Page 1

PF3000 and PF3000 Pro

1

Ag Leader Technology

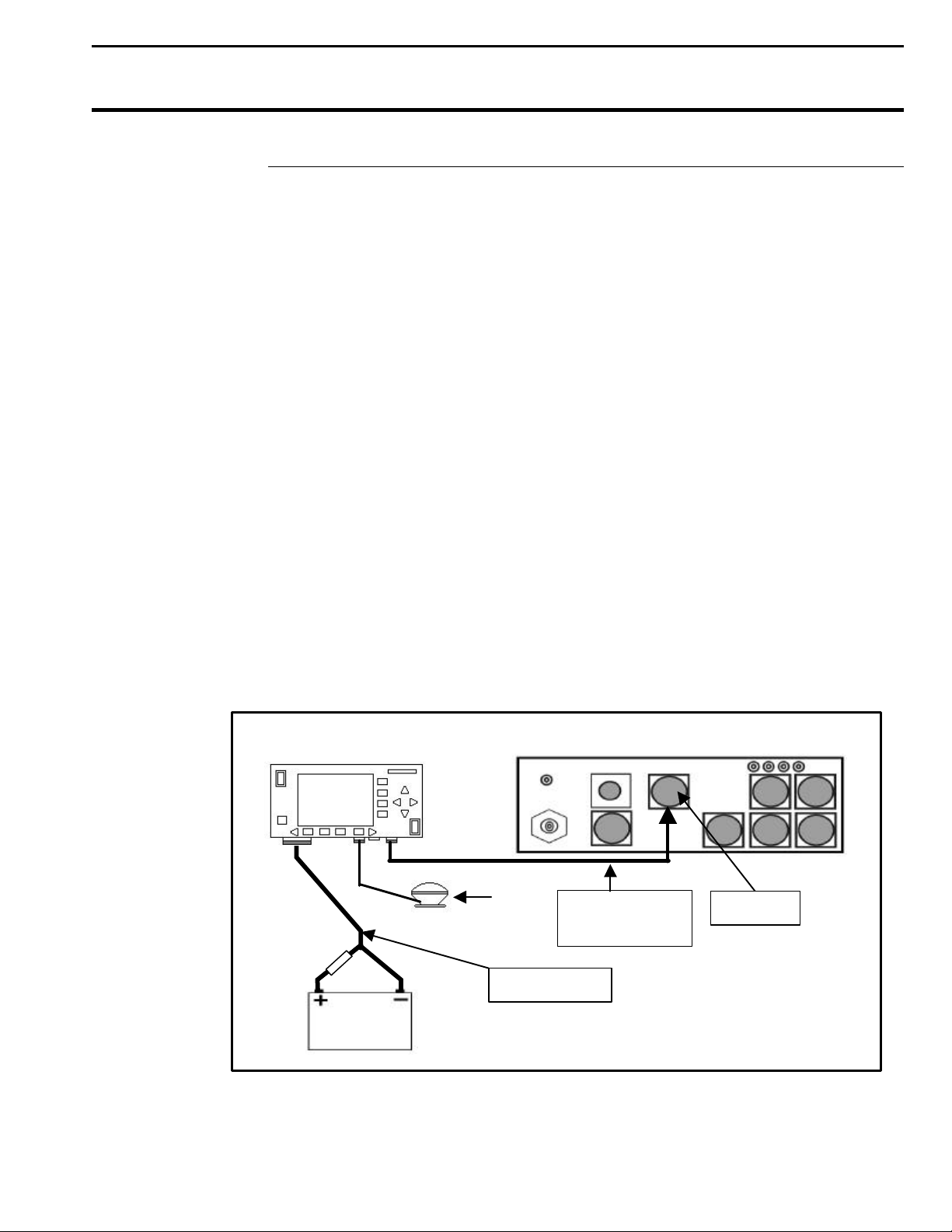

Using PF with HarvestMaster

Installation and Cable Connections

Hooking Up

PF3000 or PF3000

Pro

Step-by-Step

Procedure

NOTE: Insert these instructions in the Options Section of the PF3000 or

PF3000 Pro Operator's Manual.

