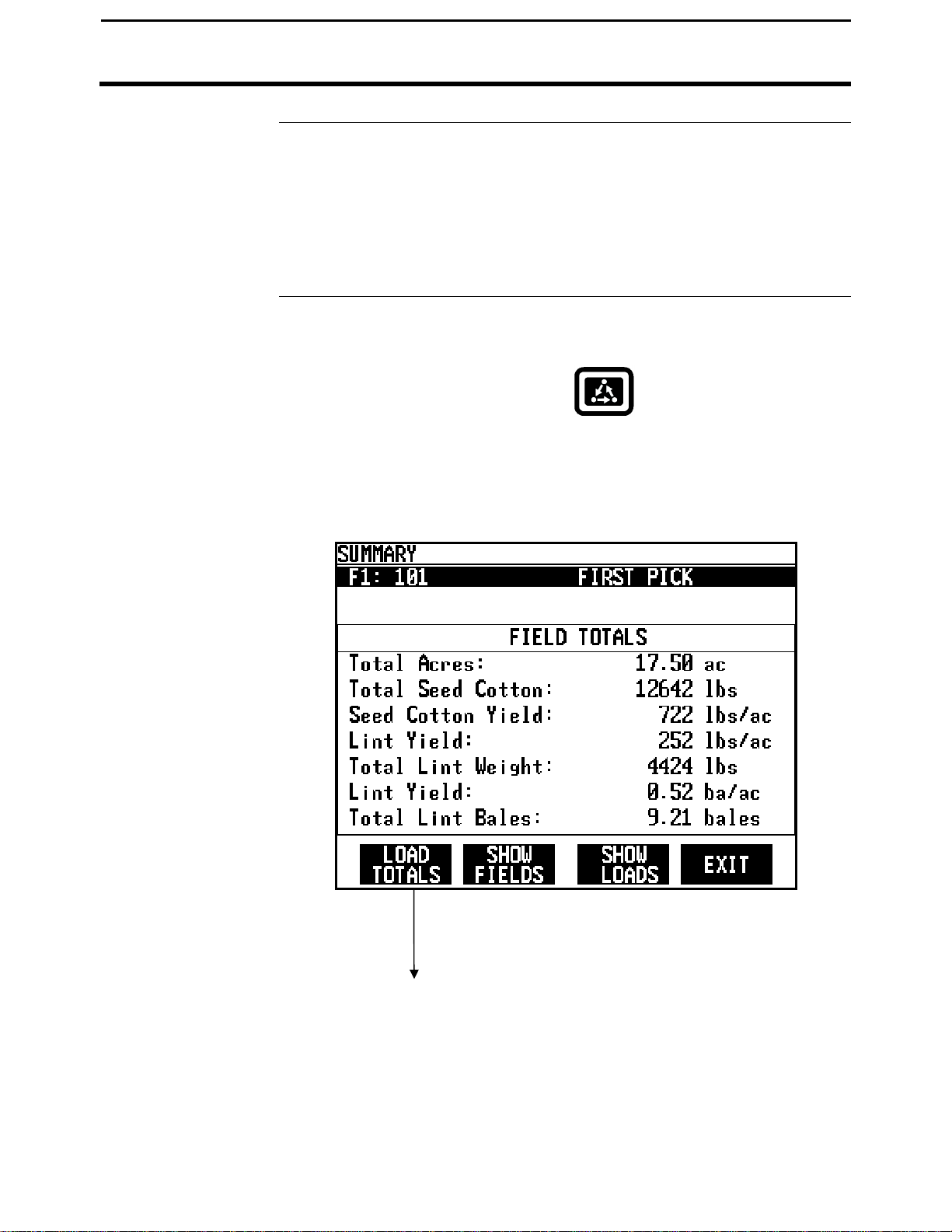

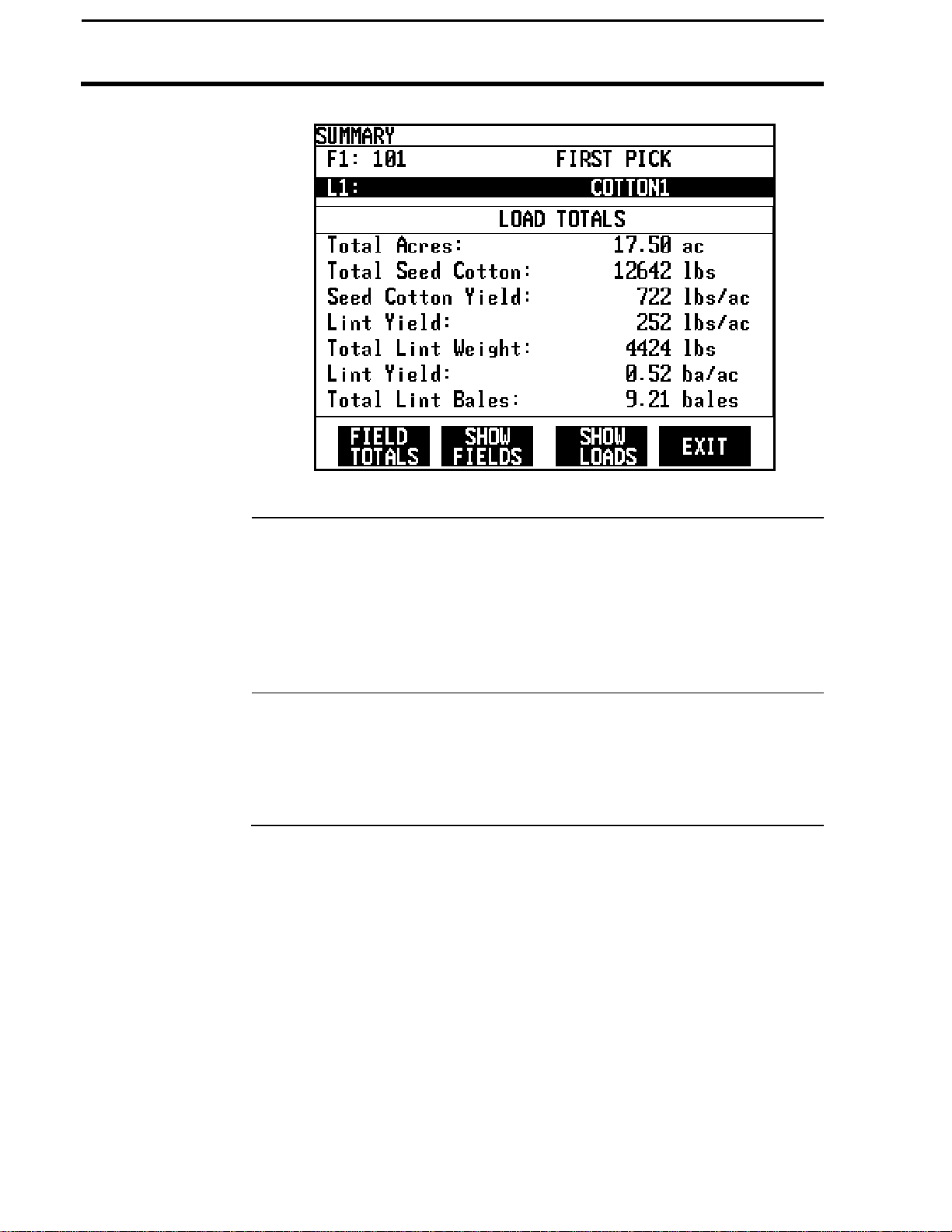

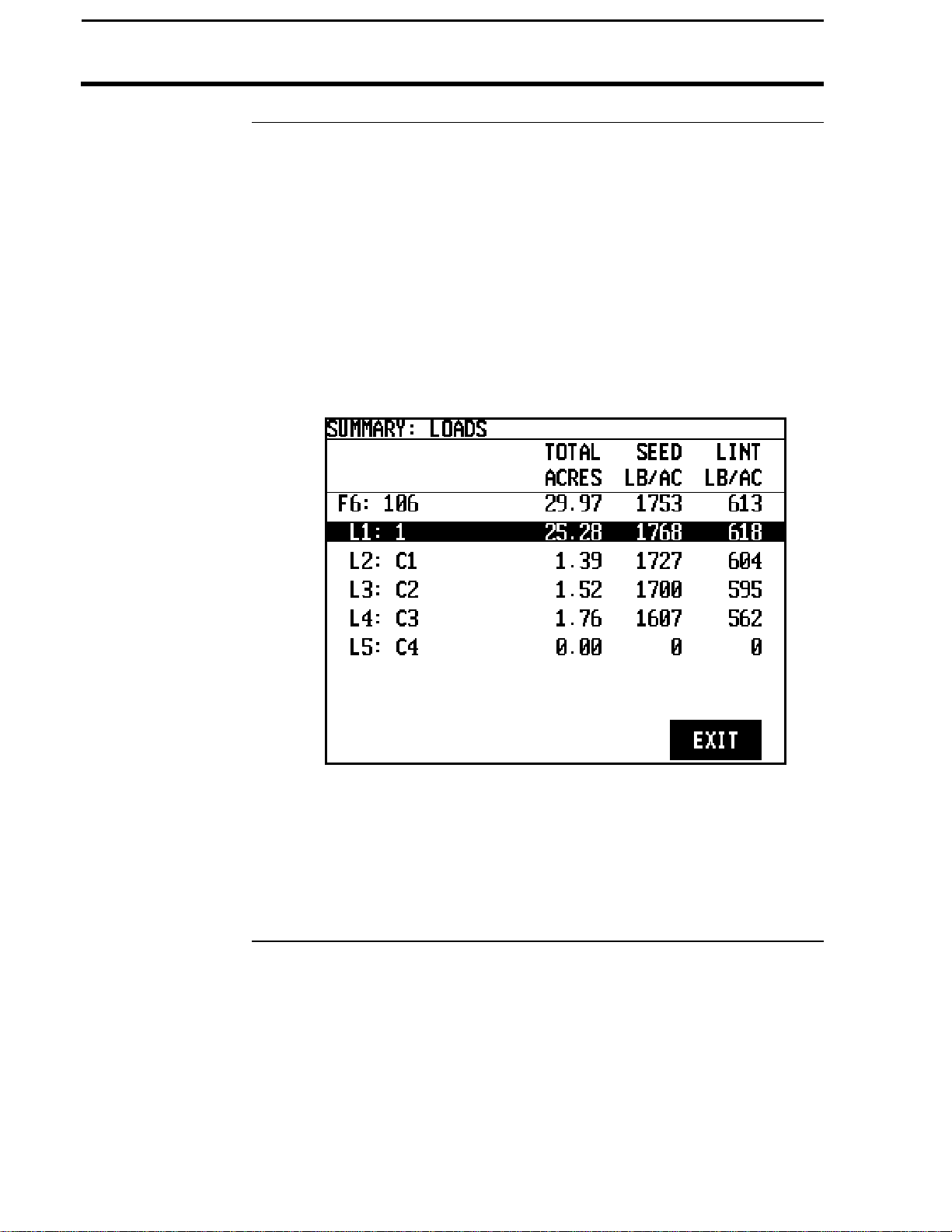

Summary 4-27

Swath Setting 4-31

Flow Sensor Alarms 4-32

Load Settings 4-35

Checking Data Accuracy 4-36

Updating Operating Program 4-39

Site Verification 4-41

Navigate 4-44

Boundary 4-49

Grid 4-52

Item Page

***

Operation Overview

March 2002

Page 70

PF3000 Cotton Yield Monitor

4-2

Fields and Loads

Recommendations

Field

Ag Leader Technology

All the information recorded by the PF3000 must be recorded in a field and

load. The field and load that the monitor is set on is found on the top line of

the main operating screen.

Fields

You should at least create all the fields and name them before you begin to

use the PF3000. You can create and name your fields using any operating

mode. You should choose field names that you can use year after year. If

you have multiple cotton monitors harvesting in the same field, setup the

same field names with the same field number. This will simplify merging

yield data into one map from multiple machines.

Loads

You can also create and name loads within fields before you use the

PF3000. New loads can be created on-the-fly. Load numbers do not have

to match between monitors of multiple machines in the field.

Definition:

Load: A load is used to subdivide a field into smaller sections. The

monitor load is not associated with the picker basket, wagon, or truck load.

Load

March 2002

Page 71

PF3000 Cotton Yield Monitor

4-3

Fields and Loads

Ag Leader Technology

Creating/Naming

Changing Fields

and

Loads

Instructions for creating and naming fields and loads are in the setup

section.

The top line of the display indicates the field and load, which are currently

selected. The monitor can display either field totals or load totals. If field

totals are displayed, the current load is not indicated.

