Page 1

Welcome to the world of precision,

hands-free steering

OPERATOR’S MANUAL

2012-09 PN 602-0295-01 REV B

Page 2

Page 3

Important Information

Refer to your hardware installation manual for complete installation requirements before operating the GeoSteer system.

Trademark

All brands and products names, unless otherwise stated, are registered trademarks of Novariant, Inc.

Technical Support

Contact your dealer for technical support.

Copyright © 2012 All Rights Reserved

Operator’s Manual i

Page 4

LEGAL DISCLAIMER

Note: Read and follow ALL instructions in this manual carefully before installing or operating the GeoSteer1 system.

Note: Take careful note of the safety information in the Safety Information section of this manual and the additional safety

messages provided throughout this and any other supplemental manuals provided.

The manufacturer disclaims any liability for damage or injury that results from the failure to follow the instructions, cautions,

and warnings set forth herein.

Please take special note of the following warnings:

1. There is NO obstacle avoidance system included with the manufacturer’s product. The owner must always have a human

present in the operator’s seat of the vehicle when the GeoSteer system is in use to look for any obstacles to avoid

including people, animals, trees, ditches, buildings, etc. and take control of the vehicle to manually avoid them if

necessary.

2. The GeoSteer system does NOT control the speed of the vehicle. The operator must always adjust the speed of the vehicle

manually so that it is operated at a safe speed that will not cause the vehicle to roll over or go out of control.

3. The GeoSteer system will take over control of the vehicle’s steering system when the GeoSteer system is activated during

testing, calibration, tuning, and automatic steering operations. The vehicle’s steering axles, tracks, articulation point, or

wheels may move unpredictably when activated. Prior to starting the vehicle and/or activating the GeoSteer system, verify

that all people and obstacles are clear of the vehicle to prevent death, injury, or damage to property.

4. Use of the GeoSteer system is NOT permitted while the vehicle is on public roads or in public areas. Verify that the

system is powered OFF before driving on roads or in public areas.

Safety Information

Warning Alerts

The GeoSteer system installer and manufacturer disclaim any responsibility for damage or physical harm caused by failure to

adhere to the following safety requirements:

•

As the operator of the vehicle, you are responsible for its safe operation.

•

The GeoSteer system is not designed to replace the vehicle’s operator.

Note: After the installation of the GeoSteer system, verify that all the screws, bolts, nuts, and cable connections are tight.

Verify that all the cables and hoses have been secured to prevent them from being damaged. If any of the hydraulic lines or

fittings were loosened during the installation, verify that they have been reattached and tightened to prevent oil leaks

1

GeoSteer is a registered trademark of Novariant, Inc

ii GeoSteer System

Page 5

To understand the potential hazards associated with the

operation of a GeoSteer equipped vehicle, read the

provided documentation prior to installing or operating the

GeoSteer system on a vehicle.

To prevent accidental death or injury from being run over by

the vehicle, never leave the vehicle’s operator seat with the

GeoSteer system engaged.

To prevent accidental death or injury from being run over by

the vehicle verify that area around the vehicle is clear of

people and obstacles before startup, calibration, tuning, or

use of the GeoSteer system.

To prevent the accidental engagement of the GeoSteer

system and loss of vehicle control, shut down the GeoSteer

system while driving on roads. Never drive on roads or in

public areas with the GeoSteer system powered up.

Operator’s Manual iii

Page 6

Verify that you are in a stable position on the vehicle’s

platform or stairs when installing or removing the GeoDock

(the antenna assembly on top of the cab) so you do not fall.

If the vehicle does not provide a safe platform, use a ladder

to safely access the vehicle’s roof.

To avoid electrical shock hazards, remove the GeoDock

and/or other antennas from the vehicle before driving under

low structures or low electrical power lines.

High-Pressure Fluid Hazard

If the installation requires working on the hydraulic system

on the vehicle, read and understand the hydraulic sections

of the vehicle manufacturer’s operators manual before

starting the installation. Wear hand and eye protection while

performing hydraulic system maintenance. Relieve hydraulic

system pressure before servicing the hydraulic system.

If the vehicle has a Wheel Angle Senor as part of the

installation, always shut off the vehicle when working

around the Wheel Angle Sensor while installing, checking,

and adjusting the Wheel Angle Sensor and rod lengths. The

steering mechanism could move suddenly and cause

severe injury or death.

iv GeoSteer System

Page 7

Caution Alerts

The GeoSteer system installer and manufacturer disclaim any responsibility for damage or physical harm caused by the failure

to adhere to the following safety requirements:

The GeoDock must be removed when transporting or

driving the vehicle at speeds above 31 mph (50 km/h). The

GeoDock can possibly detach due to wind loads at higher

speeds.

The GeoSteer system does not detect obstacles in the

vehicle’s path. The vehicle operator must observe the path

being driven and take over steering manually if an obstacle

must be avoided.

The GeoSteer system does not control the speed of the

vehicle. The operator must manually adjust the speed of the

vehicle to keep the vehicle safely under control.

The GeoSteer system must be powered OFF when

installing or removing the GeoDock, GeoSteer Control Unit,

or any other part of the GeoSteer system.

Operator’s Manual v

Page 8

The GeoDock must always be firmly secured to the

mounting plate via the magnet whenever the vehicle is in

operation to prevent the GeoDock from releasing from its

bracket and falling and to ensure the GeoDock is placed at

the same point every time.

REGULATORY INFORMATION

United States

FCC Class A Statement – Notice to Users; The GeoSteer system has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This product generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful interference to radio communication. However,

there is no guarantee that interference will not occur in a particular installation. Changes and modifications not expressly

approved by the manufacturer or registrant of this equipment can void your authority to operate this equipment under Federal

Communications Commission rules.

Our product complies with Part 15 of FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

Canada

The GeoSteer system conforms with the regulatory requirements of the ICES-003 Issue 4 February 2004; and VCCI V3/2009.04, and V-4*/2009.04, R-3074 and G-353.

European Union

The GeoSteer system is intended to be used in any of the 27 EU member countries. The GeoSteer system has been tested and

found to comply for CE and e Mark with the requirements in EN 55024:1998/A1:2001/A2:2003; EN 55022:2006/A1:2007,

Directive 2009/64/EC, IEC 61010-1 Safety, ETSI EN 301 489-1 V1.9.2 and ETSI EN 301 489-3 V1.4.1.

Australia and New Zealand

The GeoSteer system conforms to the regulatory requirements of the Australian Communications and Media Authority

(ACMA) AS/NZS CISPR 22:2009 for a Class A device, thus satisfying the requirements for C-Tick Marking and sale within

Australia.

vi GeoSteer System

Page 9

Compliance Information

The GeoSteer Control unit can contain an internal cellular-modem and can send signals through wireless technology or through

an external data communications radio. Table 1-1 lists these components and their related compliance approval numbers.

Table 1-1 Radio Compliance Information

Manufacturer Description FCC ID Europe Canada IC

Modem CDMA used for

Telit

Telit Modem GSM for Europe R17UC864G 0984 5131A-UC864G

Telit

Freewave Radio Receiver 900 MHz KNY-42182112519 NA 2329B-FGR2

Satel

North America and

Canada

Modem GSM for

Australia

Modem Receiver 403-470

MHz MRB0SATELTA10

This is a class A product. In a domestic environment this

product may cause radio interference. Do not place the

radio/cellular modem antennas within 7.9 inches (20.0 cm)

from other transmitting device antenna.

FCC RF Exposure Requirements require the user not to

operate the transmitter when someone is within 7.9 inches

(20.0 cm) from the antennas.

R17CC864 NA R17CC864

R17UC864G 0984 5131A-UC864G

2422A-SATELTA10 0523 NA

Operator’s Manual vii

Page 10

Table of Contents

Chapter 1 System Overview .............................................................................................. 1

Overview.......................................................................................................................................1

GeoSteer System Installation Overview .......................................................................................2

1

Display Kits.......................................................................................................................3

2

GeoSteer System Kits........................................................................................................3

GeoSteer CDMA ...........................................................................................................4

GeoSteer No Cell........................................................................................................... 5

GeoSteer GSM Europe ..................................................................................................6

GeoSteer GSM Australia ............................................................................................... 7

GeoDock Pro .................................................................................................................8

GeoDock Pro – No Cell................................................................................................. 8

3

Vehicle Installation Kits....................................................................................................8

4

Accessory Kits...................................................................................................................9

Accessing AutoSteer Setup Screens..............................................................................................9

Transferring GeoSteer from Vehicle to Vehicle .........................................................................10

Removing the GeoSteer System from a Vehicle..................................................................11

Installing the GeoSteer System on to Vehicle......................................................................13

Changing SIM Card in GeoSteer ................................................................................................16

GeoSteer Control Unit LED Diagnostics....................................................................................19

Chapter 2 Vehicle Tab..................................................................................................... 21

Overview.....................................................................................................................................21

Setup Wizard...............................................................................................................................22

Additional Steps for the First Time the Setup Wizard is Run..............................................22

WAAS/EGNOS Setup................................................................................................. 22

Set RTK Radio Modem Channel or Frequency........................................................... 24

Set OmniSTAR Options .............................................................................................. 25

Precision Preference Selection..................................................................................... 26

Standard Setup Wizard Steps...............................................................................................27

Select Vehicle Type..................................................................................................... 28

Select Vehicle Make .................................................................................................... 29

Select Vehicle Model................................................................................................... 29

Select Controller Type................................................................................................. 30

Naming the Vehicle ..................................................................................................... 31

Wheel Base .................................................................................................................. 31

Antenna Fore/Aft......................................................................................................... 32

Antenna Lateral Offset.................................................................................................33

Antenna Height............................................................................................................ 34

GeoSteer Fore/Aft........................................................................................................ 35

GeoSteer Lateral Offset ............................................................................................... 36

GeoSteer Height........................................................................................................... 37

GeoSteer Orientation ................................................................................................... 38

Save Changes............................................................................................................... 41

Manual Steering Override............................................................................................ 42

Manage Vehicle ..........................................................................................................................45

Select....................................................................................................................................45

Edit.......................................................................................................................................46

Delete...................................................................................................................................47

Export/Import Vehicles........................................................................................................48

Export to Display USB ................................................................................................49

Import from Display USB............................................................................................50

viii GeoSteer System

Page 11

Auto Calibrate.............................................................................................................................53

Common Calibration Steps..................................................................................................54

Compass Calibration.................................................................................................... 55

Wait For Heading ........................................................................................................55

Tilt Zero Initial Direction ............................................................................................56

Tilt Zero Opposite Direction........................................................................................ 57

Vehicle Type Specific Calibration Steps .............................................................................57

Valve / Steer-by-Wire.................................................................................................. 57

Mechanical Steering Unit / OnTrac2+......................................................................... 60

CAN Bus / ISO Controllers ......................................................................................... 62

Adjust Lateral Offset............................................................................................................63

Steering Adjust............................................................................................................................65

Steering Components..................................................................................................................65

ECU .....................................................................................................................................66

Manual Steering Override....................................................................................................66

Wheel Angle Sensor ............................................................................................................67

Zero Curvature............................................................................................................. 68

Hydraulic Valve...................................................................................................................69

ECU Sensors........................................................................................................................70

CAN.....................................................................................................................................71

Actuator ...............................................................................................................................71

Manual Steering Override (for Steering Encoders)..............................................................73

OnTrac2 ECU ......................................................................................................................73

MDU....................................................................................................................................74

Chapter 3 System Tab .................................................................................................... 77

Overview.....................................................................................................................................77

System Health .............................................................................................................................78

Manage Settings..........................................................................................................................79

Log Files ..............................................................................................................................79

Copy to Display USB .................................................................................................. 80

Delete........................................................................................................................... 80

Database...............................................................................................................................81

Backup to Display USB............................................................................................... 82

Restore from Display USB .......................................................................................... 82

Reset Factory Default ..........................................................................................................85

Reset ............................................................................................................................85

Accessories .................................................................................................................................86

Remote Switch............................................................................................................. 86