Parts required for this procedure:

• PF3000 Tall U-bracket (PN 2000105-1)

• PF3000 Pro U-bracket (PN 3001124)

• Battery Cable for PF3000 or PF3000 Pro

PN 2000497-1 (8 ft) or 2000497-2 (16ft)

• HarvestMaster Serial Cable (comes with HarvestMaster yield monitor)

1. Attach the monitor bracket to the monitor

2. Determine a mounting location for the monitor and mark the holes for the

bracket at the location you determined in Step 1. Remove the monitor from

the bracket.

3. Drill the holes for the mounting bracket and mount the bracket.

4. Attach the HarvestMaster serial cable to Port 3 of the monitor and run the

cable to the HarvestMaster unit and attach to the Host port. See Figure 1.

PF3000 or PF3000 Pro

GPS

Antenna

Battery Cable

HarvestMaster

Serial Cable

HM 500 or 570

Host Port

Figure 1. Cable attachment on HarvestMaster Unit

September 2000

Page 2

Using PF with HarvestMaster

2

Installation and Cable Connections

5. Attach the Battery power cable at the battery. The red wire connects to the

positive batter terminal. The black wire connects to the negative battery

terminal. Route the cable to the monitor, securing the cable away from

moving parts every 12 to 18 inches.

6. Attach the battery cable to the 25-pin port on the monitor.

7. Power up the monitor to ensure the monitor is working. If not recheck the

cable connections at the battery.