Changing Field

If the field totals are not displayed, press the FIELD key twice and use the

UP or DOWN ARROW key to change the field. Press the ACCEPT key to

change to a different field.

Changing Load

Press the LOAD key twice and use the UP or DOWN ARROW keys to

scroll through the loads. Press the ACCEPT key to change to the different

load.

* * *

Fields and Loads

March 2002

Page 72

PF3000 Cotton Yield Monitor

4-4

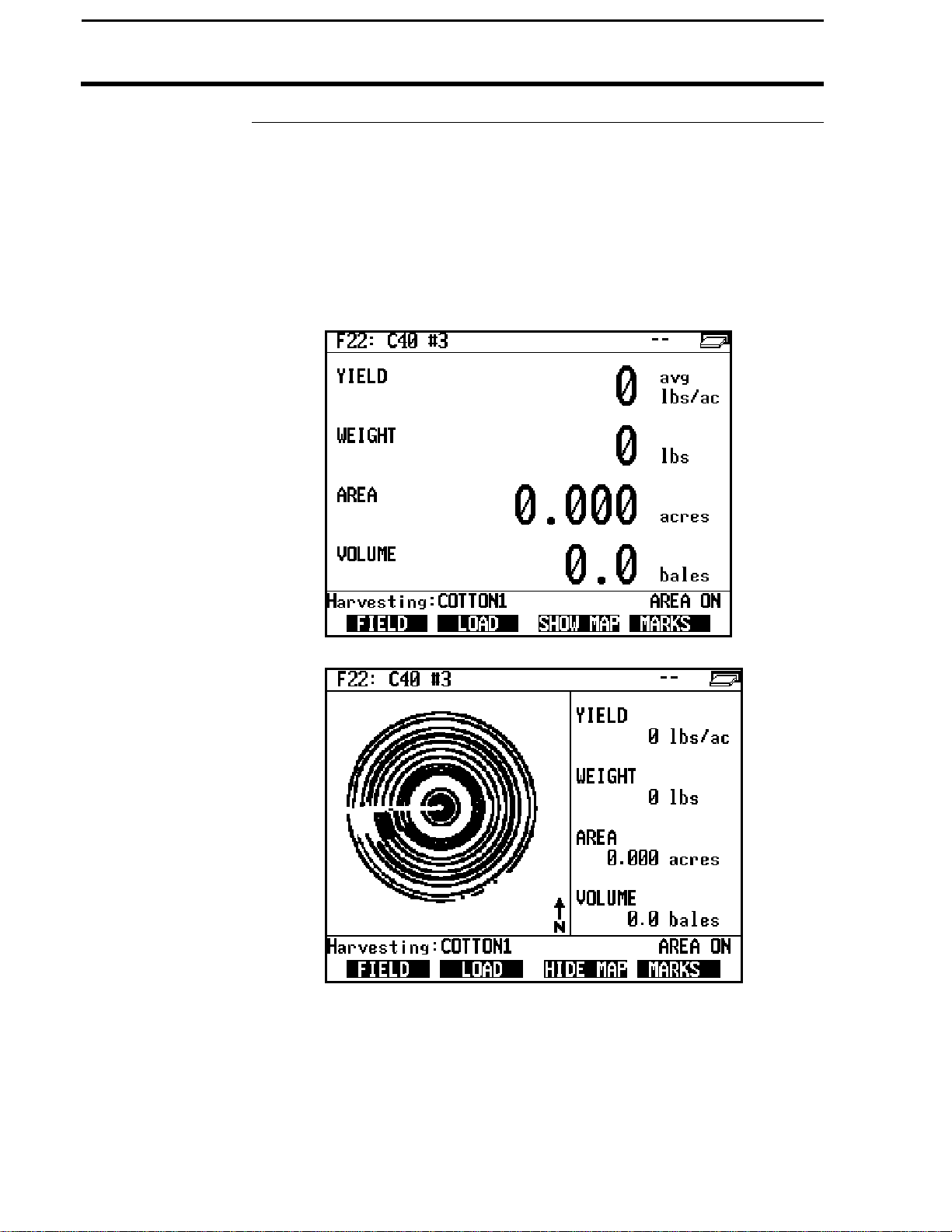

On Screen Mapping

Introduction

The PF3000 can show a coverage map on its display of the path the

combine, tractor or other vehicle has traveled for the field. The PF3000

makes the map from all the GPS data for the selected field that is on the

card inserted in the monitor.