Enable (Disable) .......................................................................................................... 87

Technician...................................................................................................................................87

Software Upgrade .......................................................................................................................88

Upgrade Procedure ..............................................................................................................88

Chapter 4

GPS Tab ......................................................................................................... 91

Overview.....................................................................................................................................91

RTK ............................................................................................................................................92

General.................................................................................................................................93

Base Protection Mode.................................................................................................. 93

RTK Connection Type.........................................................................................................94

Change RTK Connection Type.................................................................................... 94

Channel ................................................................................................................................95

Change Channel........................................................................................................... 96

Use Previous................................................................................................................ 96

Frequency ............................................................................................................................97

Change Frequency ....................................................................................................... 98

Use Previous................................................................................................................ 98

Operator’s Manual ix

Page 12

Throughput ..........................................................................................................................99

Base Satellites ......................................................................................................................99

Base Location ....................................................................................................................100

Update Base Station Location.................................................................................... 101

OmniSTAR ...............................................................................................................................103

General...............................................................................................................................104

Accuracy ............................................................................................................................104

Select Startup Accuracy............................................................................................. 105

Channel ..............................................................................................................................105

Change Channel......................................................................................................... 105

WAAS/EGNOS ........................................................................................................................106

PRN....................................................................................................................................107

Change Primary ......................................................................................................... 107

Change Alternate ....................................................................................................... 108

Precision Settings......................................................................................................................108

Changing Precision Mode.......................................................................................... 109

NTRIP.......................................................................................................................................110

General (Original Screen)..................................................................................................111

Profile ................................................................................................................................111

Add ............................................................................................................................ 112

Connect...................................................................................................................... 118

Delete......................................................................................................................... 119

General (After Profile Created)..........................................................................................120

Connect...................................................................................................................... 120

Disconnect ................................................................................................................. 120

Planning Tool............................................................................................................................121

General...............................................................................................................................121

Sky Plot..............................................................................................................................121

Forecast..............................................................................................................................122

GPS Diagnostics .......................................................................................................................122

General...............................................................................................................................123

Satellite Tracking...............................................................................................................123

NMEA Out................................................................................................................................124

Port A Messages ................................................................................................................124

Messages Configuration ............................................................................................125

Port A Configuration..........................................................................................................126

Port Configuration ..................................................................................................... 127

Port B Message ..................................................................................................................127

Port B Configuration..........................................................................................................127

Chapter 5

Chapter 6

Connections Tab............................................................................................ 129

Overview...................................................................................................................................129

Cell Modem (North America CDMA)......................................................................................130

Manage PRL ......................................................................................................................131

Cell Modem Default SIM Card (Australia and Europe GSM)..................................................132

Change Carrier...................................................................................................................132

Advanced Debug................................................................................................................134

Cell Modem Custom SIM Card (Australia and Europe GSM) .................................................134

Change Carrier...................................................................................................................135

Advanced Debug................................................................................................................135

Configure SIM ...................................................................................................................135

External Radio ..........................................................................................................................137

Change Baud Rate .............................................................................................................138

My Account Tab............................................................................................ 139

Overview...................................................................................................................................139

Call Support (If Available) .......................................................................................................140

x GeoSteer System

Page 13

Details .......................................................................................................................................141

Feature Code .............................................................................................................................142

Activating a Feature Code .................................................................................................143

Operator’s Manual xi

Page 14

Page 15

System Overview

The System Overview chapter information is provided in the following sections:

•

Overview

•

GeoSteer System Installation Overview

•

Accessing AutoSteer Setup Screens

•

Transferring GeoSteer from Vehicle to Vehicle

•

Changing SIM Card in GeoSteer

•

GeoSteer Control Unit LED Diagnostics

Overview

1

The GeoSteer system is a high precision GPS positioning system and vehicle interface controller that provides additional

functions and features to the Display. The GeoSteer system interfaces with the Display to provide GPS positioning data from

many different possible sources and sends that information to the Display to give it position information. The GeoSteer system

is also capable of taking guidance information from the Display and interfacing with a vehicle to tell the vehicle where to steer

and provide AutoSteer functionality to the Display.

This Operator’s Manual provides information on how to setup, configure, and manage the various settings on the GeoSteer

system itself. Refer to this manual for instructions that pertain to the GeoSteer system. For information about setting up fields,

farms, guidance patterns, and other Display related functions, please refer to your Display Operator’s Manual for more

information.

The GeoSteer system can be installed easily on most agricultural vehicle makes and models. This chapter provides basic

information on how the GeoSteer components are organized and installed. Refer to the Installation Manual that comes with the

vehicle installation kit for more details on the complete installation of the GeoSteer system. This manual provides information

about navigating through and using the screens of the GeoSteer system.

The GeoSteer system is designed to work with multiple Display options. Refer to the Display Operator’s Manual or AutoSteer

dealer for specific instructions on how to connect the GeoSteer system components to the Display. Also refer to the Display

Operator’s Manual for information on how to navigate through and operate the various screens used on the Display.

Operator’s Manual 1

Page 16

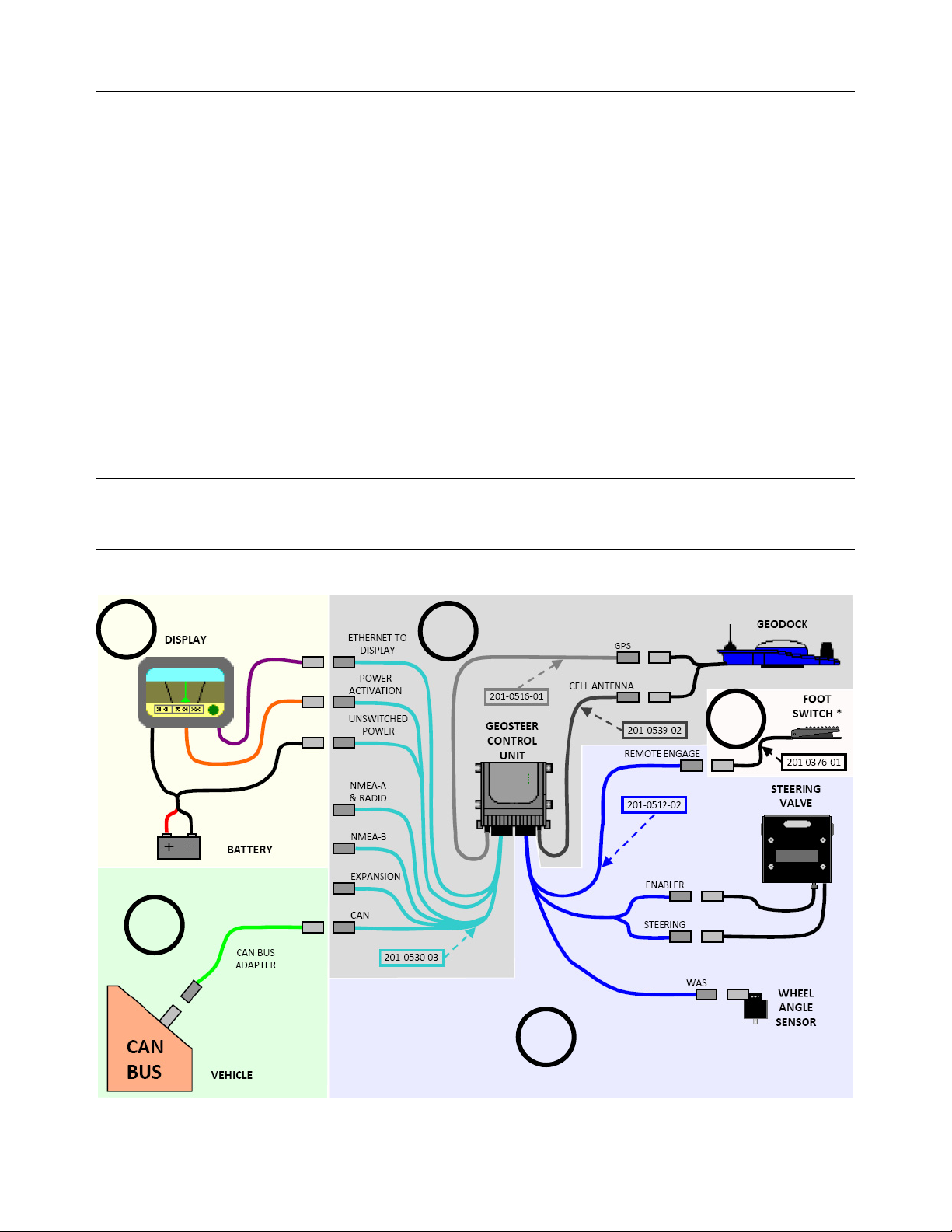

GeoSteer System Installation Overview

GeoSteer System Installation Overview

This section provides an overview of what is required to complete a GeoSteer system installation. To aid in clarifying the

complete installation, this section also includes the parts and kits that are not included with this vehicle installation kit. A

GeoSteer system installation can be broken down into four sub-categories that need to be ordered to complete the installation.

Three of the sub-categories are mandatory and the fourth is a list of accessories that add additional features and capabilities.

The four parts or sub-categories of a complete GeoSteer system installation are:

1. Display Kit

2. GeoSteer System Kit

3. Vehicle Installation Kit

a. Hydraulic, Steer by Wire, or Assisted Steering Unit

b. CAN Bus

4. Accessory Kit

Each of the sub-categories is graphically shown in the following figure and is identified by a separately shaded area and the

number from the list above. Most installations will be slightly different and required different parts.

Note: Vehicle installation kits will generally include parts from only either sub-category 3a or 3b. The following figure shows

examples of how both 3a and 3b components would be connected to the GeoSteer system for demonstration purposes. Most

installations would not require both.

Figure 1-1 Example of GeoSteer Installations Options

1

2

3b

4

3a

2 GeoSteer System

Page 17

GeoSteer System Installation Overview

There are a number of options available for each sub-category. Each of these options comes with their own installation and

operational manuals that should be referred to during their part of the installation.

1 Display Kits

GeoSteer is compatible with multiple Display options. The Displays are ordered as a separate component and include their own

installation and operator’s instructions. The Display Operator’s Manual will show how the Display and Display Harnesses are

installed on a vehicle and how they are connected to the GeoSteer Harnesses. There are three connections between the Display

and the GeoSteer Main Cable Harness that need to be connected:

•

ETHERNET TO DISPLAY – This connection is a RJ-45 connector that is plugged into the Ethernet port on the Display

or Display Harness to provide communications between the Display and the GeoSteer Control Unit.

•

POWER ACTIVATION – This connection is connected to the Display or Display Harness that provides a signal that

commands the GeoSteer to power up. When this signal is turned off, the GeoSteer will power down.

•

UNSWITCHED POWER – This is connected to a power source that provides 12 volts of unswitched DC power to the

GeoSteer. The power source should not be connected to a power supply that is connected to the vehicle’s ignition. This

source should be shown or explained in the Display Operator’s Manual.

The Display Kit will provide the necessary harnesses and instructions to provide power to the GeoSteer system and to allow

communications between the two. Use those instructions to complete the Display installation and to connect the Display to the

GeoSteer system after the Display mount has been installed.

2 GeoSteer System Kits

The GeoSteer System Kits represent the parts that are common on all installations. The GeoSteer System kits are ordered as

two parts, the System Kits and the GeoDock (GPS and Cell Modem Antenna assembly).

The System Kits include a version of the GeoSteer Control Unit, the GeoSteer Main Harness, User’s Manual, a version of the

GeoDock, GPS coax cable, and when required, the Cell Modem coax cable. There are four base versions of this kit that are

sold in different parts of the world. The listed regions are for reference only and can change over time. They System Kits are:

Note: Refer to your AutoSteer dealer for exact part numbers.

•

GeoSteer CDMA – North America

•

GeoSteer No Cell – Australia and South America

•

GeoSteer GSM Europe – Europe

•

GeoSteer GSM Australia – Australia

There are two GeoDock versions that can be ordered. The one that is ordered depends on if the GeoSteer System Kit requires a

Cell Modem or not. The two GeoDock Kits are:

•

GeoDock Pro – This GeoDock assembly has a built in Cell Modem antenna installed.