PF3000 and PF3000 Pro

Ag Leader Technology

September 2000

Page 3

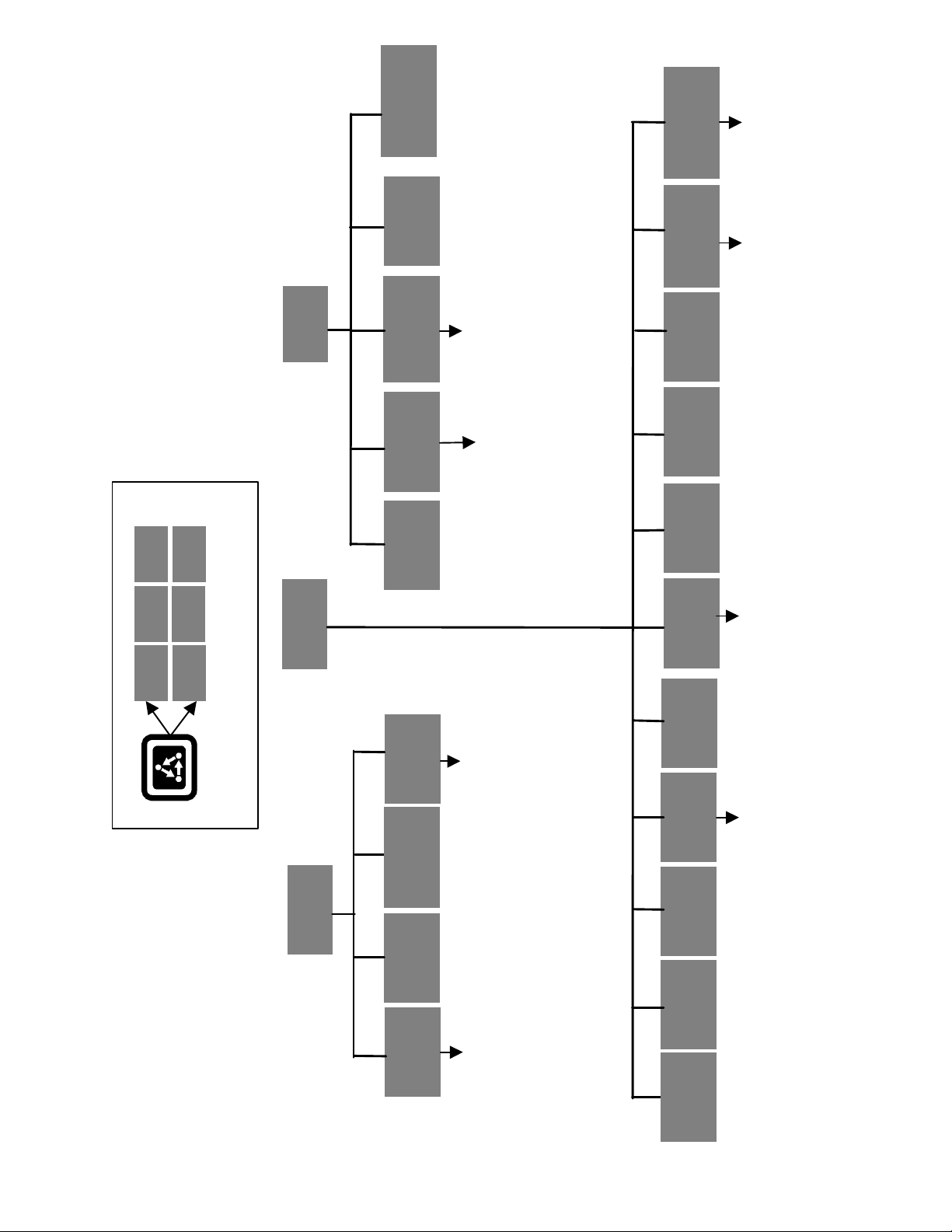

VEHICLE

Menu Key

Press Menu Key to switch between Main Menu keys

SENSOR

Area Count Switch Source

Belt Length

Belt Distance Per Pulse

Travel Distance Per Pulse

Tank Type

Discharge Delay

Discharge Rate

Area

Primary Speed Sensor

Secondary Speed Sensor

Speed Sensor Pulses/100ft

Logging Device

Logging Interval

Log File

Enter actual

weights and

perform

calibration

Tare, Load Cell A

Tare, Load Cell B

-

Tare, Profile A

Tare, Profile B

Tare, Profile C

Tare, Profile D

Tare, Profile E

RAW NEMA

DATA

SENSOR

GPSSYSTEM

HARVMAST

HARVMAST

OPTIONSLOADFIELD

DIAG

SETUP

CAL

DIAG

SETUP

GPSMEMORYCONSOLE

HARVMAST

HARVMAST

OPTION S

count stop beeps

VEHICLE

LOAD

or-

TARE

PF3000 or PF3000 Pro – Menu Tree for Harvest Master – September 2000

DISTANCE

CAL

AREA

MARKS CROP CARD

WEIGHT

SWATH

Page 4

Page 5

PF3000 and PF3000 Pro

Ag Leader Technology

Using PF with HarvestMaster

Setup

Before Setup

These instructions only cover information about interfacing with the

HarvestMaster HM500 or HM570 yield monitor. Information not found in these

instructions regarding the use of the PF3000 or PF3000 Pro can be found in the

Operators Manual.

Ensure your PF3000 or PF3000 Pro has the HarvestMaster firmware version

installed. Verify by checking the screen after turning on the monitor. It will

display "HarvestMaster Version X.XX"

NOTE: You may download the latest firmware version from our web site

at www.agleader.com.

NOTE: If you install the HarvestMaster firmware version over a nonHarvestMaster firmware version and you want to save the data from the

previous version, copy the data to the card before installing. After

installing the HarvestMaster version you will have to Newbox to get the

monitor to start. To Newbox, turn on the PF and when “Checking”

appears, press and hold down the bottom right arrow key. Press the

NEWBOX key when the monitor displays it.

To edit a setting in a setup screen, use the UP or DOWN ARROW keys to

highlight the item. Press the EDIT key and use the UP or DOWN or LEFT or

RIGHT ARROW keys to change the setting. Press ACCEPT key to make the

changed setting final.

Setup – Step 1

Metric or Imperial

Units

Setup – Step 2

HarvMast Sensor

Setup Screen

To view this screen, press the SETUP key and CONSOLE key.

Set Units of Measure to “Imperial” or “Metric”. This setting puts the PF in the

correct units’ mode.

To view this screen press the SETUP key and HARVMAST SENSOR key.

The following shows which settings are changeable based on “Yield Sensor

Type”.