The map only shows the path the vehicle has driven or covered, it does not

show any yield values.

Ag Leader Technology

March 2002

Page 73

PF3000 Cotton Yield Monitor

4-5

Ag Leader Technology

Making a Map

You must have the card that was used to log a field’s GPS data inserted into

the monitor to make an on the screen map for a field. You must also have

the log file that was used to log a field’s GPS data set as the current log file

at the card setup screen. If you used more than one log file to log the GPS

data for a field, you can only make a map from the GPS data that is on one

of the log files.

You can display the map on the go and watch it being created as you drive.

You can view the map at any time as long as the is in the monitor.

At this time you can only make a map for a field and not individual loads.

Follow the steps below to make a map.

Step Action

1 Set the monitor on the field for which you desire to make a map.

2 With the card inserted and the appropriate log file set as the current

log file at the card setup screen, press the SHOW MAP key. The

screen will change and the map will be displayed on the left half of

the screen and the other normal display items will be on the right

half of the screen.

3 Press the HIDE MAP key to stop viewing the map and see the

normal display items on the full screen.

NOTE:

• If the monitor is set on a field for which there is not any GPS data on

the card and you press the SHOW MAP key, the screen will still change

but the left half of the screen will be blank.

• The monitor automatically scales the map so that the largest view of the

map can be displayed in the left half of the screen.

* * *

On Screen Mapping

March 2002

Page 74

PF3000 Cotton Yield Monitor

4-6

Area Counting

Introduction

Stop Height

Area Count Stop

Beeps

Ag Leader Technology

In the bottom right corner of the display, the monitor always displays either:

• AREA ON

or

• AREA OFF

The area count switch is located on the bottom right corner of the front

panel. The switch manually controls area counting. The header sensor,

implement switch or spray booms automatically turns area counting on and

off if the area count switch is in the up position.

When the switch is in the down position, the monitor displays and flashes

"Area Off" and stops counting area.

When the switch is in the up position, the monitor will display "Area On"

and count area unless the header sensor, implement switch or spray booms

are connected and are automatically shutting off area counting.

The stop height number in the monitor determines at what head position the

monitor will turn on and off area counting. Refer to the calibrating stop

height instructions in the calibration section.

This setting determines how many times the monitor will beep to indicate

that the monitor is not counting area when turning on the ends. To view and

change the area count stop beeps you must press the SETUP key and then

the VEHICLE key. Instructions for changing the area count stop beeps are

in the setup section under vehicle setup.

NOTE:

• It is recommended that the area count stop beeps be set high enough so

that lowering the picker head after turning on the ends turns off the

beeping rather than the beeps just timing out. This gives the operator

an audible signal that the monitor is counting area again.

• Usually an area count stop beeps value of 20 to 30 is high enough.

March 2002

Page 75

PF3000 Cotton Yield Monitor

4-7

Ag Leader Technology

Ground Speed

Sensor

The monitor can record its ground speed from three different sources:

Ground Speed Sensor Primary Speed Sensor

Speed sensor on transmission WHEEL

Radar gun RADAR

GPS receiver (must be rated for accurate

ground speed, GPS2000/2100, Add-On

GPS3000/3100 and Trimble AgGPS receivers)

To view and change the ground speed sensor you must press the SETUP key

and then the VEHICLE key. Instructions for changing the speed sensor

setting are in the setup section under vehicle setup.

You have to calibrate distance for wheels, tracks, or radar, depending on

which ground speed sensor you use. Refer to the distance calibration

instructions in the calibration section.

The primary speed sensor type is recorded for each load. If you have

recorded data for several loads but, you had the wrong primary speed sensor

setting, you can switch the speed sensor setting on the loads. Refer to load

settings instructions in the operation instructions.

If you are getting your ground speed from a GPS receiver and you lose your

GPS signal, the monitor will take readings from the secondary speed sensor.

Area Counting

GPS

* * *

March 2002

Page 76

PF3000 Cotton Yield Monitor

4-8

Marking

Introduction

Ag Leader Technology

You must have a GPS receiver and memory card to do field marking. To

perform field marking you can use the internal marker selection keys built

into the PF3000 to identify the 4 marks available or connect the external

field marker device. You can not use both at the same time. You can make