•

GeoDock Pro – No Cell – This GeoDock assembly is the same as the GeoDock Pro except the cell antenna and coax cable

are not provided.

Operator’s Manual 3

Page 18

GeoSteer System Installation Overview

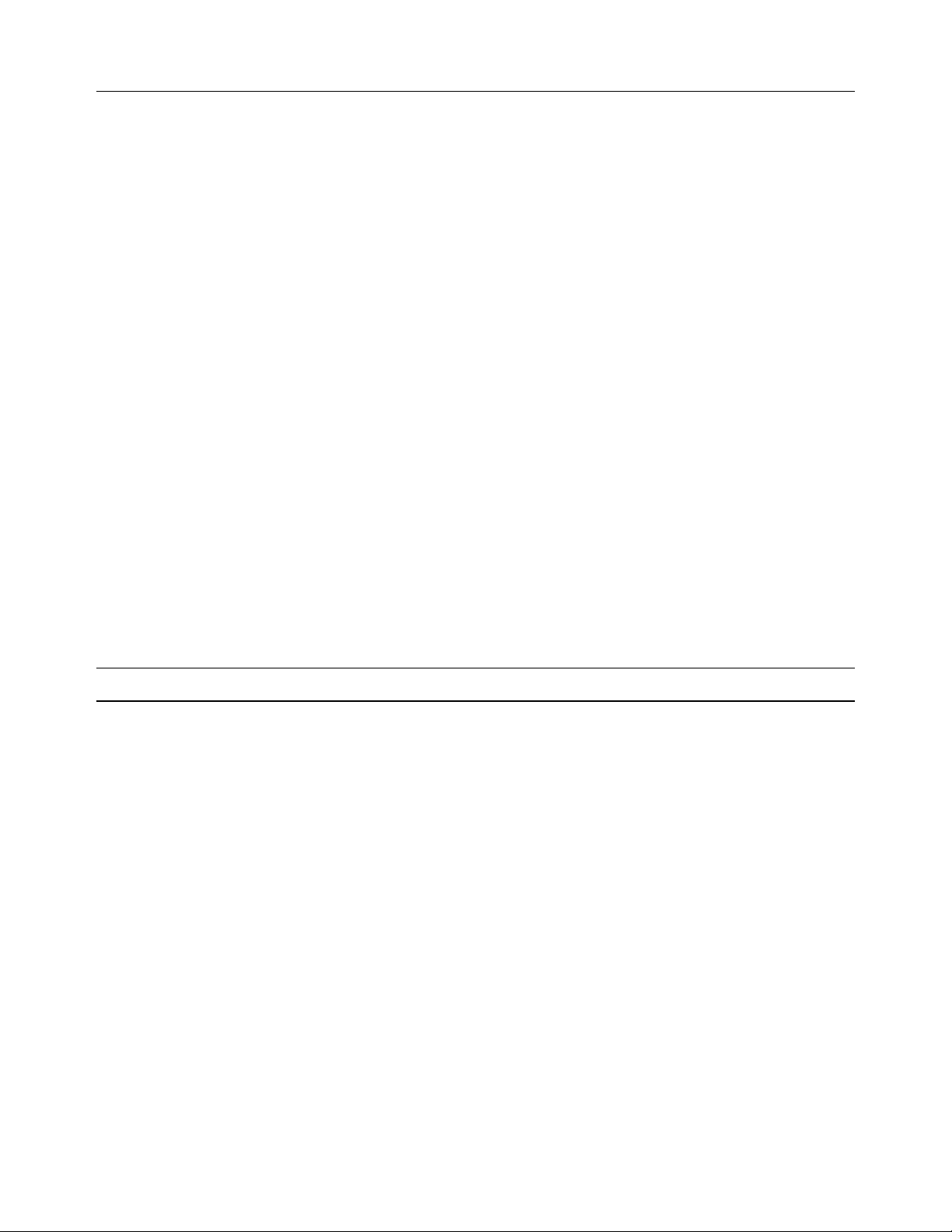

GeoSteer CDMA

This version is used primarily in North America. It has a CDMA modem installed in the GeoSteer control unit that can be used

for remote diagnostics and NTRIP correction services.

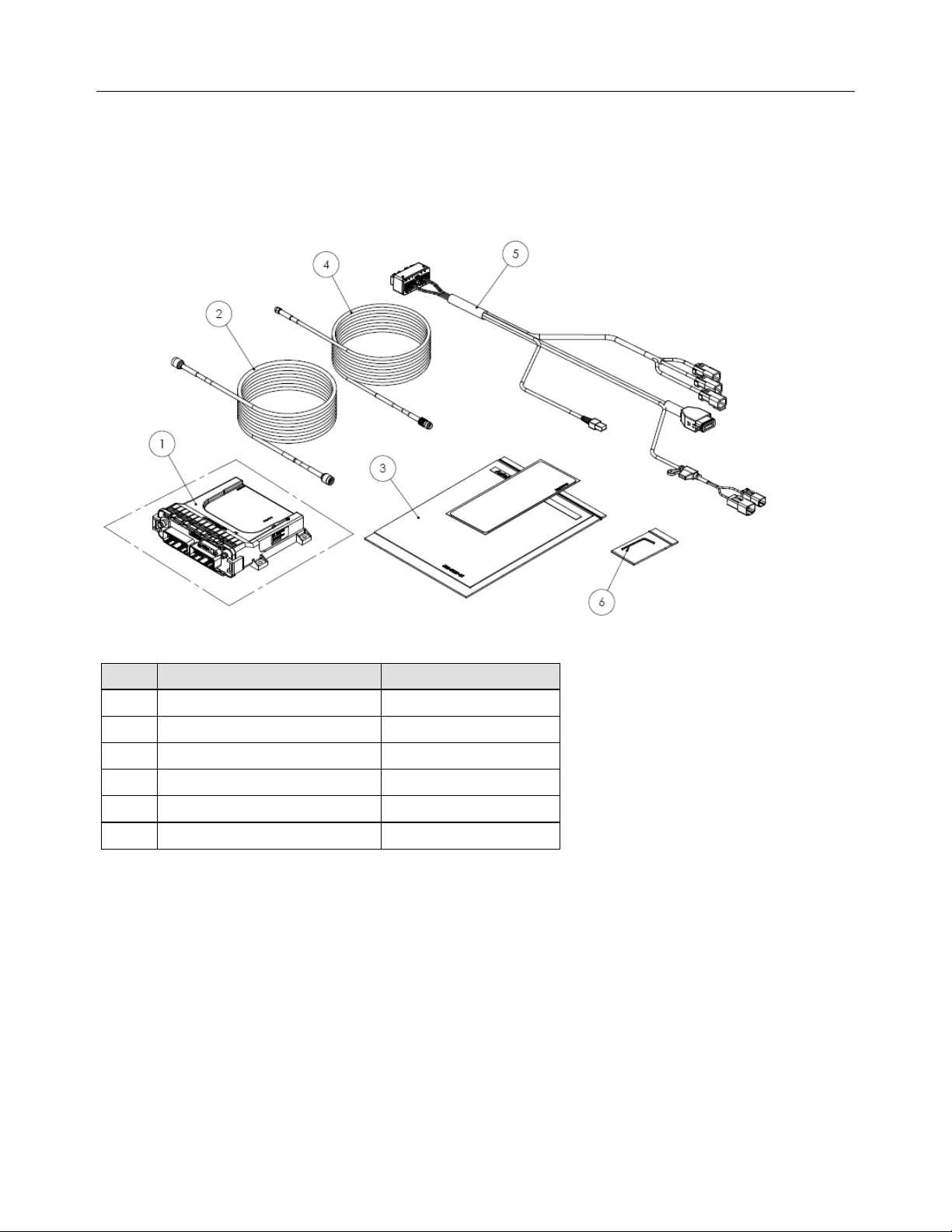

Figure 1-2 GeoSteer CDMA

Table 1-1 GeoSteer CDMA Breakdown

Item Component Part Number

1.

2.

3.

4.

5.

GeoSteer Assembly - CDMA 200-0601-XX

Cable, GPS Coax 201-0516-01

Kit Documentation 200-0593-03

Cable, Cell Modem Coax 201-0539-02

Harness, Main GeoSteer 201-0530-03

4 GeoSteer System

Page 19

GeoSteer System Installation Overview

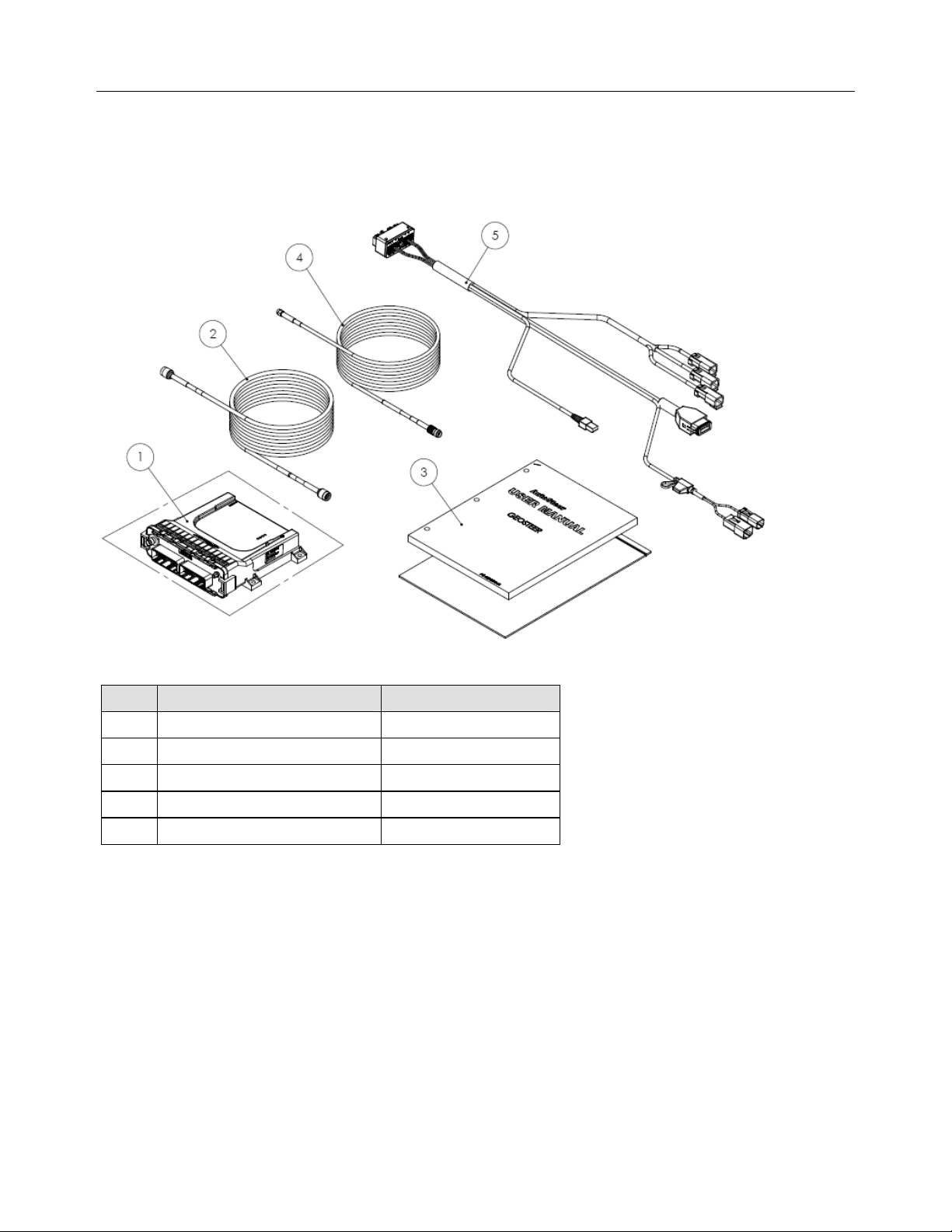

GeoSteer No Cell

This version is used primarily in South America and can be ordered as an option in Australia. There is no cell modem installed

inside the GeoSteer control unit.