Yield Sensor Type = Load Cell

Load Cell A Multiplier

Load Cell B Multiplier

Load Cell A Offset

Load Cell B Offset

Tilt Sensor Multiplier

Tilt Sensor Offset

Flow Cutoff

Yield Multiplier

Yield Sensor Type = Profile

Flow Cutoff

Profile Height Multiplier

Profile Threshold

Number of Profile Sensors

Yield Multiplier

September 2000 3

Page 6

Using PF with HarvestMaster

4

Setup

Yield Sensor Type: Set to the type of sensor used by your HarvestMaster

Load Cell A & B Multiplier:

To determine which type of load cell you have, look at the "Capacity"

value on the sticker on the load cell.

Load Cell A & B Offset: If you do not have a tilt sensor set this to 0. If

you have a tilt sensor do the following.

PF3000 and PF3000 Pro

Ag Leader Technology

yield monitor. The selections are Load Cell or

Profile. The Profile sensor is only used for grapes.

Load Cell Type Setting if Imperial Setting if Metric

500 lbs. 50.0 lbs/mV 22.7 kgs/mV

150 lbs. 15.0 lbs/mV 6.81 kgs/mV

a. Place the conveyor in a vertical position with the load cells

pointing down and the weight of the chain off the idler wheel

of load cell.

b. Go to the HarvestMaster Sensor Diagnostic screen. (Press the

EXIT key and the MENU key. Press the DIAG key and

HARVMAST SENSOR key.)

c. Write down the “gross” weight for Weight A and Weight B.

Go back to the Harvmast Sensor Setup Screen and enter gross

Weight A for Load Cell A Offset and gross Weight B for Load

Cell B Offset.

Tilt Sensor Multiplier: This is the degrees of tilt per volt. If you do not

have a tilt sensor set this to 0. If you do have a tilt sensor, obtain this

setting from the label on the tilt sensor. To check if the value is correct do

the following:

a. Place the portion of the conveyor with the load cells level. Use an

angle finder to make sure it is perfectly level.

b. Go to the HarvestMaster Sensor Diagnostic screen and view "Tilt".

c. Adjust the position of the tilt sensor until the “Tilt” reading is set to 0.

d. Using the angle finder, change the conveyor to a known angle (such

as 30 degrees).

e. Check the “Tilt” reading under the HarvestMaster Sensor Diagnostic

screen. If it does not match the known angle, divide the known angle

by the sensor reading. Multiply the result by the current Tilt Sensor

Multiplier. This is the final setting. Enter this value at the

HarvestMaster Sensor Setup Screen.

September 2000

Page 7

PF3000 and PF3000 Pro

Ag Leader Technology

Example:

Known Angle: 30 degrees

Tilt sensor reading: 33 degrees

Current Tilt Sensor Multiplier: 67 degrees

30

33

0.909 x 67 = 61

Final Tilt Sensor Multiplier Setting is 61.

Tilt Sensor Offset: This should be set to 0 if you do not have a tilt sensor.

If using a tilt sensor, and it cannot be adjusted to read “0” when the

conveyor is horizontal, set Tilt Sensor Offset according to the following:

a. With tilt sensor adjusted to its final adjustment and with conveyor

perfectly level, view "Tilt" reading under the HarvestMaster Sensor

Diagnostic Screen.

Using PF with HarvestMaster

Setup

= 0.909

b. Enter the "Tilt" reading as the setting for "Tilt Sensor Offset", but

enter the opposite sign of the “Tilt” value. Example: If “Tilt” value is

2, enter –2 for “Tilt Sensor Offset”. If “Tilt” value is –2, enter 2 for

“Tilt Sensor Offset”.

Flow Cutoff: This is the minimum flow rate for recording data. Initially,

this is usually set to zero.

Profile Height Multiplier: Set to - 3.34 inches. If using metric units set

to - 8.48 cm.

Profile Threshold: Set to 0 inches. If using metric units set to 0 cm.

Number of Profile Sensors: Set to 5.

September 2000 5

Page 8

Using PF with HarvestMaster

6

Setup

Yield Multiplier: If you have been using the HarvestMaster Mobile

Field Computer and are satisfied with the accuracy do not change this

setting. If you have not used the Mobile Field Computer or are not

satisfied with your accuracy set to:

If you change this setting you will have to calibrate for weight. See

“Weight Calibration Screen” instructions in the Calibration Section of this

instruction set.