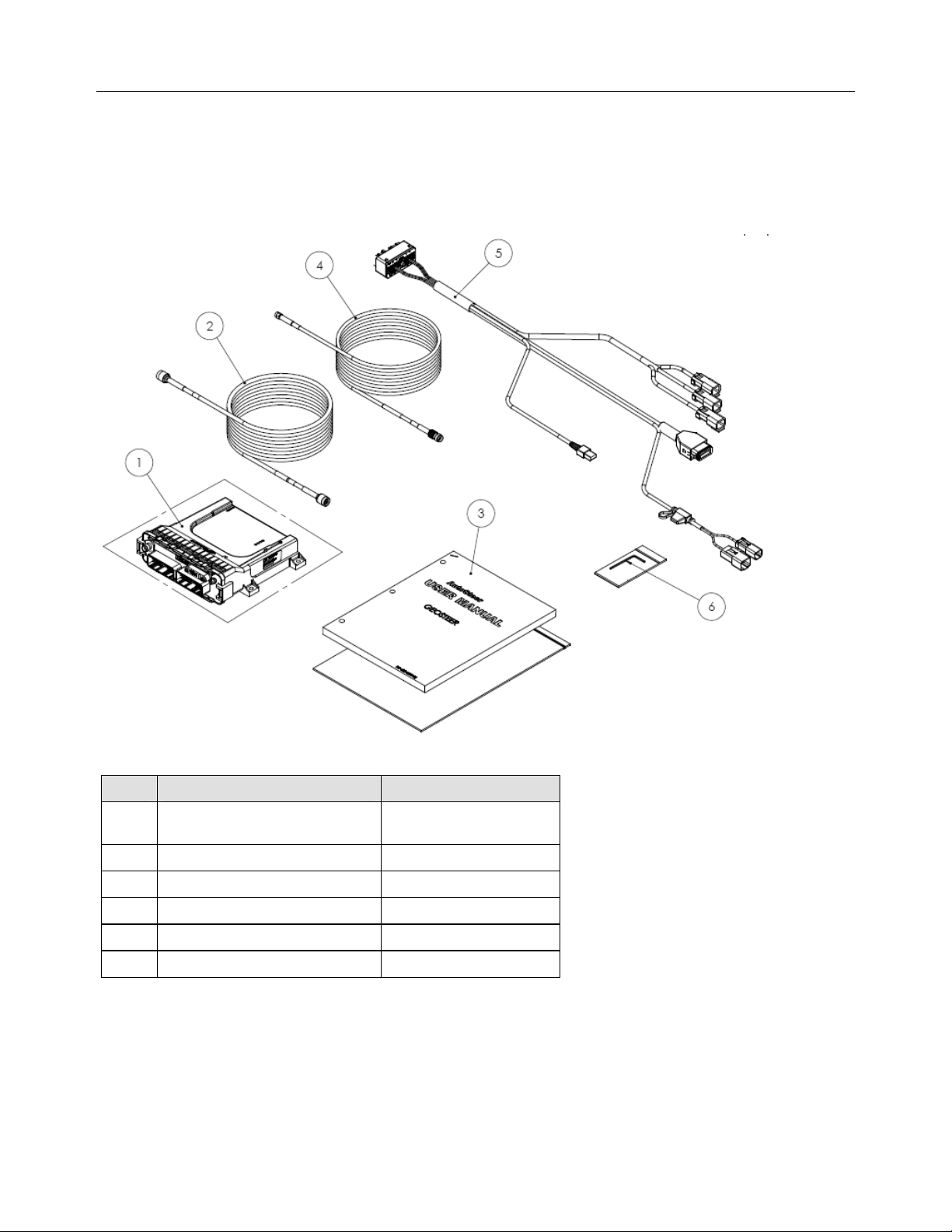

Figure 1-3 GeoSteer Cell Free

Table 1-2 GeoSteer Cell Free Breakdown

Item Component Part Number

1.

2.

3.

4.

GeoSteer Assembly - No Cell 200-0617-XX

Cable, GPS Coax 201-0516-01

Kit Documentation 200-0593-03

Harness, Main GeoSteer 201-0530-03

Operator’s Manual 5

Page 20

GeoSteer System Installation Overview

GeoSteer GSM Europe

This version is used primarily in Europe. It has a GSM modem configured to work in the European Union installed in the

GeoSteer control unit that can be used for remote diagnostics and NTRIP correction services. The GeoSteer control unit has a

SIM card slot that allows the user to easily change SIM cards for a custom data plan if necessary.

Figure 1-4 GeoSteer GSM Europe

Table 1-3 GeoSteer GSM Europe Breakdown

Item Component Part Number

1.

2.

3.

4.

5.

6.

GeoSteer Assembly - GSM Europe 200-0618-XX

Cable, GPS Coax 201-0516-01

Kit Documentation 200-0593-05

Cable, Cell Modem Coax 201-0539-02

Harness, Main GeoSteer 201-0530-03

Allen Key, 2mm 805-0006-01

6 GeoSteer System

Page 21

GeoSteer System Installation Overview

GeoSteer GSM Australia

This version is used primarily in Australia. It has a GSM modem configured to work in Australia installed in the GeoSteer

control unit that can be used for remote diagnostics and NTRIP correction services. The GeoSteer control unit has a SIM card

slot that allows the user to easily change SIM cards for a custom data plan if necessary.

Figure 1-5 GeoSteer GSM Australia

Table 1-4 GeoSteer GSM Australia Breakdown

Item Component Part Number

1.

2.

3.

4.

5.

6.

GeoSteer Assembly - GSM

Australia

Cable, GPS Coax 201-0516-01

Kit Documentation 200-0593-03

Cable, Cell Modem Coax 201-0539-02

Harness, Main GeoSteer 201-0530-03

Allen Key, 2mm 805-0006-01

Operator’s Manual 7

200-0619-XX

Page 22

GeoSteer System Installation Overview

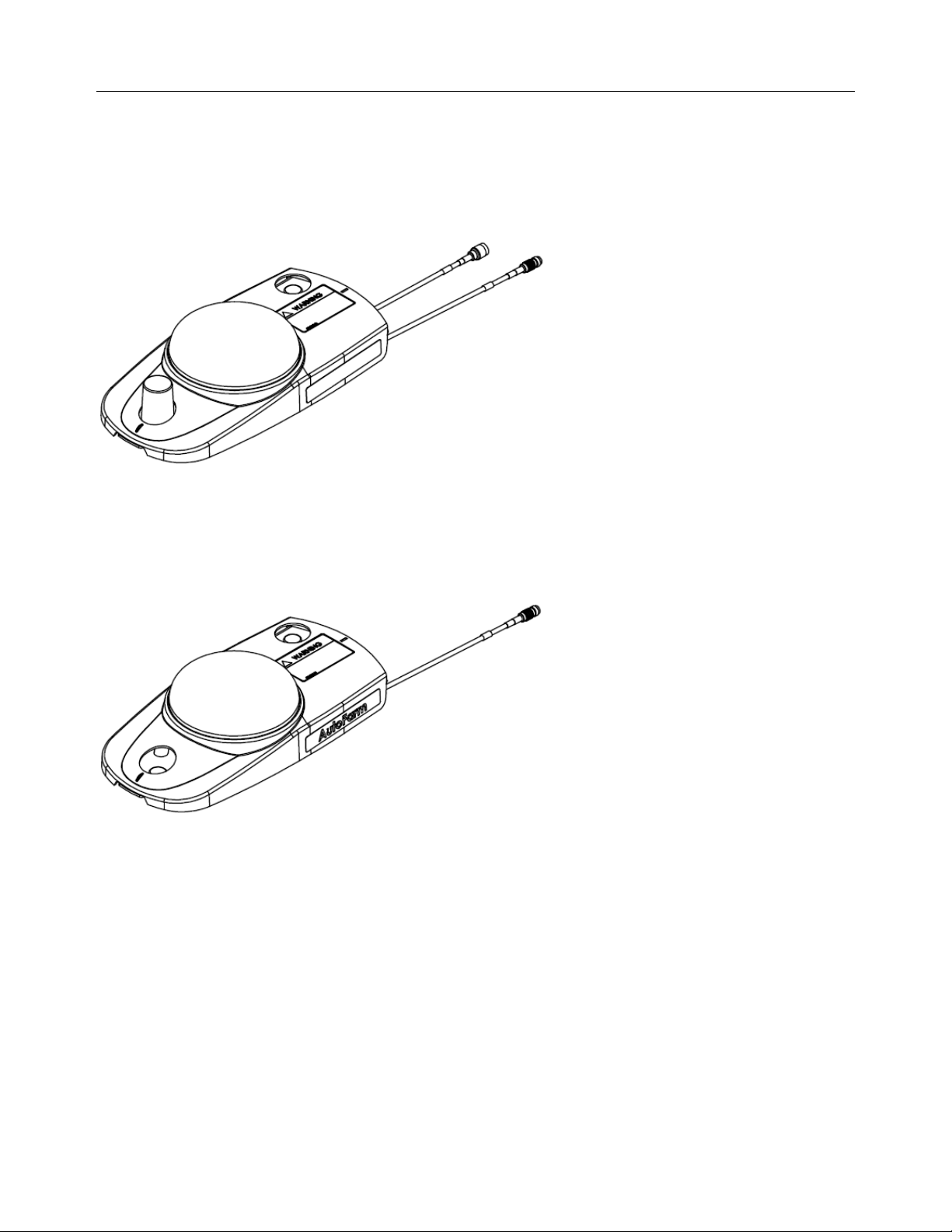

GeoDock Pro

The GeoDock Pro is the roof mounted piece of the GeoSteer system that contains the GPS Antenna and Cell Modem antenna.

The GeoDock Pro houses the optional GS-900 or GS-450 Radio Modems or the GS-OmniSTAR Demodulator when they are

installed.

Figure 1-6 GeoDock Pro

GeoDock Pro – No Cell

This version of GeoDock is the same as the GeoDock Pro except the assembly does not have a Cell Modem Antenna or coax

connector installed on it. This version is ordered with kits that do not come with a Cell Modem.

Figure 1-7 GeoDock Pro - No Cell

3 Vehicle Installation Kits

The GeoSteer system is designed to be compatible with many makes and models of vehicles available in today’s agricultural

market. GeoSteer is brand neutral and can be installed on any manufacturer’s vehicle including AGCO, Ag Chem, Case,

Challenger, Fendt, John Deere, New Holland, Massey Ferguson, and many others. The GeoSteer system is also capable of

being installed on a variety of platforms including articulated tractors, combines, MFWD and standard front axle tractors,

floaters, sprayers, swathers, track tractors, and others. The same user interface can be used on all vehicles, regardless of the

make or model, making it easy for drivers to become familiar with the controls even if the system is installed on multiple

vehicle types.

To make installations simple and reliable, many vehicle-specific installation kits have been designed to fit on each individual

make and model. These kits are available for vehicles that come from the factory with a factory installed steering system (ex.

Steer Ready, CAN Bus, or ISO Ready) as well as options for those vehicles that need a complete steering kit installed. Even if

there is not a vehicle-specific kit available for the vehicle, properly trained installers can often use a custom installation kit to

8 GeoSteer System

Page 23

Accessing AutoSteer Setup Screens

connect the GeoSteer system to the vehicle. Specific instructions for the vehicle installation kits are provided with the

installation kits. Refer to those instructions when installing the vehicle kit.

Note: The list of supported vehicle-specific kits is always being expanded. Contact your AutoSteer dealer for the latest list of

vehicle-specific installation kits to see if the vehicle being installed on has a released kit.

4 Accessory Kits

The GeoSteer system is compatible with optional accessory kits that can be ordered and installed to provide additional features

and capabilities. The primarily reason to install an accessory kit is to provide a radio modem link with a Base Station or an

OmniSTAR demodulator for OmniSTAR corrections. These accessories are not required for all installations and some are not

available in all locations. Order only the kits that are required to provide the accuracy level and communication needs required

for the installation. The accessory kits available at the time of this writing are:

•

GS-900NA (PN 200-0652-01) – 900 MHz radio modem for North America

•

GS-900AU (PN 200-0652-02) – 900 MHz radio modem for Australia

•

GS-OmniSTAR (PN 200-0653-01) – OmniSTAR demodulator for world

•

GS-410 (PN 200-0667-03) – 406-430 MHz radio modem for world

•

GS-430 (PN 200-0667-02) – 430-450 MHz radio modem for world

•

GS-450 (PN 200-0667-01) – 450-470 MHz radio modem for world

•

Remote Engage Foot Switch (PN 200-0458-01) – Remote Engage foot switch that can be attached to the GeoSteer Main

Harness to allow the user to start and stop AutoSteer with a foot switch

Note: The list of accessory kits is always being expanded. Contact your AutoSteer dealer for the latest list of accessory kits.

Specific installation instructions for each accessory kit are provided with the kits themselves. Refer to those instructions when

installing the accessory kits

Accessing AutoSteer Setup Screens

The GeoSteer system adds GPS positioning and vehicle steering control to compliment the features of your Display. The

settings, configuration options, and monitoring features for the GPS and vehicle communications are kept separate from the

Display controls. To access them in a GeoSteer system navigate to the AutoSteer Setup screens from the Display. If changes

need to be made to the GPS functionality or to move the system to a different vehicle profile, the user will need to manage

those options in the AutoSteer Setup screen.

Your Display Operator’s Manual will provide instructions on navigating to the AutoSteer Setup page. Please refer to that

document for those instructions. Figure 1-1 shows the AutoSteer Setup opening screen when it is first accessed from the

Display.

Operator’s Manual 9

Page 24

Transferring GeoSteer from Vehicle to Vehicle

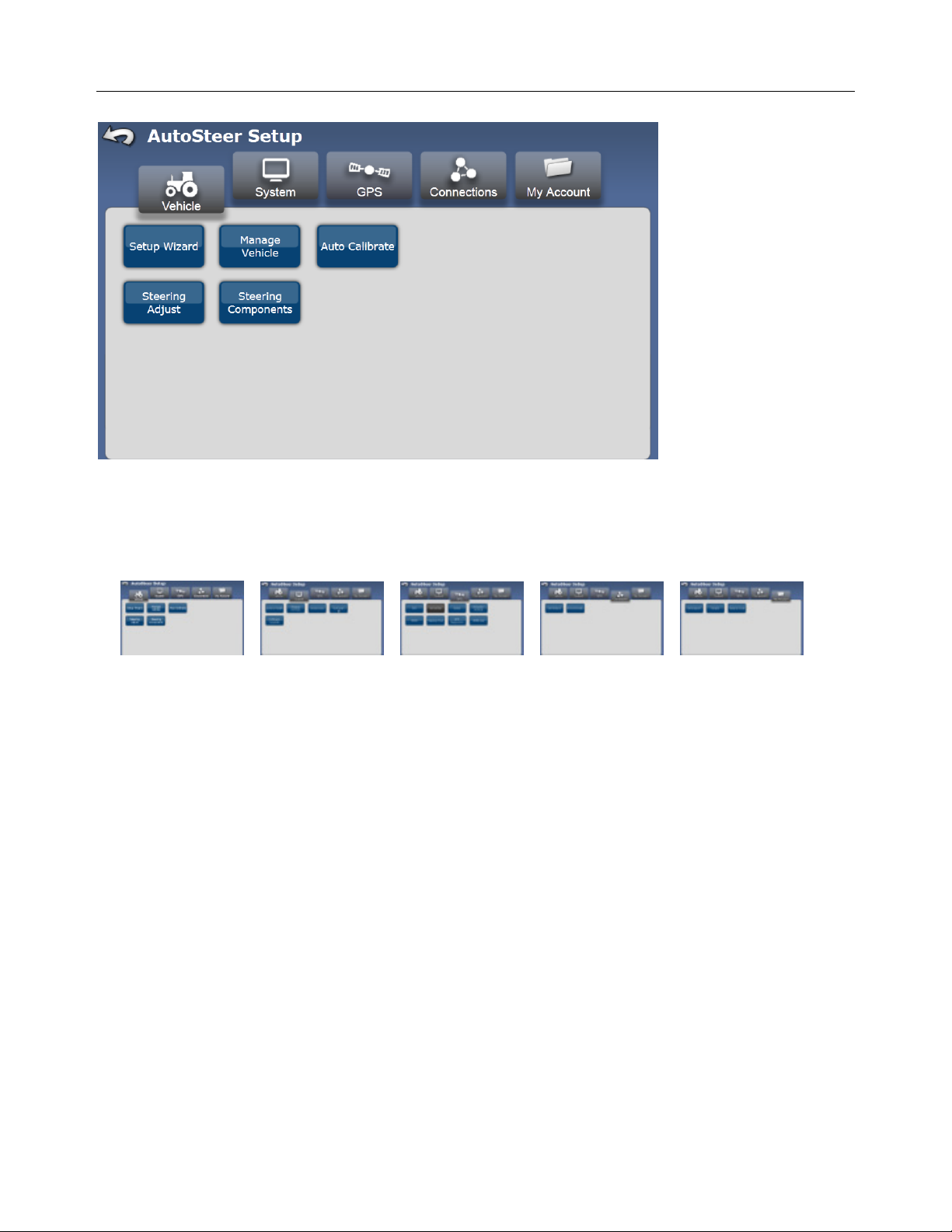

Figure 1-8 AutoSteer Setup Opening Screen

The five folder tabs along the top of the screen separate the GeoSteer configuration and monitoring functions into sub groups

to simplify management. The five tabs and the options for each are shown below:

VEHICLE SYSTEM GPS CONNECTIONS MY ACCOUNT

Setup Wizard System Health RTK Cell Modem Call Support

Manage Vehicles Manage Settings OmniSTAR External Radio Details

Auto Calibrate Accessories WAAS/EGNOS Feature Code

Steering Adjust Technician Precision Settings

Steering Components Software Upgrade NTRIP

Planning Tools

GPS Diagnostics

NMEA Out

Each of these tabs is described in detail in the following chapters. For more information about each feature shown above, refer

to the corresponding chapter.

Transferring GeoSteer from Vehicle to Vehicle

The GeoSteer system is designed to be easily transferred from vehicle to vehicle. Specific vehicle kits are available that can be

installed on each vehicle so that only the Display, GeoSteer Control Unit, and GeoDock need to be transferred from vehicle to

vehicle. Each vehicle that the GeoSteer system is to be transferred to should have the Display Harness, Power Harnesses,

Vehicle Harnesses, and GeoDock Harnesses already preinstalled. Contact your AutoSteer dealer for information about

obtaining and installing additional vehicle specific kits. Use the instructions in the section to transfer the GeoSteer system from

one vehicle to another.

10 GeoSteer System

Page 25

Transferring GeoSteer from Vehicle to Vehicle

Removing the GeoSteer System from a Vehicle

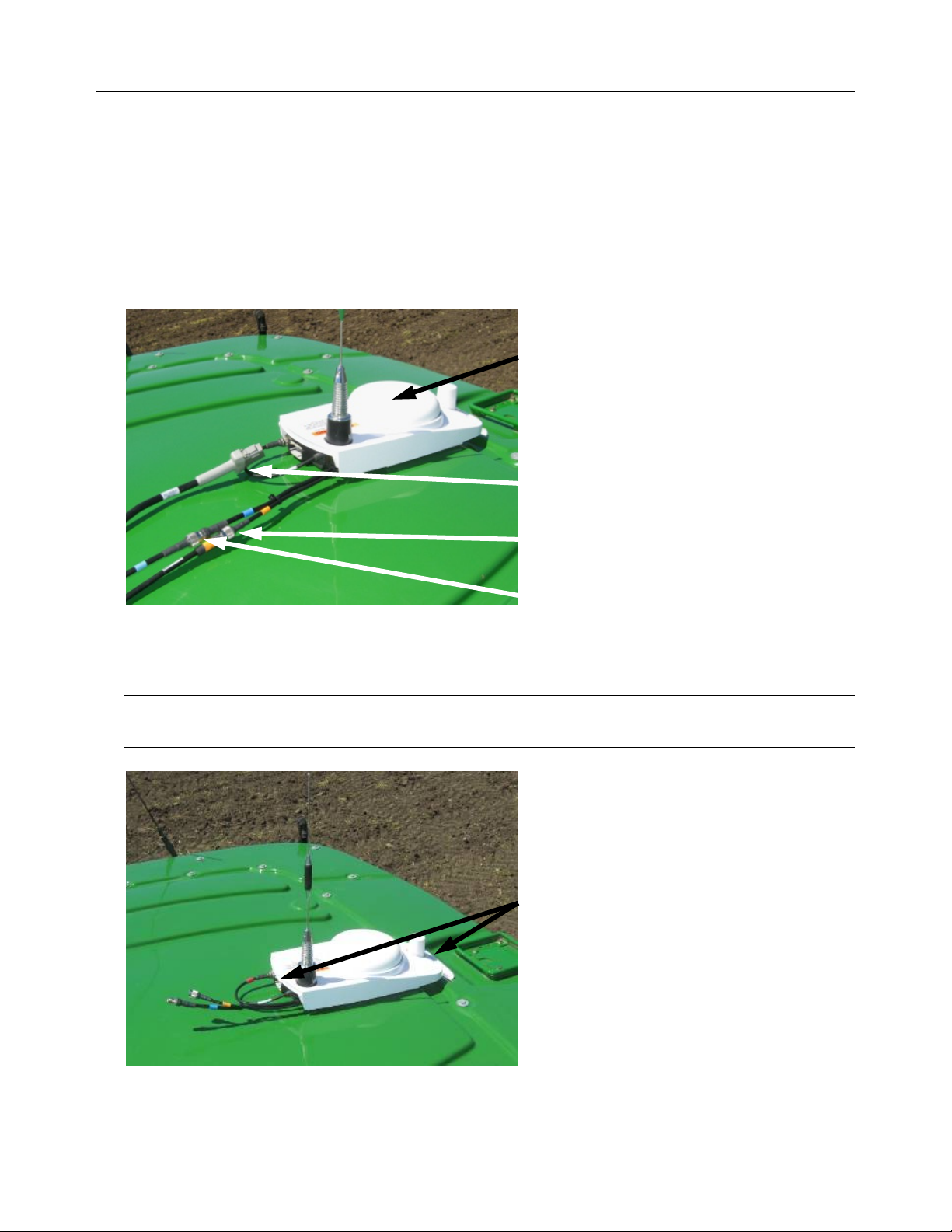

1. Locate the GeoDock on the roof of the vehicle.

2. Disconnect the GPS Coax (Blue) by splitting the TNC Connectors shown.

3. If the GeoDock has a Cell Modem Antenna, disconnect the Cell Modem Antenna Coax (Orange) by splitting the TNC

Connectors shown.

4. If the GeoDock has an optional GS-900, GS-450, or GS-OmniSTAR Demodulator, disconnect the 12-pin Power/Data

Connector shown.

Figure 1-9 Locate GeoDock and GeoDock Connections

GeoDock

Optional GS-900, GS-450, or GS-OmniSTAR

Demodulator Power/Data Connector

Cell Modem Connector (Orange) (if Applicable)

GPS Coax Connector (Blue)

5. Secure the cable connections left on the cab of the vehicle and protect them from dirt/moisture.

6. Carefully pry the magnetically attached GeoDock from the GeoDock Mounting Bracket.

Note: Only pry up on the GeoDock from the metal lip on the front or back of the GeoDock. Never pry the GeoDock using

the plastic cover or by pulling on the coax cables coming out of the back. This can damage the unit.