PF3000 and PF3000 Pro

Ag Leader Technology

1.00 if using Load Cell sensors

3.00 if using Profile sensors (only used for Grapes)

IMPORTANT: After you set the Yield Multiplier value, DO

NOT CHANGE it. Changing this value after setup will

adversely impact harvest accuracy.

Setup – Step 3

HarvMast Vehicle

Setup Screen

To view this screen press the SETUP key and HARVMAST VEHICLE key.

Area Count Switch Source: Selections are Belt Speed or Hold/Run. Set

this to "Belt Speed" for area counting to be based on when the Belt is

stopped or moving. (Stopped = Area Off, Moving = Area On). Set this to

"Hold/Run" for area counting to be based on the Hold/Run switch. (Hold

= Area Off, Run = Area On).

Note: The Ag Leader Area Count switch (located on bottom right of front

panel) must be on in order to count area.

Belt Length: Measure the conveyor belt length, enter this length for this

setting. If using Imperial units enter feet, if using Metric units enter

meters.

Belt Distance Per Pulse: This is the pulses per foot (or meters) of belt

travel detected by the speed sensor. The sensor is located on the drive

shaft.

Belt Distance Per Pulse = Sprocket Diameter (feet or meters) x 3.14.

Note: This formula assumes that the sensor outputs one pules per

revolution of sprocket. Pulse is generated by magnet passing the

speed sensor.

Measure sprocket diameter from low points where chain rests not from

the tips or ends of the sprocket cogs.

September 2000

Page 9

PF3000 and PF3000 Pro

Tank Type:

Ag Leader Technology

Travel Distance Per Pulse: Measure the diameter of the wheel that has

the ground speed sensor installed. Use the following formula to

determine the setting:

Travel Distance Per Pulse =

If you are using a sugar beet harvester, refer to the HarvestMaster

instructions for the proper setting.

Discharge Delay: If you are not using a sugar beet harvester ignore this

setting. If you are using a sugar beet harvester, this setting is the time in

seconds from when the beets come out of the tank until they pass the

weighing rollers again, on their way to the truck. Typically this setting is

8 – 11 seconds.

Using PF with HarvestMaster

Setup

Tire Diameter (feet or meters) x 3.14

Number of magnets

If you are not using a sugar beet harvester ignore this setting.

Discharge Rate: If you are not using a sugar beet harvester ignore this

setting. If you are using a sugar beet harvester, this is the rate in lbs/sec

(or kgs/sec if metric) at which the beets come out of the holding tank.

Determine this setting by timing how much material comes out. Typical

settings are 50 –100 lbs/sec (23 – 45 kgs/sec).

September 2000 7

Page 10

Using PF with HarvestMaster

8

Setup

PF3000 and PF3000 Pro

Ag Leader Technology

Setup – Step 4

Swath Setup Screen

Setup – Step 5

Vehicle Setup Screen

To view this screen press the SETUP key and SWATH key.

a) Select the crop you will harvest.

b) Press the EDIT # ROWS key and set the correct rows.

c) Press the EDIT SPACING key and set the correct spacing.

To view this screen press the SETUP key and VEHICLE key.

It is recommended to set the Primary Speed Sensor to “Serial”. The only other

valid option is “GPS”. Do not set the Primary Speed Sensor to “Wheel”, “Radar”

or “Track”.

The default secondary speed sensor is “Wheel”. It is recommended to leave it set

on “Wheel”. The PF will not actually be connected to a secondary speed signal

but has to use the calibration number of the secondary speed sensor for the

primary speed sensor.

Setup – Step 6

Card Setup Screen

To view this screen press the SETUP key and CARD key.

Log Device: If you are using a GPS receiver, set to “Memory Card”

Logging Interval: Set to 2 or 3 seconds. 1 second is not recommended because

it logs more data than needed for most users.

Log File: After pressing EDIT key, press CREATE FILE key to create a new log

file.

Note: The monitor will automatically prompt you to make a new log file

everyday.

September 2000

Page 11

PF3000 and PF3000 Pro

Ag Leader Technology

Using PF with HarvestMaster

Setup

Setup – Step 7

Create Field and

Loads and set Crop

Type

Fields and Loads can be setup ahead of harvest or during harvest. Refer to the

steps below:

a) Press MENU key until FIELD key and LOAD key is displayed on bottom.