Pry up from these Points Only

Operator’s Manual 11

Page 26

Transferring GeoSteer from Vehicle to Vehicle

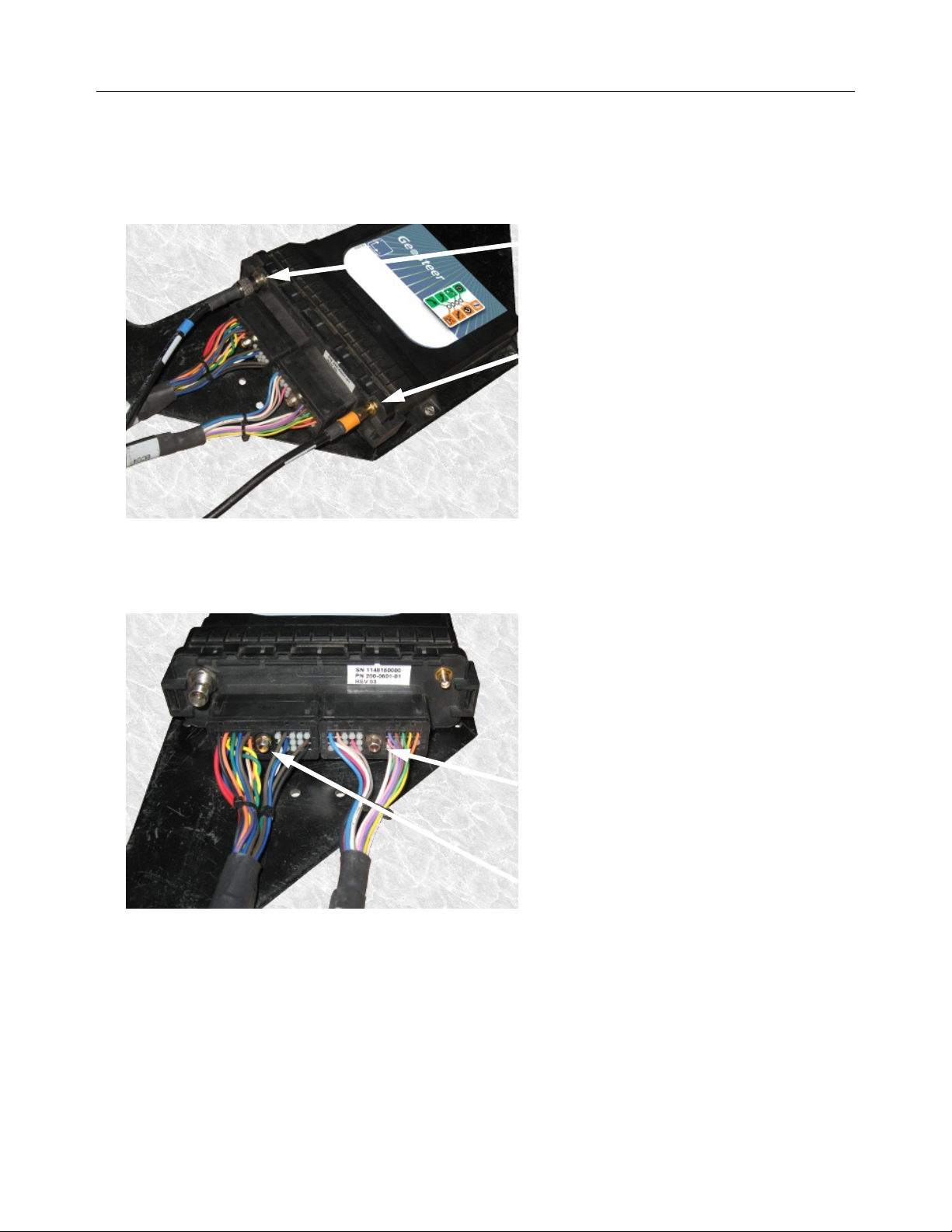

7. Locate the GeoSteer Control Unit on the vehicle.

8. Disconnect the GPS Coax (Blue) TNC Connector from the GeoSteer Control Unit.

9. If the GeoDock has a Cell Modem connection, disconnect the Cell Modem (Orange) SMA Connector from the GeoSteer

Unit.

Figure 1-10 Locate GeoSteer Control Unit on Vehicle

TNC GPS Coax (Blue) Connector

SMA Cell Modem Coax (Orange) Connector (if

equipped

10. Use a 1/4 inch nut driver to remove the GeoSteer Main Cable Harness connector from the GeoSteer Control Unit.

11. Use a 1/4 inch nut driver to remove the Vehicle Specific Cable Harness (if present) from the GeoSteer Control Unit.

Figure 1-11 Disconnect GeoSteer Control Unit Harnesses

Vehicle Specific Cable Harness Connector

(if Installed)

GeoSteer Main Cable Harness Connector

12 GeoSteer System

Page 27

Transferring GeoSteer from Vehicle to Vehicle

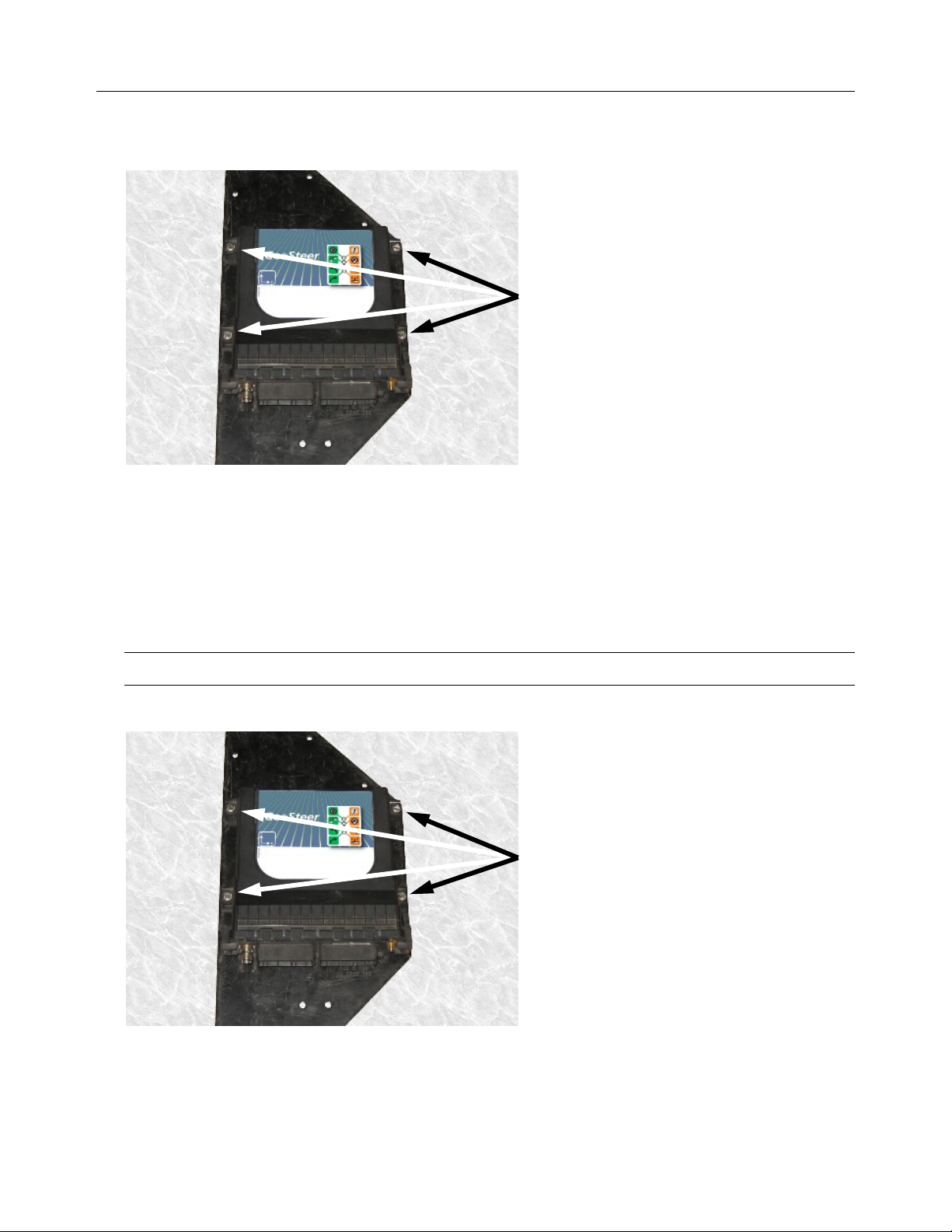

12. Remove the four 8-32 x 1/2 Hex Screws using a 1/4 inch nut driver. This releases the GeoSteer Control Unit from the

vehicle mounting bracket so it can be moved to another vehicle.

Figure 1-12 Remove Screws Holding GeoSteer Control Unit

Remove the Four Screws

13. Remove the Display from the cab using the instructions provided in the Display Operator’s Manual.

Installing the GeoSteer System on to Vehicle

1. Install the Display in the cab using the instructions provided in the Display Operator’s Manual.

2. Attach the GeoSteer Control Unit to the mounting bracket with four 8-32 x 1/2 Hex Screws. Tighten the screws using a

1/4 inch nut driver.

Note: Do not over tighten the screws.

Figure 1-13 Attach GeoSteer Control Unit with Screws

Attach GeoSteer Control Unit with Four Screws

Operator’s Manual 13

Page 28

Transferring GeoSteer from Vehicle to Vehicle

3. Attach the GeoSteer Main Cable Harness connector to the left side connector on the GeoSteer Control Unit. Match the

Yellow dots on the harness to the GeoSteer Control Unit Connector. Use a 1/4 inch nut driver to tighten the connector.

4. Attach the Vehicle Specific Cable Harness (if required) to the right side connector on the GeoSteer Control Unit. Match

the White dots on the harness to the GeoSteer Control Unit Connector. Use a 1/4 inch nut driver to tighten the connectors.

Note: Both connectors are keyed so they will only attach the proper side of the GeoSteer Control Unit and in one

orientation. The connectors should slide easily onto the receptacle. If they do not slide easily, try a different position. Do

not force the connector into the receptacle as this could damage the connectors.

Figure 1-14 Attach GeoSteer Control Unit Harnesses

Vehicle Specific Cable Harness Connector

(if Required)

GeoSteer Main Cable Harness Connector

5. Attach the GPS Coax (Blue) TNC Connector to the GeoSteer Control Unit.

6. If the GeoDock has a Cell Modem connection, attach the Cell Modem (Orange) SMA Connector from the GeoSteer Unit.

Note: Hand tighten the Coax connectors only. Do not use a tool to tighten as this may damage the connectors.

Figure 1-15 Attach Coax Connectors

TNC GPS Coax (Blue) Connector

SMA Cell Modem Coax (Orange) Connector (if

equipped

14 GeoSteer System

Page 29

Transferring GeoSteer from Vehicle to Vehicle

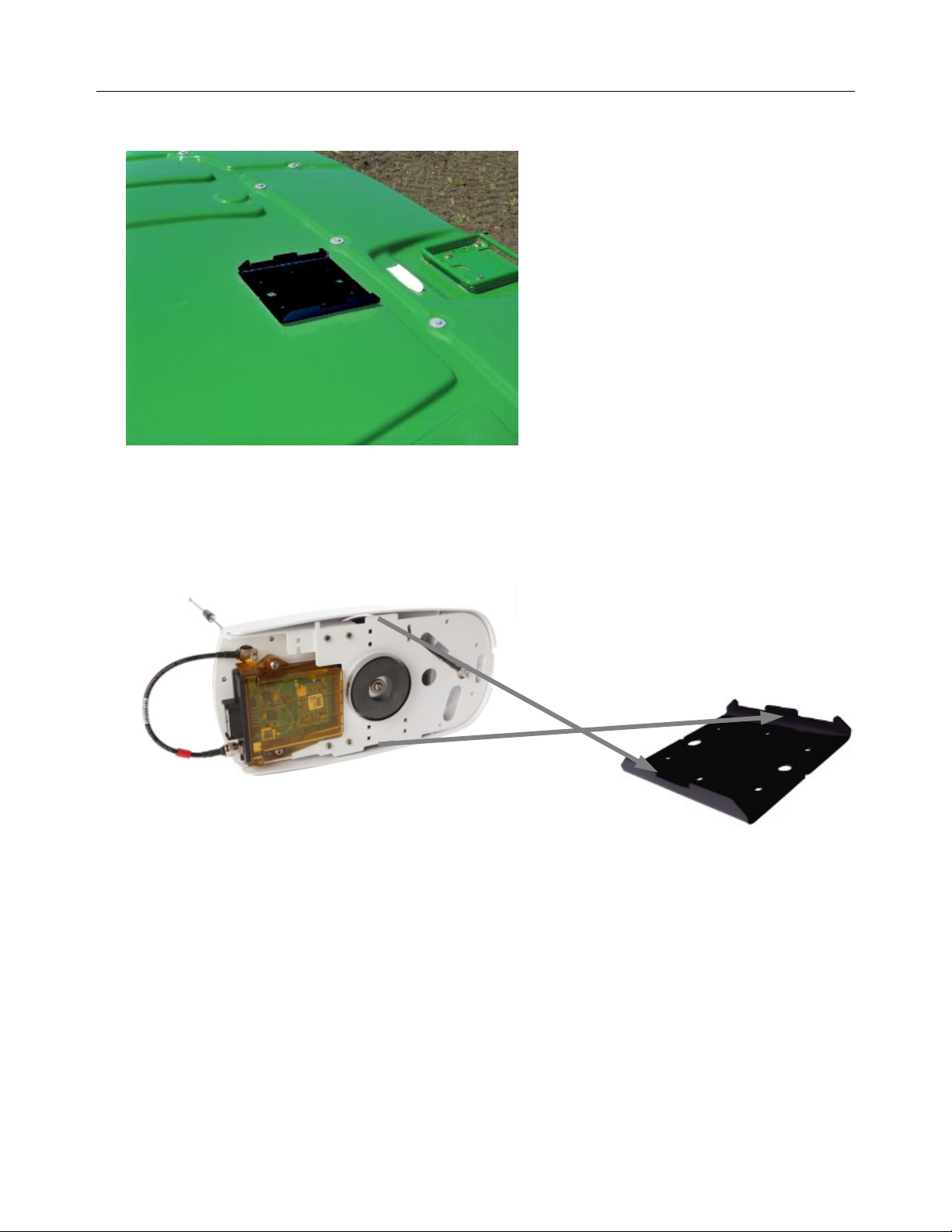

7. Locate the GeoDock Mounting Plate on top of the cab.

Figure 1-16 GeoDock Mounting Plate

8. Attach the GeoDock to the mounting plate taking care to match the mounting tabs on the GeoDock with the tabs on the

mounting plate.

Figure 1-17 Match Tabs on GeoDock to Mounting Plate

Operator’s Manual 15

Page 30

Changing SIM Card in GeoSteer

9. Attach the GPS Coax (Blue) TNC Connector to the connector on the GeoDock.

10. If the GeoDock has a Cell Modem Antenna, attach the Cell Modem Antenna Coax (Orange) TNC Connector to the

connector on the GeoDock.

11. If the GeoDock has an optional GS-900, GS-450, or GS-OmniSTAR Demodulator, connect the 12-pin Power/Data

Connector to the back of the radio modem or demodulator.

Figure 1-18 Locate GeoDock and GeoDock Connections

Optional GS-900, GS-450, or GS-OmniSTAR

Demodulator Power/Data Connector

Cell Modem Connector (Orange) (if Applicable)

GPS Coax Connector (Blue)

12. Power up the GeoSteer system and navigate to the AutoSteer Setup screen. Use the Manage Vehicles button to select the

activate the vehicle that the GeoSteer system has been installed on. Refer to the Manage Vehicle section on Page 45 for

information on setting the active vehicle.

Changing SIM Card in GeoSteer

The GSM Cell Modem versions of the GeoSteer Control Unit have an external SIM card slot that allows the user to change the

SIM card for NTRIP usage. This SIM slot is not found on CDMA Cell Modem versions of the GeoSteer Control Unit. This

section provides the instructions to change the SIM card if that becomes necessary.

1. Locate the SIM Card slot on the cable connector side of the GeoSteer Control Unit.

Figure 1-19 SIM Card Slot

16 GeoSteer System

SIM Card Slot

Page 31

Changing SIM Card in GeoSteer

2. Loosen the two screws holding the SIM Card slot cover on with a 2mm Allan wrench supplied with the GeoSteer System

and remove the cover. The screws stay attached to the cover.

Figure 1-20 Remove Cover by Loosening Screws

Remove Screws

3. The edge of the SIM Card will be visible. Gently push the SIM card into the slot and then release. The SIM Card should

pop out of the slot.

Note: The SIM Card cover has a flat blade that can be used to assist in pressing the SIM Card in so it will release.

Figure 1-21 Remove SIM Card

Press SIM Card in

4. Verify that the area around the SIM Card slot and the SIM Card cover are clean. If necessary clean with a damp cloth and

allow it to dry before reassembling.

5. Insert the new SIM Card into the slot.

Note: The SIM Card cover shows how the notch on the SIM card needs to be orientated when inserting into the slot.

Verify the SIM card is orientated properly before inserting.

Operator’s Manual 17

Page 32

Changing SIM Card in GeoSteer

Note: Never force the SIM Card into the slot. It should slide easily in. If it does not verify that it is orientated correctly.

6. Replace the SIM Card cover to protect it. Tighten the two screws with a 2mm Allan wrench.

7. Power up the GeoSteer system and navigate to the AutoSteer Setup page. Configure the SIM card following the procedure

provided in the Configure SIM section on Page 135.

18 GeoSteer System

Page 33

GeoSteer Control Unit LED Diagnostics

GeoSteer Control Unit LED Diagnostics

The GeoSteer Control Unit has been designed with four LEDs that can be used to help determine the status of the GeoSteer

system as well as provide some basic troubleshooting information. Figure 1-22 shows the front panel of the GeoSteer Control

Unit. The LEDs will be off, Green, or Amber.

Figure 1-22 Front Panel of GeoSteer Control Unit

Use Table 1-5 for the definitions of the different LEDs and colors.

Table 1-5 GeoSteer Icon Definitions

Green

Icons

Description

Solid Green – Indicates good power.

No Color – No power to the GeoSteer Control

Unit.

Flashing Green – Indicates communication with

the Display.

No Color – No communication with Display.

Green – GeoSteer Control Unit is commanding

actuator to turn left.

No Color – No output being commanded.

Green – GeoSteer Control Unit is commanding

actuator to turn right.

No Color – No output being commanded.

Amber

Icons

Description

Flashing Amber – Voltage problem detected in

the GeoSteer Control Unit.

Solid or Flashing Amber – System is loading

new firmware to the GeoSteer Control Unit.

Note: Do not cut off power to the GeoSteer

Control Unit while this light is amber.

Flashing Amber – Displays the number of

satellites being tracked.

Note: The number of quick amber flashes

indicates the number of satellites. Restart

counting after the long pause.

Flashing Amber – Indicates the GeoSteer

Control Unit is receiving a RTK correction

signal via Radio Modem.

Operator’s Manual 19

Page 34

Page 35

Vehicle Tab

The Vehicle Tab chapter contains information in the following sections:

•

Overview

•

Setup Wizard

•

Manage Vehicle

•

Auto Calibrate

•

Steering Adjust

•

Steering Components

Overview

2

Figure 2-1 AutoSteer Setup Vehicle Tab

The Vehicle menu enables the user to configure a new vehicle, manage existing vehicles, perform an auto calibration of a

vehicle, make steering adjustments and manage steering components. This menu allows the user to configure and monitor the

various components related to the vehicle interface with the GeoSteer Control Unit.

To access the Vehicle menu, refer to your Display Operator’s Manual for instructions on accessing the AutoSteer Setup

screens. The Vehicle menu will be the first one that is displayed when the AutoSteer Setup screen is accessed.

Each of the following menu options are explained in detail in this chapter.

Operator’s Manual 21

Page 36

Setup Wizard

•

Setup Wizard – Walks the user through setting up a new vehicle.

•

Manage Vehicle – Allows the user to select, edit, delete, or export/import vehicle profiles into the GeoSteer system.

•

Auto Calibrate – Allows user to start or restart a vehicle calibration for the current vehicle.

•

Steering Adjust – Allows user to make adjustments to steering response, line acquisition, heading aggressiveness, and

reverse response

•

Steering Components – Provides status screens and set some values for all the components that are connected to the

vehicle. This includes CAN communication, steering kick out information, Wheel Angle Sensor readings, Steering Valve

control, Remote Engage detection, etc.

Setup Wizard

The Setup Wizard is a step-by-step guide that leads the user thru the procedure required to create a new vehicle profile. The

Setup Wizard procedure will change depending on what type of vehicle is selected and/or what options are installed on the

GeoSteer System. This manual will describe all possible options that GeoSteer may come equipped with. Not all screens

described in this manual will be displayed for all vehicle setups. To setup a new vehicle profile, press the Setup Wizard button

from the AutoSteer Setup Vehicle tab. Depending on the conditions the Setup Wizard will begin at one of the following points:

•

Additional Steps for the First Time the Setup Wizard is Run – The wizard will start here only when the Setup Wizard is

run the first time from the factory or the first time after the system has been reset to factory defaults.

•

Standard Setup Wizard Steps – The wizard will start here almost every time and will jump to here after the Additional

Steps for the First Time the Setup Wizard is completed the first time.

Additional Steps for the First Time the Setup Wizard is Run

The first time the system is powered up from factory or after the database is reset to factory default, the first time a vehicle is

created additional steps are added at the beginning of the Setup Wizard. These steps tell the system how to configure the

various GPS correction and radio options. If the settings for these steps are unknown at the time of the initial vehicle setup,

they can be changed later via their respective configuration menus. This manual will show all possible steps that could be

displayed; however, the actual system will only show the steps for the devices that it detects during the actual Setup Wizard. If

a radio or OmniSTAR demodulator is not detected, those steps will be skipped.

To start the Setup Wizard, press the Setup Wizard button from the AutoSteer Setup Vehicle tab. The following steps may be

encountered during the initial setup depending on how the system is configured:

WAAS/EGNOS Setup

If the system is powered up in a location where the system determines a WAAS or EGNOS signal should be available, the

following screen will appear. The WAAS or EGNOS correction signal is transmitted from geostationary satellites. Each of

these satellites has a unique numerical name called its PRN. The GeoSteer system needs to be told which PRN (or satellite) to

listen to for the correction information.

Note: The system must have a clear view of the sky and the GPS antenna must be connected in order for the system to

determine its location and time.

Note: If the system is powered up in an area where EGNOS is available, the system will ask for EGNOS PRN values.

22 GeoSteer System

Page 37

Setup Wizard

Figure 2-2 WAAS/EGNOS Initial Setup Screen

The GeoSteer system can detect and simultaneously track two separate WAAS or EGNOS PRNs. If the Primary PRN becomes

unavailable, the system will automatically switch to the Secondary PRN. To change either of the PRNs to a different satellite,

press the Change Primary or Change Alternate button. Refer to the WAAS or EGNOS websites to determine satellite

availability and health for your location.

Use the keypad shown in Figure 2-3 to enter the Primary or Secondary WAAS/EGNOS PRN number. After the PRN has been

set press the Green Check Mark button to save the setting. Press the Red X button to cancel.

Figure 2-3 PRN Number Change

After both PRN values have been set, press the Blue Right Arrow button shown in Figure 2-2 to continue to the next step.

Operator’s Manual 23

Page 38

Setup Wizard

Set RTK Radio Modem Channel or Frequency

If the GeoSteer detects a GS-900 or GS-450 Radio Modem, the user will be prompted to enter a channel or frequency to match

the channel or frequency of the transmitting Base Station. Press the Change Frequency or Change Channel button to set this

value.