Press FIELD key (press twice if load displayed on top line) to display field on

entire screen.

b) If desired, name the field by pressing the Right Arrow key. Use the Up or

Down Arrow keys to set the character. Set another character by moving the

cursor using the Left or Right Arrow key. Press ACCEPT key once when

finished.

c) Press key to right of line displaying crop. Use Up or Down Arrow keys and

set the crop. Press ACCEPT key twice.

d) To create or change to a different field, press the FIELD key again. Use Up or

Down Arrow keys to select a different field. Name field and set crop. Press

ACCEPT key until at main screen. Field is now active.

e) To create or change to a different load, press the LOAD key. Change or

name the load as described for field in steps b & d. You can not set the crop

on a load.

September 2000 9

Page 12

Using PF with HarvestMaster

10

Calibration

PF3000 and PF3000 Pro

Ag Leader Technology

Calibration – Step 1

Tare Calibration

Screen

Calibration – Step 2

Weight Calibration

Screen

To view this screen, press the CAL key and TARE key.

Press the PERFORM TARE key to start the tare. Make sure the conveyor is

running empty when you press PERFORM TARE.

The tare value gets averaged over the belt length, thus the tare will take several

seconds (one complete belt revolution) to complete. The tare is complete when

“Tare Complete” gets to 100%.

In many operations, you might initiate a tare operation only once per day, or

even once every few days. In muddy operations, it is advisable to tare the

system right after completing a load.

To view this screen, press the CAL key and WEIGHT key. Refer to the steps

below:

Note: It is recommended to obtain the actual weight of three or four loads for

each crop harvested. Also, it is recommended that you tare the conveyor before

harvesting each load being used for calibration.

a) Use the Up or Down Arrow keys to select the crop.

b) Press ENTER WEIGHT key to add actual weights.

1) Use the Up or Down Arrow keys to set field.

2) Press key to right of Load and use Up or Down Arrow keys to set load.

3) Press key to right of “Act. Weight” and use Up or Down Arrow keys to

set actual weight.

4) Repeat steps 1-3 and enter all actual weights. Press EXIT key when

finished.

c) Press SHOW CAL LOADS key.

d) Press PERFORM CAL key. View the maximum and average error and

press the EXIT key.

e) If errors of any loads are too high you can uncheck the load by pressing the

CAL ON/OFF key. Press PERFORM CAL key again if you uncheck any

loads.

Note: When you calibrate weight for a crop, all the data that was previously

recorded and will be recorded (including logged data) for the crop will be

adjusted to the same calibration.

September 2000

Page 13

PF3000 and PF3000 Pro

Ag Leader Technology

Using PF with HarvestMaster

Operation

Operation

Information

Active Field and Load: This is the field and load that information will be

recorded in. These are displayed on the top line (if load not displayed, press

LOAD key once).

To change the active field and load press the FIELD or LOAD key and use the

Up or Down Arrow keys to scroll to new field or load. Press ACCEPT key to

set it as active. Refer to the “Setup-Step 7” instructions for more information.

Display Items: To change any of the four display items, press the key to the

right of a display item. After that, press the bottom right or left arrow keys to

see all the display items. Suggested items to display are: "Yield", "Crop Flow",

"Ground Speed", and "Weight". Other useful display items are “Belt Speed”,

“Swath” or “Area”

Showing fields and loads totals: To show the field totals for each display item,

display the field only on the top line (press the FIELD key once if field and load

on top line). To show the load totals for each display item, display the field and

load on the top line (press the LOAD key once if field only is on top line).

Copying data to card: When using a memory card, the monitor will prompt to

copy to the card every time the monitor is shut off. Be sure to do this. You can

manually copy data to the card under the Card Setup screen (press the SETUP

key and CARD key). Press the COPY TO CARD key to copy data to the file

set as the “Log File”.

Logging to card criteria: Anytime crop flow is greater than zero or area

counting is on, the PF will log data to the card. An arrow appears pointing

towards the card to indicate that data is being logged.

* * *

September 2000 11

Loading...

Loading...