Figure 2-4 Set RTK Radio Modem Channel or Frequency

Use the keypad shown in Figure 2-5 to enter the channel or frequency used on the Base Station. After the channel has been set

press the Green Check Mark button to save the setting. Press the Red X button to cancel.

Figure 2-5 Change Radio Channel or Frequency

After the channel or frequency has been set, press the Blue Right Arrow button shown in Figure 2-4 to continue to the next

step.

24 GeoSteer System

Page 39

Setup Wizard

Set OmniSTAR Options

If the GeoSteer detects an OmniSTAR Demodulator, the user will be prompted to enter a channel to match their location.

OmniSTAR has different satellite feeds depending on the GeoSteer system geographic location. Press the Change Channel

button to set this value.

Figure 2-6 OmniSTAR Setup

The OmniSTAR Channel Selection screen will display all the current OmniSTAR channels that are available. Select the

channel for your region and press the Green Check button to save that selection. Press the Red X button to cancel.

Note: For more information on configuring the OmniSTAR signal refer to OmniSTAR section on Page 103.

Figure 2-7 OmniSTAR Channel Selection List

The OmniSTAR Setup screen, shown in Figure 2-6 also allows the user to choose the initial startup accuracy. When the

GeoSteer is started, it takes time for the OmniSTAR signal to converge to the accuracy level provided by OmniSTAR. Some

users may not require the full accuracy of the OmniSTAR correction for the job being performed. If this is the case, some users

may choose to start before the system fully converges. The GeoSteer system allows the user to choose:

•

Fast Startup – The GeoSteer will allow the system to begin AutoSteering before it fully converges. This allows the user to

start AutoSteering sooner. Select this setting if accuracy is not as important at the initial startup as getting running quickly.

The system will continue to converge in the background and become more accurate the longer the system runs and will

eventually reach full convergence.

•

High Accuracy – The GeoSteer will not allow the system to begin AutoSteering until it has reached full convergence. The

system will take longer to allow AutoSteer operations. Select this option if accuracy is important at the initial startup.

Operator’s Manual 25

Page 40

Setup Wizard

After the channel and startup accuracy have been selected, press the Blue Right Arrow button shown in Figure 2-6 to continue

to the next step.

Precision Preference Selection

GeoSteer is designed to allow the user flexibility in selecting the accuracy level the system operates at. Depending on the

GeoSteer Feature Codes that have been unlocked, the geographic location, OmniSTAR Demodulator that may be installed, the

user can choose from Autonomous Pass-to-Pass all the way up to RTK. In RTK and OmniSTAR modes, the system also allows

the accuracy to “Flex” back to WAAS/EGNOS or Autonomous Pass-to-Pass when the RTK or OmniSTAR signal is lost for a

short time. To choose the accuracy level that GeoSteer will operate at, press the Change Mode button shown in Figure 2-8.

Figure 2-8 Set Precision Preference

The list of Available Precision Settings will display. This list will depend on which features have been unlocked, whether the

system detects an OmniSTAR Demodulator, and the geographic location the system believes it is located. Not all options will

be available to all users. Select the Precision Setting that the system will operate with and then press the Green Check button to

save that selection. Press the Red X button to cancel.

Figure 2-9 Available Precision Settings

Each of the selections has specific accuracy levels and operational requirements. An explanation of each setting is provided

below:

Note: “Flex” is a term that denotes the system switching from one accuracy level to another when a correction source is lost. In

most cases, this happens when the RTK data link between the Base Station and the GeoSteer is interrupted. This could happen

due to radio or cell communication loss or an obstacle between the GeoSteer and the communication source (ex. Base Station

Radio Modem or Cell Tower). “Flex” will not help if the GPS signals from the satellites are blocked by obstacles such as trees

or buildings.

26 GeoSteer System

Page 41

Setup Wizard

•

RTK Only – This mode is only displayed if the RTK Feature Code has been unlocked on the GeoSteer. The system must

have a RTK source from a Base Station via a Radio Modem or from a NTRIP source via the Cell Modem. If selected, the

GeoSteer assumes the user must be 99.9% sure of position. It requires a RTK link at all times and will disengage

AutoSteering if the link is lost. This setting expects good satellite geometry and low PDOP. Because of the high accuracy

expectation, the chances that degraded conditions occur and stop AutoSteering is higher. Use only when high accuracy is

needed at all times.

•

Flex High Accuracy (0-10 cm) – (0 to 3.9 inches) This mode is only displayed if the RTK Feature Code has been

unlocked on the GeoSteer. The system must have a RTK source from a Base Station or NTRIP stream. While receiving a

RTK signal, the system is just as accurate as RTK Only mode. However, this mode allows the system to lose the RTK data

link from the Base Station for a short time and allow the vehicle to continue to AutoSteering. When the RTK signal is lost,

the system will “Flex” back to WAAS/EGNOS or Autonomous Pass-to-Pass until the estimated error gets above 10 cm.

The amount of time allowed in flex mode depends on GPS conditions. The operator is warned when the system has entered

“Flex” mode and can decide if they wish to continue or wait for the RTK link to be reestablished.

•

Flex Low Accuracy (0-30 cm) – (0 to 11.8 inches) This mode is only displayed if the RTK Feature Code has been

unlocked on the GeoSteer. This mode the same as Flex High Accuracy (0-10 cm) except the system will “flex” until the

estimated error gets above 30 cm. This will allow a longer period of operation with out a RTK signal, but it is possible the

system will have more position error the longer it does not have the RTK signal. However, as long as the RTK signal is

present, the system will be just as accurate as RTK Only. The operator is warned when the system has entered “Flex”

mode and can decide if they wish to continue or wait for the RTK link to be reestablished.

•

OmniSTAR Only – This mode is only displayed if the GeoSteer detects that an OmniSTAR Demodulator has been

installed on the GeoDock. The system will use the OmniSTAR for corrections only and will not “flex” to any other mode if

the signal is lost. GeoSteer supports the OmniSTAR XP and HP signals only.

•

OmniSTAR Flex to WAAS/EGNOS/Autonomous Mode – This mode is displayed only if the GeoSteer detects that an

OmniSTAR Demodulator has been installed on the GeoDock. If the system is running in OmniSTAR mode, the user has

the option to “Flex” back to WAAS, EGNOS, or Autonomous Mode if the OmniSTAR signal is lost for some reason. The

mode the system will “Flex” to will depend on which region the GeoSteer is located. WAAS and EGNOIS are available in

North America and Europe respectively. Autonomous Mode is available for the rest of the world. Once the OmniSTAR

signal has been required, the system will return back to OmniSTAR mode.

•

WAAS/EGNOS Only – This mode is only available where WAAS or EGNOS are available. The GeoSteer will only use

the WAAS/EGNOS signal for corrections even if an OmniSTAR or RTK signal is available.

•

Autonomous Pass-to-Pass – This mode is only available in areas where WAAS or EGNOS are not available. The

GeoSteer will use the GPS signals themselves to calculate reduce the error of the position. This mode allows the system to

run with no correction sources.

After the Precision Preference has been selected, press the Blue Right Arrow button shown in Figure 2-8 to continue to the

next step.

Standard Setup Wizard Steps

If this is not the first time the Setup Wizard was run from the factory or after a reset to factory defaults, The Setup Wizard will

begin here. The Setup Wizard will take the user through each step required to setup a new vehicle. The actual steps and screen

shots may change depending on the vehicle type that is selected and the control options that are available for that vehicle.

Note: When the Setup Wizard button is pressed, the Setup Wizard will always start at this point except for the very first time

the button is pressed after the system is started the first time from the factory or after the system has been reset to factory

defaults.

Operator’s Manual 27

Page 42

Setup Wizard

Select Vehicle Type

The Vehicle Type represents the type of vehicle the GeoSteer is installed on. The various vehicle types generally have different

control parameters and measurement points. This setting allows the system to determine which options will be presented to the

user in later steps. Press the Gray Up and Down arrows or directly select the vehicle type.

Figure 2-10 Vehicle Type

The following vehicle types can be chosen from:

•

•

•

•

•

•

•

Articulated –Large four wheel drive vehicles that steer by articulating in the center of the vehicle are

in this group. This group includes Quadtrac vehicles.

Combine – Grain harvesting and forage harvesting machines where the rear axle is used to steer the

vehicle are in this group.

Floater – Three and four wheeled vehicles with large floatation tires used to spread fertilizer or

chemicals on broad acres at high speeds are in this group.

MFWD – Standard tractors with the steering axle on the front of the machine are in this group.

Sprayer – High clearance self propelled sprayers with spray booms are in this group.

Swather – Swathers and self propelled mowers are in this group.

Track – Vehicles that have tracks are in this group.

After the Vehicle Type has been selected, press the Blue Right Arrow button shown in Figure 2-10 to continue to the next step.

28 GeoSteer System

Page 43

Setup Wizard

Select Vehicle Make

The Vehicle Make represents the manufacturer of the vehicle. The vehicle manufacturers that have Vehicle Specific GeoSteer

Installation Kits available are shown in this list. Press the Gray Up and Down arrows or directly select the appropriate Vehicle

Make from the list.

Note: If the vehicle manufacturer is not listed on this screen, select Generic from the list. This allows you to create a vehicle

that does not have a factory supported installation kit.

Figure 2-11 Vehicle Make

After the Vehicle Make has been selected, press the Blue Right Arrow button to continue to the next step.

Select Vehicle Model

The Vehicle Model represents the model of the vehicle. In most cases if the model has a Vehicle Specific GeoSteer Installation

Kit available, the model will be shown in the list. Press the Gray Up and Down arrows or directly select the appropriate

Vehicle Model from the list.

Note: If the vehicle model is not listed on this screen, you can select a model that is similar to the one that is being installed on

or go back to the Vehicle Make screen and select Generic from the list. This allows you to create a vehicle and model that does

not have a factory supported installation kit.

Figure 2-12 Vehicle Model

Operator’s Manual 29

Page 44

Setup Wizard

After Vehicle Model has been selected, press the Blue Right Arrow button to continue to the next step.

Select Controller Type

The Controller Type represents the controller the GeoSteer will be interfaced with in order to steer the vehicle. GeoSteer can be

interfaced with a number of controller options including the standard AutoSteer valves, OnTrac2+, as well as a number of

factory installed steering systems. Press the Gray Up and Down arrows or directly select the appropriate Controller Type from

the list.

Note: The screen shot in Figure 2-13 shows the possibilities for one particular make and model. The list of options will change

depending on what Vehicle Type, Make, and Model are selected in the previous steps.

Figure 2-13 Controller Type

The possible Controller Types that may display are:

•

Standard – Hydraulic – This is an AutoSteer steering valve that was installed on the vehicle with the Vehicle Specific

Installation kit. This valve is not a factory installed option.

•

OnTrac2

•

AccuGuide Ready

•

Auto-Guide2

2

– This is an OnTrac2, OnTrac2+, or other mechanically steered controller.

3

– This represents a factory installed steering system used by CaseIH.

4

– This is used to communicate to the ISO Bus of vehicles under the AGCO manufacturing umbrella.

Vehicle makes in this group include AGCO, Challenger, Fendt, Gleaner, Massey Ferguson, and others using the same ISO

Bus communications hardware.

•

AutoTrac Ready

5

– This represents a factory installed steering system used by John Deere if the GeoSteer is being

connected directly to the sensors and valves on the vehicle.

•

AutoTrac Ready ISO – This represents a factory installed steering system used by John Deere if the GeoSteer is being

connected directly to the ISO Bus on the vehicle and not being connected to the individual sensors and valve.

•

Vehicle – CAN This is used for vehicles that use a standard ISO Bus interface such as for Challenger Track and

Articulated vehicles and Krone to interface directly with the vehicles CAN Bus.

•

IntelliSteer Ready

6

- This represents a factory installed steering system used by New Holland.

After the Controller Type has been selected, press the Blue Right Arrow button to continue to the next step

2